Desulfurization synergistic additive

A synergistic additive and component technology, applied in other chemical processes, separation methods, dispersed particle separation, etc., can solve the problems of different droplet sizes, blockage of spray devices, and reduced absorption efficiency, so as to achieve enhanced solubility and avoid Effects of glitches and enhanced absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

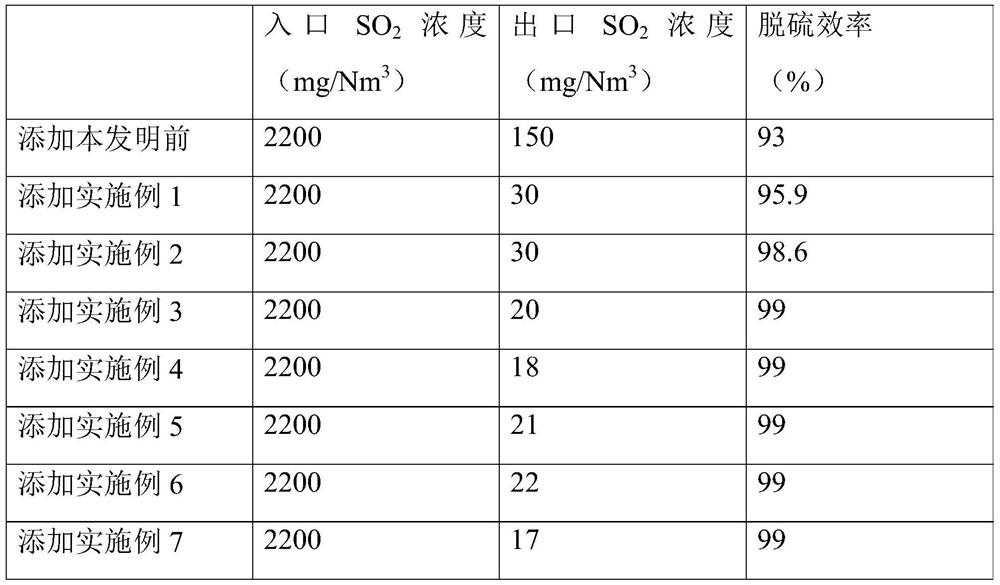

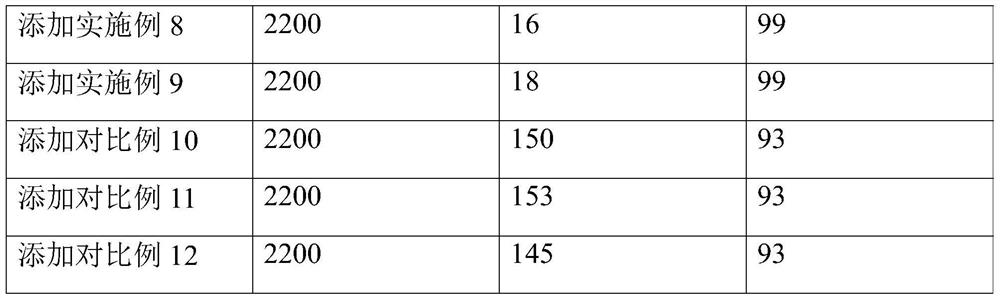

Examples

Embodiment 1

[0014] The desulfurization synergist additive in this embodiment is in the form of white crystal powder, and the weight ratio of each component is 30 parts of sodium formate, 25 parts of glutaric acid, 15 parts of succinic acid, 10 parts of sodium acetate and 20 parts of adipic acid. Under normal temperature and pressure and in a dry state, weigh the crystal powders of sodium formate, glutaric acid, succinic acid, sodium acetate and adipic acid respectively according to the weight and number ratios of the above components, and then weigh the crystal powders of each component It can be mixed evenly, and can also be compressed into a solid sheet, which is convenient for use and transportation.

Embodiment 2

[0016] The weight ratio of each component of the desulfurization synergistic additive of the present embodiment is 35 parts of sodium formate, 15 parts of glutaric acid, 10 parts of succinic acid, 5 parts of sodium acetate, 15 parts of adipic acid, and 10 parts of polycarboxylate sodium salt , 10 parts of hydroxyethylidene diphosphonic acid. At normal temperature and pressure and in a dry state, weigh sodium formate, glutaric acid, succinic acid, sodium acetate, adipic acid, polycarboxylate sodium salt, and hydroxyethylidene diphosphonic acid according to the weight and number ratios of the above components. The crystal powder of each component can be mixed evenly, and it can also be compressed into a flake solid, which is light yellow after compression.

Embodiment 3

[0018] The weight ratio of each component of the desulfurization synergist additive in this embodiment is 20 parts of sodium formate, 20 parts of glutaric acid, 12 parts of succinic acid, 8 parts of sodium acetate, 15 parts of adipic acid, 15 parts of polycarboxylate sodium salt, 5 parts of hydroxyethylidene diphosphonic acid, 5 parts of amorphous iron oxyhydroxide. At normal temperature and pressure and in a dry state, weigh sodium formate, glutaric acid, succinic acid, sodium acetate, adipic acid, polycarboxylate sodium salt, and hydroxyethylidene diphosphonic acid according to the weight and number ratios of the above components. , crystal powder of amorphous iron oxyhydroxide, and then mix the crystal powder of each component evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com