Molten iron full-domain stirring and desulfurization stirrer and using method thereof

A stirring desulfurization and agitator technology, which is applied in the field of molten iron pretreatment, can solve the problems of not being able to meet the improvement target of stirring the molten iron in the entire area of the molten iron tank, unable to achieve effective stirring and mixing of the molten iron in the lower part of the molten iron tank, and failing to achieve the full stirring effect of the molten iron in the entire area of the molten iron tank, etc. , to achieve the effects of reducing the forced vortex zone, expanding the stirring depth and effective stirring area, and improving the dynamic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

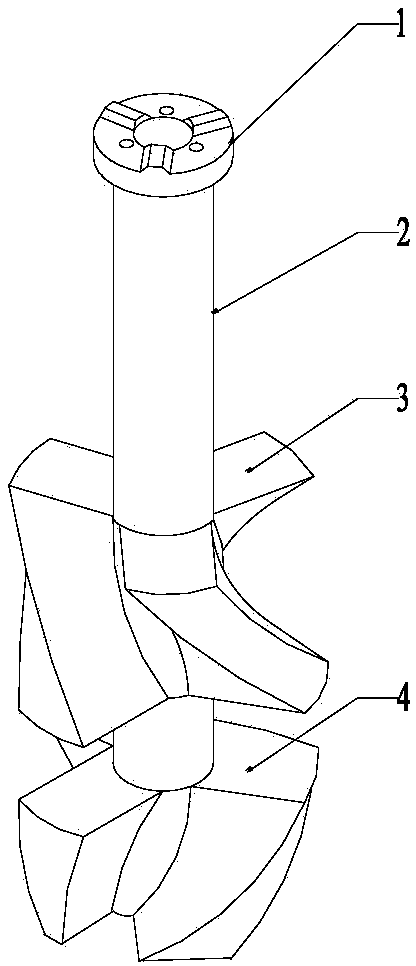

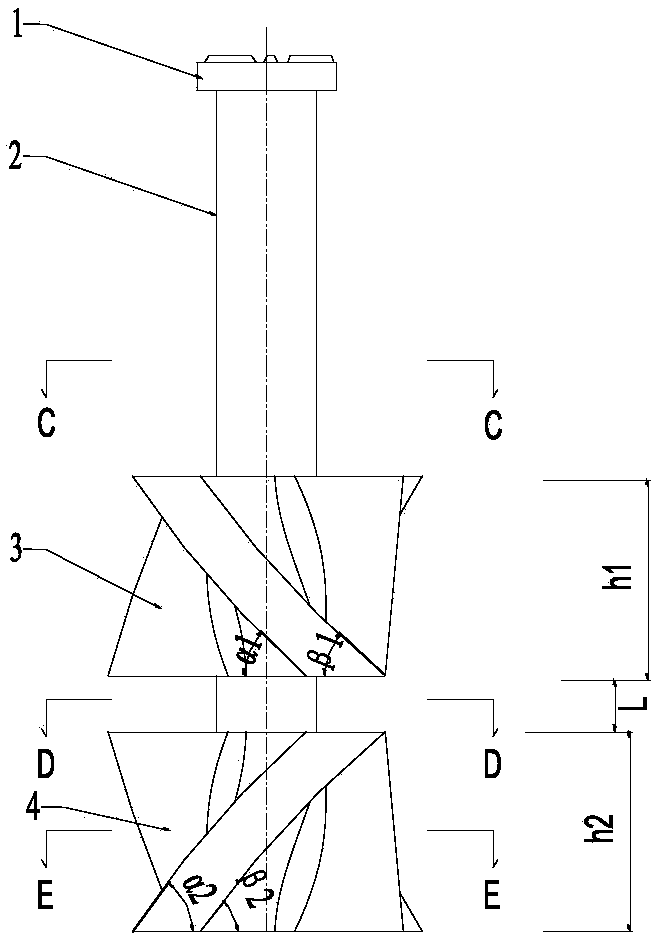

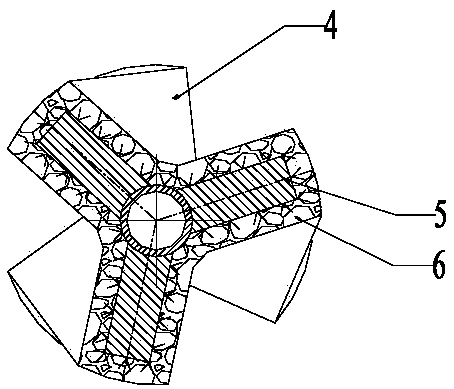

[0039] Such as Figure 1-5 The shown agitator for global stirring and desulfurization of molten iron includes agitator shaft 2, agitator connecting flange 1 arranged at the top of agitator shaft 2, and 2 to 4 flanges fixed on the outer periphery of agitator shaft 2 and evenly distributed around the circumference of agitator shaft 2. The upper stirring blade 3 and 2 to 4 lower stirring blades 4 fixed on the outer periphery of the stirring shaft 2 and around the circumferential direction of the stirring shaft. The numbers are the same, and at the same time, the lower stirring blades 4 are located below the upper stirring blades 3, and each upper stirring blade 3 and each lower stirring blade 4 include a stirring blade core 5 and a stirring blade core refractory castable lining 6. Each upper stirring blade 3 is a left-handed helical bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com