Patents

Literature

33results about How to "Speed up the mixing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

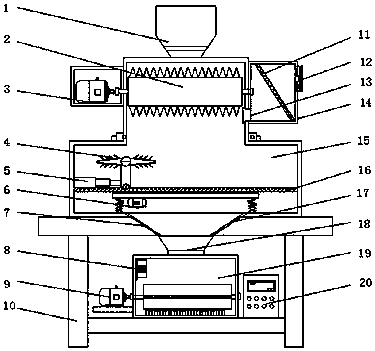

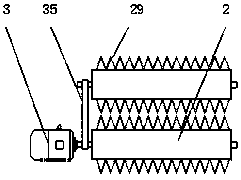

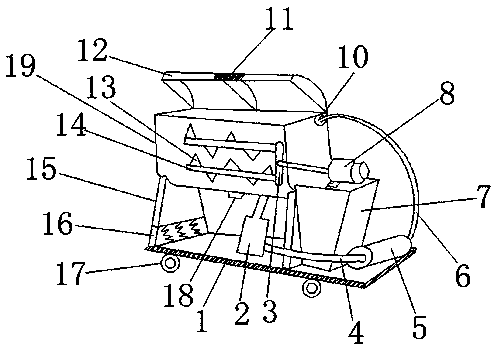

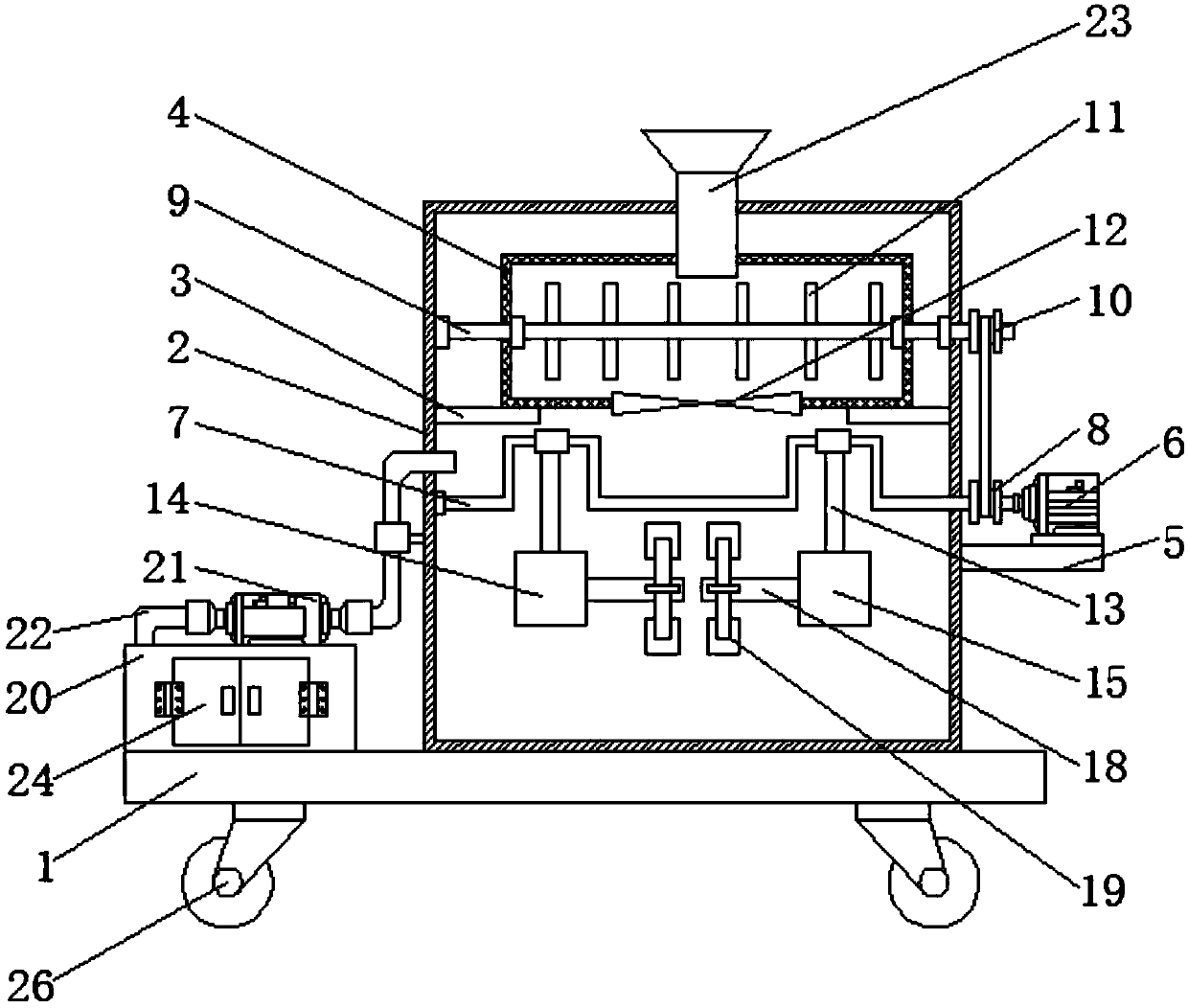

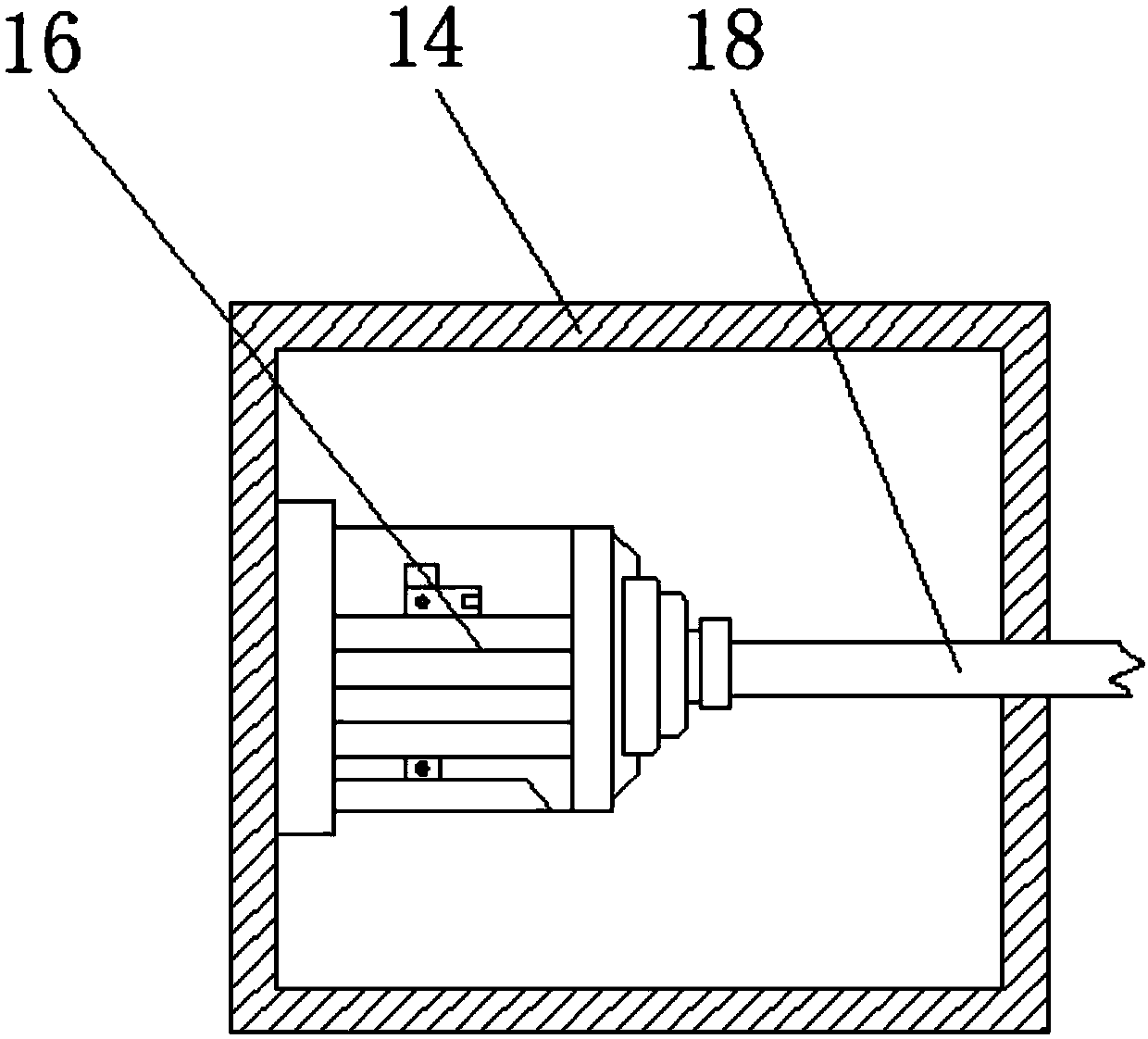

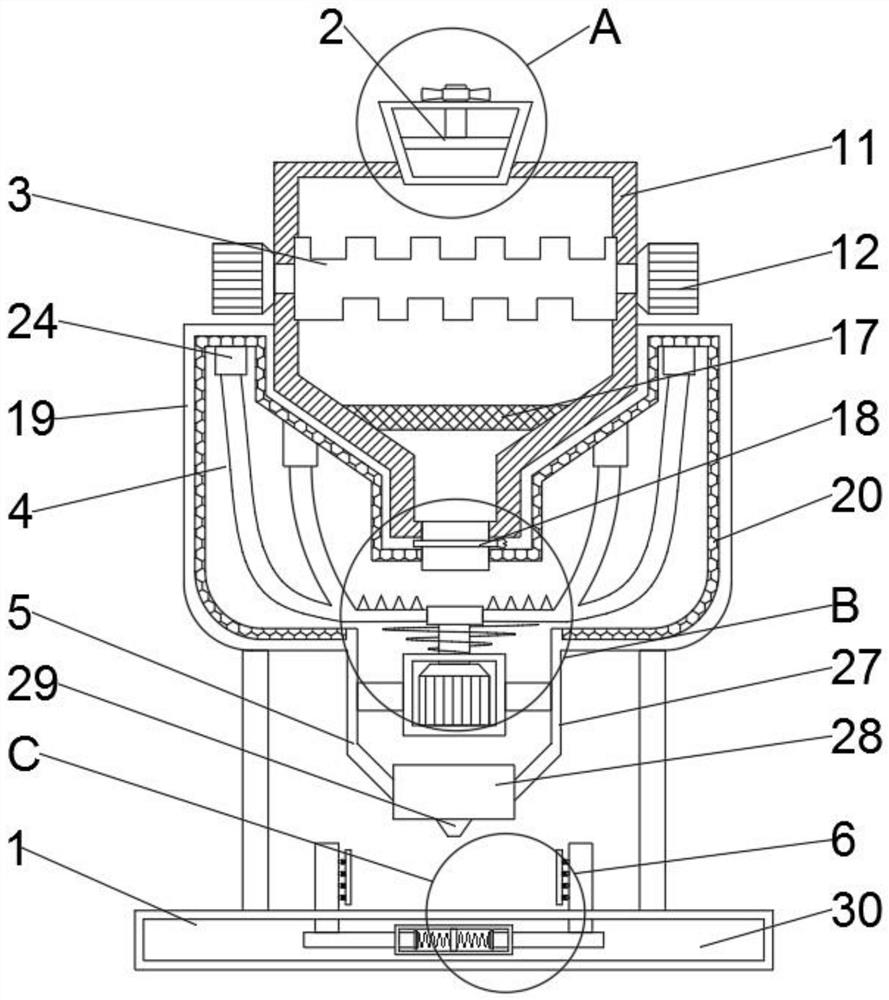

Crusher for preparation of agricultural fertilizer

InactiveCN107876140AStir quicklyFast crushingRotary stirring mixersTransportation and packagingAgricultural scienceReciprocating motion

The invention discloses a crusher for preparation of agricultural fertilizer. The crusher comprises a frame body and a crushing box arranged on the frame body, wherein a feeding hopper is arranged onthe top of the crushing box; a material storage cavity is formed in the bottom of the crushing box; the bottom of the material storage cavity is connected with a discharging hopper; a material storagebox is arranged under the discharging hopper; a second motor is fixed to one side of the material storage box, and a control box is arranged on the other side of the material storage box; a dust collecting box is arranged on the side, far away from a first motor, of the top end of the crushing box; and a fan is arranged on the outer side of the dust collecting box. Stirring blades are arranged inthe material storage box of the crusher and can be used for rapidly stirring the fertilizer, a heating wire is arranged inside the material storage box and can be used for heating the fertilizer, thus the wet caking fertilizer can be rapidly stirred into particles, and the stirring process is accelerated. A sliding rod, a hydraulic telescopic rod and a third motor are arranged, so that crushing fan blades can do reciprocating motion back and forth while rotating and crushing is more thorough.

Owner:CHANGSHU HAOYU ELECTRONICS INFORMATION TECH

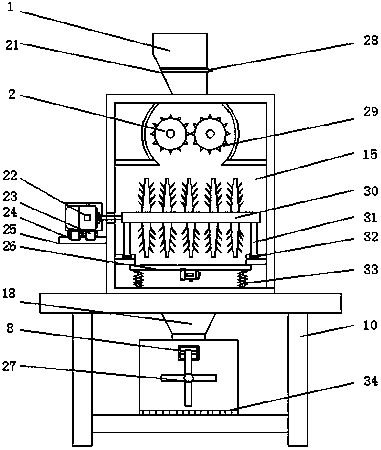

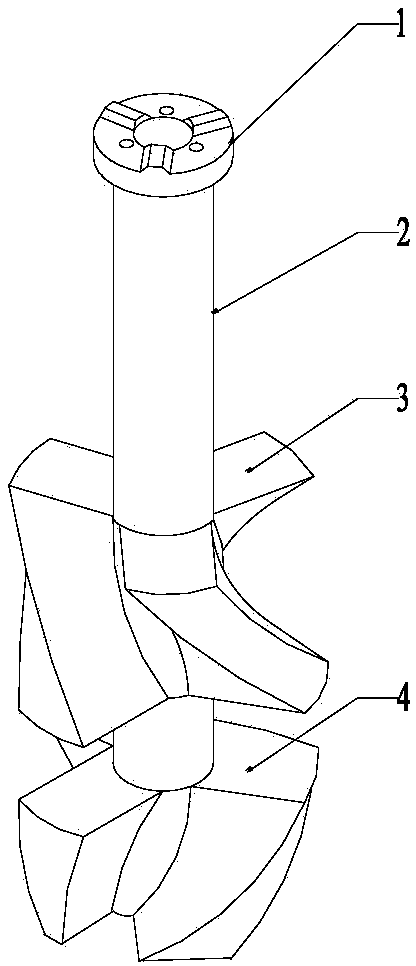

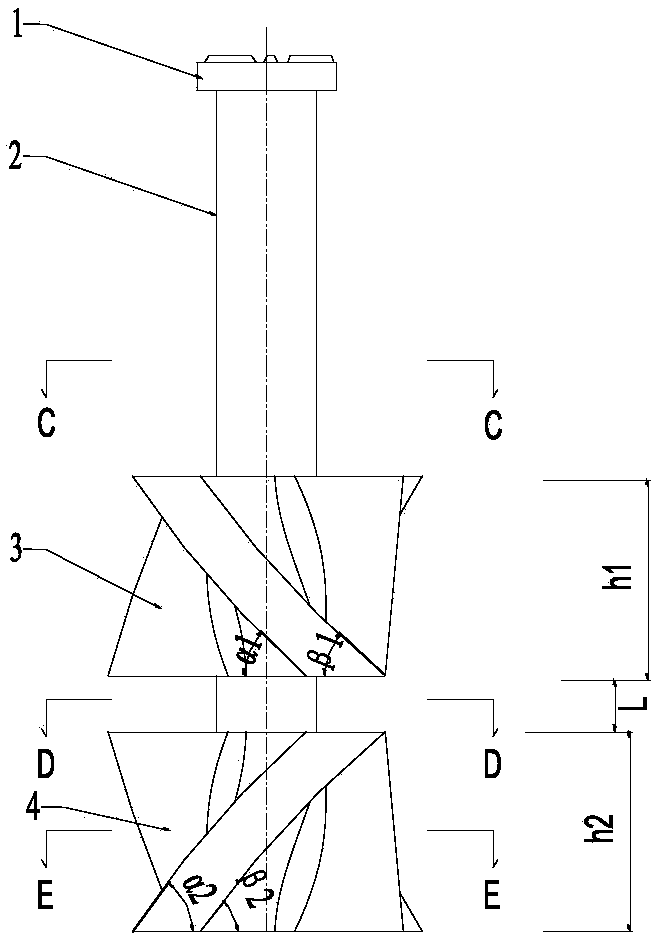

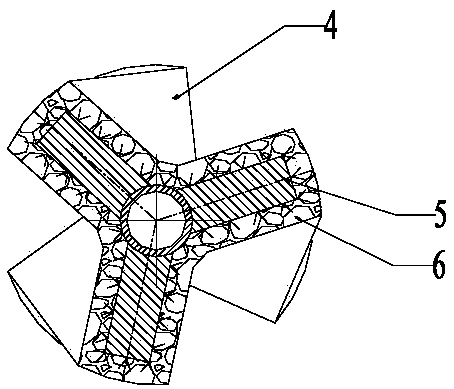

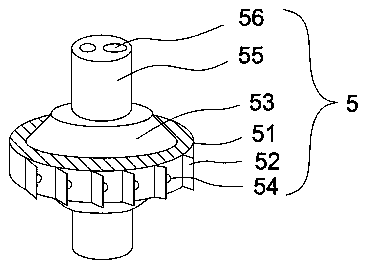

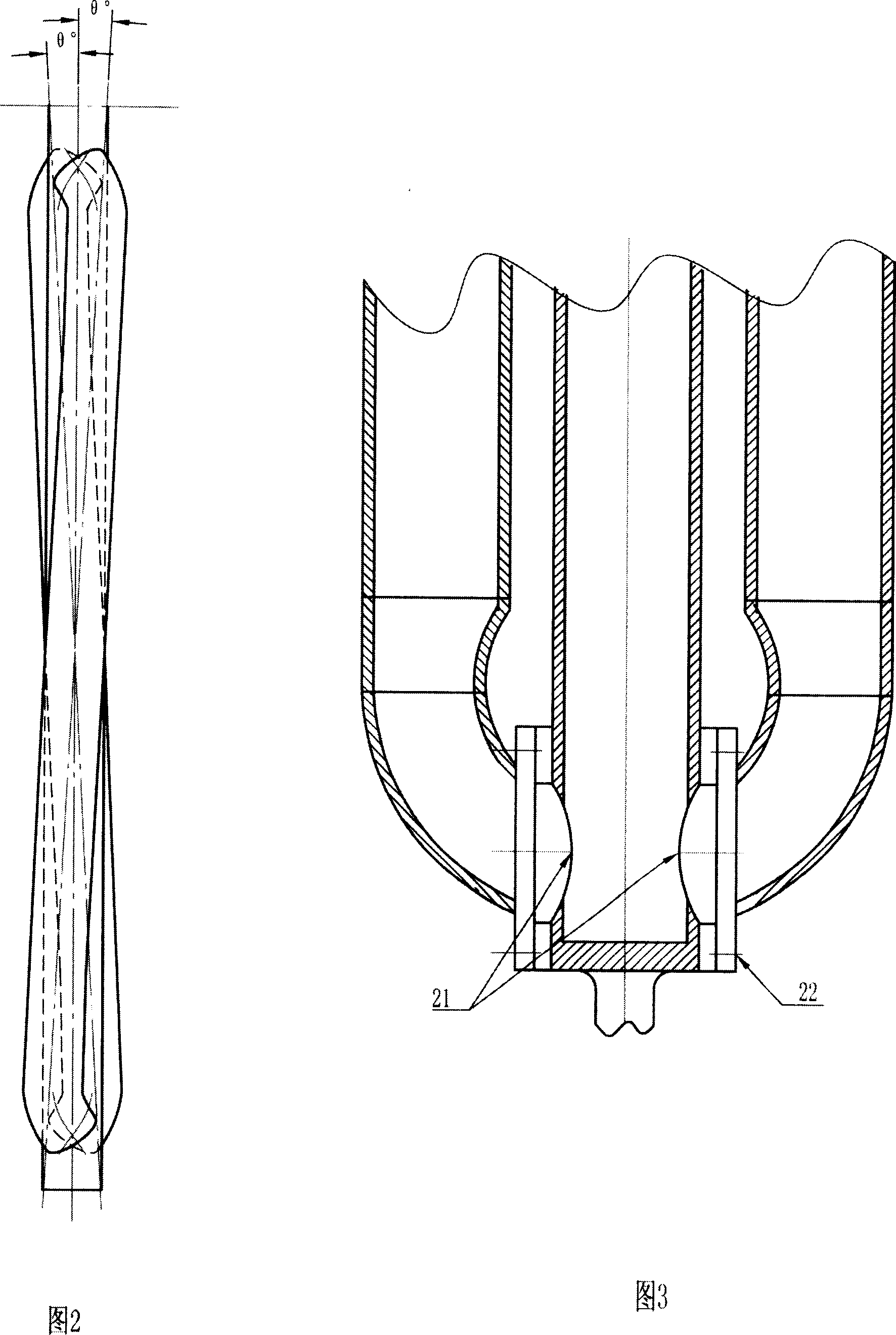

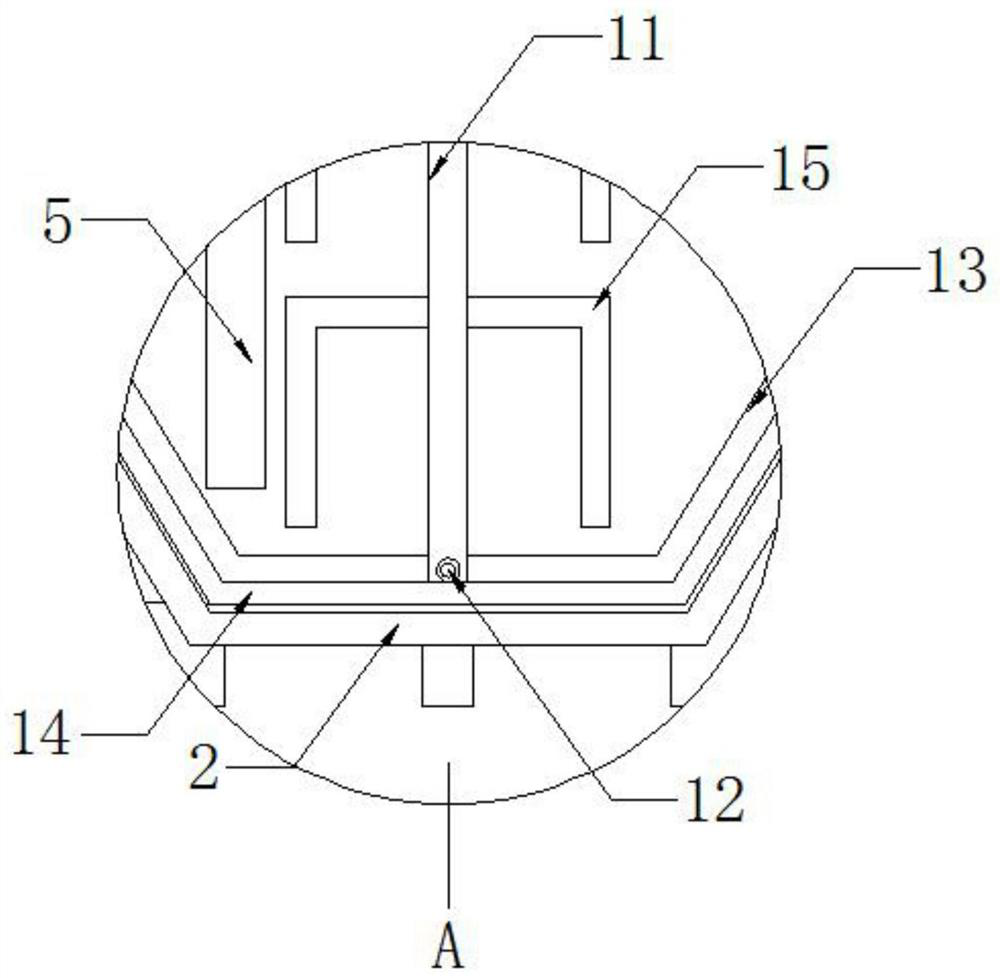

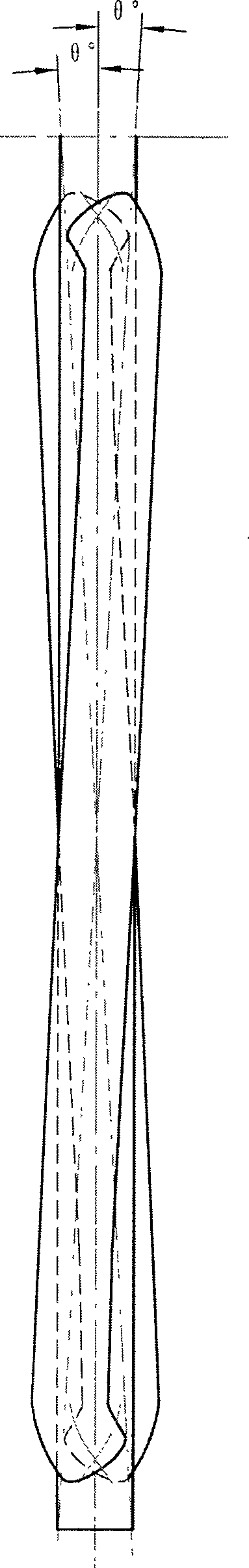

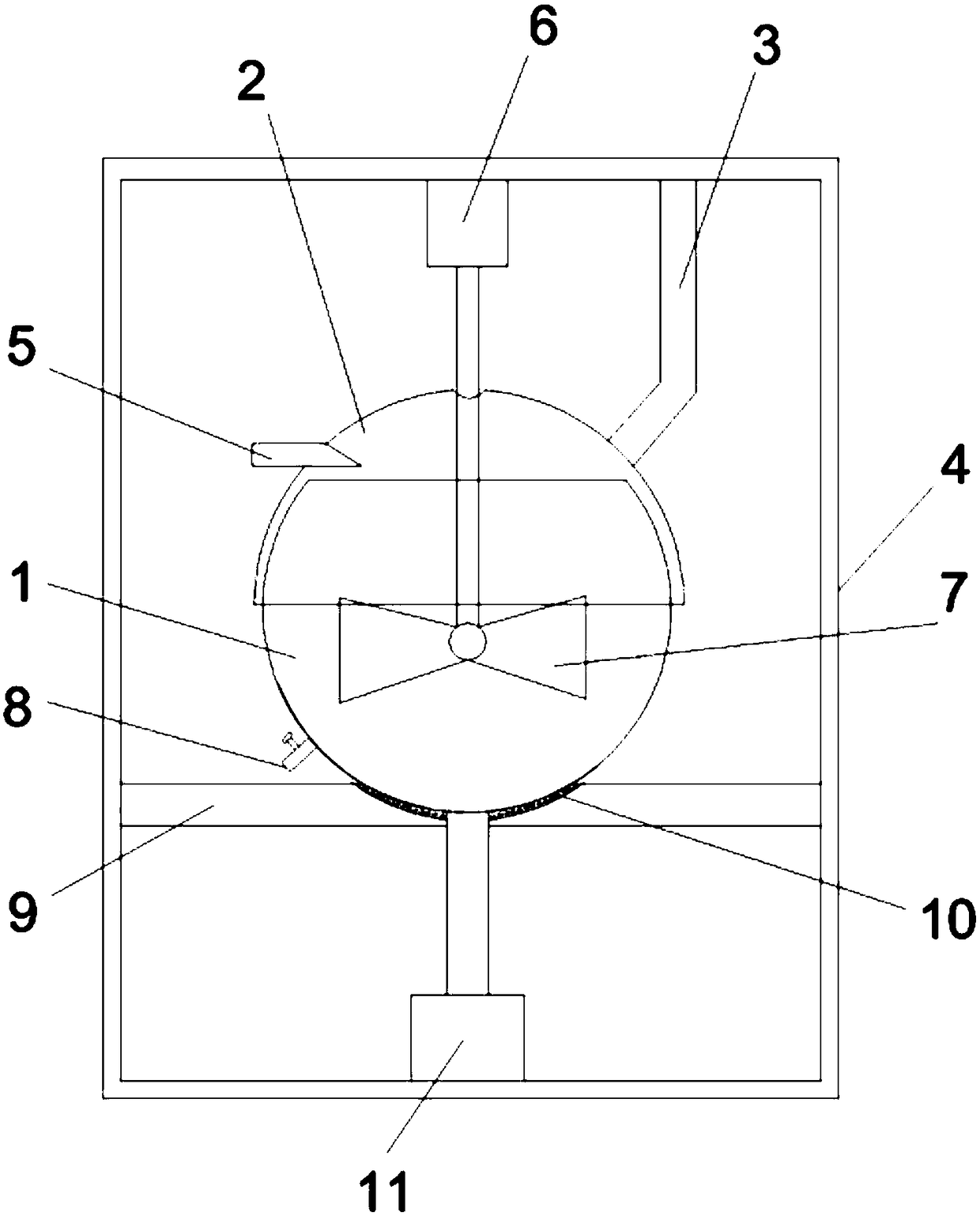

Molten iron full-domain stirring and desulfurization stirrer and using method thereof

The invention discloses a molten iron full-domain stirring and desulfurization stirrer. The stirrer comprises a stirring shaft, a stirrer connecting flange, upper-layer stirring blades and lower-layerstirring blades, each upper-layer stirring blade and each lower-layer stirring blade each comprises a stirring blade core and a stirring blade core fire-resistant pouring material lining, each upper-layer stirring blade is a left-rotated spiral blade rotating in the same direction as the stirring direction, each lower-layer stirring blade is a right-rotated spiral blade rotating in the directionopposite to the stirring direction, and the lower-layer stirring blades and the upper-layer stirring blades are arranged at the same circumferential angle in the circumferential direction of the stirring shaft or are arranged in a front-back equal-angle staggered angle mode. Through the double-layer stirring blade structure arranged up and down, the arrangement distance of the stirring blades in the length direction of the stirring shaft is greatly increased, the stirring depth and the effective stirring area of the stirrer on the molten iron in a molten iron ladle are expanded, stirring of the molten iron at the bottom of the molten iron ladle and stirring, mixing and mass transfer of the full-domain molten iron are remarkably enhanced, and the dynamic conditions of the full-domain molteniron stirring and desulfurization reaction are greatly improved.

Owner:武汉钢铁有限公司

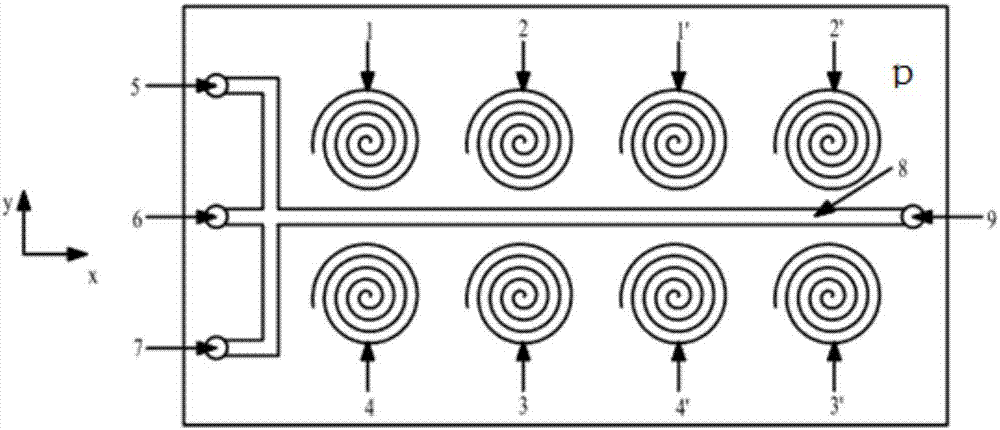

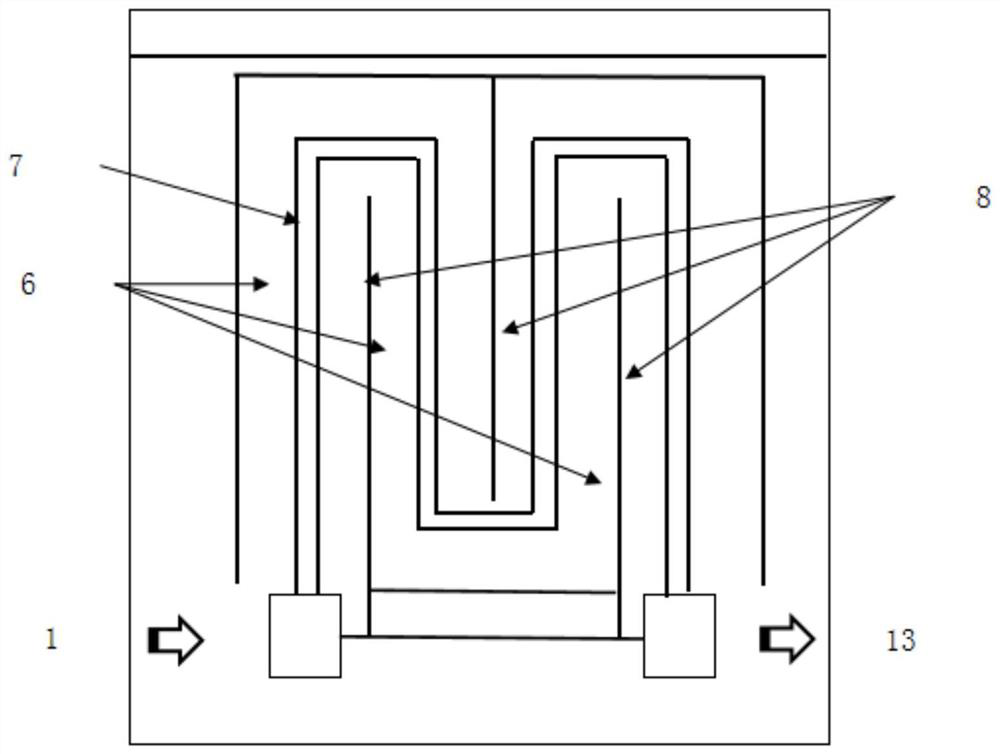

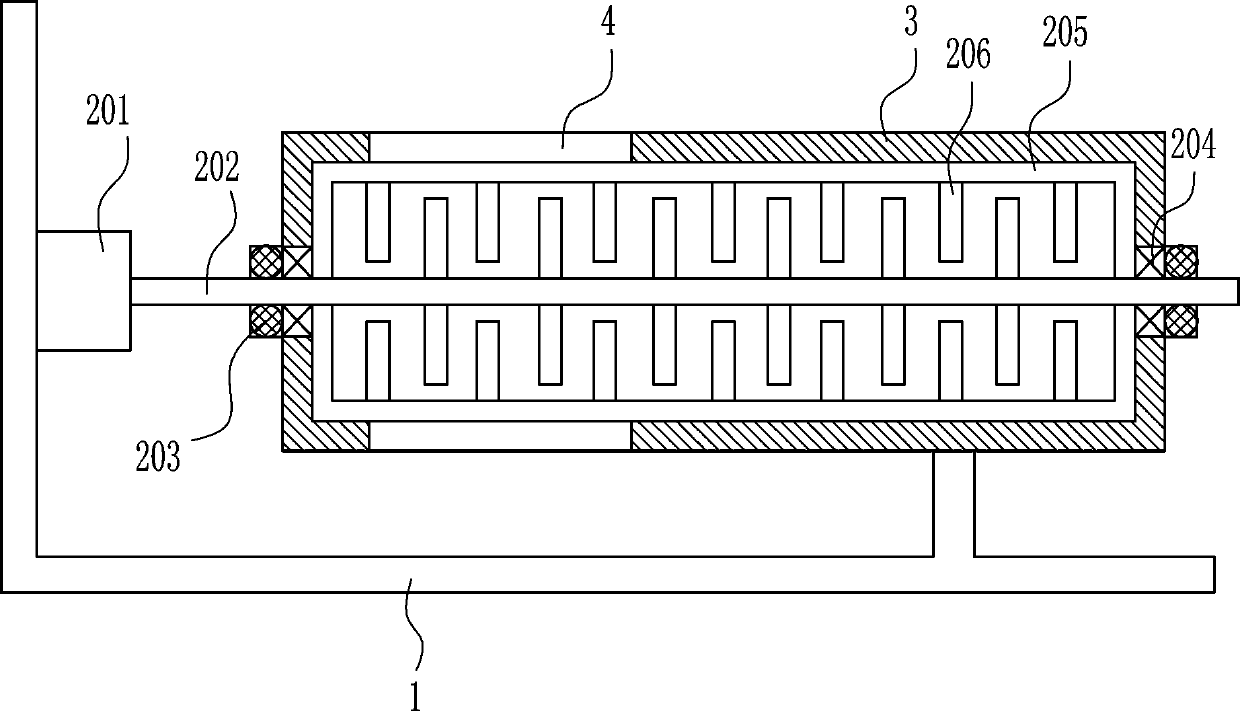

Rapid microfluidic mixer based on coplanar coil group

InactiveCN107029612AFlexible Quantity AdjustmentEasy to adjust the quantityTransportation and packagingMixersMicrofluidicsMagnetite Nanoparticles

The invention belongs to the related field of microfluidic equipment and discloses a rapid microfluidic mixer based on a coplanar coil group. The mixer comprises a mixing channel, multiple inlets and outlets arranged on two opposite sides of the mixing channel as well as multiple coil group units sequentially arranged in the axis direction of the mixing channel and located in the same plane, wherein the multiple inlets are used for guiding different fluids and magnetic nanoparticles which are to be mixed, each coil group unit consists of four coils which are symmetrically arranged above and below the axis of the mixing channel, alternating currents which have identical frequency and amplitude and whose phases sequentially have 90-degree difference pass through the four coils, thus, rotating magnetic fields are generated continuously along the mixing channel to drive the nanoparticles to rotate, and the stirring and mixing process is accelerated. Tests indicate that compared with the prior art, the mixer has the advantages that the mixing process can be accelerated significantly and the high-quality fluid mixing effect can be obtained at a longer distance and in a wider range.

Owner:HUAZHONG UNIV OF SCI & TECH

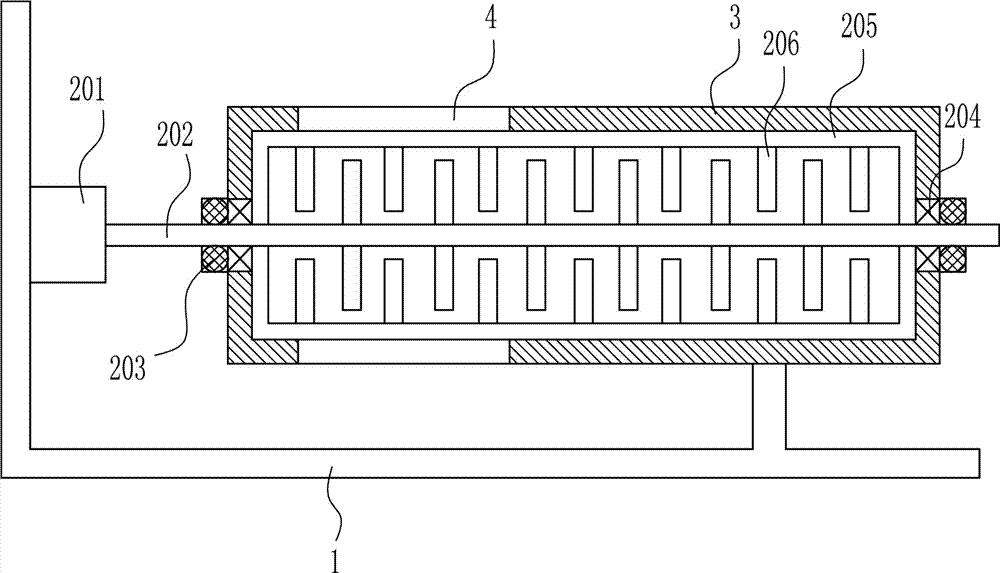

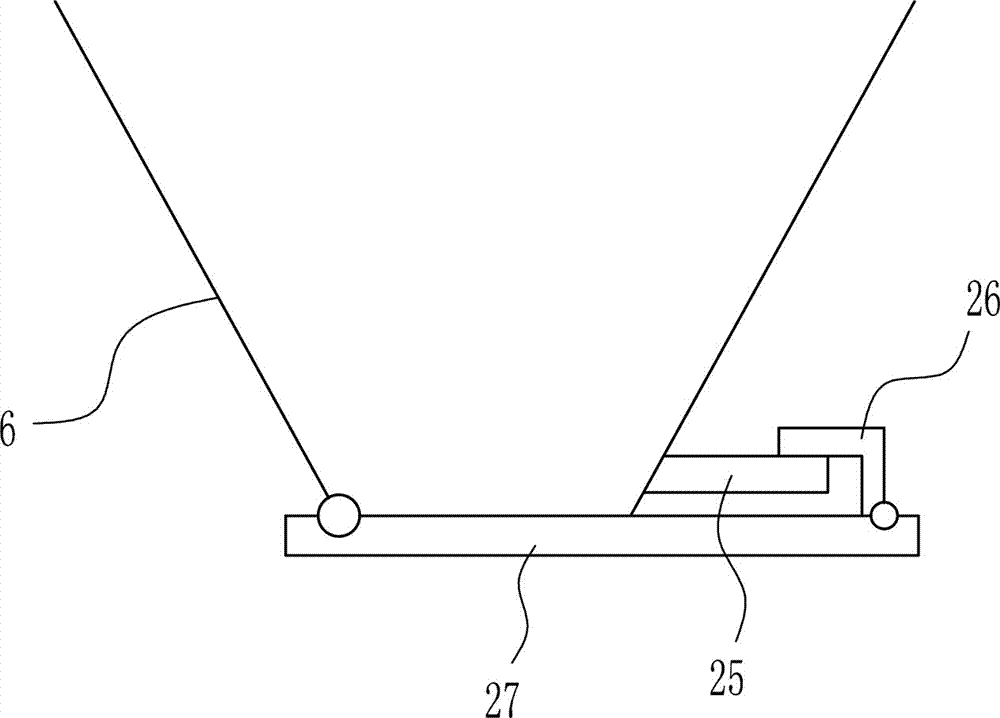

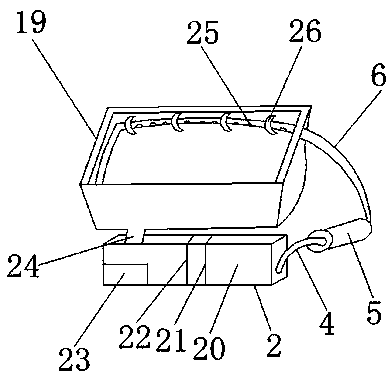

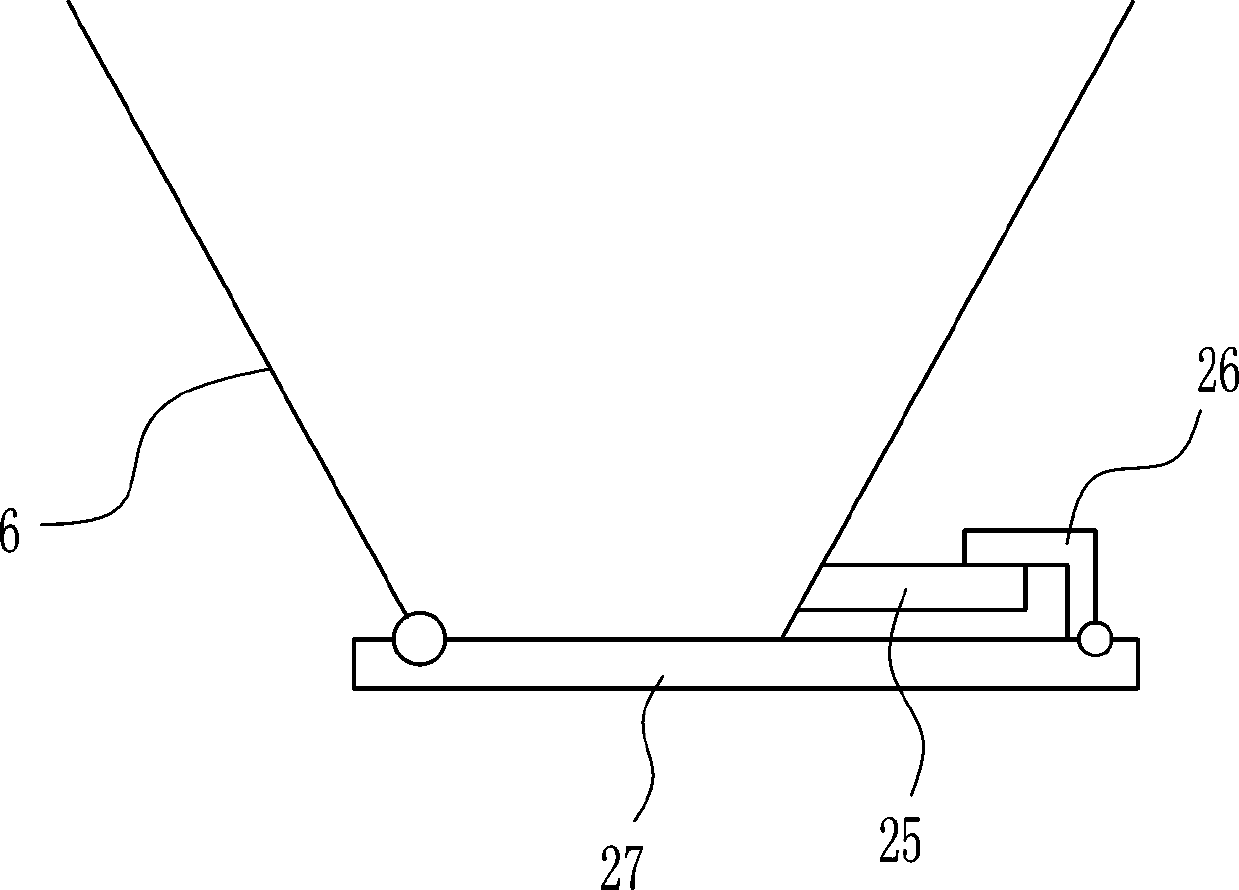

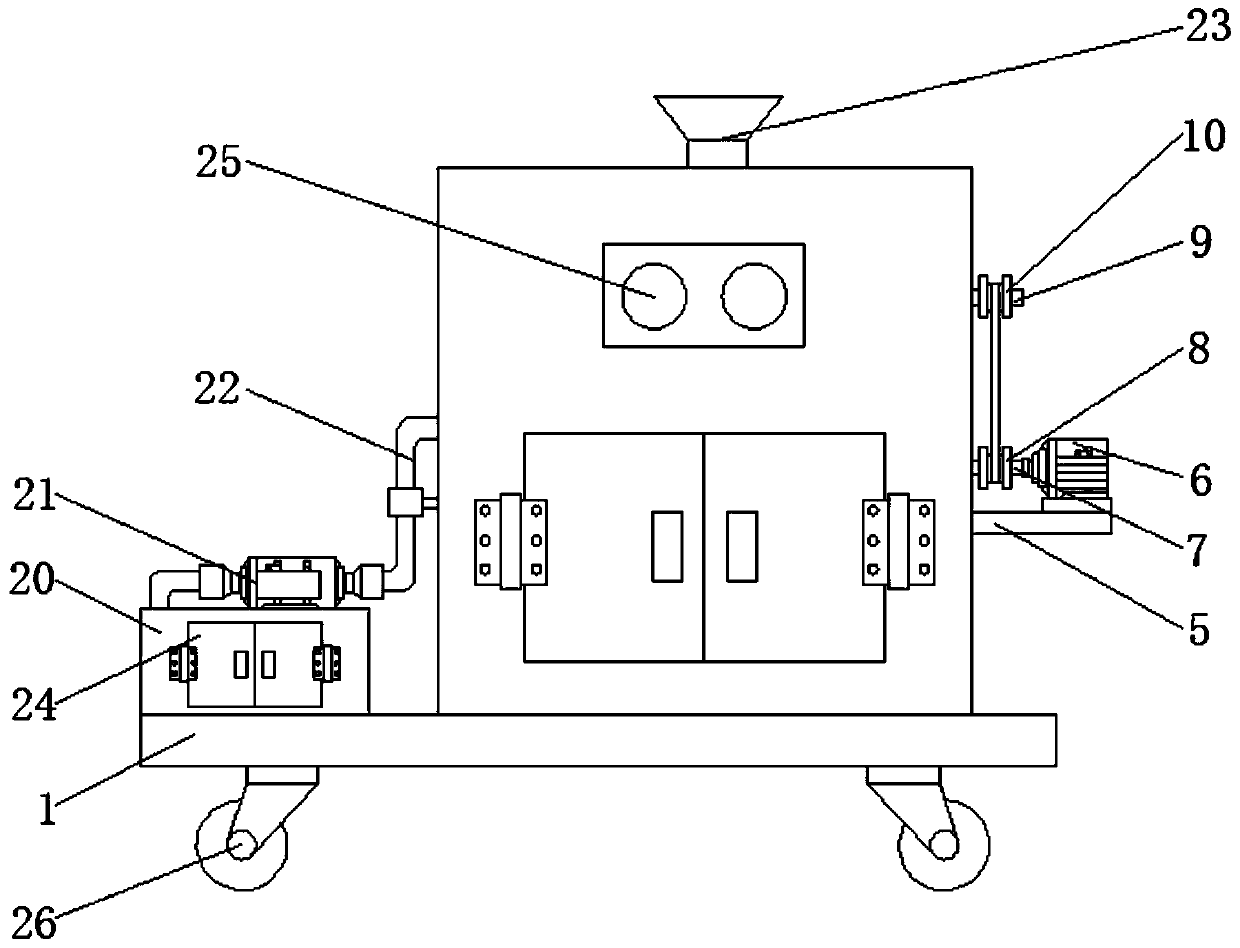

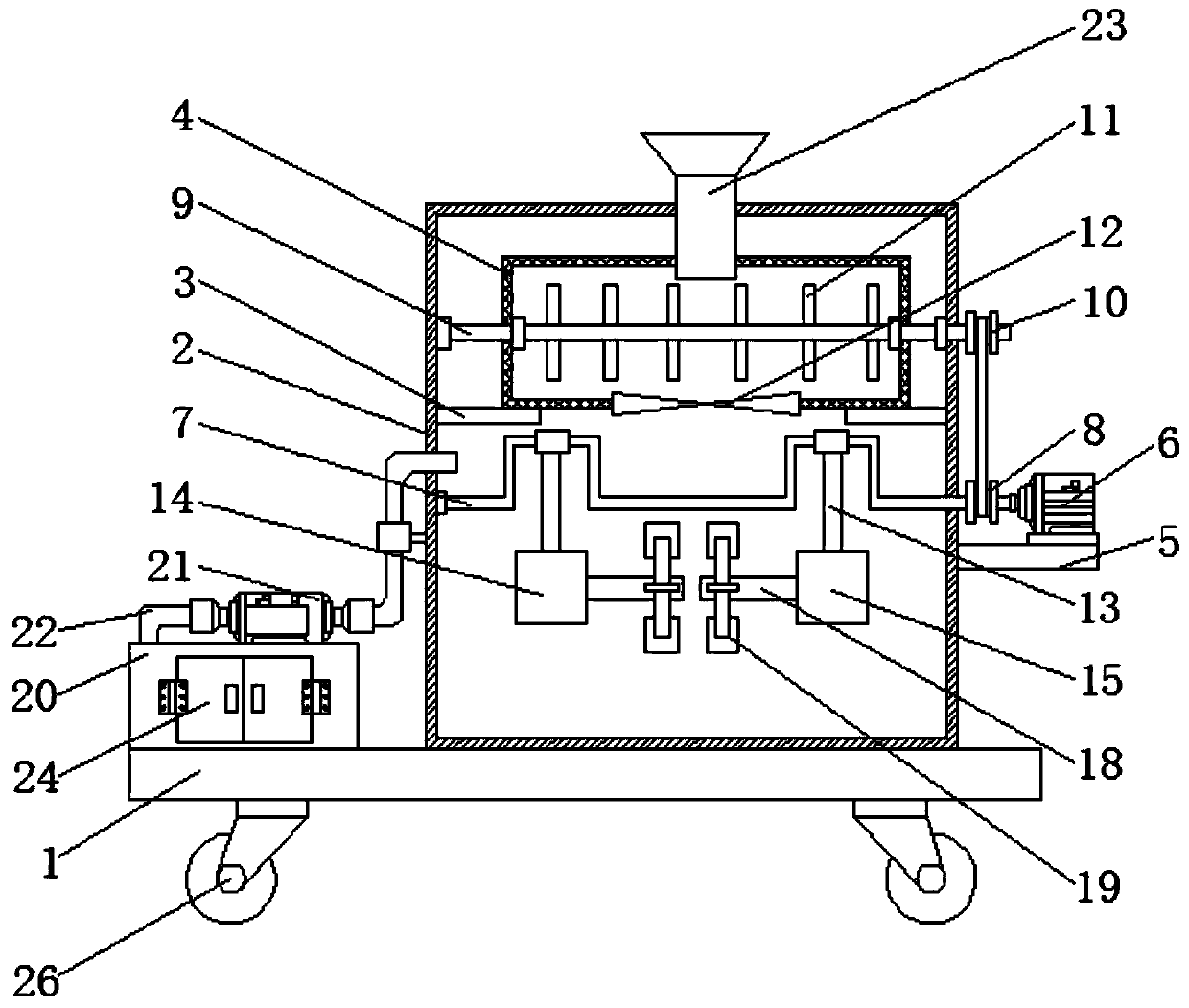

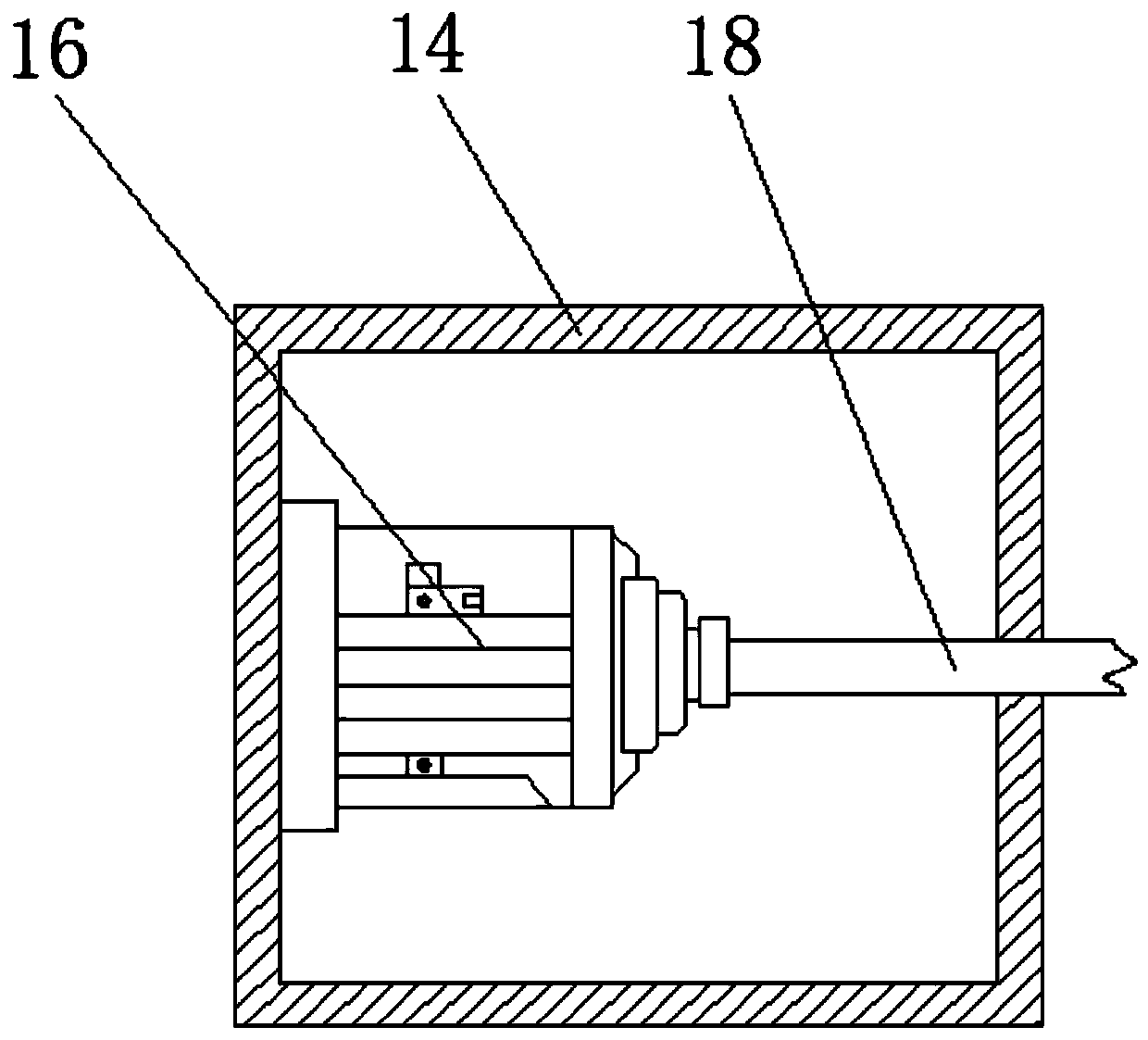

Petroleum asphalt placement stirring box

InactiveCN107308837ASpeed up the mixing processSave time at workRotary stirring mixersTransportation and packagingPetroleumAsphalt

The invention relates to a stirring box, in particular to a petroleum asphalt placement stirring box. By the petroleum asphalt placement stirring box, asphalt cannot be caked easily, cannot be adhered to walls easily and is discharged conveniently in an asphalt placement process. In order to solve the technical problem, the petroleum asphalt placement stirring box comprises a rack and the like, wherein the top of the rack is connected with a placement box; through holes are separately formed in the left sides of the top and the bottom of the placement box; switch mechanisms are separately arranged on the left sides of the top and the bottom of the placement box; a stirring mechanism is arranged in the placement box; and the left side of the bottom of the rack is connected with a funnel. The petroleum asphalt placement stirring box is designed; by the stirring mechanism, condensation and wall adhering of the asphalt can be prevented; and meanwhile, by a reel, a steel wire rope and the like, processes of stirring operation and wall scraping operation can be accelerated, and the working efficiency is improved. Meanwhile, the petroleum asphalt placement stirring box is provided with a guide track, a guide sleeve, a push rod and the like, the asphalt can be prevented from being adhered to the inner wall of the funnel, and waste is reduced.

Owner:FOSHAN LUBANG ASPHALT CO LTD

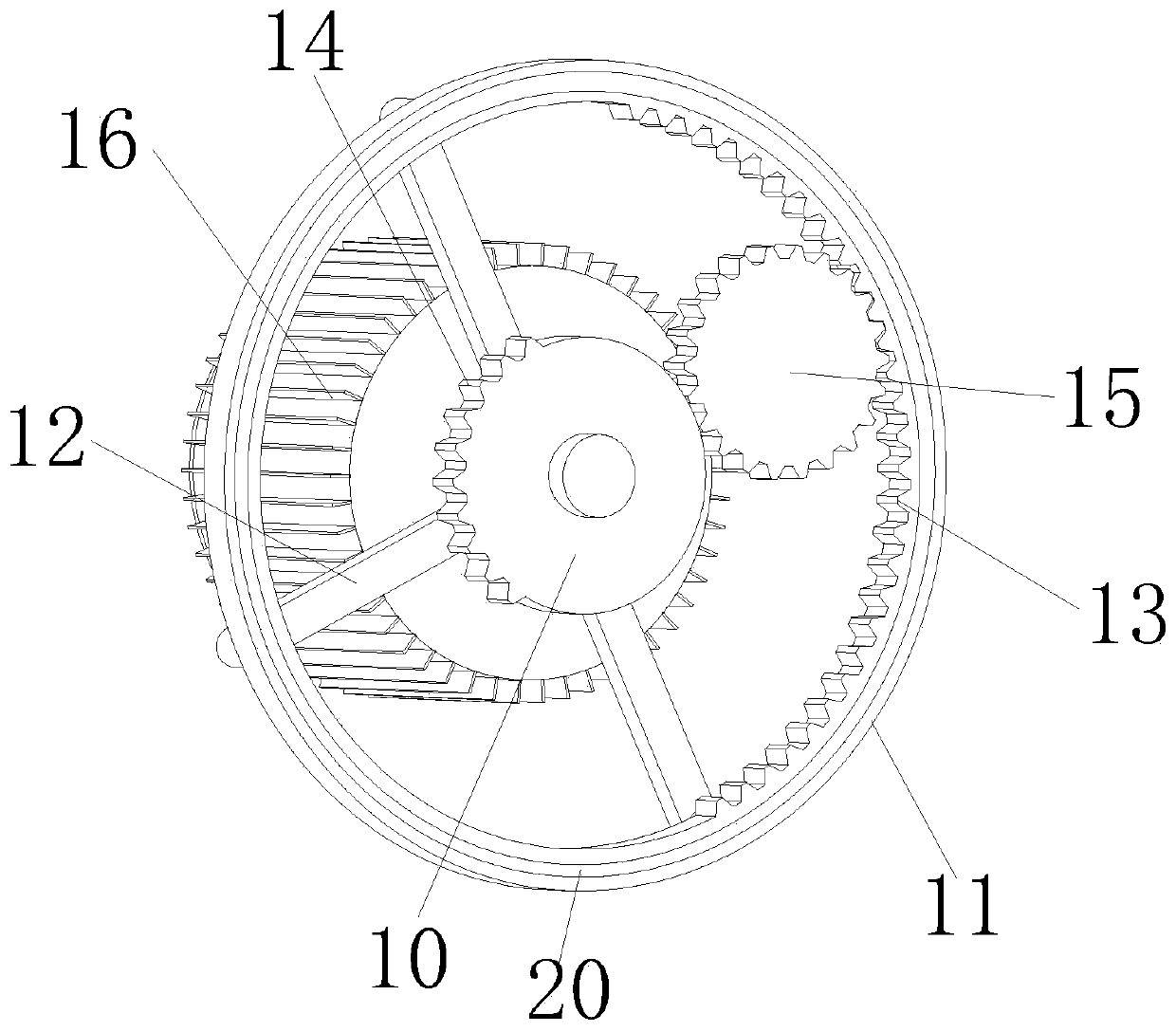

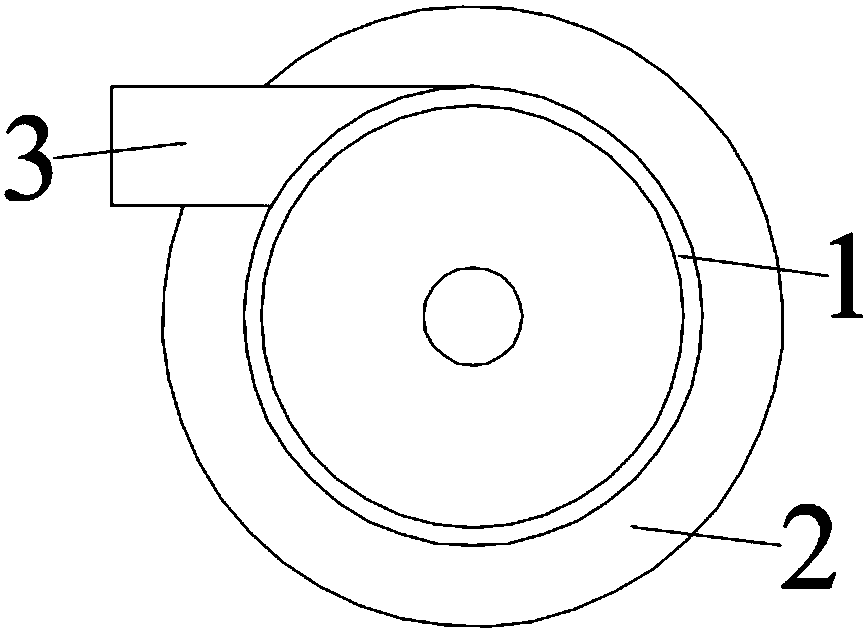

Milk stirring and mixing drum with bidirectional driving mechanism

InactiveCN111389275AImprove the mixing effectImprove stirring efficiencyShaking/oscillating/vibrating mixersTransportation and packagingRotational axisCircular disc

Belonging to the technical field of milk production and mixing equipment, the invention provides a milk stirring and mixing drum with a bidirectional driving mechanism to overcome the defect of low stirring efficiency of a stirring device for milk products in the prior art. The milk stirring and mixing drum comprises a drum body, a rotating shaft is arranged in the drum body, and a stirring mechanism is arranged on the rotating shaft; a bidirectional driving mechanism is arranged on the drum body, the bidirectional driving mechanism comprises a transmission disc and a transmission circular ring, a fixed rod is arranged between the transmission disc and the transmission circular ring, a section of continuously arranged first transmission teeth are arranged on an inner side face of the transmission circular ring, a section of continuously arranged second transmission teeth are arranged on one side, back to the first transmission teeth, of the transmission disc, a gear is fixedly connected to the upper end of the rotating shaft, and a motor is further arranged at the upper end of the drum body. By arranging the bidirectional driving mechanism, the rotating shaft can be driven to perform bidirectional reciprocating switching stirring, the stirring effect is good, the stirring efficiency can be greatly improved, and the stirring time is saved.

Owner:浙江龙游李子园食品有限公司

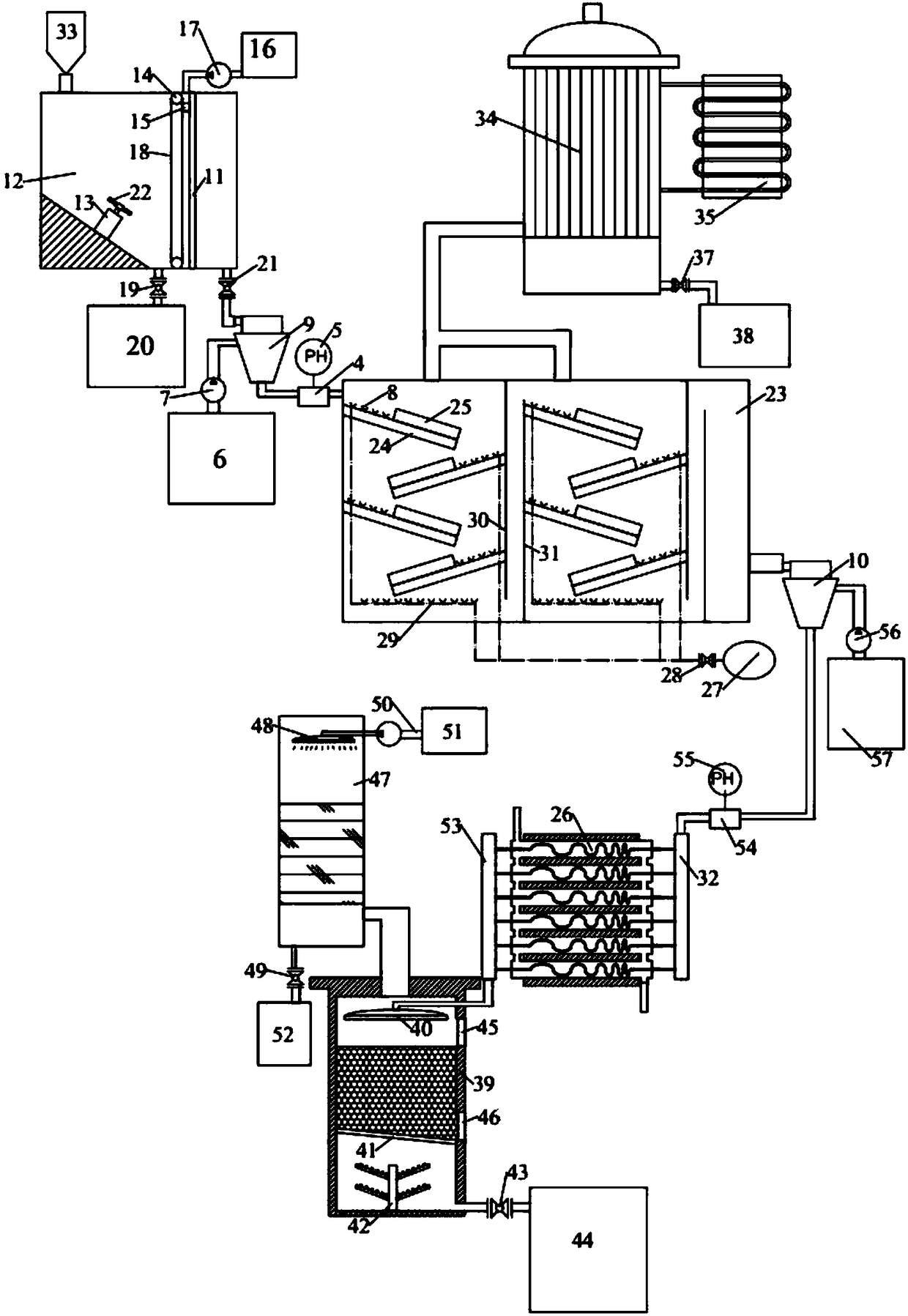

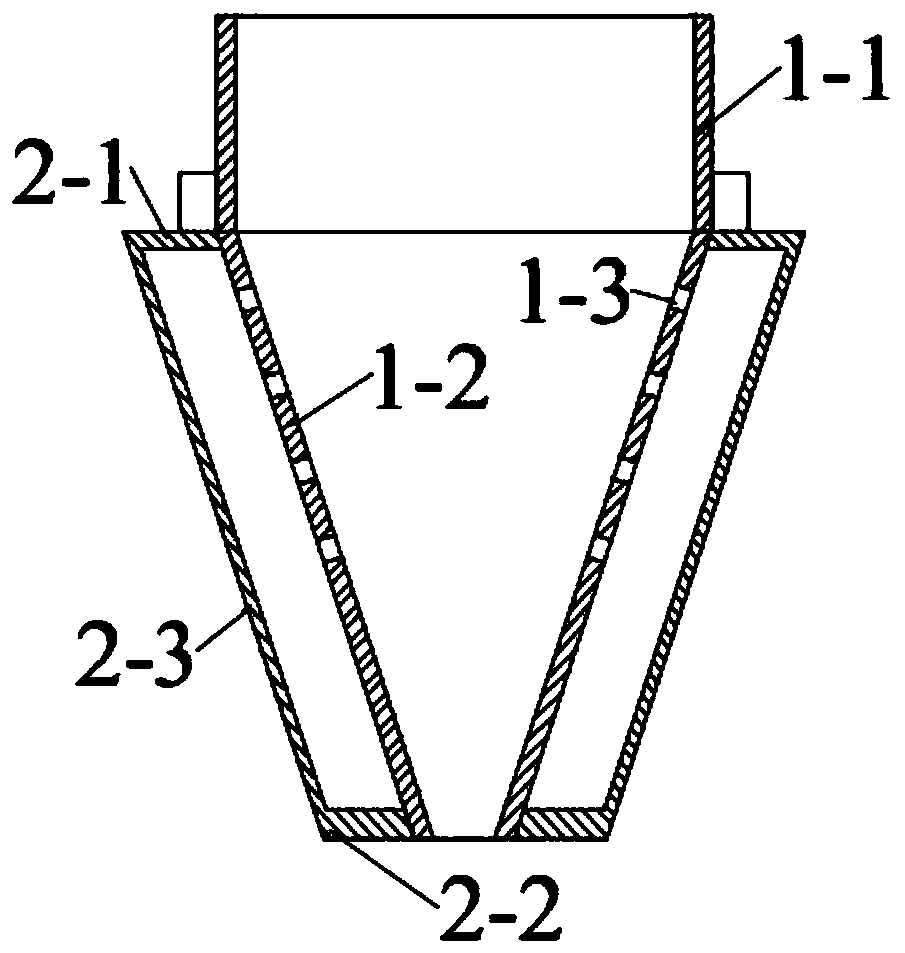

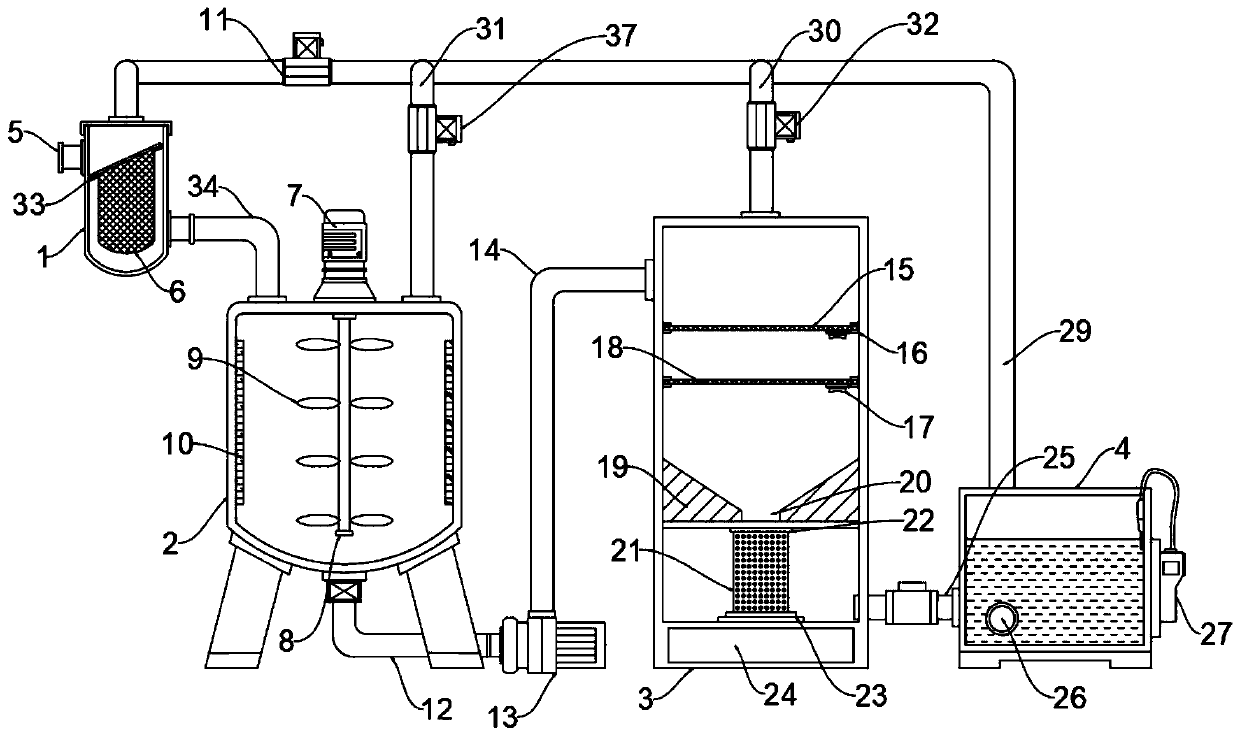

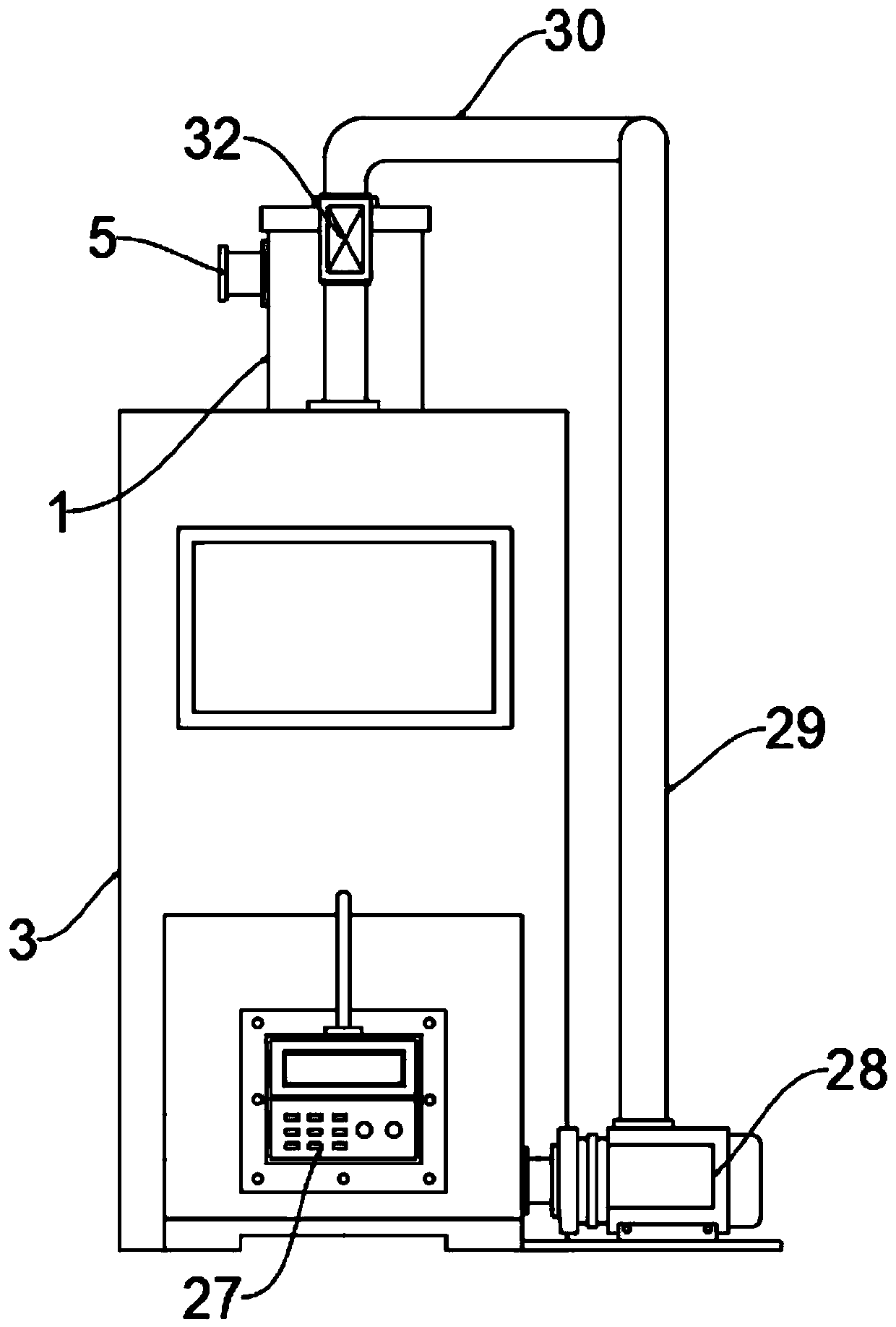

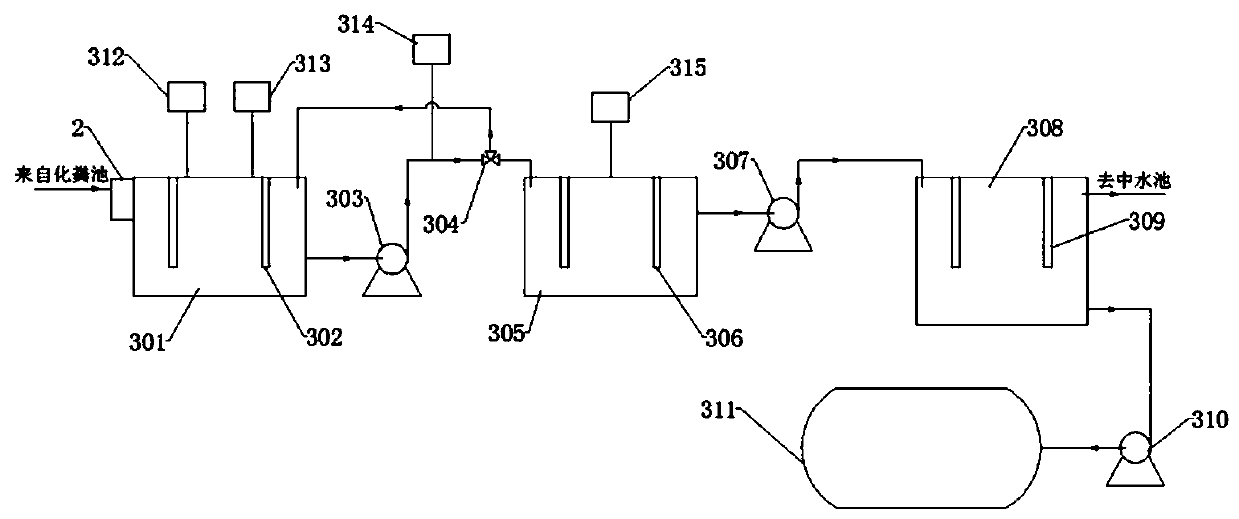

Dithioformate containing wastewater treatment device

ActiveCN108128971AReduce pollutionAvoid damageWater treatment parameter controlTreatment using aerobic processesEngineeringNitrogen gas

Owner:杭州沁欣环保科技有限公司

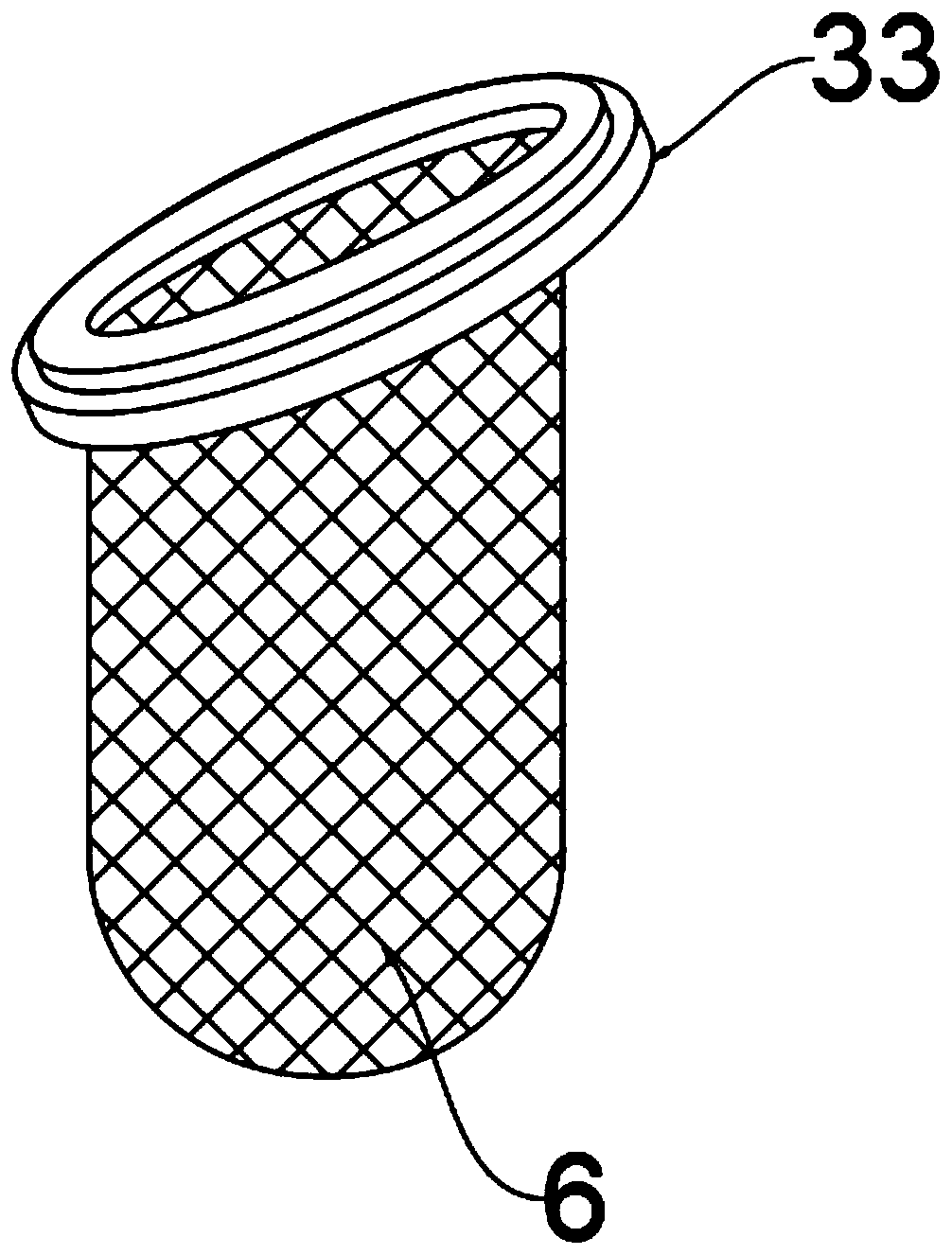

Camellia oleifera seed oil finished product purification device

InactiveCN110669584AGuaranteed qualityAvoid the problem of degraded purification qualityFatty-oils/fats refiningCamellia oleiferaEngineering

Relating to the technical field of camellia oleifera seed processing, the invention discloses a camellia oleifera seed oil finished product purification device, and can solve the problem that existingdevices cannot guarantee the oil product quality. One side of a filter cylinder is equipped with an oil inlet, a reaction kettle is disposed below the other side of the filter cylinder, a separationtower is arranged on one side of the reaction kettle, the bottoms of a first filter screen plate and a second filter screen plate are both equipped with a vibrator, a flow guide cylinder is arranged below the second filter screen plate, a separation cylinder is mounted below the flow guide cylinder, a detection pool is arranged on one side of the separation tower, an oil product detector is mounted on one side of the detection pool, a circulating pump is installed at the rear end of the detection pool, a circulating pipeline is installed on the circulating pump, a first branch pipe and a second branch pipe are arranged above the circulating pipeline respectively, a second electromagnetic valve is installed at a middle position of the first branch pipe, and a third electromagnetic valve isinstalled at a middle position of the second branch pipe.

Owner:湖北人人爱油脂有限公司

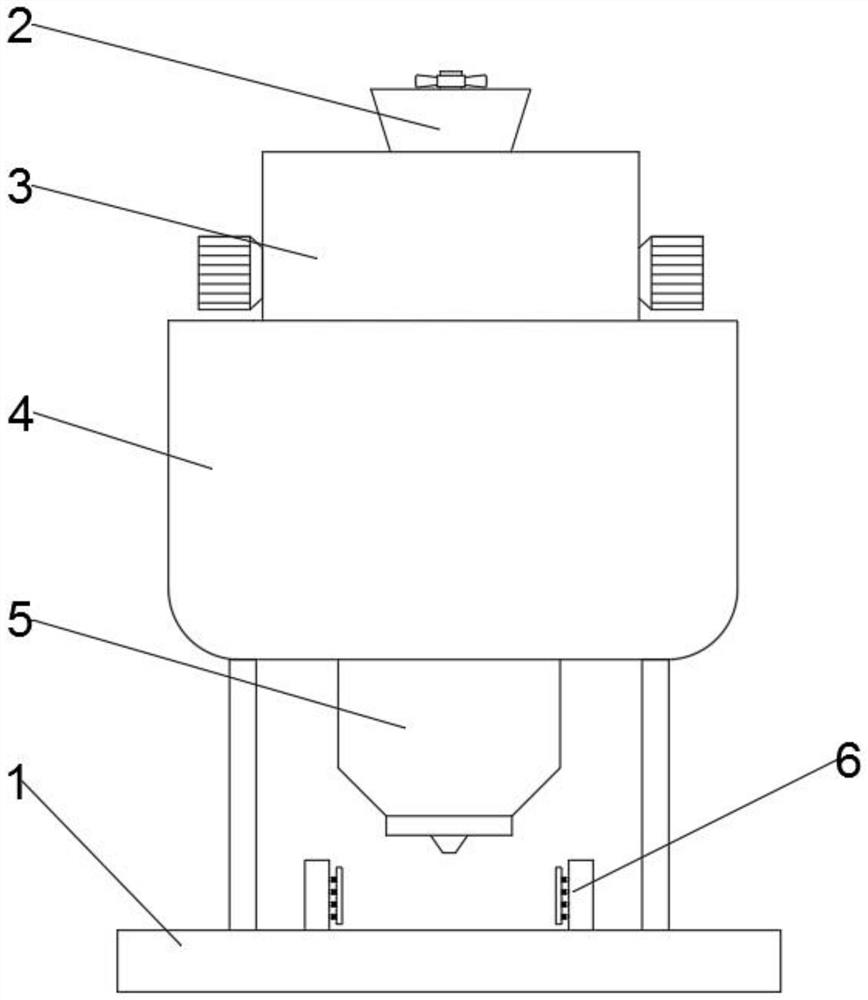

Rapid and efficient feed stirring equipment

InactiveCN108970456ASpeed up the fallImprove mixing uniformityFeeding-stuffRotary stirring mixersEngineeringLinkage concept

The invention discloses rapid and efficient feed stirring equipment. The rapid and efficient feed stirring equipment comprises a base; a lower end of the base is provided with support legs; a shell isconnected to an upper end of the base; a discharge port is disposed at the downside of the shell; an upper end of the shell is connected with a lower side surface of a blanking box; a middle end of the bottom of the blanking box is in a recessed shape and is fixedly connected with a middle part of a two-shaft output motor; an output shaft at a lower end of the two-shaft output motor is connectedwith a linkage rod; a stirring shaft is respectively and vertically connected to lower parts of two ends of the linkage rod; stirring rods which are disposed horizontally are uniformly distributed onthe stirring shafts at two ends in a staggered manner. Through the disposed linkage rod, the feed stirring equipment can do a circular movement under rotation of the two-shaft output motor so that thetwo stirring shafts vertically connected to the lower parts of the two ends of the linkage rod rotate correspondingly and the stirring rods disposed on the stirring shafts respectively and alternately stir feeds, thus the feed stirring process is accelerated, the feed stirring efficiency is improved and the feed stirring is more uniform.

Owner:金华市邀特科技有限公司

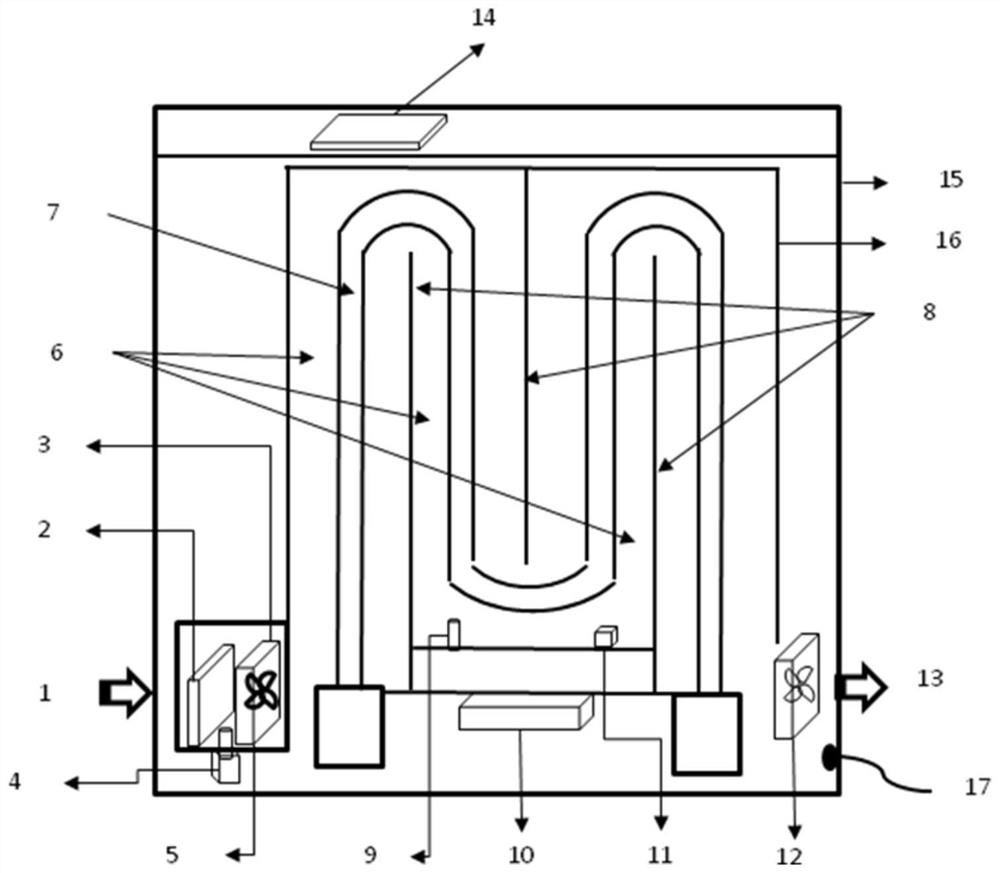

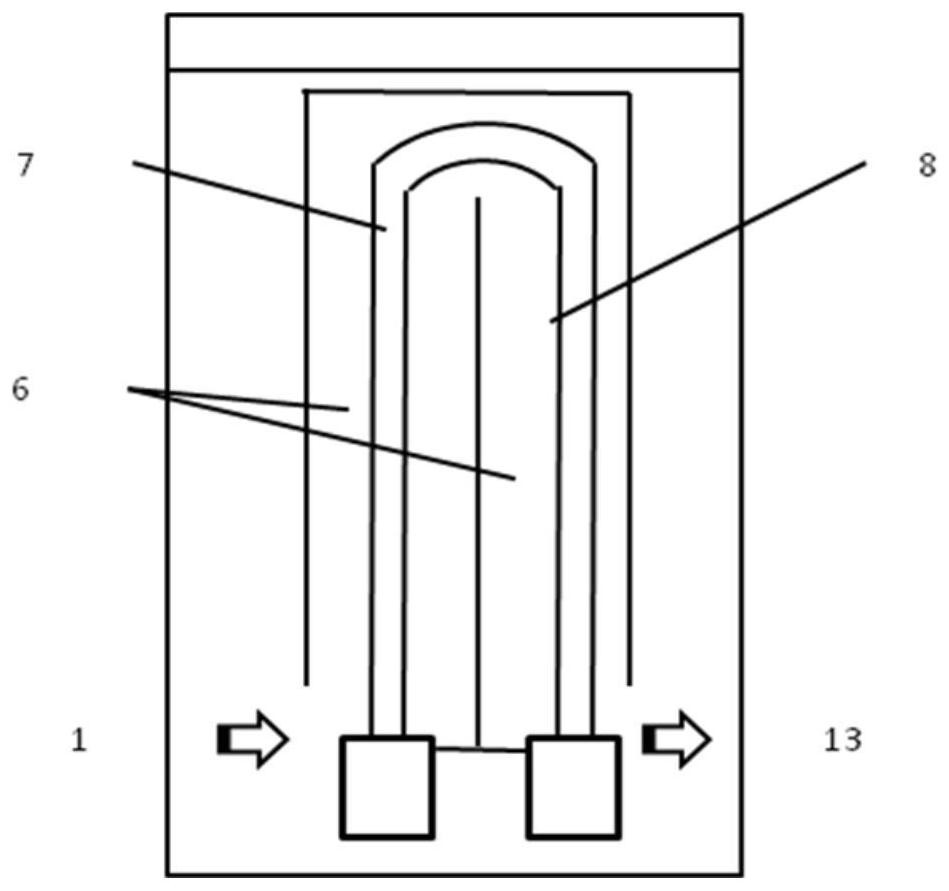

Air sterilization device and method

InactiveCN113048599AExtension of timeHigh strengthMechanical apparatusSpace heating and ventilation safety systemsElectrical ballastUltraviolet lights

The invention discloses an air sterilization device. The air sterilization device comprises an outer cover; an inner cover; air inlet area disinfection cavity being sequentially provided with an air inlet filtering device, an ozone generator and an air inlet fan in the air inlet direction; an air outlet pipe cavity being provided with an exhaust fan; at least one reflective current-limiting partition; an ultraviolet lamp tube being arranged along the near-center position of an airflow channel; a ballast being arranged at the bottom of the outer cover; a temperature sensor and an ultraviolet irradiation intensity sensor being uniformly distributed on the inner side wall of the airflow channel; an control mainboard with the input end being connected to the output end of the ultraviolet irradiation intensity sensor / the temperature sensor, and with the output end being connected to the input end of the air inlet fan / the ozone generator / the ballast / the exhaust fan; and a power supply module with one end being externally connected to commercial power, and with the other end being electrically connected to the control mainboard, the air inlet fan, the ozone generator, the ballast and the exhaust fan. The invention further discloses an air sterilization method.

Owner:陈长宏

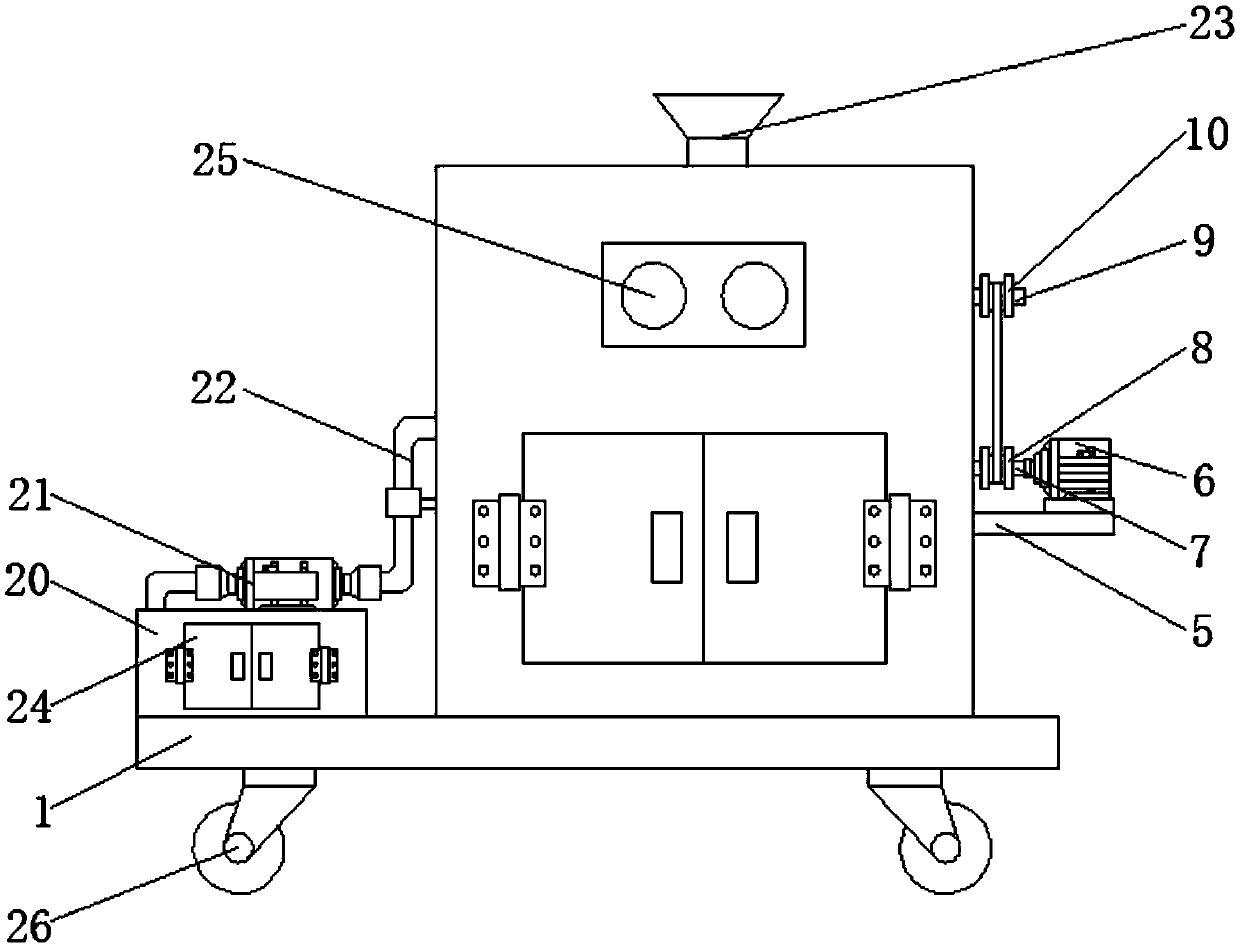

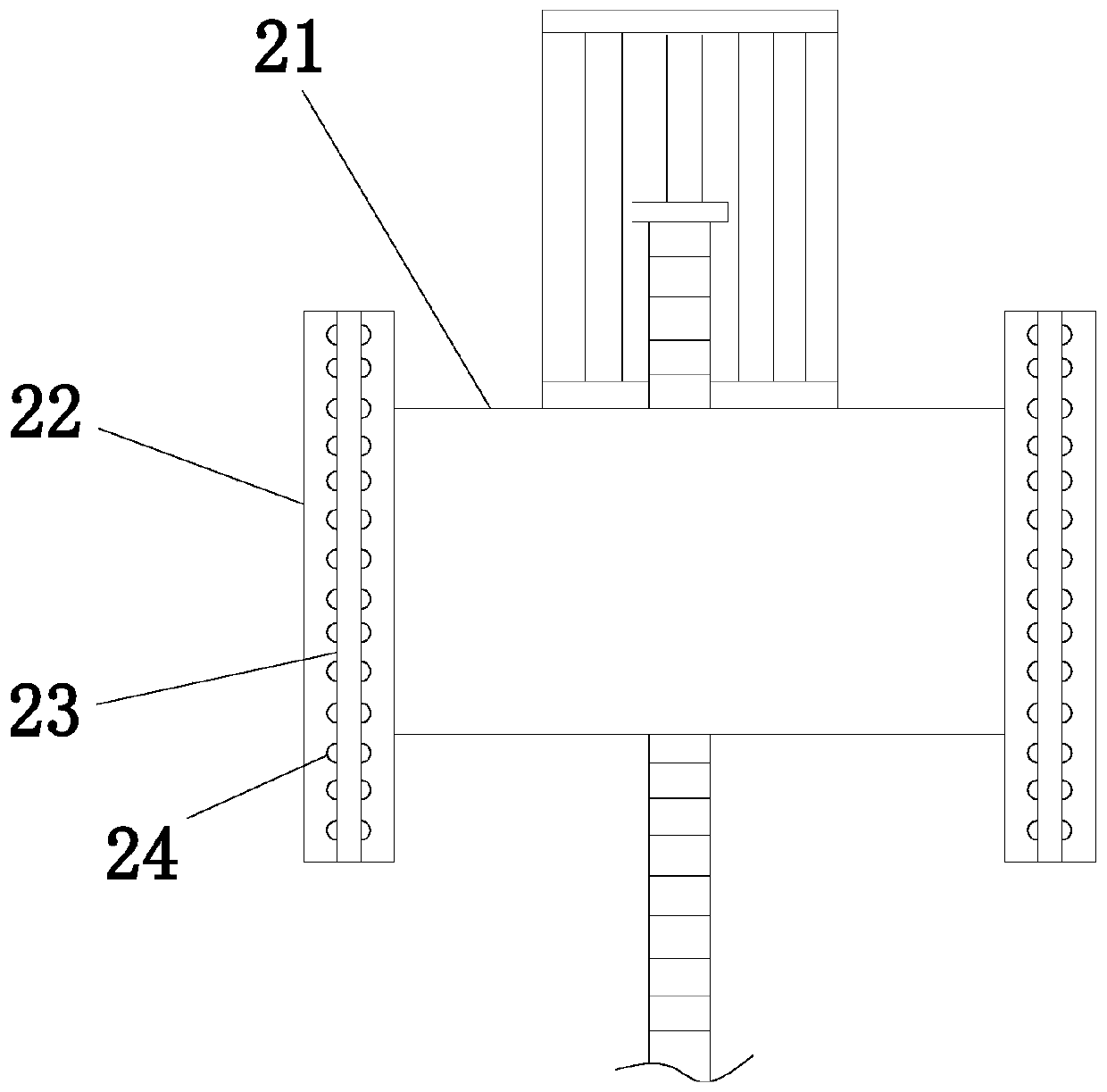

Mixing equipment for preparing environment-friendly fluorine-containing surfactant

InactiveCN109126572AEffective agitation and mixingSpeed up the mixing processShaking/oscillating/vibrating mixersTransportation and packagingEngineeringSURFACTANT BLEND

Mixing equipment for preparing an environment-friendly fluorine-containing surfactant comprises a bottom plate, a supporting device positioned above the bottom plate, a positioning device, an electriccylinder device, a moving frame device arranged on the positioning device, a frame device arranged on the moving frame device, a stirring device contained in the frame device, a driving device positioned below the frame device and a wire drawing device. Simultaneous continuous upward-downward and leftward-rightward movement of the frame can be realized, so that the fluorine-containing surfactantinside the frame can be driven to flow sufficiently; the fluorine-containing surfactant at corners in the frame is effectively stirred and mixed, so that effect of mixing the fluorine-containing surfactant can be enhanced remarkably; continuous upward-downward movement of a stirring net inside the frame can be realized in the process of upward, downward, leftward and rightward of the frame, so that the fluorine-containing surfactant in the frame can be effectively stirred.

Owner:张萍

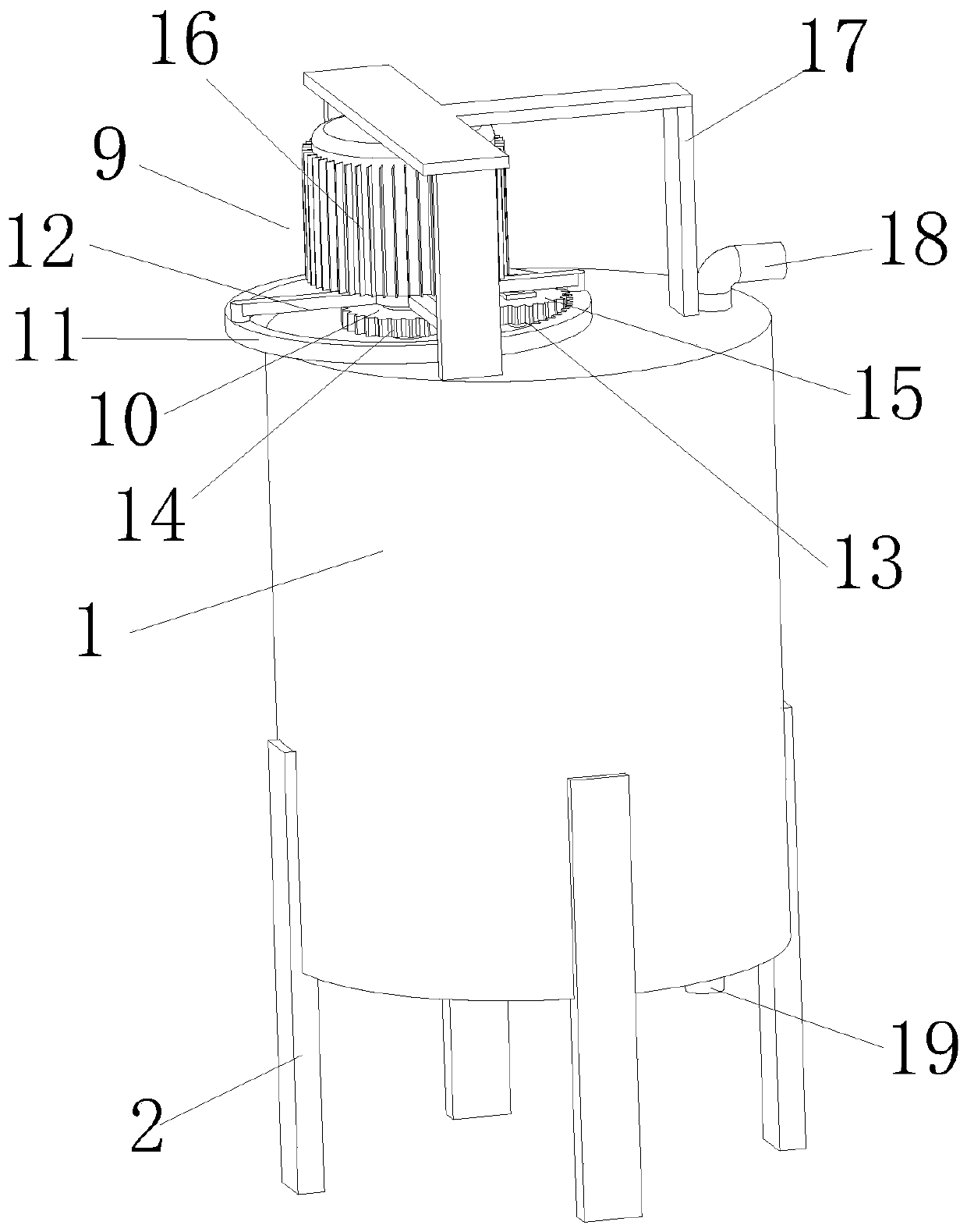

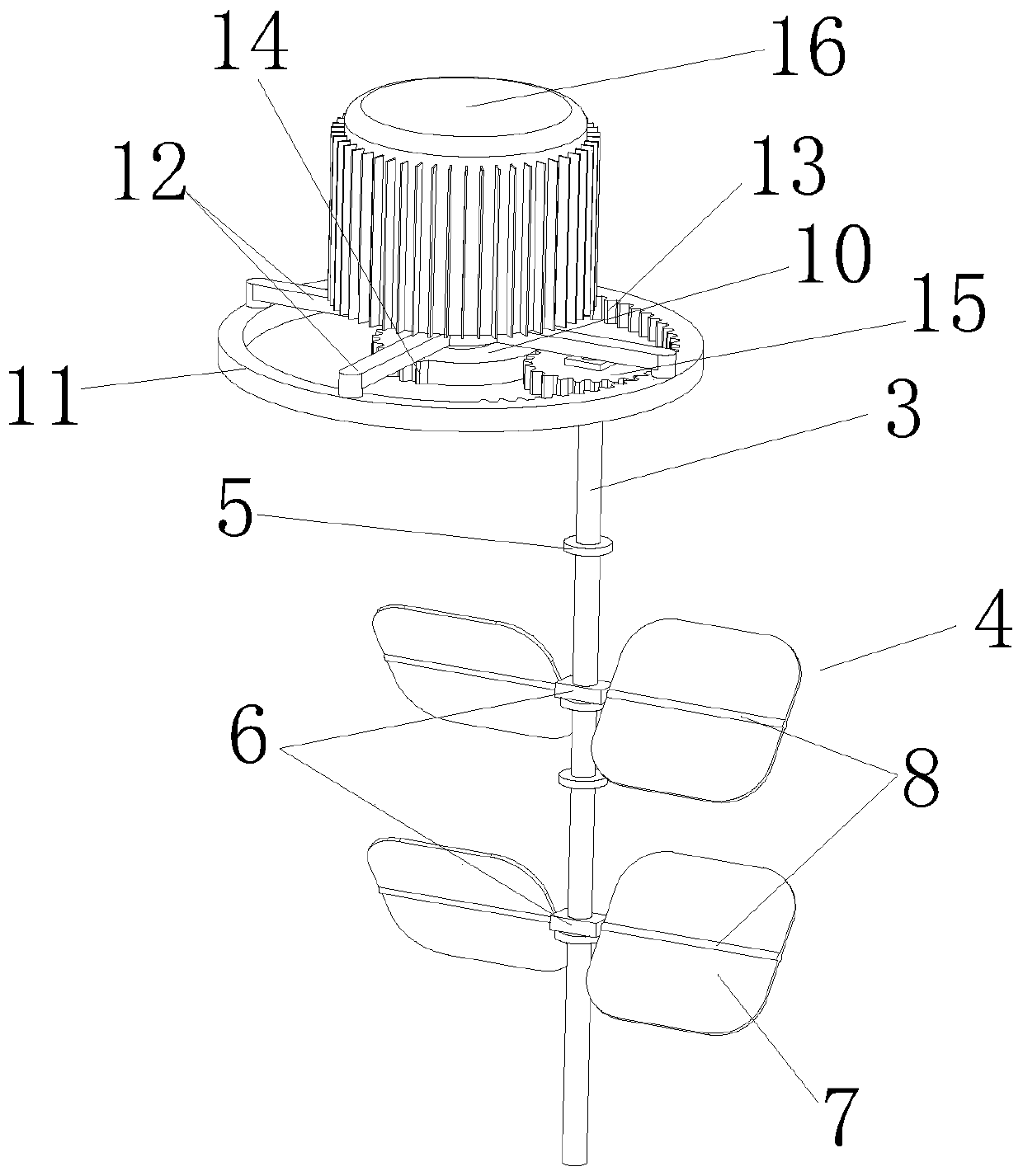

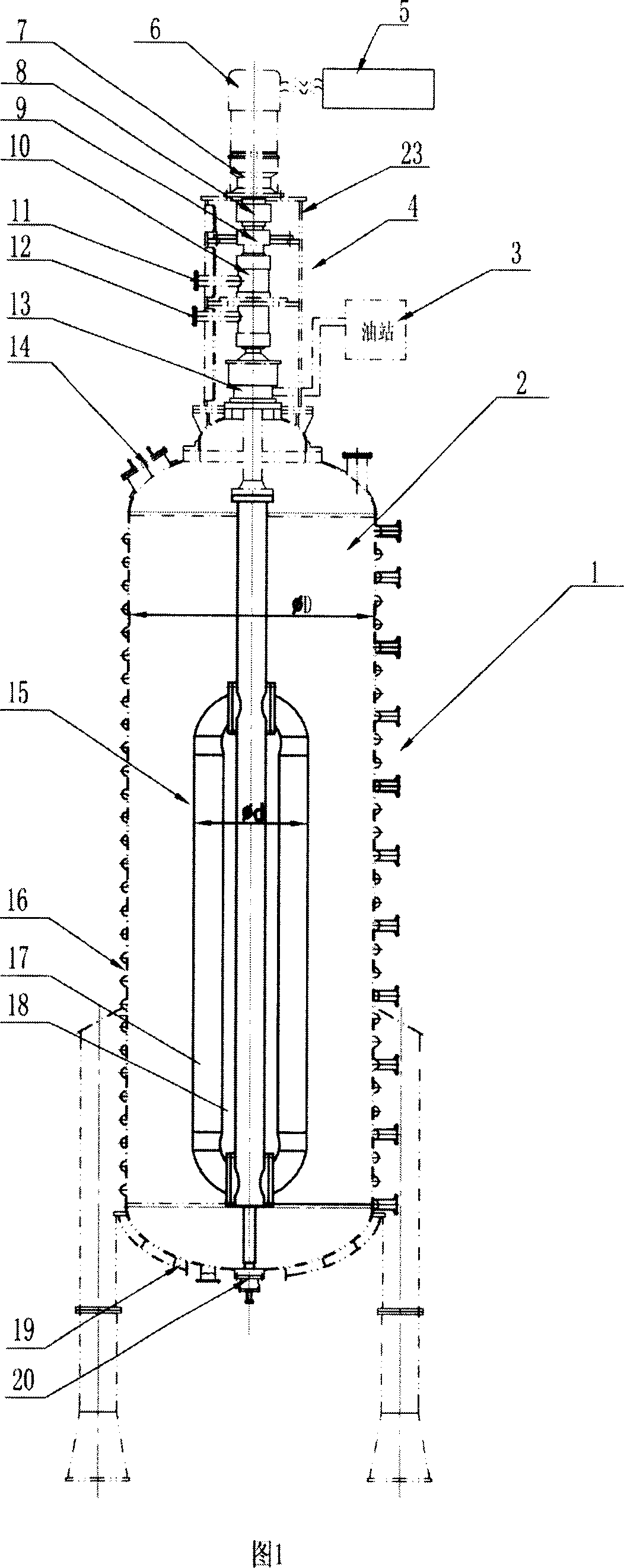

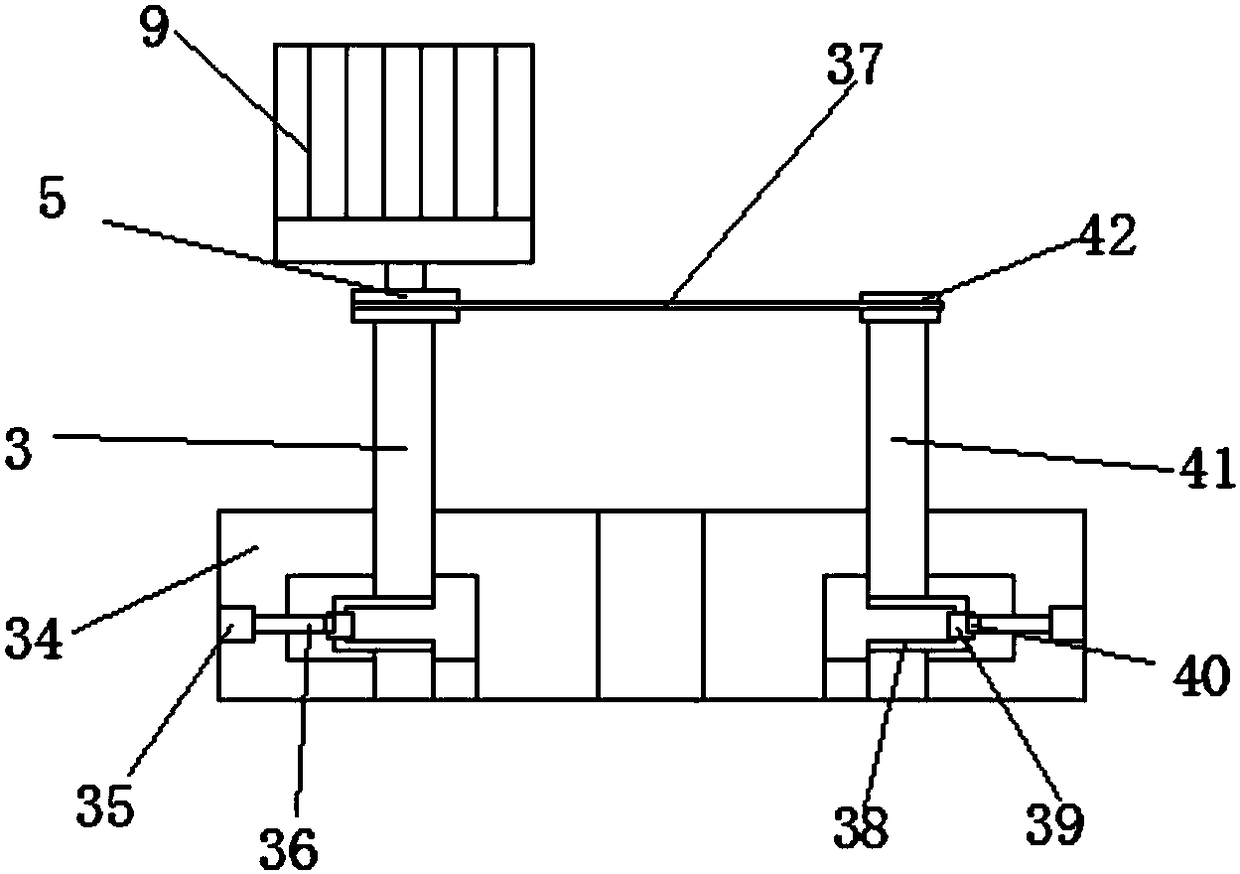

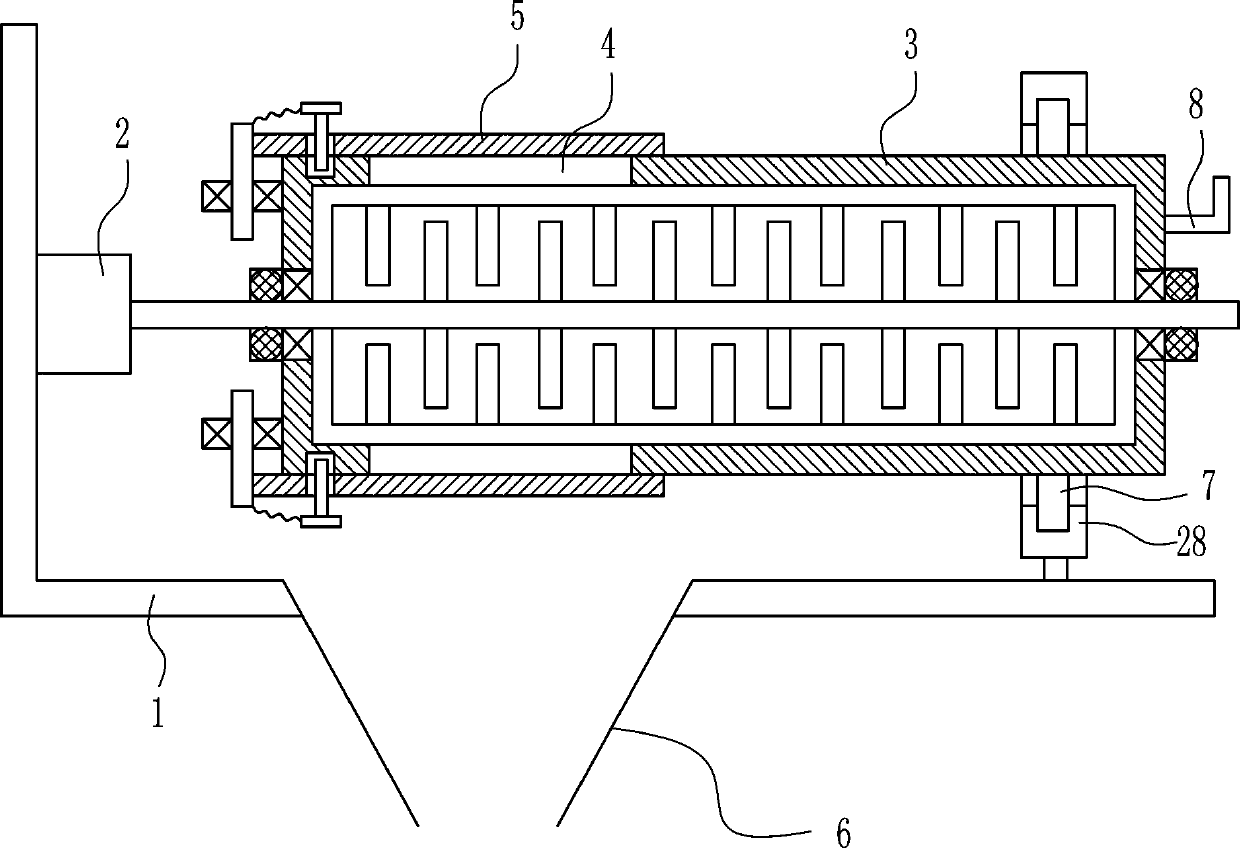

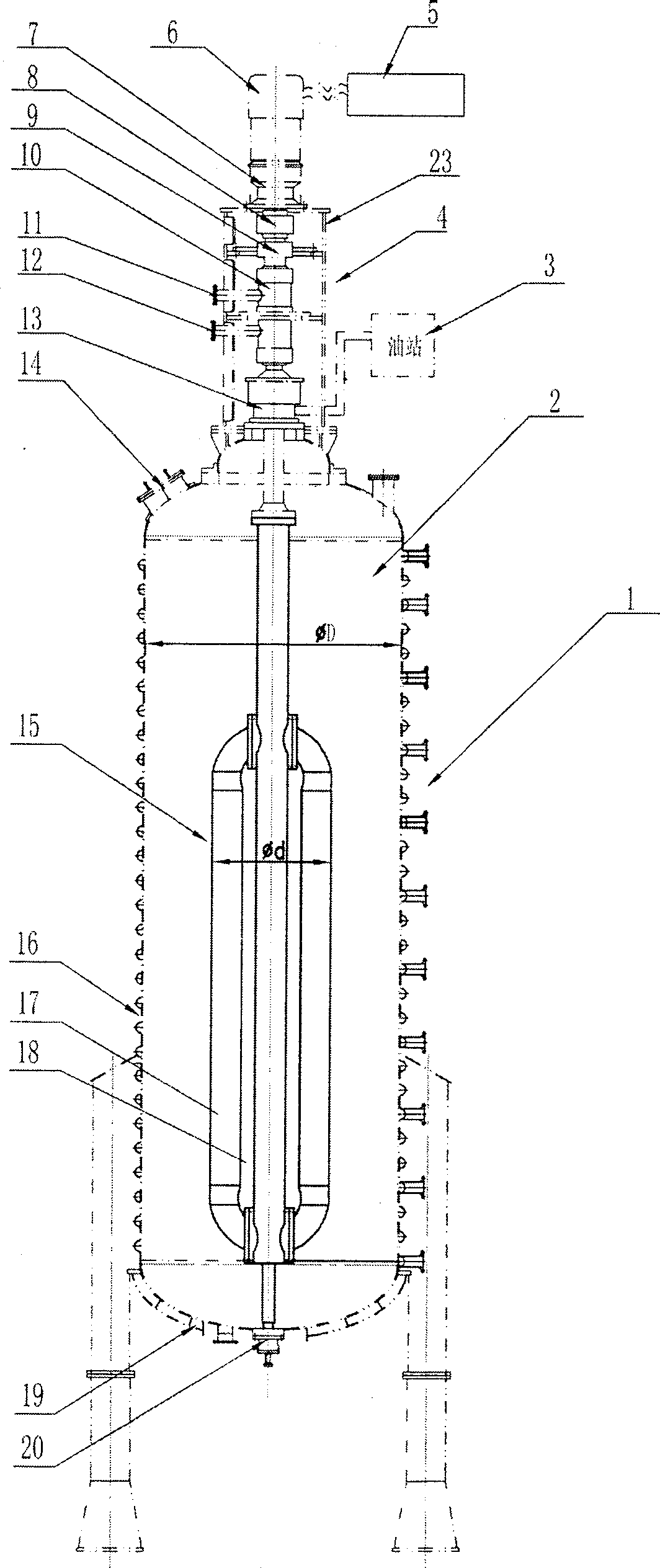

Agitator of polymerizer for producing PVC resin paste by emulsion polymerization

InactiveCN1978469ASpeed up the mixing processImprove heat transfer performanceWater useEmulsion polymerization

Owner:AVIC LIMING JINXI CHEM MASCH GRP CO LTD

Energy-saving and environmentally-friendly stirrer for building

InactiveCN108527644AEasy to clean automaticallyAchieve recyclingTreatment involving filtrationMultistage water/sewage treatmentWastewaterWater resources

The invention discloses an energy-saving and environmentally-friendly stirrer for building. The stirrer comprises an electric cabinet, a motor, a tank body, a tank cover, a rotating shaft, stirring blades and stirring rods; the tank body is connected to one side of the tank cover in a hinged mode; the motor is located on the upper surface of the electric cabinet and is fixedly connected to the rotating shaft; the two groups of stirring rods are fixedly connected to one side of the rotating shaft; the stirring blades are arranged on the surfaces of the stirring rods; a high-pressure water pumpis arranged on one side of the electric control cabinet; one end of the high-pressure water pump is connected to a water inlet pipe, and the water inlet pipe penetrates through a round hole to be annularly arranged on the inner surface of the tank body; the other end of the high-pressure water pump is fixedly connected to a waste water recycling device through a water return pipe; supporting legsare arranged under the tank body; and a damping device is arranged between one supporting leg and the base. The stirrer has the advantages that the water inlet pipe is annularly arranged on the innersurface of the tank body, water spraying ports are formed in the bottom end of the water inlet pipe, the high-pressure water pump is started, and therefore the inner surface of the tank body can be cleaned conveniently; and the water after being used for cleaning is treated by the waste water recycling device, and therefore water resources can be recycled.

Owner:黄华生

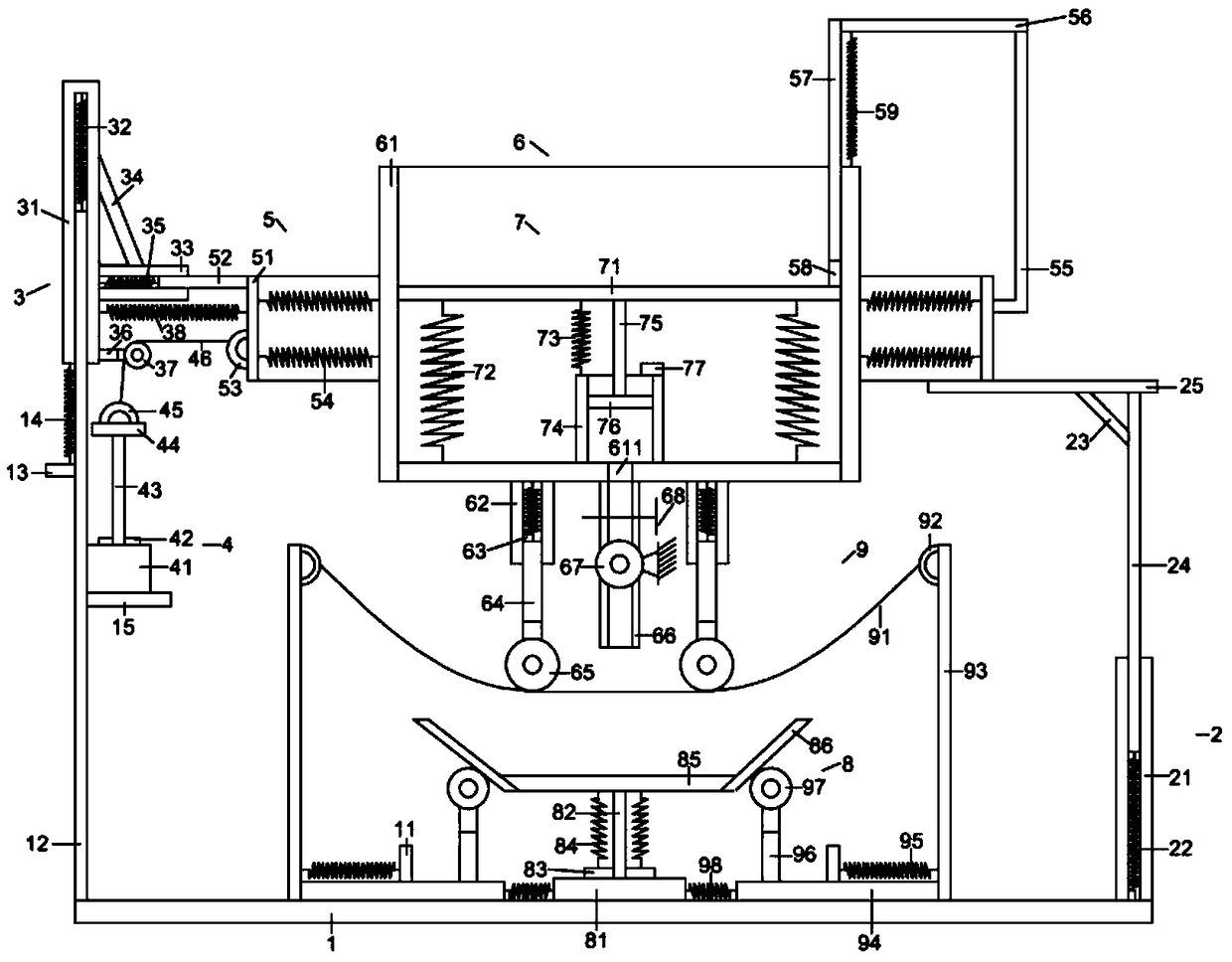

Building concrete preparation device

ActiveCN107932724AStir wellQuality improvementCement mixing apparatusLiquid ingredients supply apparatusCouplingTransverse plane

The invention discloses a building concrete preparation device which comprises a bottom plate. A first box is fixedly connected to the top of the bottom plate, and supporting plates are fixedly connected to the two sides of the inner wall of the first box. A second box is fixedly connected to the tops of the two supporting plates. A transverse plate is fixedly connected to one side of the first box, and the top of the transverse plate is fixedly connected with a first motor through a connecting block. One end of an output shaft of the first motor is fixedly connected with a rotating crankshaftthrough a coupling, and the end, away from the first motor, of the rotating crankshaft penetrates the first box and extends into the first box. The invention relates to the technical field of building equipment. According to the building concrete preparation device, stirring in the concrete preparation process can be achieved, stirring is quite quick and sufficient, and therefore time is saved, the burdens of workers are reduced, the work efficiency is improved, and the quality of prepared concrete is good.

Owner:金华市城建混凝土有限公司

Reaction stirring device for coating manufacturing

InactiveCN107866164ASpeed up the mixing processSolve the long and uneven stirring timeRotary stirring mixersTransportation and packagingDrive motorEngineering

The invention discloses a reaction stirring device for coating manufacturing. The reaction stirring device for coating manufacturing comprises a cylinder body and a machine base; a feeding port is formed in the left side of the upper surface of the cylinder body; the middle position of the upper surface of the cylinder body is fixedly connected with a main driving motor; an output shaft of the driving motor runs through the upper surface of the cylinder body and is fixedly connected with a main rotating shaft through a shaft coupler; and the tail end of the main rotating shaft is movably connected with the middle position of the bottom of an inner cavity of the cylinder body through a bearing pedestal. Through mutual cooperation of the cylinder body, the main driving motor, the main rotating shaft, a main stirring blade, an auxiliary driving motor, an auxiliary rotating shaft and an auxiliary stirring blade, uniform mixing of the coating is benefited, the stirring progress of the coating is accelerated, and the problem that the existing coating stirring device has long stirring duration and is stirred non-uniformly is solved; and through mutual cooperation of the machine base, a guide column, a guide block, a strong spring and a buffer device, the problem that the existing coating reaction stirring device has bad damping effect is solved.

Owner:博艳萍

Fish aquaculture feed uniform-stirring equipment

InactiveCN109126554ASpeed up the fallImprove mixing uniformityFeeding-stuffRotary stirring mixersEngineeringAquaculture

The invention discloses fish aquaculture feed uniform-stirring equipment, which comprises a base. Supporting legs are arranged at the lower end of the base, a shell is connected to the upper end of the base, a discharging device is arranged on the lower side of the shell, the upper end of the shell is connected with the lower lateral side of a discharging tank, two ends of the bottom of the discharging tank are provided with discharging ports, and measurers are arranged in the discharging ports. The middle end of the bottom of the discharging tank is inwardly concave and fixedly connected withthe middle of a main motor, an output shaft of the lower end of the main motor is connected with a linkage rod, stirring shafts are vertically connected below two ends of the linkage rod, and stirring rods in horizontal arrangement are uniformly staggered on the stirring shafts. By arrangement of the linkage rod, alternate stirring of bait feed can be realized through the stirring rods on the stirring shafts, so that a bait feed stirring process is accelerated, and bait material stirring efficiency is improved; by the discharging ports in two bottom ends of the discharging tank, the bait feedfalling speed is increased, and by the measurers in the discharging ports, real-time calculation of bait feed quantity can be realized in a falling process. Therefore, the fish aquaculture feed uniform-stirring equipment is suitable for large-scale popularization.

Owner:金华市凌特水产养殖技术有限公司

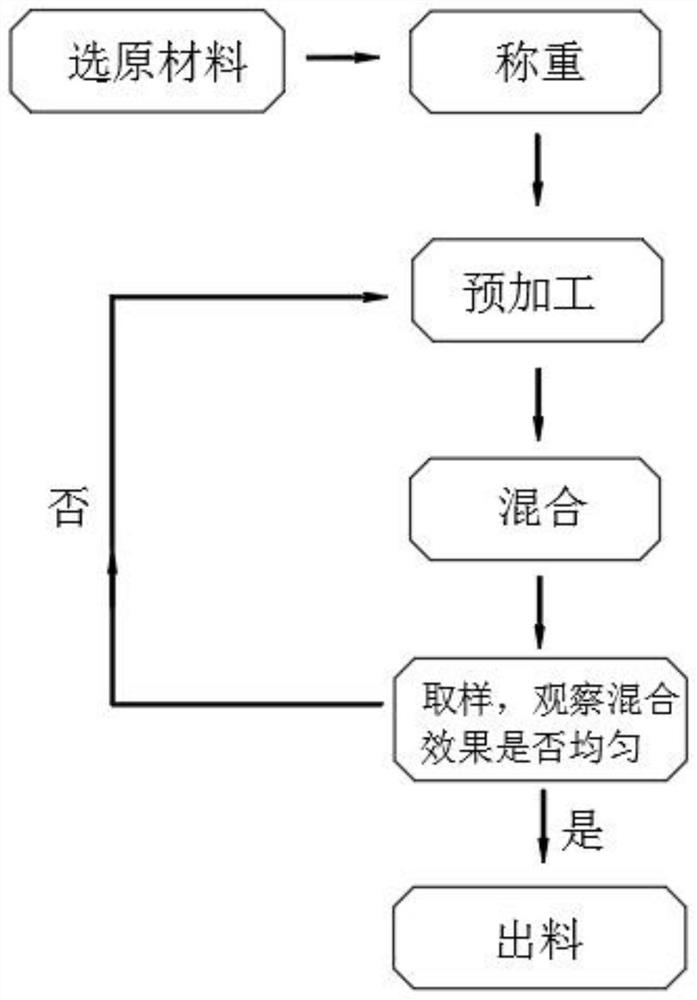

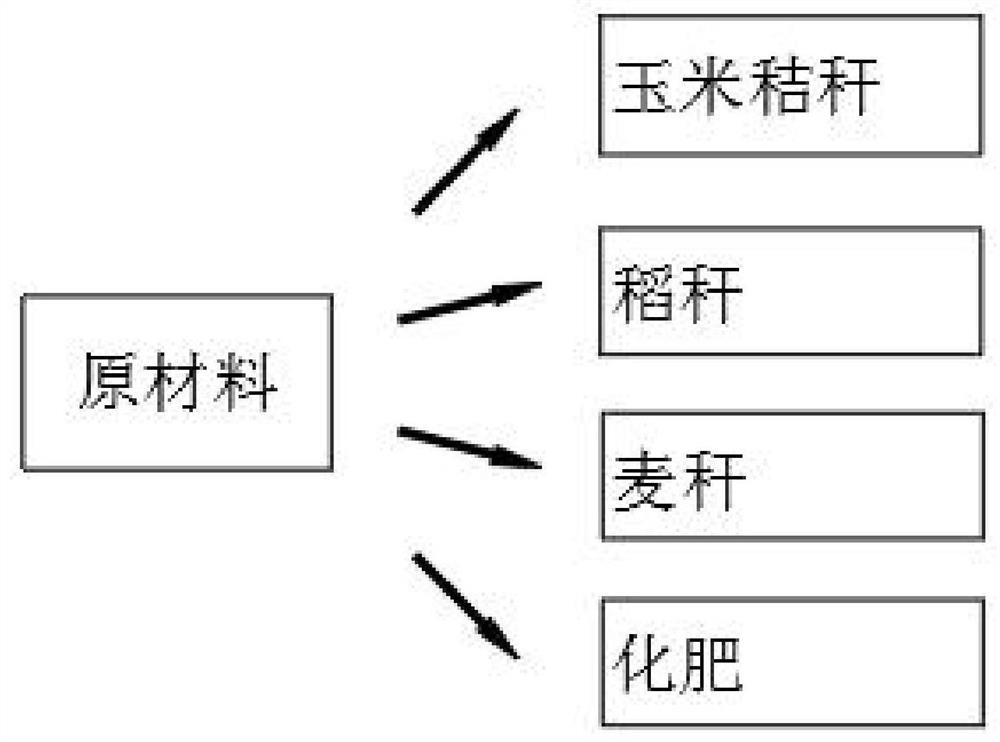

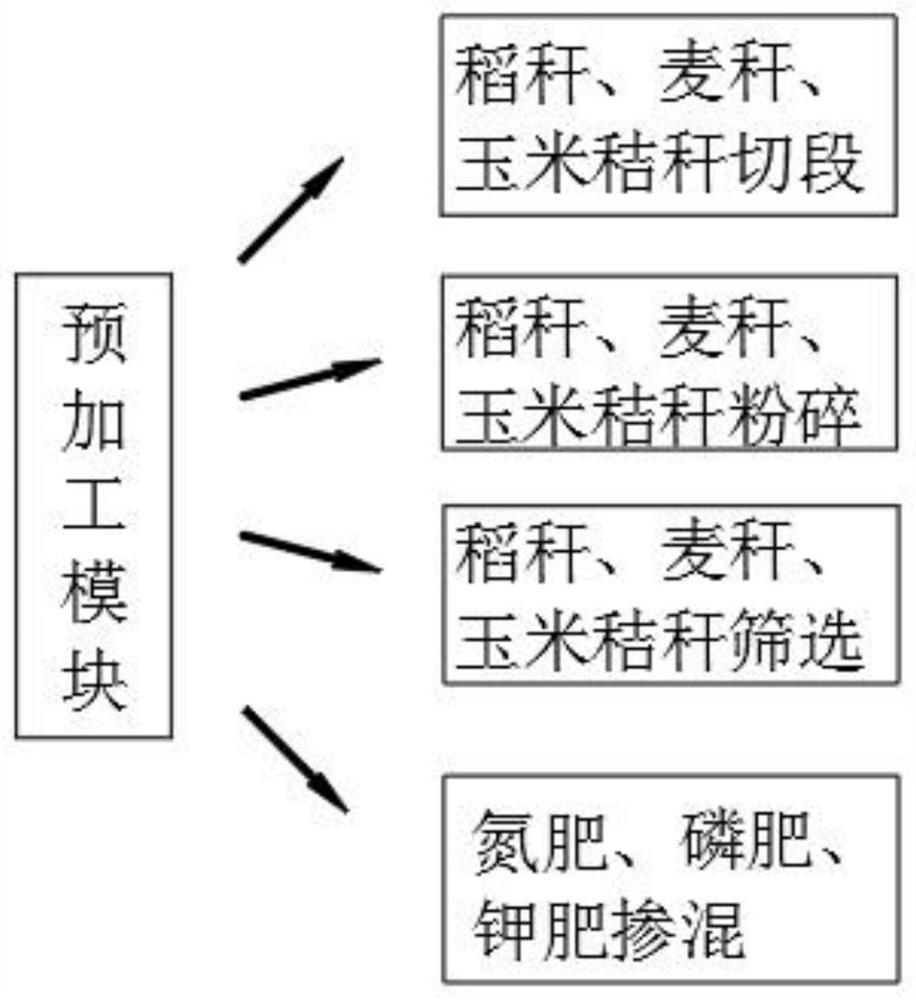

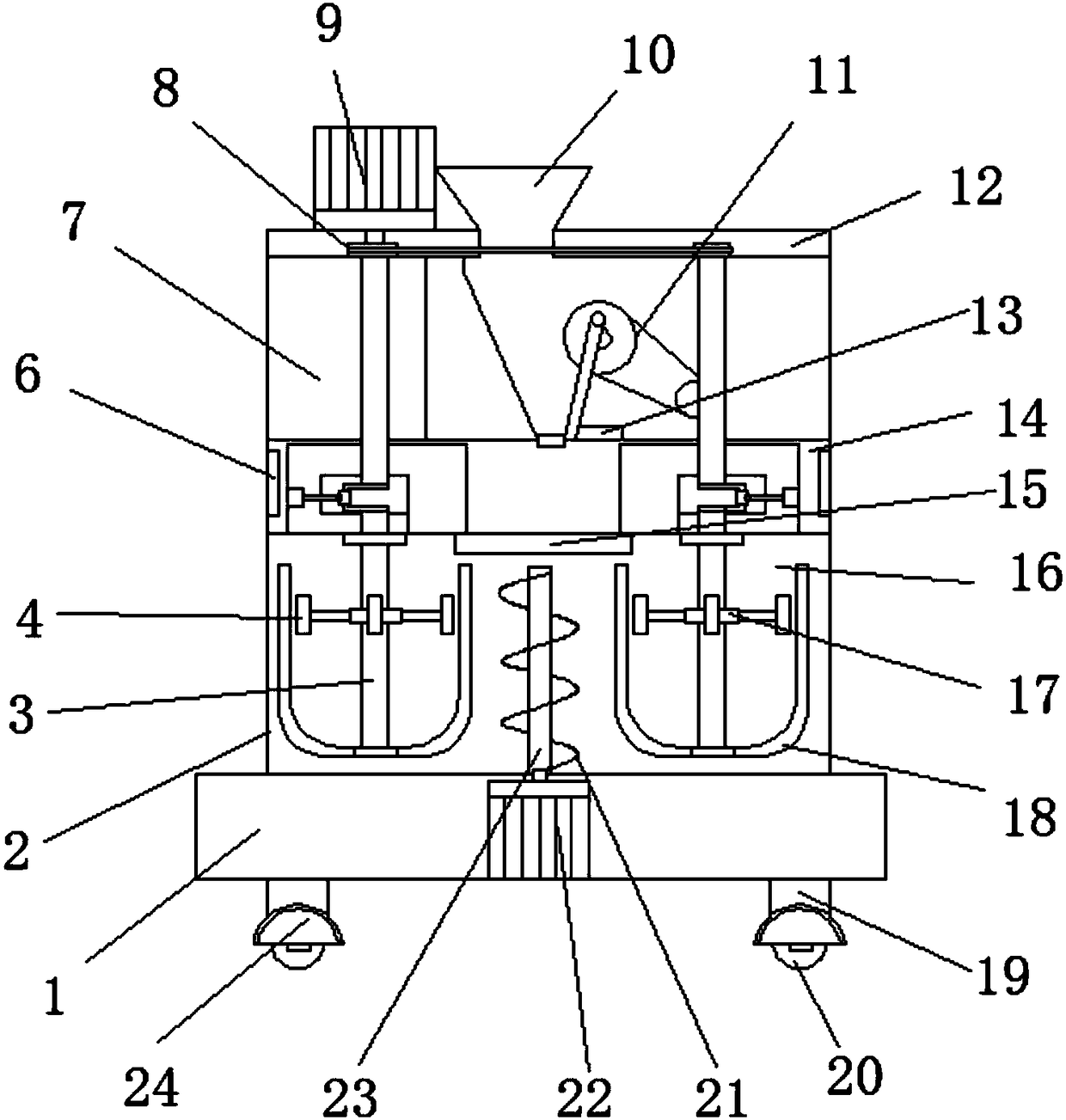

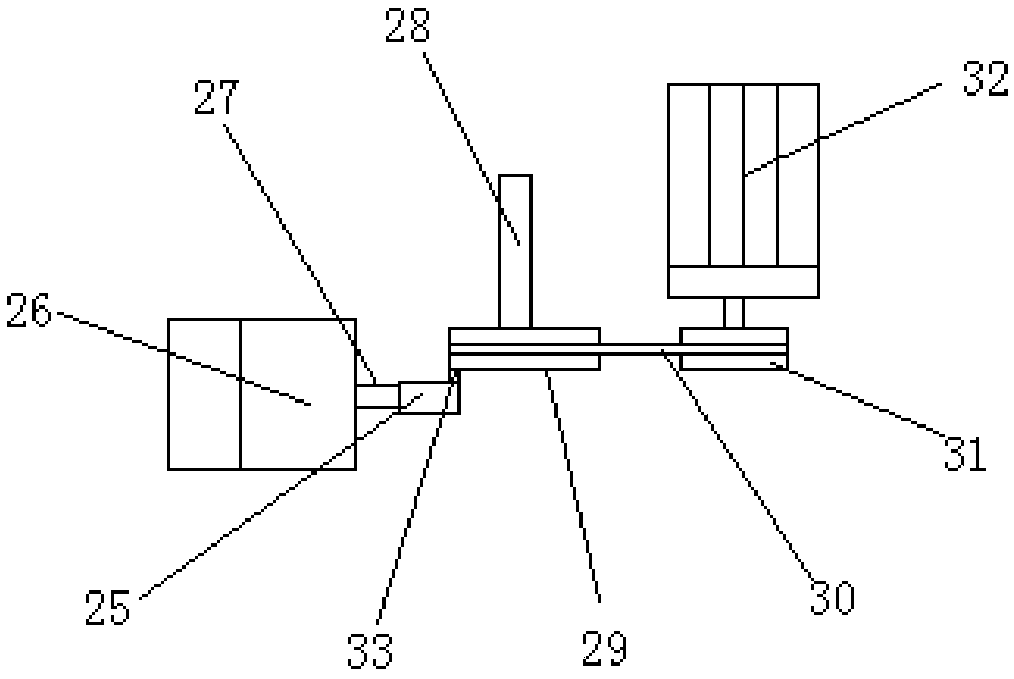

Mixing method for woody peat for producing nutritional soil conditioner

InactiveCN113135810AReduce generationAvoid Conditions That Affect Mixing EffectsOrganic fertilisersSoil conditioning compositionsSoil sciencePeat

The invention belongs to the technical field of agricultural planting soil conditioning, and particularly relates to a mixing method for woody peat for producing a nutritional soil conditioner, wherein the mixing method comprises the following steps: selecting raw material woody peat and ingredients; weighing the woody peat and the ingredients; preprocessing the weighed ingredients; putting the preprocessed ingredients and woody peat into a mixing device for mixing; after mixing for a period of time, taking out a part of samples, and observing the mixing effect of the samples; and discharging. The woody peat is used as the main raw material of the soil conditioner and is mixed with other various ingredients, and the soil conditioner is suitable for improving the soil structure, improving the soil fertility, reducing the soil salt and alkali damage, adjusting the soil acidity and alkalinity, improving the soil moisture condition or repairing the polluted soil and the like; and the the soil conditioner is mixed with other ingredients for use, so that environment-friendly conditioning of the soil is realized.

Owner:JIANGXI PURUIFENG ECOLOGICAL TECH CO LTD

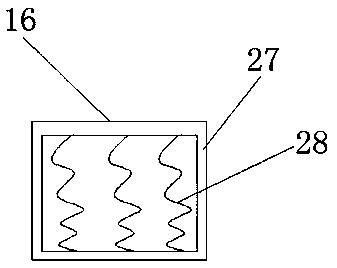

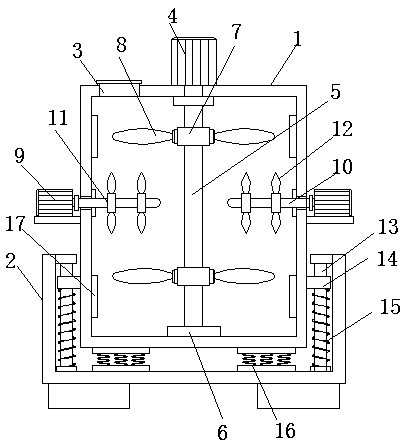

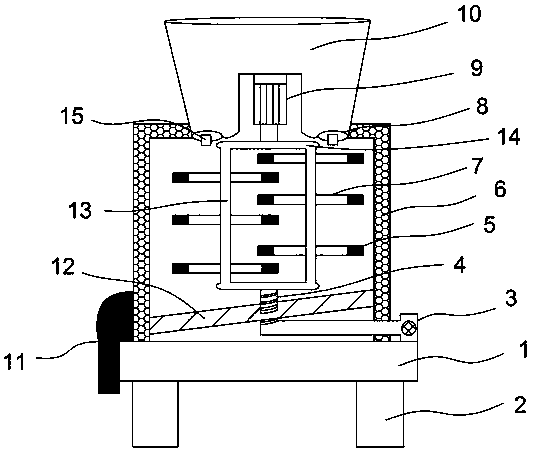

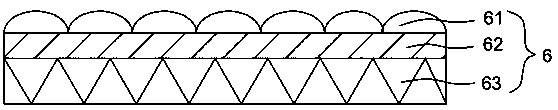

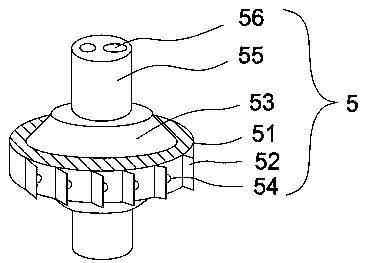

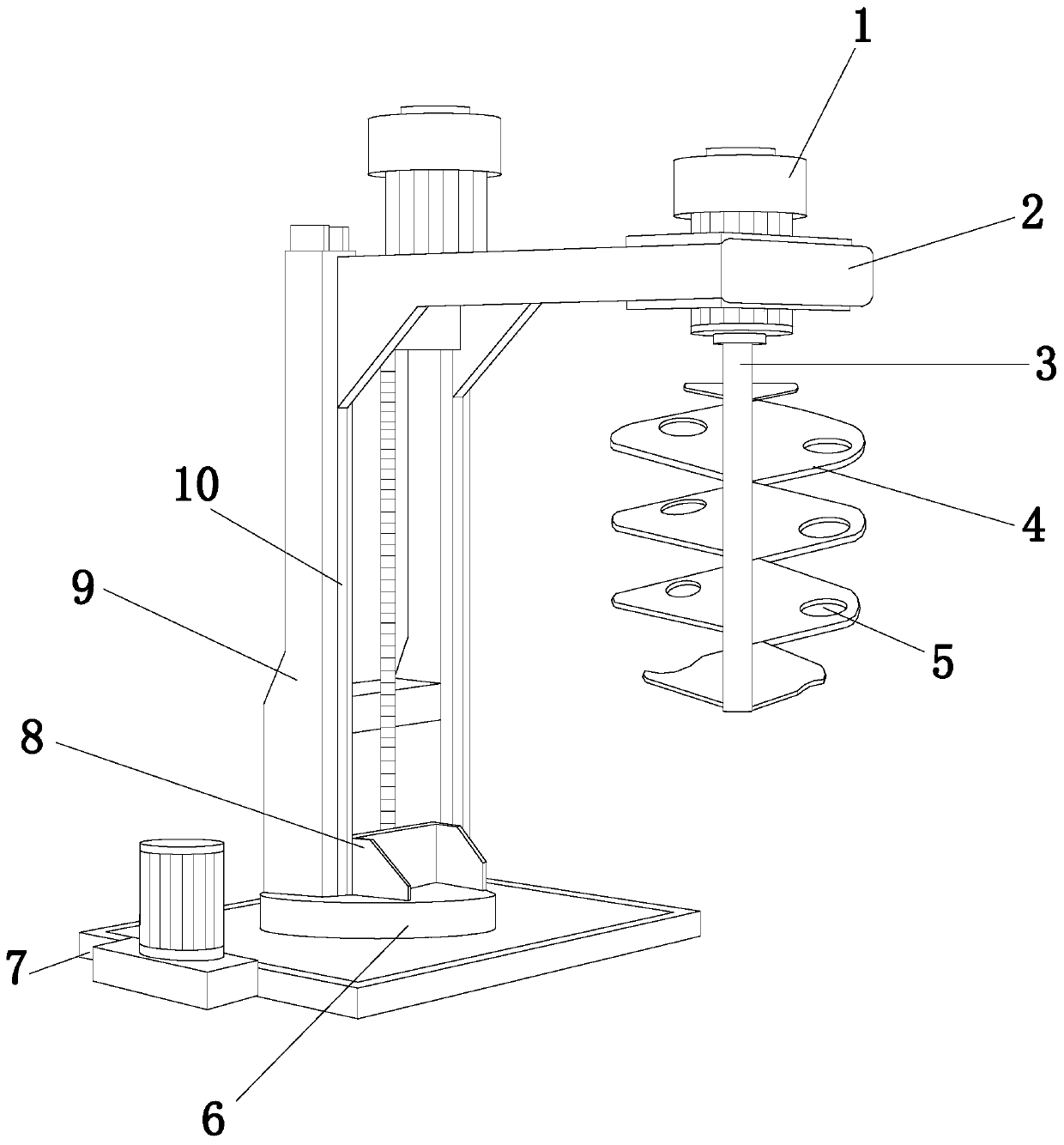

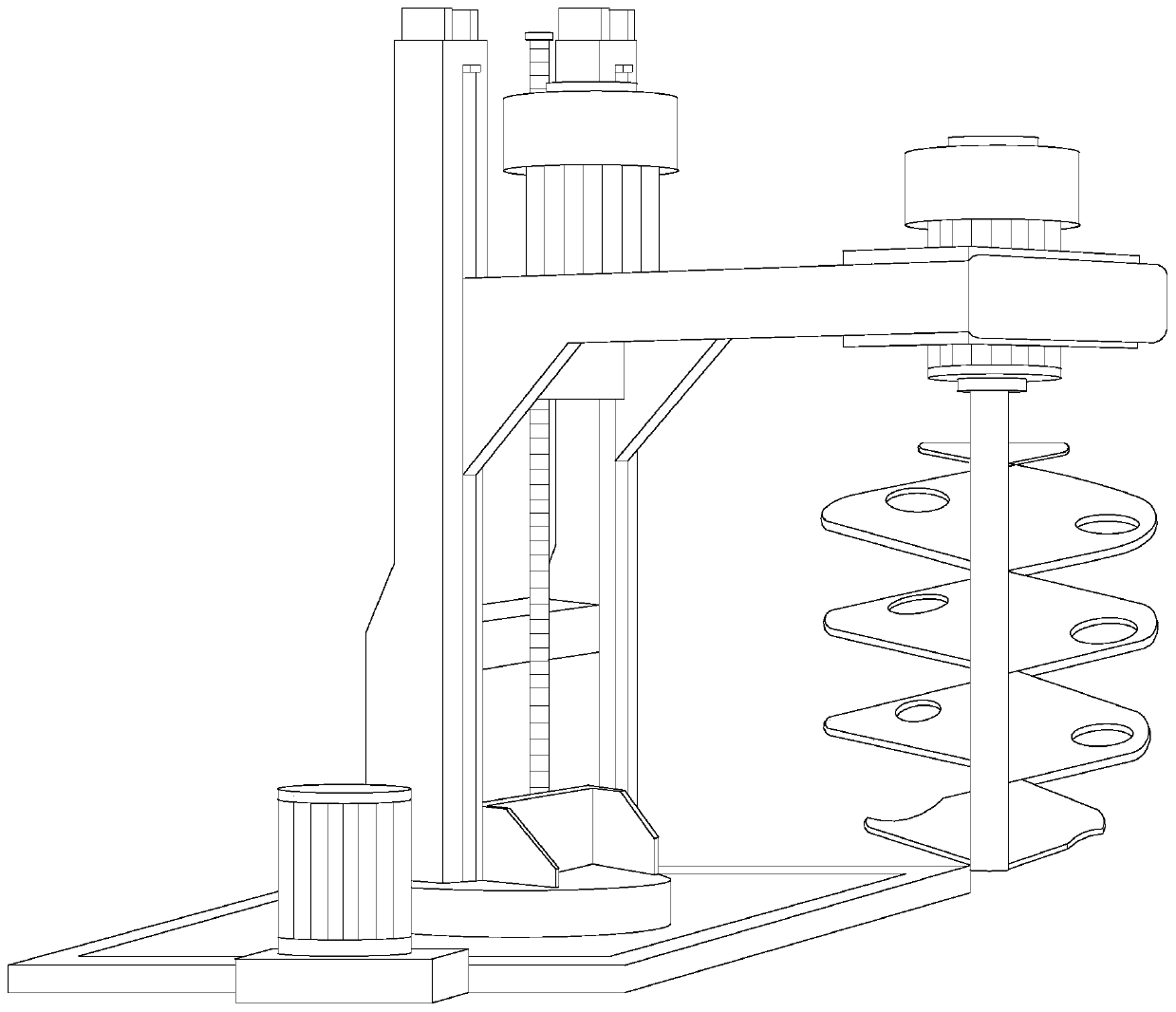

Stirring device

InactiveCN108283896ASpeed up the mixing processImprove stirring efficiencyRotary stirring mixersTransportation and packagingPulp and paper industryPlinth

The invention discloses a stirring device. The stirring device comprises a pedestal and a casing arranged at the top of the pedestal, several supporting legs are arranged at the bottom of the pedestal, protection sleeves are arranged at the bottom of the supporting legs, mobile wheels are arranged at the bottom of the protective sleeves, a broken stone chamber, a grinding chamber and a stirring chamber are arranged in the casing in order, the grinding chamber is positioned between the broken stone chamber and the stirring chamber, the broken stone chamber is positioned over the stirring chamber, and a case cover is arranged at the top of the casing. The stirring device has the beneficial effects that a second rotation shaft on a rotation wheel is driven to rotate by a rotation belt, the adjacent grinding stones are continuously bumped for grinding materials, arrangement of a third rotation motor is capable of continuously rotating a spiral stirring blade on the rotation shaft for stirring, the U-shaped stirring blade at a first rotation shaft and the stirring blade on a connecting ring are capable of continuously stirring, the stirring progress is greatly accelerated, the stirringefficiency is increased, during a grinding process, two-time grinding is carried out, grinding is finely carried out, and the grinding quality is greatly increased.

Owner:黄祥航

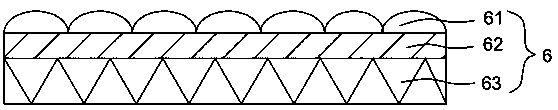

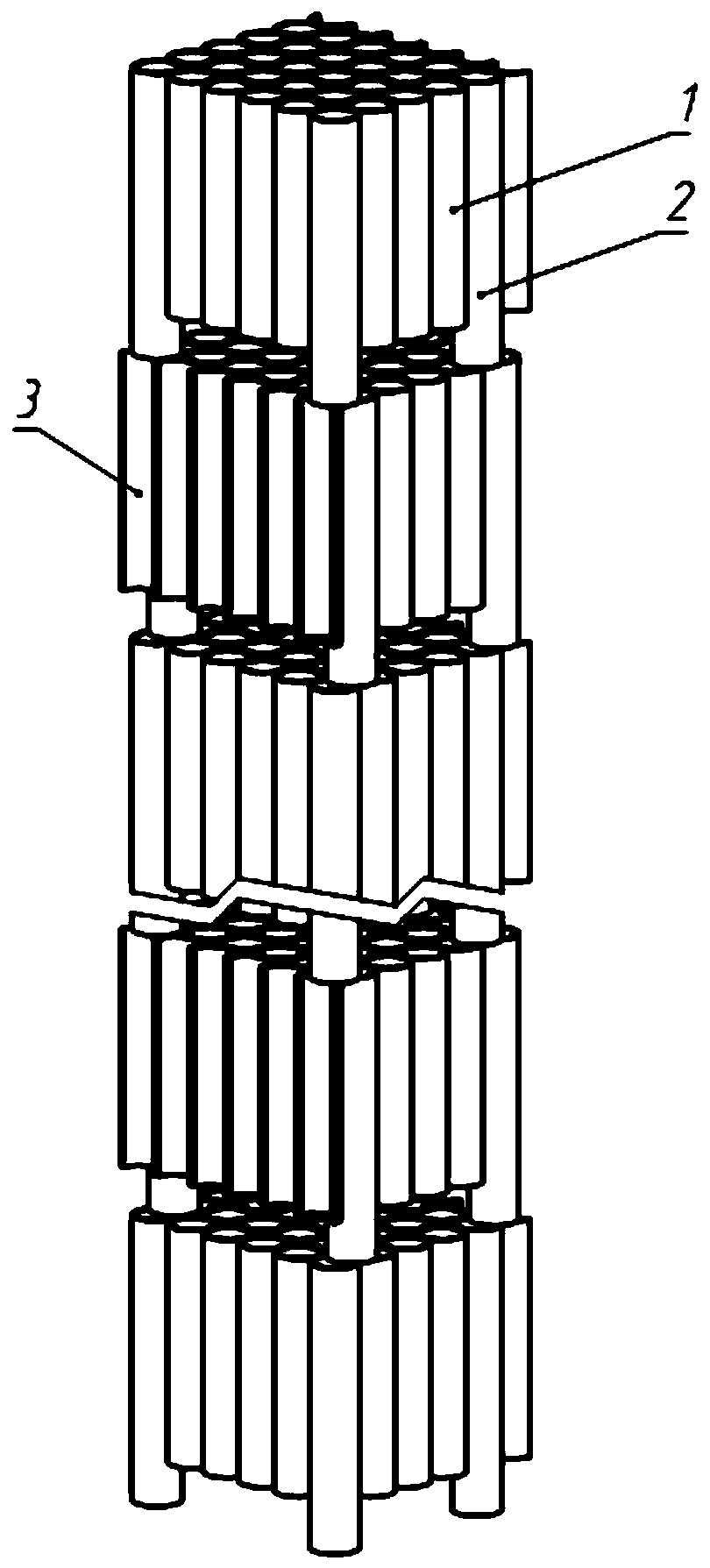

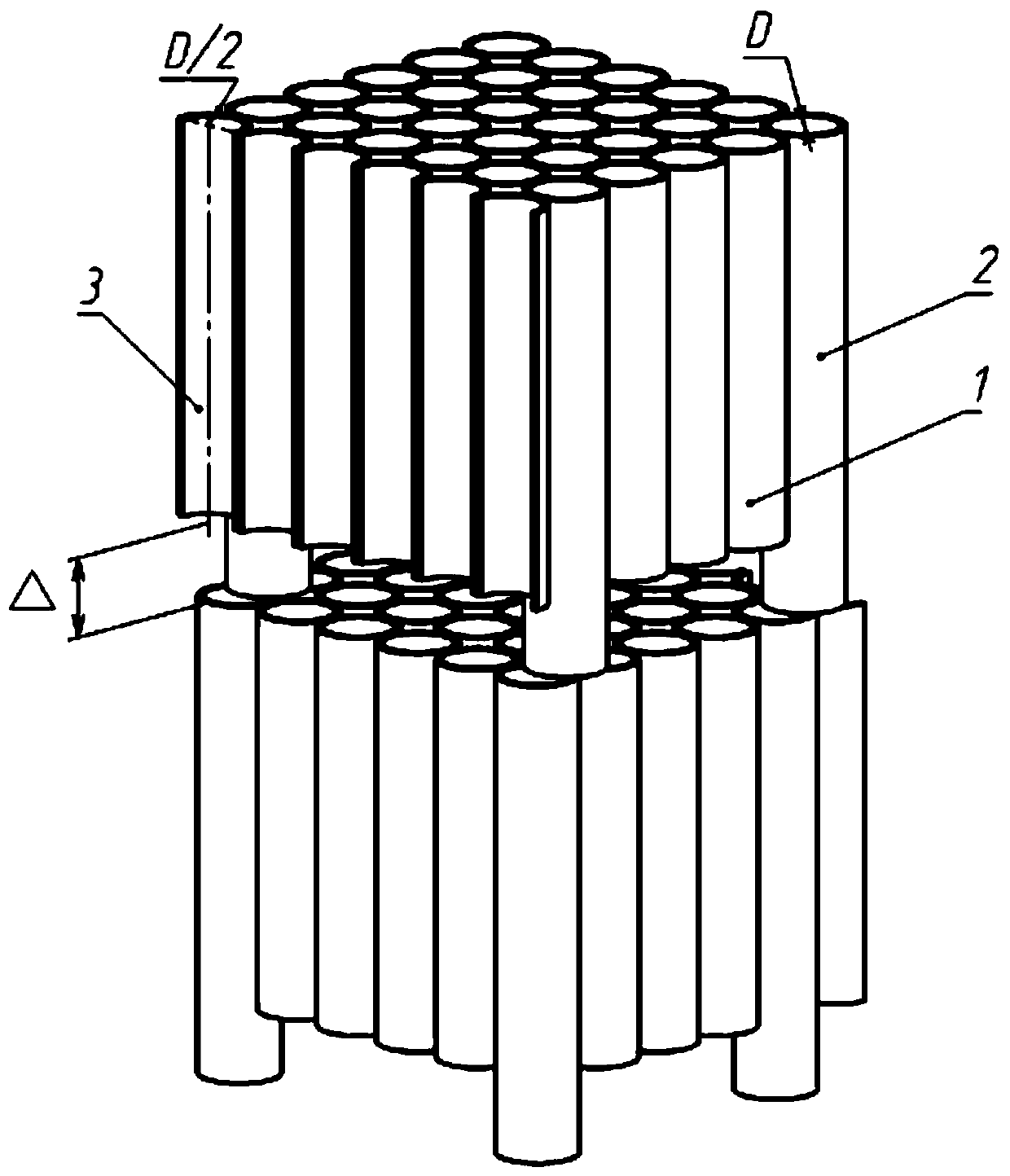

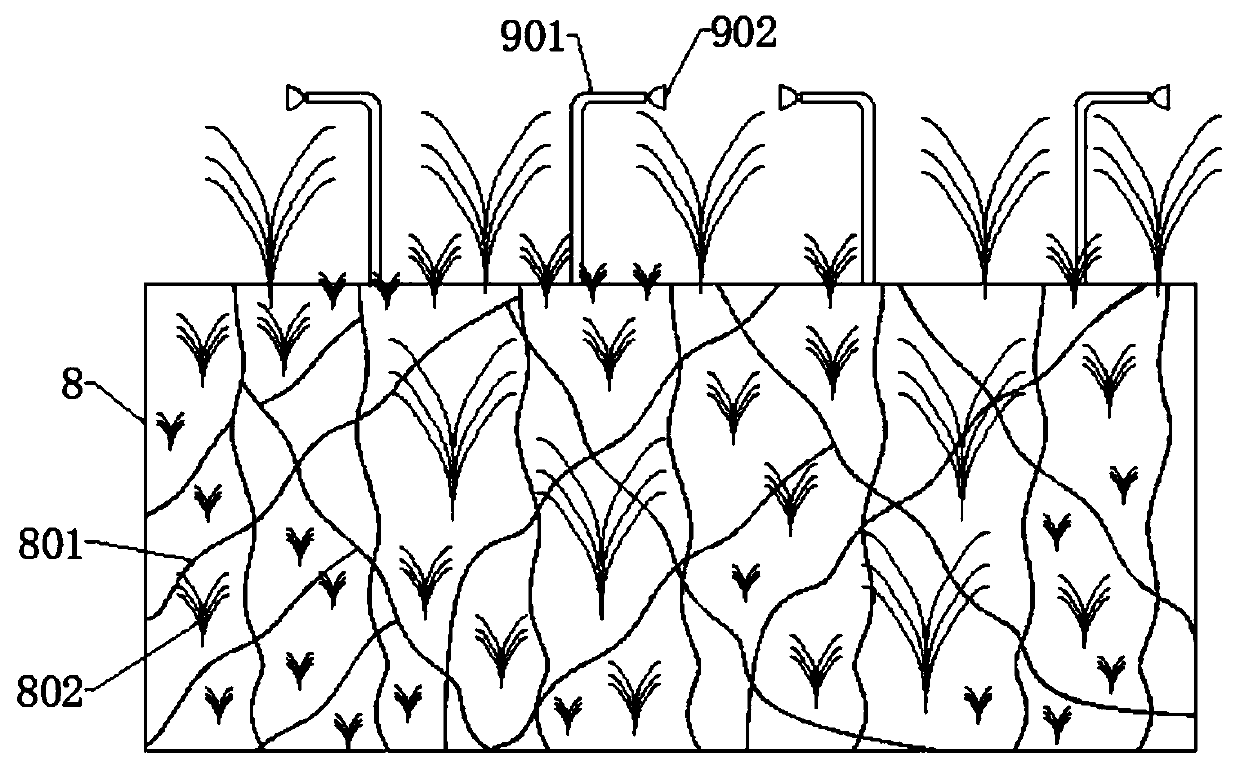

Biological loading unit

InactiveCN110921822ASpeed up the mixing processEasy to handleTreatment with anaerobic digestion processesSustainable biological treatmentMicroorganismBiochemical engineering

The invention discloses a biological loading module which is used as a biomass carrier required in an anaerobic bioreactor. The anaerobic bioreactor is used for treating organic wastes from animals and plants so as to produce organic fertilizers and biogas. The module comprises a model for microbial colonization formed by vertically oriented tubular elements fixed along a longitudinal surface; themodule has a layered structure; the module elements located in adjacent layers leave gaps between the layers; the module elements are made of a polymer material, have a porous structure, and can ensure the penetration of microorganisms. The present invention can accelerate the process of treating biomass by improving the degree of mixing of biomass and increasing the number of microorganisms in the module volume.

Owner:OBSHCHESTVO S OGRANICHENNOJ OTVETSTVENNOSTYU EVOLYUTSIYA BIOGAZOVYKH SISTEM

A kind of petroleum asphalt is placed in the mixing box

InactiveCN107308837BAvoid condensationAvoid stickingRotary stirring mixersTransportation and packagingAsphaltPetroleum

Owner:FOSHAN LUBANG ASPHALT CO LTD

Stirring device for investment casting wax liquid

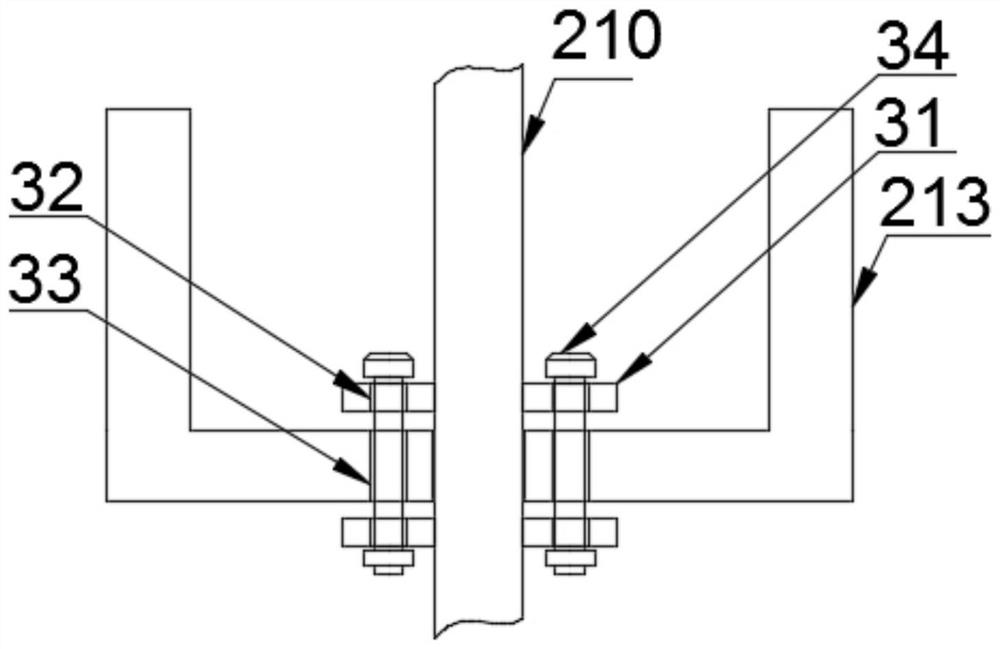

InactiveCN112569842AAvoid wastingReduce production efficiencyRotary stirring mixersTransportation and packagingInvestment castingProcess engineering

The invention discloses a stirring device for investment casting wax liquid. The stirring device comprises a rack, a feeding assembly, a grinding assembly, a stirring assembly, a discharging assemblyand a clamping assembly. The feeding assembly, the grinding assembly, the stirring assembly and the discharging assembly are sequentially connected in the working direction and arranged on the rack. The clamping assembly is arranged on the rack and located below the discharging assembly. The feeding assembly is arranged at the feeding end of the grinding assembly. By arranging the grinding assembly, wax block raw materials used for investment casting are smashed, the situation that due to the fact that the wax block raw materials are rough, the heating and stirring time is too long, energy waste is caused, and the production efficiency is reduced is avoided; the wax block is pretreated, so that the later stirring efficiency is improved; by arranging the stirring assembly and a stirring rodwith the stirring teeth, the stirring efficiency is improved, and the stirring process is accelerated; a guide piece is arranged, so that the stirring rod is prevented from being broken due to overlarge stress; by arranging a screw rod, guiding is conducted at the discharging end of a stirring hopper, and wax liquid is prevented from being blocked in the stirring hopper.

Owner:上海万泽精密铸造有限公司

A new type of concrete mixer

ActiveCN107839067BSpeed up the mixing processIncrease speedLifting framesCement mixing apparatusTypes of concreteMechanical engineering

Owner:NANJING FUYUAN RESOURCES UTILIZATION CO LTD

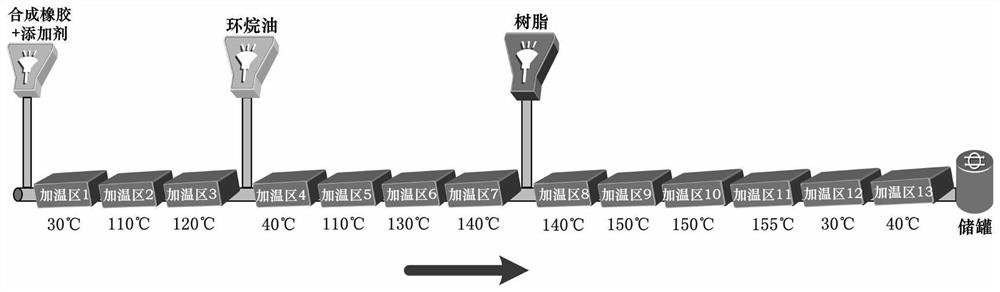

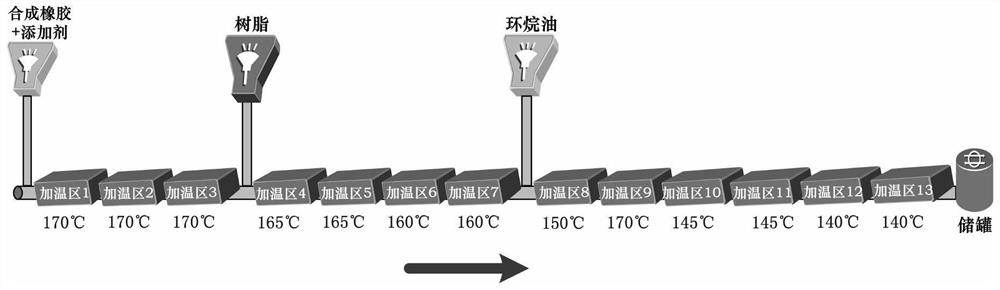

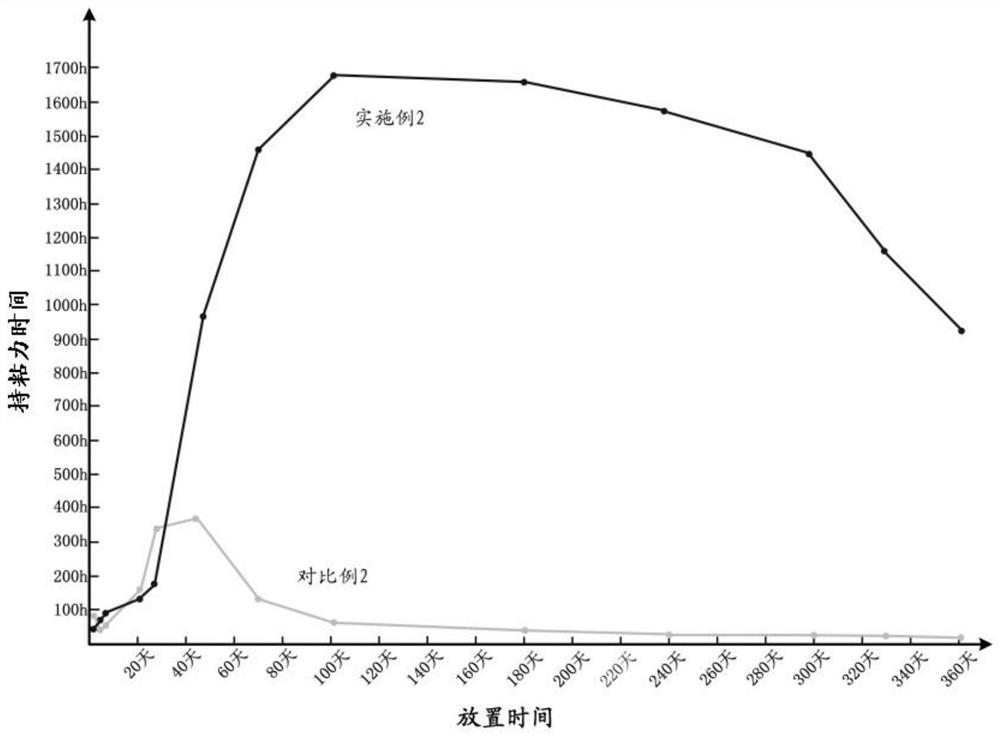

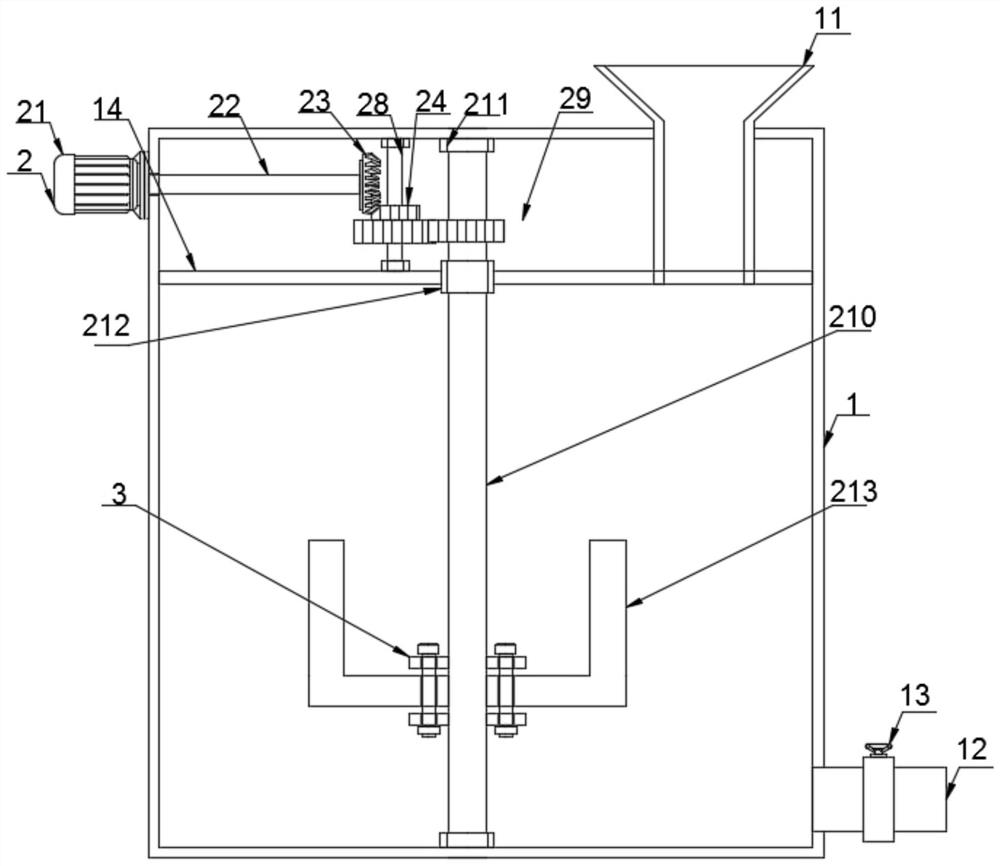

A kind of low temperature preparation hot melt adhesive and its preparation method and a kind of adhesive tape

ActiveCN111040686BAvoid damageReduce the energy consumption of glue makingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive belt

The invention belongs to the technical field of hot-melt adhesives, and relates to a low-temperature prepared hot-melt adhesive, a preparation method thereof and an adhesive tape. The method for preparing hot-melt adhesive at low temperature provided by the invention uses synthetic rubber, additives, naphthenic oil and resin as raw materials, and obtains low-temperature hot-melt adhesive with high stickiness through ingenious design of feeding sequence and temperature setting in temperature zone , the experimental results show that when the hot melt adhesive prepared by the preparation method provided by the present invention is used to prepare adhesive tapes at low temperatures, the adhesive tapes obtained after being placed for 1 year still have a high holding force, which meets the requirement of continuous high holding viscosity for more than 1 year, and the adhesive tape The peel force is not affected, and the original good performance is still maintained.

Owner:SHANGHAI YONGGUAN ADHESIVE PROD CORP LTD

New material stirrer

PendingCN112495242AIncrease rotation speedSpeed up the mixing processRotary stirring mixersTransportation and packagingGear ratioEngineering

The invention discloses a new material stirrer. According to the technical scheme, the novel material stirrer comprises a box body, a supporting plate is fixedly installed in the box body, a rotatingdevice is fixedly installed on the supporting plate, the rotating device comprises a motor, the motor is fixedly installed on one side of the box body, and the output end of the motor extends into thebox body to be fixedly connected with a connecting rod; a helical gear is fixedly installed at the end, away from the motor, of the connecting rod, a double-gear is connected to the side, away from the motor, of the helical gear in an engaged mode, the double-gear comprises an upper gear body, a lower gear body is fixedly installed below the upper gear body, a fixing rod is fixedly installed in the double-gear, and the top end of the fixing rod is fixedly connected with the box body; and the bottom end of the fixing rod is fixedly connected with the supporting plate. The stirrer has the beneficial effects that the gear ratio of the bevel gear to the upper gear body to the lower gear body to the first gear is set to be 3:1:3:3, so that when the bevel gear rotates by one circle, the first gear rotates by three circles, the rotating speed of the rotating rod is increased, the stirring progress is accelerated, and the energy consumption is reduced.

Owner:中创科技孵化器泰州有限公司

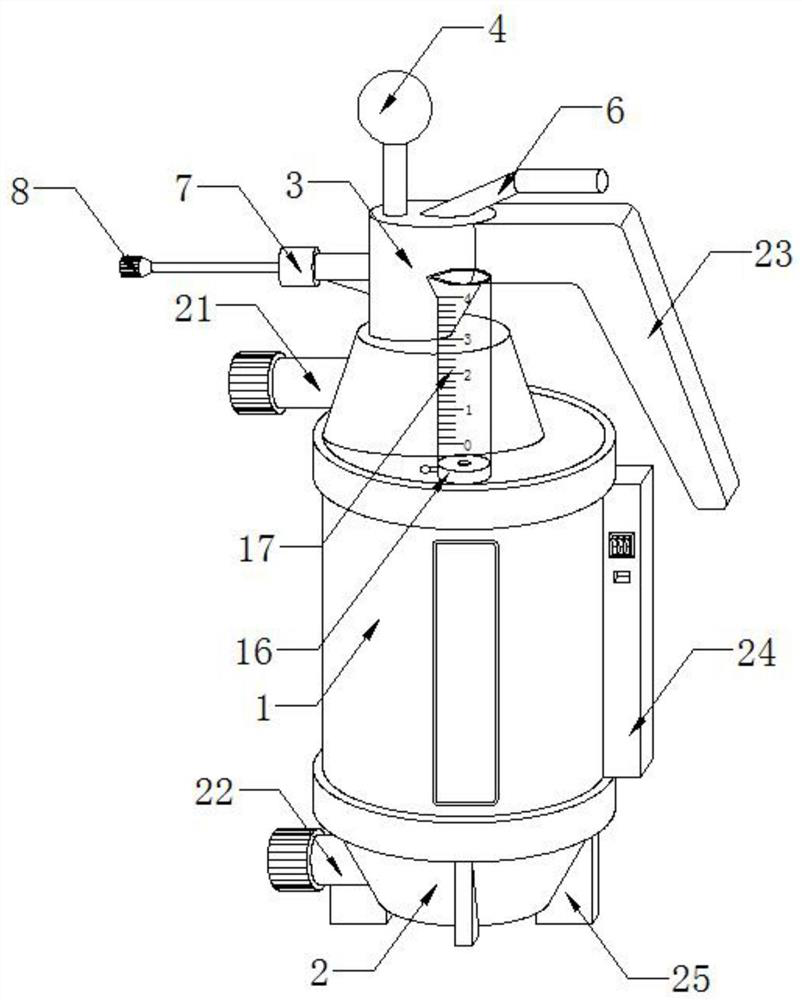

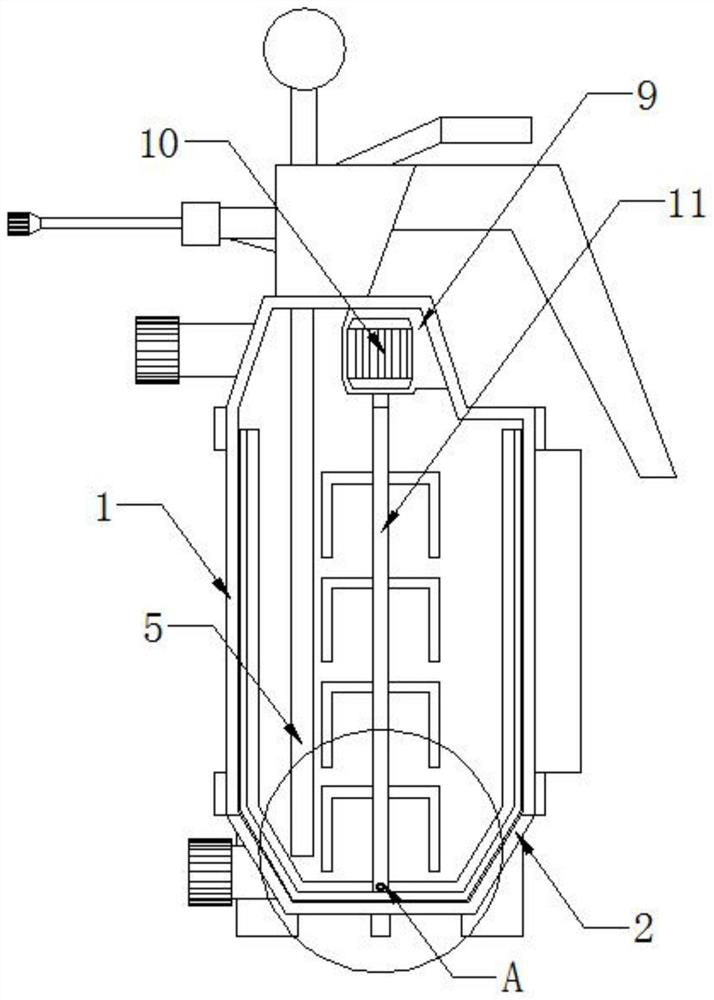

Disinfectant fluid electronic proportioning sprinkling can

InactiveCN112058532AEasy to measure accuratelyEasy to controlLavatory sanitorySingle-unit apparatusStructural engineeringProcess engineering

The invention belongs to the technical field of sprinkling cans, and particularly relates to a disinfectant fluid electronic proportioning sprinkling can which comprises a can body. A can bottom is inthreaded connection with the bottom end of the can body, a hydraulic pipe is in threaded connection with one side of the top end of the can body, a handle is arranged at the top of the hydraulic pipe, a water pumping pipe is fixedly installed at the bottom of the hydraulic pipe, and a pressing handle is fixedly installed on one side of the top end of the hydraulic pipe. A spray pipe is fixedly mounted on one side of the hydraulic pipe, one end of the spray pipe is in threaded connection with a nozzle, a motor box is fixedly mounted at the top end of the inner wall of the can body, and a motoris fixedly mounted in the motor box. Through mutual cooperation of the motor, a stirring rod and a stirring bar, a disinfectant fluid stock solution in the can body can be fully mixed conveniently, so that the disinfectant fluid stock solution is mixed more uniformly, the mixing efficiency is improved, the operation difficulty is reduced, and the mixing progress is accelerated. Through mutual cooperation of a cleaning plate and a brush, the inner wall of the sprinkling can is conveniently cleaned, and the later cleaning difficulty is reduced.

Owner:HANGZHOU KUANFU TECH

Method for auxiliary pressurization of heavy oil rail through air

InactiveCN110145421AEasy to disassemble and replaceEasy to operateCombustion enginesLiquid fuel feedersCombustion chamberFuel oil

The invention discloses a method for auxiliary pressurization of heavy oil rail through air. The method comprises the following steps that an engine drives an air compressor to press the air, and meanwhile, an ECU of the engine sends an instruction to an electromagnetic pump to incorporate the fuel oil into a fuel oil pressurization chamber of the oil rail, a pressure sensor on each containing chamber on the oil rail feeds back a pressure value to the ECU of the engine correspondingly, when both the oil pressure and the air pressure on the oil rail reach a designed pressure value, electromagnetic valve instructions of an air nozzle and an oil nozzle given by the ECU enable two electromagnetic valves to inject the air and the oil into a oil-gas mixing chamber, when the pressure in the oil-gas mixing chamber reaches a proper value, the ECU commands the fuel gas electromagnetic valves to be opened and closed according to the feedback information, so that the heavy oil fuel gas is injectedinto a combustion chamber, and the ignition of the heavy oil is realized. According to the oil rail, the method for auxiliary pressurization through the air is utilized, heat energy carried by the air is utilized, the fuel gas atomized can be warmed up, so that the heavy oil reaches an ignition effect similar to that of clear oil, and the purpose that the heavy oil can be used on an ignition typeengine is achieved.

Owner:ZHEJIANG PIONEER MACHINERY & ELECTRON

Concrete preparation device for construction

ActiveCN107932724BStir wellQuality improvementCement mixing apparatusLiquid ingredients supply apparatusCouplingArchitectural engineering

The invention discloses a building concrete preparation device which comprises a bottom plate. A first box is fixedly connected to the top of the bottom plate, and supporting plates are fixedly connected to the two sides of the inner wall of the first box. A second box is fixedly connected to the tops of the two supporting plates. A transverse plate is fixedly connected to one side of the first box, and the top of the transverse plate is fixedly connected with a first motor through a connecting block. One end of an output shaft of the first motor is fixedly connected with a rotating crankshaftthrough a coupling, and the end, away from the first motor, of the rotating crankshaft penetrates the first box and extends into the first box. The invention relates to the technical field of building equipment. According to the building concrete preparation device, stirring in the concrete preparation process can be achieved, stirring is quite quick and sufficient, and therefore time is saved, the burdens of workers are reduced, the work efficiency is improved, and the quality of prepared concrete is good.

Owner:金华市城建混凝土有限公司

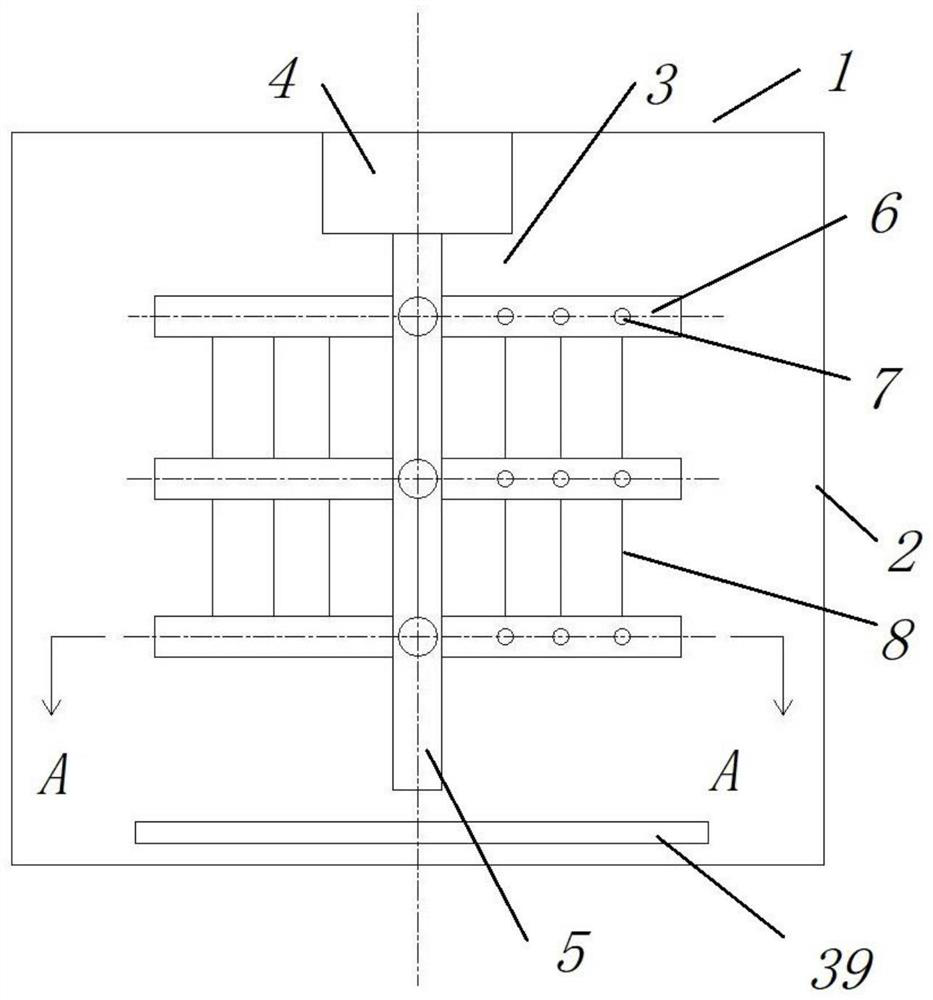

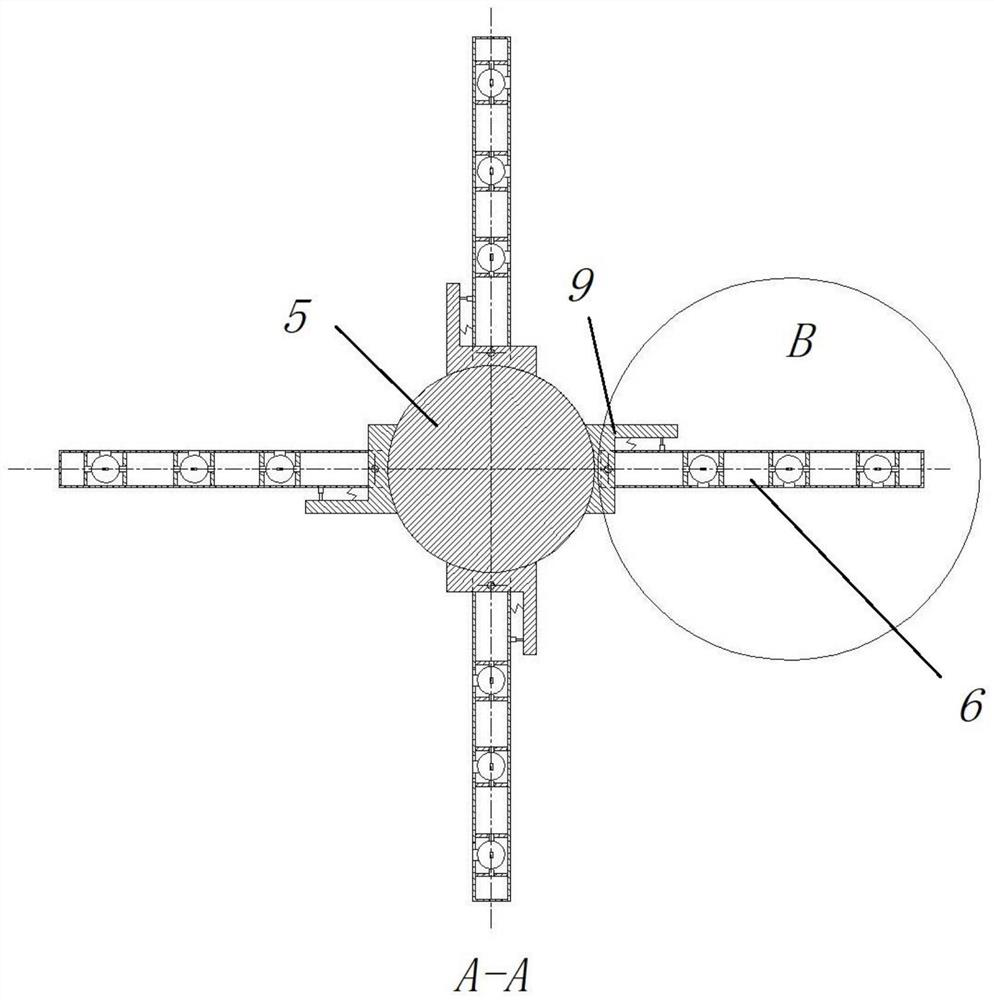

FCC kaolin preparation method

PendingCN113828213ASpeed up the mixing processStir wellShaking/oscillating/vibrating mixersTransportation and packagingPhysicsTelescopic cylinder

The invention discloses an FCC kaolin preparation method. When kaolin is subjected to acid liquor mixing, a stirring device comprising a flexible part is used, a stirring rod in the stirring device is arranged in a multi-layer structure and is rotationally arranged on a stirring main shaft in a hinged mode, and a spring and a telescopic cylinder structure are arranged at the hinged position; the stirring rods on the same layer can be uniformly stressed, the stirring condition of a stirring barrel in the horizontal direction can be balanced, meanwhile, the flexible part structures are arranged between the stirring rods on different layers, the stirring condition of the stirring barrel in the vertical direction can be balanced, and meanwhile, a spherical air injection part is arranged in the stirring rod and can inject air in acid liquor to further enhance the stirring effect, further, the spherical air injection part is connected with the flexible part and can adapt to bending of the flexible part to change the air injection direction, and the stirring effect can be further enhanced.

Owner:XIAMEN XINYISHENG NONMETAL MATERIAL SCI & TECH

Community domestic sewage ecological treatment system

InactiveCN111268853ASimplify the processSpeed up the mixing processSludge treatment by de-watering/drying/thickeningUsing liquid separation agentReclaimed waterEcosystem

The invention discloses a community domestic sewage ecological treatment system, and belongs to the technical field of sewage treatment. The system comprises a septic tank, a sewage treatment device,a reclaimed water tank, an ecologicalization system, a reservoir and an atomization system, which are connected in sequence; a liquid outlet of the septic tank is close to the upper end surface of theseptic tank and is higher than a liquid inlet of the sewage treatment device; the sewage treatment device comprises a PH regulating tank, a flocculation tank and a sedimentation tank, the ecologicalization system comprises an artificial wetland with a slope; wherein the constructed wetland is provided with a plurality of criss-cross water tanks; the atomization system comprises a water delivery pipe network buried in a community, atomization nozzle brackets arranged at different positions in the community, and atomization nozzles arranged at the upper ends of the atomization nozzle brackets and communicated with the water delivery pipe network through pipelines. Domestic sewage sequentially passes through a septic tank, a sewage treatment device, a reclaimed water tank, an ecosystem and awater storage tank and finally becomes landscape water.

Owner:河南恒托电子科技有限公司

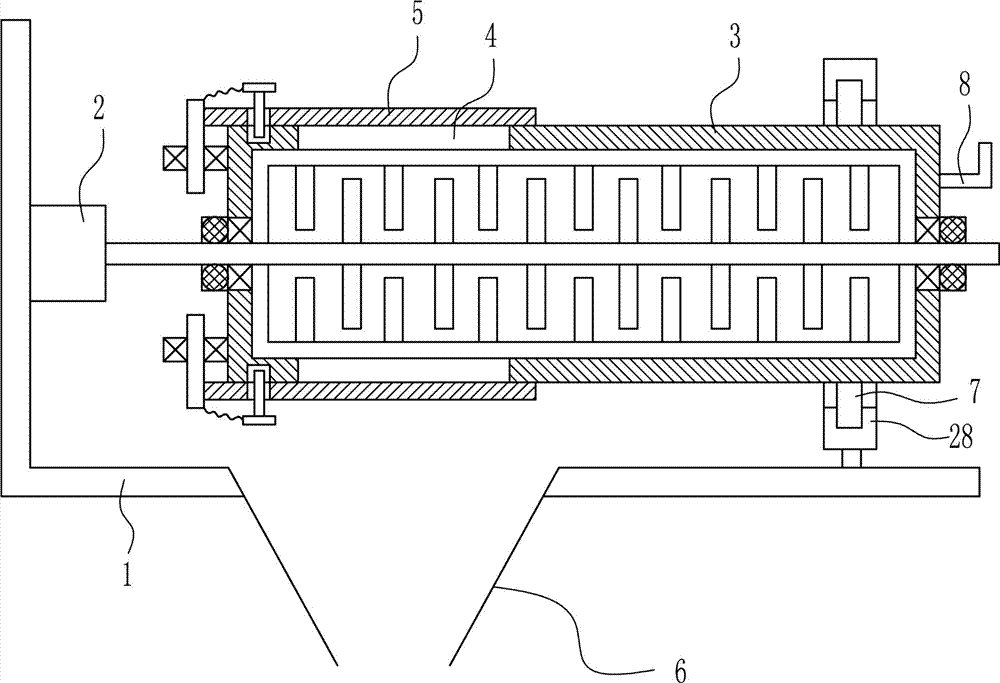

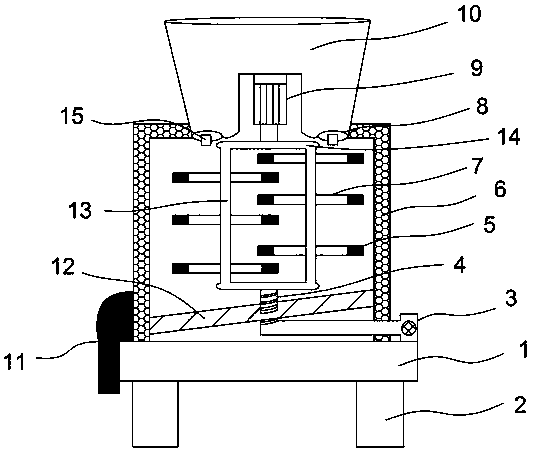

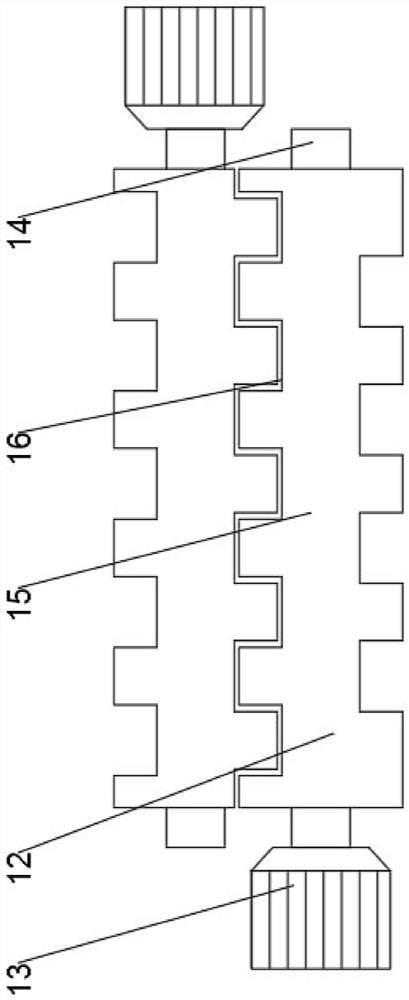

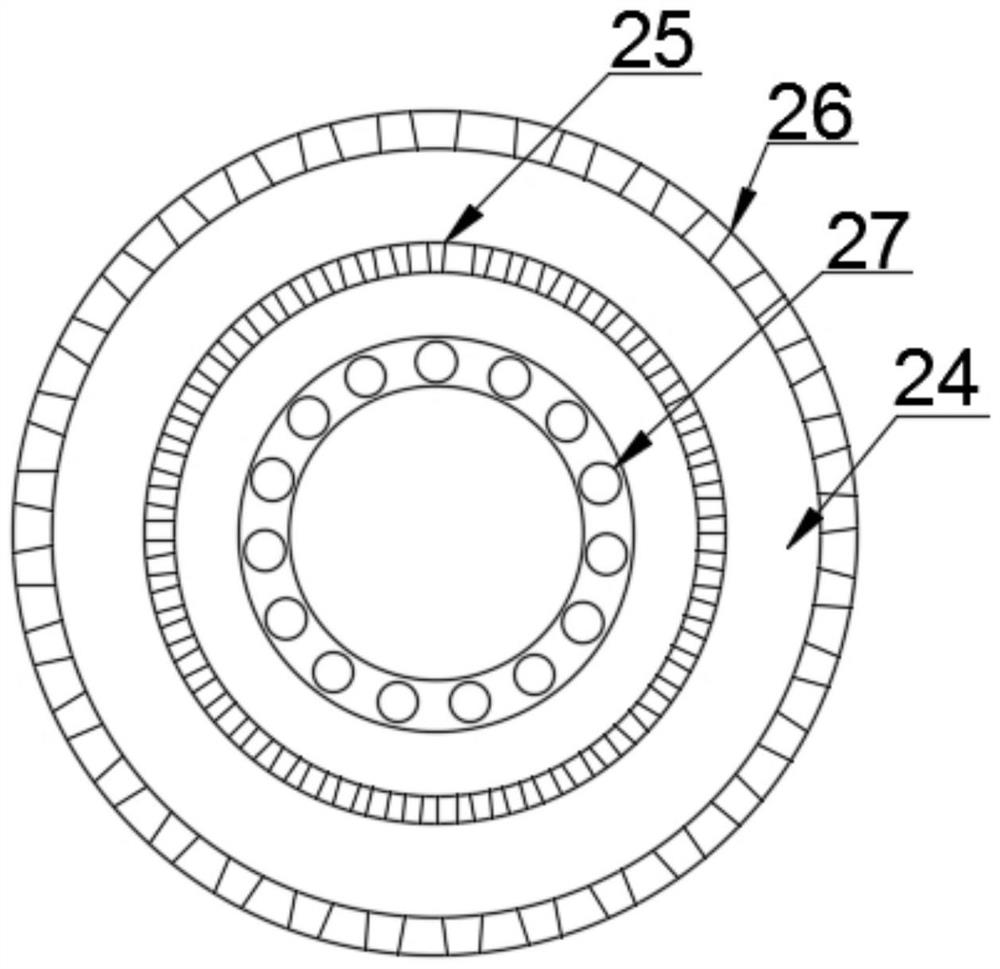

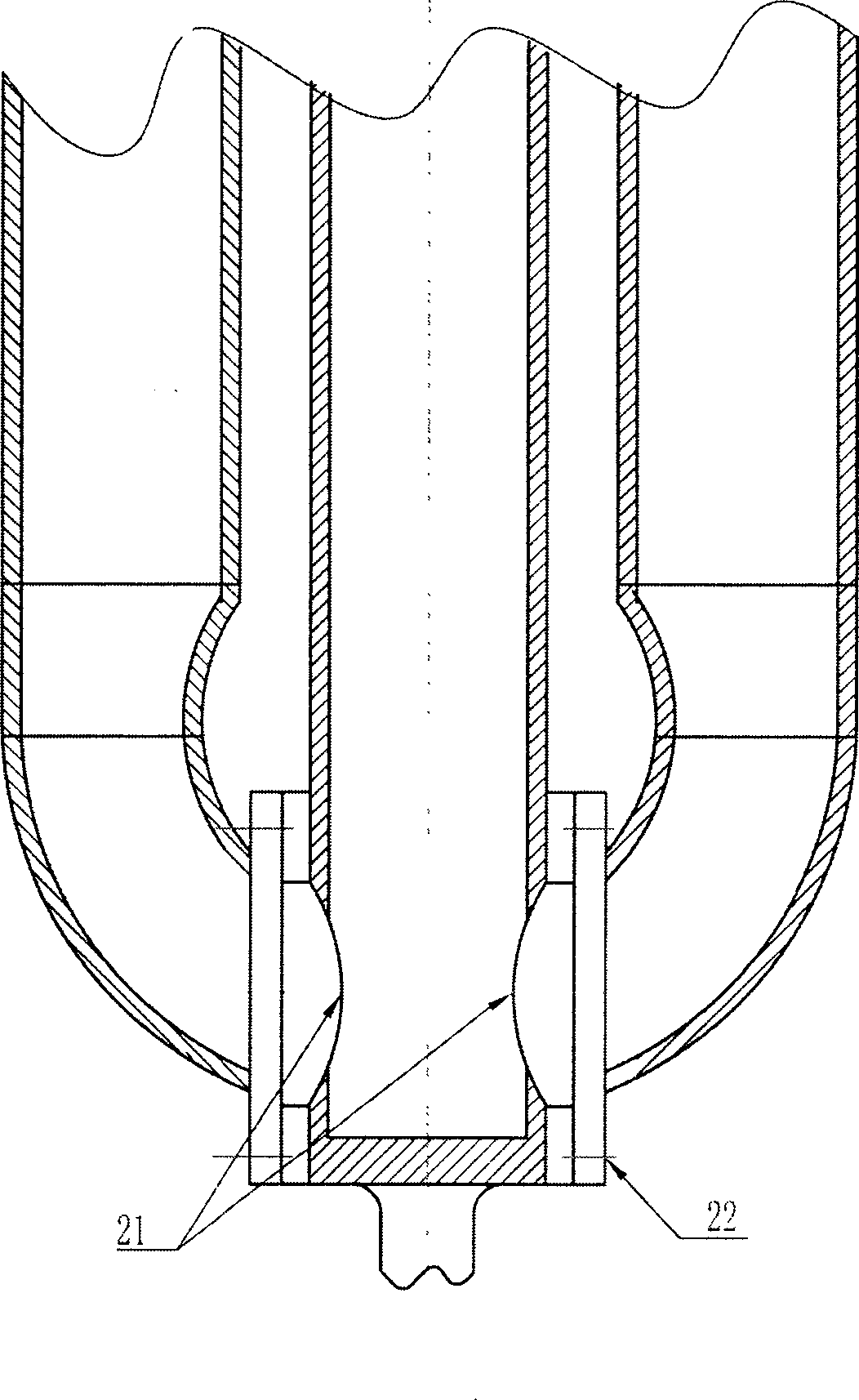

Agitator of polymerizer for producing PVC resin paste by emulsion polymerization

InactiveCN100482692CIncrease production capacitySpeed up the mixing processWater useEmulsion polymerization

This invention relates to a reactor agitator use for the production of PVC paste resin polymerization in Emulsion polymerization method. It includes polymerizer and blender. In polymerizer with the installation of blenders, and the blender includes mixing axis, ring canal type stirring paddle. The mixing axis is hollow shaft type, and with installation of ring canal type stirring paddle. Blender equipped with cooling water import and export of cooling water. Cooling water import and export of cooling water used PTFE packing seal; The diameter ratio of ring canal type stirring paddle and kettle is 0 .45-0.50:1. The angle between ring canal centerline of ring canal type stirring paddle and mixing axis is 3 -5 degree. The ring canal type stirring paddle and mixing axis connect through removable heavy head screw, and the lower part of the connection has a cooling water circulation mouth.

Owner:AVIC LIMING JINXI CHEM MASCH GRP CO LTD

Stirring device for ink and resin mixing

InactiveCN108654480ASpeed up the mixing processRotating receptacle mixersTransportation and packagingDrive motorChemical engineering

The invention discloses a stirring device for ink and resin mixing. The stirring device comprises a stirring kettle body, an upper cover of the kettle body, a connecting part of the upper cover, an outer framework body, a material inlet, a stirring motor, a stirring rod, a material discharge valve, a fixed support plate of the kettle body, balls, and a drive motor of the kettle body. The stirringdevice for the ink and resin mixing has the advantage that the whole horizontal rotation of the stirring kettle body is combined with the reverse rotation of the stirring rod, so as to futher accelerate the stirring process of the ink and the resin.

Owner:常熟国和新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com