Fish aquaculture feed uniform-stirring equipment

A uniform stirring and fish breeding technology, which is applied in the direction of feed, mixer accessories, mixers with rotating stirring devices, etc., can solve the problems of limiting the efficiency of fish bait output, reducing the income of farmers, and consuming a lot of physical strength, so as to improve the quality of bait Effects of utilization rate, improvement of bait mixing efficiency, and improvement of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

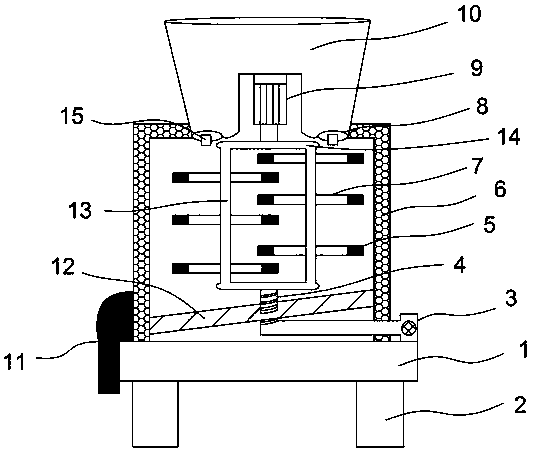

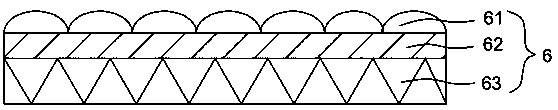

[0021] Such as Figure 1-2As shown, the uniform mixing equipment for fish breeding feed includes a base 1, the lower end of the base 1 is provided with a foot 2, the upper end of the base 1 is connected with a housing 6, and the lower side of the housing 6 is provided with a discharge device 11, and the upper end of the housing 6 is connected to the The lower side of the blanking box 10 is connected, and the two ends of the bottom of the blanking box 10 are provided with a blanking port 8, and a meter 15 is arranged in the blanking port 8. Fixedly connected, the output shaft at the lower end of the main motor 9 is connected to the linkage rod 14, the two ends of the linkage rod 14 are vertically connected with stirring shafts 13, and the stirring shafts 13 at both ends are staggered and evenly distributed with horizontally arranged stirring rods 7. The bait mixing equipment sets a base under the shell, so that the shell can be stably fixed above the base, so that when the bait...

Embodiment 2

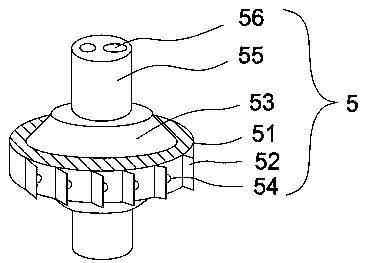

[0025] Such as Figure 3-4 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: the linkage rod 14, the stirring rod 7, and the stirring shaft 13 are hollow built in, and the rotating cleaning device 5 is installed at both ends of the stirring rod 7, and the rotating cleaning device 5 includes Cleaning disc 51, the upper and lower ends of cleaning disc 51 are equipped with mutually symmetrical round platform 53, the upper surface of round platform 53 is provided with connecting column 55, the inside of connecting column 55 is provided with two through holes 56 of different sizes, the axis of through hole 56 and the connecting column 55 axes are parallel, one end of the two through holes 56 communicates with the hollow structure of the stirring rod 7, and the other end of the two through holes 56 communicates with the symmetrical two spiral passages 16 in the round platform 53 respectively, and the spiral passages 16 are connected with the two bu...

Embodiment 3

[0029] Such as Figure 5 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is as follows: the discharge device 11 is provided with a delivery port 30 communicating with the lower side of the housing 6, and the inside of the discharge device 11 is provided with a drum 19. There are T-shaped teeth 20 evenly distributed on the outside of the cylinder 19, a gear rolling chamber matching the T-shaped teeth 20 is provided in the discharge device 11, and a discharge port 29 is provided at the bottom of the discharge device 11, and the discharge port 29 has a built-in support rod 21 , the surface of the strut 21 circumscribes a downwardly inclined spiral slideway 22 . The drum installed inside the discharge device can bring the bait falling into the delivery port into the discharge port through the rotation of the drum. There are T-shaped teeth evenly distributed outside the drum, and there are T-shaped teeth in the discharge device. The matching gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com