Patents

Literature

783results about How to "Speed up the fall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

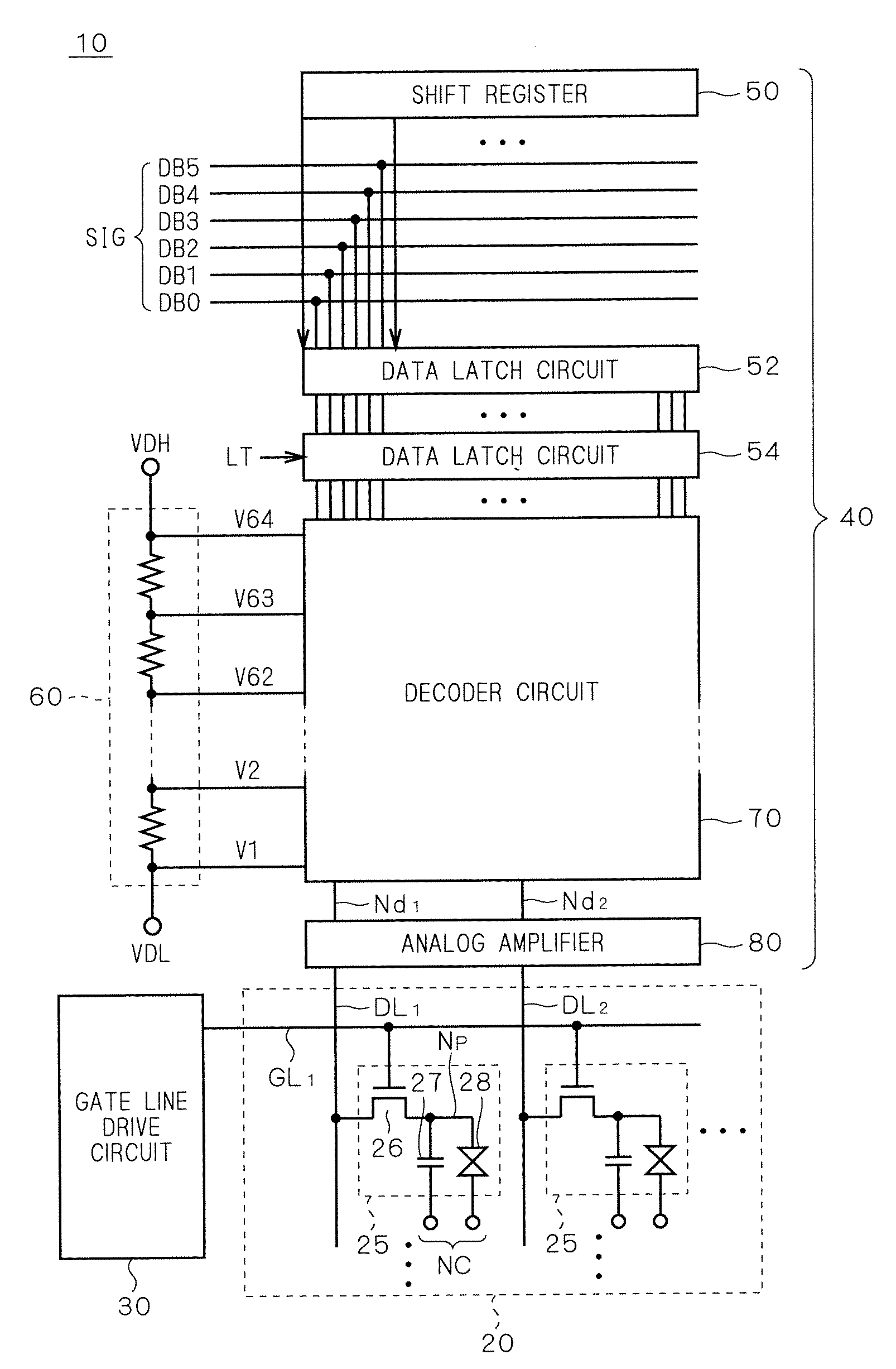

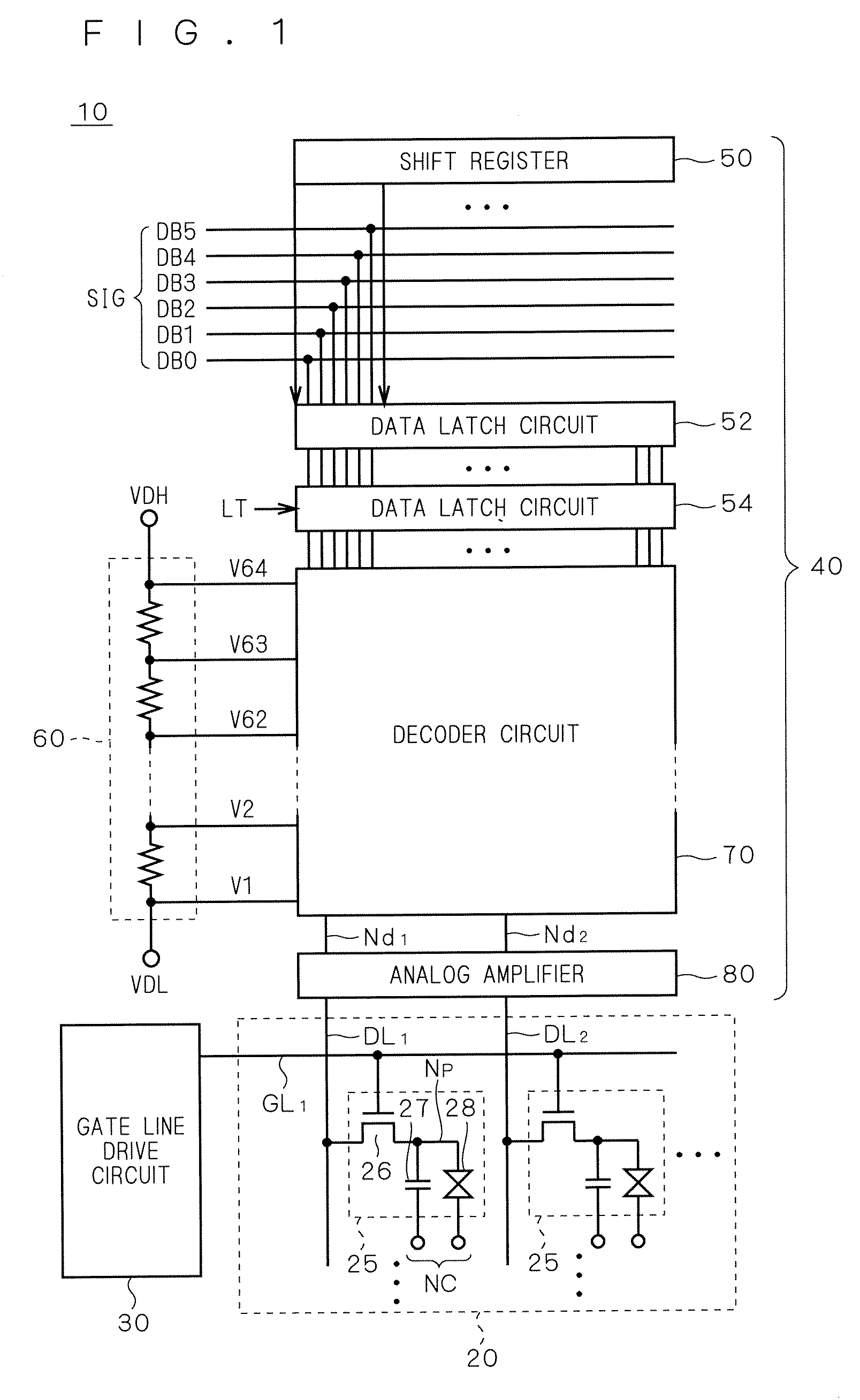

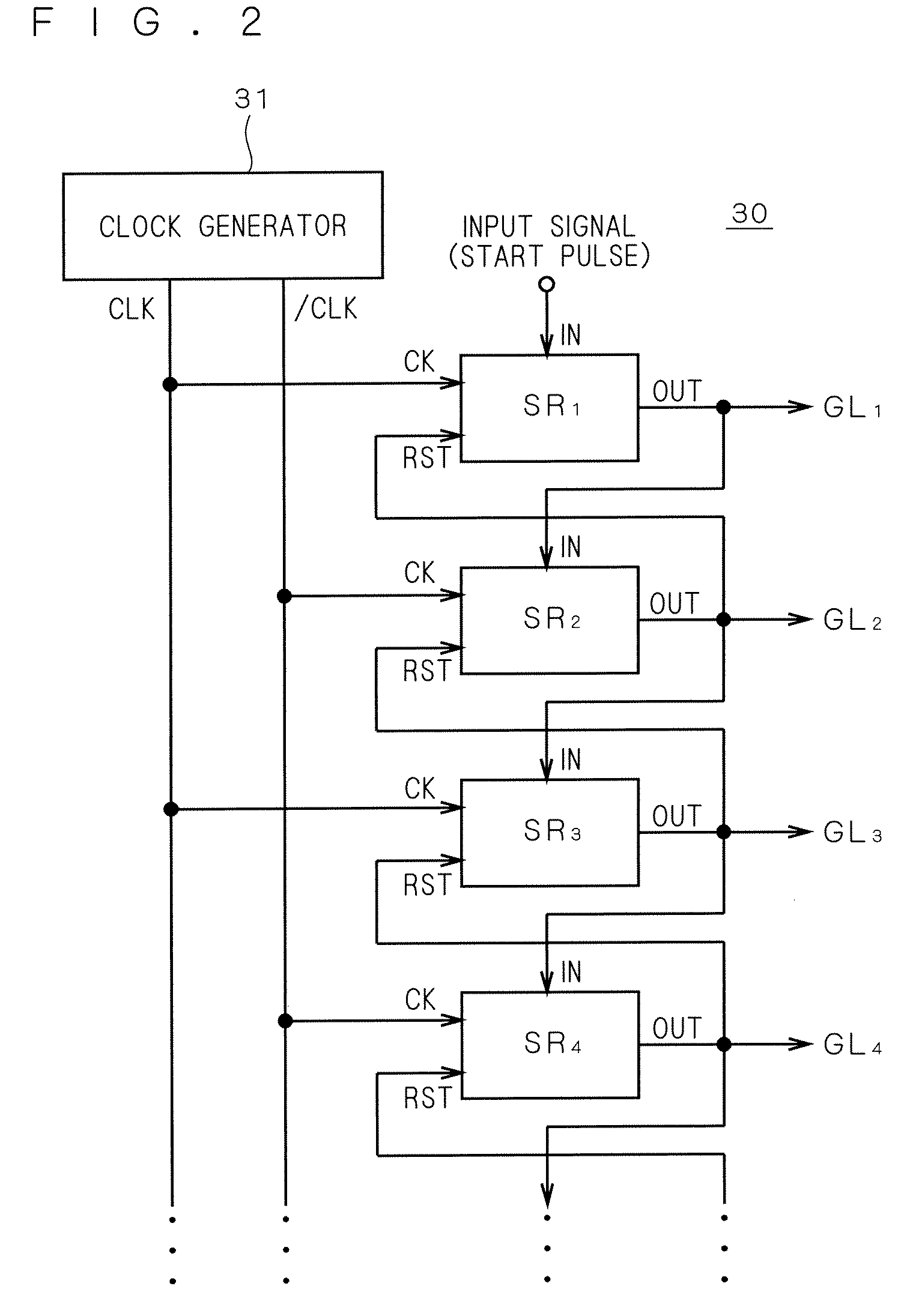

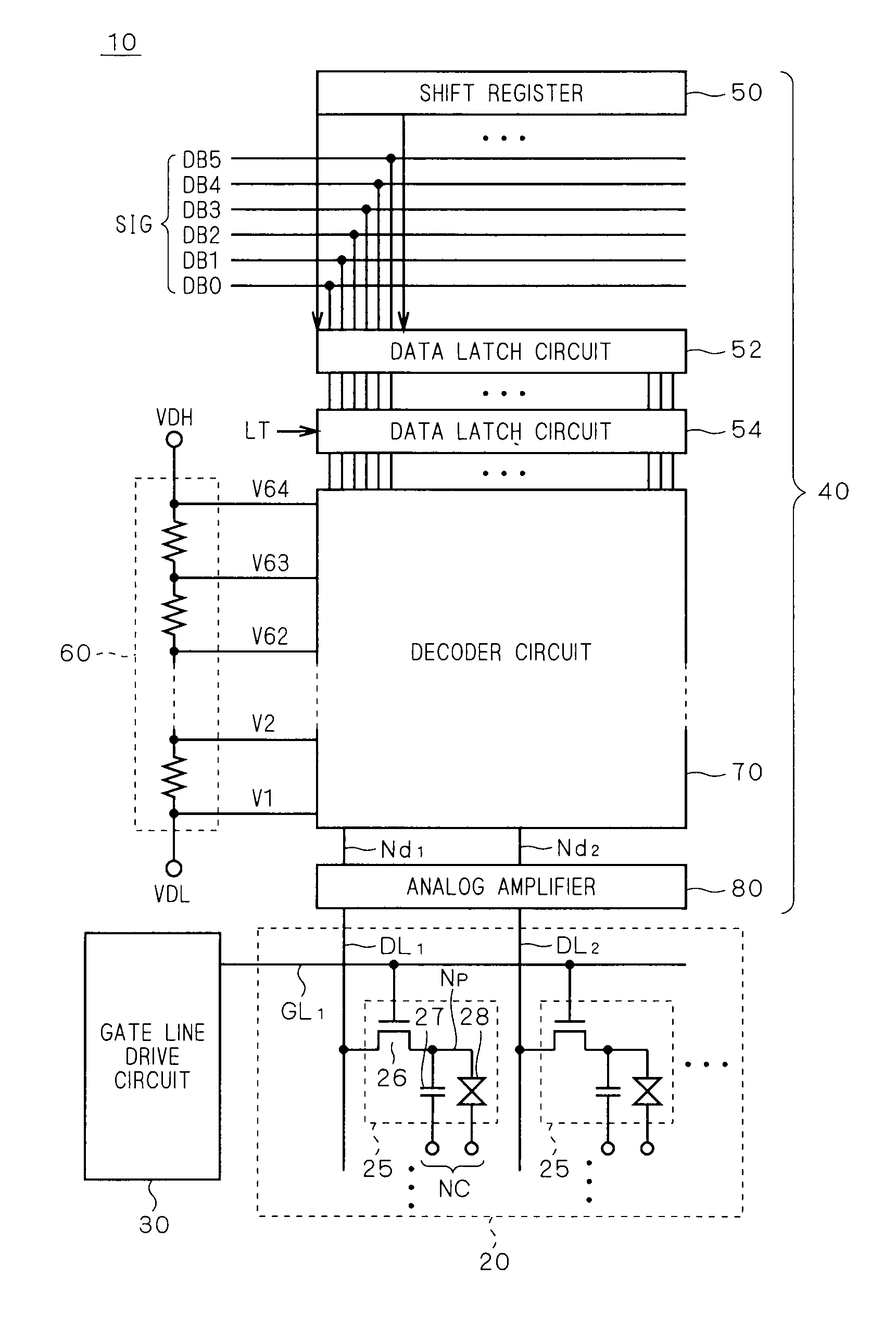

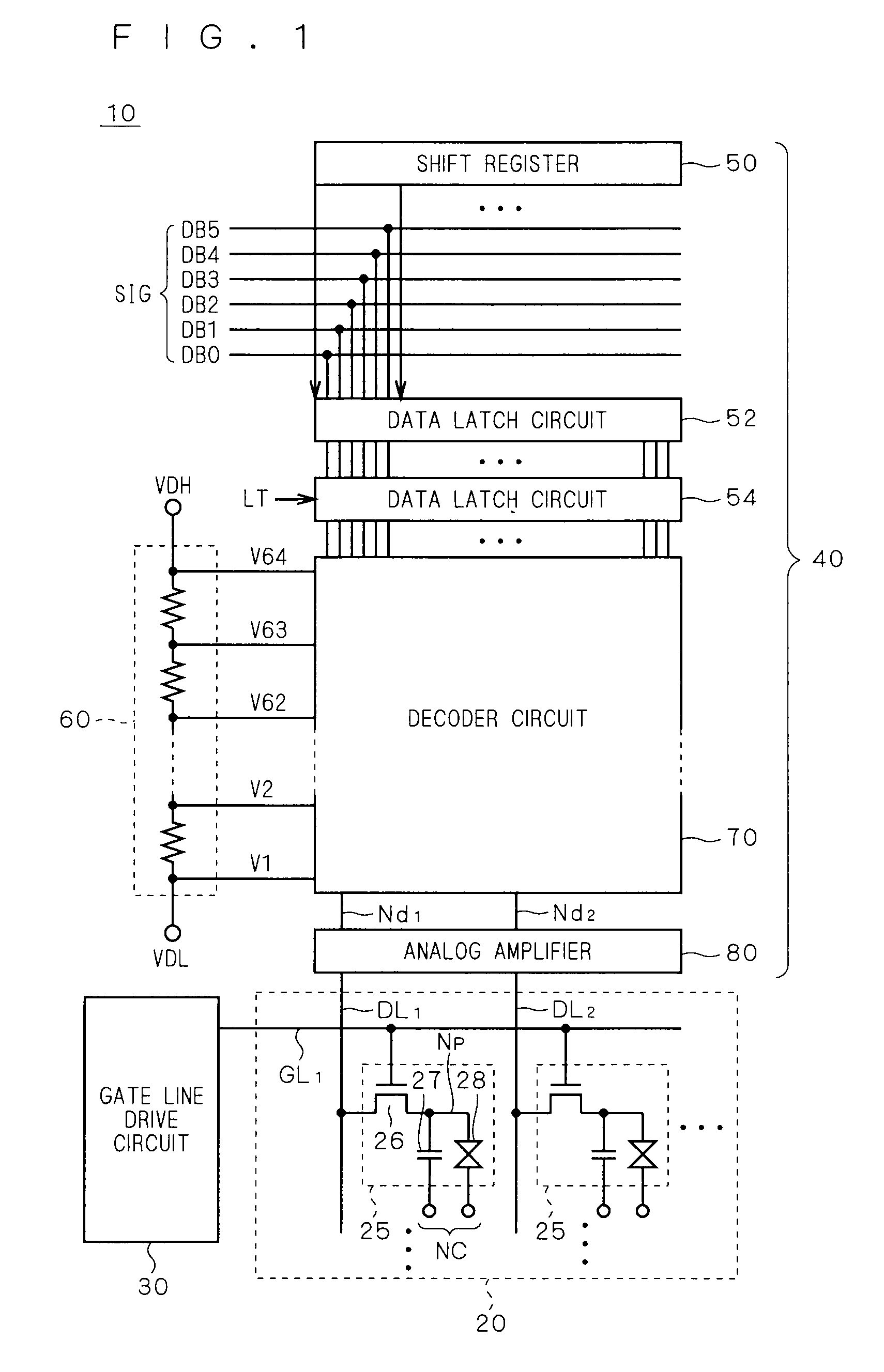

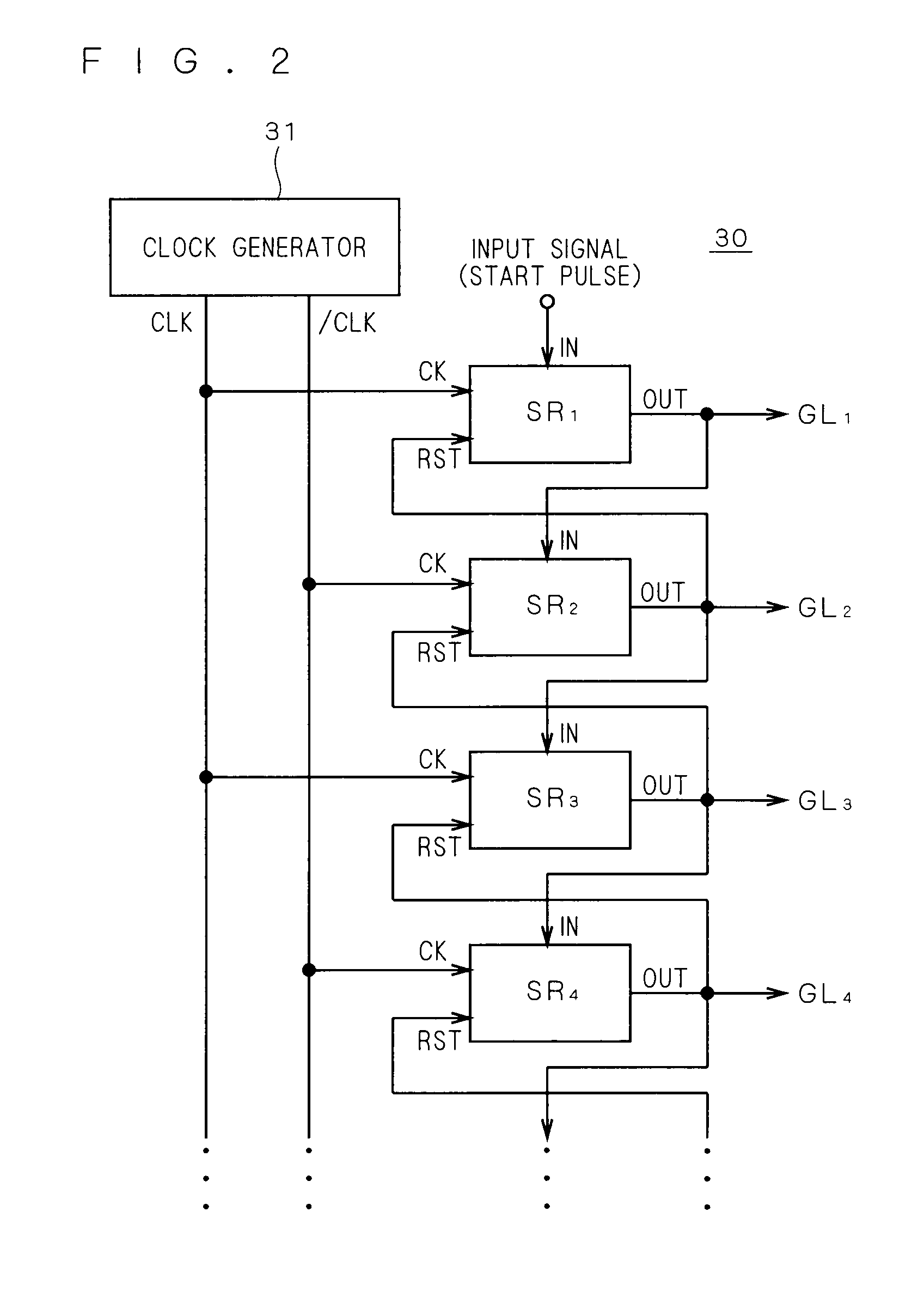

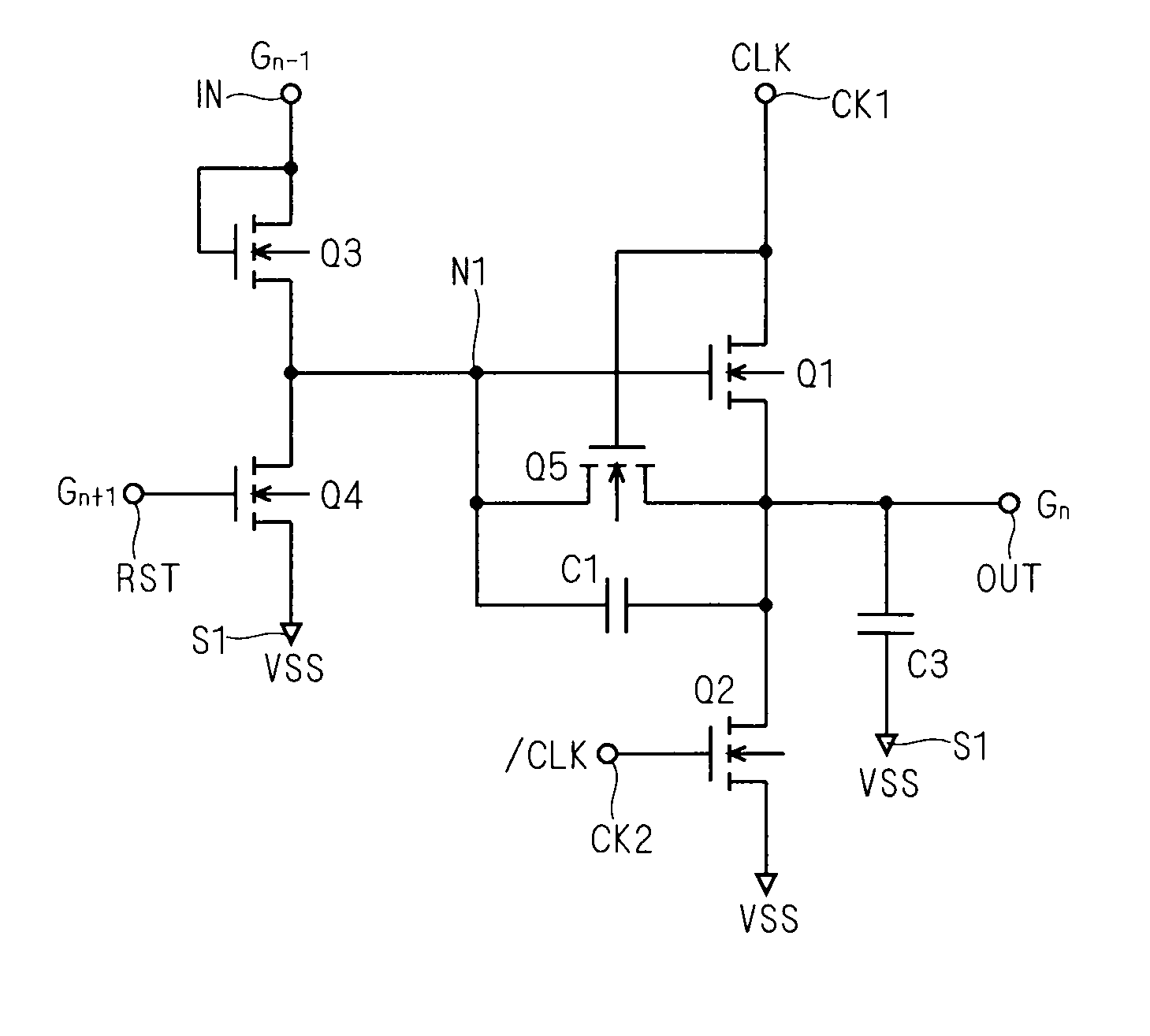

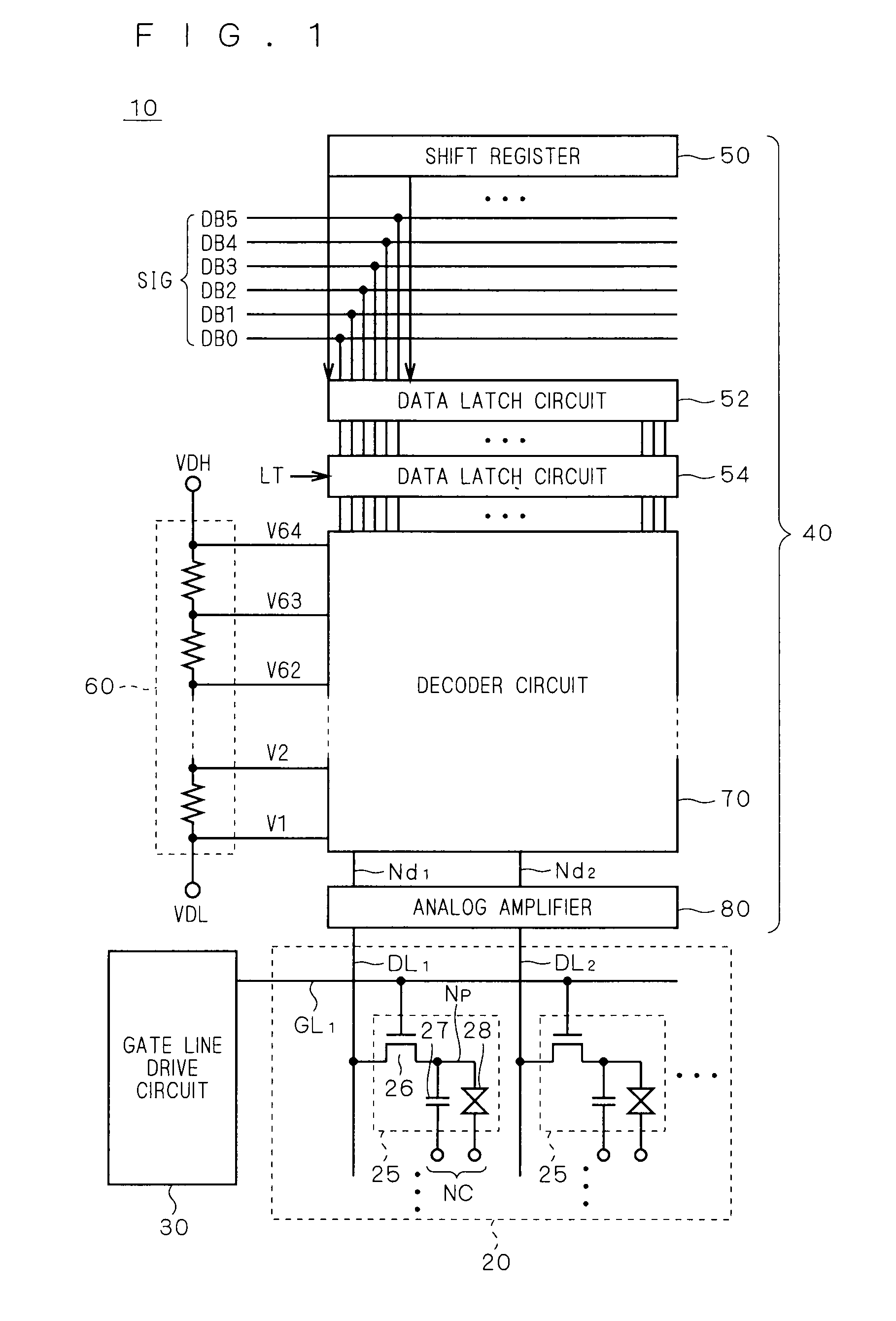

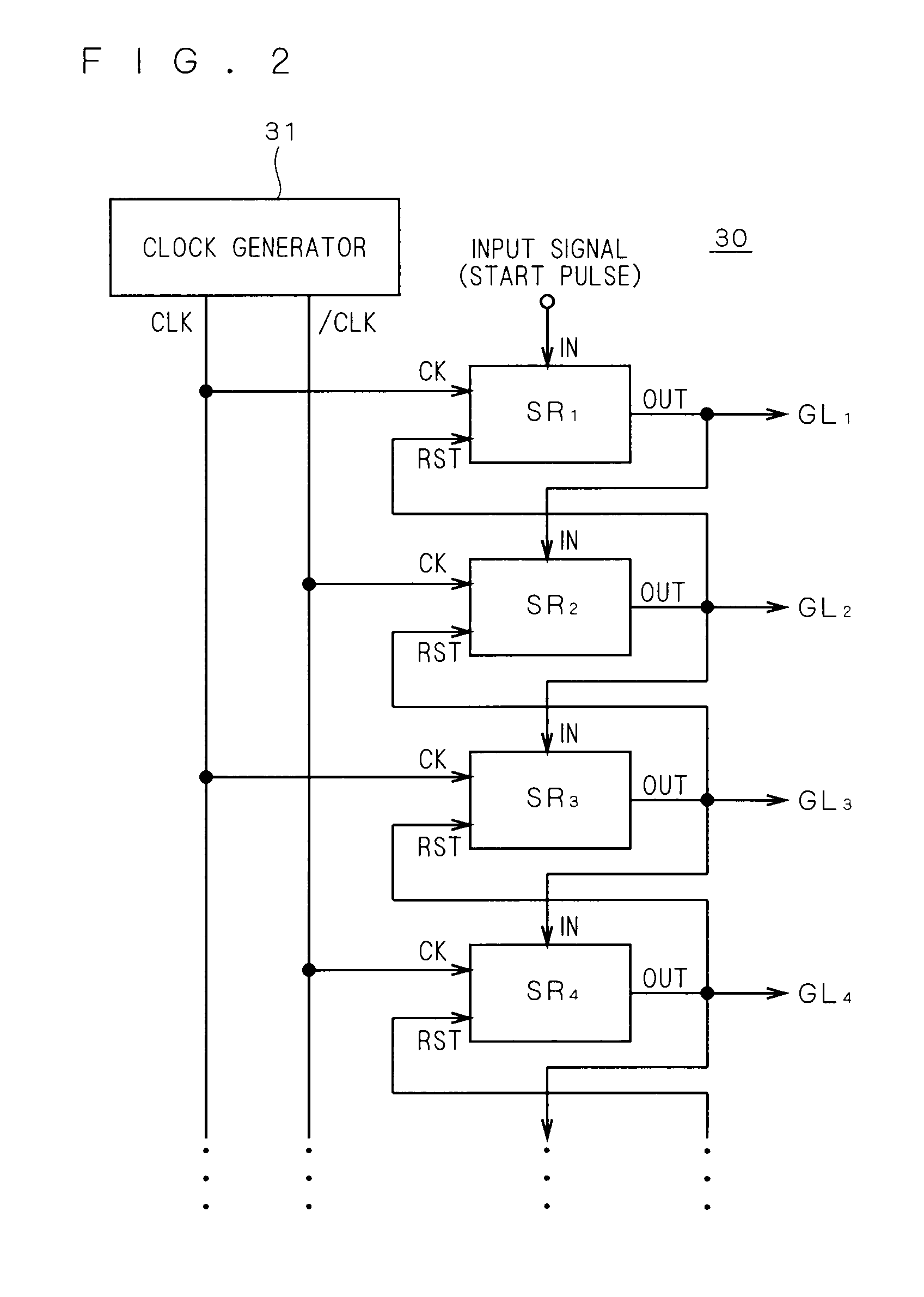

Shift register circuit and image display comprising the same

InactiveUS20070247932A1Defective operation is preventedDrive capability is prevented being loweredStatic indicating devicesDigital storageShift registerProcessor register

In a shift register circuit, a defective operation while an output signal is not outputted and a drive capability lowering while the output signal is outputted are prevented. A unit shift register comprises a first transistor for supplying a clock signal inputted to a first clock terminal to an output terminal, and the first transistor is driven by a drive circuit. A second transistor is connected between the gate of the first transistor and the output terminal and has a gate connected to the first clock terminal. The second transistor connects the gate of the first transistor to the output terminal based on the clock signal when the gate of the first transistor is at L (Low) level.

Owner:MITSUBISHI ELECTRIC CORP

Shift register circuit and image display comprising the same

ActiveUS8493309B2Lower capability requirementsImprove driving abilityStatic indicating devicesDigital storageShift registerProcessor register

In a shift register circuit, a defective operation while an output signal is not outputted and a drive capability lowering while the output signal is outputted are prevented. A unit shift register comprises a first transistor for supplying a clock signal inputted to a first clock terminal to an output terminal, and the first transistor is driven by a drive circuit. A second transistor is connected between the gate of the first transistor and the output terminal and has a gate connected to the first clock terminal. The second transistor connects the gate of the first transistor to the output terminal based on the clock signal when the gate of the first transistor is at L (Low) level.

Owner:TRIVALE TECH

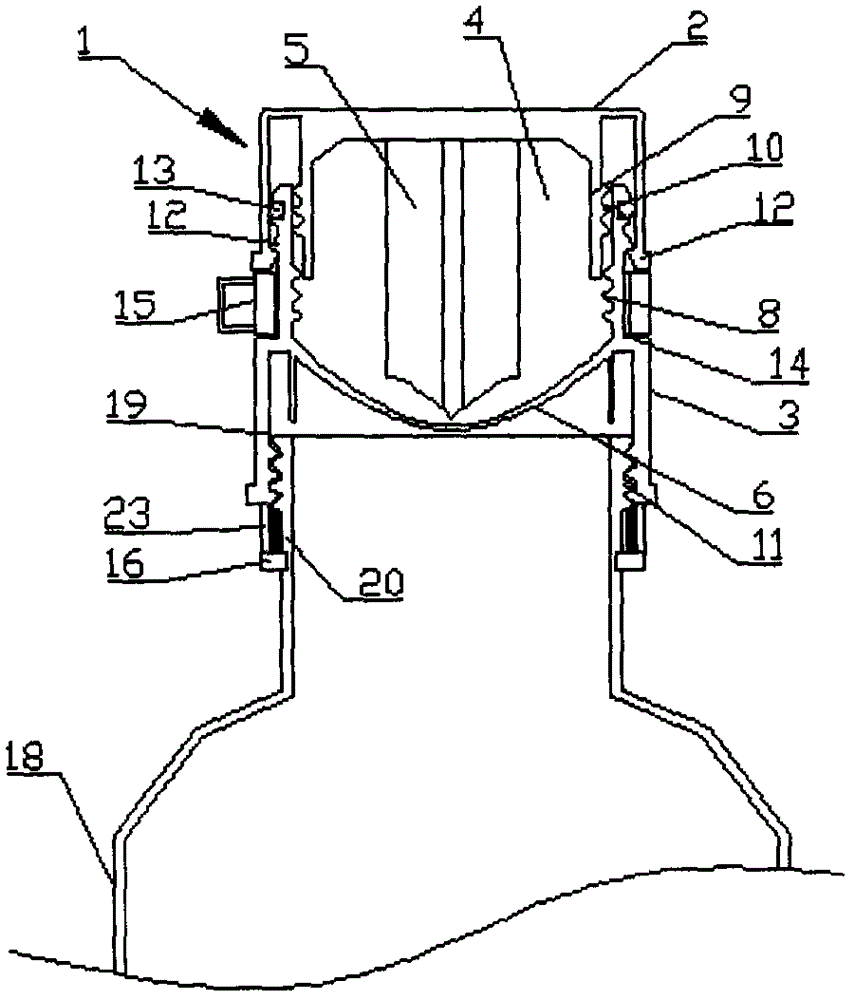

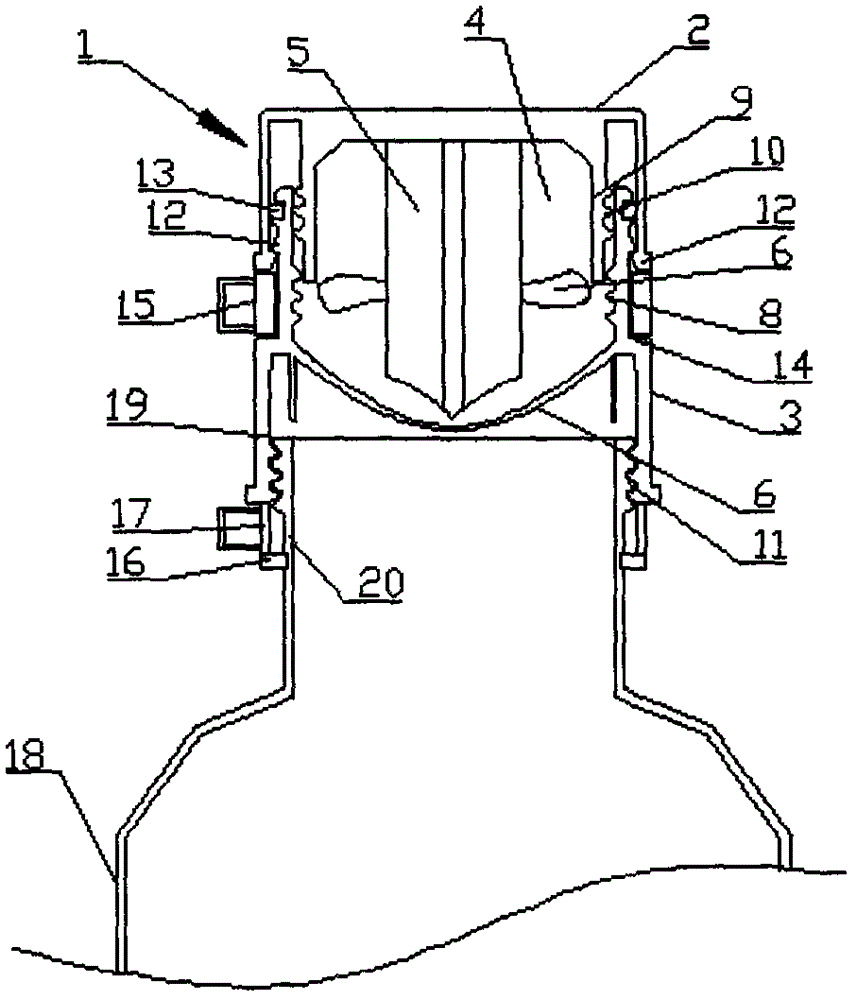

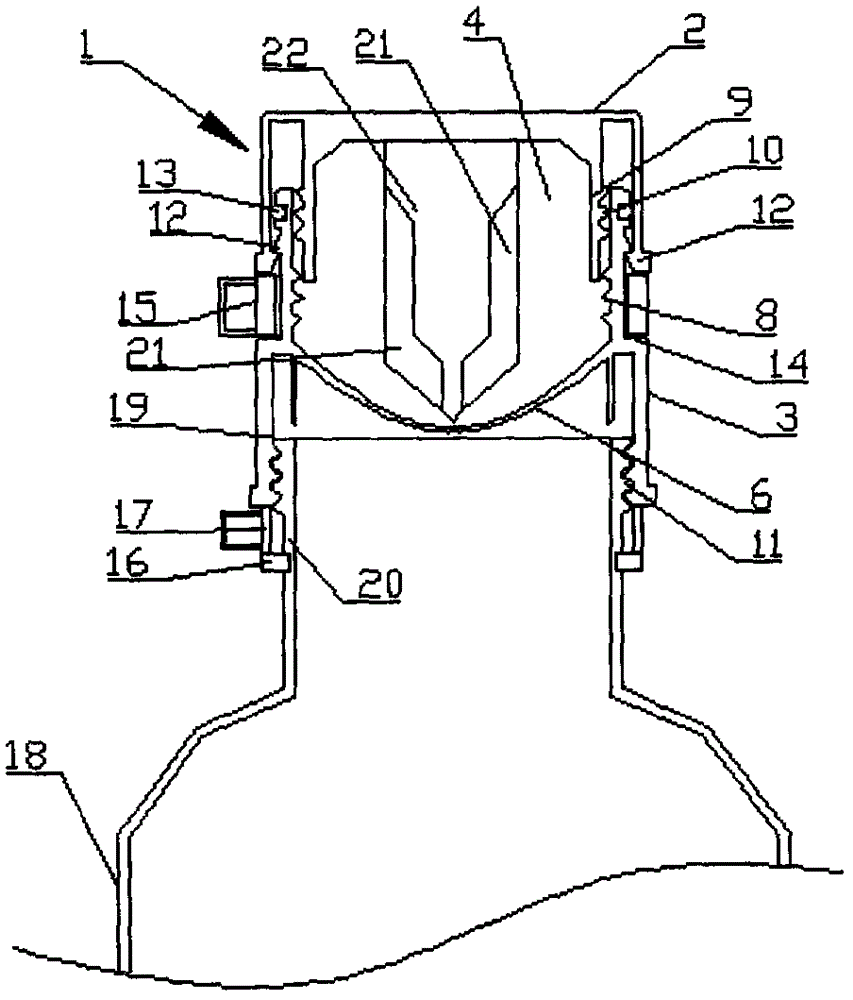

Bottle cap containing solid-state beverage and beverage bottle with bottle cap

The invention discloses a bottle cap containing solid-state beverage and a beverage bottle with the bottle cap. The bottle cap comprises an upper cap body and a lower cap body which are fixed above a bottle opening, the upper cap body is connected to the outer side of the lower cap body in a sleeving manner, a containing cavity for containing and storing the solid-state beverage is formed inside the upper cap body and the lower cap body, and a sealing thin film is arranged in the bottom of the lower cap body; and a sealing ring is arranged at a port of the top end of the lower cap body, so that the containing cavity in the upper cap body and the lower cap body keeps sealed with the outside, and harmful effects such as wetting and deterioration of the solid-state beverage contained and stored in the containing cavity are prevented. A cross-shaped puncture pole in the upper cap body completely punctures the sealing thin film at the bottom of the lower cap body, the solid-state beverage falls into liquid-state beverage in a bottle body, and a user can swing the bottle body to accelerate fusion of the solid-state beverage and the liquid-state beverage in the bottle body while the solid-state beverage falls into the bottle body more rapidly. In-advanced separated storage can be carried out according to different flavors of the solid-state beverage and the liquid-state beverage, convenience is brought to different crowds, and different flavor requirements can be met.

Owner:杭州千岛湖饮料食品有限公司

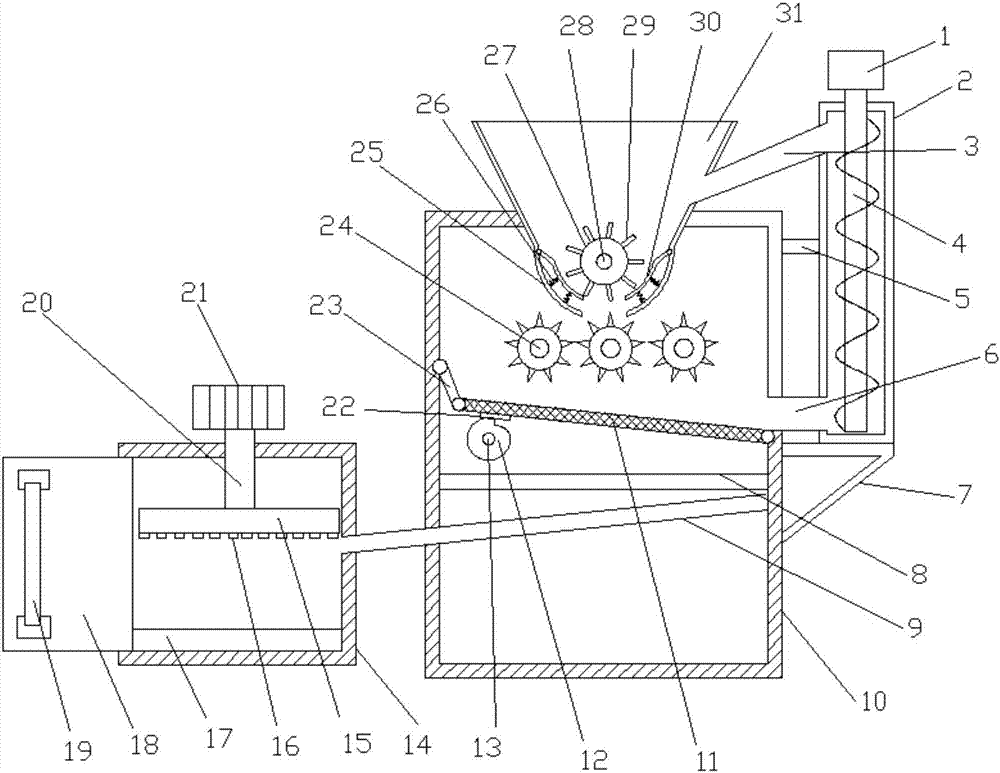

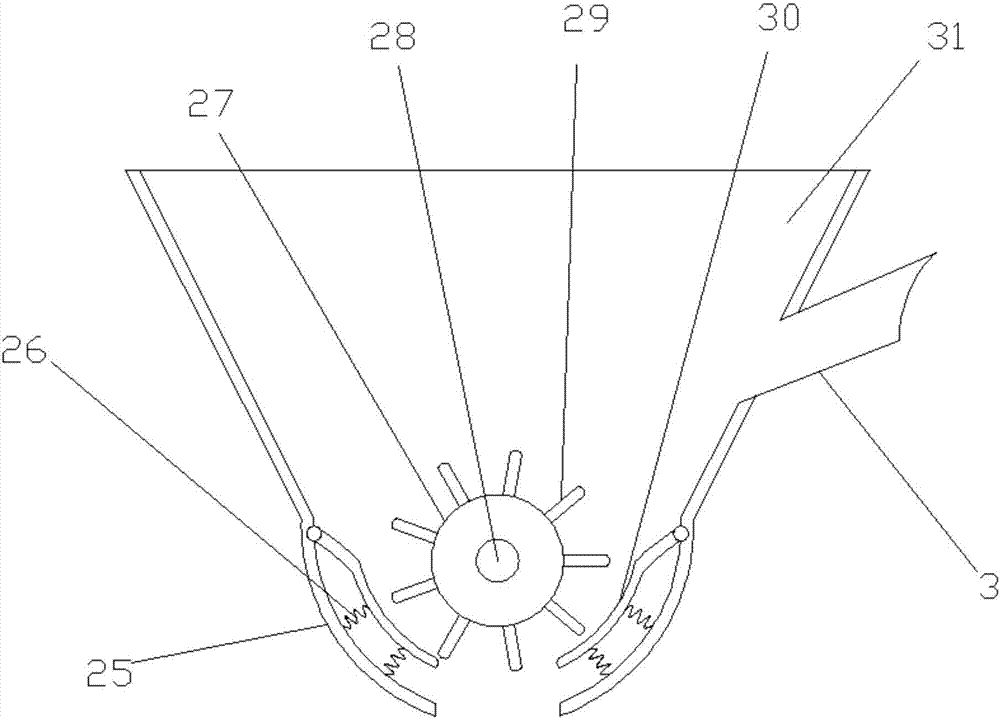

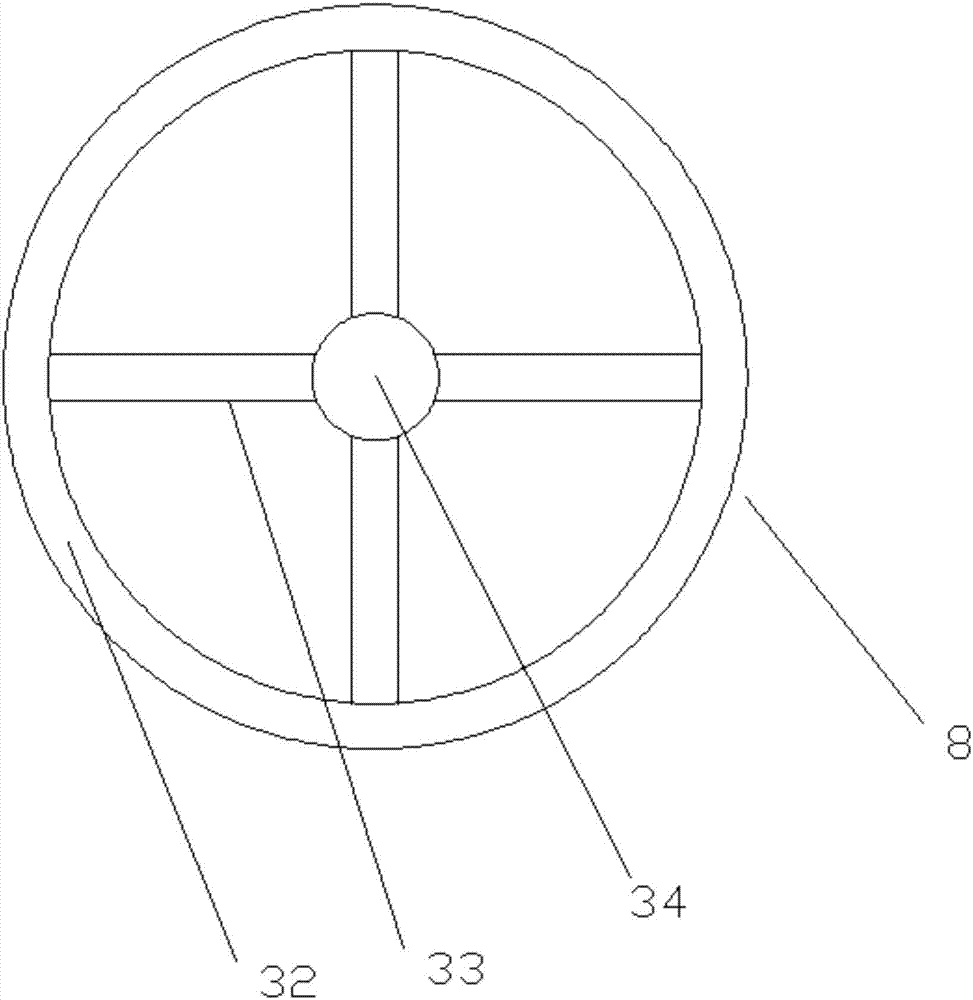

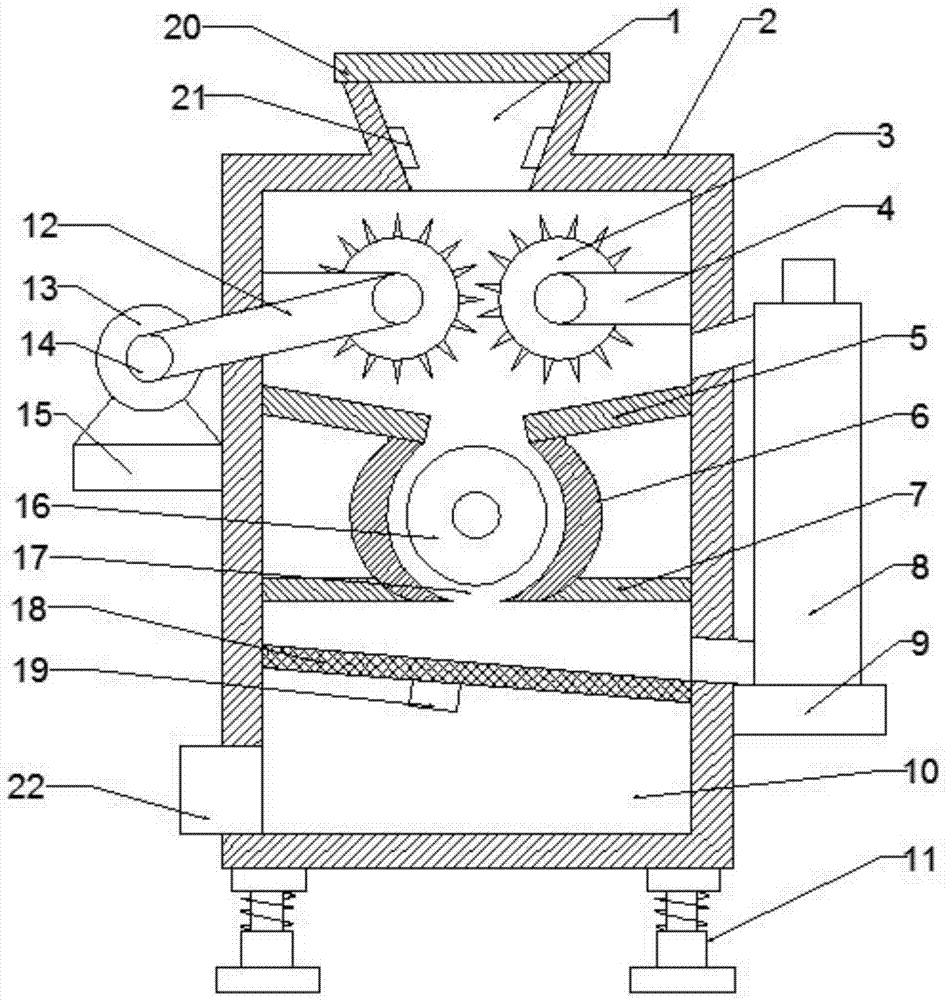

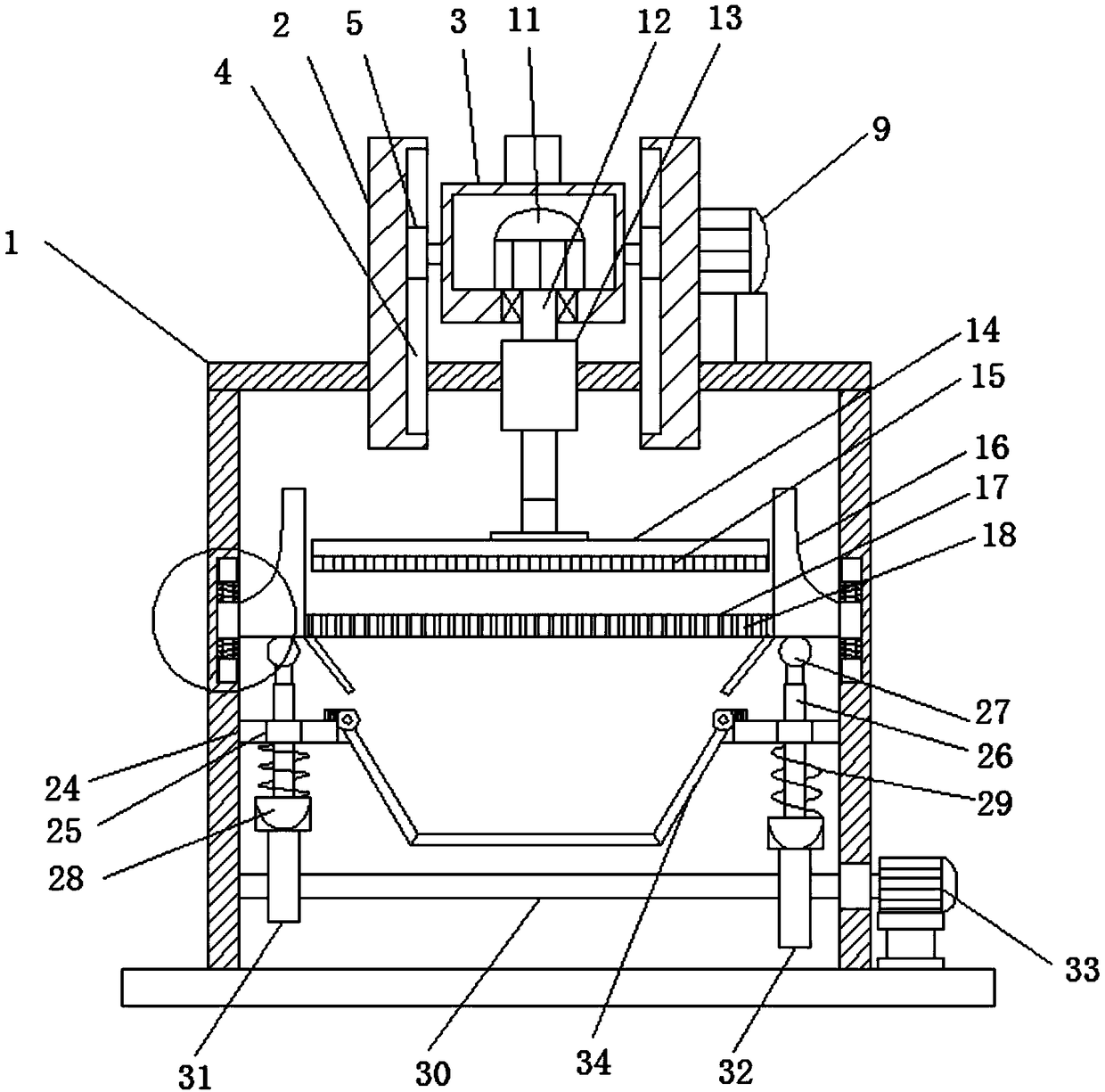

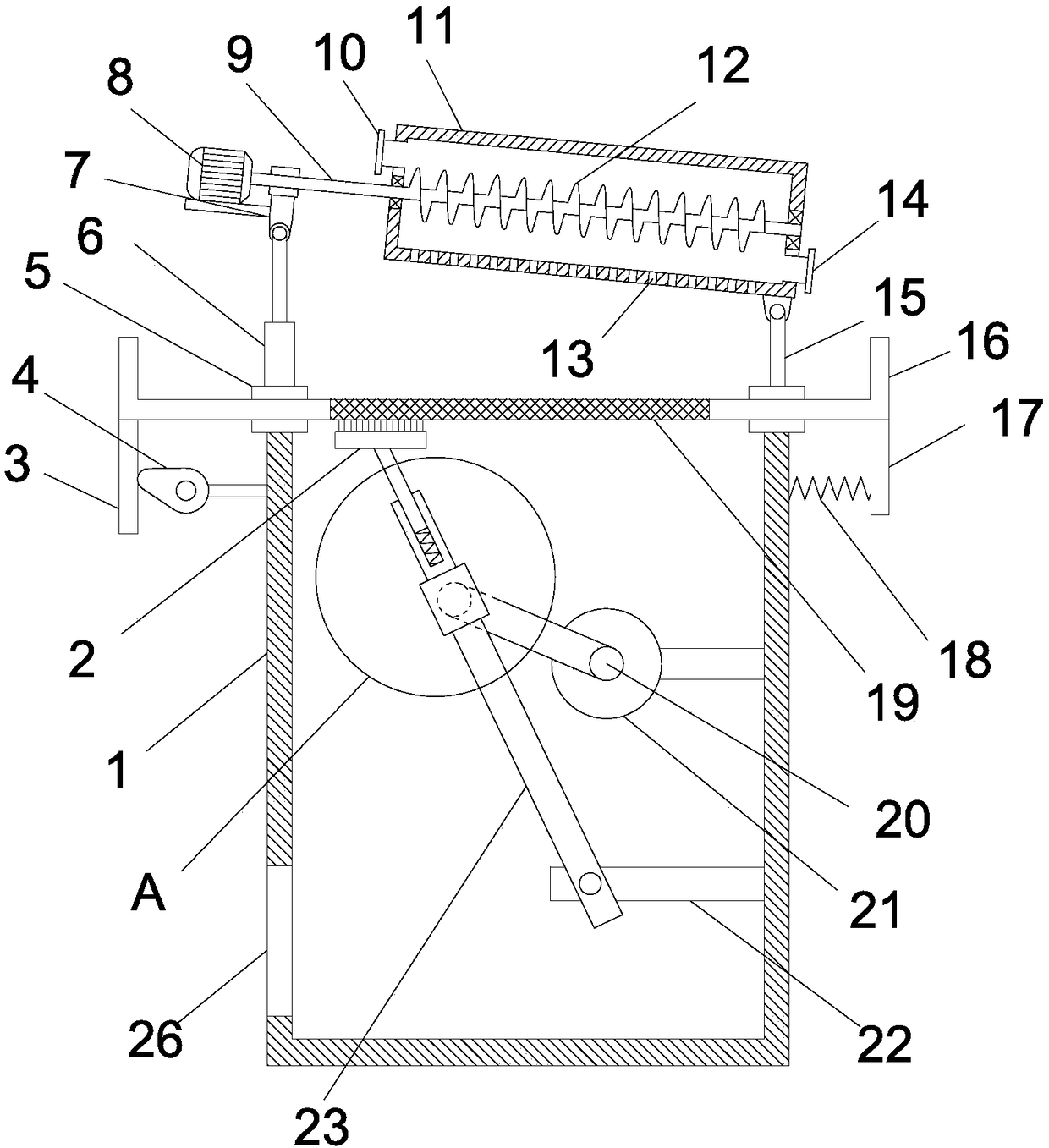

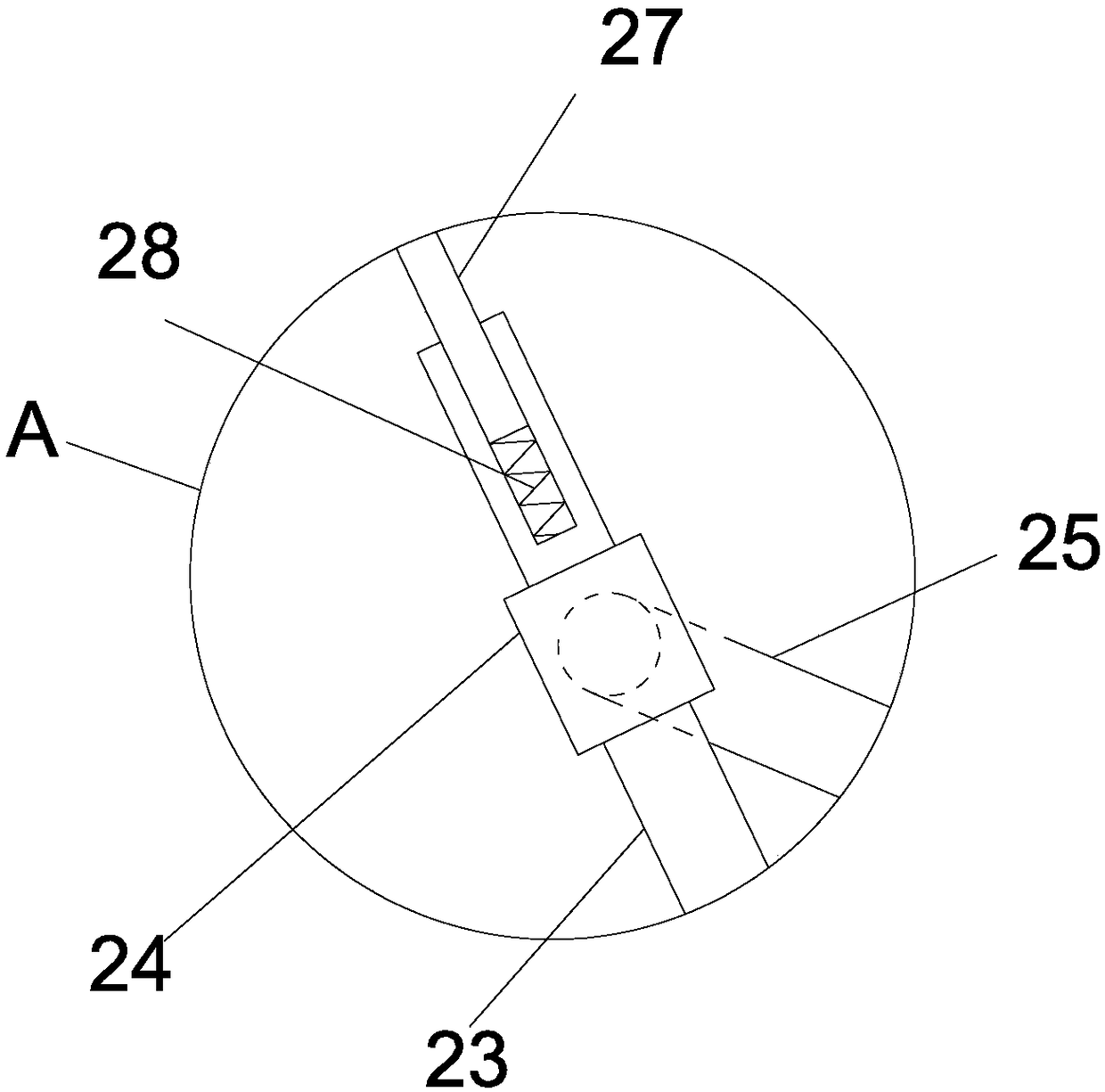

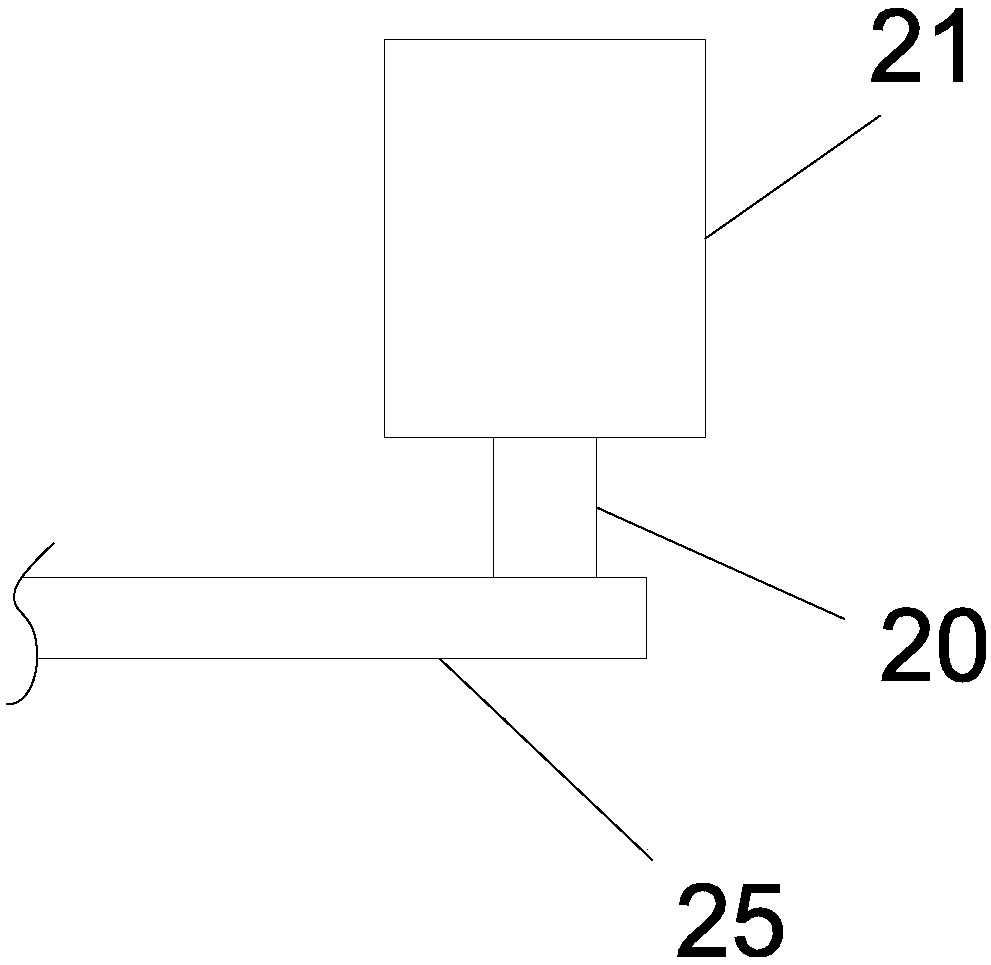

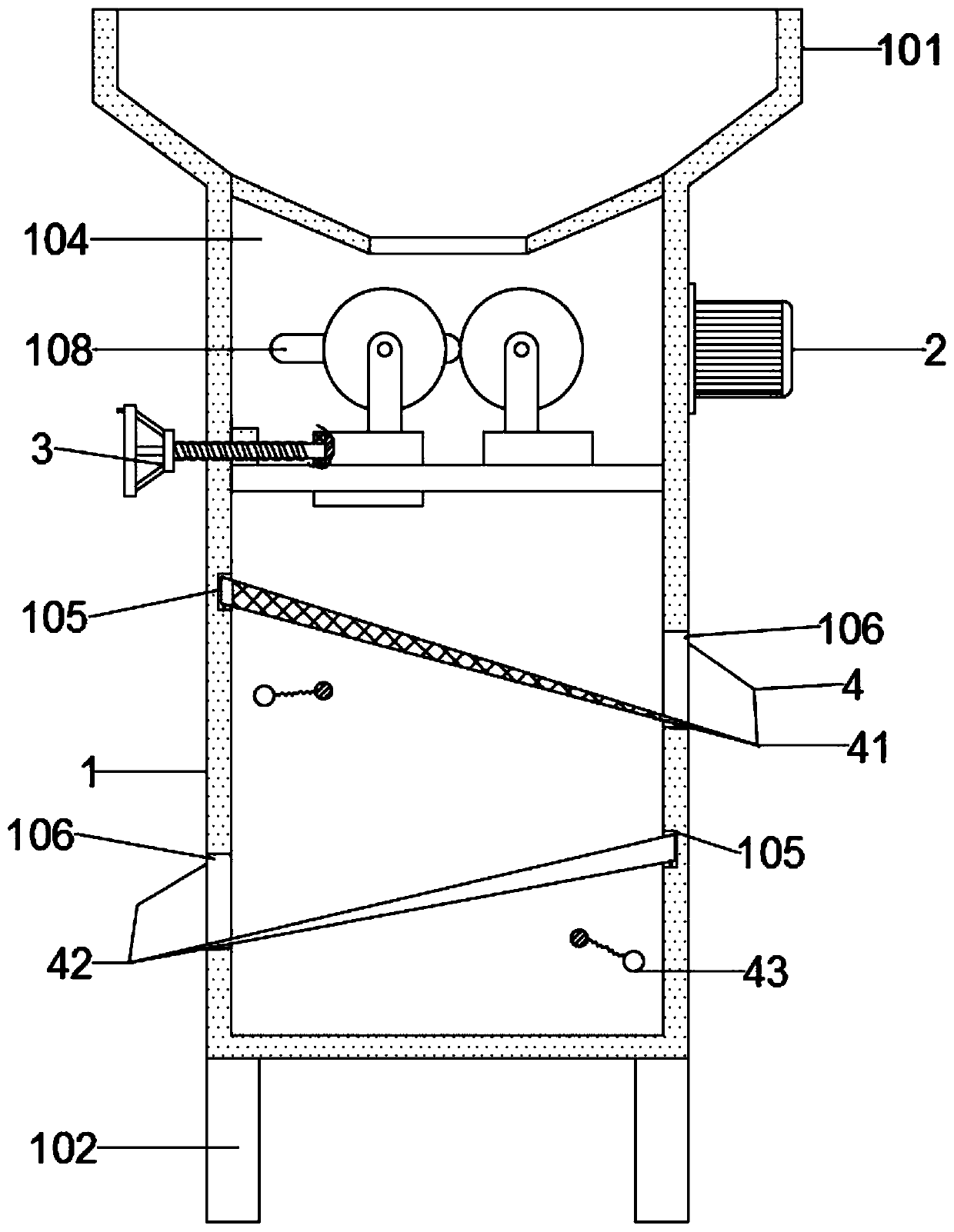

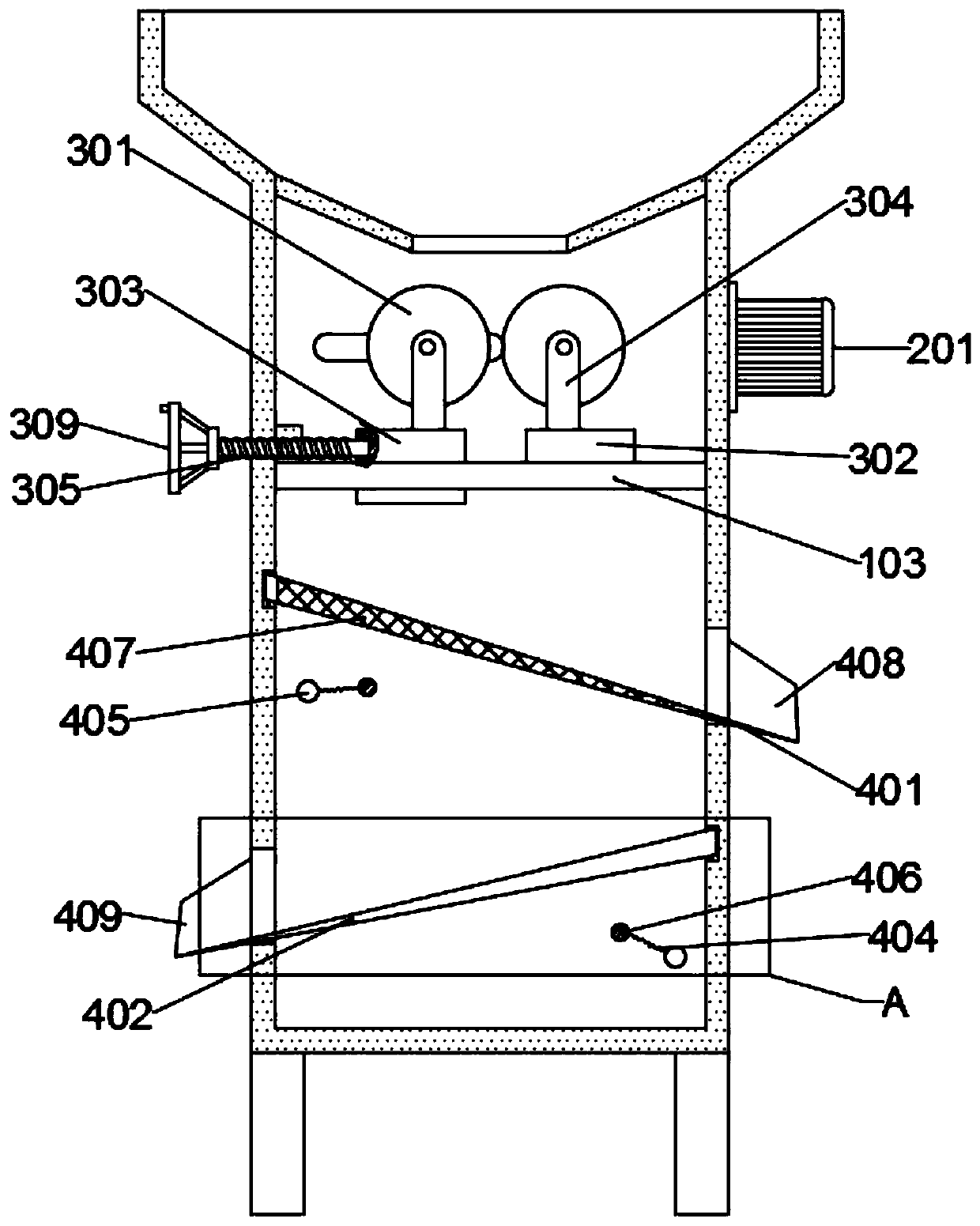

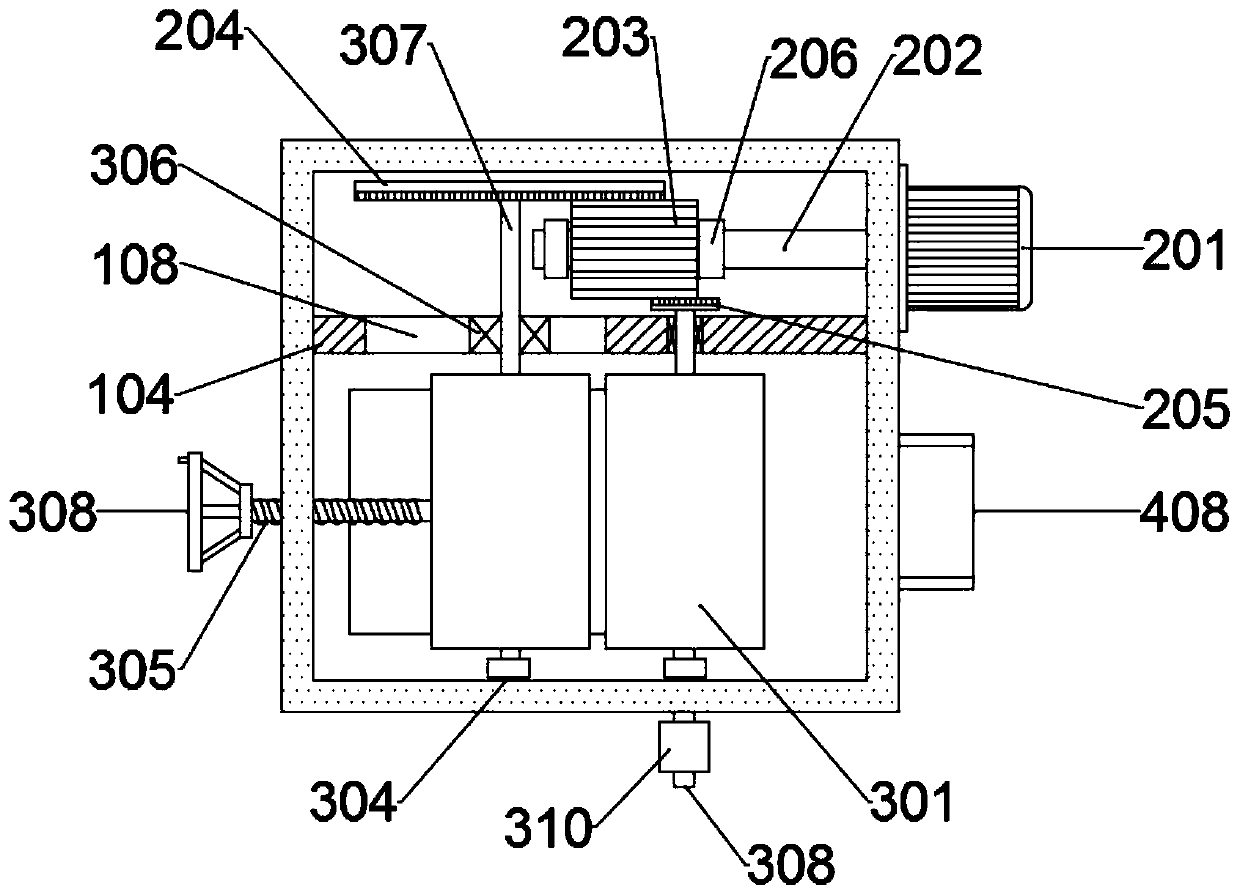

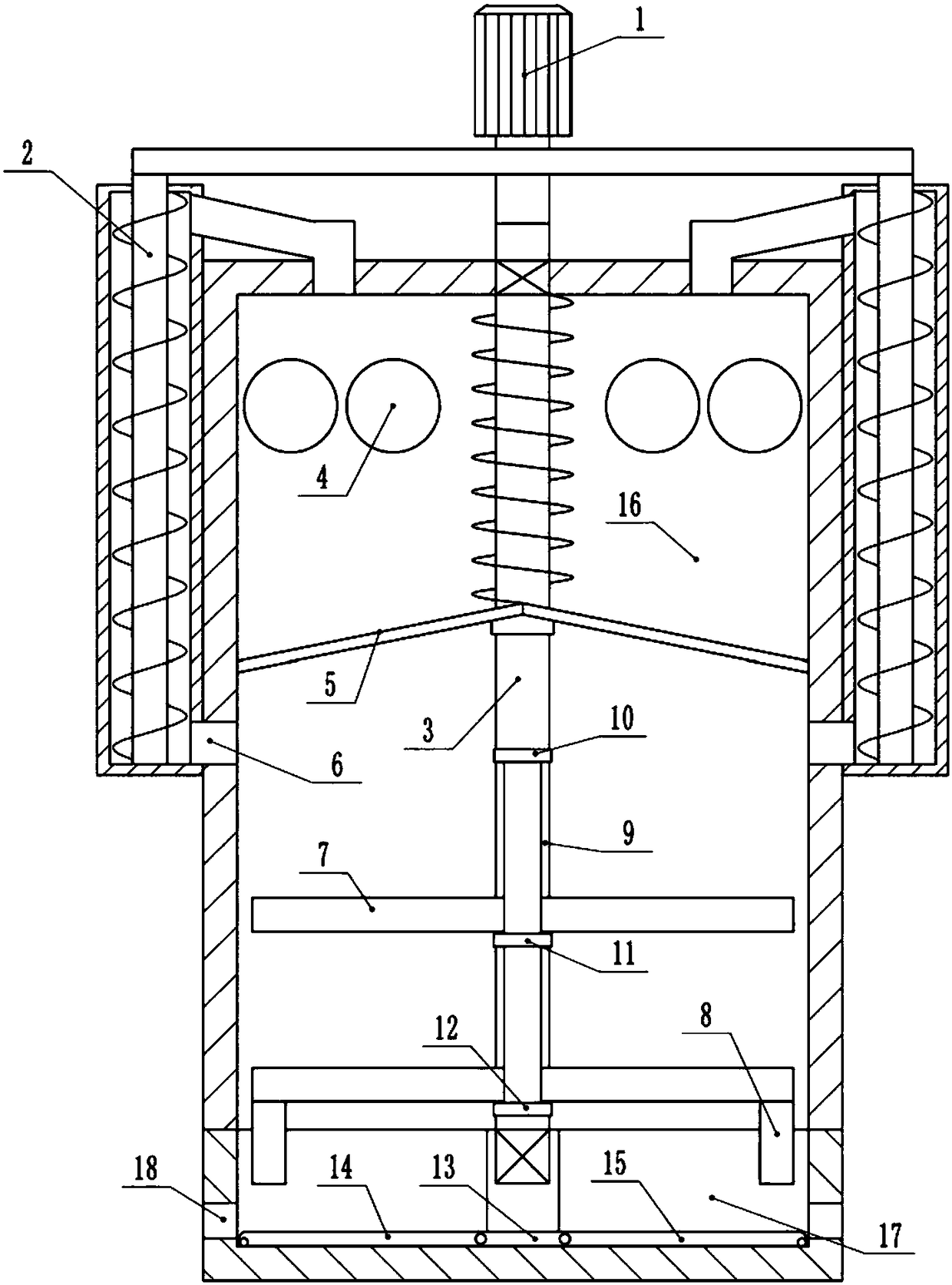

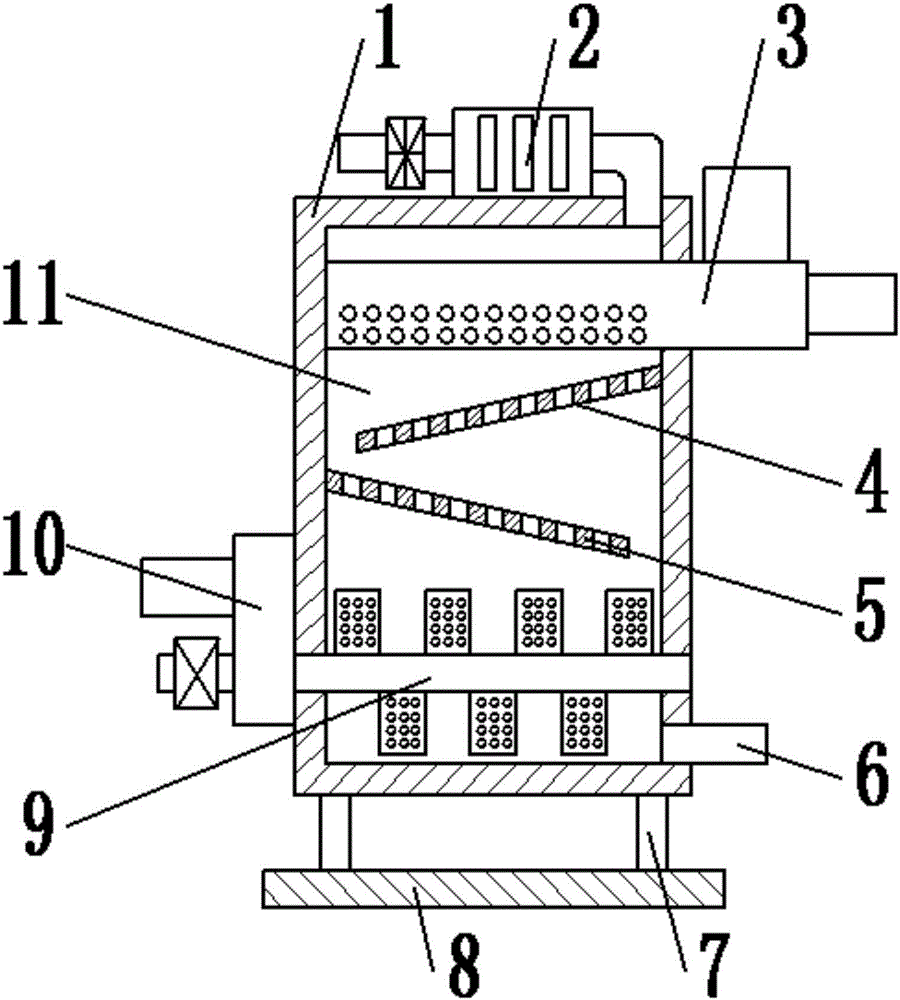

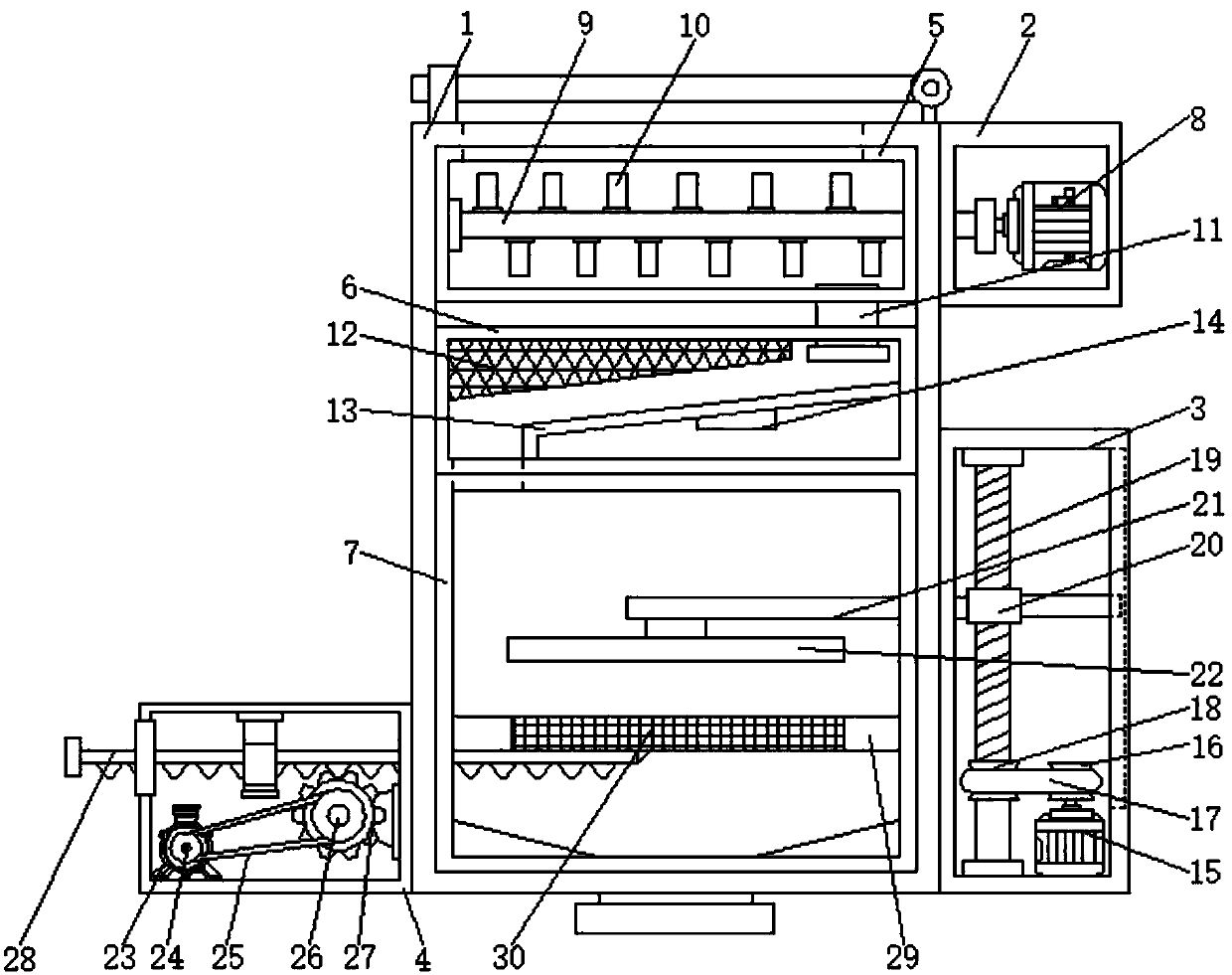

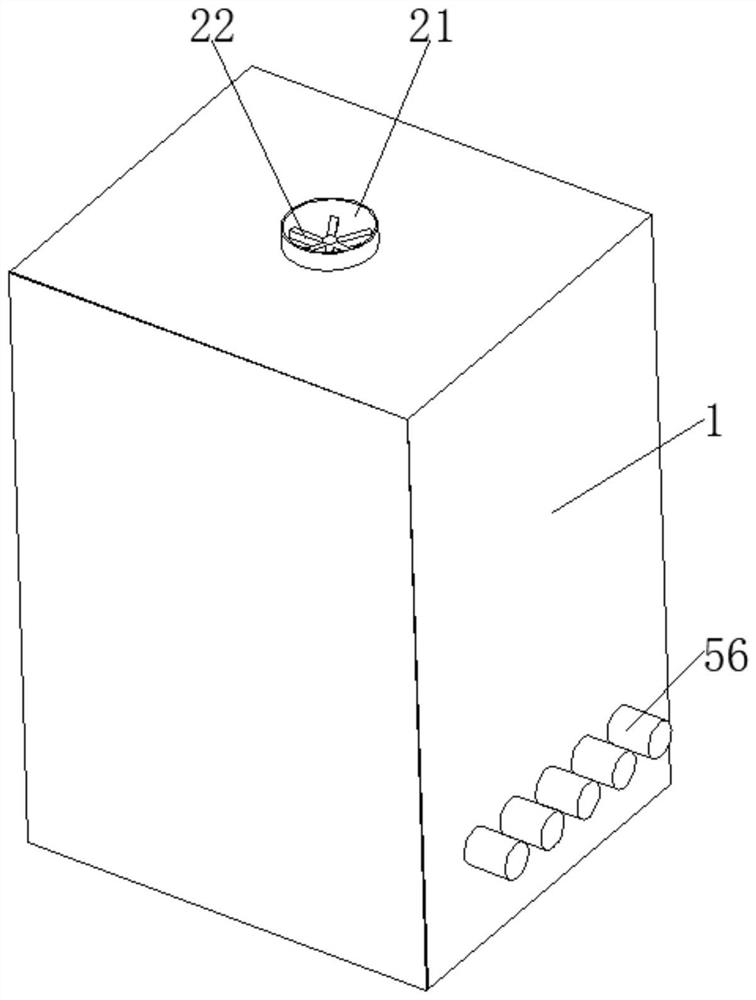

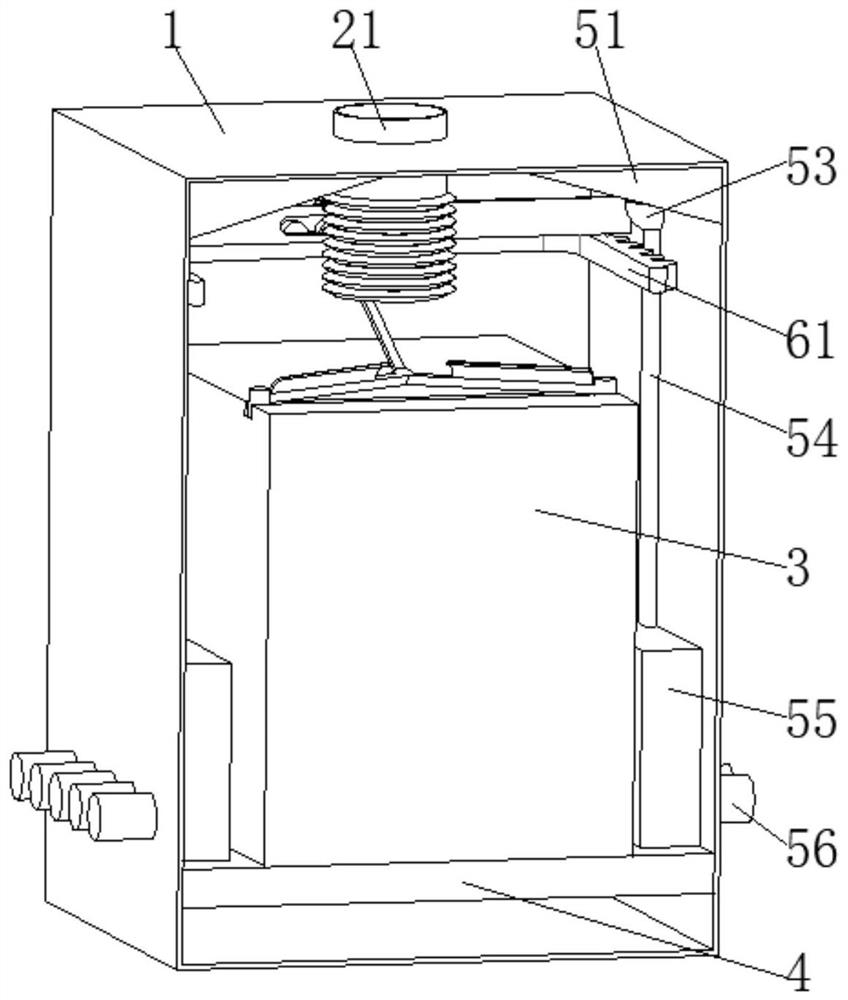

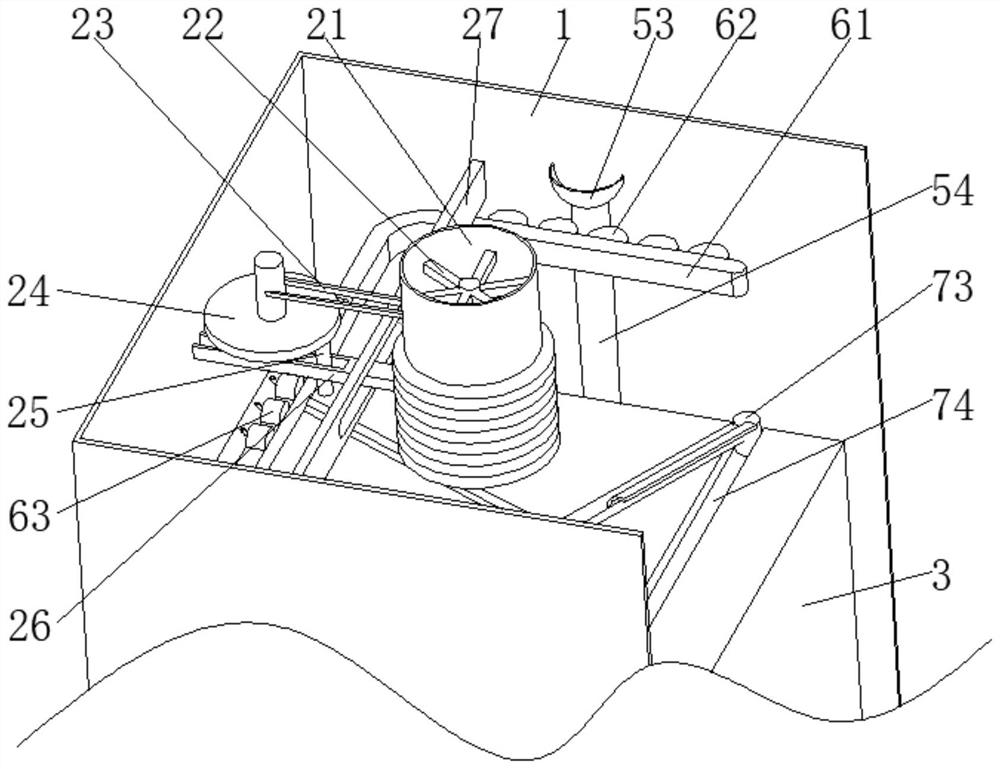

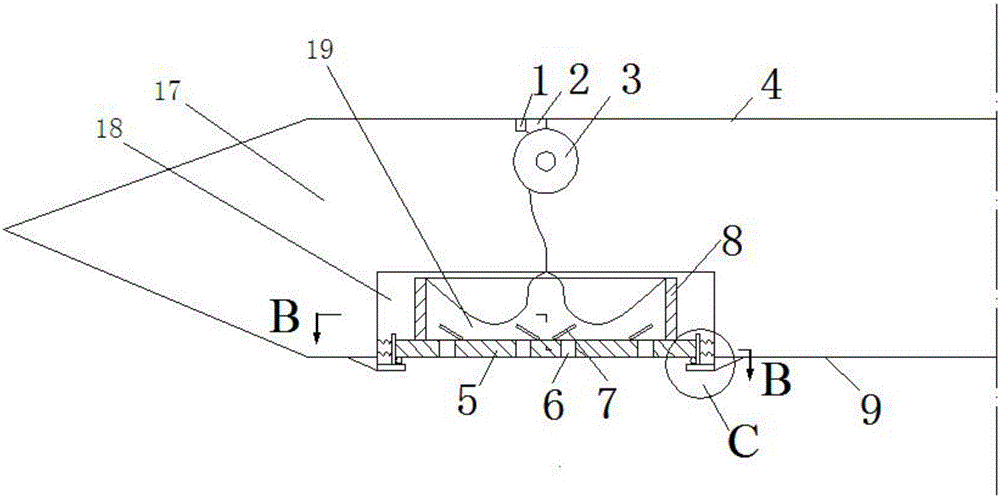

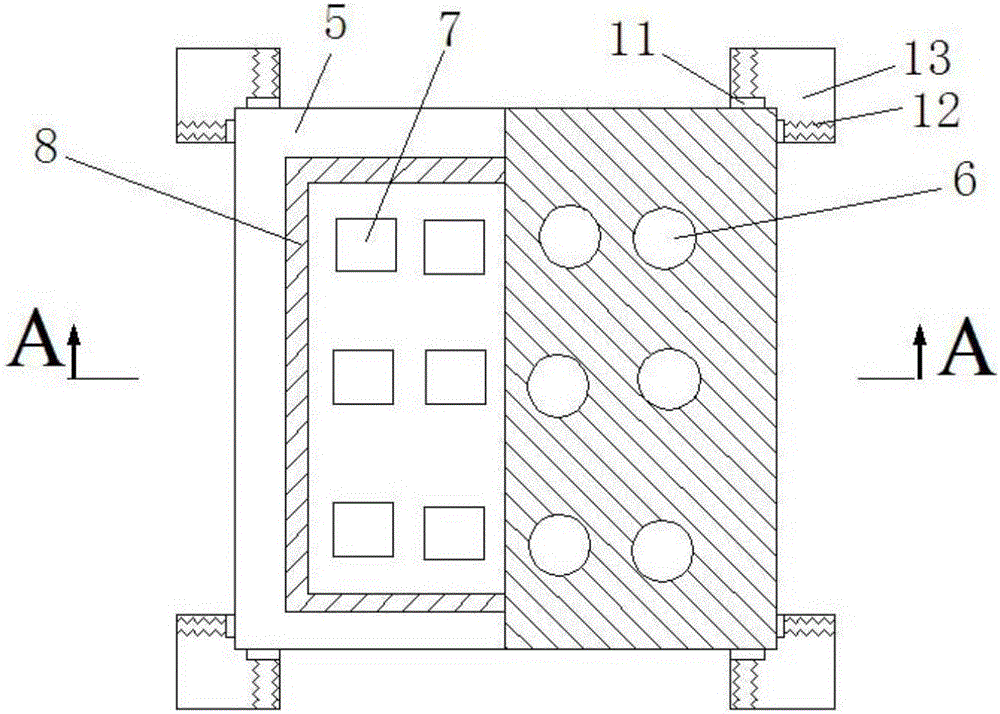

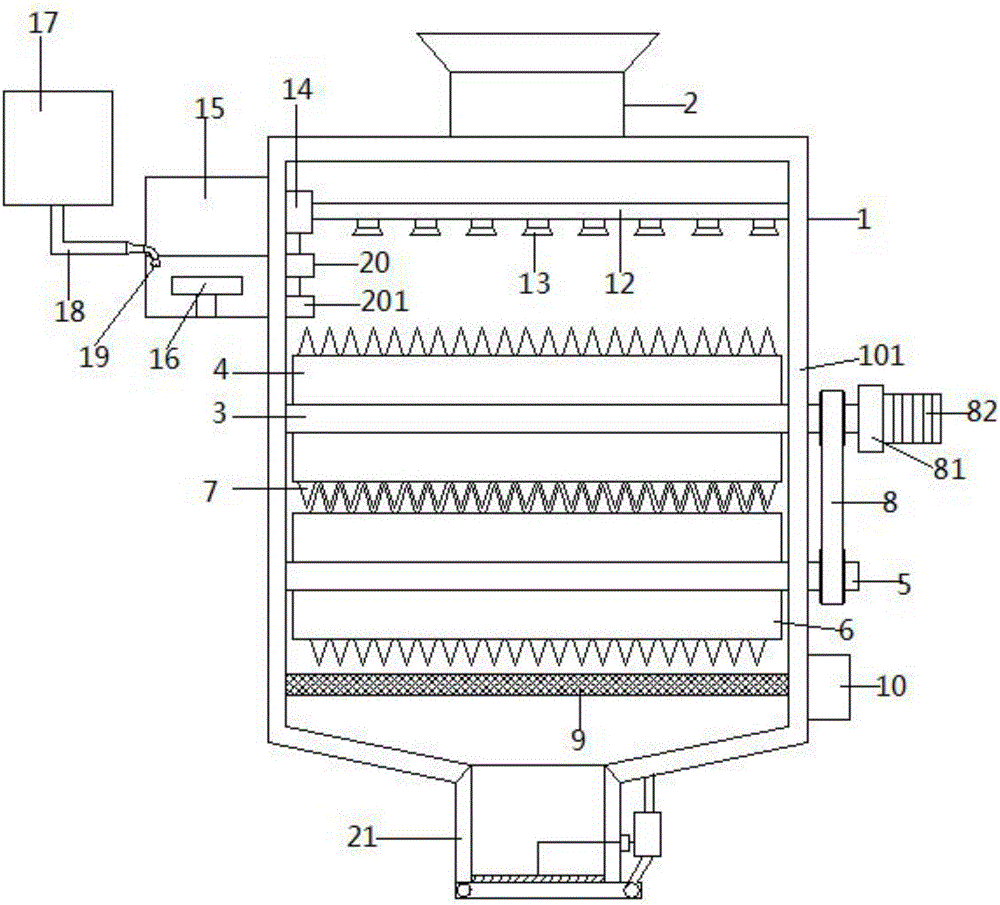

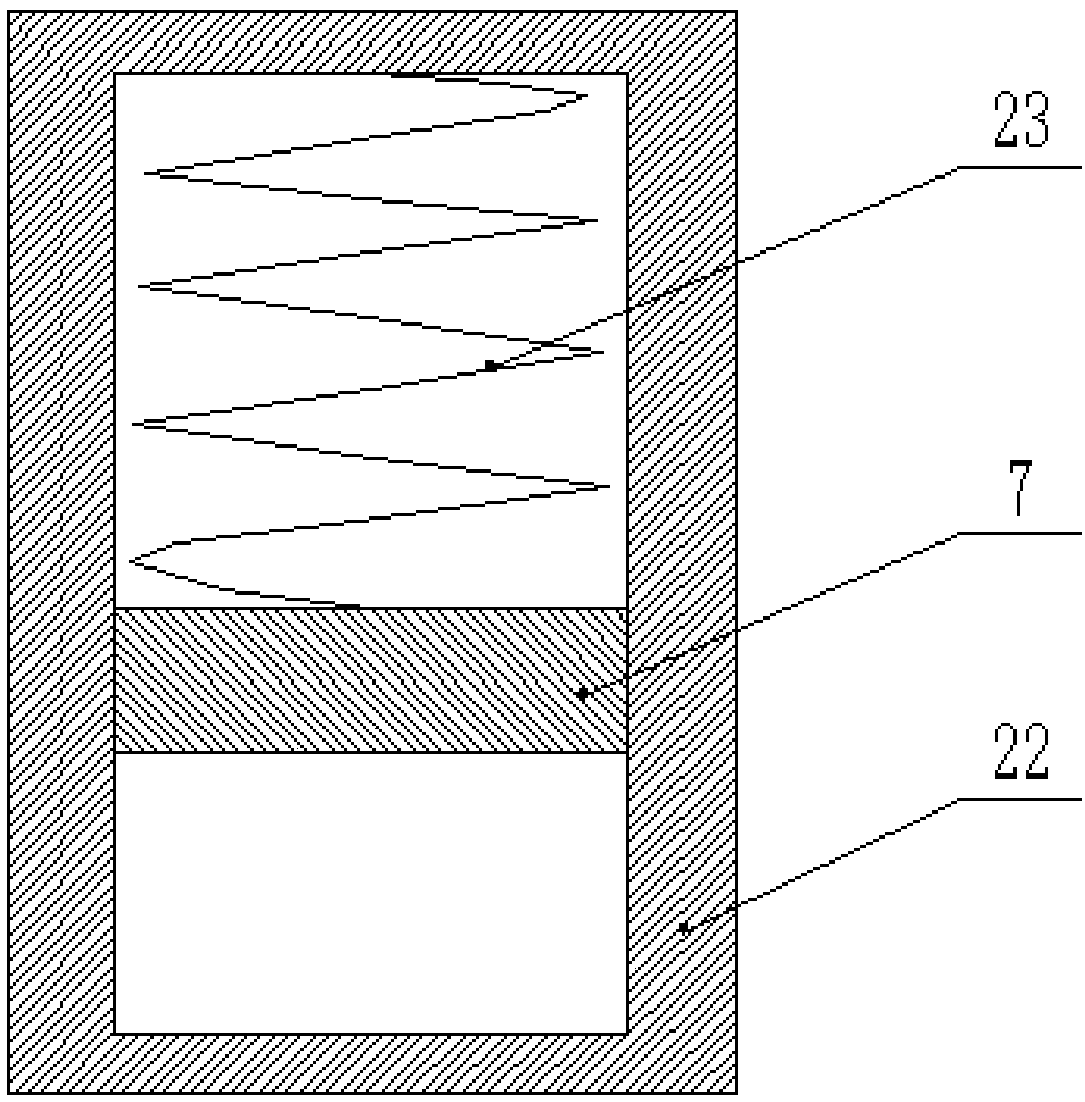

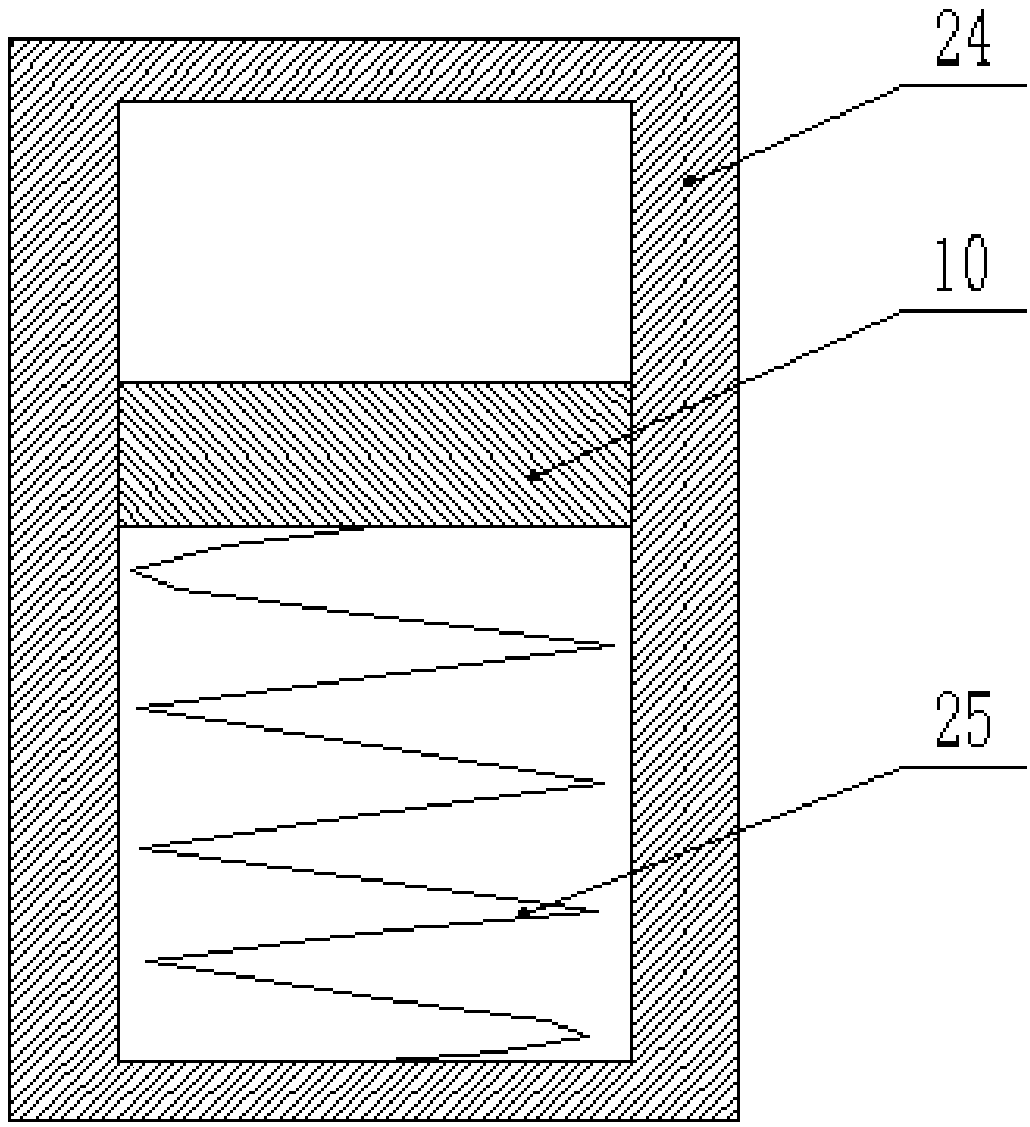

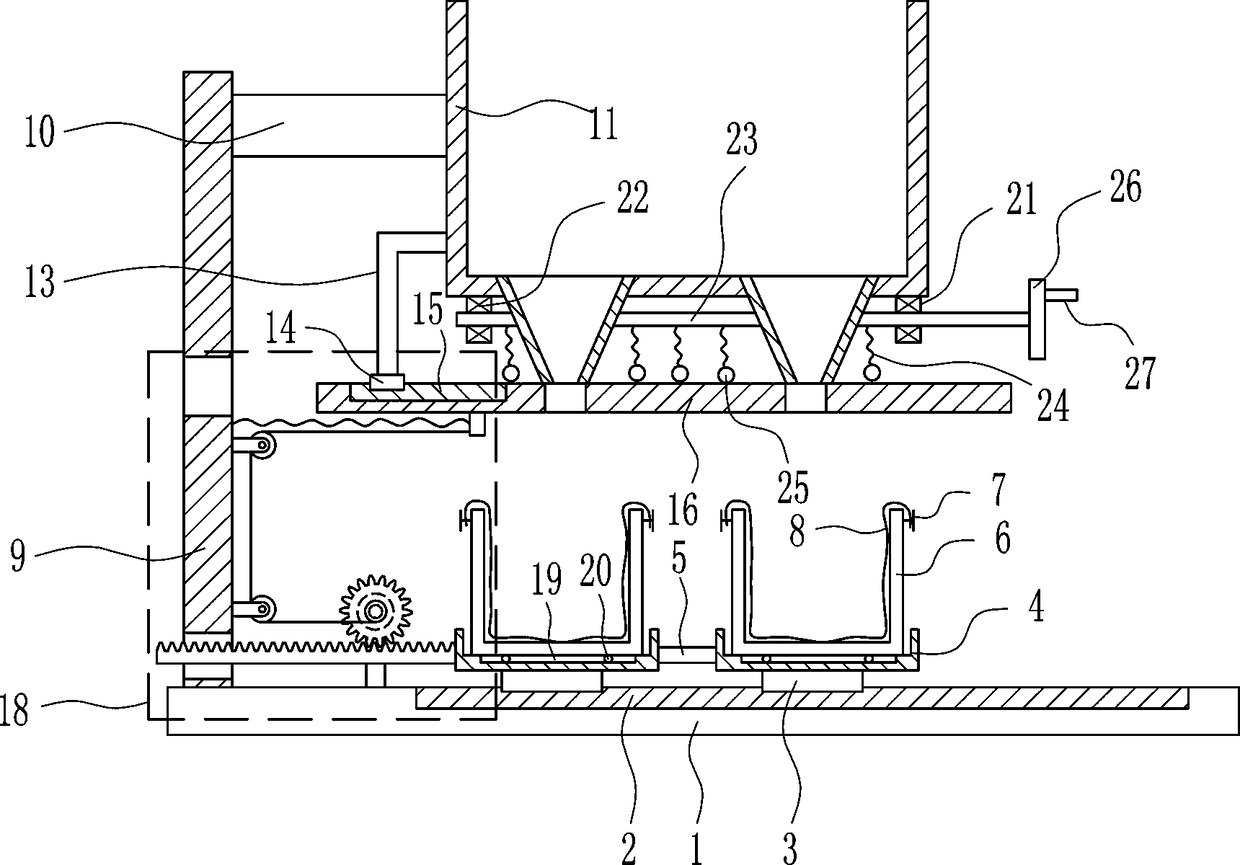

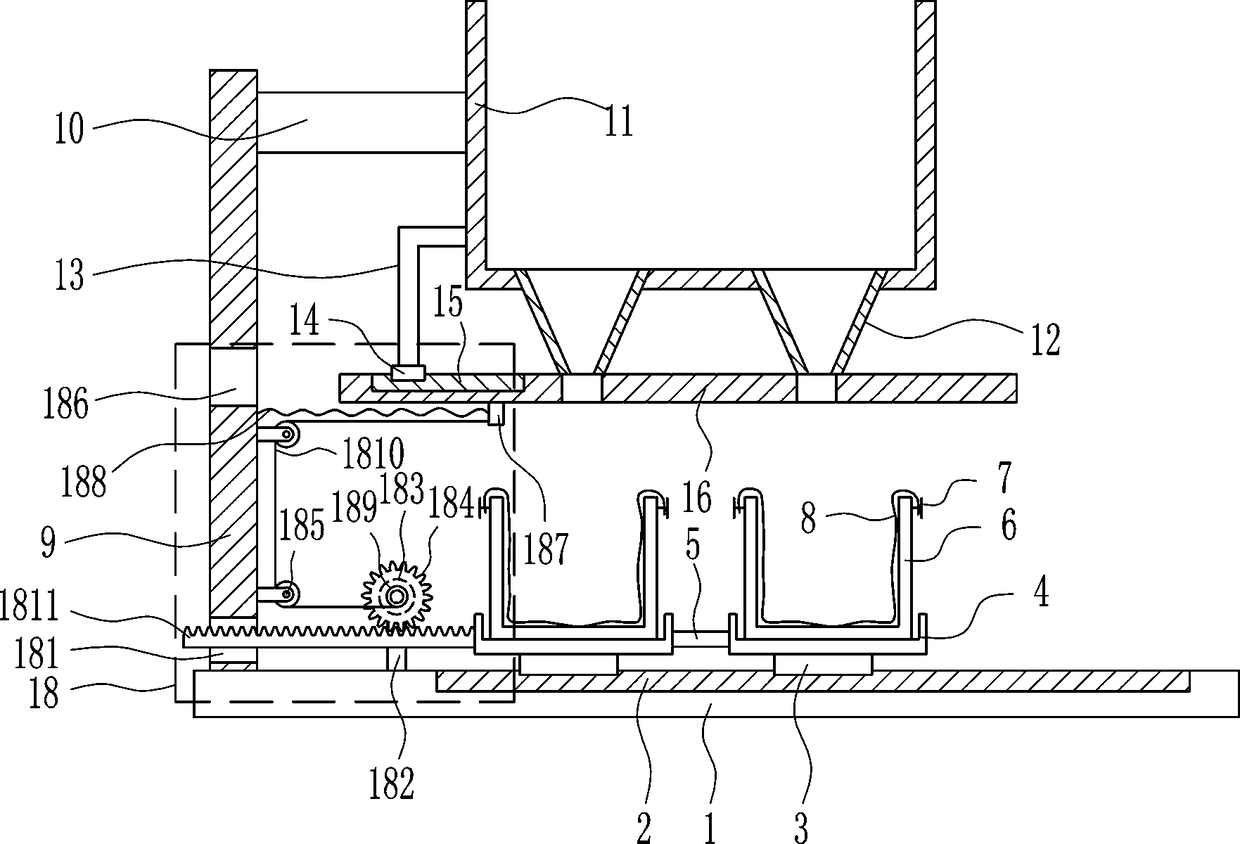

Efficient bone smashing and grinding device for food processing

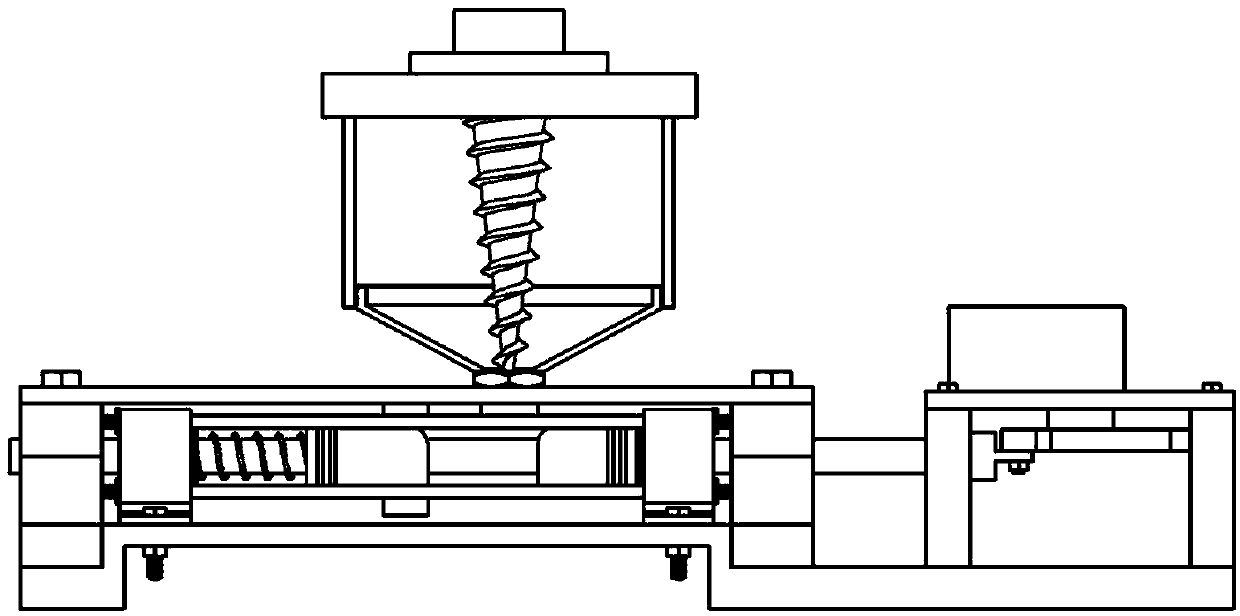

InactiveCN107413498ASpeed up the fallPrevent overflowSievingScreeningMechanical engineeringFood processing

The invention discloses an efficient bone smashing and grinding device for food processing. The efficient bone smashing and grinding device comprises a smashing box and a grinding box. The smashing box is provided with a material control device, a circulation feeding device, a smashing device, a screen cloth, a screen cloth vibrating mechanism, an iron removing plate and a discharging plate. The material control device comprises a discharging hopper. The discharging hopper is arranged at the upper end of the smashing box. An arc-shaped volute is arranged at the bottom end of the discharging hopper. The bottom end of the volute is provided with an opening and further communicates with the smashing box. A material distributing rotary table is sleeved with the volute. The material distributing rotary table is arranged on a material distributing rotating shaft in the middle of the volute in a sleeving mode. The two ends of the material distributing rotating shaft are arranged on bearings on the corresponding side walls of the volute in a sleeved mode separately. A plurality of material distributing plates are evenly and symmetrically arranged on the material distributing rotary table. According to the efficient bone smashing and grinding device for food processing, feeding is stable, the sealing property is good, circulation smashing is achieved, grinding can be facilitated, working efficiency is high, the screen cloth and the screen cloth vibrating mechanism are ingeniously arranged and thus screening efficiency is high.

Owner:汪云霞

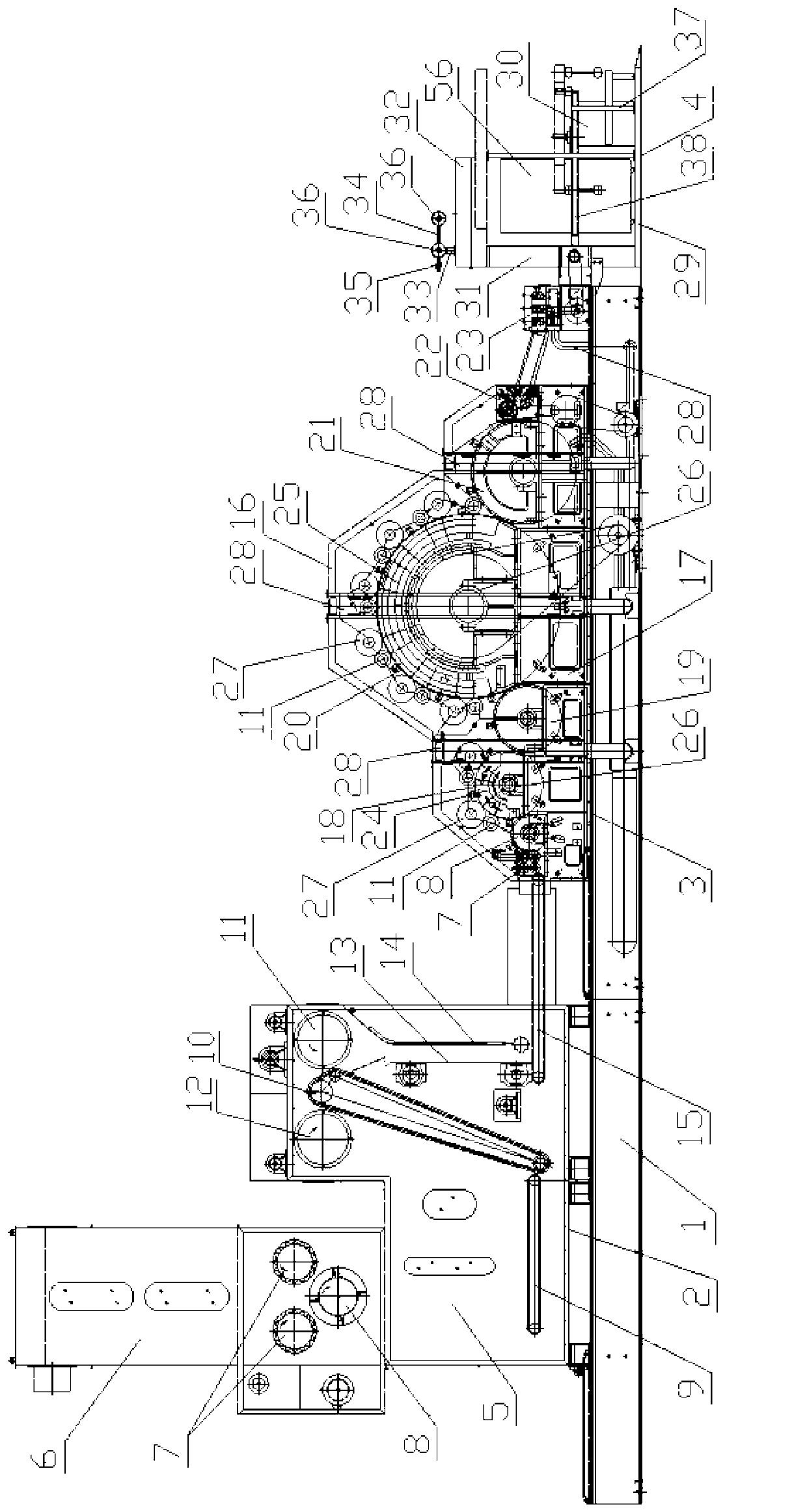

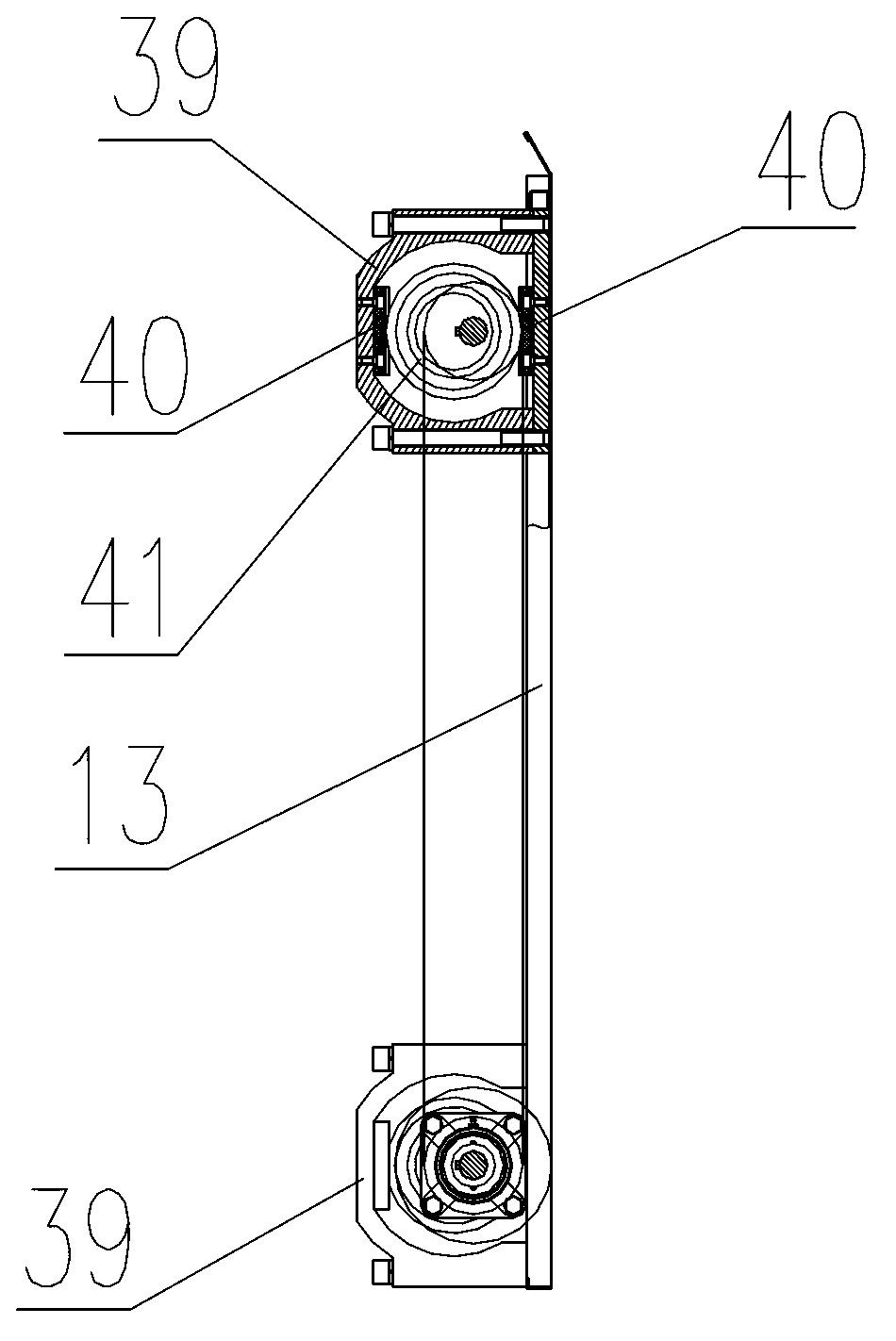

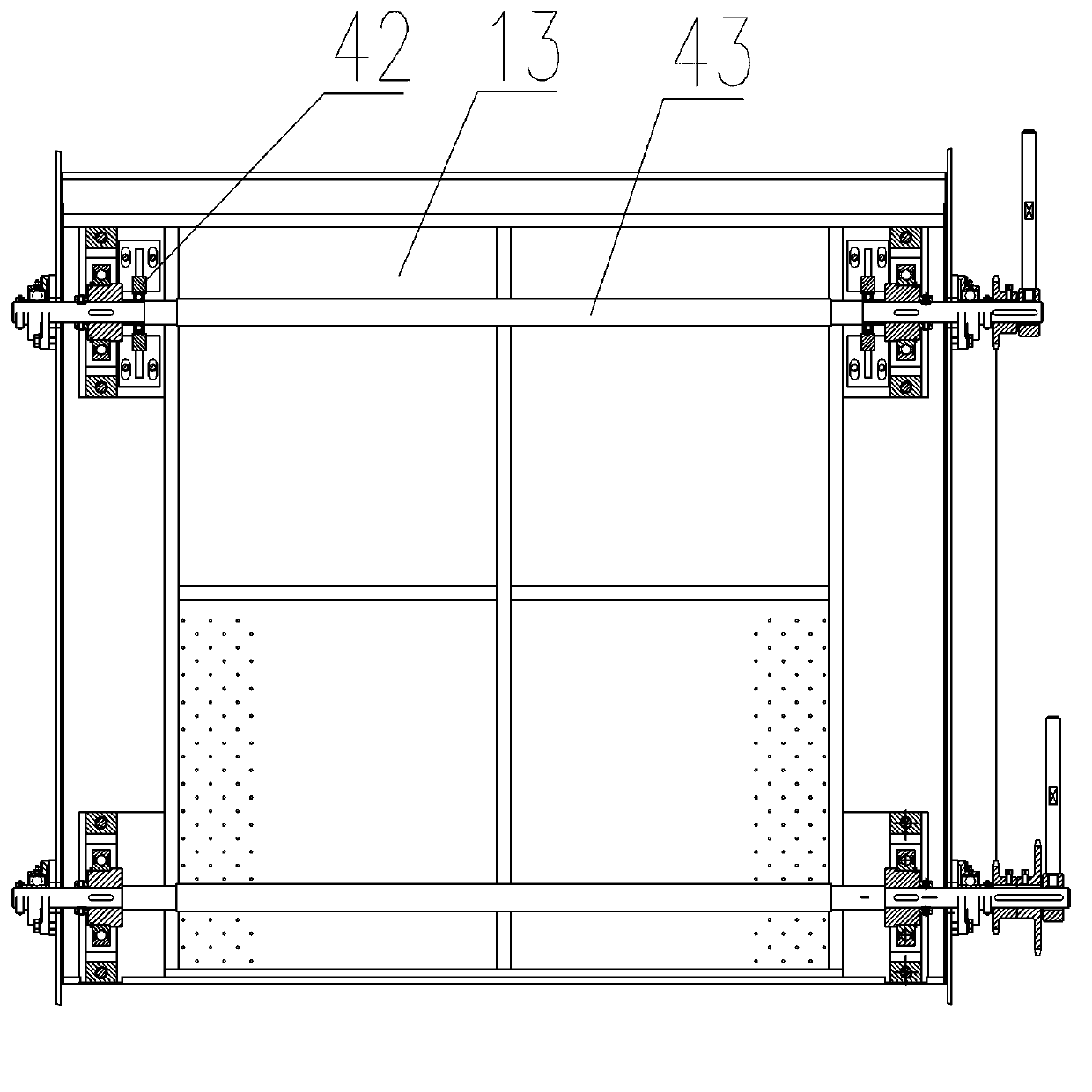

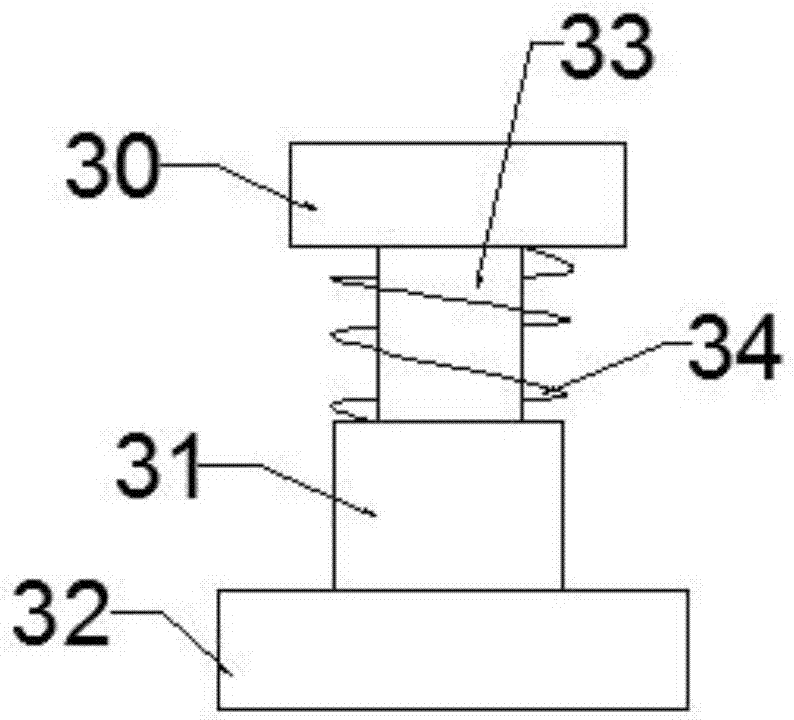

High-speed carding machine

InactiveCN102995167AGuaranteed stabilityGuaranteed speedCarding machinesEngineeringUltimate tensile strength

A high-speed carding machine comprises a base and a vibration wool feeding machine, a high-speed carding device and an automatic three-position barrel changing device which are connected with one another sequentially. The vibration wool feeding machine in the high-speed carding machine utilizes a translational vibration plate and a baffle to push textile raw materials uniformly, and moreover, the falling and outputting speeds of the textile raw materials are increased. A shaft seat of the high-speed carding machine is arranged on a breast cylinder wallboard and a large cylinder wallboard, so that the phenomenon that the positions of a breast cylinder and a large cylinder are changed relatively to the positions of a working roller and a wool stripping roller due to the high-speed rotation is avoided, the production quality is ensured, a suction pipe is arranged to suck the textile raw materials and reduce air flow which is generated by high-speed rotation, and the operation stability and high speed of the carding machine are ensured. The automatic three-position barrel changing device can control rotating wheels to change collection barrels, so that the high-speed carding machine is simple in structure and the labor intensity of the working personnel is reduced; and a U-shaped guardrail can ensure that the operation tracks of the collection barrels are stable when the collection barrels are changed, so that the whole barrel changing operation is carried out stably, and the collection barrels are prevented from tipping over during the barrel changing process.

Owner:青岛诚利佳机械有限公司

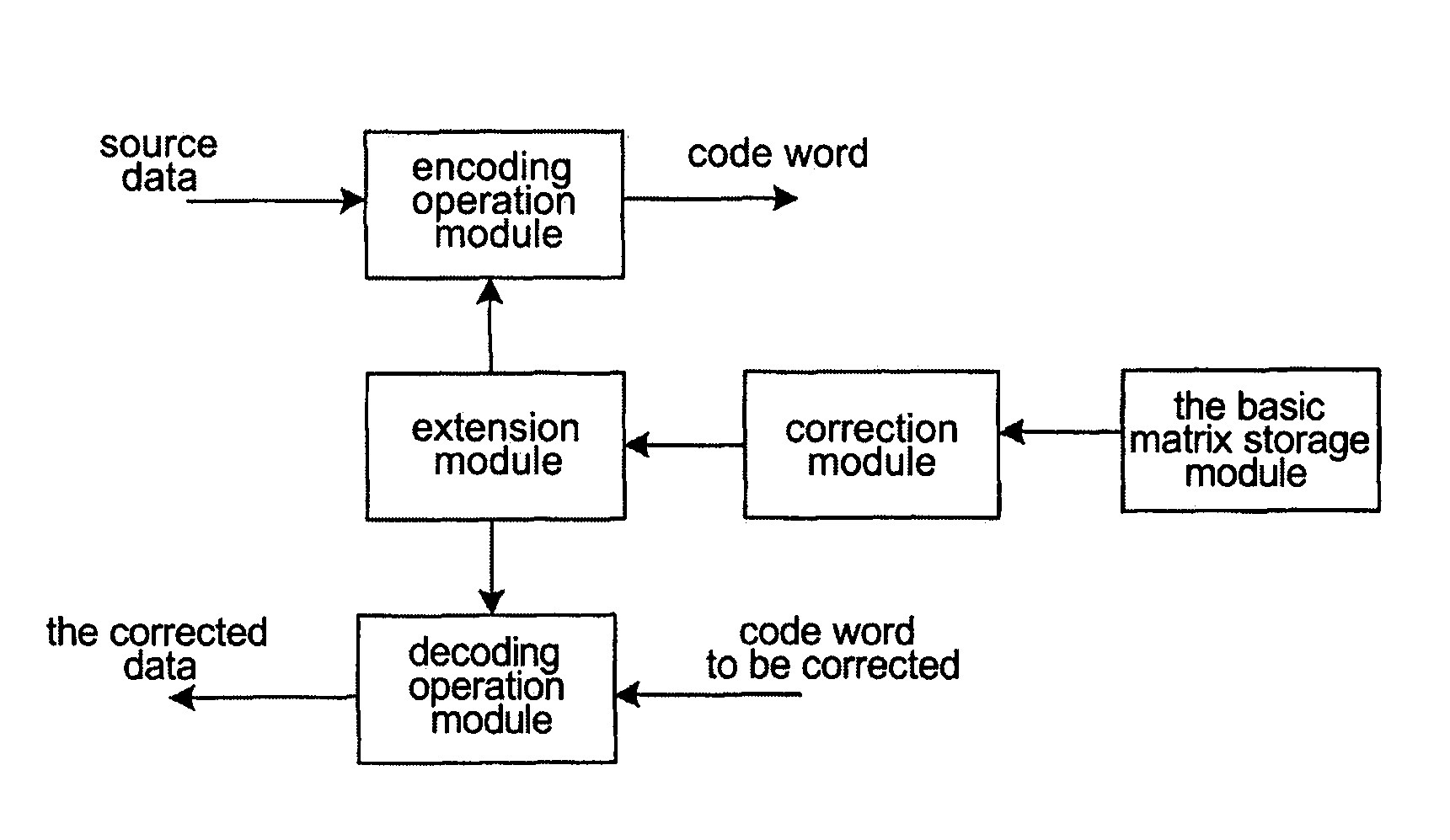

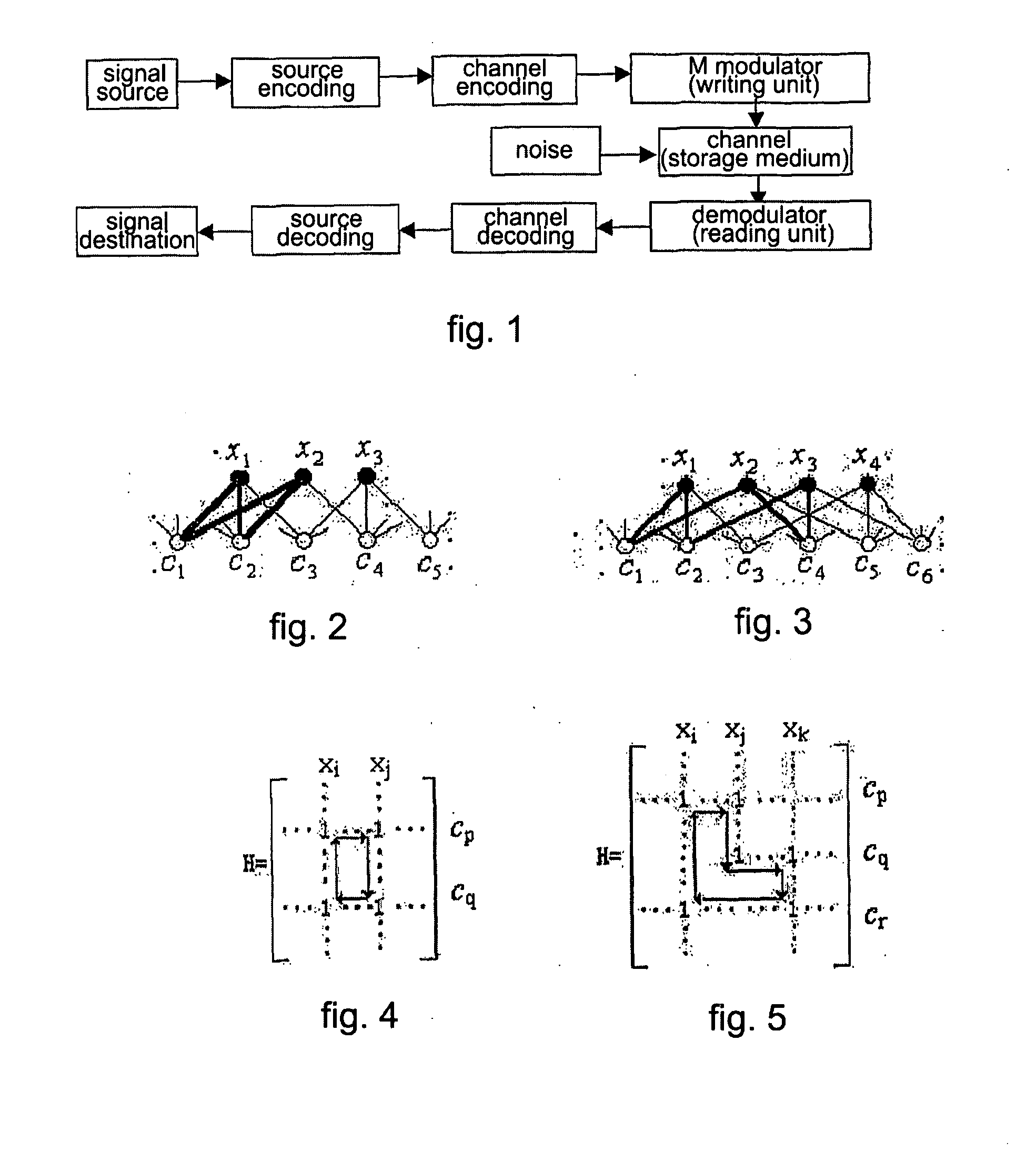

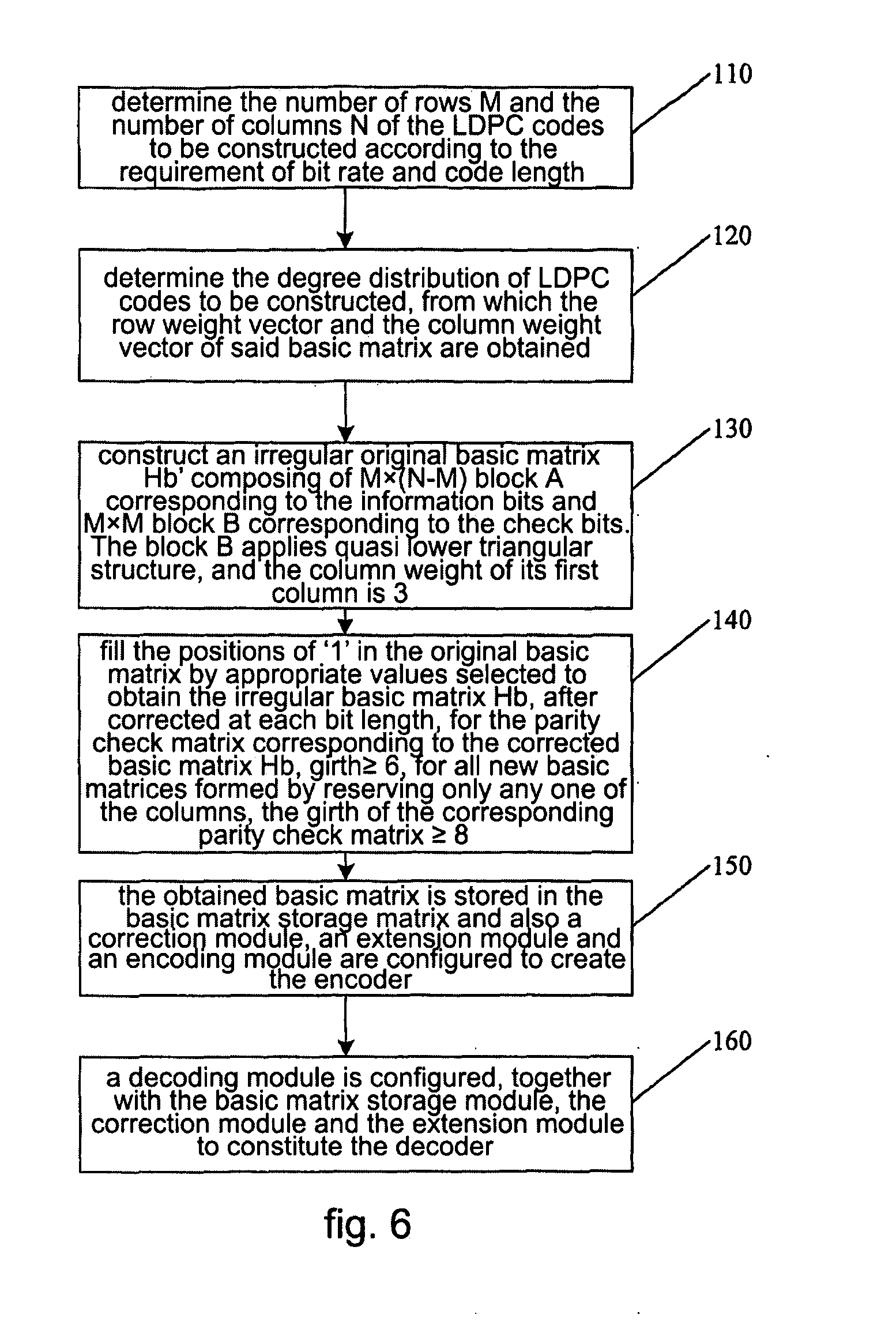

Basic Matrix Based on Irregular Ldpc, Codec and Generation Method Thereof

ActiveUS20080168324A1Eliminate phenomenonSpeed up the fallError detection/correctionParty-line systemsEssential matrixEuclidean vector

Basic matrix based on irregular LDPC codes, codec and generation method thereof. The codec includes an encoding / decoding operation module and a basic matrix storage module. In the stored basic matrix Hb, for all girths with length of 4, any element of i, j, k or l constituting the girths in anti-clockwise or clockwise always satisfies inequality: mod(i−j+k−l, z)≠0, wherein z is the extension factor. When generating the basic matrix, firstly the number of rows M, number of columns N, and weight vectors of the rows and columns are determined, an irregularly original basic matrix is constructed; then the position of ‘1’ is filled by a value chosen from set {0, 1, 2, . . . , z−1} to obtain the basic matrix Hb, which is made to satisfy the above-mentioned inequality. The basic matrix Hb obtained by storing, which is configured with corresponding encoding / decoding operation module, constitutes the desired encoder / decoder. The encoder / decoder according to the present invention can effectively eliminate error-floor phenomenon of LDPC codes and accelerate the falling speed of BER curve.

Owner:ZTE CORP

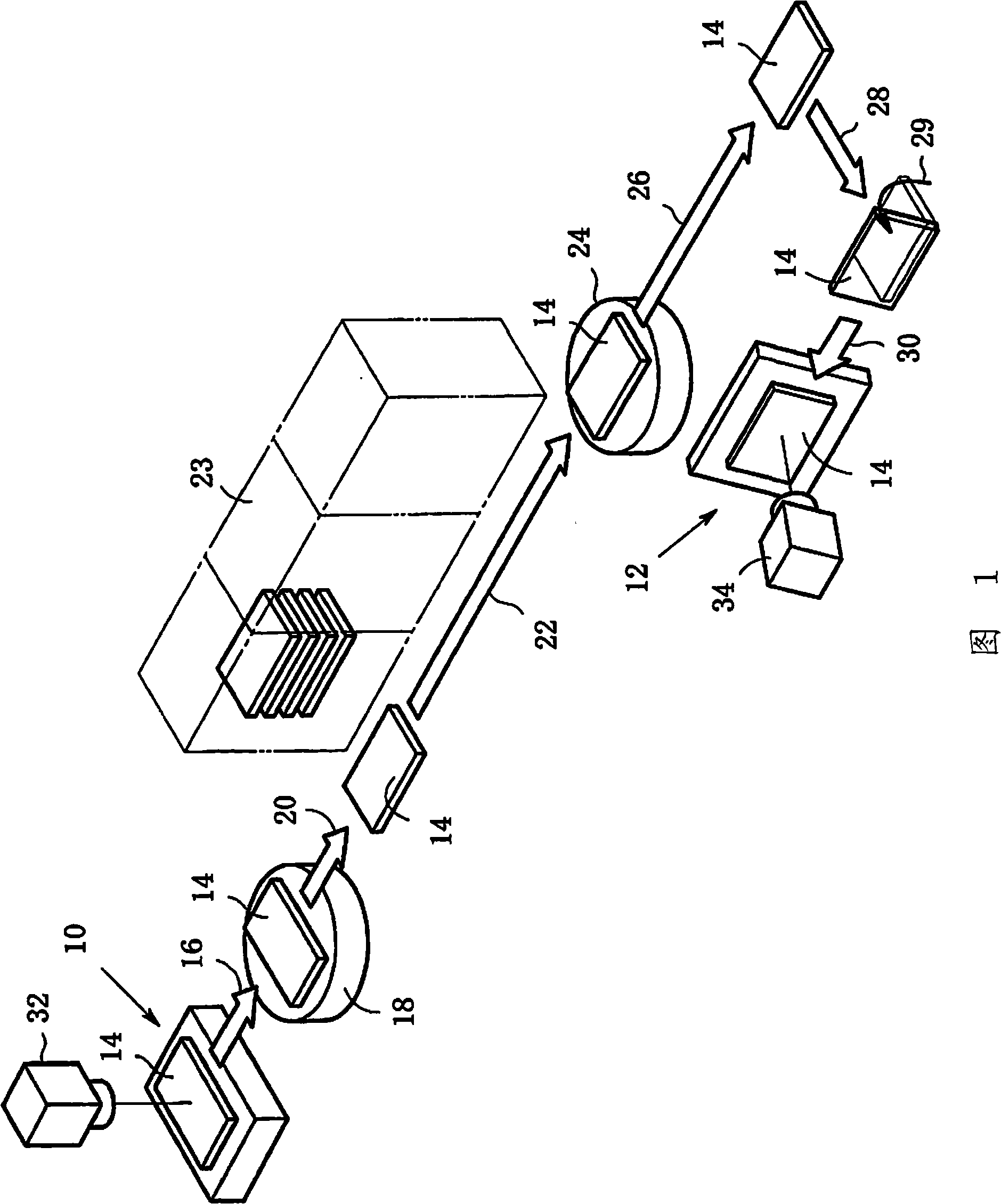

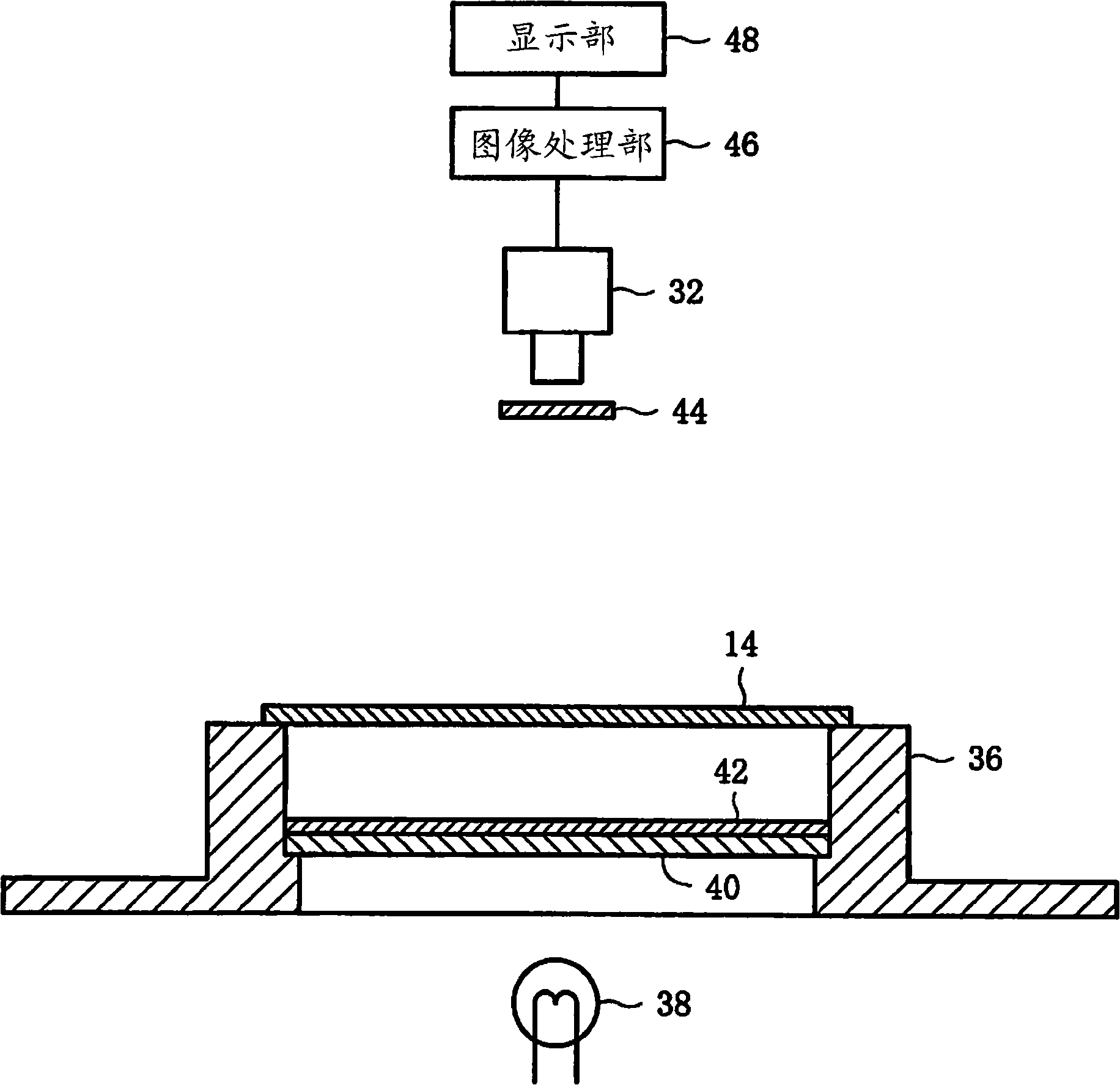

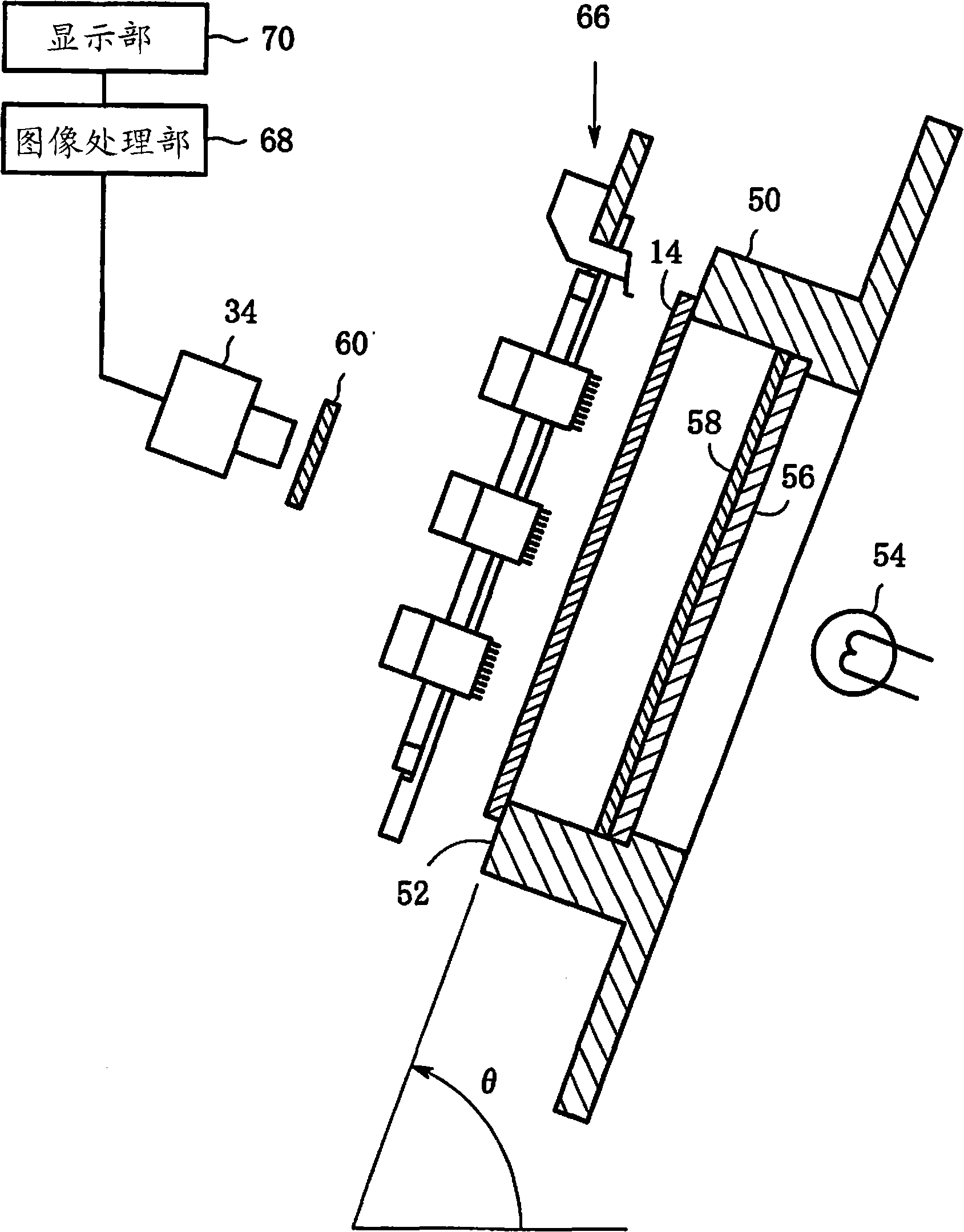

Liquid crystal panel inspection method and apparatus

InactiveCN101324713ARaise the possibilitySpeed up the fallMaterial analysis by optical meansNon-linear opticsLiquid crystalEngineering

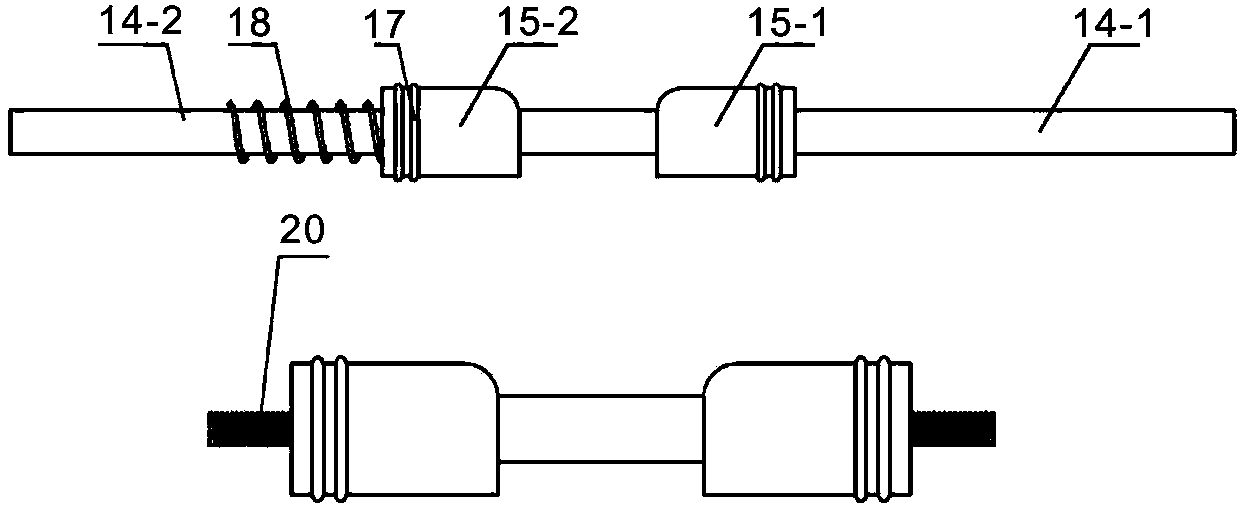

The invention provides a liquid crystal panel detection method and the device thereof. When detecting the defect of the liquid crystal panel by a camera, a simple device can be used to distinguish the image of the dust attached on the liquid crystal panel and the image of the defect of the liquid crystal panel. A liquid crystal panel (14) arranged between a pair of transparent substrates is configured in a first detection part (10), and illumination light irradiates from one side of the liquid crystal panel (14), while taking a first image from the other side. The liquid crystal panel (14) is conveyed to a second detection part (12) from the first part (10). At the same time, the liquid crystal panel is inclined relative to at least one level surface in conveying process. The liquid crystal panel (14) is configured in a second detection part (12), and the dust on the inclined liquid crystal panel (14) is blown off by air. And the second image of the liquid crystal panel (14) is picked up by the second detection part (12). The bright spot of the first image in the dark display is compared with that of the second image so as to distinguish the defect of the liquid crystal panel and the dust on the liquid crystal panel.

Owner:NIHON MICRONICS

Damping type building rubbish crushing treatment device

InactiveCN107497582AAvoid damageReduced service lifeNon-rotating vibration suppressionGrain treatmentsArchitectural engineeringDrive motor

The invention discloses a damping type building rubbish crushing treatment device, and belongs to the field of building rubbish treatment equipment. The device comprises a box body, a supporting rod, a supporting plate, a storage bin, a damping base, a motor base, a grinding bin and a screen net; the motor base is fixedly arranged on the left side of the box body in a welded manner, a drive motor is arranged on the motor base, a belt wheel is arranged on the drive motor, the belt wheel is connected with a crushing roller through a belt, and a grinding roller is arranged between two grinding frames, and is connected with an external drive device through a rotating shaft; the supporting plate is fixed to the lower left portion of the box body in a welded manner, a lifting device is arranged on the supporting plate, the device is reasonable in structural design, capable of absorbing magnetic metal in building rubbish, and capable of preventing the magnetic metal from damaging the crushing device; the crushing roller, the grinding roller and the lifting device are arranged to circularly crush the building rubbish, and thorough crushing is ensured.

Owner:王书愚

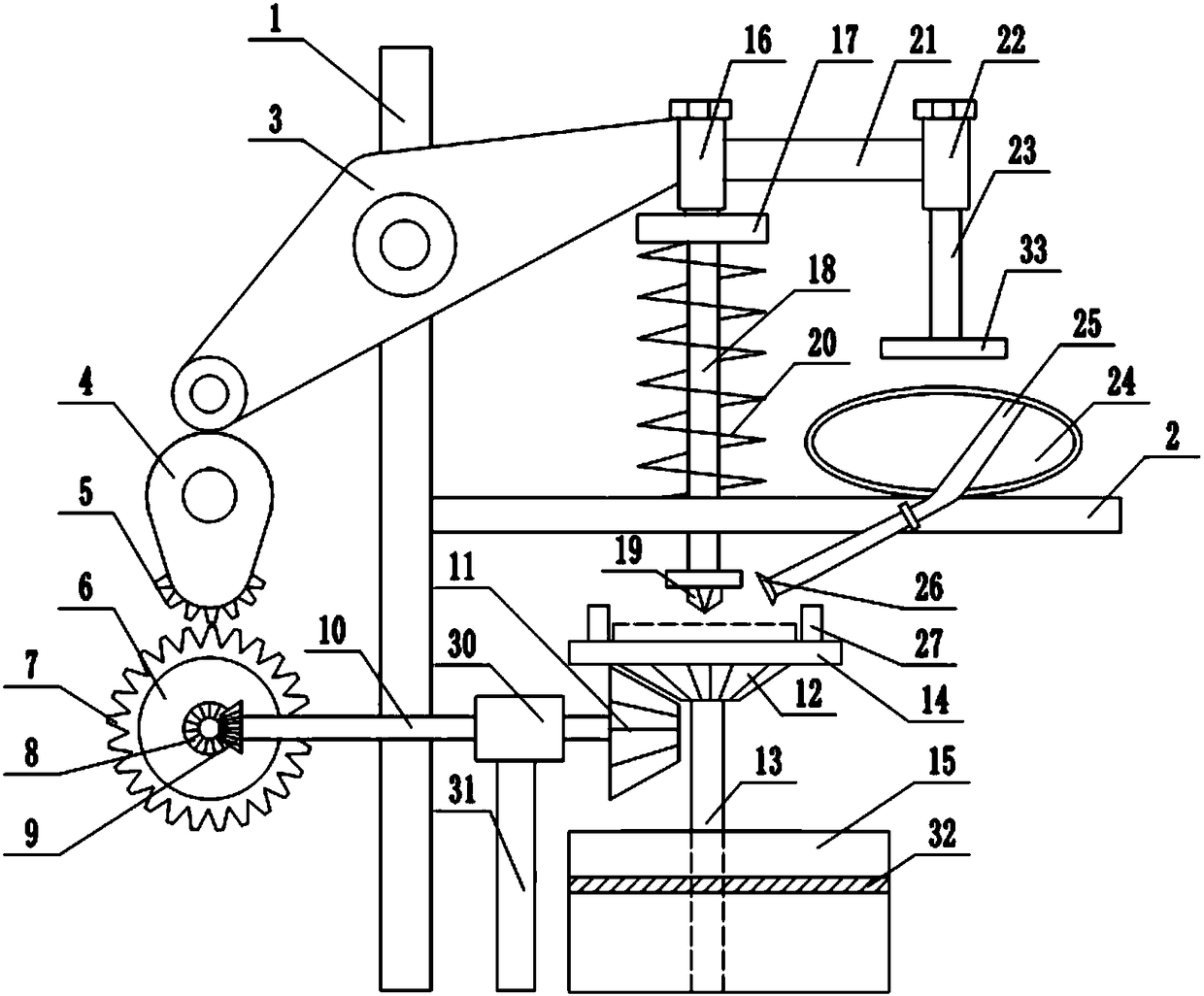

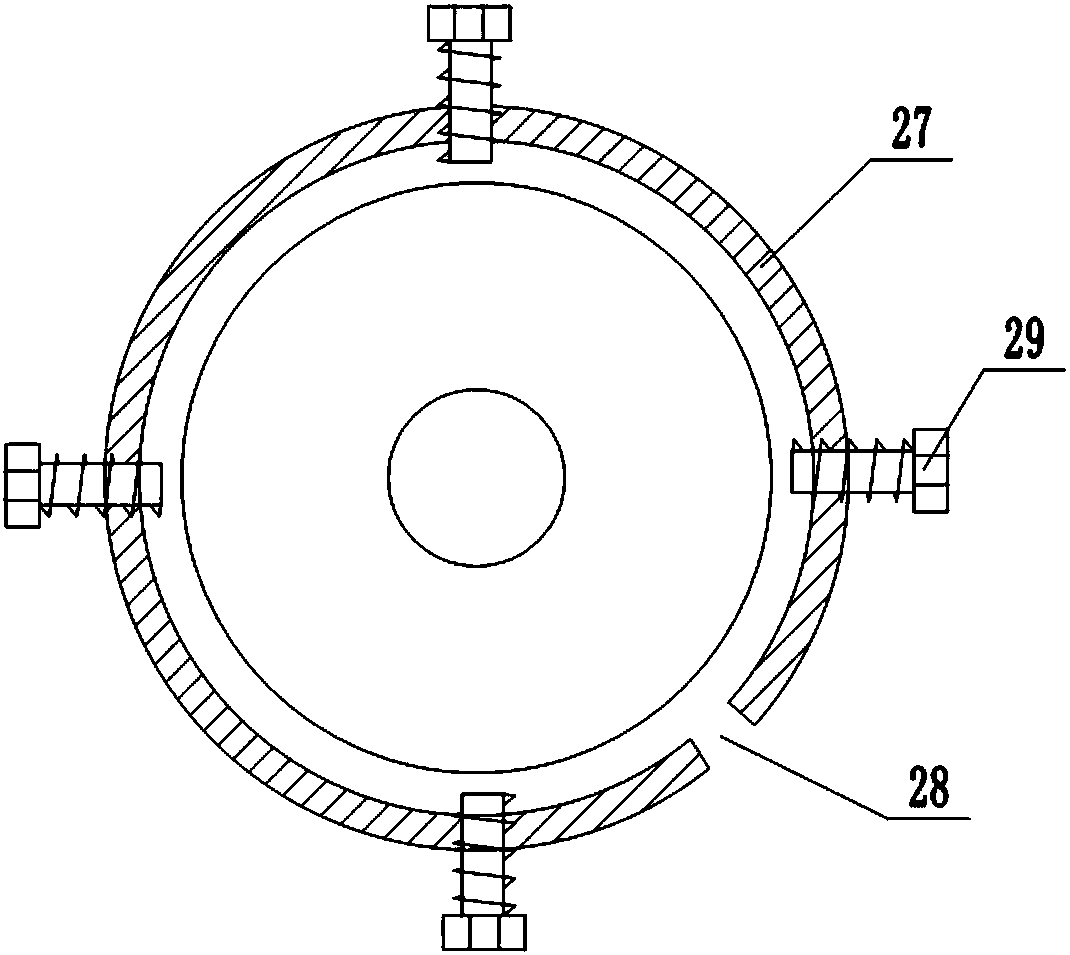

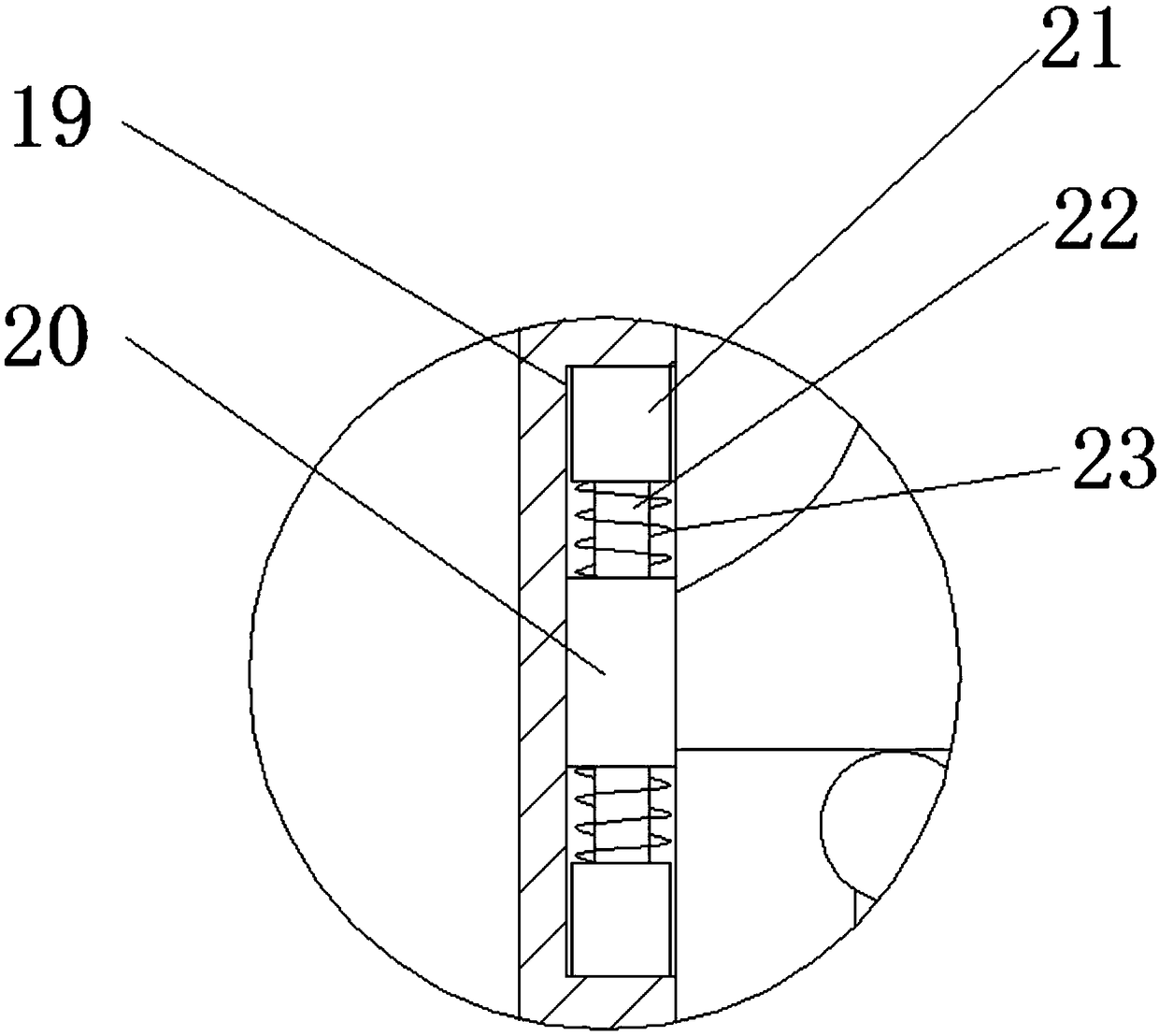

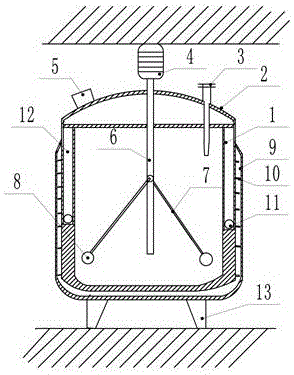

End shaft drilling device

ActiveCN108161066AAvoid burnsAvoid not easy to rule outFeeding apparatusLarge fixed membersAgricultural engineeringTransverse plane

The invention relates to an end shaft drilling device. The end shaft drilling device comprises a machine frame and a supporting table, wherein a triangular plate is connected to the machine frame, a cam is arranged below one end of the triangular plate, a rotating shaft is arranged below the cam, a rotating shaft is coaxially connected with a rotating disc, the rotating disc can be meshed with thecam, the rotating shaft is connected with a transverse shaft and a supporting shaft through a bevel gear, a supporting disc is fixedly connected to the top end of the supporting shaft, and a collecting box is rotationally connected to the bottom end of the supporting shaft, the other end of the triangular plate is connected with a first fixing block, and the bottom end of the first fixing block is connected with a first supporting plate, the first supporting plate is connected with a sliding rod, the other end of the sliding rod is connected with a drill bit, a supporting spring sleeves the sliding rod, the first fixing block is fixedly connected with a transverse plate, the other end of the transverse plate is connected with a second fixing block, the bottom end of the second fixing block is connected with a push rod, a water bag is fixedly connected to the supporting table, the water bag is connected with a water spraying pipe, and the water spraying pipe is connected with a spray head. According to the device, the problems that the drill bit needs to be moved in a drilling process and iron scraps are not easy to remove due to excessively high temperature are solved.

Owner:CHONGQING HONGLEI MACHINERY MFG

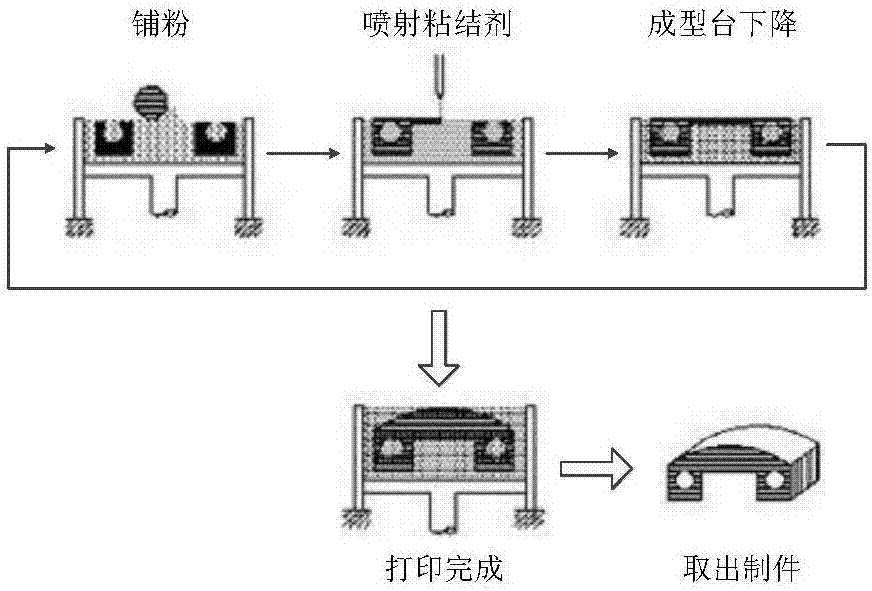

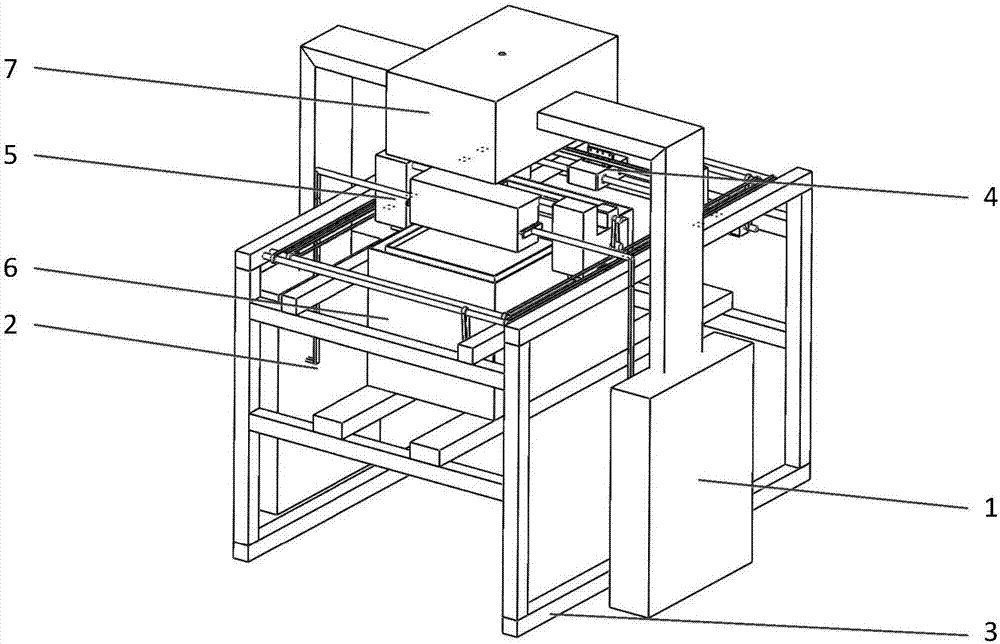

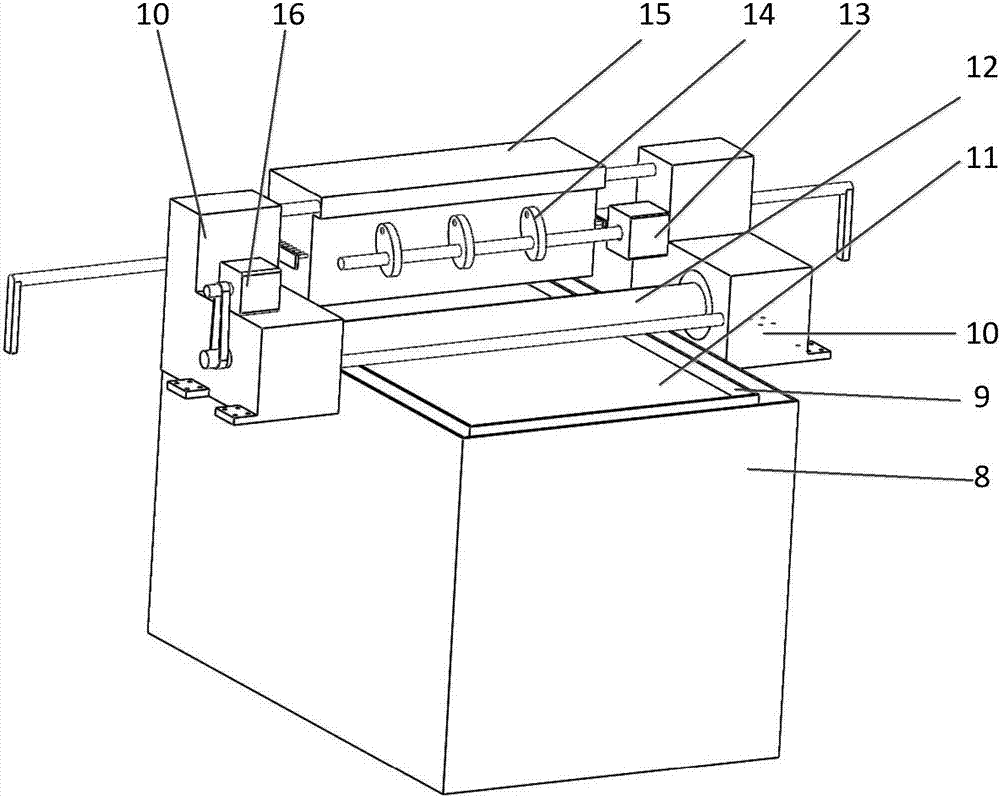

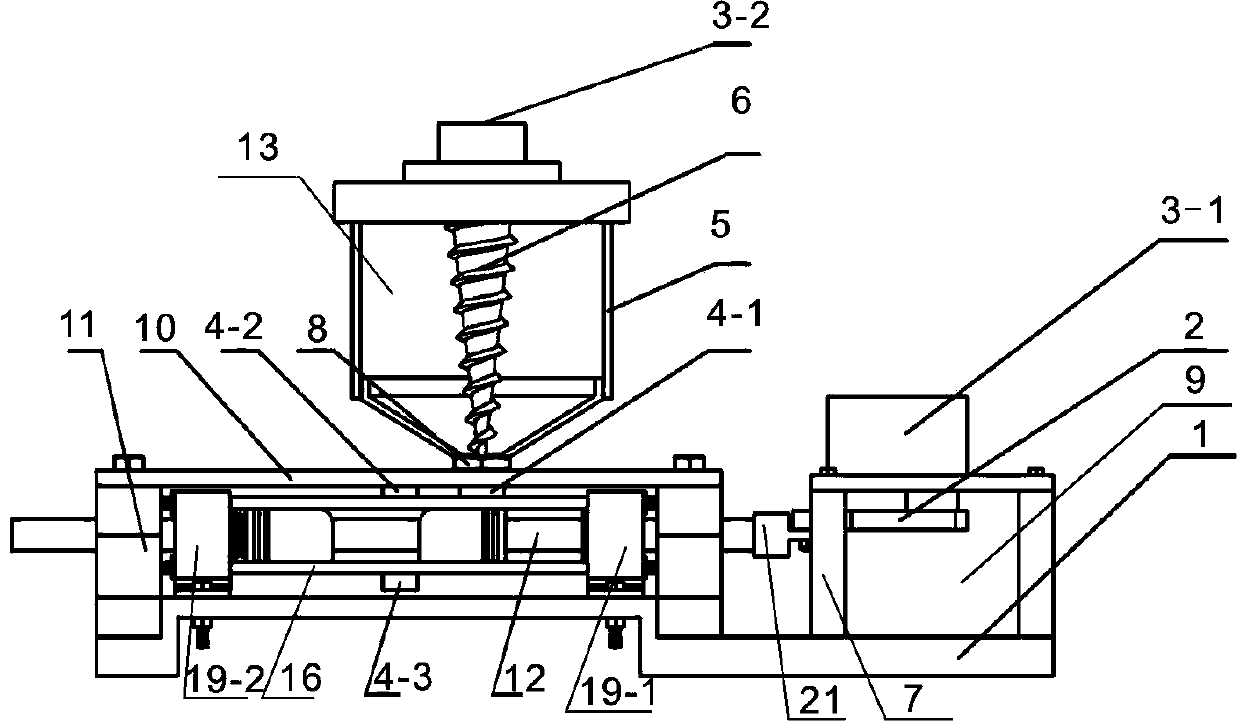

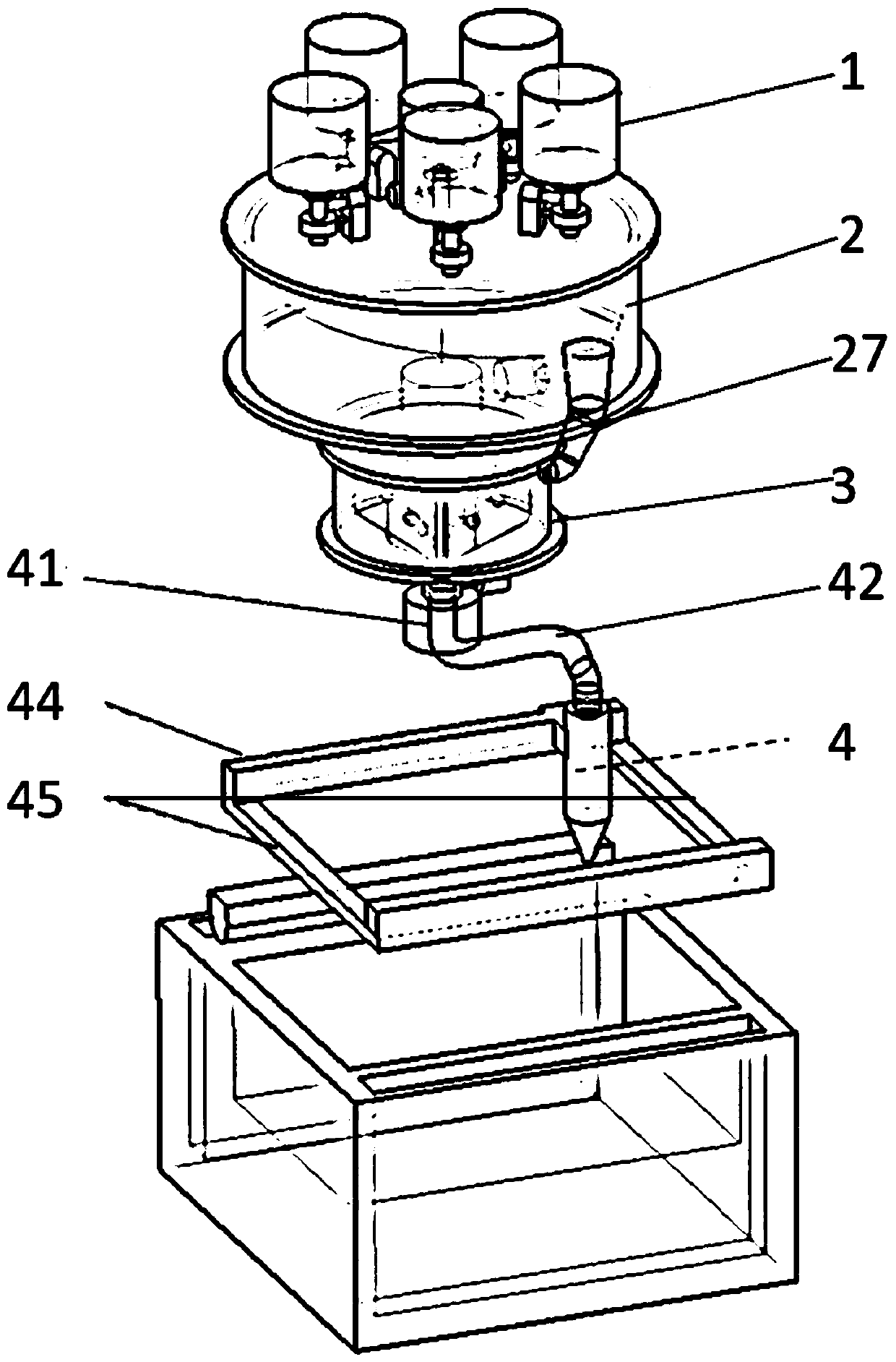

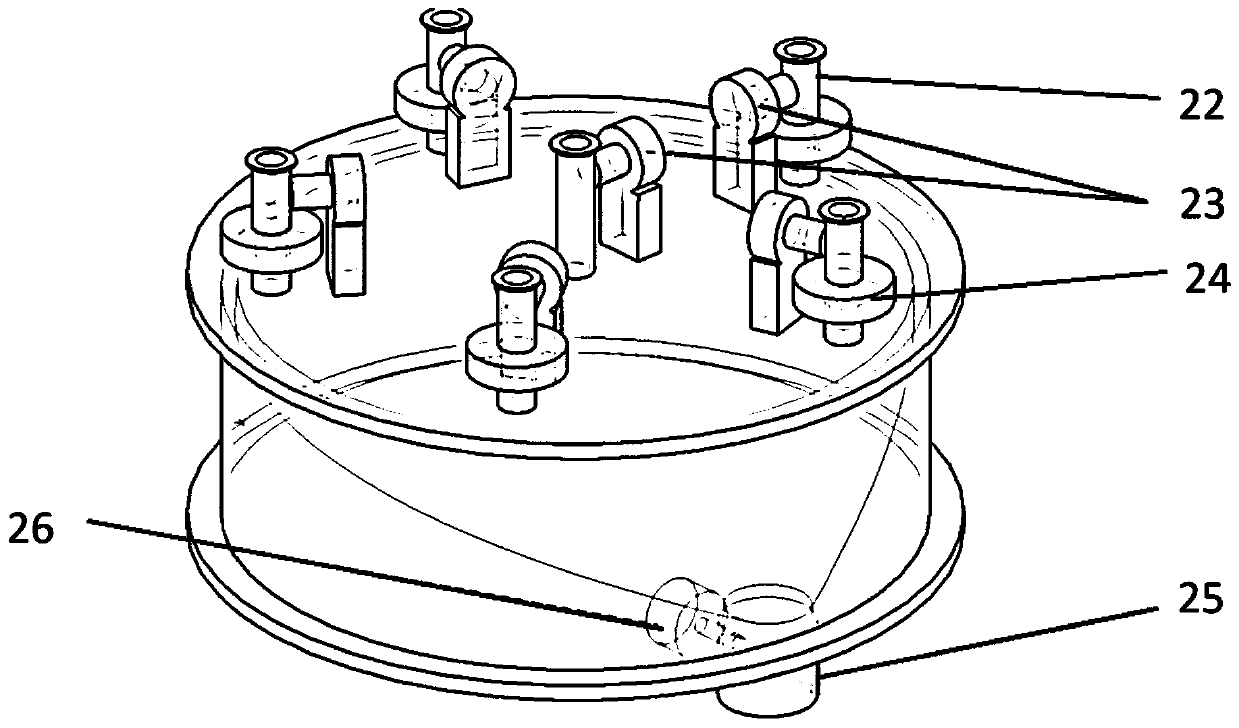

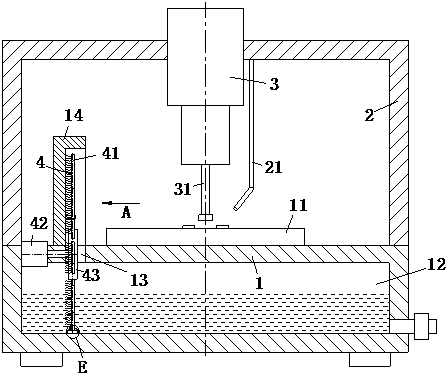

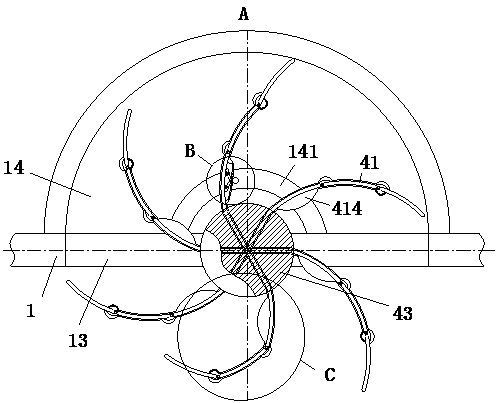

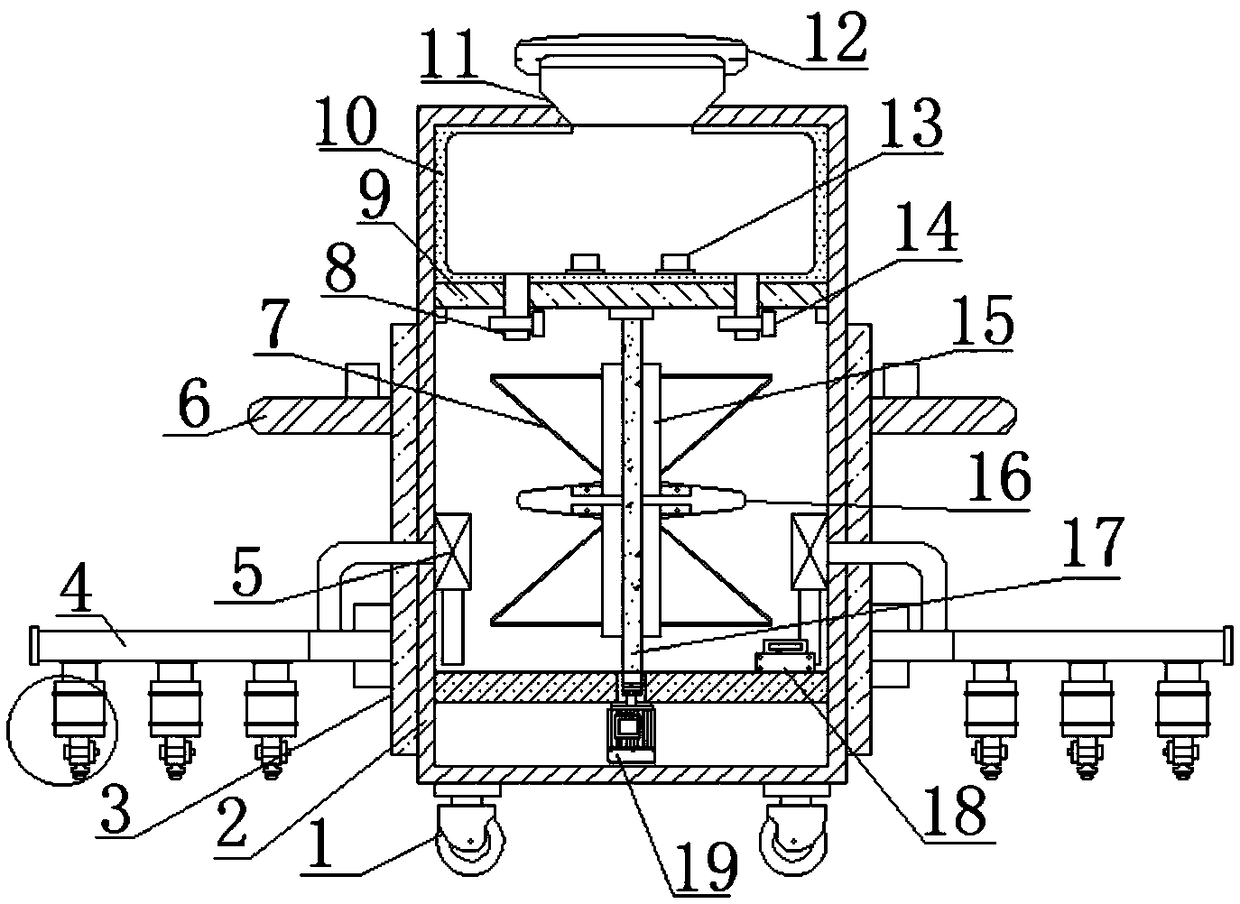

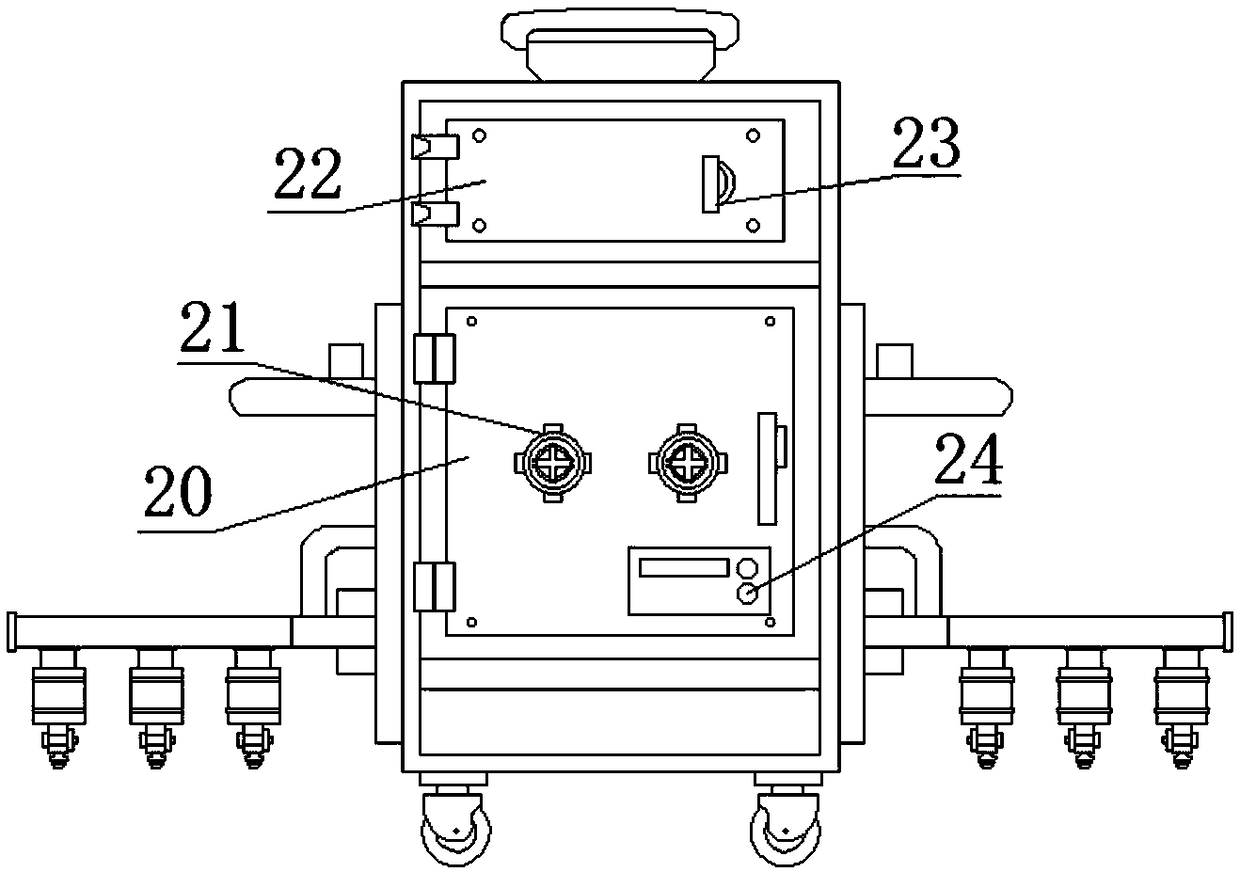

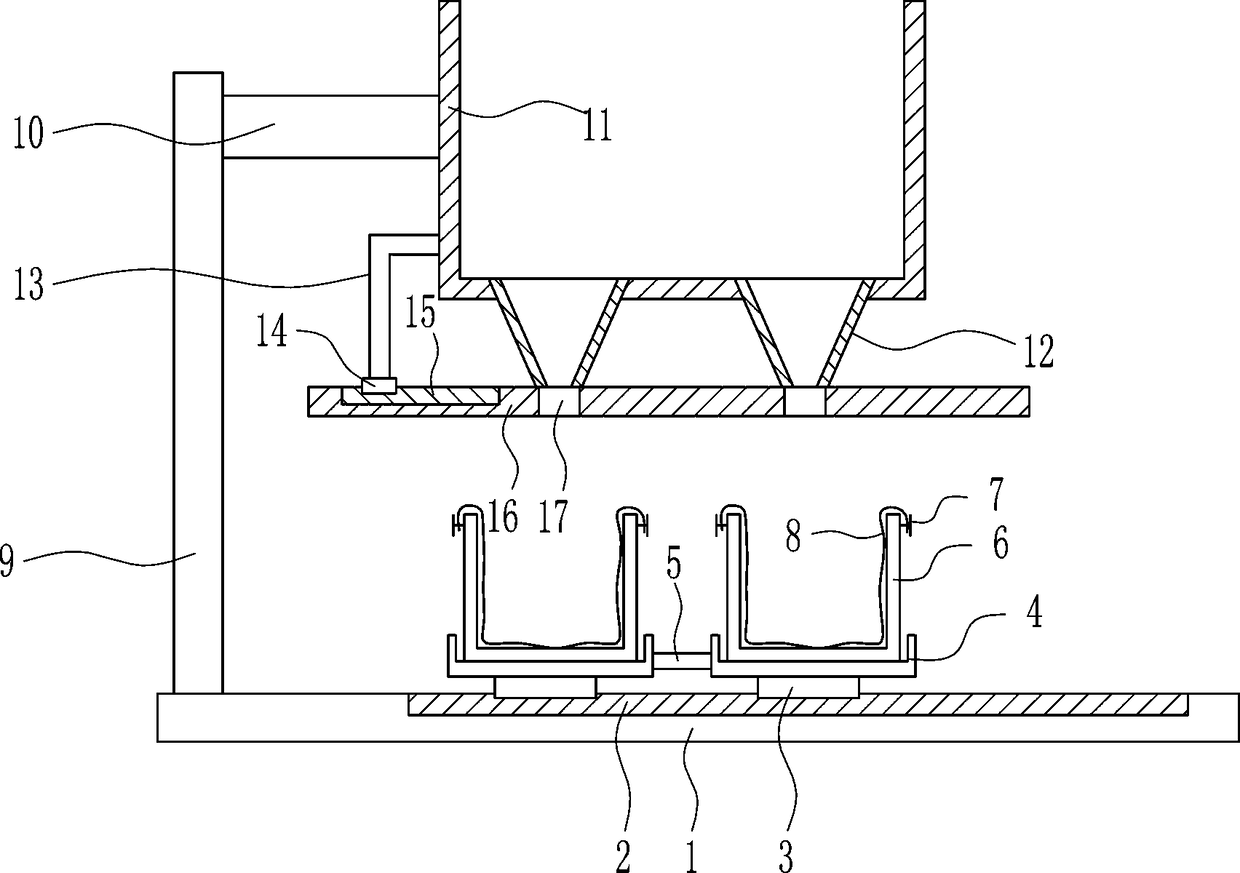

3DP process forming system and operation method thereof

ActiveCN108000870AAvoid cloggingExtend working life3D object support structuresAdditive mnaufacturing with solid and fluidEngineeringMetal

The invention discloses a 3DP process forming system and an operation method thereof. The 3DP process forming system comprises a rack of a metal frame structure. A modular forming cylinder is arrangedin the rack. A printing device and a powder feeding device are arranged at the position, on the upper portion of the modular forming cylinder, of the rack. The printing device and the powder feedingdevice are connected with Y-direction linear guide rails on the rack through sliding blocks and are used for moving on the Y-direction linear guide rails to carry out powder laying and printing. A part taking auxiliary device is arranged at the top of the rack. A physical curing device is arranged in the part taking auxiliary device. Powder storage boxes are arranged on the two sides of the rack.According to the 3DP process forming system and the operation method thereof, the problem that the uniformity of powder particles laid on a powder bed and the density of the powder bed cannot be guaranteed at the same time is solved, the problem of nozzle blocking caused by raising dust caused by laid powder motion is effectively avoided, and the equipment forming efficiency and the part taking efficiency are greatly improved.

Owner:XI AN JIAOTONG UNIV

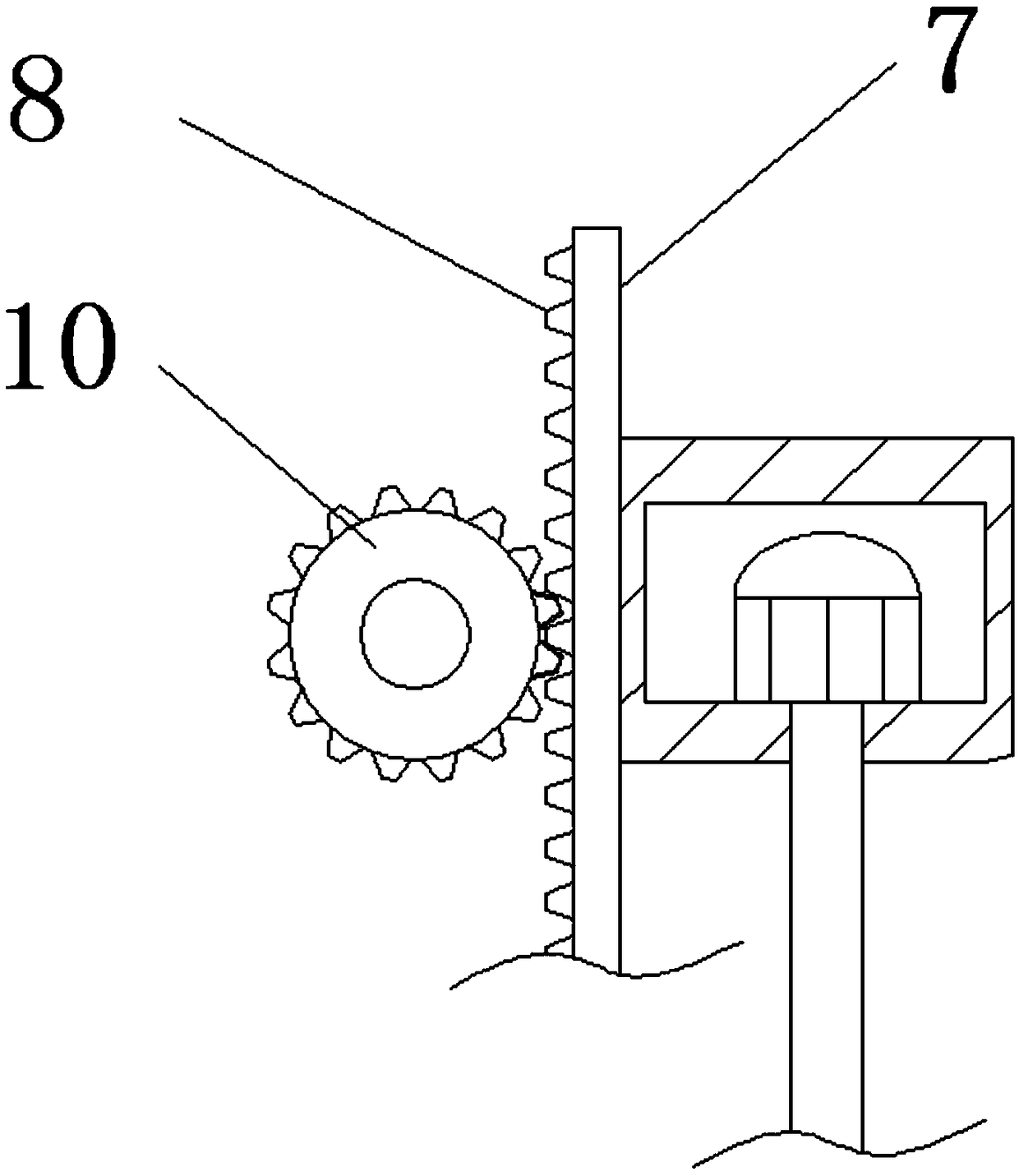

Grinding device for flour processing

The invention discloses a grinding device for flour processing. The grinding device for the flour processing comprises a grinding box. Grinding disks are mounted on the inner wall of the grinding box.Grinding grooves are formed in the grinding disks. A transmission frame is mounted at the top of the grinding box. A motor box is mounted in the transmission frame. Sliding blocks are mounted on theleft side and right side of the motor box through connection blocks. Sliding grooves are formed on the left side and the right side of the transmission frame correspondingly. Both the sliding blocks are mounted in corresponding sliding grooves. A movable plate is mounted on the rear side of the motor box. Racks are mounted on the movable plate. A transmission motor is mounted on the rear wall of the transmission frame. A transmission gear is mounted at the front end of the transmission motor through a rotary shaft. The transmission gear is meshed with the racks. A plurality of material sievingholes are formed in a base plate of each grinding disk. According to the grinding device for the flour processing, through rack transmission, materials in the grinding grooves reduce; meanwhile, a grinding plate declines along with the materials; the grinding plate is laminated with the materials from beginning to end; and thus high-quality grinding effect is continuously guaranteed.

Owner:临泉县生产力促进中心

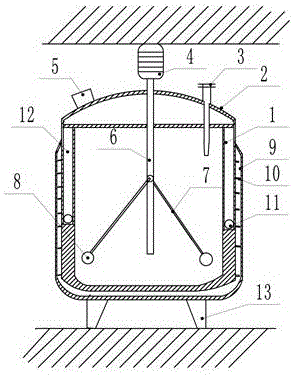

Anti-wall-adhering reaction kettle

ActiveCN106669565AEnhance detackification effectTemperature monitoringRotary stirring mixersTransportation and packagingEngineering

The invention belongs to the field of chemical equipment, and particularly discloses an anti-wall-adhering reaction kettle. The anti-wall-adhering reaction kettle comprises a kettle body, wherein the inner wall of the kettle body is made from a non-ferromagnetic material, and provided with an isolated cavity; a movable block which can be attracted by a magnetic substance is arranged in the isolated cavity; the top end of the kettle cover is provided with a driver which is fixed to the machine frame; the driver is rotatablely connected with a stirring unit positioned in the kettle body; the stirring unit comprises a stirring shaft; a plurality of stirring rods are hinged on the stirring shaft; and the working end of each stirring rod is fixedly provided with a stirring magnetic block. The anti-wall-adhering reaction kettle has the advantages of simple structure, uniform stirring and obvious anti-adhering effect.

Owner:重庆依尔双丰科技有限公司

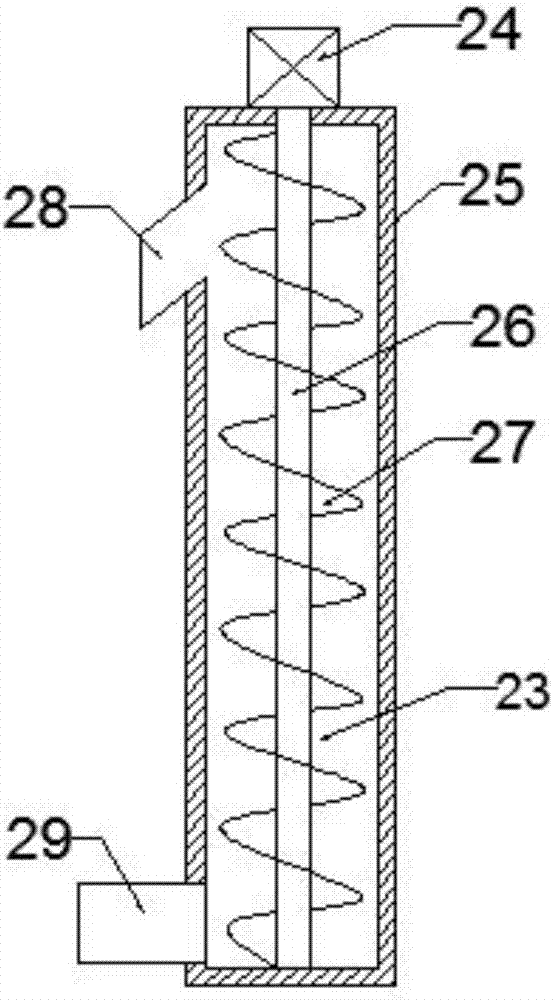

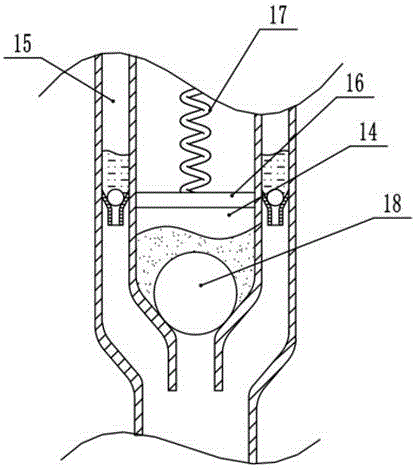

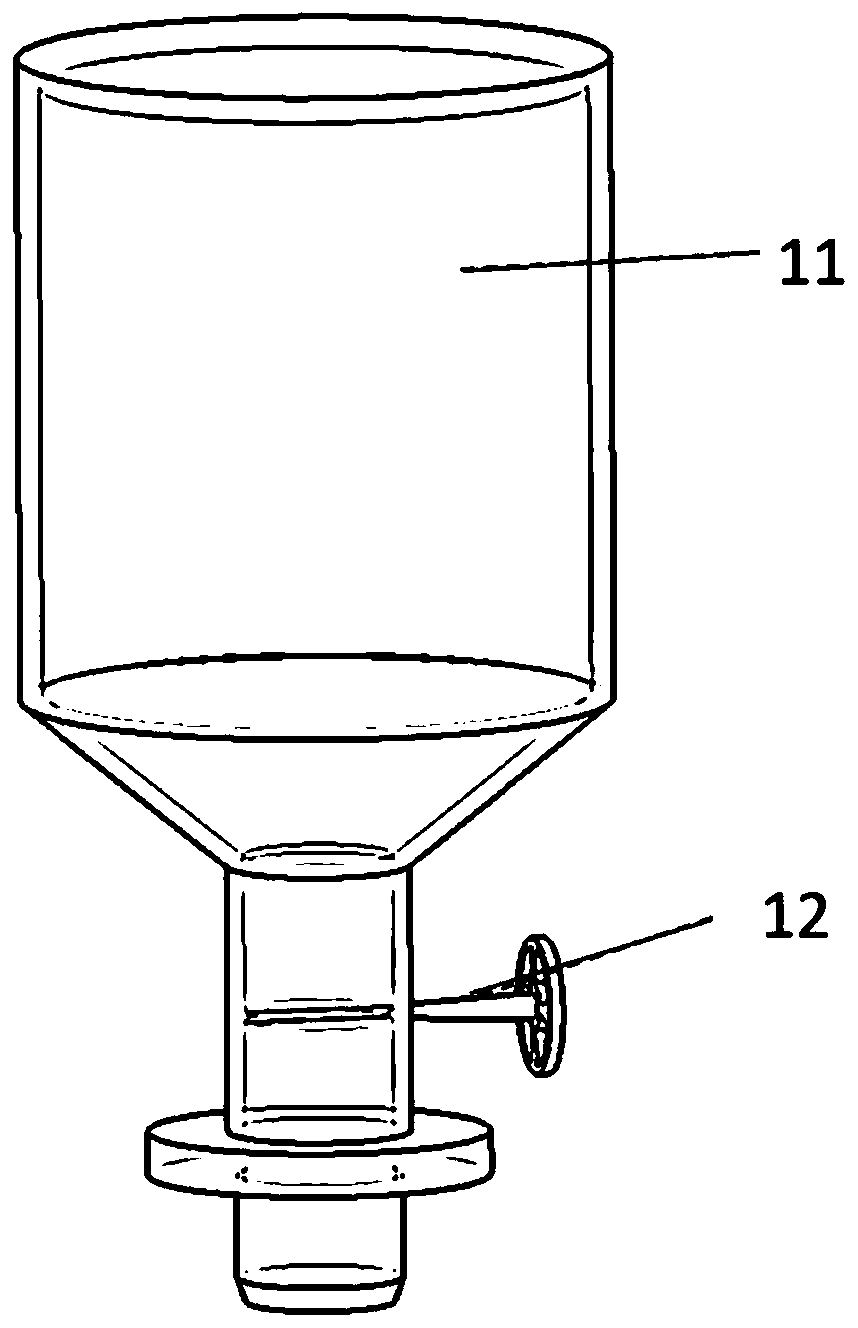

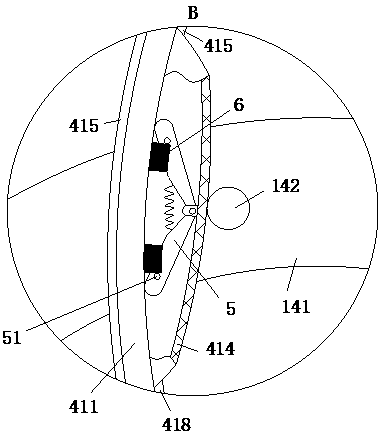

Powdered graphite quantitative conveying device

ActiveCN104192504AAdequately meet specific requirementsMeet specification requirementsPackagingConveyor partsCamFlake graphite

The invention provides a powdered graphite quantitative conveying device. The powdered graphite quantitative conveying device comprises a supporting frame with a protrusion, a reciprocating driving mechanism, a plunger type powdered graphite conveying mechanism and a spiral powdered graphite supplying mechanism, wherein the plunger type powdered graphite conveying mechanism is arranged on the protrusion part of the supporting frame, a supporting pad is arranged outside the plunger type powdered graphite conveying mechanism and is fixed to the spiral powdered graphite supplying mechanism through a supporting plate, plunger rods are arranged at the two ends of the plunger type powdered graphite conveying mechanism respectively, and the plunger rod at one end is connected with the reciprocating type driving mechanism through a cam roller. The powdered graphite quantitative conveying device is simple in structure, low in manufacturing cost, and suitable for accurate weighing and accurate conveying of flake graphite, nanometer graphite sheets and other light, low-mobility and fragile powder.

Owner:湖北天烽精密机械有限公司

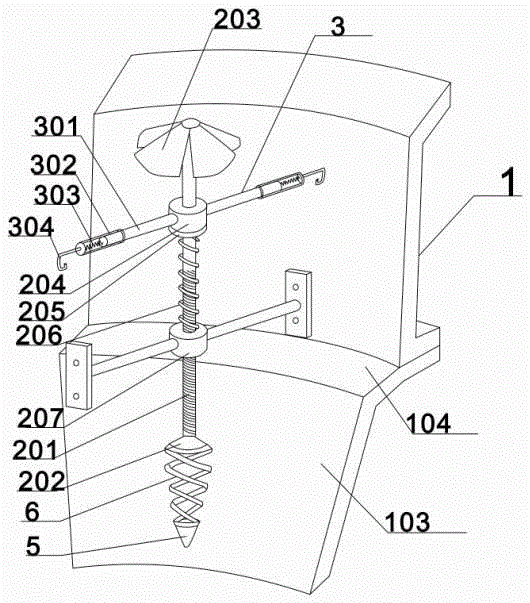

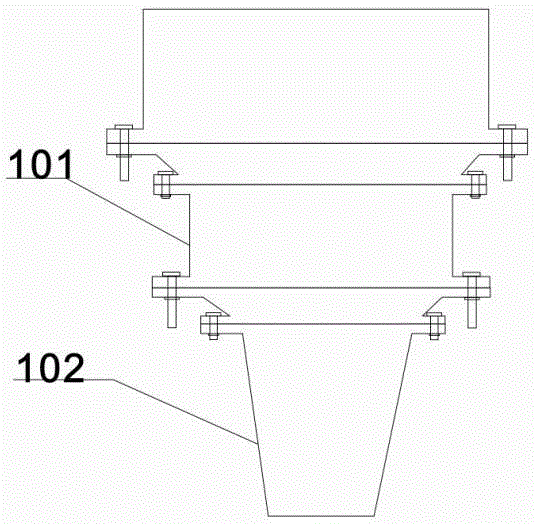

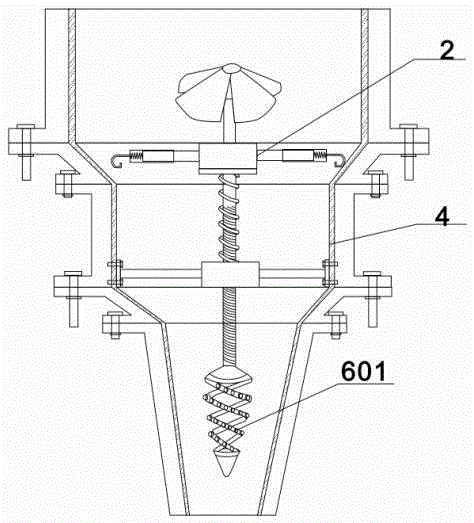

Automatic dredging type coal discharging hopper

The invention provides an automatic dredging type coal discharging hopper. The automatic dredging type coal discharging hopper is provided with a stepped hopper body. An automatic dredging device is fixed into the hopper body and provided with a dredging rod with one end provided with a thread. The threaded end of the dredging rod is connected with a dredging cone and the other end is connected with fan blades. An upper fixing sleeve, a pressure bearing, a spring and a lower fixing sleeve are sequentially arranged on the dredging rod from top to bottom. The upper fixing sleeve is fixedly arranged on the dredging rod. The fan blades rotate after bearing force. The dredging rod is driven by the fan blades to rotate for automatic dredging operation.

Owner:DATANG LUOYANG CO GENERATION POWER

Seed screening device for garden breeding

InactiveCN108080247AAchieve repeated improvementAchieve repeated scrapingSievingScreeningScreening effectDrive shaft

The invention discloses a seed screening device for garden breeding. The device comprises a collection box. A limiting sleeve is fixedly installed at the upper end of the collection box. A screening groove is formed in the limiting sleeve in a sliding mode, a transmission rod is fixedly installed at the end of a rotating shaft, a swing rod is arranged in the collection box, a driving motor is fixedly installed on a supporting frame, and an output shaft of the driving motor is coaxially and fixedly provided with a driving shaft. Seeds are repeatedly lifted through rotation of spiral lifting blades, the seeds slide downwards along the inner side wall of a collection barrel to be subjected to the repeated screening effect, first-level screening of the seeds is promoted, a screen net is repeatedly scraped through transverse reciprocating movement of a brush scraper plate at the bottom of the screening groove, and the screening effect of the screen net on the seeds in the screening groove is promoted. A cam drives the screening groove through a first limiting baffle to swing back and forth under the elastic effect of a reset spring, the seeds can more rapidly penetrate through the screen net to fall into the bottom of the collection box, second-level screening of the seeds is achieved, the screening effect is good, and the screening efficiency is high.

Owner:储昭汉

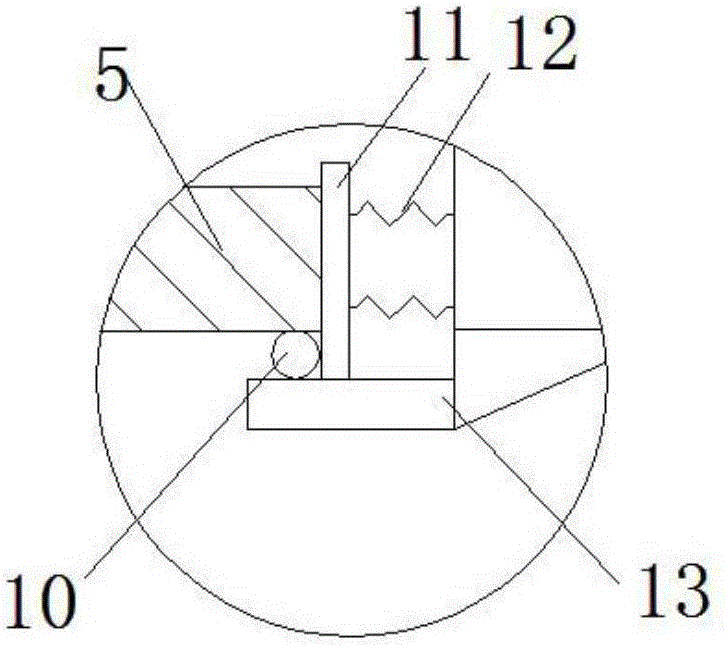

Space-adjustable smashing device for micro powder production

The invention relates to the technical field of smashing devices for micro powder production, in particular to a space-adjustable smashing device for micro powder production. The device is simple in structure, convenient to use, low in production cost and suitable for smashing treatment in the micro powder production process. Through rotation of a motor, rotation of two sets of smashing rollers can be achieved, micro powder smashing is achieved, through manual rotation of a hand rotation disc, adjusting of the gap between the two sets of smashing rollers is achieved, micro powder smashing is achieved, the hand rotating disc is manually rotated by the manual work, adjusting of the gap between the two sets of smashing rollers can be achieved, different powder required in the different needscan be produced, and the application range is wide. The smashed micro powder falls on a screening plate from falling holes, the micro powder smaller than the diameter of screening meshes falls on a guide plate, and slides out of a second discharging hopper connected with the guide plate, and the micro powder larger than the diameter of the screening meshes directly slides out of a first discharging hopper connected with the screen plate for subsequent machining. A gear shaft rotates to drive a vibration ball to continuously beat the screening plate and the guide plate, falling of the micro powder is promoted, and the screening efficiency is improved.

Owner:连云港市沃鑫高新材料有限公司

Shift register circuit and image display comprising the same

ActiveUS20110182399A1Lower capability requirementsImprove driving abilityStatic indicating devicesDigital storageElectricityShift register

In a shift register circuit, a defective operation while an output signal is not outputted and a drive capability lowering while the output signal is outputted are prevented. A unit shift register comprises a first transistor for supplying a clock signal inputted to a first clock terminal to an output terminal, and the first transistor is driven by a drive circuit. A second transistor is connected between the gate of the first transistor and the output terminal and has a gate connected to the first clock terminal. The second transistor connects the gate of the first transistor to the output terminal based on the clock signal when the gate of the first transistor is at L (Low) level.

Owner:TRIVALE TECH

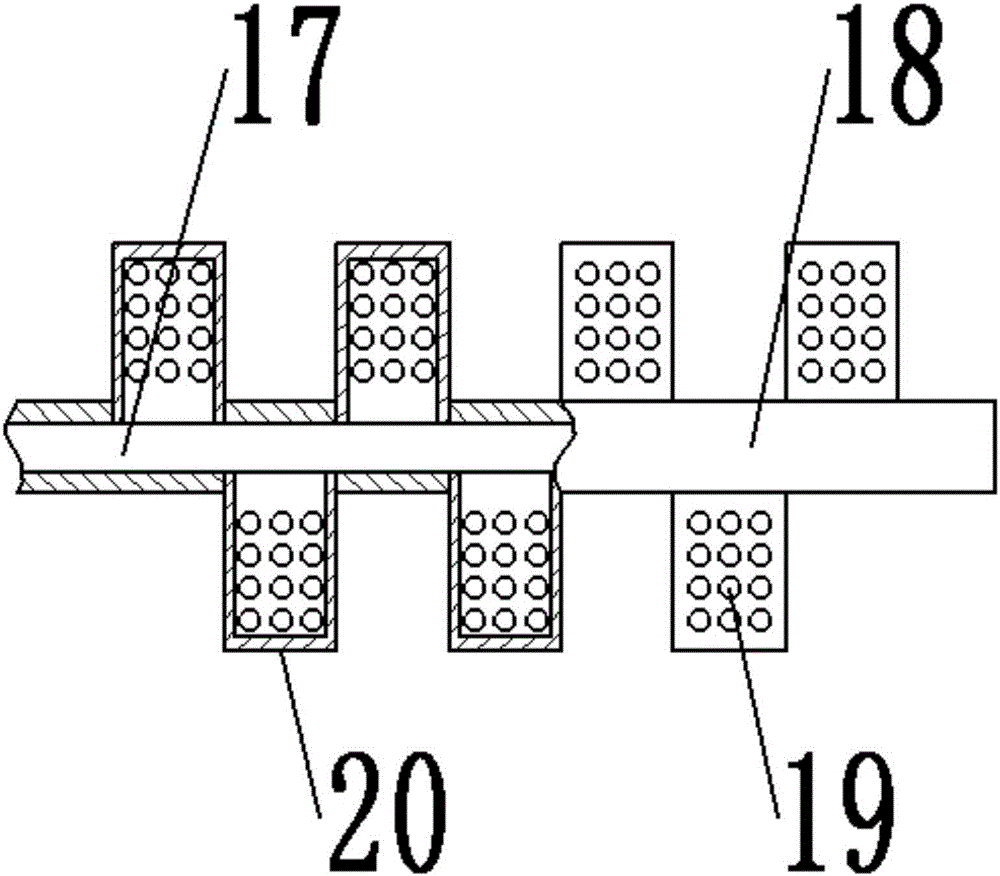

Stirring device

ActiveCN108310995AAvoid cloggingAvoid mixingShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringElectromagnet

The invention belongs to the technical field of stirring equipment and in particular discloses a stirring device. The stirring device comprises a stirring barrel and a charging basket, wherein a motoris arranged on the stirring barrel; a rotating shaft is connected onto an output shaft of the motor; the lower end of the rotating shaft is rotationally connected into the charging basket; two feeding holes are formed in top walls of the stirring barrel; two grinding roller groups are arranged in the stirring barrel; a spring is arranged on the rotating shaft in a sleeving manner; the upper end of the spring is fixed on the top wall of the stirring barrel; a screen is arranged at the lower end of the spring and connected onto the inner wall of the stirring barrel in a sliding manner; a chuteis formed in a side wall of the rotating shaft; two upper and lower layers of stirring paddles are connected onto the chute in a sliding manner; a first electromagnet, a second electromagnet and a third electromagnet are sequentially arranged at the top end, in the middle and at the lower end of the chute; permanent magnets are arranged on the screen and the two groups of stirring paddles; the left and right sides of the screen are downwards inclined; circulating orifices are formed in side walls on two sides of the stirring barrel; screw feed mechanisms are arranged outside the circulating orifices; orifices in the upper ends of the two screw feed mechanisms are respectively communicated with the two feeding holes.

Owner:青岛泰富科技有限公司

Multi-material powder supplying and laying device for powder bed melting and control method of multi-material powder supplying and laying device

InactiveCN111408718AImprove the efficiency of hybrid printingIncrease productivityAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedHigh entropy alloys

The invention discloses a multi-material powder supplying and laying device for powder bed melting and a control method of the multi-material powder supplying and laying device. A plurality of powderinlets are formed in the upper end of a main powder storage tank, an independent sub-powder storage tank is installed at each powder inlet, and powder in the sub-powder storage tanks are premixed by the main powder storage tank, then a powder mixer in a powder mixing device is used for mixing the premixed mixture, the main powder storage tank and the powder mixing device are adopted for premixingand sufficient mixing respectively, the powder mixing device serves as a buffer section, the powder mixing printing efficiency is improved, and meanwhile printing materials of different mixing contents and types can be added through the plurality of sub-powder storage tanks; and a printing moving frame is used for driving a powder spray head to spray powder, manufacturing of a functionally gradedmaterial and a multi-component alloy / high-entropy alloy-based composite material with components continuously changing in any direction is achieved, long powder mixing time is saved, real-time powderlaying and real-time machining can be achieved, the production cycle is greatly shortened, the production cost is greatly reduced, and the production efficiency is improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Burr removal device for parts of mechanical valve element

ActiveCN110465854AImprove cleaning efficiencyReduce the difficulty of cleaningEdge grinding machinesGrinding drivesMechanical valveFixed frame

The invention belongs to the technical field of part machining, and specifically discloses a burr removal device for parts of a mechanical valve element. The burr removal device for the parts of the mechanical valve element comprises a rack and a U-shaped frame, wherein the U-shaped frame is arranged at the top of the rack; a water storage bin is arranged at the inner side of the rack; a fixed frame used for clamping the parts is installed at a part located at the inner side of the U-shaped frame, of the top of the rack; and a semicircular frame is fixedly connected to a part located at one side of the fixed frame, of the rack. According to the burr removal device for the parts of the mechanical valve element, a sweeping unit is enabled to rotate through a second motor, chippings generateddue to grinding are collected, air in an inner cavity of an air bag is extruded to be guided into a first air guide hose and a second air guide hose, so that a third arc-shaped rod close to the vertical center line of the semicircular frame and located above a rotary disc reversely rotates, and the falling-off of the chippings on a soft brush is accelerated while a crack in the inner side of thesemicircular frame is cleaned; and meanwhile, a second arc-shaped rod and the third arc-shaped rod which are located below the rotary disc rotate towards a direction close to the rotary disc, clear water is stirred to accelerate the falling-off of the chippings on the soft brush, so that the sweeping efficiency is effectively increased, and the cleaning difficulty is reduced.

Owner:嘉兴蘑菇云科技有限公司

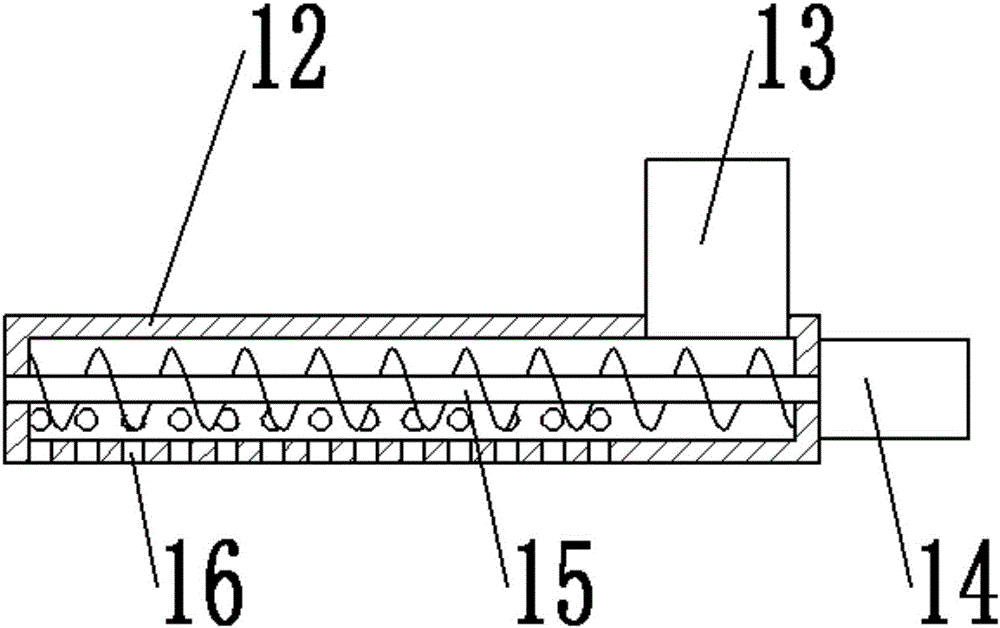

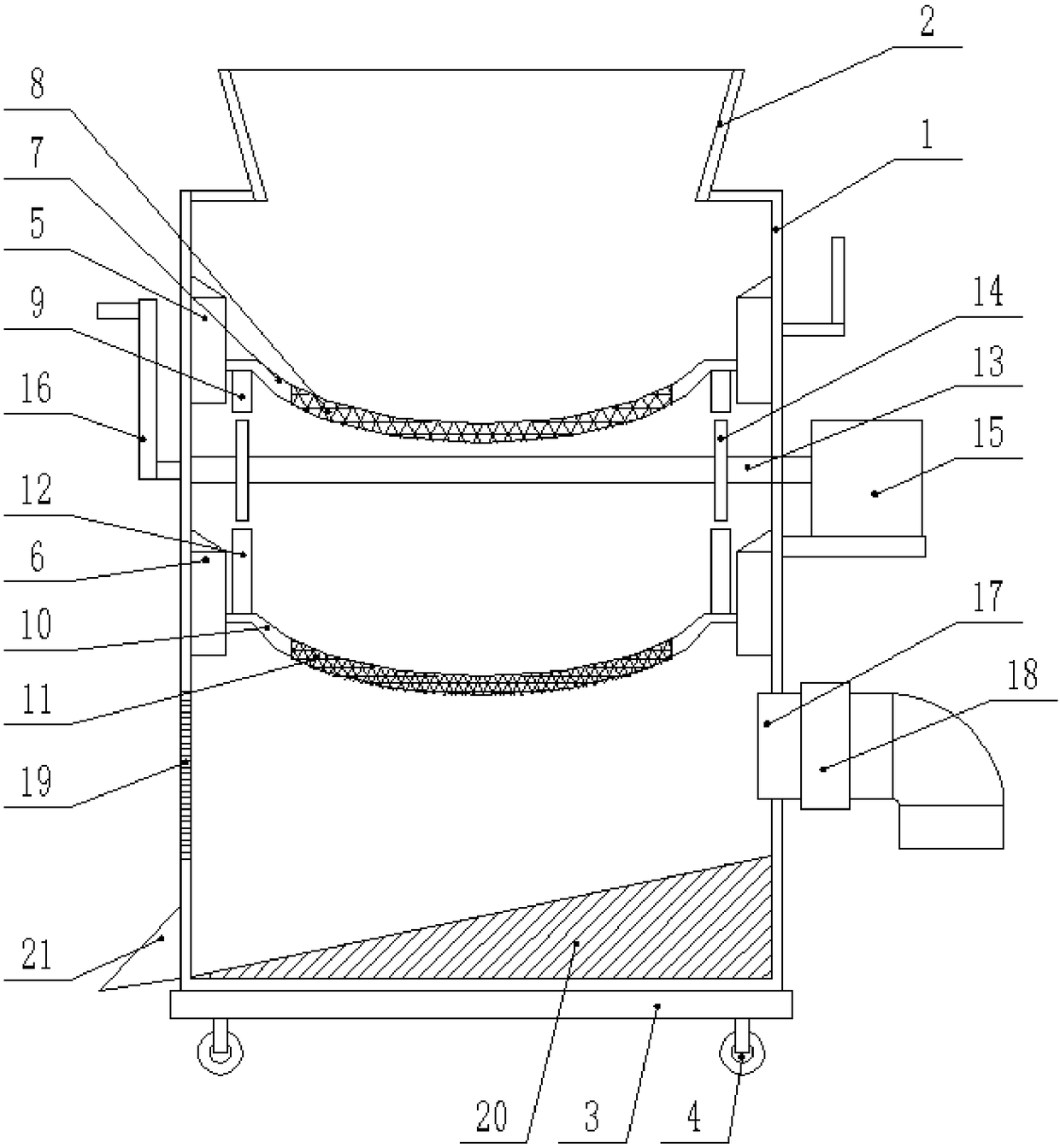

Pueraria powder hot air drying equipment with dehumidifying device

InactiveCN106440740APrevent drying efficiency from decreasingIncrease drying speedGranular material dryingDrying gas arrangementsEngineeringAir drying

The invention provides pueraria powder hot air drying equipment with a dehumidifying device. The pueraria powder hot air drying equipment comprises a tank body. A drying cavity is formed in the tank body. A feeding device is arranged on the top of the drying cavity. An upper material guide plate and a lower material guide plate are arranged in the middle of the drying cavity. A stirring device is arranged at the bottom of the drying cavity. The feeding device is composed of a conveying pipe and a feeding pipe. The upper material guide plate and the lower material guide plate are obliquely arranged. Multiple through holes are evenly formed in the surface of the upper material guide plate and the surface of the lower material guide plate. The stirring device is composed of a stirring shaft and stirring pieces. One end of the stirring shaft is connected with a drying and driving device. The drying and driving device is composed of a transmission box, a rotary motor and an air inlet pipe. The dehumidifying device is arranged on the top face of the tank body and is composed of a dehumidifying pipe, a filtering tank and a dehumidifier. According to the pueraria powder hot air drying equipment, the situation that too much pueraria powder is added once and consequently the drying efficiency is lowered is prevented through the feeding device; the falling distance of pueraria powder is increased through the upper material guide plate and the lower material guide plate; and the pueraria powder is dried efficiently through the drying and driving device.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

Solid waste treatment device

InactiveCN107891052AEasy to handleGuaranteed treatment effectSolid waste disposalMedical waste disposalCouplingEngineering

The invention discloses a solid waste treatment device. The solid waste treatment device comprises a box; the top of the right side of the box is fixedly connected with a top box; the bottom of the right side of the box is fixedly connected with a bottom box; the bottom of the left side of the box is fixedly connected with a motor box; the top of the inner wall of the box is fixedly connected witha crushing box; a disinfection box is fixedly connected between two sides of the inner wall of the box at the bottom of the crushing box; an extrusion box is fixedly connected between two sides of the inner wall of the box at the bottom of the disinfection box; one side of the inner wall of the top box is fixedly connected with a first motor through a first motor base; an output shaft of the first motor is fixedly connected with a crushing shaft through a coupling; and the solid waste treatment device relates to the technical field of waste treatment. The solid waste treatment device can extrude wastes to guarantee that the wastes can pass through a filter screen, so that the later treatment is convenient, the treatment effect is guaranteed, and the stability of the device is greatly improved; and the device is simple in structure and high in operability, and saves the treatment cost.

Owner:易亮

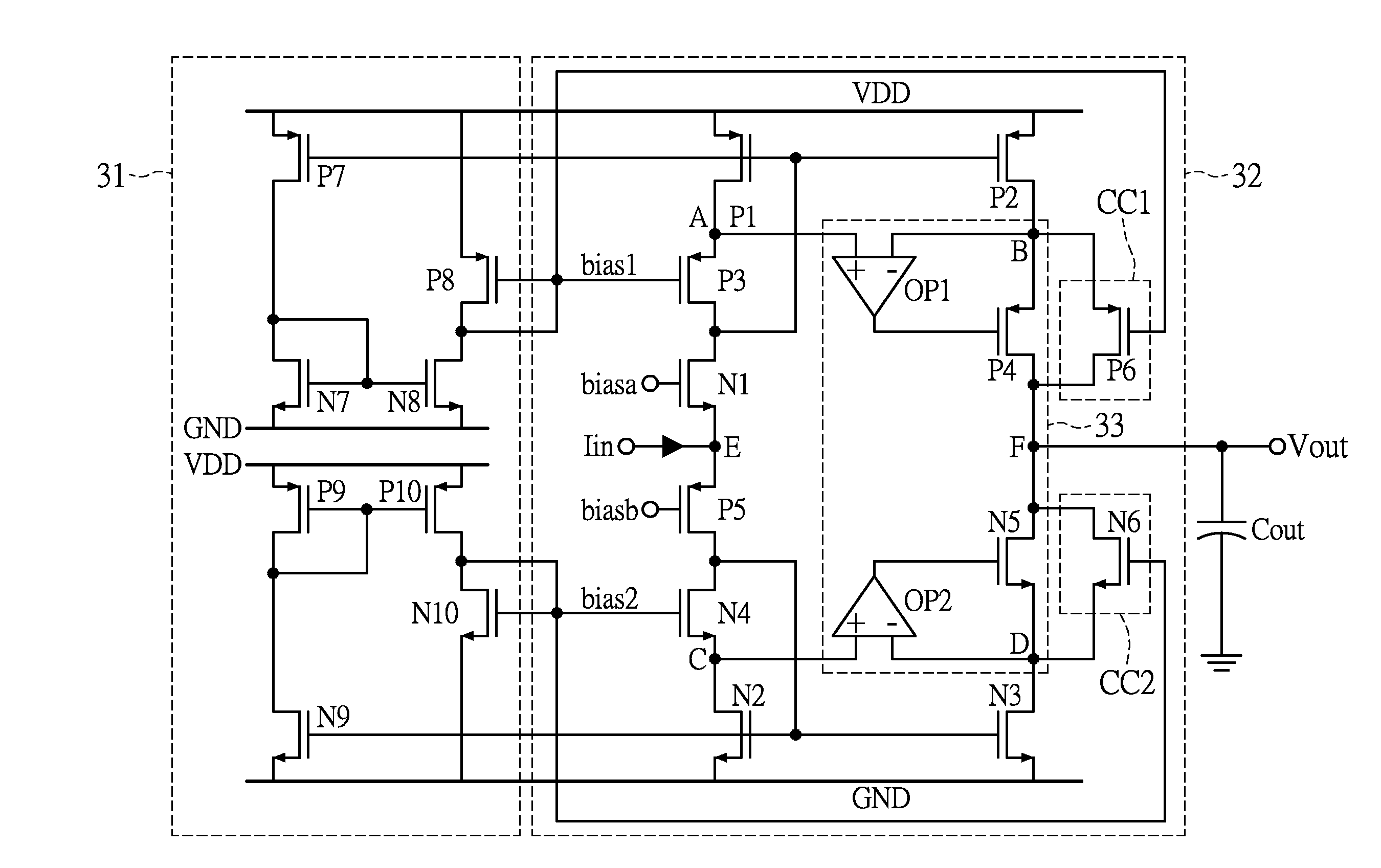

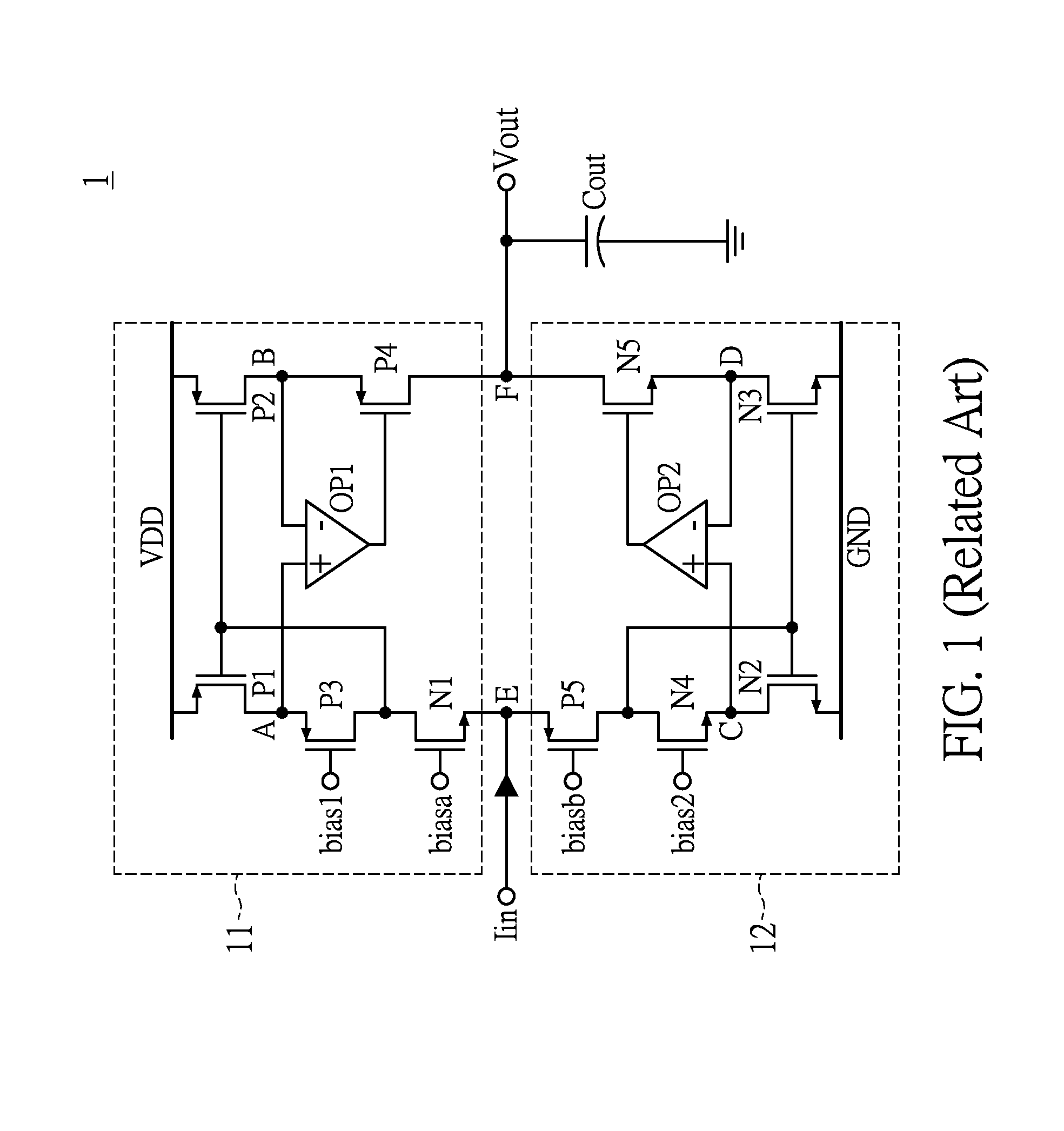

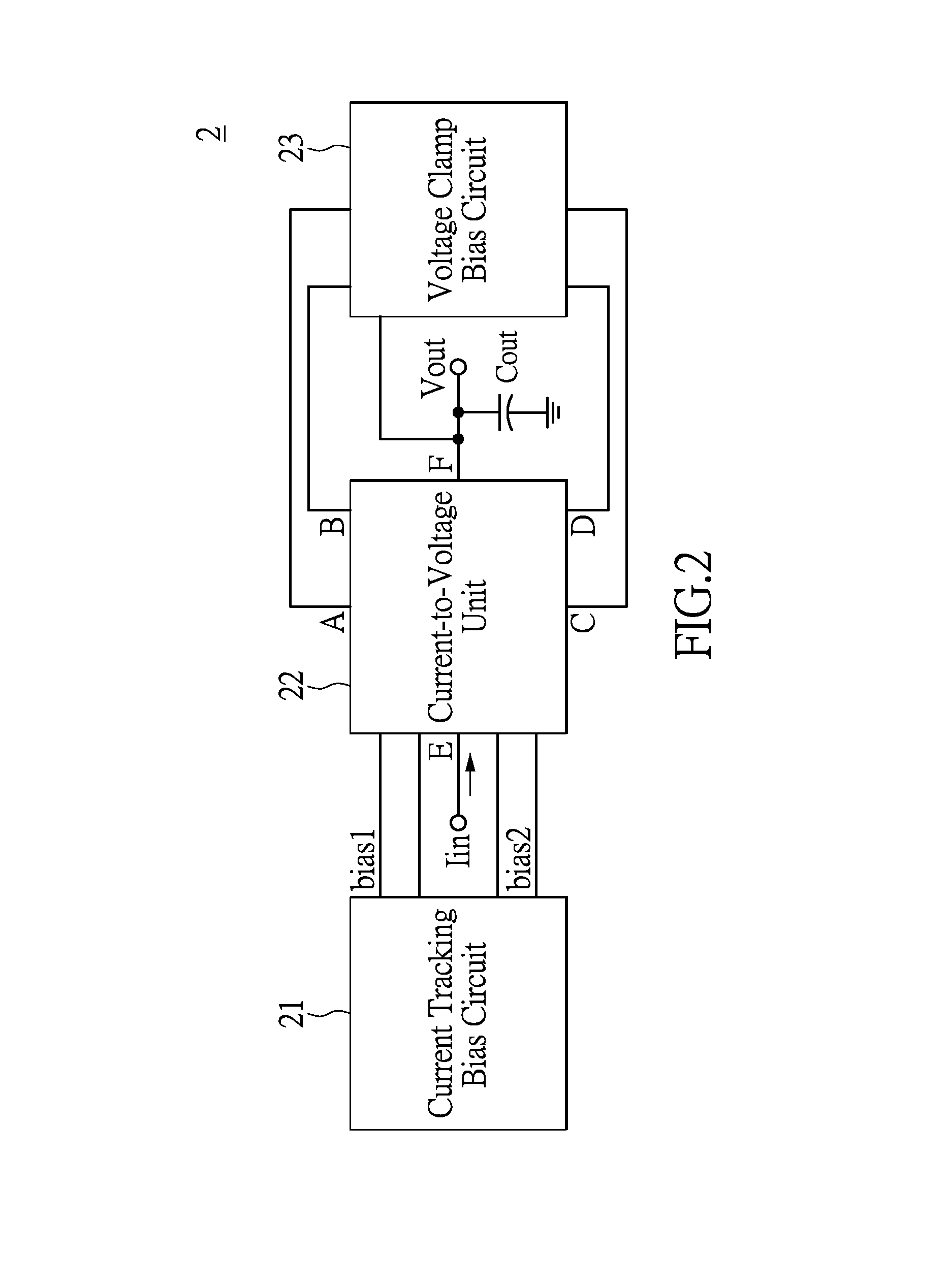

Current-to-voltage converter and electronic apparatus thereof

ActiveUS20140333348A1Expand the input rangeWide output swingDifferential amplifiersDc-amplifiers with dc-coupled stagesVoltage converterEngineering

A current-to-voltage converter which is used to receive an input current and to generate an output voltage accordingly comprises a current tracking bias circuit, a current-to-voltage unit, and a voltage clamp bias circuit. The current tracking bias circuit generates a first bias according to the input current. The current-to-voltage unit receives the first bias and the input current, and generates the output voltage according to the input current, wherein the first bias determines a range of the input current, the current-to-voltage unit has a first current control device, and the first current control device changes a current conduction level thereof in response to the first bias, such that a rising or falling speed of the output voltage is enhanced. The voltage clamp bias circuit clamps voltage levels of two ends where the voltage clamp bias circuit is connected to the current-to-voltage unit.

Owner:ILI TECHNOLOGY CORPORATION

Spraying agent spraying device for soil restoration

ActiveCN109500076AImprove efficiencyAvoid blockageContaminated soil reclamationEngineeringSoil restoration

The invention belongs to the technical field of spraying devices, and particularly relates to a spraying agent spraying device for soil restoration. Directing at the problems that protecting and dehumidifying of a powdery soil restoration agent are not good, a heating device for restoration designing of solid soil does not exist, the restoration agent and water cannot be merged well enough, and the spraying effect is relatively poor, the following scheme is put forwards, a spraying box is included, and universal wheels are fixed to the outer walls of the bottom four corners of the spraying boxthrough bolts; installing plates are fixed to the outer walls of the two sides of the spraying box through bolts; the outer walls of the tops of the sides, away from the spraying box, of the two installing plates are provided with first inserting holes, and connection pipes are inserted and connected in the inner walls of the two first inserting holes; and the outer walls of the bottoms of the two connection pipes are connected with a flow dividing pipe through threads. Due to the spraying agent spraying device for soil restoration, a restoration agent which is not dissolved and caked, and mixed in water can be cut and broken, the merging degree of the restoration agent is improved, then the spraying efficiency of the spraying device is improved, and the spraying quality of the whole device is improved.

Owner:宣城良知知识产权服务有限公司

Power distribution cabinet with temperature adjusting function

InactiveCN113964678AExpand the cooling rangeAdequate heat dissipationSubstation/switching arrangement cooling/ventilationCircular discElectric power equipment

The invention discloses a power distribution cabinet with a temperature adjusting function, and relates to the technical field of power equipment. The cabinet comprises a power distribution cabinet, a heat dissipation device is arranged in the power distribution cabinet, the heat dissipation device comprises a heat dissipation pipe, the top of the heat dissipation pipe is fixedly installed at the top of the power distribution cabinet, the lower half portion of the heat dissipation pipe is in a plastic elastic shape, and a heat dissipation fan is rotatably installed on the inner wall of the heat dissipation pipe. A rotating shaft of the heat dissipation fan is in transmission connection with a rotating shaft of the disc through a belt, the disc is rotationally installed on the inner wall of the top of the power distribution cabinet, a cylinder is fixedly installed at the bottom of the disc, and the cylinder is installed at the fork-shaped end of the fork-shaped rod in a sliding mode. According to the power distribution cabinet with the temperature adjusting function, the heat dissipation device is arranged, and when heat dissipation operation is performed on the power distribution cabinet through a heat dissipation fan and a heat dissipation pipe, a fork-shaped rod can drive the lower half part of the heat dissipation pipe to swing, so that the heat dissipation range of the heat dissipation pipe is expanded, and the problem of insufficient heat dissipation is effectively solved.

Owner:郭一鸣

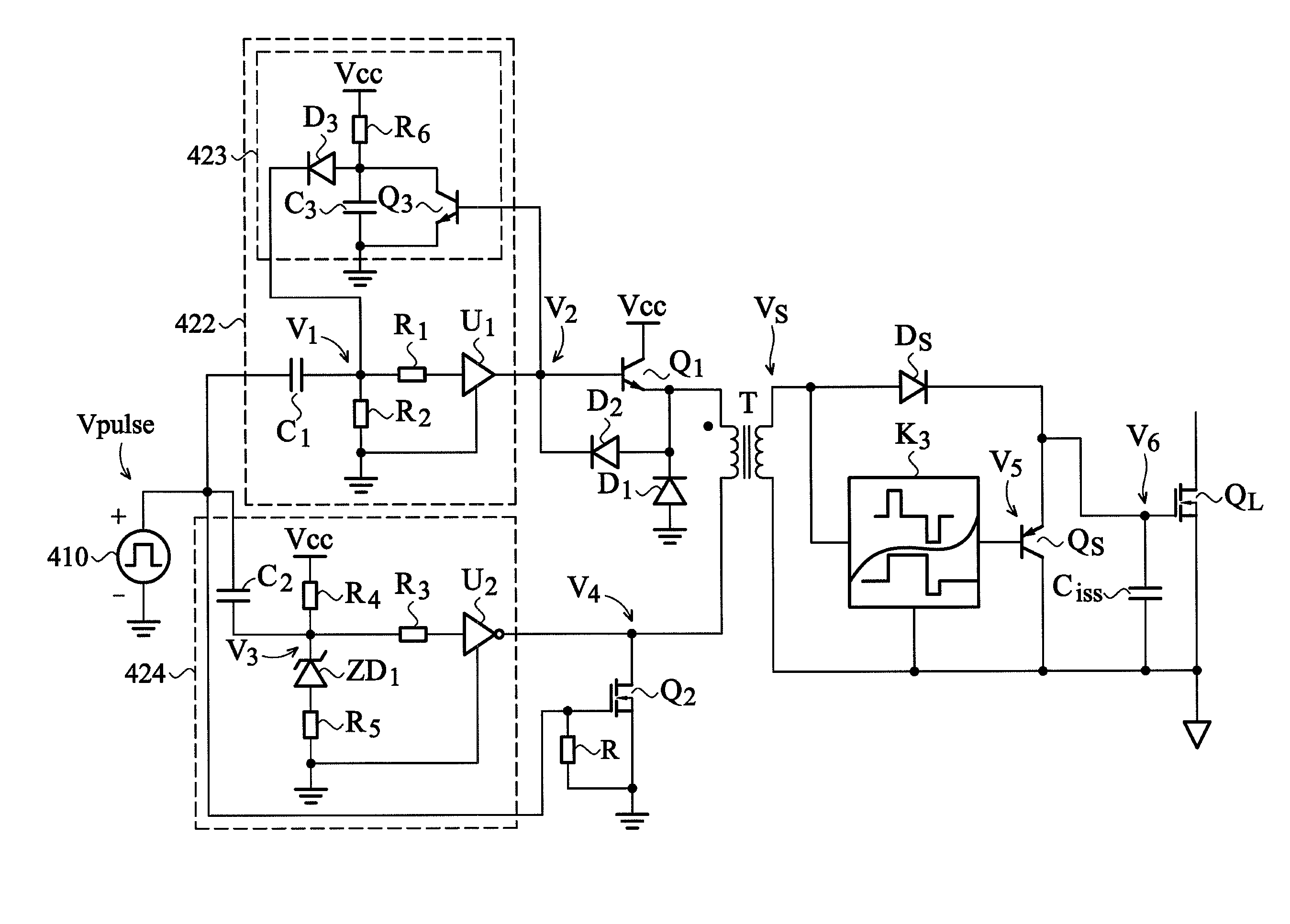

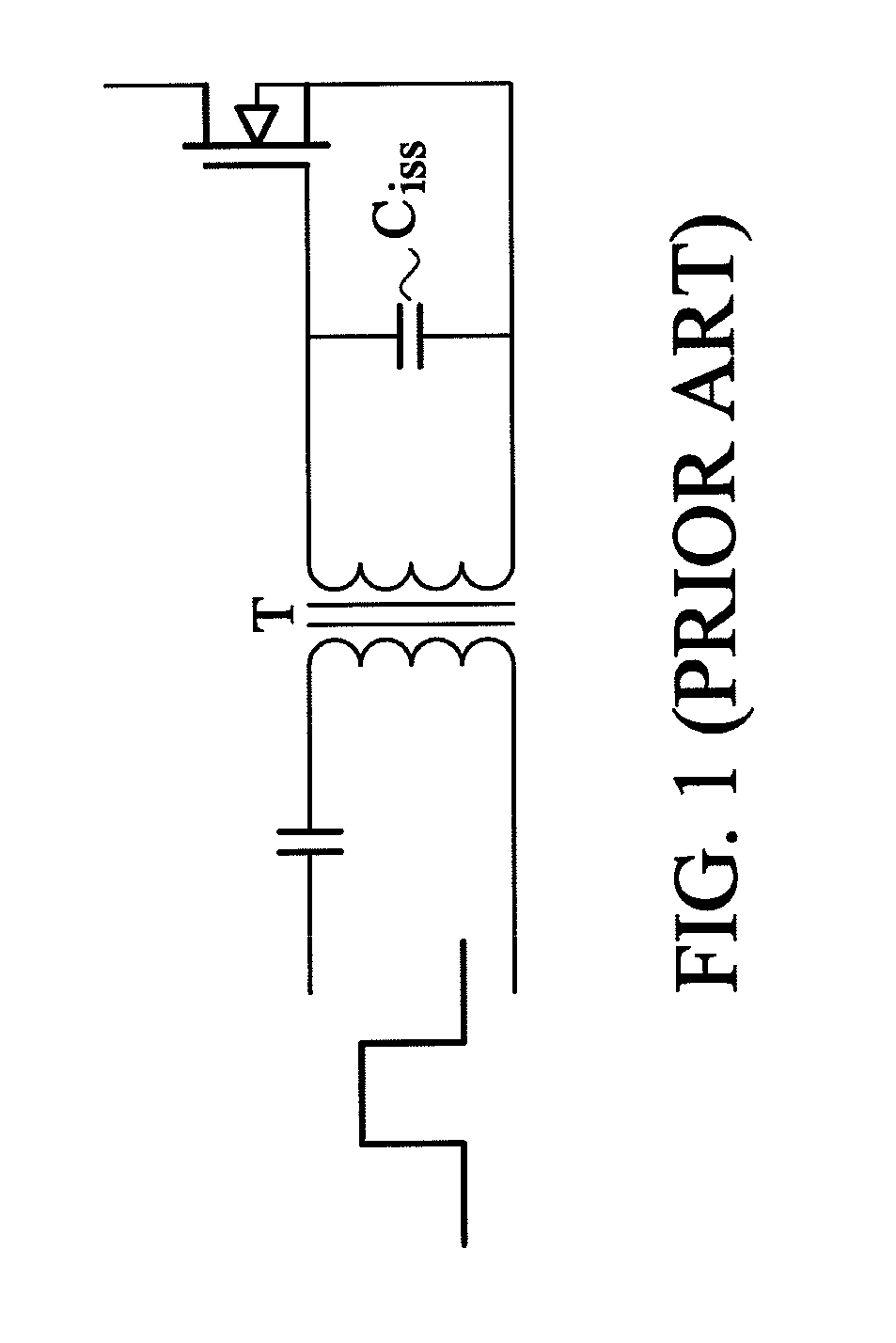

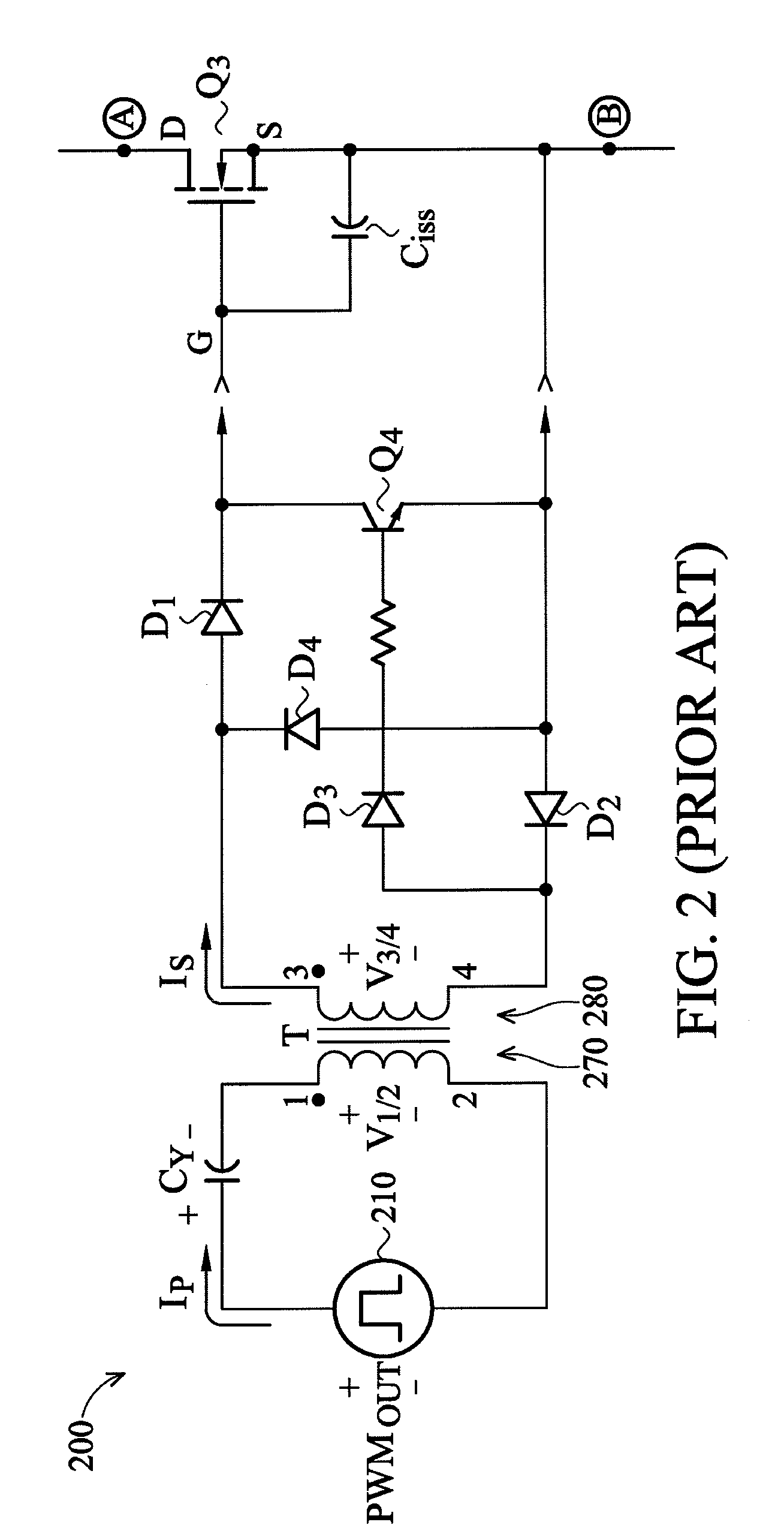

Driver for driving power switch element

ActiveUS8680837B2Reduce widthSmall sizeDc network circuit arrangementsElectronic switchingPower switchingTransformer

A driver for driving a driving element includes: a signal source, for providing a square signal; a first modulation circuit, for providing on-pulses and off-pulses according to edges of the square signal; a transformer for coupling output signals of the first modulation circuit to a secondary winding of the transformer to form coupled signals; a second modulation circuit for providing first operating pulses according to coupled on-pulses of the coupled signals, and providing second operating pulses according to coupled off-pulses of the coupled signals; a switch device for turning off the switch device according to the first operating pulses and turning on the switch device according to the second operating pulses, and when the switch device is turned off, coupled on-pulses charge an equivalent capacitor of the driving element to a first driving potential to turn on the driving element, and when the switch device is turned off, the equivalent capacitor discharges to a second driving potential to turn off the driving element, and the width of the on-pulses is less than 1000 ns.

Owner:DELTA ELECTRONICS INC

Self-opening velocity type hydraulic energy absorption and consumption device

ActiveCN105951581AReduce frictionReduce the impact of navigationBridge structural detailsEnergy absorptionHanging basket

The invention discloses a self-opening velocity type hydraulic energy absorption and consumption device. The self-opening velocity type hydraulic energy absorption and consumption device mainly comprises a steel box girder and a hanging basket, wherein the hanging basket is arranged in a square concave hole at the bottom of the steel box girder; the hanging basket comprises a hanging basket bottom plate and peripheral side walls; the hanging basket bottom plate is provided with a plurality of water through holes; a cover plate is hinged above the water through holes; one rope is connected with each of four corners at the upper part of the hanging basket; after the four ropes are bound together, the four ropes are connected with a hanging rope; the other end of the hanging rope is wound on one side of a rotary barrel; the rotary barrel is fixedly arranged on a top plate of the steel box girder; a pressing device and a friction sheet are mounted above the rotary barrel; a horizontal supporting plate is arranged at each of four corners of the bottom of the square concave hole; a vertical baffle is arranged on each horizontal supporting plate; the vertical baffles are connected with a side plate at the bottom of the square concave hole through limiting springs; and the four corners of the hanging basket bottom plate are supported on the four horizontal supporting plates at the bottom of the square concave hole through round balls. An energy consumption device can be automatically opened when a bridge starts to vibrate, and the vibration of the bridge is inhibited through hydraulic energy consumption.

Owner:HUNAN UNIV OF SCI & TECH

Environment-friendly smashing device with quantitative discharging function

InactiveCN106423387AGood crushing effectSpeed up the fallUsing liquid separation agentGrain treatmentsEnergy consumptionMechanical engineering

The invention discloses an environment-friendly smashing device with a quantitative discharging function. The environment-friendly smashing device comprises a device body. A silencing layer is arranged on the outer wall of the device body. A feed hopper is arranged on the upper side of the device body. A first rotary shaft is arranged on the upper side of the inside of the device body. A first squeeze roller is arranged on the outer wall of the first rotary shaft. A second rotary shaft is arranged below the first rotary shaft. A second squeeze roller is arranged on the outer wall of the second rotary shaft and arranged parallel to the first squeeze roller. Smashing teeth are arranged on the outer walls of the first squeeze roller and the second squeeze roller. According to the environment-friendly smashing device with the quantitative discharging function, the smashing teeth on the two squeeze rollers arranged vertically are engaged to smash materials, and the smashing effect is good; the two squeeze rollers are driven by one motor, so that the energy consumption is lowered; water mist can be sprayed into the device body through an atomizing device, the water mist fully covers the materials, the materials are humidified while dust is reduced, and the quality of the materials is guaranteed; and in addition, automatic discharging can be achieved, the discharging quantity in the discharging process can be controlled, and quantitative discharging is achieved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

Agricultural wheat grain impurity removal device

The invention discloses an agricultural wheat grain impurity removal device. The device comprises a box body, wherein a feed hopper is fixedly arranged at the top end of the box body; two first fixedseats and two second fixed seats are fixedly arranged in the box body; a first screen plate is arranged between the two first fixed seats in a sliding mode; a first screen mesh is fixedly arranged onthe first screen plate; a second screen plate is arranged between the two second fixed seats in a sliding mode; a second screen mesh is fixedly arranged on the second screen plate; two ends of the bottom surface of the first screen plate are fixedly connected with first chock blocks; two ends of the top surface of the second screen plate are fixedly connected with second chock blocks; a horizontalrotating shaft is arranged between the first screen plate and the second screen plate; the rotating shaft is fixedly connected with two cams; and a driving motor is fixedly arranged at one side of the exterior of the box body. The driving motor is adopted to drive the cams to rotate so as to enable the first screen mesh and the second screen mesh to shake up and down, thereby increasing the wheatgrain impurity removal speed and efficiency; and by arranging a fan, impurities in wheat grains can be separated more perfectly.

Owner:朱明新

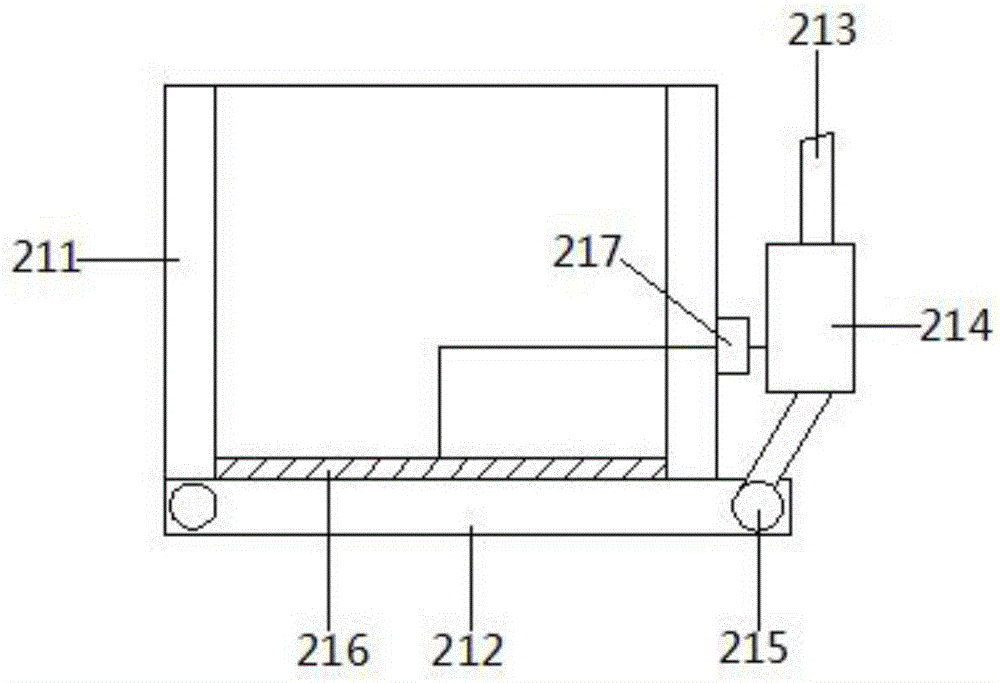

Medical medicine residue packing equipment

InactiveCN108945541ASpeed up the fallImprove work efficiencySolid materialPackaging machinesMedicineMobile device

The invention relates to packing equipment, in particular to medical medicine residue packing equipment. The technical effect of providing the medical medicine residue packing equipment having advantages that the efficiency of packing medicine residues is high, and clothes of people cannot be polluted in the packing process of the medicine residues is aimed to be achieved. According to the technical scheme, the medical medicine residue packing equipment comprises a bottom plate, a first sliding rail, first sliding blocks, placing frames, a connecting rod, a frame body, a nail, a support, a supporting plate, a material storage frame, a discharging hopper, an L-shaped supporting rod and the like; the first sliding rail is embedded on the right portion of the upper side of the bottom plate, the two first sliding blocks are arranged on the first sliding rail in a sliding mode, the placing frames are arranged on the tops of the first sliding blocks on the left side and the right side, the connecting rod is connected between the placing frames on the left side and the right side. According to the equipment, the effects that the efficiency of packing the medicine residues is high, and theclothes of people cannot be polluted in the packing process of the medicine residues are achieved; and due to the arrangement of a mobile device, a baffle and the frame body can automatically, synchronously and reversely move, then automatic falling and automatic falling pause of the medicine residues can be realized, and the packing efficiency of the medicine residues can be improved.

Owner:李春明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com