Patents

Literature

110results about How to "Eliminate phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

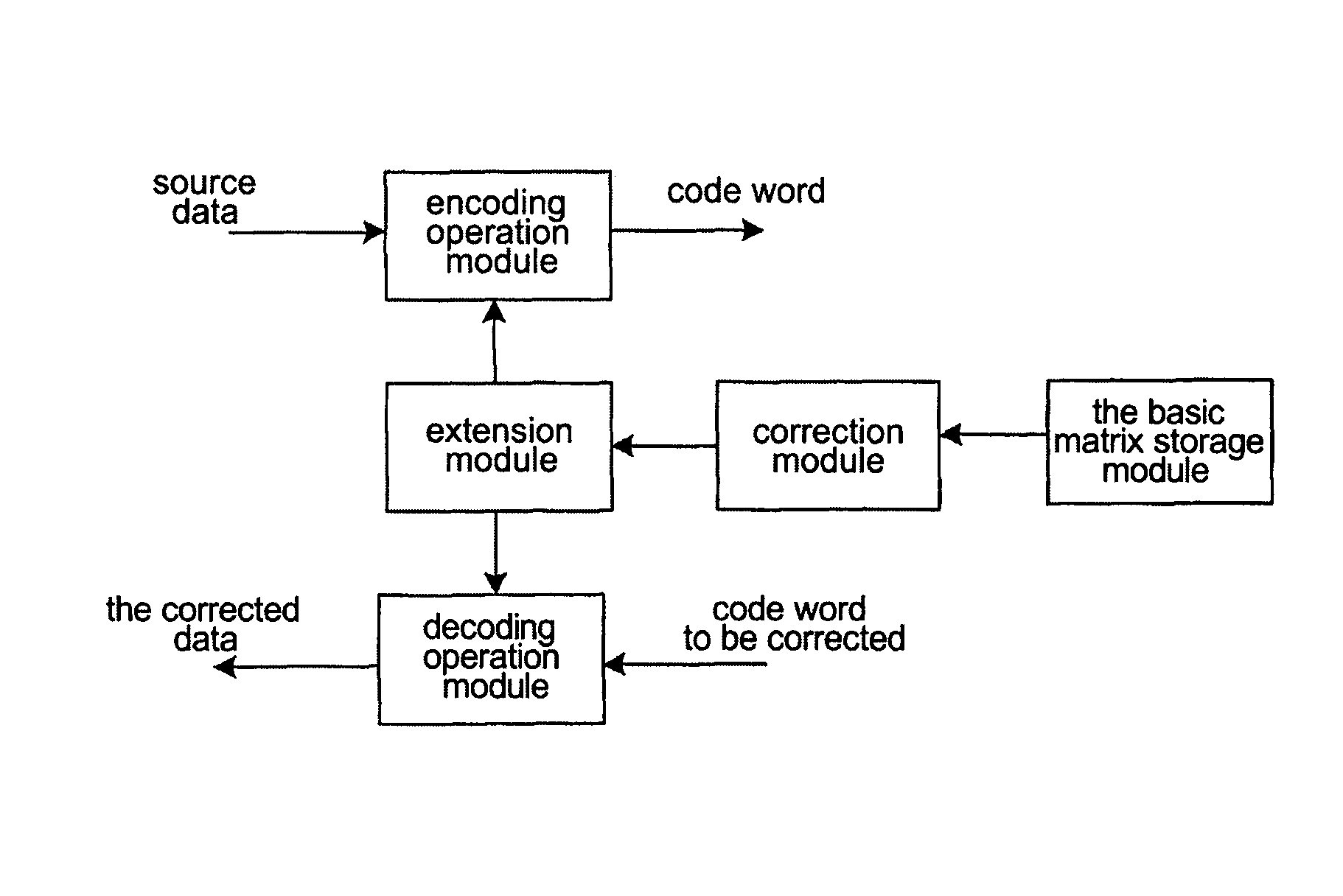

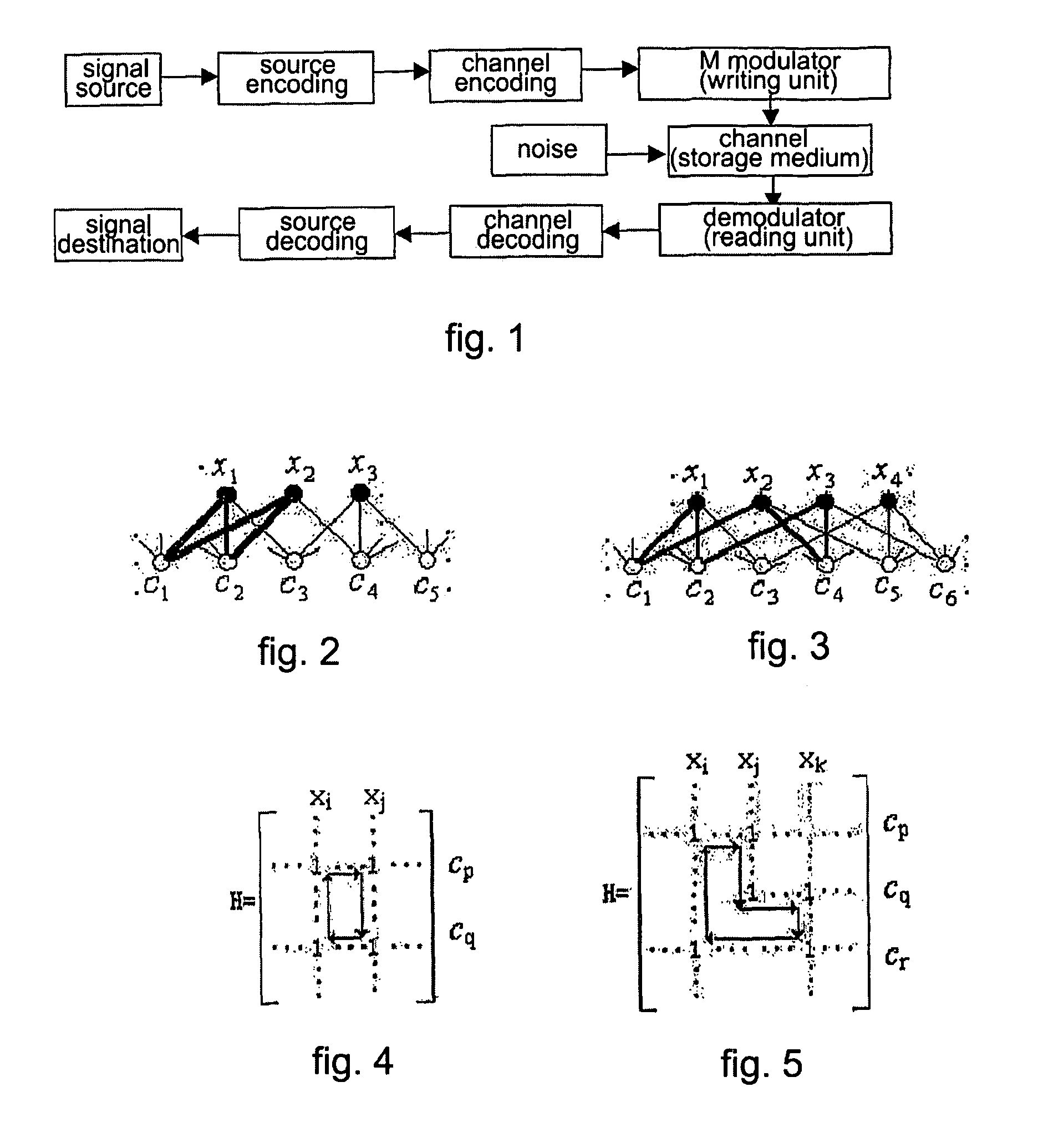

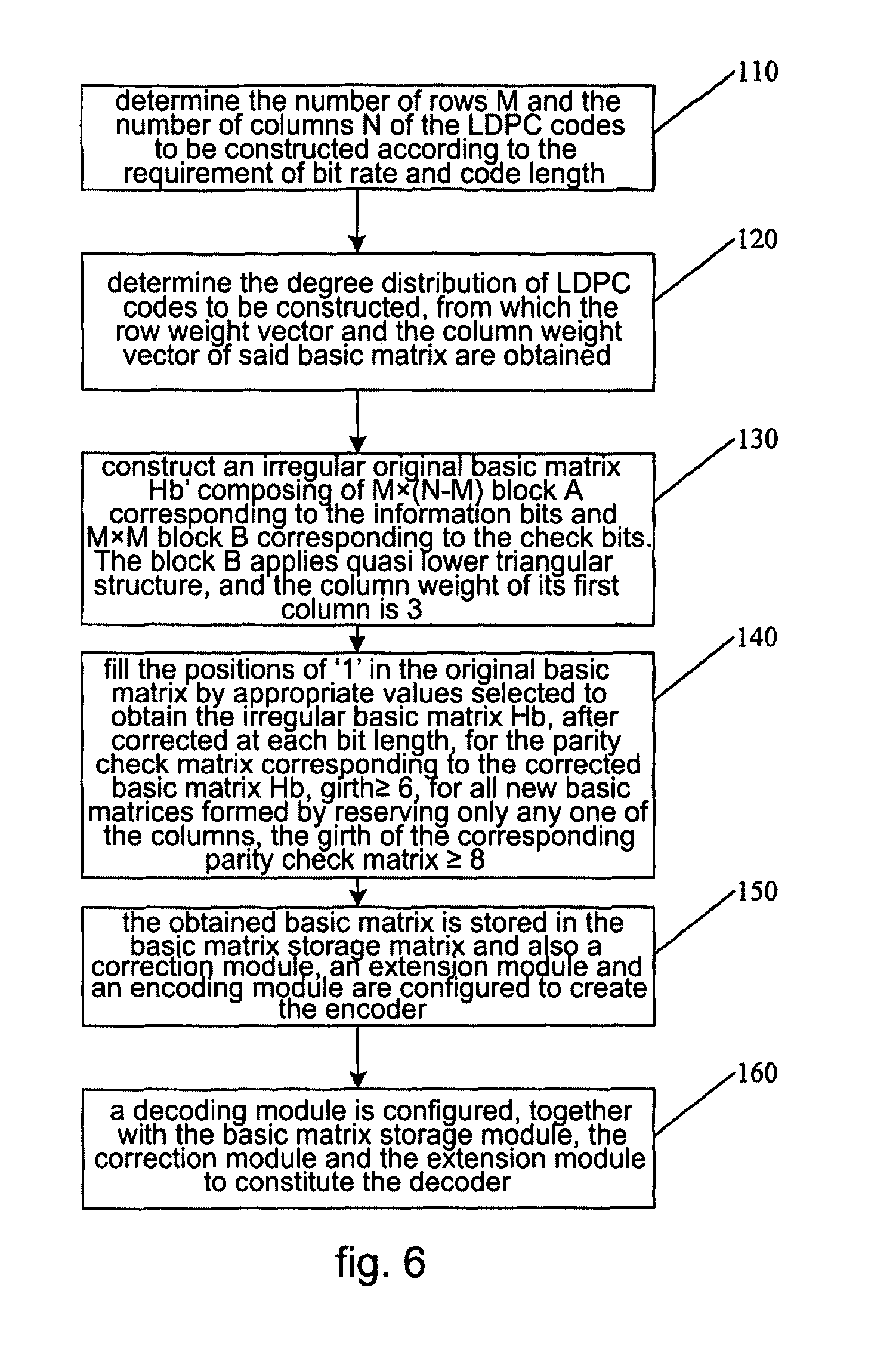

Basic Matrix Based on Irregular Ldpc, Codec and Generation Method Thereof

ActiveUS20080168324A1Eliminate phenomenonSpeed up the fallError detection/correctionParty-line systemsEssential matrixEuclidean vector

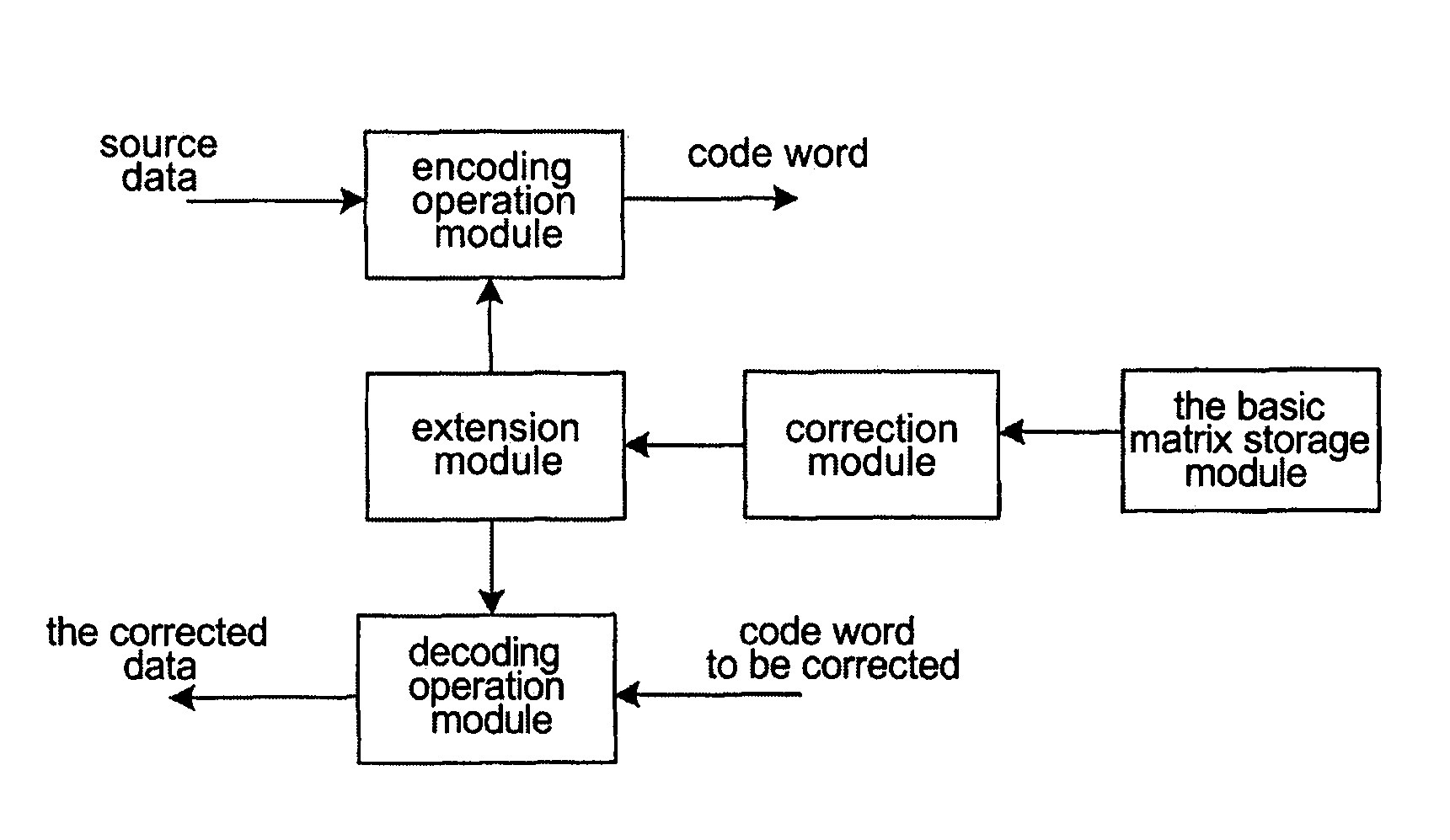

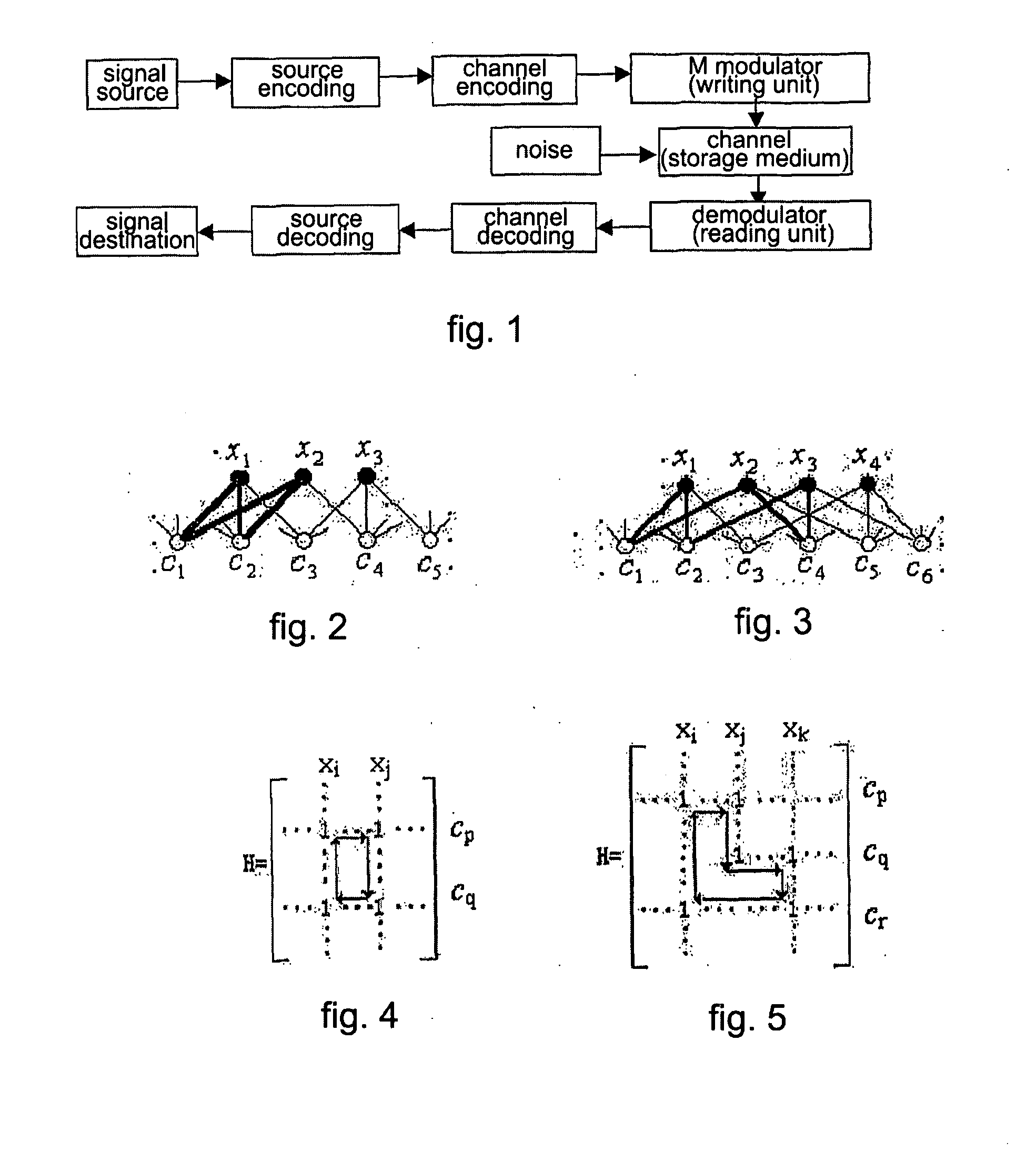

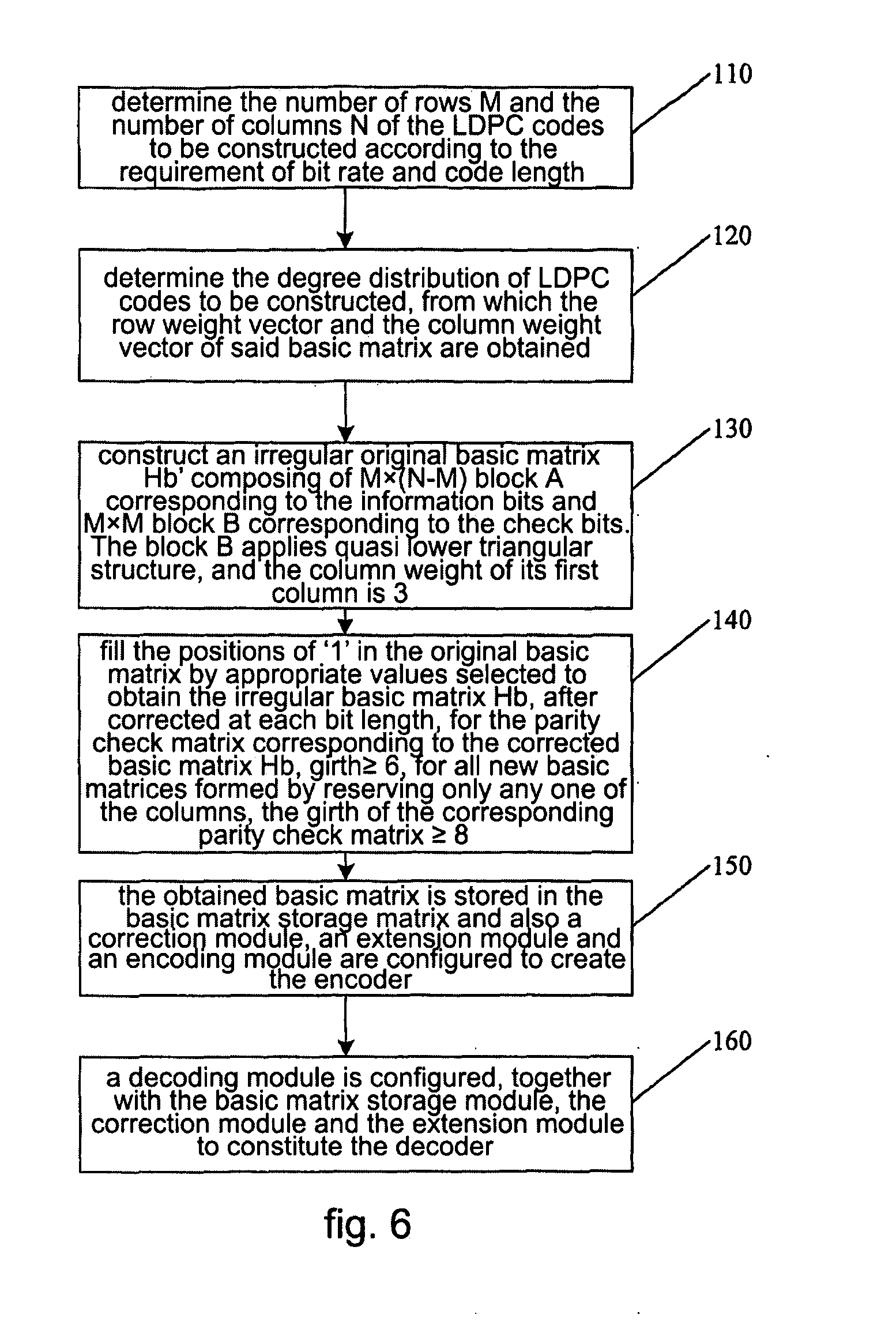

Basic matrix based on irregular LDPC codes, codec and generation method thereof. The codec includes an encoding / decoding operation module and a basic matrix storage module. In the stored basic matrix Hb, for all girths with length of 4, any element of i, j, k or l constituting the girths in anti-clockwise or clockwise always satisfies inequality: mod(i−j+k−l, z)≠0, wherein z is the extension factor. When generating the basic matrix, firstly the number of rows M, number of columns N, and weight vectors of the rows and columns are determined, an irregularly original basic matrix is constructed; then the position of ‘1’ is filled by a value chosen from set {0, 1, 2, . . . , z−1} to obtain the basic matrix Hb, which is made to satisfy the above-mentioned inequality. The basic matrix Hb obtained by storing, which is configured with corresponding encoding / decoding operation module, constitutes the desired encoder / decoder. The encoder / decoder according to the present invention can effectively eliminate error-floor phenomenon of LDPC codes and accelerate the falling speed of BER curve.

Owner:ZTE CORP

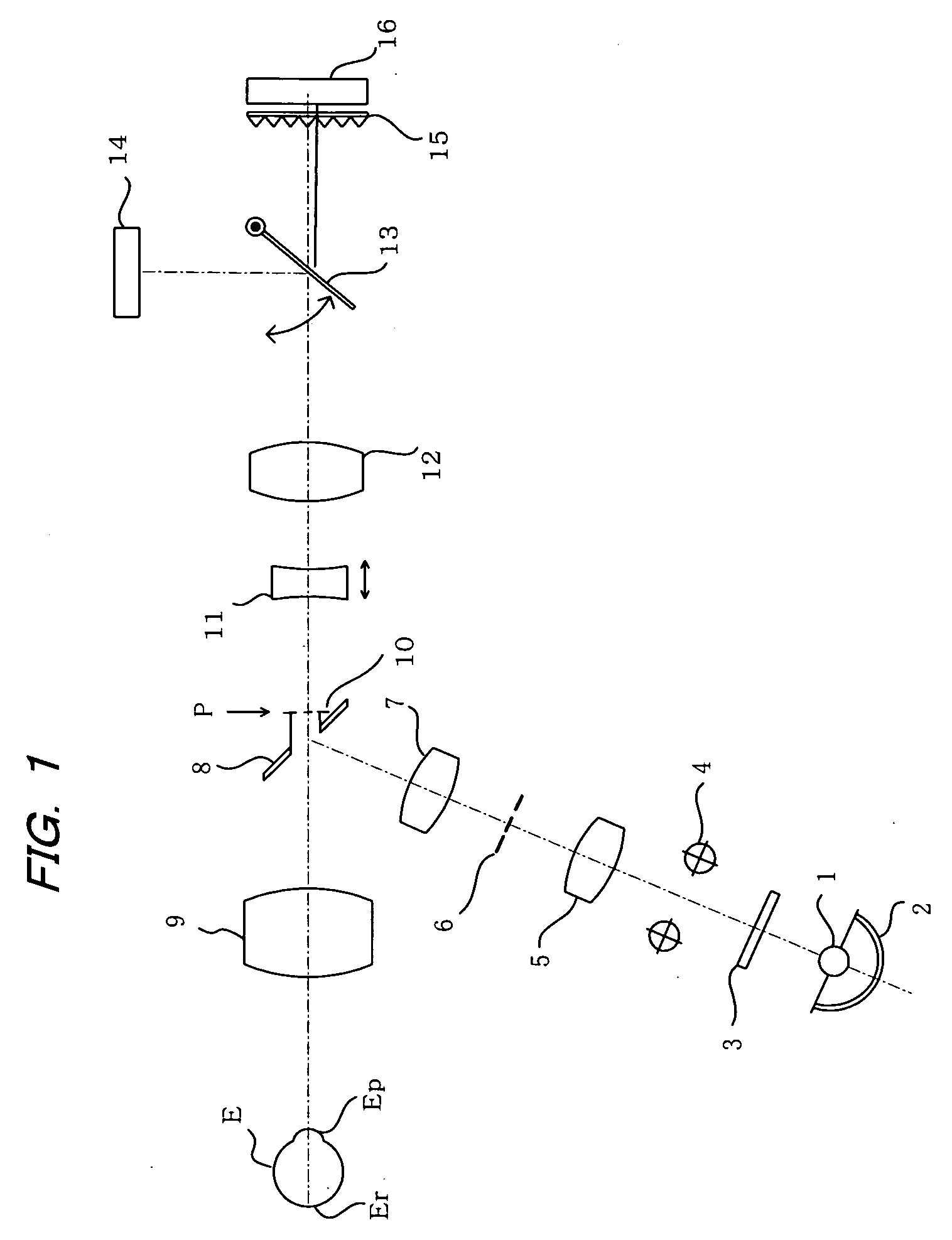

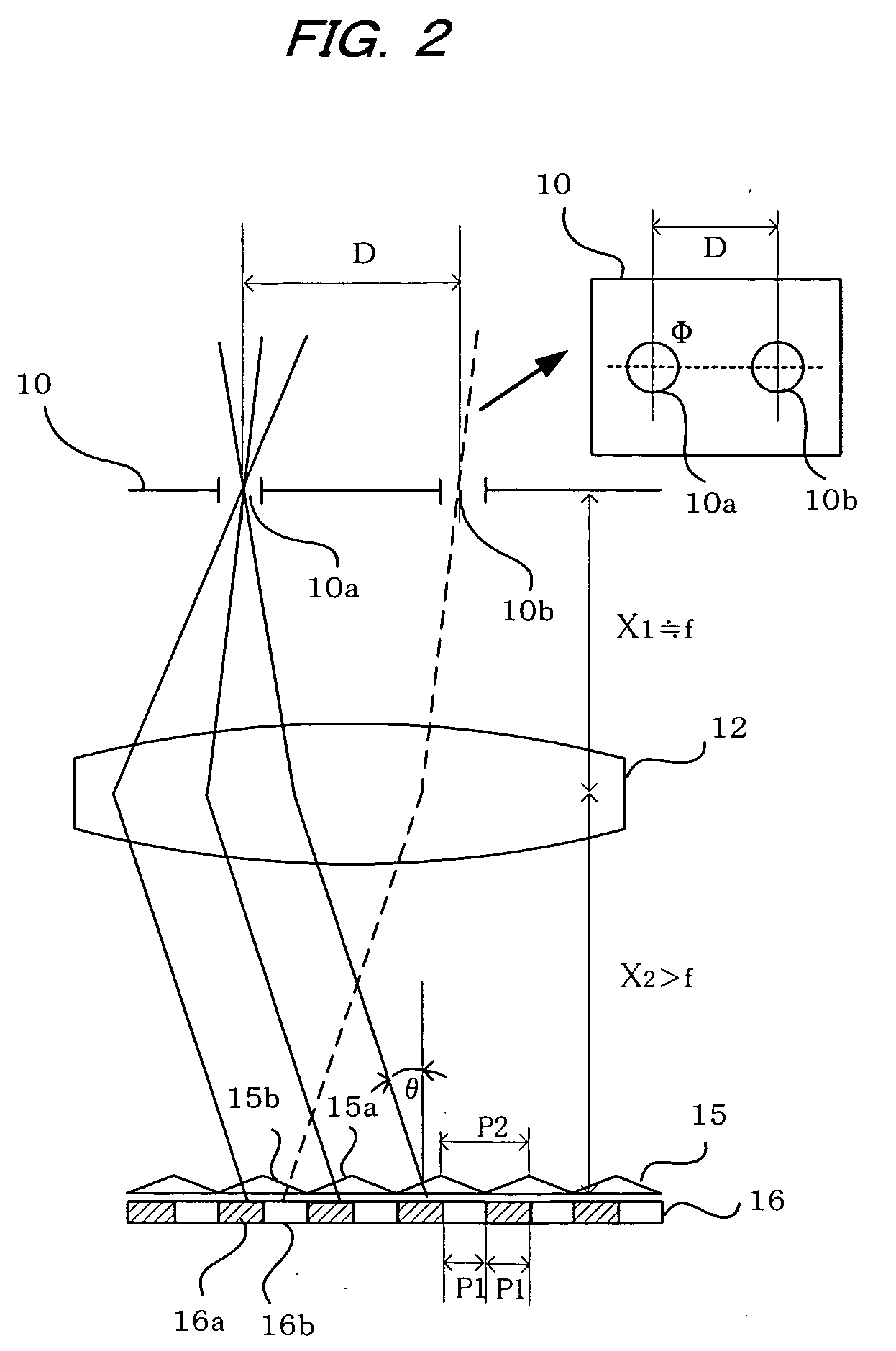

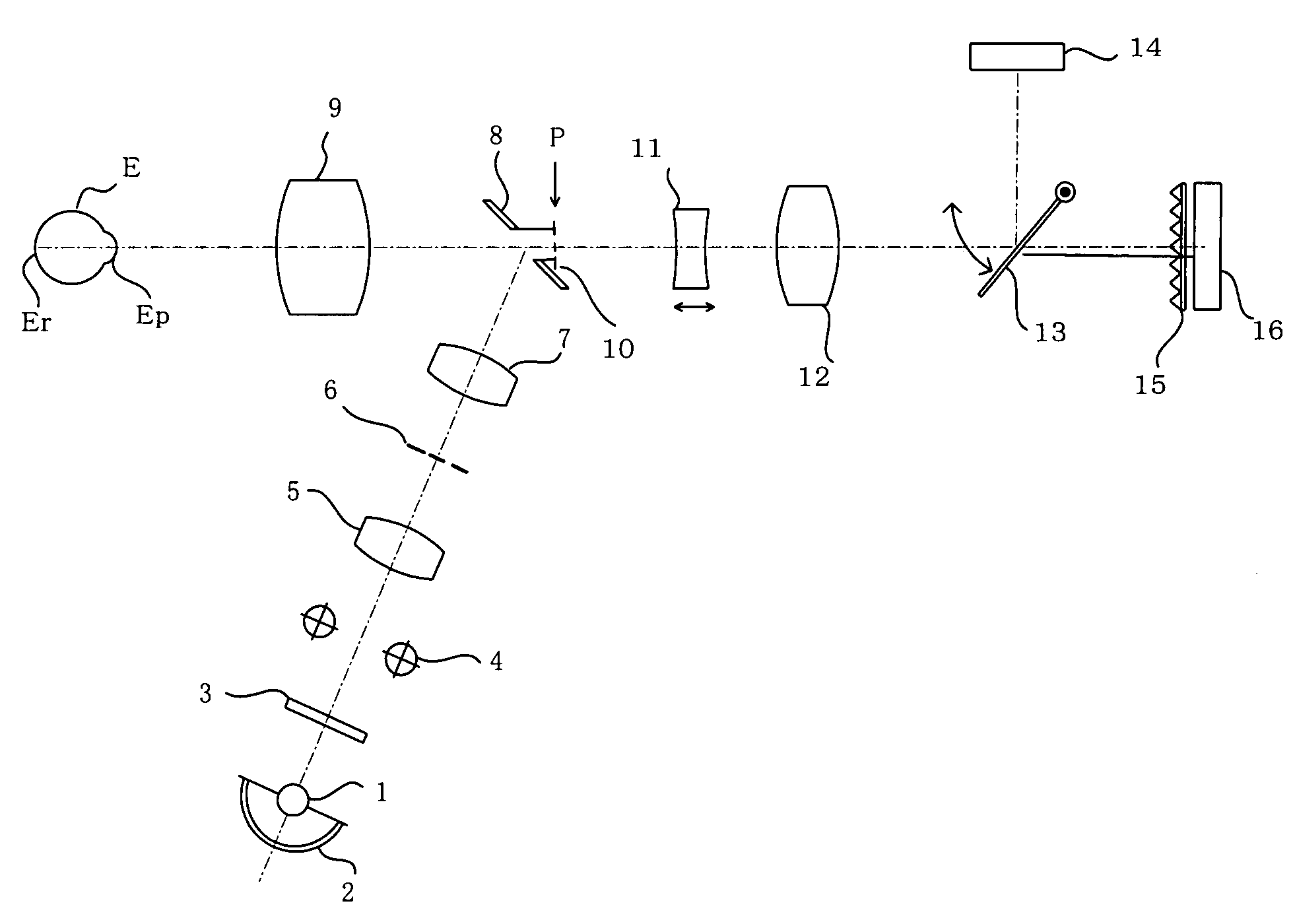

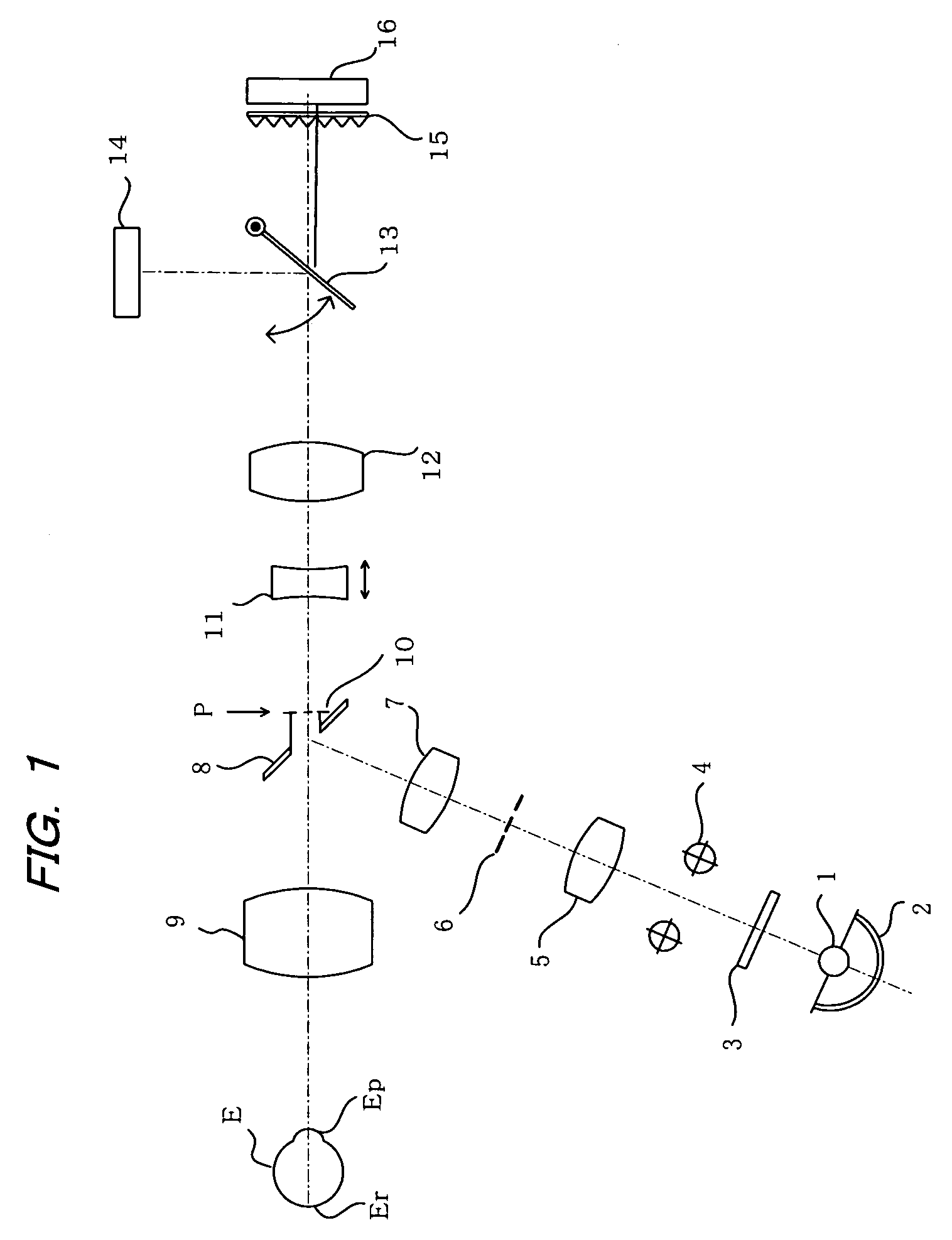

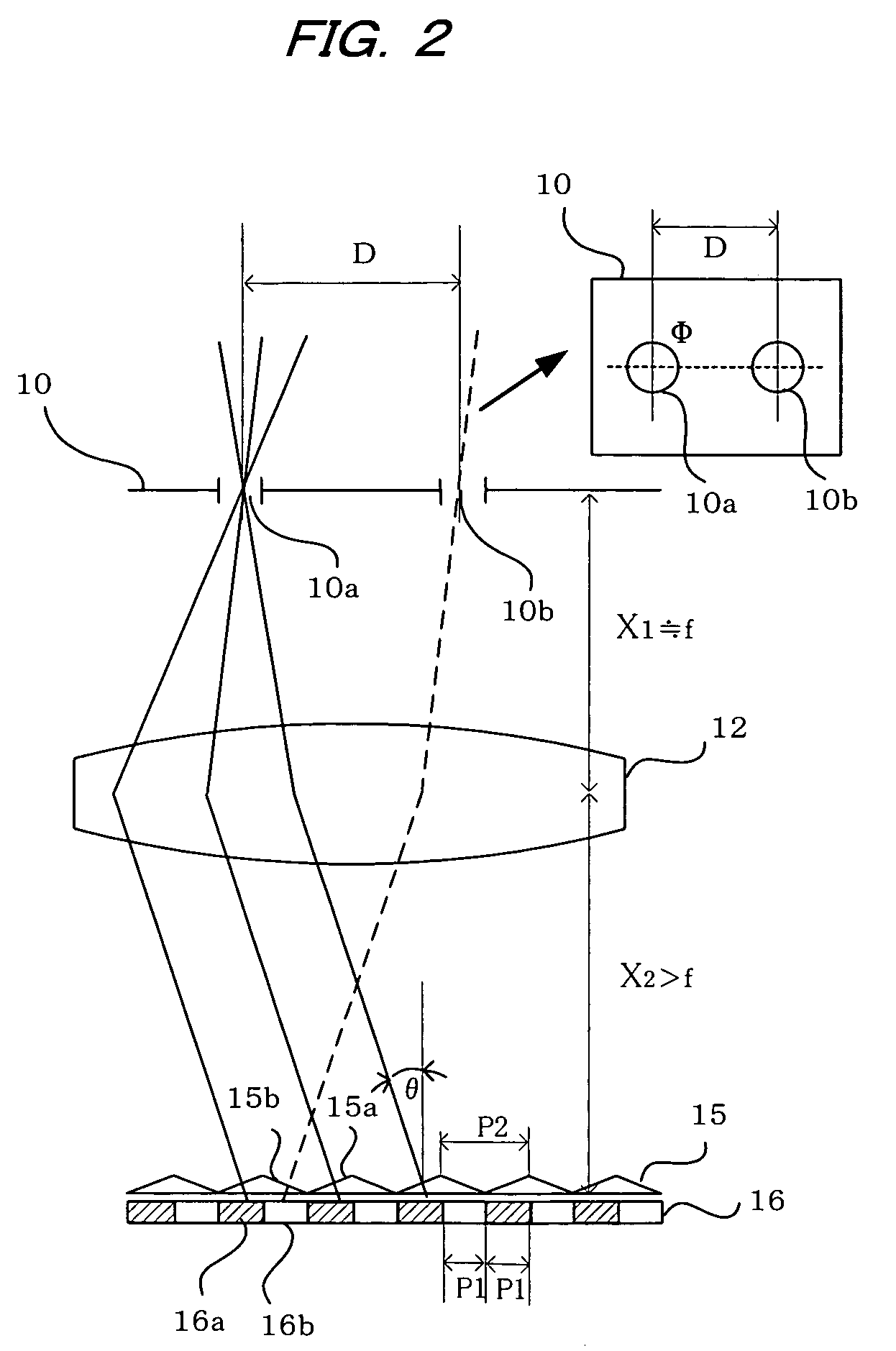

Ophthalmic photography apparatus

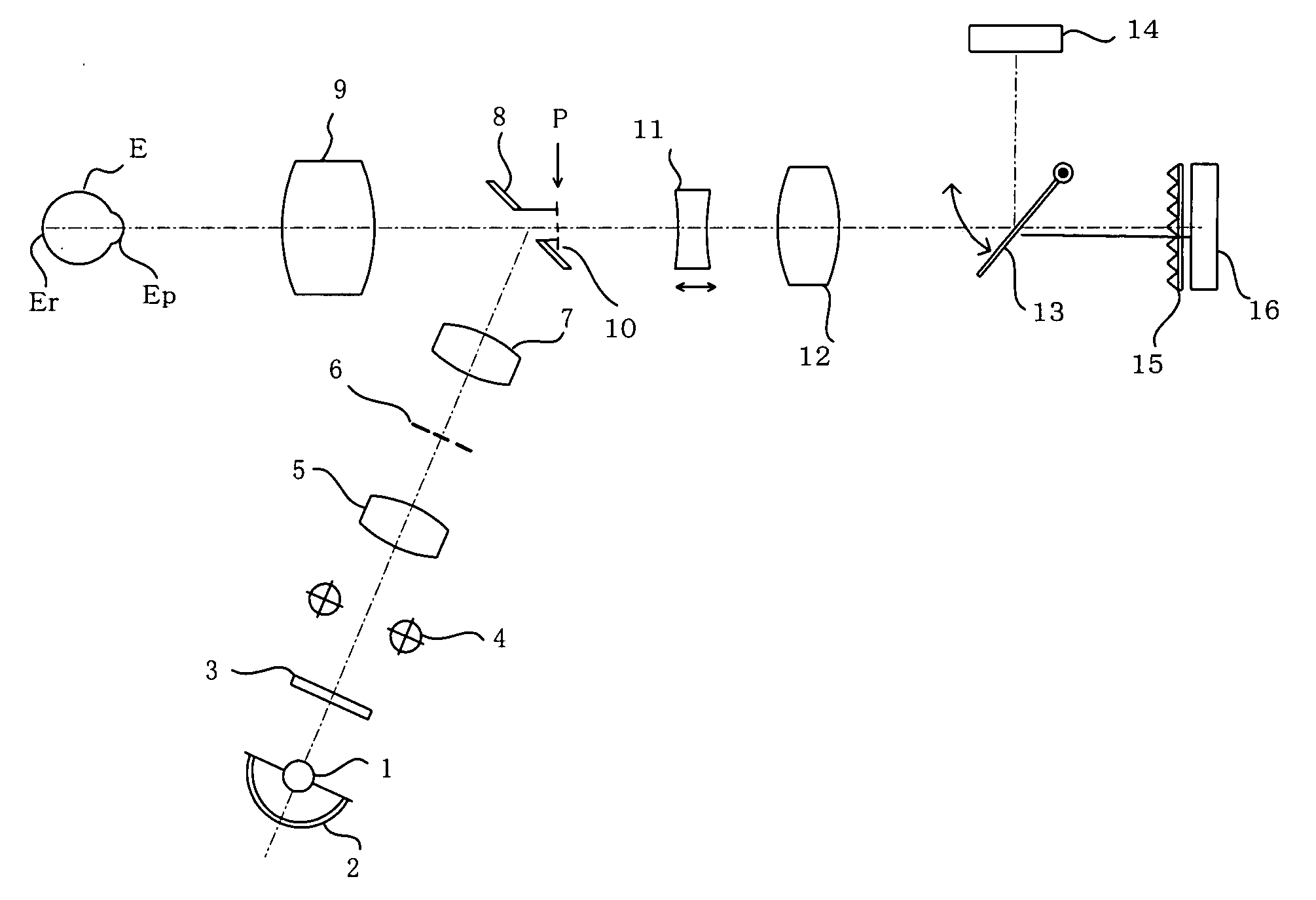

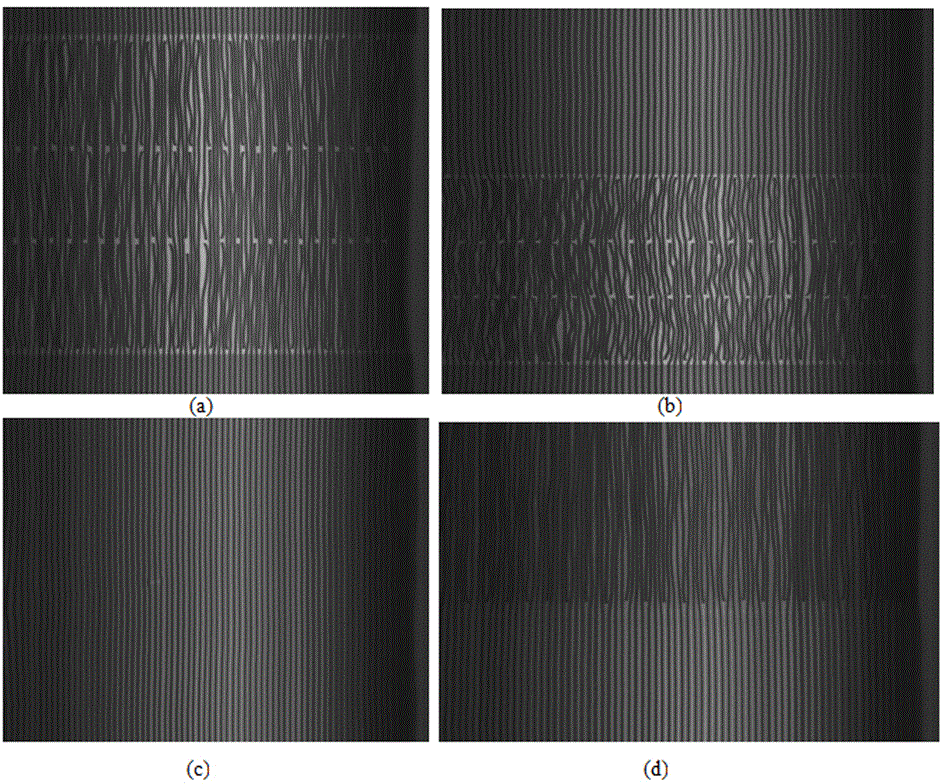

A photographic stop with two apertures is disposed at a position substantially conjugate to the anterior ocular segment of the eye being examined and at a position on the object-side focal surface of an image-forming lens. An eye fundus image is guided via a lattice barrier disposed on the image-side focal surface of the image-forming lens to an imaging CCD. The photographic stop, image-forming lens, lattice barrier and CCD are moved as a unit for focus adjustment. With such a configuration, the photographic stop is always positioned upon the object-side focal surface of the image-forming lens with the optical system kept telecentric even when the focus is adjusted to compensate for differences in diopter of the eye. This eliminates the phenomenon of a stereoscopic view that becomes more concave or convex the nearer to the periphery of the screen and provides good images of the fundus for stereoscopic viewing without any crosstalk of the left and right fundus images upon the image pickup surface.

Owner:KOWA CO LTD

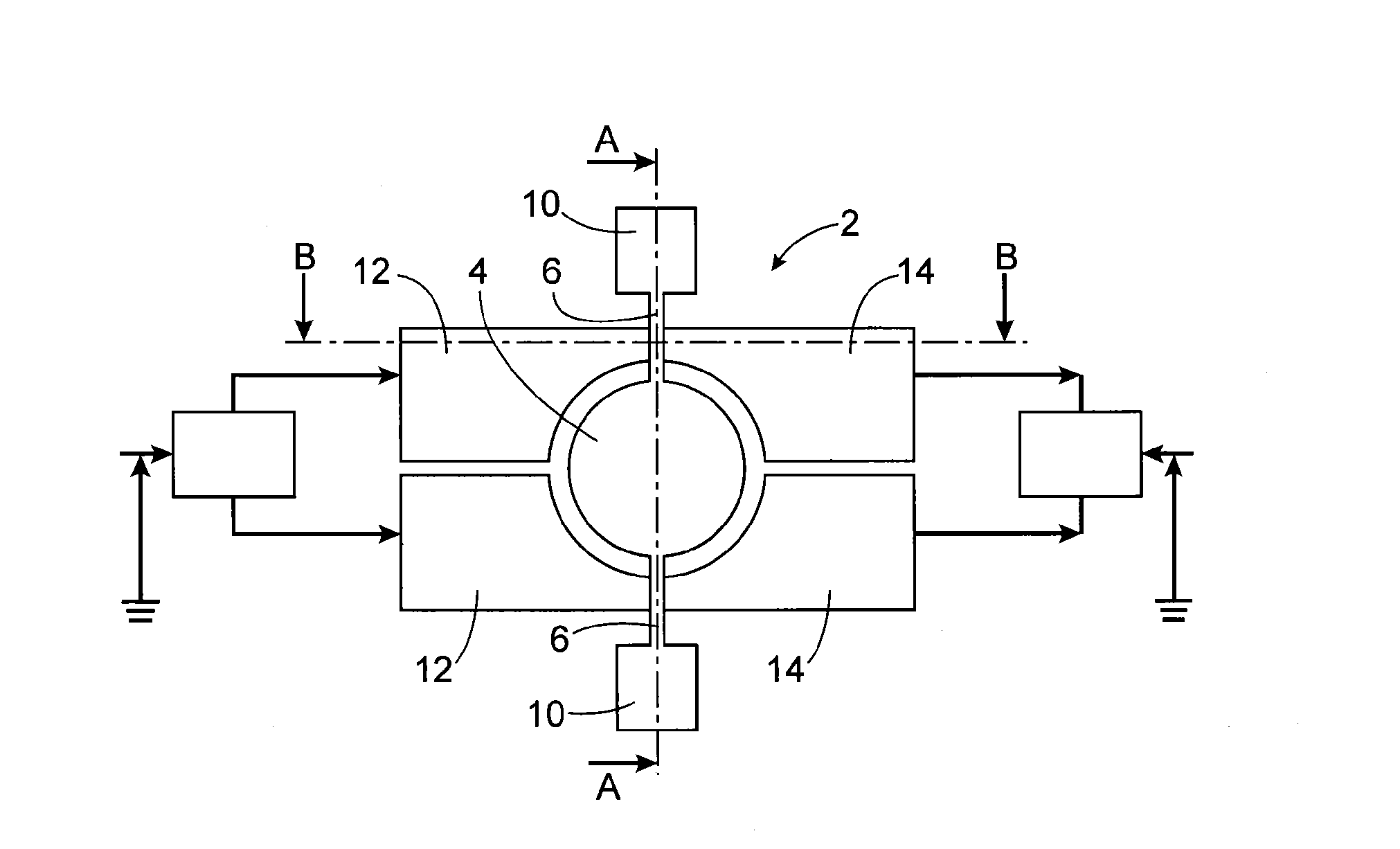

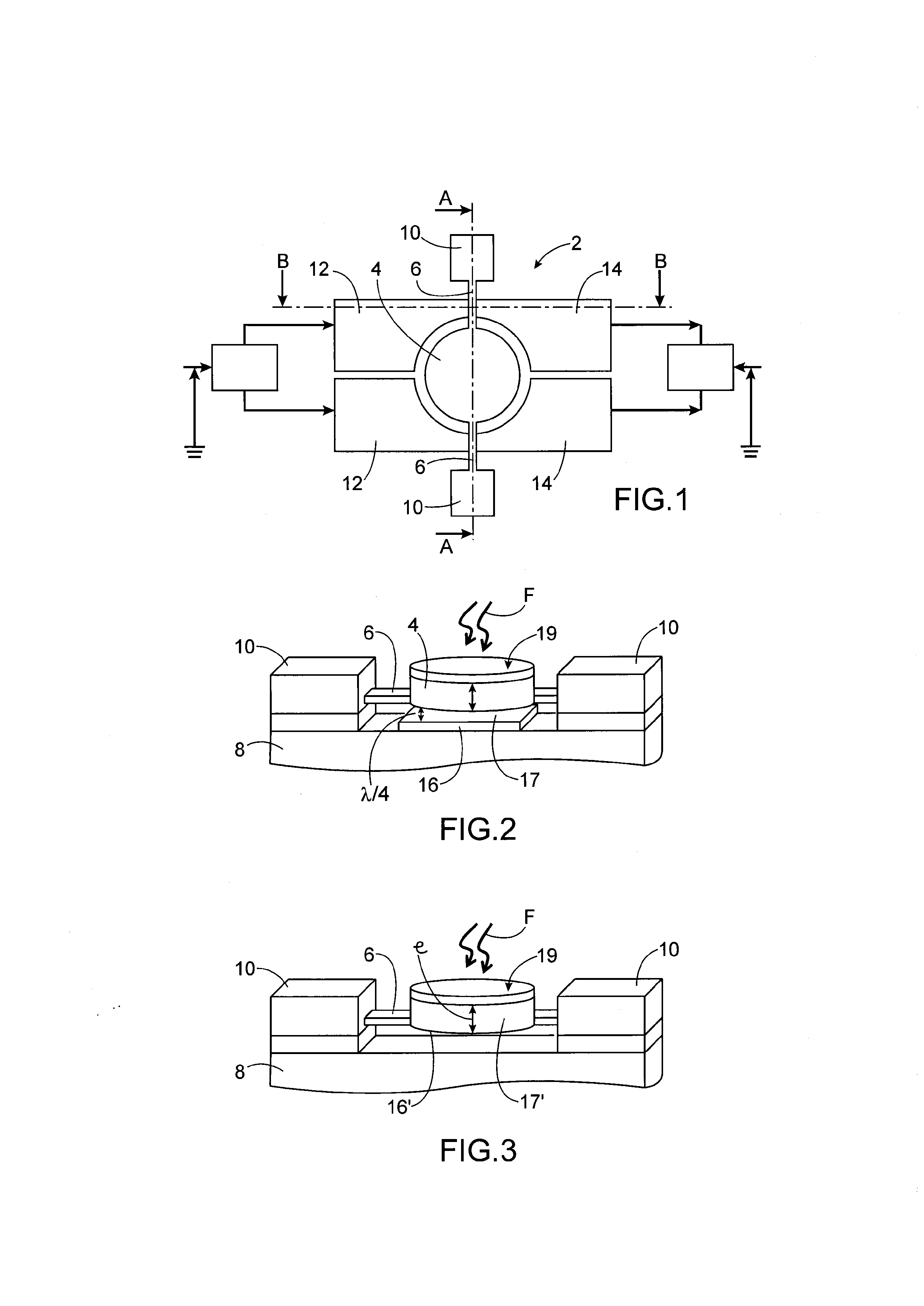

Bolometer having frequency detection

InactiveUS20130170517A1Avoid modificationEliminate phenomenonSolid-state devicesSemiconductor/solid-state device manufacturingClassical mechanicsFrequency detection

A bolometer including: at least one electromechanical microsystem or nanosystem, the microsystem or nanosystem including a support and a mobile mass hung from beams above the support, the mobile mass forming an absorber of optical flux; actuation electrodes configured to set the mobile mass in vibration and arranged laterally relative to the mobile mass; and detection electrodes to detect variation in vibration frequency of the mobile mass arranged laterally relative to the mobile mass.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

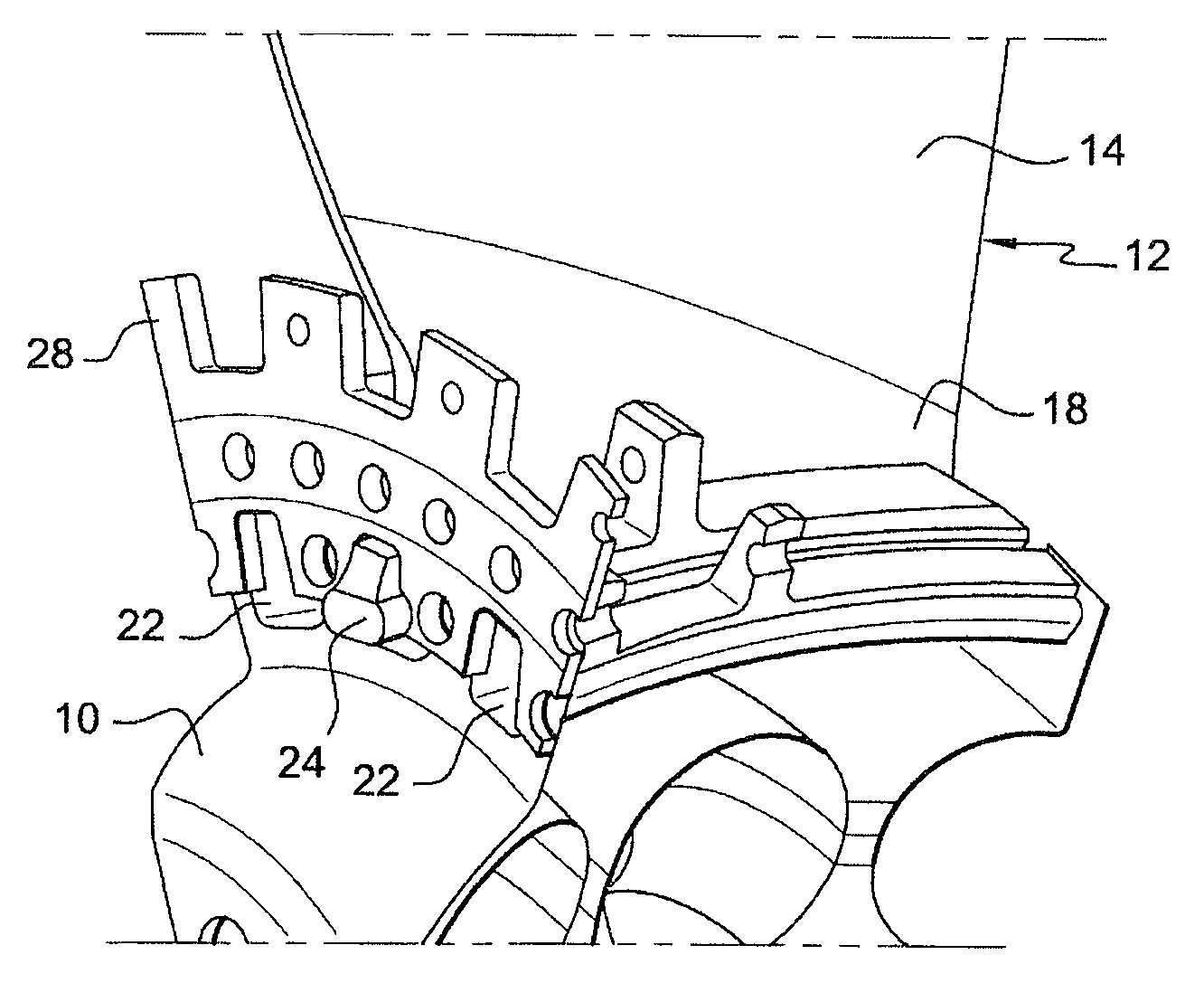

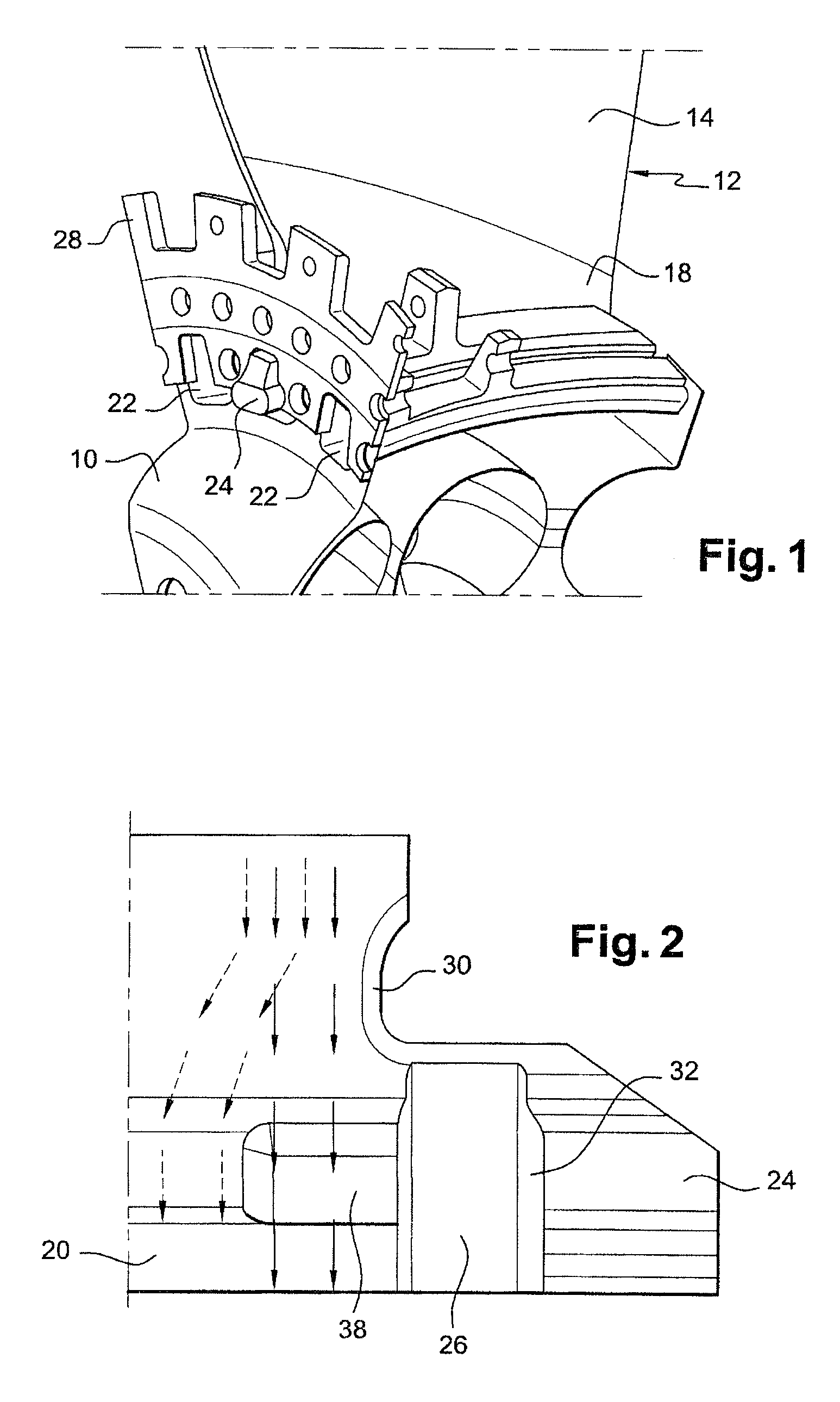

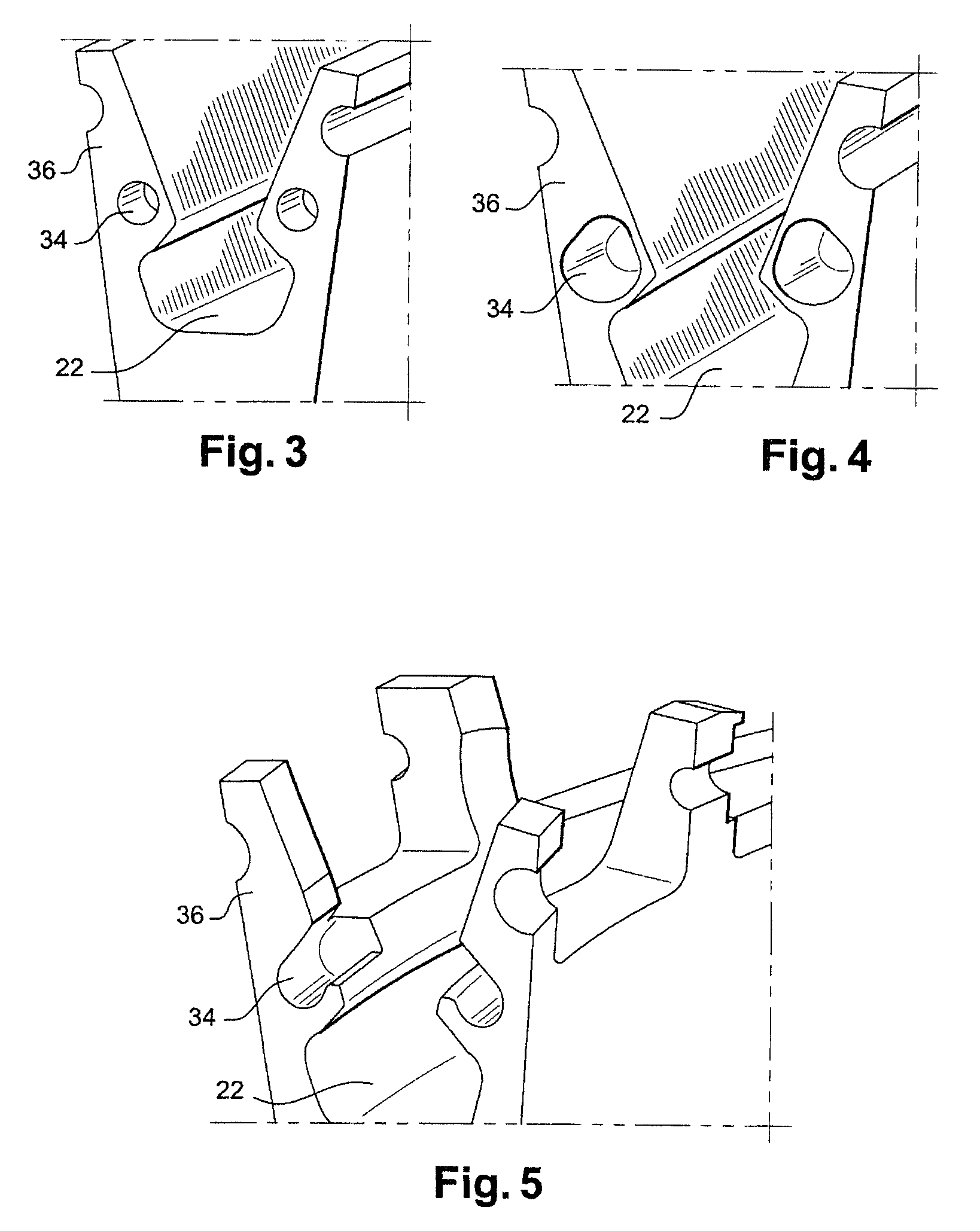

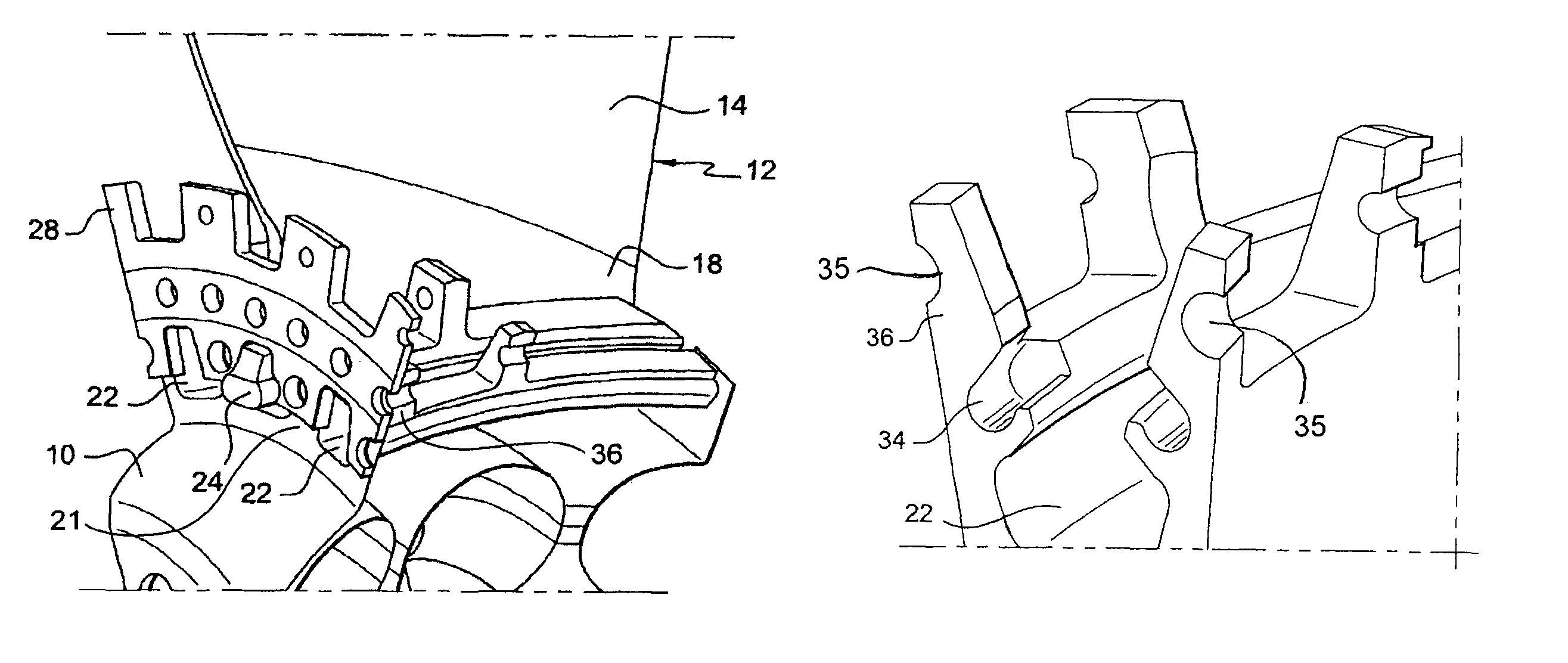

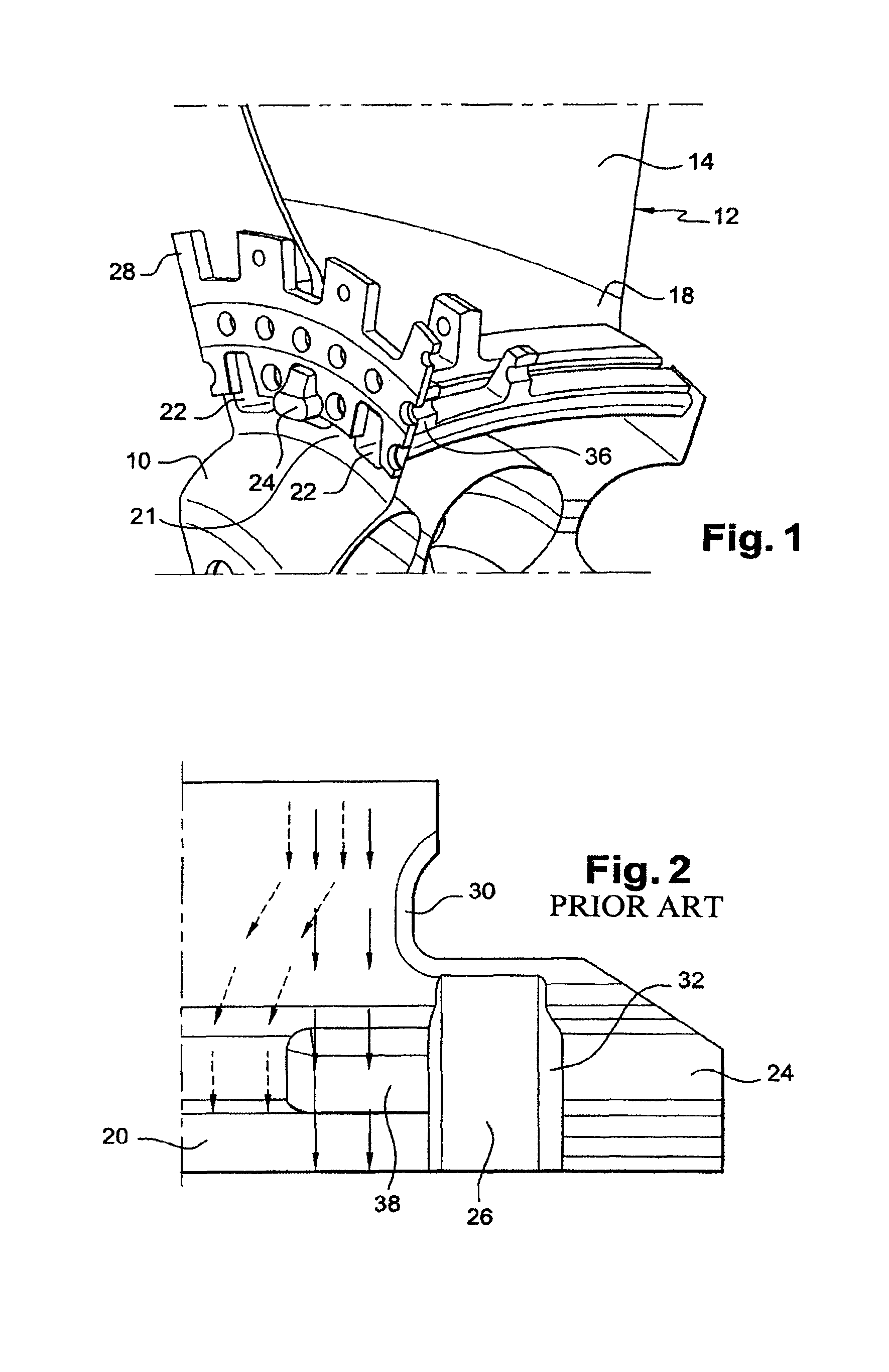

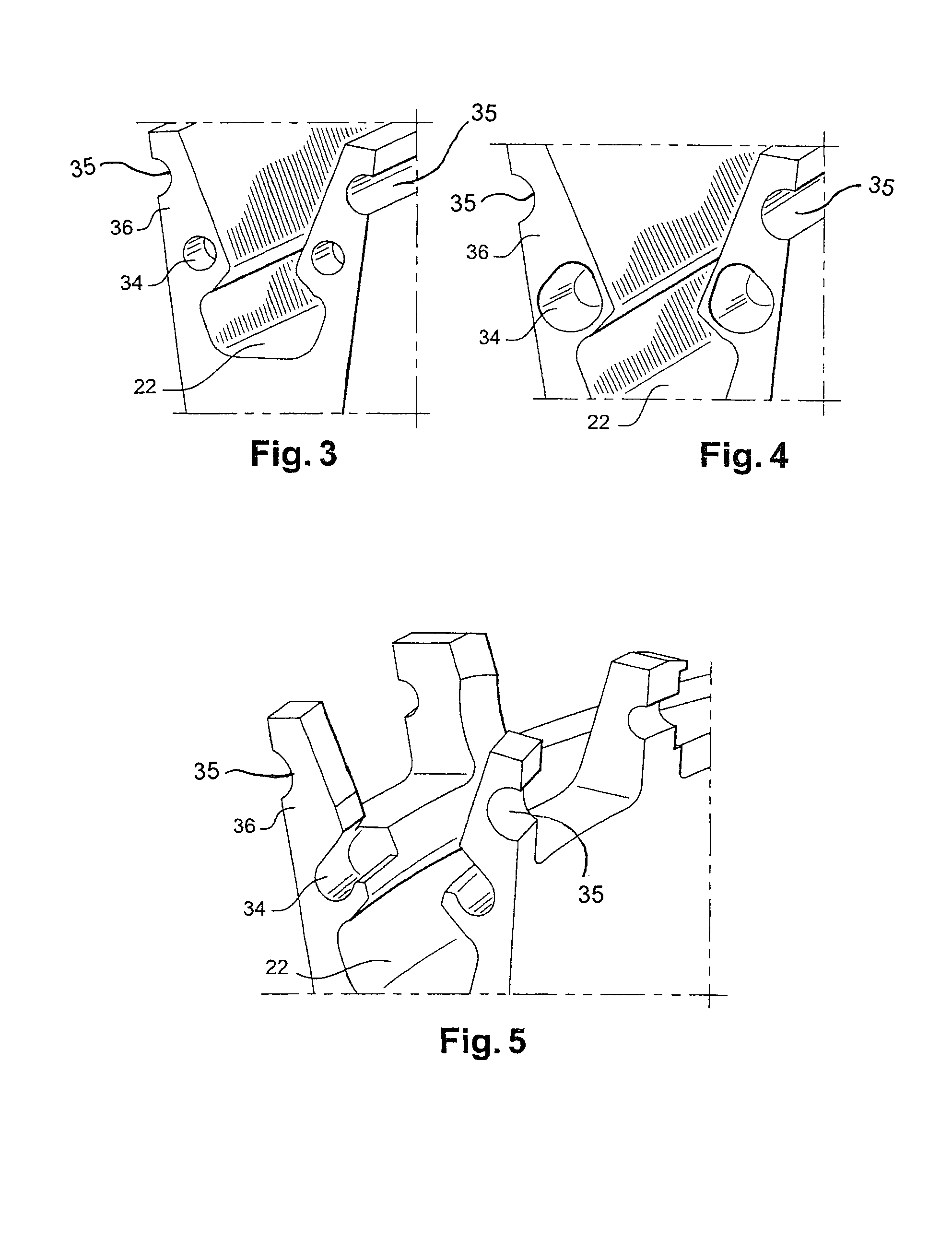

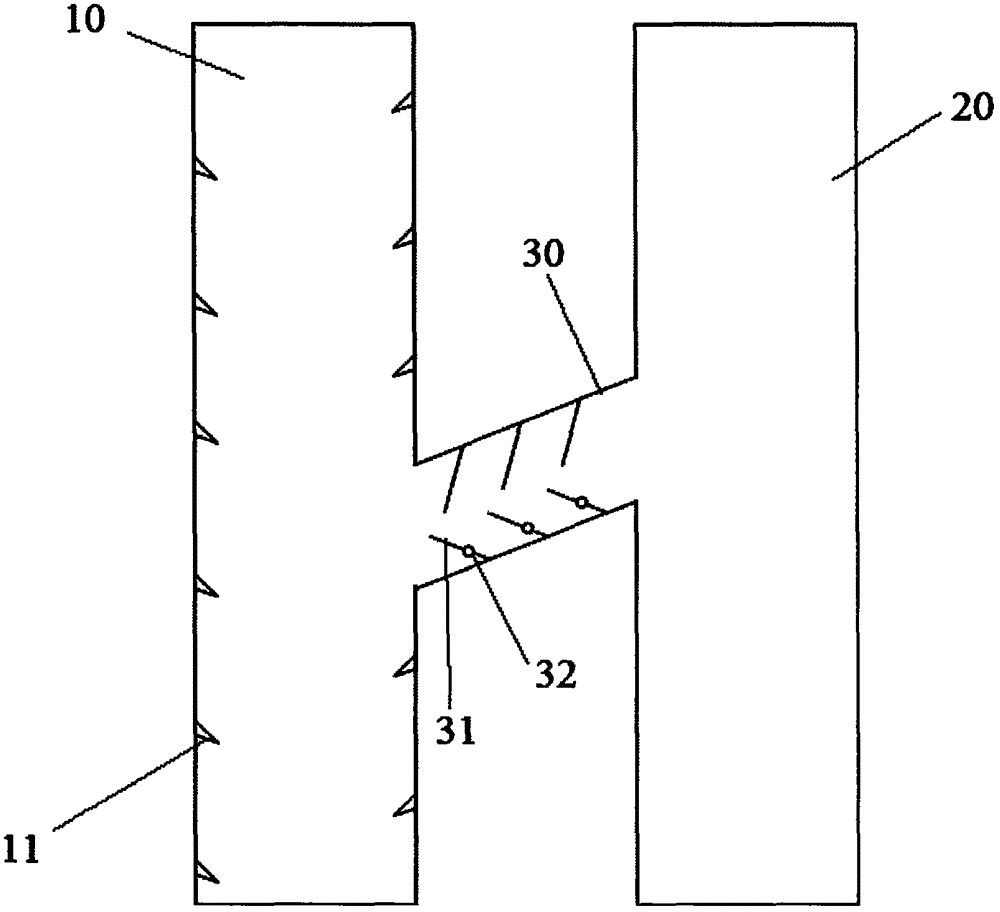

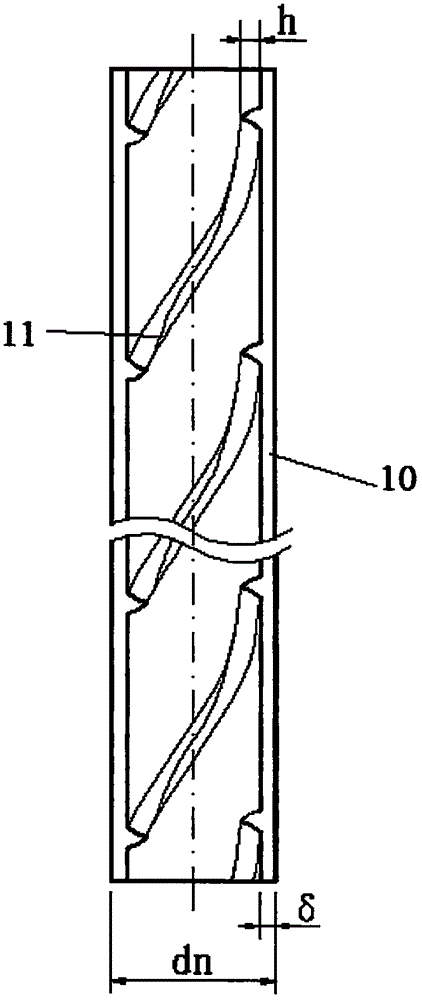

Rotor disk for turbomachine fan

A rotor disk (10) for a fan in a turbomachine, comprising in its perimeter a plurality of essentially axial grooves (22) for the installation and retention of vane roots (20) having hooks at their downstream ends, deformable regions formed by cavities (34) being situated at the downstream end of the grooves (22) in attachment flanges (36) for inter-vane platforms to absorb the stresses between the disk and the vane roots.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

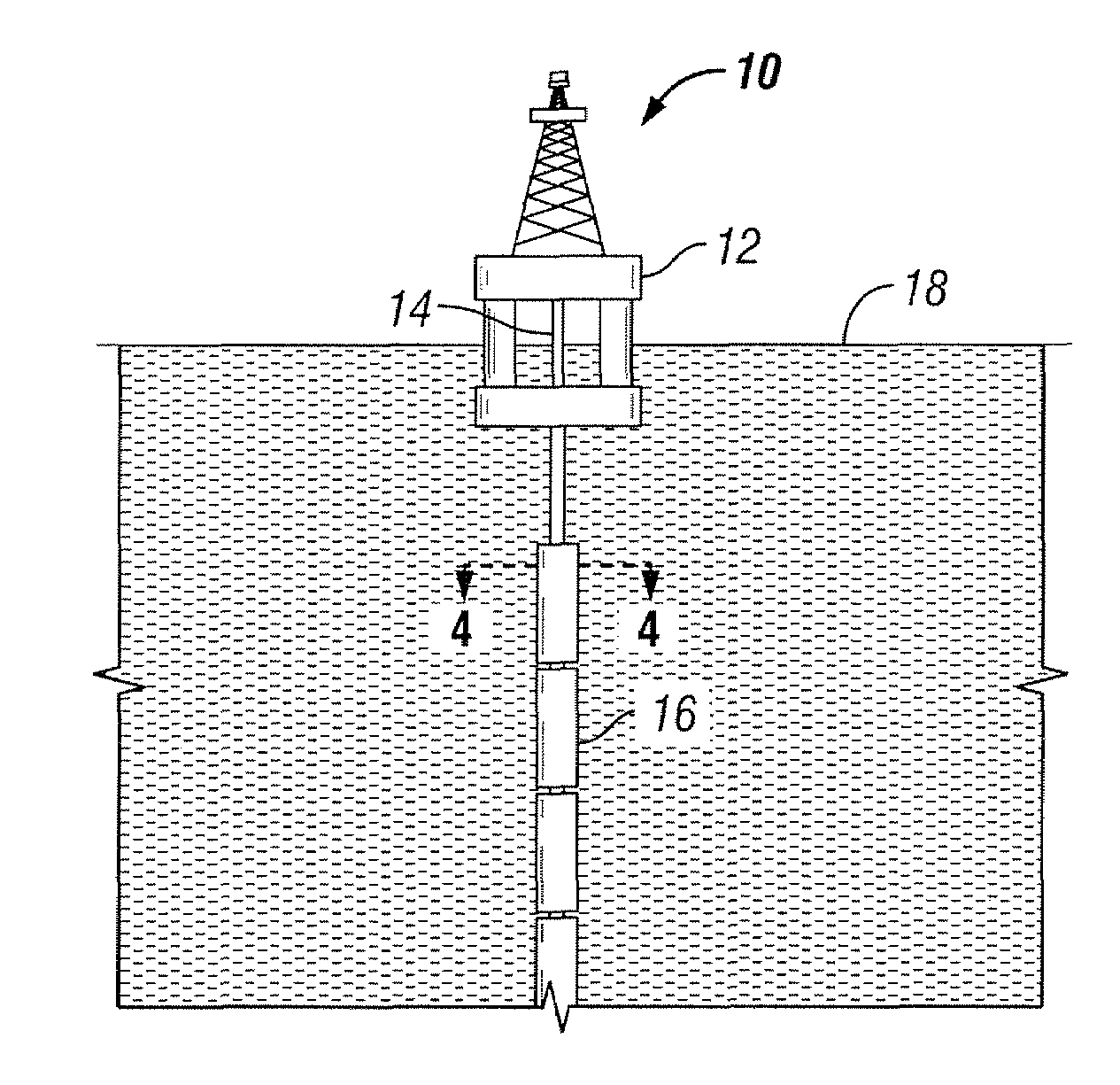

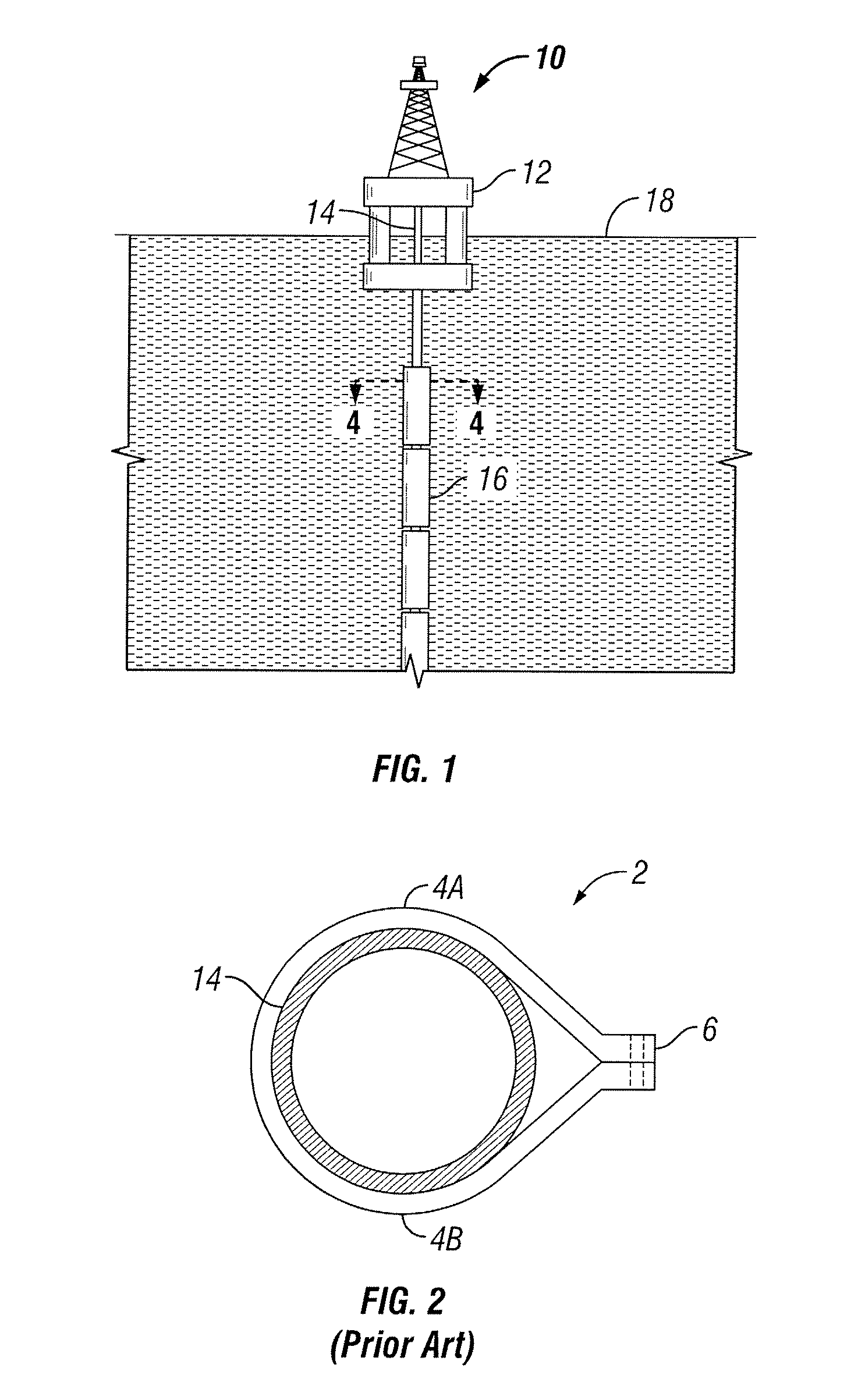

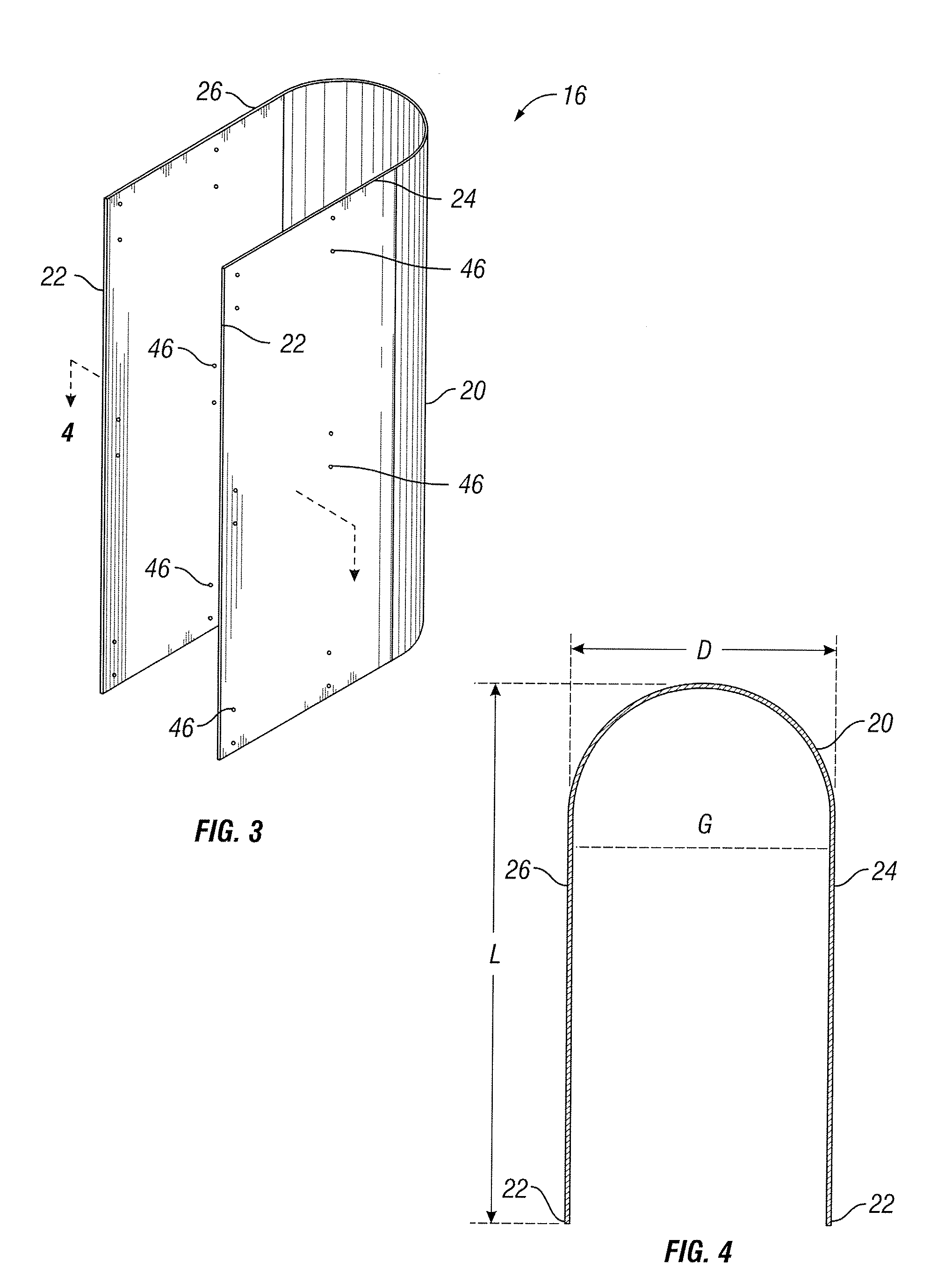

Twin fin fairing

ActiveUS7337742B1Eliminate phenomenonReduce vibrationPipe laying and repairDrilling rodsDiameter ratioDrag minimization

Owner:SEAHORSE EQUIP

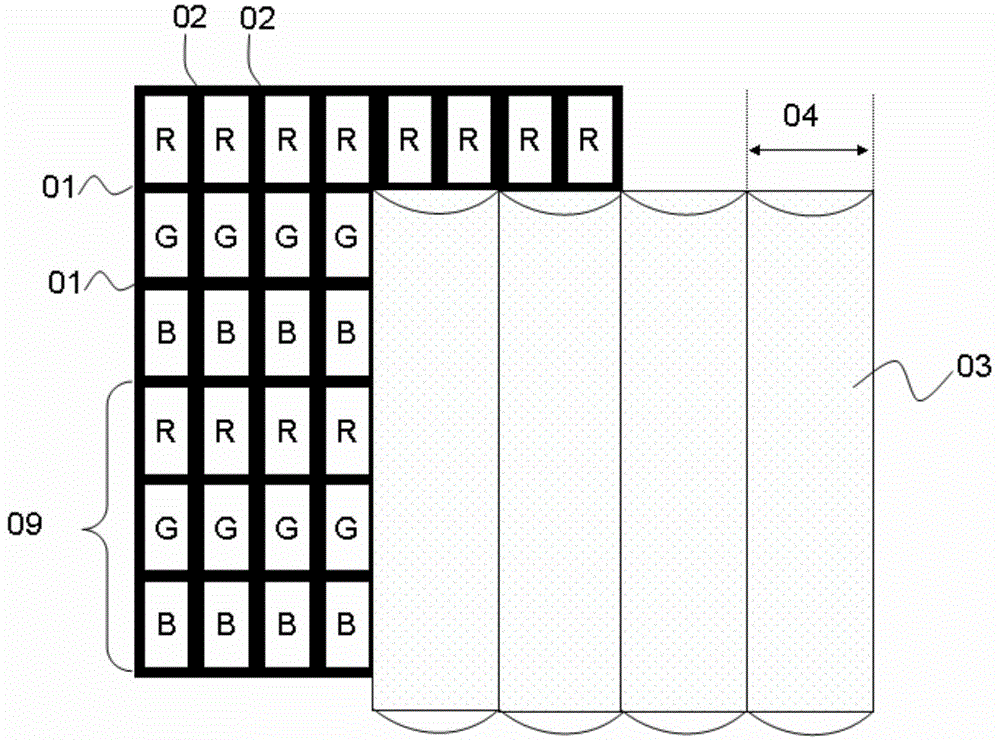

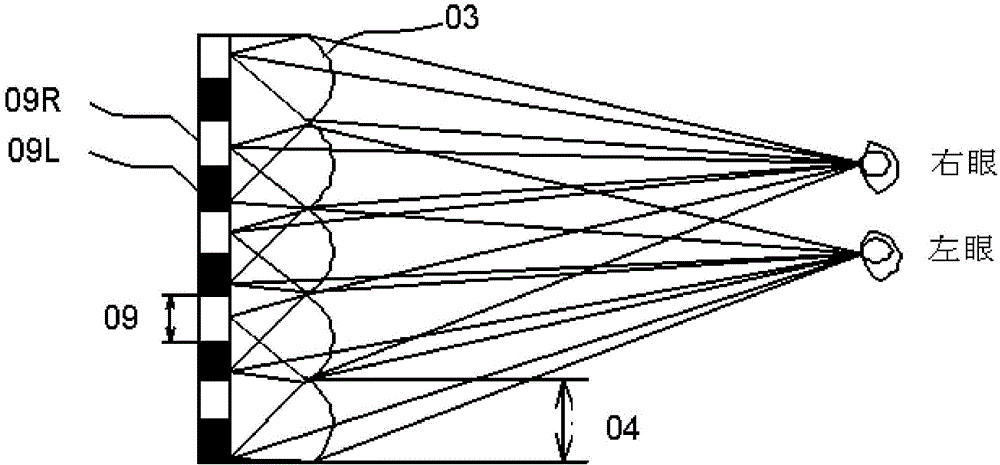

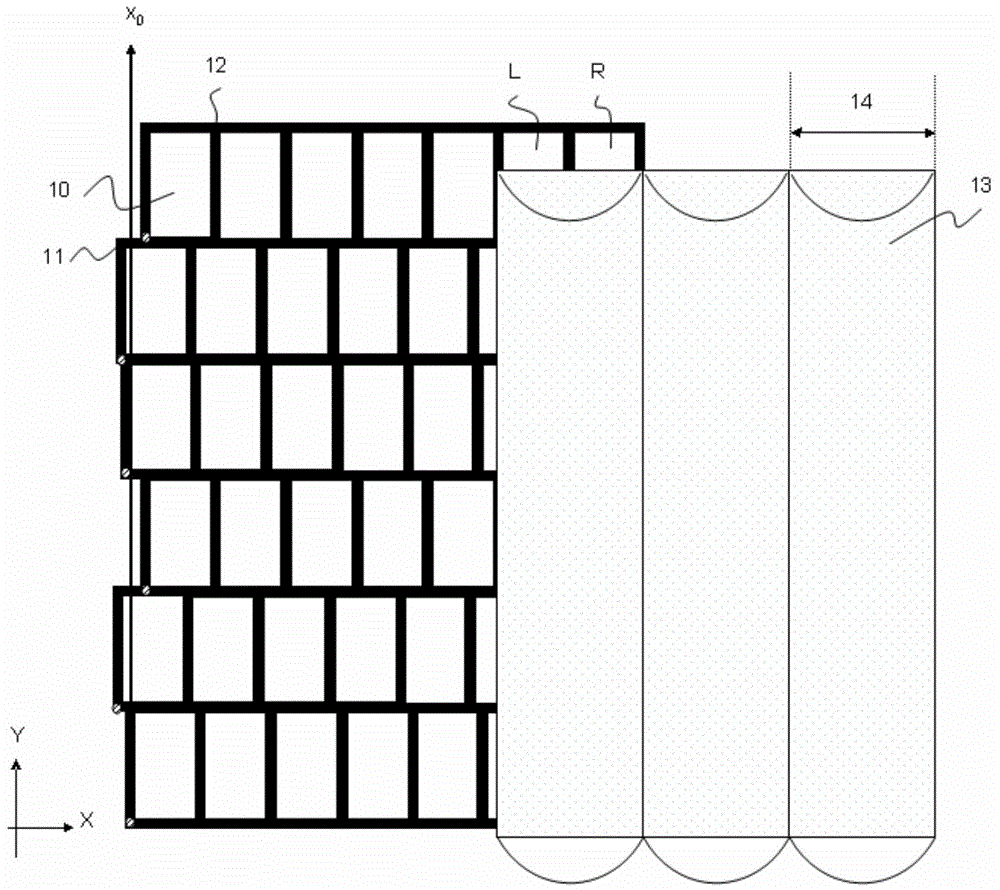

Stereo image display device

InactiveCN103945203AEliminate phenomenonImprove the display effectSteroscopic systemsOptical elementsComputer graphics (images)Display device

The invention provides a stereo image display device comprising multiple display units which are arranged in rows and columns. First black matrixes are arranged between adjacent display unit rows, and second black matrixes are arranged between adjacent display unit columns. The stereo image display device also comprises lens boards which are arranged to be corresponding to multiple pixel units. The lens boards are composed of multiple half-cylindrical lenses via arrangement. In an X-axis direction, one cycle length of the half-cylindrical lenses of the lens boards is positive even times than one cycle length of the display units. Besides, in one cycle of the lens boards, X-axis coordinate values of the multiple display units are non-periodically repeated. Adverse effects like black and white strips can be solved by the stereo image display device so that display effect is enhanced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

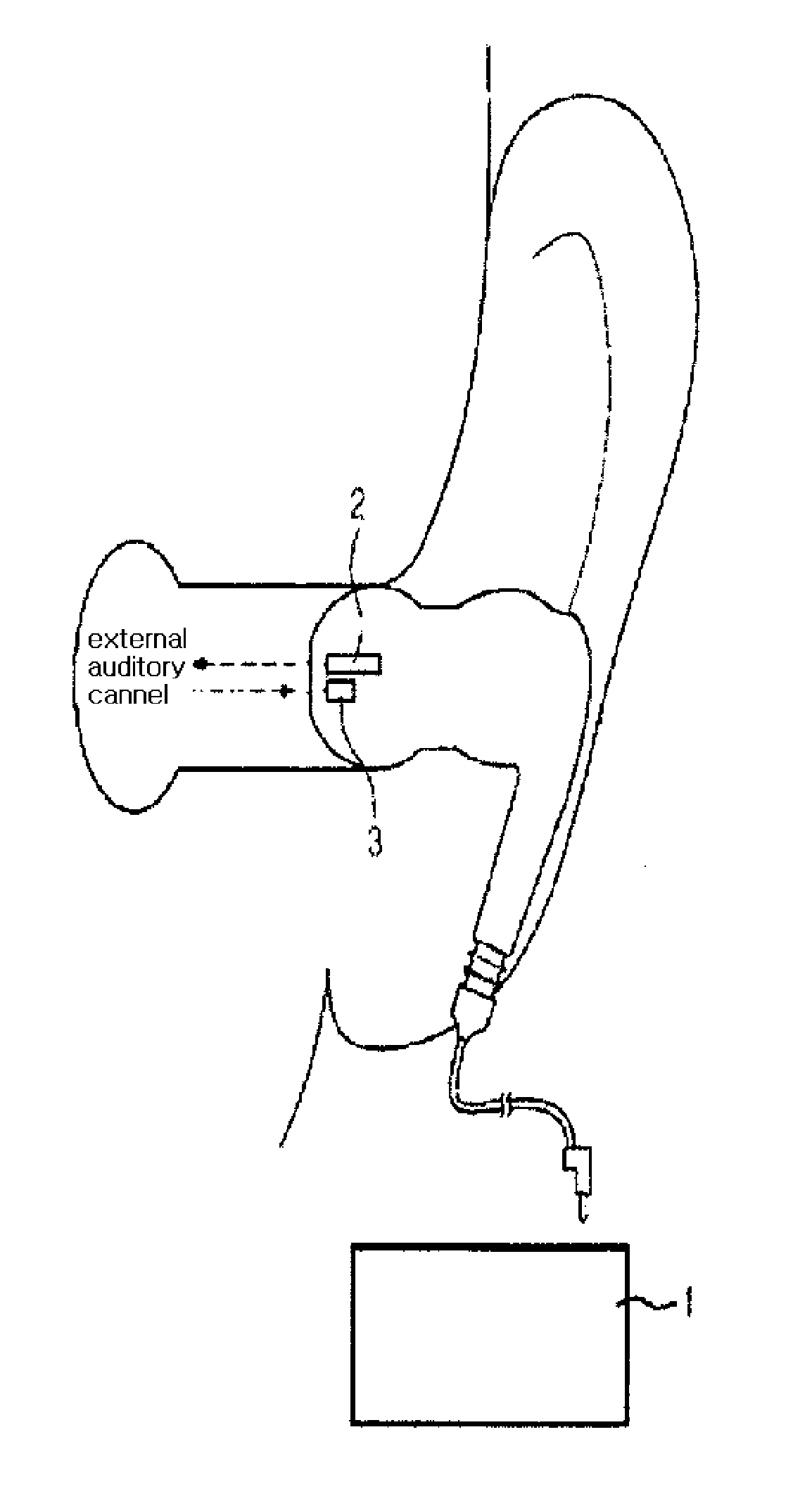

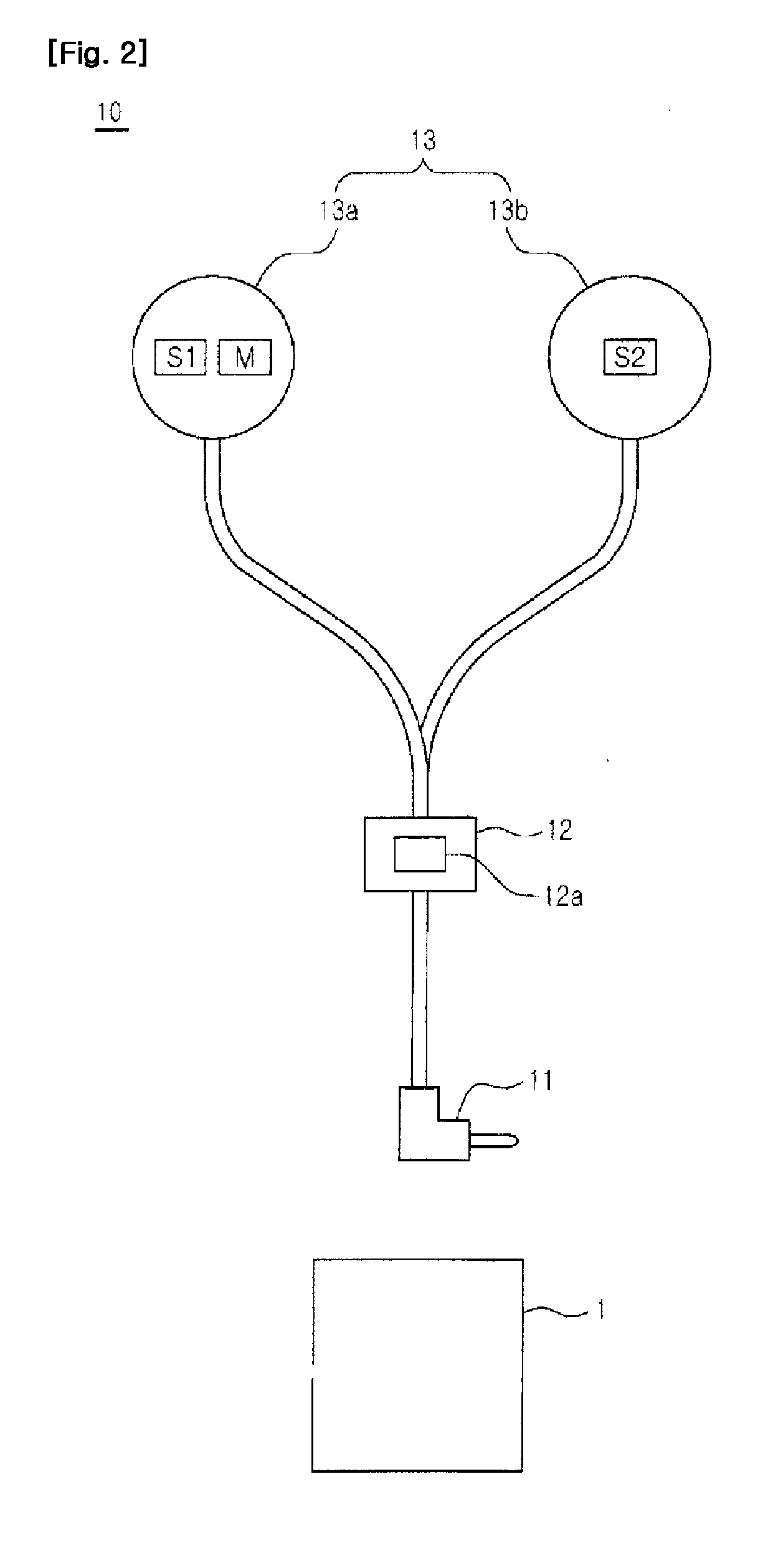

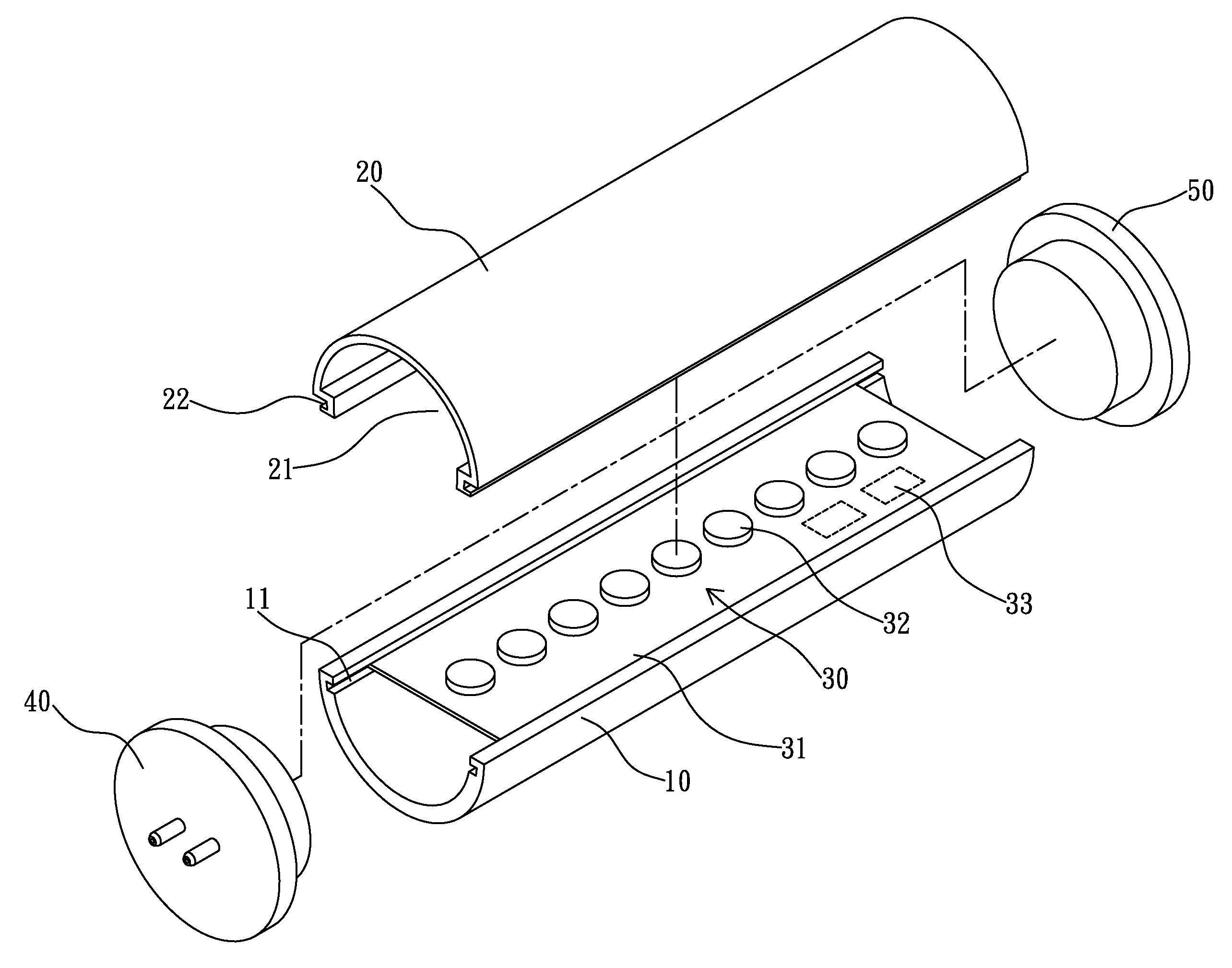

Ear microphone

InactiveUS20130034239A1Eliminate phenomenonBlocking phenomenonMicrophonesLoudspeakersEngineeringHeadphones

The present invention relates to an ear microphone for providing clear sound by preventing echo and howling phenomena by blocking external noise, and for providing an effective telephone call in a noisy environment by improving the recognition ability of a voice-recognizing device. For the ear microphone, a connector for connection to an external device, a control unit for controlling the ear microphone overall, and an earphone unit to be worn by a user for outputting or inputting voice are electrically connected to each other through cables. The earphone unit consists of a first earphone unit which includes first and second speakers wearable on the ear, a first microphone having directivity, and a second earphone unit which includes a third speaker. For the control unit, a grounding terminal and one terminal of the control unit are connected to the connector such that the other terminal is connected to the first to third speakers, and one terminal is connected to the connector such that the other terminal is connected to the first microphone. The microphone output terminal is configured to be connected to a resistor in series. The third speaker is configured as a voltage-dividing resistor on a speaker input terminal. Each voltage dividing resistor is differently designed for the first and second speakers such that the second speaker has phase characteristics that are opposite those of the first speaker, and at the same time has a voltage different from the first speaker. A negative terminal of the first speaker and a positive terminal of the second speaker connected to the speaker output terminal are connected to a volume-adjusting unit.

Owner:HAEBORA

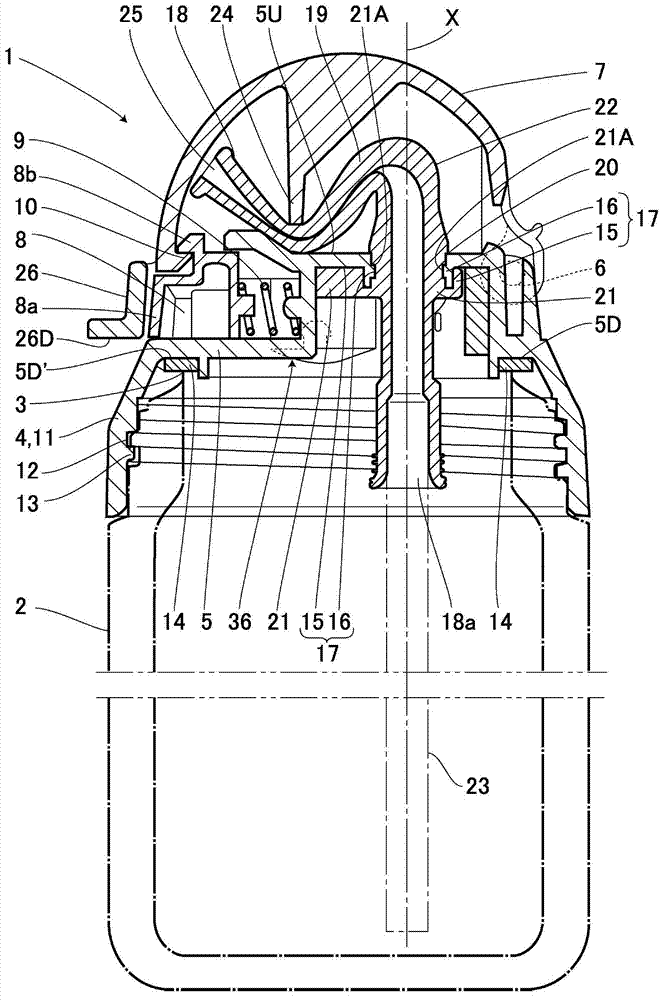

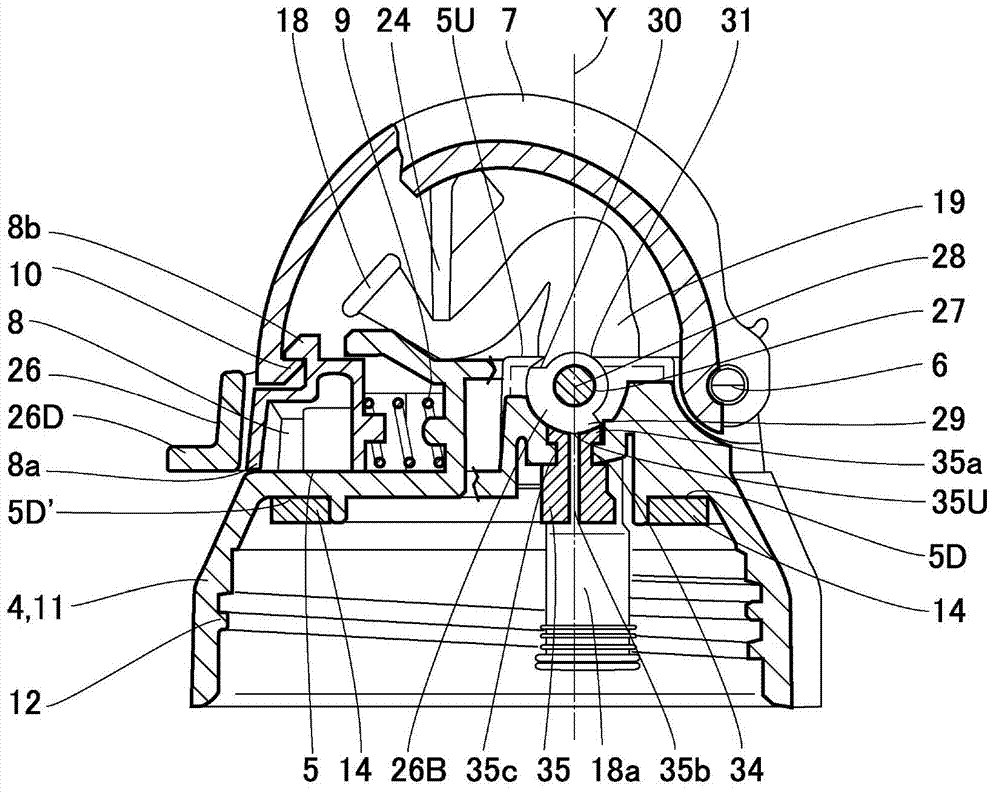

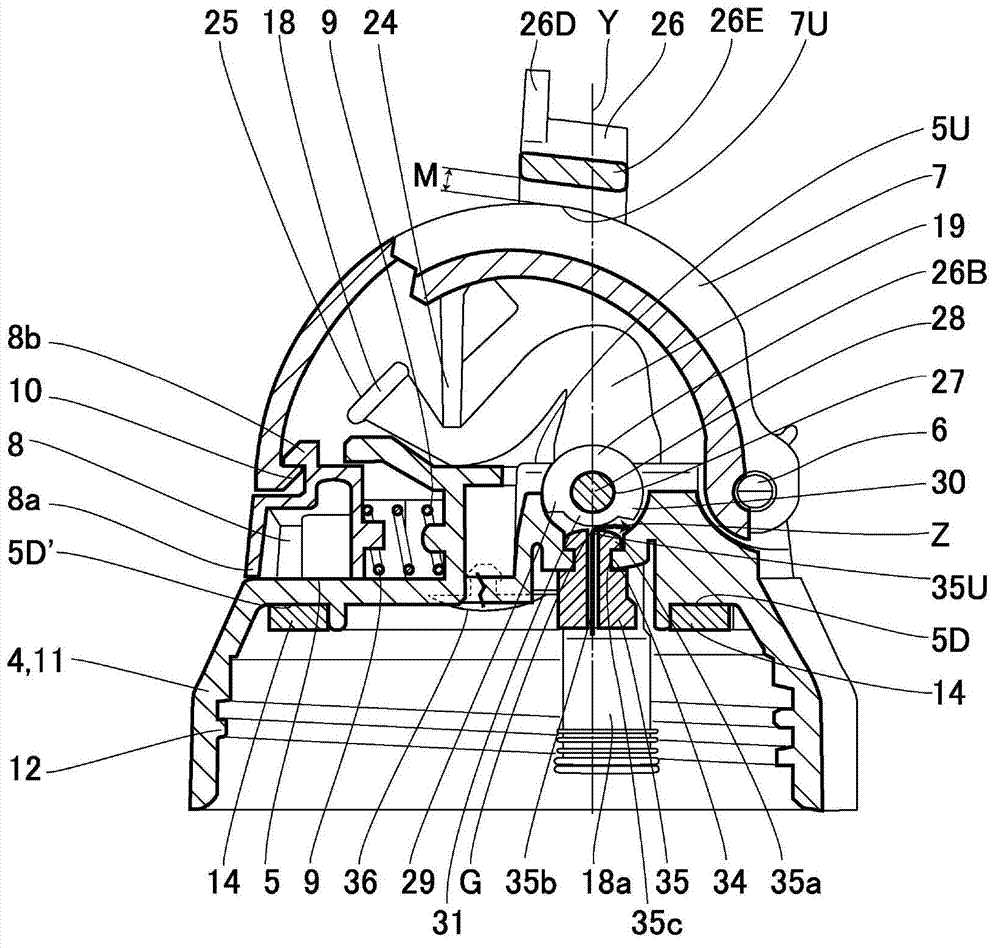

Plug of beverage vessel

The invention provides a plug of a beverage vessel. The plug cannot be easily opened due to misoperations or the like, and the operation and closure states of a locking mechanism are definite so that content liquid is prevented from spraying from the front end of a sucker. The plug comprises a plug main body (11), a shaft supporting cover (7), a clamping part (8), a drinking port member (22), and a blocking member (14). The clamping part (8) is arranged in a manner allowing a cover to be kept in or released from the closure state. The drinking port member (22) is clamped in the plug main body (11). The blocking member (14) is pressed against a vessel opening (3) and blocks a vessel main body. The blocking member (14) is clamped in a hole (34), and a ventilation hole (35b) is formed in the through part of the hole (34). The ventilation hole is in the closure state when the cover is in the closure state and temporarily in the open state when a reversing handle member is in a circumferential reversing process, and the ventilation hole is back to the closure state again by virtue of further reversing the reversing handle member, so that the closure state is enabled to be definite and the closure / open / closure action time of the ventilation hole is delayed accurately.

Owner:THERMOS LLC +1

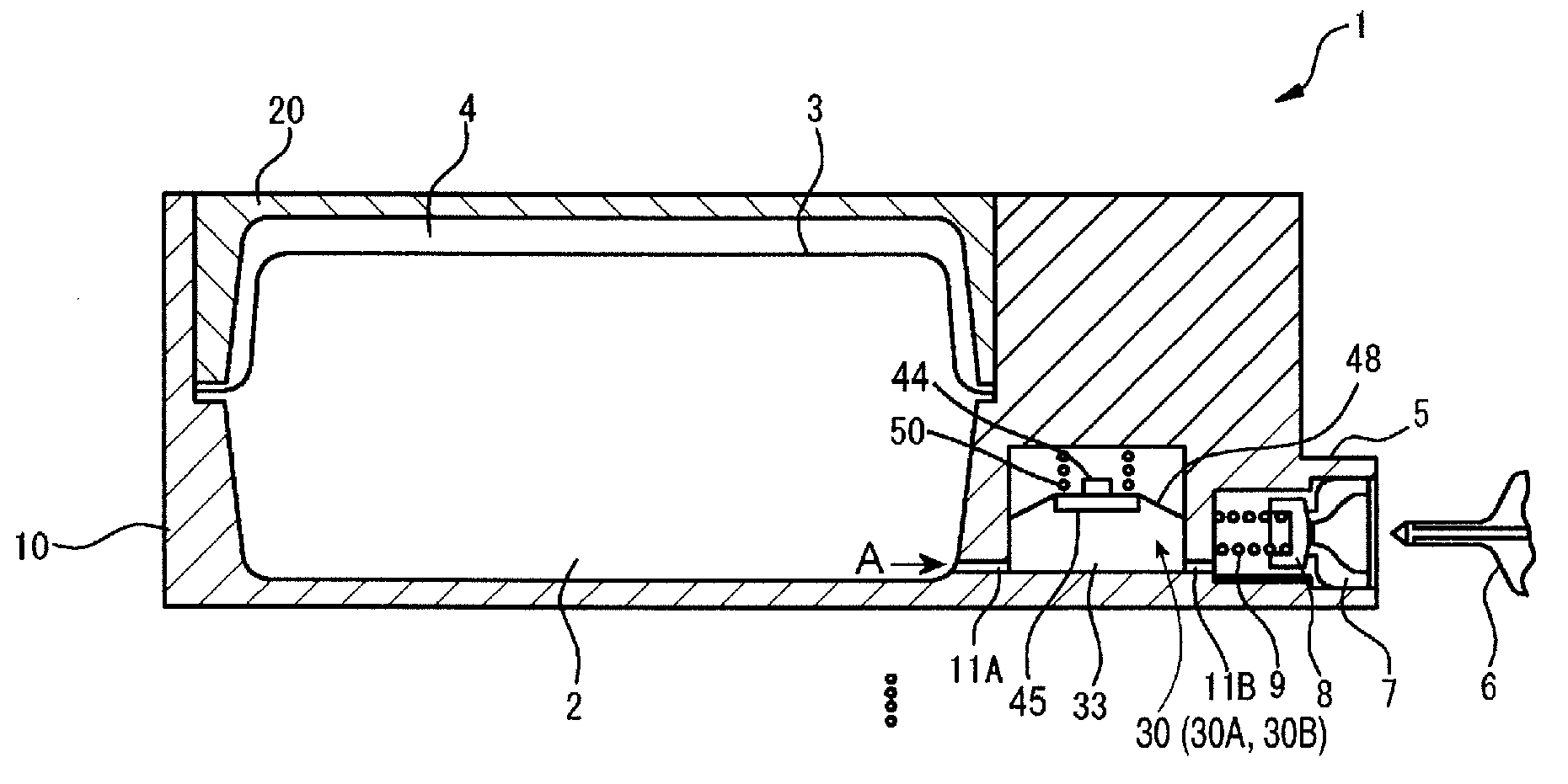

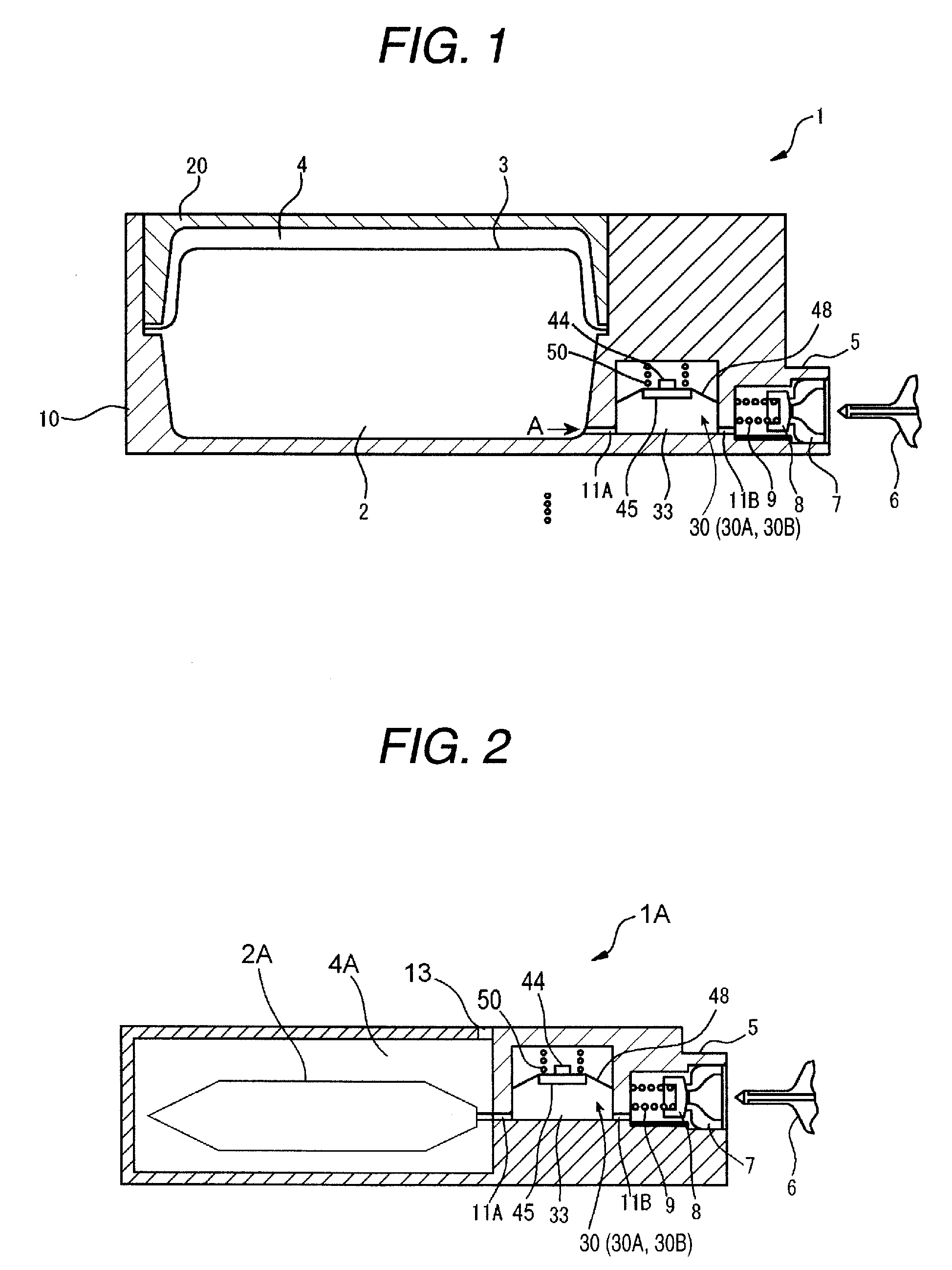

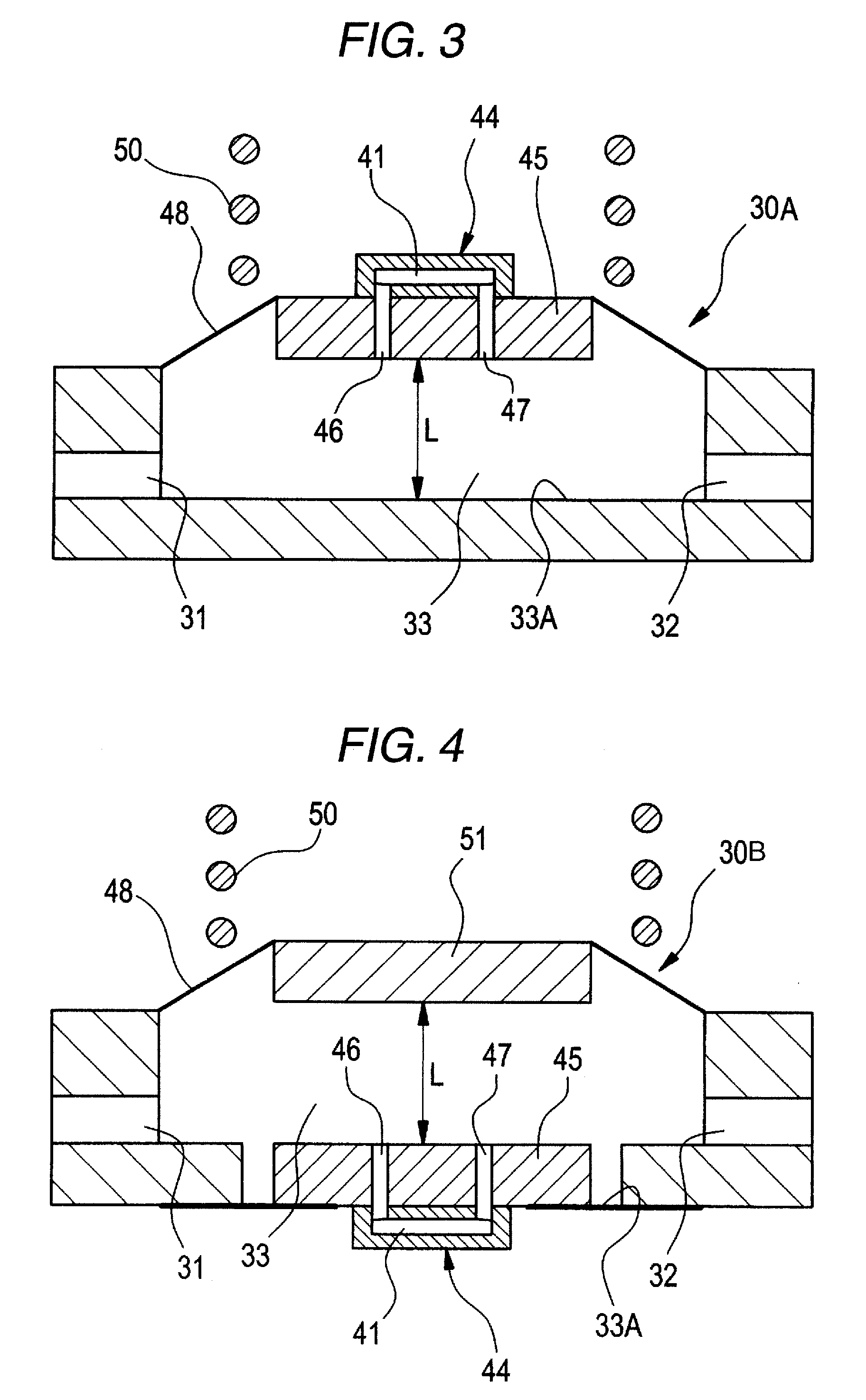

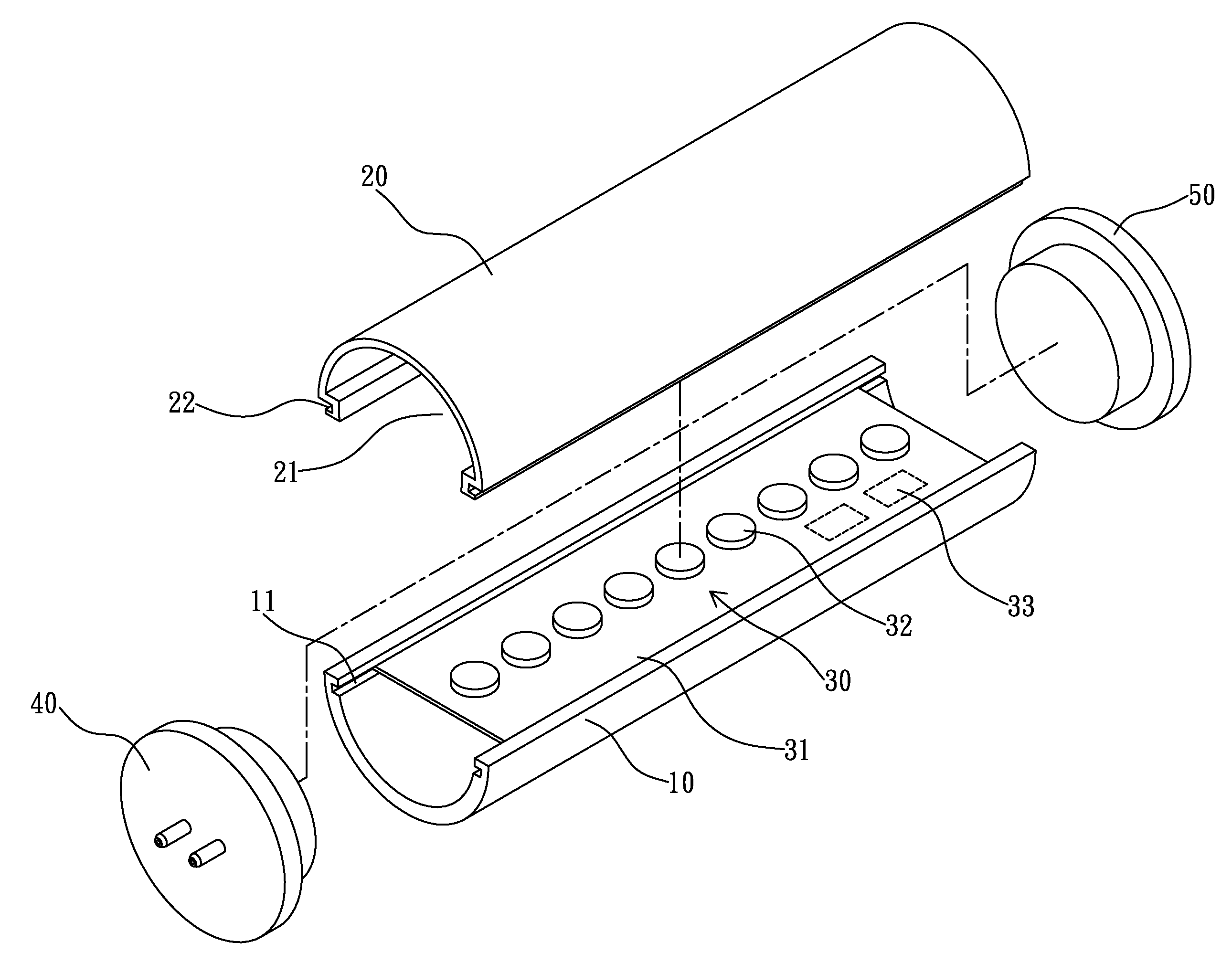

Liquid residual amount detection apparatus for liquid container

InactiveUS20080198187A1Improve air tightnessHigh degreeMachines/enginesLevel indicatorsElectricityResidual vibration

A liquid residual amount detection apparatus for a liquid container, includes: a sensor chamber that has a liquid supply port introducing liquid to be delivered from a liquid containing portion, and supplies the liquid to an external liquid consuming apparatus; a diaphragm that defines a part of the sensor chamber and is movable in response to a liquid containing amount in the sensor chamber; a pressure receiving plate that is attached to the diaphragm; a recess portion that is connected to the sensor chamber and is closed by the pressure receiving plate when the liquid containing amount in the sensor chamber becomes a predetermined amount or less; a piezoelectric element that applies vibration to at least a part of the recess portion so as to detect a free vibration state according to the applied vibration; a detection portion that detects an amplitude value or a frequency of a residual vibration waveform of a counter electromotive force by the free vibration state detected by the piezoelectric element; and a calculation portion that calculates a liquid residual amount in the liquid container on the basis of the amplitude value or the frequency of the residual vibration waveform detected by the detection portion.

Owner:SEIKO EPSON CORP

Pointless illumination device

InactiveUS8011805B2Eliminate phenomenonEasy to understandLighting support devicesElectric lightingLight-emitting diodeLight emitting device

The present invention relates to a pointless illumination device, comprising: a body; a cover, made of a light spreading material which can uniformly spread out the light of a plurality of light emitting devices; a light source module; a first contact portion; and a second contact portion. The light emitted from the light source module is uniformly spread through the cover so that the phenomenon of pointwise illumination does not exist in the illumination device.

Owner:BRIGHT VIEW ELECTRONICS

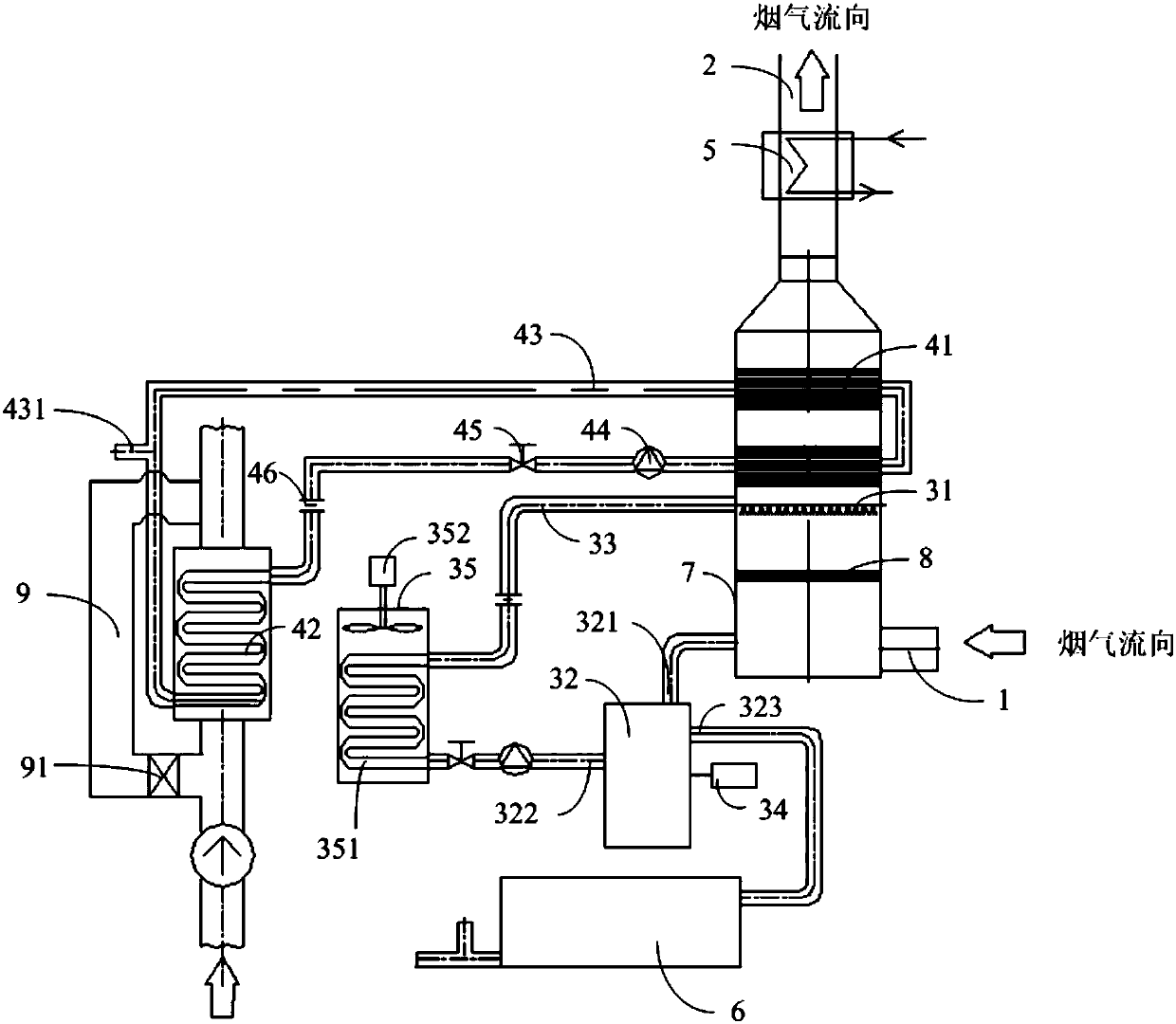

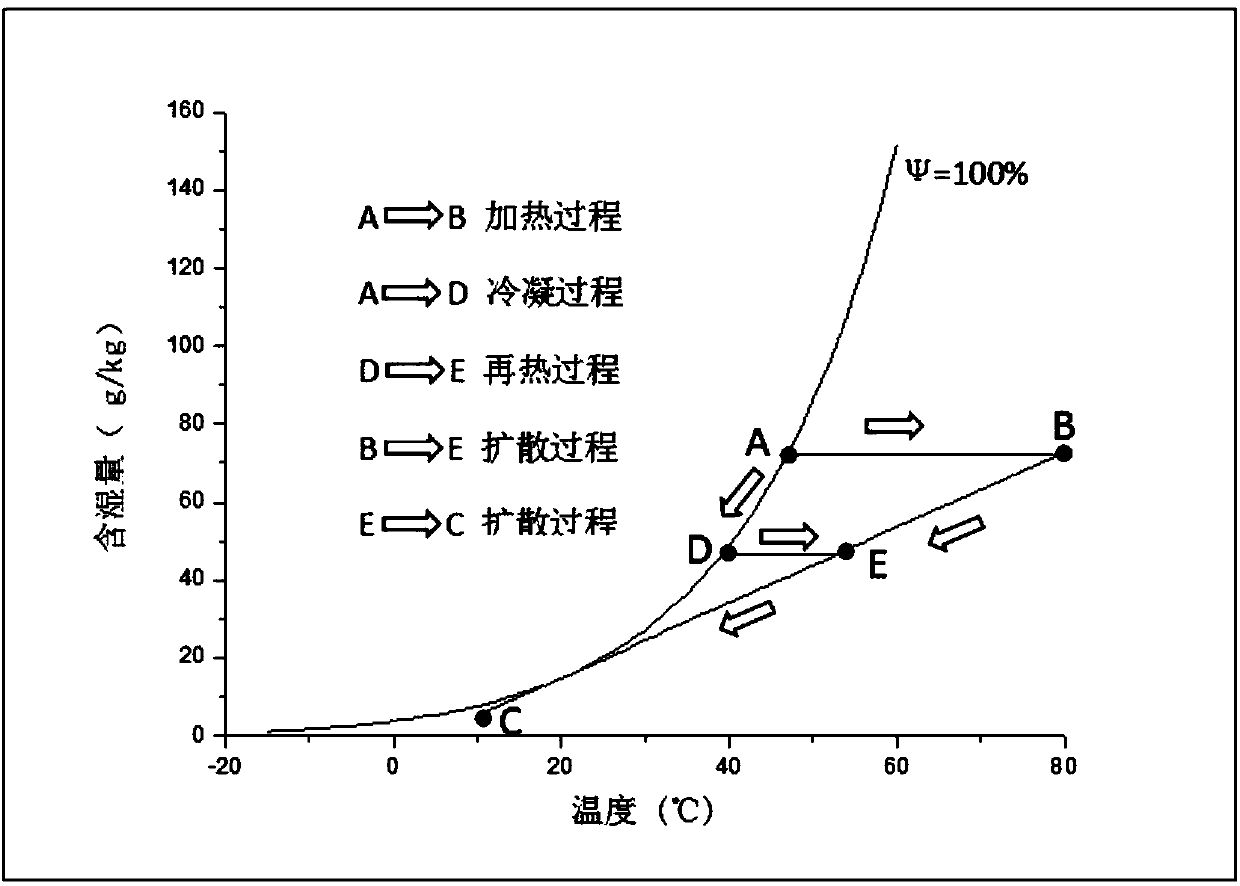

Wet smoke plume eliminating system

ActiveCN107930309AImprove thermal efficiencyImprove water efficiencyCombination devicesUsing liquid separation agentWater useWater storage tank

The invention relates to a wet smoke plume eliminating system. The wet smoke plume eliminating system comprises a first cooling subsystem, a second cooling subsystem and a heater which are successively arranged between a smoke outlet of a desulphurization tower and a chimney; the first cooling subsystem comprises a first circulating water loop, the first circulating water loop is provided with a spraying apparatus and a circulating water tank, the second cooling subsystem comprises a fluoroplastic heat exchanger communicated with the spraying apparatus; the circulating water tank is communicated with the first cooling subsystem and the second cooling subsystem and used for collecting condensed water and sprayed water and providing circulating water circularly entering the spraying apparatus along the first circulating water loop; and the water smoke plume eliminating system also comprises a water storage tank, and the water storage tank is communicated with an overflow opening of the circulating water tank. By adopting the wet smoke plume eliminating system, water can be effectively extracted from smoke, the wet smoke plume phenomenon can be completely eliminated, the environment is purified, and the water use efficiency of a power plant can be increased at the same time.

Owner:FUJIAN LONGKING

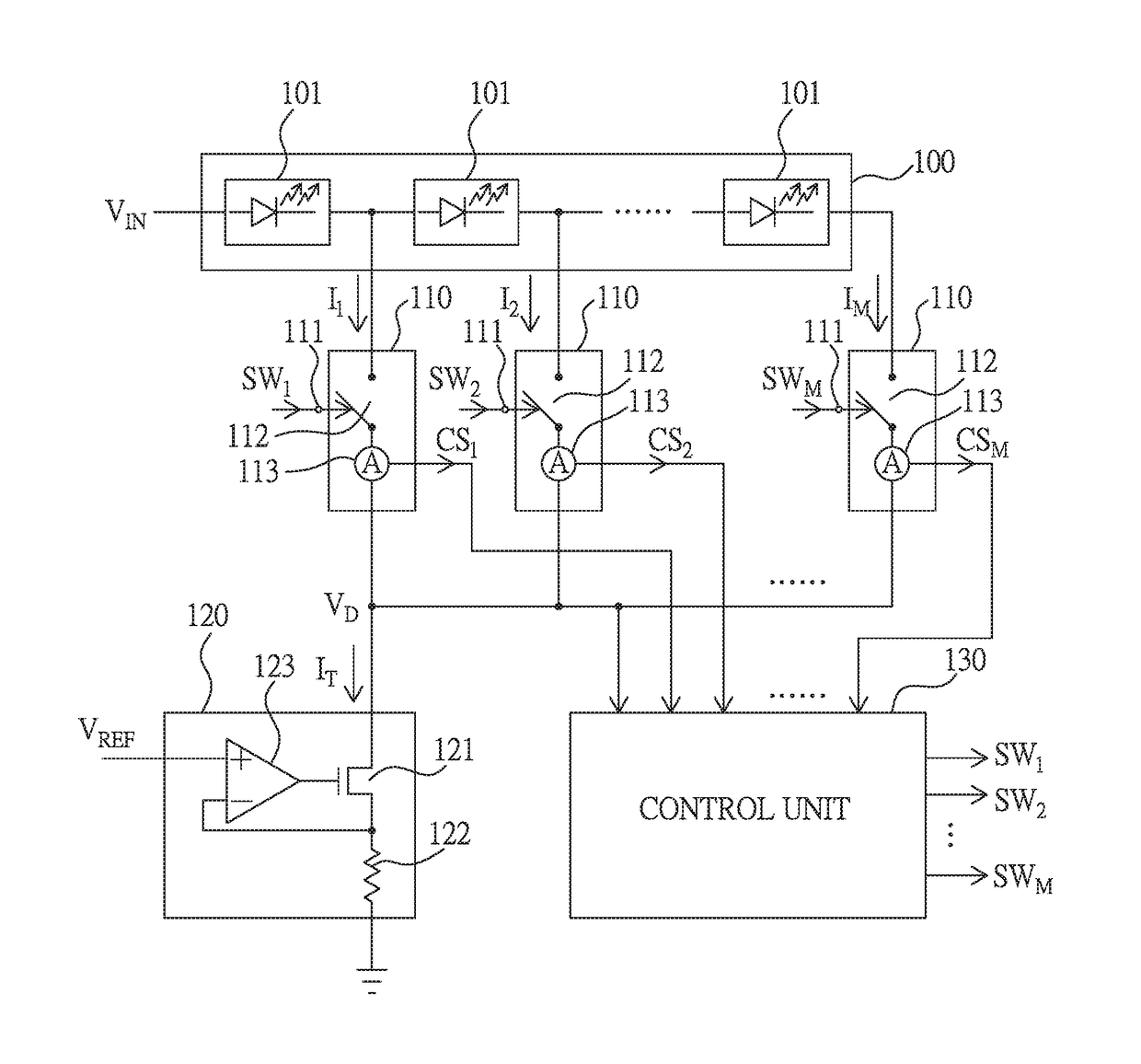

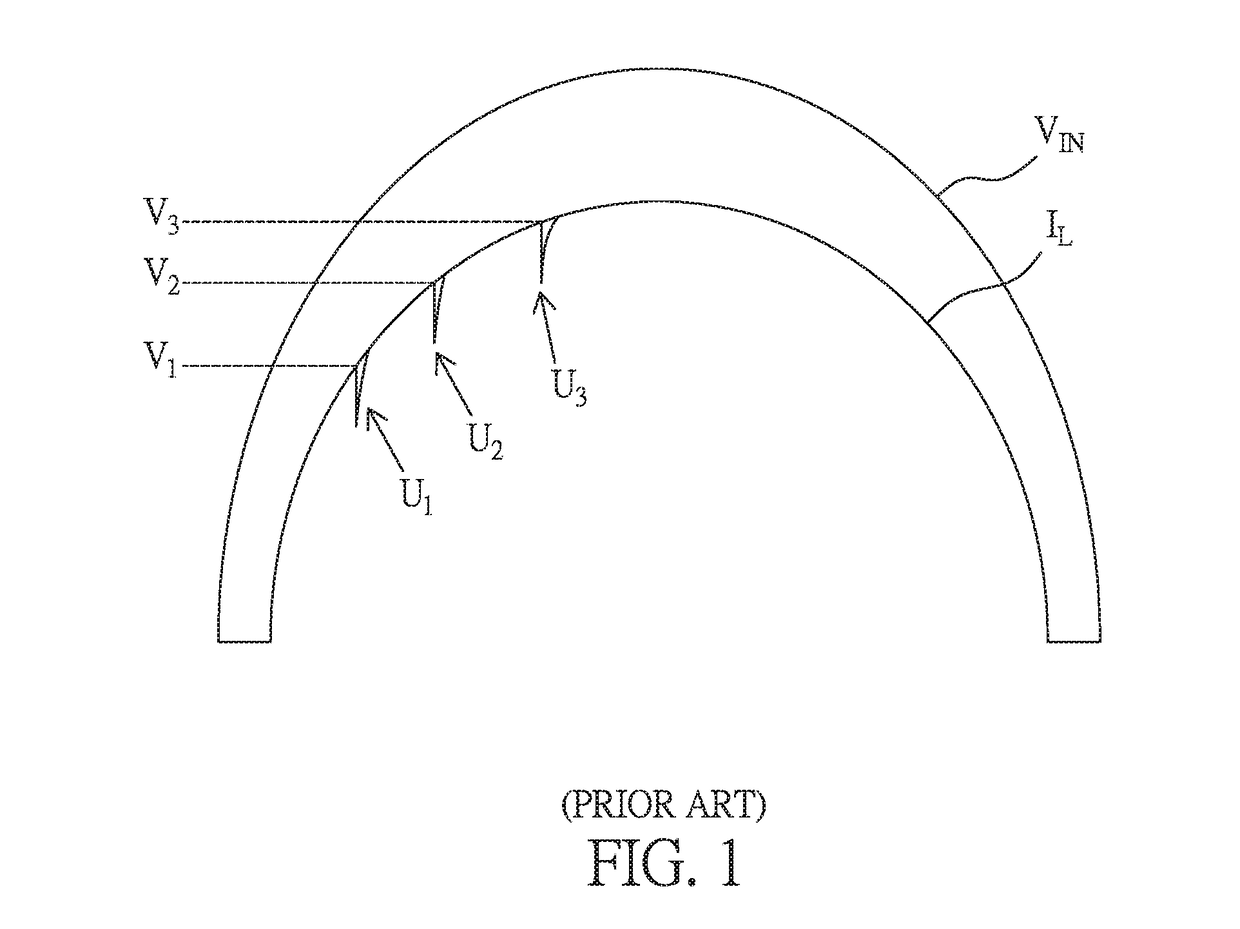

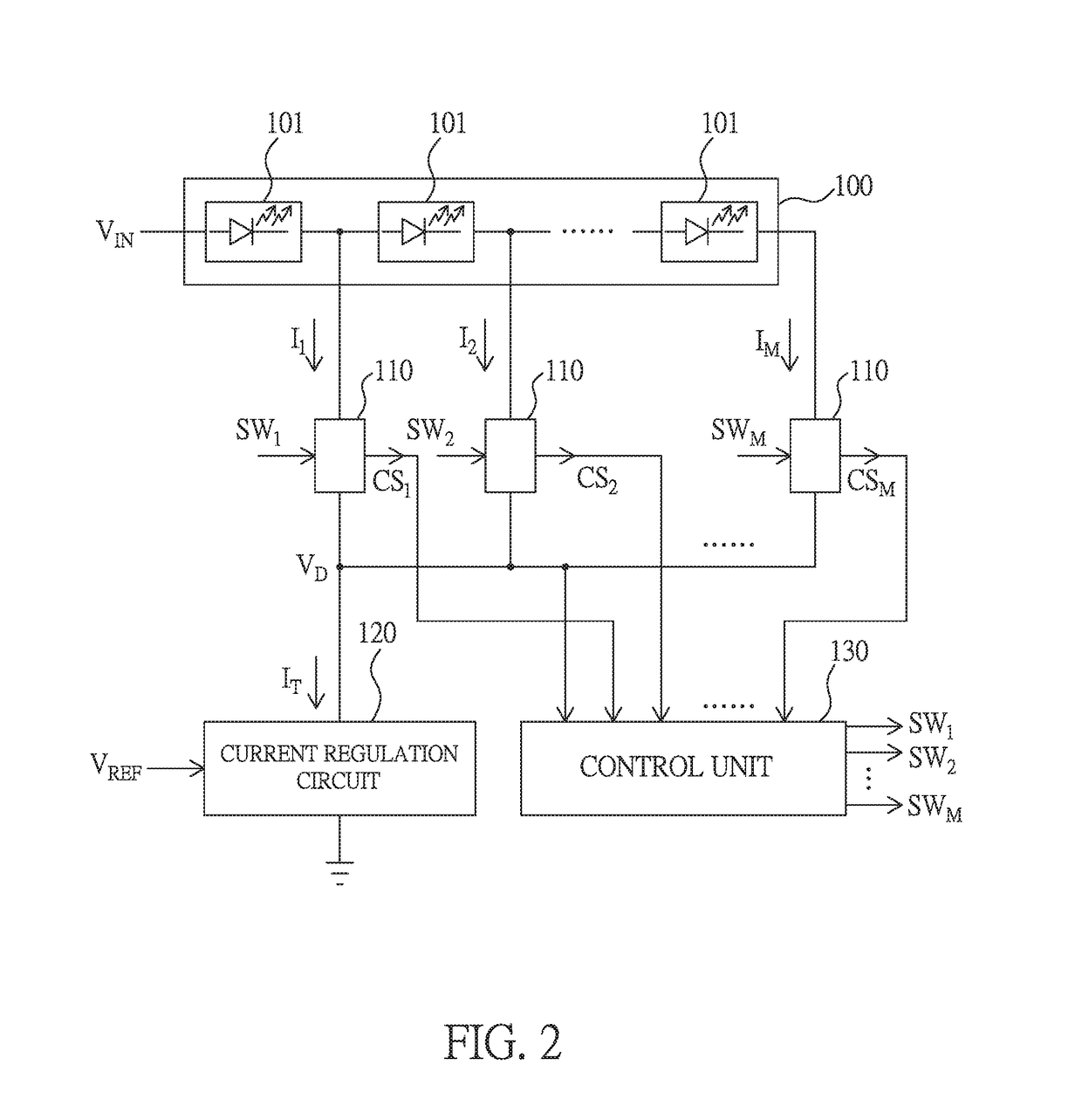

Multi-Stage Led Driving Circuit Capable of Eliminating Current Undershoot

InactiveUS20170079112A1Eliminate phenomenonEffectively eliminating phenomenonElectrical apparatusElectroluminescent light sourcesPower flowComputer module

A multi-stage LED driving circuit capable of eliminating current undershoot, including: an LED module having a plurality of stage output terminals; a plurality of switch units coupled with the stage output terminals to receive a plurality of branch currents and provide a plurality of current sensing signals; a current regulation circuit, having a control end coupled with a variable reference voltage, and a current path for receiving the branch currents; and a control unit, receiving the current sensing signals and a voltage signal at an input terminal of the current path, and controlling the switch units; wherein, the control unit uses every two adjacent signals of the current sensing signals to get a ratio in turn to determine whether to switch off a corresponding switch unit of the switch units after a deferred time, and uses the voltage signal to determine whether to change the deferred time.

Owner:LUXMILL ELECTRONICS

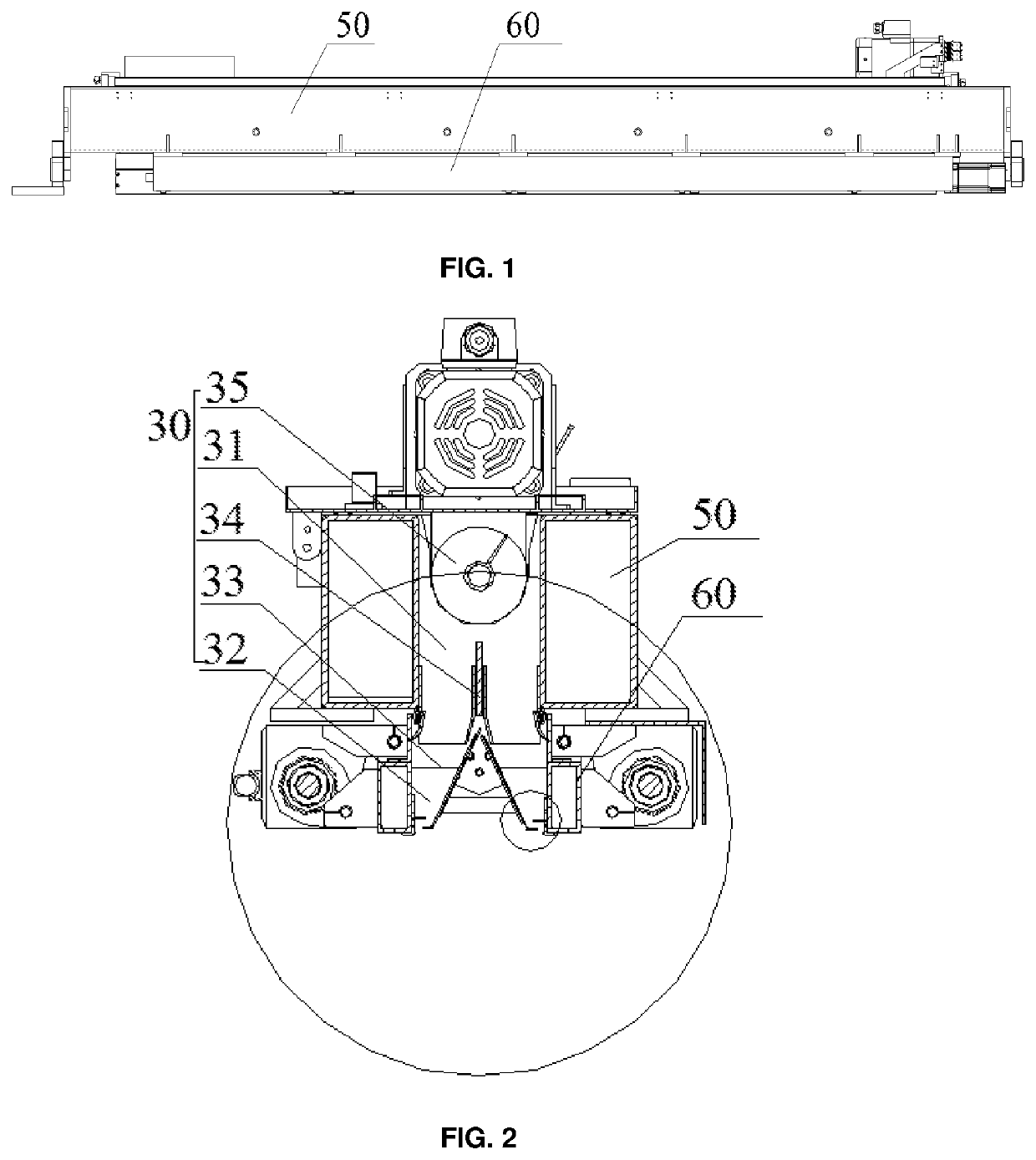

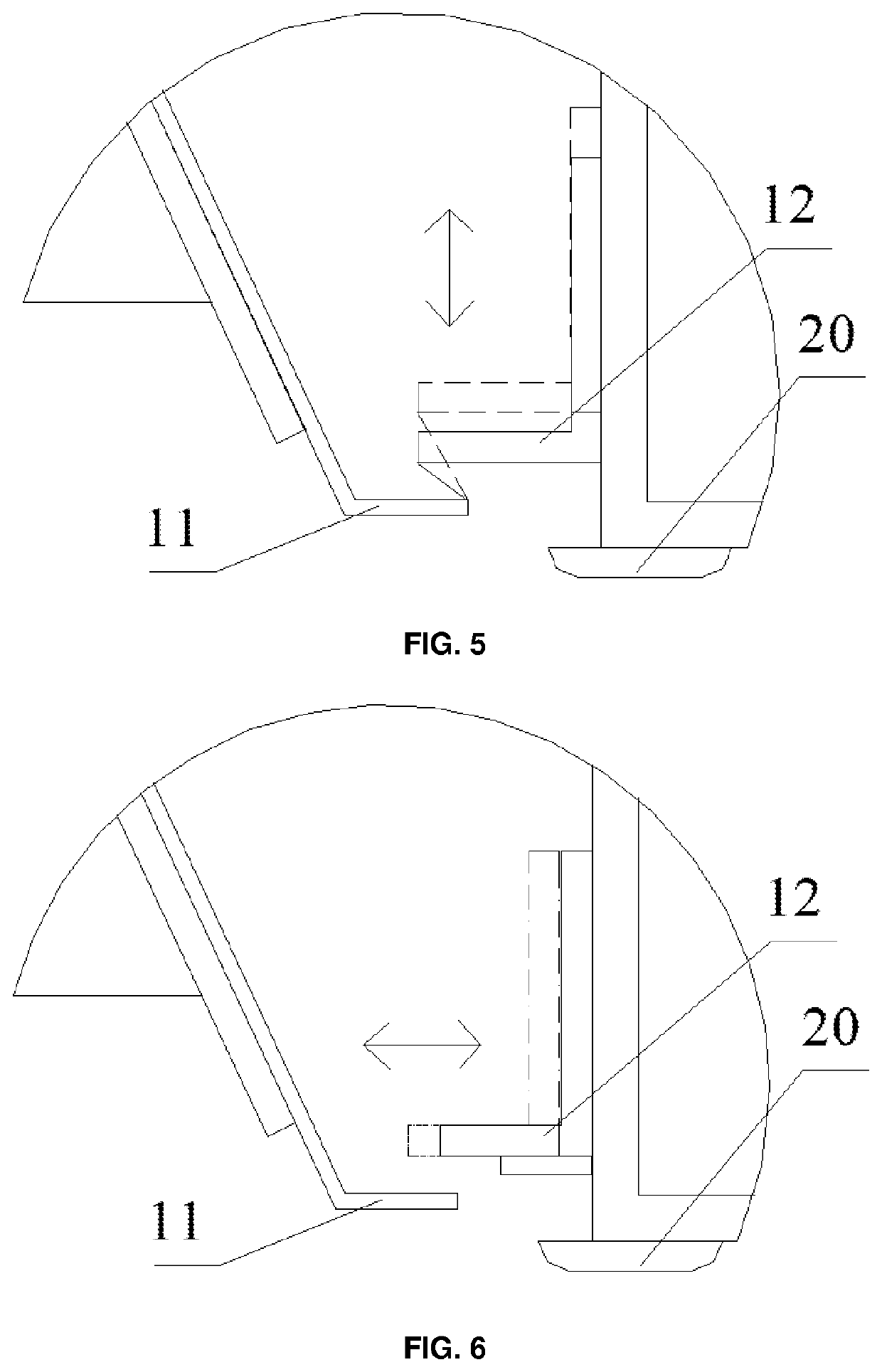

Unidirectional or Bidirectional Sand Dispensing Device

ActiveUS20210362215A1Eliminate leaksUniform dispensingAdditive manufacturing apparatusFoundry mouldsParticulatesWater leak

A unidirectional or bidirectional sand dispensing device, including a discharge port (10), the discharge port includes a lower plate (11) and an upper plate (12), the upper plate is provided above the lower plate, an included angle between a horizontal plane and a straight line where an endpoint of a free end of the upper plate and an endpoint of a free end of the lower plate are located is a leakage angle (13), that is to say, a particulate material forms an inclined plane between the upper plate and the lower plate, and an included angle between the inclined plane and the horizontal plane is the leakage angle, which can be adjusted by changing relative positions of the upper plate and the lower plate. The direction of an opening of the sand passing passage is opposite to a moving direction during the sand dispensing operation. When the sand dispensing operation is stopped, the leakage angle is less than or equal to the static repose angle of the particulate material, and is greater than or equal to zero, which ensures that the particulate material will not slide down, and the phenomenon of sand leakage is eliminated. When the sand dispensing operation is being carried out, the leakage angle is greater than or equal to the dynamic repose angle of the particulate material, which ensures that the particulate material will slide down along the inclined plane and that the sand is dispensed relatively uniformly.

Owner:NINGXIA KOCEL MOLD

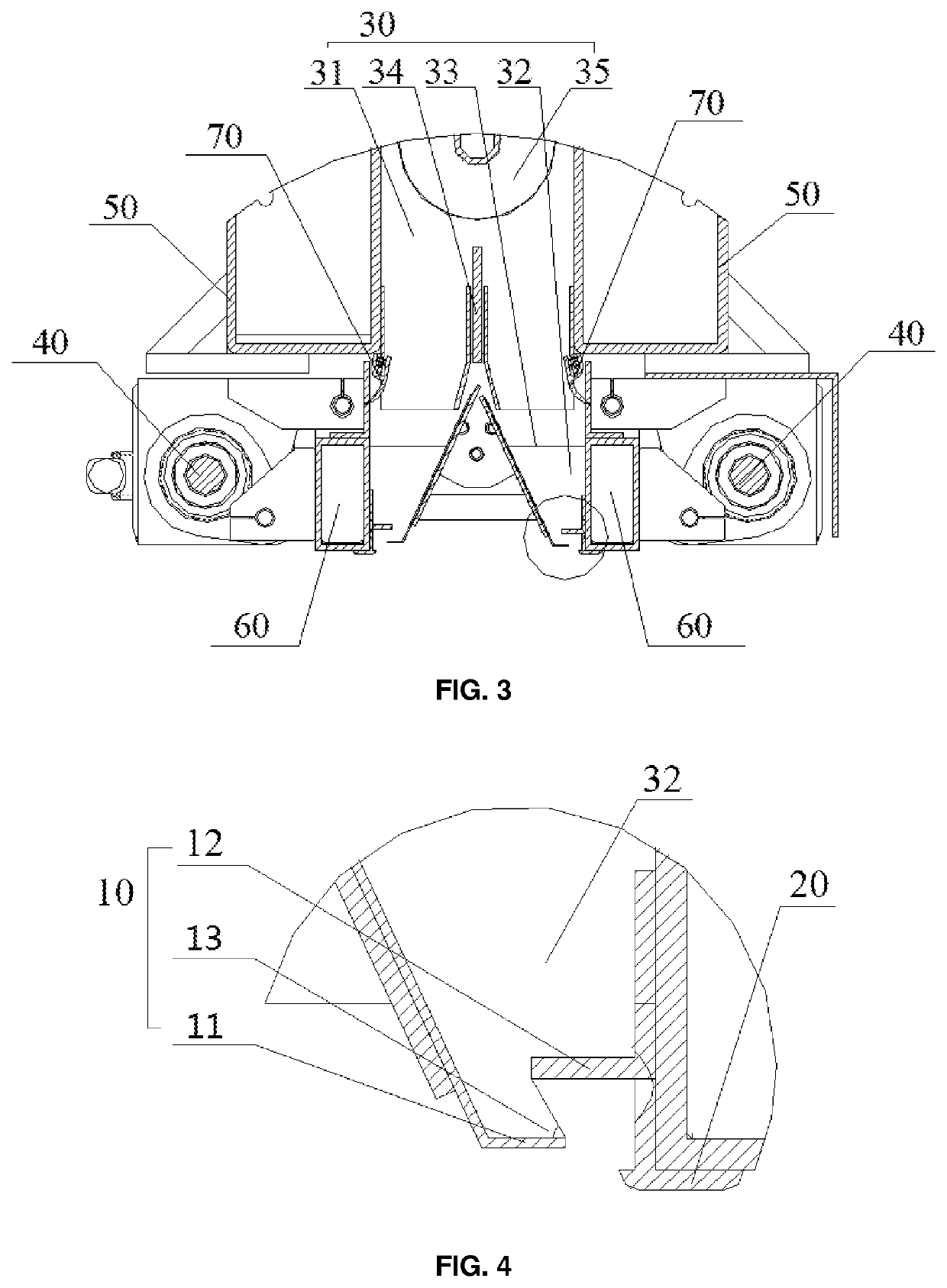

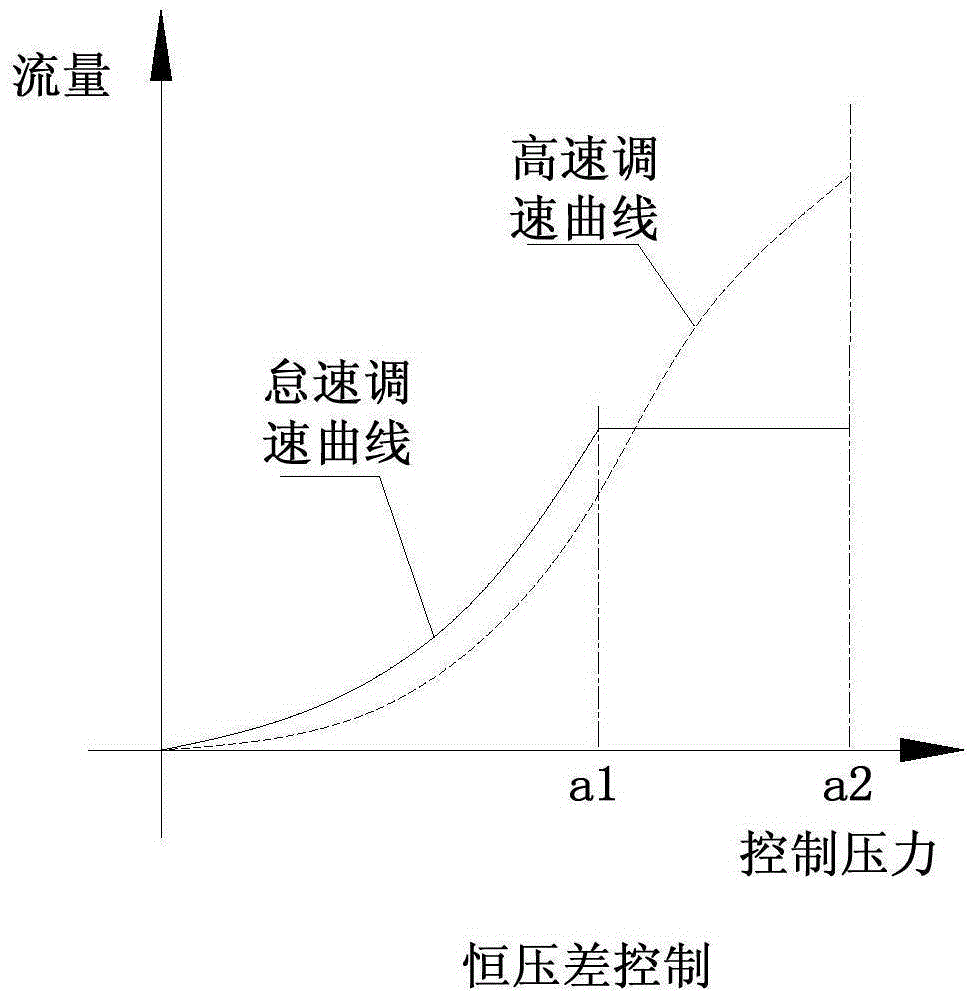

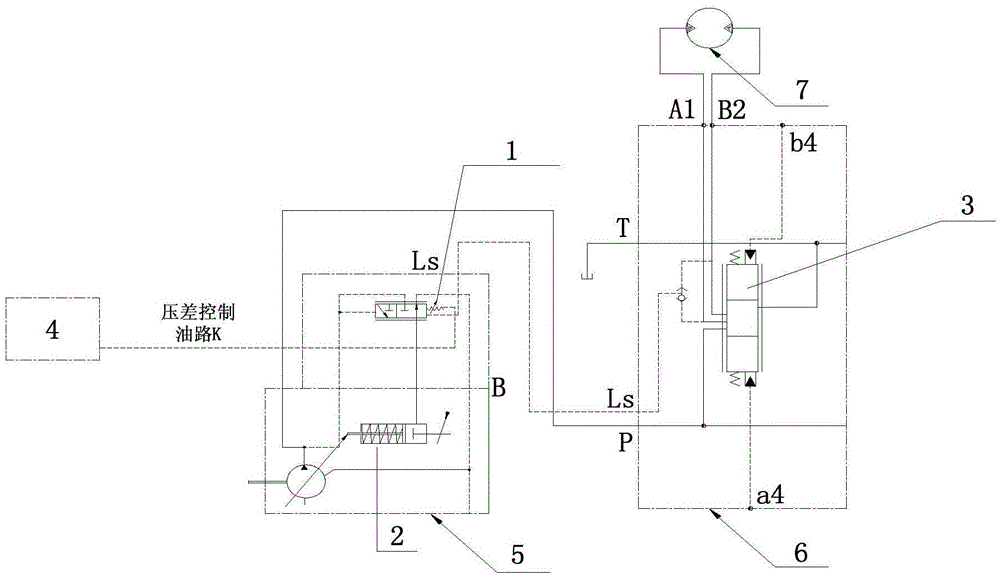

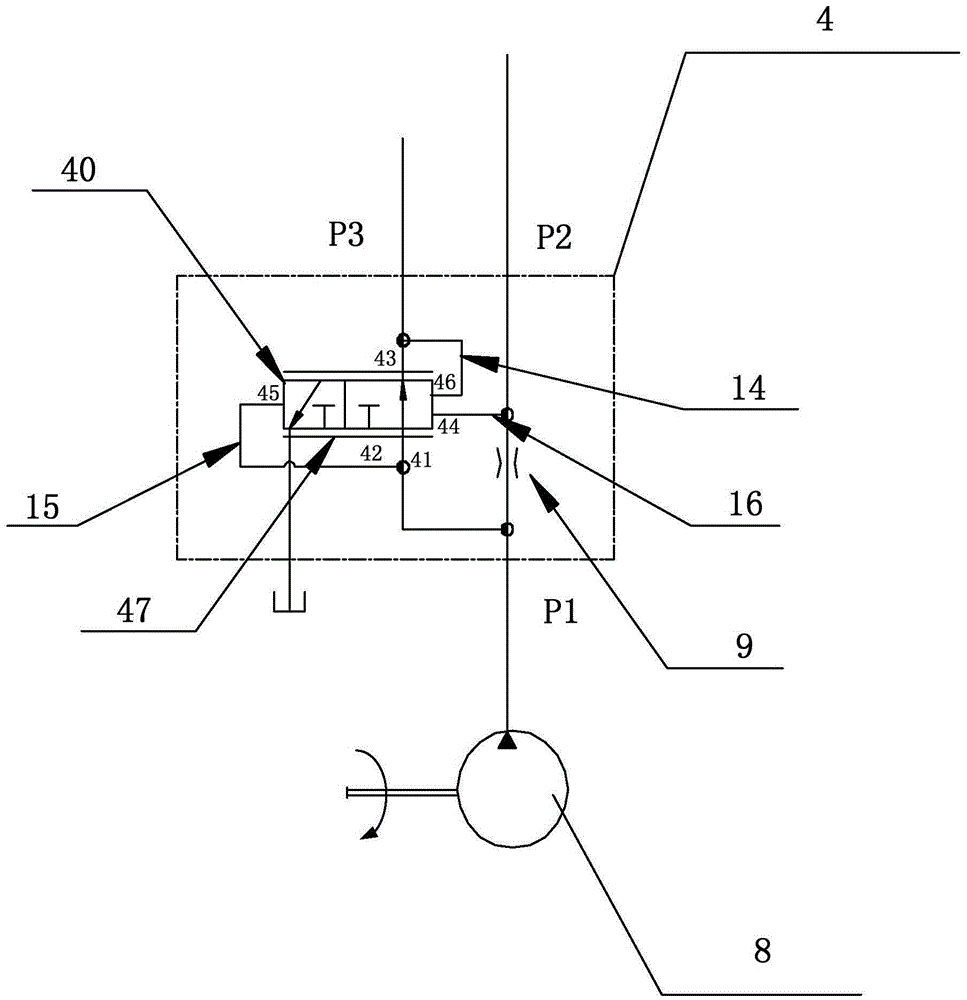

Load-sensitive control system, control method and hydraulic system

ActiveCN105604996AGood speed regulation characteristicsEliminate flow saturationServomotorsControl systemDifferential pressure

The invention discloses a load-sensitive control system, a control method and a hydraulic system, and relates to the field of engineering machinery. The load-sensitive control system, the control method and the hydraulic system are used for achieving self-adaptive matching of system pressure and load pressure. The load-sensitive control system comprises a variable pump, a load-feedback oil circuit and a differential pressure control valve; the differential pressure control valve is connected with the variable pump and the load-feedback oil circuit, and the differential pressure control valve can enable a difference value between pressure of an outlet of the variable pump and pressure of a load on the load-feedback oil circuit to be changeable. According to the technical scheme, the load-sensitive system with the differential pressure changeable is provided, the system can eliminate the flow saturation phenomenon occurring in the idle-speed operation process of an engine and improve the speed regulating characteristic of the load-sensitive system, and meanwhile the energy-saving property of the system is improved.

Owner:XUZHOU HEAVY MASCH CO LTD

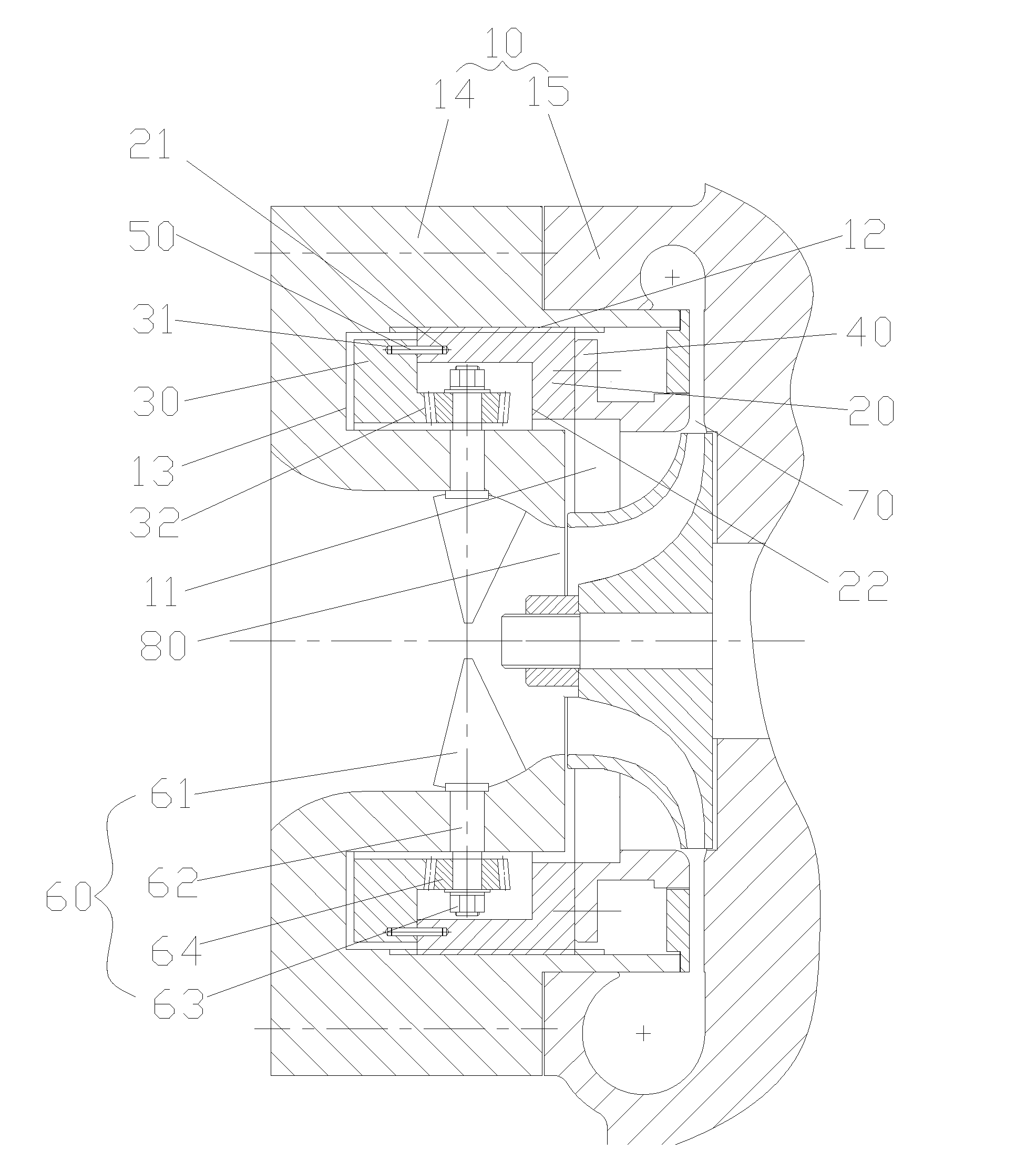

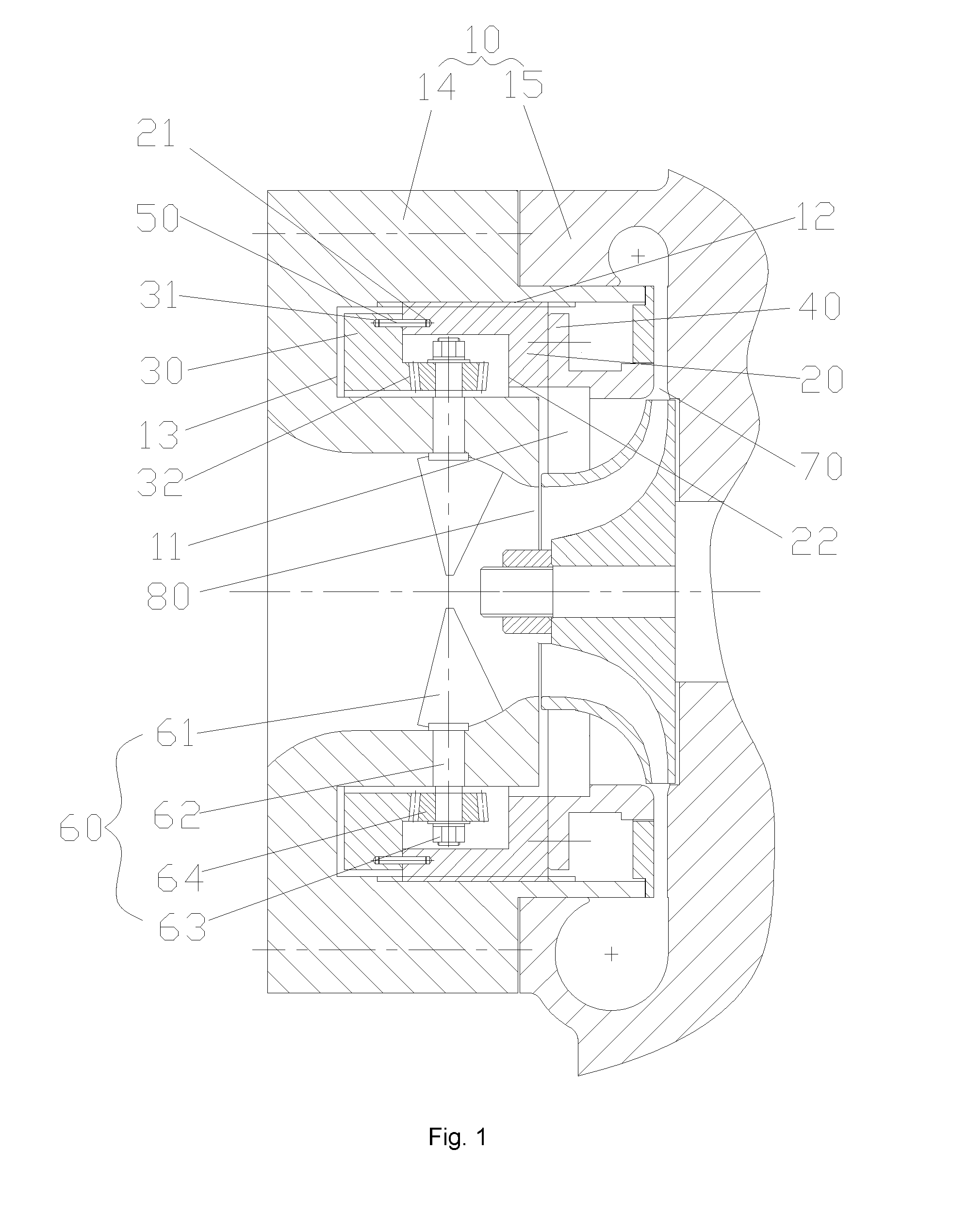

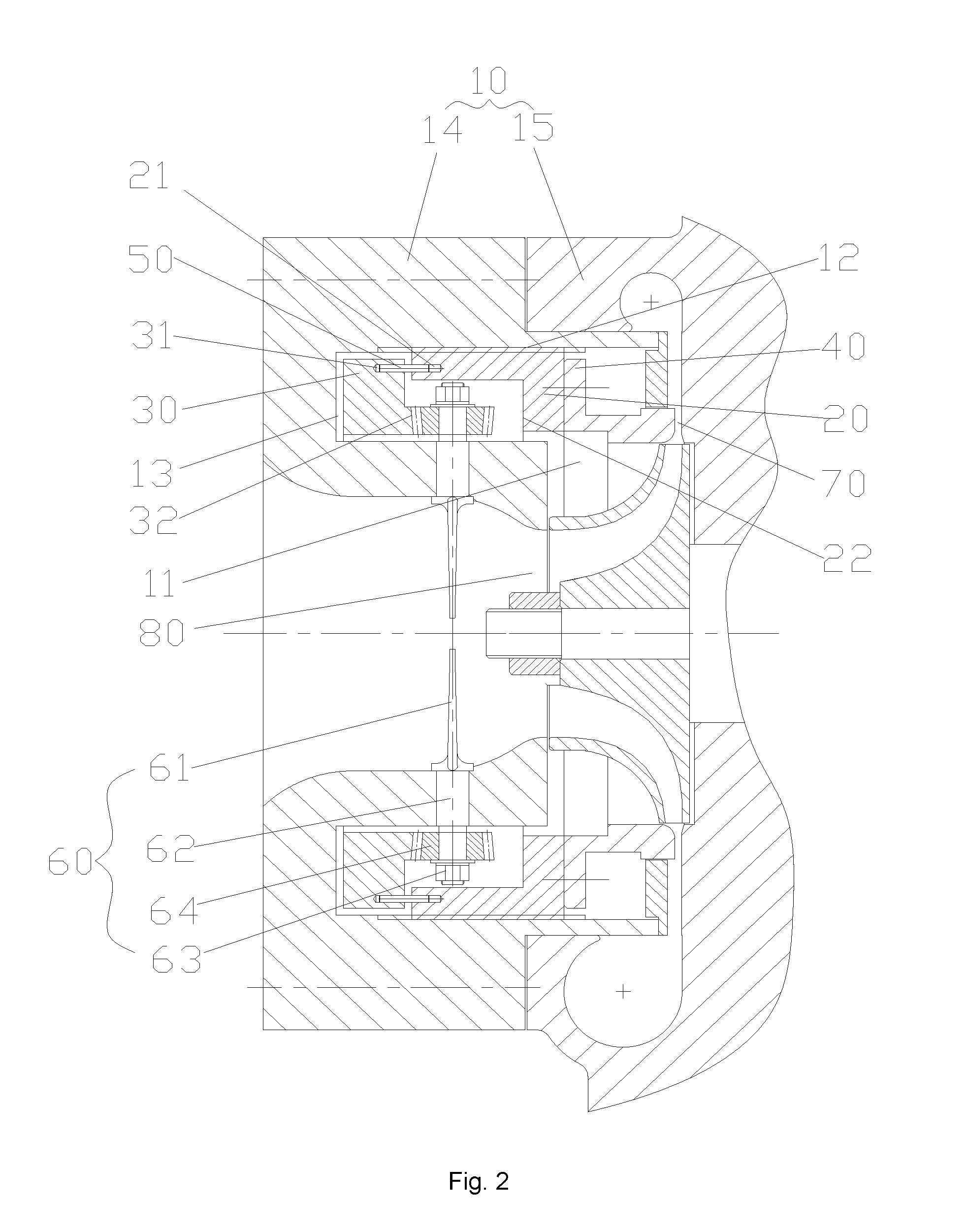

Centrifugal Compressor and Centrifugal Water Chilling Unit

ActiveUS20160281735A1Improve reliabilityEliminate phenomenonEngine manufacturePump componentsCentrifugal compressorMechanical engineering

The invention discloses a centrifugal compressor. The centrifugal compressor comprises: a housing (10), provided with a mounting chamber (11), a thread section (12) being provided on a side wall of the mounting chamber (11); an adjusting piece (20), mounted in the mounting chamber (11), the adjusting piece (20) being provided with threads adapting to the thread section (12); a driving piece (30), mounted in the mounting chamber (11) and configured to drive the adjusting piece (20) to move forwards or backwards along the thread section (12); and an adjustable diffuser (40), fixedly connected to the adjusting piece (20). The invention also discloses a centrifugal water chilling unit having the centrifugal compressor. The centrifugal compressor and the centrifugal water chilling unit can solve the problem that the adjustable diffuser easily inclines and is stuck, thereby greatly improving the reliability of the centrifugal compressor.

Owner:GREE ELECTRIC APPLIANCES INC

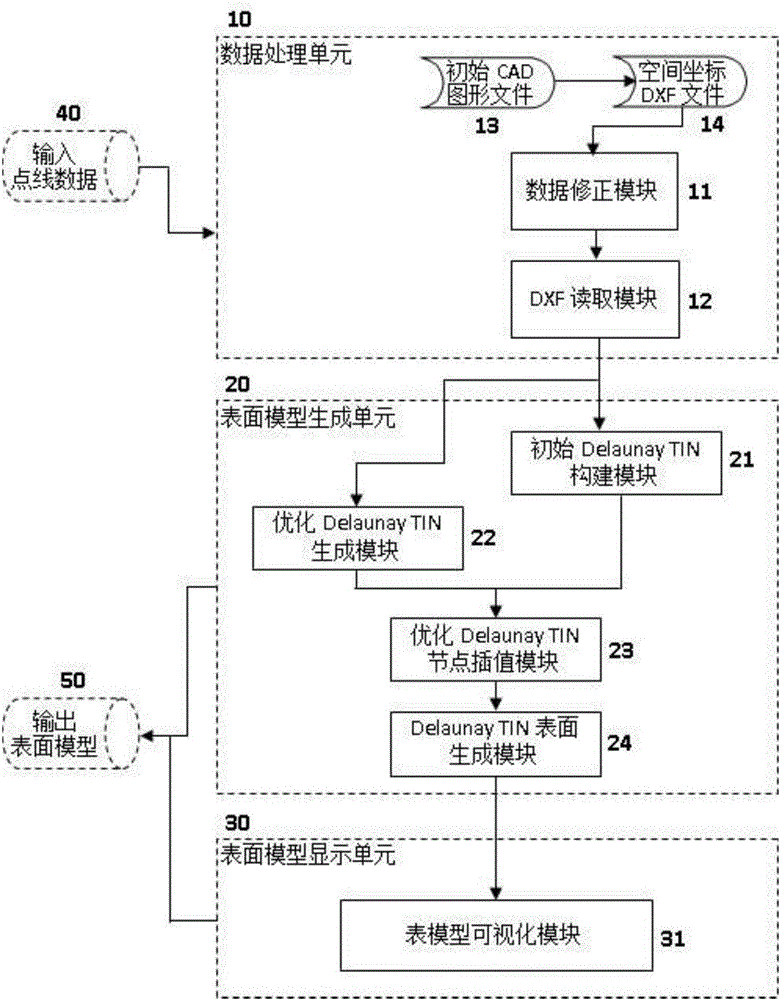

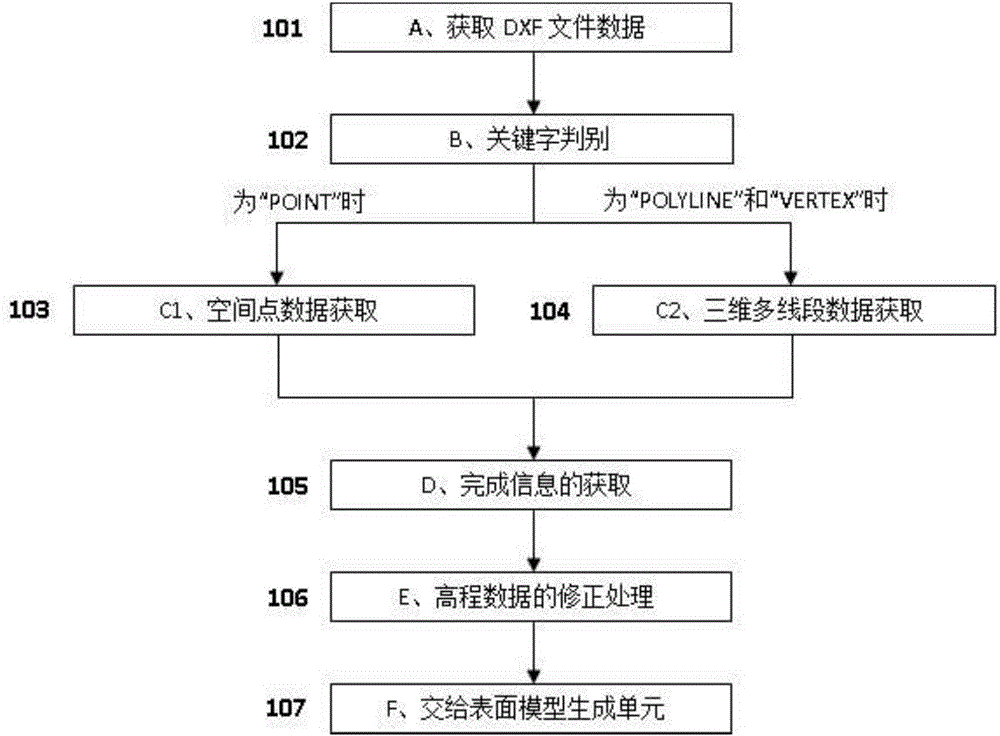

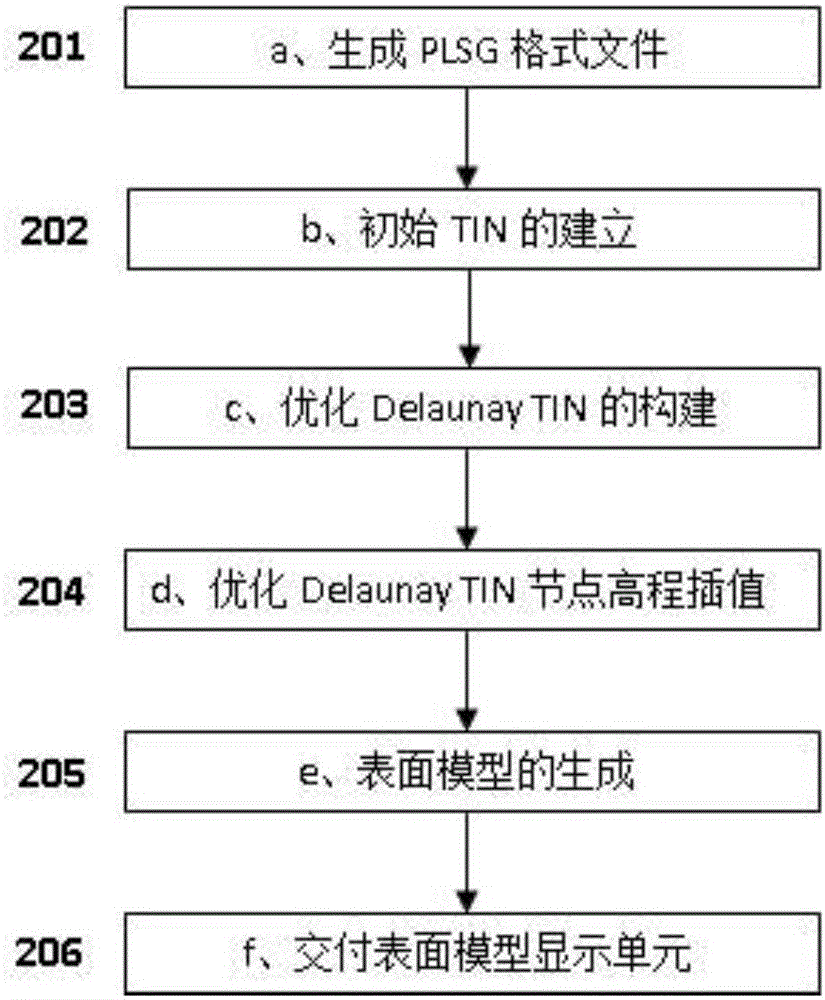

Constrained DelaunayTIN interpolation algorithm-based surface model building method

The invention discloses a constrained DelaunayTIN interpolation algorithm-based surface model building method, and relates to the technical field of computer software development, in particular to three-dimensional visualization, geological modeling, numerical calculation and geological disaster assessment. According to a system, input point line data, a data processing unit, a surface model generation unit, a surface model display unit and an output surface model interact in sequence; and the surface model generation unit interacts with the output surface model. The method comprises the steps of (1) processing data for a three-dimensional multi-line segment DXF file; (2) generating a surface model based on a constrained DelaunayTIN interpolation algorithm; and (3) displaying the surface model based on vtkpython. According to the method, the phenomenon that a slender and narrow pathological triangular patch occurs locally is effectively eliminated; the locally generated distortion of evaluation is effectively eliminated; and the surface model is relatively high in accuracy and relatively good in reasonability, and makes up for the deficiency of an existing method for building an earth surface model in a constraint condition.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Pointless illumination device

InactiveUS20100157600A1Eliminate phenomenonEasy to understandLighting support devicesElectric lightingLight sourceLight-emitting diode

The present invention relates to a pointless illumination device, comprising: a body; a cover, made of a light spreading material which can uniformly spread out the light of a plurality of light emitting devices; a light source module; a first contact portion; and a second contact portion. The light emitted from the light source module is uniformly spread through the cover so that the phenomenon of pointwise illumination does not exist in the illumination device.

Owner:BRIGHT VIEW ELECTRONICS

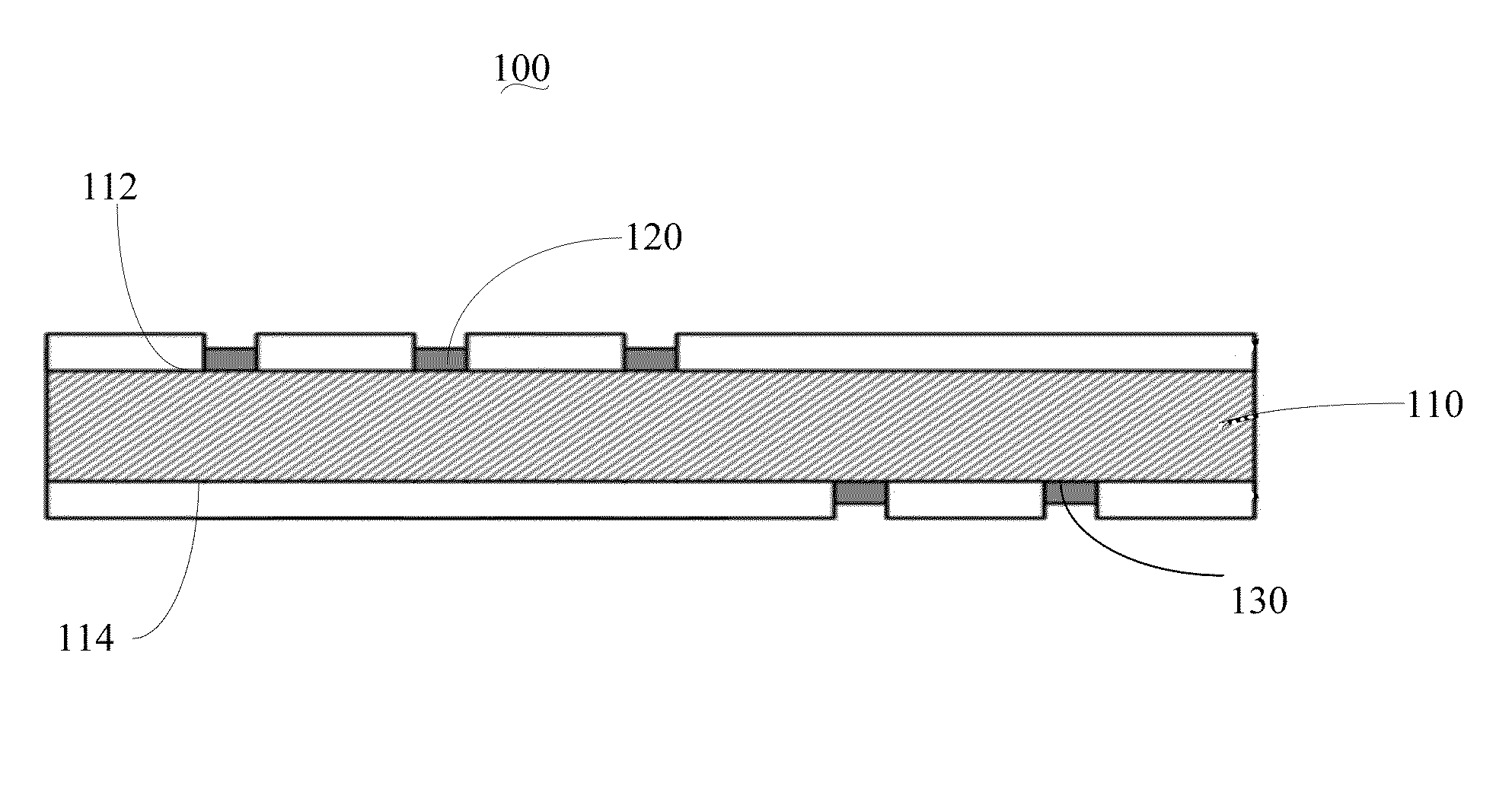

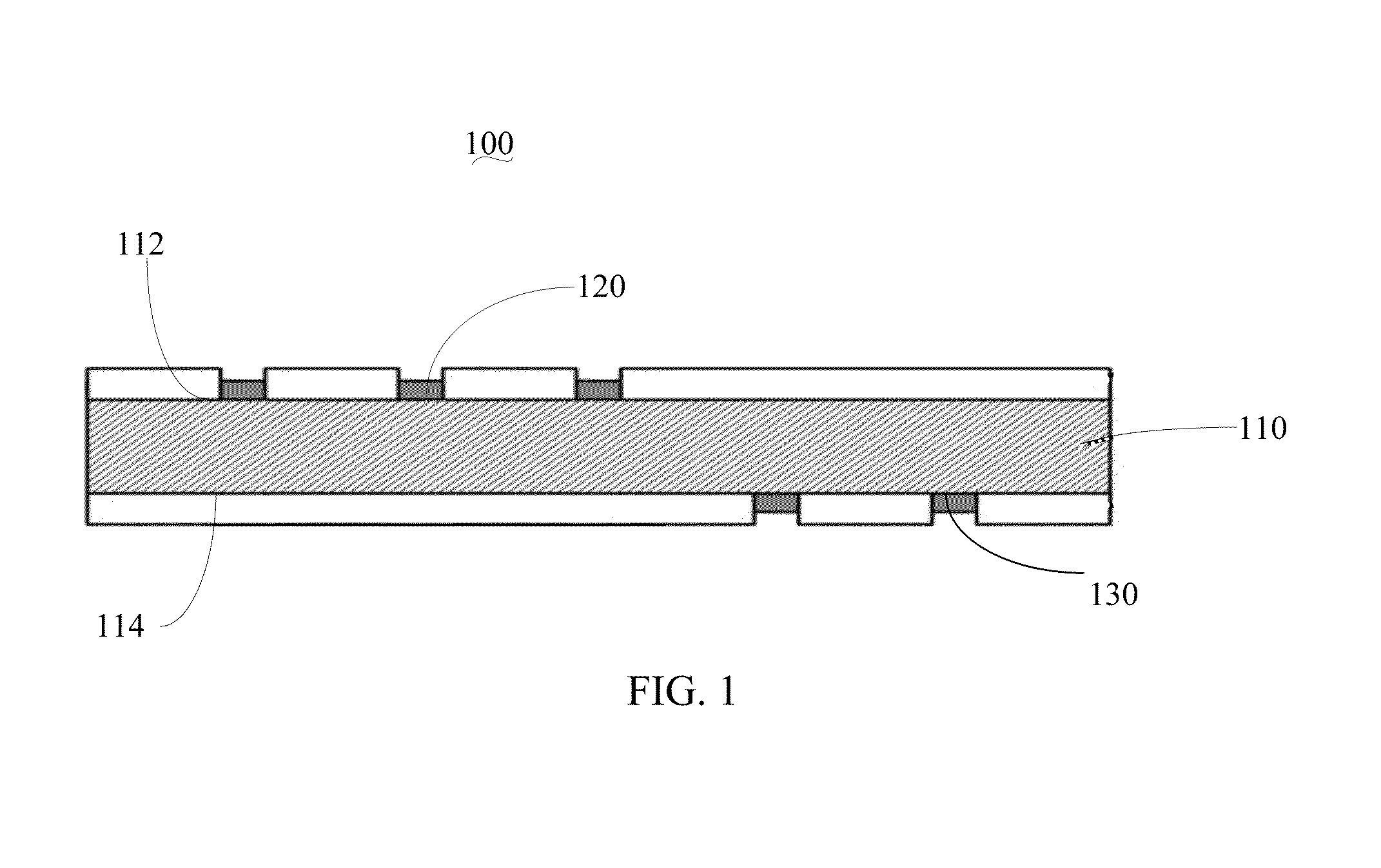

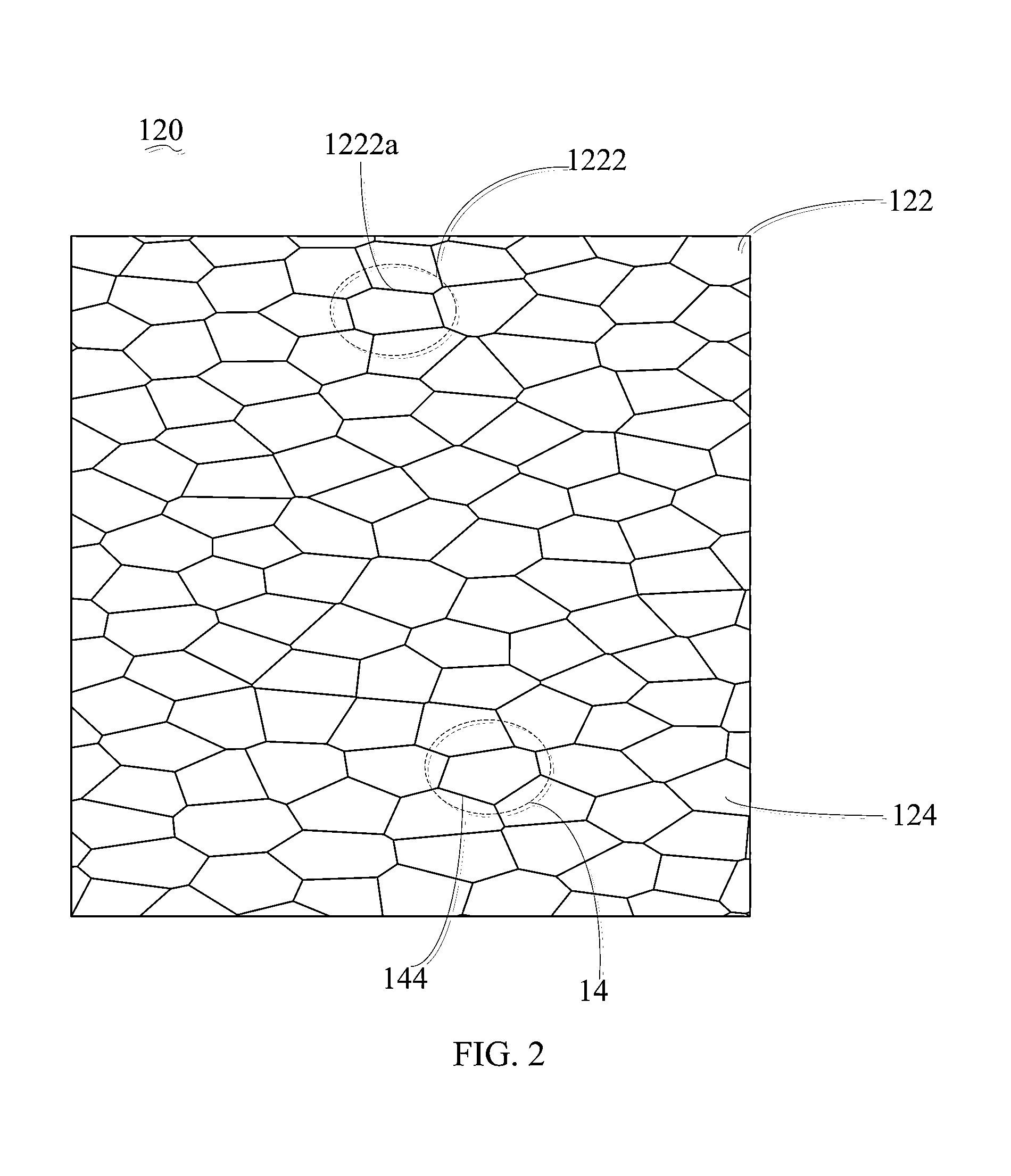

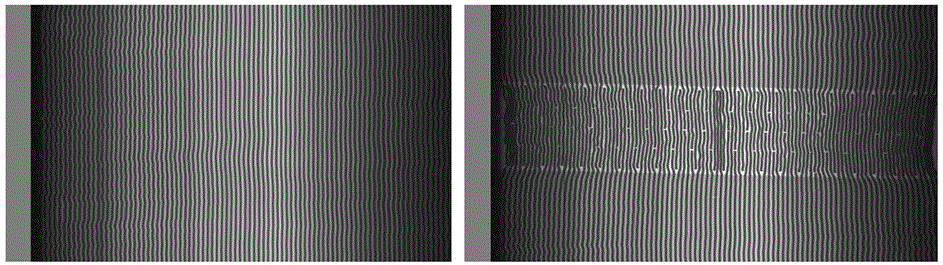

Patterned transparent conductive film

ActiveUS20140216785A1Eliminate phenomenonHigh light transmittanceCircuit optical detailsPrinted circuit aspectsTransmittanceTransparent conducting film

A patterned transparent conductive film is disclosed in the present invention, which includes a substrate, a first conductive layer, a second conductive layer, both the conductive layer includes a conductive area and an insulating area, the conductive area includes a metal mesh formed by a plurality of metal lines; the metal mesh is a buried metal mesh with random irregular grids, a probability density of the slope of the metal lines of the first conductive layer close to transverse direction is greater than that close to longitudinal direction, a probability density of the slope of the metal lines of the second conductive layer close to transverse direction is greater than that close to longitudinal direction, the two conductive layers are laminated and insulated in the thickness direction, the laminated metal meshes are evenly distributed, the light transmittance is increased and the conductivity is constant, the moire fringe is eliminated.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

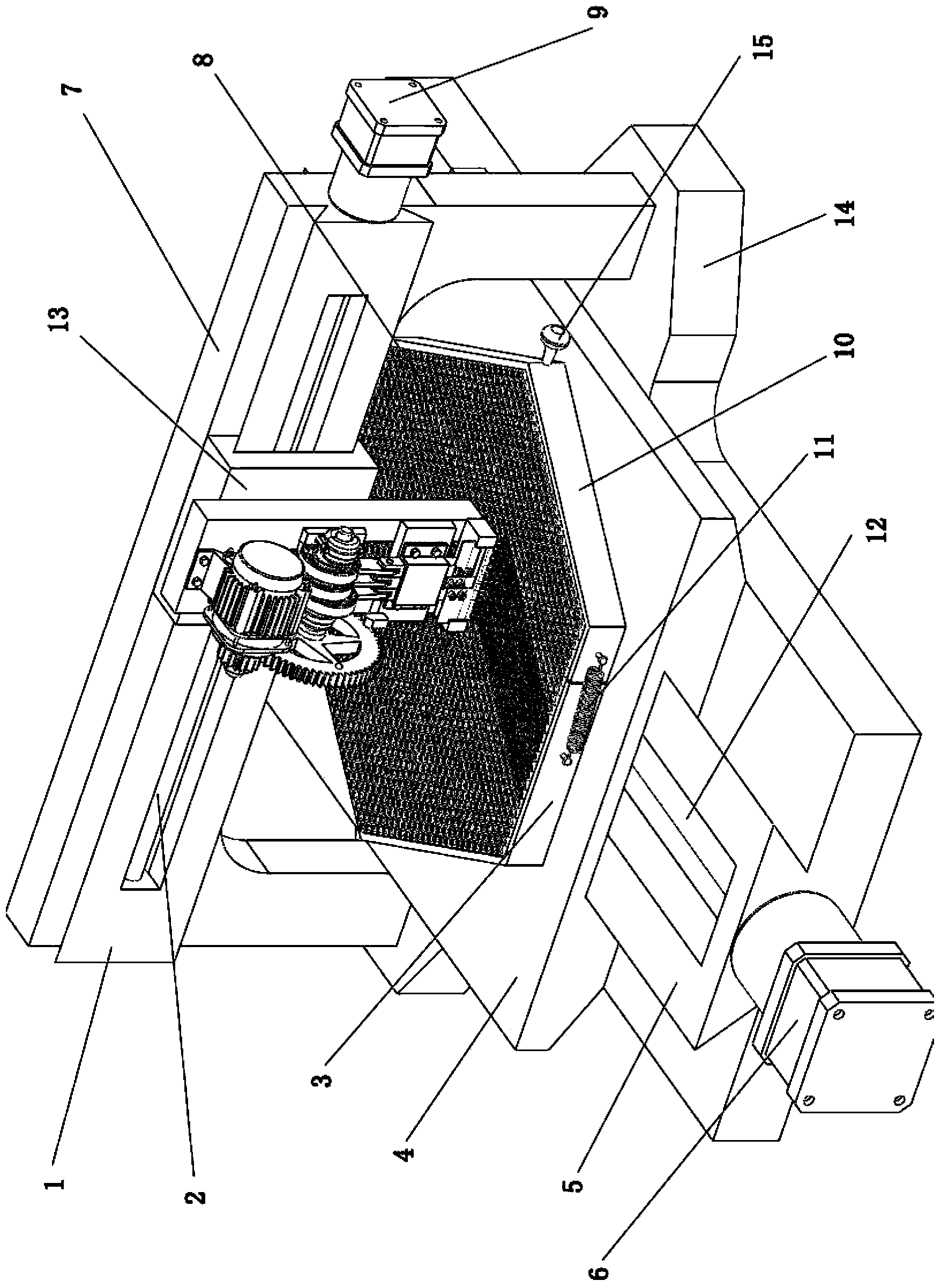

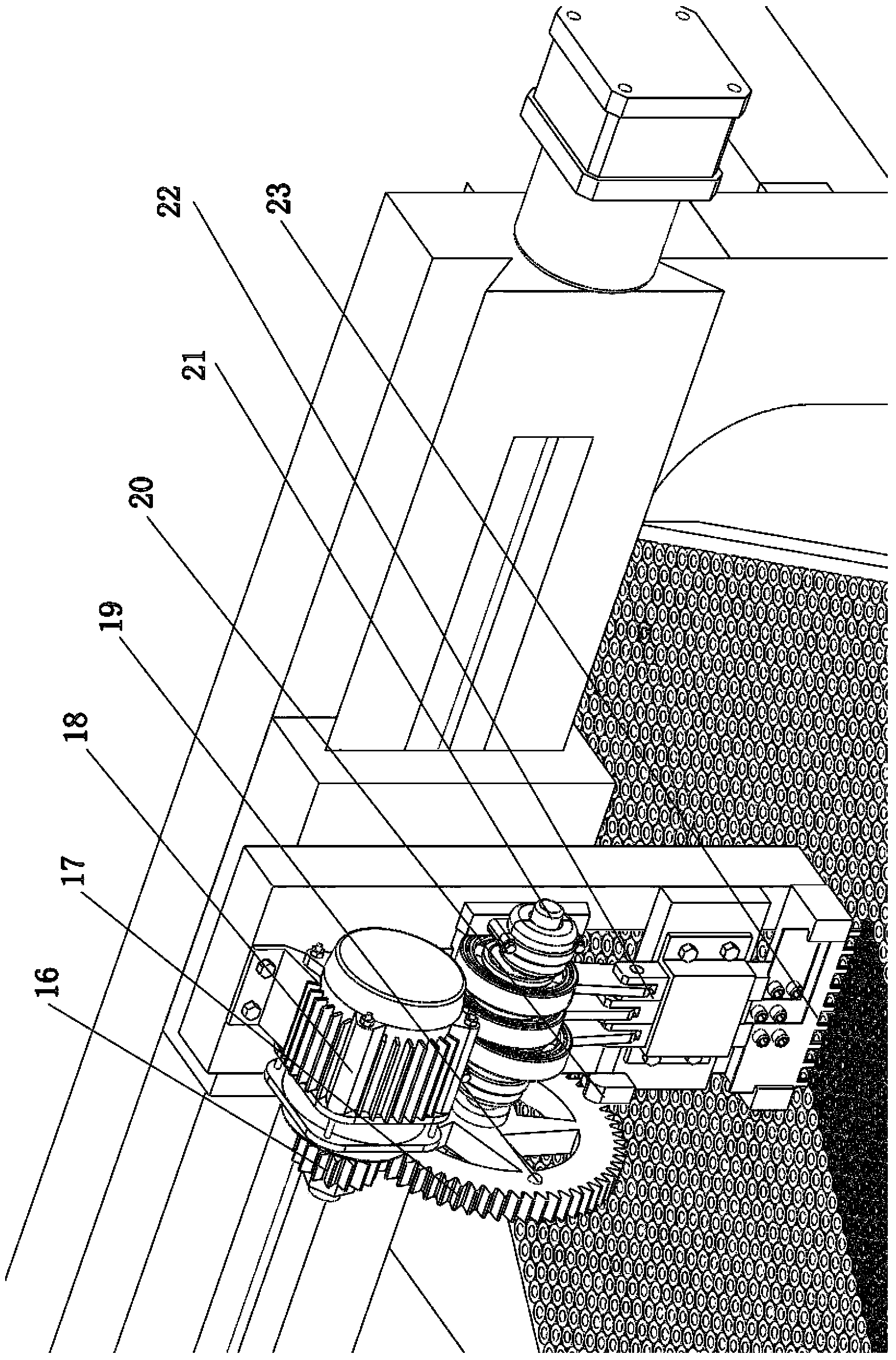

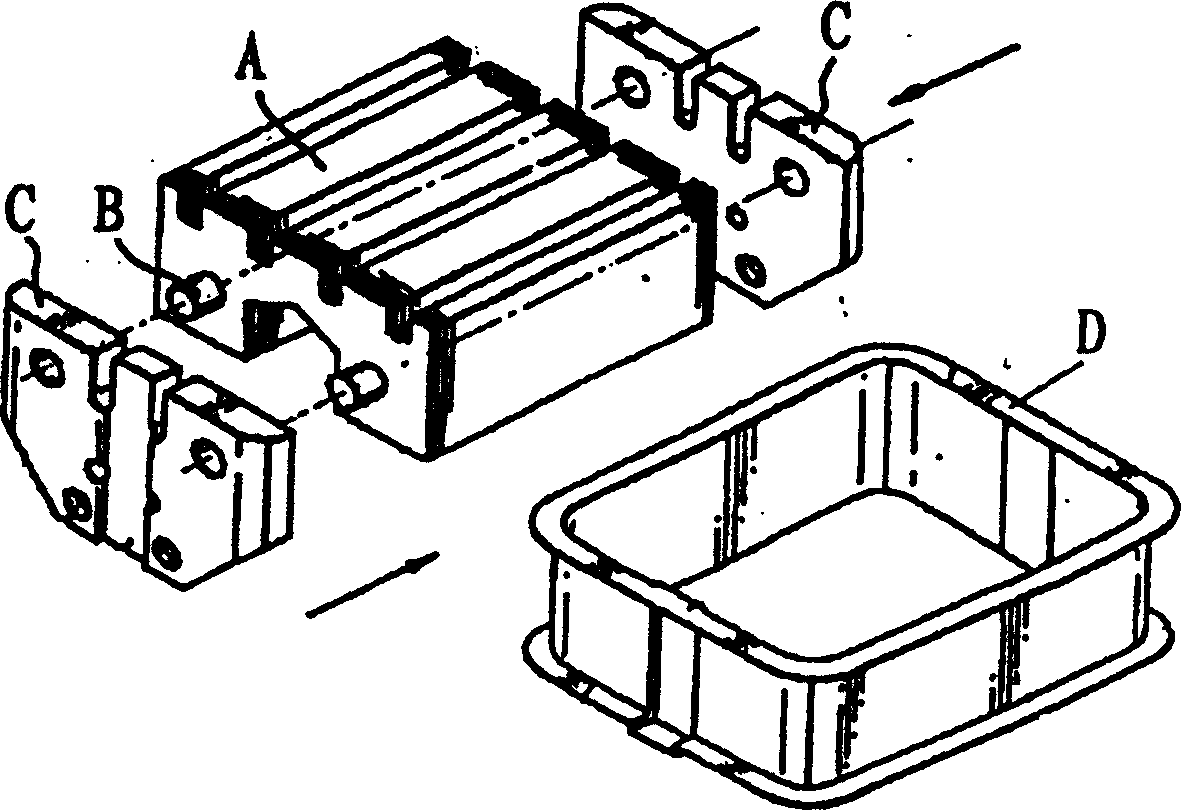

Numerical control firecracker binding and firecracker barrel tail blocking machine

ActiveCN103411481AReduce labor intensityImprove feed positioning accuracyFireworksFirecrackerNumerical control

The invention provides a numerical control firecracker binding and firecracker barrel tail blocking machine to overcome the defects that a large number of waste firecracker barrels are produced due to the fact that an existing hand-operated firecracker binding and firecracker barrel tail blocking machine is high in labor intensity and positioning is inaccurate due to manual feeding, and belongs to the technical field of firework and firecracker machinery. According to the scheme, some technical measures are taken, namely, mechanical power replaces manual power, and numerical control automatic feeding replaces manual feeding. According to numerical control automatic feeding, firecracker barrels are fixed, clamped and bound on a longitudinal sliding table, and an electric firecracker barrel tail blocking machine head is arranged on a transverse sliding table. Through a single board computer and the like, the longitudinal sliding table and the transverse sliding table are controlled to move synchronously, therefore, firecracker barrel tail blocking needles can be aligned with each row of firecracker barrels, and numerical control automatic feeding can be achieved. According to the scheme, due to the fact that manual power is replaced by an electromotor, labor intensity of workers is greatly relieved, and meanwhile the working speed is greatly raised. After manual feeding of the firecracker barrel tail blocking machine is replaced by the numerical control automatic feeding, the feeding positioning accuracy of the firecracker barrels is greatly improved, and the phenomenon of appearance of the waste firecracker barrels caused by inaccurate positioning is basically eliminated.

Owner:启东市天汾电动工具技术创新中心

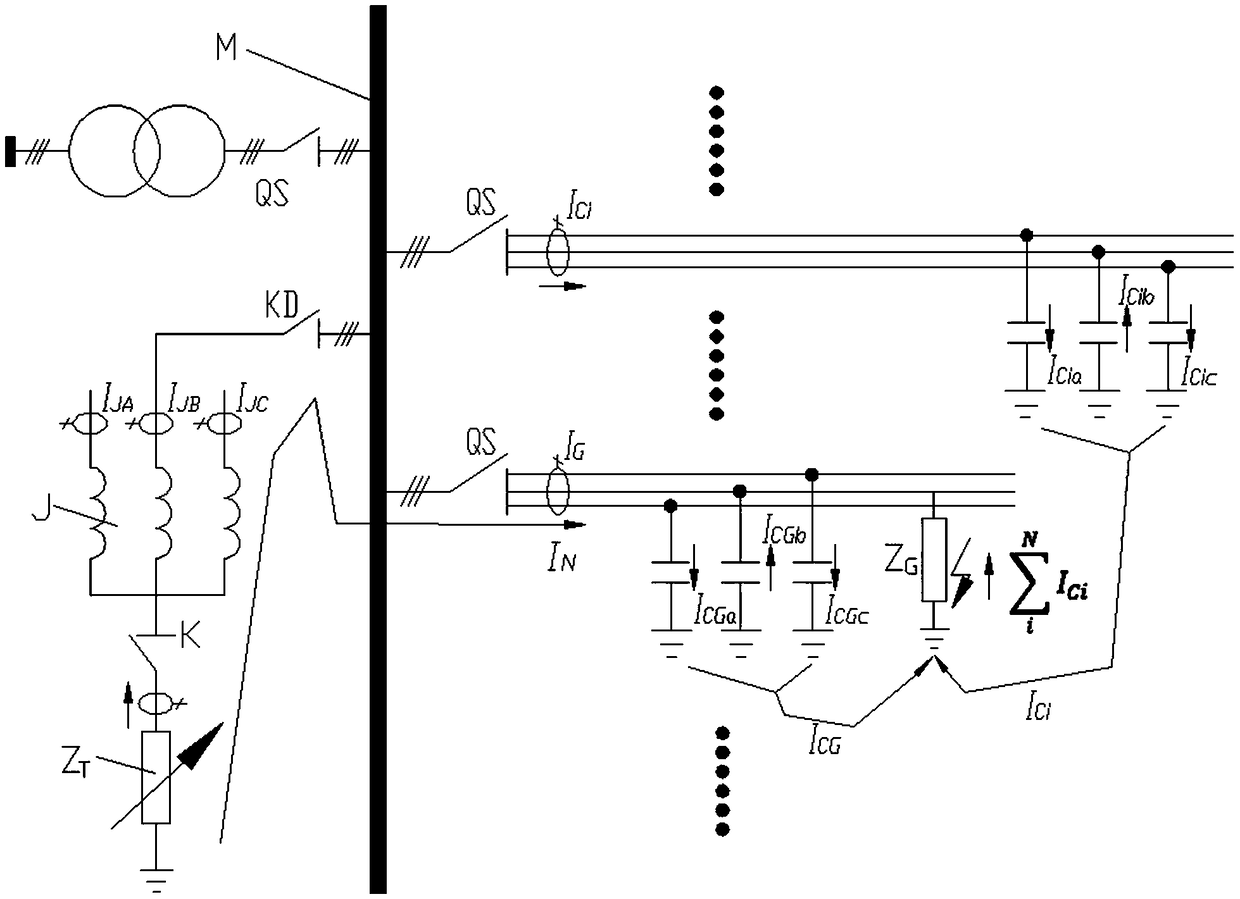

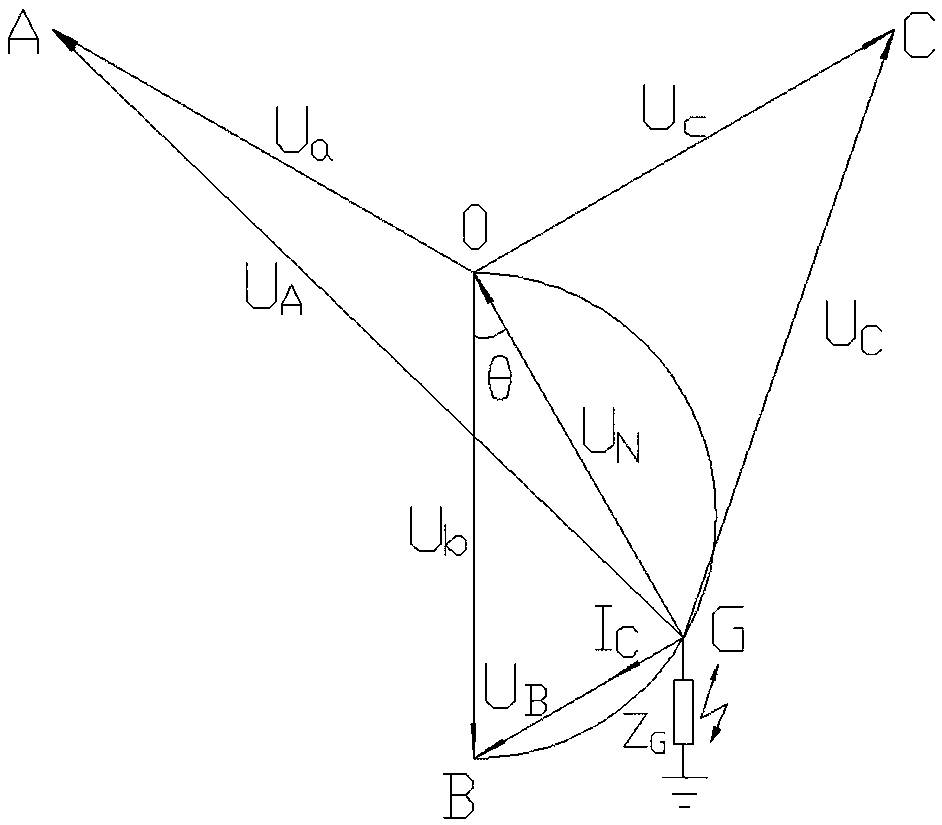

Automatic tracking small-current line selection device and line selection method

PendingCN109444672ALine selection is accurateAccurate judgmentFault location by conductor typesElectrical resistance and conductanceHigh resistance

The invention discloses an automatic tracking small-current line selection device and a line selection method. The device is characterized in that a neutral point is arranged in a system with a small-current grounding mode, a controllable impedance part capable of achieving automatic tracking adjustment is arranged between the neutral point and the ground, and a maximum value of the controllable impedance part is set according to the rated voltage of the system; the controllable impedance part is tracked and adjusted according to the system-to-ground voltage or the current of the controllableimpedance part. According to the device and the method, the zero sequence current of a fault line is maximized, the judgment precision of the line selection current is high, the fault line is accurately judged, and line selection is not affected by an arc suppression coil; moreover, the device can be applied to judgement of the fault line when a small-resistance grounding system is grounded with high resistance, and a protection dead zone of the neutral point small-resistance grounding system is removed.

Owner:张安斌

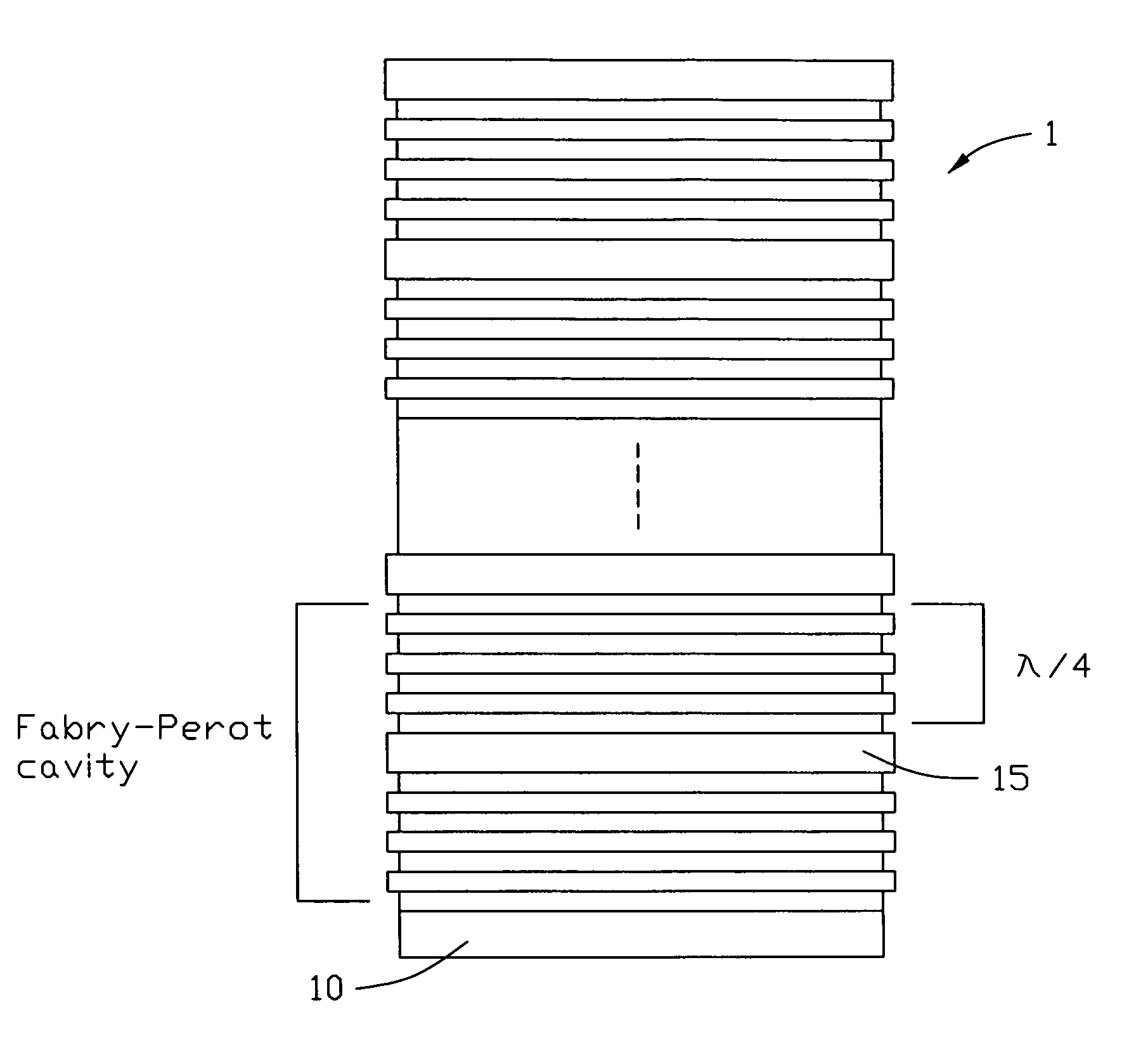

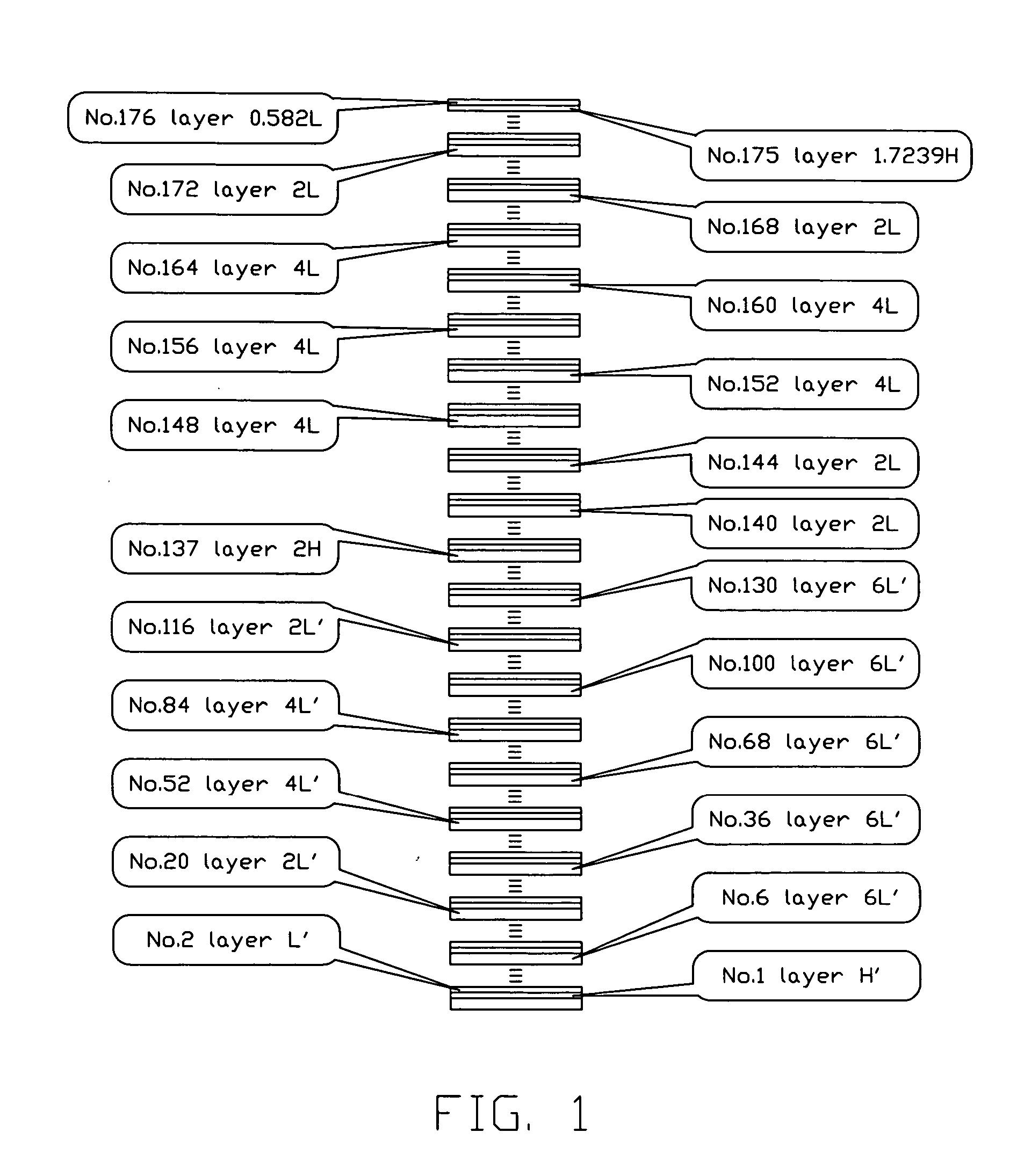

CWDM filter for eliminating noise

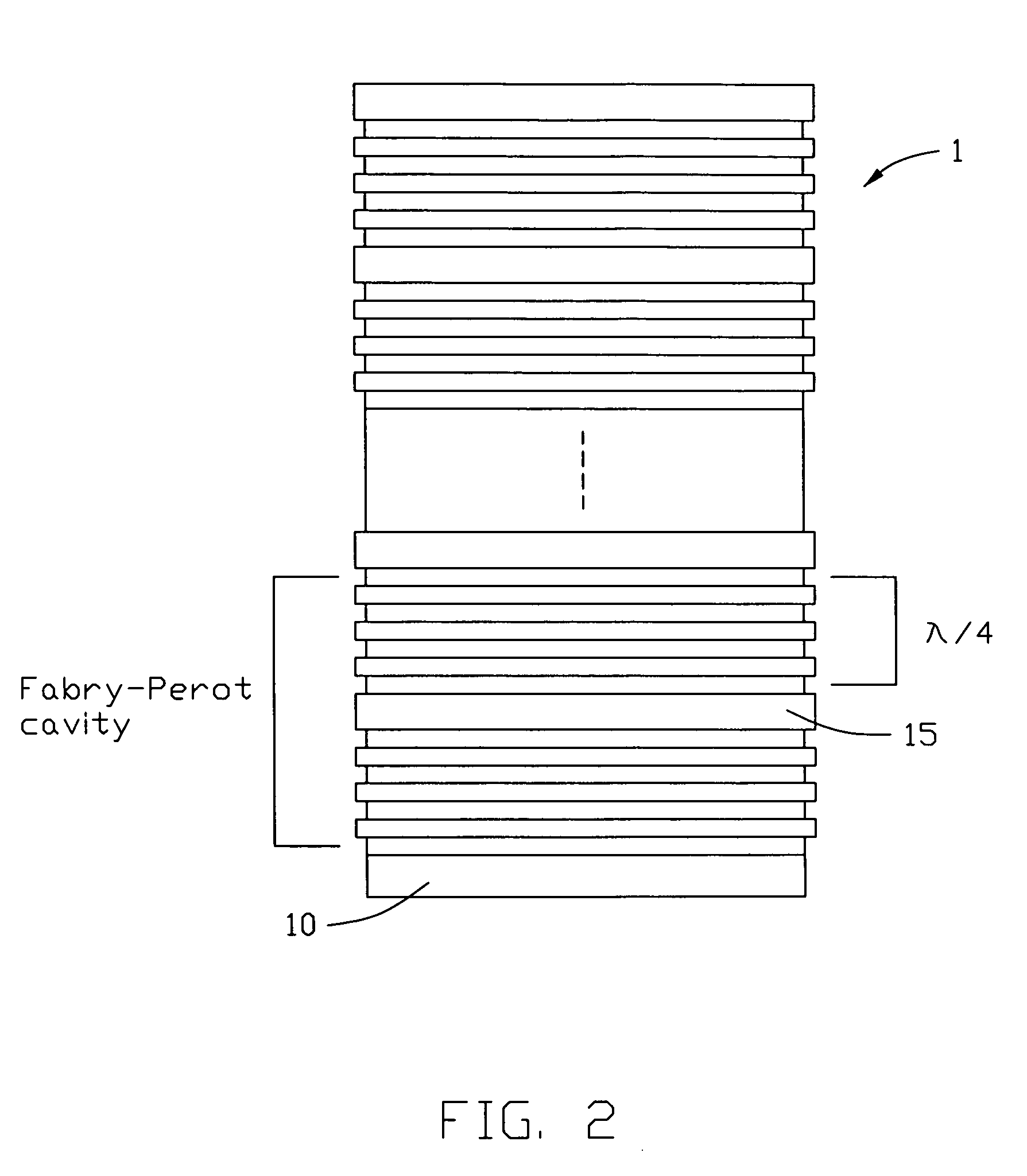

InactiveUS20060012882A1Cancel noiseEliminate phenomenonOptical filtersCoupling light guidesCouplingRefractive index

A CWDM filter of the present invention comprises a substrate; a first portion formed on the substrate having at least two first stacking structures; a second portion superposed on the first portion including at least two second stacking structures; and a first matching layer sandwiched between the first and second portions. Each of the first stacking structures of the first portion has a Fabry-Perot cavity and a first coupling layer which are stacked over each other in turn from the substrate. Each second stacking structure has a (HnLH) structure and a second coupling layer, wherein n represents a positive integer greater than 1, L represents a low index layer with a thickness of λo / 4, H represents a high index layer with a thickness of λo / 4, and λo is the center wavelength of said noise.

Owner:ASIA OPTICAL CO INC

Basic matrix based on irregular LDPC, codec and generation method thereof

ActiveUS8607125B2Eliminate phenomenonSpeed up the fallError detection/correctionCode conversionEssential matrixAlgorithm

The codec includes an encoding / decoding operation module and a basic matrix storage module. In the stored basic matrix Hb, for all girths with length of 4, any column element of i, j, k or l constituting the girths in anti-clockwise or clockwise always satisfies inequality: (i−j+k−1) mod z≠0, wherein z is the extension factor. When generating the basic matrix, firstly the number of rows M, number of columns N, and weight vectors of the rows and columns are determined, an irregularly original basic matrix is constructed; then the position of ‘1’ is filled by a value chosen from set {0, 1, 2, . . . , z−1} to obtain the basic matrix Hb. The basic matrix Hb obtained by storing constitutes the desired encoder / decoder. The encoder / decoder according to the present invention can effectively eliminate error-floor phenomenon of LDPC codes and accelerate the falling speed of BER curve.

Owner:ZTE CORP

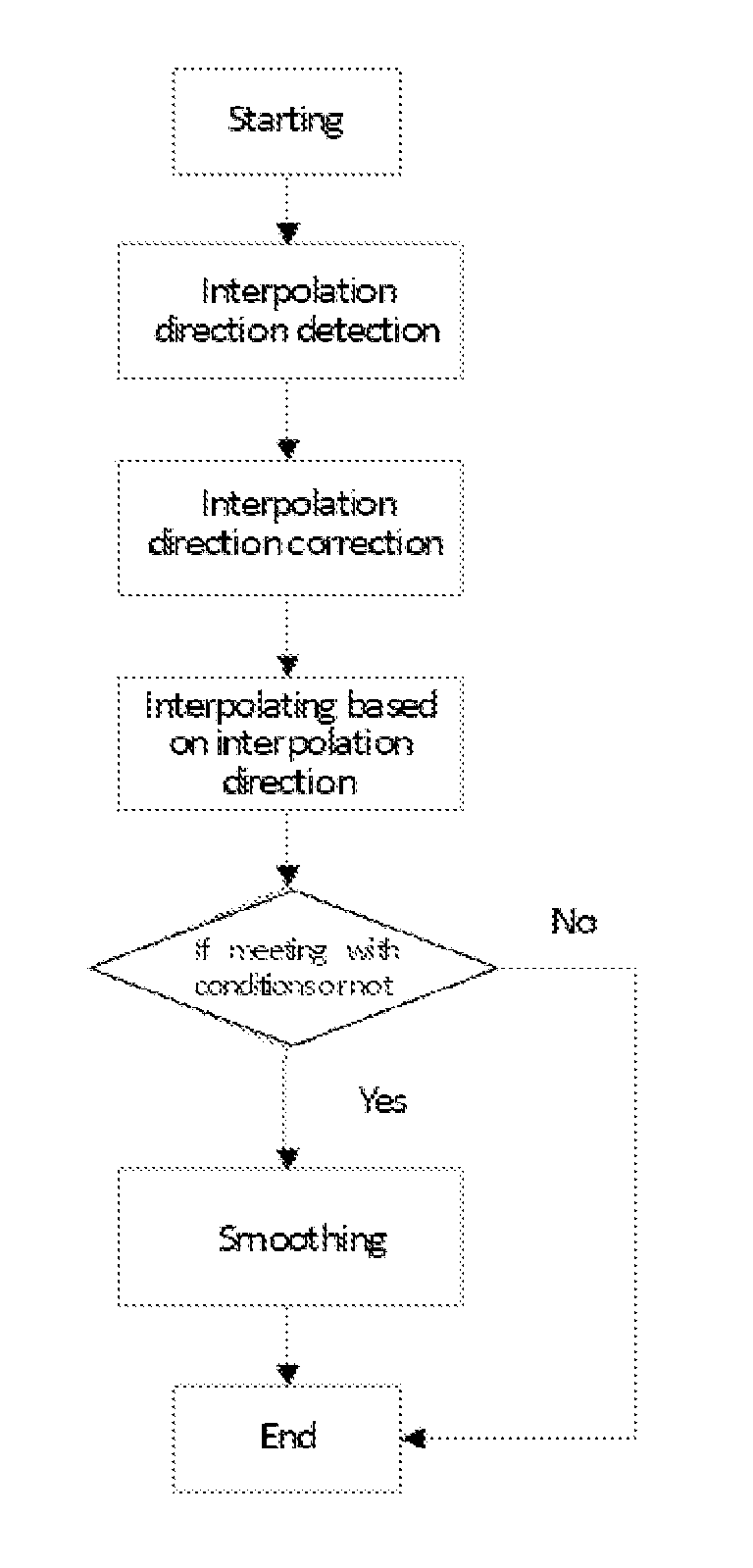

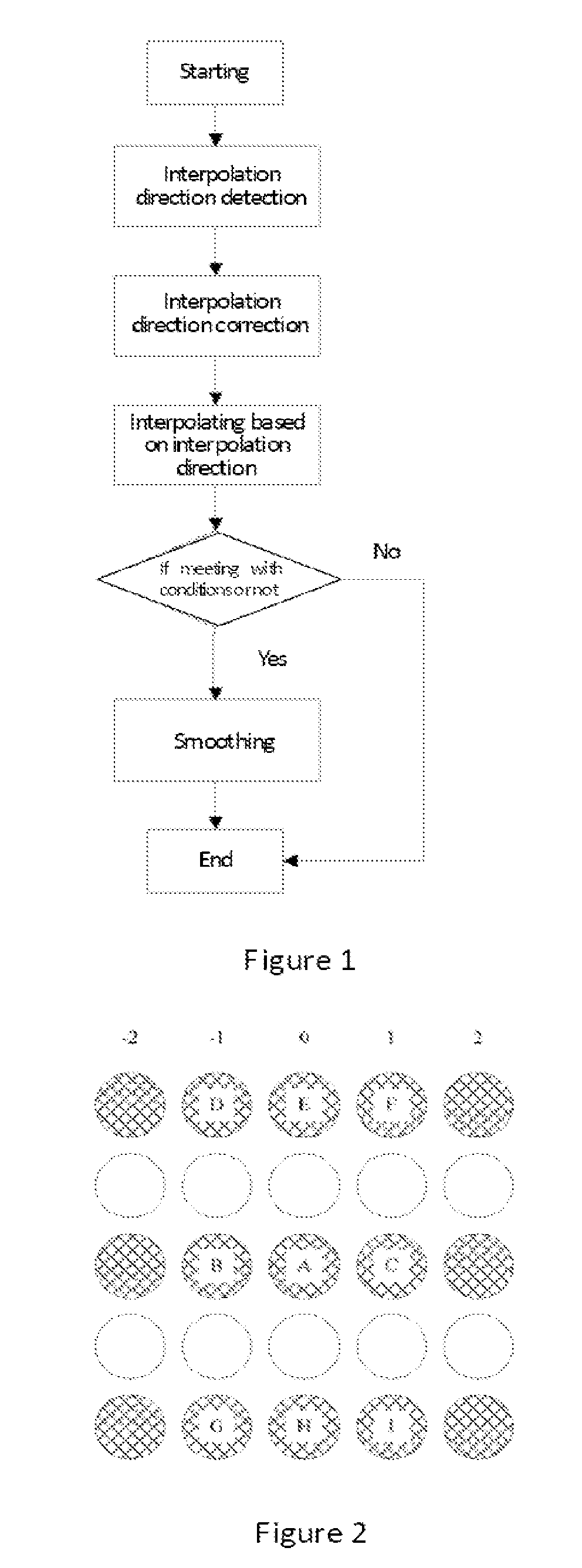

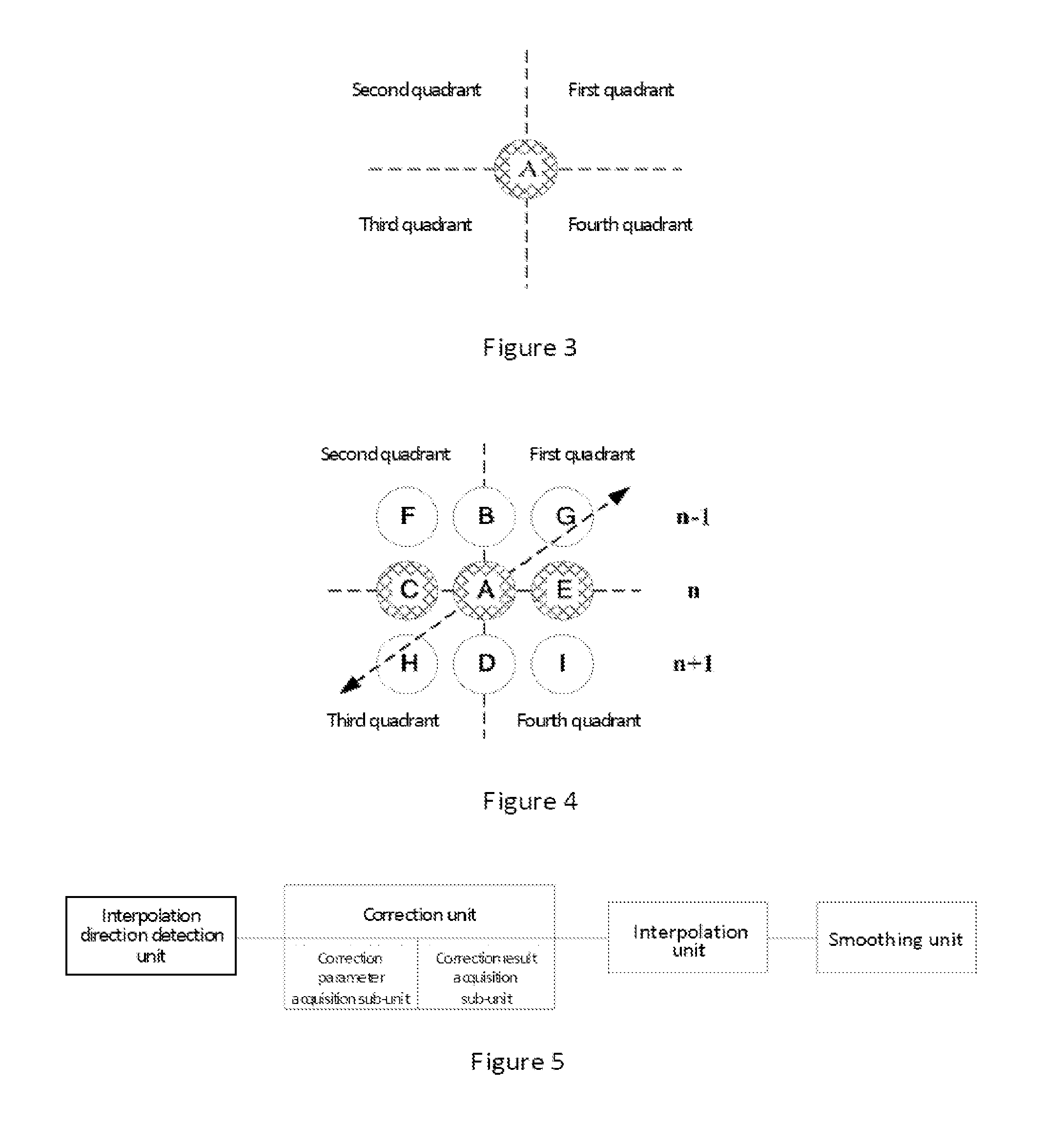

Image interpolating method based on direction detection and device thereof

InactiveUS20120002902A1Decrease and eliminate influenceThe test result is accurateGeometric image transformationCharacter and pattern recognitionAlgorithmDirection detection

An accurate image interpolation method based on direction detection and device thereof are disclosed. The image interpolation method based on direction detection includes the following steps: step a, detecting an interpolating direction of a pixel to be processed to obtain interpolating direction information of the pixel; step b, utilizing the result of detecting an interpolating direction to interpolate the pixel to be processed. Another step a′ between the step a and step b is also included: utilizing the interpolating direction information of the pixel adjacent to the pixel to be processed for correcting the result of step a; at step b, utilizing the detection result of interpolating direction corrected at the step a′ to interpolate the pixel to be processed.

Owner:POWERLAYER MICROSYST HLDG

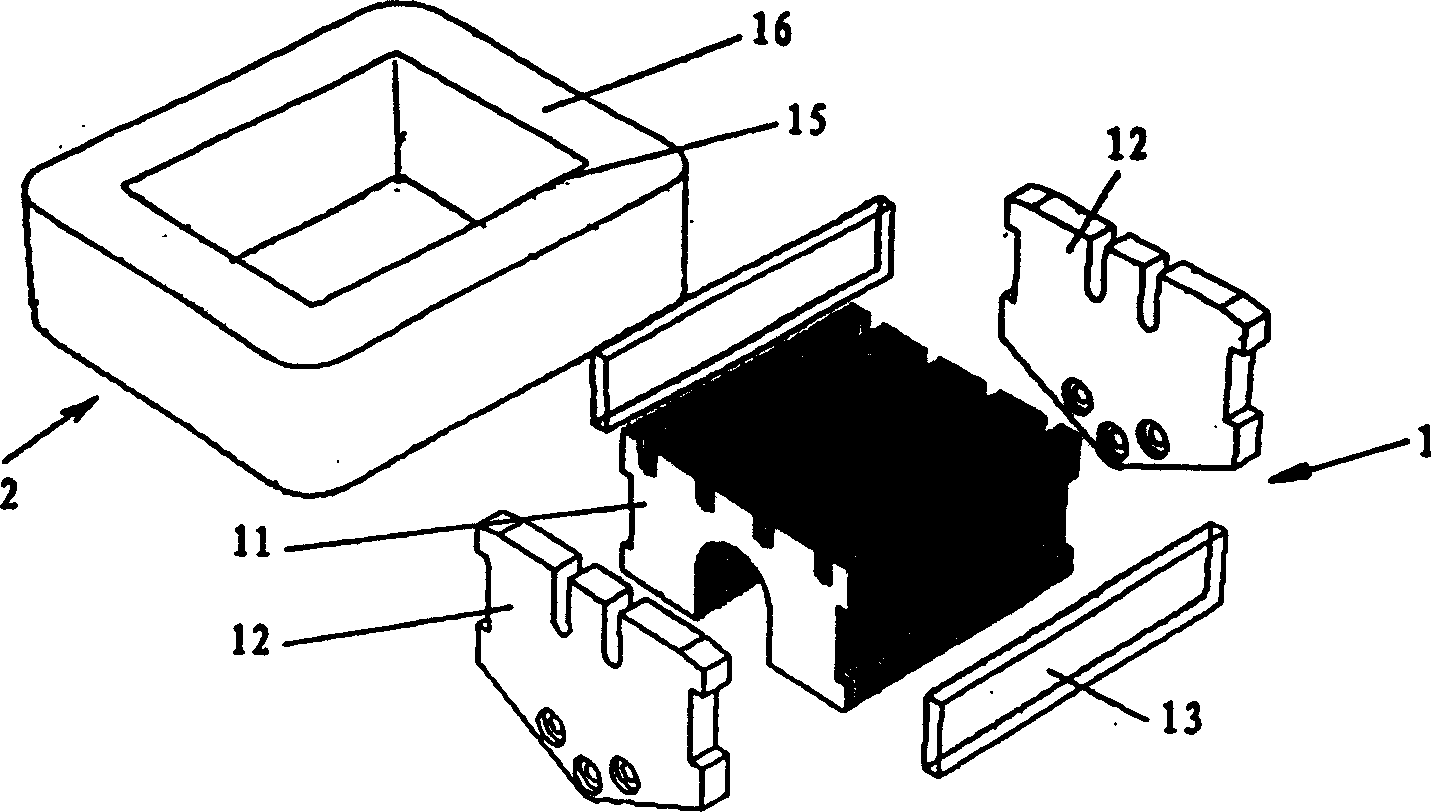

Suspension magnet of high speed magnetic suspension train and manufacturing method thereof

InactiveCN1758504AShort magnetic circuitEliminate flux density saturationMagnetic circuit shape/form/constructionPropulsion systemsSUSPENDING VEHICLEEngineering

This invention relates to suspend electromagnets for high speed magnetic suspend vehicles and their manufactured method, in which, the magnet includes a core and suspend coils characterizing that the chip of the core and an end plate are opened with key slots at the corresponding places of both side edges and pin keys fixedly connecting the chip and the end plates are set in the key slots with an insulation layer set between them and the suspend coil is composed of an internal insulation bush closely adhered to the core and winded to formation on it and excitation coils winded directly.

Owner:TONGJI UNIV

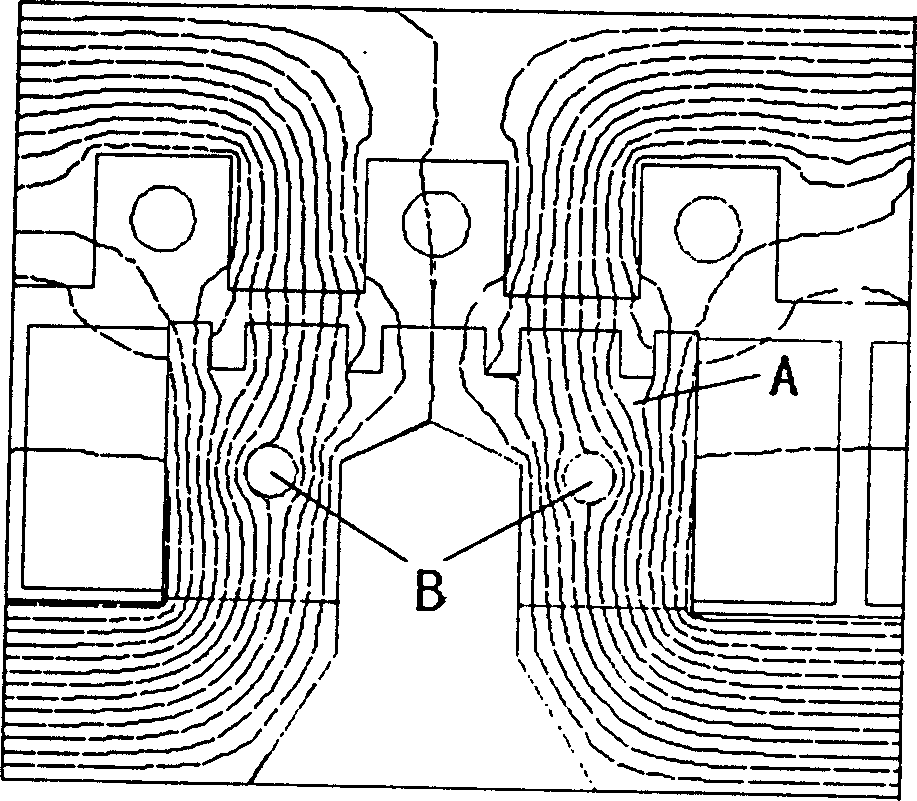

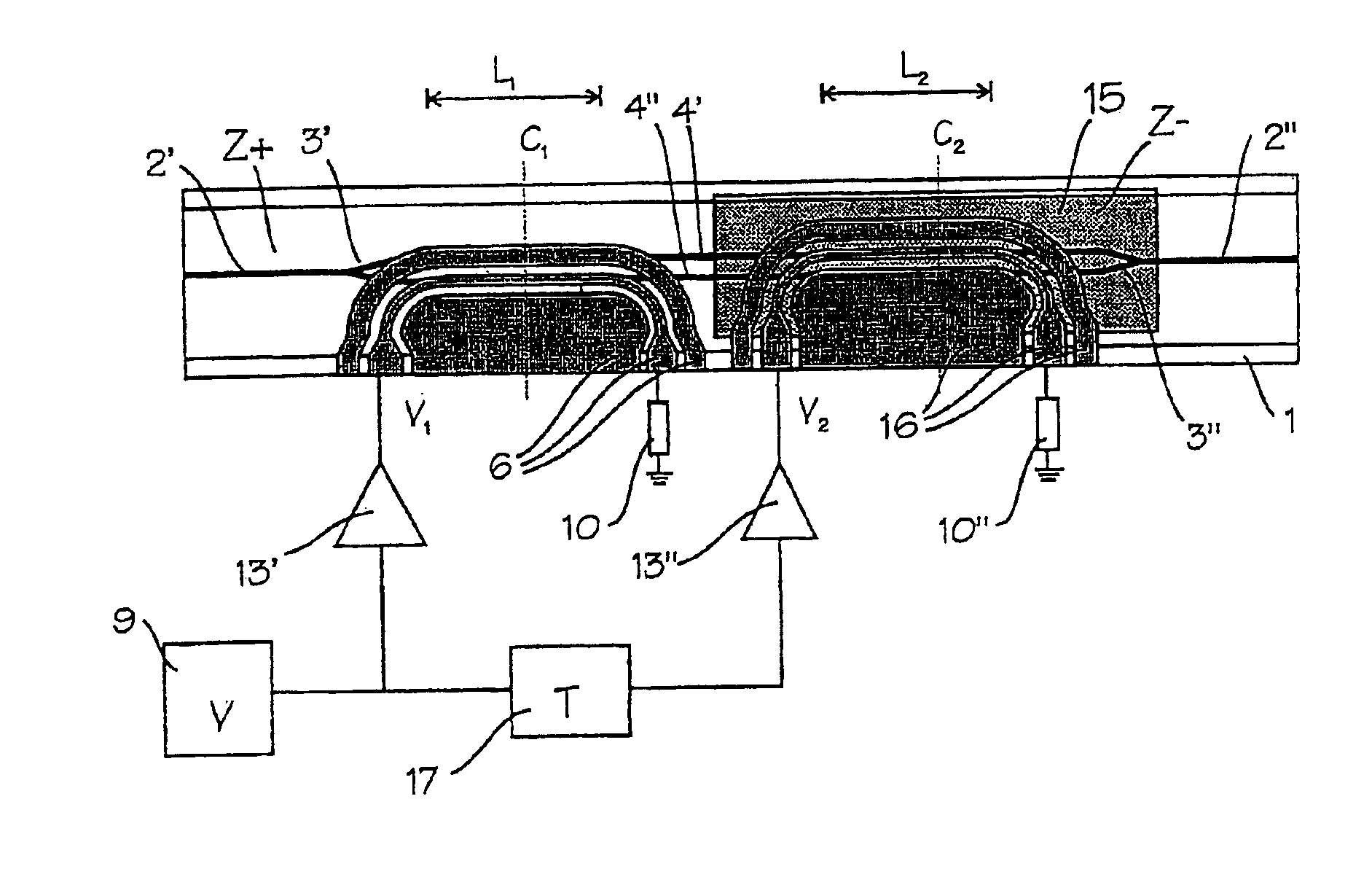

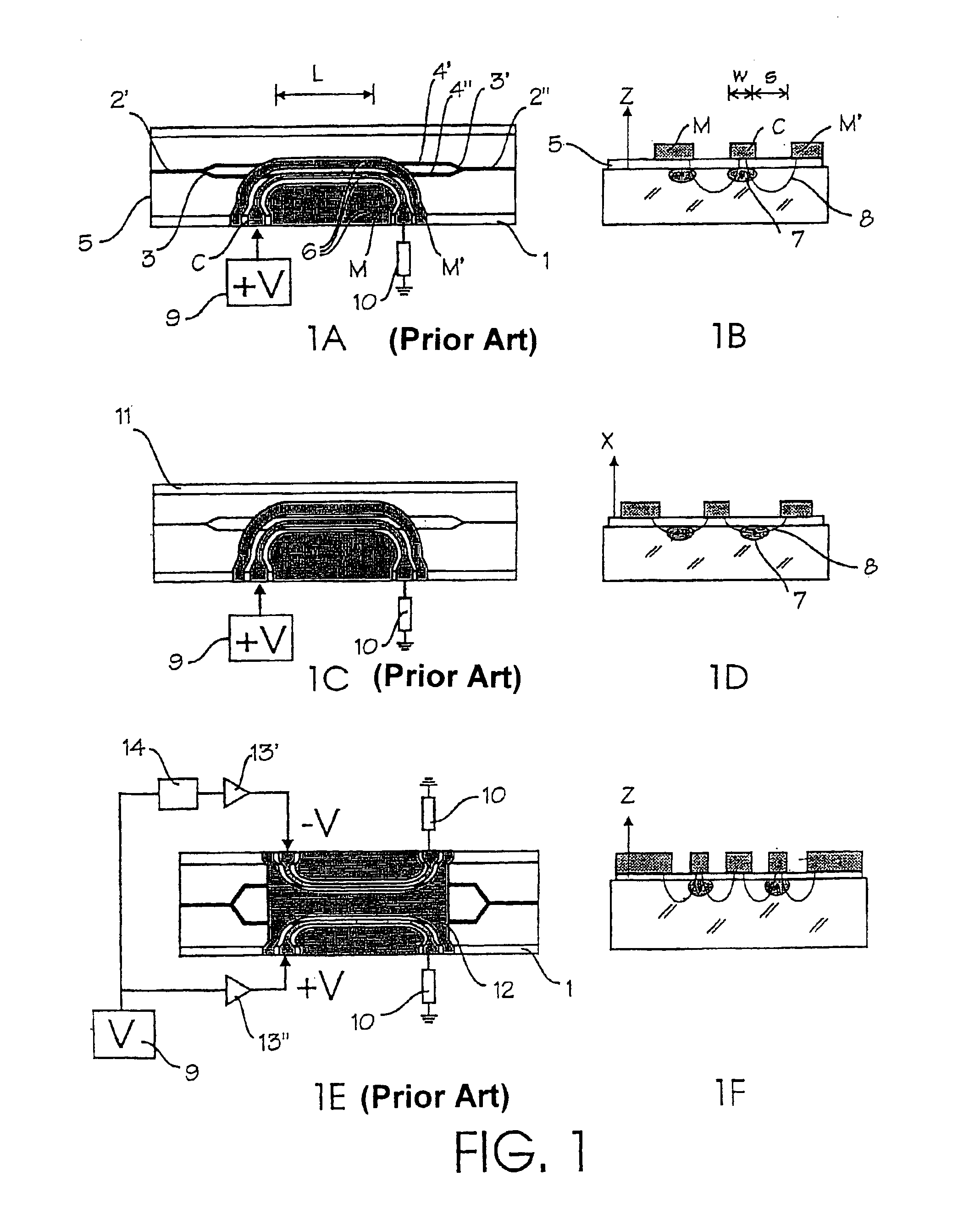

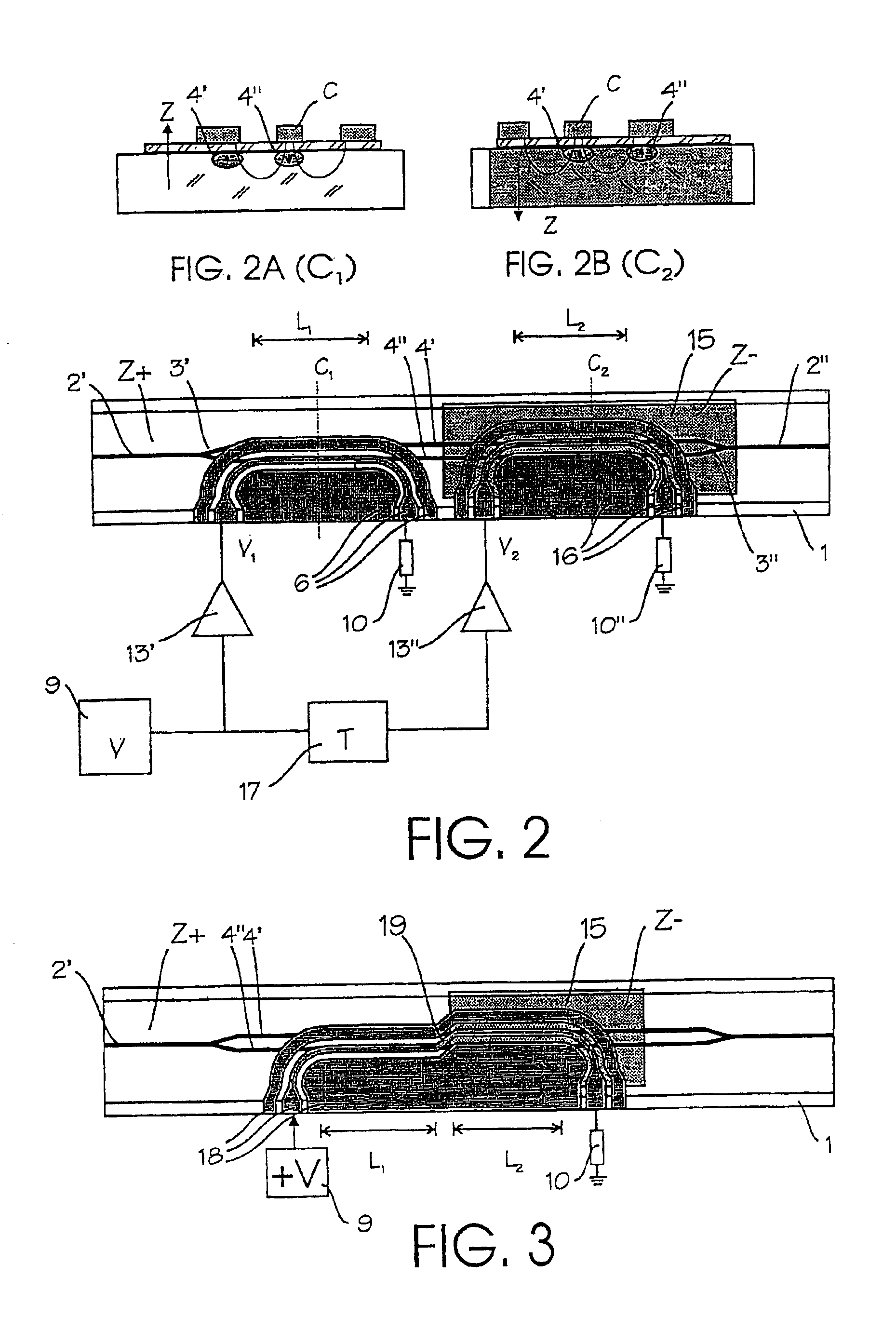

Wide band electro-optical modulators

InactiveUS6947614B2Improve frequency responseEliminate phenomenonCoupling light guidesOptical waveguide light guidePhase differenceControl electronics

An optical modulator includes a waveguide structure forming a two-wave interferometer made of an electro-optical material, and two arms, a set of electrodes connected to a controllable electric source for applying an electric field on at least one of the arms of the interferometer, so as to vary the phase difference between light waves along one or the other of the two arms. The modulator includes two sets of electrodes placed respectively on each of the interferometer arms, one in the non-reversed region of the electro-optical material, the other in the reversed region, and a delay line placed between the control electronics of the electrode sets introducing a delay equal to the light propagation time in the first electrode set.

Owner:CENT NAT DE LA RECHERCHE SCI

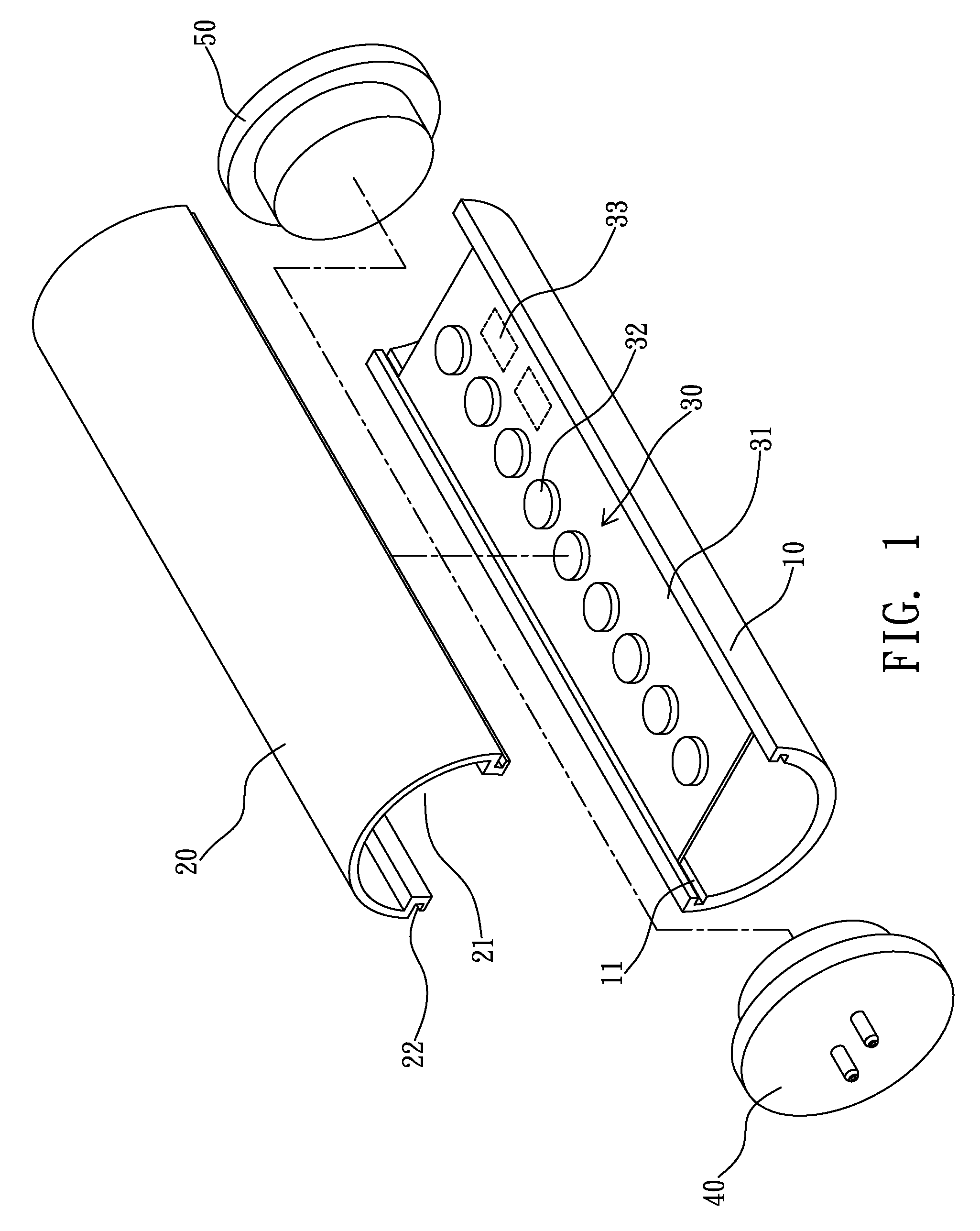

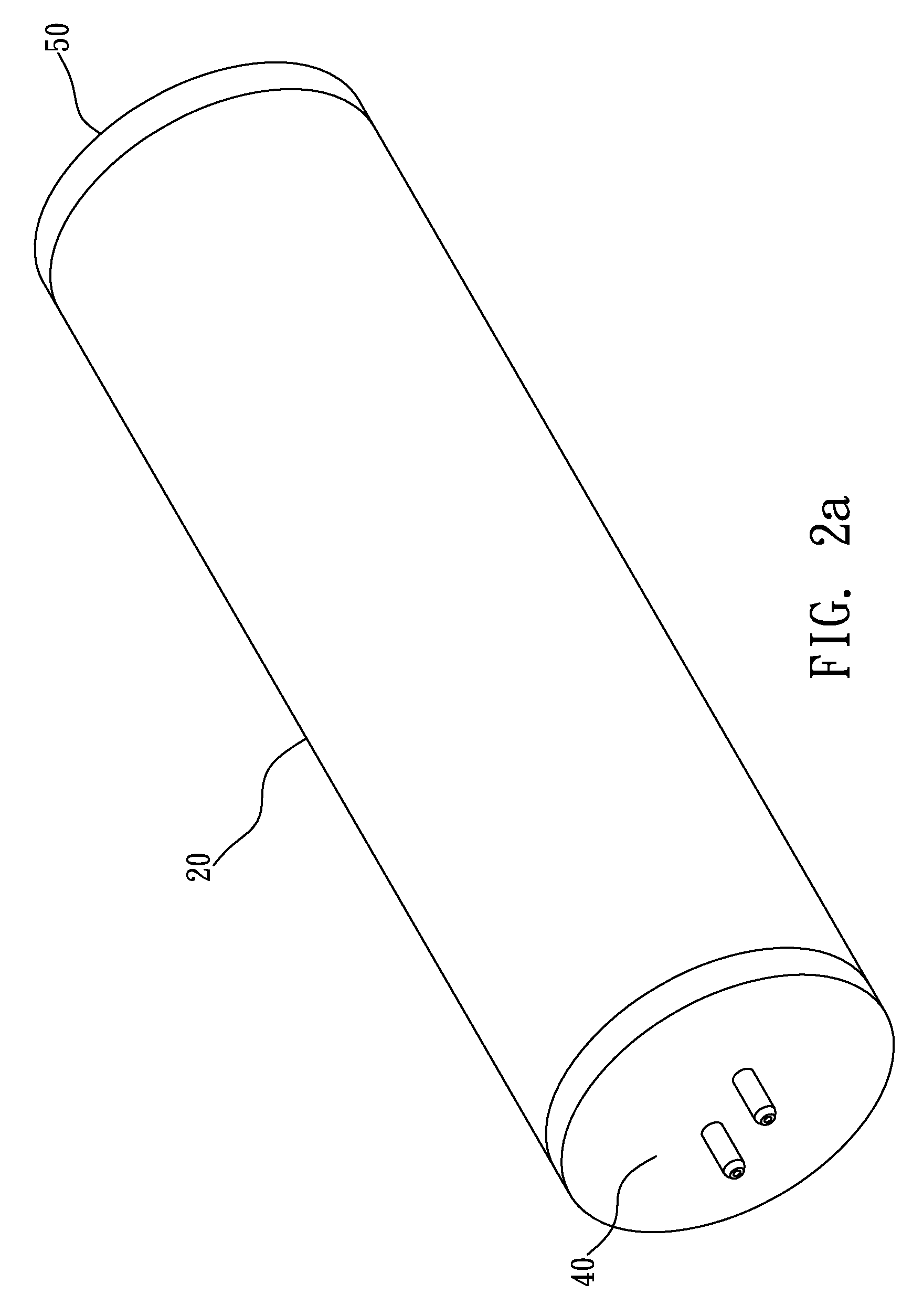

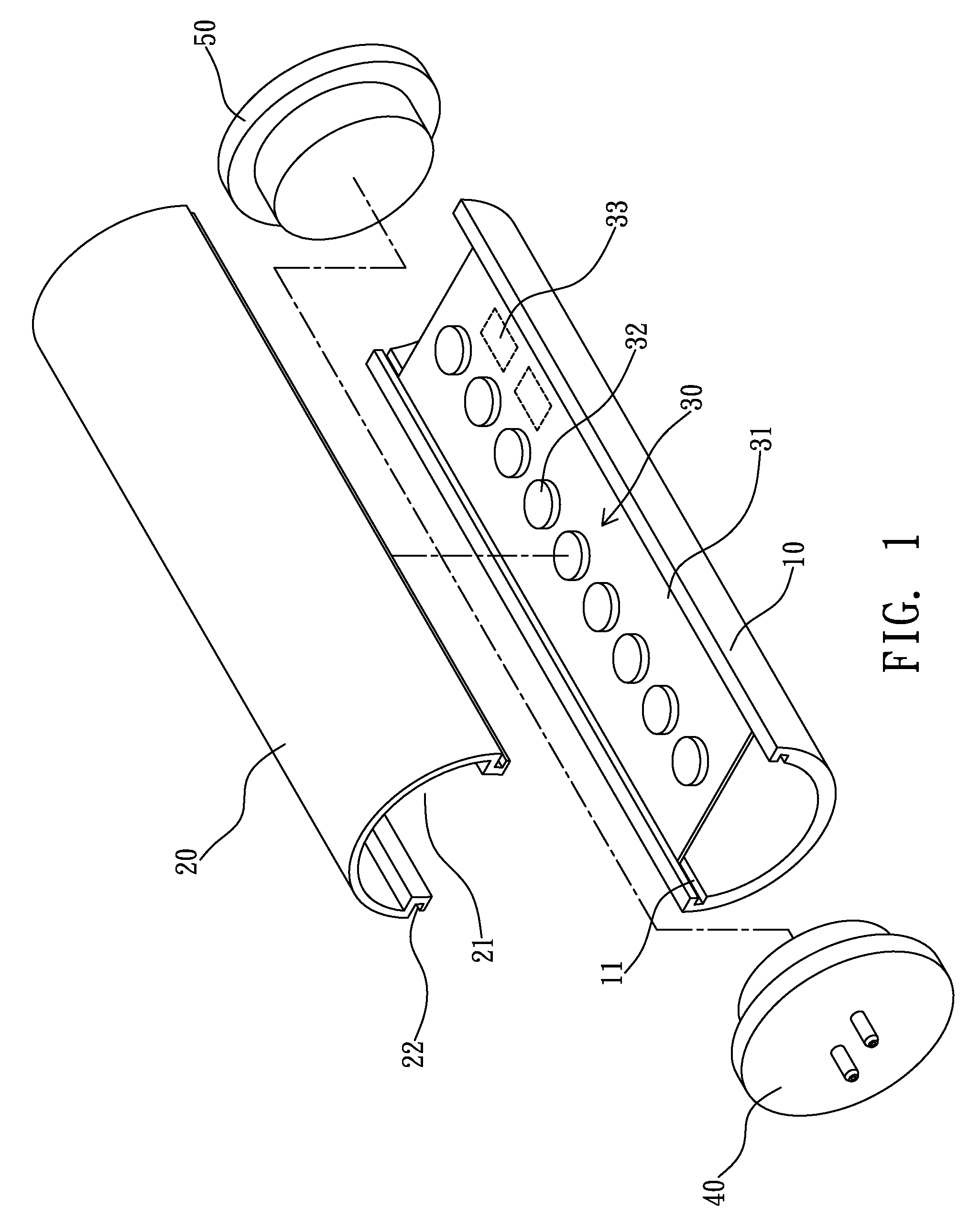

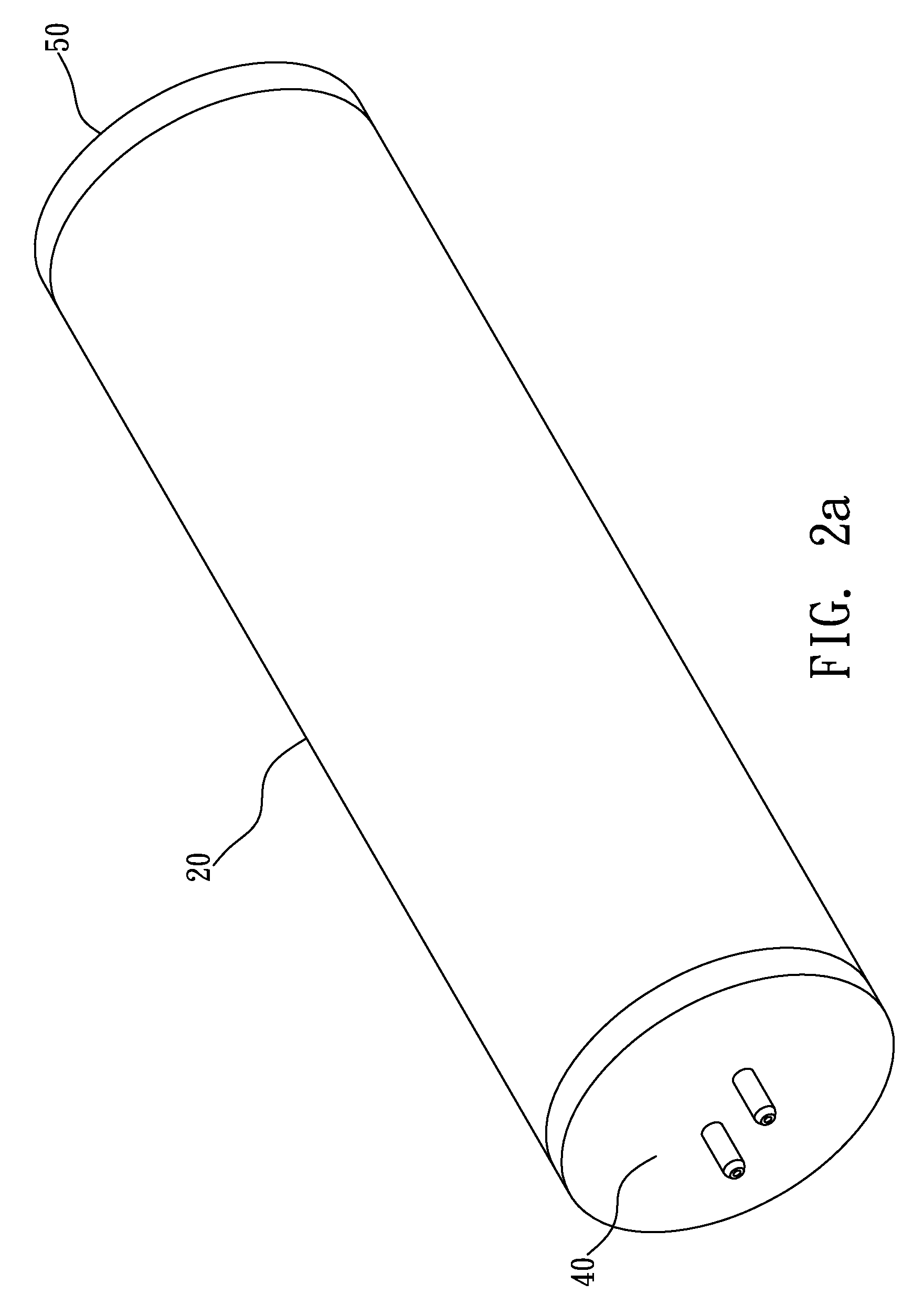

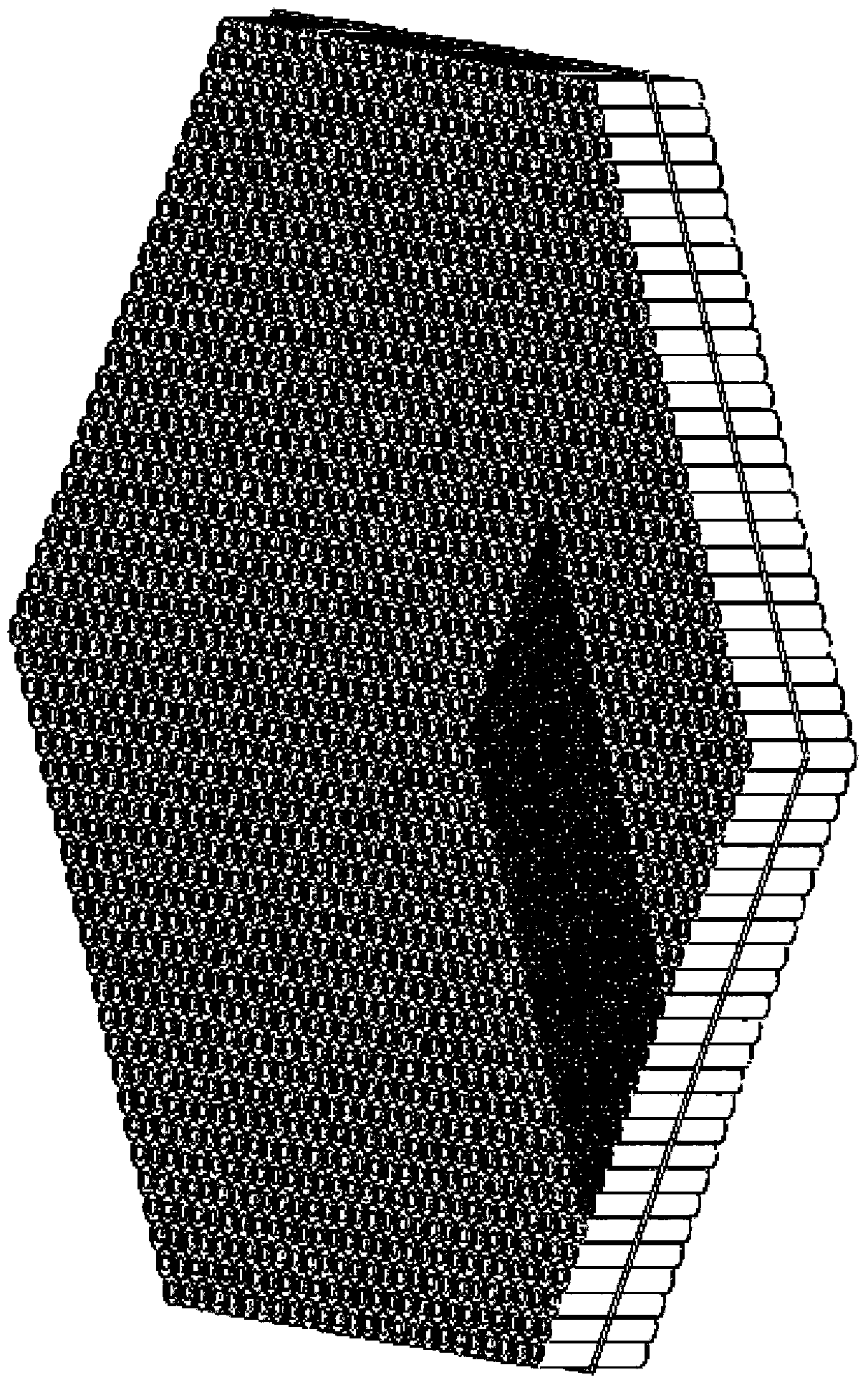

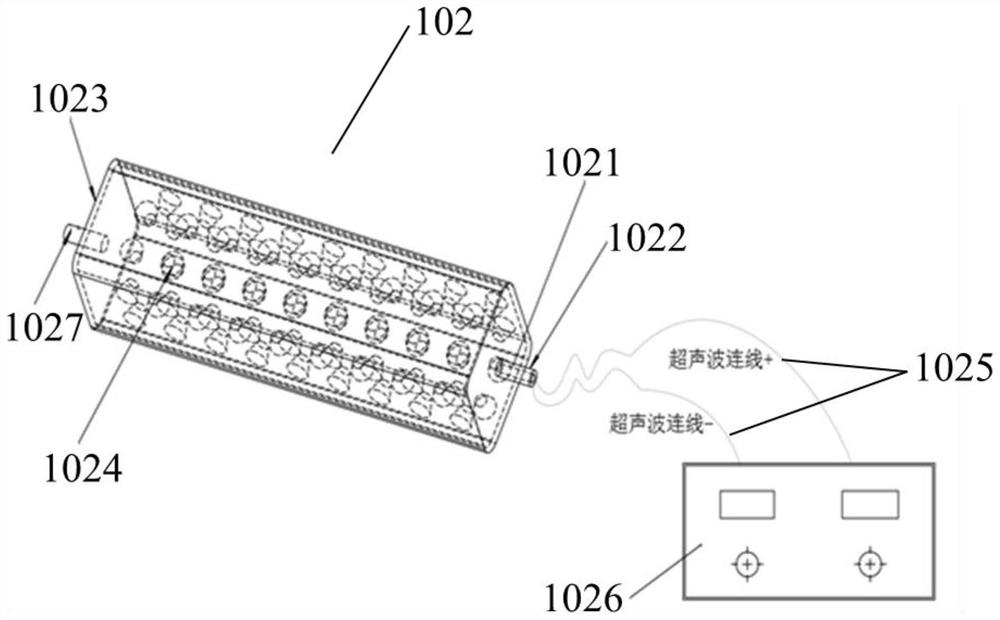

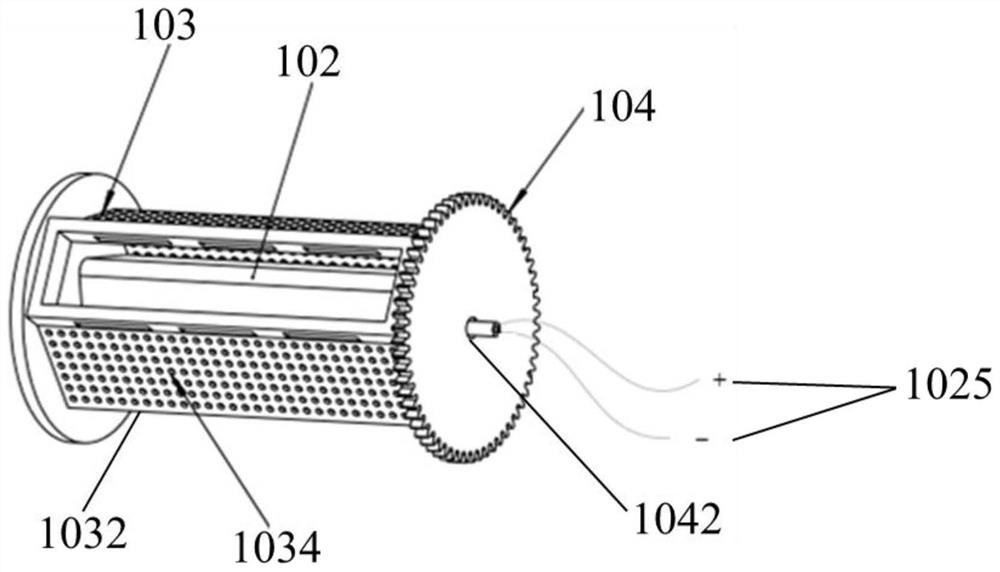

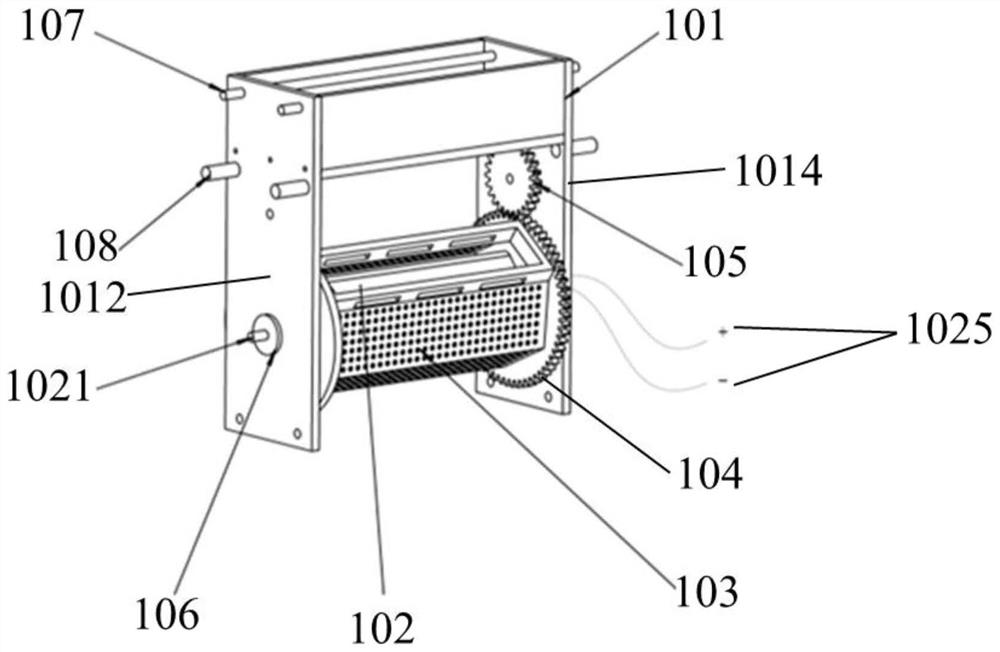

Drum-type ultrasonic cleaning machine and method for cleaning workpieces

PendingCN111889442AEliminate phenomenonFully automatedCellsCleaning using liquidsMegasonic cleaningEngineering

The invention provides a drum-type ultrasonic cleaning machine (10). The drum-type ultrasonic cleaning machine (10) comprises a frame (101), an ultrasonic vibration box (102) and a drum (103); the frame (101) comprises a first plate (1012) and a second plate (1014) which are arranged opposite to each other; the ultrasonic vibration box (102) is fixed on the frame (101) and arranged between the first plate (1012) and the second plate (1014), and the ultrasonic vibration box (102) is provided with a shaft (1021) extending through the first plate (1012) and the second plate (1014); and the drum (103) is arranged between the first plate (1012) and the second plate (1014) and surrounds a shell (1023) of the ultrasonic vibration box (102), and the drum (103) is arranged to be rotatable around the ultrasonic vibration box (102). On the other hand, the invention further provides a method for cleaning workpieces. The drum-type ultrasonic cleaning machine (10) can be used for at least eliminating the phenomenon of workpiece lamination.

Owner:北京麦戈龙科技有限公司 +1

Rotor disk for turbomachine fan

A rotor disk for a fan in a turbomachine is disclosed. The disk includes in its perimeter a plurality of essentially axial grooves for the installation and retention of vane roots having hooks at their downstream ends, and deformable regions formed by cavities being situated at the downstream end of the grooves in attachment flanges for inter-vane platforms to absorb the stresses between the disk and the vane roots.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Ophthalmic photography apparatus

Owner:KOWA CO LTD

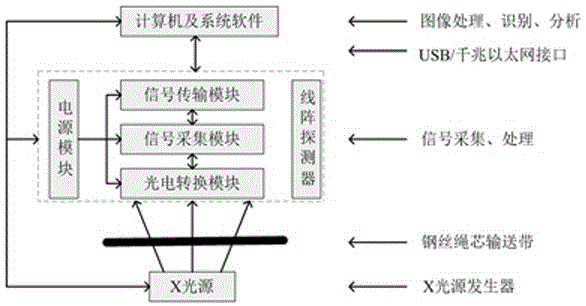

Calibration method for self-adaptive threshold in X-ray on-line detection of joint of wire-cored belt

InactiveCN105911074AReduce computing loadIncreased computing loadMaterial analysis using wave/particle radiationComputer visionSelf adaptive

The invention relates to an on-line detection method for a belt joint, specifically to a calibration method for a self-adaptive threshold in X-ray on-line detection of a joint of a wire-cored belt. The method comprises the following steps: zeroing a joint counter; reading in each image of a video stream one by one on line; sampling the images so as to obtain numbers of wire cores, a maximum number of wire cores, a minimum number of wire cores and an average number of wire cores; substituting the results obtained in the previous step into a variance calculating formula and reading in a next image if the formula is not satisfied, or implementing a next step if the formula is satisfied; going through all the sampling rows and caliberating rows with wire core numbers greater than an optimal threshold as joint rows, otherwise as common rows; and recording the initial position and end position of a joint area so as to obtain the height of the joint area, wherein the joint area is defined as an area with given height and with a joint row count greater than a given threshold, adding 1 to the joint counter, storing the joint area into a memory and reading in a next image. The method provided by the invention overcomes the problem of inaccurate calibration of the joint image due to empirical selection of a threshold in joint row calibration in the prior art.

Owner:SHANXI UNIV

Swirling flow type double-vertical-pipe drainage system

ActiveCN106400901AEliminate water tongue phenomenonSlow down the flow of waterDomestic plumbingWater velocityMarine engineering

The invention discloses a swirling flow type double-vertical-pipe drainage system. The drainage system comprises a first vertical pipe and a second vertical pipe which are arranged in parallel, wherein the first vertical pipe is used for draining water, the second vertical pipe is used for exhausting air, the first vertical pipe and the second vertical pipe communicate with each other through a communicating pipe, the air in the first vertical pipe flows into the second vertical pipe through the communicating pipe to be exhausted, the first vertical pipe is an enhanced type inner-spiral water drain pipe, a plurality of spiral ribs are arranged in the first vertical pipe, and the communicating pipe is arranged slantwise upwards from the first vertical pipe to the horizontal direction of the second vertical pipe, so that the water in the first vertical pipe is prevented from overflowing to the second vertical pipe. With the adoption of the swirling flow type double-vertical-pipe drainage system, the nappe phenomenon can be effectively eliminated, the water velocity of the vertical pipes can be retarded, the hydraulic condition of the vertical pipes can be improved, the water flow pressure fluctuation and water flow noise of the vertical pipes can be reduced, and thus the water discharge capacity is greatly enhanced.

Owner:SHANGHAI HENGGONG WIRE & CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com