Patents

Literature

78results about How to "Uniform dispensing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

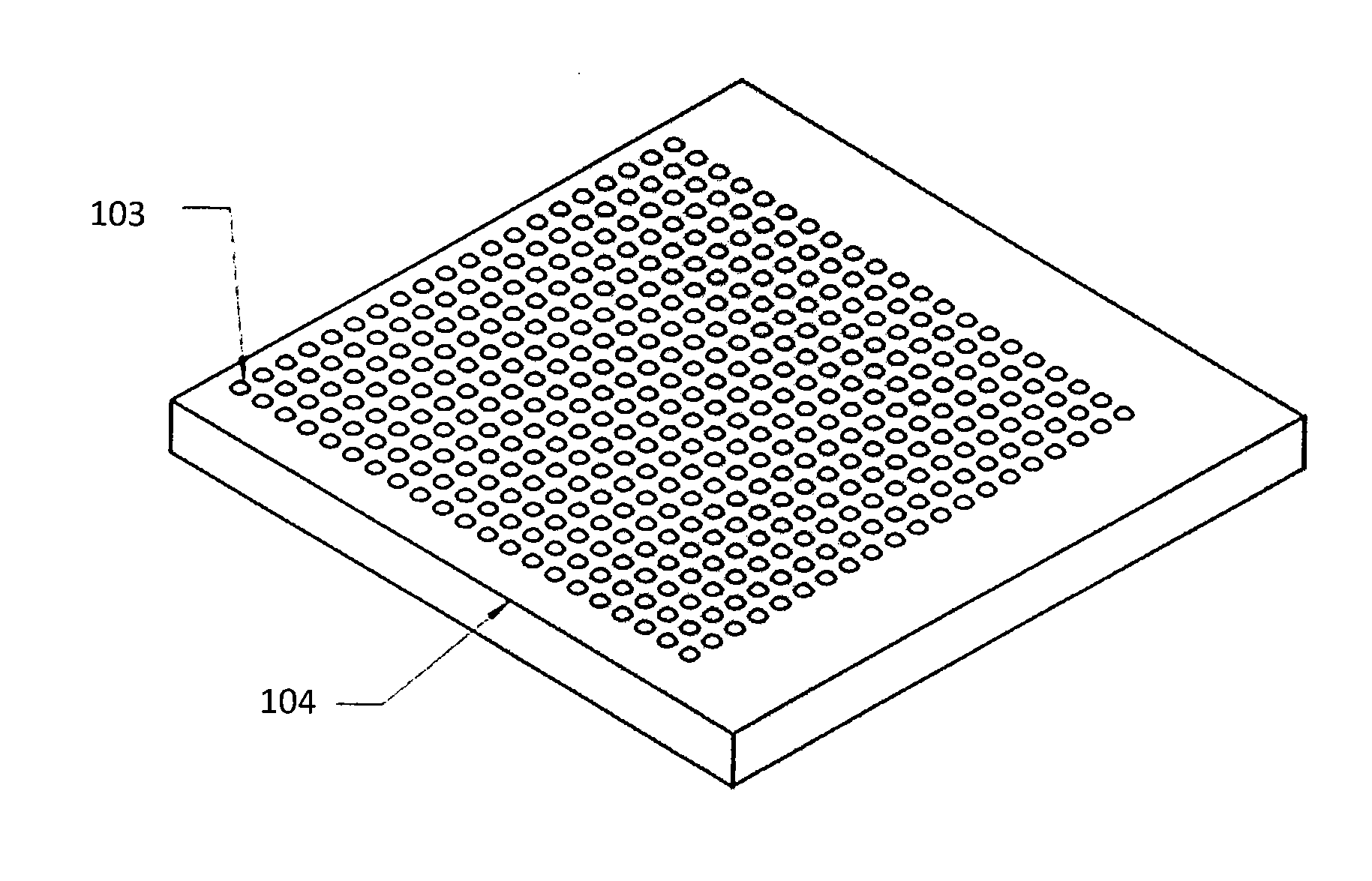

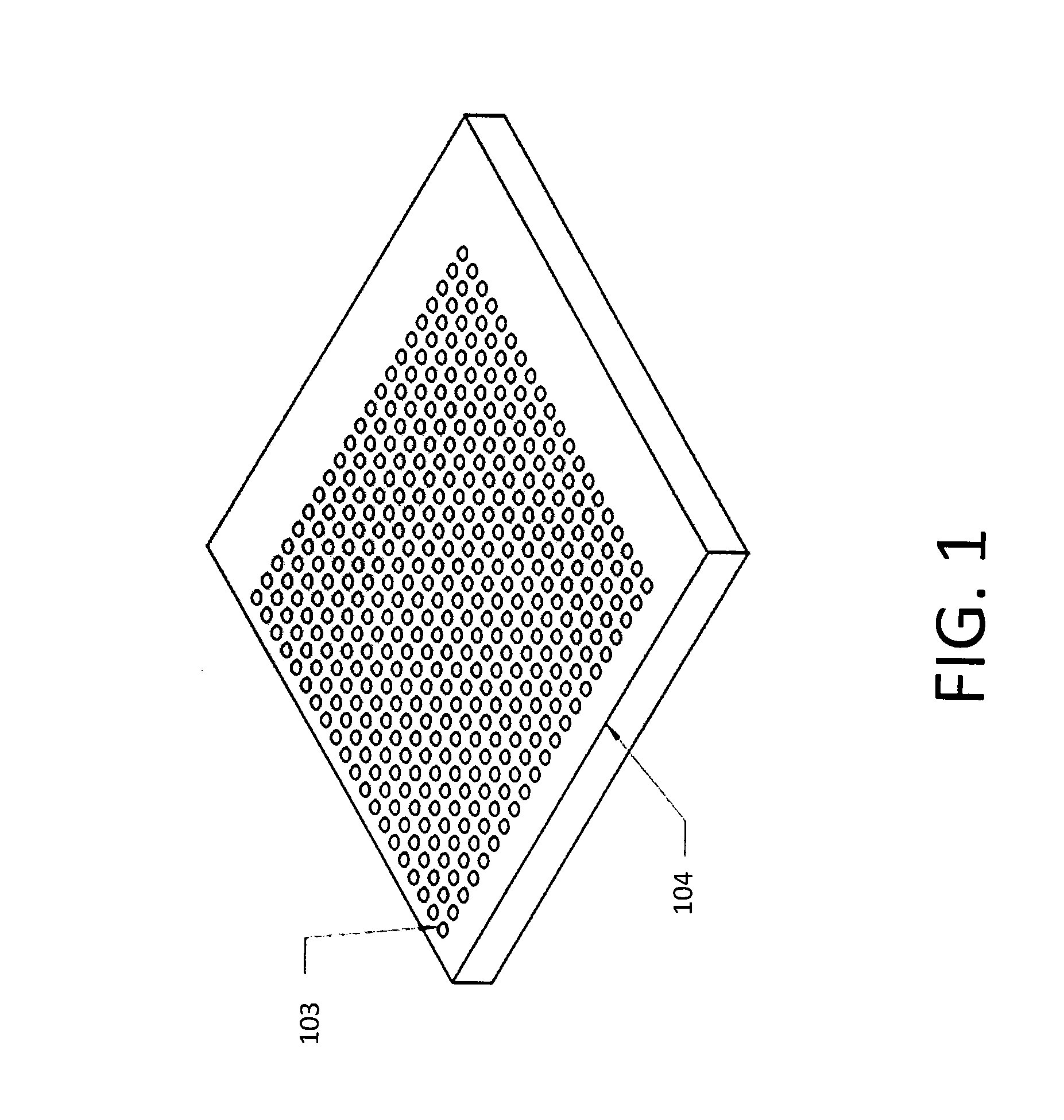

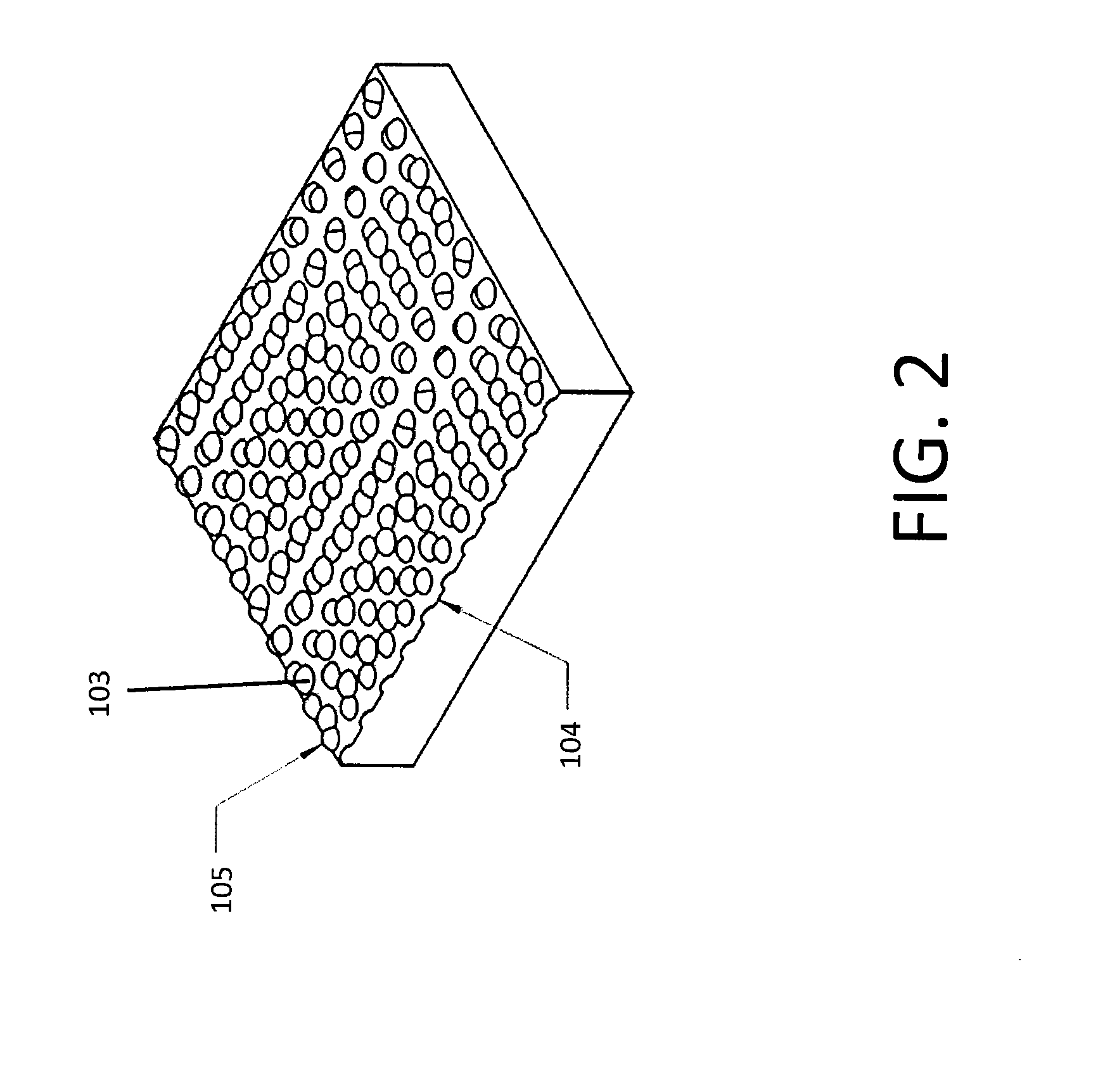

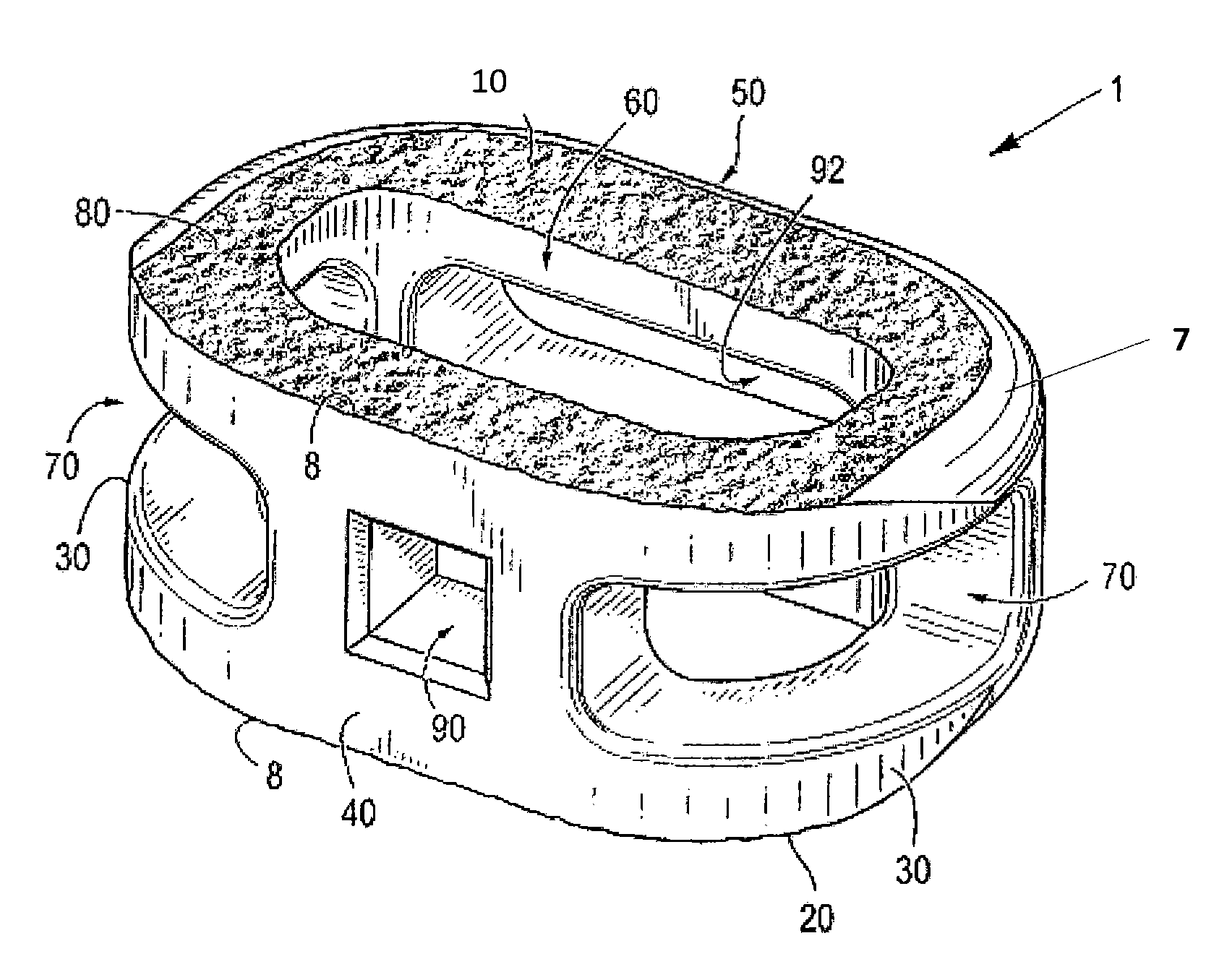

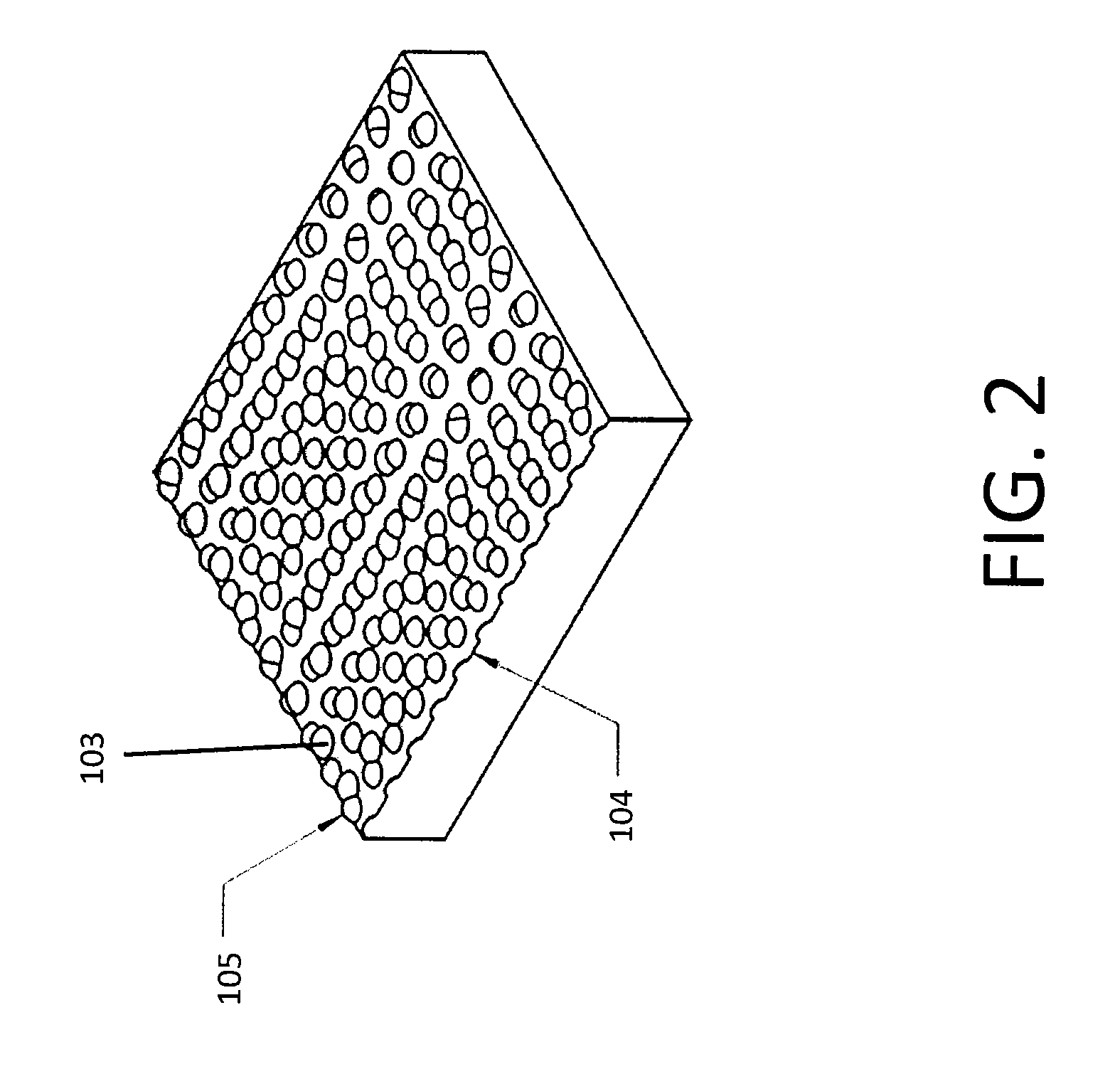

Processes for producing regular repeating patterns on surfaces of interbody devices

ActiveUS20120312778A1Sufficient bioactivityHigh positioning accuracyDecorative surface effectsVacuum evaporation coatingRough surfaceMedicine

Processes for producing interbody spinal implants having a body with a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, a substantially hollow center, and a single vertical aperture; and optionally, one or two integration plates affixed to the body. The processes include applying an additive process, a subtractive process, or both processes to at least one surface of the interbody spinal implant to form a roughened surface topography having a regular repeating pattern. The roughened surface topography is specifically designed to provide certain frictional characteristics, load dispersion, and to influence the biological responses that occur during bone healing and fusion.

Owner:TITAN SPINE

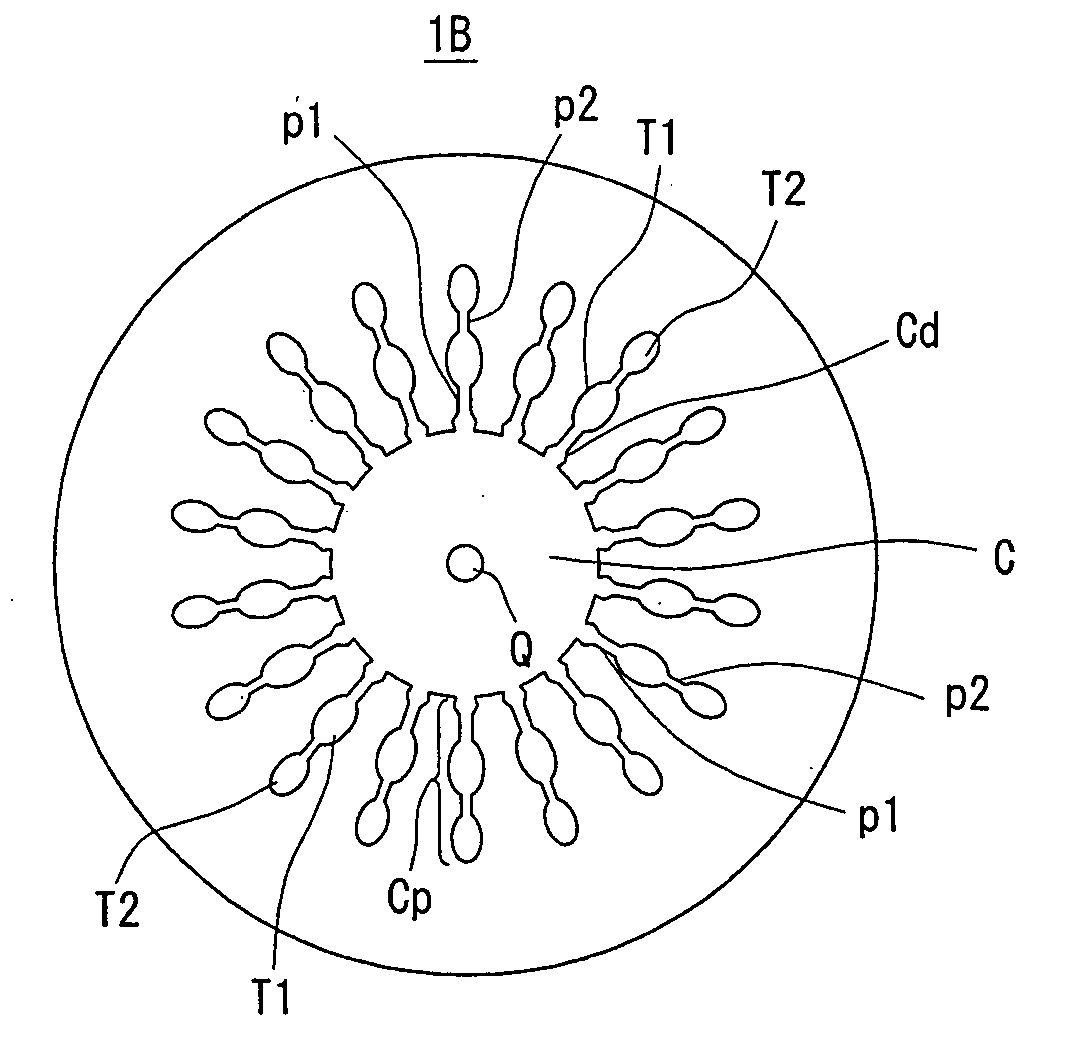

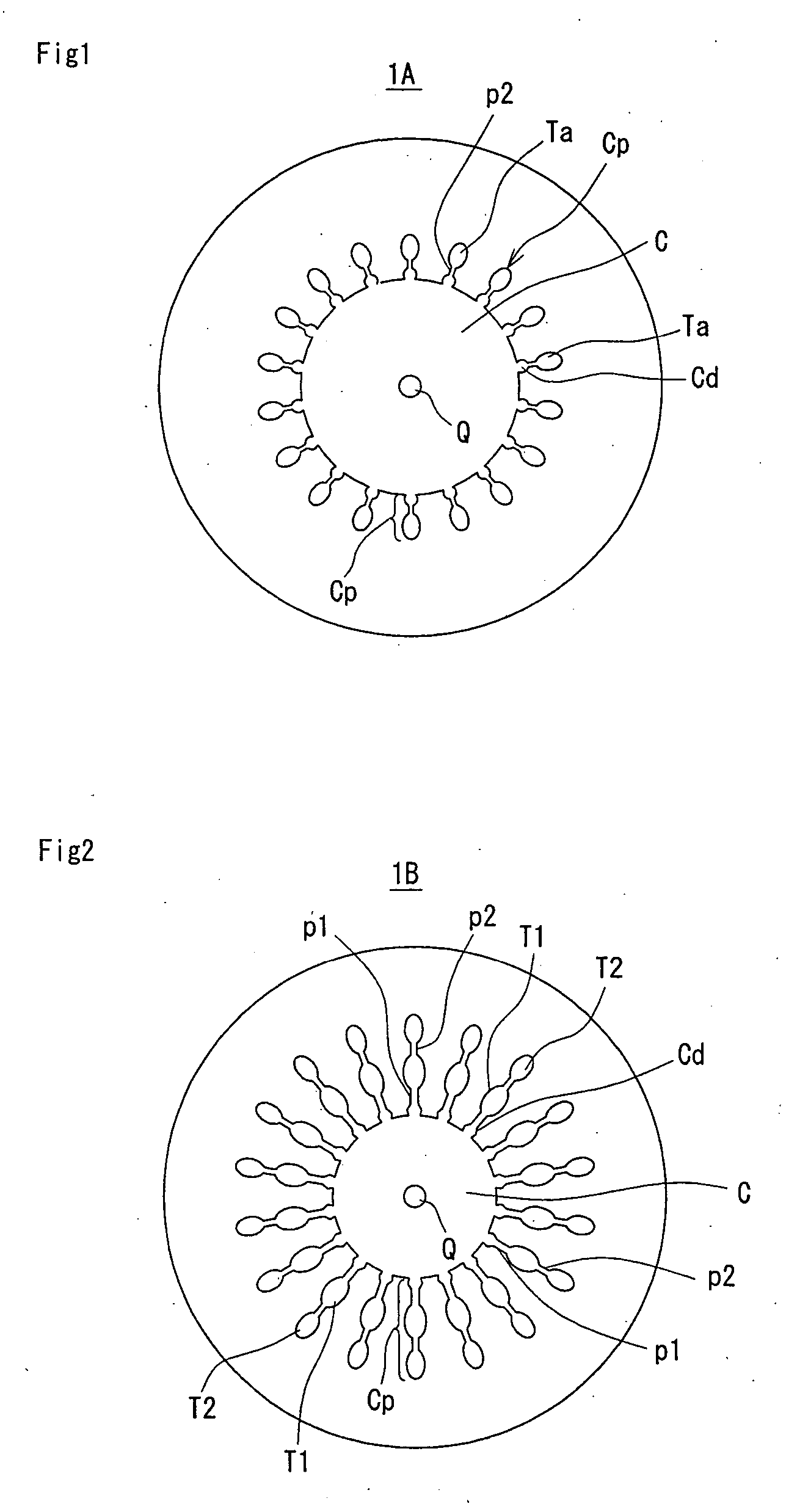

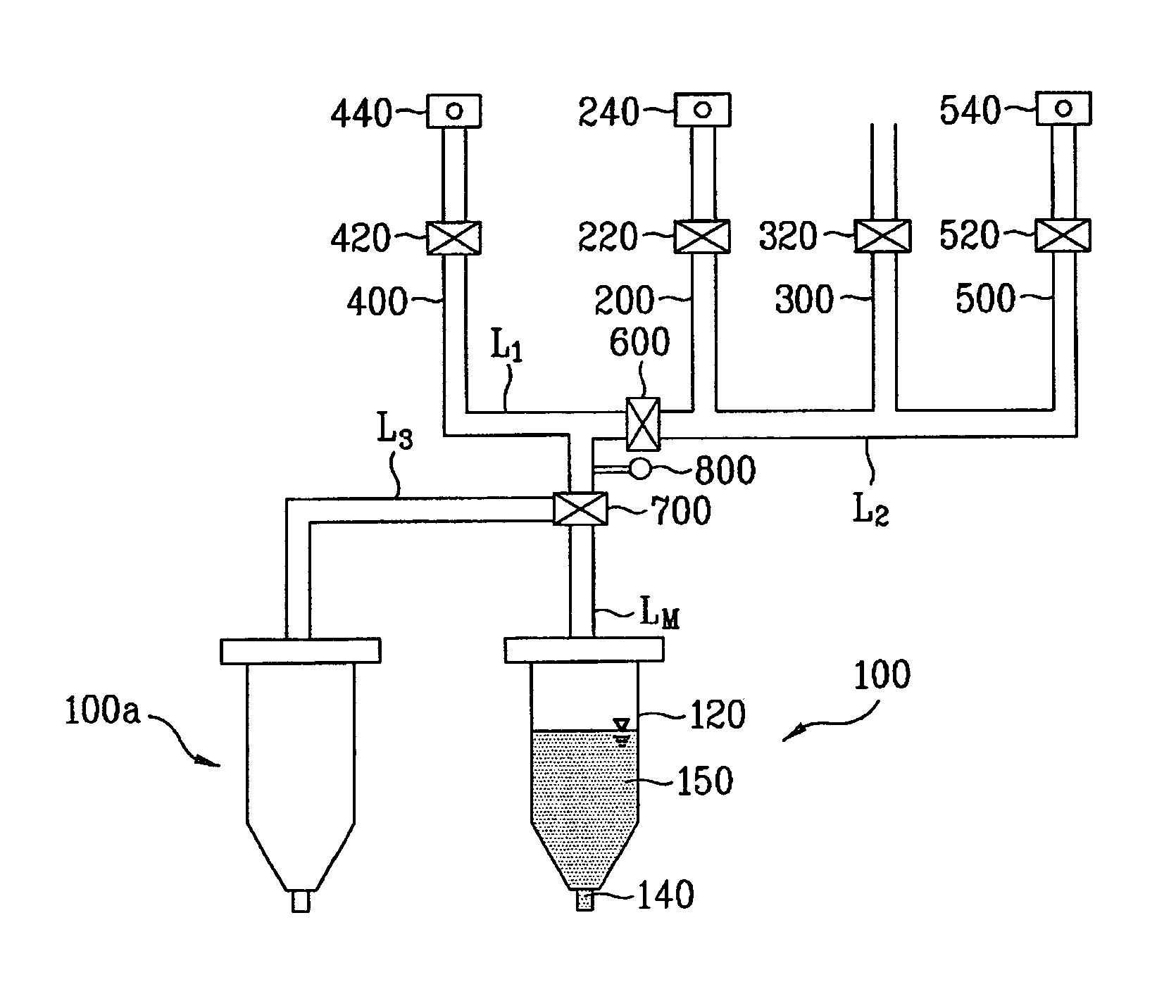

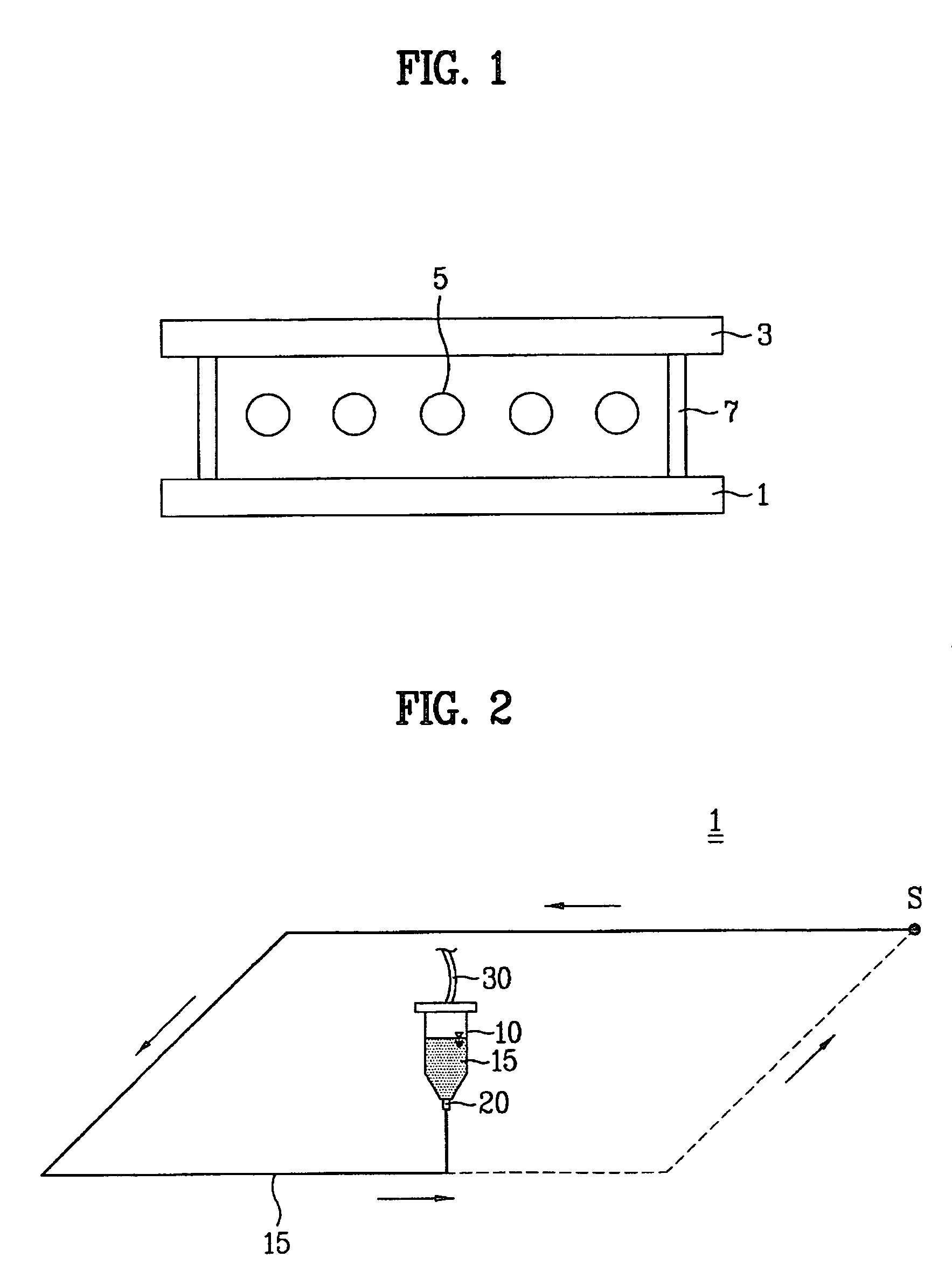

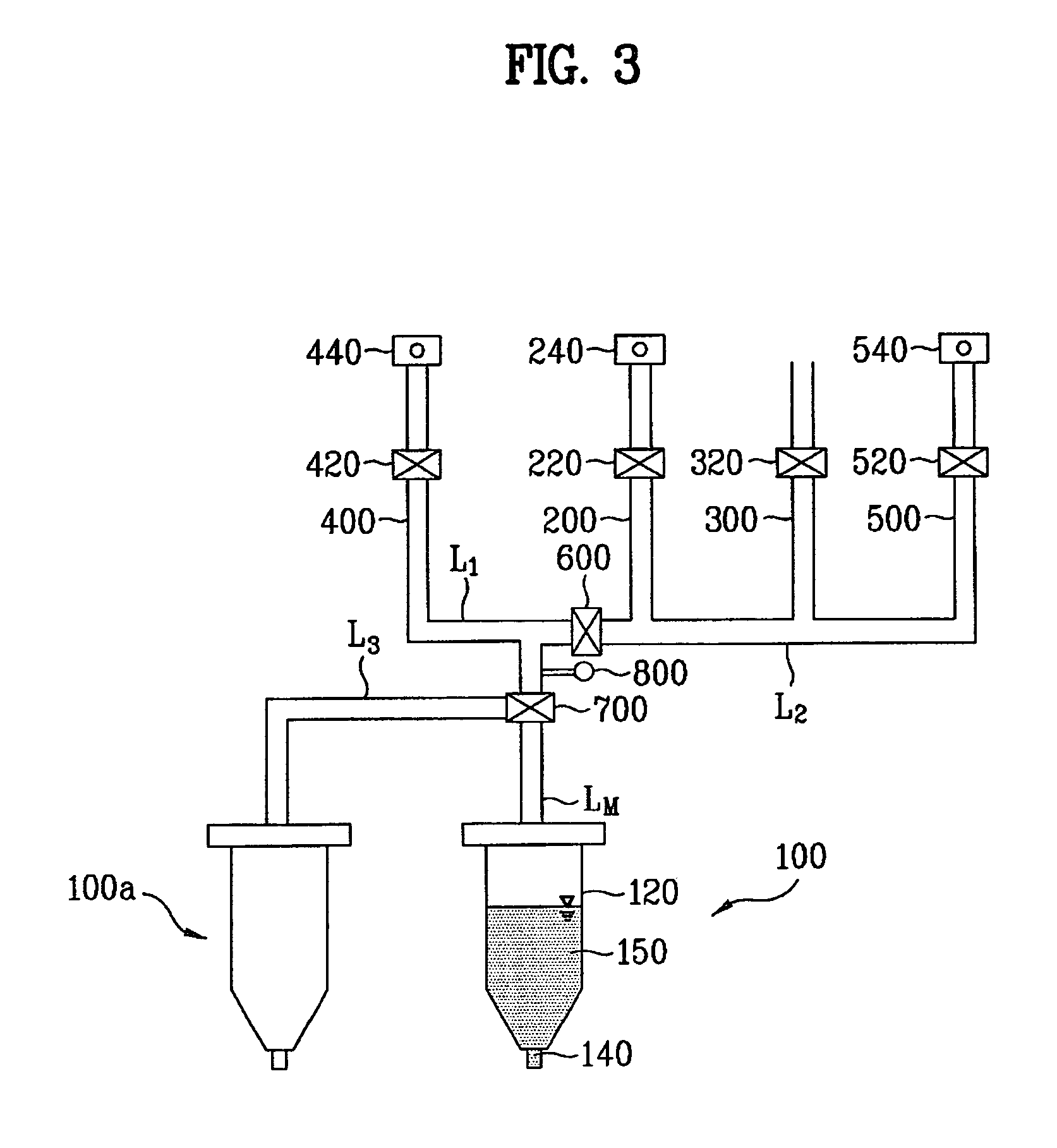

Microchip for sample, centrifugal dispension method of sample using the microchip and centrifugal dispenser

InactiveUS20060091085A1Lower the volumeUniform dispensingWater/sewage treatment by centrifugal separationHeating or cooling apparatusEngineeringChannel pattern

Owner:ISHIKAWA SEISAKUSHO +1

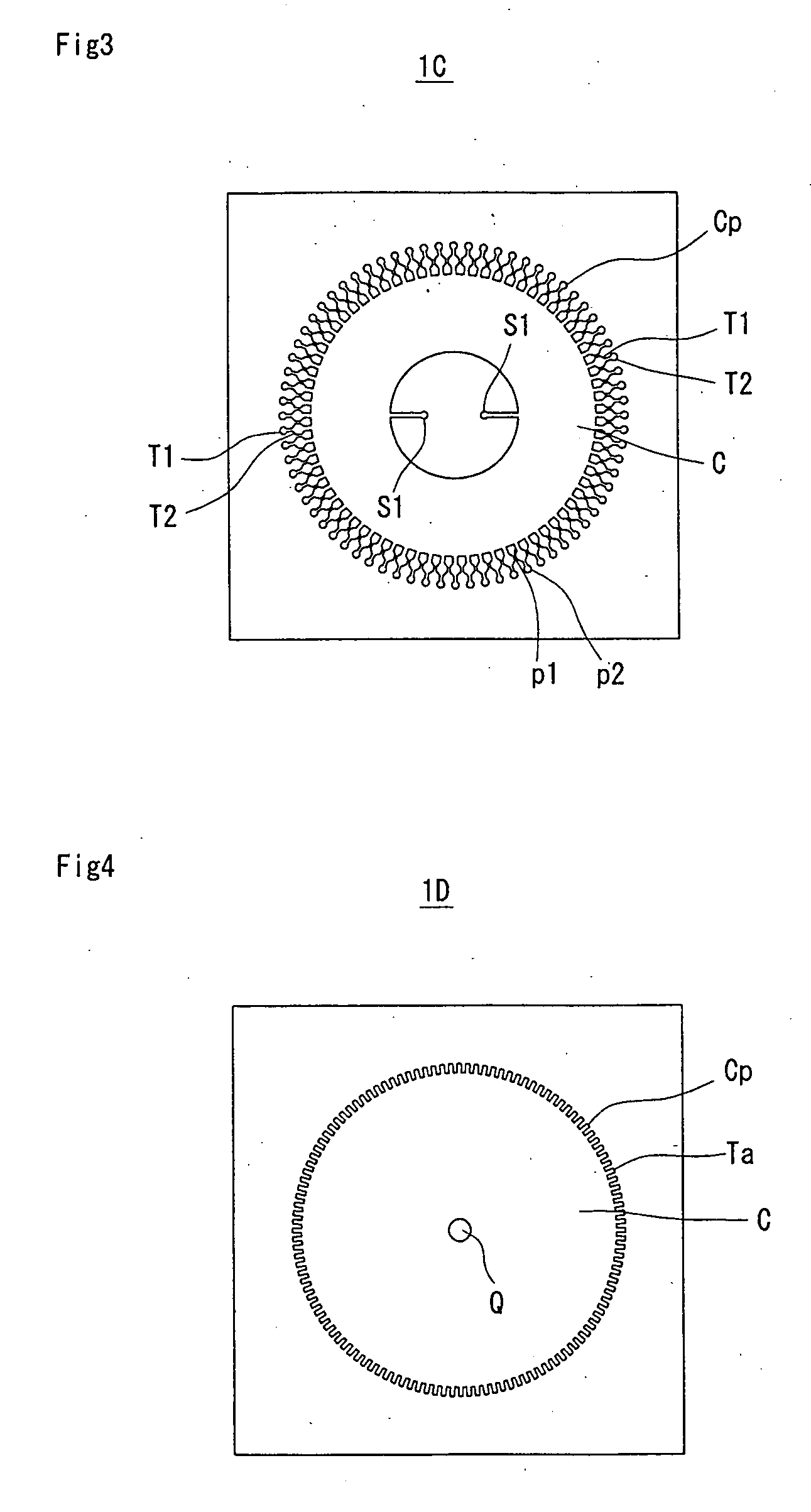

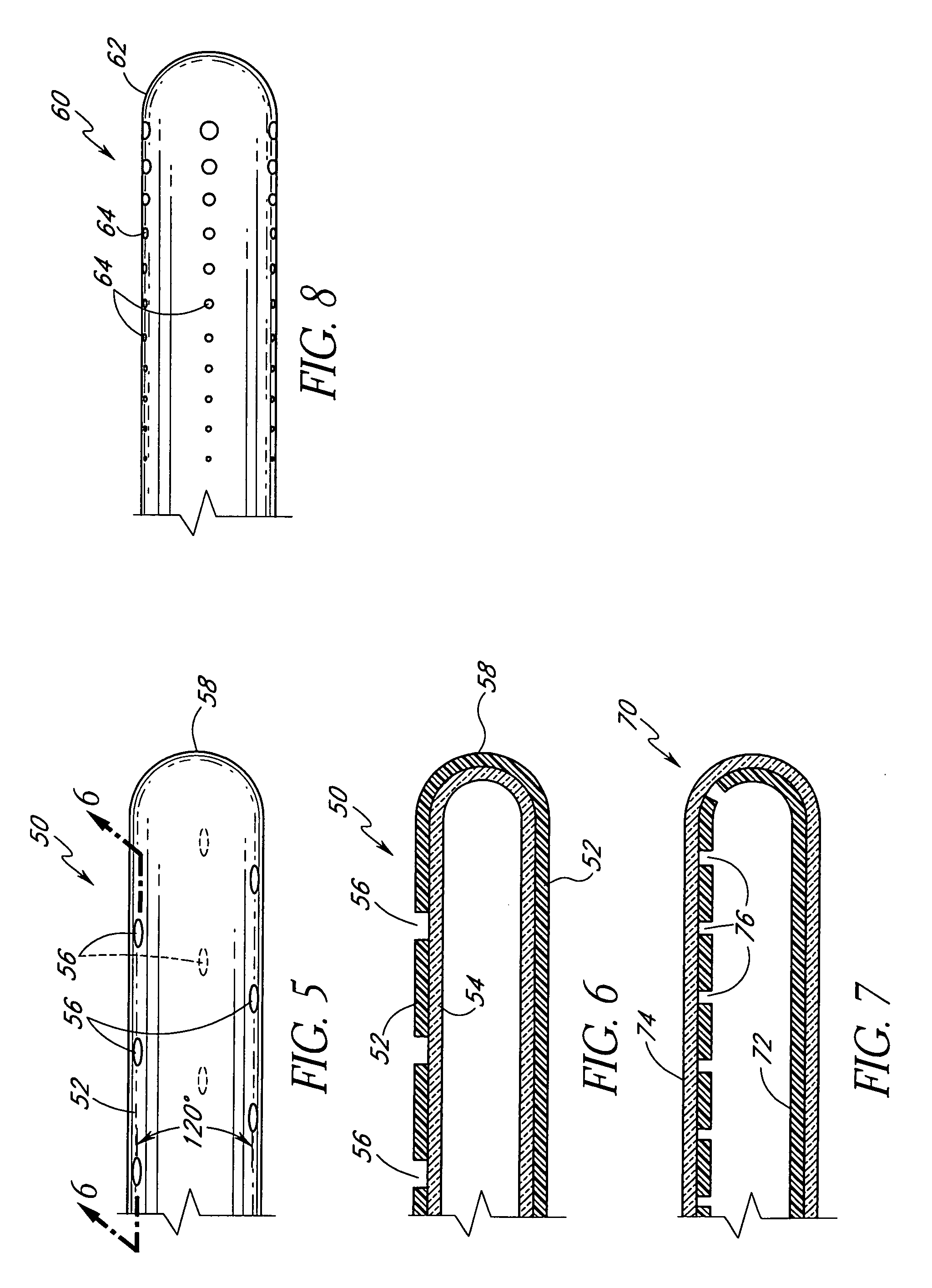

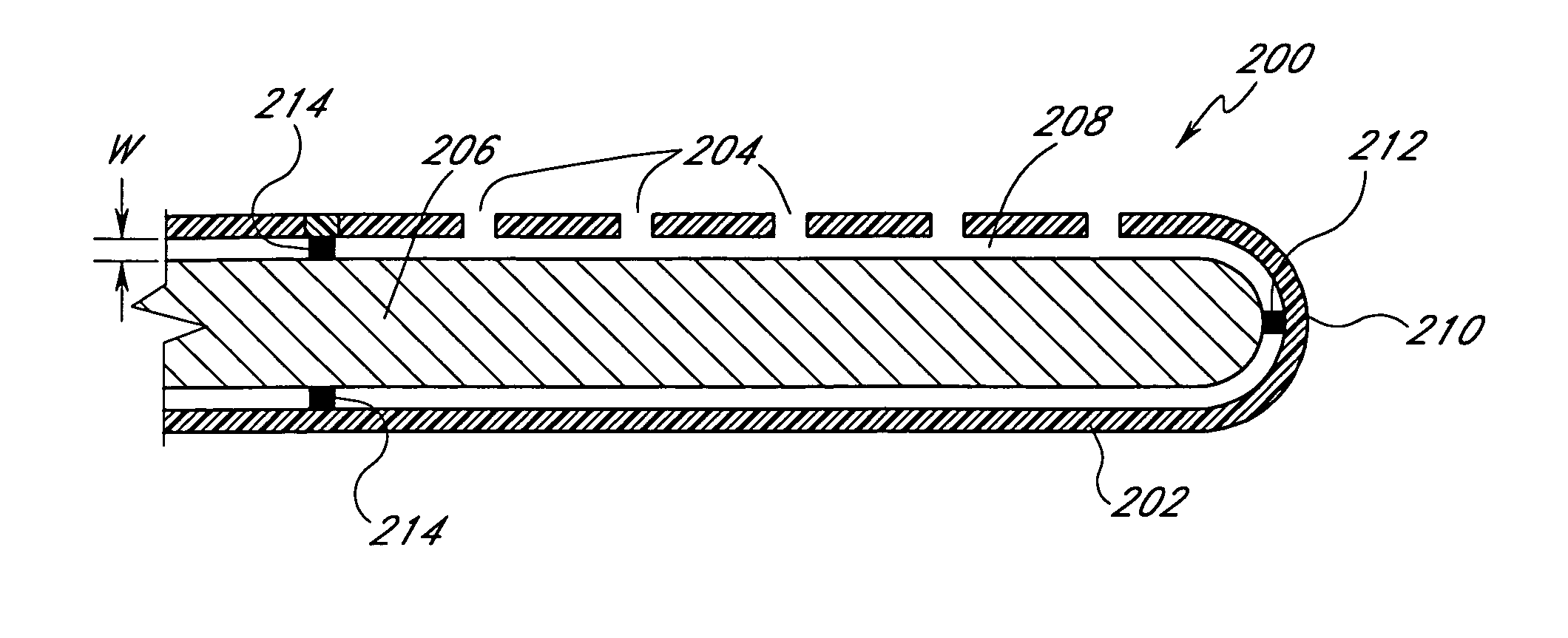

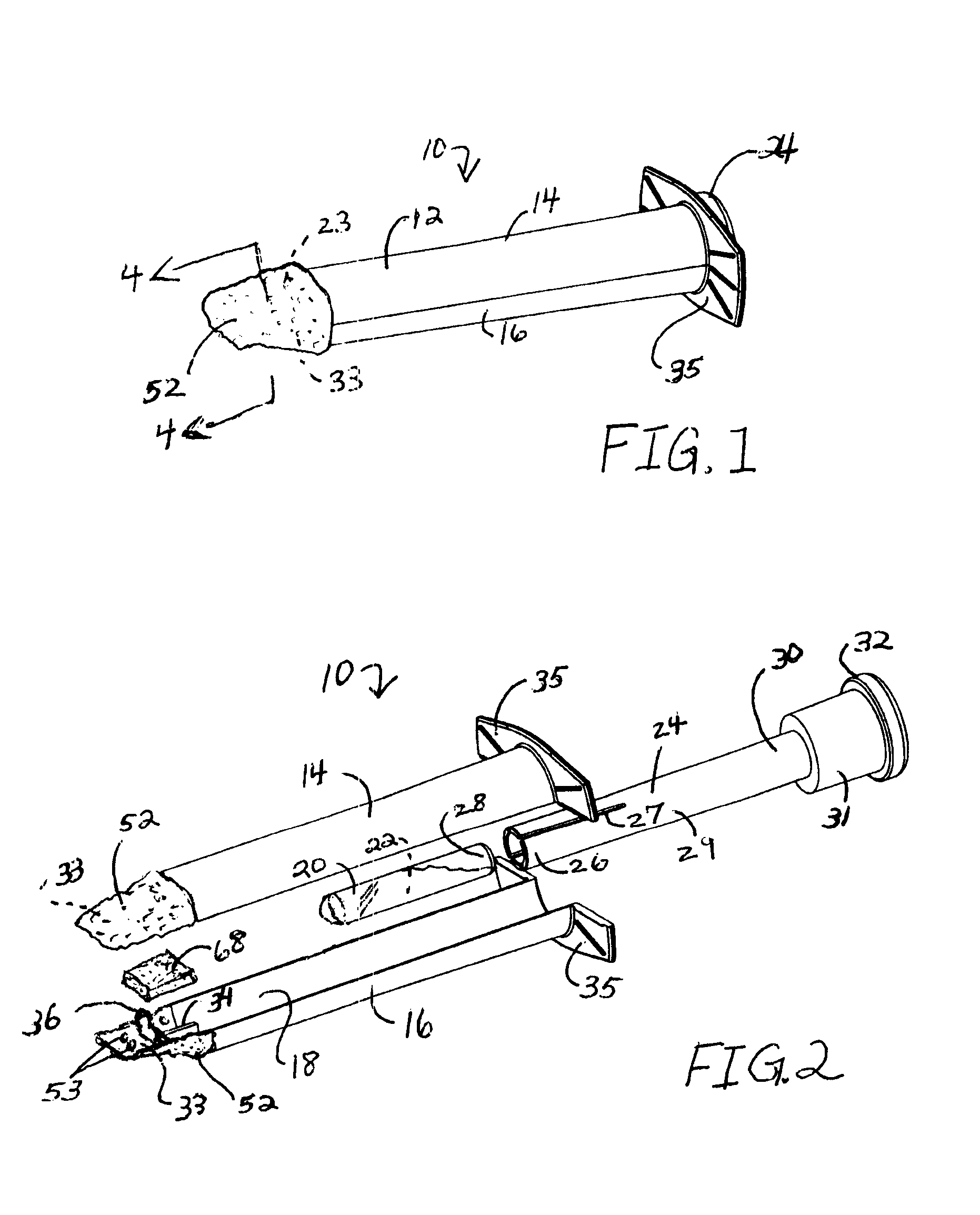

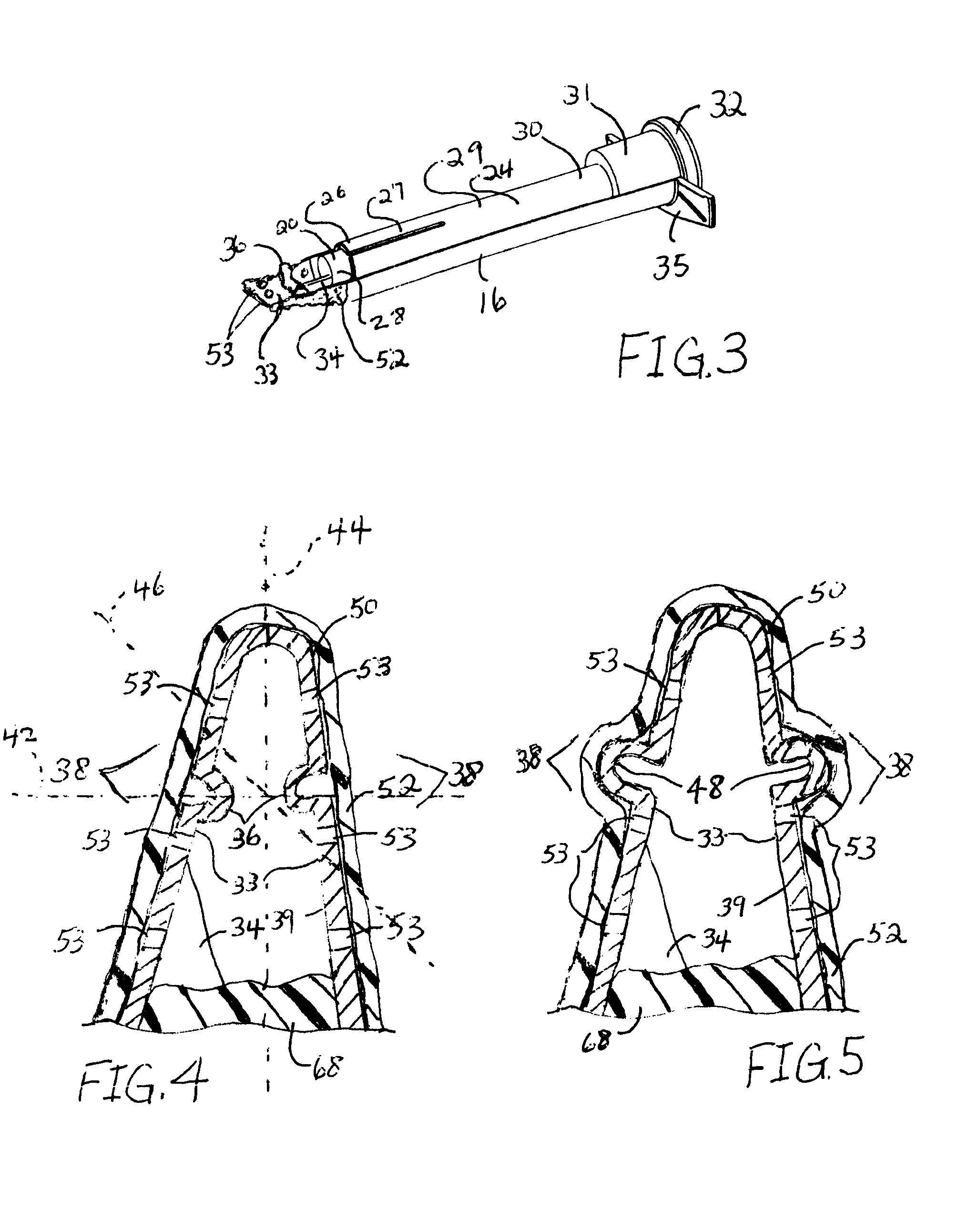

Catheter for uniform delivery of medication

The present invention provides a catheter for the delivery of fluid medication across an anatomical region. In accordance with one embodiment, the catheter comprises an elongated tube with a plurality of exit holes along an infusion section of the catheter, and an elongated flexible porous member residing within the tube and forming an annular space between the tube and the member. In accordance with other embodiments, the catheter includes a tube having a plurality of exit holes in a side wall of the tube. The exit holes may combine to form a flow-restricting orifice of the catheter. In one particular embodiment, the catheter comprises a tube having elongated exit slots therein. In accordance with other embodiments, the catheter includes an elongated tubular member made of a porous membrane. In accordance with other embodiments, the catheter includes an elongated “weeping” tubular coil spring attached to an end of, or enclosed within, a tube.

Owner:AVENT INC

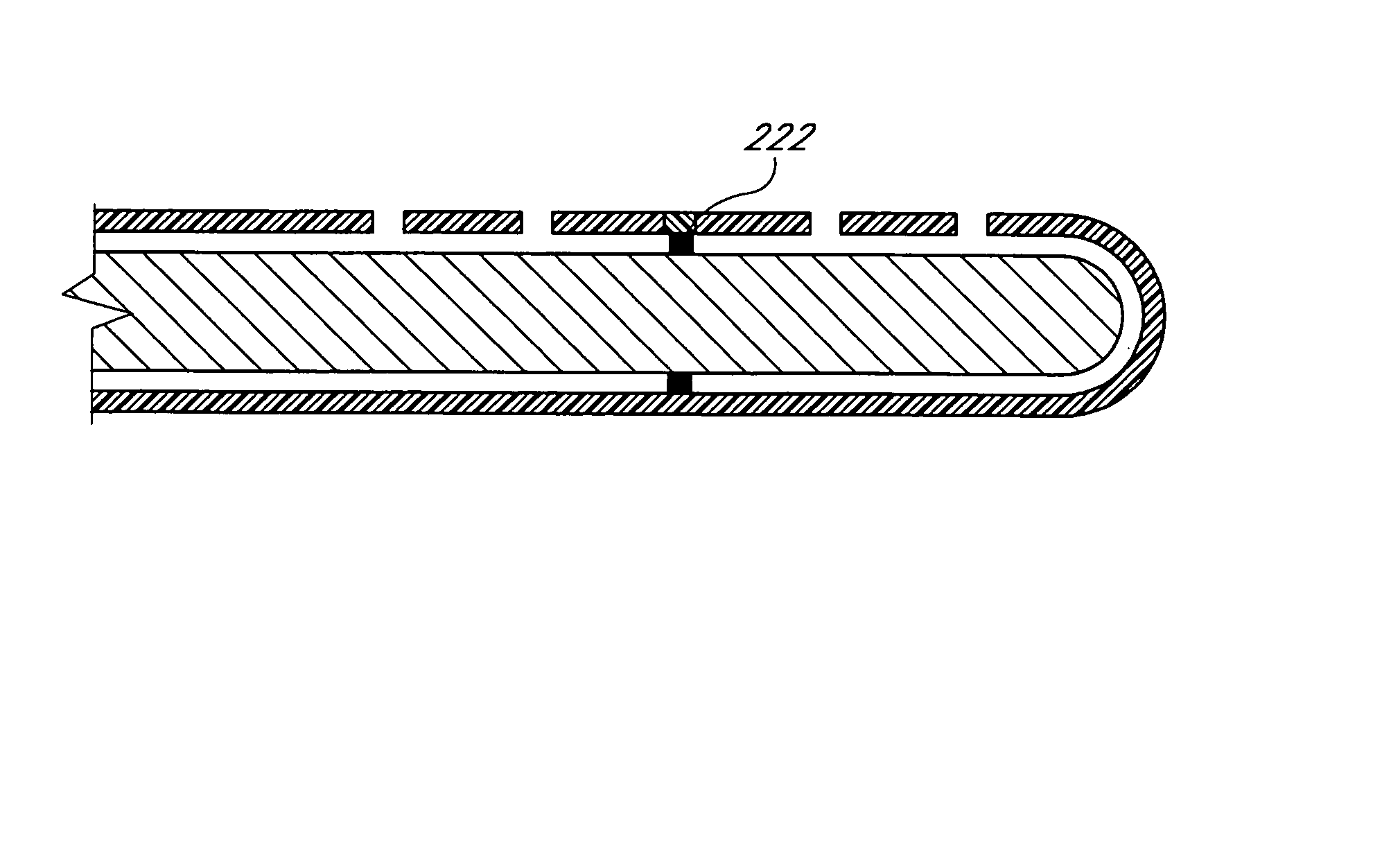

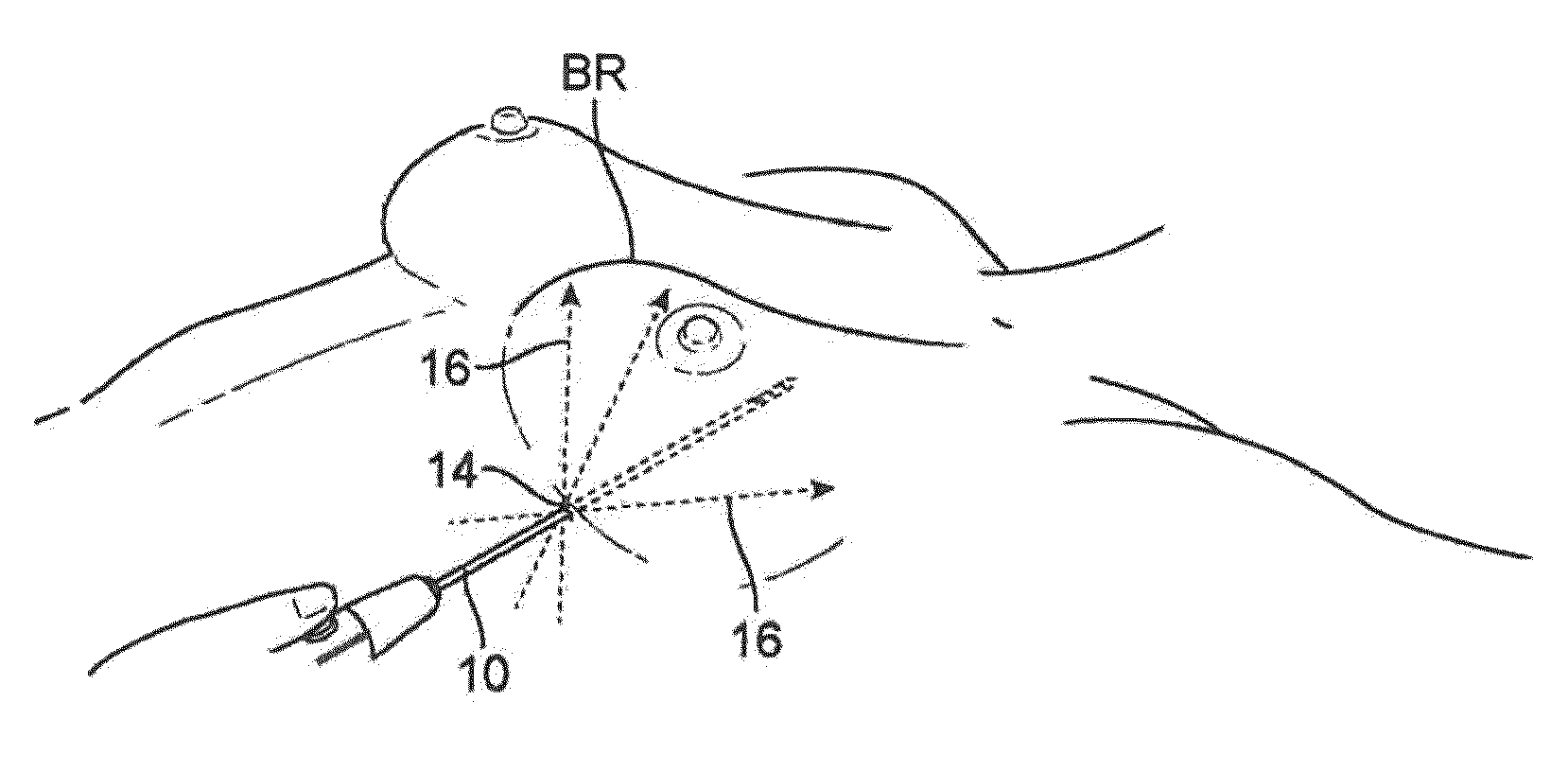

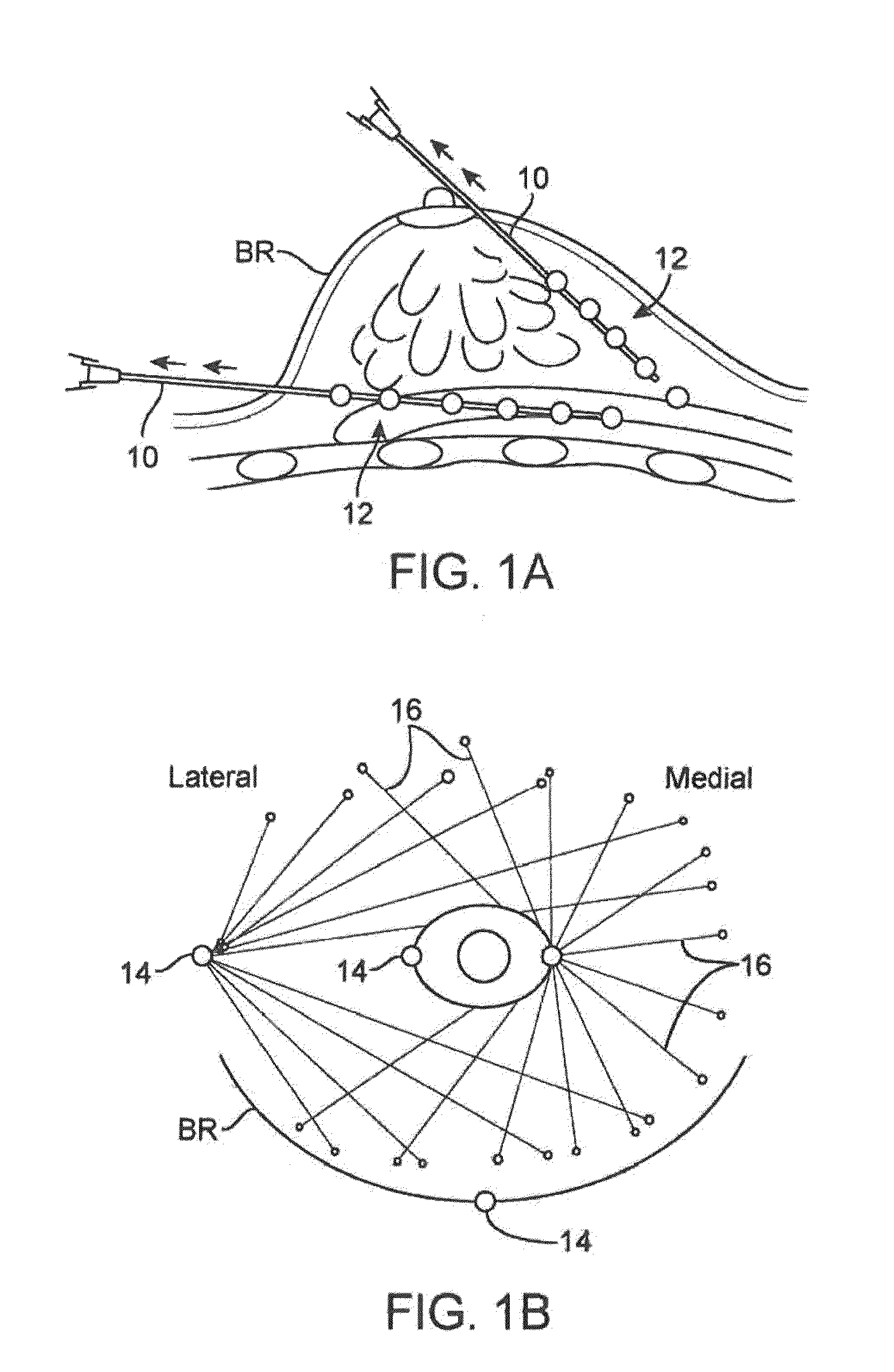

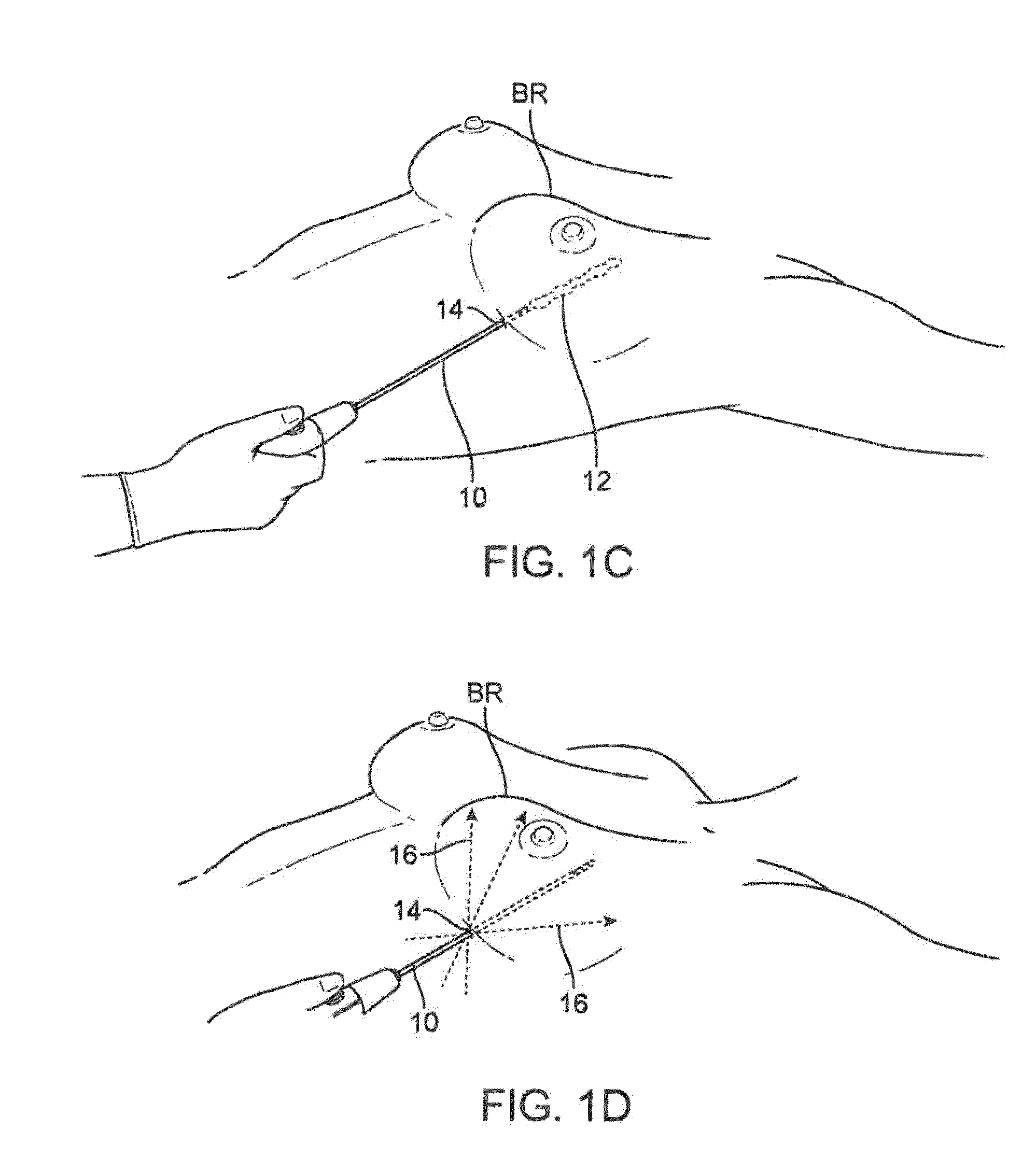

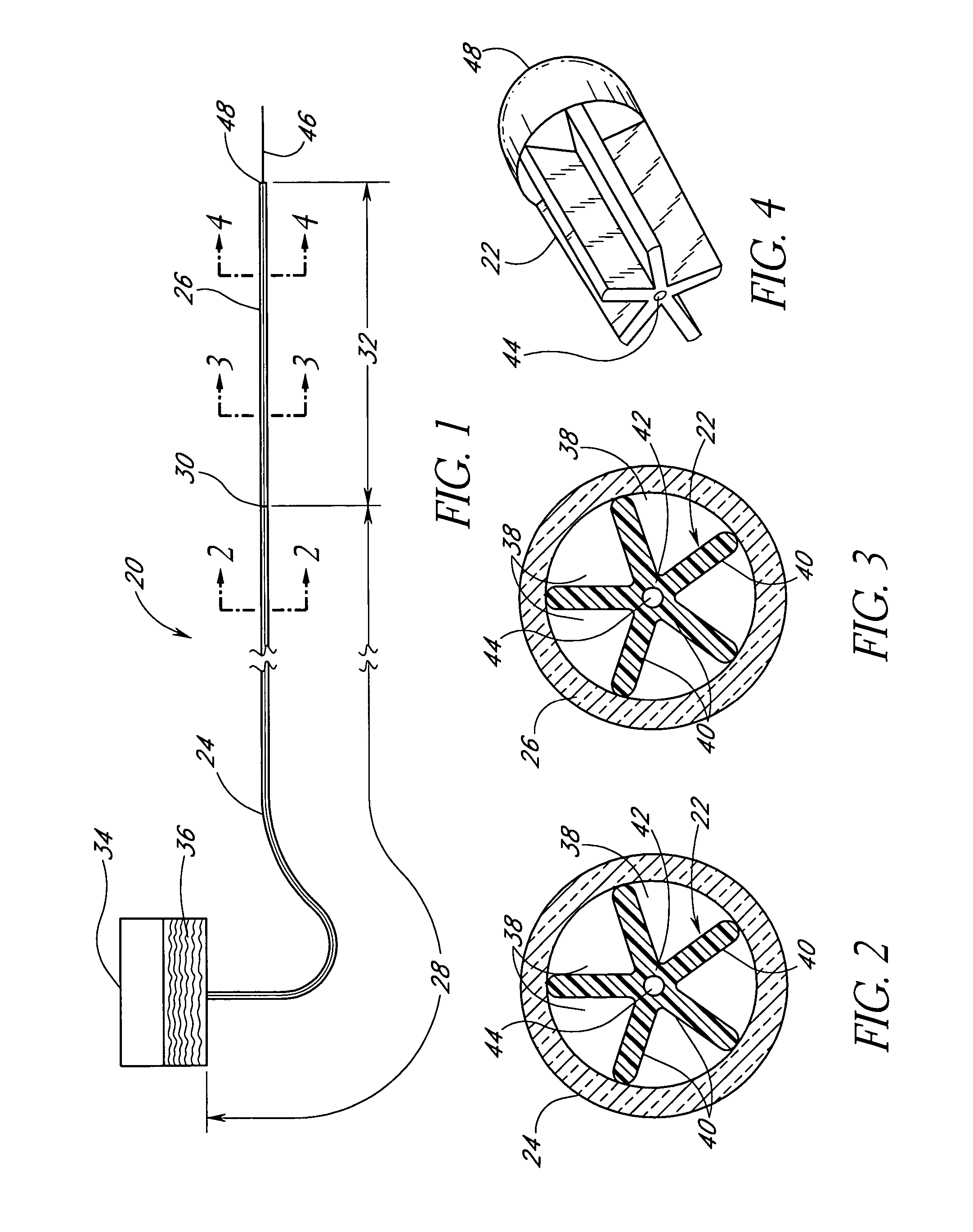

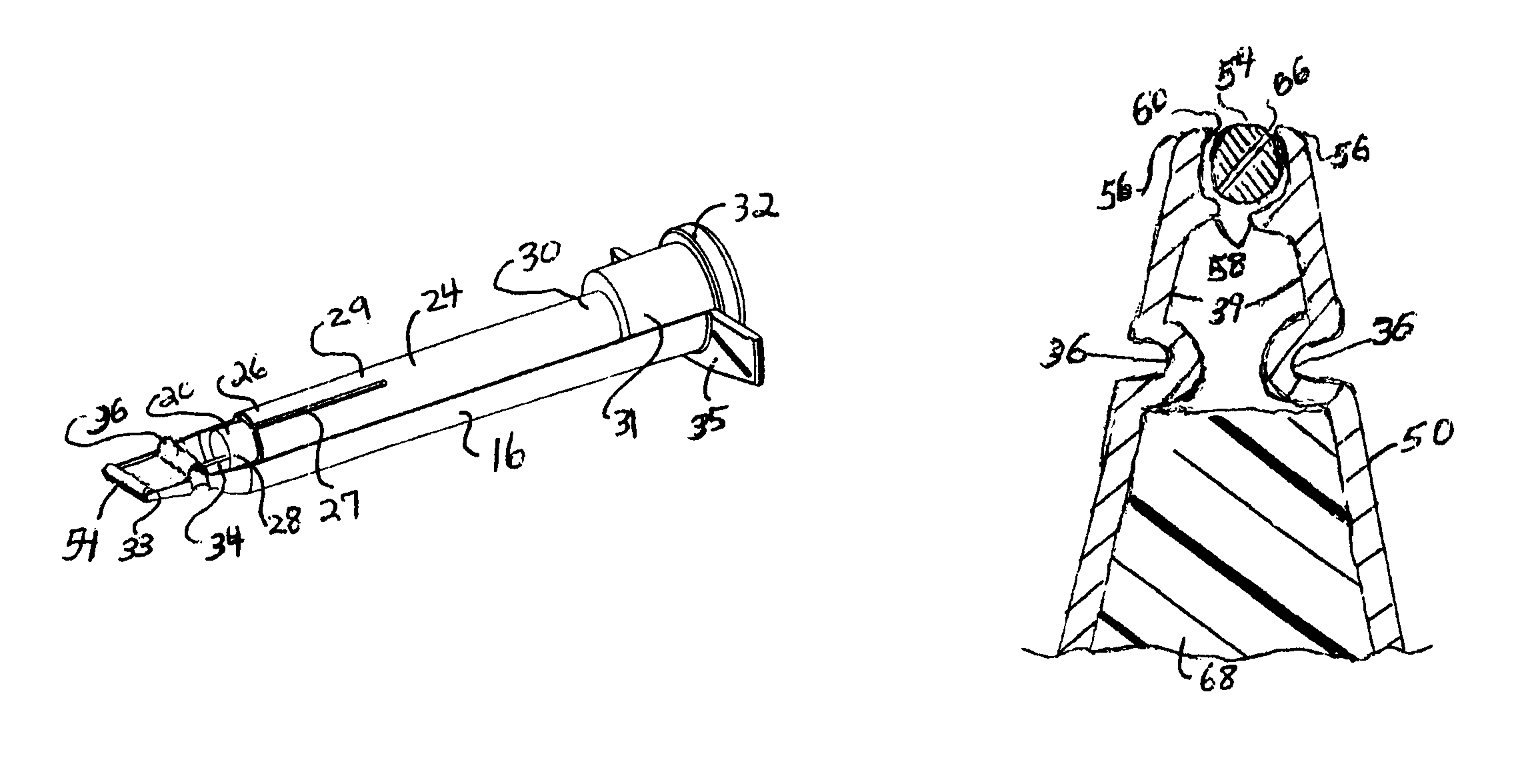

Tissue transfer systems

ActiveUS20130131635A1Easy to controlPrecision injectionDiagnosticsPharmaceutical delivery mechanismGuidance systemTransfer system

Devices and methods for tissue transfer are described where a cannula may be inserted into the breast of a subject at one of several points of entry. Insertion of the cannula into the breast may be accomplished by using a guidance system to distinguish between tissue types. Once desirably positioned, the cannula may be withdrawn from the breast while automatically (or manually) injecting the fat in multiple deposits of adipose tissue or fat such that the deposited fat remains within the tract formed by the withdrawn cannula. Multiple tracts of the deposited fat may be injected within the breast until the breast has been desirably remodeled and / or augmented.

Owner:LIFECELL

Catheter for uniform delivery of medication

The present invention provides a catheter for the delivery of fluid medication across an anatomical region. In accordance with one embodiment, the catheter comprises an elongated tube with a plurality of exit holes along an infusion section of the catheter, and an elongated flexible porous member residing within the tube and forming an annular space between the tube and the member. In accordance with other embodiments, the catheter includes a tube having a plurality of exit holes in a side wall of the tube. The exit holes may combine to form a flow-restricting orifice of the catheter. Advantageously, fluid within the catheter flows through all of the exit holes, resulting in uniform distribution of fluid within an anatomical region. In one particular embodiment, the catheter comprises a tube having elongated exit slots therein. In accordance with other embodiments, the catheter includes an elongated tubular member made of a porous membrane. The porous membrane is configured so that a fluid introduced into an open end of the tubular member will flow through side walls of the tubular member at a substantially uniform rate along a length of the tubular member. In accordance with other embodiments, the catheter includes an elongated “weeping” tubular coil spring attached to an end of, or enclosed within, a tube. Fluid within the spring and greater than or equal to a threshold pressure advantageously flows radially outward between the spring coils. Advantageously, the fluid is dispensed substantially uniformly throughout a length of the spring.

Owner:AVENT INC

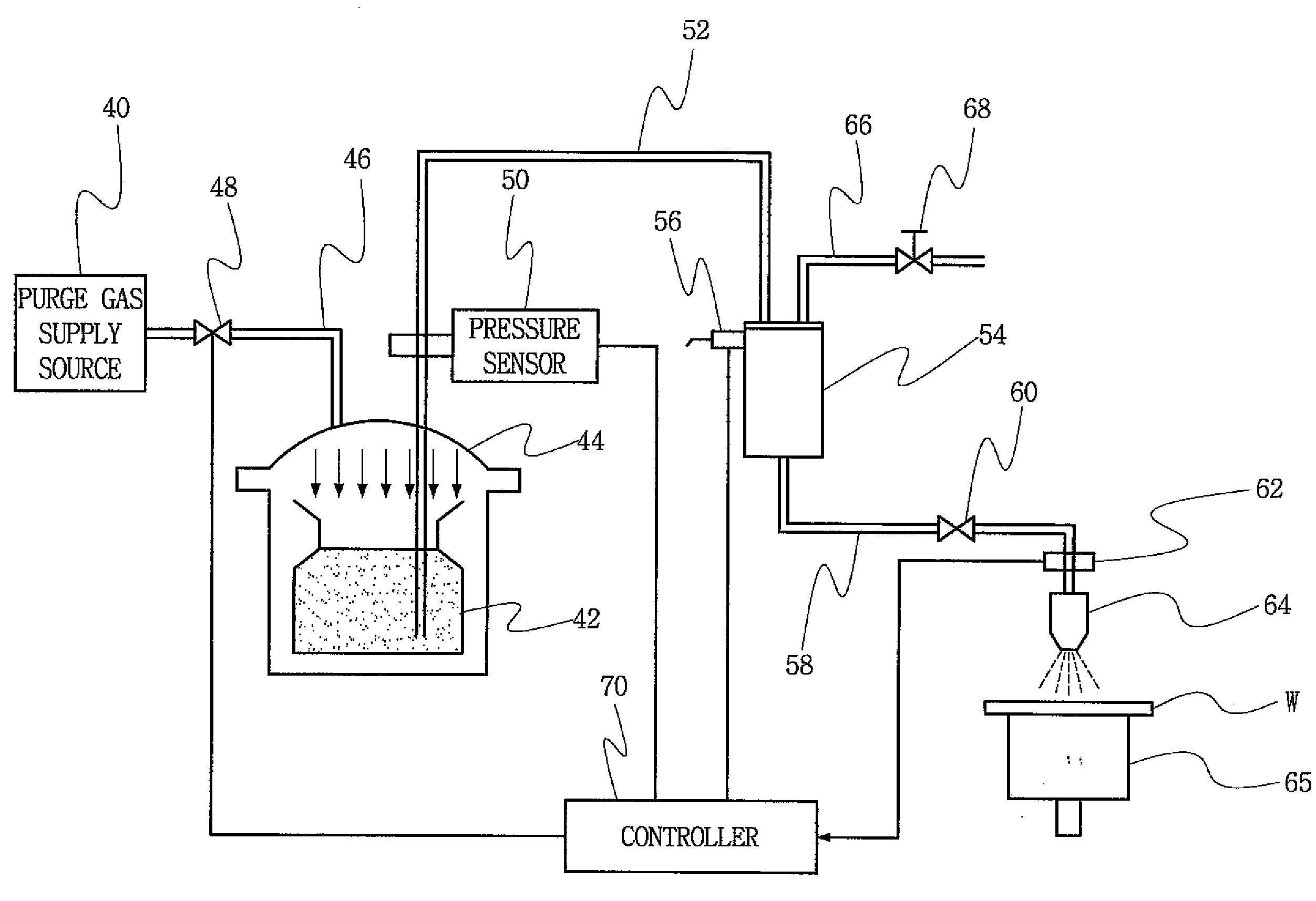

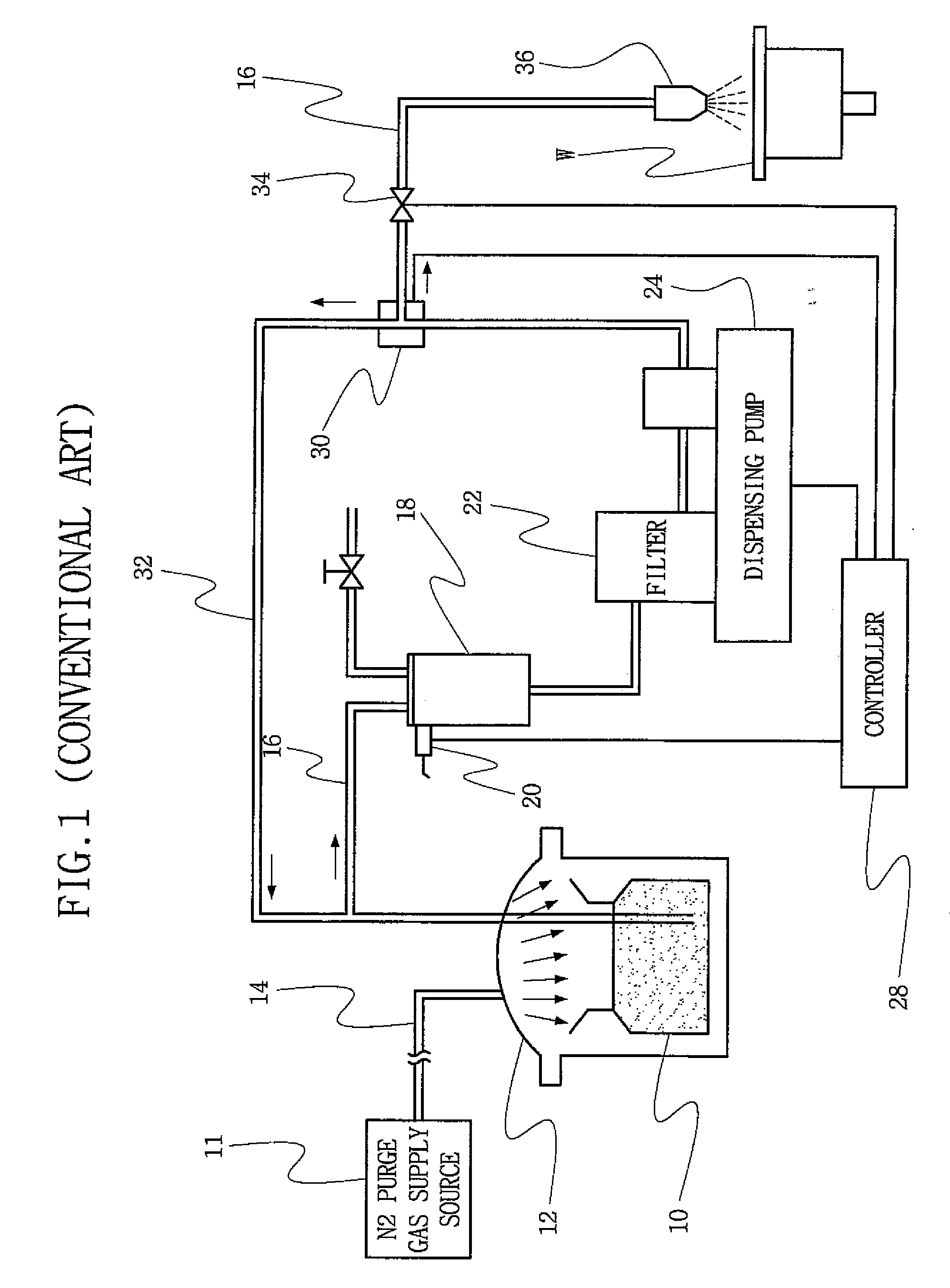

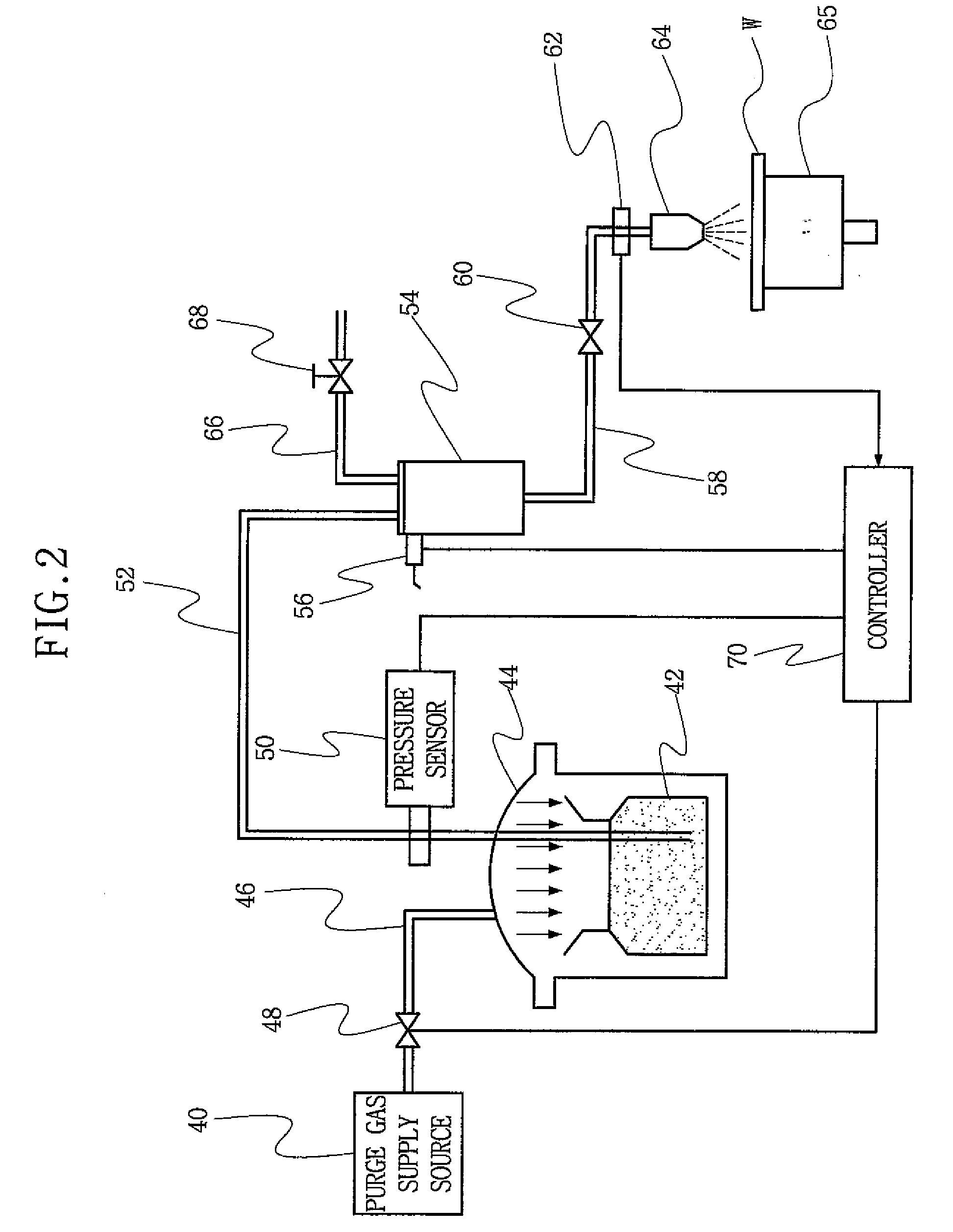

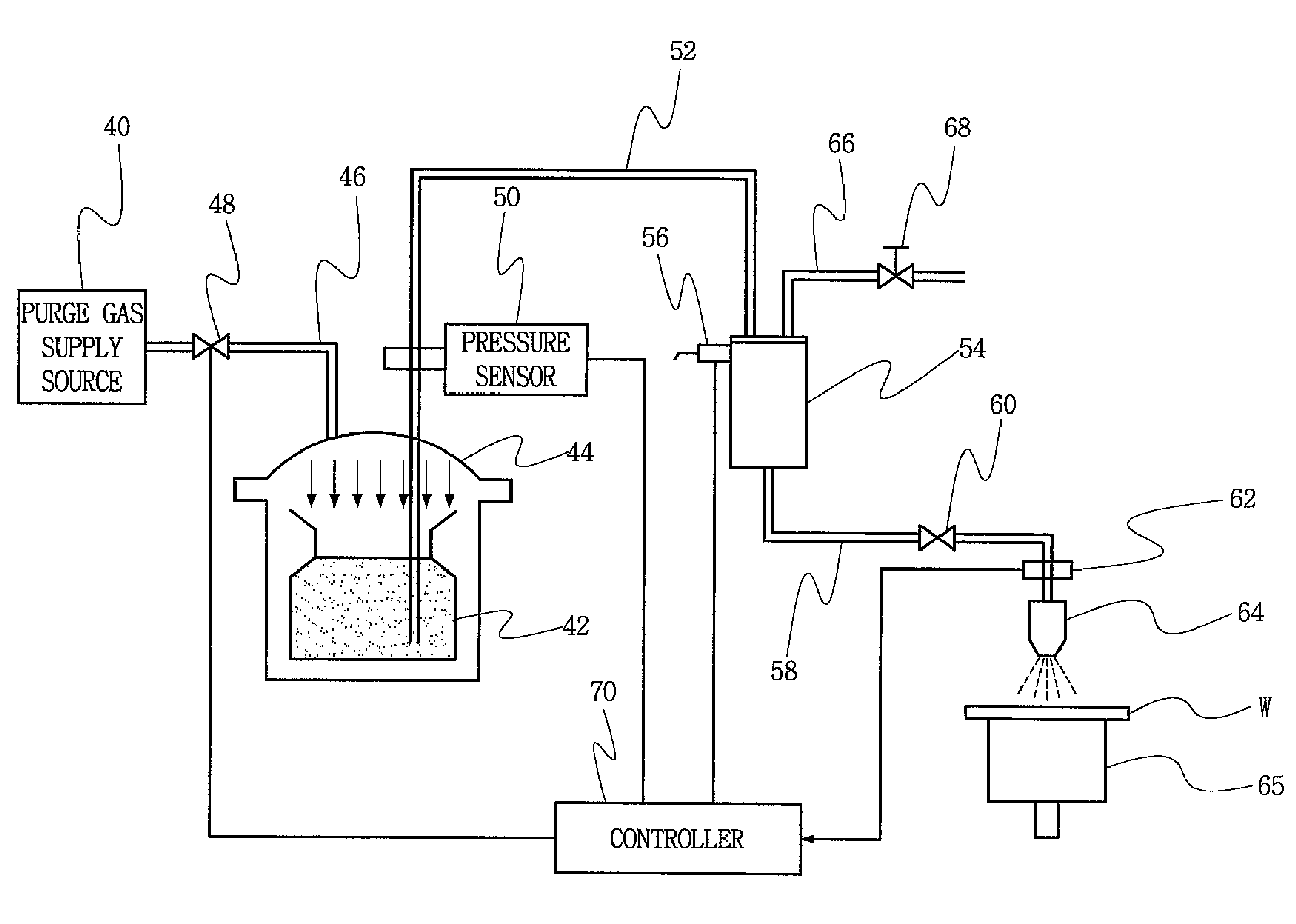

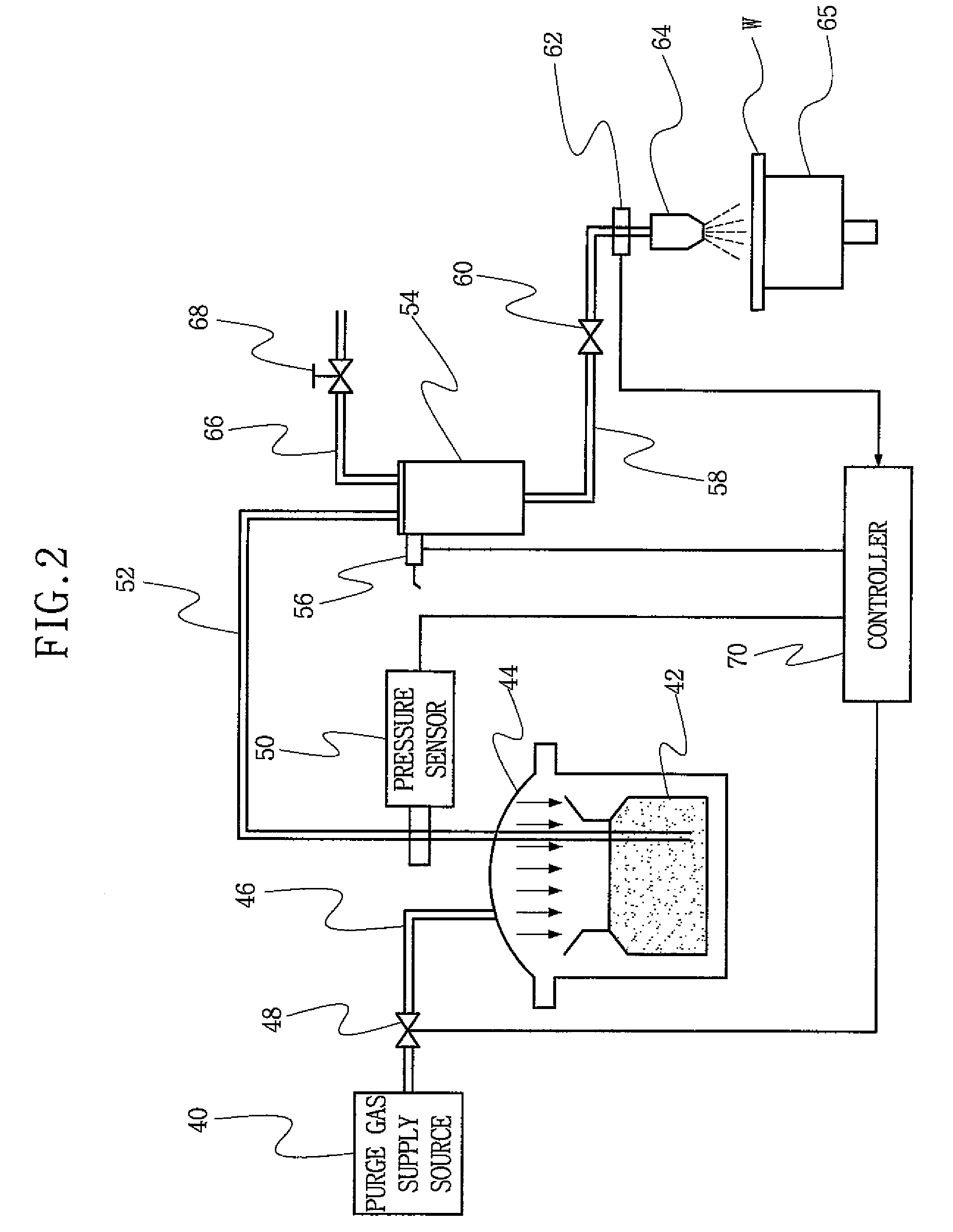

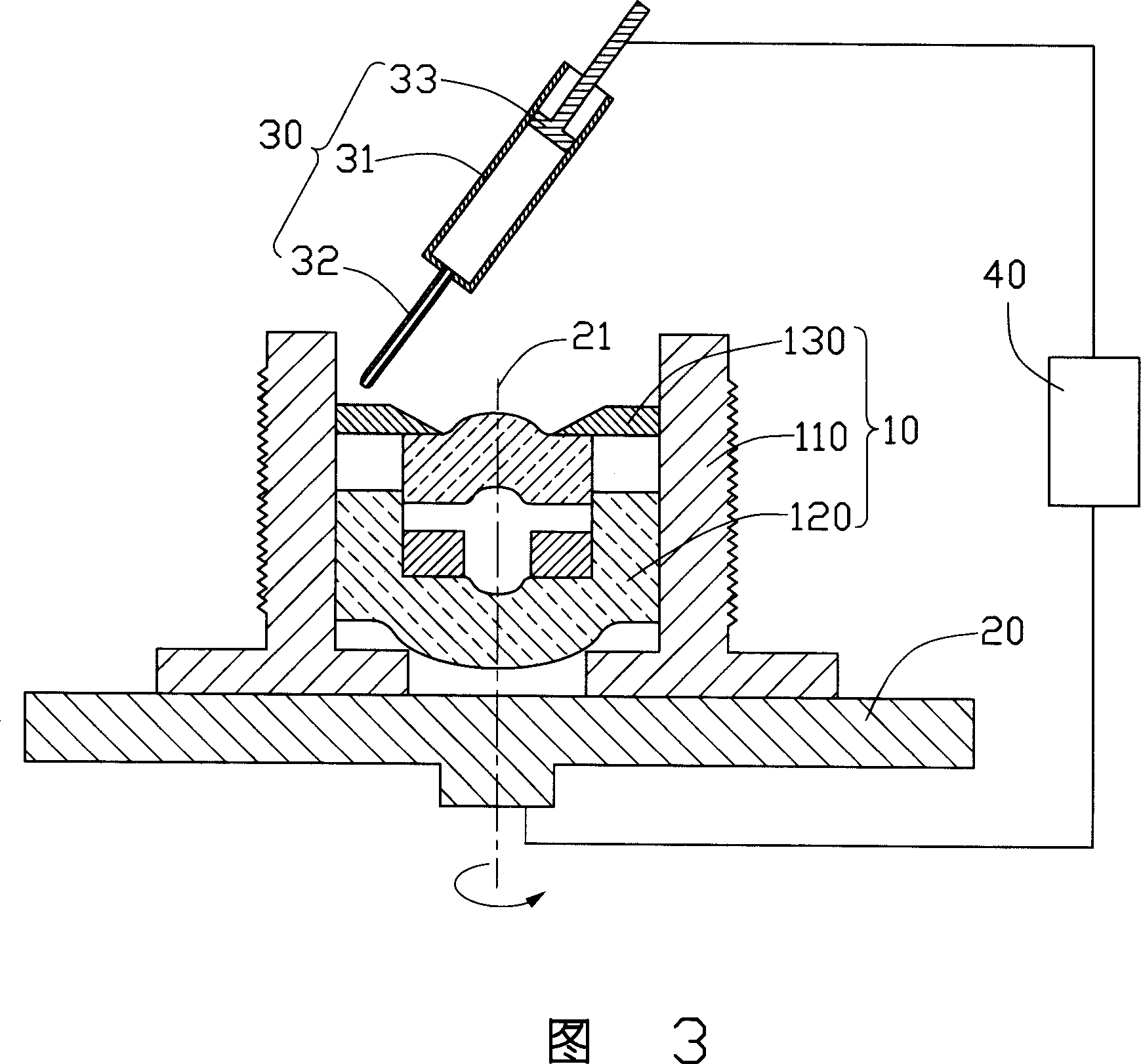

Apparatus for and method of dispensing chemical solution in spin-coating equipment

ActiveUS20080107796A1Low costUniform dispensingLiquid surface applicatorsPhotomechanical apparatusChemical solutionPressure sense

A chemical solution is uniformly dispensed from a nozzle by N2 in spin-coating equipment. The dispensing apparatus includes a canister configured to receive a bottle containing the chemical solution, gas supply piping connecting a source of N2 to the inside of the canister, a pressure control valve disposed in the gas supply piping, a chemical supply line by which the bottle is connected to the nozzle, a pressure sensor for sensing the pressure of the chemical solution supplied from the bottle, and a controller that controls the pressure control valve on the basis of the pressure sensed by the pressure sensor. The controller opens the pressure control valve further when the value of the signal output by the pressure sensor is less than a value representative of the minimum of a predetermined pressure range, and closes the pressure control valve further when the value of the signal output by the pressure sensor is greater than a value representative of the maximum of the predetermined pressure range. The degree to which the pressure control is open is thus controlled by feedback from the pressure control sensor such that the pressure of the chemical solution remains substantially constant as it is dispensed from the nozzle.

Owner:SAMSUNG ELECTRONICS CO LTD

Processes for producing regular repeating patterns on surfaces of interbody devices

ActiveUS9125756B2High positioning accuracyRapid productionDecorative surface effectsVacuum evaporation coatingSpinal columnRough surface

Processes for producing interbody spinal implants having a body with a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, a substantially hollow center, and a single vertical aperture; and optionally, one or two integration plates affixed to the body. The processes include applying an additive process, a subtractive process, or both processes to at least one surface of the interbody spinal implant to form a roughened surface topography having a regular repeating pattern. The roughened surface topography is specifically designed to provide certain frictional characteristics, load dispersion, and to influence the biological responses that occur during bone healing and fusion.

Owner:TITAN SPINE

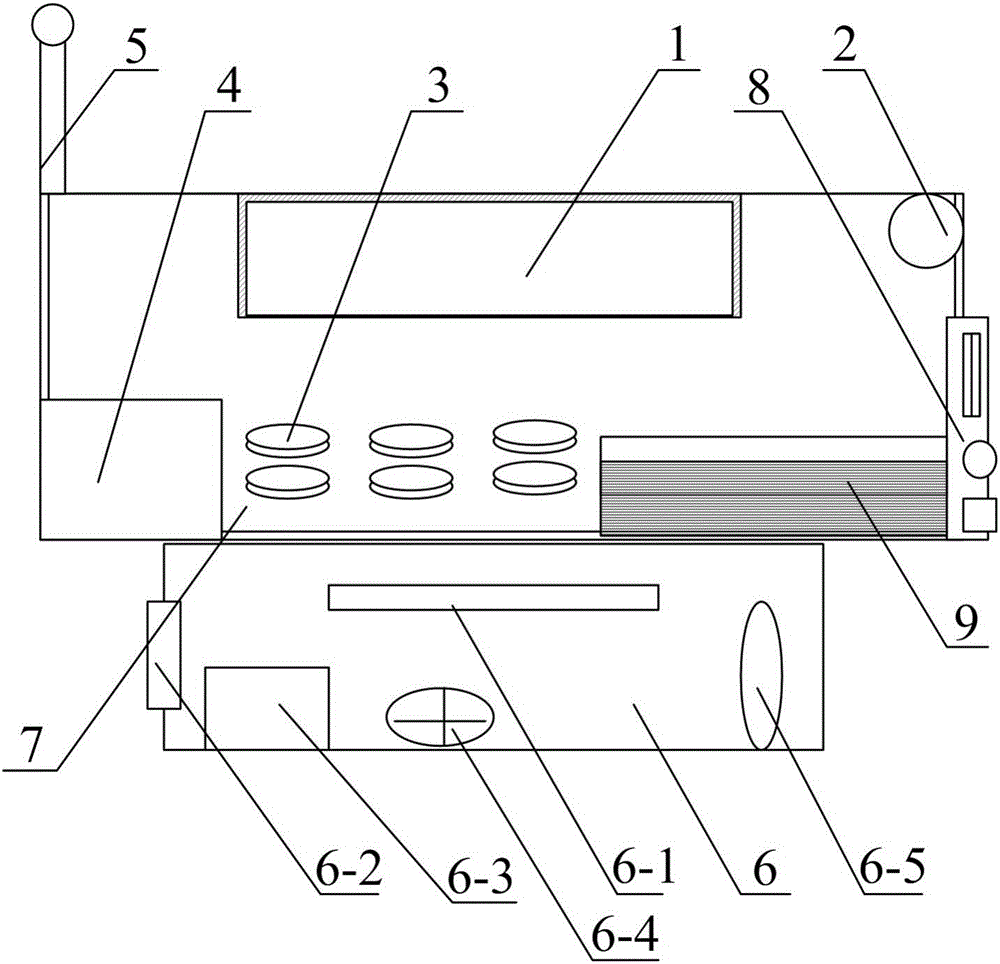

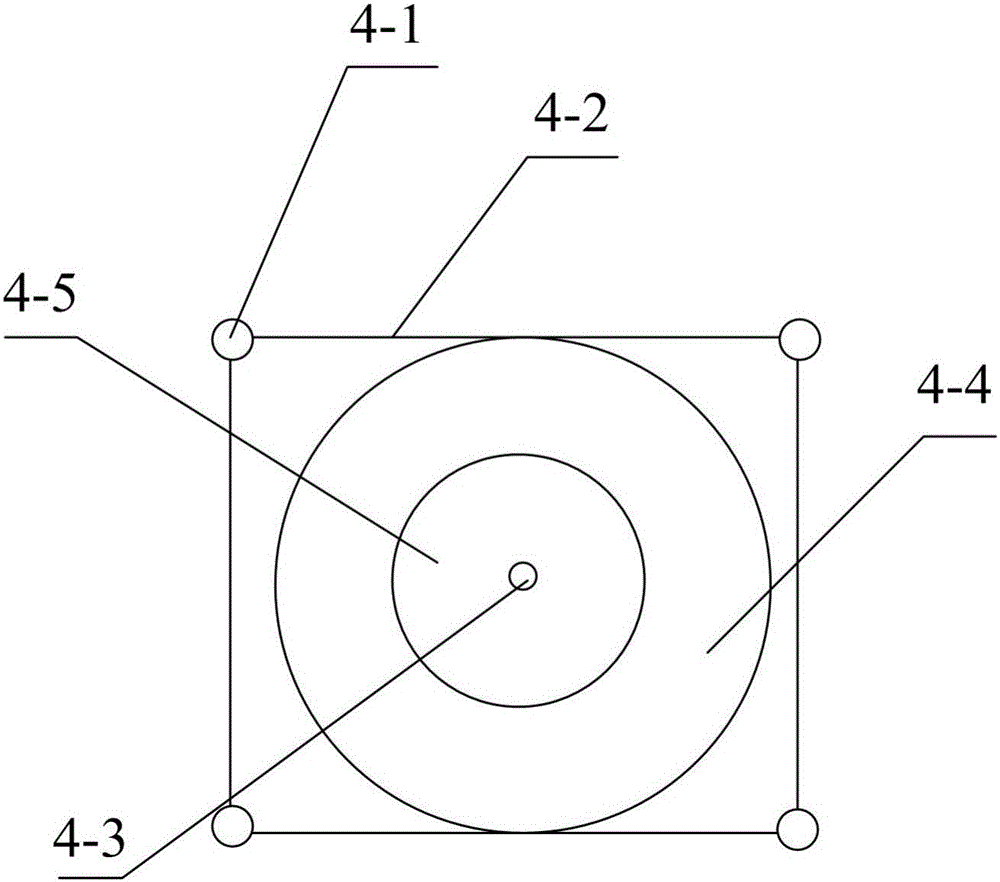

Automatic detection system for traditional-Chinese-medicine quality

InactiveCN105973858AObjective testing standardUnified testing standardsImage enhancementImage analysisPattern recognitionMicroscopic image

The invention discloses an automatic detection system for the traditional-Chinese-medicine quality. Traditional-Chinese-medicine original images are collected, outlines of target areas are partitioned, the images are subjected to noise removing, a neural network PCNN corresponds to the images, central neuron corresponds to pixel points of the images, multi-wavelength LED lamps are illumed respectively, several LED lamps capable of motivating remarkable fluorescence signals are selected and alternately illumed, traditional-Chinese-medicine samples with fluorescence spectrums of 300 nm-1,100 nm are collected, the one-dimensional time-series signal characteristics of all two-dimensional images are extracted, characteristic information is stored, the airspace characteristics of traditional-Chinese-medicine microscopic images are extracted, and the traditional-Chinese-medicine quality is detected. According to the automatic detection system, the traditional-Chinese-medicine external parameters are synthetically evaluated with the electronic technology, the traditional-Chinese-medicine inherent quality is automatically detected by combing traditional-Chinese-medicine chemical-component content parameters, safety detection parameters and conventional detection parameters, the detection standard is objective and uniform, and accurate medicine making can be achieved.

Owner:YICHUN UNIVERSITY

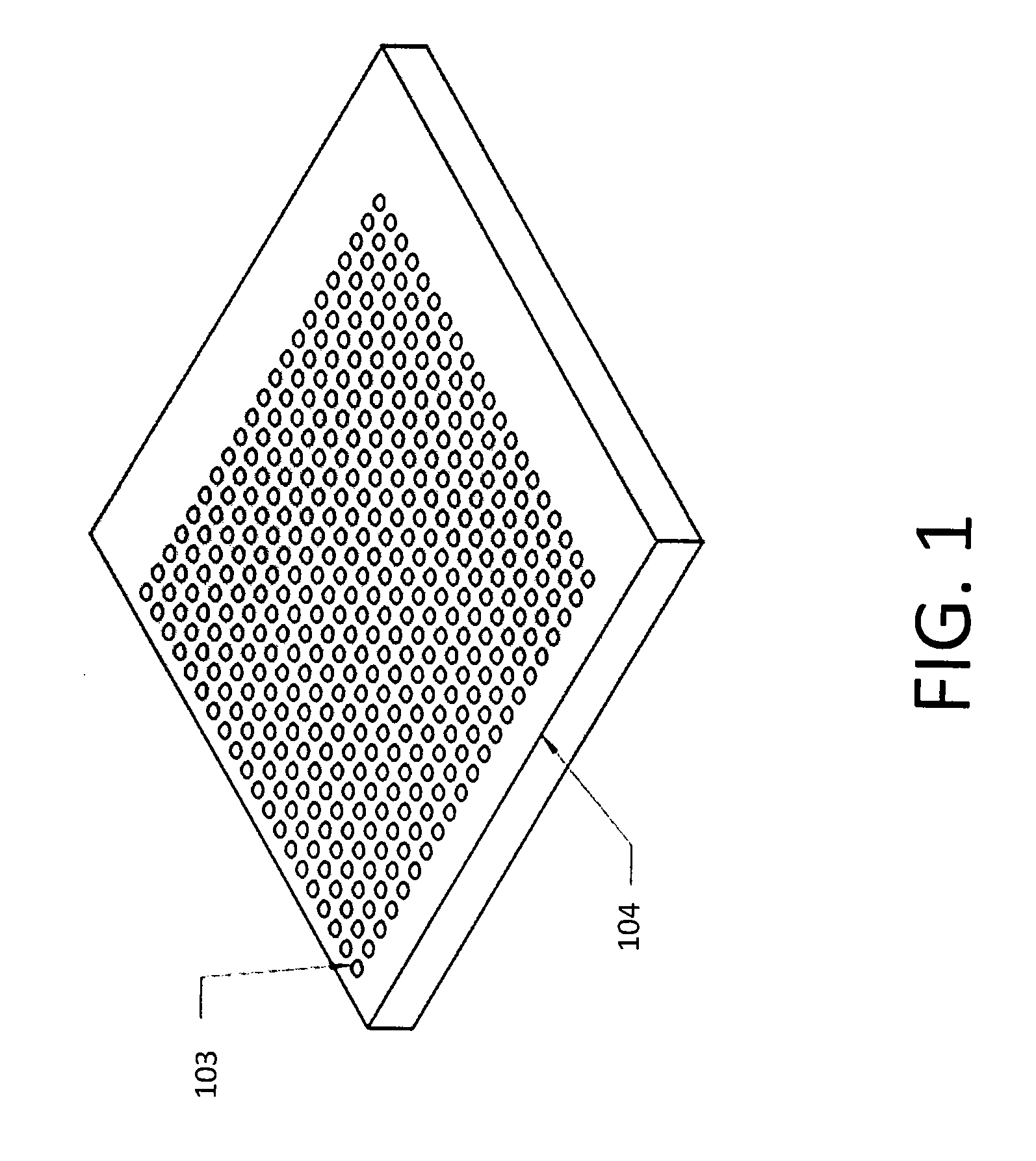

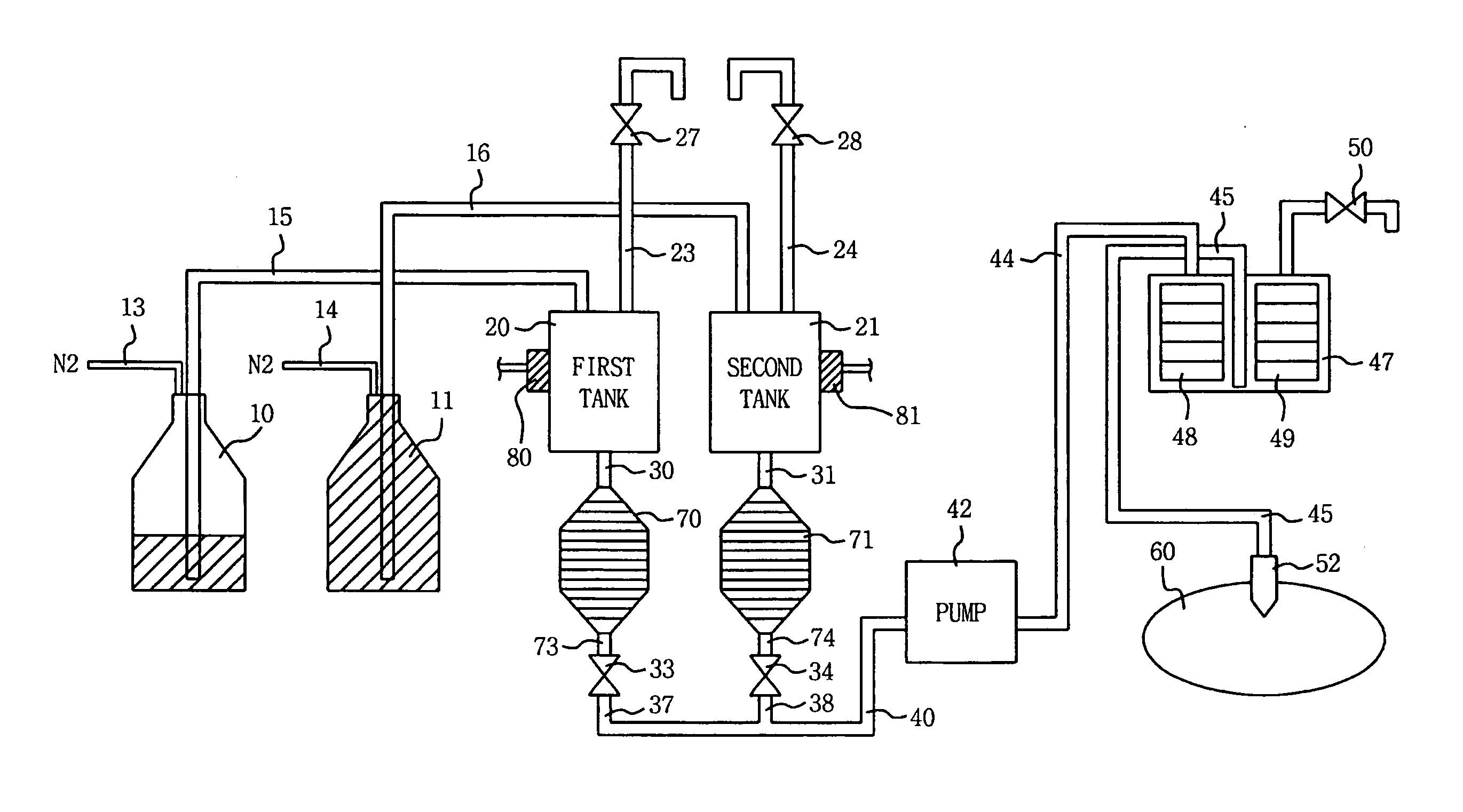

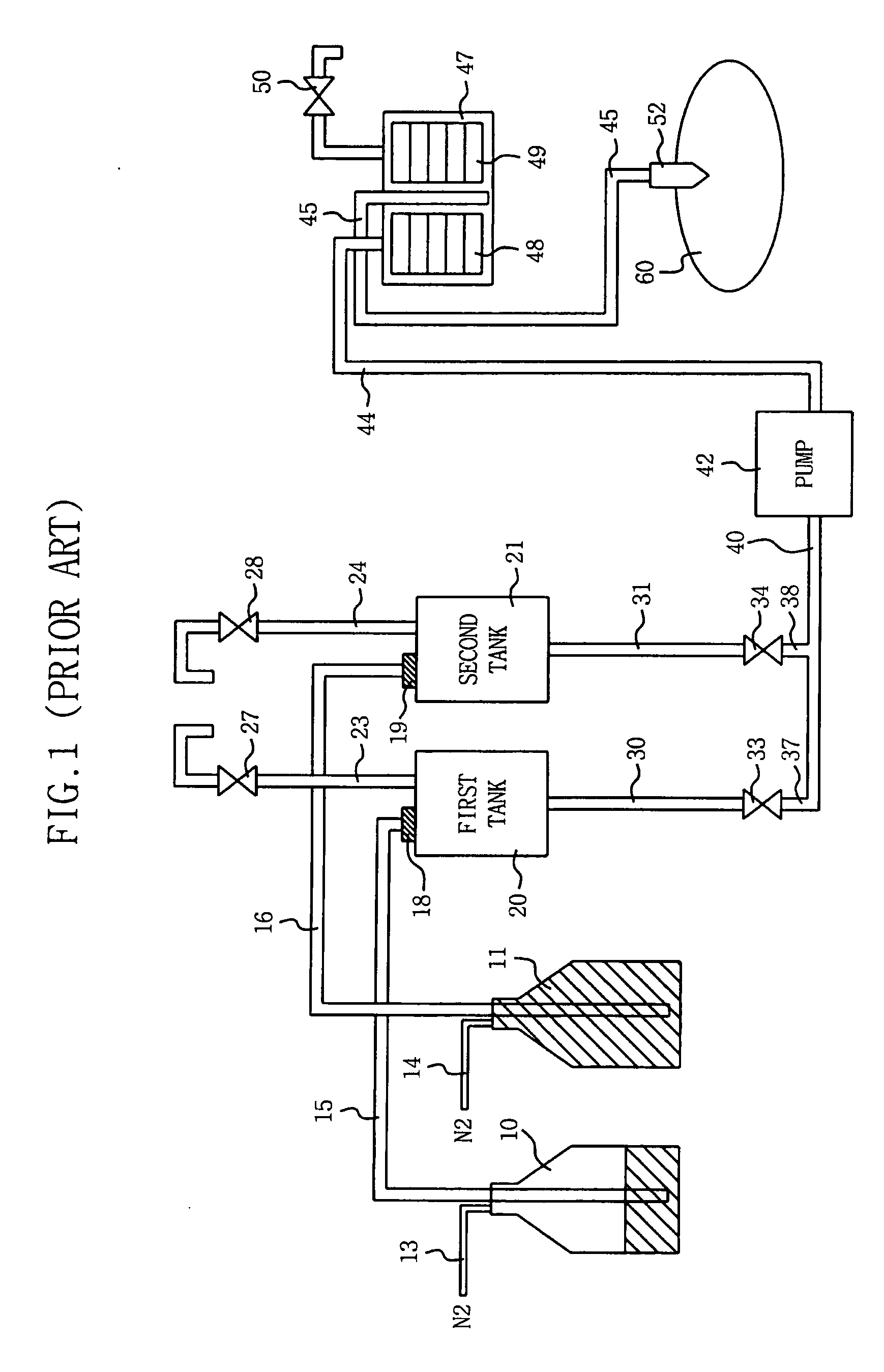

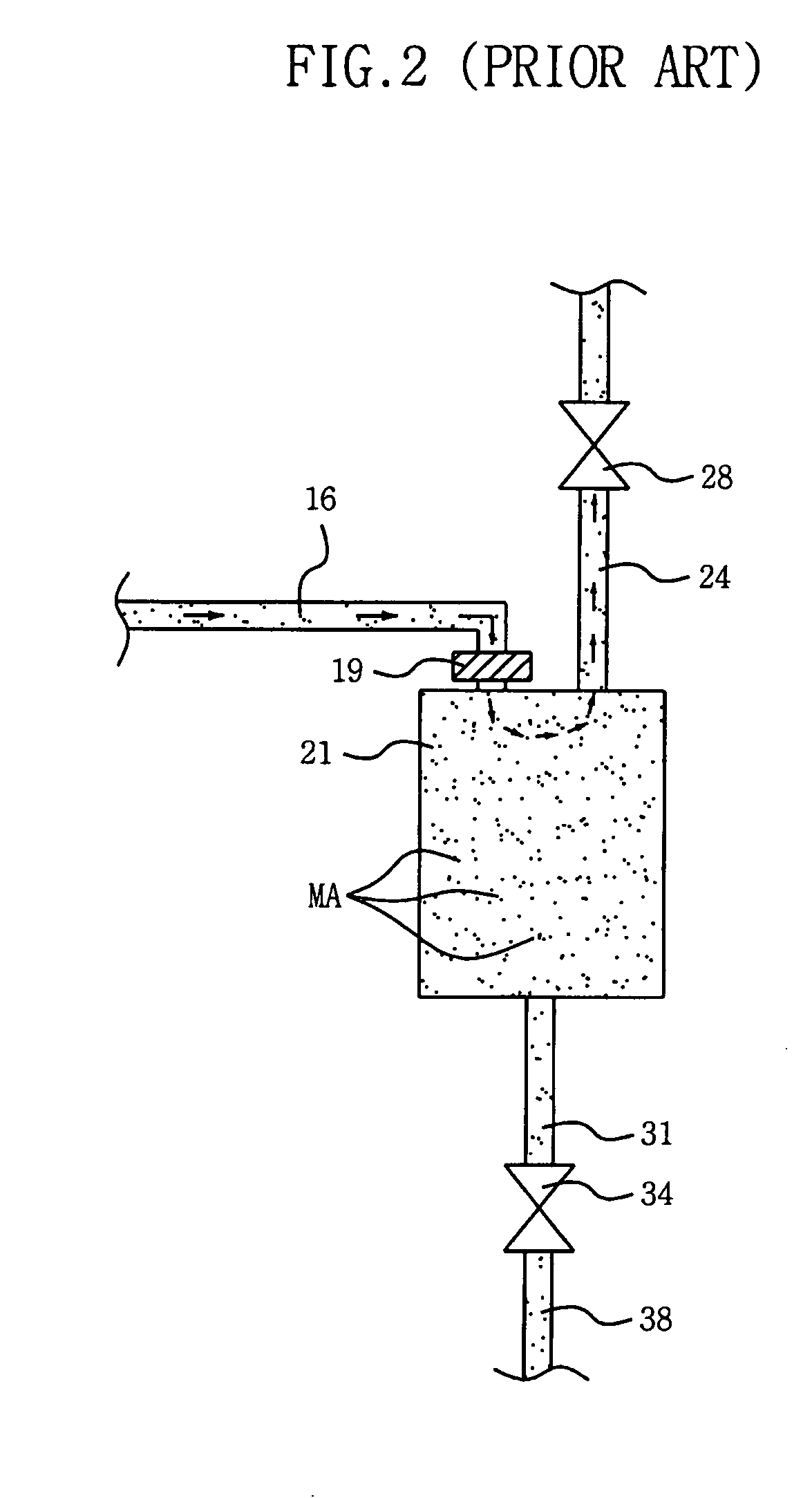

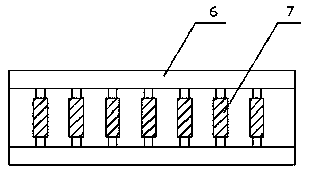

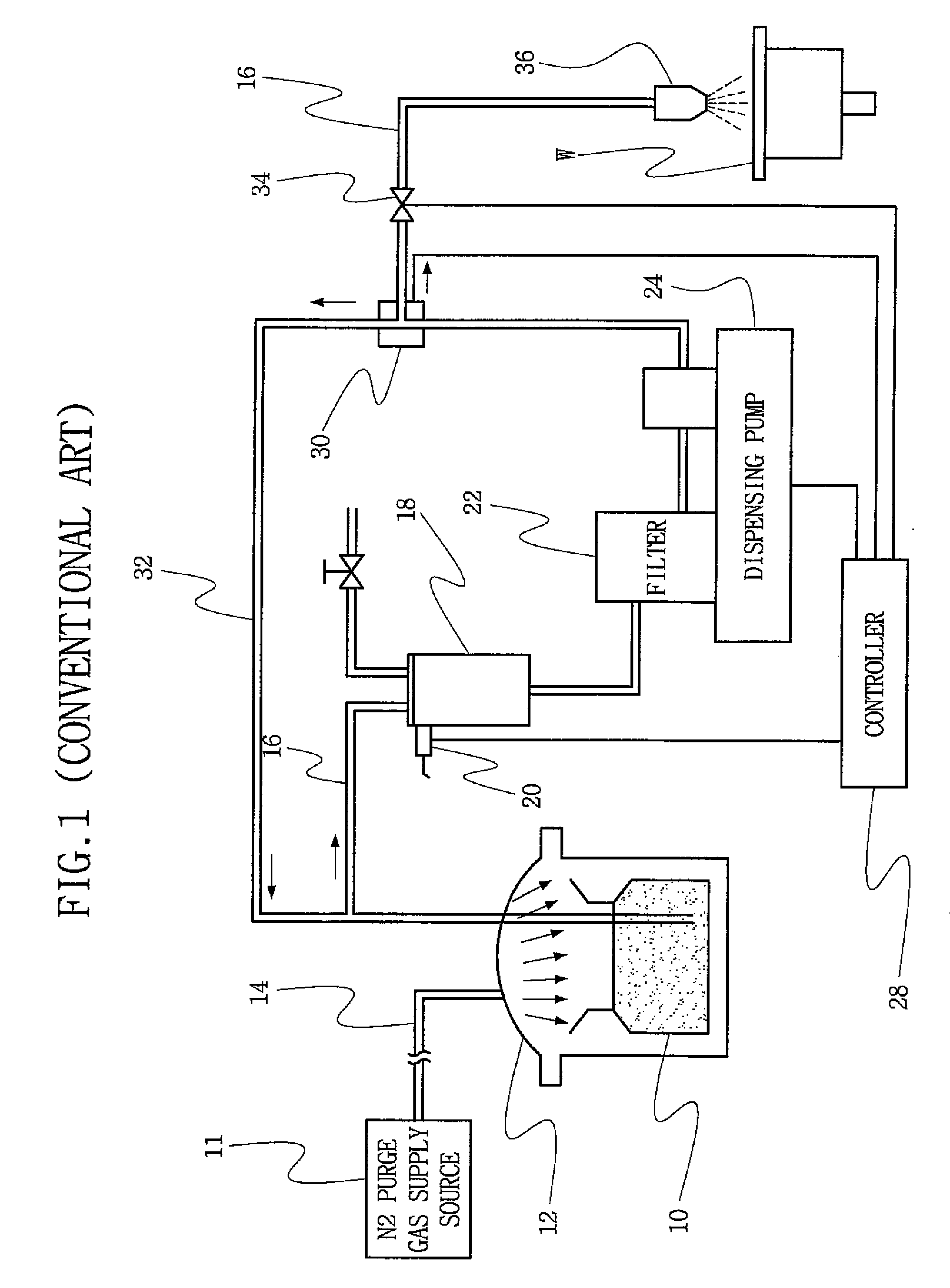

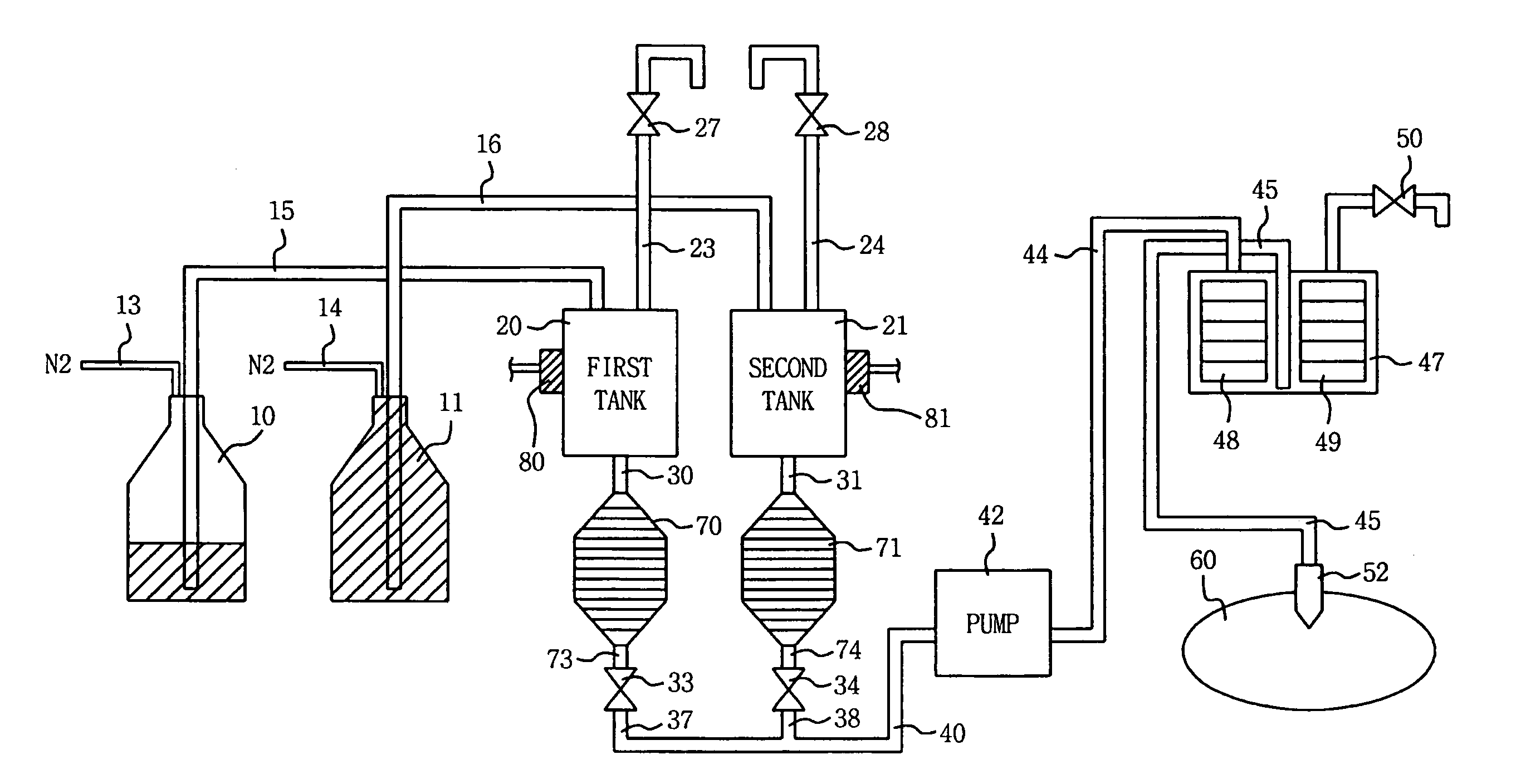

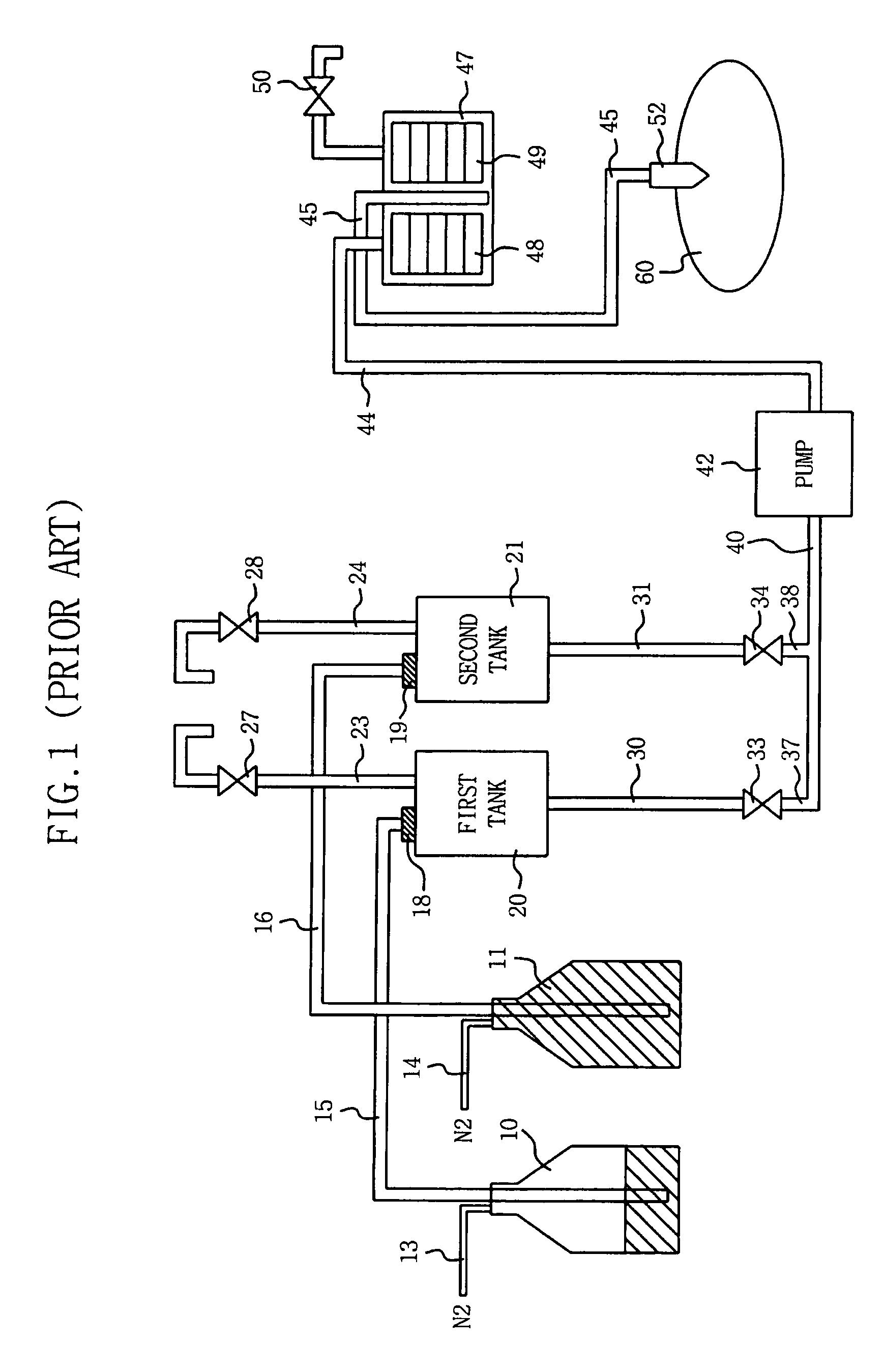

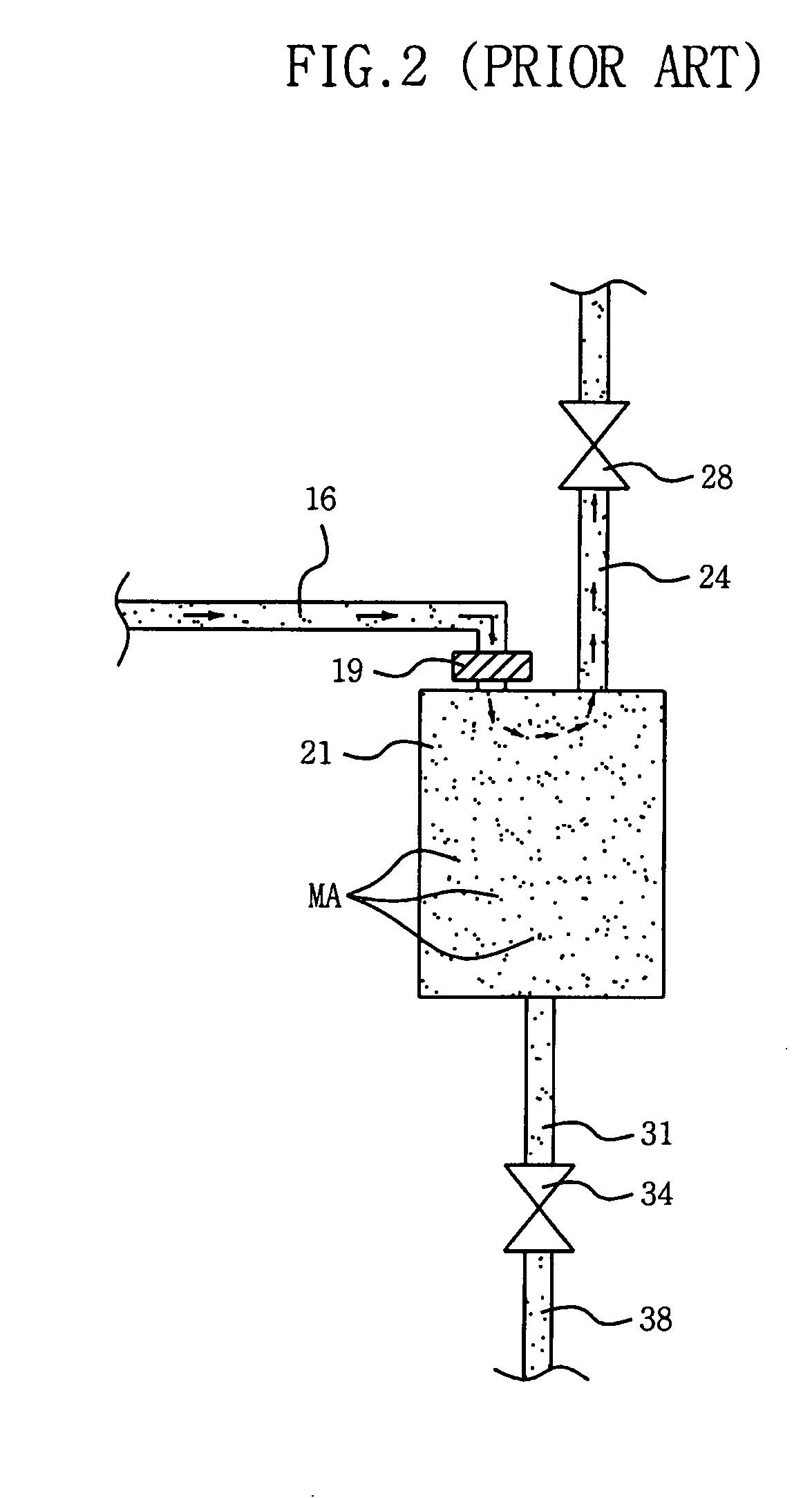

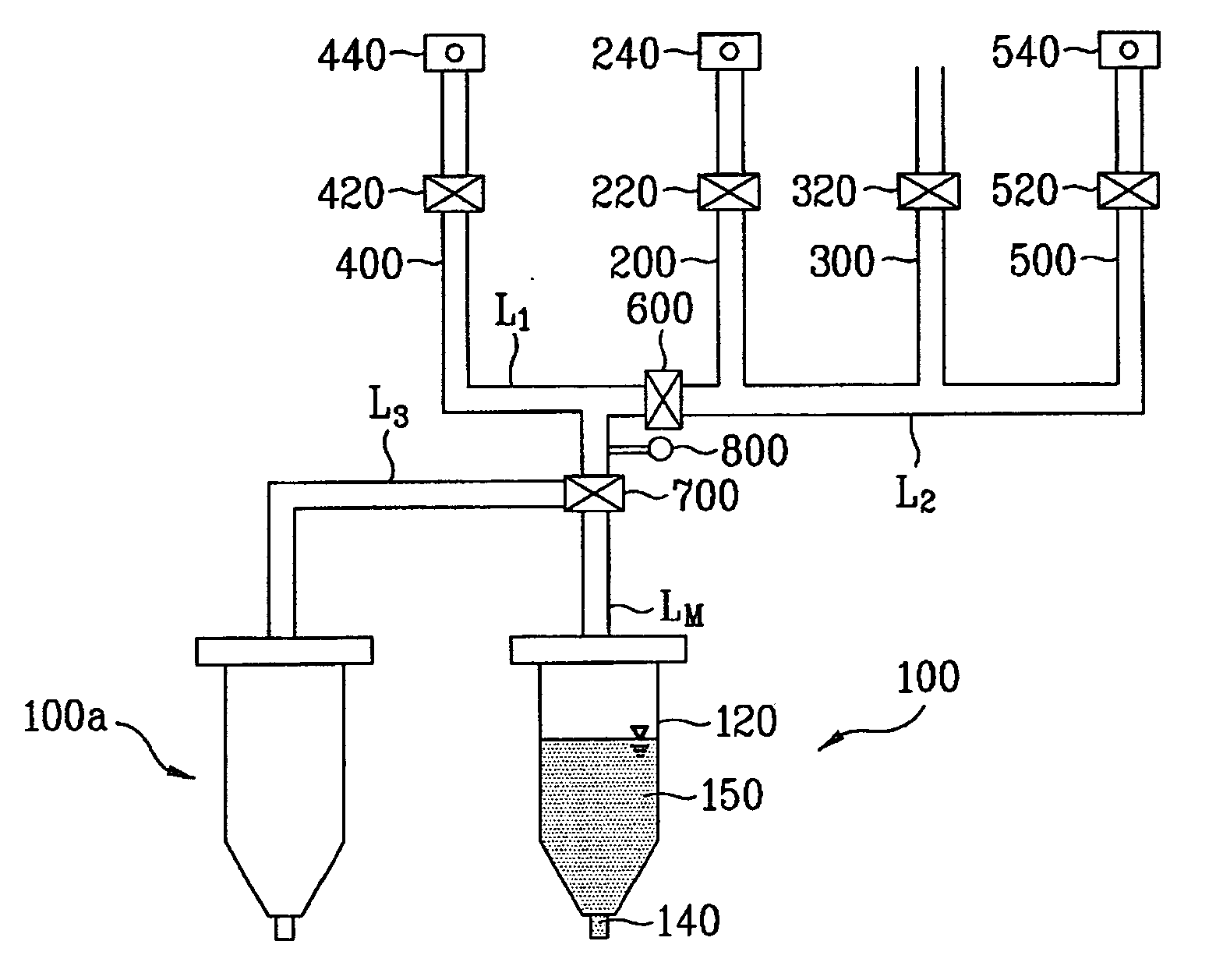

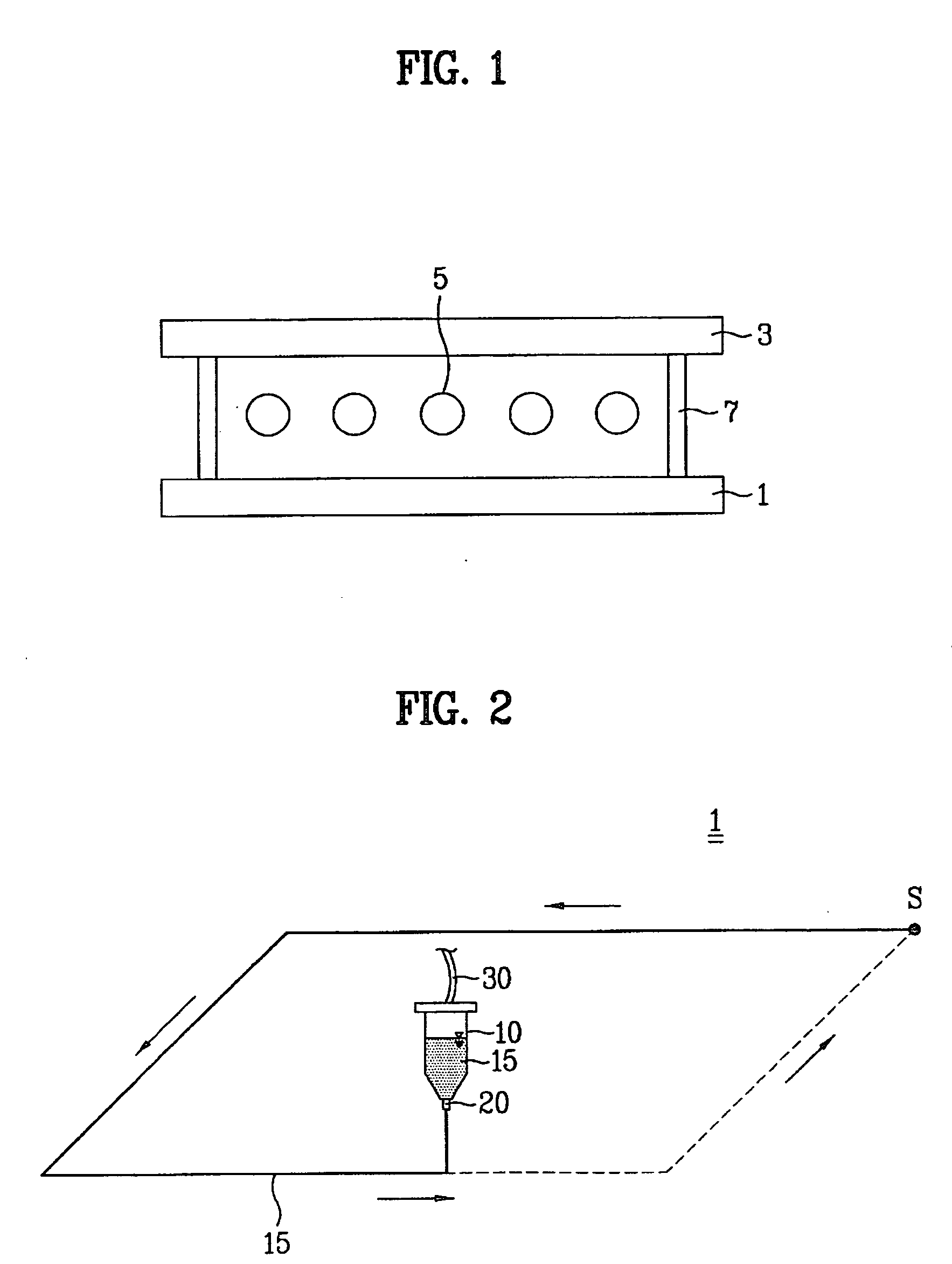

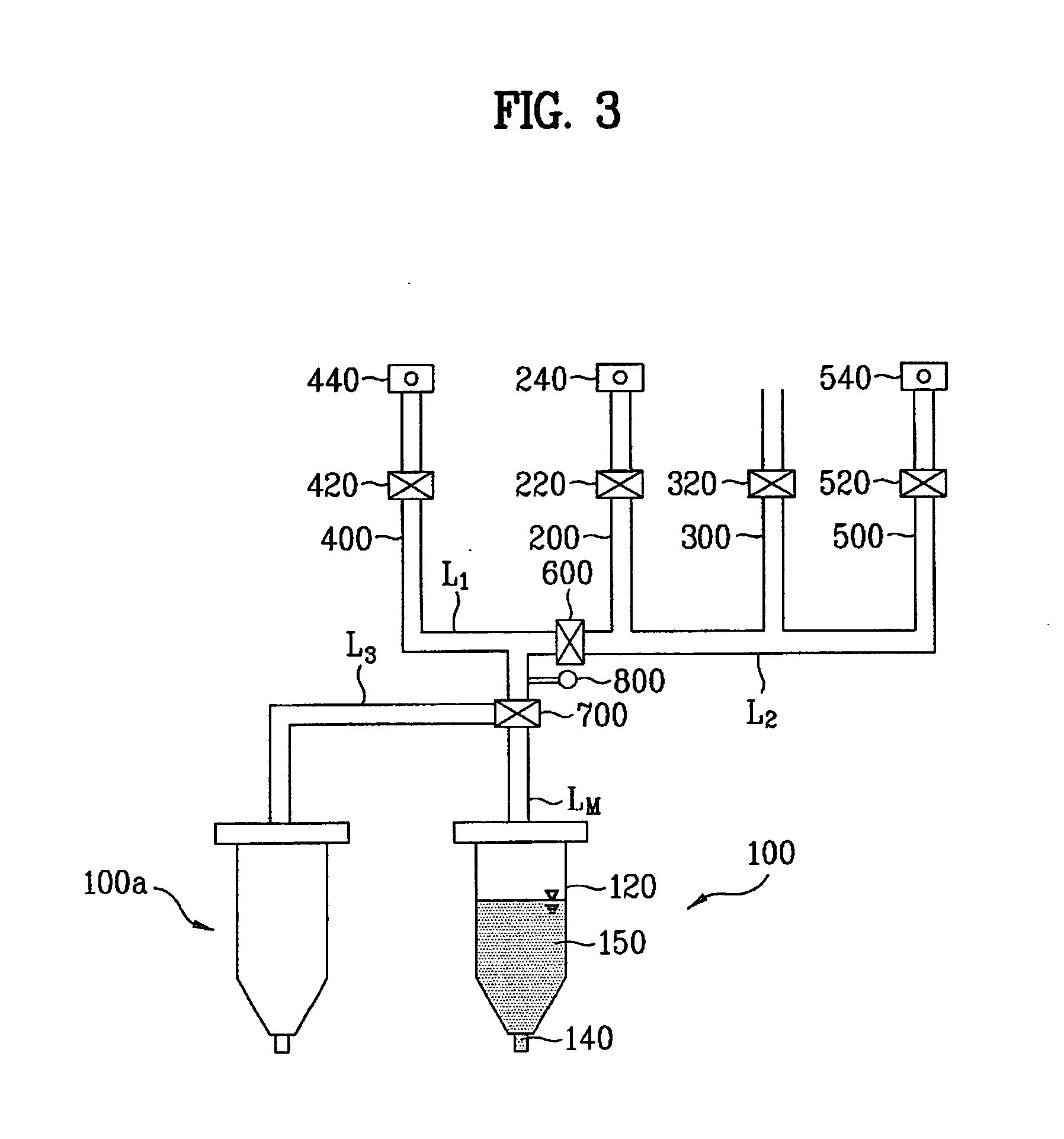

Apparatus and method of dispensing photosensitive solution in semiconductor device fabrication equipment

ActiveUS20050224132A1Uniform layersReduce the presence of air bubblesLiquid degasificationLiquid fillingBuffer tankSemiconductor

A method of and apparatus for dispensing photosensitive solution. substantially reduces the amount of air bubbles in the photosensitive solution during the dispensing operation. The photosensitive solution dispensing apparatus includes at least one supply vessel that contains the solution, a respective buffer tank that buffers the solution supplied from each supply vessel, a filter unit for filtering the solution, a pump for pumping the solution pumped from the buffer tank to the filter unit, a dispensing nozzle connected to the filter unit, and a dedicated bubble removal filter that is interposed between the buffer tank and the pump. The bubble removal filter is configured to remove air bubbles from the solution before the solution flows into the pump and is dispensed through the nozzle.

Owner:SAMSUNG ELECTRONICS CO LTD

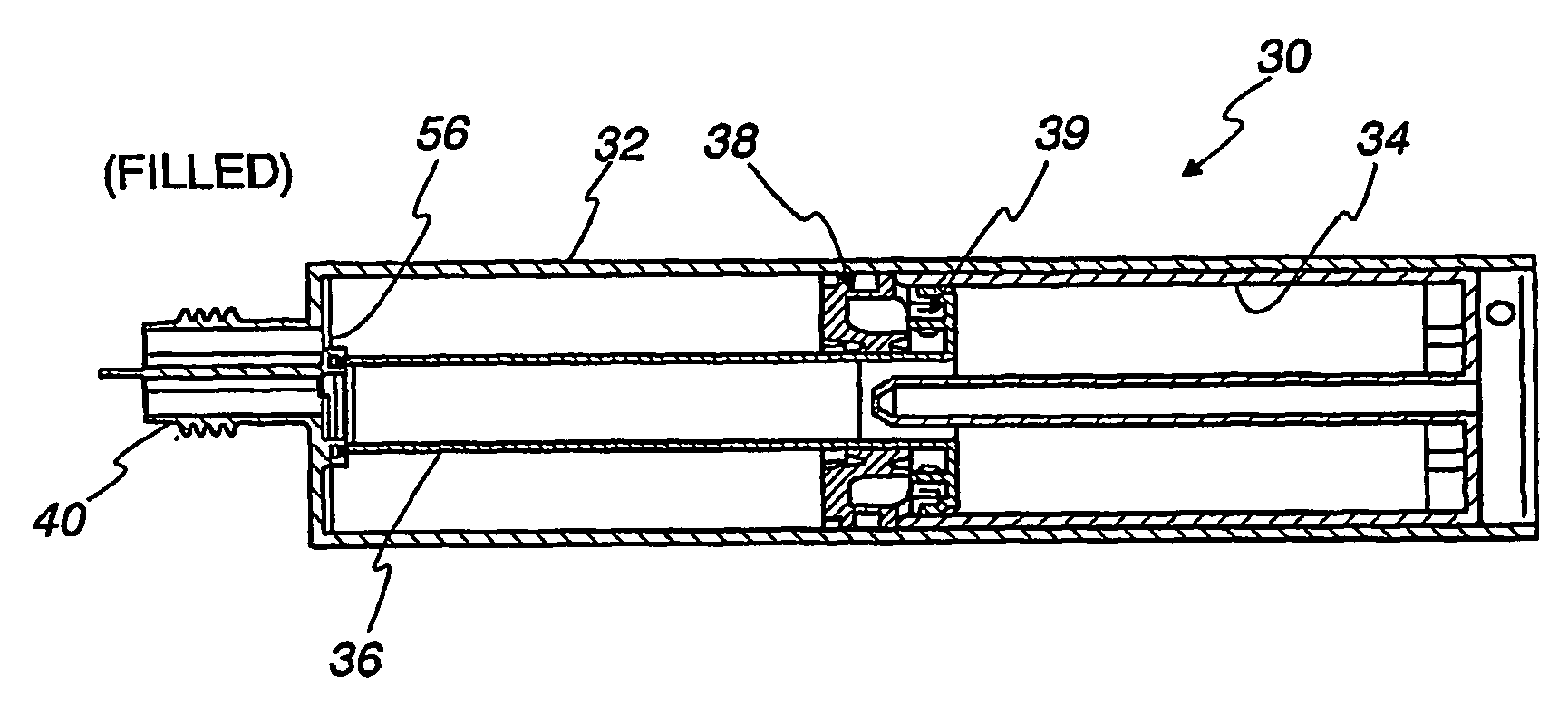

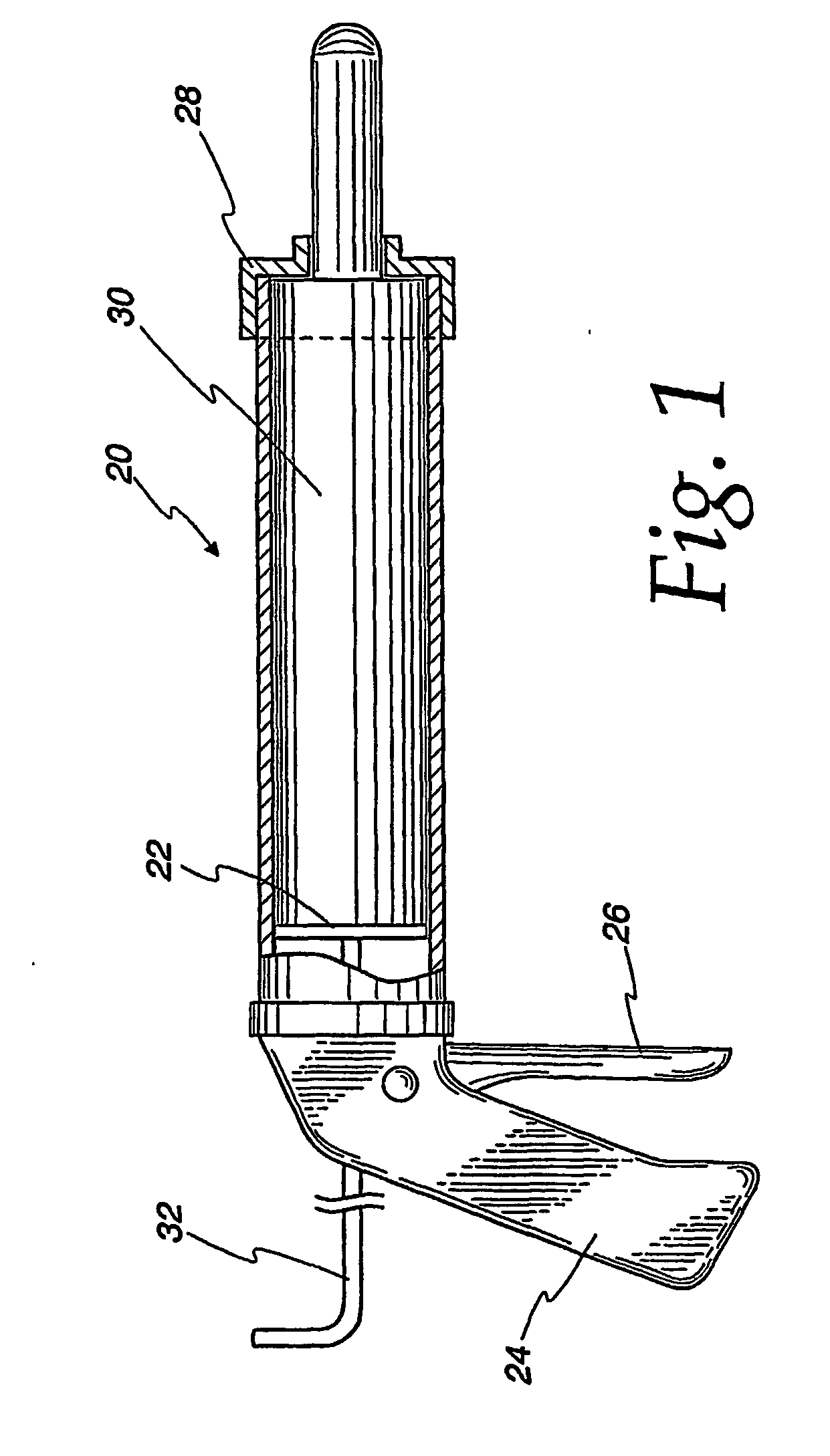

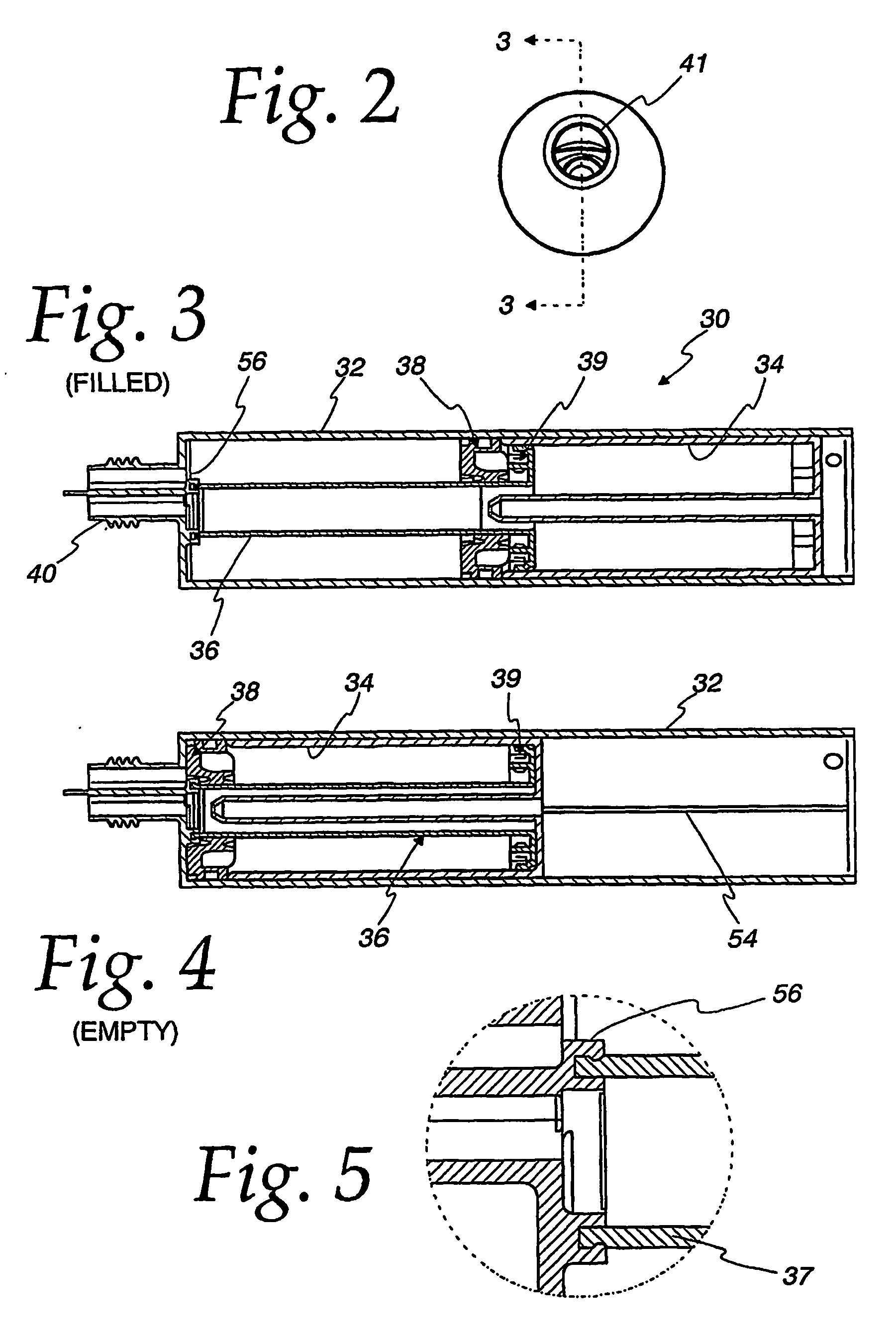

Dual fluid cartridge assembly

A dual fluid cartridge assembly (30) is adapted to be used with a conventional caulking gun (20). The dual fluid cartridge assembly includes an outer cartridge (32), a piston seal and delivery tube (36), an upper piston seal (38) and an inner cartridge (34). The outer cartridge includes a cartridge outlet (40) for dispensing fluids and as configured to accept conventional mixing nozzles. Fluids are back-filled through the cartridge outlet into the inner cartridge and the outer cartridges. In order to prevent trapped air pockets during the filling of the fluid in the inner cartridge, one or more slots (54) are formed in a base plate (42) of the inner cartridge.

Owner:NORDSON CORP

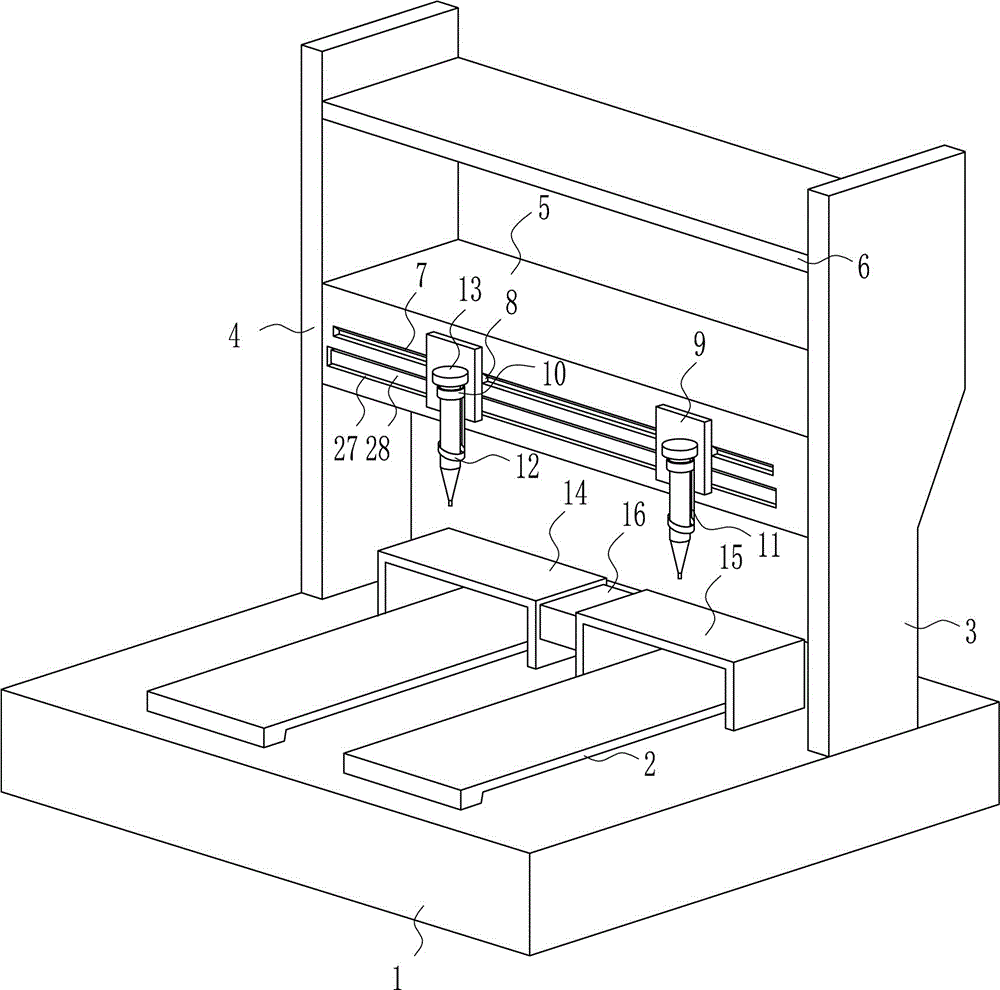

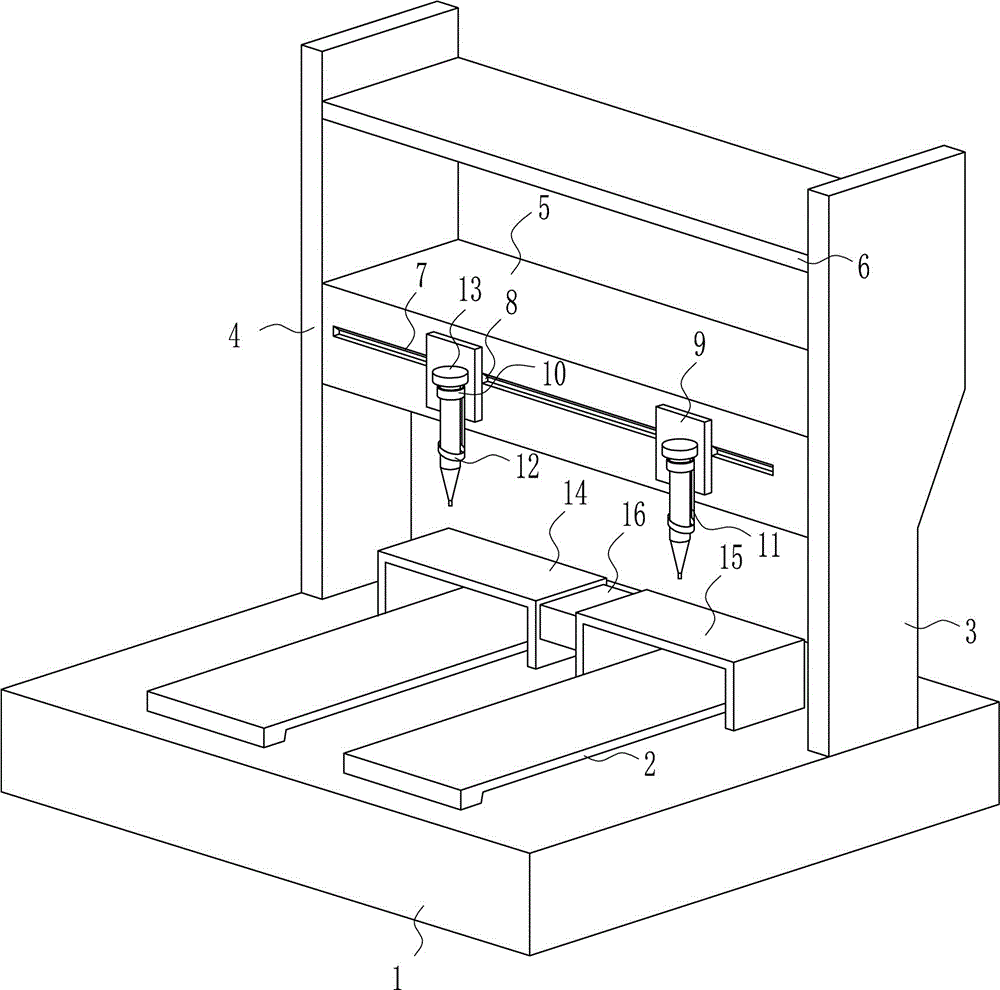

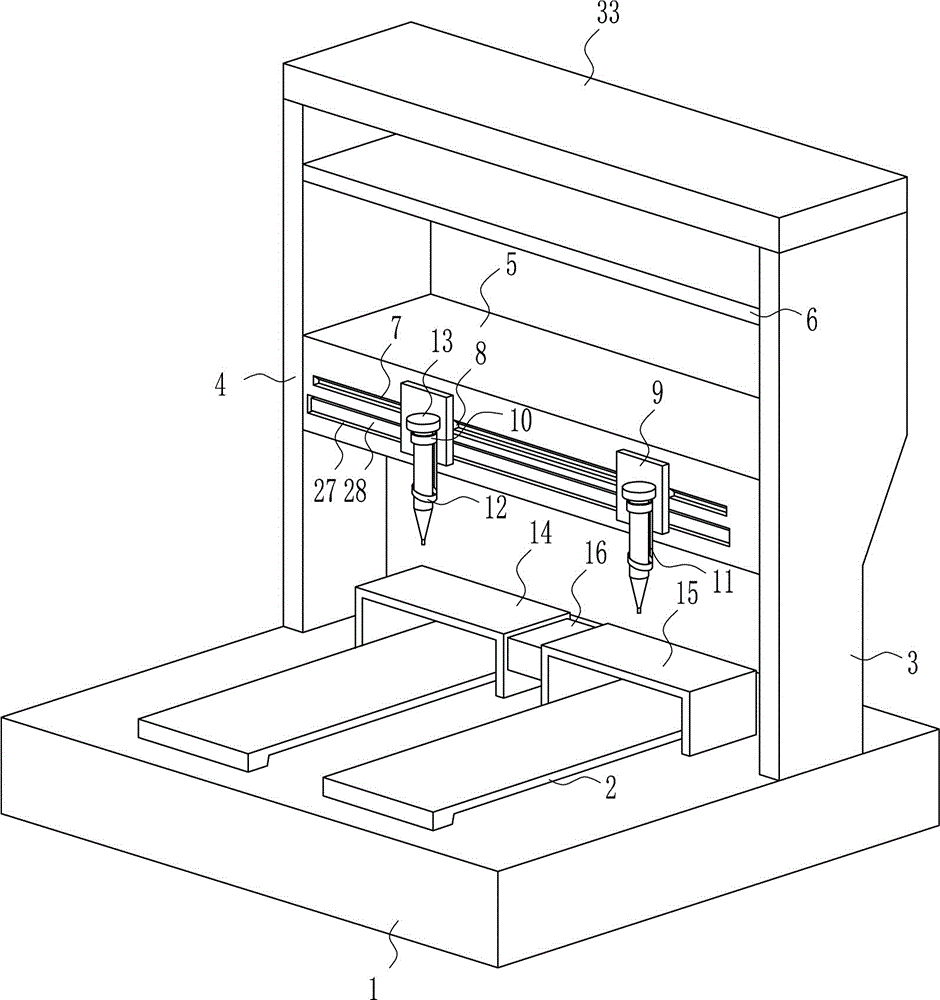

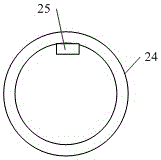

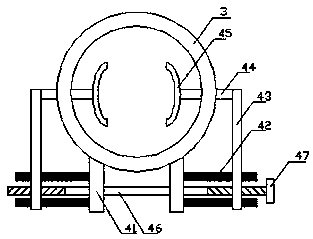

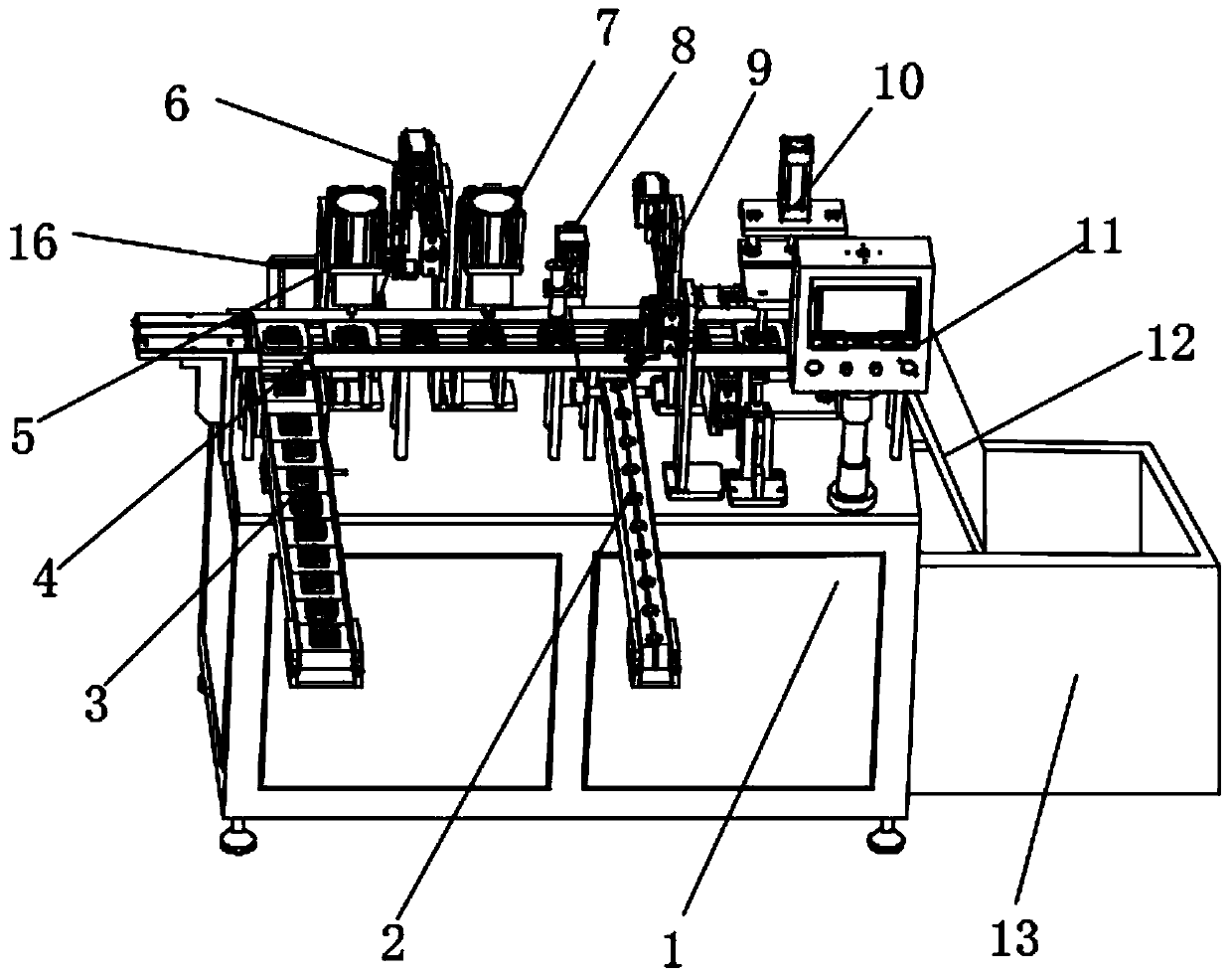

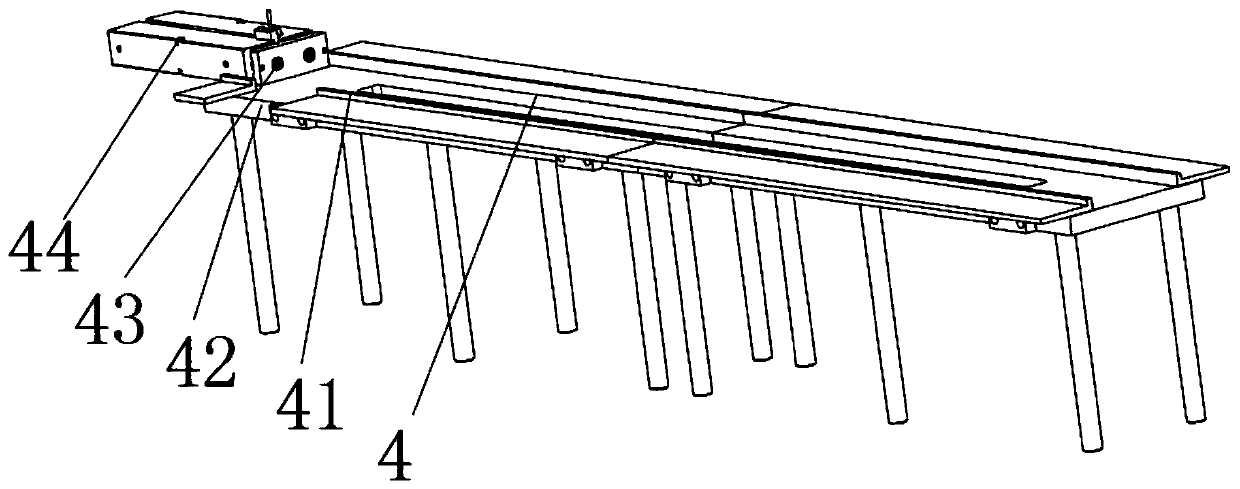

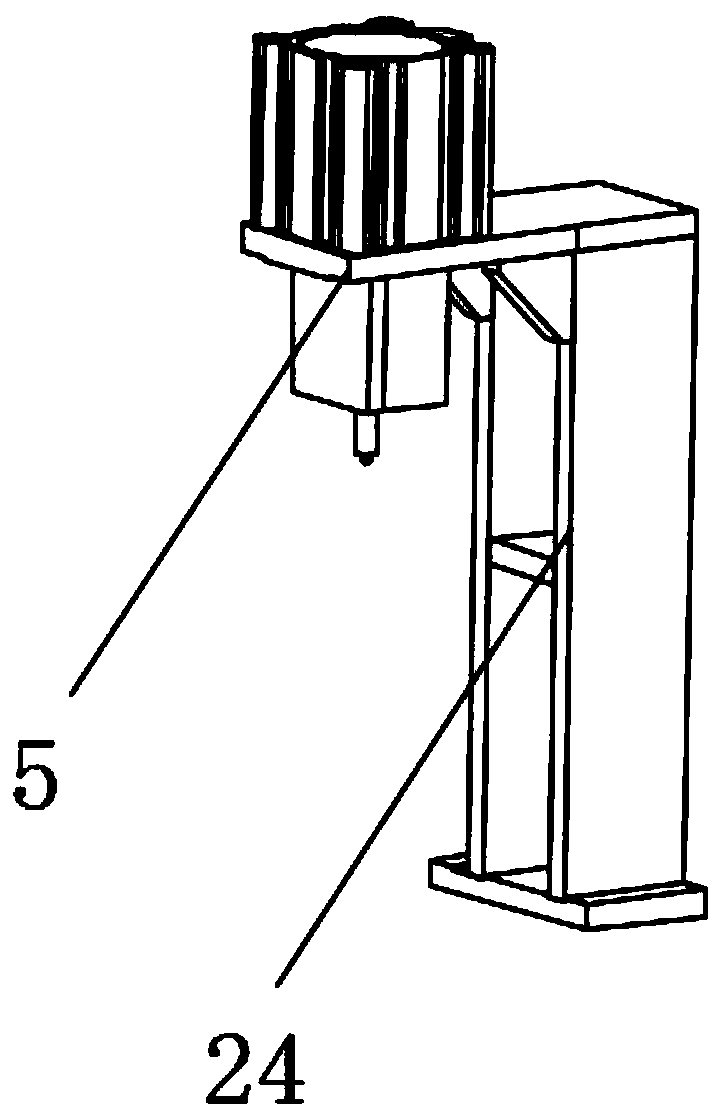

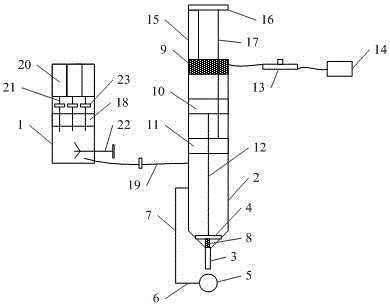

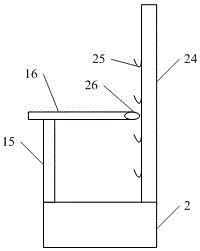

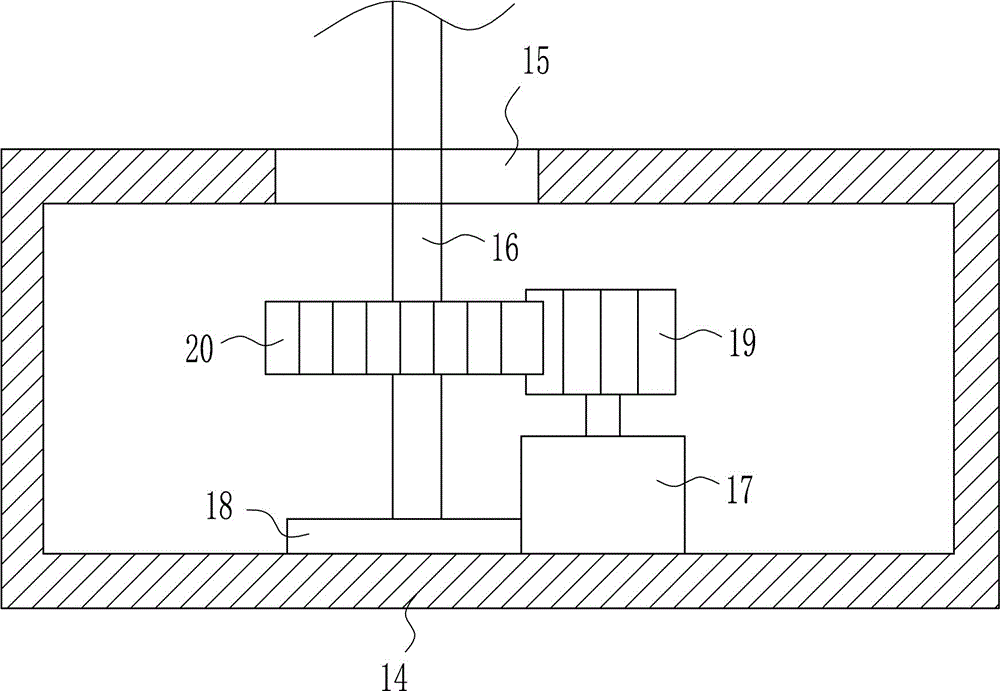

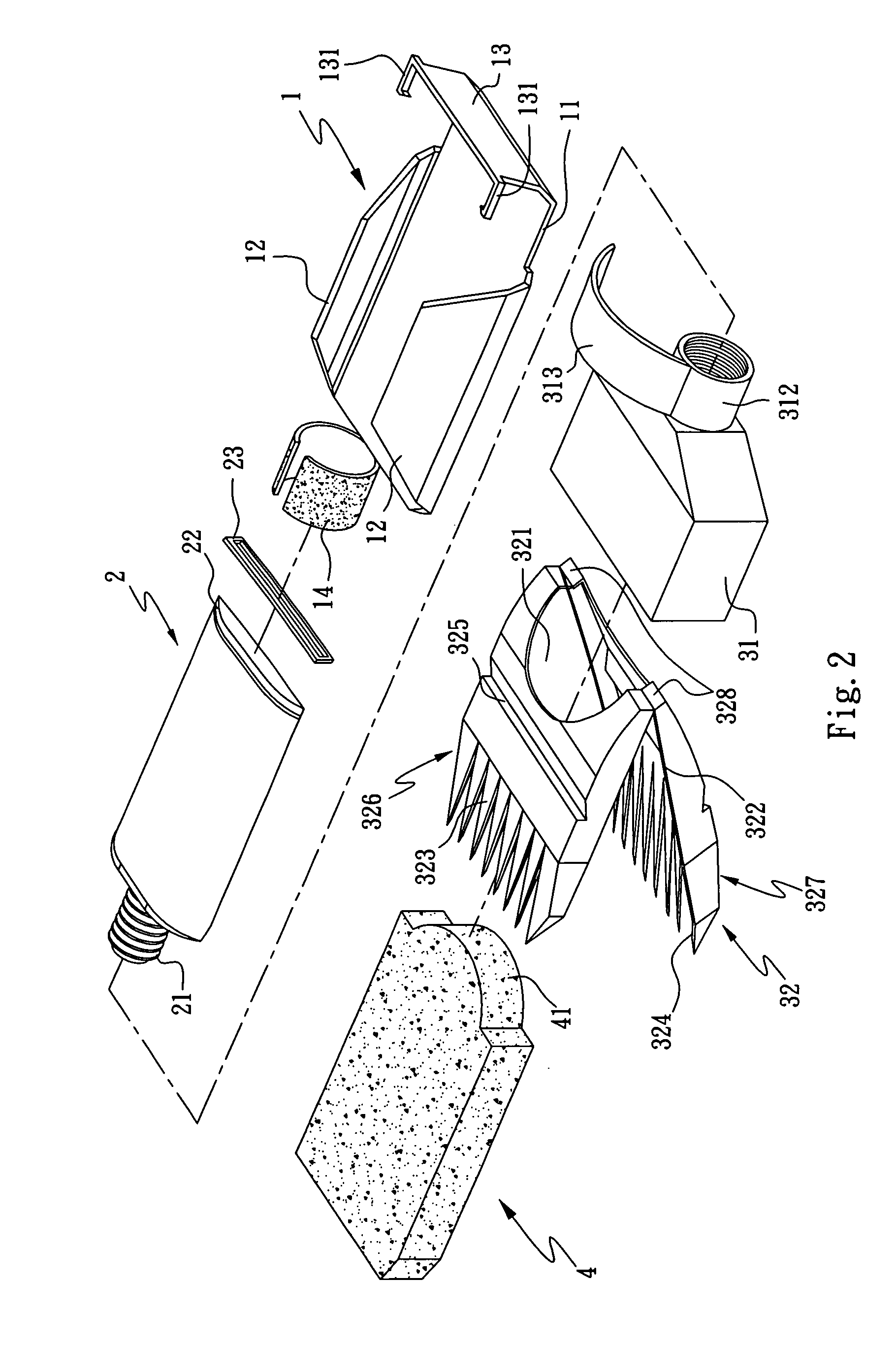

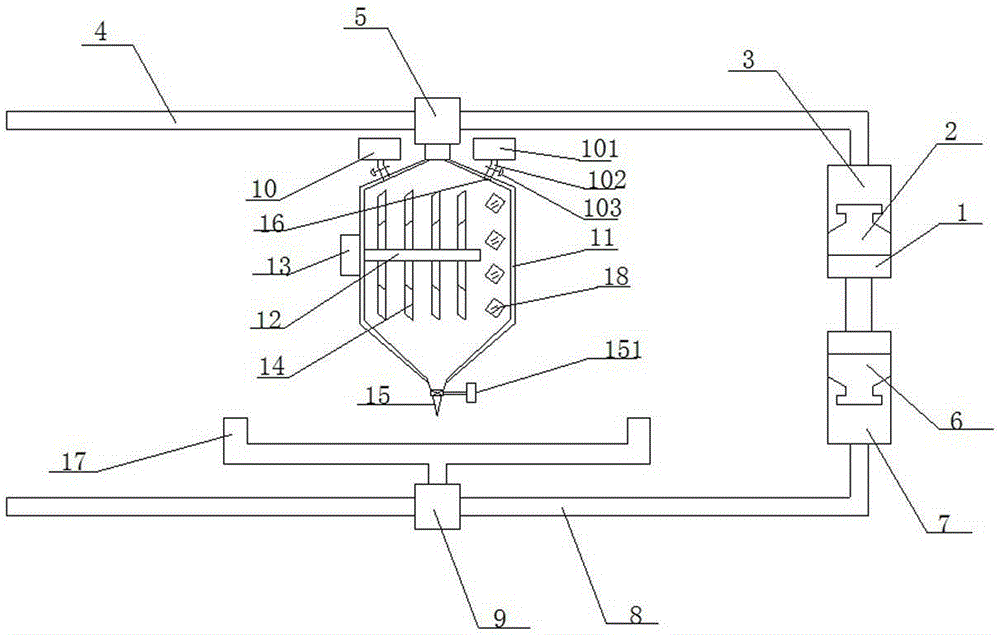

Glue dispensing and drying device for electronic component

InactiveCN106733468AFast dryingEvenly heatedLiquid surface applicatorsCoatingsPulp and paper industryElectronic component

The invention belongs to the technical field of electronic components, particularly relates to a glue dispensing and drying device for an electronic component. According to the technical purpose, the glue dispensing and drying device for the electronic component can fully perform glue dispensing for the electronic component, uniform in glue dispensing, and high in drying speed. In order to achieve the technical purposes, the invention provides the glue dispensing and drying device for the electronic component, and the glue dispensing and drying device for the electronic component comprises a base, operating tables, a right side plate, a left side plate, a box body, a containing plate, a first slider and the like; the two operating tables are welded to the middle of the top of the base; the left side plate is welded to the top of the portion, on the left side of the operating tables, of the base; the right side plate is welded to the top of the portion, on the right side of the operating tables, of the base; and the box body is welded between the middle portion of the right side plate and the middle portion of the left side plate. The glue dispensing and drying device for the electronic component performs glue dispensing on the electronic component through a glue pipe, meanwhile, a scraper blade is utilized to make glue scraping of the electronic component uniform, and the electronic component subjected to glue dispensing is fast dried through a heating lamp.

Owner:新沂市瓦窑工业园区有限公司

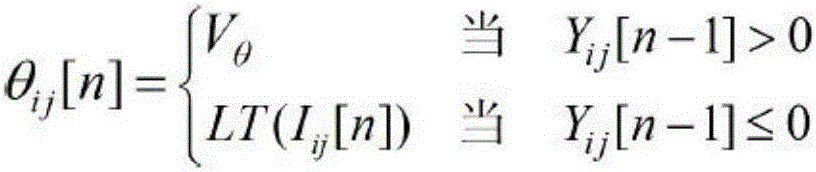

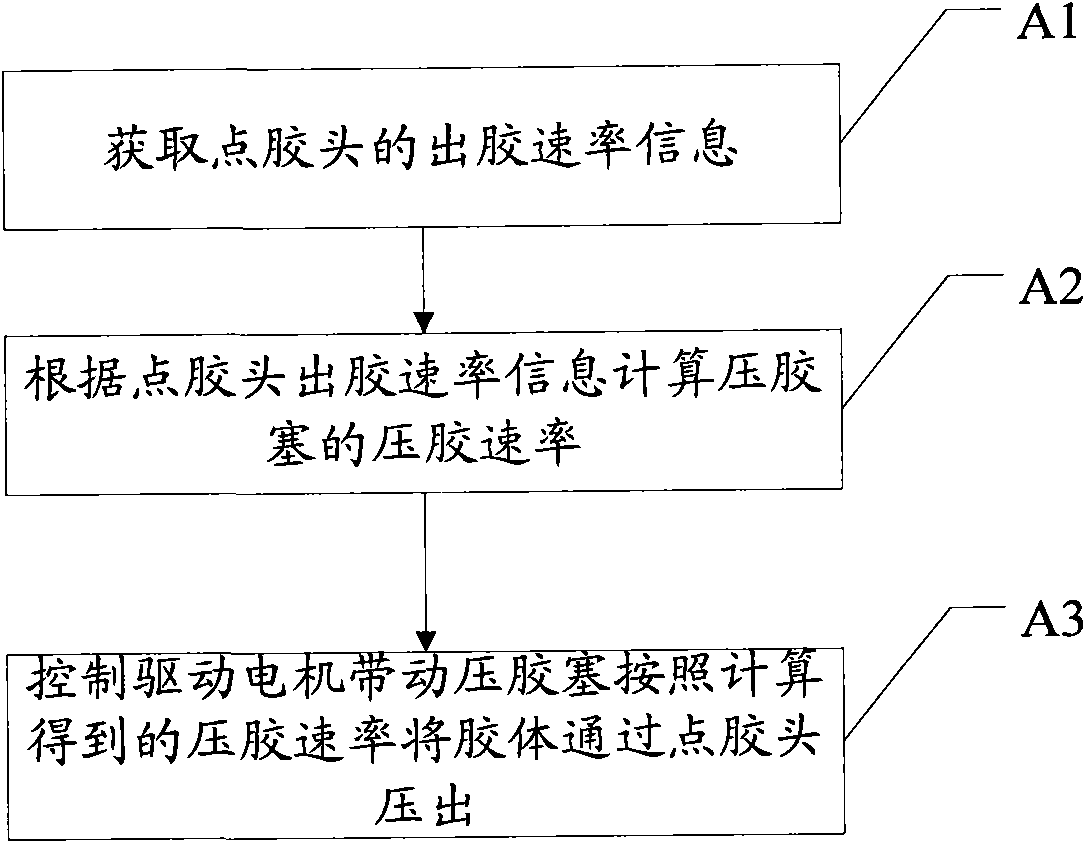

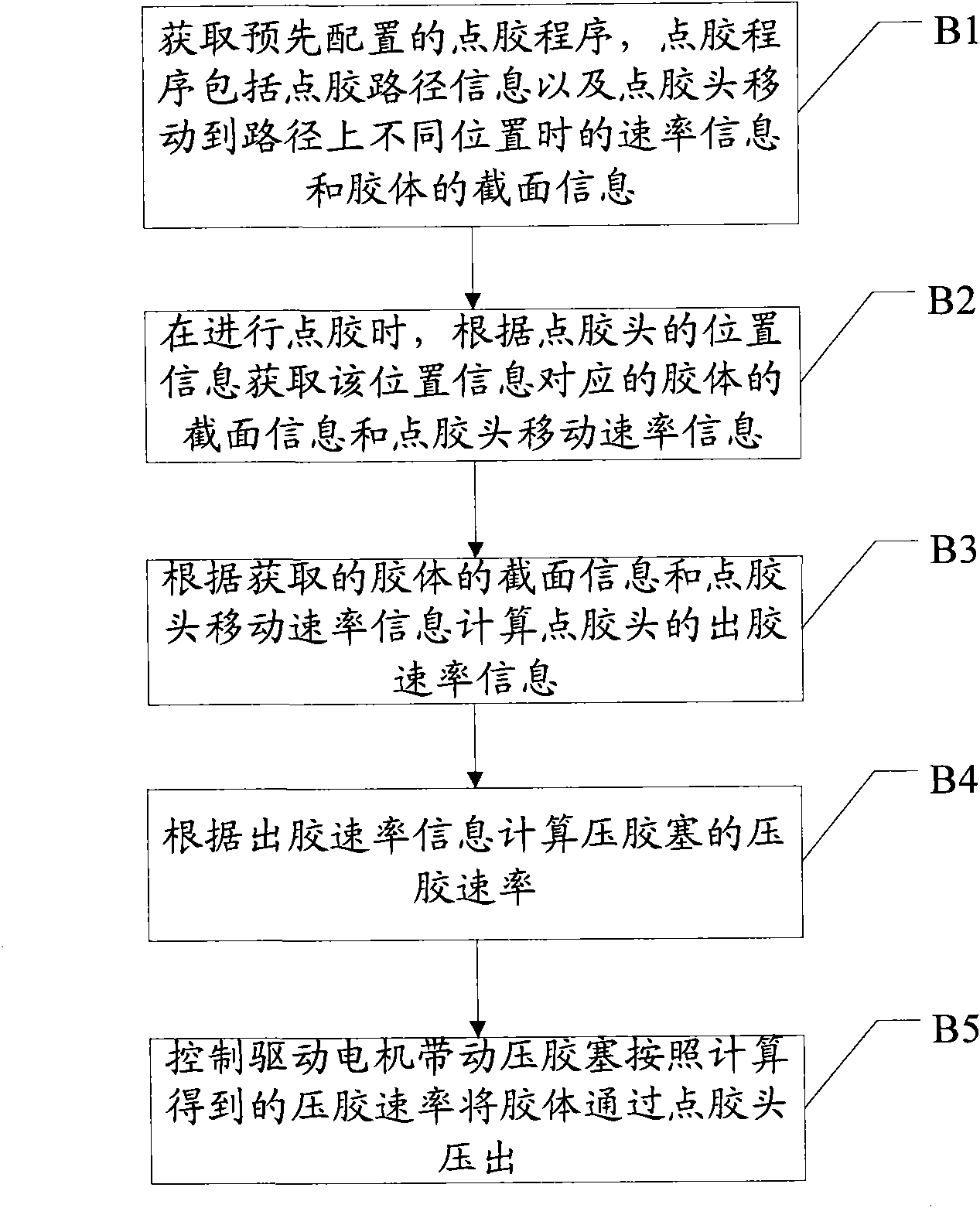

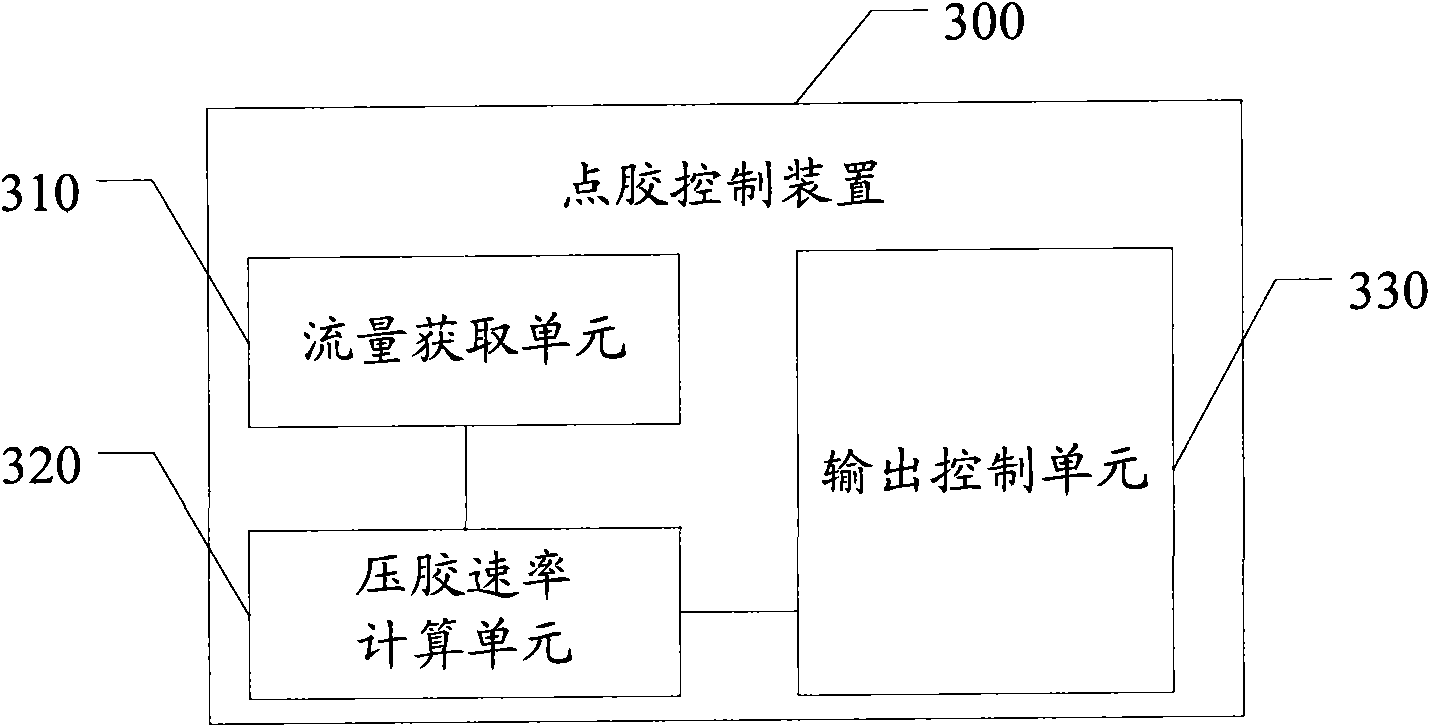

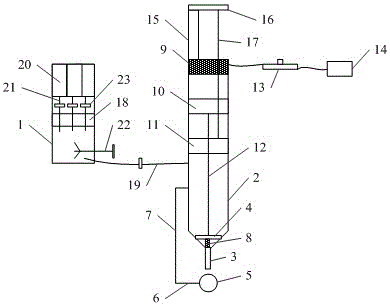

Glue dispensing control method, glue dispenser and related device

ActiveCN101875040AAccurate Dispensing ControlUniform dispensingLiquid surface applicatorsCoatingsProcess engineeringMechanical engineering

The invention discloses a glue dispensing control method, a glue dispenser and a related device. In the embodiment of the invention, the glue pressing rate of a glue pressing plug is calculated through obtaining the glue extruding rate information of a glue dispensing head, and a driving motor is controlled to drive the glue pressing plug to extrude glue through the glue dispensing head accordingto the calculated glue pressing rate. Compared with the prior art in which an air pressure glue pressing mode is adopted, the invention adopts the motor to drive the glue pressing, the glue extrudingrate is not influenced by the viscosity of glue, and the glue pressing rate and the glue extruding rate are in an accurate linear relation, therefore, accurate glue dispensing control is realized, and the glue dispensing is more uniform. In addition, when an operator performs glue dispersing each time, complex debugging is not needed so that the production efficiency is greatly improved.

Owner:SCBD (ANHUI) E TECH CO LTD

Dispensing device with relatively low cost

InactiveCN105944900ALow costGuarantee efficiencyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a dispensing device with relatively low cost. The device comprises a first cylinder and a glue barrel, wherein a baffle plate is arranged inside the lower end of the glue barrel; the lower end of a needle extends to the upper surface of a sliding ball; the upper end of a return spring is connected with the lower surface of the baffle plate; the lower end of the return spring is connected with the inner bottom end of the glue barrel; an electromagnet, a first piston and a second piston are sequentially arranged inside the glue barrel in the vertical direction from up to down; a liquid adding hole is formed in the side wall of the glue barrel; a first partition plate is arranged in the middle of the first cylinder to divide the first cylinder into an upper half cylinder and a lower half cylinder; one end of a glue tube is in the lower half cylinder; and the other end of the glue tube is connected with the liquid adding hole. According to the dispensing device, the technical effect that the dispensing efficiency and accuracy are guaranteed while the device design is reasonable and the cost is relatively low is achieved.

Owner:成都联超工业自动化有限公司

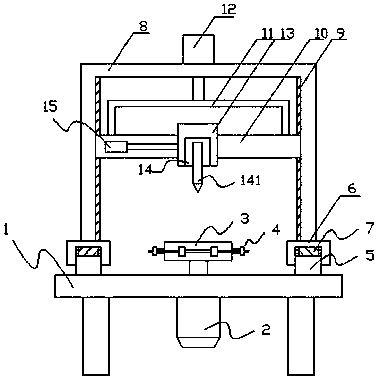

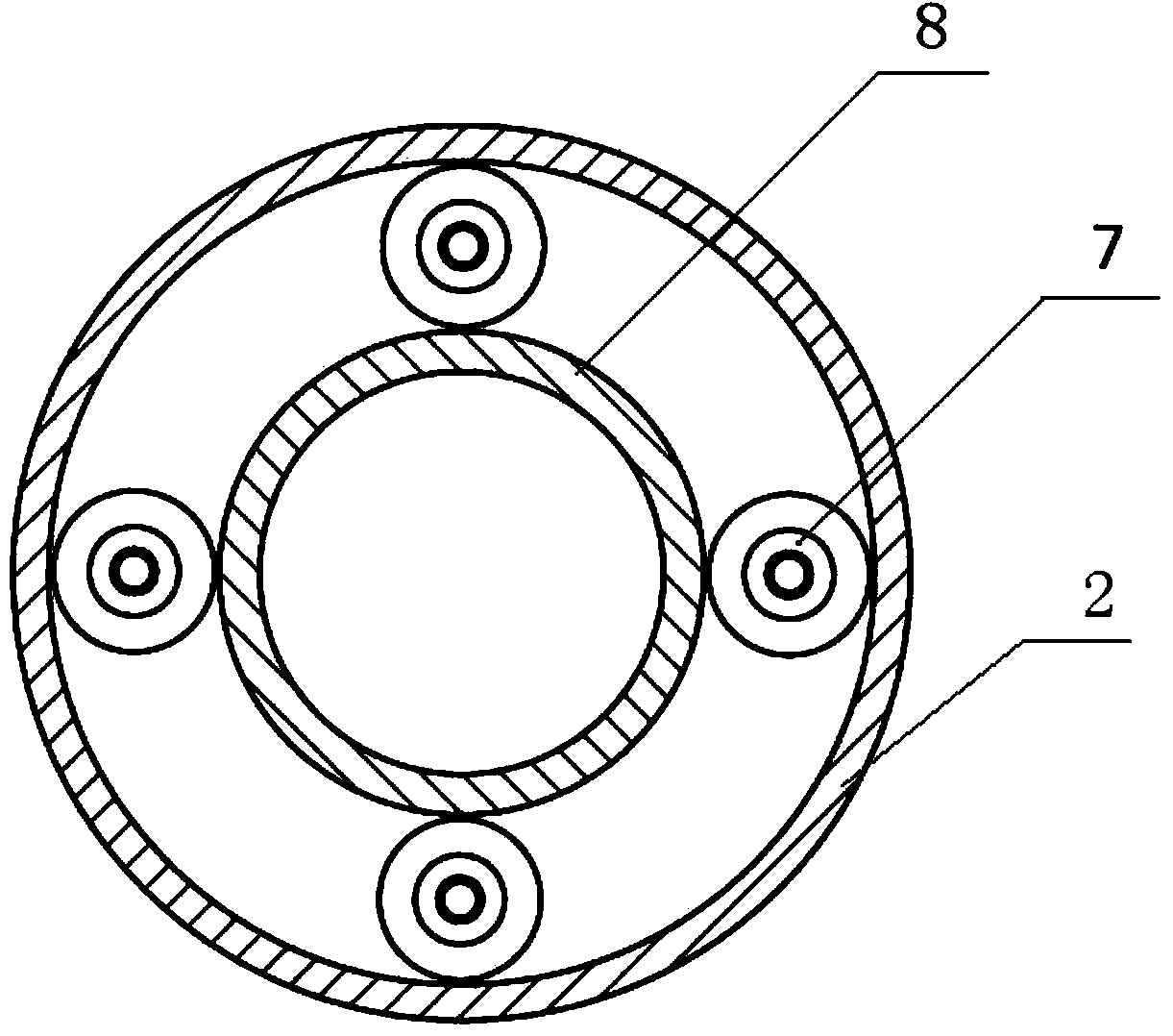

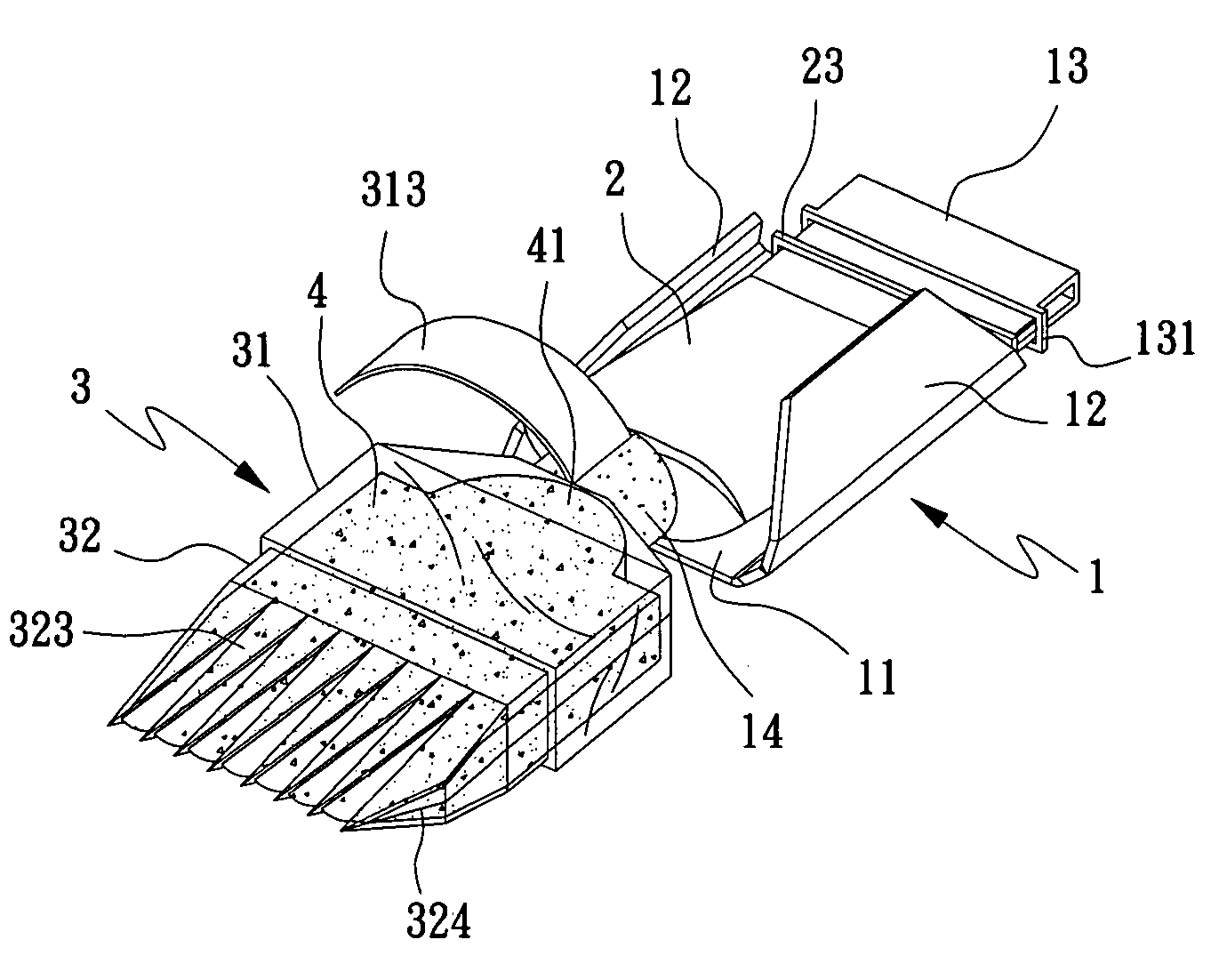

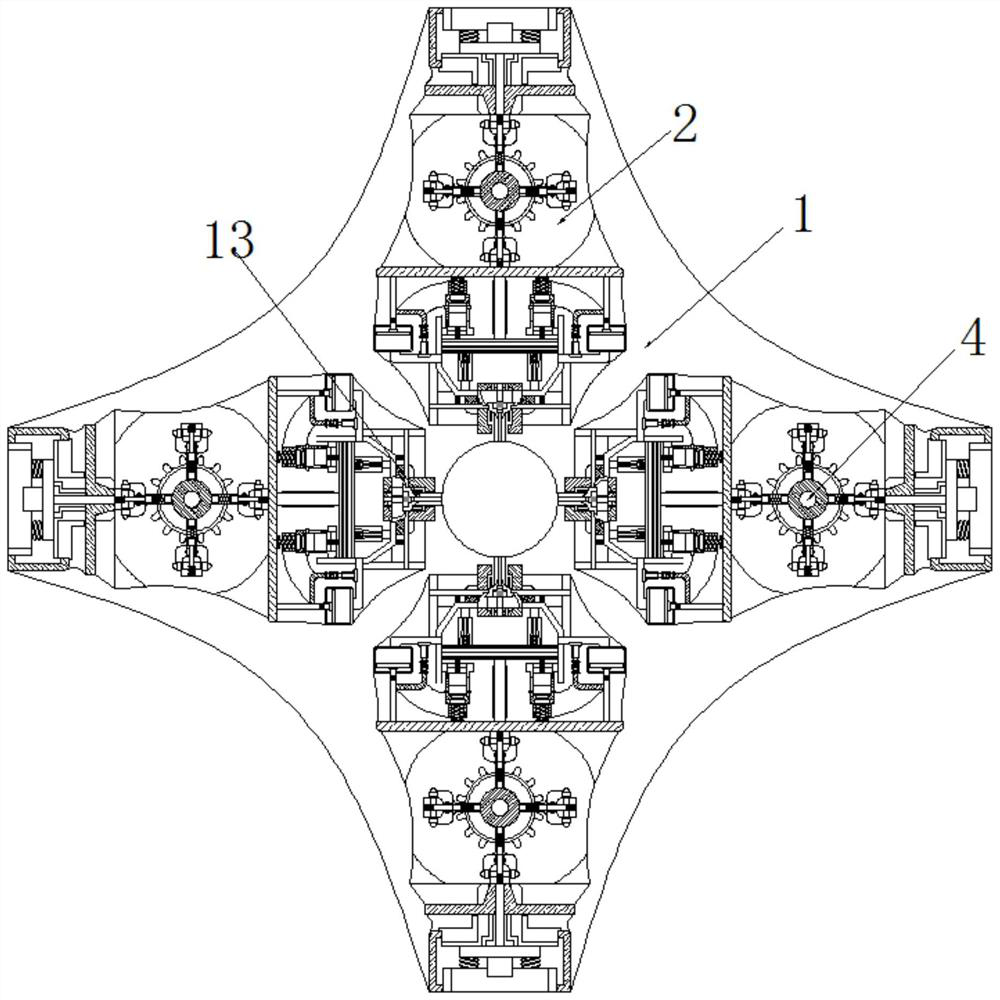

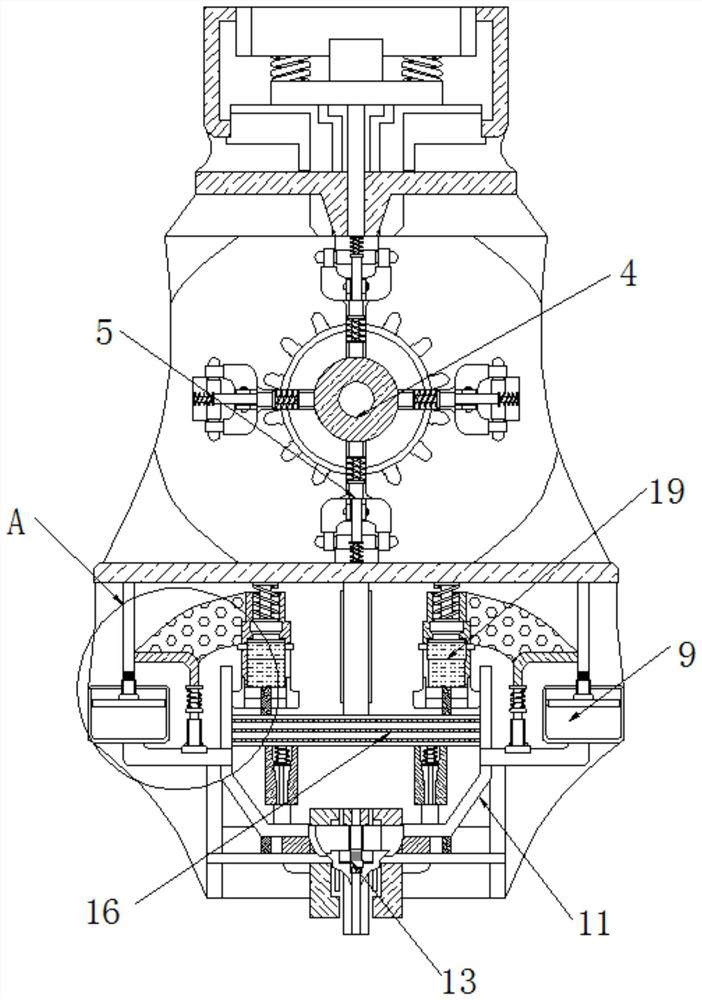

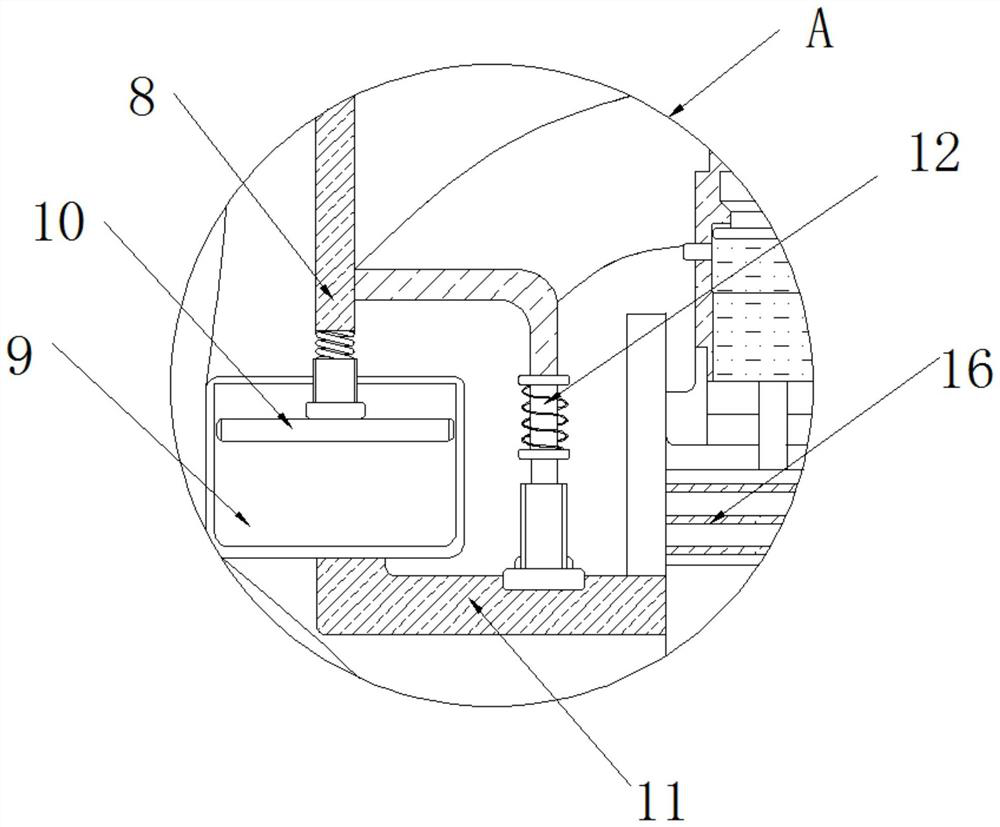

Glue dispensing device for filter machining

InactiveCN109365214AEfficientQuality improvementLiquid surface applicatorsCoatingsEngineeringMachining

The invention discloses a glue dispensing device for filter machining. According to the glue dispensing device for the filter machining, the tail end of an output shaft of a variable frequency motor is fixedly connected with the lower end face center of a tray after the output shaft of the variable frequency motor penetrates through a rack upwards, the tray is provided with a clamping mechanism, walking rails comprises two and are parallelly and fixedly connected to the left side and the right side of the upper end face of the rack, and each walking rail is slidably provided with a U-shaped sliding seat, the lower ends of two vertical portions of a door type rack are fixedly connected with the upper end faces of the U-shaped sliding seats on the left side and the right side correspondingly, the end face of the side, facing the rack center, of each vertical portion of the door type rack is vertically and fixedly connected with a guide rail, a strip-type block is slidably arranged on thedoor type rack through grooves, the upper end face of the strip-type block is fixedly connected with a U-shaped connection part, the tail end of a piston rod of a first air cylinder is fixedly connected with a horizontal portion of the U-shaped connection part after the piston rod of the first air cylinder penetrates through the door type rack downwards, the strip-type block is slidably providedwith an installation seat, the outer end face of the installation seat is provided with a glue dispensing machine through bolts, and the tail end of the piston rod of a second air cylinder is fixedlyconnected with the left end face of the installation seat. The glue dispensing device for the filter machining has the advantages that time and labor are saved, and the efficiency is high.

Owner:蚌埠市同升滤清器有限公司

Apparatus for and method of dispensing chemical solution in spin-coating equipment

ActiveUS8136477B2Low costDispense the chemical solution substantially uniformlyLiquid surface applicatorsPhotomechanical apparatusChemical solutionPressure sense

A chemical solution is uniformly dispensed from a nozzle by N2 in spin-coating equipment. The dispensing apparatus includes a canister configured to receive a bottle containing the chemical solution, gas supply piping connecting a source of N2 to the inside of the canister, a pressure control valve disposed in the gas supply piping, a chemical supply line by which the bottle is connected to the nozzle, a pressure sensor for sensing the pressure of the chemical solution supplied from the bottle, and a controller that controls the pressure control valve on the basis of the pressure sensed by the pressure sensor. The controller opens the pressure control valve further when the value of the signal output by the pressure sensor is less than a value representative of the minimum of a predetermined pressure range, and closes the pressure control valve further when the value of the signal output by the pressure sensor is greater than a value representative of the maximum of the predetermined pressure range. The degree to which the pressure control is open is thus controlled by feedback from the pressure control sensor such that the pressure of the chemical solution remains substantially constant as it is dispensed from the nozzle.

Owner:SAMSUNG ELECTRONICS CO LTD

Apparatus and method of dispensing photosensitive solution in semiconductor device fabrication equipment

ActiveUS7237581B2Reduce the presence of air bubblesReduce the amount requiredLiquid surface applicatorsLiquid fillingBuffer tankEngineering

A method of and apparatus for dispensing photosensitive solution substantially reduces the amount of air bubbles in the photosensitive solution during the dispensing operation. The photosensitive solution dispensing apparatus includes at least one supply vessel that contains the solution, a respective buffer tank that buffers the solution supplied from each supply vessel, a filter unit for filtering the solution, a pump for pumping the solution pumped from the buffer tank to the filter unit, a dispensing nozzle connected to the filter unit, and a dedicated bubble removal filter that is interposed between the buffer tank and the pump. The bubble removal filter is configured to remove air bubbles from the solution before the solution flows into the pump and is dispensed through the nozzle.

Owner:SAMSUNG ELECTRONICS CO LTD

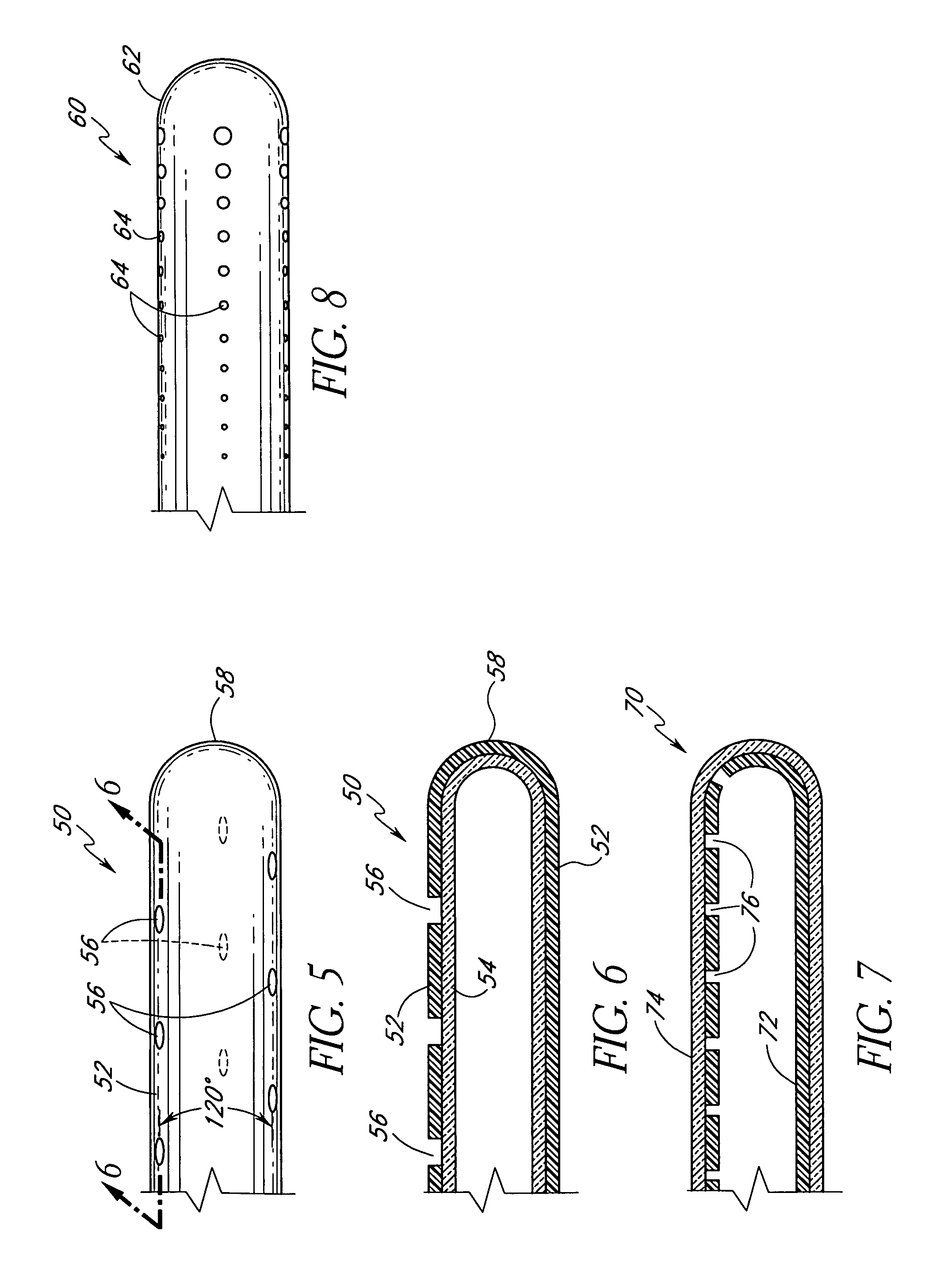

Applicator with flexible dispensing end

An applicator with a flexible dispensing end is provided. The applicator includes a housing having an internal compartment configured to hold a container of skin sealant. The housing includes a dispensing end having at least one opening to permit the skin sealant to be dispensed. The housing includes an actuator configured to contact the container and release the skin sealant. The dispensing end has at least one movable member. The dispensing end is flexible and is configured to move on more than one axis, and up to three axes, sequentially or simultaneously, so that the skin sealant dispensed from the applicator may be uniformly applied to contours on a patient's skin.

Owner:AVENT INC

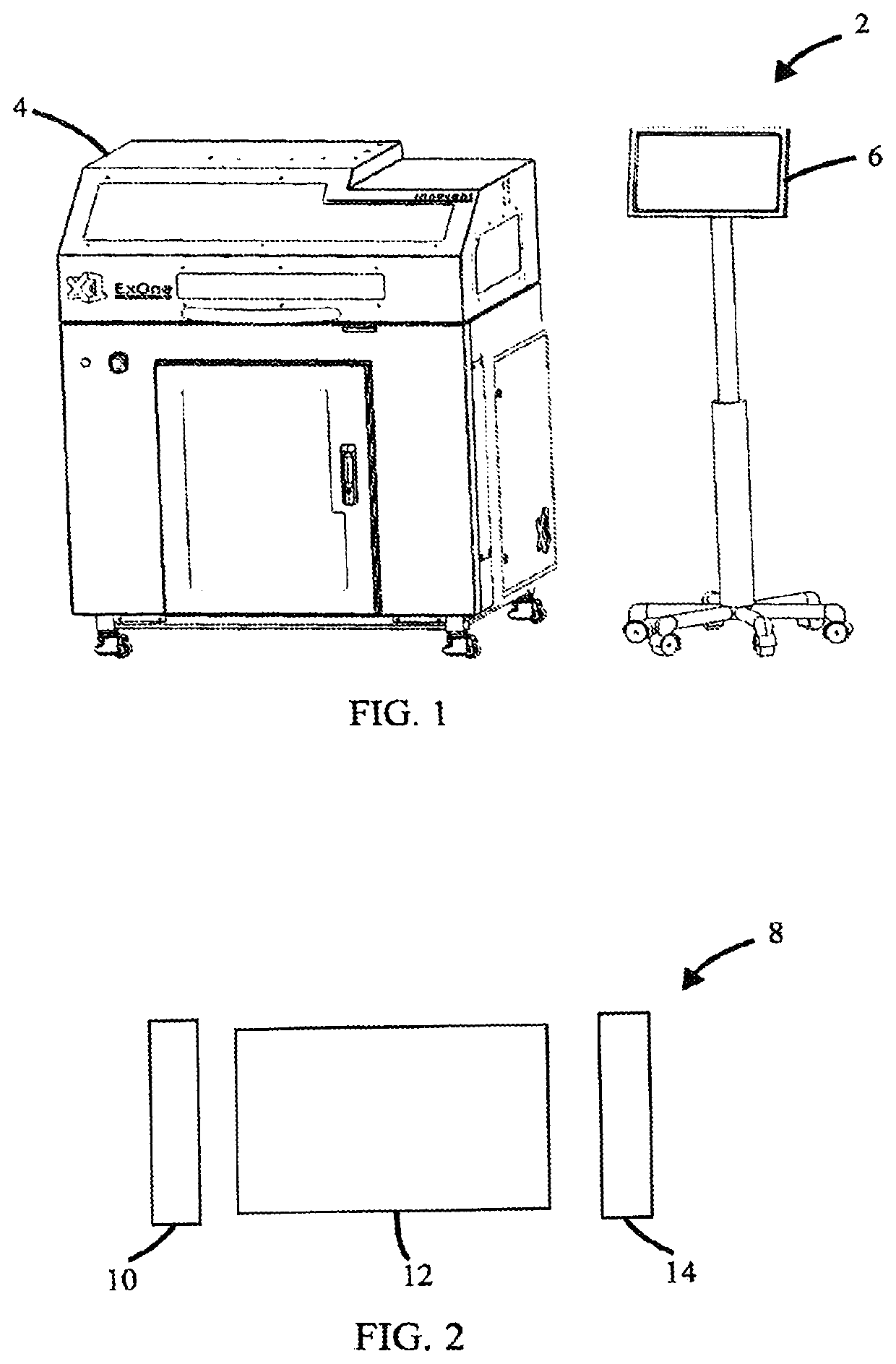

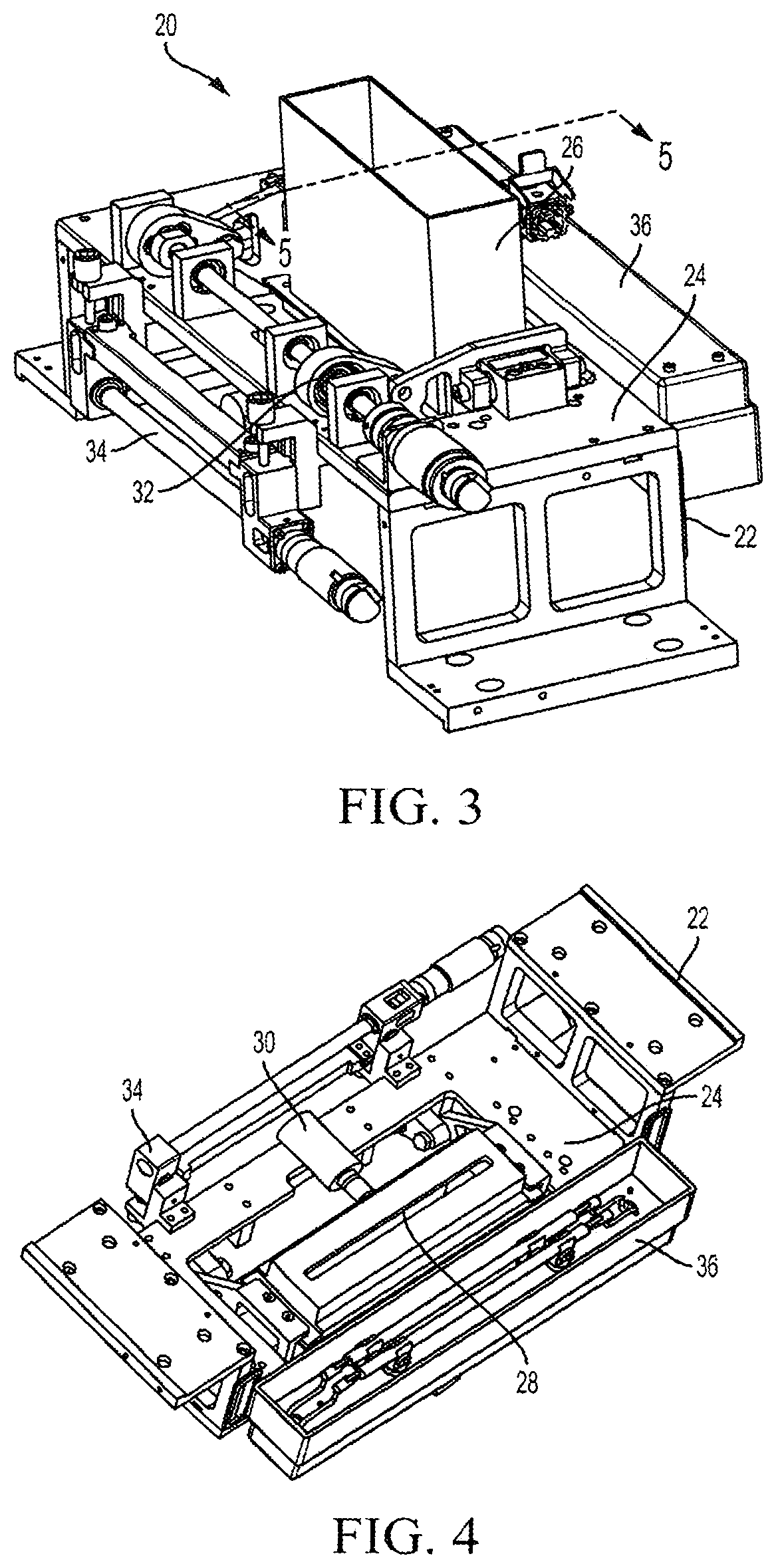

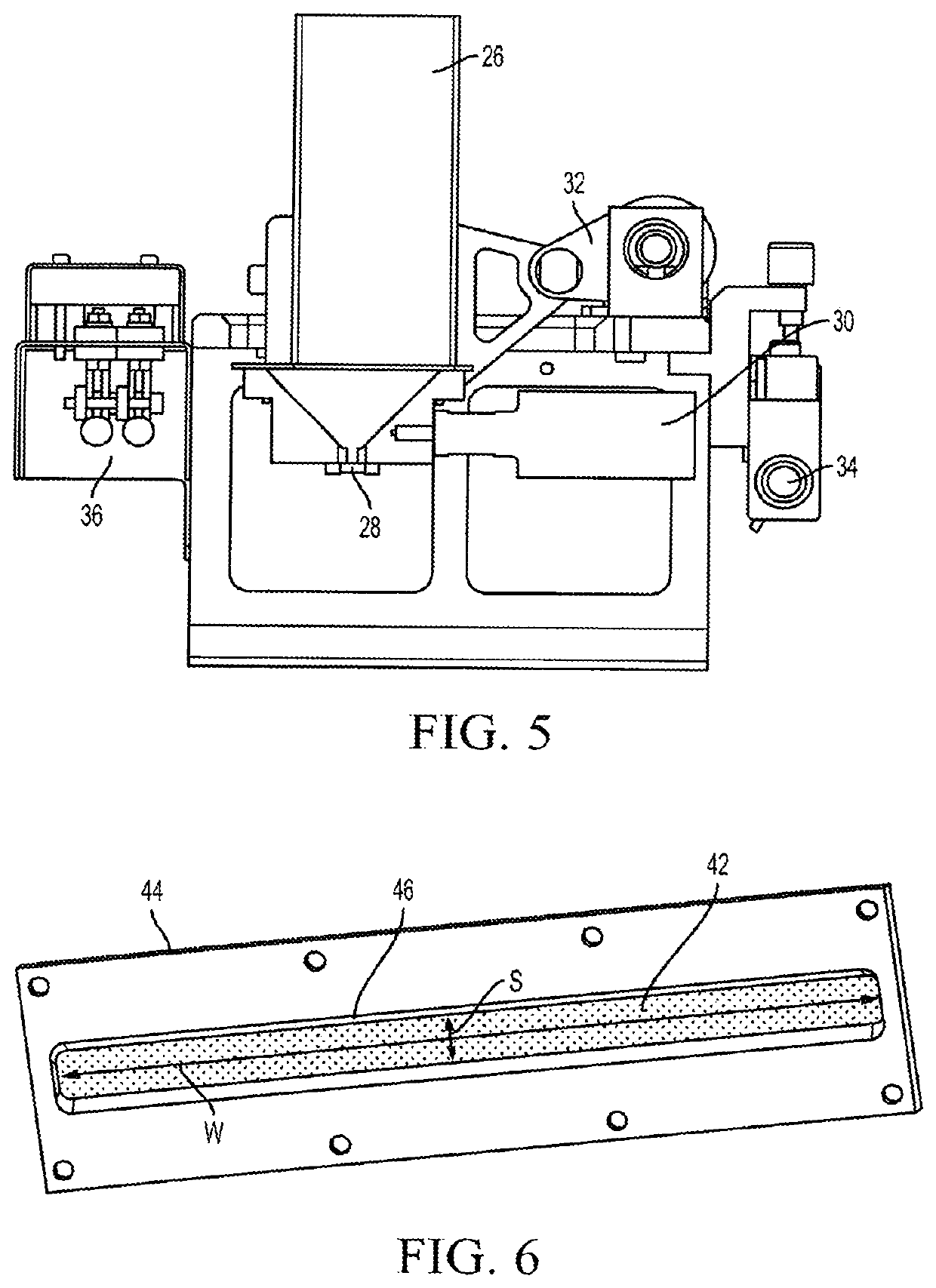

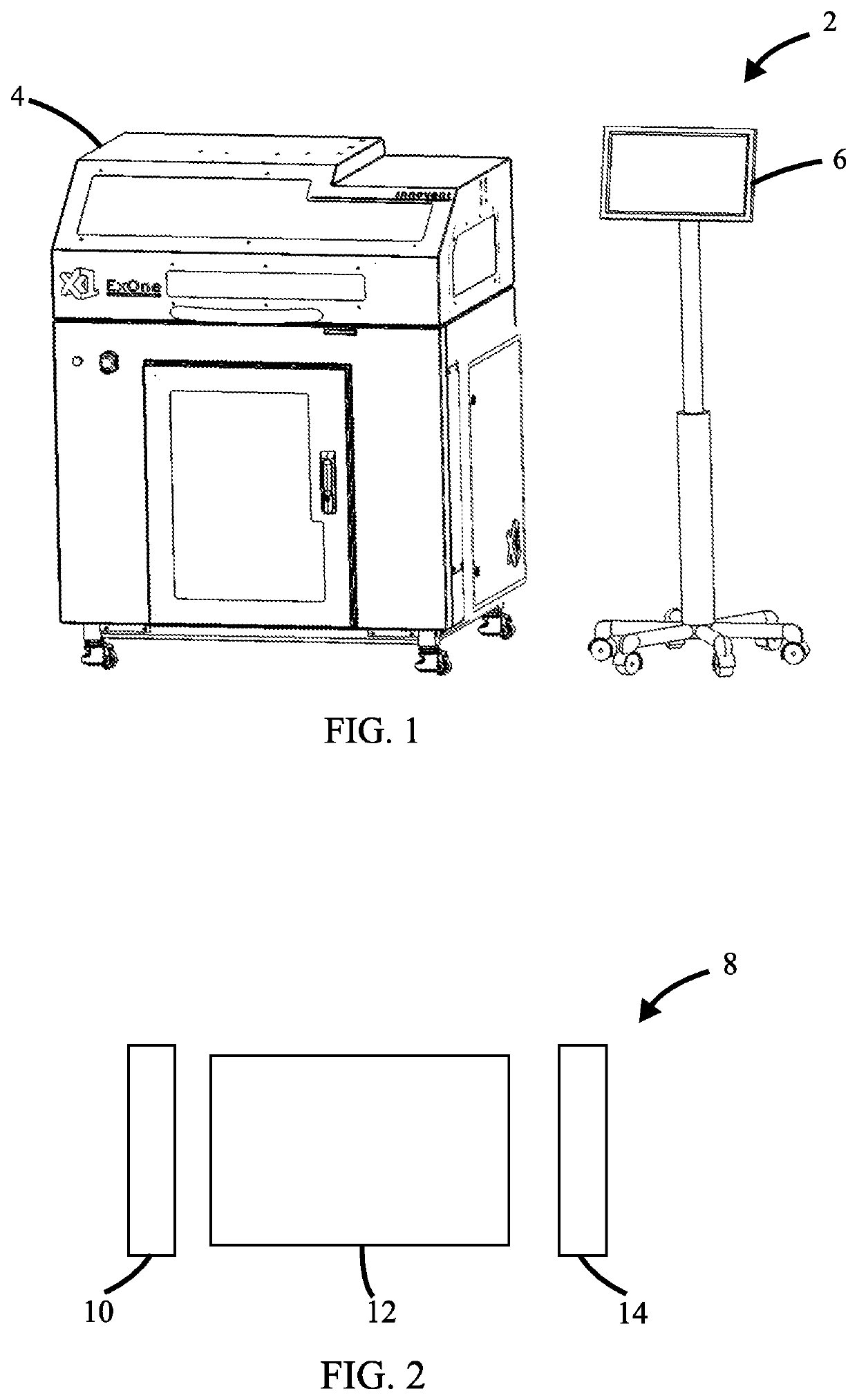

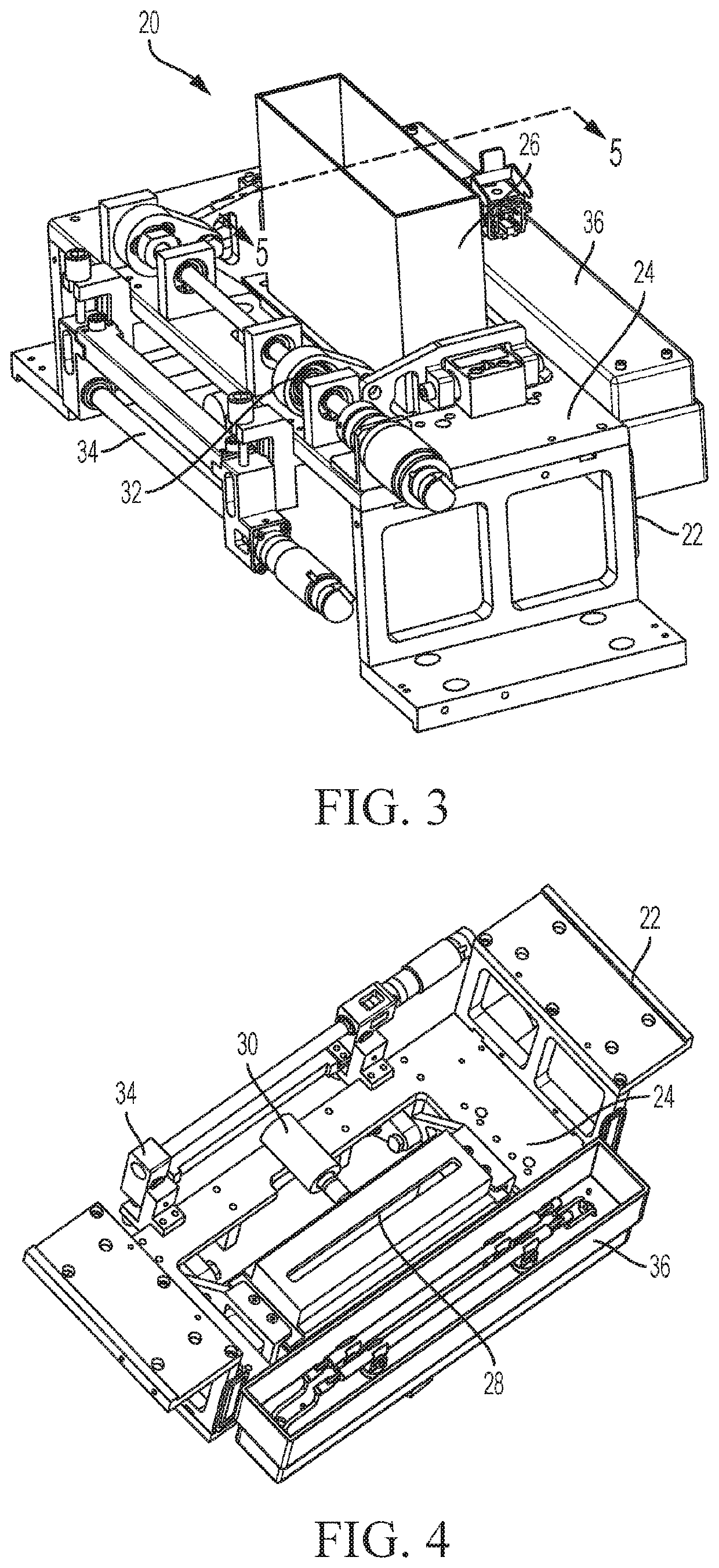

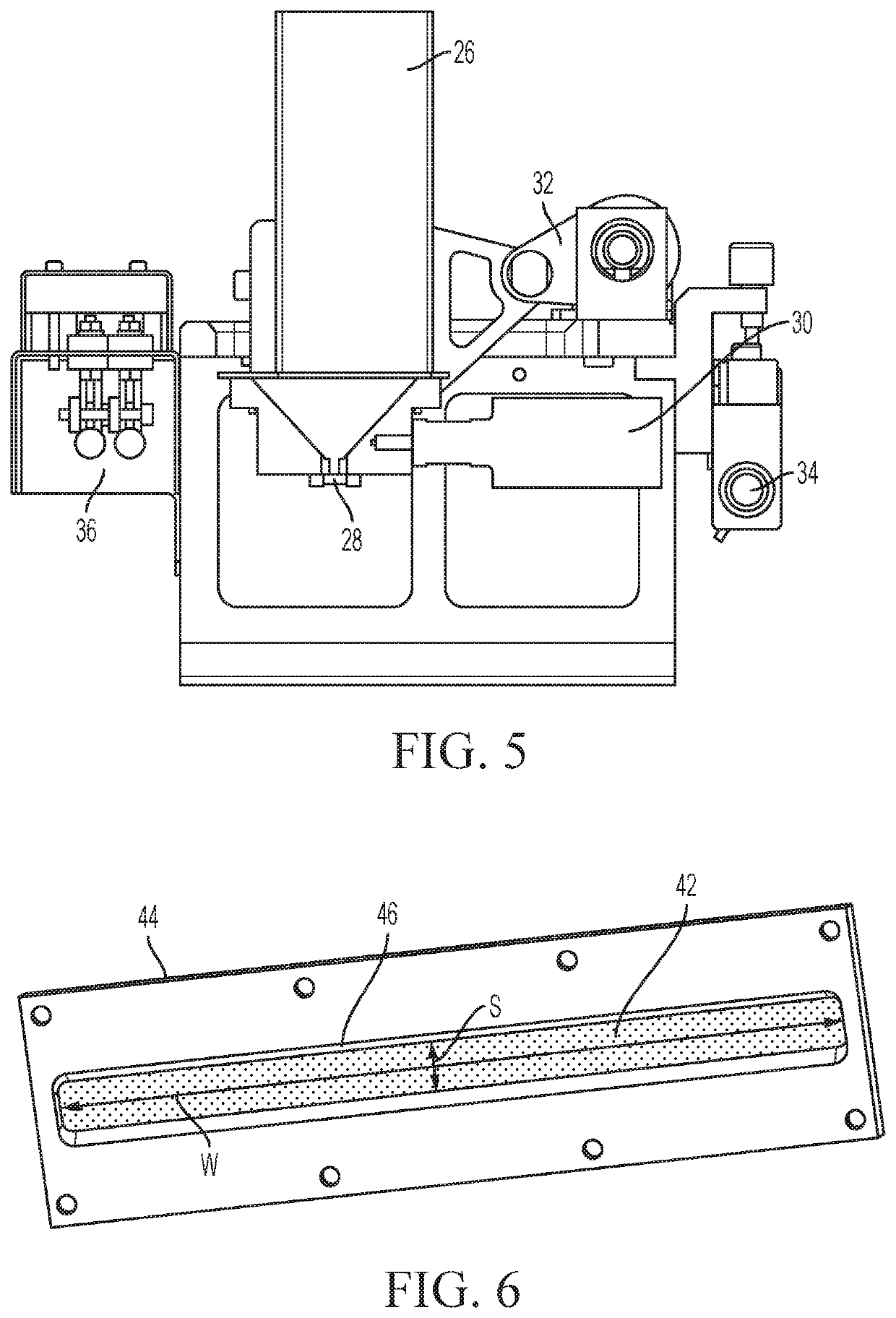

Powder Distribution System for Three-Dimensional Printer

ActiveUS20200147884A1Improve uniformityDiminish and prevent powderSievingManufacturing enclosuresComputer printingDistribution system

The present invention relates to powder-layer three-dimensional printers (2) having a discrete supply hopper (340) and a recoater (20). The discrete supply hopper (340) is configured to transfer a build powder to the recoater (20) in a manner that enhances the uniformity of build powder layers that are dispensed from the recoater (20). In some embodiments, at least one of the discrete supply hopper and the powder hopper of the recoater is adapted to selectively contact the other, seal against the other, and / or have one partially inserted inside the other so as to diminish or prevent powder pluming during the transfer of build powder from the discrete supply hopper to the recoater.

Owner:THE EX ONE

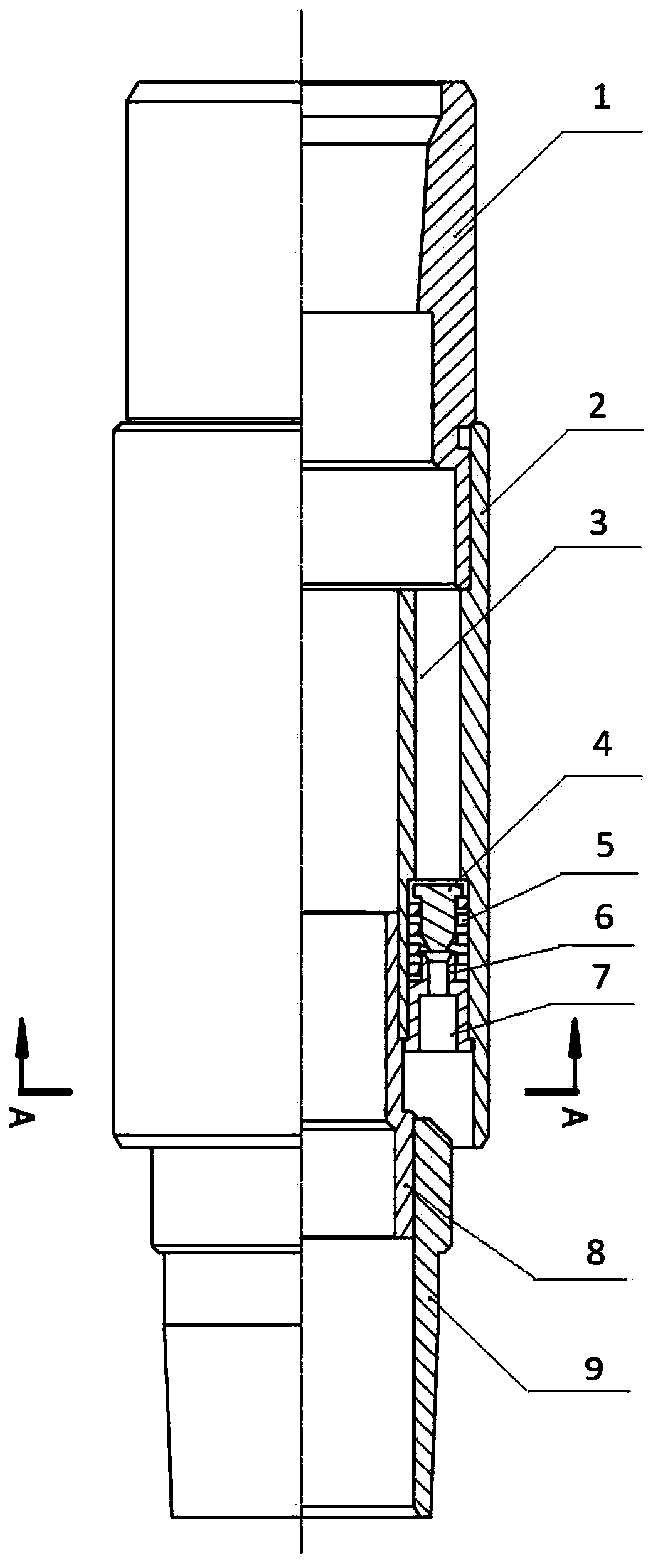

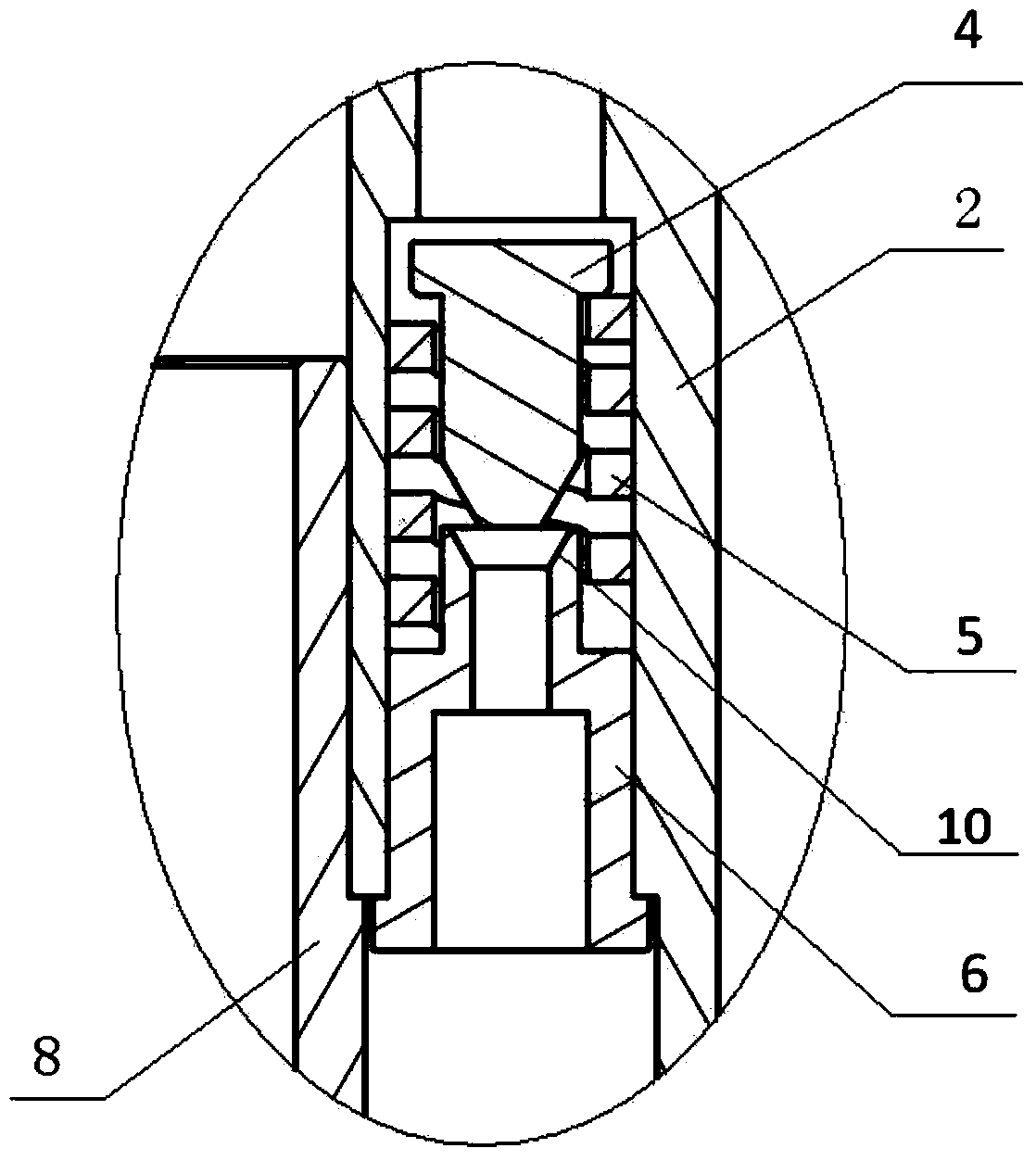

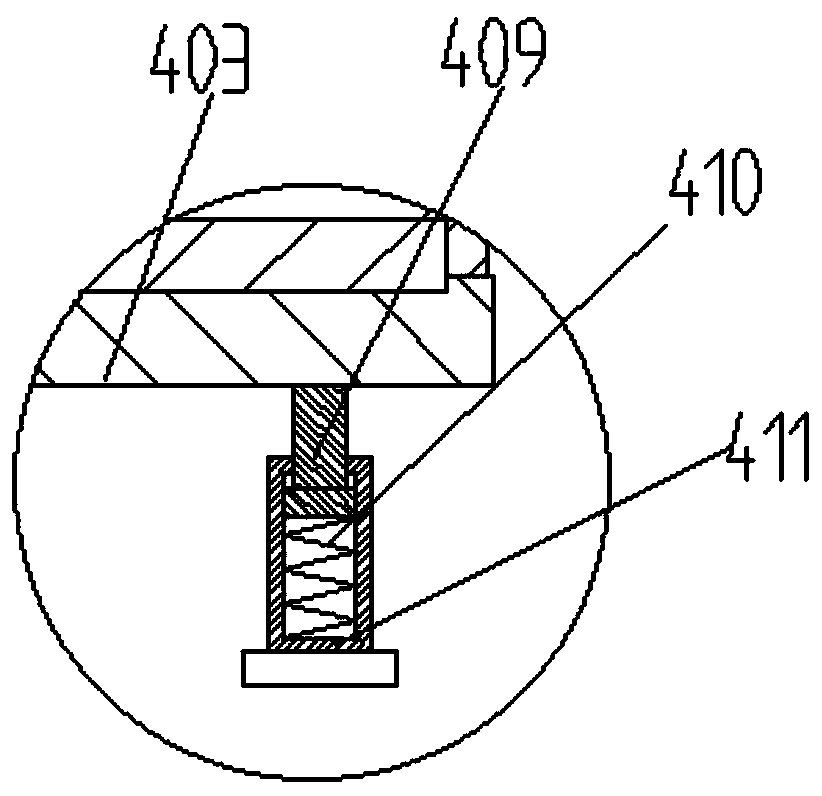

Thermal injection pipe column and thermal injection valve of heavy oil thermal recovery well

ActiveCN103410470AReduce shockAvoid harmFluid removalWell/borehole valve arrangementsUpper jointEngineering

The invention provides a thermal injection valve of a heavy oil thermal recovery well. The thermal injection valve comprises an upper joint, a guide cylinder, a center pipe and a lower joint which are sequentially connected from top to bottom; the cylinder wall of the guide cylinder is provided with a plurality of flow dividing hole channels which are communicated from top to bottom; the axis of the flow dividing hole channels is parallel to the axis of the guide cylinder; a flow regulating ring, a springback body and a valve core are arranged in the flow dividing hole channels; the flow regulating ring is fixed at the lower end in the flow dividing hole channels; the valve core is located above the flow regulating ring; the outer circular conical surface which is arranged at the lower end of the valve core is matched with the inner circular conical surface which is arranged at the upper end of the flow regulating ring; the flow regulating ring is provided with a flow channel from the inner circular conical surface of the flow regulating ring to the lower end of the flow regulating ring; the springback body is located between the valve core and the flow regulating ring. The thermal injection valve of the heavy oil thermal recovery well has the advantages of enabling the flow of injected fluid to be automatically regulated and being uniform in gas injection, simple in structure, free of large moving parts, sensitive in flow control and convenient to replace.

Owner:CHINA NAT OFFSHORE OIL CORP +1

PCB quick glue dispensing method

InactiveCN110124943APrecise dispensingImprove adhesionLiquid surface applicatorsMaterial gluingMechanical engineering

The invention discloses a PCB quick glue dispensing method. The PCB quick glue dispensing method comprises the steps that PCBs are conveyed through a second conveyor belt and fed onto a fixed base, and a second cylinder operates to drive a push plate to push the PCBs to slide along the space between two baffles through a telescopic rod; when the PCBs arrive at the position below a first glue dispensing head, the first glue dispensing head conducts glue dispensing on the PCBs; the PCBs continuously slide to the position under a first conveying mechanism, a third cylinder operates to drive a suction cup to descend to suck a chip conveyed through a conveying track, and then the suction cup restores. Through the PCB quick glue dispensing method, glue dispensing is accurate, so that the glue dispensing effect is good in the glue dispensing process; moreover, after glue dispensing, the chip is squeezed through a pressing plate and can be quickly bonded and fixed, the bonding effect is good,time is saved, and using is convenient; meanwhile, the PCB quick glue dispensing method has the advantages that glue dispensing on chips, glue dispensing on chip covers and discharging are integrated;using is more convenient; there is no need to replace equipment at each step of the glue dispensing process, the method is simple, and the investment is little.

Owner:绍兴上虞威拓机械电子有限公司

Sealant forming apparatus, sealant forming method, and method of manufacturing liquid crystal display device using the same

ActiveUS20070151512A1Prevent coagulationUniform dispensingLiquid surface applicatorsLiquid transferring devicesLiquid-crystal displaySealant

A sealant forming device, a sealant forming method and a method for manufacturing a liquid crystal display device using the same are disclosed. According to the present invention, a sealant coagulated in a nozzle can be minimized or prevented by performing an instantaneous suction process. A sealant forming device includes a dispenser including a syringe, and a nozzle connected to a lower end of the syringe to discharge a sealant therethrough; a dispensing tube connected to the syringe to apply a pressure to the syringe; and an instantaneous suction tube connected to the syringe to extract the sealant remaining in the nozzle after discharging the sealant.

Owner:LG DISPLAY CO LTD

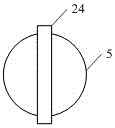

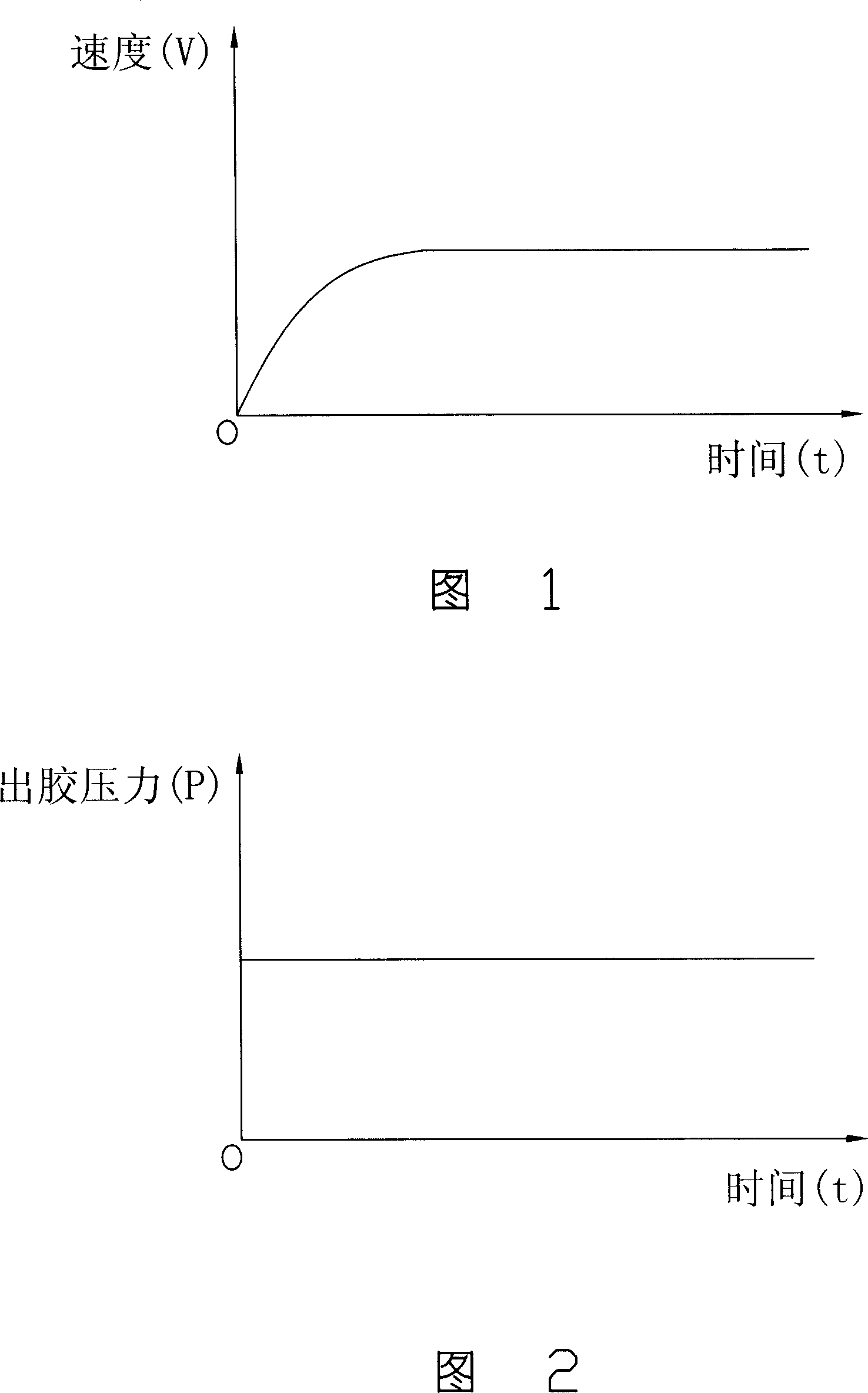

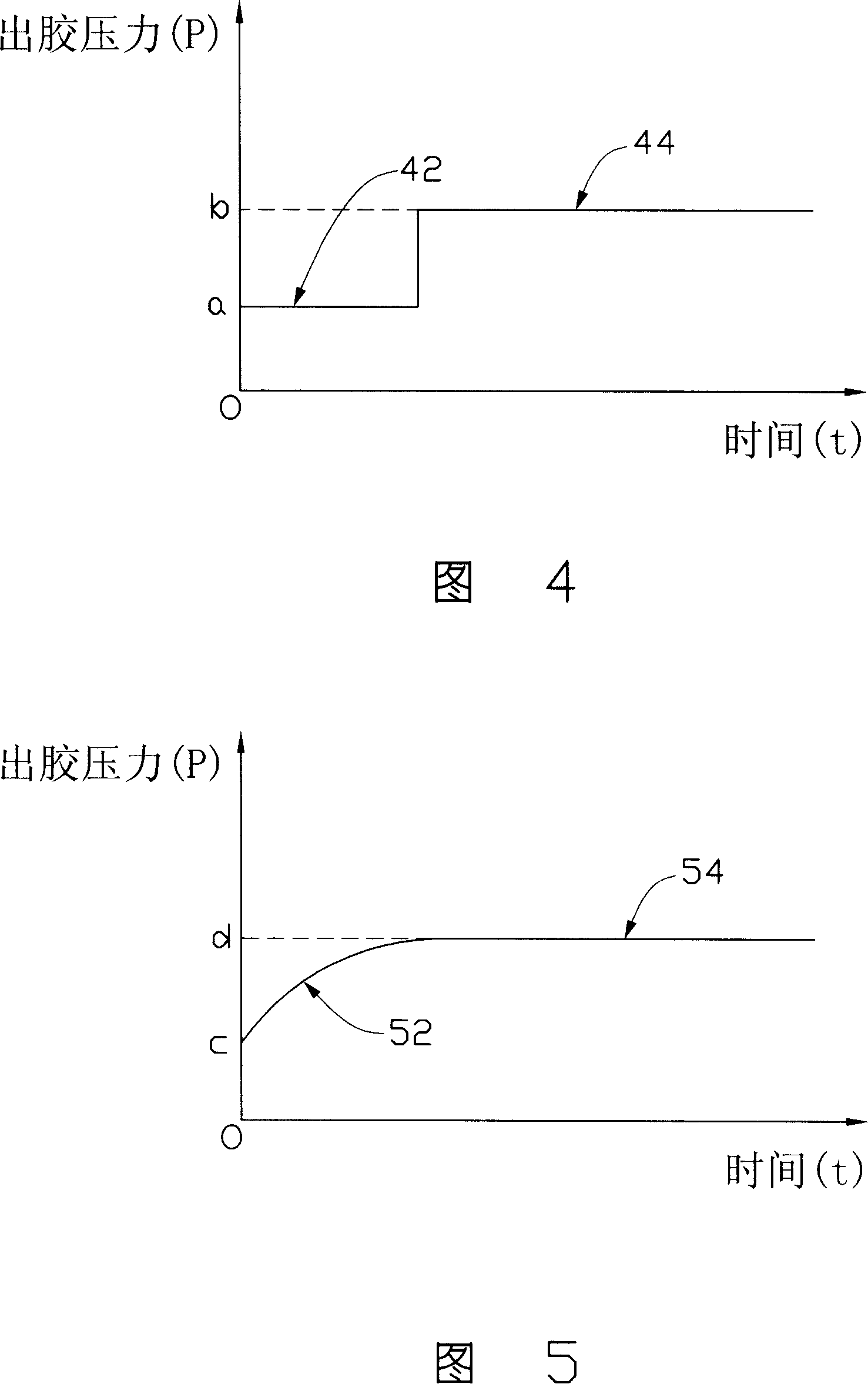

Glue dropping method

The present invention relates to a gluing method, which comprises: Providing a lens module to be glued and a gluing device; making the lens module to be glued rotate towards the gluing device and using a first glue extrusion pressure to control the gluing device to glue in a stage from rotation of the lens module to the stable rotation; imposing a second glue extrusion pressure to control the gluing device to glue while the lens module to be glued is stable and ensuring the first extrusion pressure is lower than the second extrusion pressure; stopping using the second glue extrusion pressure to control the gluing device while the lens module to be glued rotates by one circle to stop the gluing device. With different glue extrusion pressure, the present invention can match the gluing volume of the gluing device with rotational speed of the lens module to be glued, thus fulfilling even gluing.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Dispensing equipment convenient to use

InactiveCN105921346AGuarantee efficiencyGuaranteed accuracyLiquid surface applicatorsCoatingsEngineeringPiston

The invention discloses dispensing equipment convenient to use. The equipment comprises a first cylinder and a glue barrel, wherein a baffle plate is arranged in the lower end of the glue barrel; the lower end of a needle head extends to the upper surface of a slide ball; the upper end of a return spring is connected with the lower surface of the baffle plate; the lower end of the return spring is connected with the inner bottom end of the glue barrel; an electromagnet, a first piston and a second piston are sequentially arranged in the glue barrel from top to bottom in a vertical direction; a liquid adding hole is formed in the side wall of the glue barrel; the middle part of the first cylinder is provided with a first partition plate for dividing the first cylinder into an upper half cylinder and a lower half cylinder; one end of a glue tube is positioned in the lower half cylinder; and the other end of the glue tube is connected with the liquid adding hole. The dispensing equipment convenient to use realizes the technical effects of a reasonable design and low cost while the dispensing efficiency and an accuracy rate are guaranteed.

Owner:成都联超工业自动化有限公司

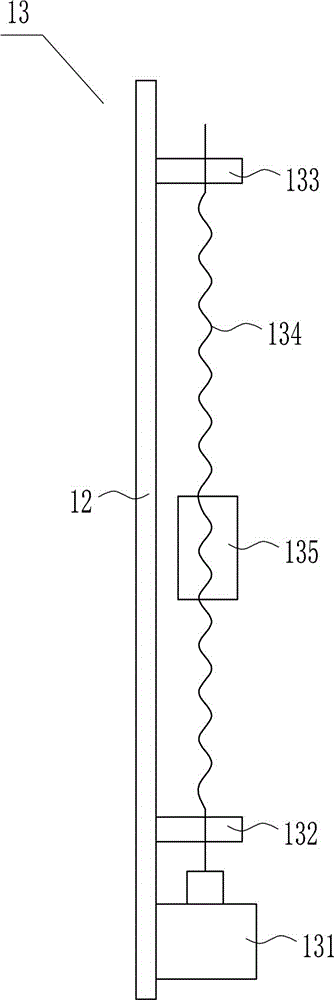

Rapid adhesive dispensing and drying device for electronic accessories for electronic components

The invention belongs to the technical field of electronic components, and particularly relates to a rapid adhesive dispensing and drying device for electronic accessories for electronic components. The technical problem to be solved by the invention is to provide a rapid adhesive dispensing and drying device for electronic accessories for electronic components, which is capable of adequately carrying out adhesive dispensing on the electronic components, uniform in adhesive dispensing, high in drying speed and high in safety. In order to solve the abovementioned technical problem, the invention provides a rapid adhesive dispensing and drying device for electronic accessories for electronic components. The rapid adhesive dispensing and drying device comprises a bottom plate, a left side plate, a right side plate, support rods, a slide block, a placement frame, an adhesive storage box and the like, wherein the left side plate is welded at the left side of the top of the bottom plate; the right side plate is welded at the right side of the top of the bottom plate; the two support rods are arranged between the right side plate and the left side plate; and the support rods are connected with the top part of the bottom plate in a manner of welding. According to the rapid adhesive dispensing and drying device disclosed by the invention, adhesive dispensing is carried out on the electronic components through an adhesive pipe, and rapid drying is carried out on the electronic components subjected to the adhesive dispensing by virtue of hot gas.

Owner:JIANGSU TETRA NEW MATERIAL TECH

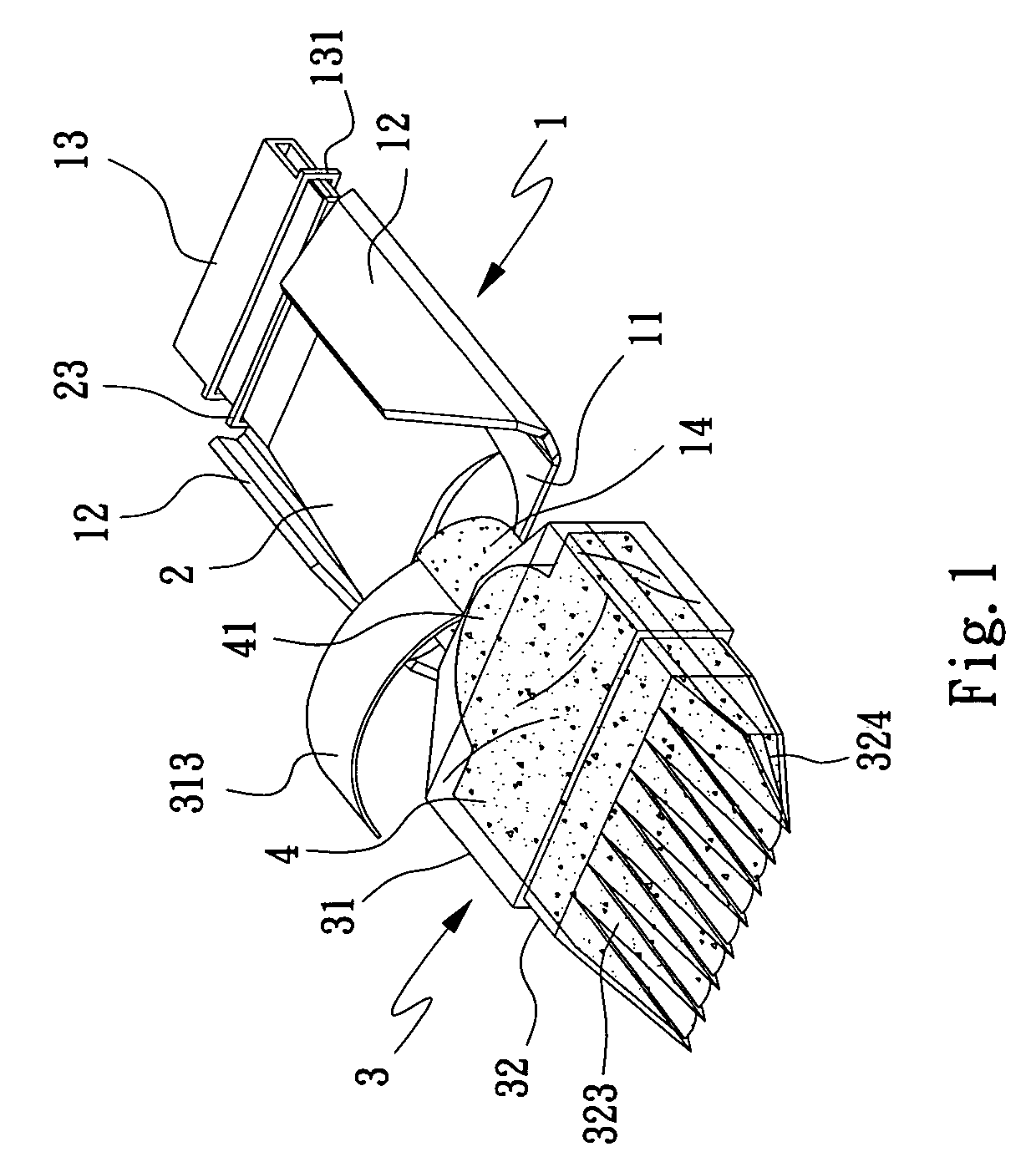

Hair Dyeing Device

InactiveUS20090320867A1Prevent oxidationUniform dispensingHair combsInk reservoir pensHair dyesEngineering

A hair dyeing device includes a handle unit having a connecting section; a hair dye container removably positioned in the handle unit and having a front mouth and a rear zip lock opening; a comb unit including a base and a comb element defining a hollow space each; and an elastic absorbent member positioned in the hollow spaces of the comb unit. One end of the base of the comb unit has a sleeve for detachably fitting in the connecting section of the handle unit to engage with the mouth of the container, and a fastening element is provided on the sleeve for wrapping around the connecting section of the handle unit. The comb element has a rear portion formed into a fixing section for detachably inserting into the base and a front portion formed into upper and lower rows of teeth communicating with the second hollow space.

Owner:LEE CHENG SHENG

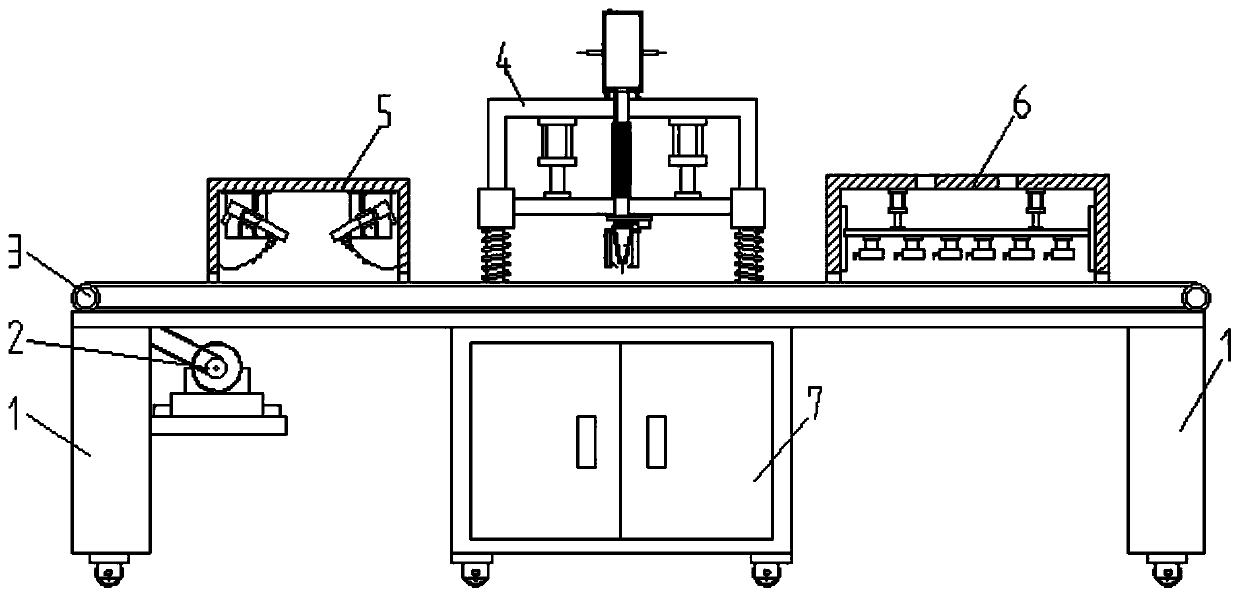

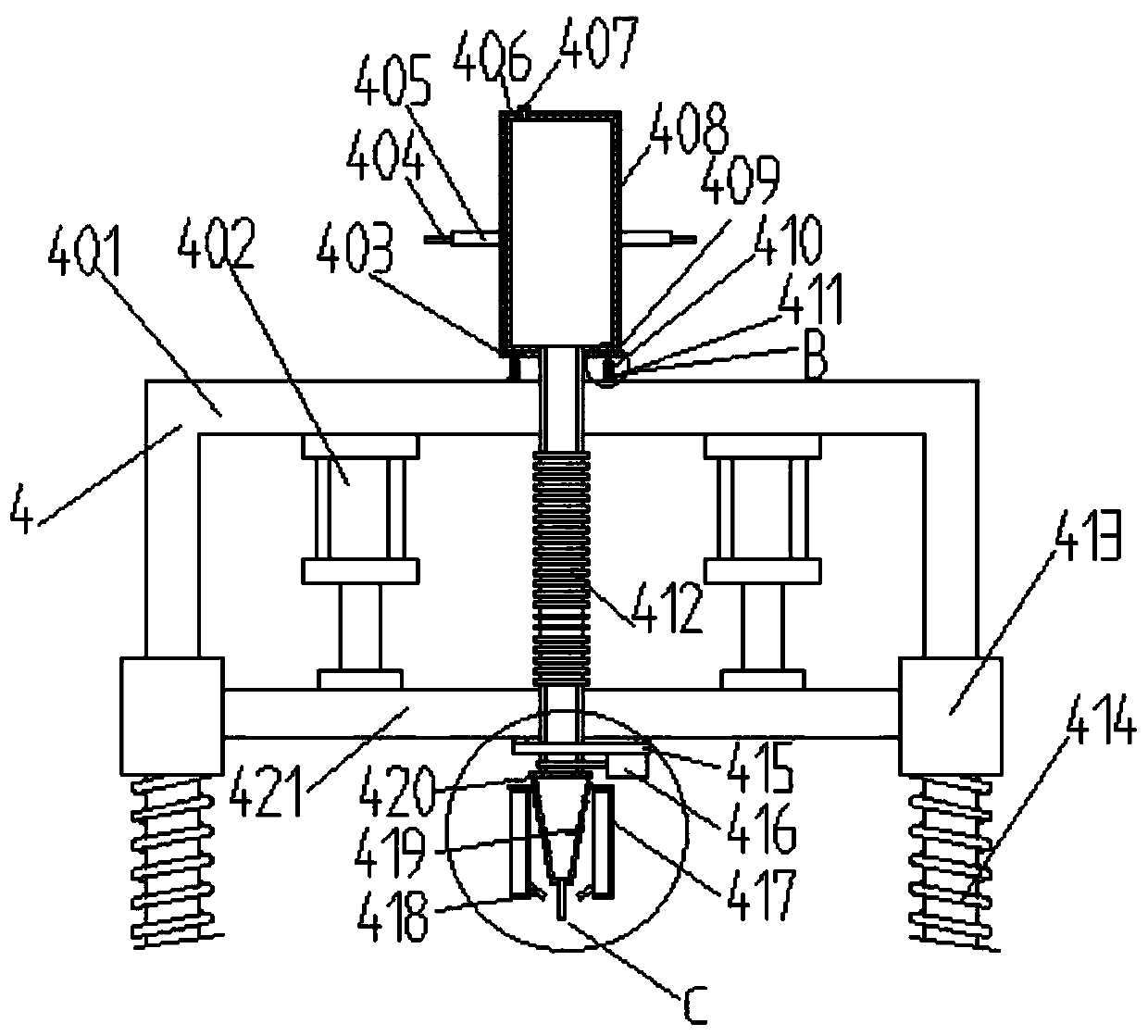

Device for clearing, dispensing and drying of electron components

The invention discloses a device for clearing, dispensing and drying of electron components. The device comprises a side supporting frame and a middle frame. A conveying device is arranged at the upper ends of the side supporting frame and the middle frame and is connected with a drive device. A clearing device and a drying device are arranged on the side supporting frame. The clearing device comprises connecting plates on a first frame body. A moving sleeve is movably arranged on each connecting plate, and a dust blowing gun is arranged on each moving sleeve in a penetrating manner. A dispensing device is arranged at the upper end of the middle frame and comprises a fixed frame, first sliding blocks, a moving plate, a corrugated pipe and a glue containing barrel. A heat preservation layeris arranged at the outer end of the glue containing barrel. The glue containing barrel is connected with a glue dripping box through the corrugated pipe. A glue dripping pipe is arranged at the bottom end of the glue dripping box. Air blowing devices are arranged at the two ends of the glue dripping box. The drying device comprises a second frame body, guide rails are arranged on the two sides ofthe second frame body, second sliding blocks are arranged on the guide rails and are on a lifting plate, and the electron components move on the lifting plate through transverse plates. The device can carry out clearing, dispensing and drying on the electron components rapidly and efficiently in batches.

Owner:湖南碧建精密机械有限公司

Improved Powder Distribution System for Three-Dimensional Printer

ActiveUS20200180227A1Reduce amountUniform dispensingSievingManufacturing enclosuresParticulatesSuspended particles

Owner:THE EX ONE

Intelligent automatic glue dispensing device for computer mainboard production

InactiveCN112024286AUneven solutionPrecise dispensing positionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention belongs to the technical field of computers, and particularly relates to an intelligent automatic glue dispensing device for computer mainboard production. A protective seat is fixedly connected to the upper portion of a glue dispensing seat, a mounting seat is fixedly connected to the upper surface of the protective seat, a rotating disc is rotatably connected to the interior of theprotective seat, and an elastic rod is movably connected to the interior of the rotating disc. One end of the elastic rod is fixedly connected with an abutting seat, the upper surface of the glue dispensing seat is slidably connected with an extrusion plate, a pushing rod is slidably connected to the position, located in the glue dispensing seat, of the lower surface of the extrusion plate, and one end of the pushing rod penetrates in an air pressure seat, and a piston column is slidably connected to one end of the pushing rod and located on the inner wall of the air pressure seat. Under thecondition that the pressure intensity is changed, glue in a glue dispensing head cannot drop again, so that the phenomenon that the glue drops again from the glue dispensing head after glue dispensingis finished is avoided, and the normal use of the device is guaranteed.

Owner:魏姗姗

Sealant forming apparatus, sealant forming method, and method of manufacturing liquid crystal display device using the same

ActiveUS7748342B2Prevent coagulationUniform dispensingLiquid surface applicatorsLiquid transferring devicesLiquid-crystal displaySealant

A sealant forming device, a sealant forming method and a method for manufacturing a liquid crystal display device using the same are disclosed. According to the present invention, a sealant coagulated in a nozzle can be minimized or prevented by performing an instantaneous suction process. A sealant forming device includes a dispenser including a syringe, and a nozzle connected to a lower end of the syringe to discharge a sealant therethrough; a dispensing tube connected to the syringe to apply a pressure to the syringe; and an instantaneous suction tube connected to the syringe to extract the sealant remaining in the nozzle after discharging the sealant.

Owner:LG DISPLAY CO LTD

Blending glue filling machine

InactiveCN105327834ALow costReduce labor intensityLiquid surface applicatorsCoatingsMechanical engineeringEngineering

The invention discloses a blending glue filling machine. The blending glue filling machine comprises an I-shaped support, a glue storage mechanism and an object placing mechanism. A first longitudinal rod is connected on the I-shaped support. A first motor is slidably arranged on the first longitudinal rod. The first motor is fixedly connected with an upper transverse sliding rod. A second motor is slidably arranged on the upper transverse sliding rod. A lower longitudinal rod is connected under the I-shaped support. A third motor is slidably arranged on the lower longitudinal rod. The third motor is fixedly connected with a lower transverse sliding rod. A fourth motor is slidably arranged on the lower transverse sliding rod. The glue storage mechanism is arranged on the second motor and comprises matching mechanisms and a barrel. A rotary shaft is arranged on the side portion of the barrel. A rotary motor is fixedly connected with the outer side of the barrel, and a stirring rod set is arranged on the rotary shaft. The object placing mechanism is arranged on the fourth motor and comprises a supporting plate used for placing an object to be subjected to glue dispensing. The blending glue filling machine is simple in structure, even in glue dispensing, high in speed and capable of reducing the glue cost, so that the cost is reduced and the working efficiency is improved.

Owner:SUZHOU XINGYA PURIFICATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com