Glue dispensing device for filter machining

A dispensing device and filter technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of time-consuming and labor-intensive dispensing, uneven dispensing, poor dispensing effect, etc., and achieve quality improvement , Dispensing effect is good, efficient and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

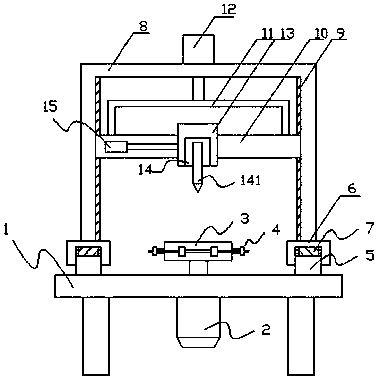

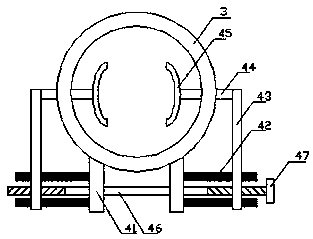

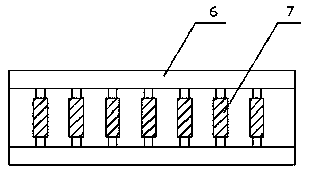

[0015] Such as Figure 1-3 As shown, the present invention discloses a dispensing device for filter processing, including: a frame 1, a frequency conversion motor 2, a tray 3, a clamping mechanism 4, a walking track 5, a U-shaped sliding seat 6, and a roller 7 , portal frame 8, guide rail 9, strip block 10, U-shaped connector 11, cylinder one 12, mounting seat 13, glue dispenser 14, cylinder two 15, and the frequency conversion motor 2 is installed in the middle of the lower end face of the frame 1 , the output shaft of the frequency conversion motor 2 passes through the rear end of the frame 1 and is fixed to the center of the lower end surface of the tray 3, the tray 3 is provided with a clamping mechanism 4, and the walking track 5 is two parallel and fixed on the On the left and right sides of the upper end surface of the frame 1, the walking track 5 extends longitudinally from the outside to the inside, and a U-shaped sliding seat 6 is slidably arranged on each walking tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com