Patents

Literature

103results about How to "Improve dispensing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dispensing device (CAT)

ActiveUS20090139517A1Reduce the speed of propagationLong durationOpening closed containersBottle/container closureBiomedical engineeringAirflow

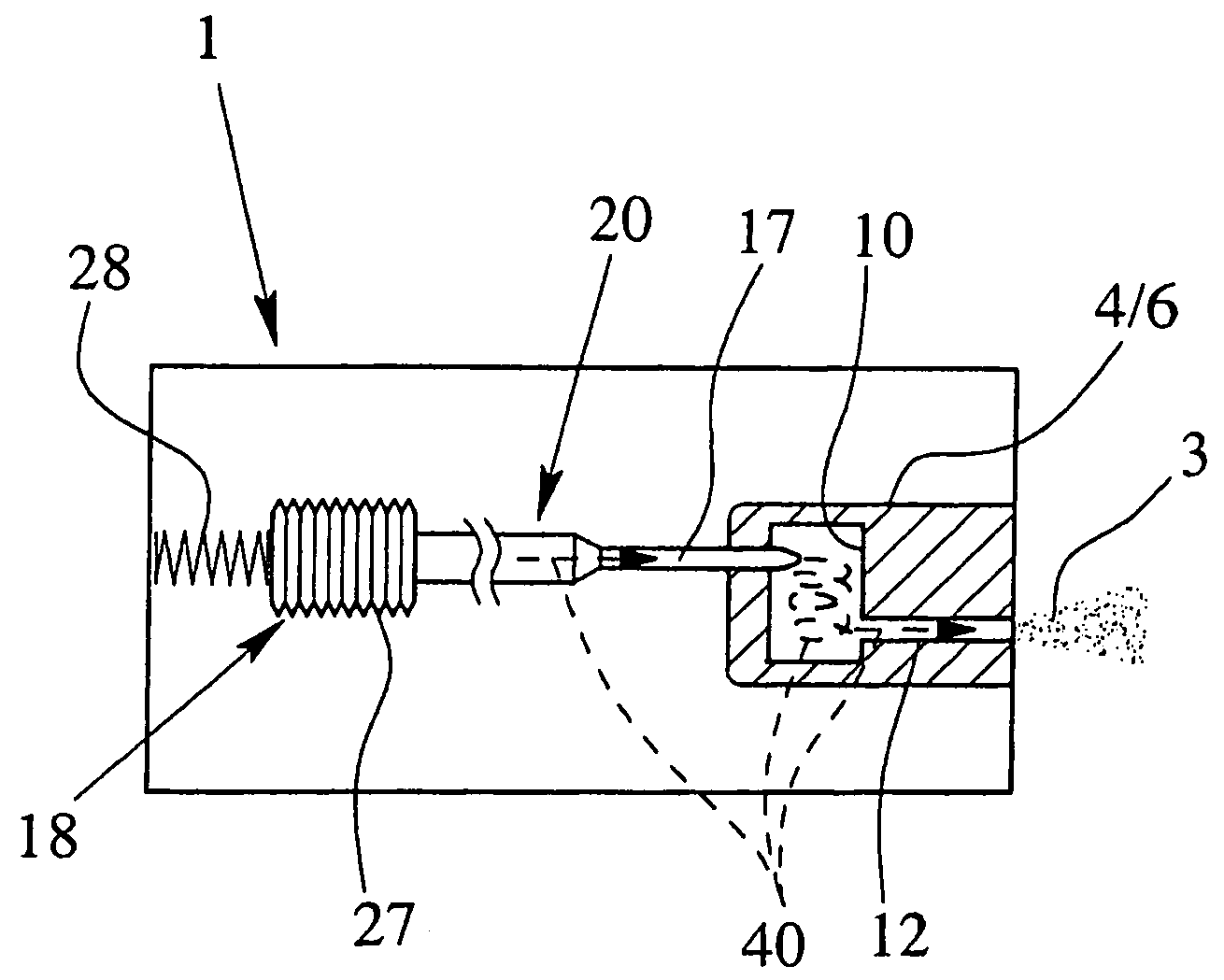

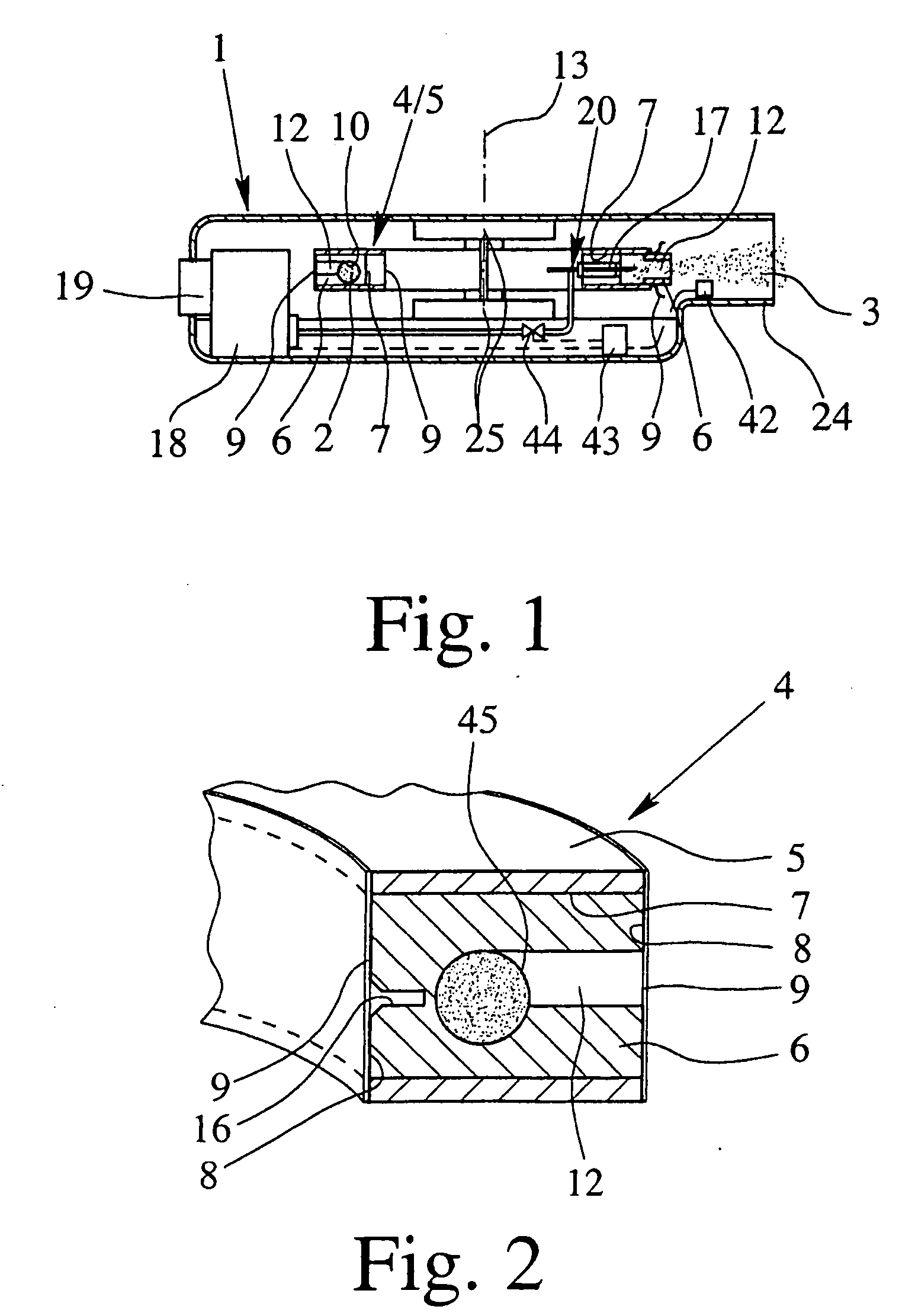

A dispensing device, a storage device and a method are proposed for dispensing a formulation as a spray. The formulation is dispensed by means of a gas stream. To improve the dispensing effect, pressure pulses are generated in the gas stream and / or the direction of gas flow alternates. The formulation is dispensed through a duct. The duct is connected to a storage chamber containing the formulation via a sharp edge or transition portion.

Owner:BOEHRINGER INGELHEIM INT GMBH

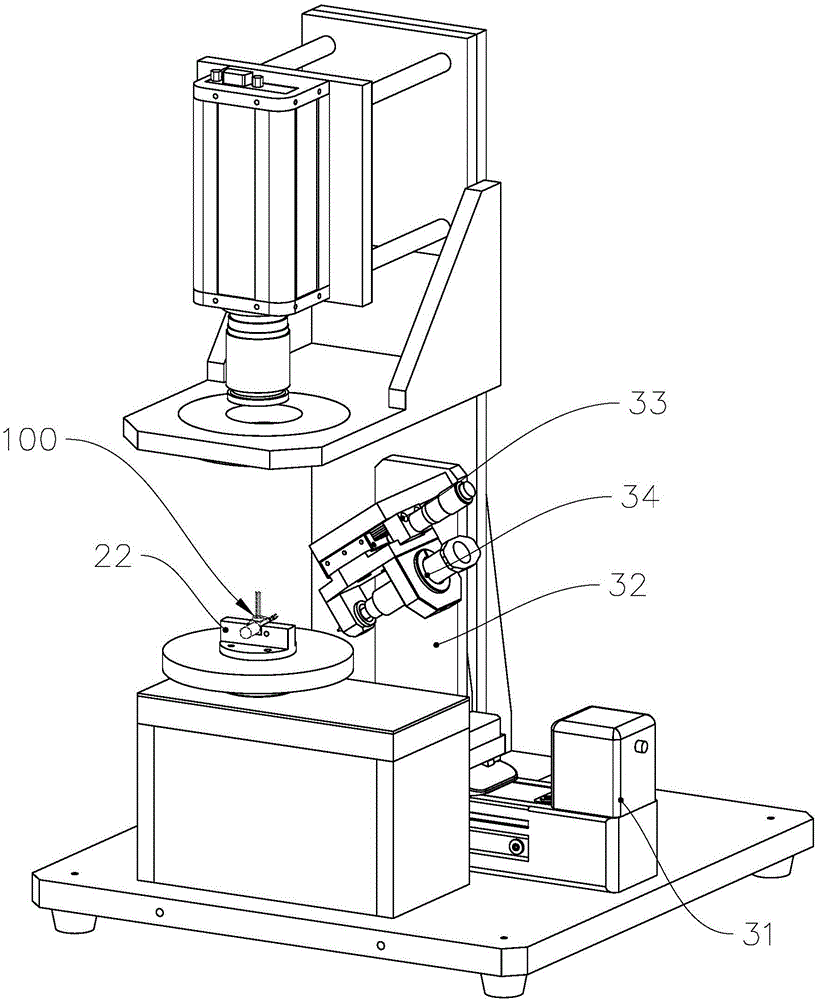

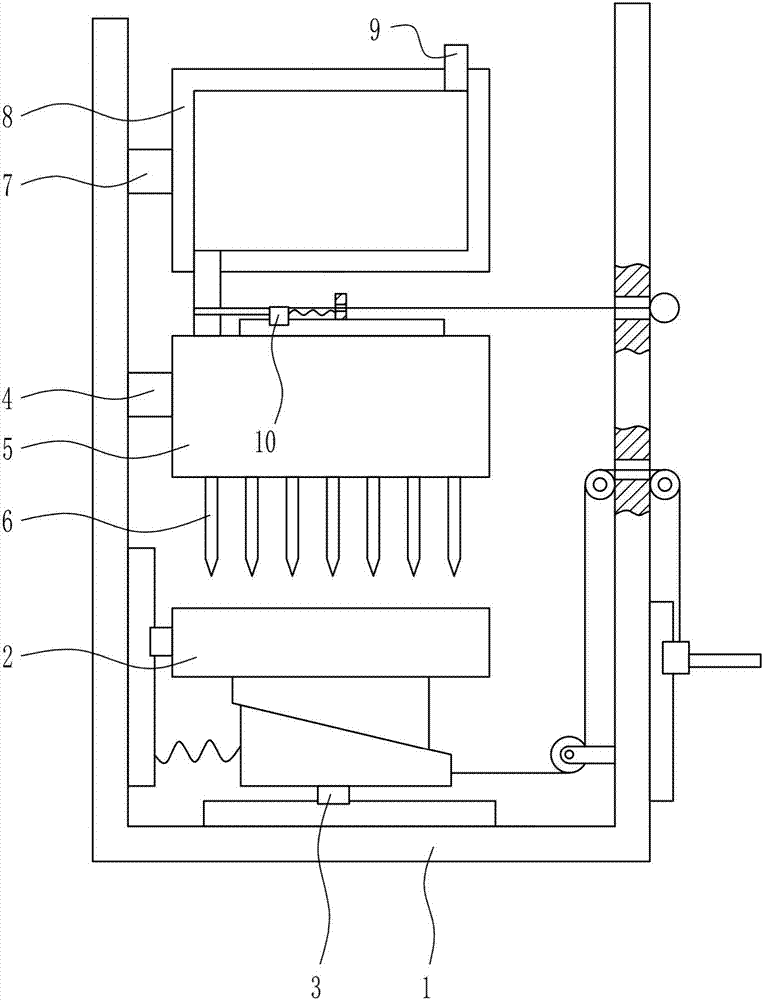

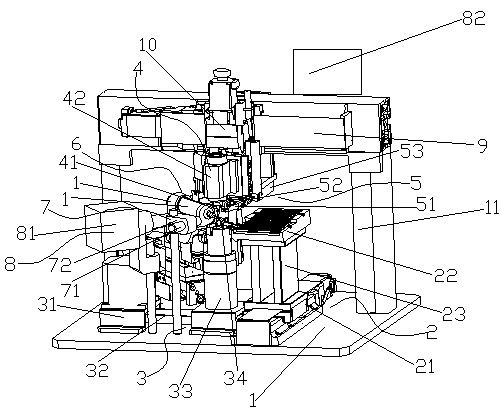

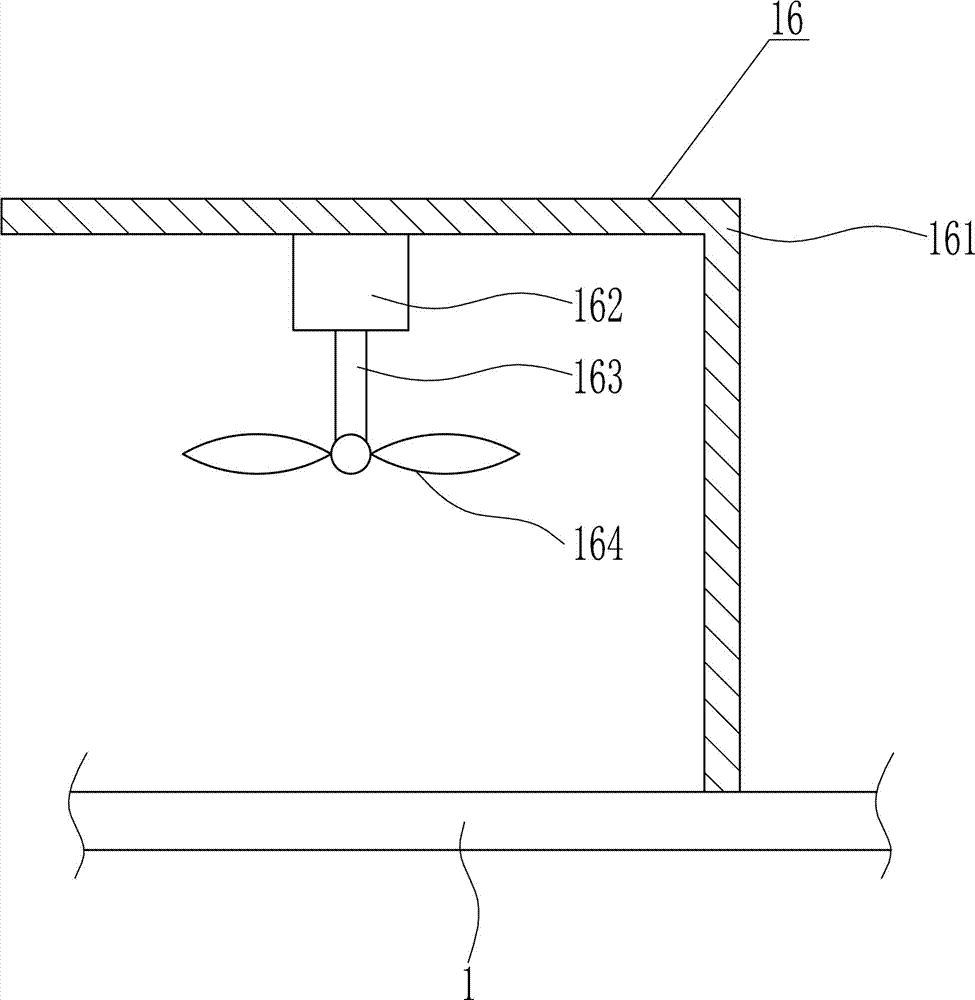

Fully automatic dispensing device and dispensing method

ActiveCN105750163ACompact structureIncrease flexibilityLiquid surface applicatorsCoatingsLinear motionAdhesive

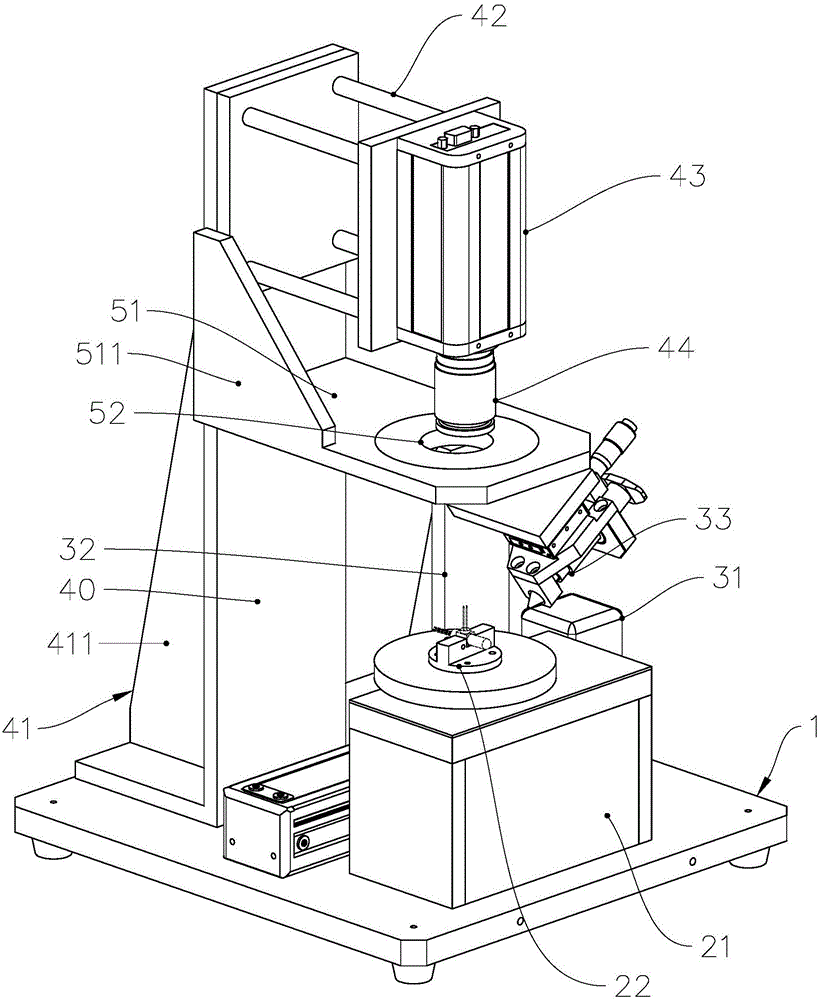

The invention provides a fully automatic dispensing device and a dispensing method based on the fully automatic dispensing device. The fully automatic dispensing device comprises a rotating driving part, a dispensing device, a light source, a camera, a clamp, a translation driving part, a mounting rack, a vertical rack and a controller, wherein the rotating driving part drives the clamp to rotate; the camera faces the clamp; the translation driving part drives the mounting rack to perform linear motion; the dispensing device is detachably mounted on the mounting rack; the camera is mounted on the vertical rack; the light source is detachably mounted on the vertical rack, performs image information acquisition on a BOSA device on the clamp through the camera, and sends image information to the controller, so as to analyze the image information; the controller sends control signals to the rotating driving part, the translation driving part and the dispensing device to enable the clamp to rotate at variable speed or enable the dispensing device to perform variable dispensing, so that variable dispensing according to the size of a gap in the BOSA device is realized, the situations of lacking adhesive and excessive adhesive are avoided, and the product quality of the BOSA device is improved.

Owner:珠海恒讯科技有限公司

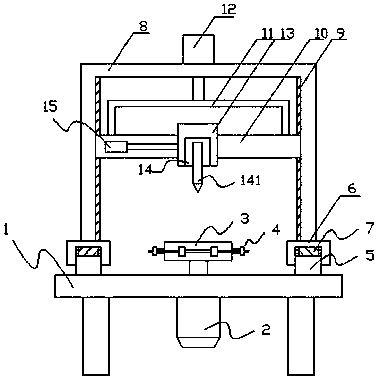

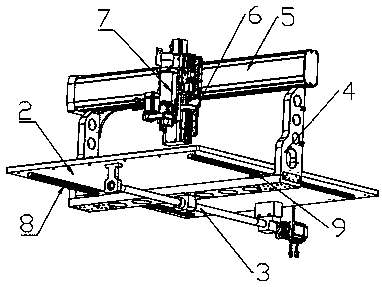

Glue dispensing device for filter machining

InactiveCN109365214AEfficientQuality improvementLiquid surface applicatorsCoatingsEngineeringMachining

The invention discloses a glue dispensing device for filter machining. According to the glue dispensing device for the filter machining, the tail end of an output shaft of a variable frequency motor is fixedly connected with the lower end face center of a tray after the output shaft of the variable frequency motor penetrates through a rack upwards, the tray is provided with a clamping mechanism, walking rails comprises two and are parallelly and fixedly connected to the left side and the right side of the upper end face of the rack, and each walking rail is slidably provided with a U-shaped sliding seat, the lower ends of two vertical portions of a door type rack are fixedly connected with the upper end faces of the U-shaped sliding seats on the left side and the right side correspondingly, the end face of the side, facing the rack center, of each vertical portion of the door type rack is vertically and fixedly connected with a guide rail, a strip-type block is slidably arranged on thedoor type rack through grooves, the upper end face of the strip-type block is fixedly connected with a U-shaped connection part, the tail end of a piston rod of a first air cylinder is fixedly connected with a horizontal portion of the U-shaped connection part after the piston rod of the first air cylinder penetrates through the door type rack downwards, the strip-type block is slidably providedwith an installation seat, the outer end face of the installation seat is provided with a glue dispensing machine through bolts, and the tail end of the piston rod of a second air cylinder is fixedlyconnected with the left end face of the installation seat. The glue dispensing device for the filter machining has the advantages that time and labor are saved, and the efficiency is high.

Owner:蚌埠市同升滤清器有限公司

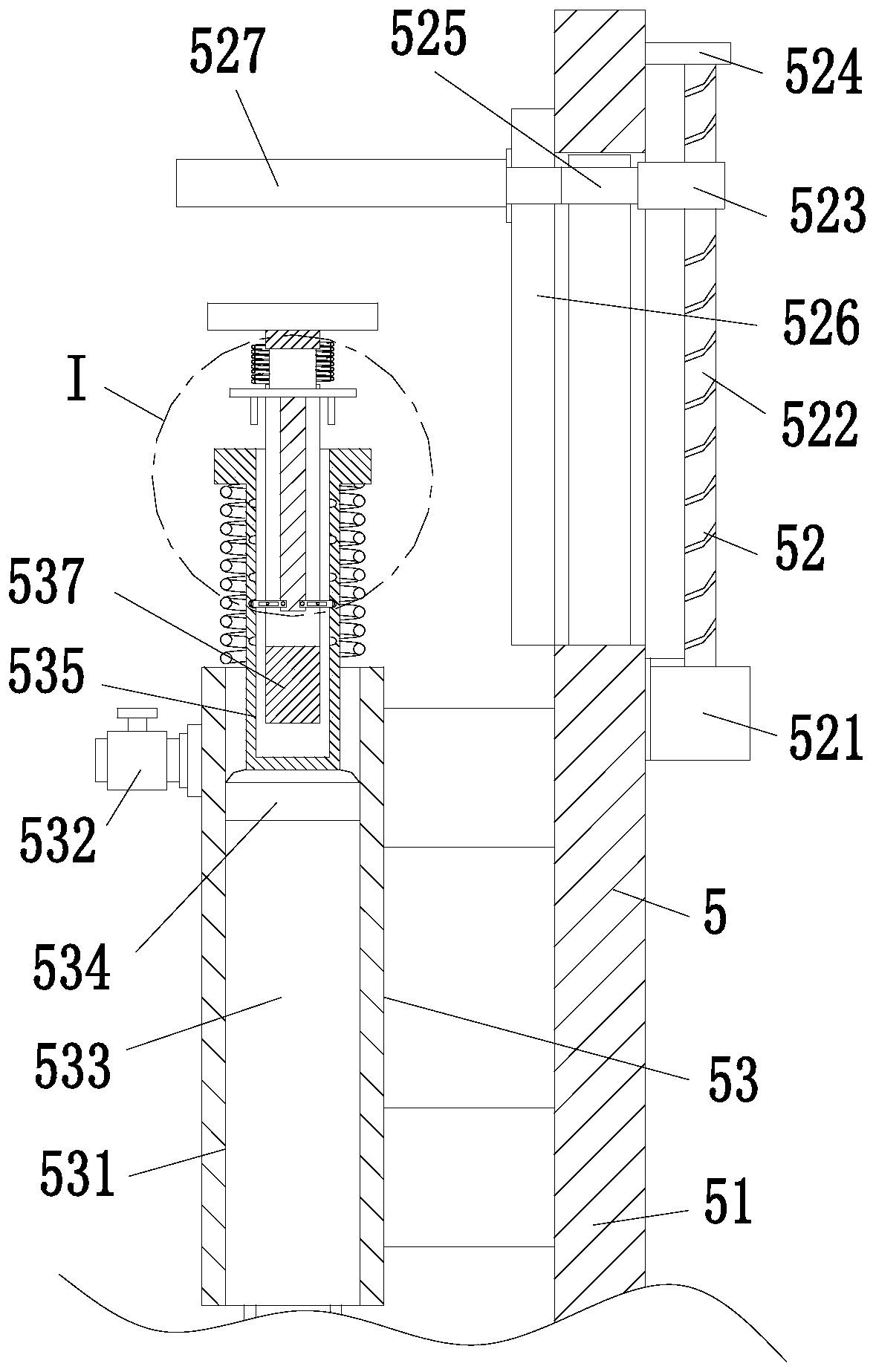

Flexible and adjustable glue dispenser

InactiveCN111151414AAchieve fine-tuningGuaranteed heightLiquid surface applicatorsCoatingsMotor driveStraight tube

The invention relates to a flexible and adjustable glue dispenser, and belongs to the technical field of dispensing equipment. The dispenser comprises a rack, a glue dispensing platform, an electric screw nut pair, a sliding frame, a linear module, an electric cylinder, a glue dispensing mechanism, a sliding rail I and a sliding block I. Glue dispensing of different positions and heights of a product can be achieved, the walking path of a glue dispensing head can be subjected to amplifying and shooting, whether the glue dispensing position of the product is correct or not can be determined, meanwhile, the height of glue drops of the glue dispensing head can be detected, it is ensured that the glue drops can meet the product foot seal needs, meanwhile, a glue outlet shaft is arranged to connect the glue dispensing head with a glue outlet valve, the glue outlet shaft is connected with a motor through a belt wheel transmission mechanism, when a non straight pipe glue dispensing needle isadopted for glue dispensing, the motor drives the glue dispensing head to rotate, it is ensured that the non straight pipe dispensing needle can dispense the glue to the product designated position accurately, fine adjusting of the height of the glue dispensing needle can be achieved, it is ensured that the height and the bottom area of the dispensed glue drops can meet needs, and the glue dispensing effect and the quality can be improved.

Owner:中山牛耳智能科技有限公司

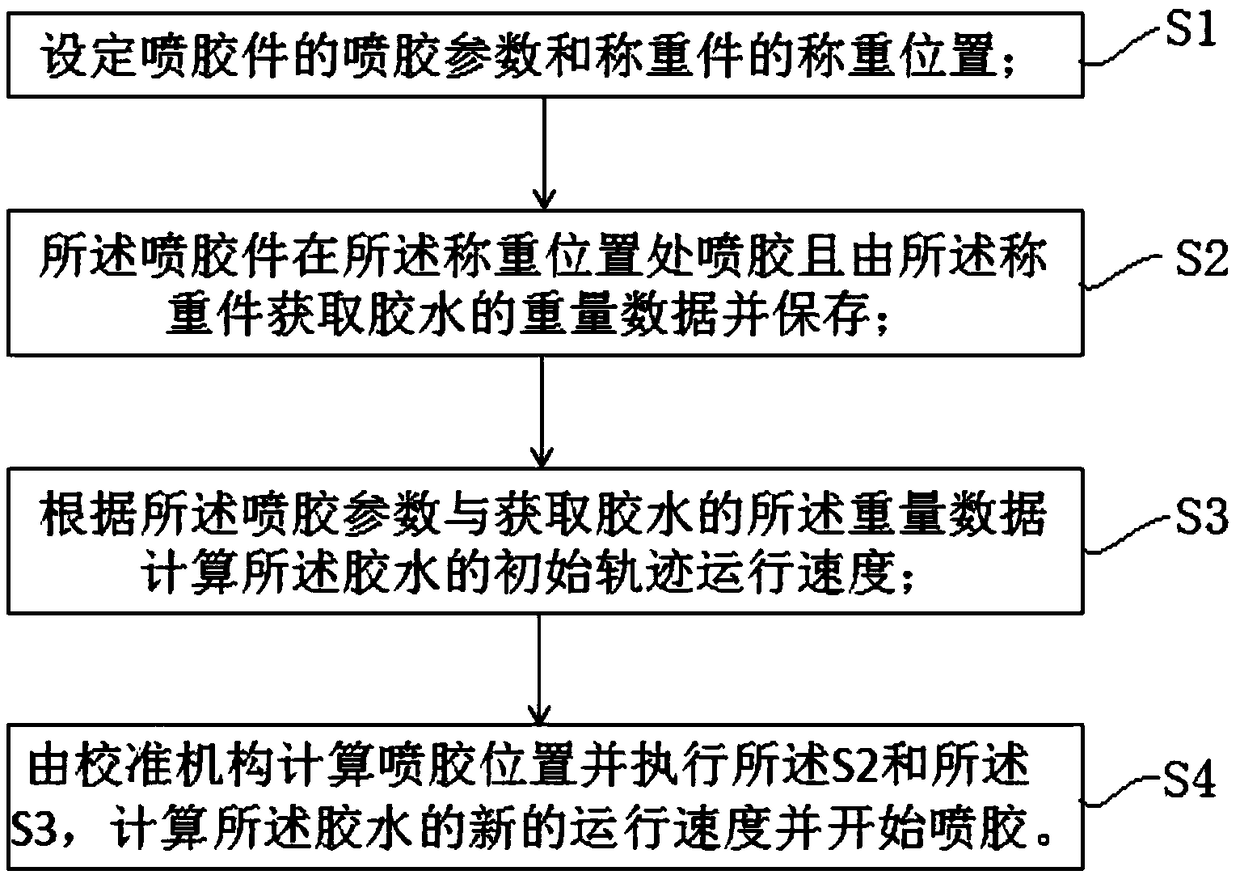

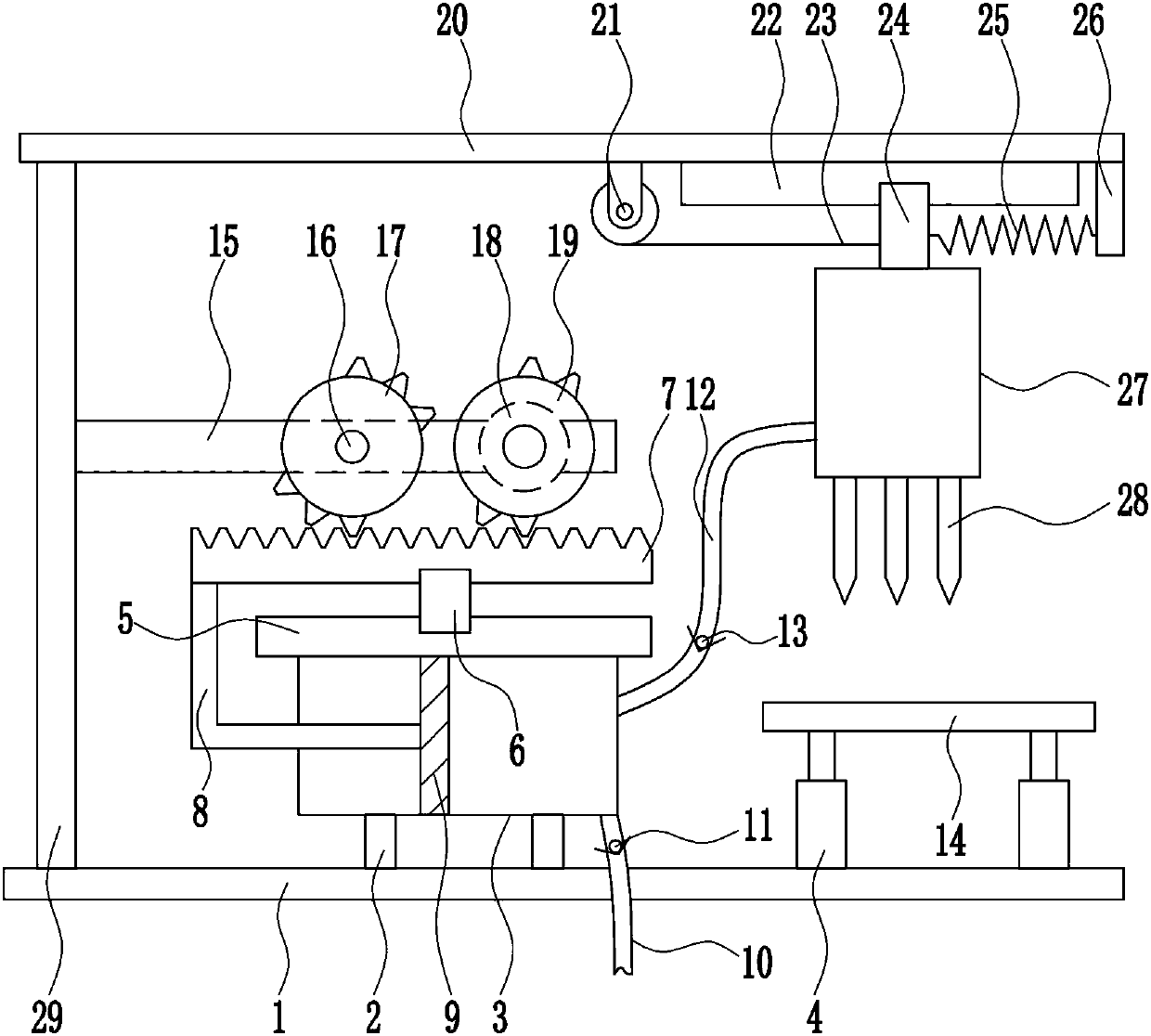

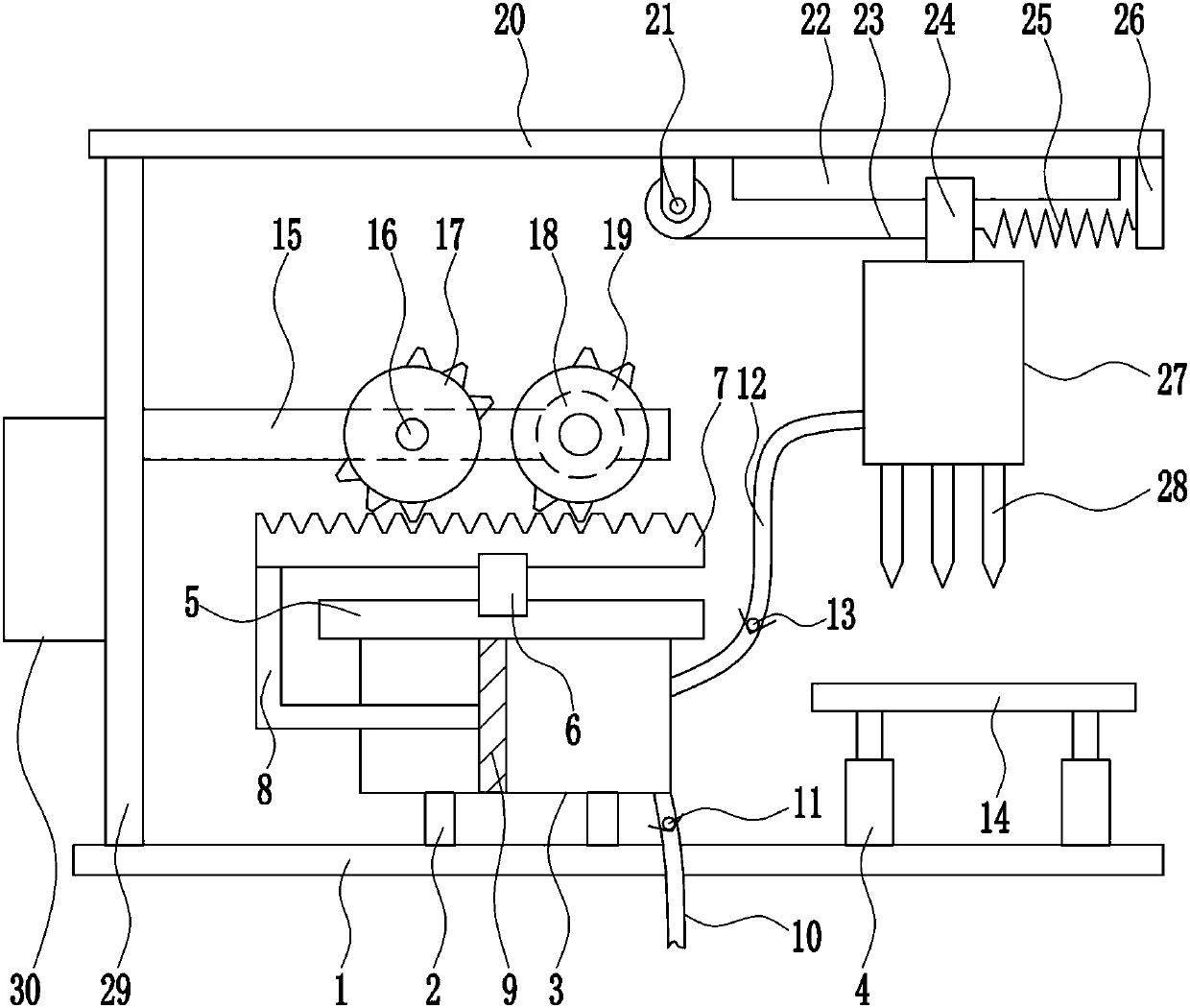

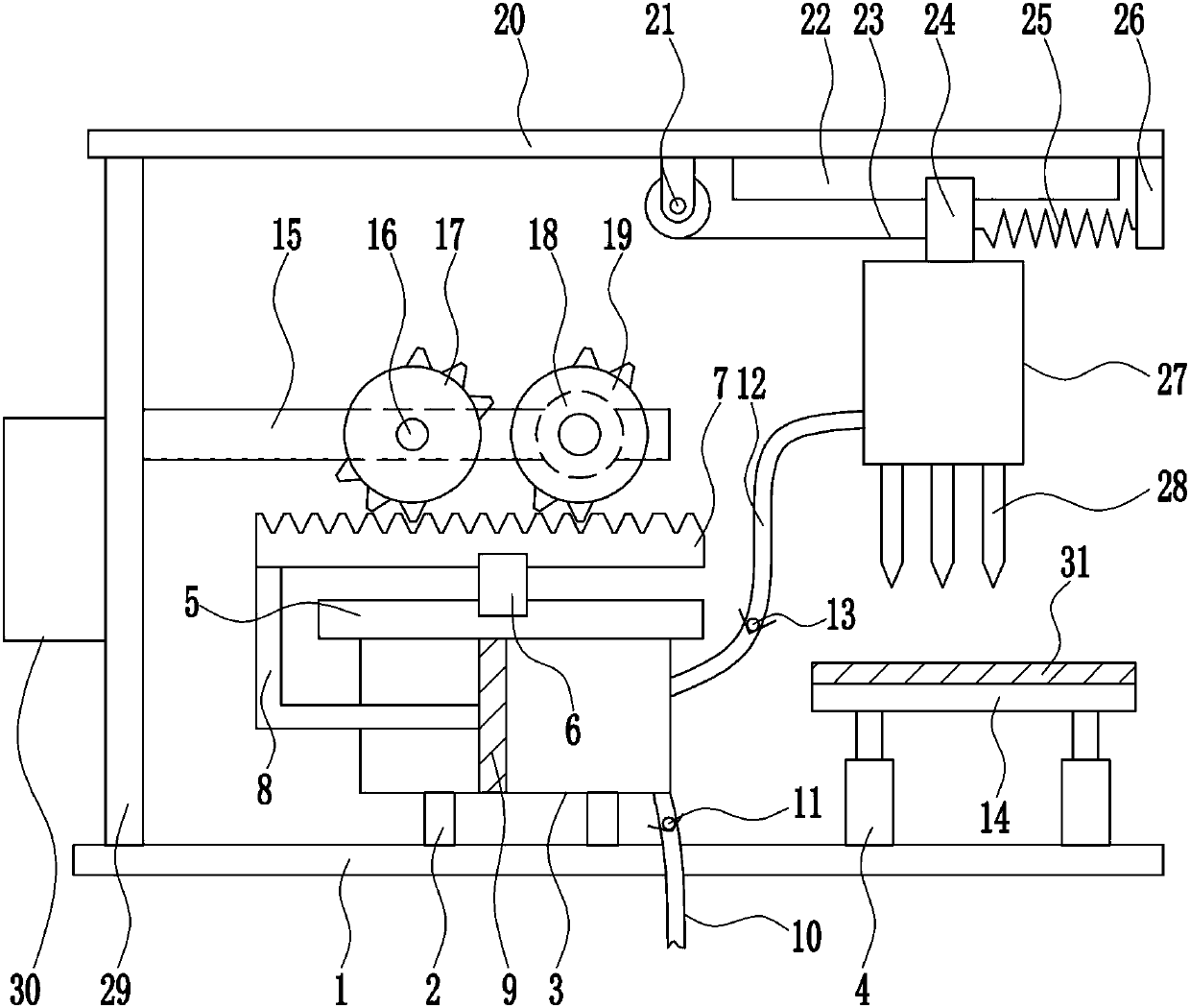

Glue spraying method for correcting running speed through weighing and fluid coating device

ActiveCN108636672ASolve the problem of unstable glue spraying and unsatisfactory glue spraying effectSolve the problem of unstable glue quantity and unsatisfactory glue spraying effectSpraying apparatusMechanical engineeringCoating

The invention provides a glue spraying method for correcting the running speed through weighing and a fluid coating device. The glue spraying method for correcting the running speed through weighing comprises the following steps that firstly, the glue spraying parameters of a glue spraying piece and the weighing position of a weighing piece are set; secondly, the glue spraying piece sprays glue atthe weighing position, and the weighing piece is used for obtaining and storing weight data of glue; thirdly, the initial track running speed of the glue is calculated according to the glue sprayingparameters and the obtained glue weight data; and fourthly, a calibration mechanism is used for calculating the glue spraying position, the second step and the third step are executed, the new glue running speed is calculated, and glue spraying is started. According to the glue spraying method for correcting the running speed through weighing in the embodiment, the problems that the glue sprayingglue amount is not stable, and the glue spraying effect is not ideal are effectively solved, and the dispensing effect of products is obviously improved. The glue spraying method for correcting the running speed through weighing is simple, easy to control and suitable for large-area application and popularization.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

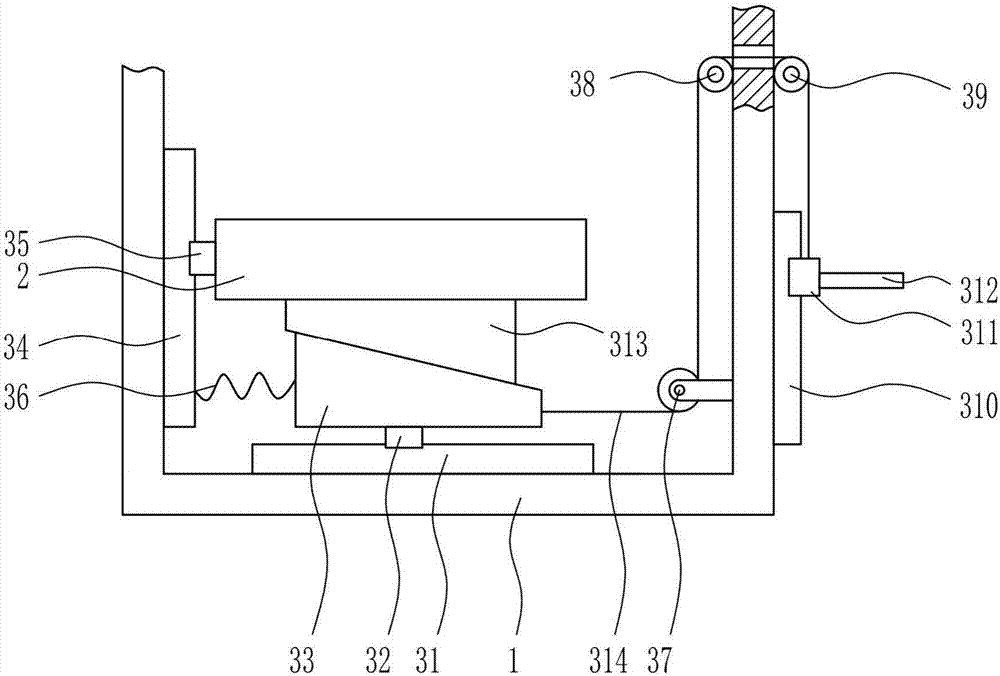

Dispensing device for production of electronic components of LED lamp

InactiveCN109926267AImprove plasticityGood welding performanceLiquid surface applicatorsCoatingsEngineeringCylinder block

The invention relates to a dispensing device, in particular to a dispensing device for production of electronic components of an LED lamp. The dispensing device for production of the electronic components of the LED lamp is high in pertinence, high in dispensing speed and good in dispensing effect. The dispensing device for production of the electronic components of the LED lamp comprises a bottomplate, supporting plates, a cylinder block, an electric pushing rod, a first sliding rail, a first sliding block, a rack, an L-shaped connecting rod, a piston, a first pipeline, a first check valve and the like; and a left frame is welded to the left side of the top of the bottom plate, the supporting plates are welded to the middle of the top of the bottom plate in a bilateral symmetry mode, andthe tops of the supporting plates are connected with the cylinder block in a bolt connection mode. Through left-right moving of the piston, glue can continuously enter a glue storage tank from the cylinder block, and then through cooperation of an electric winding wheel, left-right dispensing of the electronic components of the LED lamp is achieved.

Owner:惠州市晶盛电子有限公司

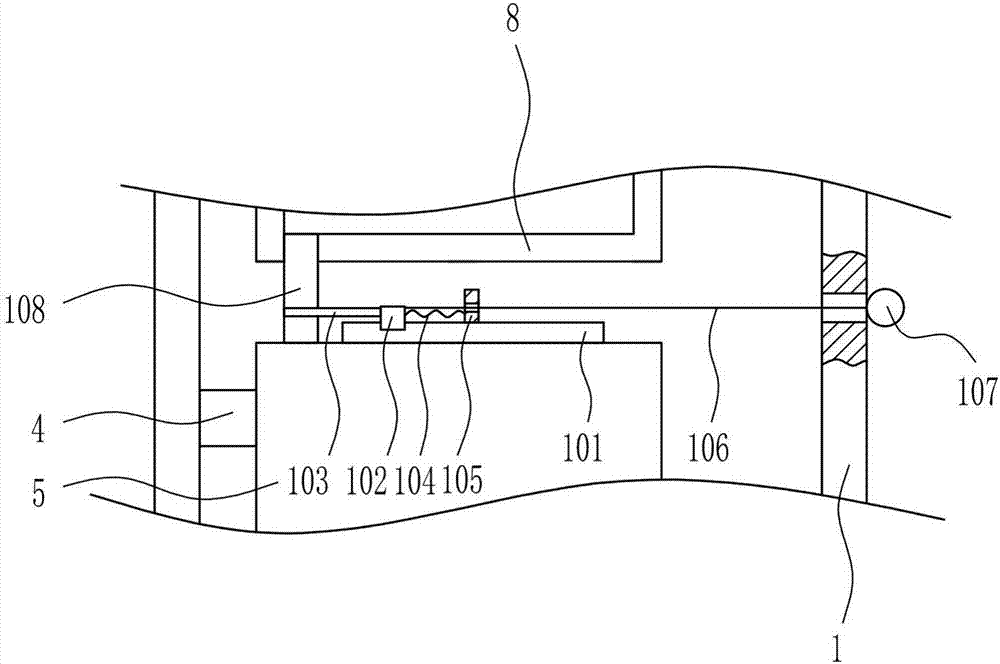

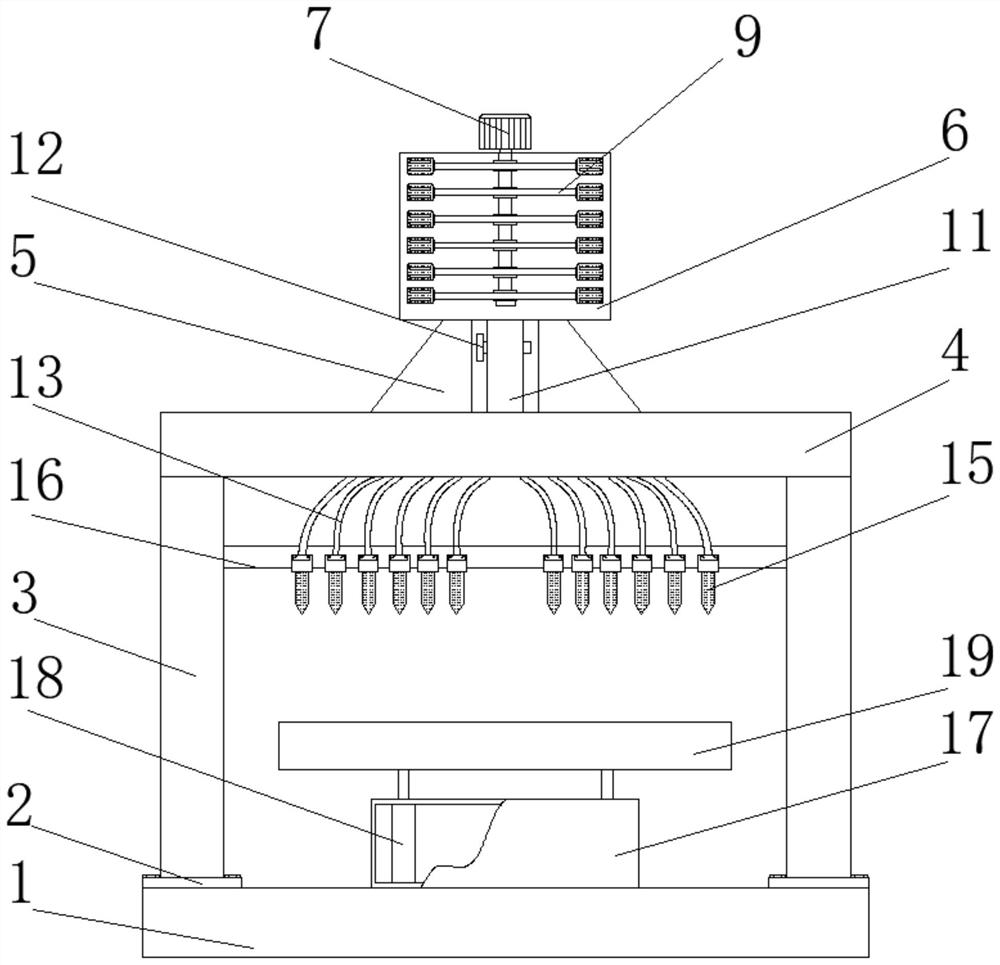

Dispensing equipment for energy saving lamp manufacturing

InactiveCN106914381ANot easy to condenseQuality assuranceLiquid surface applicatorsCoatingsAdhesiveArchitectural engineering

The invention relates to dispensing equipment, and especially relates to dispensing equipment for energy saving lamp manufacturing. The invention aims to provide dispensing equipment having the advantages that the adhesive is difficult to cure and the adhesive amount can be controlled easily. The provided dispensing equipment comprises an installation rack, a disposing plate, an elevating device, a first support rod, a material storage tank, and dispensing heads. The elevating device is installed in the installation rack. The top of the elevating device is provided with the disposing plate. The middle of the left wall in the installation rack is provided with the first support rod. The right end of the first support rod is connected to the material storage tank. Dispensing heads are evenly arranged on the bottom of the material storage tank. A second support rod is arranged on the upper part of the left wall in the installation rack. The right end of the second support rod is connected to a box. The right side of the top of the box is provided with a feed pipe. By pressing a pedal, an LED support, which is placed on the disposing plate and needs to be dispensed, is raised to a proper height, the dispensing position becomes more accurate, and the dispensing effect is better.

Owner:GRACE(NINGBO) LIGHTING CO LTD

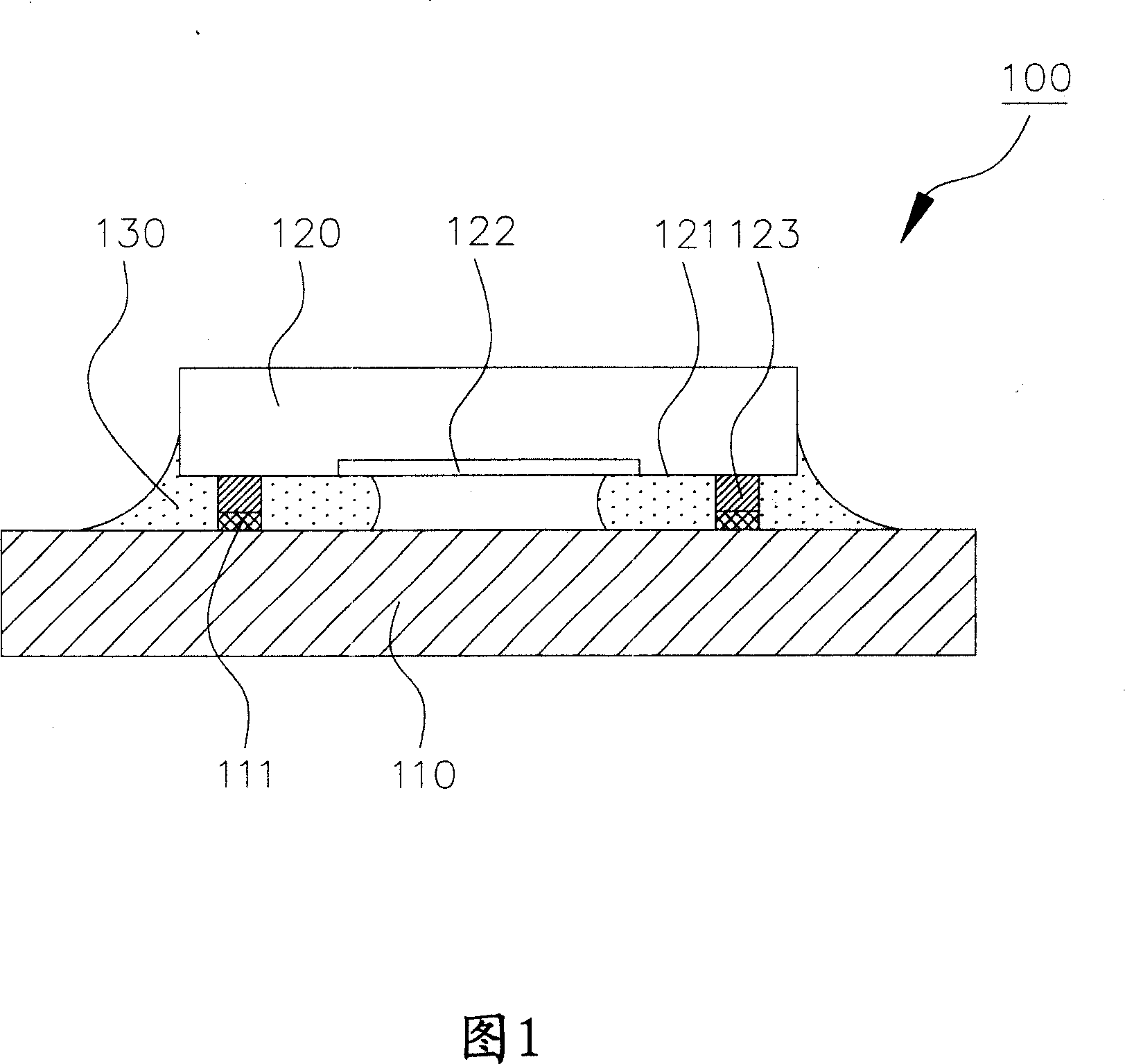

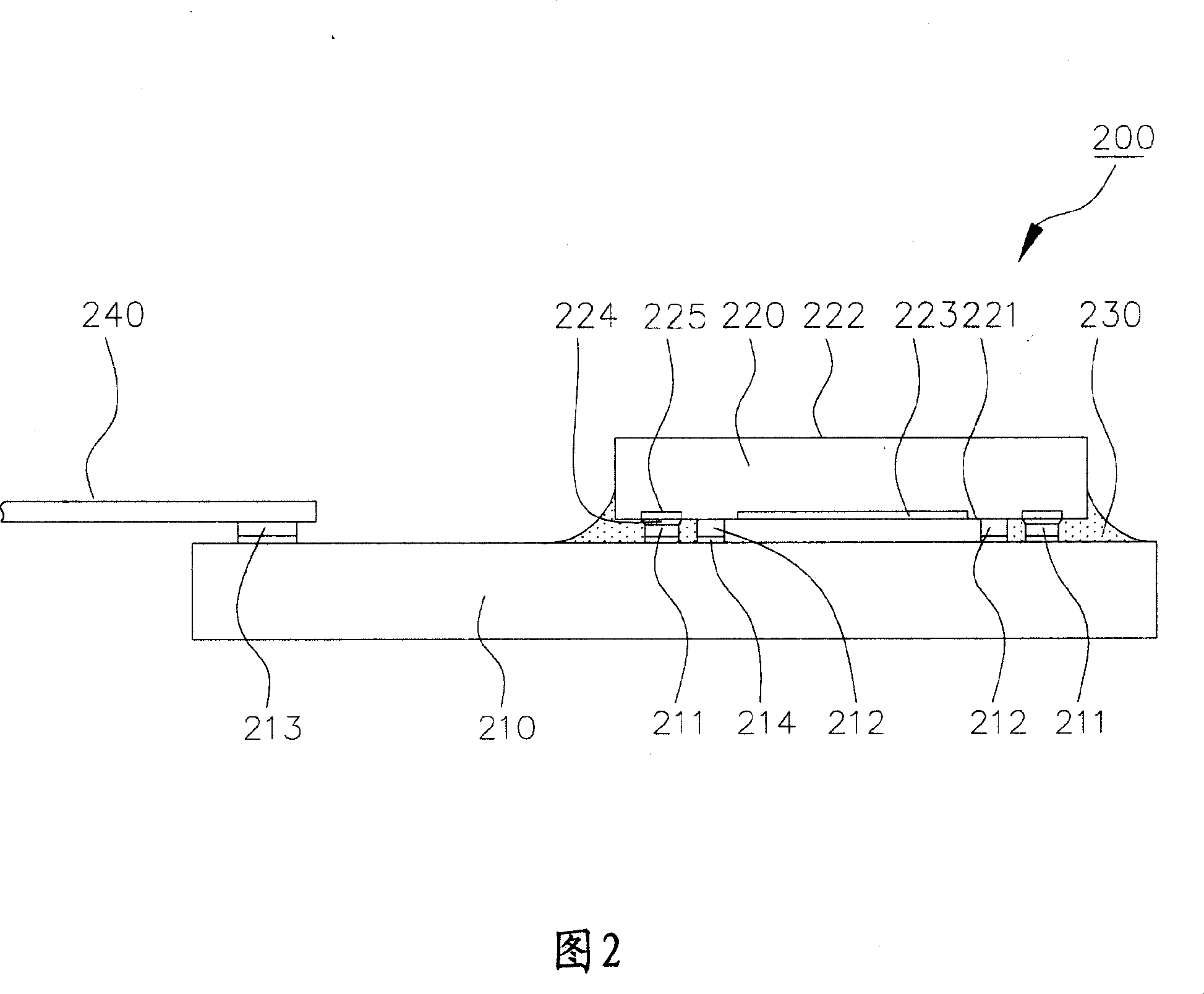

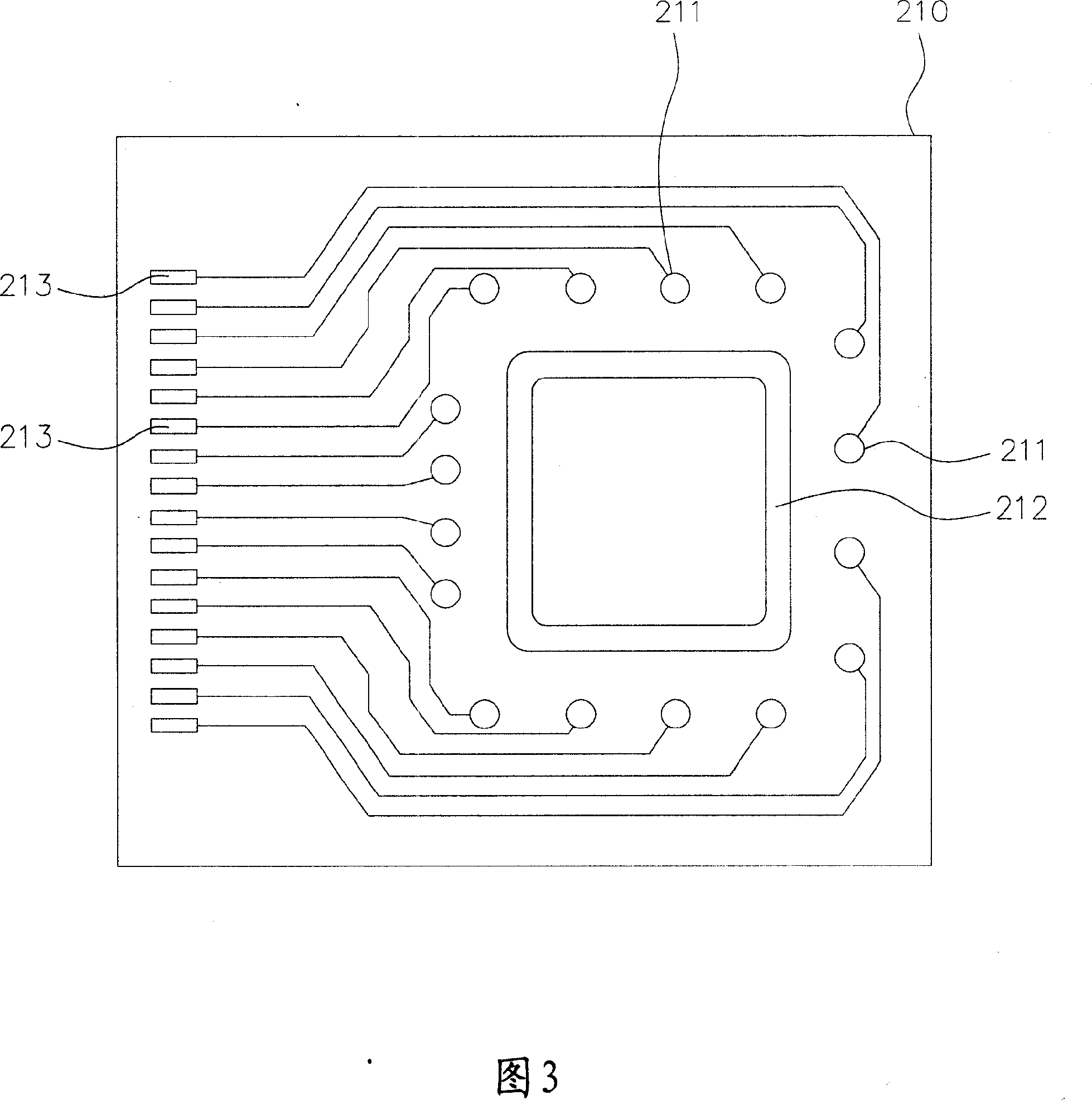

Glass crystal packaging structure for image sensory element

InactiveCN101118882AGuaranteed dispensing effectReduce gapSemiconductor/solid-state device detailsSolid-state devicesLight sensingColloid

The present invention relates to a glass crystal coating sealing structure for the image sensor, which mainly comprises a glass basal plate, an image sensor crystal and a point photoresist coating body. One active face of the image sensor crystal comprises a light sensing area, and the glass basal plate has a closed blocking ring around the light sensing area, and the active face of the image sensor crystal is provided with a plurality of protruding blocks which can be distorted, and when the protruding blocks which can be distorted are connected with the connecting cushion of the glass basal plate, the present invention can reduce the clearance between the image sensor crystal and the glass basal plate to make the closed blocking ring easily blocking the flowing to the light sensing area of the image sensor crystal for the point photoresist coating body, thereby ensuring having good point coating effect.

Owner:CHIPMOS TECH INC

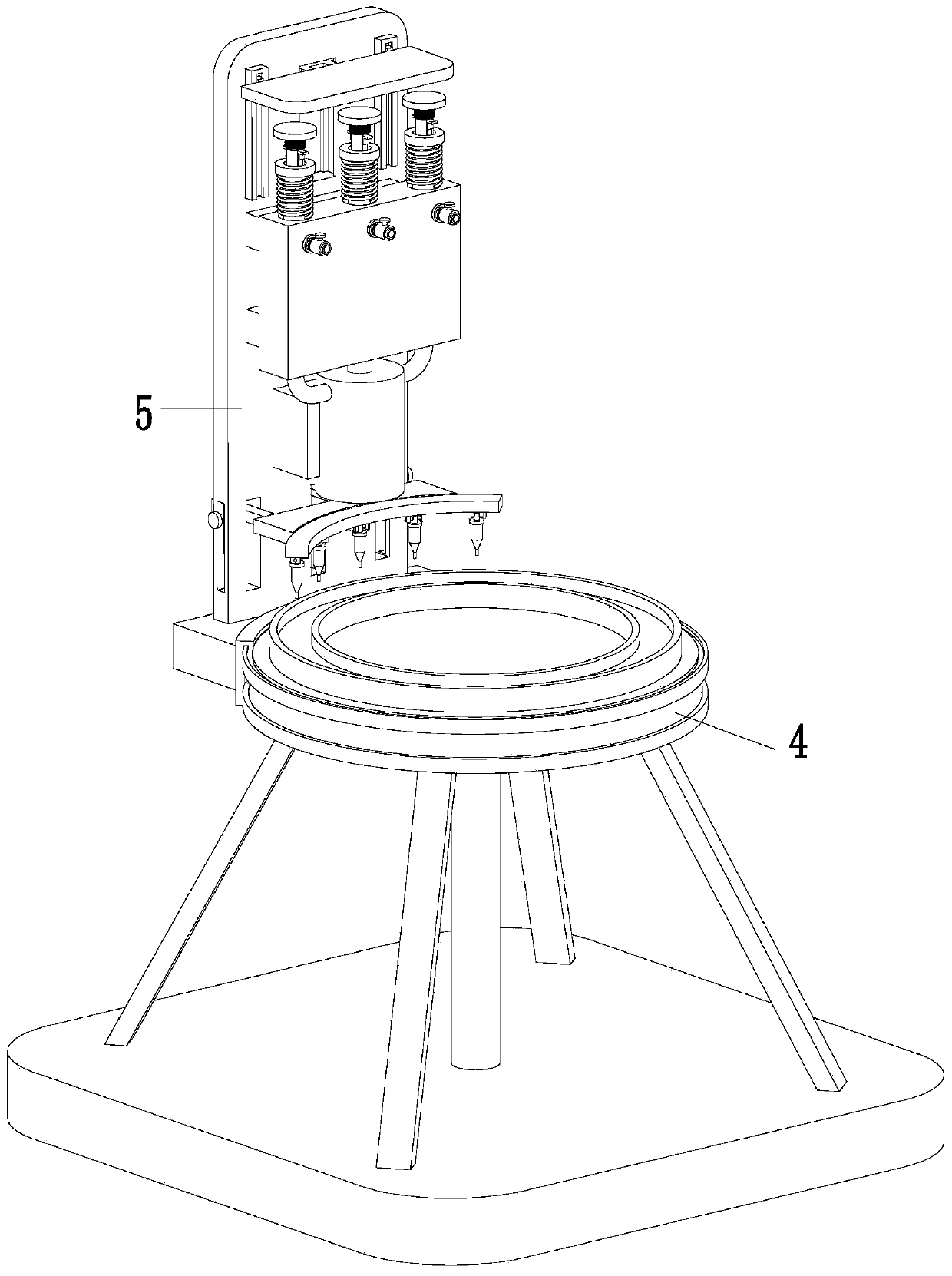

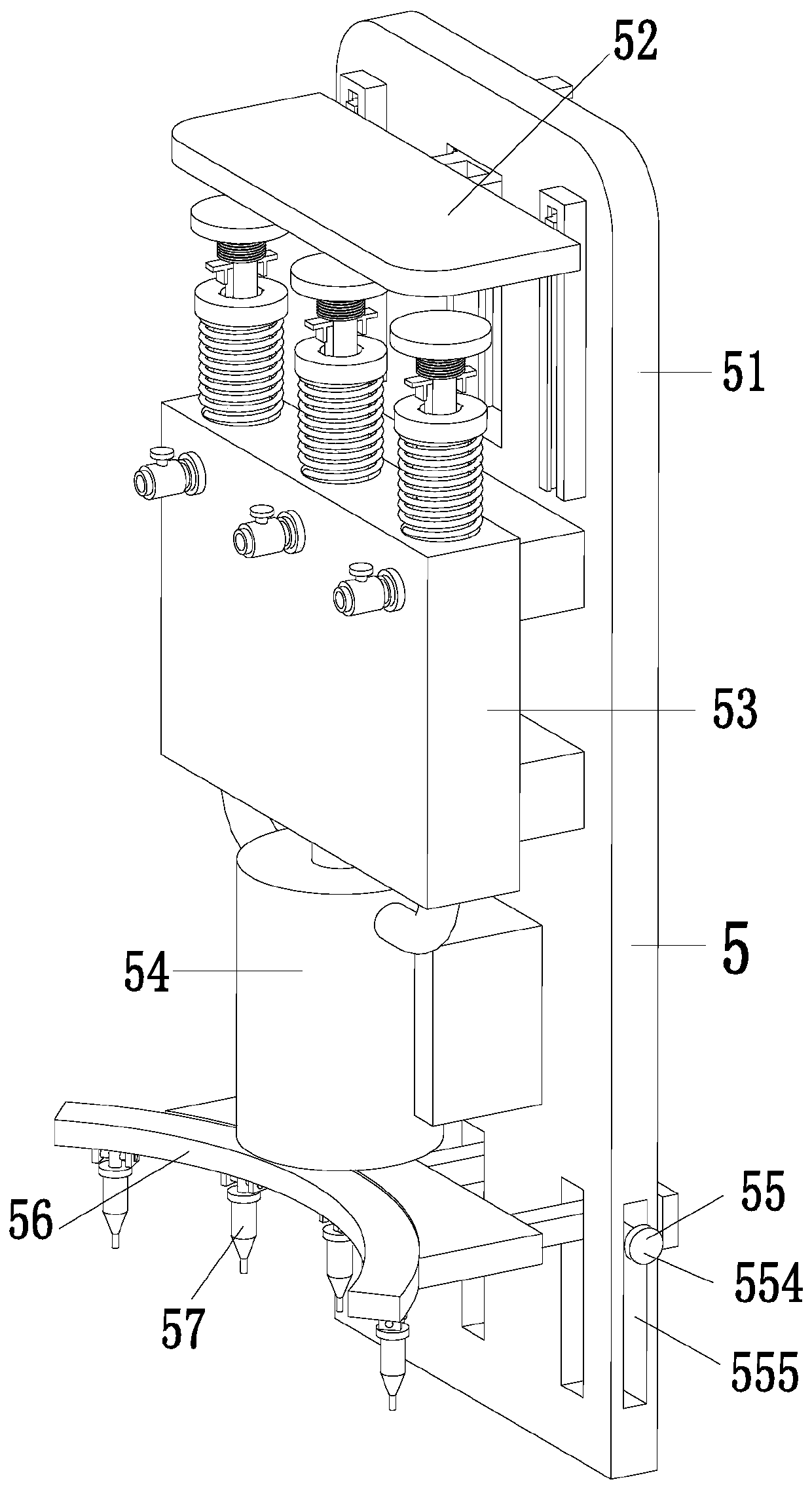

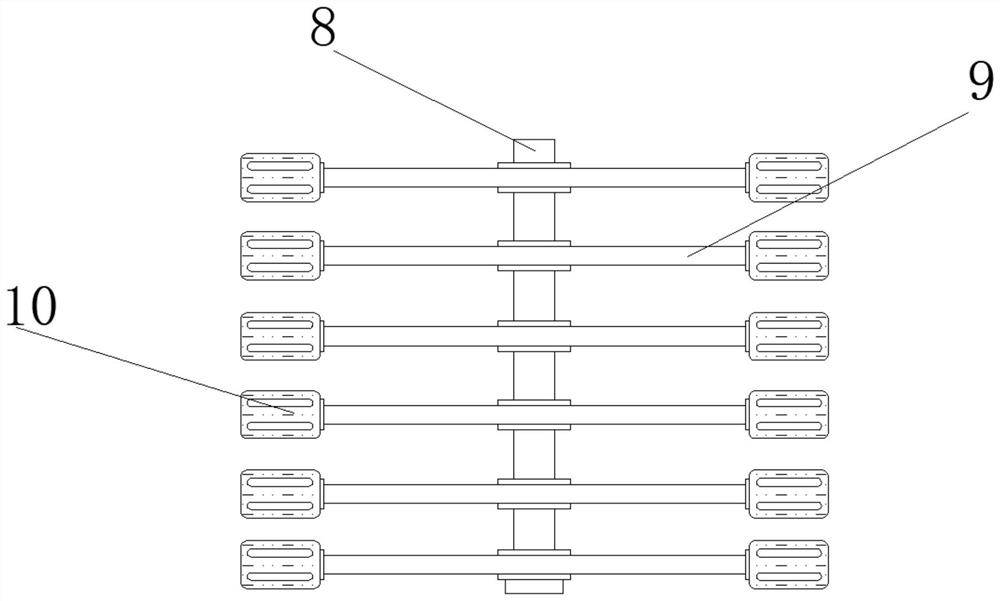

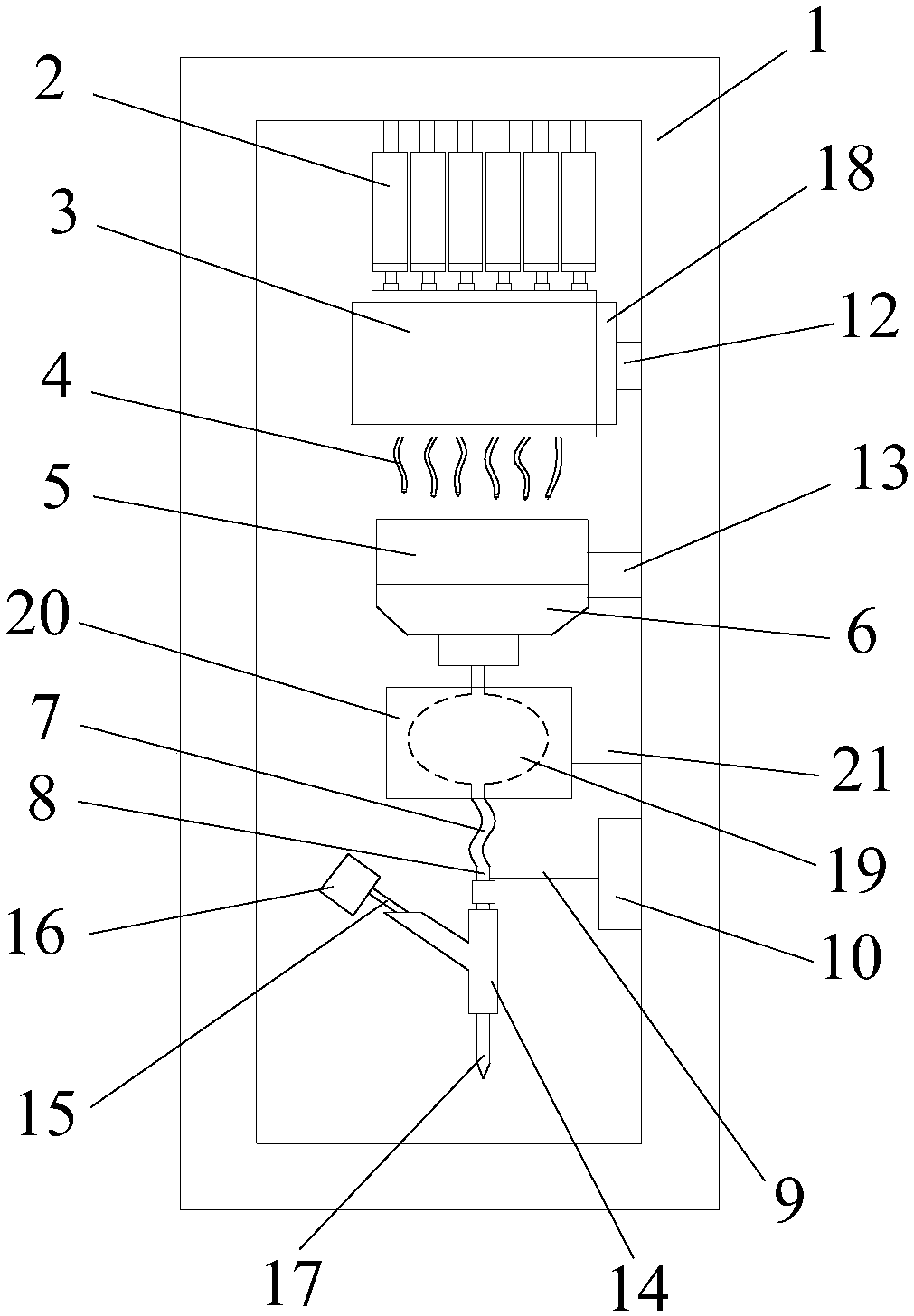

Intelligent glue dispenser

ActiveCN109894322ADispensing effect is goodImprove dispensing efficiencyLiquid surface applicatorsRotary stirring mixersAdhesiveColloid

The invention relates to an intelligent glue dispenser. The intelligent glue dispenser comprises an electric rotating disc and a glue injection device, wherein the glue injection device is fixed on the outer side wall of the electric rotating disc; and the glue injection device is capable of doing rotation motion along with the electric rotating disc. The intelligent glue dispenser is capable of solving the problems that the glue is inconveniently dispensed when injecting the glue into ring-shaped lamp bars, the adjustment is inconvenient when dispensing the glue, the glue dispensing efficiency is low, the mixing ratio of glue adhesives cannot be accurately adjusted when the glue is mixed, and the glue cannot be uniformly stirred during mixing. According to the intelligent glue dispenser,parallel multi-station glue dispensing heads are adopted, the glue dispensing effect is good, the glue dispensing efficiency is high, the mixing ratio of the glue adhesives is accurate when dispensingthe glue, meanwhile, the height of the glue injection heads can be manually adjusted, and the glue dispenser is capable of preventing the glue from splashing in the glue injection process.

Owner:ZHUHAI HUAYA MACHINERY TECH CO LTD

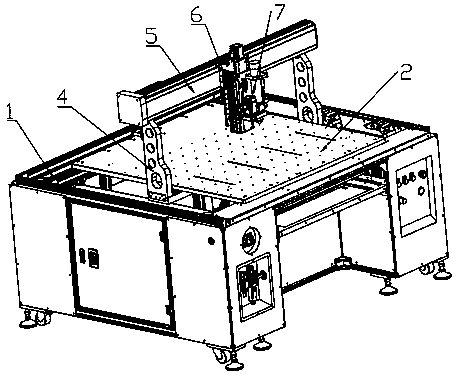

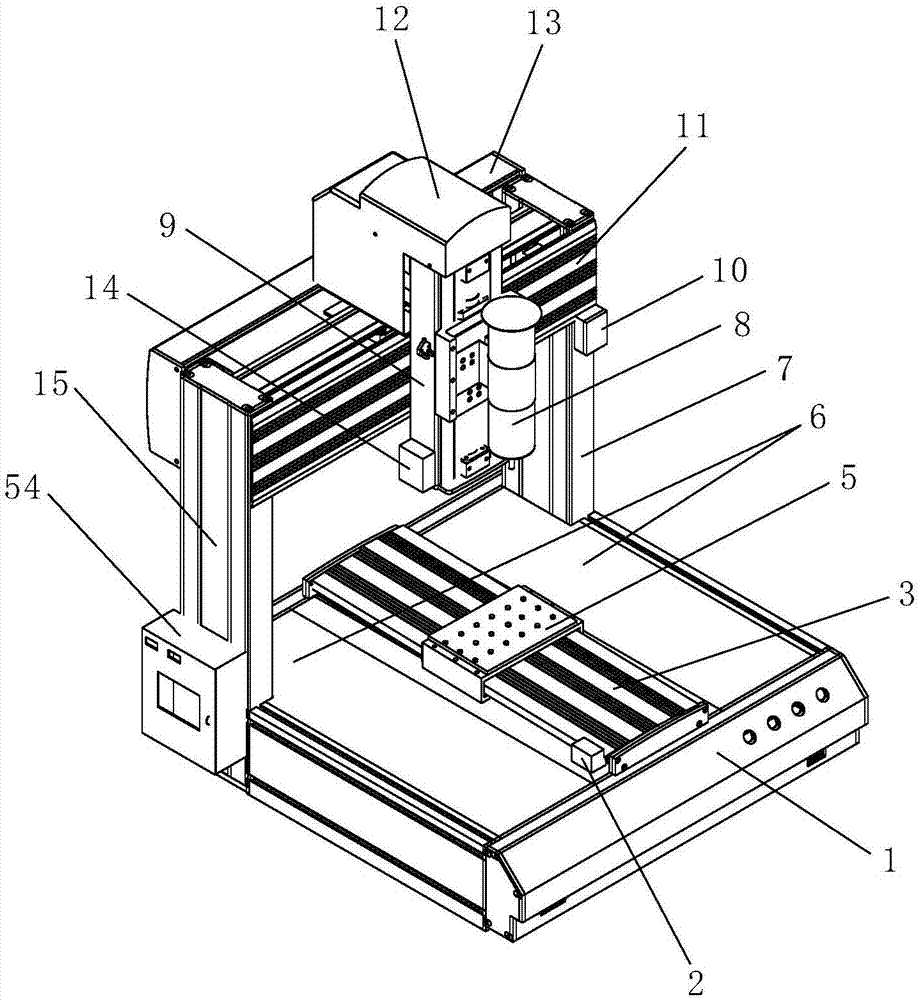

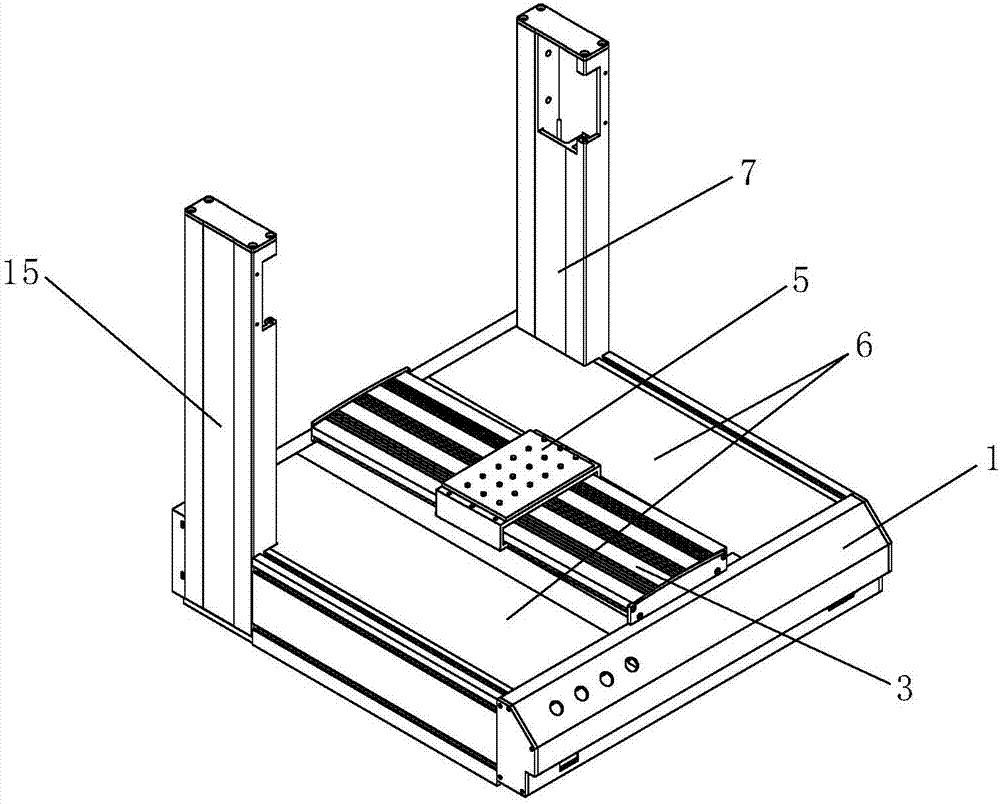

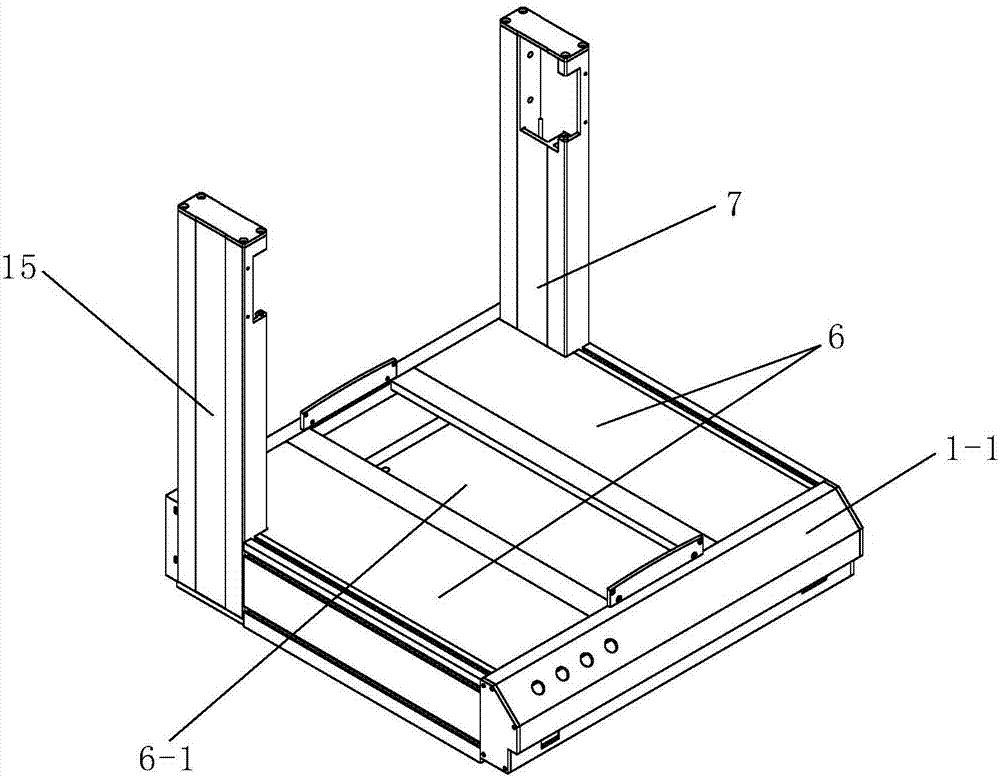

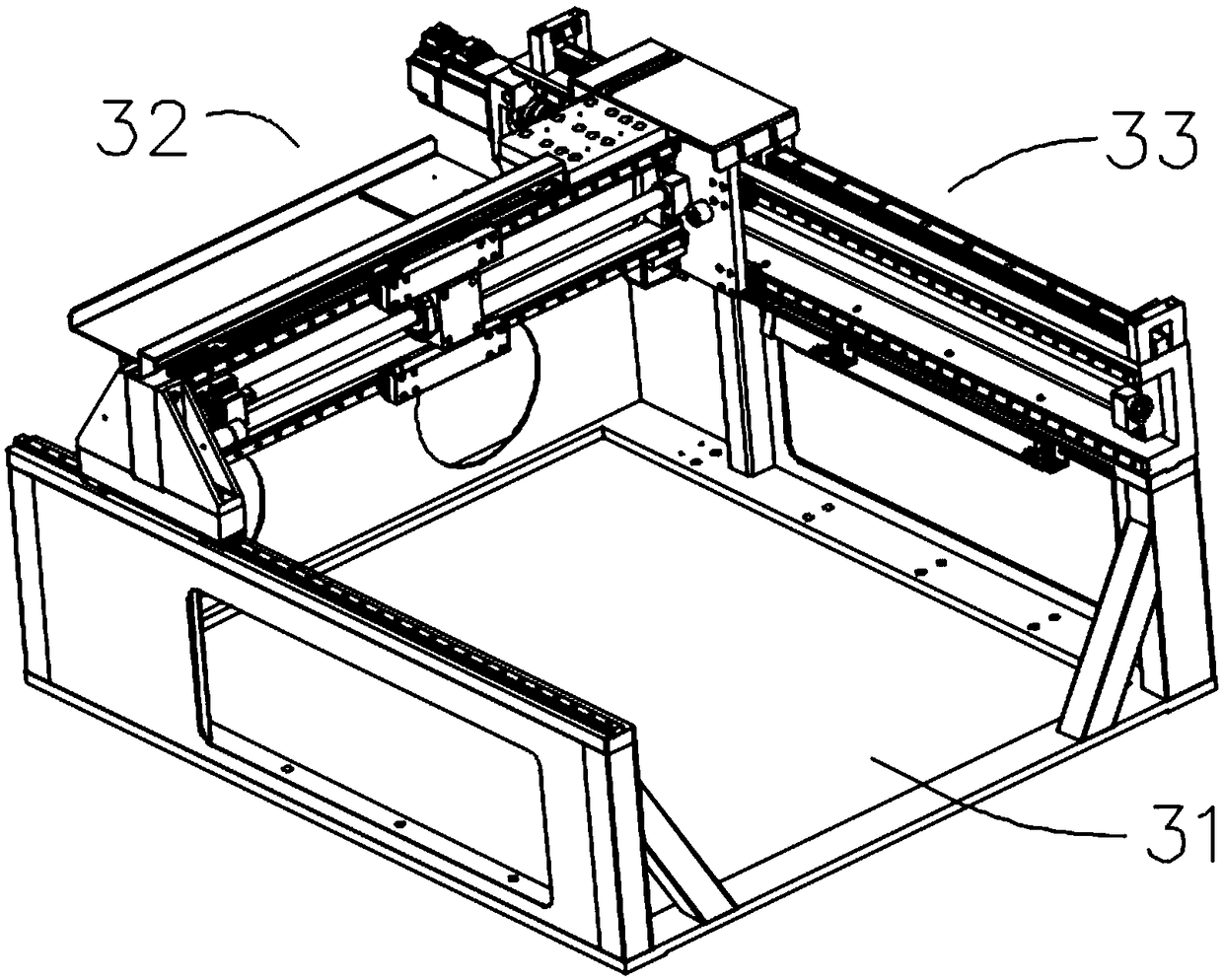

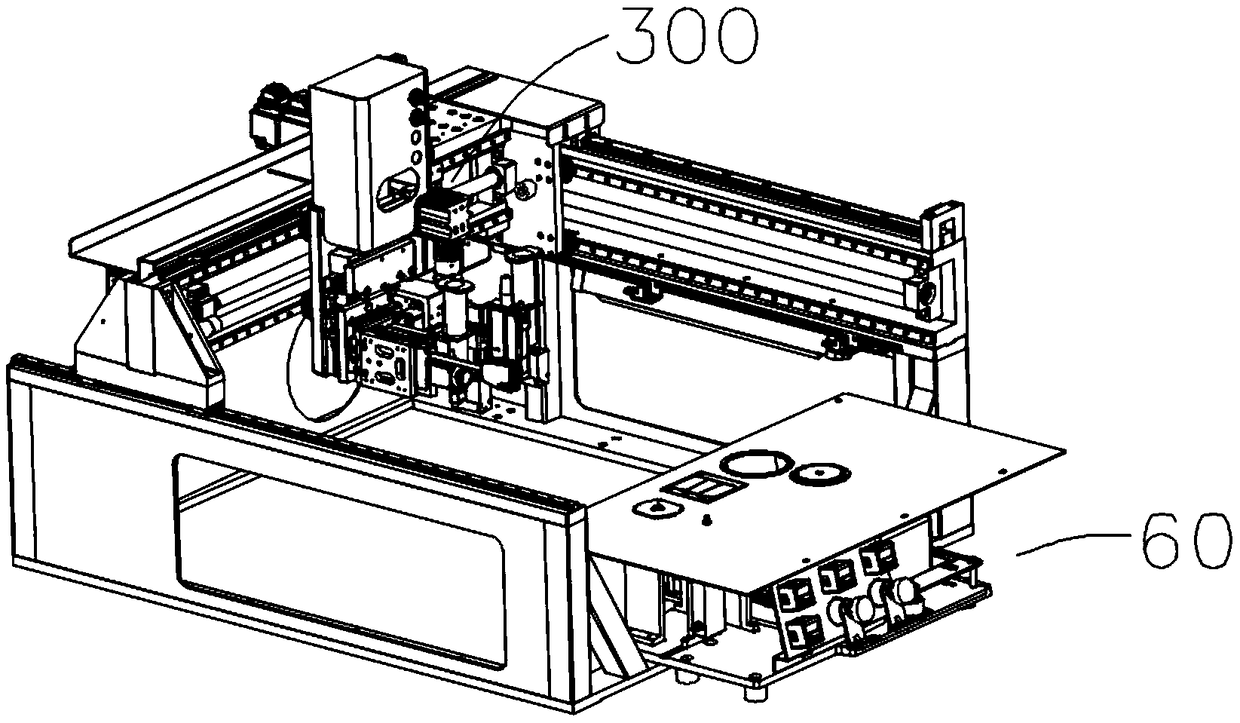

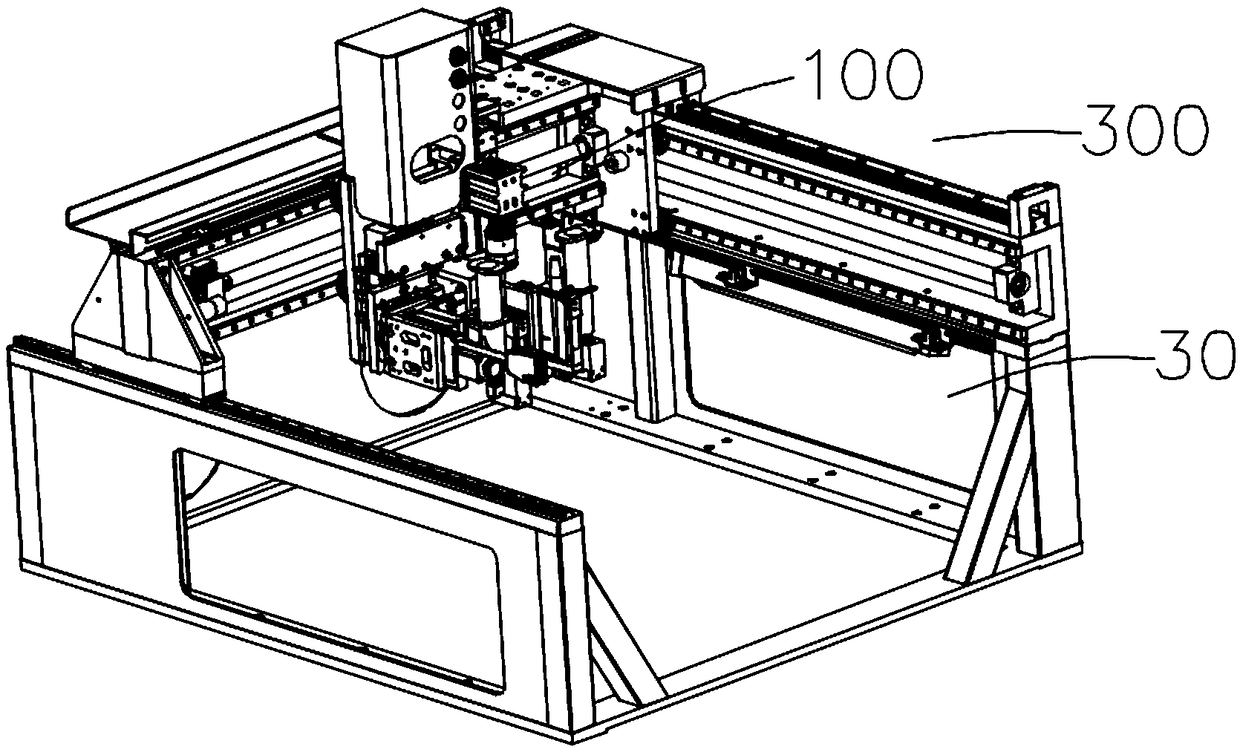

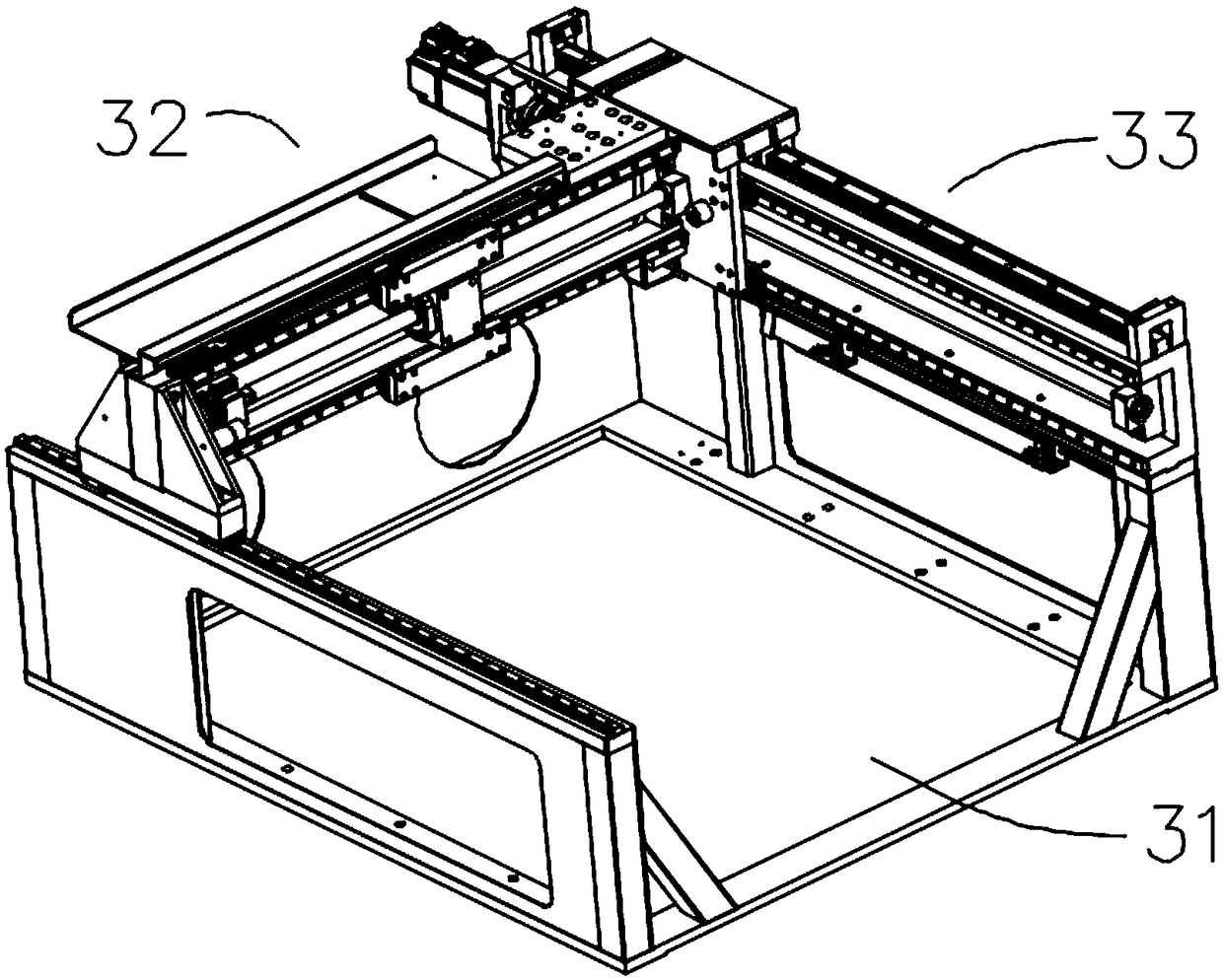

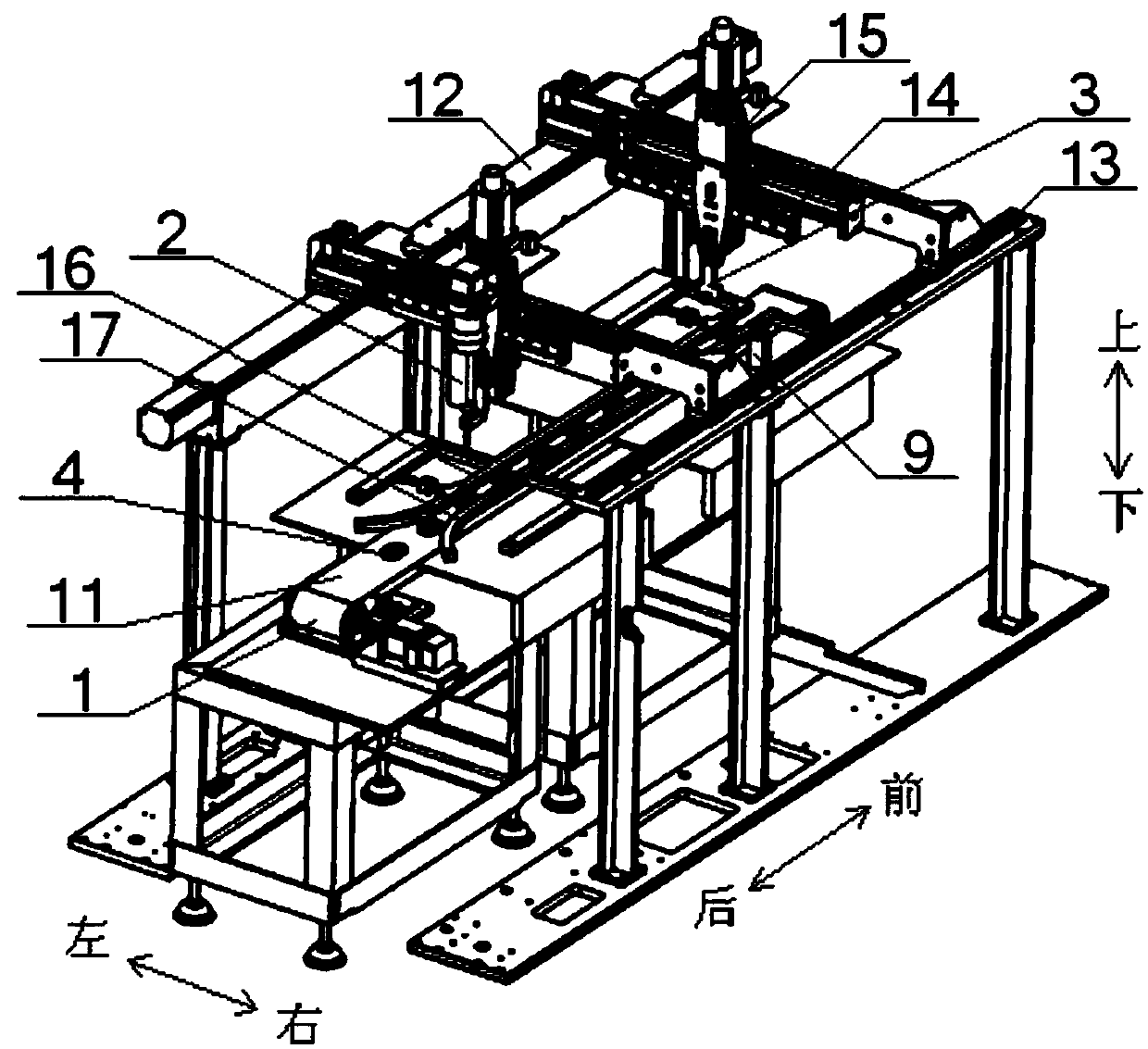

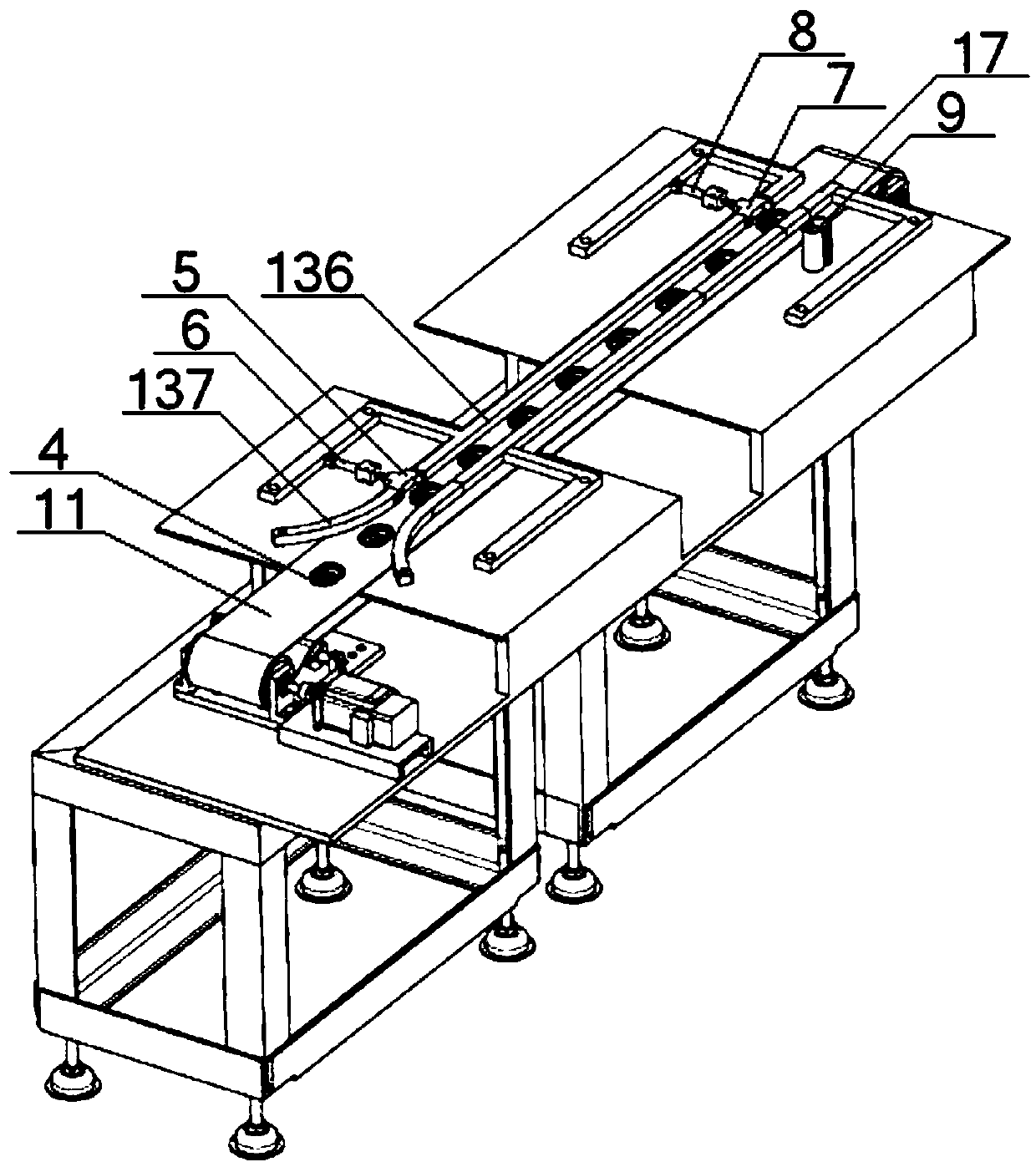

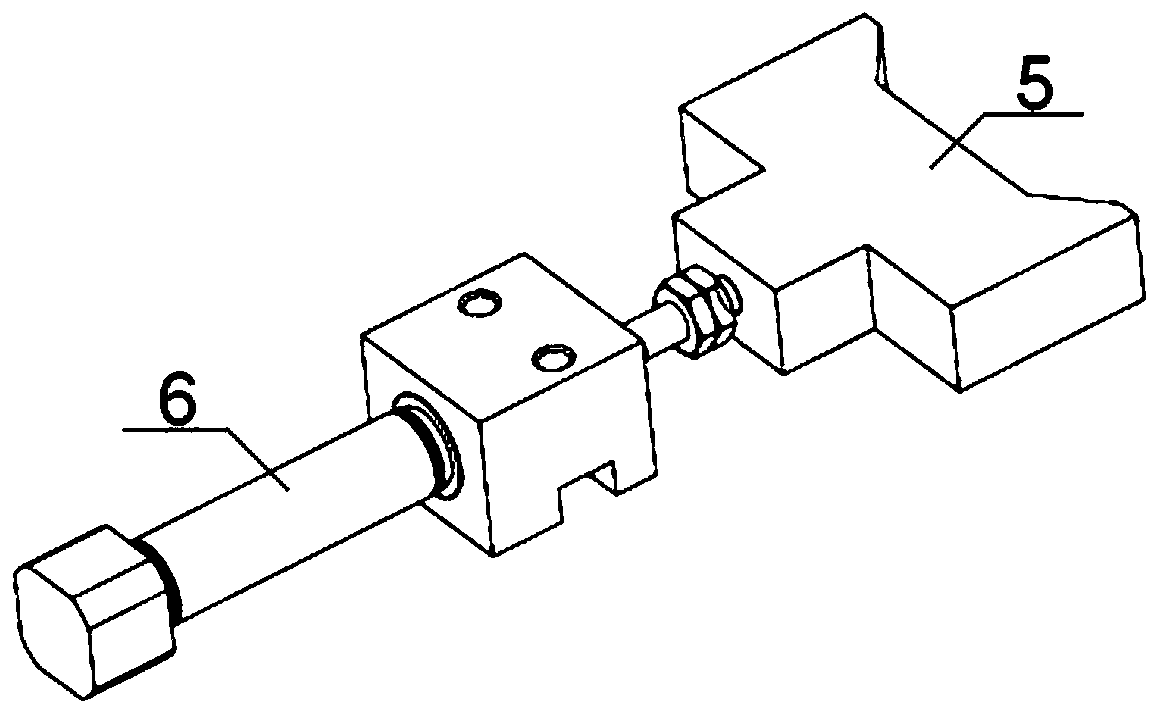

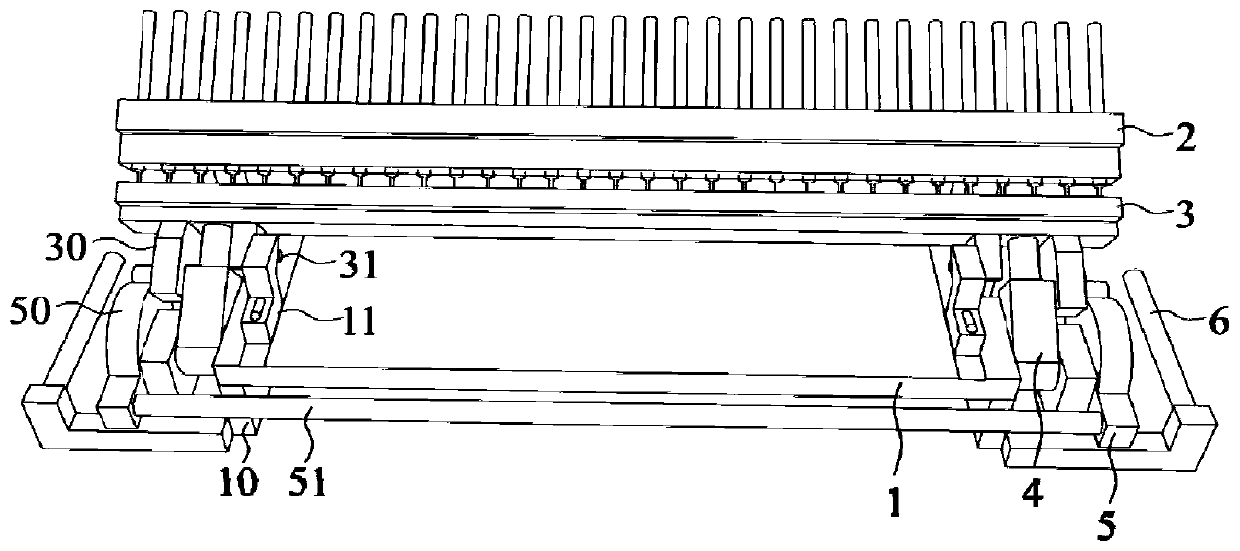

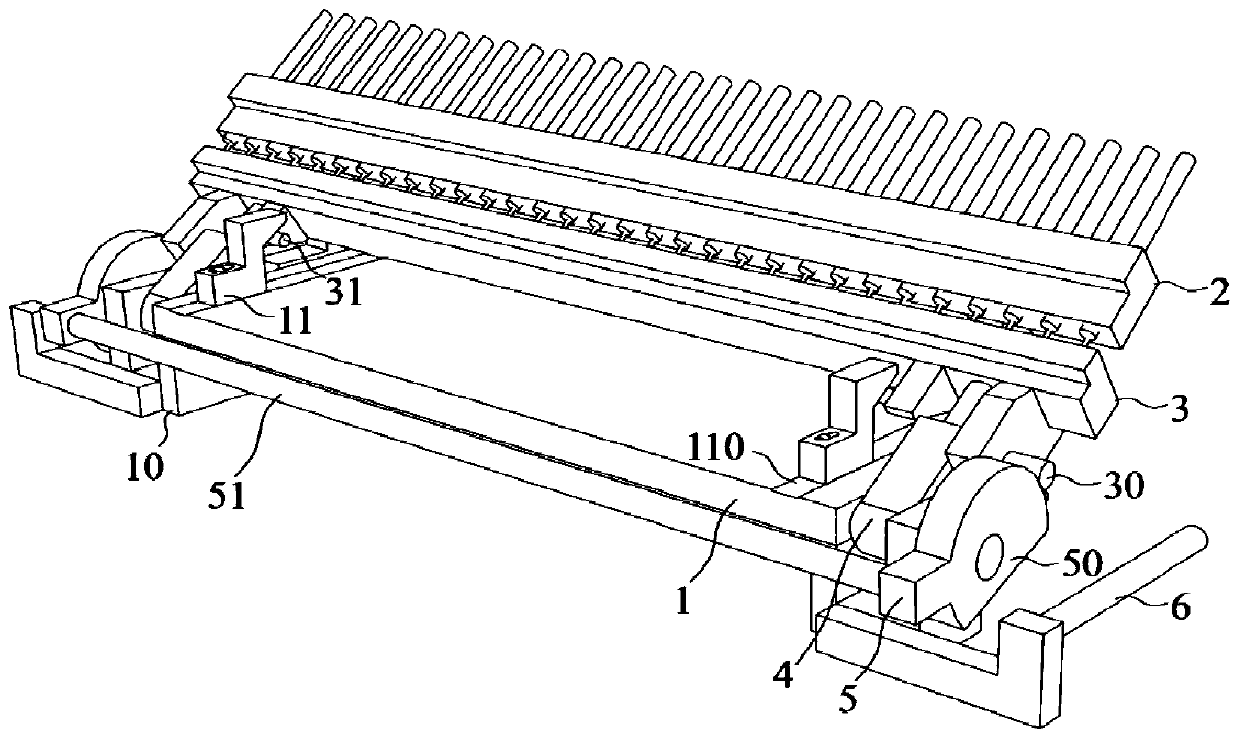

Dispensing machine with accurate positioning performance and consistent dispensing quantity

PendingCN107282370ASimple structureReasonable designLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a dispensing machine with accurate positioning performance and consistent dispensing quantity. The dispensing machine comprises a frame assembly body, an x-axis assembly body, a y-axis assembly body, a z-axis assembly body and a glue outlet assembly body; the frame assembly body comprises a square frame, a left bracket and a right bracket, and the left bracket and the right bracket are mounted on the two sides of the back of the square frame; horizontal operation platforms are mounted on the left and right sides of the square frame, the x-axis assembly body is mounted between the two horizontal operation platforms, the two ends of the y-axis assembly body are connected with the upper end of the left bracket and the upper end of the right bracket respectively, the z-axis assembly body is mounted on the y-axis assembly body, and the glue outlet assembly body is mounted on the front side of the z-axis assembly body; a workpiece platform is mounted on the upper side of the x-axis assembly body, an x-axis displacement sensor is mounted on the left side of the front end of the x-axis assembly body, a y-axis displacement sensor is mounted on the lower side of the right end of the y-axis assembly body, and a z-axis displacement sensor is mounted on the left side of the lower end of the z-axis assembly body. The dispensing machine has the advantages that positioning can be accurate, the dispensing quantity is consistent, the scrap rate of parts is reduced, and the glue is saved.

Owner:XIAN UNIV OF SCI & TECH

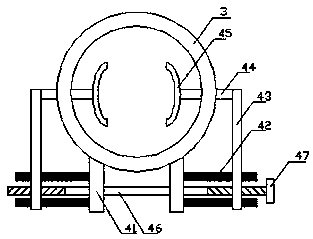

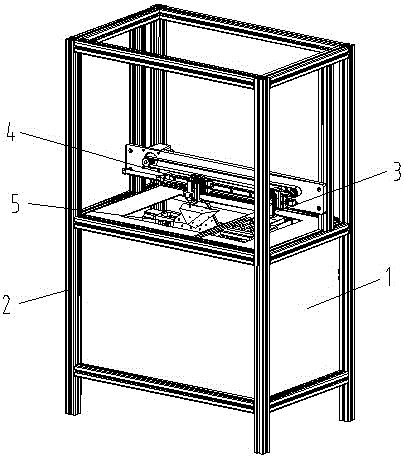

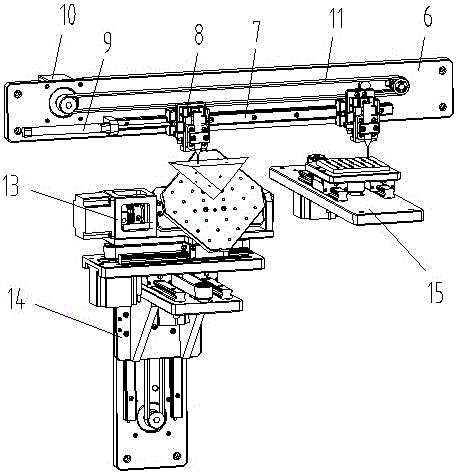

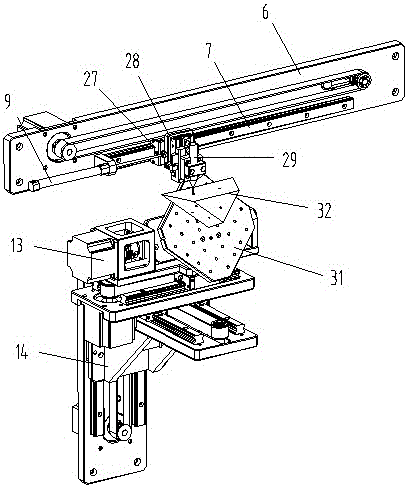

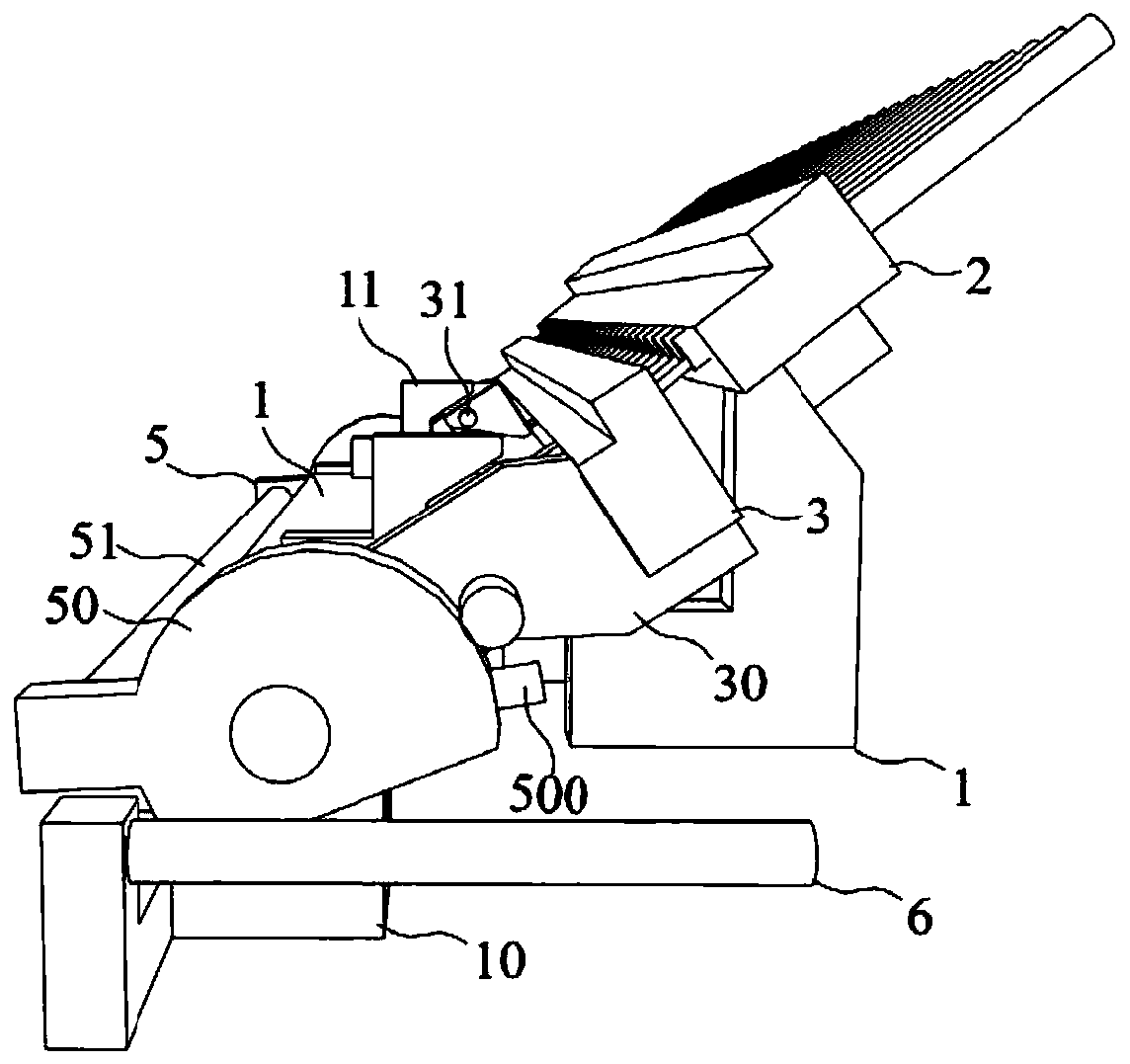

Automatic glue dispensing machine applicable to irregular products

ActiveCN106807589ARealize multi-surface dispensingFlexible adjustmentLiquid surface applicatorsCoatingsDistribution controlEngineering

The invention relates to an automatic glue dispensing machine applicable to irregular products. The automatic glue dispensing machine comprises a machine frame. A power distribution control cabinet and an irregular product glue dispensing mechanism are arranged on the machine frame. An irregular product carrying mechanism matched with the irregular product glue dispensing mechanism is arranged below the irregular product glue dispensing mechanism. The irregular product carrying mechanism comprises an irregular product carrying device and an irregular product movable device connected with the irregular product carrying device. The irregular product carrying device comprises a swing plate which is arranged on the irregular product movable device obliquely. An installation rotary shaft is arranged on the swing plate and connected with a rotation motor arranged on the swing plate through a rotary belt and a synchronous wheel. The installation rotary shaft is fixedly connected with an irregular product carrier. According to the automatic glue dispensing machine, the installation rotary shaft is arranged on the oblique swing plate, the irregular product carrier is installed on the installation rotary shaft arranged on the swing plate, then, the rotation motor can drive the irregular product carrier to rotate, and accordingly multi-surface glue dispensing of the irregular multi-surface products can be achieved.

Owner:天长市富达电子科技股份有限公司

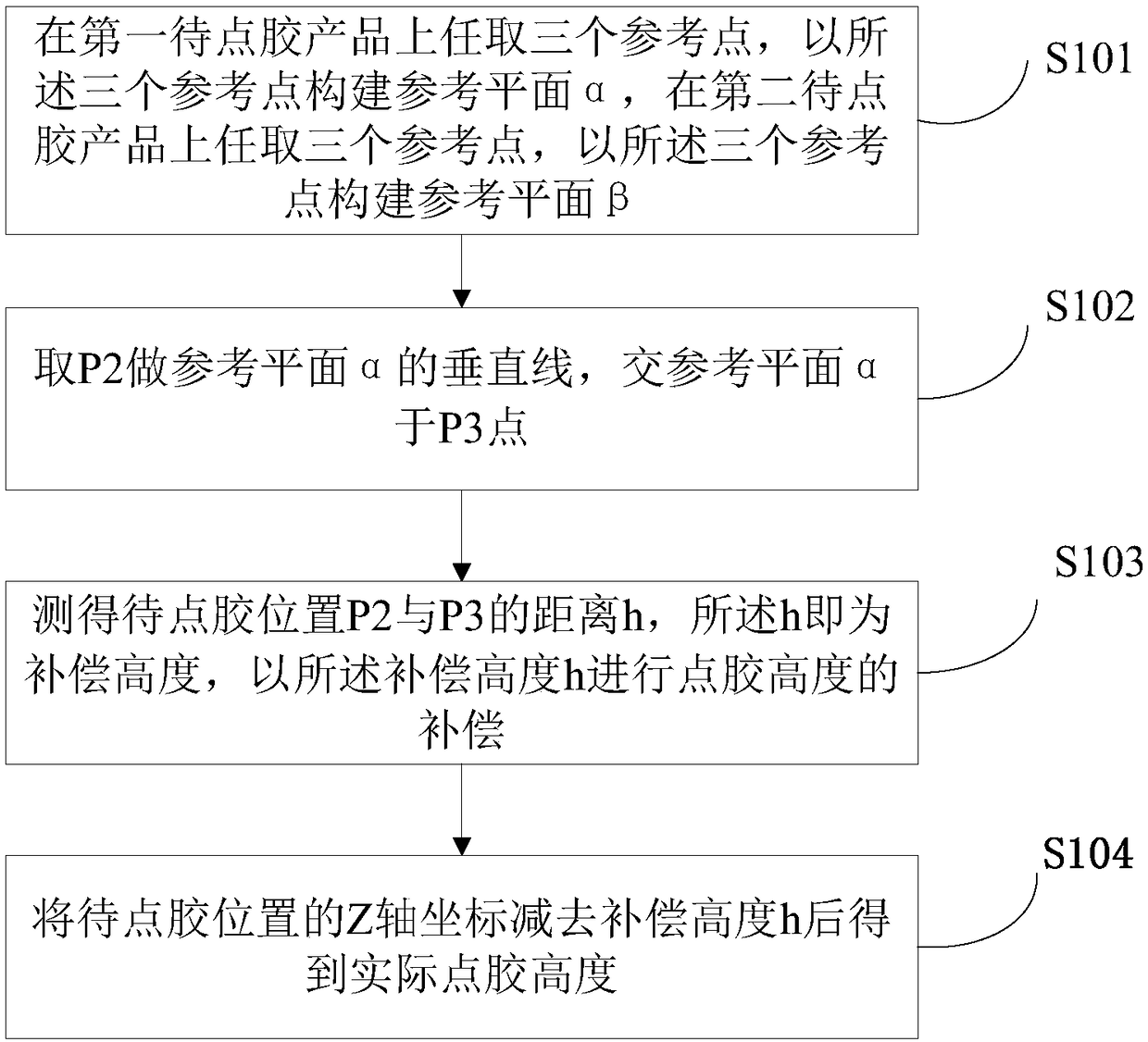

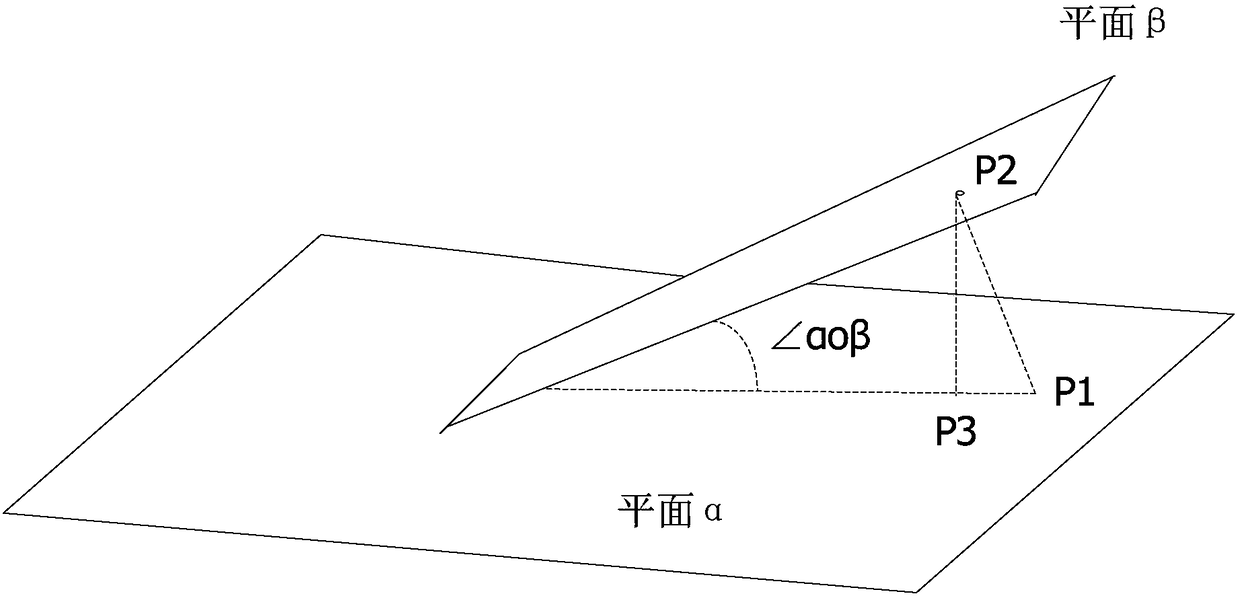

Dispensing height compensating method and device

ActiveCN108620288AWill not affect the dispensing effectImprove dispensing efficiencyLiquid surface applicatorsCoatingsEngineeringHeight difference

The invention discloses a dispensing height compensating method and a dispensing height compensating device, and relates to the technical field of dispensing. The dispensing height compensating methodcomprises the following steps: randomly taking three reference points on a first product to be dispensed, constructing a reference plane alpha with the three reference points, randomly taking three reference points on a second product to be dispensed, and constructing a reference plane beta with the three reference points, wherein the reference plane alpha is provided with a position P1 to be dispensed, the reference plane beta is provided with a position P2 to be dispensed, and the position P1 to be dispensed and the position P2 to be dispensed are the same position on the product to be dispensed; taking the P2 for drawing a vertical line of the reference plane alpha, and enabling the vertical line to intersect with the reference plane alpha at a point P3; measuring a distance h betweenthe position P2 to be dispensed and the P3, wherein the h is compensating height, and using the compensating height h for compensating dispensing height of the second point P2 to be dispensed. Duringbatch dispensing, the dispensing effect is not affected by height difference caused by uneven displacement of the product to be dispensed, so that the dispensing effect is more stable.

Owner:SHENZHEN TENSUN IND EQUIP

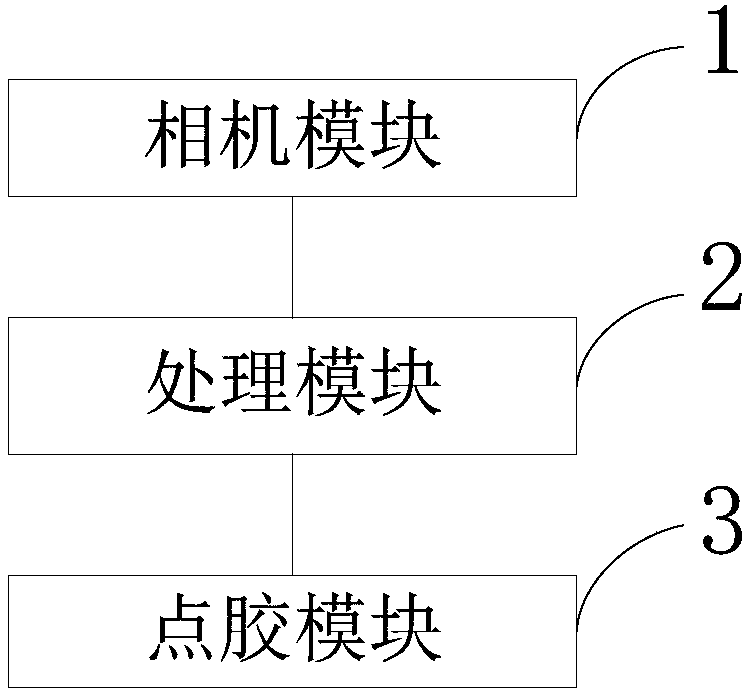

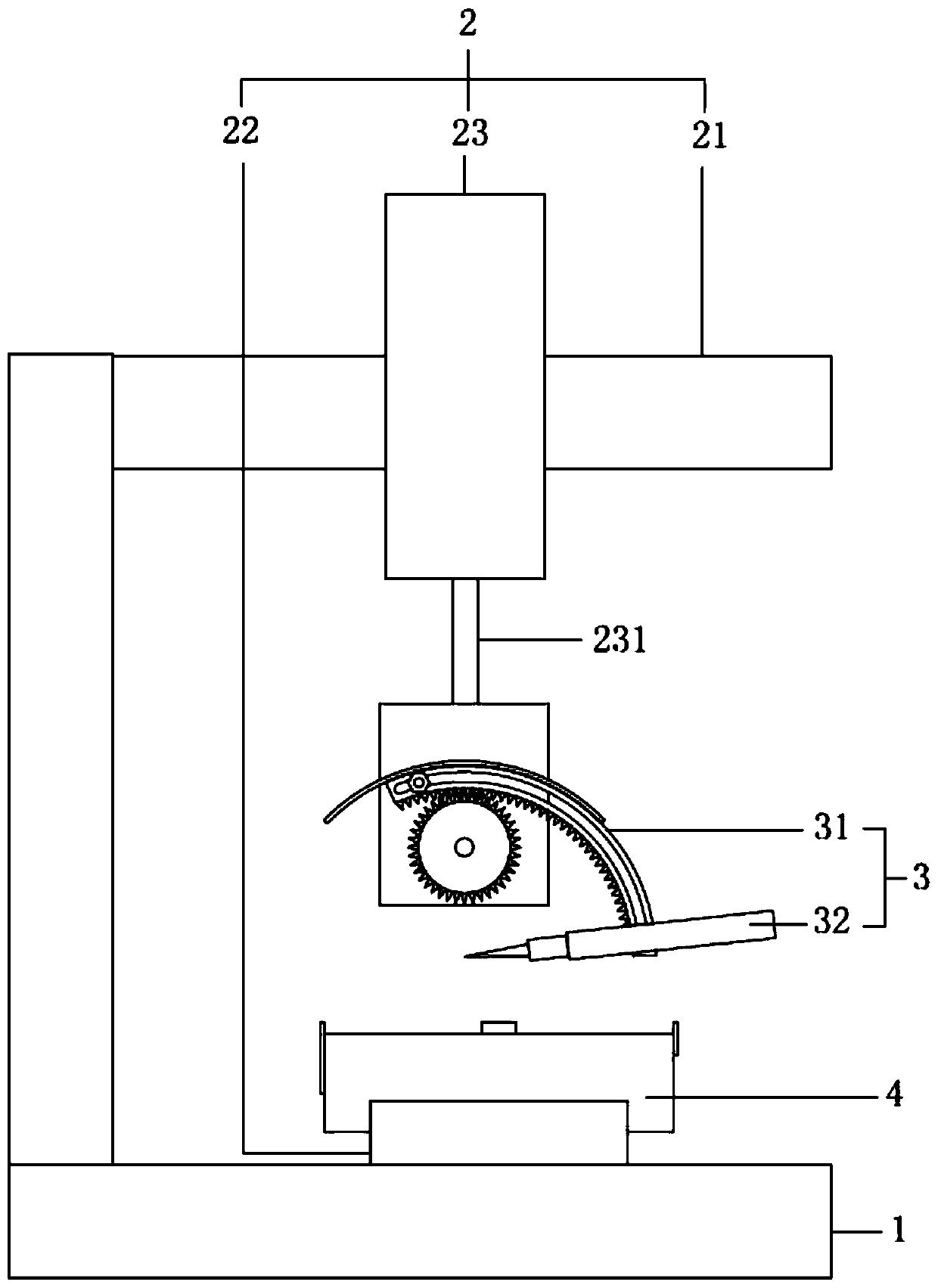

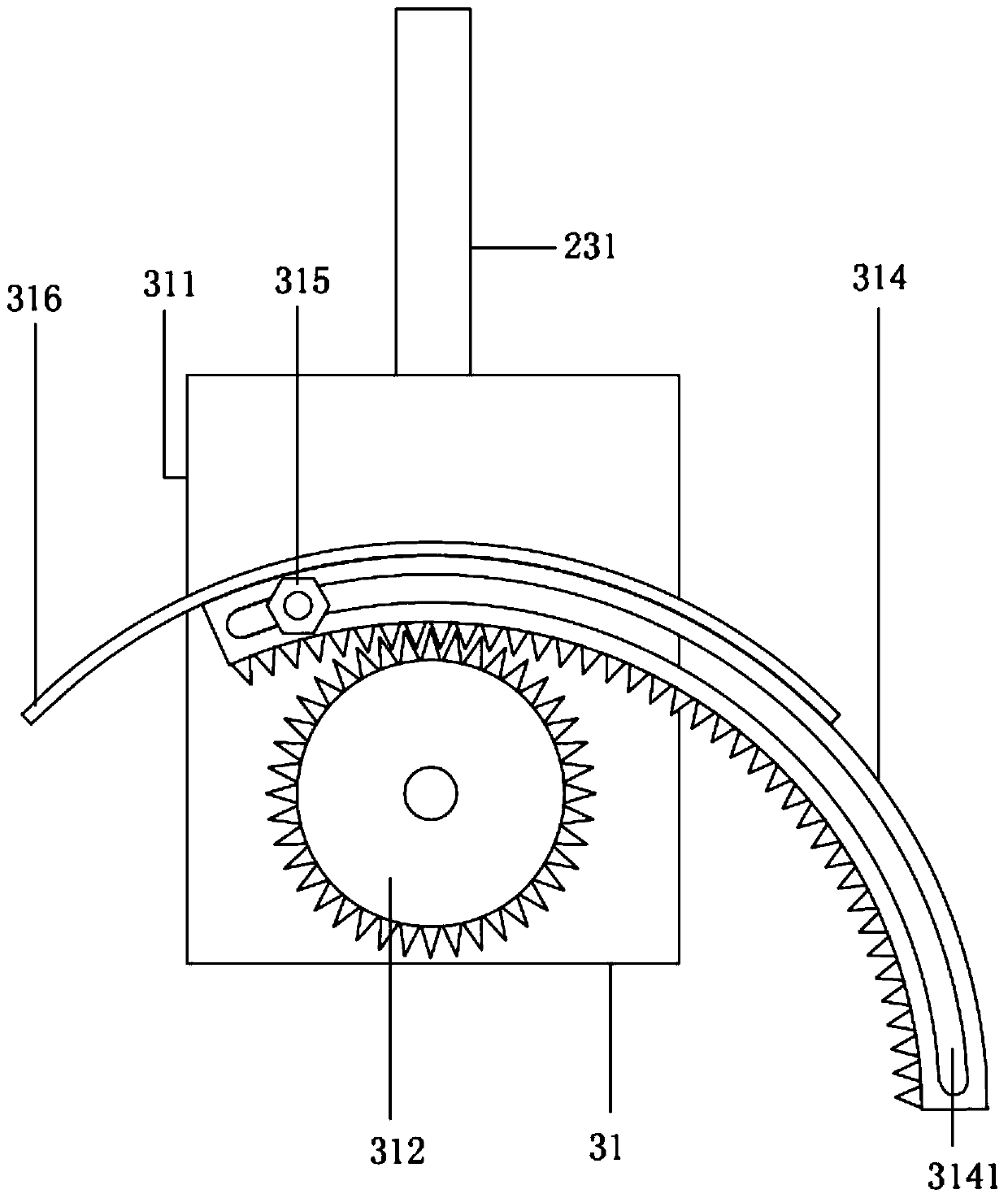

Glue dispenser with adjustable glue dispensing angle

PendingCN111330807AEasy to adjustDispensing Angle AdjustmentLiquid surface applicatorsCoatingsCardboardGear wheel

The invention provides a glue dispenser with an adjustable glue dispensing angle. The glue dispenser comprises a base, a running gear and a glue dispensing mechanism; the running gear includes an X-axle running gear, a Y-axle running gear and a Z-axle running gear; the Y-axle running gear is fixedly mounted on the base; a load-bearing work platform is arranged on the Y-axle running gear; a first movable cardboard and a second movable cardboard are symmetrically arranged on the opposite side edges of the load-bearing work platform; the glue dispensing mechanism is fixedly arranged at the bottomof the Z-axle running gear; the glue dispensing mechanism comprises an adjusting mechanism and a glue dispensing head; the adjusting mechanism is fixedly arranged on a rotating shaft of the Z-axle running gear; and the glue dispensing head is fixedly arranged on the adjusting mechanism. According to the glue dispenser with the adjustable glue dispensing angle, a first gear on the adjusting mechanism is meshed with a sliding block, so that the glue dispensing angle of a glue dispensing tube can be adjusted more accurately, the glue dispensing position is more accurate, and the glue dispensingeffect is better.

Owner:苏州市吴通智能电子有限公司

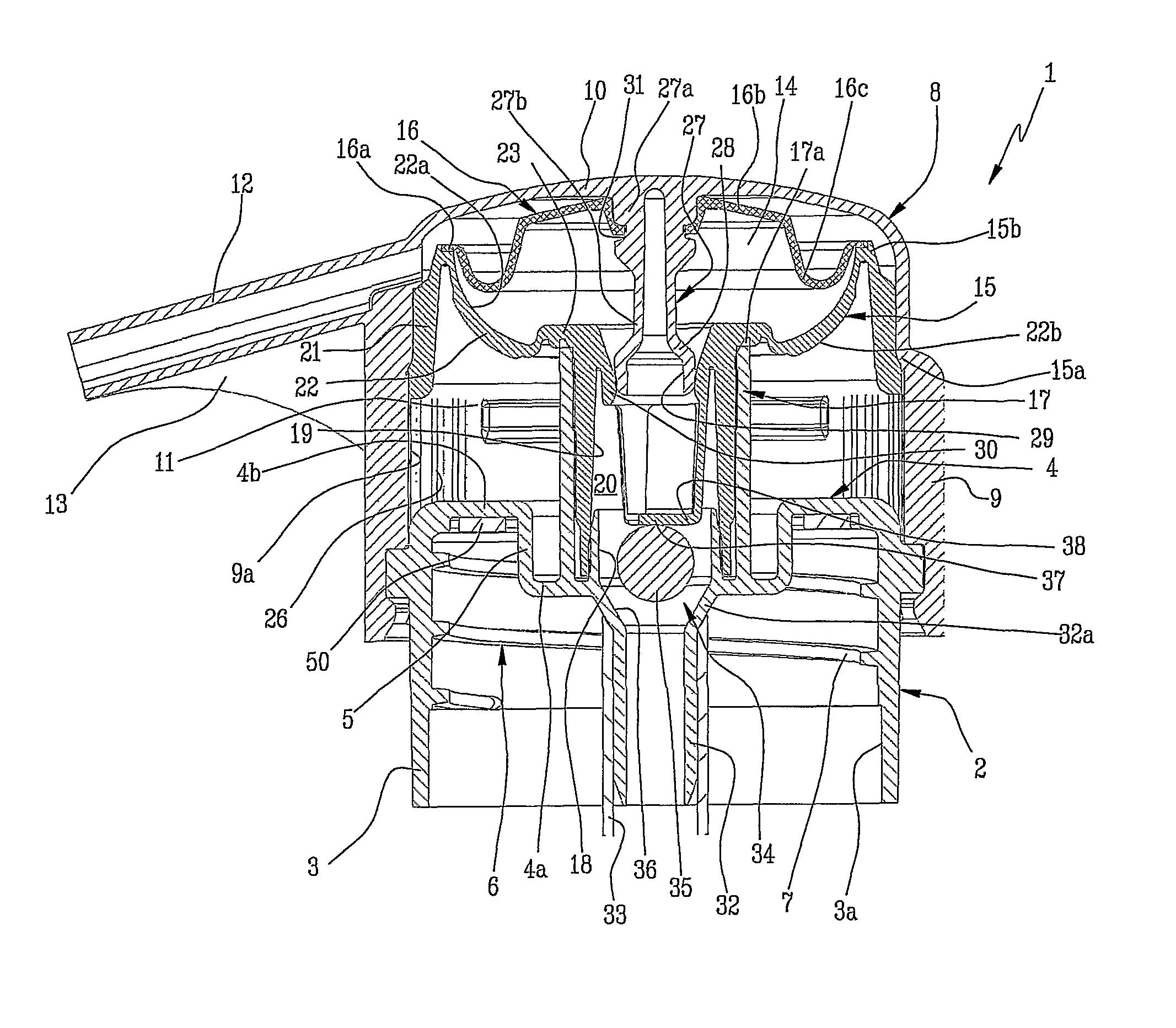

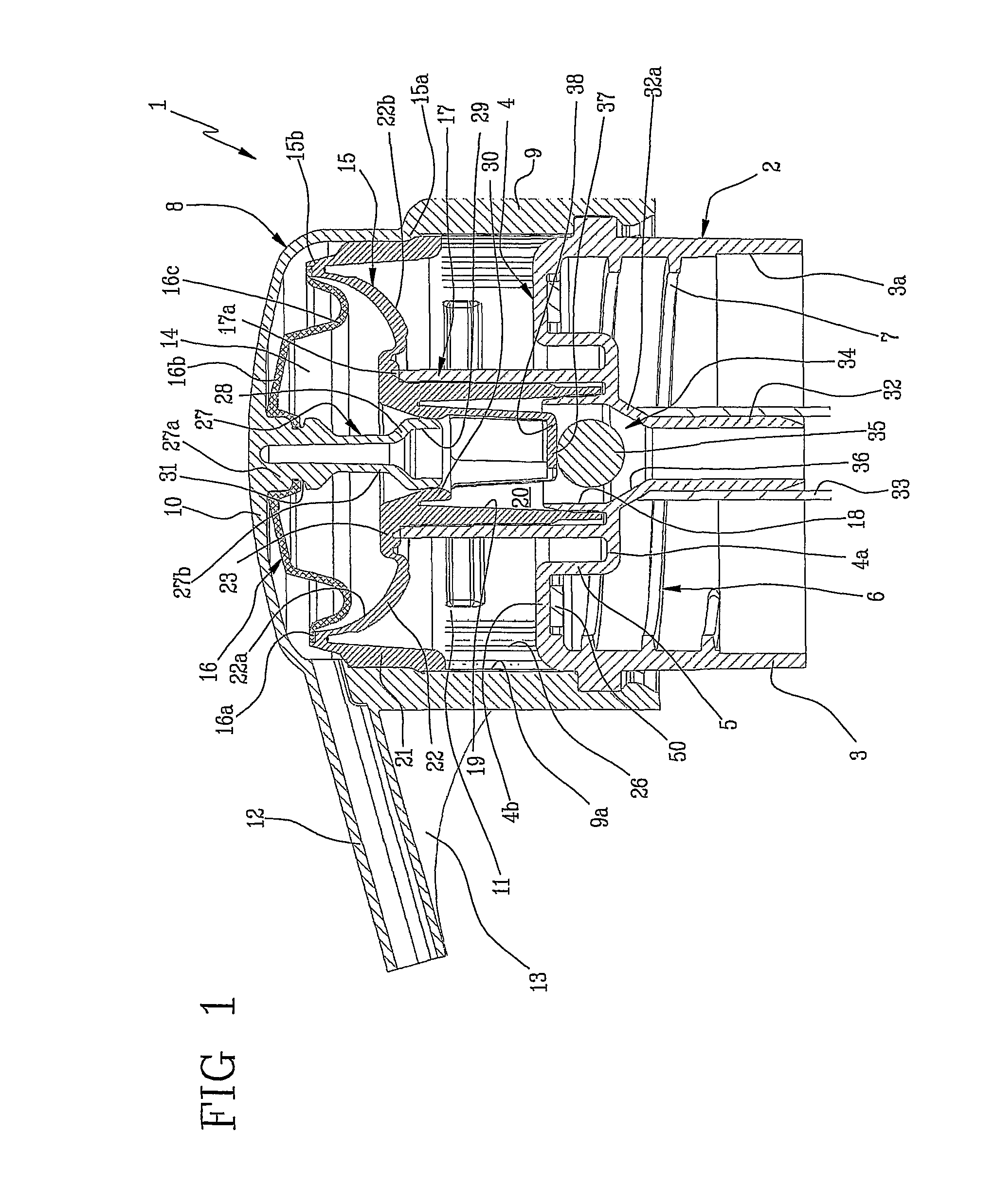

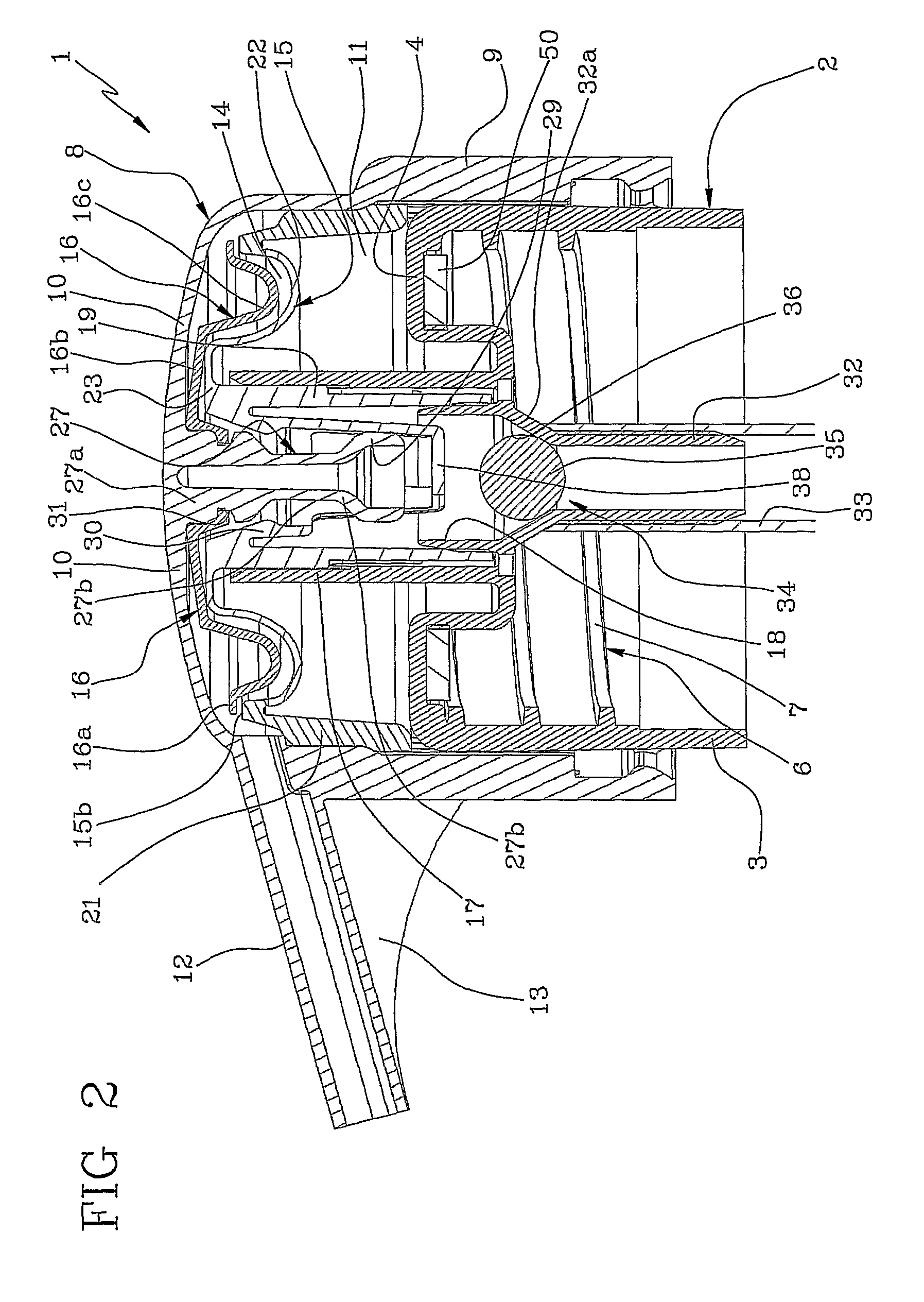

Dispenser of fluid products

ActiveUS8474661B2Improve dispensing effectEasy and pleasant to useClosure using stoppersSingle-unit apparatusBiomedical engineeringNozzle

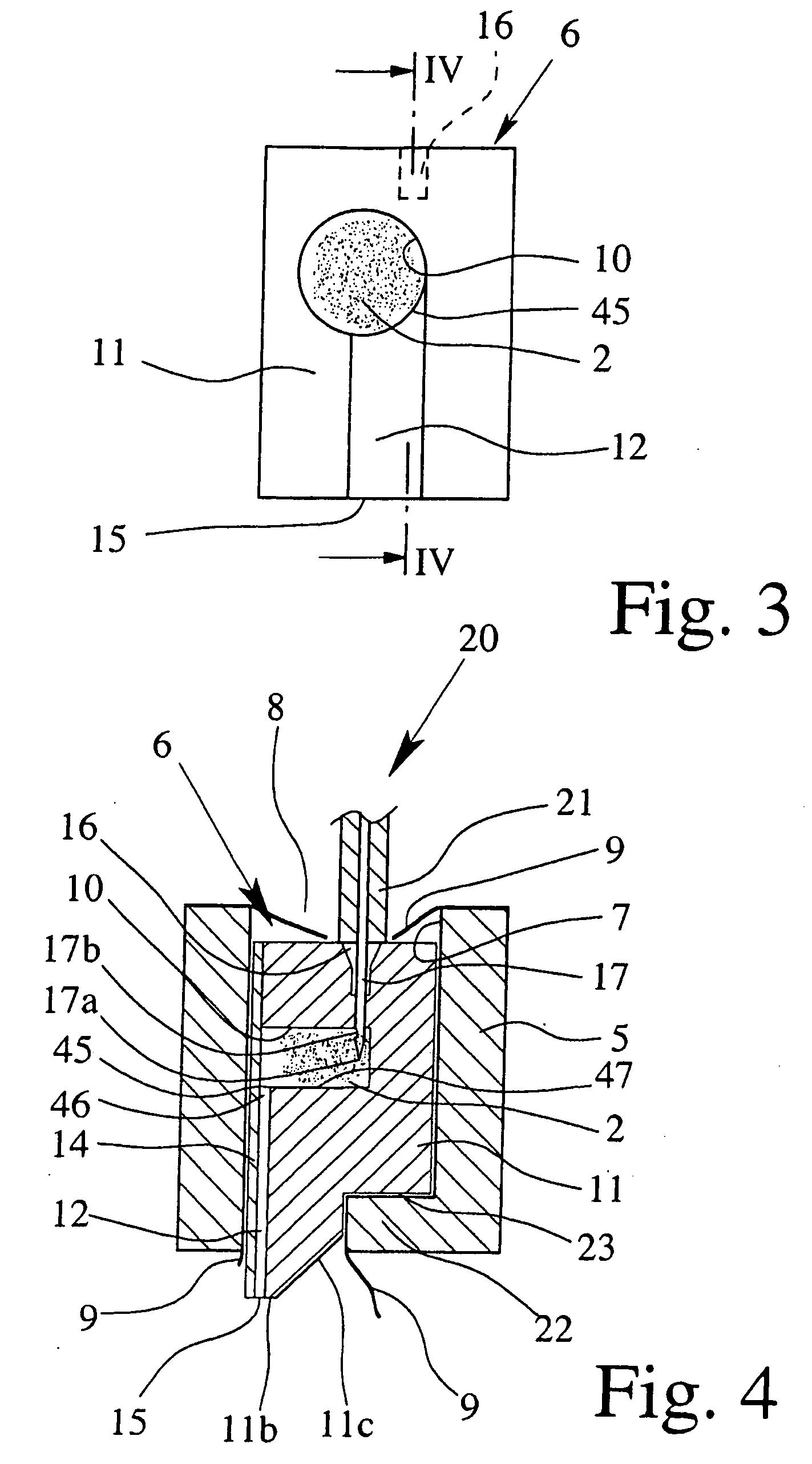

A dispenser of fluid products includes a ring nut (2) able to be associated to a container of a fluid product and a substantially hollow dispensing head, able to slide coaxially relative to the ring nut (2); the dispensing head (8) includes a dosing chamber (14) obtained within the dispensing head (8) and a dispensing nozzle (12) to allow the outflow of the fluid product; the dosing chamber (14) has a containment volume variable between a configuration of maximum volumetric capacity when the dosing chamber (14) is isolated and a configuration of minimum volumetric capacity; the dispenser further includes a deformable membrane (15) fastened to the ring nut (2) and a deformable disc-shaped body (16) fastened to the dispensing head (8) and defining the dosing chamber (14) in combination with the membrane (15).

Owner:APTAR ITAL

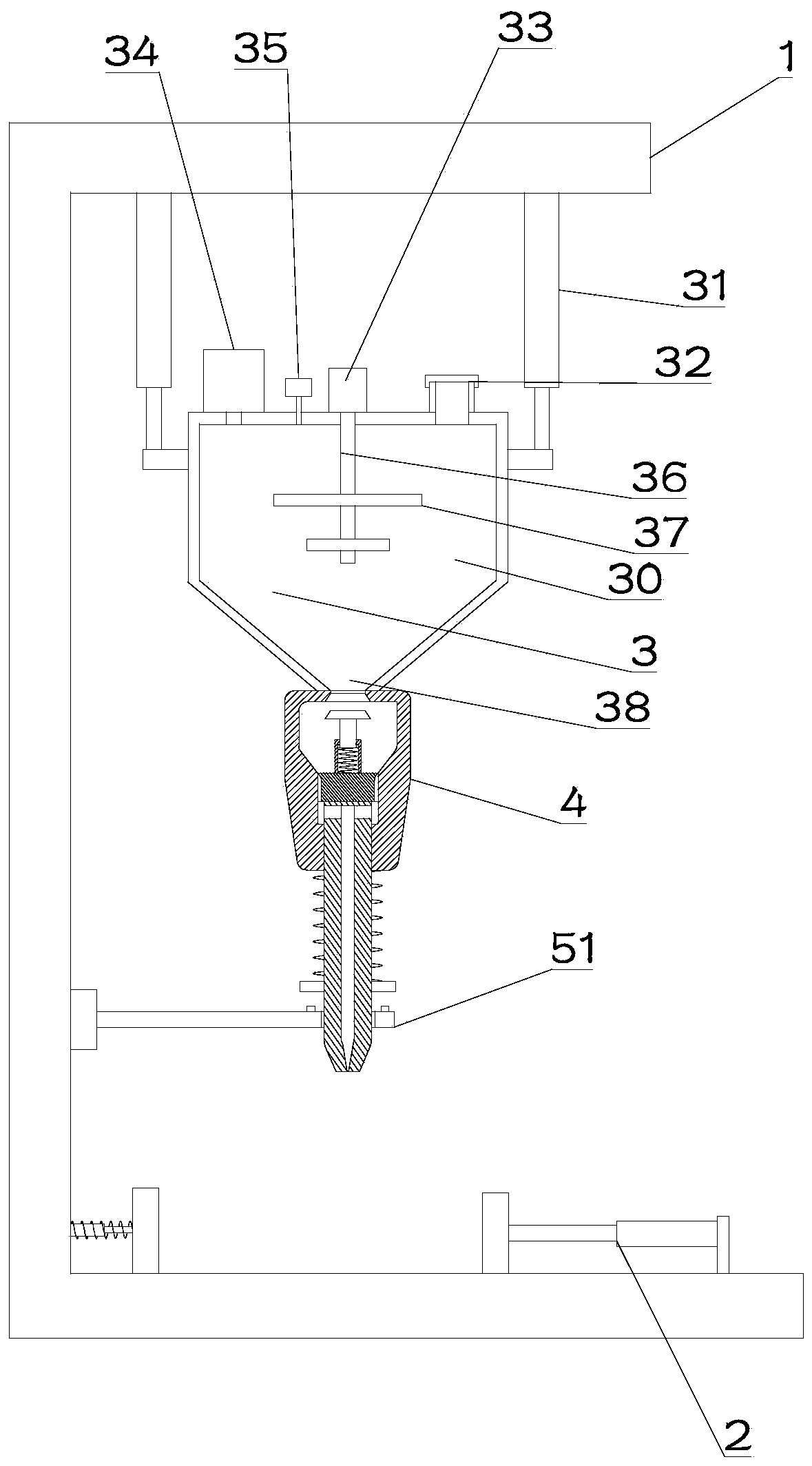

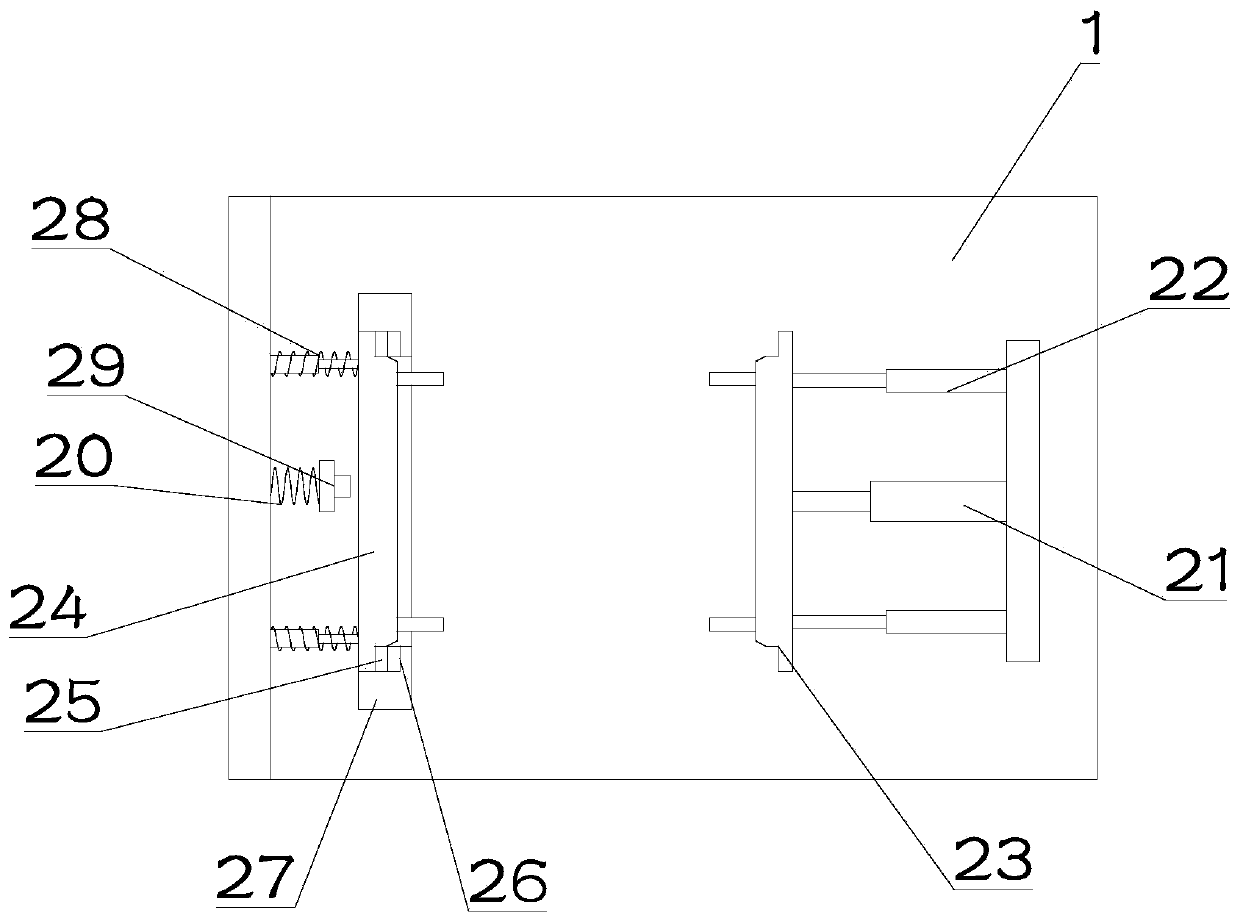

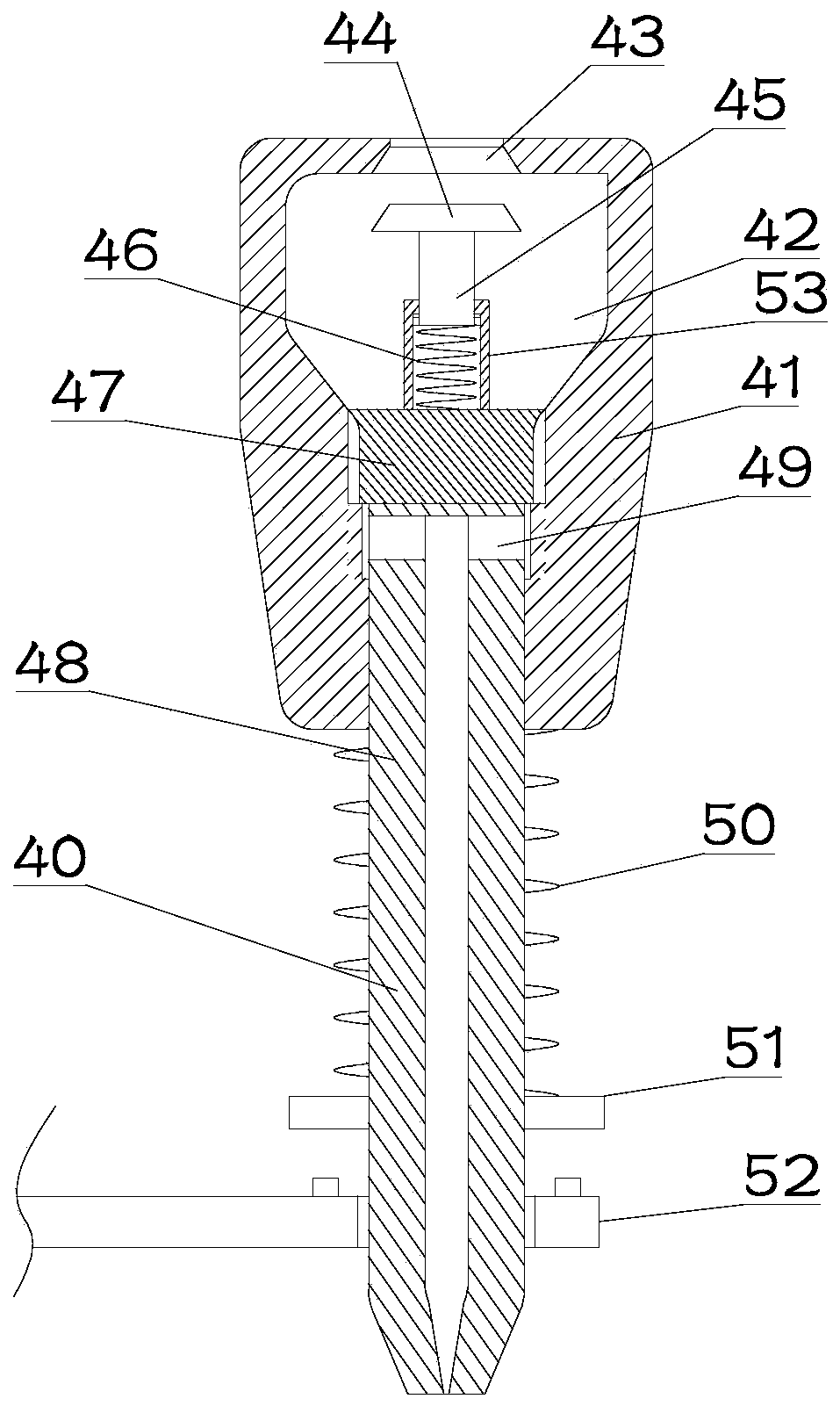

Glue dispensing device for electronic component

ActiveCN110918403AAvoid pinchingGuaranteed uniformityLiquid surface applicatorsCoatingsEngineeringElectronic component

The invention discloses a glue dispensing device for an electronic component, and relates to the technical field of electronic equipment production. The device comprises a frame. A clamping componentused for clamping a component is arranged at the bottom of the frame; a discharging component is arranged above the clamping component; the discharging component is installed under a material storagecomponent; the discharging component is communicated with the material storage component; and the material storage component is installed on the frame. The clamping component comprises a clamping piece A and a clamping piece B which are arranged in a matched mode, wherein the clamping piece B is arranged in an installation hole in an installation piece, and the two sides of the clamping piece B are respectively provided with an adsorption piece 1 matched with an adsorption piece 2 on the installation piece, the adsorption pieces 1 and the adsorption pieces 2 are attracted together, and the adsorption pieces 2 are fixedly installed on the installation piece; the side, away from the clamping piece B, of the clamping piece A is connected to a telescopic cylinder A and a guide rod; and the telescopic cylinder A and the guide rod are fixedly installed on the frame. Components are well protected, and the glue dispensing effect is good.

Owner:黄昌宾 +1

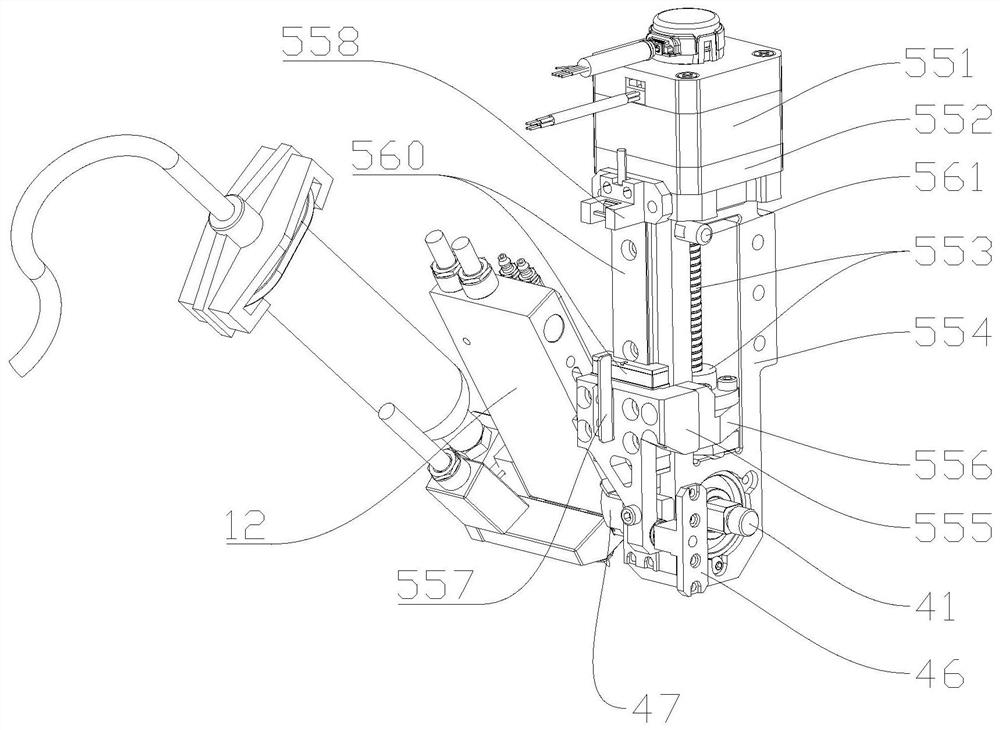

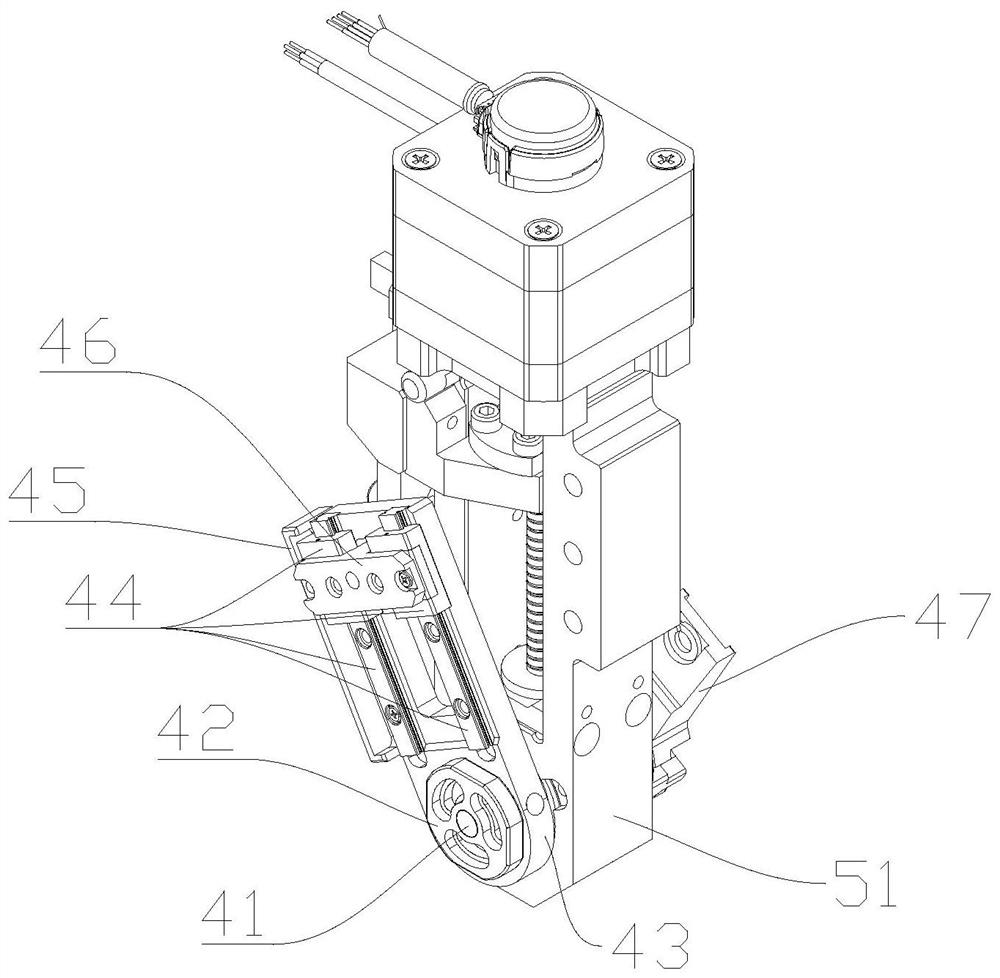

Dispensing device and dispensing equipment

PendingCN112275543AImprove dispensing effectLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a dispensing device, and belongs to the field of dispensing manufacturing. The dispensing device comprises a dispensing mechanism, a driving mechanism, a movable block, a follow-up block and a swing frame, wherein the movable block is connected with the driving mechanism; the driving mechanism is used for driving the movable block to reciprocate in the driving direction; one end of the follow-up block is hinged to the movable block; the other end of the follow-up block is connected to the swing frame in a sliding mode; the swing frame and the dispensing mechanism are both fixedly installed on the same rotating shaft; and when the follow-up block moves along with the movable block and slides relative to the swing frame, the swing frame and the dispensing mechanism can be driven to rotate around the rotating shaft at the same time. The problems that in the prior art, due to the fact that the inclination angle of a dispensing spray head is fixed and cannot easily meet the dispensing requirement of special-shaped coating faces such as a conical face and a curved face due to electronic product updating, and the dispensing effect is poor are solved; the dispensingrequirement of the special-shaped coating faces is met; and the dispensing effect is improved.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

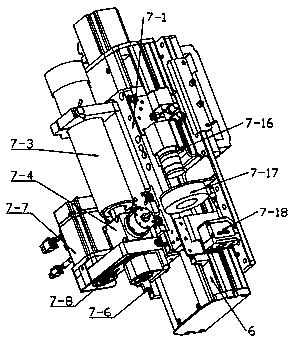

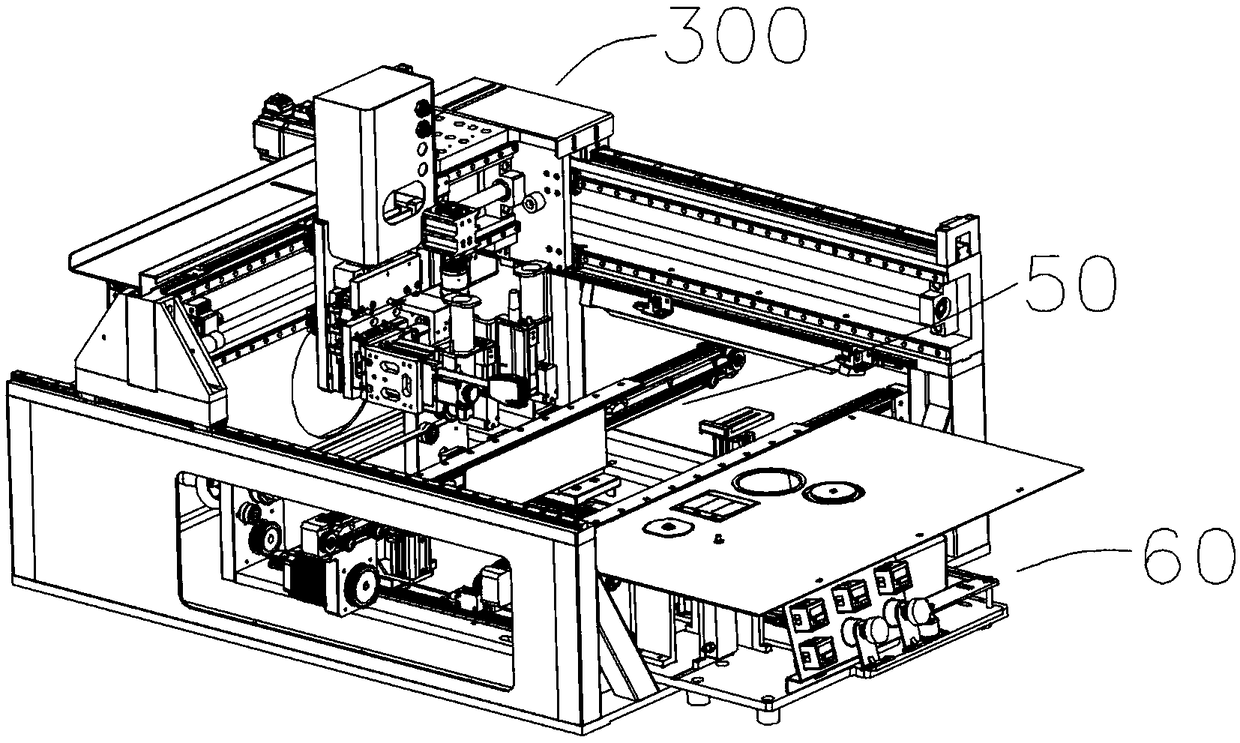

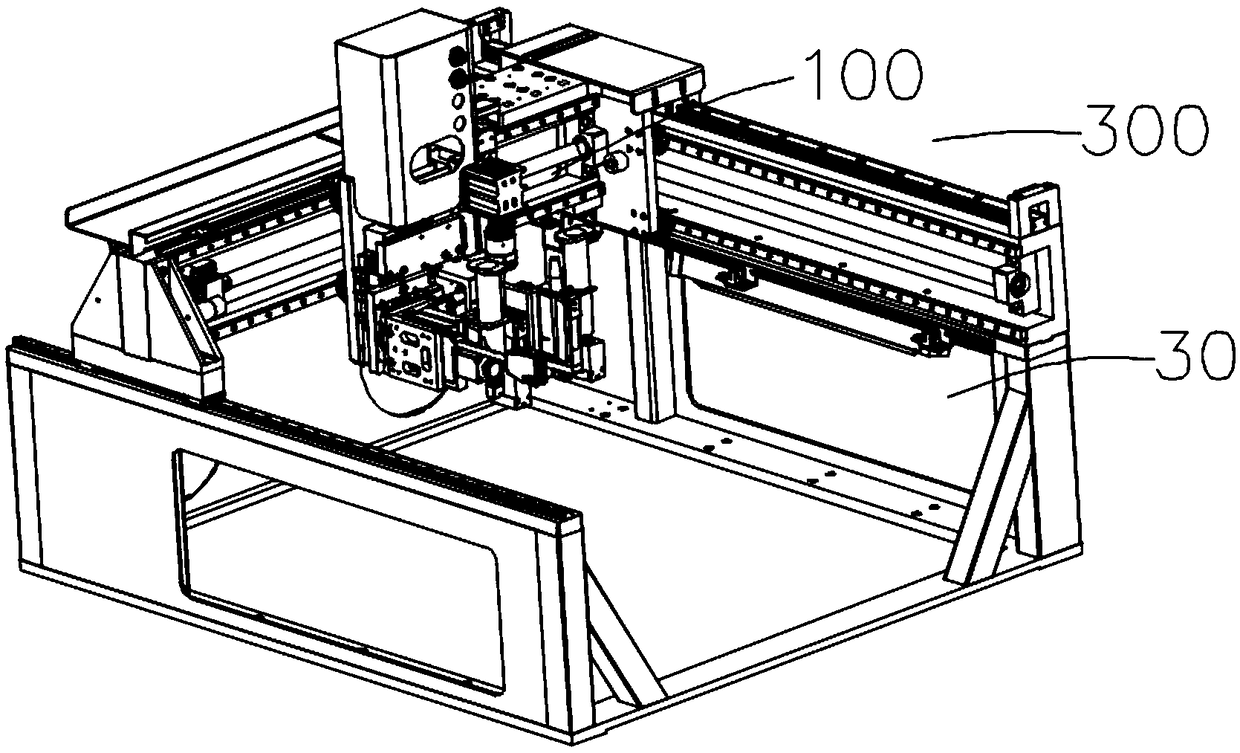

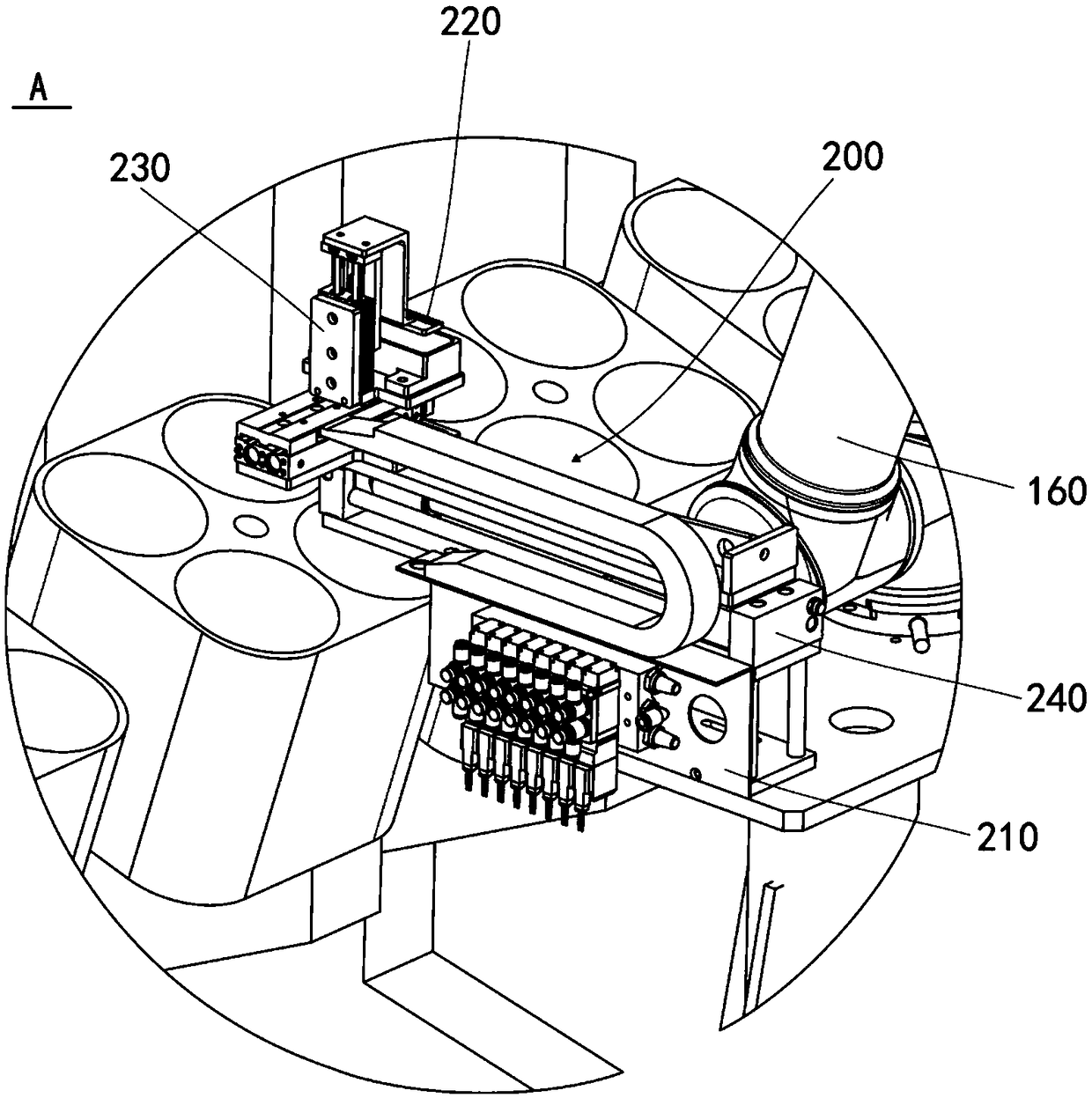

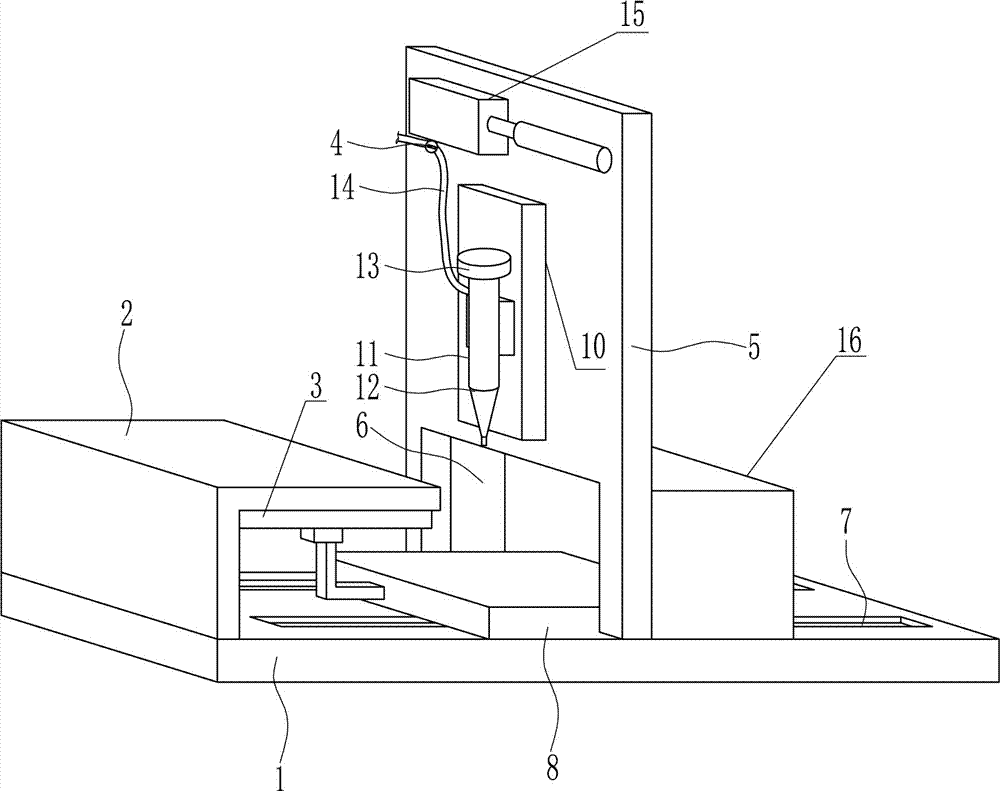

Double valve piezoelectric injection online dispensing machine and dispensing method

ActiveCN109395976AGuaranteed positioningStable deliveryLiquid surface applicatorsFinal product manufactureElectricityEngineering

The invention discloses a double valve piezoelectric injection online dispensing machine which comprises a double valve dispensing device, a carrier positioning assembly line and an industrial weighing structure. The double valve dispensing device is used for dispensing, the carrier positioning assembly line is used for transporting and positioning a carrier, the carrier carries a product to be dispensed, and the industrial weighing structure is used for weighing whether the double valve dispensing device meets customer requirements. After the carrier is positioned by the carrier positioning assembly line, the double valve dispensing device dispenses the product. The machine not only ensures the positioning and the conveying of the product to be dispensed on the carrier, but also ensures the glue volume required by customers, and is high in degree of automation, high in dispensing efficiency and good in dispensing effect.

Owner:SUZHOU RS TECH

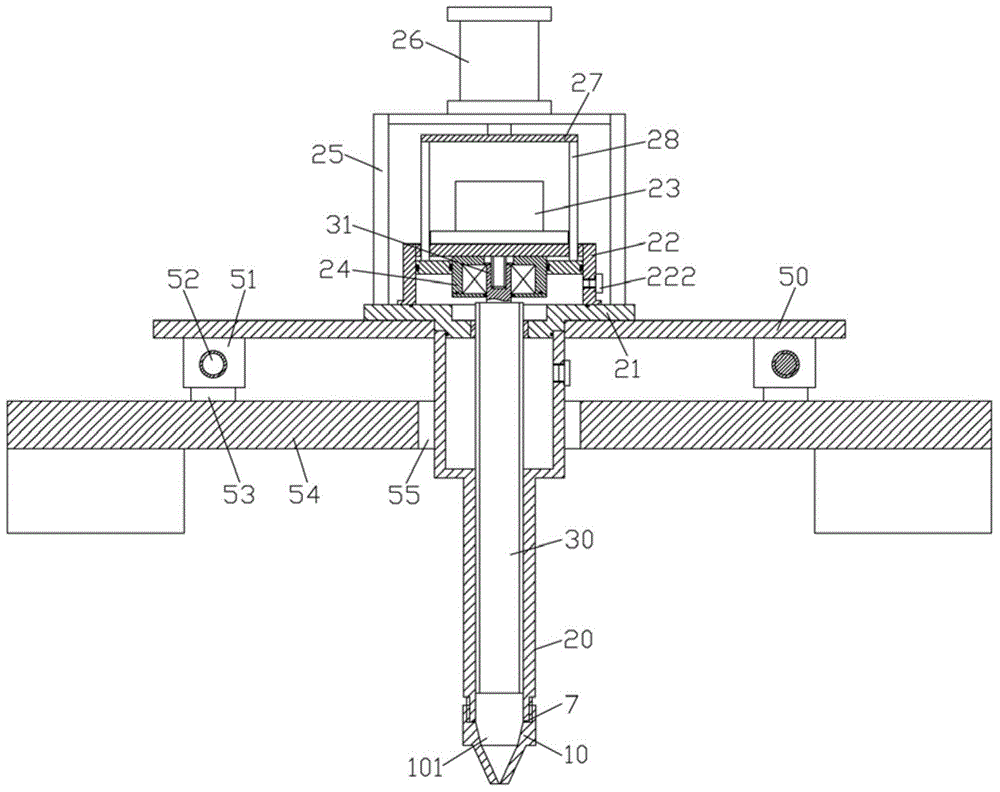

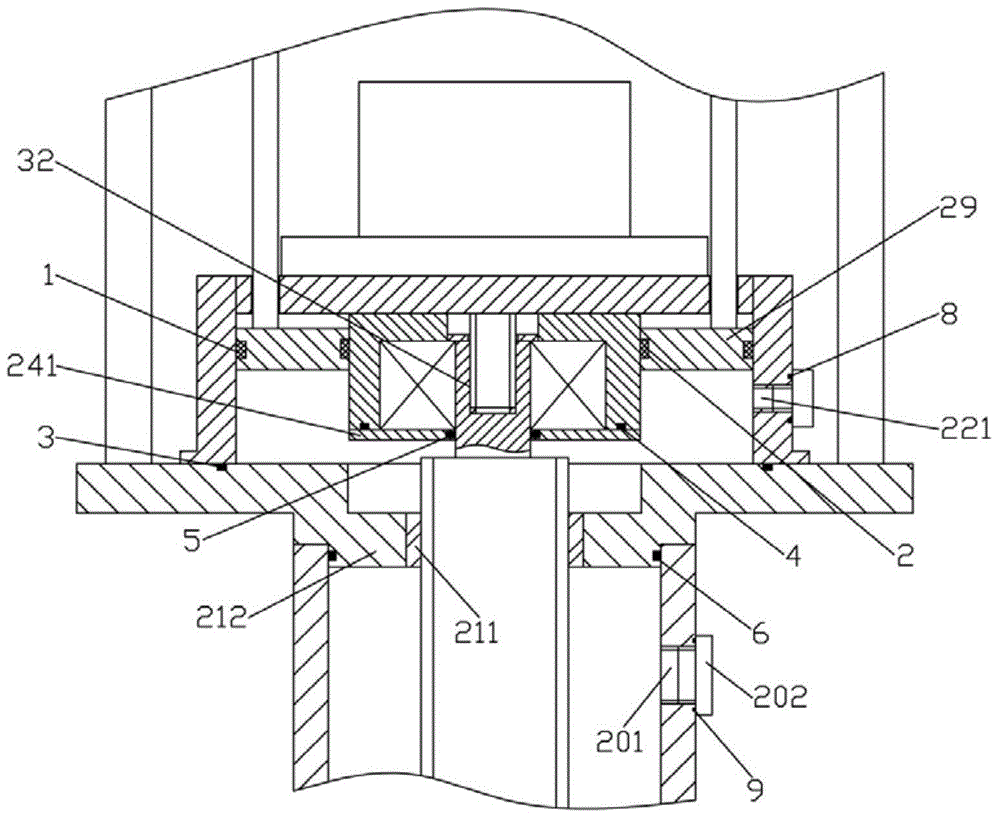

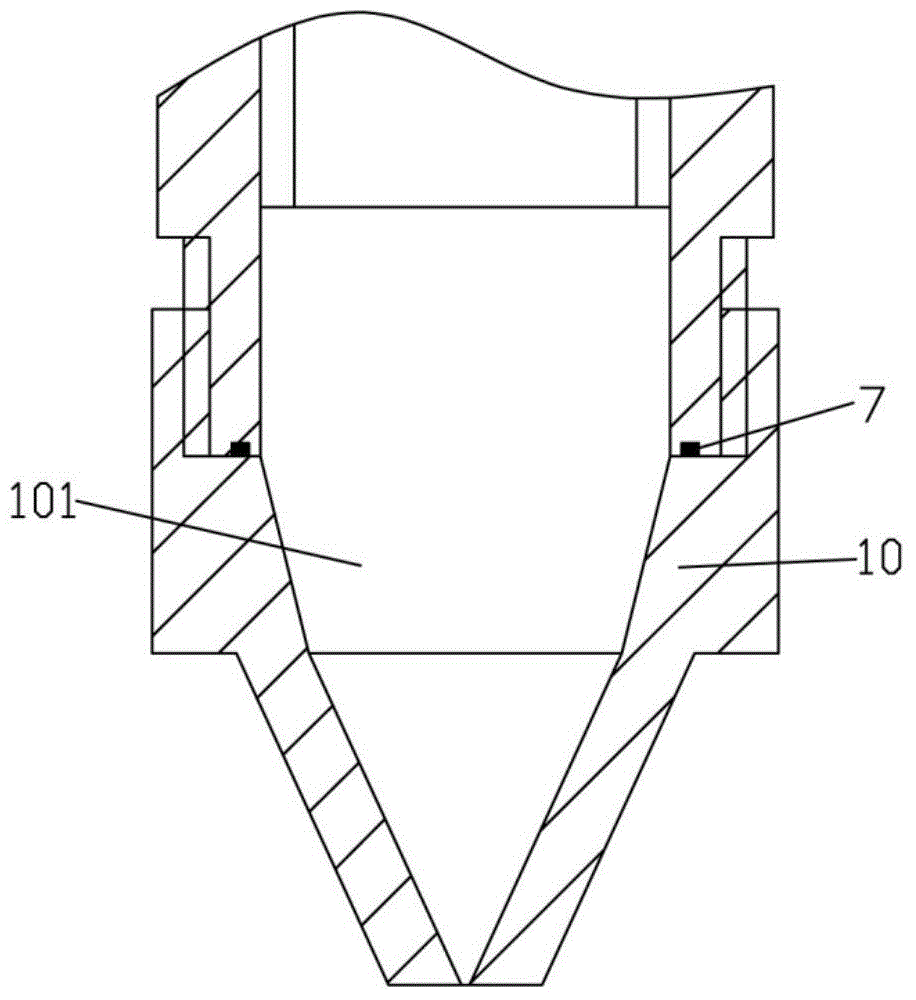

Double-valve built-in weighing type precise dispensing device

PendingCN109433526ASmall form factorLow costLiquid surface applicatorsSpraying apparatusElectricityEngineering

The invention discloses a double-valve built-in weighing type precise dispensing device. The device comprises a double-valve dispensing device and an industrial weighing structure; the double-valve dispensing device comprises a double-valve positioning height difference compensation dispensing mechanism and a base mechanism; the double-valve positioning height difference compensation dispensing mechanism comprises a visual positioning system, a glue discharging height adjusting structure and a small-distance double-valve piezoelectric jetting dispensing mechanism, wherein the visual positioning system is used for positioning a to-be-dispensed workpiece; the base mechanism comprises a supporting seat, a transverse mechanism and a longitudinal mechanism, wherein the transverse mechanism is arranged on the longitudinal mechanism in a sliding mode, the longitudinal mechanism is arranged on the supporting seat, the double-valve positioning height difference compensation dispensing mechanismis arranged on the transverse mechanism in a sliding mode, and the small-distance double-valve piezoelectric jetting dispensing mechanism is used for dispensing; and the industrial weighing structureis used for weighing the glue discharging amount of the small-distance double-valve piezoelectric jetting dispensing mechanism. The positioning and conveying of a dispensed product on a carrier are guaranteed, the glue dispensing amount required by a client also can be guaranteed; and the automation degree is high, the dispensing efficiency is high, and the dispensing effect is good.

Owner:SUZHOU RS TECH

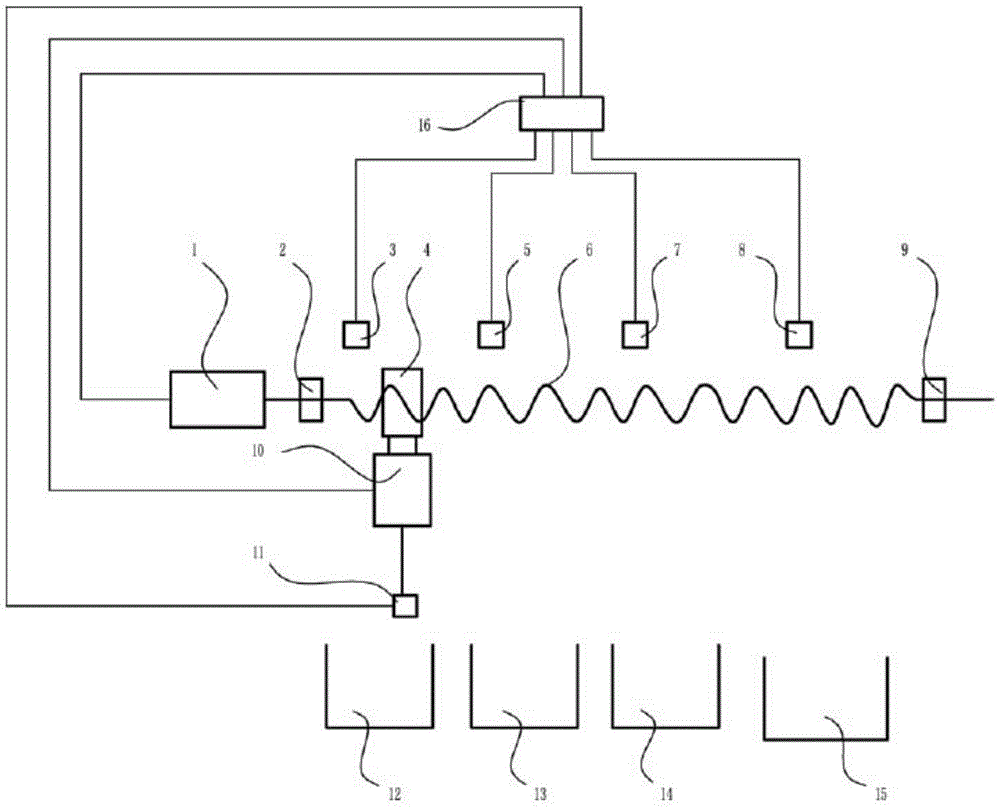

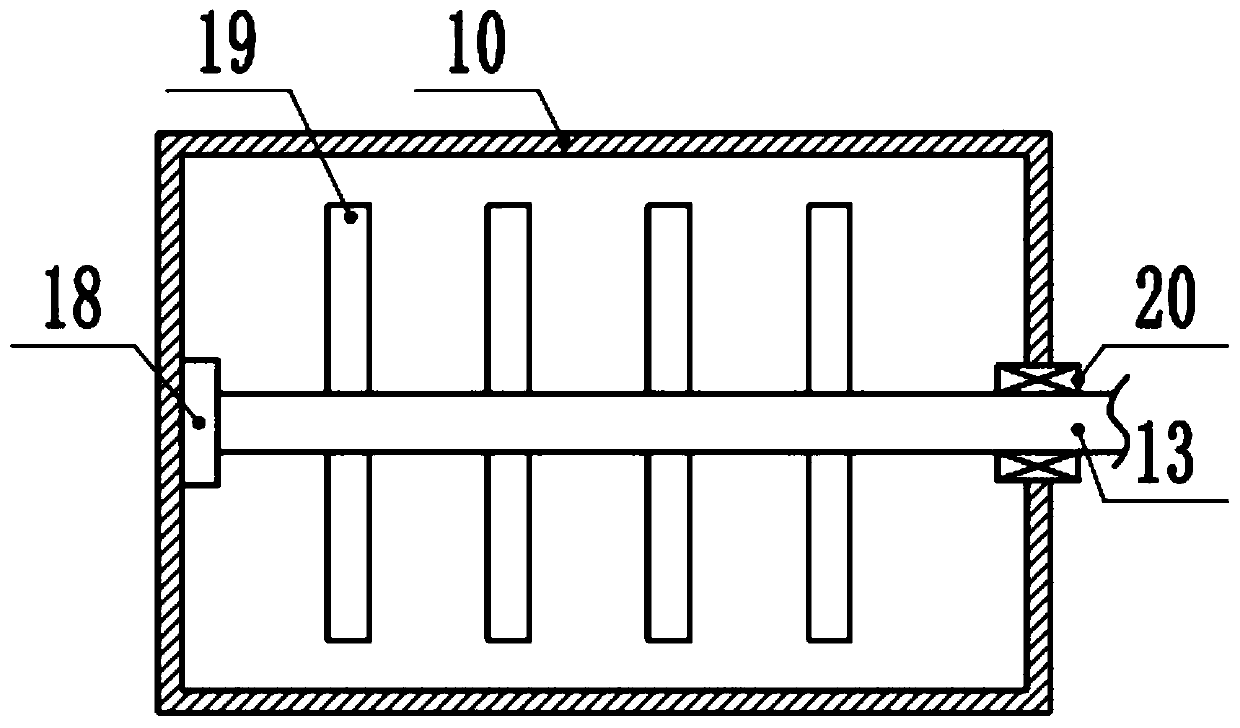

Automatic traditional Chinese medicine dispensing device

ActiveCN104785156ARealize fully automated operationChange the way of manual dispensingMixer accessoriesBiomedical engineeringElectromagnetic valve

The invention relates to a medicine dispensing device, in particular to an automatic traditional Chinese medicine dispensing device, and solves the technical problem about the automatic traditional Chinese medicine dispensing device. The automatic traditional Chinese medicine dispensing device comprises a rotary motor, a nut, a lead screw, a material taking device and other parts, wherein the material taking device comprises a material taking barrel, a stop disc, a connecting column, a spring and an electromagnetic valve; a left bearing and the lead screw are arranged on the right side of the rotary motor, the rotary motor is connected with the lead screw, and the nut is arranged on the lead screw and is movably connected with the lead screw; a material taking air cylinder is arranged below the nut and is connected with the nut; the material taking device is arranged below the material taking air cylinder and is connected with the material taking air cylinder; the connecting column is fixedly connected with the material taking barrel, the stop disc is movably connected with the material taking barrel, the connecting column penetrates through a hole in the stop disc, the spring sleeves the connecting column, and the material taking barrel is connected with the electromagnetic valve. The automatic traditional Chinese medicine dispensing device achieves full-automation operation and has good medicine dispensing effect.

Owner:TONGXIANG HUIFENG ELECTRICAL APPLIANCE DIE CASTING PLANT

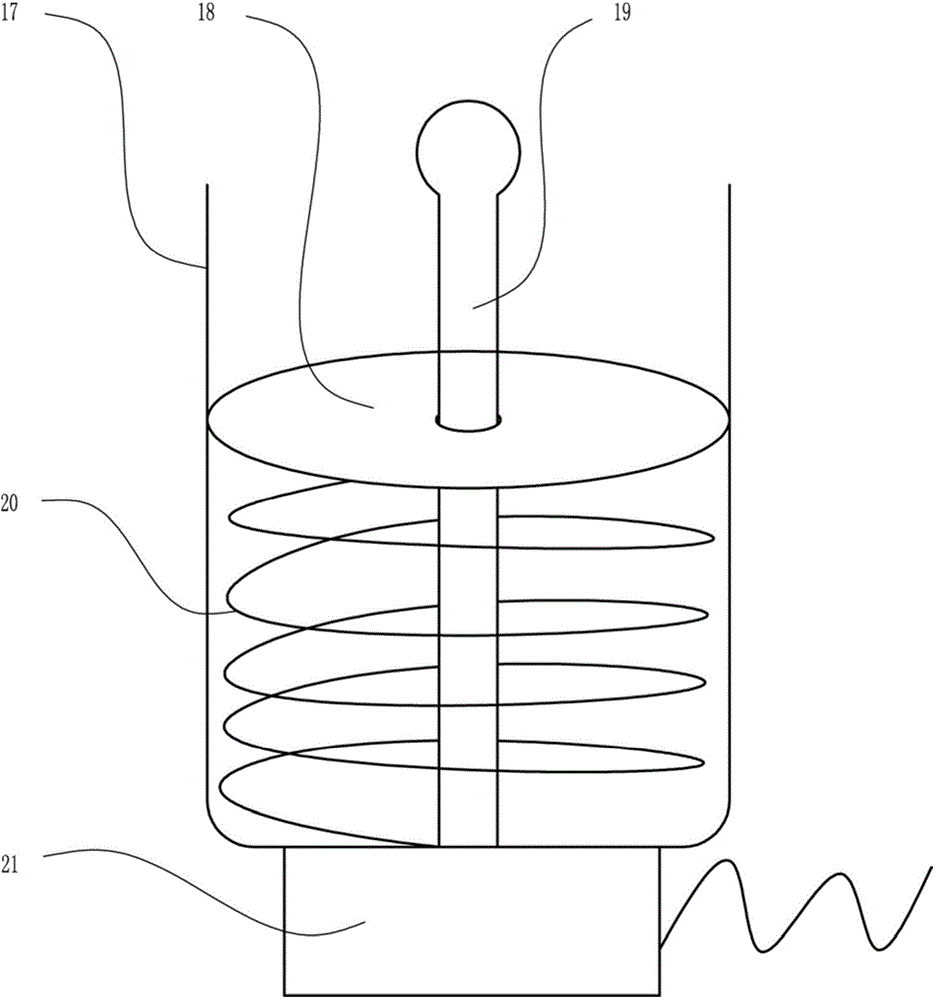

Multifunctional clinical pharmacy transfusion automatic dispensing device

PendingCN110404438AEasy to controlWell mixedTransportation and packagingRotary stirring mixersEngineeringElectric control

The invention discloses a multifunctional clinical pharmacy transfusion automatic dispensing device which comprises a device box, wherein an electric control box is fixedly arranged on the box body onthe left side surface of the device box, a connecting rod is fixedly connected with the middle part of the box body on the right side surface of the device box, an operation control screen is fixedlyarranged on the right end of the connecting rod, the operation control screen is electrically connected with the electric control box, a medicine distribution box is arranged in the middle part of the device box, and a shaft sleeve is fixedly connected with the inner wall of the box body on the left side of the medicine distribution box. One side, far away from the inner wall of the box body on the left side of the medicine dispensing box, of the shaft sleeve is rotatably connected with a medicine dispensing rod, the other end of the medicine dispensing rod passes through the box body on theright side of the medicine dispensing box and is connected with the medicine dispensing box through a bearing, and the right end of the medicine dispensing rod is fixedly provided with a rotating motor. The multifunctional clinical pharmacy transfusion automatic dispensing device has better dispensing effect, realizes automatic dispensing, avoids the disadvantages of manual dispensing, saves timeand labor, has more accurate control on liquid medicine metering and higher safety, can also be used for preparing other liquids, and has wide application and strong practicability.

Owner:李会

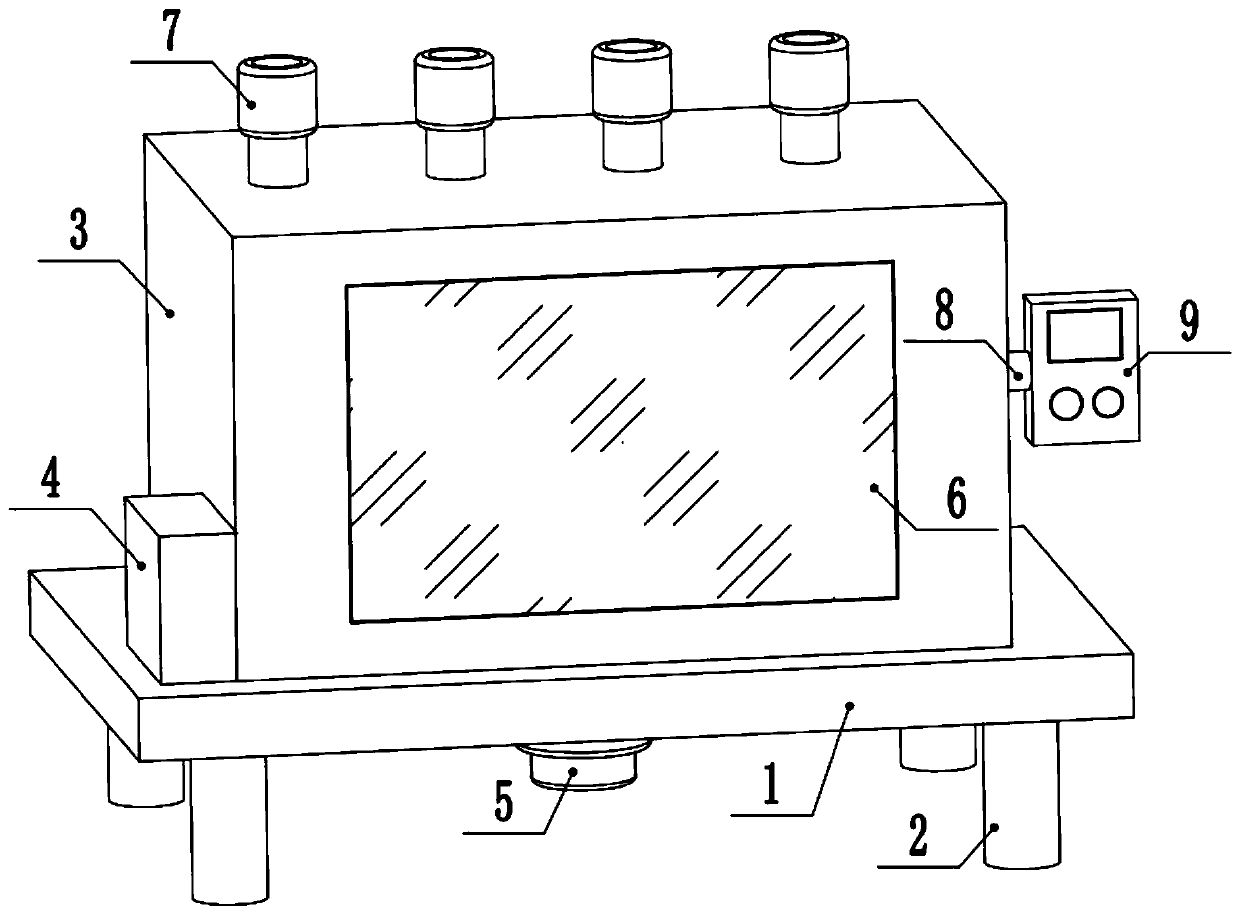

Automatic laminating machine for optical filter

The invention discloses an automatic laminating machine for an optical filter. The machine comprises a base, a feeding mechanism, a rotating mechanism, a suction nozzle material taking mechanism, a correcting mechanism, an automatic dispensing mechanism, a UV curing mechanism, a CCD visual mechanism, an X-axis linear module and a Z-axis linear module. A jig rotating mechanism is arranged in the center of the base, and the feeding mechanism, the correcting mechanism, the automatic dispensing mechanism, the UV curing mechanism and the CCD visual mechanism are arranged on the outer side of the rotating mechanism. The X-axis linear module is arranged on the upper portion of one side of the base, the Z-axis linear module is movably arranged on the X-axis linear module, and the suction nozzle material taking mechanism is arranged on the Z-axis linear module and located above the rotating mechanism. Products are automatically clamped and fixed to a clamping jaw, corrected and subjected to rotary dispensing and curing in sequence, manual operation is not needed, the operation efficiency is high, the labor intensity is low, the labor cost is low, the dispensing effect is good, the fitting precision is high, the yield is high, frequent reworking is not needed, the products are not easily damaged, glue solution product waste is small, the material cost is low, no harm is caused to eyes, and hidden health hazards are avoided.

Owner:厦门贝莱信息科技有限公司

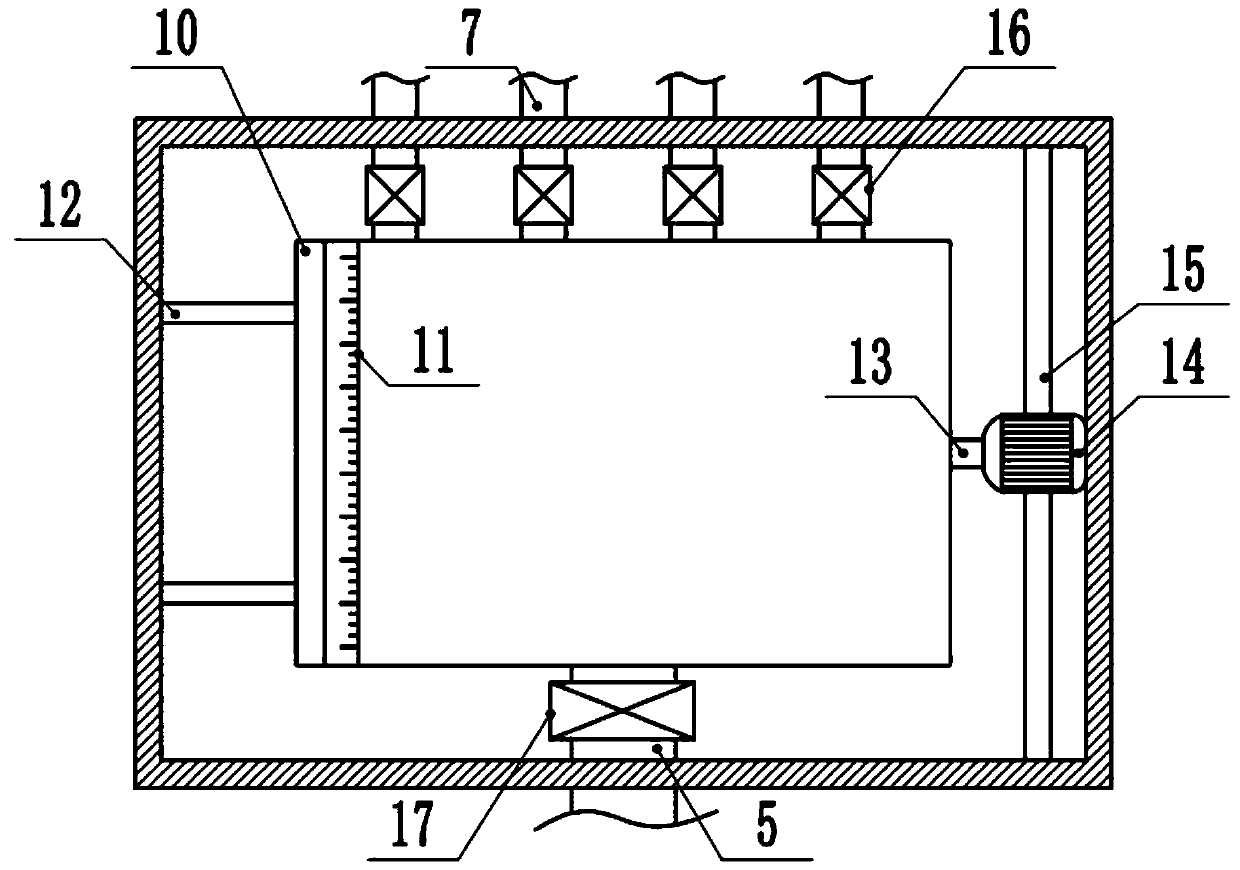

Full-automatic glue dispensing machine

InactiveCN112808524AImprove dispensing efficiencySave manpower and material resourcesLiquid surface applicatorsRotary stirring mixersDrive shaftElectric machinery

The invention belongs to the technical field of glue dispensing machines, and particularly relates to a full-automatic glue dispensing machine. The full-automatic glue dispensing machine comprises a base, wherein fixing seats are fixedly connected to two sides of the top of the base, supporting plates are fixedly connected to the tops of the fixing seats, a mounting top plate is fixedly connected to the supporting plates, and supporting frames are fixedly connected to two sides of the mounting top plate; and the tops of the two supporting frames are fixedly connected with a same stirring box, a stirring motor is mounted at the top of the stirring box, a transmission shaft is rotatably connected to an output shaft of the stirring motor, and fixing rods are fixedly connected to the outer wall of the transmission shaft. Through cooperative use of a main flow pipe, a control valve, branch flow pipes, glue solution boxes, glue dispensing heads and glue dispensing grooves, a plurality of workpieces can be subjected to glue dispensing operation at the same time, the glue dispensing efficiency is greatly improved, manpower and material resources are saved, besides, when the glue solution amount is not enough, glue can be added under the condition that the glue dispensing machine is not stopped, the production efficiency is further improved, and the purpose of maximizing production benefits is achieved.

Owner:SUZHOU TIANRUIDA ELECTRONICS TECH CO LTD

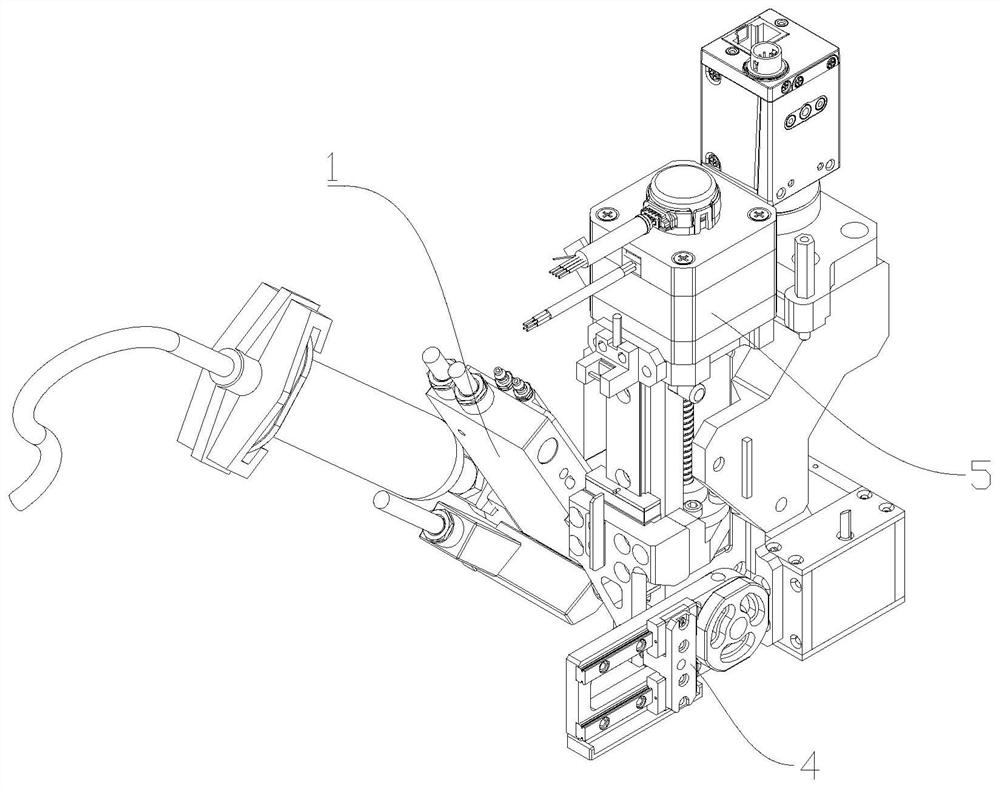

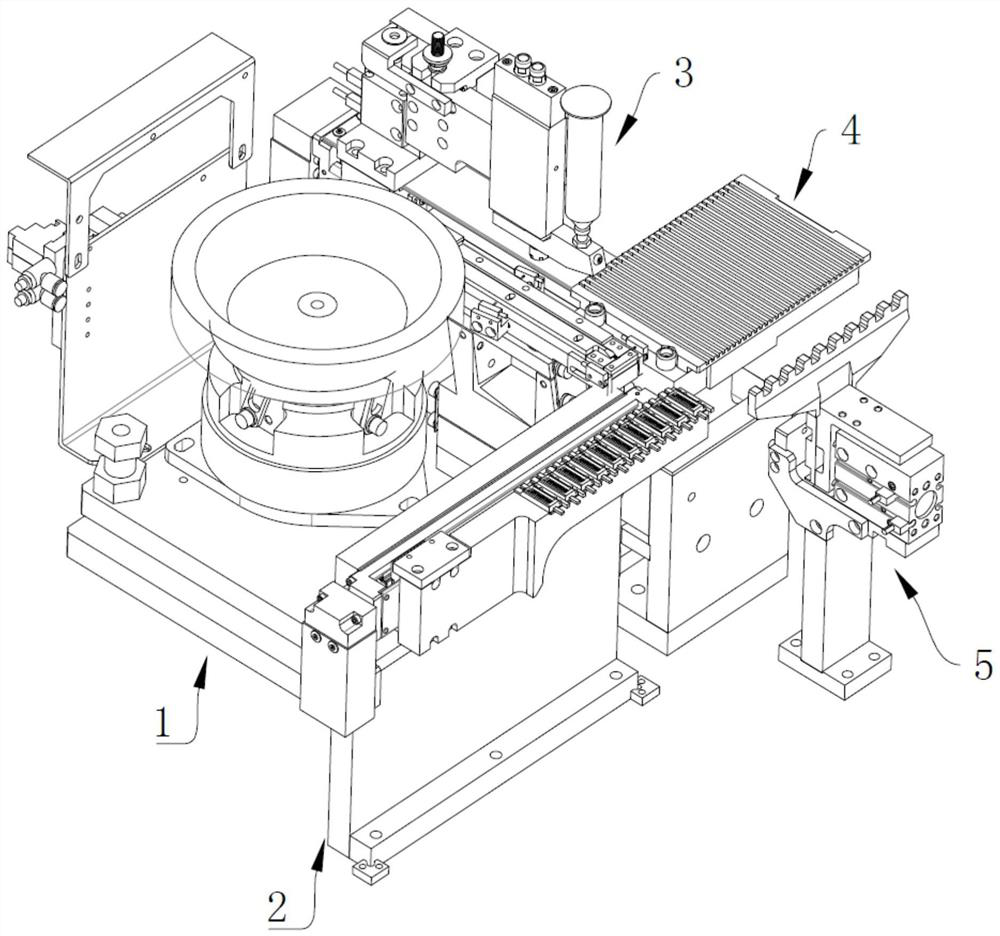

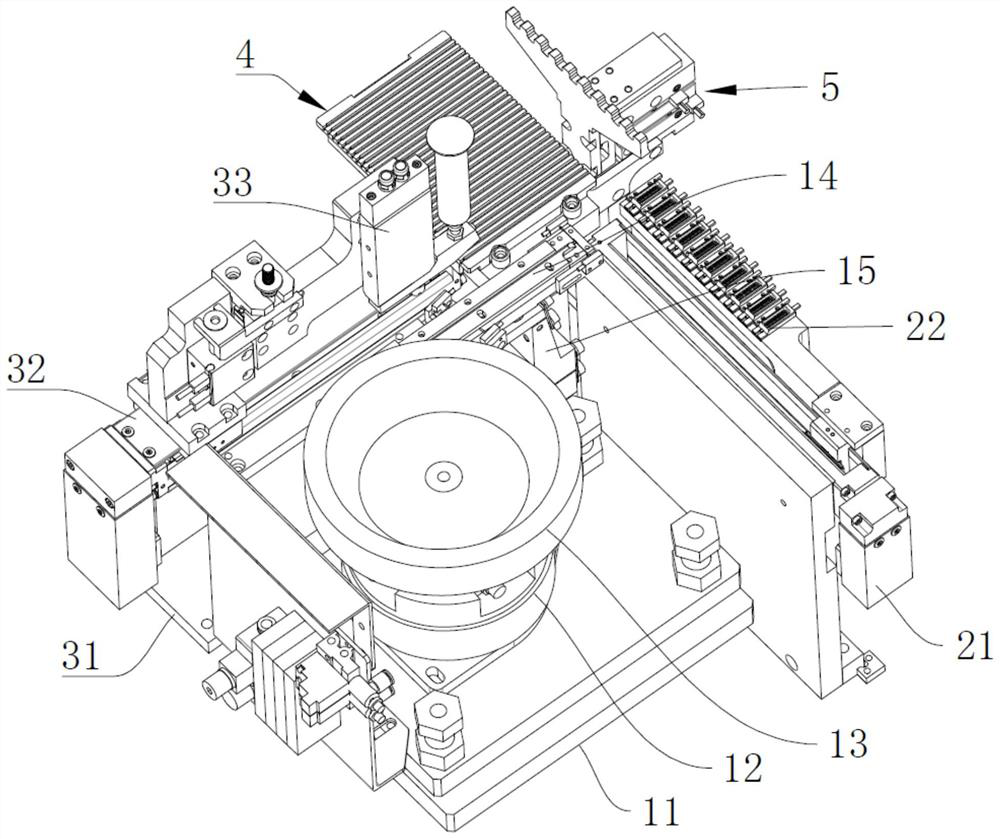

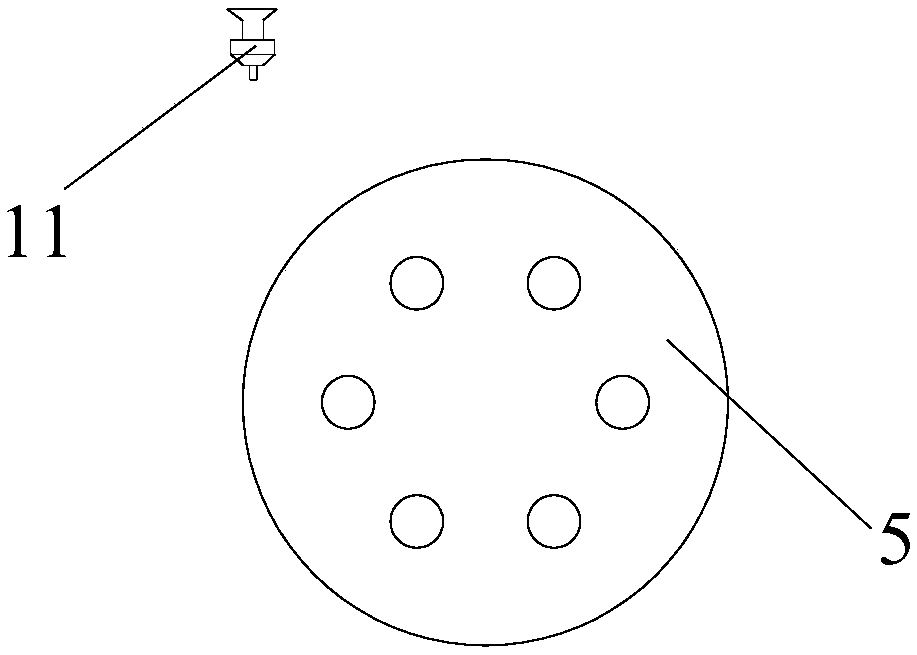

Ultrasonic probe piezoelectric wafer automatic glue-dispensing and chip-mounting machine

ActiveCN109638150AHigh degree of automationPrecise Control of DisplacementPiezoelectric/electrostrictive device manufacture/assemblyLiquid surface applicatorsAtmospheric pressurePneumatic cylinder

Disclosed is an ultrasonic probe piezoelectric wafer automatic glue-dispensing and chip-mounting machine. The ultrasonic probe piezoelectric wafer automatic glue-dispensing and chip-mounting machine comprises a belt, a first guide rail and a second guide rail, wherein the first guide rail and the second guide rail are arranged on the two sides of the belt in parallel; two first guide columns are connected between the first guide rail and the second guide rail in a sliding mode, and the two first guide columns are connected with guiding-sliding columns in a sliding mode; a glue dispensing machine and a chip mounter are connected to the two guiding-sliding columns in a sliding mode respectively; two limiting guide rails are symmetrically arranged above the belt; a piezoelectric wafer shell is arranged on the part, located between the two limiting guide rails, of the belt; two movable blocks are arranged on one limiting guide rail, and the movable blocks are connected with a pneumatic cylinder, and the movable blocks are used for enabling the piezoelectric wafer shell to be abutted against the other limiting guide rail during glue dispensing and chip mounting; a piezoelectric wafer isarranged on the side of the belt; the glue dispensing machine is used for injecting glue liquid into the piezoelectric wafer shell; and the chip mounter is used for attaching the piezoelectric waferto the part, coated with the glue liquid, of the piezoelectric wafer shell. According to the design, the glue dispensing effect is good, the chip mounting effect is good, and the automation degree ishigh.

Owner:WUHAN TEXTILE UNIV

Yarn dispensing mechanism and yarn dispensing method

PendingCN108970894AHigh degree of automationImprove dispensing efficiencyLiquid surface applicatorsFilament handlingYarnEngineering

The invention discloses a yarn dispensing mechanism and method. The yarn dispensing mechanism comprises a yarn clamping device, a dispensing device and a heating device. The yarn clamping device comprises a yarn clamping base, a first clamp, a second clamp, a yarn clamping driving part and an overturning driving part. The overturning driving part is connected to the yarn clamping base and used fordriving the yarn clamping base to be overturned. The yarn clamping driving part is installed on the yarn clamping base and connected with the first clamp and the second clamp. The yarn clamping driving part is used for driving the first clamp and the second clamp to be operated. The dispensing device comprises a dispensing base, a dispensing plate and a dispensing driving part. The dispensing base is provided with a glue groove for accommodating glue. The dispensing driving part is installed on the dispensing base and connected with the dispensing plate. The dispensing plate is positioned inthe glue groove in a reset state. The dispensing driving part is used for driving the dispensing plate to be lifted from the glue groove or reset. The heating device comprises a heating plate. The heating plate is connected to the yarn clamping base and positioned between the first clamp and the second clamp. The yarn dispensing mechanism is high in dispensing efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

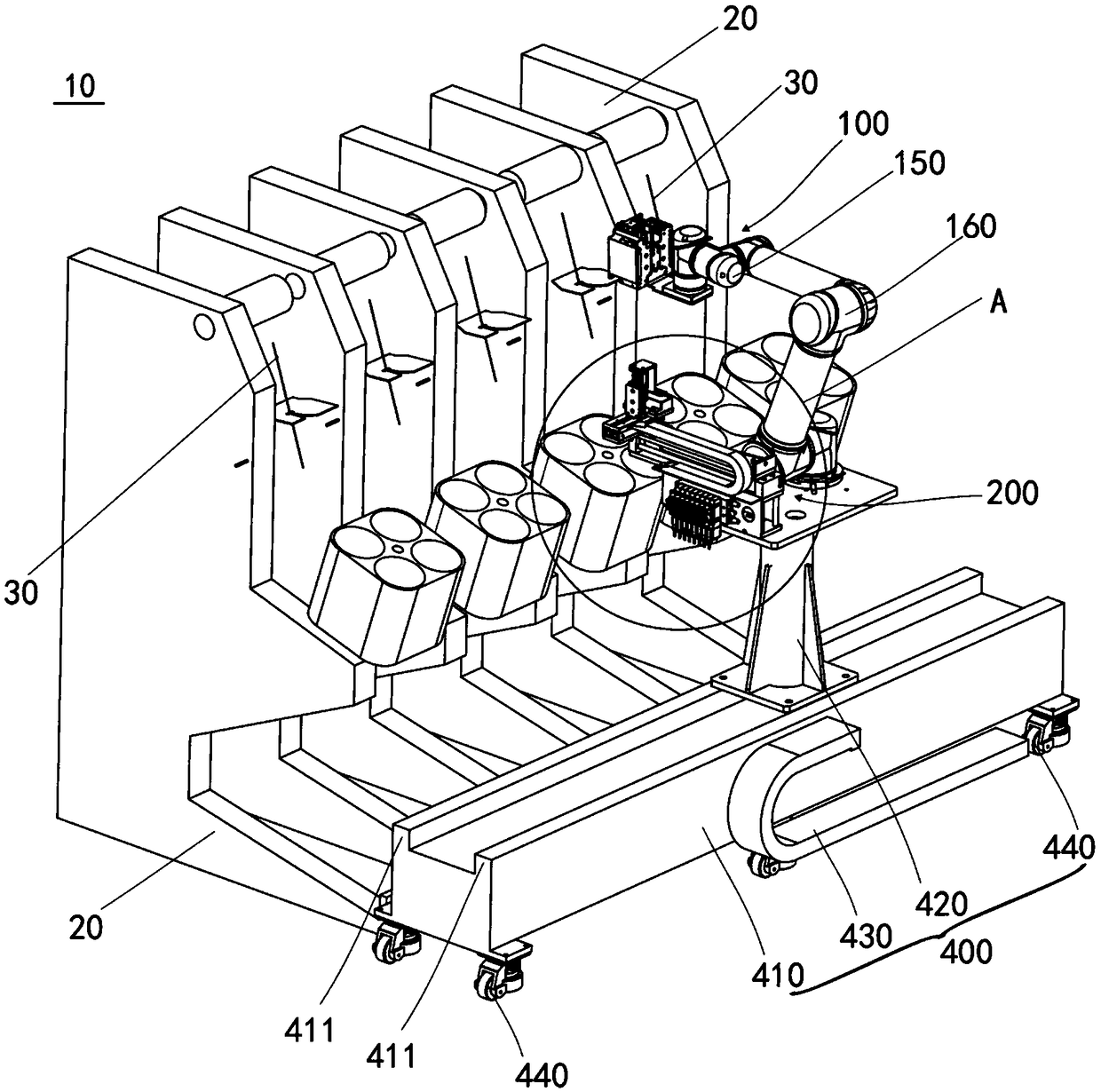

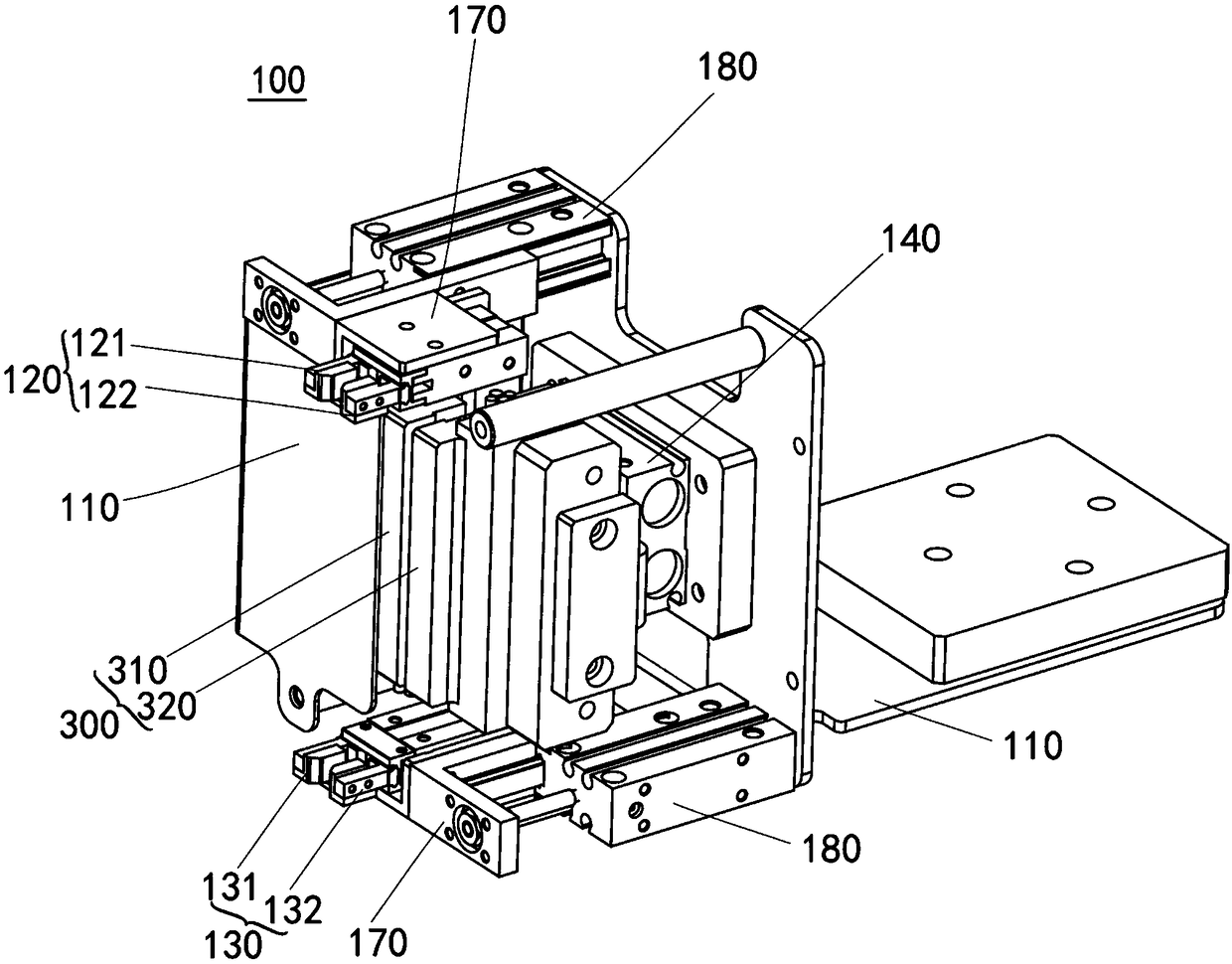

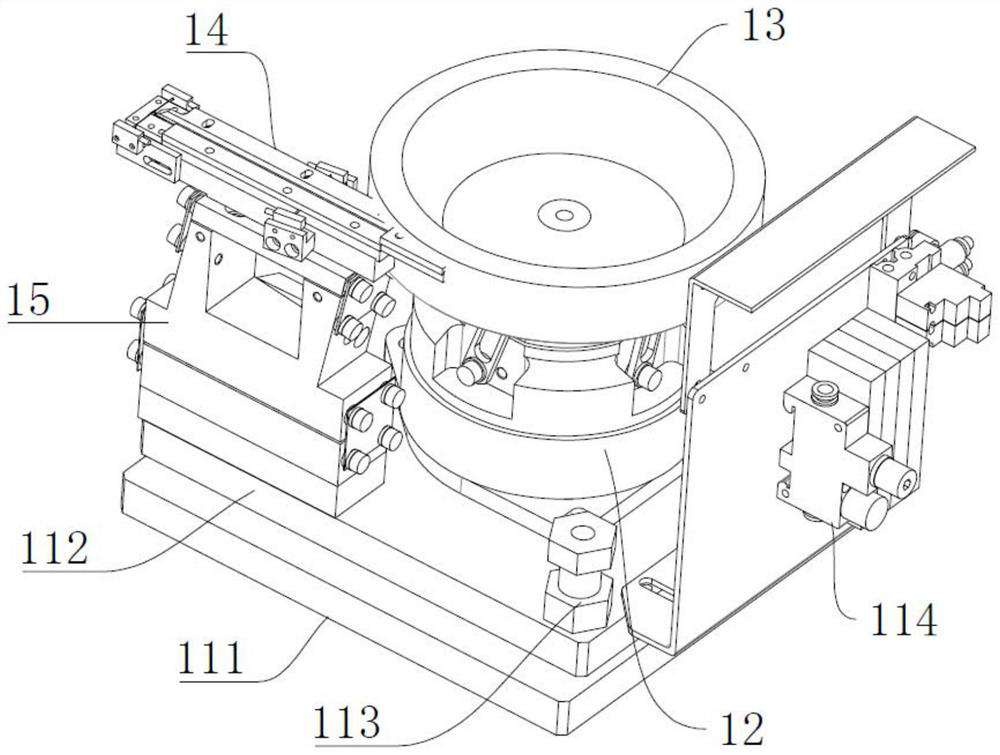

Automatic adhesive dispensing and pushing mechanism for electronic element

ActiveCN113198696AHigh degree of automationSave human effortLiquid surface applicatorsCoatingsPhysicsEngineering

The invention relates to the technical field of electronic element adhesive dispensing, in particular to an automatic adhesive dispensing and pushing mechanism for an electronic element. The automatic adhesive dispensing and pushing mechanism for the electronic element comprises a material supplying device used for supplying the electronic element, a feeding device connected to the material supplying device and used for receiving the electronic elements supplied by the material supplying device, an adhesive dispensing device arranged on one side of the feeding device and used for dispensing adhesive on the electronic elements on the feeding device, a material tray device arranged on one side of the feeding device and used for receiving the electronic elements with the dispensed adhesive on the feeding device, and a pushing device arranged on one side of the material tray device and used for pushing the electronic elements on the feeding device into the material tray device. According to the automatic adhesive dispensing and pushing mechanism for the electronic element, adhesive dispensing is conducted in the linear conveying process after feeding, the electronic elements reach the front end of the material tray after adhesive dispensing, then the electronic elements are pushed into the material tray through the pushing device, full-automatic feeding, conveying, adhesive dispensing, material pushing and tray charging are achieved, the overall automation degree is high, manpower is saved, and the production efficiency is high.

Owner:DONGGUAN TB ELECTRONICS TECH CO LTD

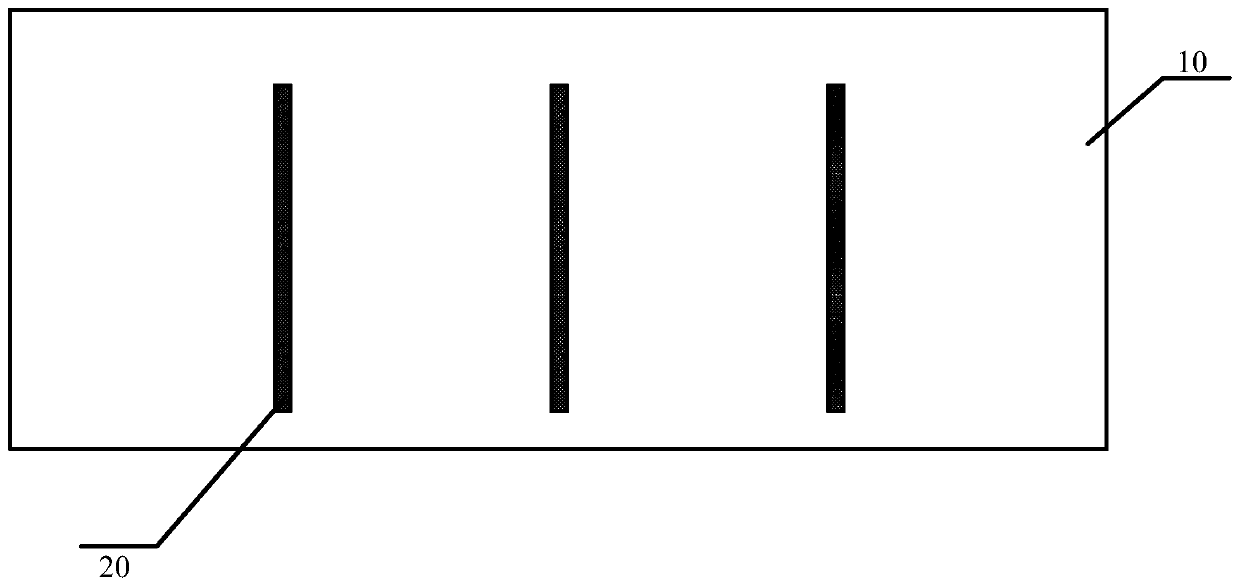

Reinforcing plate, flexible printed circuit board and dispensing method

PendingCN111132451ADispensing will not affectReduce gapCircuit bendability/stretchabilityPrinted circuit aspectsFlexible electronicsPrinted circuit board

The invention relates to a reinforcing plate, a flexible printed circuit board and a dispensing method. The reinforcing plate comprises a reinforcing substrate, and at least one gap penetrating through a thickness direction of the reinforcing substrate is etched on the reinforcing substrate. A strippable coating is included and is coated in at least one gap on a lower surface of the reinforcing substrate, strippable paint is fully filled in the strippable coating, and the strippable paint filled in at least one gap is flush with an upper surface of the reinforcing substrate. Therefore, when adevice on the upper surface of the reinforcing plate is dispensed, the gap on the reinforcing plate is filled with the strippable coating so that a liquid glue cannot flow to the gap and directly flowto a position between the device and the reinforcing plate, and after the liquid glue is solidified, the strippable coating on the reinforcing plate can be directly peeled off so that the gaps for reducing an internal stress can be ensured to exist on the reinforcing plate, the gaps do not influence glue dispensing between the device and the reinforcing plate, and a good glue dispensing effect isensured while flatness is improved.

Owner:昆山丘钛生物识别科技有限公司

Movement mechanism with multifunctional dispensing device

ActiveCN105032704AEpoxy uniformGuaranteed dispensing effectLiquid surface applicatorsCoatingsMultiple functionChassis

The invention discloses a movement mechanism with a multifunctional dispensing device. The movement mechanism comprises a dispensing head and a dispensing barrel. The dispensing head is fixed to the bottom end of the dispensing barrel. A top end cover is fixed to the top end of the dispensing barrel and fixed to a connecting plate. A connecting inserting hole is formed in the middle of the connecting plate. The dispensing barrel is inserted in the connecting inserting hole in a sleeved manner. Movement blocks are fixed to the two sides of the bottom face of the connecting plate and arranged in adjusting screw rods in a screwed joint manner. The two ends of each adjusting screw rod are hinged to two supporting plates. The supporting plates are fixed to a bottom frame. A long through groove is arranged in the middle of the bottom frame. The lower portion of the dispensing barrel is inserted in the long through groove in a sleeved manner. One end of each adjusting screw rod stretches out of the corresponding supporting plate and is connected with an output shaft of a servo motor fixed to the corresponding supporting plate through a coupler. The dispensed adhesive amount is fixed, adhesive dripping is even, and the dispensing effect is guaranteed. The dispensing head is moved at high precision through the servo motors, and dispensing precision is guaranteed.

Owner:盐城康鼎机械有限公司

A dispensing device for electronic components

ActiveCN106423744BEasy to operateEasy to useLiquid surface applicatorsCoatingsEngineeringElectronic component

The invention relates to a gluing device and especially relates to a gluing device for an electronic component. The technical problem to be solved by the invention is to provide the gluing device for the electronic component, which has the advantages of simple operation, convenience in use, capability of accurately aligning with a gluing point of the electronic component in a gluing process, good gluing effect and high working efficiency. For solving the technical problem, the gluing device for the electronic component, provided by the invention, comprises a base plate, an L-shaped support plate, a left and right moving device, a pressure regulating valve, a vertical plate, a loading plate, a slide block, an up and down moving device, a glue filling drum, a gluing needle cylinder and a cover, wherein the L-shaped support plate is welded at the left end of the top of the base plate; the vertical plate is vertically welded in the middle of the top of the base plate; an opening is formed in the lower part of the vertical plate; and slide slots are symmetrically formed in the base plate from front to back. The gluing device for the electronic component, provided by the invention, has the advantages of simple operation, convenience in use and capability of accurately aligning with the gluing point of the electronic component in the gluing process.

Owner:深圳市怡海智芯科技有限公司

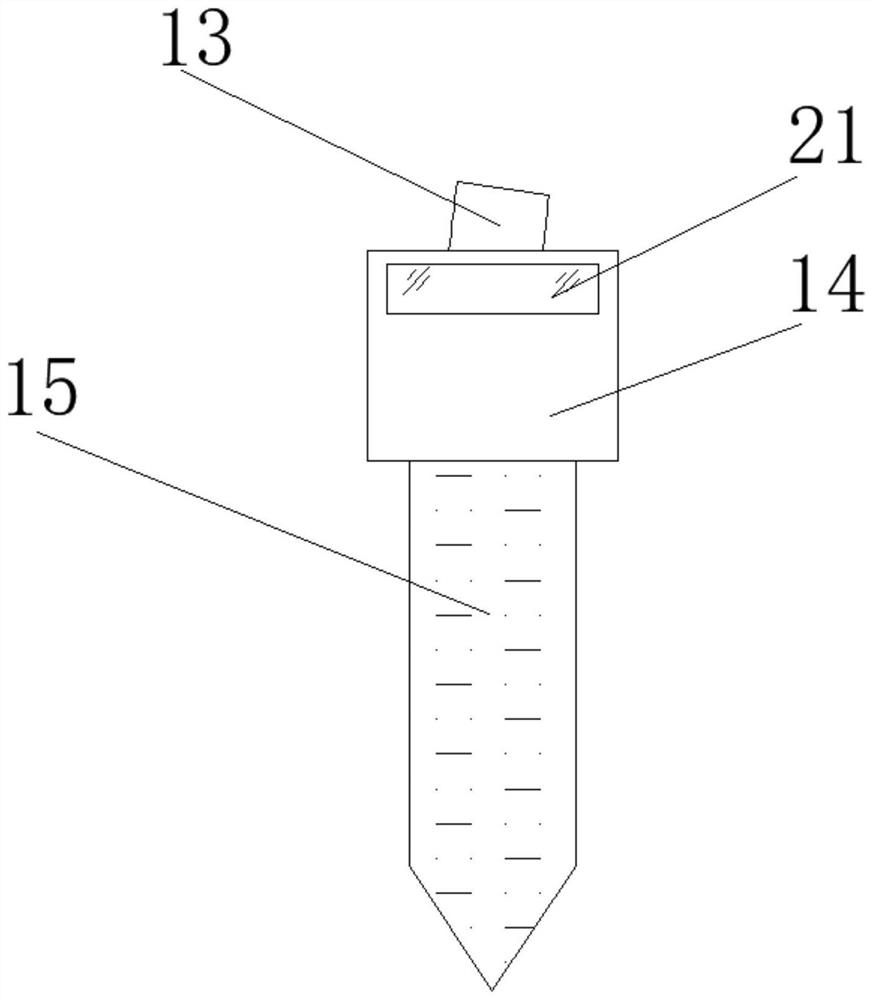

Casing pipe and needle dispensing assembly tool and dispensing assembly method

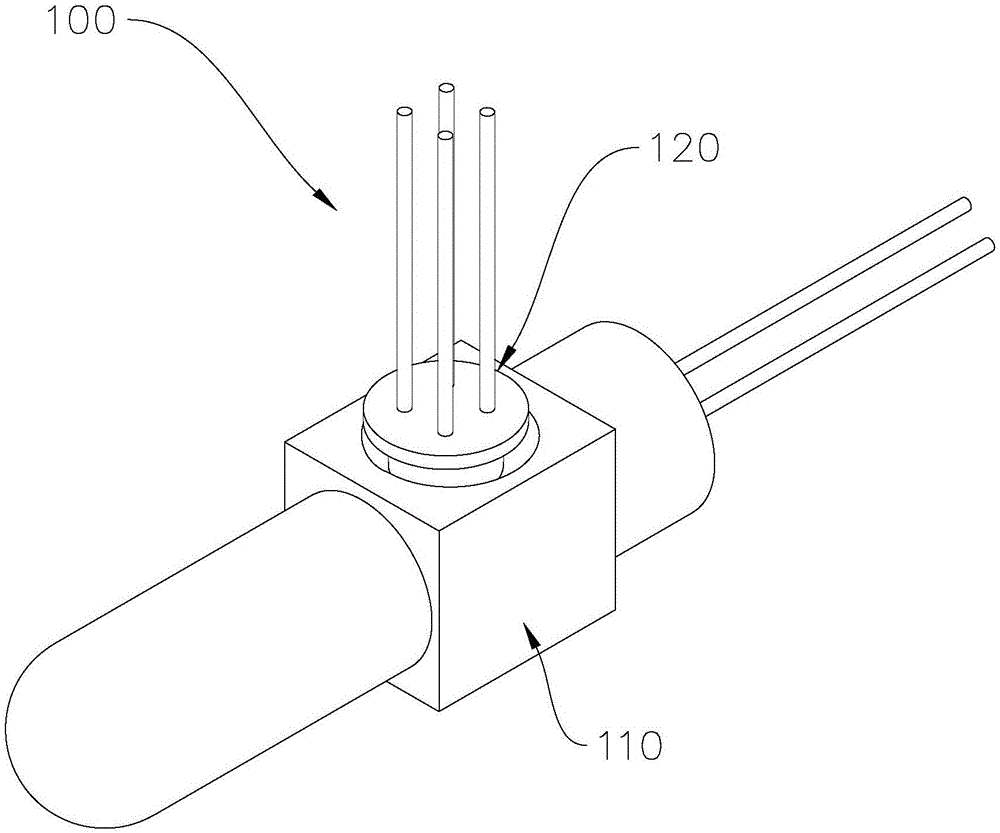

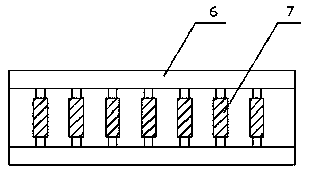

ActiveCN109967307AGuaranteed space utilizationEfficient fillingLiquid surface applicatorsMaterial gluingEngineeringAssembly line

The invention discloses a casing pipe and needle dispensing assembly tool and a dispensing assembly method, and belongs to the field of workpiece assembly. The tool comprises a base frame, an assemblyplate, casing pipe assembly holes and a needle guiding block; the assembly plate is connected to the upper side of one side of the base frame; the length direction of the assembly plate is parallel with the length direction of the base frame; the casing pipe assembly holes are transverse through holes formed in the assembly plate and are arranged in parallel in the length direction of the assembly plate; the needle guiding block is connected with the base frame and is located on the inner side of the assembly plate; the casing pipe assembly holes are formed obliquely relative to the horizontal plane; the needle guiding block is connected with the base frame through telescopic rods; and one end of each telescopic rod is rotationally connected with the base frame, and the other end is fixedly connected with the needle guiding block. According to the tool and the method, casing pipes are assembled in the casing pipe assembly holes in the assembly plate in batches, needles are assembled in the casing pipes, then the dispensing operation is performed, the casing pipe and needle dispensing assembly tool cooperates with a dispensing machine, batched dispensing assembly of the casing pipes and the needles is realized, thus the dispensing assembly efficiency is greatly improved, and the dispensing effect is guaranteed.

Owner:马鞍山邦德医疗器械有限公司

Multi-liquid hot melting glue dispenser

InactiveCN108144803AFlexible adjustment of position relationshipGuaranteed hot melt effectLiquid surface applicatorsCoatingsEngineeringHot melt

The invention discloses a multi-liquid hot melting glue dispenser. The multi-liquid hot melting glue dispenser comprises a glue dispenser frame; a plurality of glue buckets are fixed to the top end ofthe glue dispenser frame, and glue outlets of the glue buckets communicate with a glue feeding adjusting assembly capable of adjusting the glue feeding amount; the outer side wall of the glue feedingadjusting assembly is provided with a pre-heating sleeve pipe; a plurality of fluororubber guide pipes communicating with the glue outlets of the glue buckets are arranged in the glue feeding adjusting assembly, glue outlets of the fluororubber guide pipes are connected with a glue inlet of a mixed glue liquid temporary storage assembly, a glue outlet of the mixed glue liquid temporary storage assembly is connected with a glue inlet of a glue conveying pump, and a glue outlet of the glue conveying pump is connected with a glue inlet of a heating glue head pipe; the outer side wall of the heating glue head pipe is sleeved with a glue heating barrel, and a glue outlet of the heating glue head pipe is connected with a glue head through a soft glue head pipe; the glue head is connected with aservo motor through a glue head supporting rod; and the servo motor is fixed to the glue dispenser frame. According to the multi-liquid hot melting glue dispenser, the two-time heating mode is applied to glue liquid, hot melting is more sufficient, moreover, multiple kinds of glue liquid can be used at the same time, and the using flexibility is high.

Owner:SUZHOU RSHTEK ELECTRICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com