Patents

Literature

237results about How to "Not easy to condense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

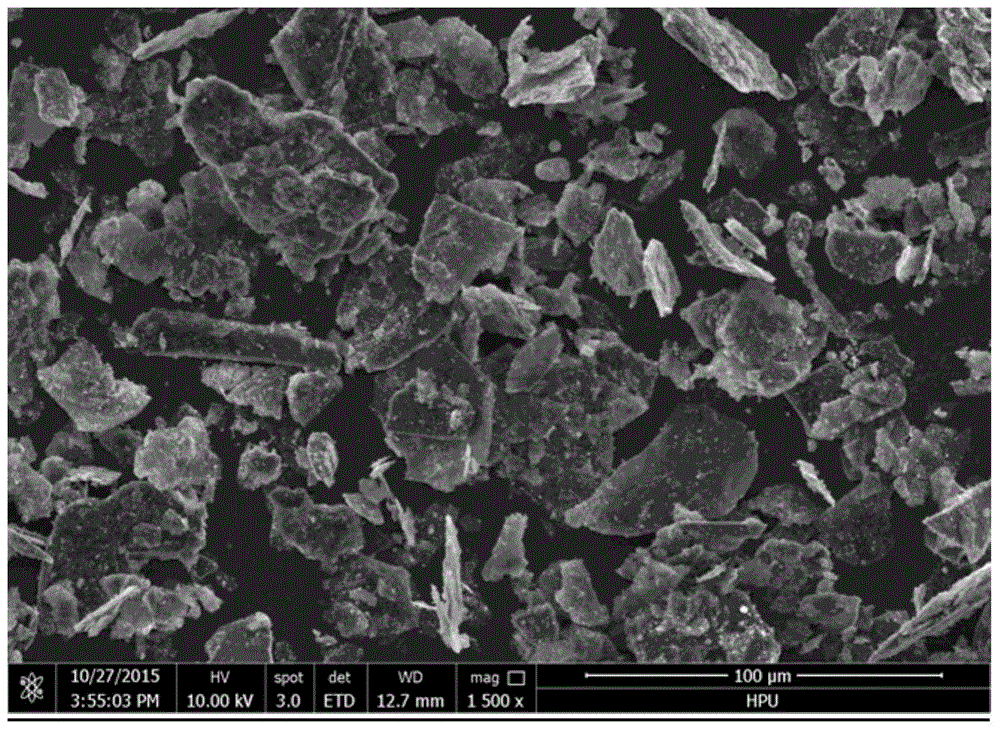

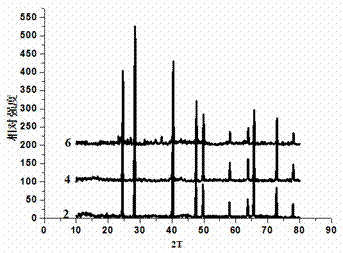

Method for manufacturing ultrafine powder from polytetrafluoroethylene through irradiation cracking

InactiveCN102672968AHigh powerHigh radiation processing efficiencyGrain treatmentsAirflowPolytetrafluoroethylene

The invention discloses a method for manufacturing ultrafine powder from polytetrafluoroethylene through irradiation cracking. The method is characterized in that polytetrafluoroethylene raw materials are dried; the dried polytetrafluoroethylene raw materials are subjected to low-temperature cold treatment by liquid nitrogen; the polytetrafluoroethylene raw materials subjected to the low-temperature treatment are crushed into powder materials with the particle diameter being 100-1000mum by a crushing machine; the powder materials are subjected to sealed package under the gas protection effect; the packed powder materials are placed into an electronic accelerator irradiation system for irradiation cracking; and the irradiated powder materials pass through an air flow crushing machine to be subjected to air flow crushing and grading, and the ultrafine polytetrafluoroethylene powder with the particle diameter reaching 0.2-3mum is obtained. The method has the characteristics that the preparation process is simple, the control is easy, the energy consumption is low, the process continuous degree is high, the product performance is stable, the prepared ultrafine polytetrafluoroethylene powder has the characteristics that the dispersibility is good, and the agglomeration cannot easily occur. The prepared ultrafine polytetrafluoroethylene powder can be widely applied to the fields of paint, ink, dray powder lubricating agents and space flight and aviation appliances, and the material performance is obviously improved.

Owner:四川久远科技股份有限公司

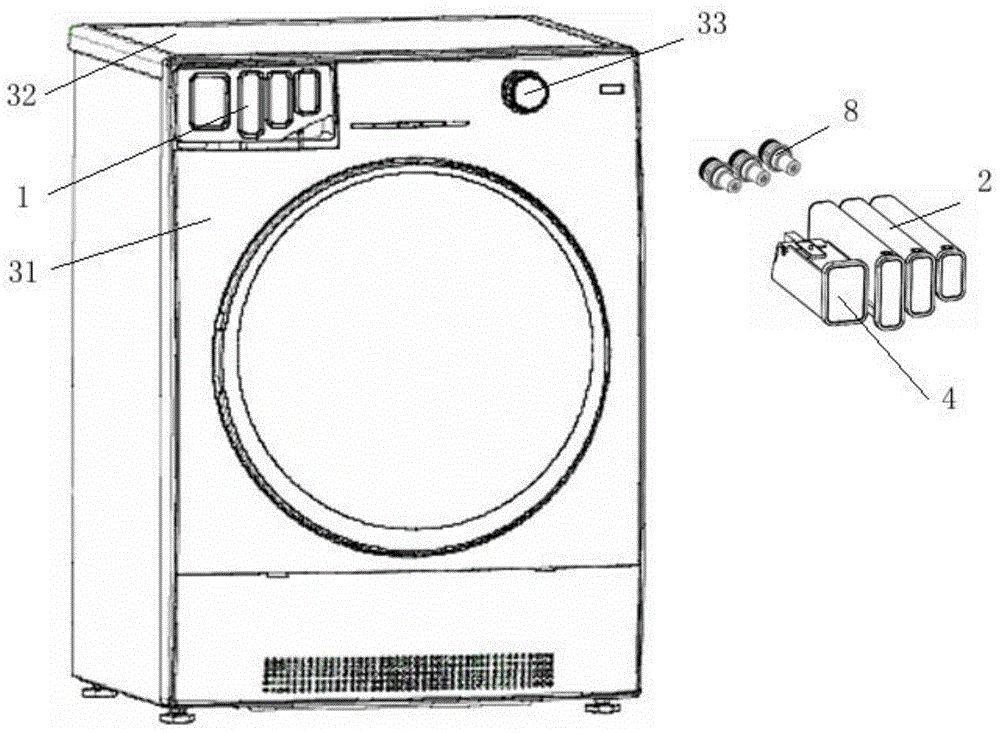

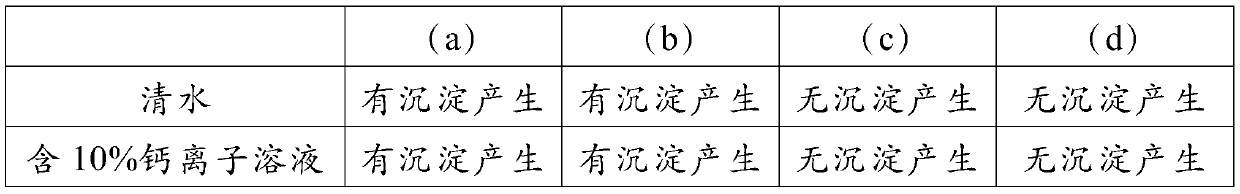

Washing machine with function of automatic release of additives and method

ActiveCN104652098ANot perishableNot easy to condenseOther washing machinesControl devices for washing apparatusPush and pullEngineering

Disclosed are a washing machine with an automatically-added additive and a method. The washing machine comprises an apparatus for automatically adding an additive and an additive accommodating box for accommodating a liquid additive, the additive accommodating box is of a structure of an independently sealed ink box, a washing machine casing is provided with at least one opening, and the additive accommodating box is disposed in the opening in a push-and-pull manner in a one-to-one correspondence, and is / is not in communication with the apparatus for automatically adding an additive. By means of the foregoing washing machine, the additive neither easily deteriorates nor easily condenses after being placed in the additive accommodating box for a long time, thereby improving additive adding convenience, and reducing the number of times a user adds the additive; avoiding that the additive cannot drive blades of a metering apparatus to rotate to perform metering on the additive because the additive is excessively sticky, and meanwhile also avoiding that the metering apparatus is blocked because the additive is coagulated; and avoiding an undesired washing effect caused because different types of additives are mixed up.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

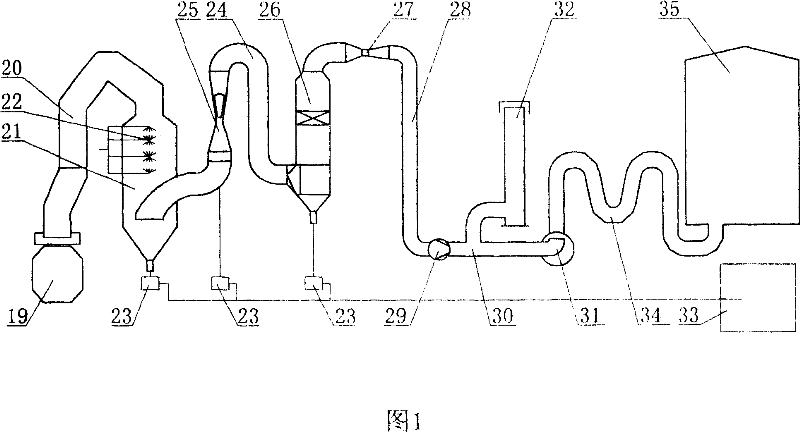

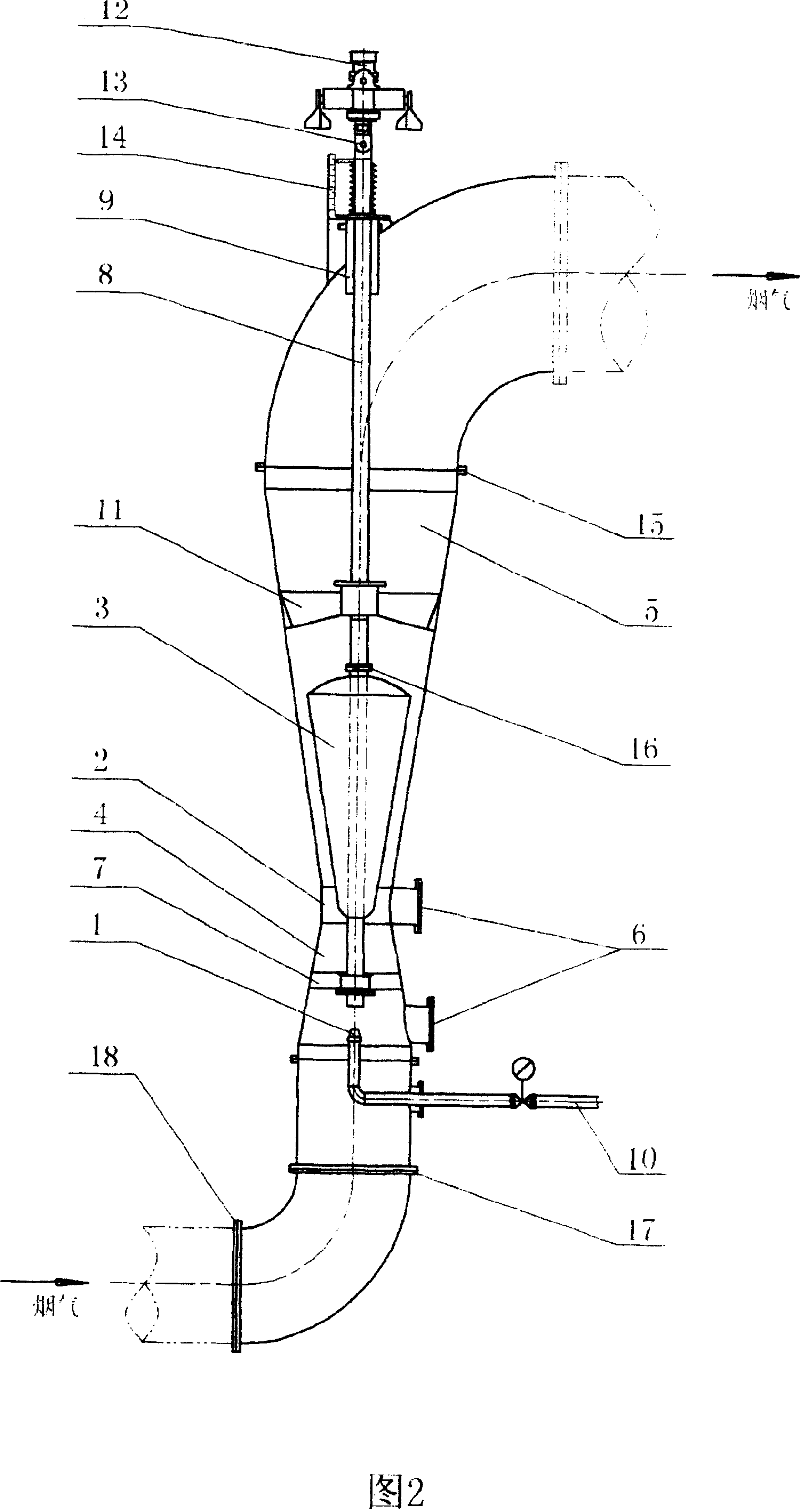

Device for purifying air by eliminating smoke and dust and the technique thereof

ActiveCN101036847AImprove purification effectImprove dust removal effectCombination devicesLighting and heating apparatusFlue gasTranspiration

A flue gas purifying collector and process method thereof are provided. The flue gas purifying collector comprises a transpiration cooling flue, a water seal, a flue, a ring-seal Venturi tube, a dehydrator, a flowmeter, pipelines, a main air blower, a three-way valve, a rotary water seal, an irradiation flue pipe, a water treatment device, a U-shape water seal, a gas cabinet, etc, characterized in that the transpiration cooling flue is connected with a cooling washing tower with a nozzle arranged inside the cooling washing tower, the flue gas outlet on the lower part of the collector is connected to the flue gas inlet on the lower part of the ring-seal Venturi tube, the flue gas outlet of the ring-seal Venturi tube is connected to the dehydrator, and on the throat opening of the ring-seal Venturi tube and below the heavy iron are arranged a water supply pipe and a nozzle, and a heavy iron inversed cone is arrange inside the throat opening. An up-running type flue gas flowing manner and water supply below the heavy iron are employed in the process provided in the invention, redundant mechanical water can be directly reclaimed without passing through the throat opening of the ring-seal Venturi tube, water is atomized thoroughly and agglomerates with dust on the throat opening of the ring-seal Venturi tube, thereby improving dust purifying and dust collecting effect, facilitating the adjustment of the heavy iron, and preventing dust agglomeration below the heavy iron and dust deposit on the throat opening of the ring-seal Venturi tube.

Owner:北京中冶设备研究设计总院有限公司

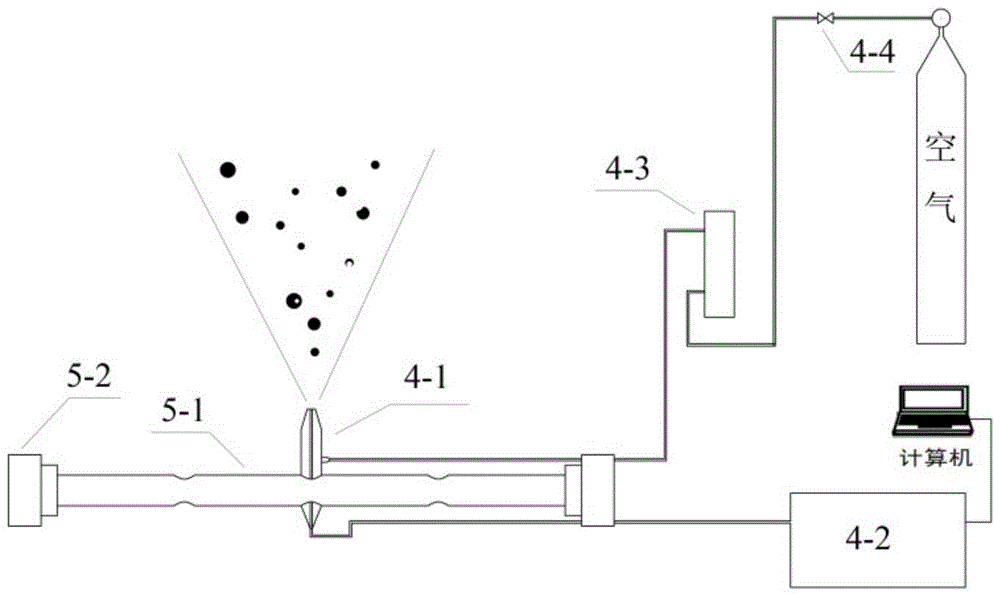

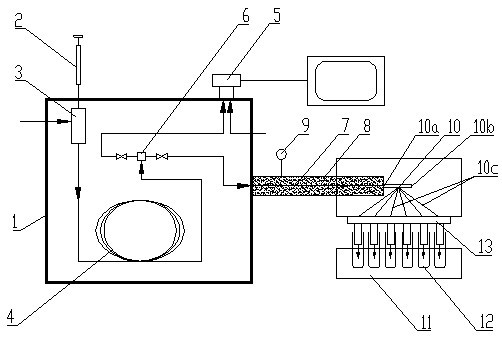

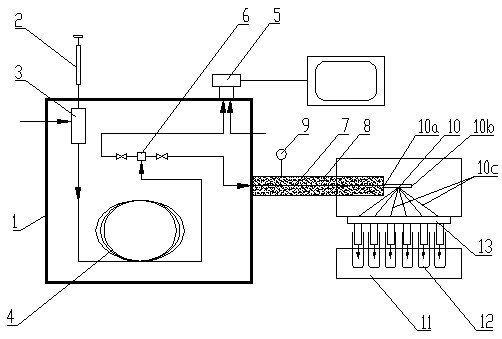

Experimental facility and experimental method for fire suppression effectiveness evaluation of additive-containing water mists

InactiveCN104614485AUniform speedReduce testing costsChemical analysis using combustionMaterial heat developmentStagnation pointData acquisition

The invention discloses an experimental facility and an experimental method for the fire suppression effectiveness evaluation of additive-containing water mists. The experimental facility comprises an oxidizing agent flow quantitative supplying and conveying system, a combustible gas quantitative supplying and conveying system, a representation system, and a data acquisition and remote control system, wherein the oxidizing agent flow quantitative supplying and conveying system is composed of a frequency conversion vortex fan, a vortex shedding flowmeter, a small wind tunnel, an atomization device and a sprayer support; the combustible gas quantitative supplying and conveying system is composed of a columnar porous burner and an automatic gas distributing system; the representation system is composed of a water mist and flame action observation device, a flame temperature measurement device and a condensed phase grain size and speed measurement device. The experimental facility can realize quantitative supplying of air and combustible gas, the adjustability of the particle size distribution and the release amount of the liquid phase fire extinguishing agent and the adjustability of the concentration of additive, and the representation of the temperature of a position nearby a stagnation point, the particle diameter and the speed. The experimental facility can be used for screening high-efficiency water mist additives, quantitatively evaluating the fire suppression effectiveness for specific flames in the aspects of the variety and the concentration of the additive, and researching the physical and chemical mechanism of the action of the condensed phase fire extinguishing agent and the flame.

Owner:UNIV OF SCI & TECH OF CHINA

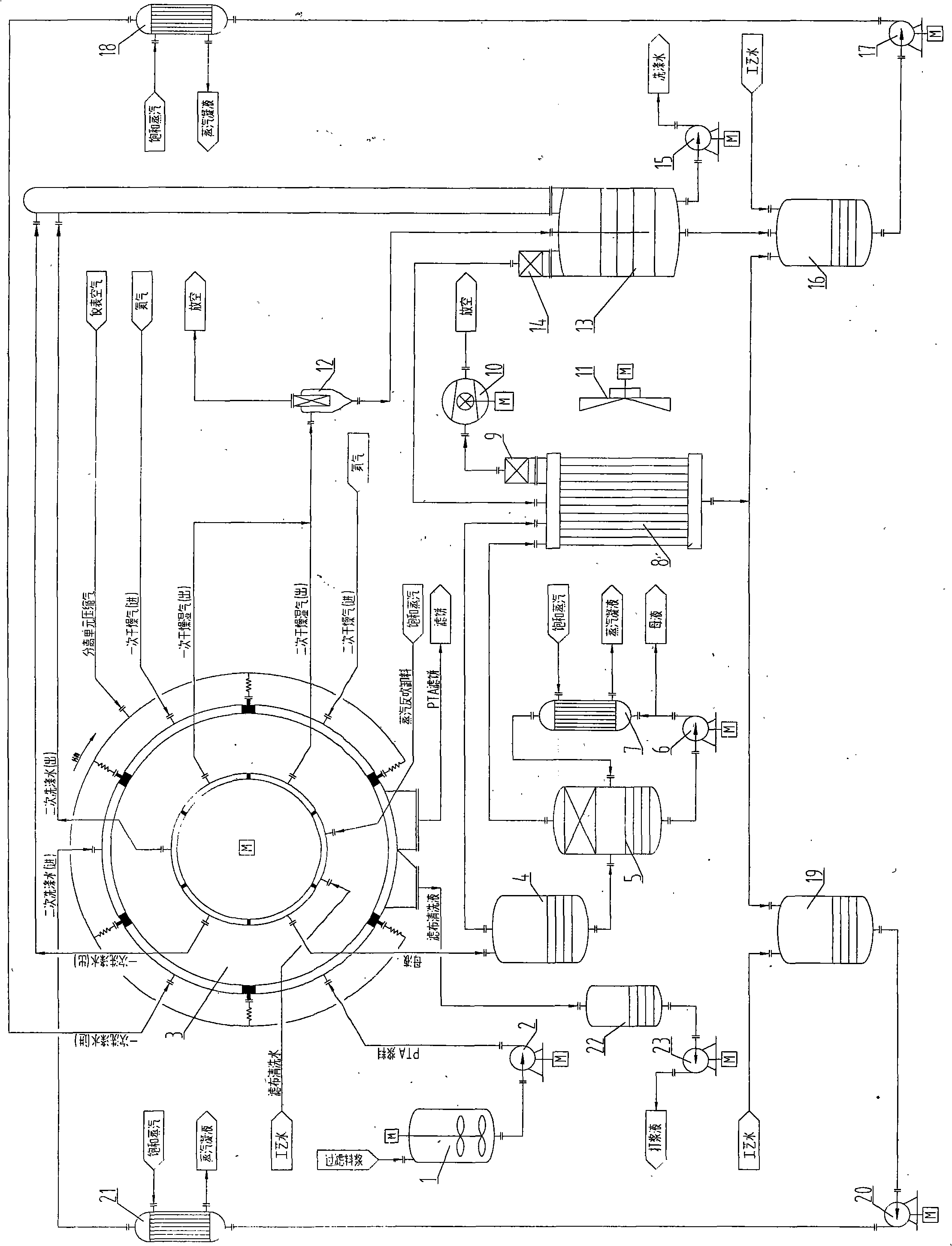

Integral process for washing and filtering terephthalic acid and water recovery

InactiveCN102381964AReduce consumptionNot easy to condenseCarboxylic compound separation/purificationWater recoveryMother liquor

The invention discloses an integral process for washing and filtering terephthalic acid and water recovery, comprising the steps of: pumping a PTA suspension from a PTA slurry tank by a pressure filter to a filter unit chamber with a surface filtrate tube of a rotary drum connected with a control joint; after filtering, collecting the mother liquid in a mother liquid collecting tank; then overflowing in high position to a mother liquid flash drum in which 0.008-0.020MPa (A) vacuum is generated; generating clean steam at 5-60 DEG C by flashing the mother liquid, and at the same time generating 0.008-0.20MPa (A) vacuum in an air cooler so that the clean steam at 5-60 DEG C is condensed to clean water in the air cooler. The recycled clean water can be used as primary and secondary washing water of the pressure filter so as to save water and reduce consumption.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +2

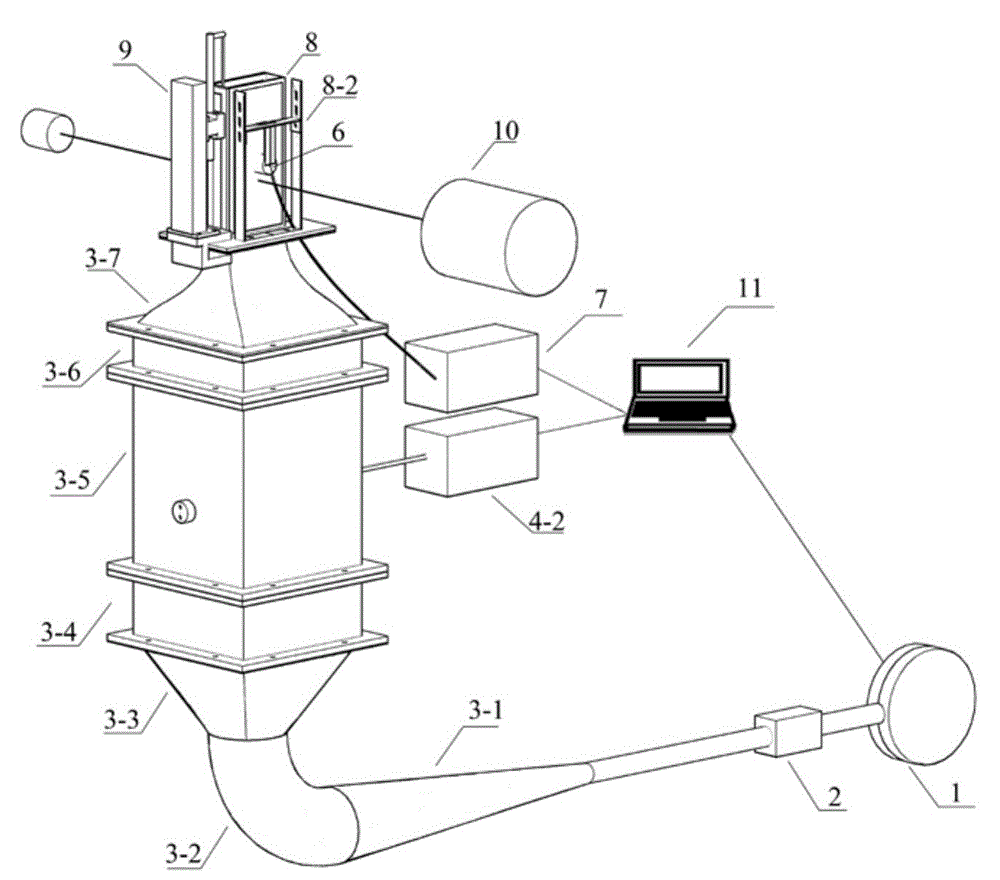

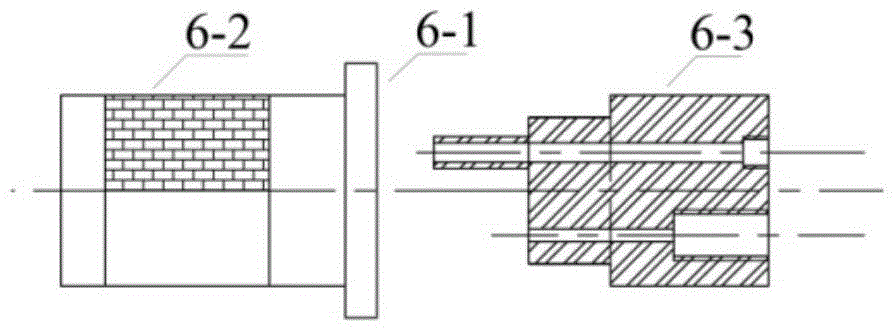

Fixed type flying ash sampling device of coal-fired boiler and method

ActiveCN102928258AFly ash sampling is representativeWith self-calibration functionWithdrawing sample devicesCyclonic separationEngineering

The invention discloses a fixed type flying ash sampling device of a coal-fired boiler. The fixed type flying ash sampling device comprises a sampling device, a cyclone separation and storage device, a fume flow measuring system and a heating device. The invention also provides a fixed type flying ash sampling method of the coal-fired boiler. The method comprises steps of: preheating and sampling a return gas pipeline and blowing sampling system pipelines. By utilizing the device and the system, the operation is simplified, and at the same time the characteristic that the flying ash sampling is good in representativeness is maintained, and sampling at a constant speed under different boiler loads is realized; and furthermore, the possibility that the flying ash is accumulated in the sampling pipeline is greatly reduced, the sampling system is large in fume pressure difference, and meanwhile the sampling pipeline is small in resistance, and thus the sampling system is good in adjustment performance.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

High-recovery-ratio tertiary oil recovery displacement agent

InactiveCN110437814AImprove stabilityReduce interfacial tensionDrilling compositionEmulsionActive agent

The invention discloses a high-recovery-ratio tertiary oil recovery displacement agent which comprises the following raw materials in parts by weight: 1-2 parts of polyacrylamide, 0.4-0.6 part of modified nano silicon dioxide, 6-8 parts of a surfactant, 0.5-1 part of sodium carbonate and 100-150 parts of water. By compounding the modified nano silicon dioxide with the proper surfactant, the compatibility of the two-phase interface is improved, so that the dispersed phase is not easy to condense, the stability of the emulsion is improved, the capillary resistance is reduced, the oil-water interfacial tension is greatly reduced, and the recovery ratio is improved. Furthermore, through mutual cooperation of the other substances, the temperature resistance, the salt resistance and the recoveryratio of the tertiary oil recovery oil displacement agent are further improved.

Owner:HEFEI UNIV

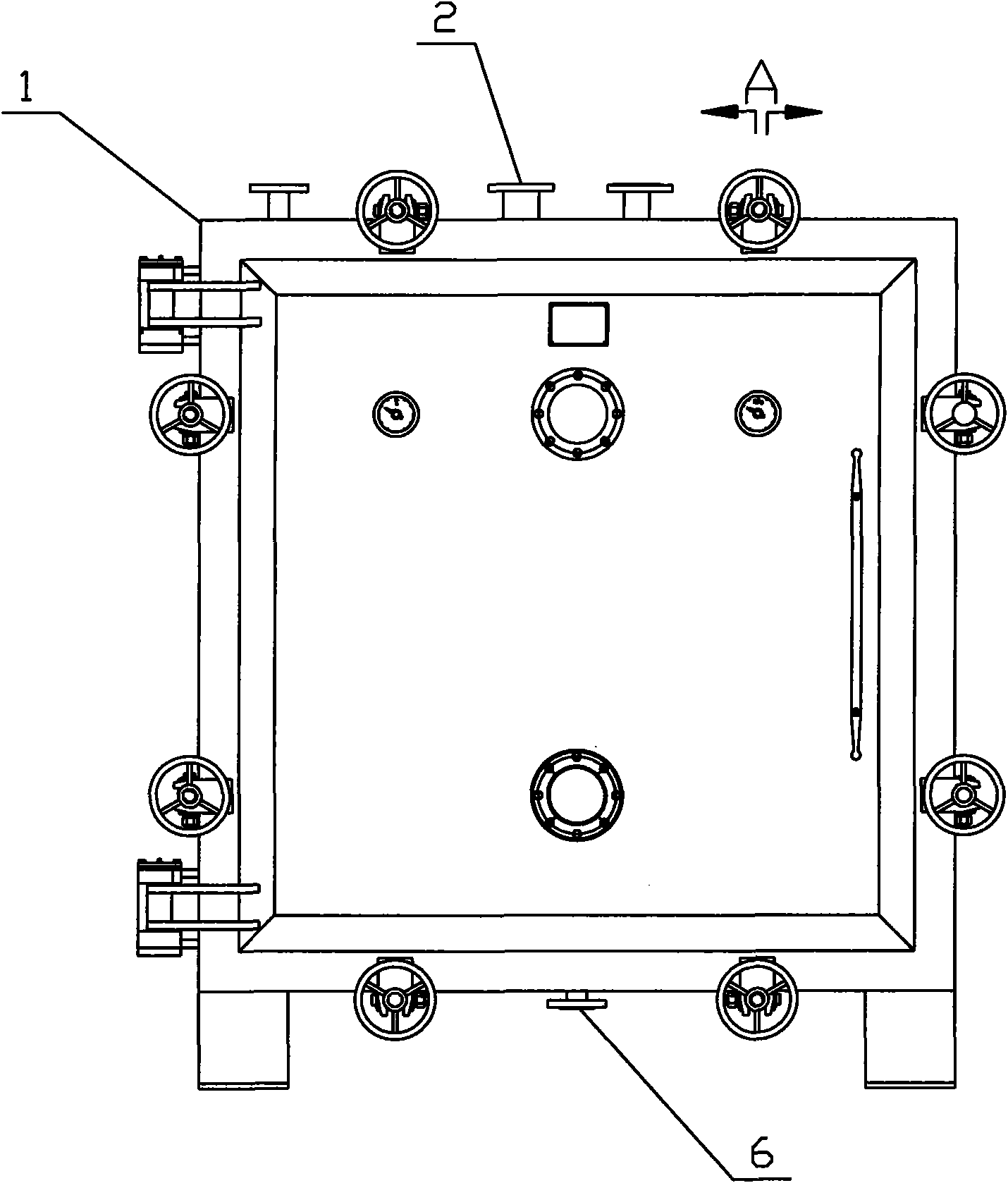

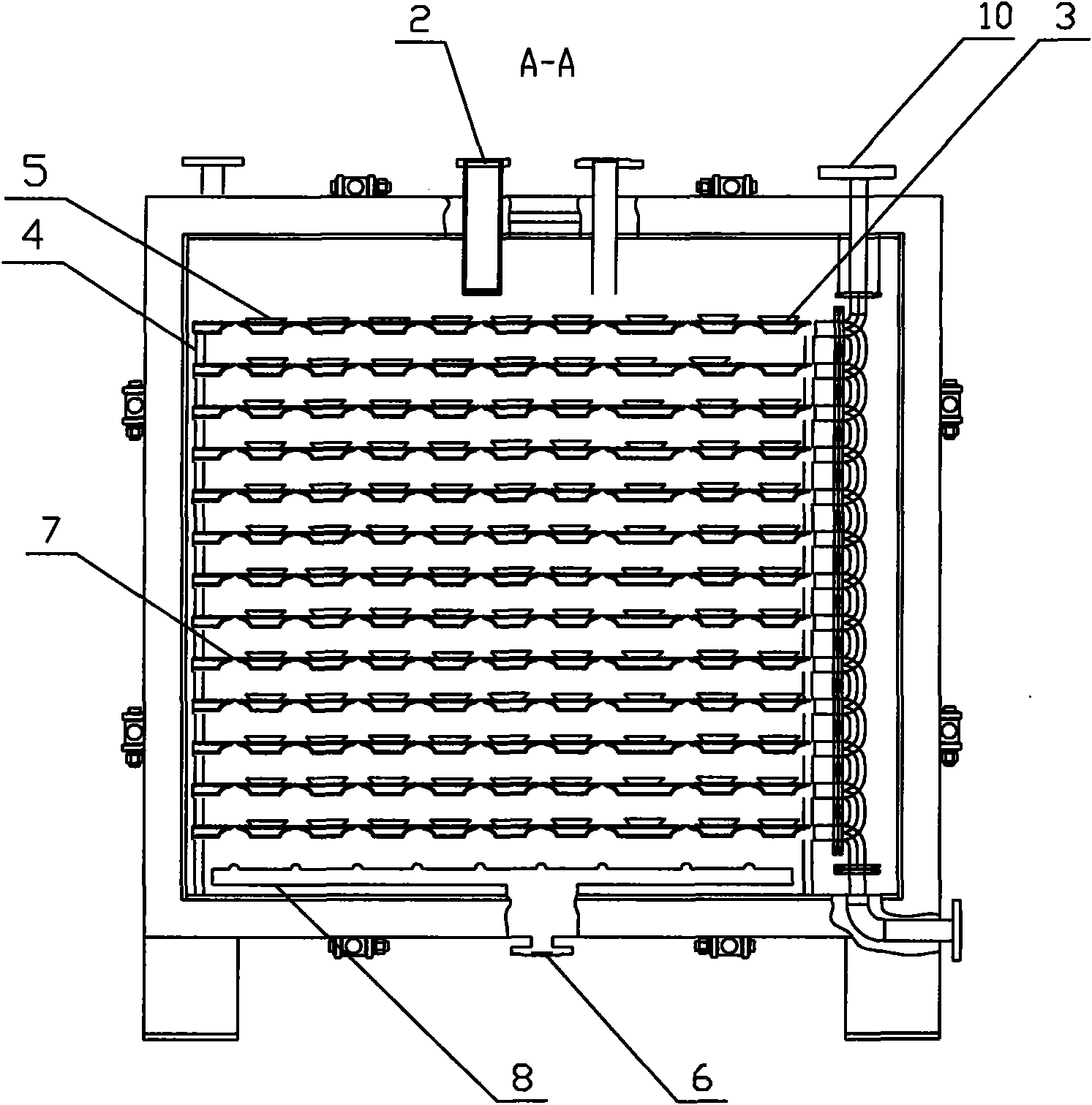

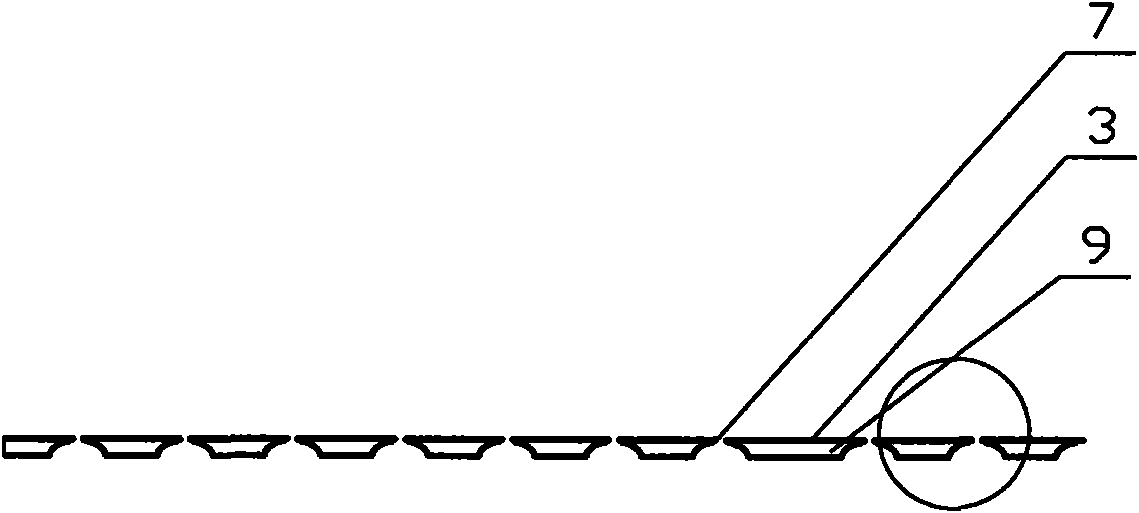

Novel drying oven and drying method thereof

ActiveCN101818985ATake away quicklyReduce steam pressureDrying using combination processesDrying solid materials with heatSteam pressureNitrogen

The invention discloses a novel drying oven. The novel drying oven comprises an oven shell, an air exhaustion hole, an air inlet, a flat plate and a support used for placing the flat plate, wherein a tray used for placing dried materials is arranged on the flat plate; the flat plate is an air-permeable type flat plate; and an air inlet tube is arranged on a drying box for inlet nitrogen or carbon dioxide or inert gases. In the novel drying oven, steam evaporated from wet materials to be dried can be quickly exhausted through an air-permeable structure due to the adoption of the air-permeable type flat plate, and the mass transfer is rapid, so steam pressure of the evaporated steam is lowered, the steam is not easily detained and condensed, and the drying speed is greatly improved; and under the condition of introducing a proper gas such as nitrogen into the air inlet tube, permeable holes can obviously improve the flowing and distribution of the nitrogen in the drying oven, so the steam at all parts of the drying oven can be quickly taken away along with the nitrogen, and the drying speed is further quickened.

Owner:康纳新型材料(杭州)有限公司

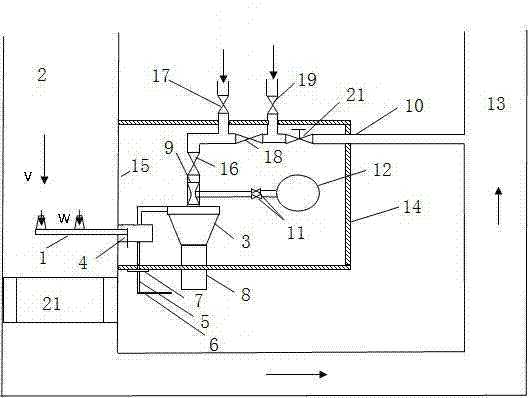

Nozzle device for building 3D printing and control method

ActiveCN110171053AEasy to remove and replaceEasy to clean and repairAdditive manufacturing apparatusDischarging apparatusConstruction 3D printingPrint-through

The invention relates to a nozzle device for building 3D printing and a control method. The device comprises a square port module and a steering module; and the steering module comprises a motor fixedframe, a steering motor, a coupling, a transmission shaft, a driving gear and a driven gear. The steering motor, the coupling, the transmission shaft and the driving gear are connected in sequence; the steering motor is mounted on the motor fixed frame; the driving gear is engaged with the driven gear; the square port module comprises a square nozzle, an inner ring, an outer ring and a sleeve; the square nozzle is mounted at the lower end of the inner ring; the outer ring is embedded at the upper end of the inner ring, and is connected with the sleeve; the motor fixed frame is fixed on the sleeve; and the driven gear is engaged in the inner ring. Compared with the prior art, the device precisely controls free steering of the square port module, can always maintain a tangential state between the angle of the square nozzle and a printing path, preferably solves the arc layering problem on the outer surface of a wall caused by printing through a circular port nozzle, and improves the overall surface quality of the wall.

Owner:TONGJI UNIV

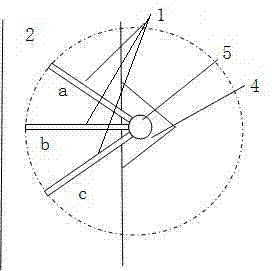

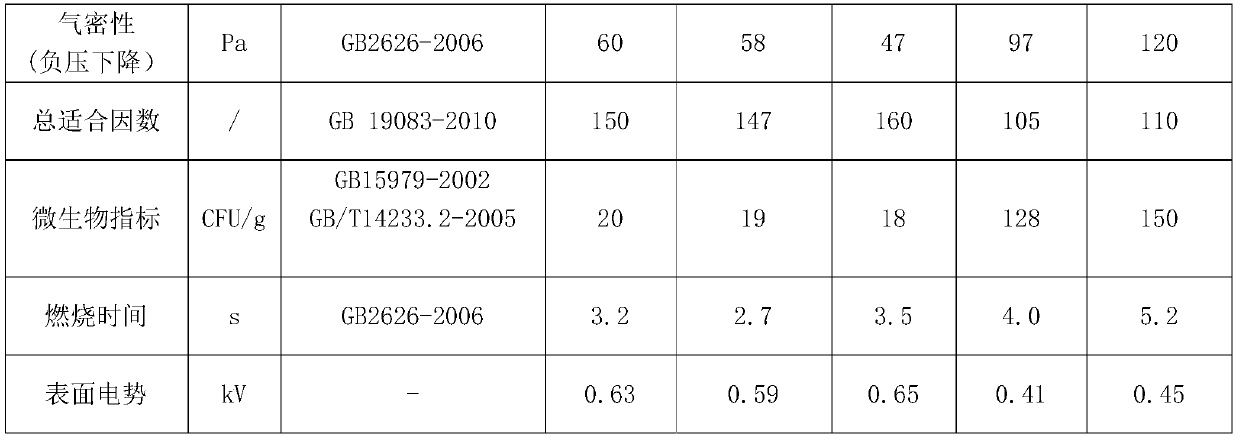

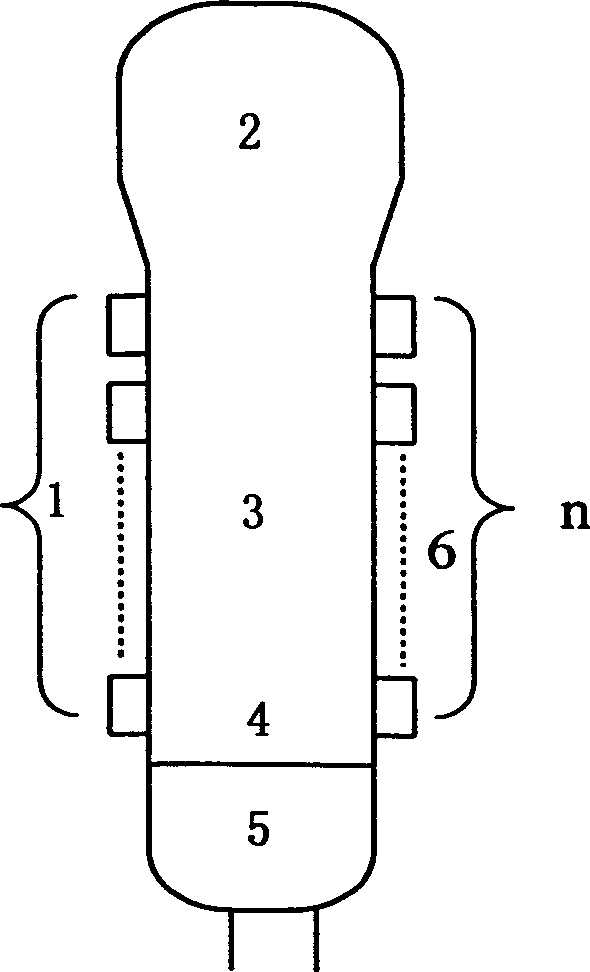

Preparative gas-phase chromatograph device for separating and purifying high-boiling-point volatile monomer component

InactiveCN102141488ANot easy to condenseHigh purityComponent separationPreparing sample for investigationTemperature controlGas phase

The invention discloses a preparative gas-phase chromatograph device for separating and purifying a high-boiling-point volatile monomer component, comprising a column temperature tank, a shunting three-way valve, a sample collection device, a post-column heating device, a sample inlet, a vaporizing chamber, a separation system and a detection device, wherein the sample inlet, the vaporizing chamber, the separation system and the detection device are sequentially communicated, the shunting three-way valve, the vaporizing chamber and the separation system are arranged in the column temperature tank, the sample collection device and the post-column heating device are arranged outsides the column temperature tank, the inlet of the shunting three-way valve is communicated with the outlet of the separation system, one outlet of the shunting three-way valve is communicated with the sample collection device through a pipeline, and the post-column heating device comprises an insulation sleeve sleeved on a pipeline and a temperature control device used for detecting and regulating the temperature in the insulation sleeve. The temperature of the pipeline controlled by the post-column heating device is higher than that in the column temperature tank, thereby the high-boiling-point volatile monomer component is difficult to condense when transported to the sample collection device in the pipeline, mixing of components which sequentially flow out is efficiently avoided, and the purity of a preparative target object is enhanced.

Owner:CHONGQING UNIV

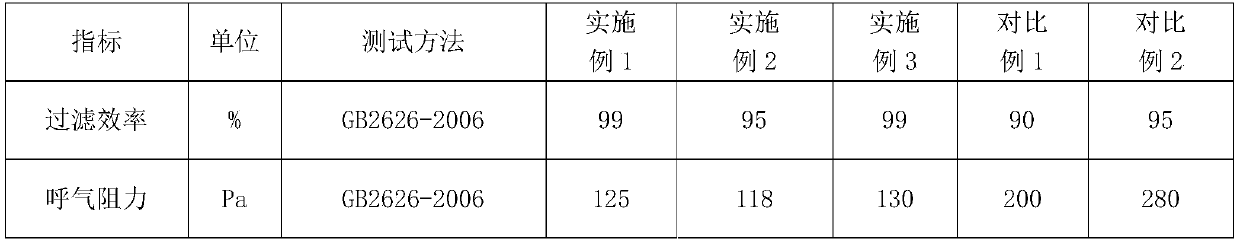

Long-acting electret PP non-woven fabric and preparation method thereof

ActiveCN111321516AReduce surface tensionLow densityUltrasonic/sonic fibre treatmentConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention provides long-acting electret PP non-woven fabric. The long-acting electret PP non-woven fabric is mainly prepared from the following components in parts by weight: 30 to 35 parts of electret master batch, 36 to 44 parts of melt-blown polypropylene, 8 to 17 parts of surface-treated silicon dioxide, 3 to 5 parts of polyvinylidene fluoride, 5 to 7 parts of polytetrafluoroethylene and 3to 5 parts of PFA. According to the long-acting electret PP non-woven fabric and the preparation method thereof provided by the invention, after the non-woven fabric is treated by an electret process, the filtering performance and charge storage performance of fibers are greatly improved, the high temperature resistance and high humidity resistance of the non-woven fabric are effectively improved, meanwhile, the hydrophobic and oleophobic properties of the fibers are also improved, and the service life is prolonged. In addition, the long-acting electret non-woven fabric also has the functionsof antibiosis, disinfection, deodorization and the like.

Owner:青岛科凯达橡塑有限公司 +1

Casting rolling roller surface treatment method of aluminum casting rolling machine

ActiveCN101864567AHigh hardnessQuality improvementMetallic material coating processesGraphiteHardness

The invention relates to a casting rolling roller surface treatment method of an aluminum casting rolling machine, which comprises the following steps: 1) cleaning the surface of a casting rolling roller by a solution prepared from methanol and nitric acid according to a volume ratio of 5 to 20 / 1, and forming an Fe2O3 ferric oxide covering layer with the uniform thickness between 0.05 and 0.1 mm on the surface of the roller; 2) using alcohol for dissolving colloidal graphite, then, adding water to prepare graphite lubrication liquid according to a volume ratio of colloidal graphite / alcohol / water=1 / 0.5 to 2 / 20 to 60, and spraying the graphite lubrication liquid onto the surface of the casting rolling roller; and 3) heating circulated water by steam so that the water temperature can reach 30 to 70 DEG C, introducing the water into the inside of the casting rolling roller to cyclically heat the casting rolling roller, and then, drying the surface of the roller. The casting rolling roller surface treatment method of the aluminum casting rolling machine of the invention improves the surface hardness of the casting rolling roller, improves the friction characteristics, improves the lubrication effect, eliminates the stress enrichment of the roller in the plate standing process, slows down the generation trend of cracks on the surface of a roller sleeve, and prolongs the service life of the roller sleeve of the roller.

Owner:YUNNAN ALUMINUM

Aluminum scrap recycling device

ActiveCN105522434AReduce energy consumptionIncrease productivityMagnetic separationMaintainance and safety accessoriesMagnetic separatorEngineering

The invention relates to an aluminum scrap recycling device which comprises a duplex packing auger, a crusher, a dehydrator, a magnetic separator, a dryer and a melting tank, wherein a first spreading plate lifter is arranged between the duplex packing auger and the crusher; a second spreading plate lifter is arranged between the crusher and the dehydrator; a third spreading plate lifter is arranged between the dehydrator and the magnetic separator; and a fourth spreading plate lifter is arranged between the magnetic separator and the dryer. The aluminum scrap recycling device is used for recycling aluminum scraps, is low in energy consumption, is high in production efficiency, is safe and reliable, and saves cost.

Owner:ZHENJIANG YUJIU INTELLIGENT EQUIP LTD BY SHARE LTD

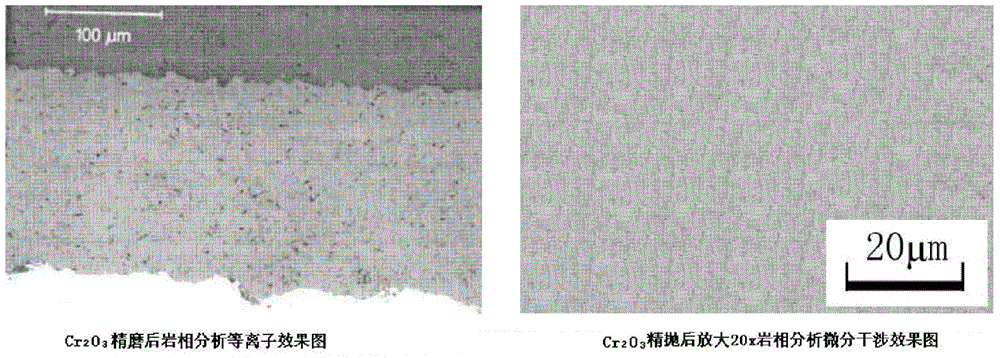

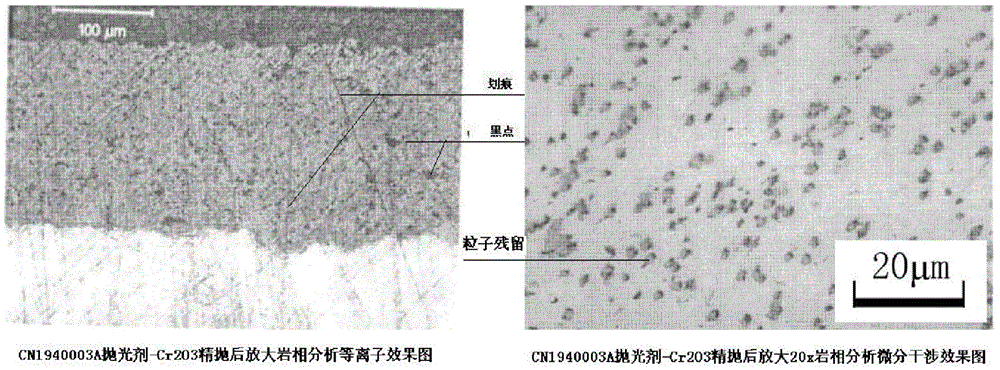

High-efficiency diamond polishing agent and preparation method thereof

ActiveCN104059539APlay a buffer roleImprove polishing effectPolishing compositions with abrasivesOctahedronHigh carbon

The invention discloses a high-efficiency diamond polishing agent which is prepared from the following raw materials in percentage by weight: 5-20 percent of ultra-precision diamond micro powder, 10-20 percent of ethyl orthosilicate, 20-30 percent of solvent, 0.2-0.8 percent of strong acid, 10-30 percent of surface active agent, 10-25 percent of wetting agent, 5-15 percent of dispersing agent and 0.1-5 percent of PH conditioning agent. According to the high-efficiency diamond polishing agent, the diamond micro powder is subjected to surface modification by using ethyl orthosilicate, so that a silicon dioxide coating layer is formed on the surface of the diamond micro powder, and during polishing, the coating layer plays a role in buffering the diamond micro powder on the inner layer; through performing multiple times of crushing and shaping on the diamond micro powder and improving surface modification process, the morphology of the diamond micro powder is closer to an octahedron; the prepared polishing agent has a better polishing effect to high-hardness metal materials such as high-carbon steel, also has a better polishing effect to crisp and hard materials such as Cr2O3, ceramics, jade and quartz, and is capable of completely preventing the damage on the surface of a material to be polished, and free from generating scratches, black points, and particle surface residues during polishing.

Owner:武汉三灵新材料有限责任公司

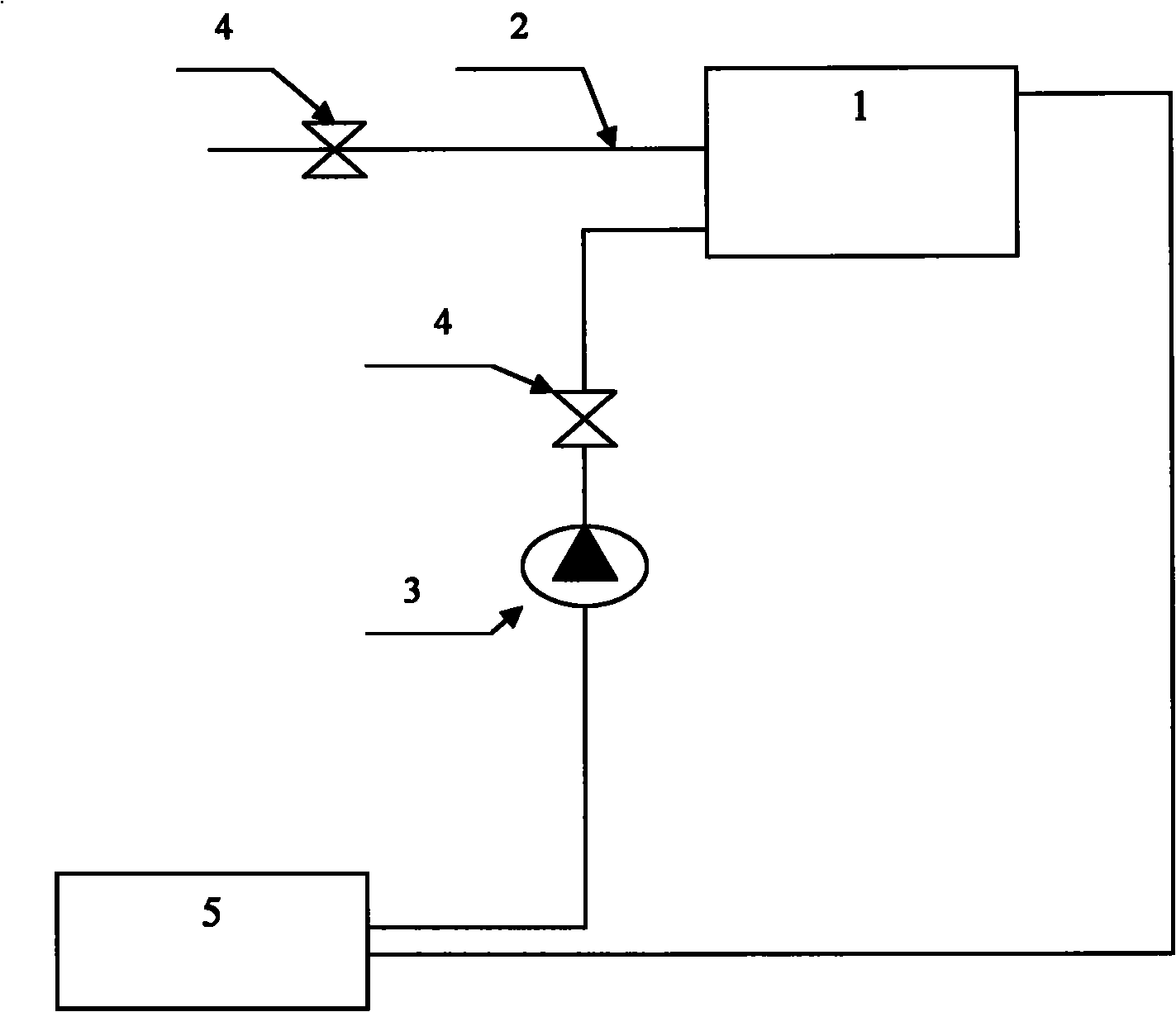

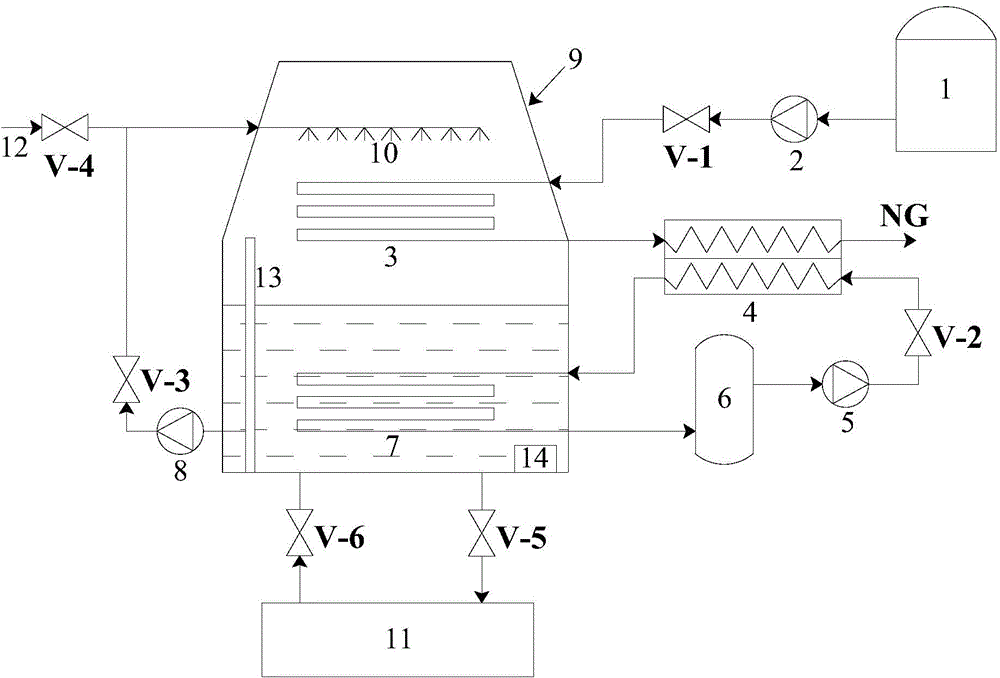

Ice storage method and device comprising an atmospheric tower and utilizing cold energy of LNG

InactiveCN104154416ASmall temperature differenceNot easy to condenseLighting and heating apparatusIce productionIce storageWater source

The invention discloses an ice storage method and device comprising an atmospheric tower and utilizing the cold energy of LNG. In the gasification process of LNG, a liquid nozzle is utilized to spray water onto a first heat exchange coil, water and LNG exchange heat directly, the LNG temperature rises to be close to the lowest work temperature of a refrigerant, then LNG exchanges heat with the refrigerant through a heat exchanger to be gasified, the cooled refrigerant transmits cold energy to water through a second heat exchange coil, and ice storage is performed in water of the atmospheric tower; at the same time, water which is not condensed in the atmospheric tower is mixed with an external supplement water source through a circulating pump, and then the mixture enters the liquid nozzle and returns to the bottom of the tower after passing through the first heat exchange coil. On one hand, the direct heat exchange between water and LNG can be carried out, on the other hand, a refrigerant delivery pipe is free of condensation blockage caused by a condition that the LNG temperature is far lower than the lowest work temperature of the refrigerant.

Owner:ZHEJIANG RUNQI ENERGY SAVING TECH +1

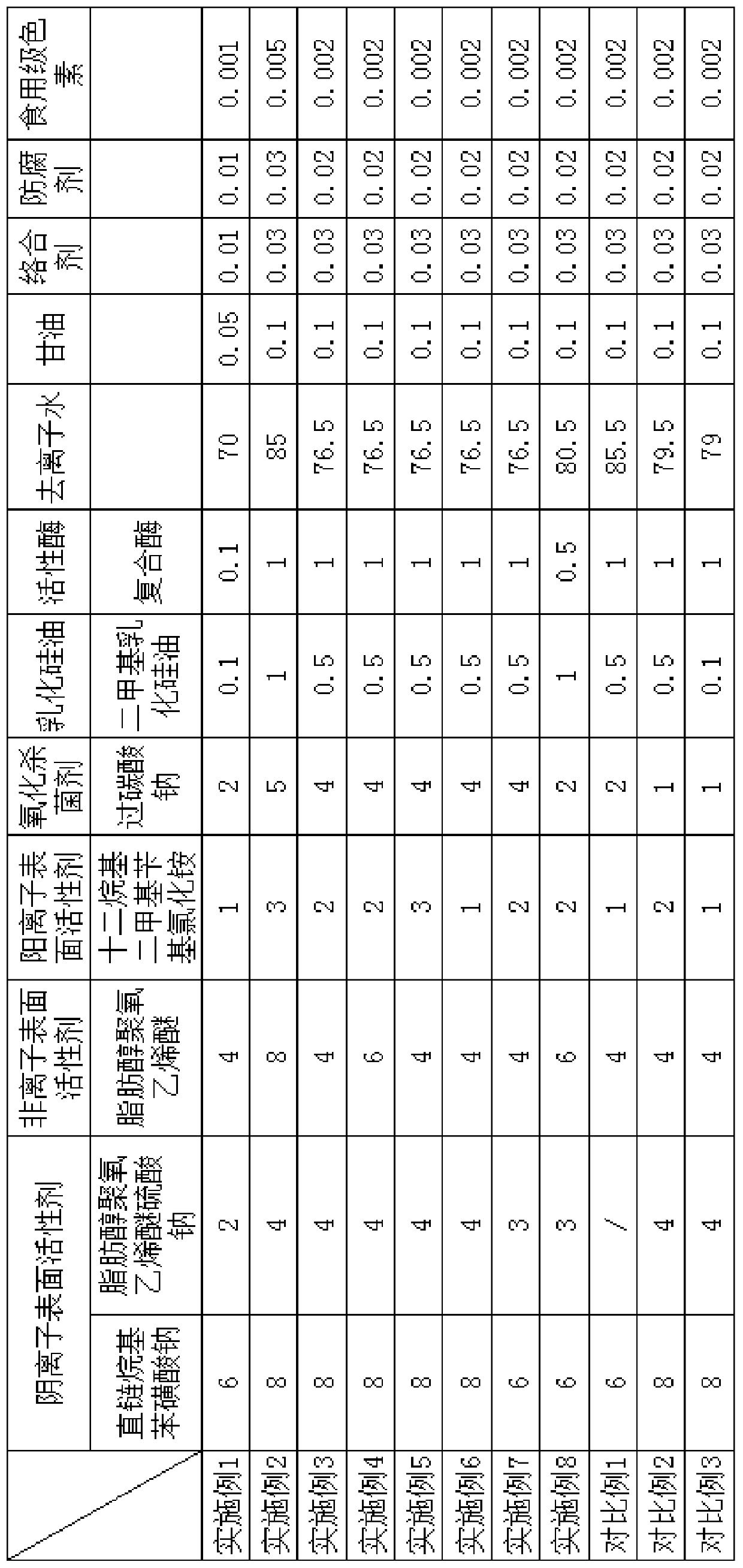

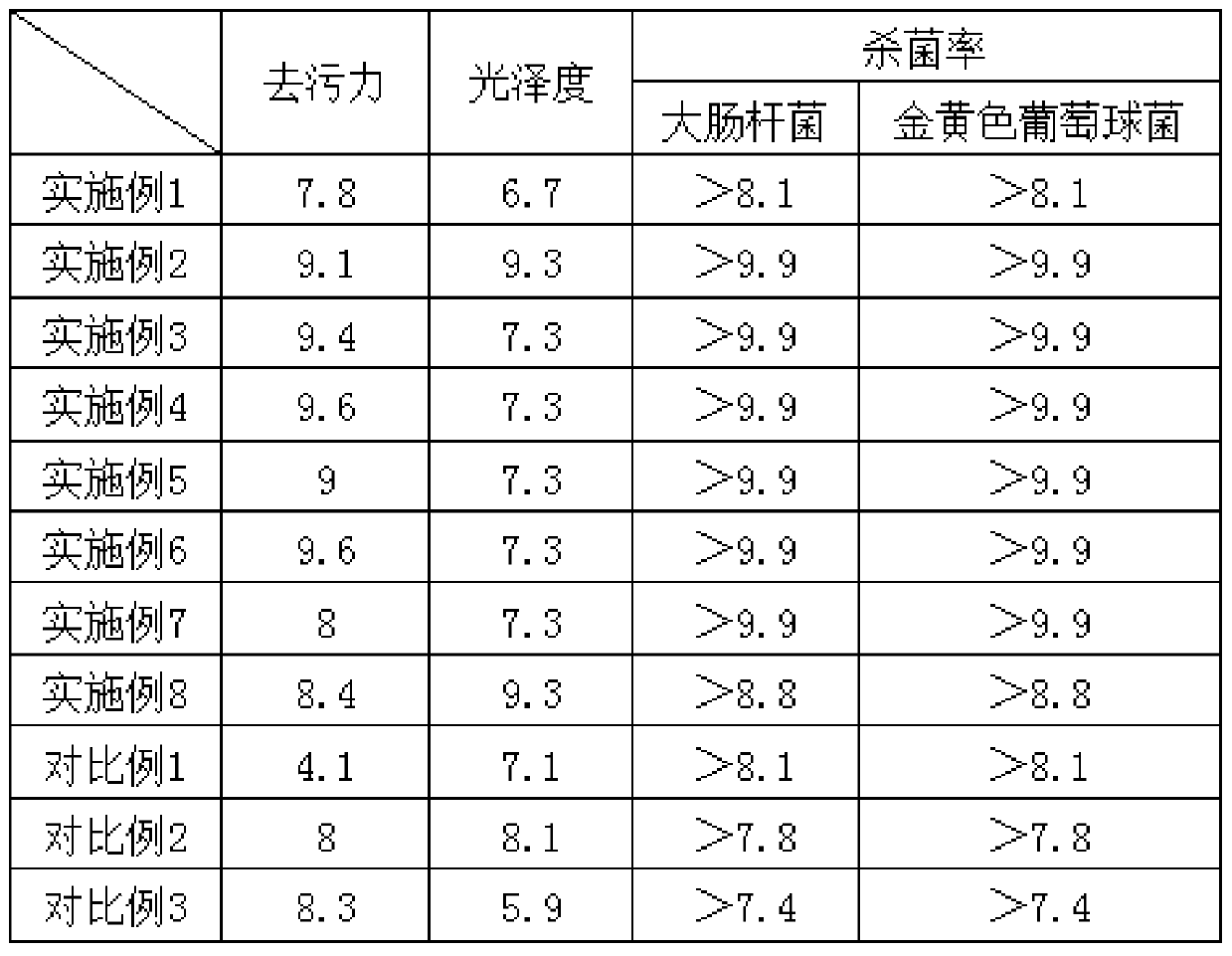

Environment-friendly vehicle interior cleaning fluid and preparation method and using method thereof

InactiveCN110373279AEliminate odorNot easy to condenseCationic surface-active compoundsOrganic detergent compounding agentsEscherichia coliSterile environment

The invention provides environment-friendly interior cleaning fluid and a preparation method and using method thereof. The environment-friendly interior cleaning fluid is prepared from the componentsin parts by weight: 8-12 parts of an anionic surfactant, 4-8 parts of a nonionic surfactant, 1-3 parts of a cationic surfactant, 2-5 parts of an oxidization bactericide, 0.1-1 part of a silicone emulsion, 0.1-1 part of an active enzyme, and 70-85 parts of deionized water. The environment-friendly interior cleaning fluid is mild and does not hurt hands, further has strong bactericidal and bacteriostatic functions besides the ability to quickly remove dirt of vehicle interiors, 99% of escherichia coli, staphylococcus aureus and the like can be completely killed, mouldproof and mothproof effectsare achieved, the effects of sterilization and bacteriostasis on bacterium breeding are achieved, the foreign flavor in a vehicle can be eliminated, protective films are formed on the surfaces of theinteriors after cleaning, regenerated dirt is not prone to being coagulated, the interiors are clean as new, and meanwhile the protection effect on interior plastic parts and genuine leather is achieved; and all the adopted materials are environmentally friendly and degradable, the requirement of environmental protection is achieved, and after cleaning, a vehicle owner can drive in a clean and sterile environment with safety.

Owner:上海旗致环保新材料有限公司

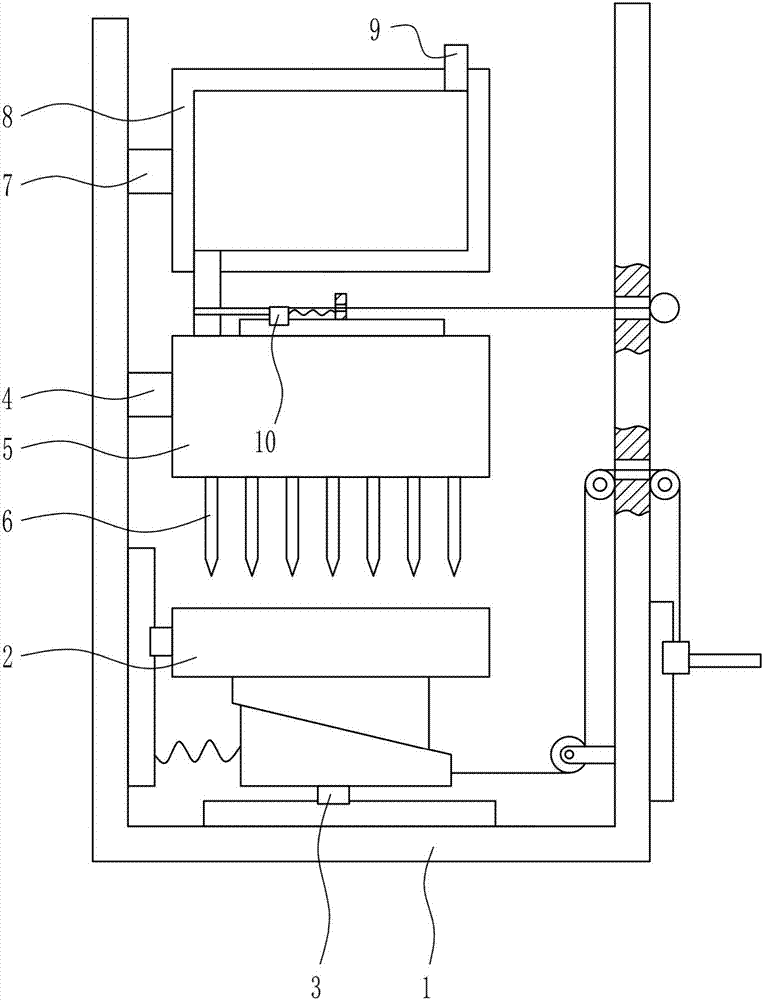

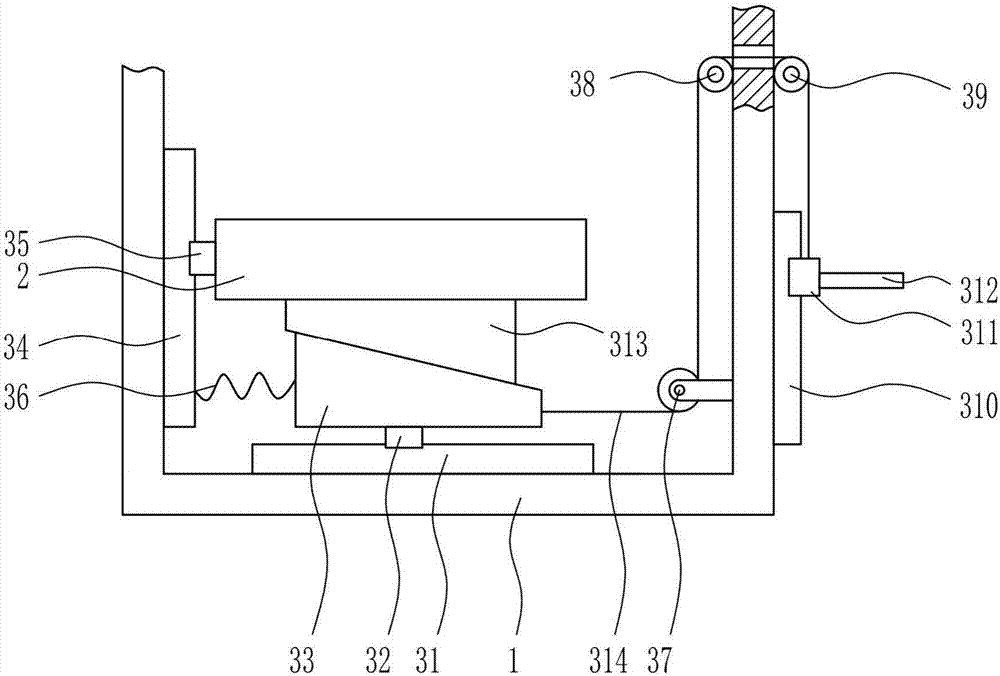

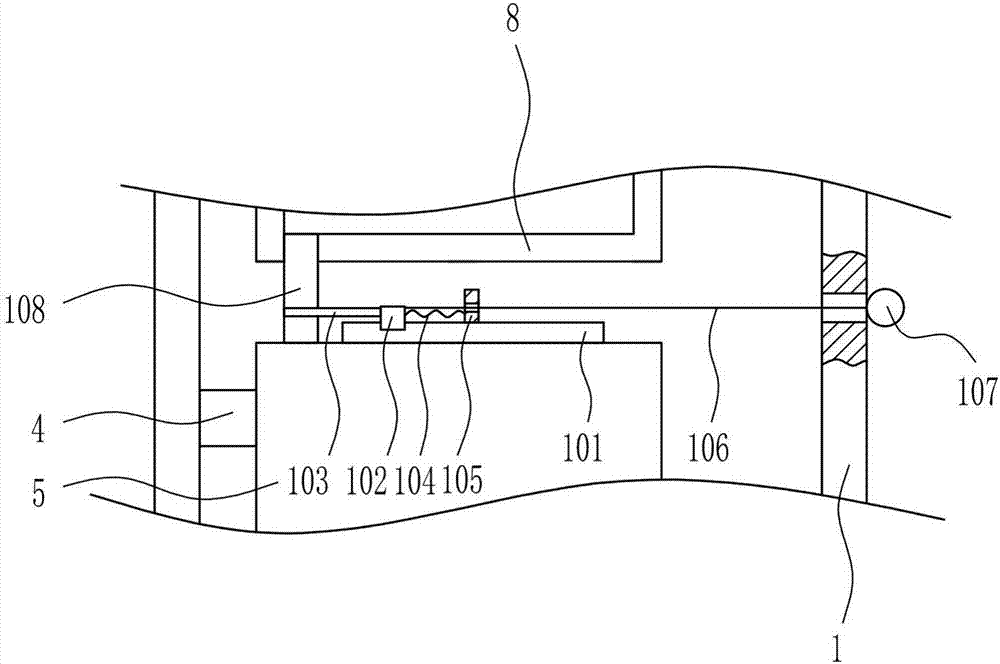

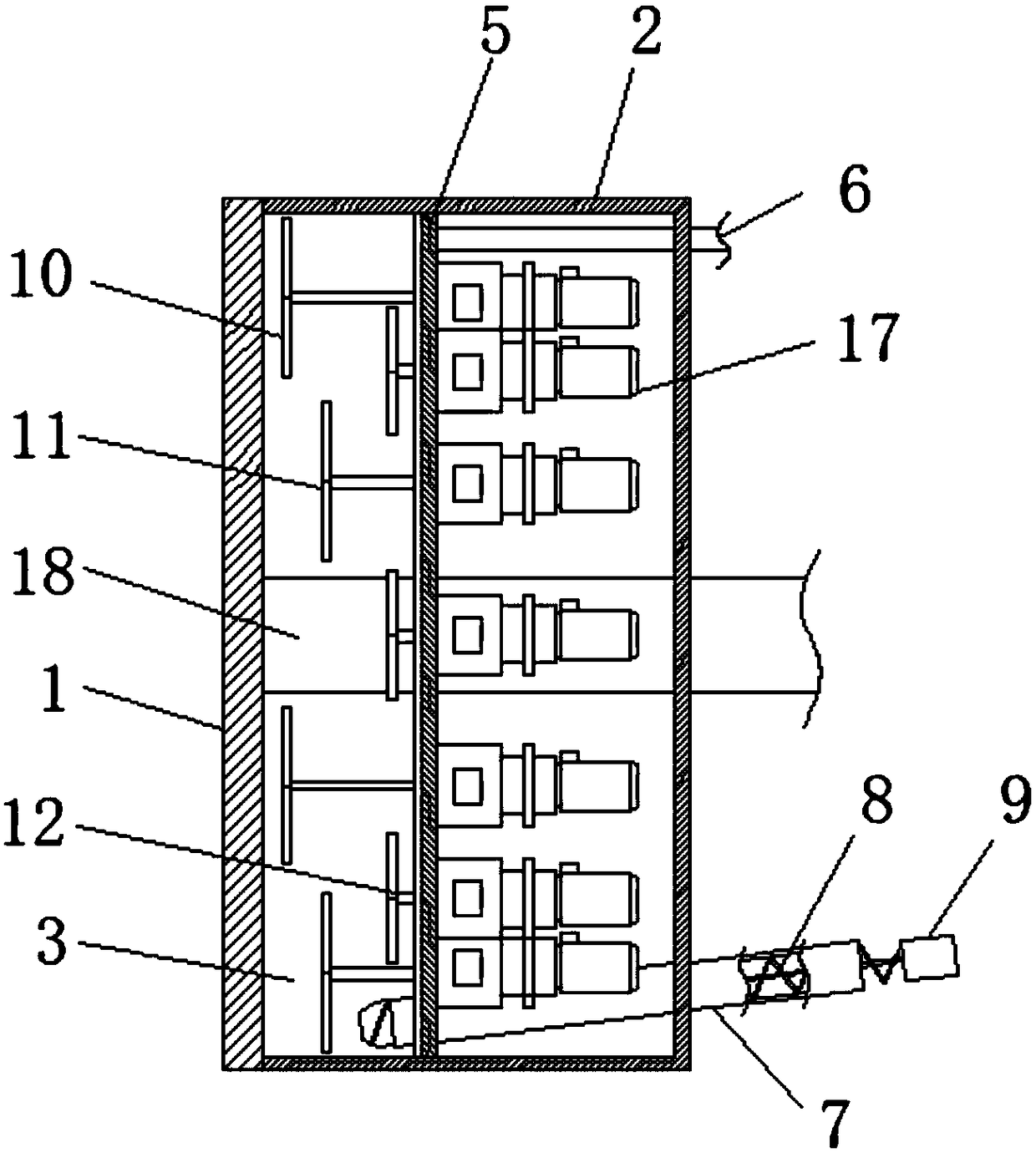

Dispensing equipment for energy saving lamp manufacturing

InactiveCN106914381ANot easy to condenseQuality assuranceLiquid surface applicatorsCoatingsAdhesiveArchitectural engineering

The invention relates to dispensing equipment, and especially relates to dispensing equipment for energy saving lamp manufacturing. The invention aims to provide dispensing equipment having the advantages that the adhesive is difficult to cure and the adhesive amount can be controlled easily. The provided dispensing equipment comprises an installation rack, a disposing plate, an elevating device, a first support rod, a material storage tank, and dispensing heads. The elevating device is installed in the installation rack. The top of the elevating device is provided with the disposing plate. The middle of the left wall in the installation rack is provided with the first support rod. The right end of the first support rod is connected to the material storage tank. Dispensing heads are evenly arranged on the bottom of the material storage tank. A second support rod is arranged on the upper part of the left wall in the installation rack. The right end of the second support rod is connected to a box. The right side of the top of the box is provided with a feed pipe. By pressing a pedal, an LED support, which is placed on the disposing plate and needs to be dispensed, is raised to a proper height, the dispensing position becomes more accurate, and the dispensing effect is better.

Owner:GRACE(NINGBO) LIGHTING CO LTD

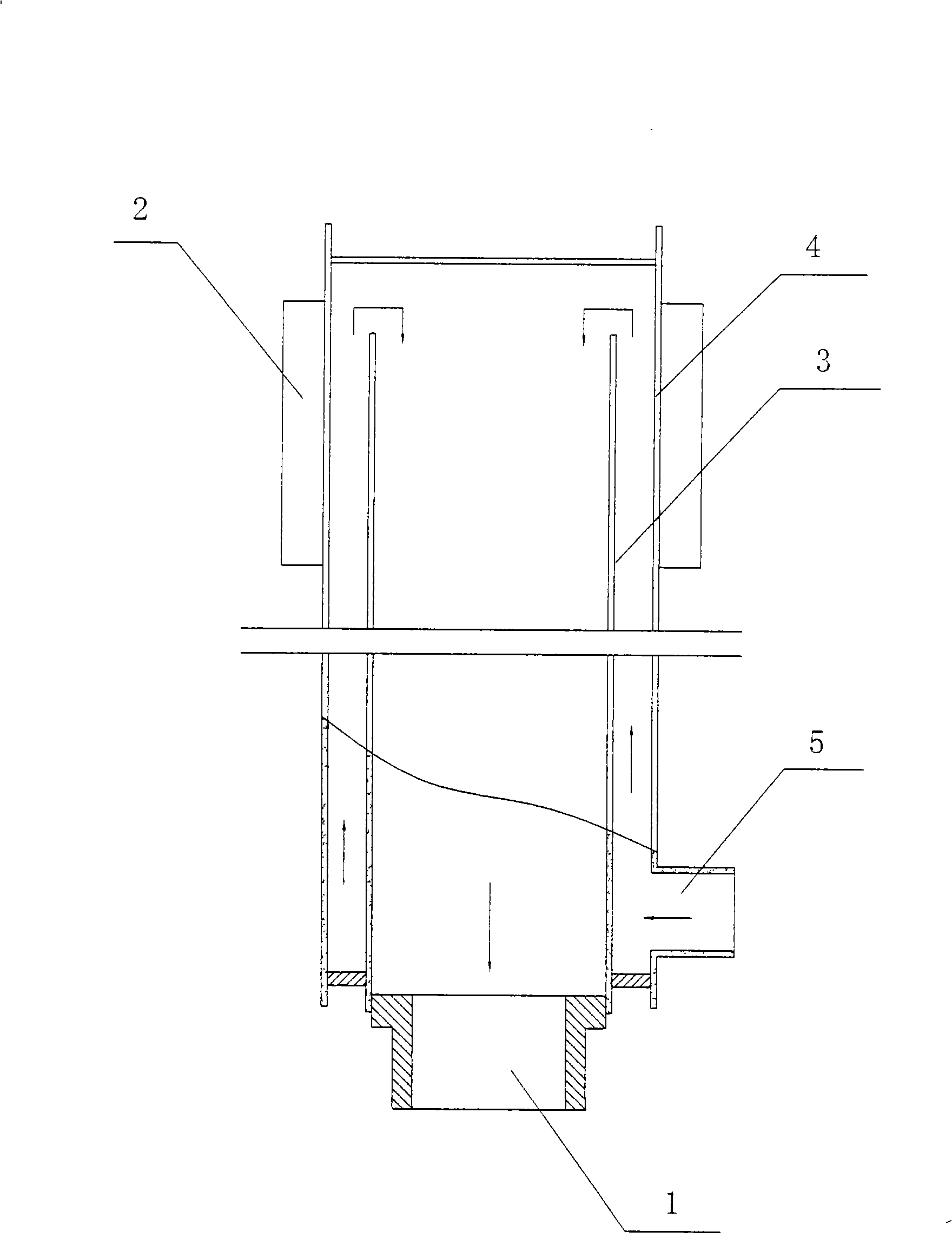

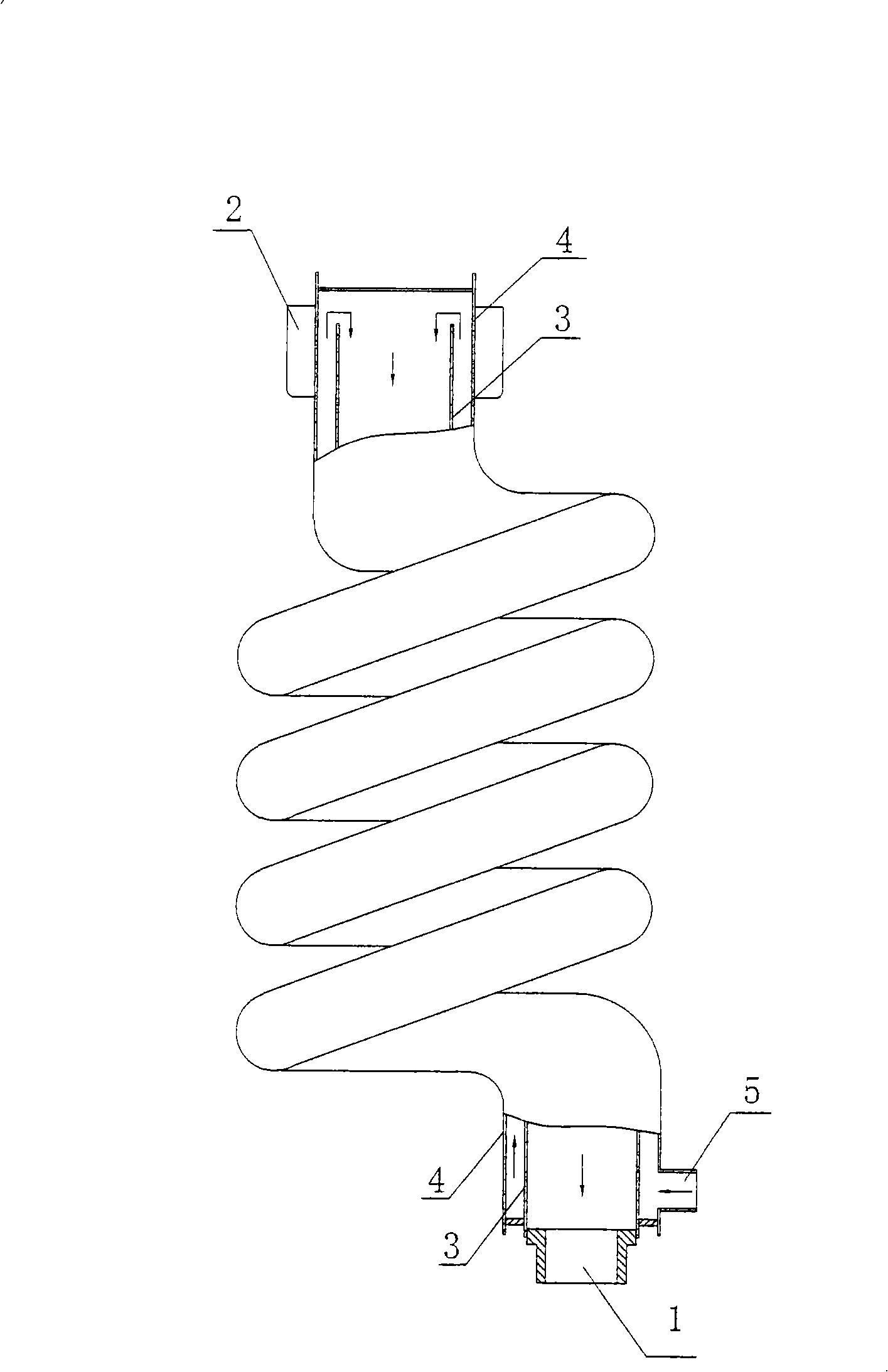

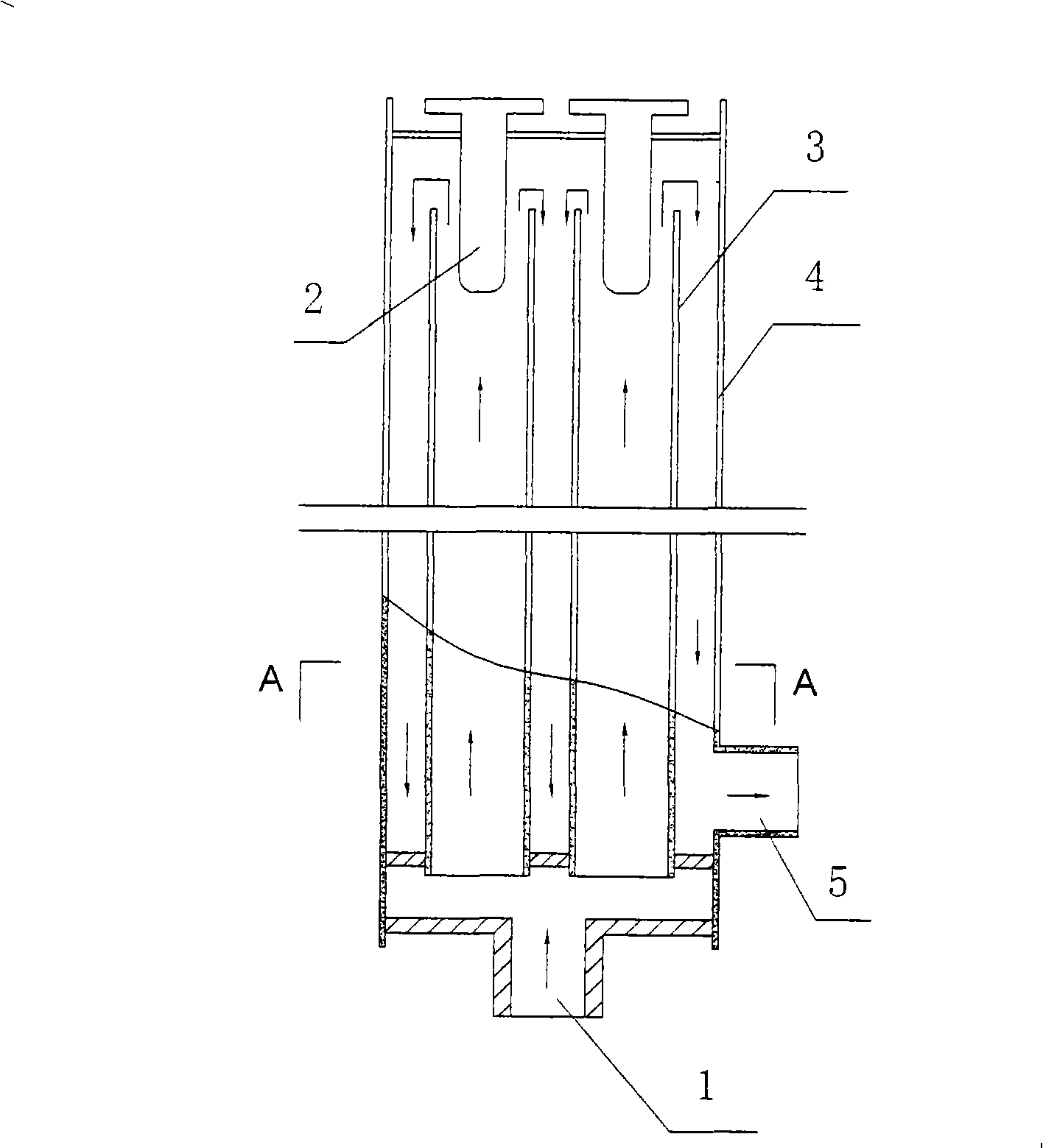

Drinking water heat exchange system and drinking machine

InactiveCN101344364ANot easy to condenseSolve the problem of thermal efficiency impactBeverage vesselsStationary tubular conduit assembliesThermal energyEngineering

The invention belongs to the technical field of water heating devices, in particular to a drinking water heat exchange device and a drinking fountain which is provided with the heat exchange device. The drinking water heat exchange device and the drinking fountain are designed against the problem of waste of heat energy during the process from boiling drinking water to cooling the drinking water by people for drinking in the previous years. The drinking water heat exchange device of the invention allows water which is boiled by a heating component and supplementary cold water to be divided by the pipe wall of an inner pipe in an outer pipe and to carry out reverse flow by the arrangement of the inner pipe and the outer pipe, the heat exchange is carried by a dividing wall, the pre-heating of the cold water is carried out at the same time of reducing the temperature of the boiled water, thereby allowing the temperature to be gradually improved for easily boiling, the recovered heat energy is recycled in the continuous heating, thereby reducing the requirements on the power of the heating component; compared with the prior art, the drinking water heat exchange device has obvious energy-saving potential; the boiled water which is cooled after the temperature decrease can be directly drunk.

Owner:陈宇彤

Full-sea-depth unmanned submersible

ActiveCN106828834ALow costReduce weightVessel partsUnderwater equipmentMaterial typeStructure of the Earth

The invention discloses a full-sea-depth unmanned submersible. The full-sea-depth unmanned submersible is characterized in that low-cost easily-available lightweight common materials resistant to seawater corrosion and collision and having a certain structural strength are used for making a dimensional shell of the submersible; the interior of the submersible and all interior gaps of all equipment, facilities and components carried by the submersible are filled with liquid, so that a closed space type pressure resisting mode that an exterior hard pressure-resistant dimensional shell of a previous submersible bears all pressure is converted into a material-type pressure resisting mode that materials for manufacturing the dimensional shell of the submersible as well as the equipment, the facilities and the components carried inside the submersible bear pressure jointly. The full-sea-depth unmanned submersible has the advantages that the characteristics that liquid is incompressible, liquid with a roughly consistent density bears no larger pressure and the pressure is conductible are used, so that manufacturing cost of the submersible is reduced significantly, and the submersible is not restricted by a submerged depth.

Owner:王晓航

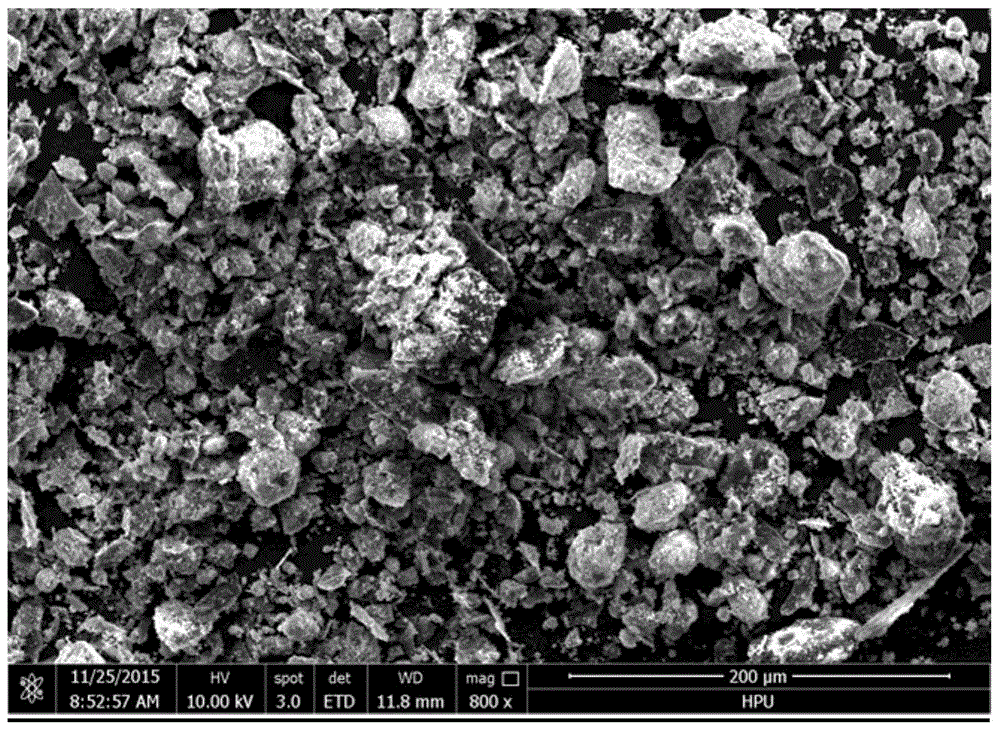

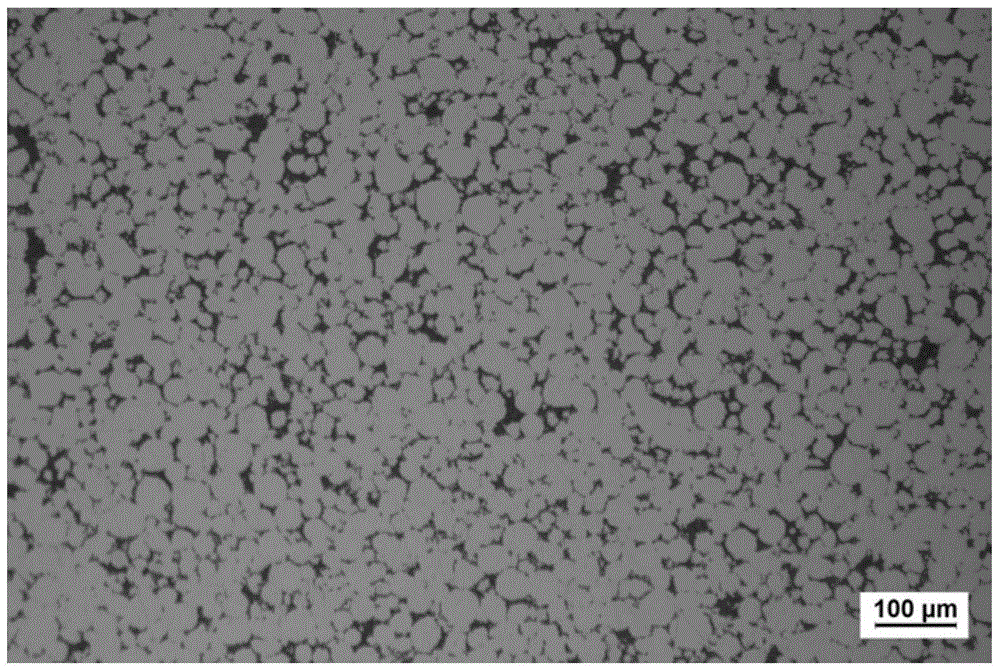

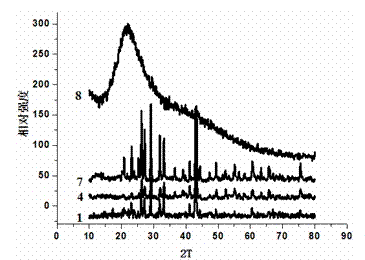

Aluminum-coated graphite composite powder, aluminum-graphite composite comprising composite powder and preparation method thereof

InactiveCN105689702AGood vibration absorptionEasy to processTransportation and packagingMetal-working apparatusEthylenediamineEpoxy

The invention provides aluminum-coated graphite composite powder, an aluminum-graphite composite comprising the composite powder and a preparation method thereof. The aluminum-coated graphite composite powder comprises nanoscale aluminum powder or aluminum alloy powder, graphite and an adhesive, wherein the particle size of the nanoscale aluminum powder or aluminum alloy powder is 50-100nm; the particle size of the graphite is 20-70 microns; the graphite is a coated core; the adhesive is composed of epoxy resin and / or phenolic resin, diluted epoxy liquid, ethylenediamine and / or an NL curing agent; the nanoscale aluminum powder or aluminum alloy powder is coated on the surface of the graphite via the adhesive. Through the aluminum-coated graphite composite powder, the problems of the segregation of the graphite in the preparation process of the aluminum-graphite composite and the limitation of a process of chemically plating copper / nickel on the surface of the graphite can be solved.

Owner:HENAN POLYTECHNIC UNIV

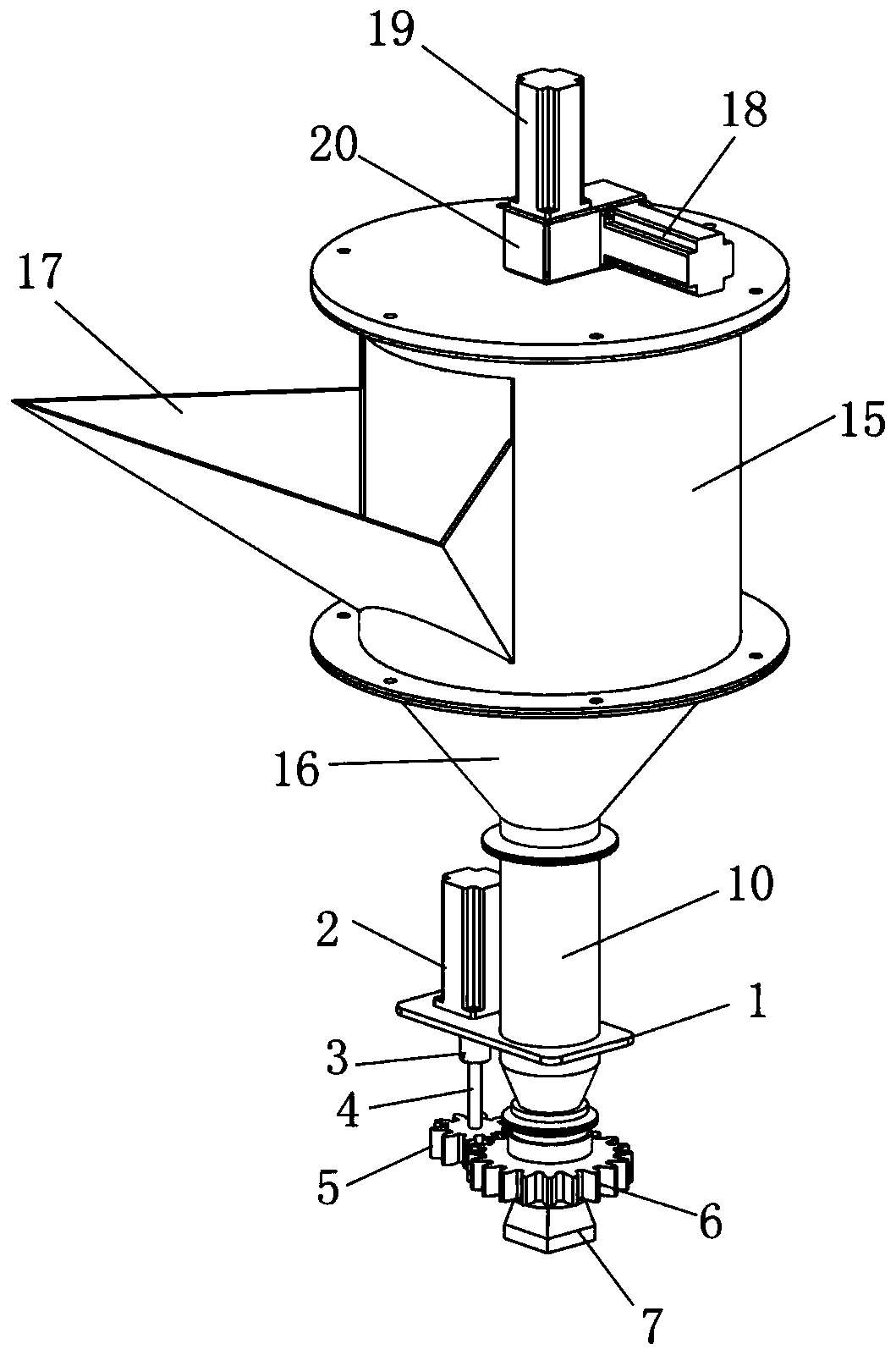

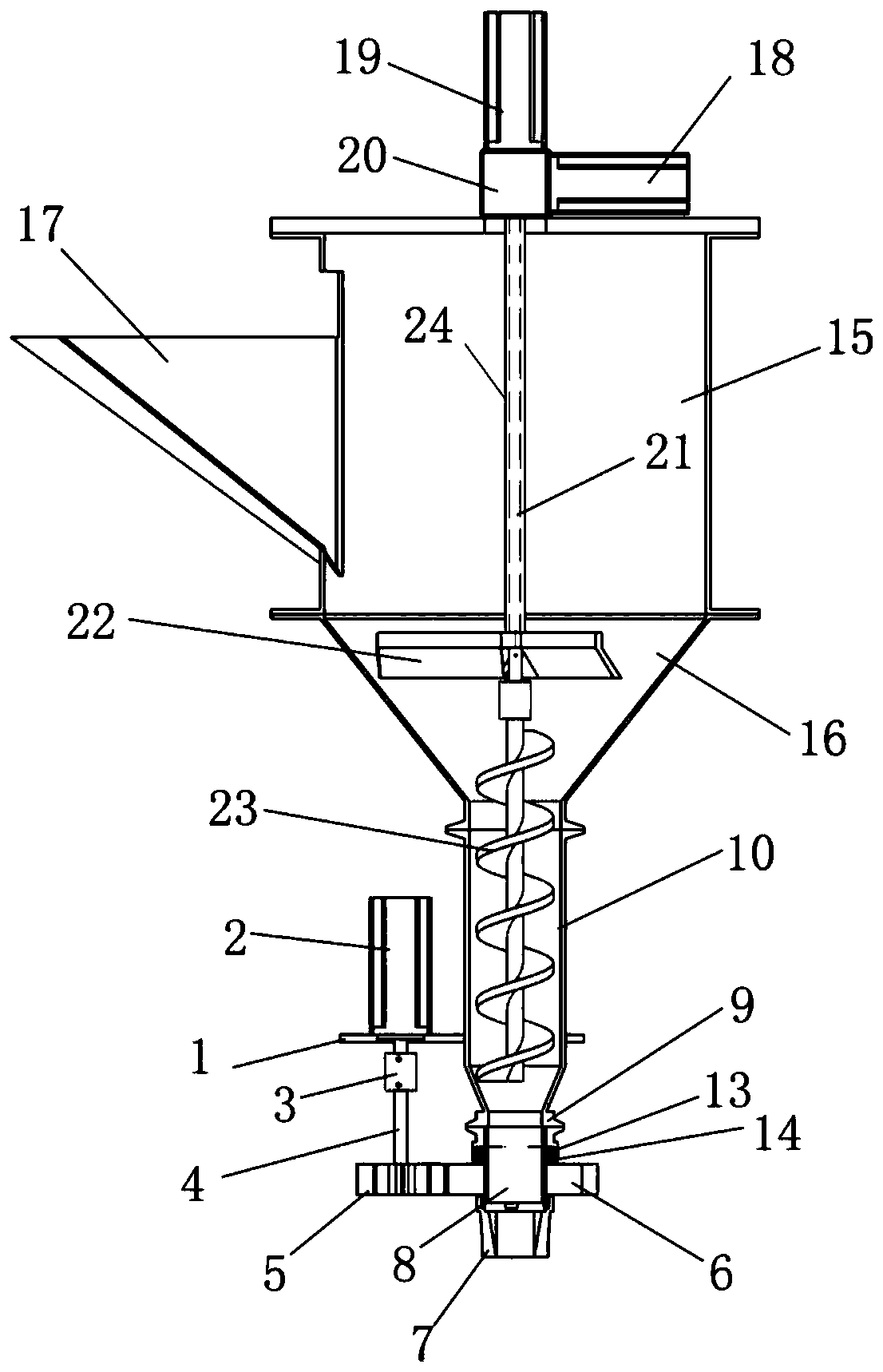

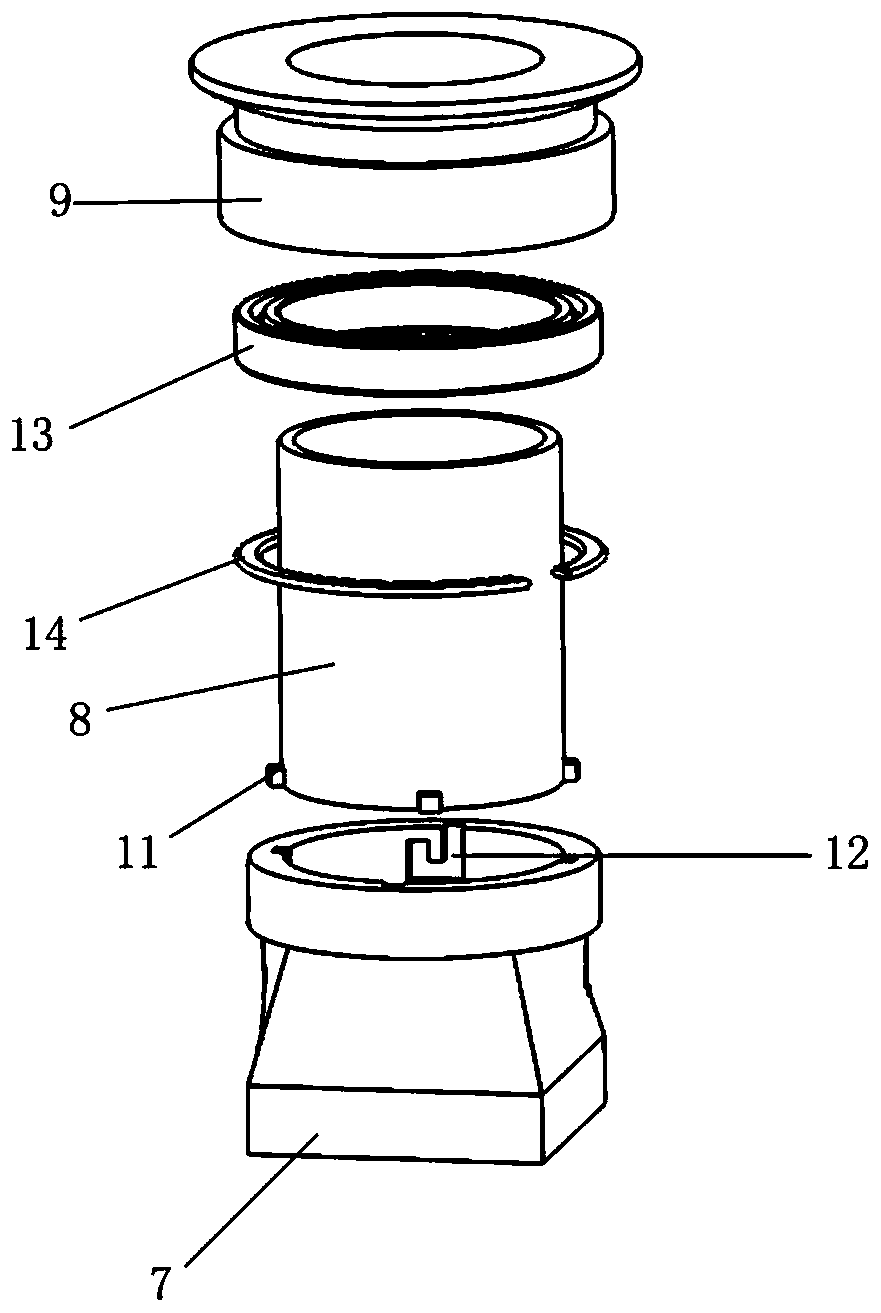

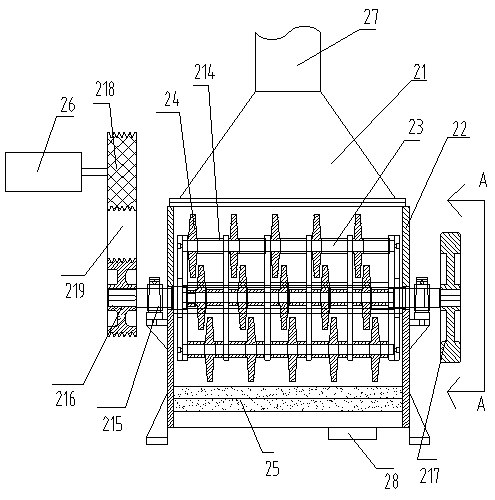

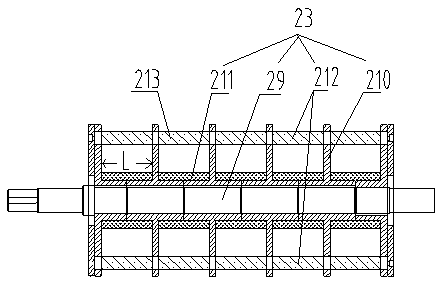

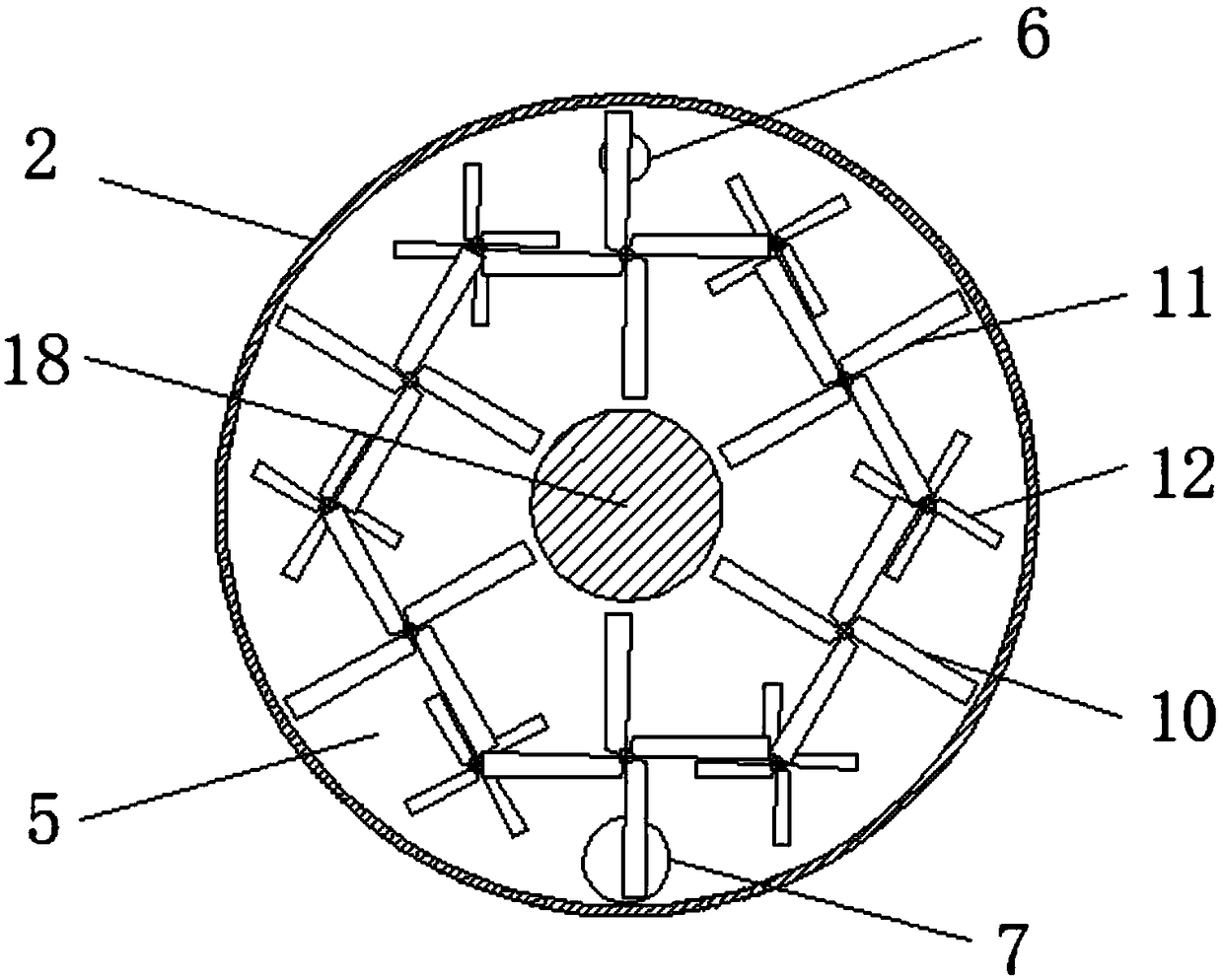

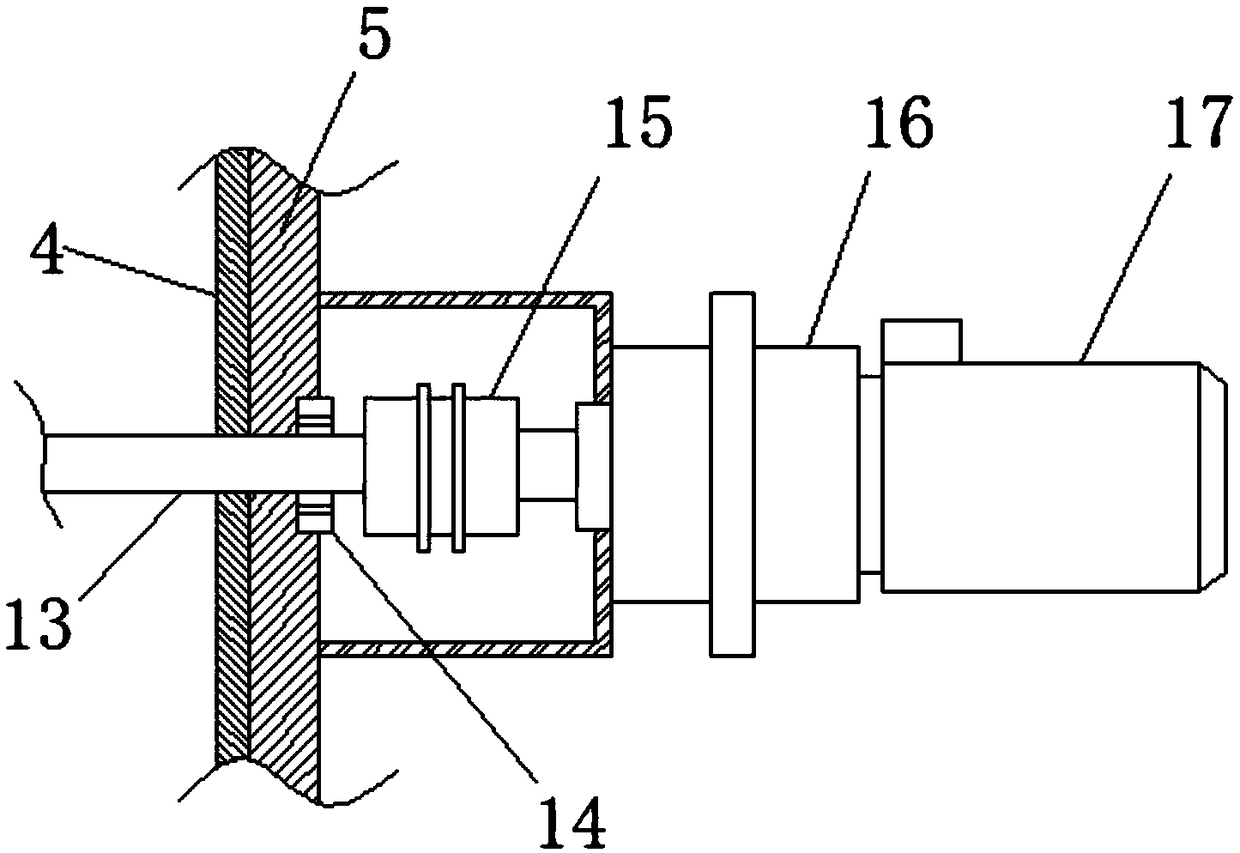

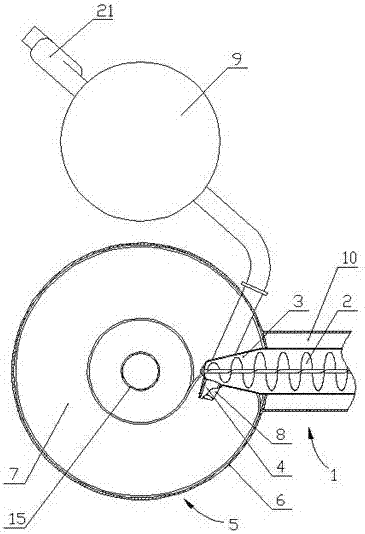

Anti-blocking muddy water type shield tunneling machine stirring device

The invention discloses an anti-blocking muddy water type shield tunneling machine stirring device. The anti-blocking muddy water type shield tunneling machine stirring device comprises a cutter headand a first stirring paddle. A shell is arranged at the rear of the cutter head, and an earth bin is arranged at the inner side of the shell. A sealing ring is arranged at the rear of the earth bin, and a pressure-bearing partition plate is arranged at the rear of the sealing ring. A feeding pipe is arranged above the pressure-bearing partition plate, and a threaded rod is arranged on the inner side of a discharging pipe. The first stirring paddle is located in front of the pressure-bearing partition plate, and a second stirring paddle is arranged at the rear of the first stirring paddle. A third stirring paddle is arranged at the rear of the second stirring paddle. A self-aligning roller bearing is arranged at the rear of a transmission rod, and a reducer is arranged at the rear of a coupling. According to the anti-blocking muddy water type shield tunneling machine stirring device, the second stirring paddle can be matched with the third stirring paddle during the use of the device, the mud crushed by the first stirring paddle can be stirred for many times, so that the soil can be stirred more finely and not prone to congealed.

Owner:GUIZHOU UNIV

Preparation method of modified precipitating method white carbon black

InactiveCN108033453AThe amount of surface hydroxyl groups is reducedLower surface energySilicaAmmonium hydroxideAqueous solution

The invention discloses a preparation method of modified precipitating method white carbon black, and relates to the technical field of rubber strengthening agents. The preparation method comprises the following steps: (1) adding liquid sodium silicate into a reaction kettle, and adding nano-silicon dioxide with the mass of 0.15 to 0.18 percent of that of the liquid sodium silicate into the liquidsodium silicate; (2) adding a sulphuric acid aqueous solution into the reaction kettle, and adding bentonite of which the surface is subjected to isocyanate esterification; (3) regulating the pH value by adopting ammonium hydroxide, adding a settling agent, and continuously stirring; (4) after the reaction is ended, performing water washing and suction filtering on a reactant, and drying to obtain the modified precipitating method white carbon black. Compared with the conventional precipitating method white carbon black, the physical and chemical indicators (the BET specific surface area, theoil absorption value, the particle size and the like) of the modified white carbon black prepared by the preparation method are all improved by over 10 percent, and the yield is 95 percent.

Owner:安徽凤阳赛吉元无机材料有限公司

Preparation method of barium sulfate-carbon aerogel composite support supported palladium catalyst

ActiveCN104741135AHigh strengthGood dispersionHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsBarium saltPalladium catalyst

The invention discloses a preparation method of a barium sulfate-carbon aerogel composite support supported palladium catalyst. The preparation method comprises the following steps: in a closed container, dissolving water-soluble carbohydrate compounds and water-soluble polymers as well as barium hydroxide or soluble barium salt in water; adding sulfuric acid or soluble sulfate to react at 140-300 DEG C; washing and drying to obtain a barium sulfate-carbon aerogel support; and supporting palladium on the barium sulfate-carbon aerogel support to obtain the barium sulfate-carbon aerogel composite support supported palladium catalyst. The barium sulfate-carbon aerogel composite support supported palladium catalyst prepared by the preparation method is good in dispersibility, difficult to condensate, high in stability, strong in catalytic performance and long in service life.

Owner:NORTHWEST UNIV

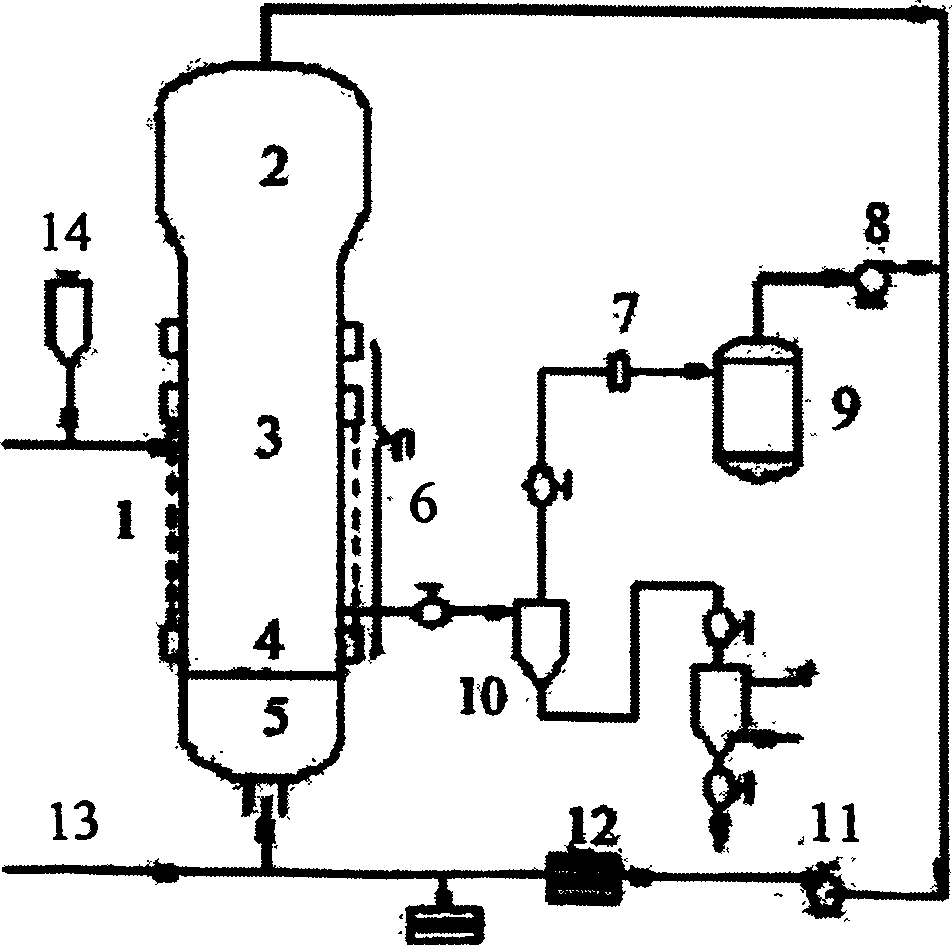

Condensation and cooling combined gas-phase fluidized-bed polymerization method and apparatus

The invention discloses a gas-phase fluid bed polymerizing method combining condensation and cooling and the equipment. Inside or outside the reactor, adopt the combination of the cooling and condensing-state evaporation to remove reaction heat, the heat percentage of condensation / cooling is 65-75%. The temperature range of cooling medium is 0-50 deg.C. It improves the ability of the reactor to remove heat.

Owner:CHINA PETROLEUM & CHEM CORP +1

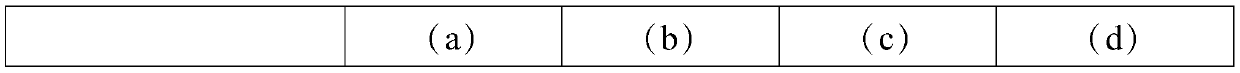

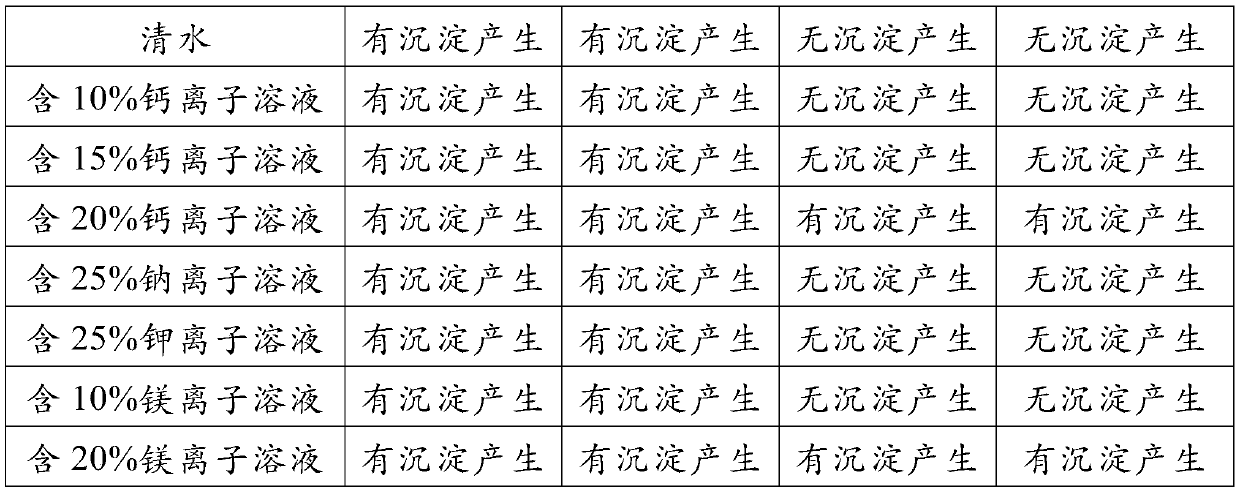

Emulsified asphalt and brushing type rubber asphalt waterproof coating, and preparation methods thereof

InactiveCN110791109AImprove stabilitySave resourcesConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer scienceBitumen emulsion

The invention provides emulsified asphalt, a preparation method of the emulsified asphalt, a brushing type rubber asphalt waterproof coating and a preparation method of the brushing type rubber asphalt waterproof coating. The emulsified asphalt comprises the following components by the mass percentage: 60%-63% of petroleum asphalt, 0.3%-2% of a fatty alcohol-polyoxyethylene ether sulfate emulsifier, 0.1%-0.5% of a pH value regulator, 0.1%-0.5% of a stabilizing agent, and deionized water. According to the technical scheme of the invention, the emulsified asphalt with good stability is prepared;the emulsifier contains an ethoxy group and a sulfonic group, and the anion and non-ion characteristics are realized at the same time; when meeting cations such as calcium ions and the like, the emulsified asphalt is not easy to condense, rubber latex with good stability is compounded by the emulsified asphalt, lumps are not easy to form during brushing, the waterproof construction quality is improved, the attractiveness is improved, and a brushing tool can be directly cleaned by clean water after being used up; the emulsified asphalt can be repeatedly used, resources are saved, and waste isreduced.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

Sludge dewatering device

ActiveCN106966564ASimple structureReasonable designSludge treatment by de-watering/drying/thickeningIncinerator apparatusThermal energySludge dewatering

The invention discloses a sludge dewatering device which comprises a conveying mechanism, wherein the conveying mechanism comprises an auger; the diameter of the end part of the auger gradually shrinks to form an extraction part; a sludge nozzle is arranged at the end part of theextraction part; the conveying mechanism is connected with a sludge ball rolling mechanism; the sludge ball rolling mechanism comprises a cylindrical shell; theextraction part stretches into the shell; the projection of an axis of the sludge nozzle is located on an eccentric chord of the projection of the shell; a hot air nozzle is arranged on the side wall of the shell; an outlet of the hot air nozzle is located below the sludge nozzle; a heating cavity connected with the shell is encircled at the outer part of the auger; an air blower 1 is arranged at the top end of the shell and is connected with an air guide pipe; the air guide pipe 14 is communicated with the heating cavity. The scheme has the beneficial effects that according to the description of the scheme, the structure is simple; the design is reasonable; sludge is dried, smoke of thermal energy equipment for drying the sludge is purified, and germs in the sludge are eliminated.

Owner:北控水务建设发展有限公司

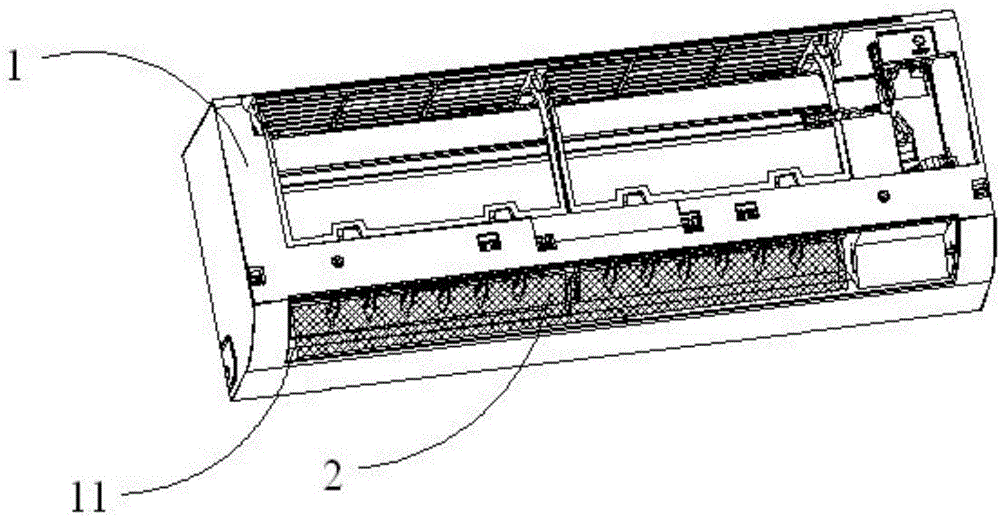

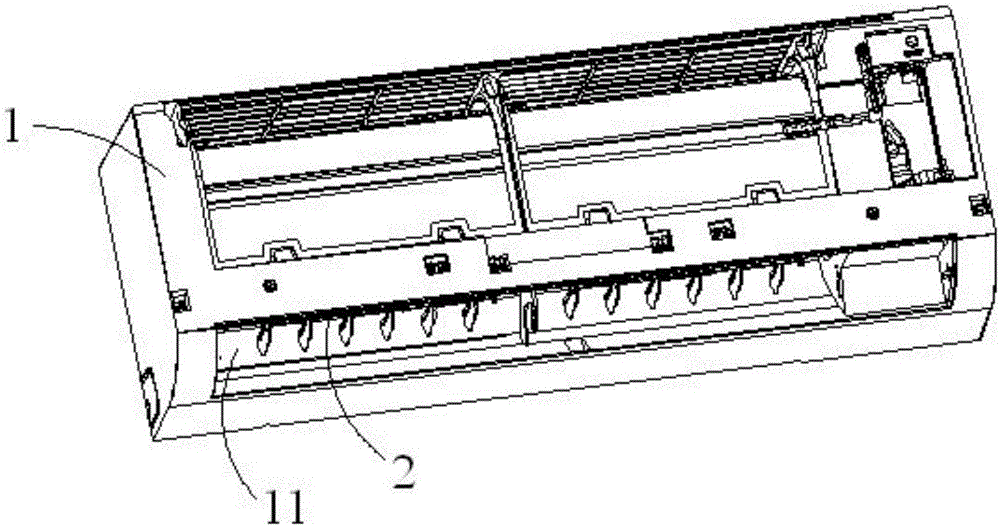

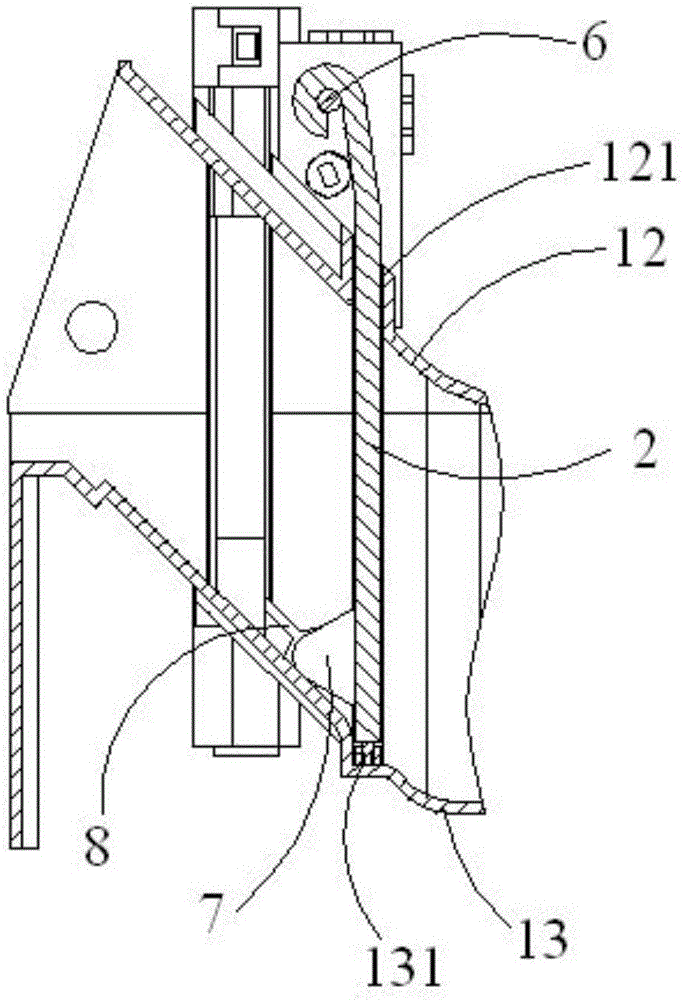

Air conditioner having breezeless function and control method thereof

InactiveCN106839107ANot easy to condenseImprove comfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringMoisture sensor

The invention discloses an air conditioner having a breezeless function and a control method thereof and relates to the technical field of air conditioners. The air conditioner is invented for solving the problem that an air guiding plate of an air conditioner in the prior art easily produces condensation in a breezeless mode. The air conditioner having the breezeless function comprises a shell, wherein the shell is provided with an air outlet, an air outlet net assembly is arranged at the air outlet and comprises a flexible air outlet net and a driving device, and the driving device can drive the flexible air outlet net to spread or be put away. When the flexible air outlet net spreads, the flexible air outlet net blocks the air outlet, outlet air of the air conditioner is blown out of net holes of the flexible air outlet net. A humidity sensor is used for detecting the humidity of indoor air, and a control unit is connected with the humidity sensor and the driving device. The air conditioner can be used for indoor air regulation.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Aluminium calcium manganese titanium iron alloy for steel-smelting deoxygenation and alloying

Owner:郭庆成

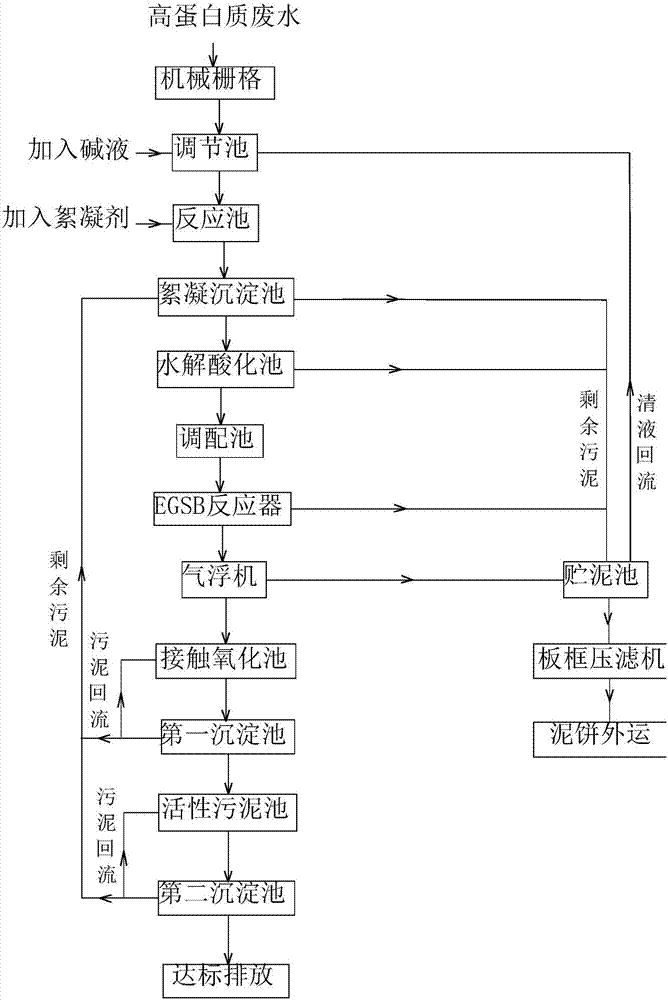

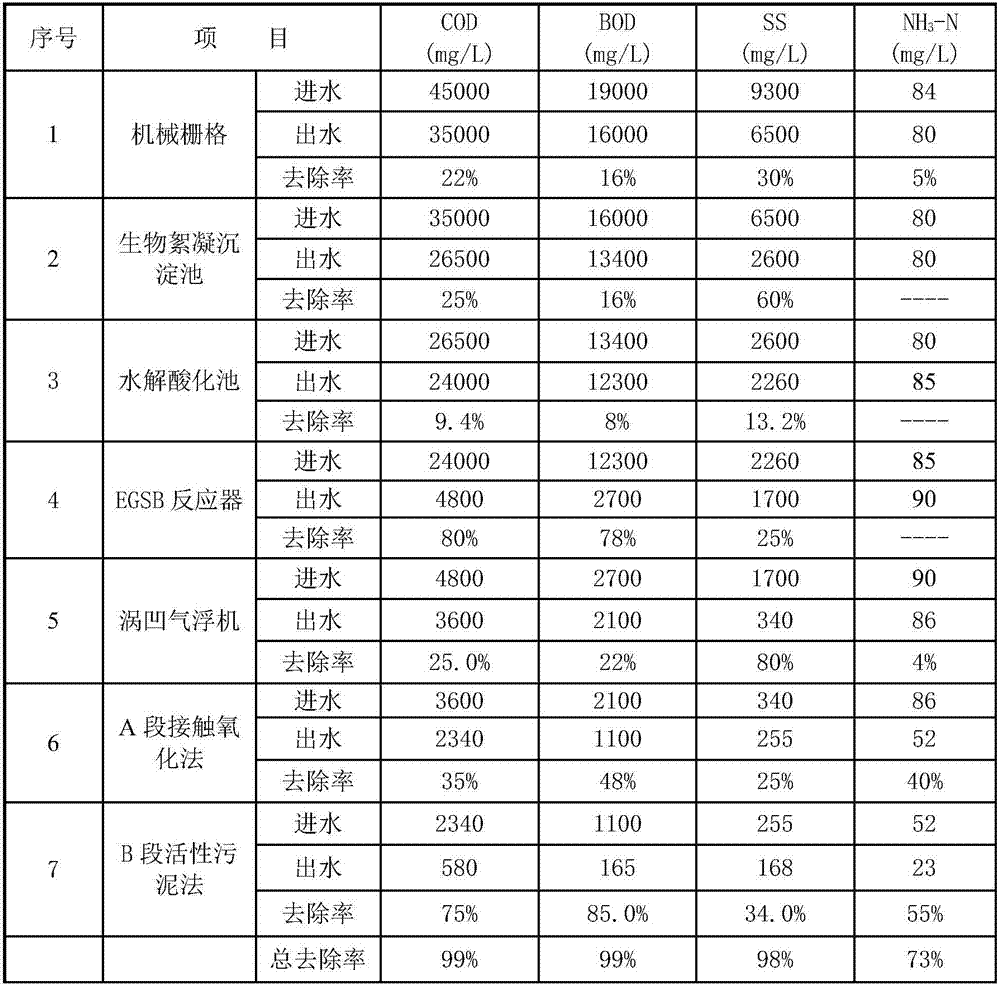

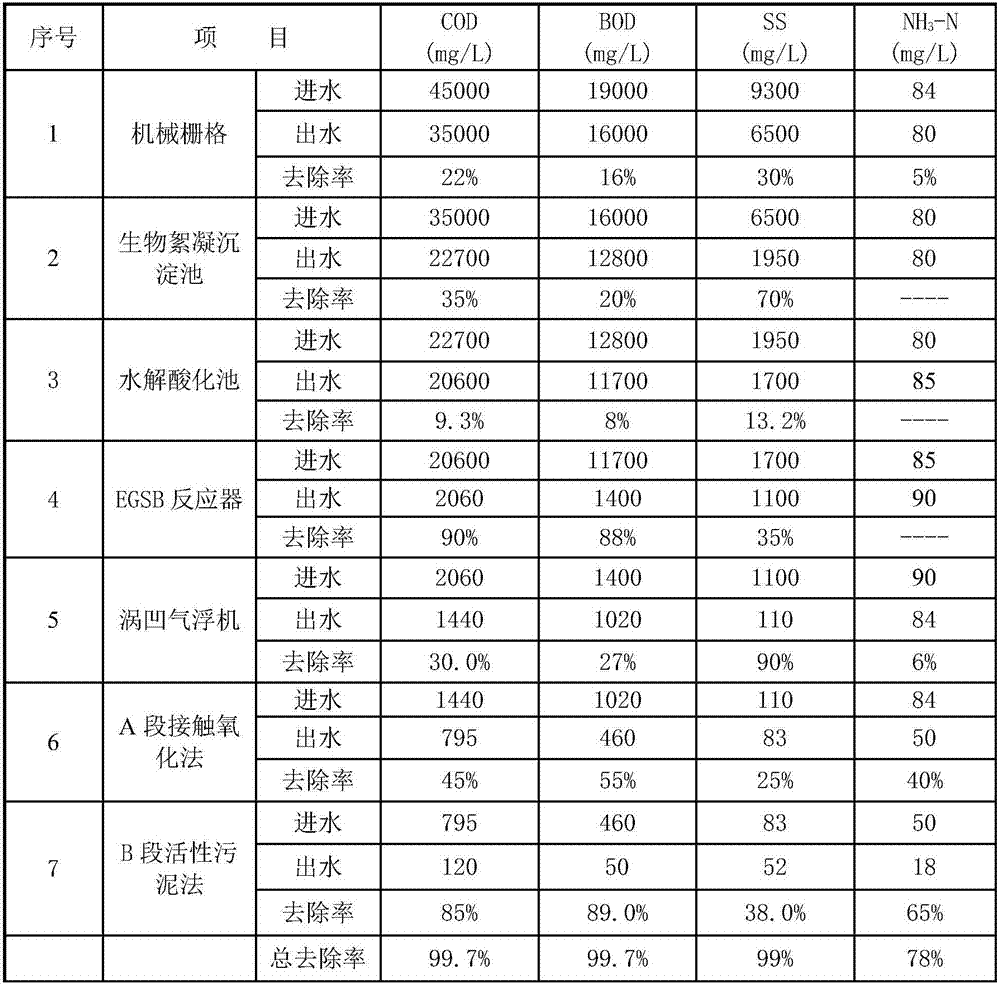

High-protein wastewater treatment process

InactiveCN107500476ALow running costEasy to handleTreatment involving filtrationTreatment with anaerobic digestion processesFlocculationTreatment effect

The invention belongs to the technical field of wastewater treatment and provides a high-protein wastewater treatment process. The high-protein wastewater treatment process adopts a mechanical grid, a regulating pond, a reaction pond, a flocculation settling pond, a hydrolysis acidification pond, a mixing pond, an EGSB reactor, an air-floated machine, a contact oxidation pond, a first settling pond, an active silt pond and a second settling pond. By means of the technical solution, the problems of poor high-protein wastewater treatment effect and high operation cost of a wastewater treatment process in the prior art are solved.

Owner:河北德龙环境工程股份有限公司

Double-layer anti-bacterial freshness protection package and processing method thereof

InactiveCN105438614AAvoid getting lostAvoid infectionPretreatment with alkaline reacting compoundsBagsFiberPulp and paper industry

The invention discloses a double-layer anti-bacterial freshness protection package and a processing method thereof. The double-layer anti-bacterial freshness protection package comprises an outer layer and an inner layer. The outer layer is made of a paper material containing enteromorpha fibers. The mass ratio of the enteromorpha fibers and pulp in the paper material is 1:20. The inner layer is made of a plastic film. The plastic film is connected with the paper material through excessive plasticizing. The thickness of the paper material is 0.9-1.2 mm. The thickness of the plastic film is 0.3-0.6 mm. According to the double-layer anti-bacterial freshness protection package and the processing method thereof, the paper material and the plastic film are combined, so that the double-layer anti-bacterial freshness protection package both has the advantages of the paper material and has the advantages of the plastic film, the loss of moisture of fruits and vegetables can be prevented, the freshness protection package is breathable, and condensation of water drops is unlikely to occur; in addition, the double-layer anti-bacterial freshness protection package is not pervious to light and can be used outdoors; the enteromorpha fibers in the paper material and nano-silver materials in the plastic film both has the anti-bacterial function, so that food is prevented from being infected by microorganisms, and health and sanitation are guaranteed.

Owner:ANHUI MEIXIANG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com