Aluminum scrap recycling device

A technology of recycling device and aluminum scraps, applied in maintenance and safety accessories, solid separation, magnetic separation, etc., which can solve the problems of more waste of cutting liquid, increased labor cost, and difficult separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with accompanying drawing.

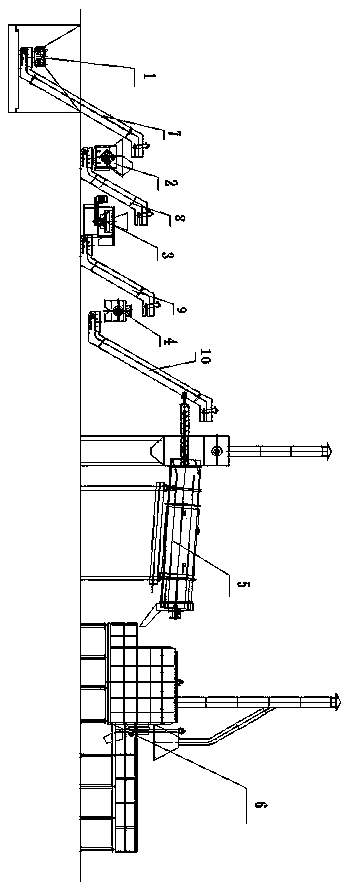

[0067] As shown in the figure, an aluminum chip recovery device includes a duplex stirring 1, a crusher 2, a dehydrator 3, a magnetic separator 4, a dryer 5, and a melting pool 6. The first expansion plate hoist 7 is arranged between, the second expansion plate hoist 8 is arranged between the crusher and the dehydrator, the third expansion plate hoist 9 is arranged between the dehydrator and the magnetic separator, the magnetic separator and the magnetic separator A fourth expansion plate hoist 10 is arranged between the dryers;

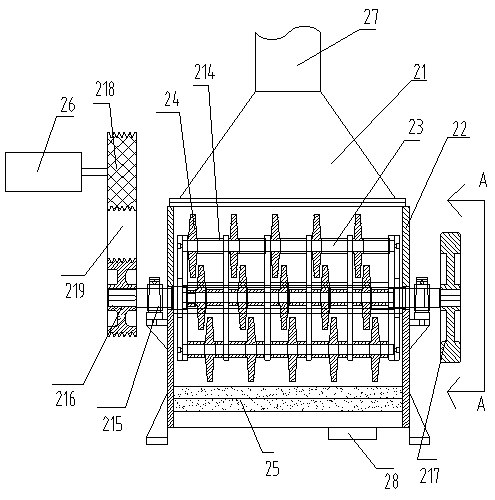

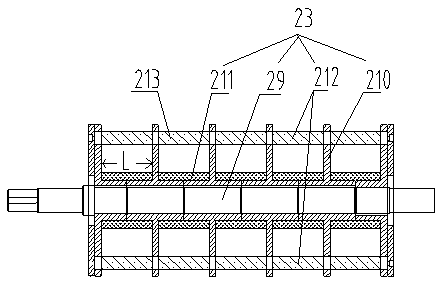

[0068] The duplex stirring 1 comprises a first housing 125, a cycloid reducer 126 and two stirring mechanisms 127, and the first housing 125 comprises a first upper housing 128 and a first lower housing 129, so The cross-sectional shape of the first lower housing 129 is a w-shaped structure, so that two cavities 130 for stirring mechanisms are fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Spiral diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com