Casting rolling roller surface treatment method of aluminum casting rolling machine

A technology for surface treatment and casting rolls, which is applied in the field of surface treatment of casting rolls for aluminum casting and rolling mills. It can solve problems such as potential safety hazards, unstable lubrication, and uneven lubrication of the roll surface, so as to prolong the service life, improve surface quality, and eliminate stress. enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

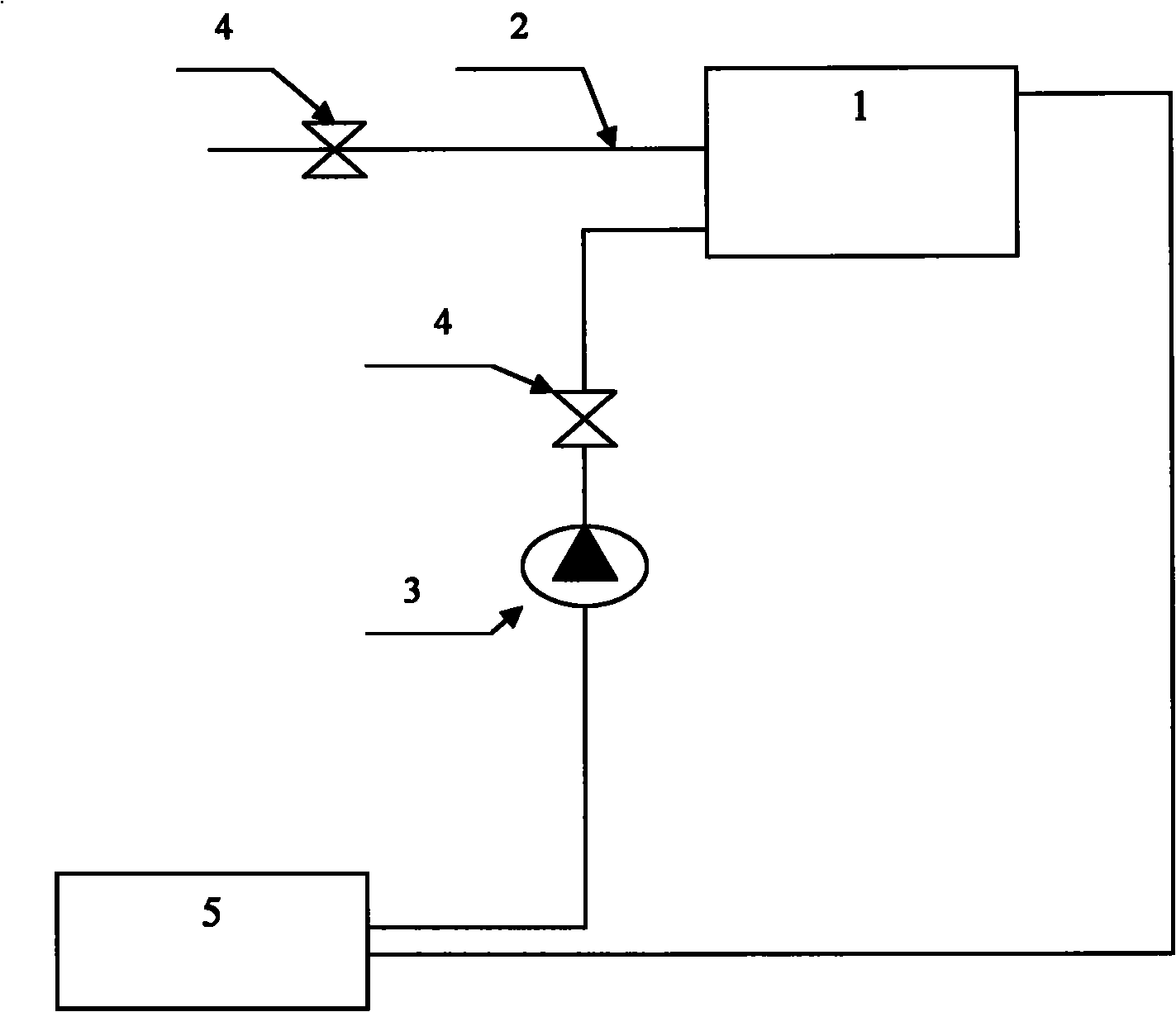

Image

Examples

Embodiment 1

[0015] (1) After the casting roll is ground, clean it with gasoline to remove the oil on the surface, dip a towel into a solution prepared by methanol and nitric acid (methanol: nitric acid is 5-20:1 by volume), wring out the towel and wipe the roll surface once, then water Clean the surface; the surface of the roller sleeve forms Fe with a uniform thickness of 0.05-0.1mm 2 o 3 Iron oxide coating, Brinell hardness (HB) ≥ 410N / mm 2 ;

[0016] (2) Spray a layer of graphite lubricant on the surface of the casting roll. As the graphite milk cannot be fully dissolved in water, first use alcohol and graphite milk to fully stir and mix for about 2 minutes (using alcohol as a solvent, first fully dissolve the graphite milk in alcohol. ), then add water and stir for about 2 minutes to dilute, and be mixed with graphite lubricant of required concentration; graphite milk: alcohol: water=1: 0.5: 20 (volume ratio);

[0017] (3) Circulating heating of the casting roll with hot water at a...

Embodiment 2

[0020] The difference from Example 1 is: graphite milk in the graphite lubricant: alcohol: water=1:1:40 (volume ratio). All the other methods are the same as in Example 1.

Embodiment 3

[0022] The difference from Example 1 is: graphite milk in the graphite lubricant: alcohol: water=1:2:60 (volume ratio). All the other methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com