Patents

Literature

147results about How to "Fully condensed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for recovery of carbon disulfide in viscose fiber production

InactiveCN103331078AInhibition releaseHigh ignition pointDispersed particle separationHigh absorptionVapor–liquid separator

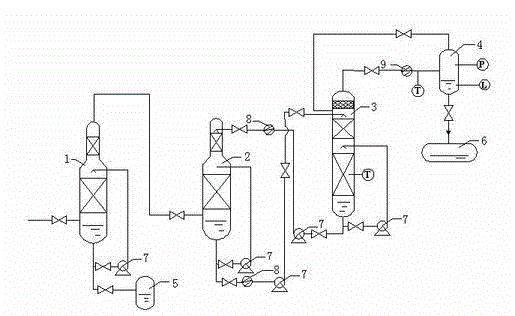

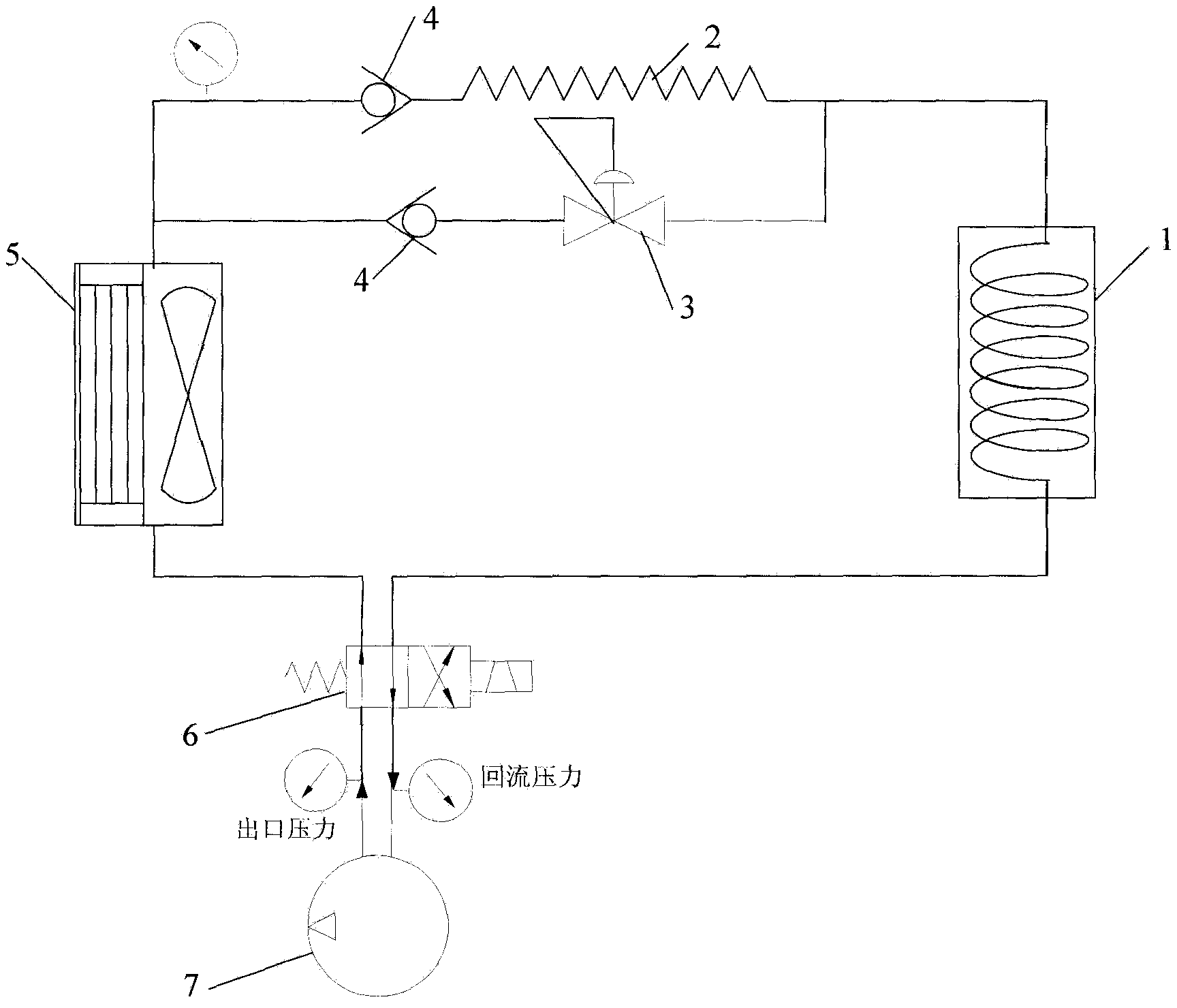

The invention relates to the exhaust gas recovery field in the viscose fiber industry, and provides a device for recovery of carbon disulfide in viscose fiber production. The device is characterized in that: it comprises an alkali spray tower, an absorption tower, a heat exchanger, a desorption tower, a condenser and a gas-liquid separator. The spray tower is connected to the absorption tower, the absorption tower is in connection with the heat exchanger, the heat exchanger is connected to the desorption tower, the desorption tower is connected to the condenser, which is in connection with the gas-liquid separator. The device provided in the invention has the characteristics of simple structure, high absorption rate, low investment and operation cost, and suitability for industrialized application.

Owner:YIBIN HIEST FIBER +2

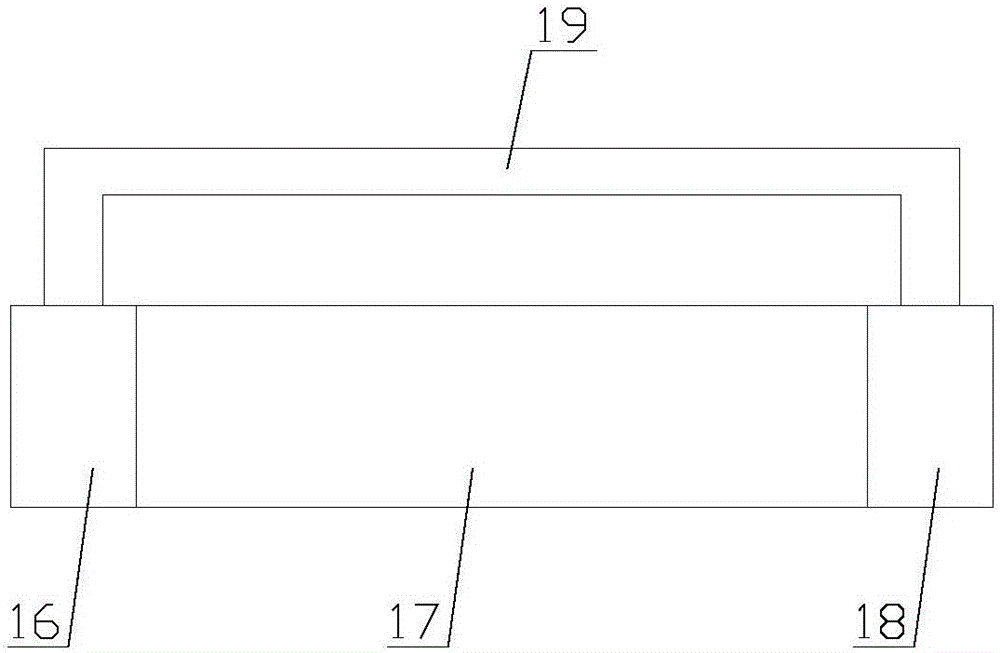

Sewage treatment system and sewage treatment method

ActiveCN104787926ASecondary precipitationEfficient purificationMultistage water/sewage treatmentFlocculationWater treatment system

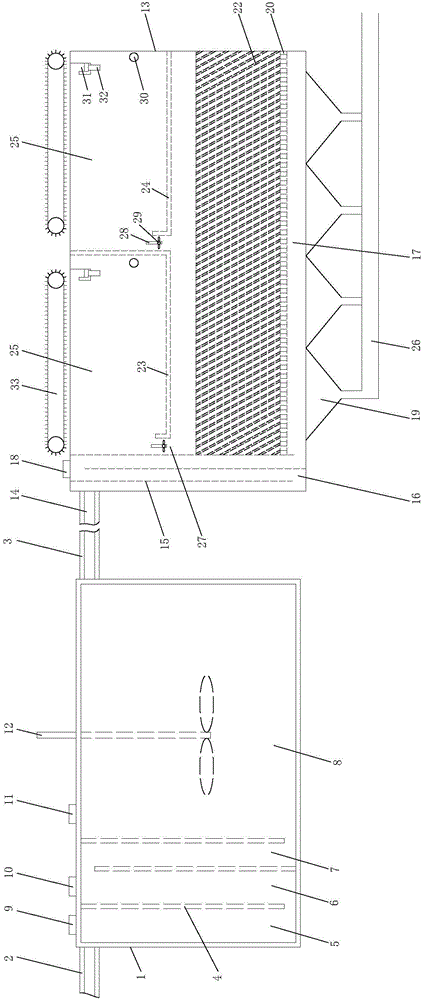

The invention creatively relates to a sewage treatment system and a sewage treatment method. According to the adopted technical scheme, the sewage treatment system is composed of a flocculation tank and a sedimentation tank. According to the flocculation tank, a sewage inlet and a reaction water outlet are formed in a tank body I, and three baffle plates I are arranged in the tank body I to sequentially divide the interior of the tank body I into a cavity I, a cavity II, a cavity III and a cavity IV. According to the sedimentation tank, a reaction water inlet is formed in a tank body II, and three baffle plates II are arranged in the tank body II to divide the interior of the tank body II into a baffling area and a sedimentation area; a polyacrylamide inlet is formed in the baffling area, a sludge hopper is arranged at the lower end of the sedimentation area, a sludge discharging pipe is arranged at the lower end of the sludge hopper, a water distribution plate with a great number of water distribution holes is mounted at the upper end of the sludge hopper, a plurality of inclined plates are mounted on the water distribution plate, and a water drainage outlet is formed in the tank body II. According to the sewage treatment system and the sewage treatment method, the principle of sedimentation and air floatation is adopted, the efficiency of solid-liquid separation is improved to the greatest extent, and the final quality of drained water which is treated is guaranteed.

Owner:SHENGDA ENVIRONMENTAL ENG CO LTD

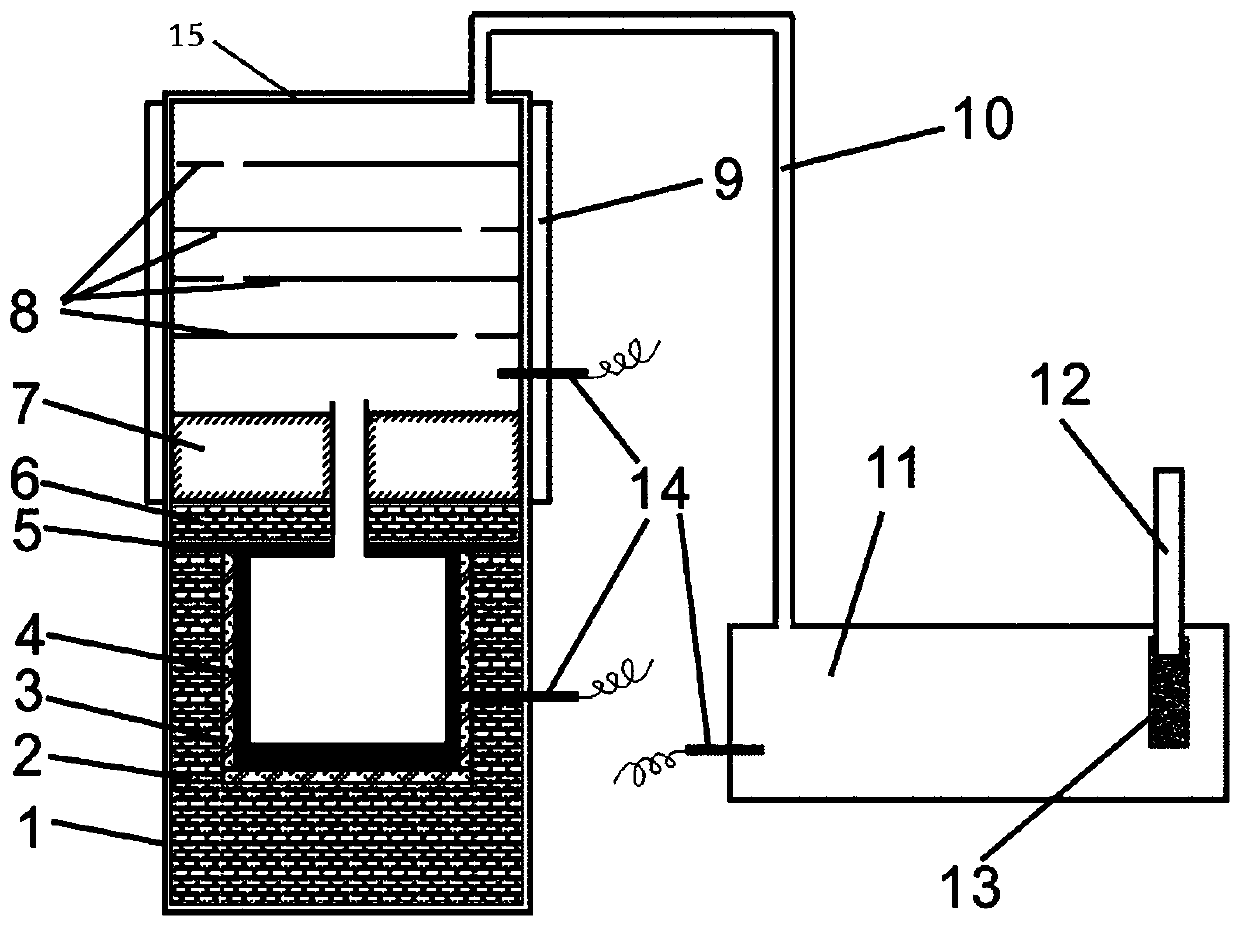

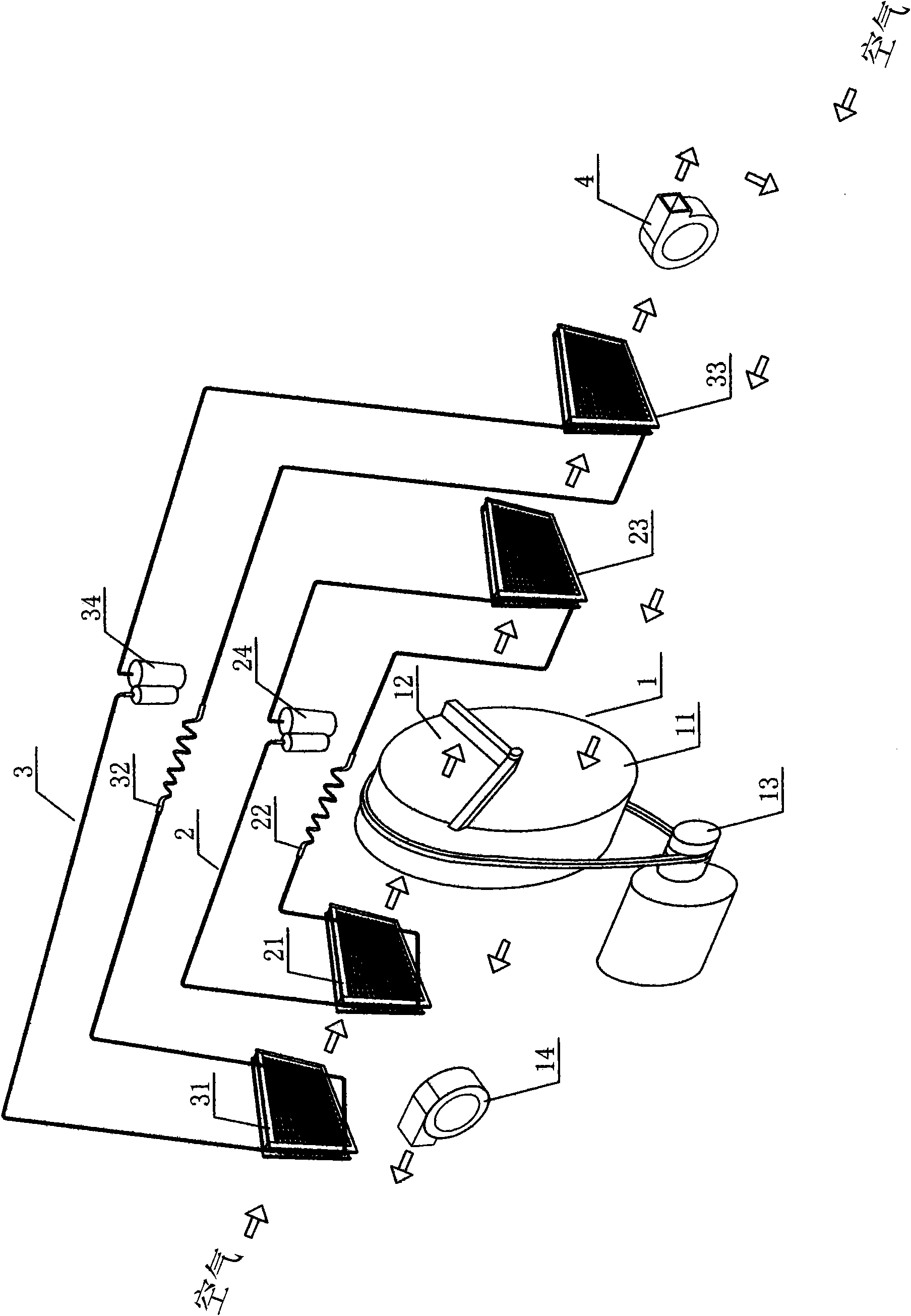

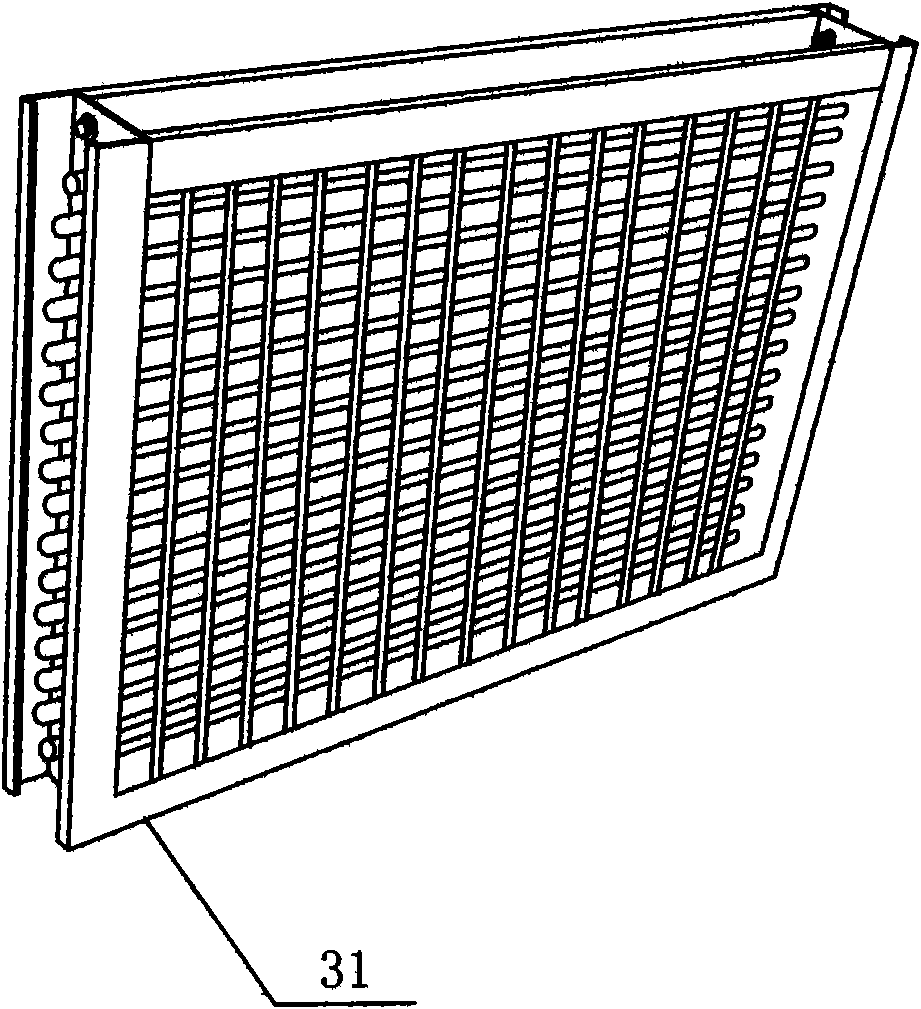

Grading type condensing device for coal/biomass pyrolysis equipment

InactiveCN102225244AHigh yieldFacilitate high value utilizationBiofuelsVapor condensationLiquid productCondensation process

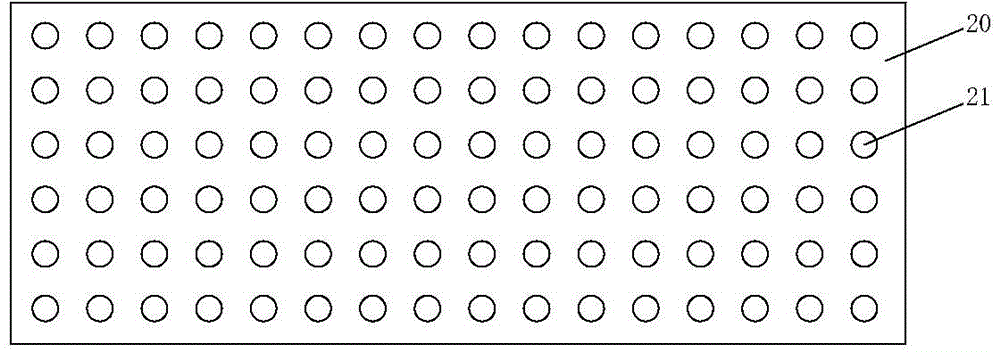

The invention relates to a grading type condensing device for coal / biomass pyrolysis equipment. The grading type condensing device comprises a falling-film type condenser and a spray type condenser which are connected in series; The main body of the falling-film type condenser is cylinder-shaped, a pyrolysis vapor inlet is arranged on one side of the upper part of the falling-film type condenser, a tube type indirect heat exchanger is arranged in the middle part of the falling-film type condenser, and a liquid storage section is arranged at the lower part of the falling-film type condenser; and an air outlet is arranged on one side of the main body above the liquid storage section, and a first-grade liquid product outlet is arranged at the bottom of the main body. The main body of the spray type condenser is cylinder-shaped, atomizing nozzles are uniformly distributed at the inner top part of the spray type condenser, a liquid storage section and a coil heat exchanger are arranged at the inner bottom part of the spray type condenser, a liquid outlet is arranged on one side of the main body of the liquid storage section, the liquid outlet is communicated with an inlet of an oil pump, and an outlet of the oil pump is communicated with a liquid inlet at the top of the main body; and an uncondensable gas outlet is arranged on one side of the main body above the liquid storage section, and a second-grade liquid product outlet is arranged at the bottom of the main body. The grading type condensing device can be used for fully condensing high-temperature pyrolysis vapor and grading pyrolysis liquid products in the condensation process.

Owner:ANHUI HESHENG BIOLOGICAL ENERGY

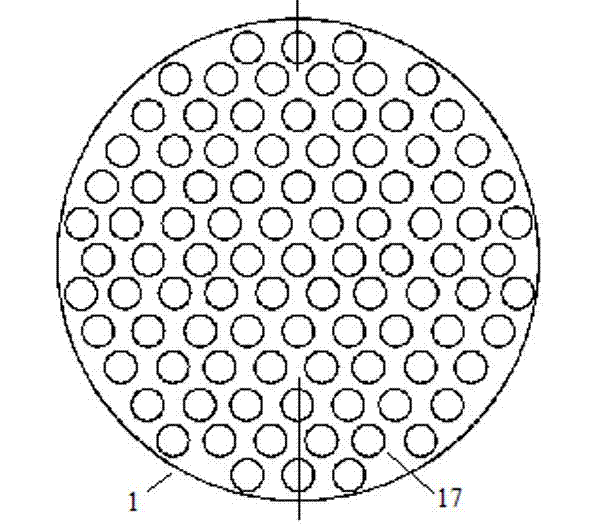

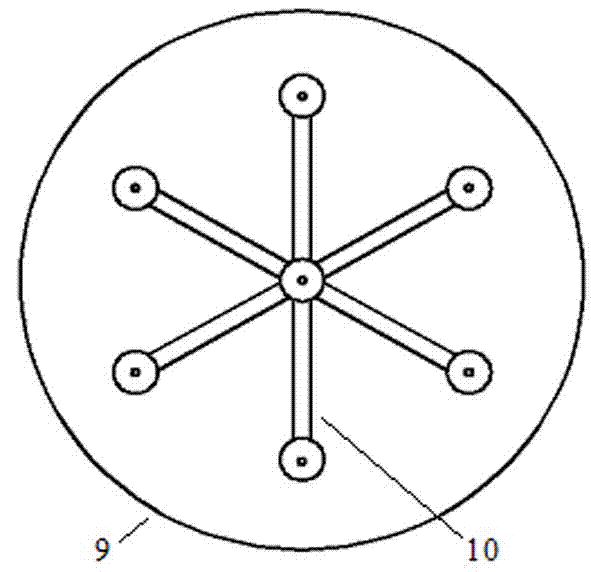

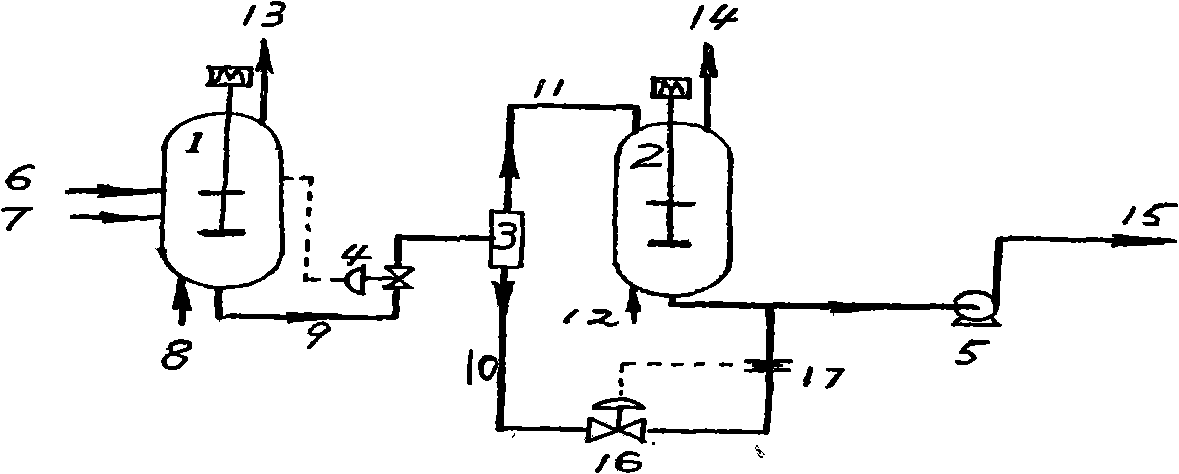

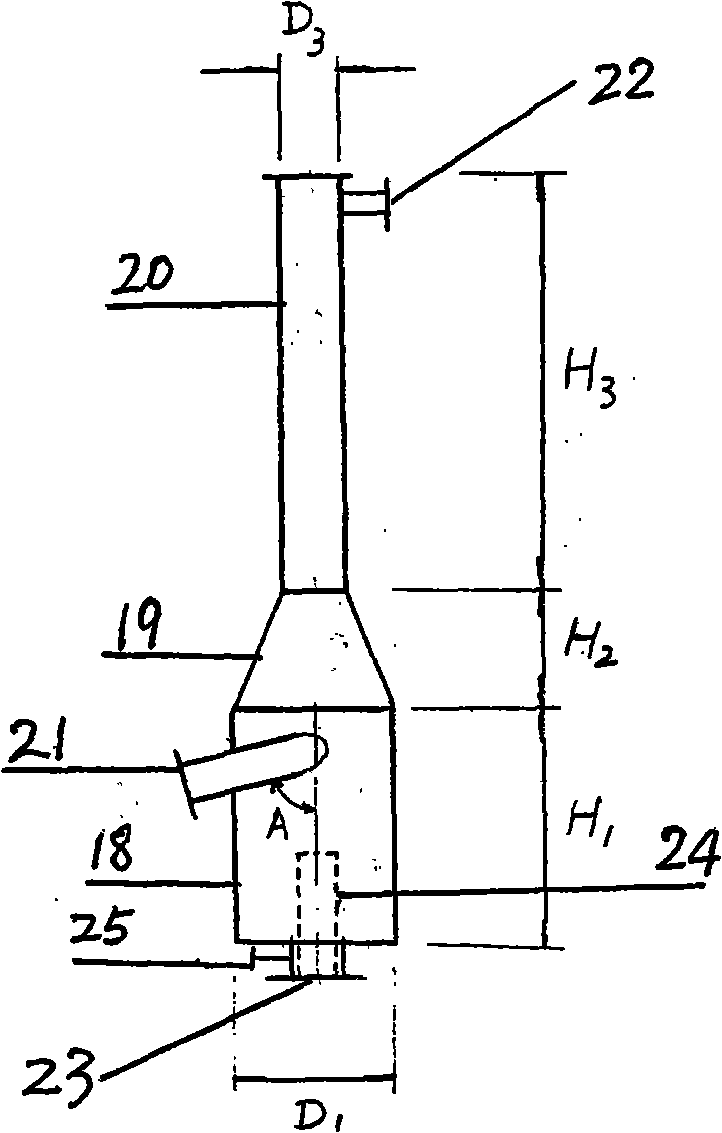

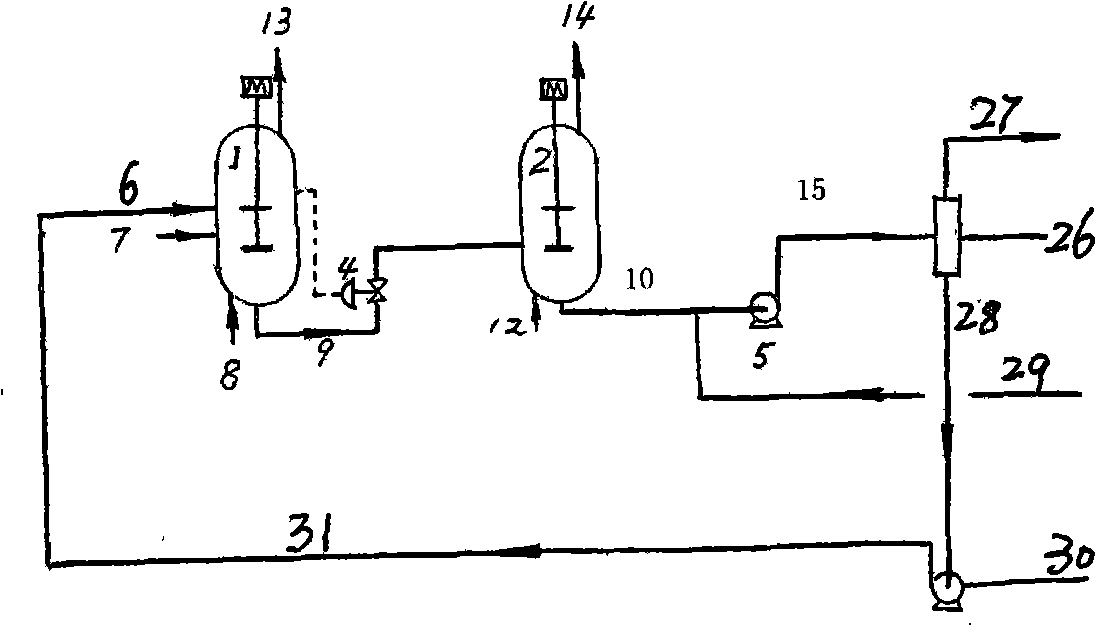

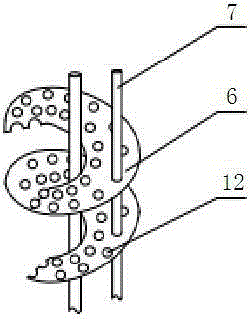

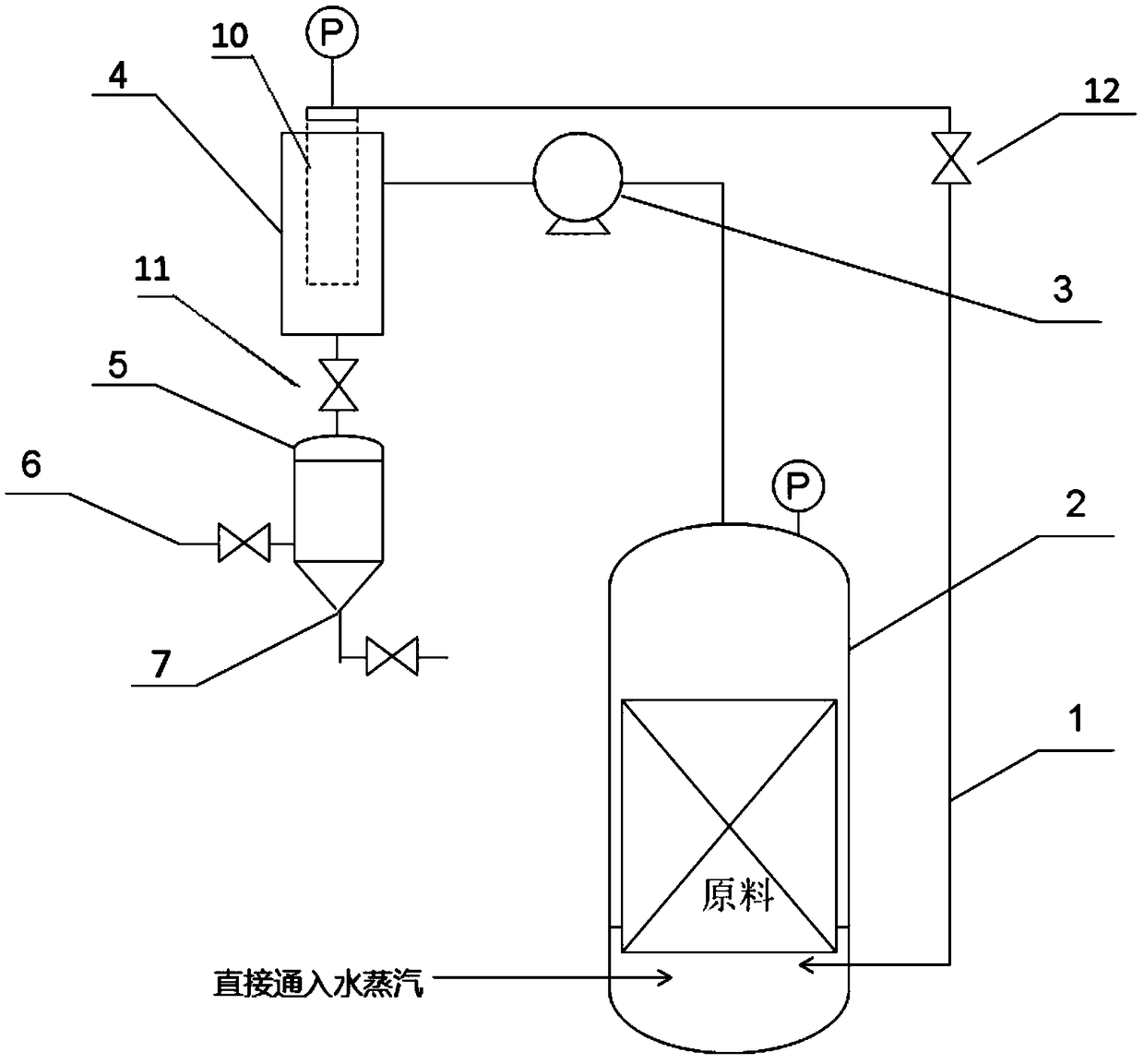

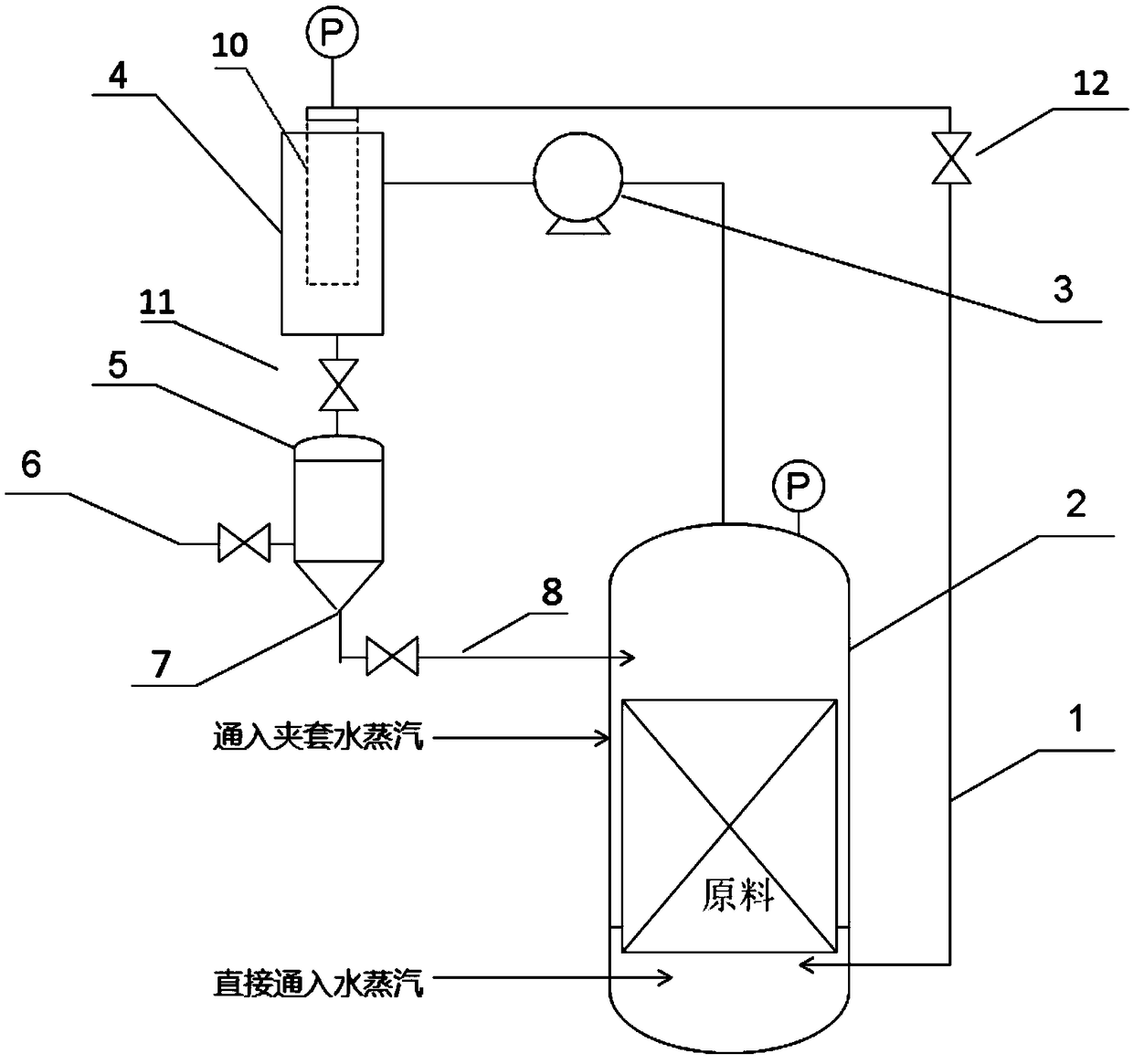

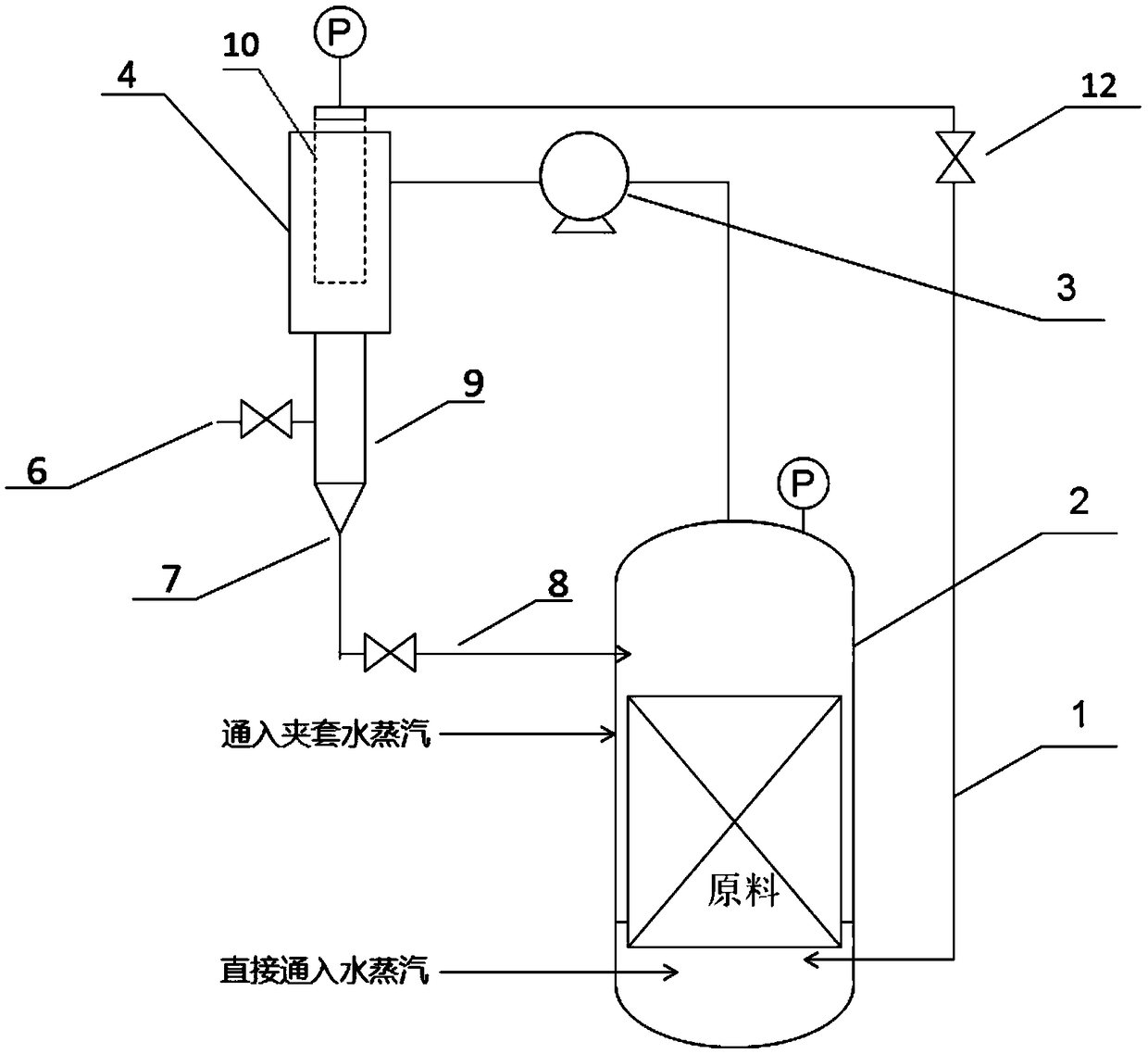

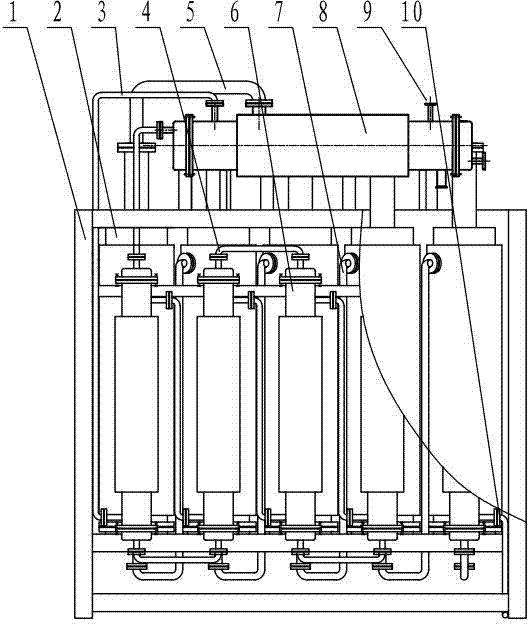

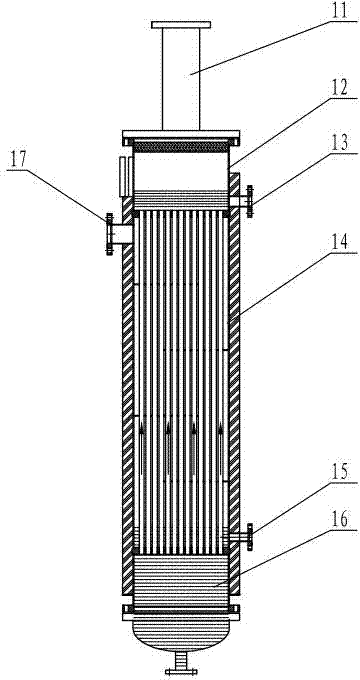

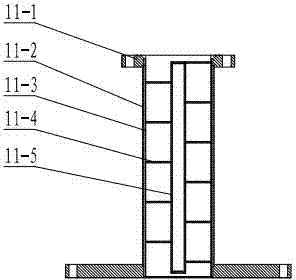

Polymer solution steam stripping flocculation separation method and apparatus

ActiveCN101314086AFully condensedLow solvent contentChemical industrySteam distillationCondensation processFlocculation

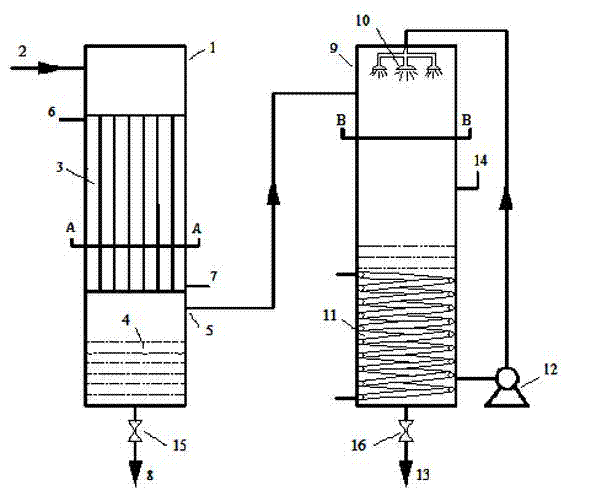

The invention belongs to the polymer production technical field, relating to a highly-efficient energy-saving method for separating a polymer solution of synthetic rubber, synthetic resin and plastic by stripping condensation and a device for carrying out the same. A concentration separator for polymer grainy water is arranged on a polymer grainy water pipe between a first condensation boiler and a second condensation boiler which are in serial connection in a two-boiler condensation process of a polymer solution to increase the polymer concentration of the polymer grainy water, and carry out phrase separation in the concentration separator; the concentration separator is arranged vertically, and consists of a cylindrical suspension section at the lower part, a cone-shaped transition section in the middle and a cylindrical lifting section at the upper part which are communicated; a metal wire net cage is arranged outside the export pipe of the concentration water at the bottom of the suspension section, a steam lifting pipe is arranged at the lower part of the lifting section; the device can improve the condensation effect, obviously reduces the content of the remaining solvent of polymer particles, has remarkable economic benefits, and reduces environmental pollution caused by the solvent.

Owner:FUSHUN YIKESI NEW MATERIAL

Small intermittent reducing distillation device

PendingCN107723472AFull condensate recoveryHigh yieldProcess efficiency improvementReaction layerDistillation

The invention relates to a small intermittent reducing distillation device. The small intermittent reducing distillation device is mainly used for laboratory investigation or preparation of small-batch volatile metal and oxide and comprises a reducing distillation furnace, wherein an opening is formed in the top of the reducing distillation furnace, a matched furnace lid is arranged at the opening, a gas outlet is formed in the furnace lid, inside of the reducing distillation furnace body is arranged in a layered manner and specially comprises a reduction reaction layer at the lower part, a sedimentation layer between the reduction reaction layer and the gas outlet and an accommodating layer between the reduction reaction layer and the sedimentation layer; the device further comprises a condensation chamber; the reducing distillation furnace is communicated with the condensation chamber through the gas outlet in the furnace lid. According to the device, gas is blocked by sedimentationpartitions, gaseous substances in a product are condensed sufficiently, the product that is not condensed sufficiently in the sedimentation layer is cooled again in the condensation chamber, dust is collected by a bag at an outlet of the condensation chamber, and the product is prevented from entering an induced draft fan. The product yield of the reducing distillation device is high, and the device is simple in structure and easy to manufacture, mount and maintain.

Owner:HUNAN UNIV OF TECH

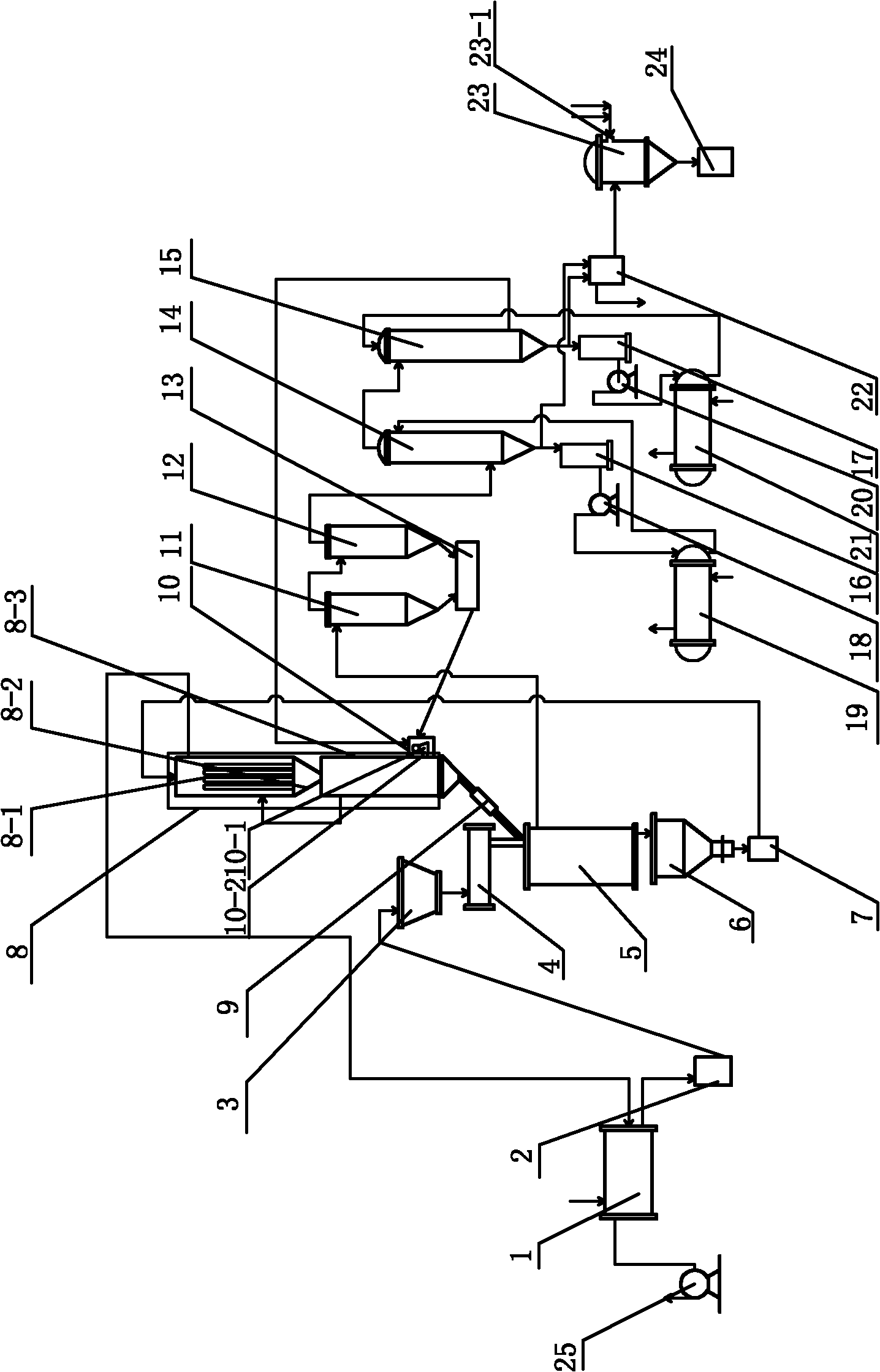

Device and method for producing biological fuel oil by quickly cracking biomass

InactiveCN102031133AStable temperature controlFully condensedDirect heating destructive distillationBiofuelsThermal energyTemperature control

The invention discloses a device and a method for producing biological fuel oil by quickly cracking biomass, relates to a device and a method for producing biological fuel oil and aims to solve the problems of low energy utilization ratio, high operating cost and poor practical production continuity existing in the conventional biomass thermal cracking process and the problem of the absence of accurate heat carrier heating temperature regulating function in the conventional biomass thermal cracking process device. In the scheme of the device, the bottom of a heat carrier heating device is communicated with a heat carrier inlet end of a cracking reactor through an accurate heat carrier temperature control device; the cracking reactor is communicated with a separator; the separator is communicated with a condenser; the condenser is communicated with a heat energy supply device; and the heat energy supply device is communicated with the heat carrier heating device. In the scheme of the method, products produced by the thermal cracking reaction of biomass powder comprise thermal cracking gas and carbon; a heat carrier enters a heat carrier collecting box; and uncondensed thermal cracking gas enters a non-condensable gas burner to burn, and then smoke gas is produced and enters the heat carrier heating device. The device and the method are used for producing biological fuel oil.

Owner:NORTHEAST FORESTRY UNIVERSITY

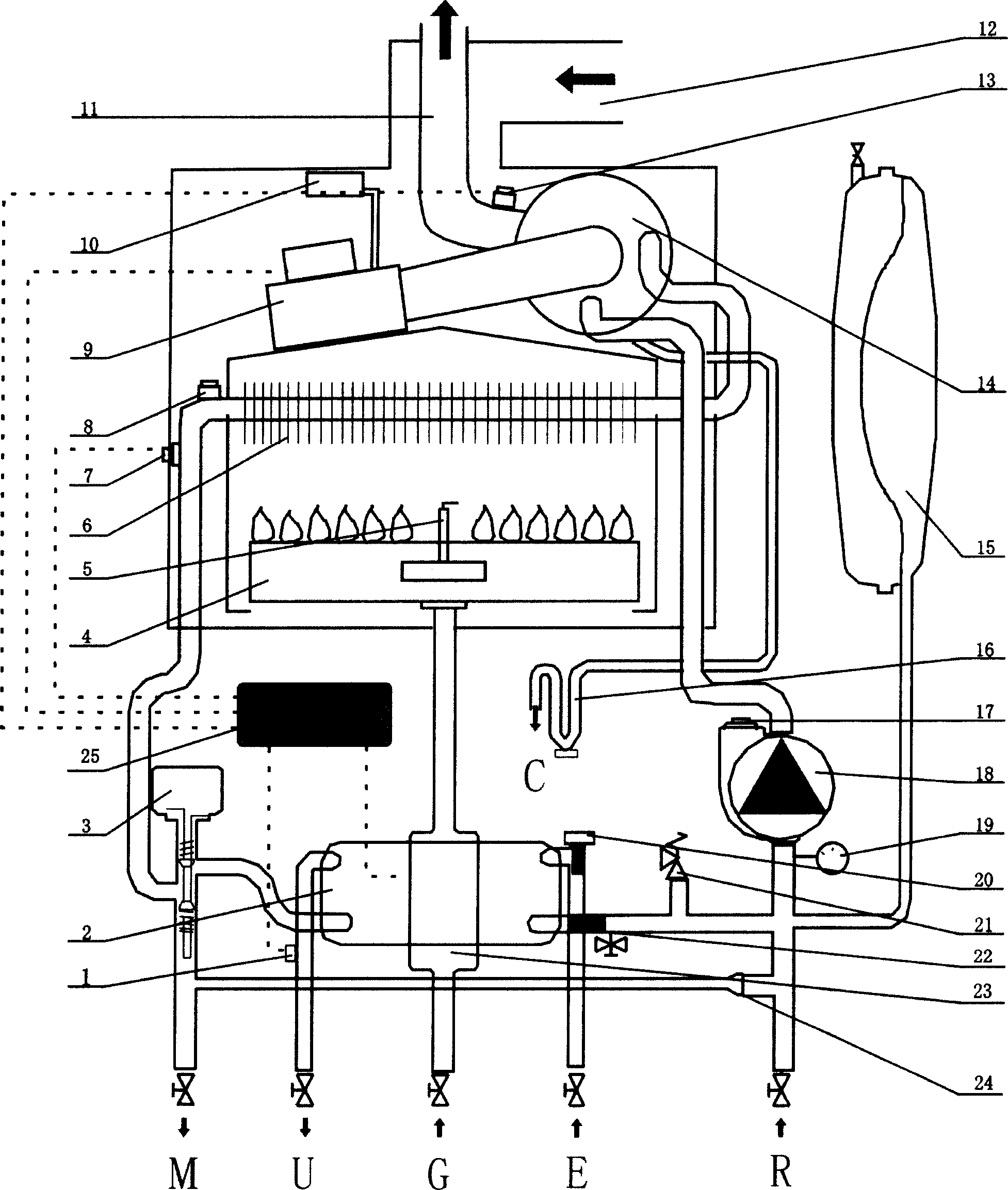

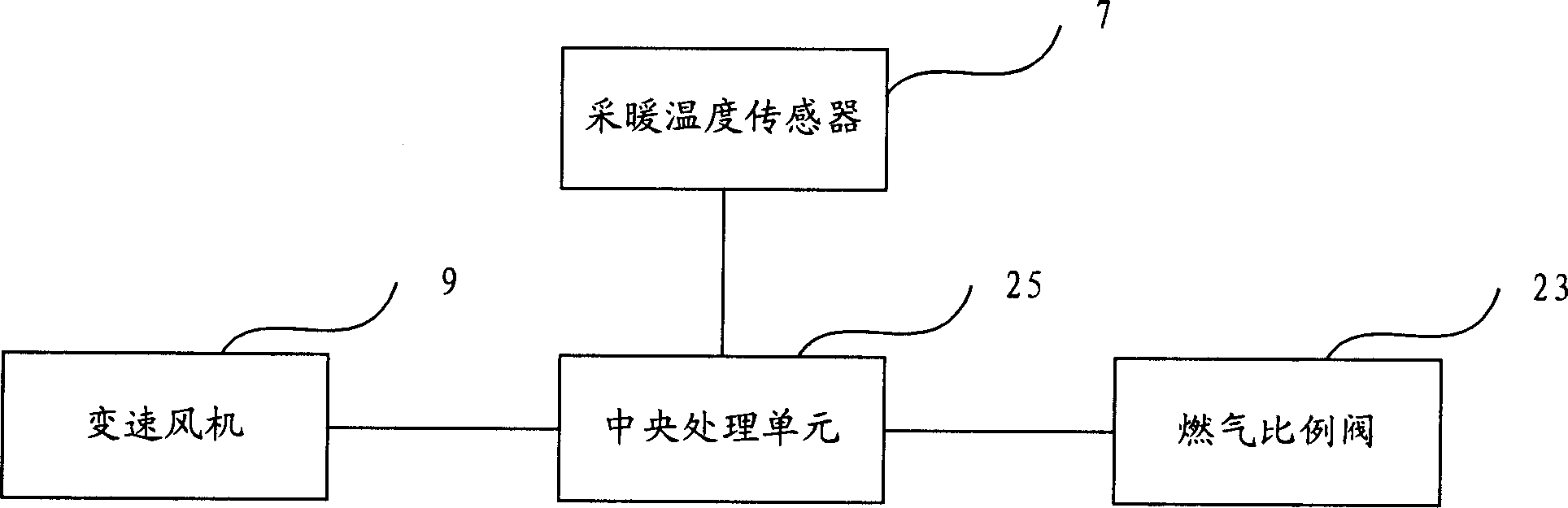

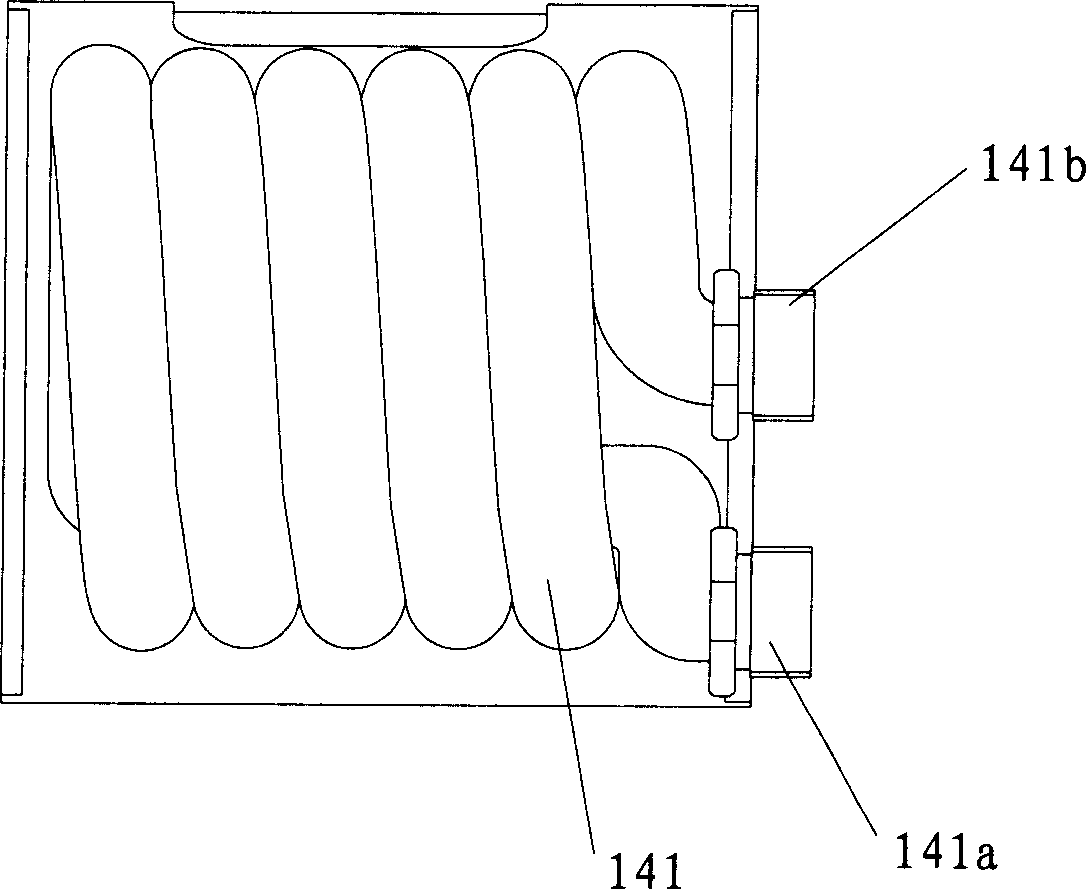

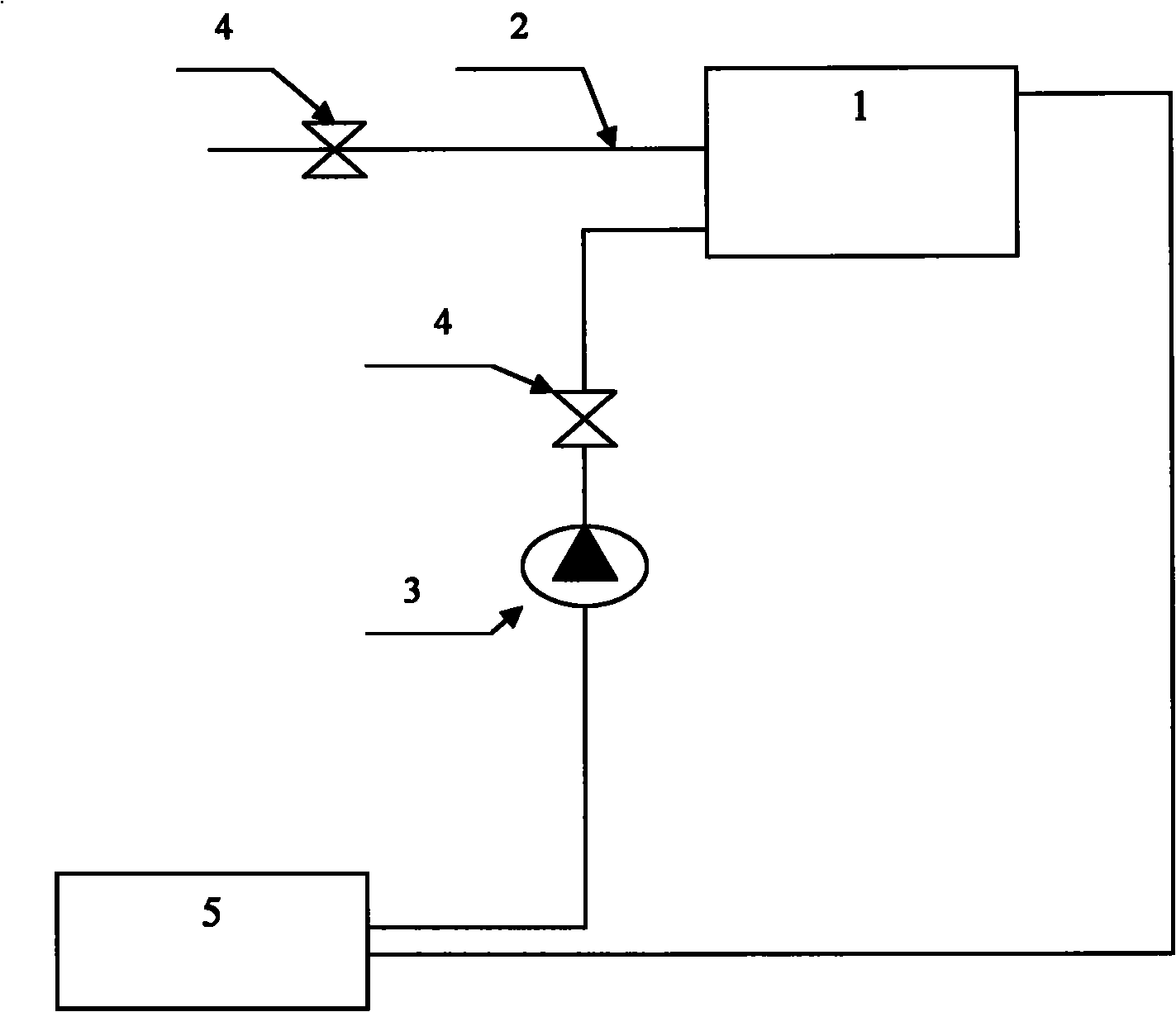

Gas heating stove

The invention relates to a fuel gas heating furnace which comprises a main heat exchanger and a secondary heat exchanger, a water tank, a water tube, a temperature sensor, a central processing unit, a speed-variable fan whose rotation speed is controlled by the central processing unit, and a fuel gas rate valve whose output power is controlled by the central processing unit. The invention can fully condense the vapor and effectively recycle the heat of vapor in the discharged smoke.

Owner:HAIER GRP CORP +1

Casting rolling roller surface treatment method of aluminum casting rolling machine

ActiveCN101864567AHigh hardnessQuality improvementMetallic material coating processesGraphiteHardness

The invention relates to a casting rolling roller surface treatment method of an aluminum casting rolling machine, which comprises the following steps: 1) cleaning the surface of a casting rolling roller by a solution prepared from methanol and nitric acid according to a volume ratio of 5 to 20 / 1, and forming an Fe2O3 ferric oxide covering layer with the uniform thickness between 0.05 and 0.1 mm on the surface of the roller; 2) using alcohol for dissolving colloidal graphite, then, adding water to prepare graphite lubrication liquid according to a volume ratio of colloidal graphite / alcohol / water=1 / 0.5 to 2 / 20 to 60, and spraying the graphite lubrication liquid onto the surface of the casting rolling roller; and 3) heating circulated water by steam so that the water temperature can reach 30 to 70 DEG C, introducing the water into the inside of the casting rolling roller to cyclically heat the casting rolling roller, and then, drying the surface of the roller. The casting rolling roller surface treatment method of the aluminum casting rolling machine of the invention improves the surface hardness of the casting rolling roller, improves the friction characteristics, improves the lubrication effect, eliminates the stress enrichment of the roller in the plate standing process, slows down the generation trend of cracks on the surface of a roller sleeve, and prolongs the service life of the roller sleeve of the roller.

Owner:YUNNAN ALUMINUM

Soot desulfurization deduster

The invention discloses a soot desulfurization deduster which comprises a shell with a cavity inside. An air inlet is formed in the middle of the shell, an air outlet is formed in the top of the shell, the shell is divided into a left chamber and a right chamber, the two chambers are the desulfurization chamber and the water curtain dedusting chamber, the middle of the desulfurization chamber is communicated with the water curtain dedusting chamber through a pipeline, the air inlet is located in the position where the desulfurization chamber is located, the air inlet is in parallel connection with a plurality of Venturi tubes in the desulfurization chamber, a wavy baffle is fixed above the Venturi tubes, a scrubbing solution sprayer is arranged between every two adjacent Venturi tubes, a sediment tank is arranged on the lower portion of the desulfurization chamber, the water curtain dedusting chamber comprises a spraying device, water curtain baffles and a waste liquid pool, and the spraying device is communicated with a clear water region of the sediment tank through a circulating water pump. The deduster is good in filtering effect, convenient to use and high in stability.

Owner:GUANGXI NANNING HUAGUO ENVIRONMENT SCI & TECH

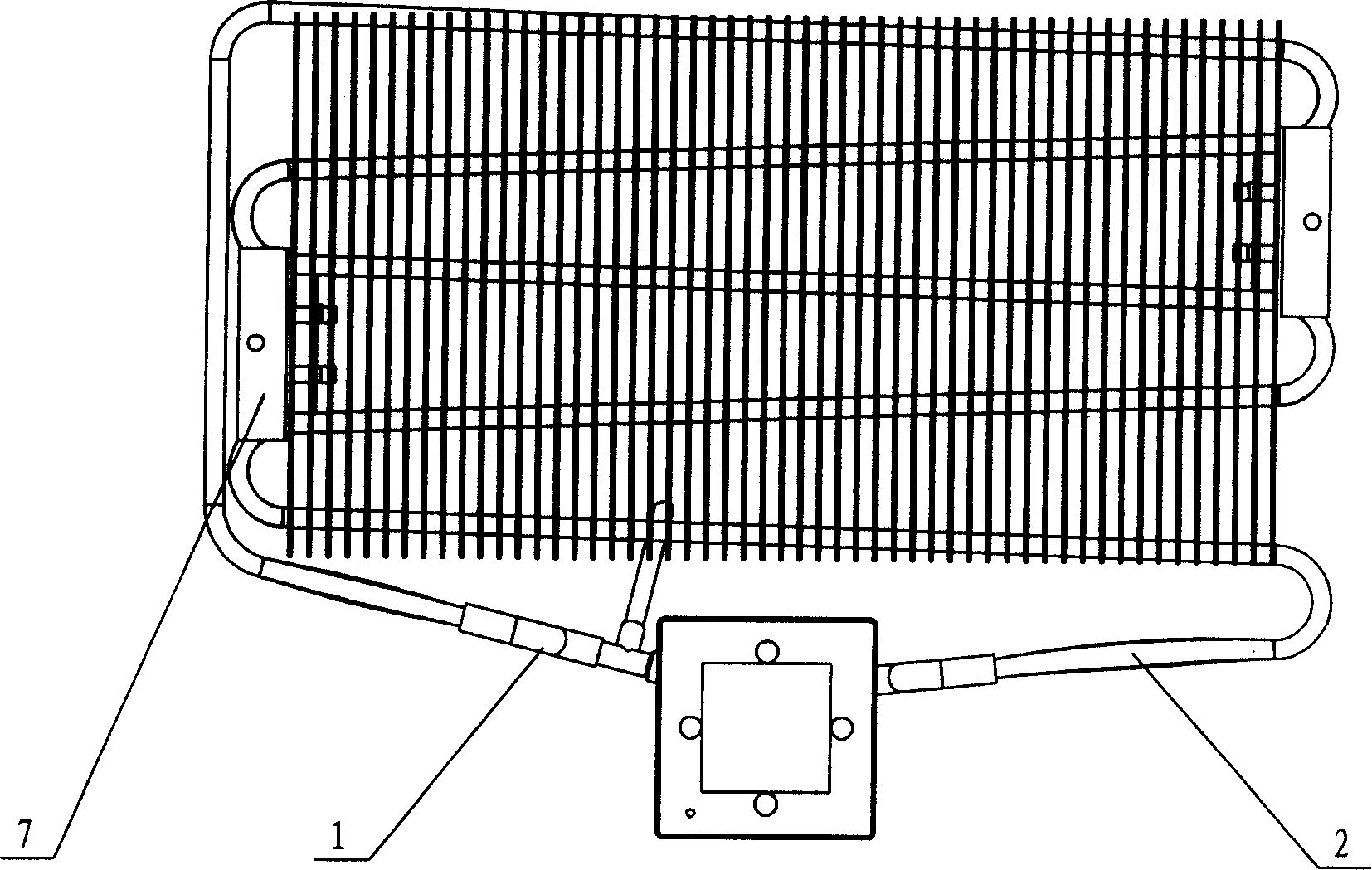

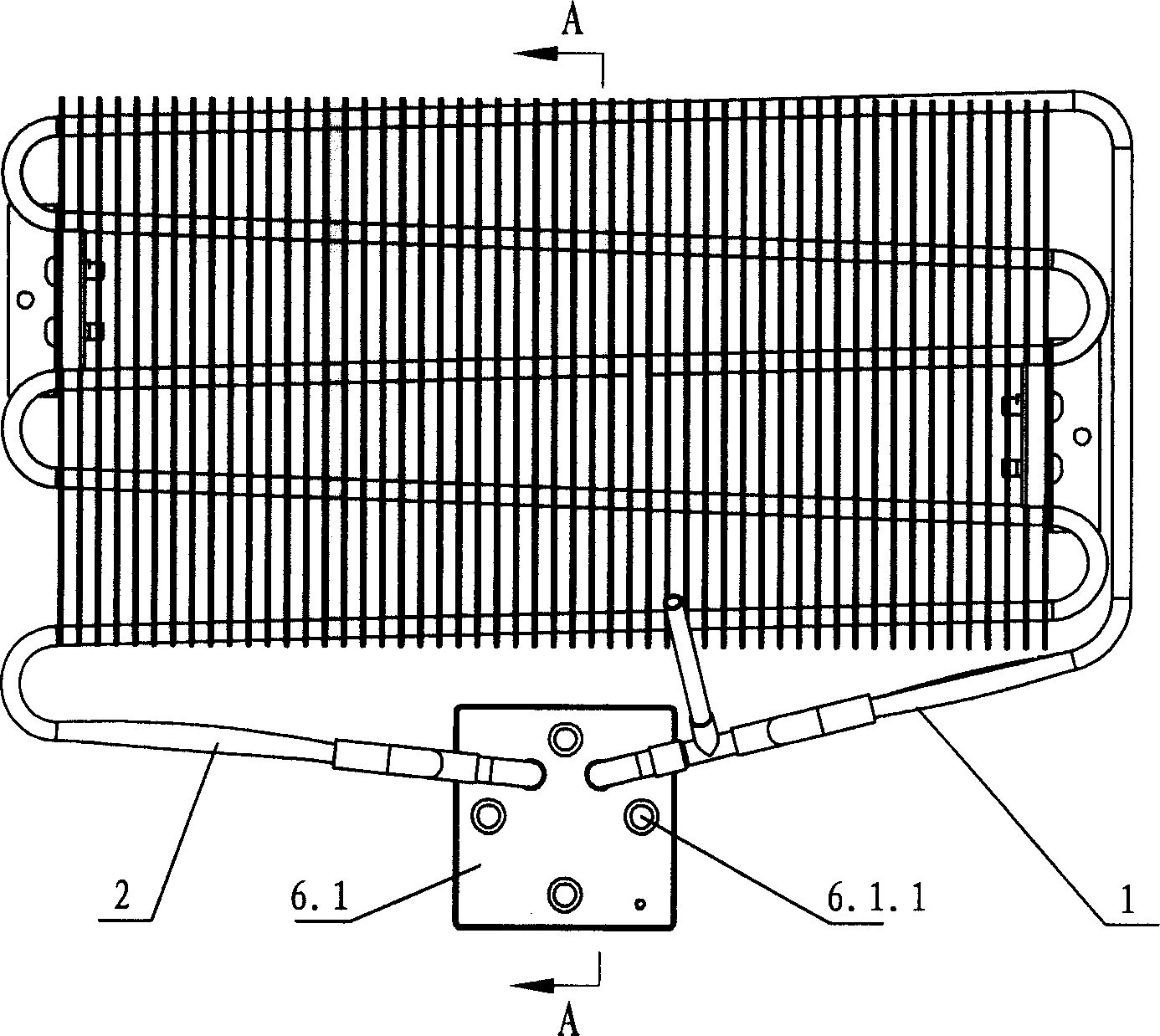

Heat pipe device for electronic refrigerator and making method thereof

ActiveCN1862146AGuaranteed StrengthImprove heat transfer efficiencyIndirect heat exchangersMachines using electric/magnetic effectsCondensation processLiquid state

The present invention relates to a heat tube device of electronic refrigerator. It includes heat tube set on the heat end of refrigeration semiconductor, on the heat tube several fins are set. Said heat tube includes evaporation tube for evaporating refrigeration working medium and condenser tube for condensing refrigeration working medium. Said heat tube is connected with the refrigeration semiconductor heat end by means of a prefabricated liquid storage tank, said liquid storage tank includes left and right two cavity chambers, the evaporation tube and condenser tube are respectively connected with said two cavity chambers, said two cavity chambers are communicated by means of communicating tube between them, said invention is simple in structure, stable in quality and good in heat exchange efficiency.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

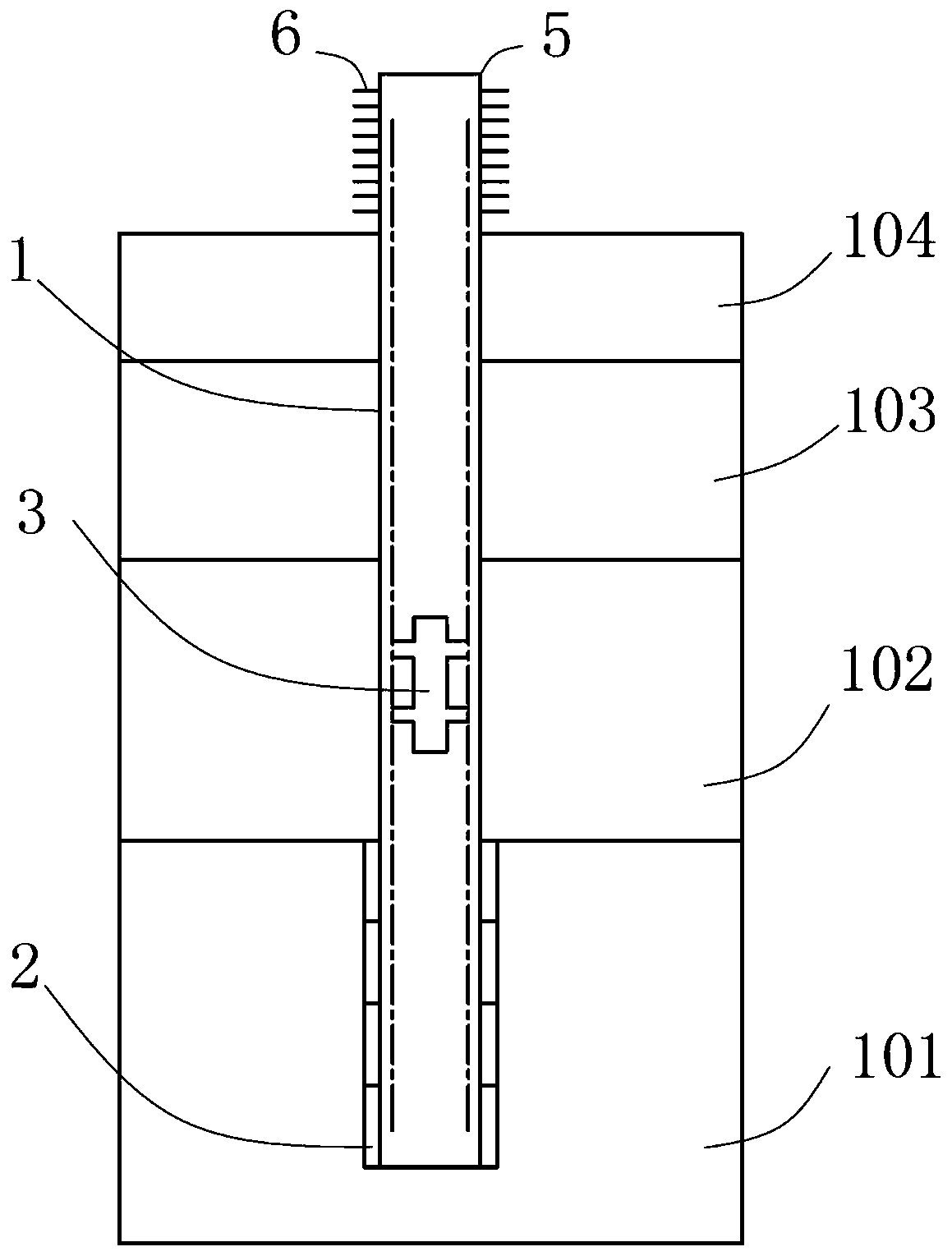

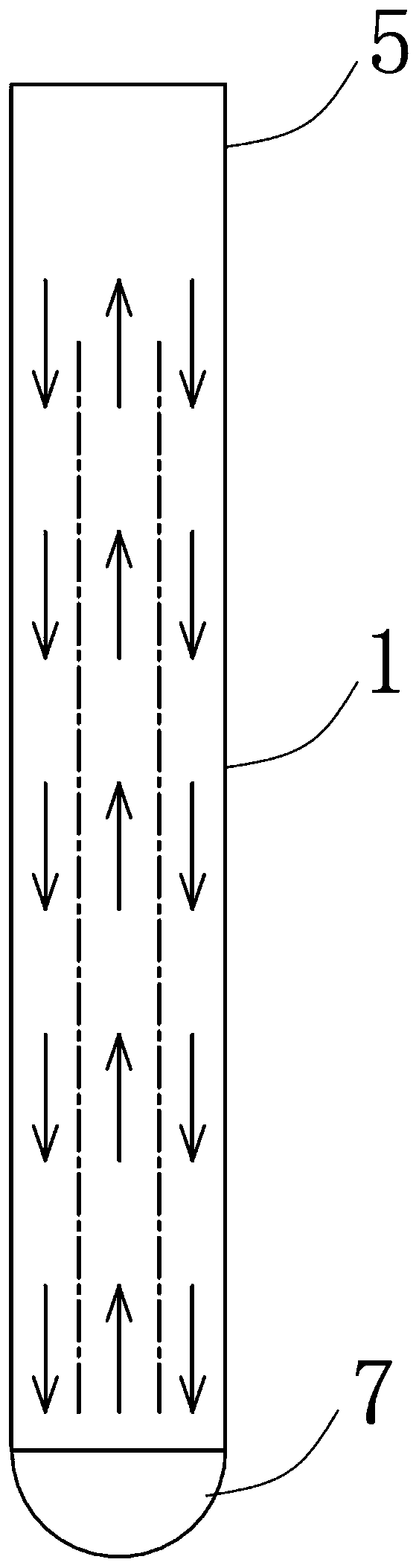

In-situ geothermal power generation system

PendingCN111207047AReduce lossImprove power generation efficiencyGeothermal energy generationMachines/enginesThermodynamicsMechanical engineering

The invention provides an in-situ geothermal power generation system. The system comprises a heat pipe, a thermoelectric temperature difference power generation device and a magnetic levitation powergeneration device. The upper end of the heat pipe extends to the earth's surface or a water body. The lower end of the heat pipe is located at a geothermal source. A circulating cavity is formed in the heat pipe. A circulating working medium is arranged in the circulating cavity. The thermoelectric temperature difference power generation device is located at the lower end of the heat pipe. The magnetic levitation power generation device is located in the middle of the heat pipe. The thermoelectric temperature difference power generation device and the magnetic levitation power generation device output electric energy outwards through electric energy output ports correspondingly. According to the system provided by the invention, the heat pipe is directly buried deep underground, the heat pipe is located at the geothermal source, on the one hand, the thermoelectric temperature difference power generation device located on the lower segment of the heat pipe can directly convert geothermal energy into electric energy, on the other hand, a formed upward gaseous working medium drives the magnetic levitation power generation device in the middle of the heat pipe when the circulating working medium becomes the gaseous working medium during phase changing, geothermal energy is converted into mechanical energy which is then converted into electric energy, and the system has the advantages of geothermal in-situ power generation, low energy loss, high power generation efficiency and the like.

Owner:SHENZHEN UNIV +2

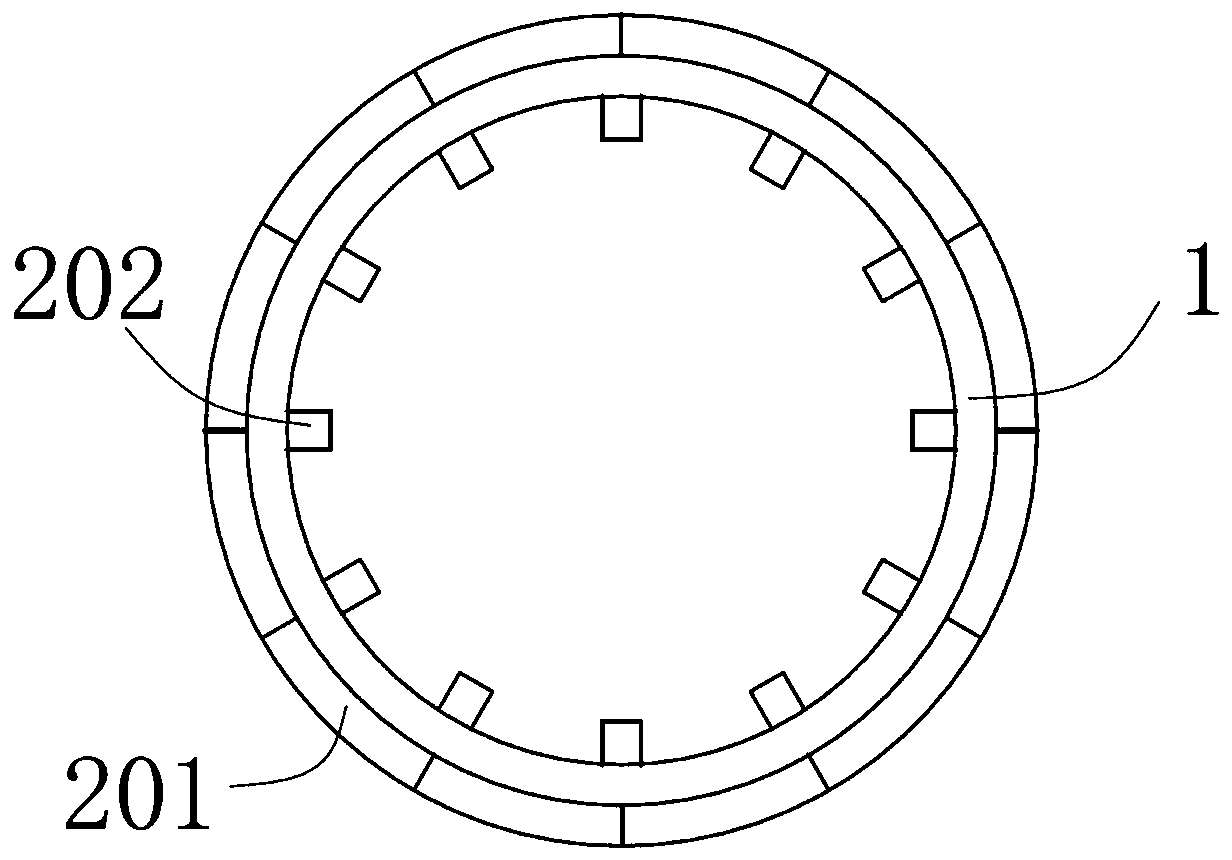

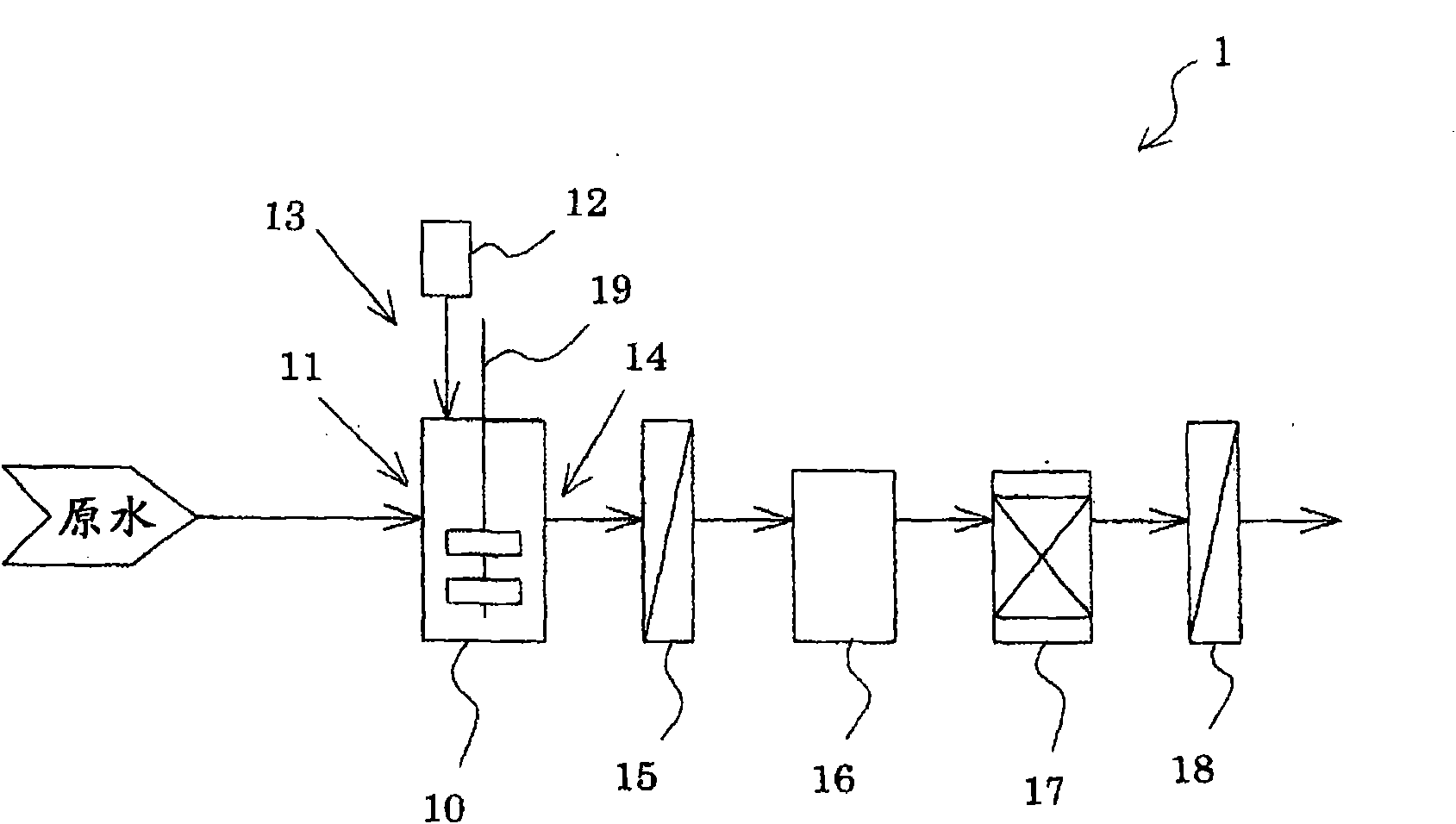

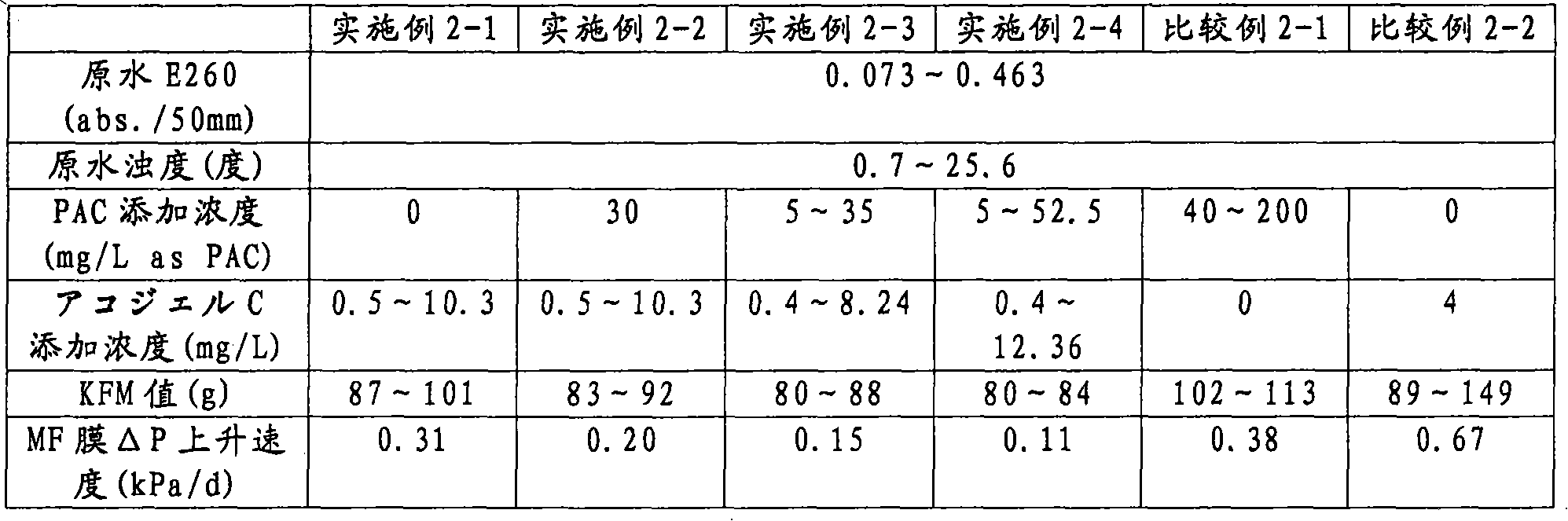

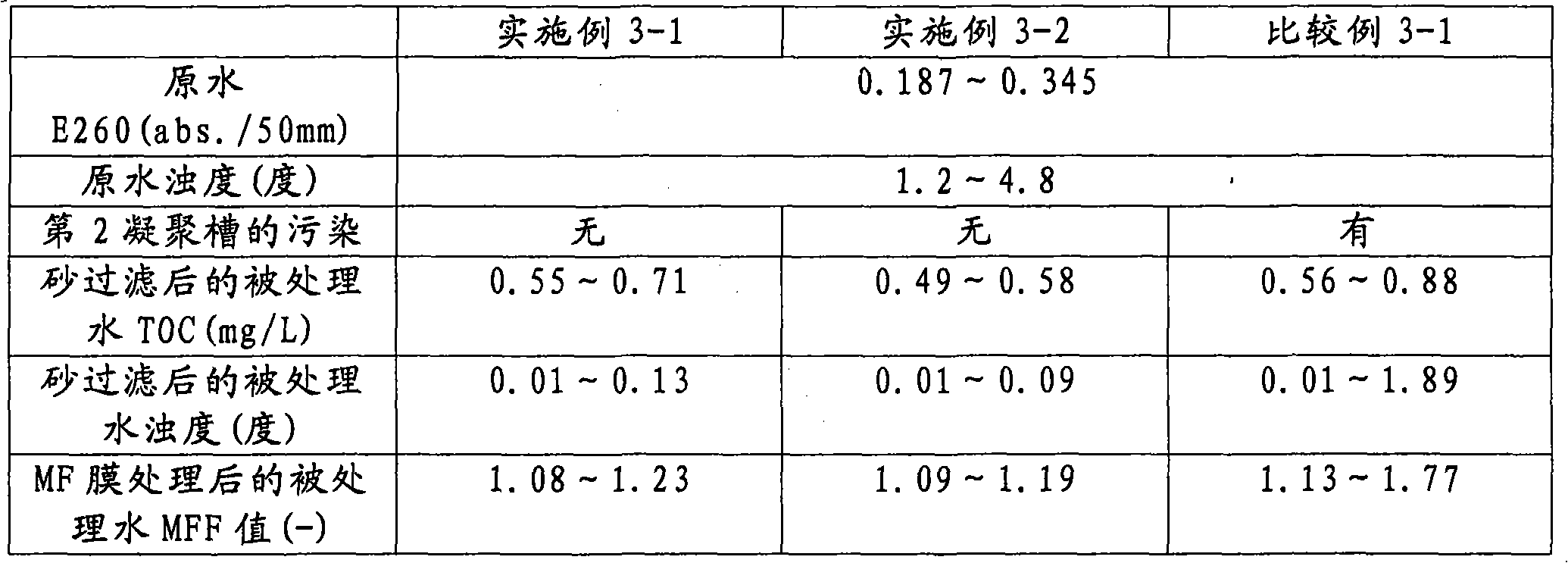

Membrane separation method and membrane separation device

InactiveCN101815677AReduced deterioration of separation performanceReduce adsorptionUltrafiltrationReverse osmosisChemical physicsMembrane surface

Disclosed are a membrane separation method and a membrane separation device, each of which enables to reduce deterioration in membrane separation performance during membrane separation of water to be processed by reducing adsorption of membrane contaminating materials contained in the water onto the membrane surface. Specifically, water to be processed is subjected to membrane separation after being added with particles made of a cationic polymer which swells but does not substantially dissolve in water.

Owner:KURITA WATER INDUSTRIES LTD

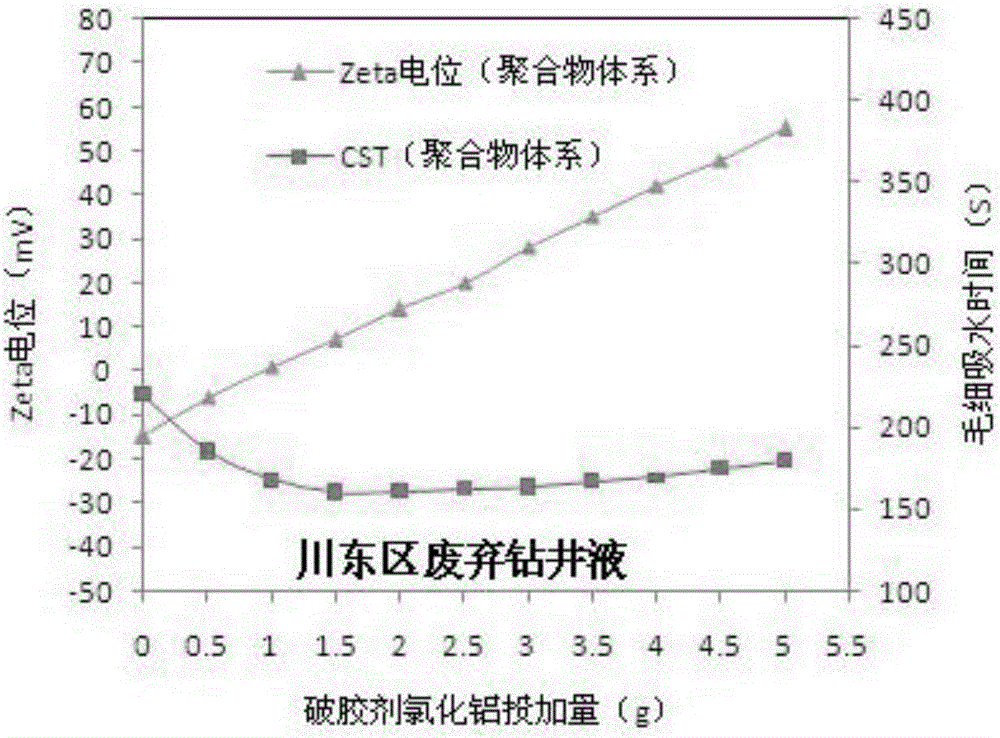

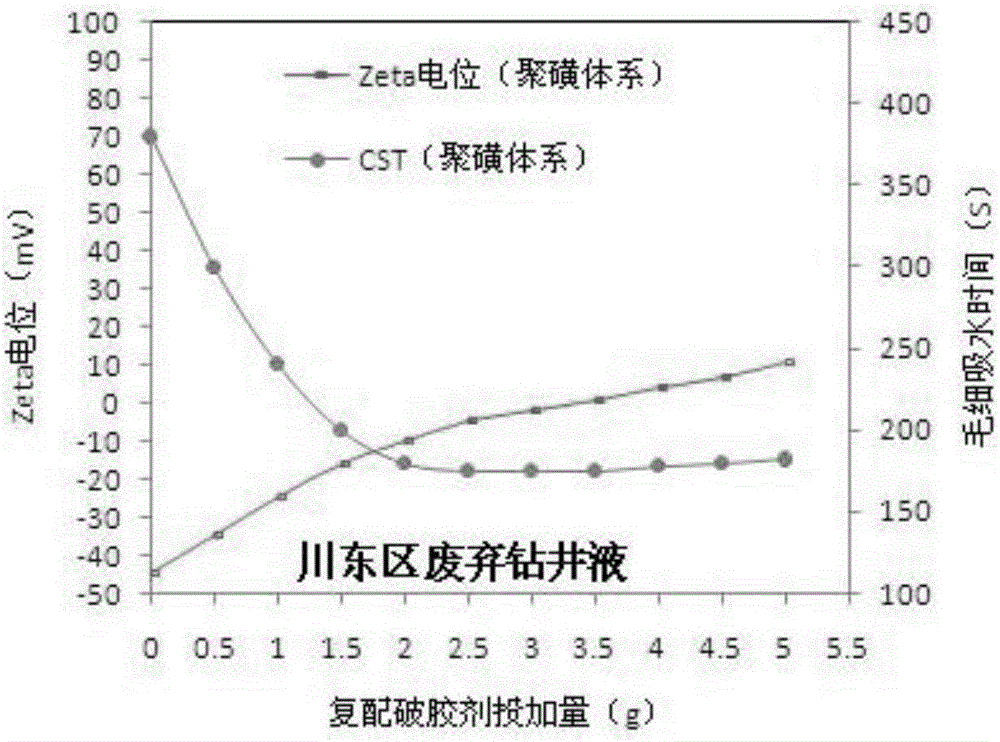

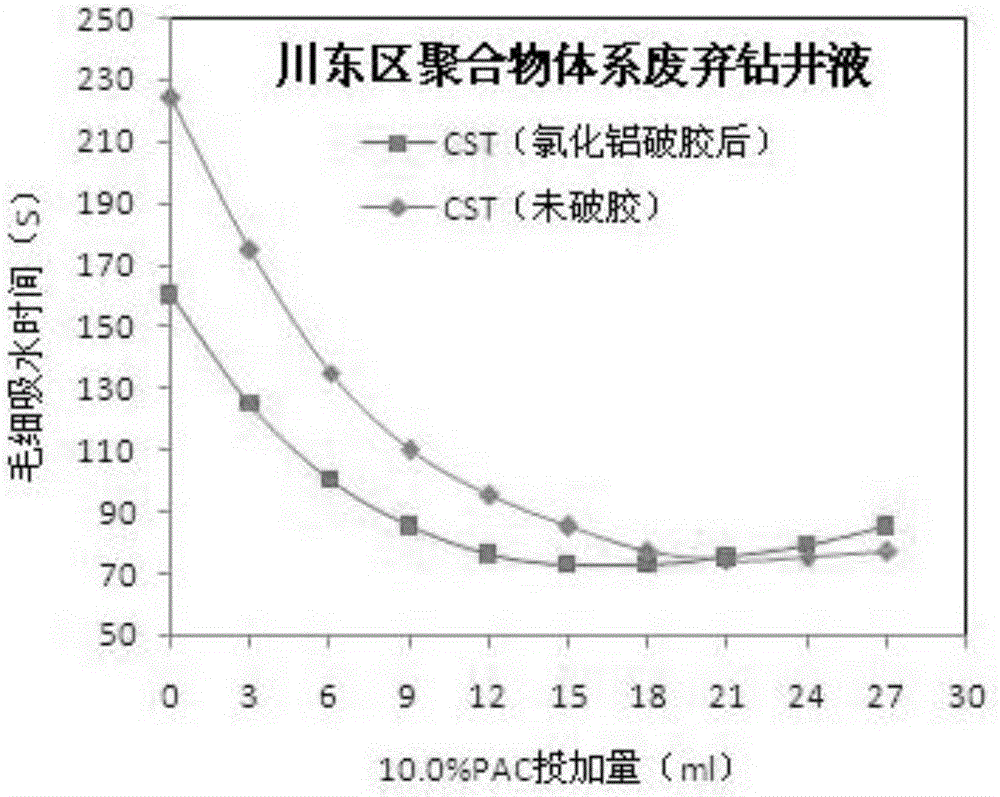

Solid-liquid separation method for oil-gas field waste water-based drilling fluid

ActiveCN106145440AFully condensedGood glue breaking effectWaste water treatment from quariesTreatment involving filtrationWater basedWell drilling

The invention discloses a solid-liquid separation method for oil-gas field waste water-based drilling fluid. Mainly, a proper waste water-based drilling fluid destabilization reagent formula is screened out, waste water-based drilling fluid at various drilling stages of oil-gas fields in Xingjiang, the eastern Sichuan region and the western Sichuan region is subjected to gel breaking treatment, liquid-phase matter in the drilling fluid is completely released, solid-phase matter fully settles, solid-liquid separation is achieved through filtering, and preconditions are created for following filtrate treatment.

Owner:中石化石油工程技术服务有限公司 +1

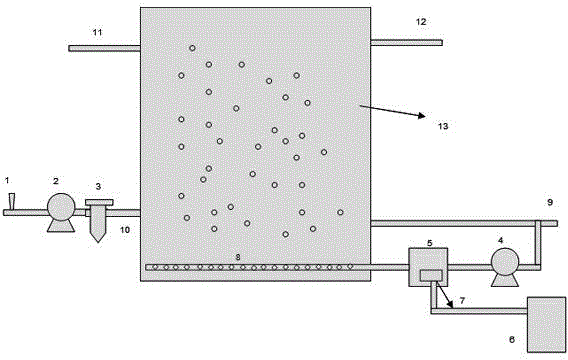

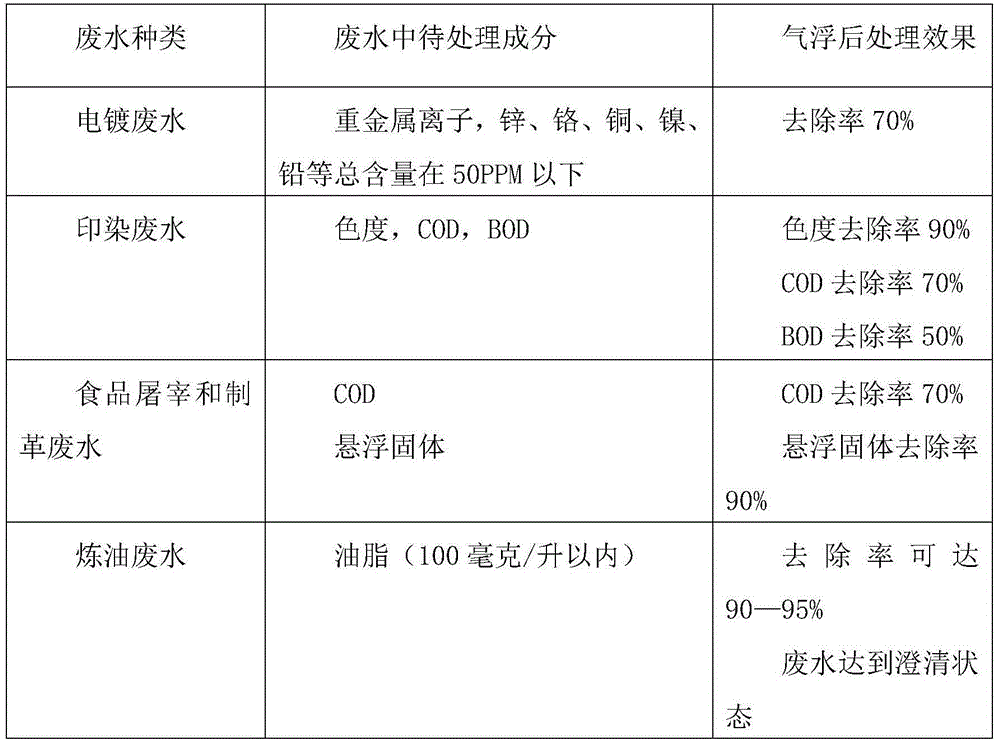

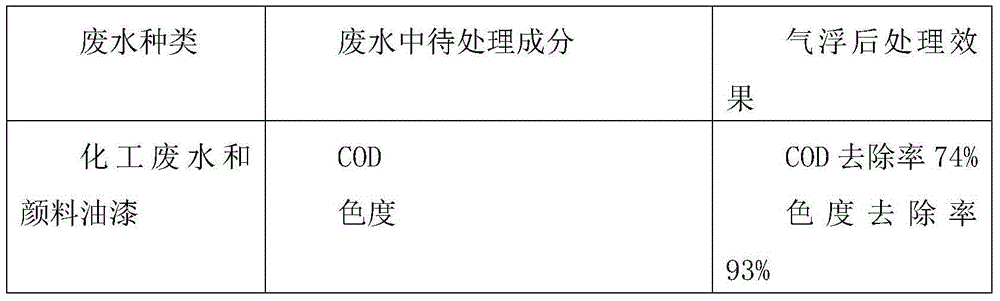

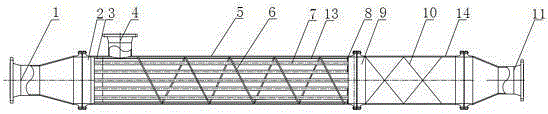

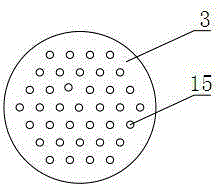

Air flotation equipment and working method thereof

InactiveCN104925888AFully condensedWell mixedWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationSuspended particlesSewage

The invention provides air flotation equipment and a working method thereof. The equipment comprises an air floatation tank, wherein a clear water outlet, a sewage inlet, a sewage outlet and a slag discharge opening are respectively formed in the air flotation tank; the sewage inlet is sequentially connected with a swirling reactor, a sewage pump, a dosing opening and a sewage inlet; a releaser is arranged in the air flotation tank, the releaser is sequentially connected with a mixer and a pressurizer pump out of the air flotation tank, and the pressurizer pump is connected with the clear water outlet; a jet device which is connected with a pressure tank is arranged in the mixer. The equipment provided by the invention can be used for removing emulsified oil, which is difficult to remove by naturally settling or floating upwards, in wastewater or micro suspended particles with the relative density being close to 1, and has the advantages of being compact in structure, high in decontamination efficiency, low in energy consumption, high in degree of automation and the like.

Owner:WUXI LVZHIXING ENVIRONMENTAL PROTECTION CO LTD

Efficient boiled off gas (BOG) after-condenser

The invention discloses an efficient boiled off gas (BOG) after-condenser. The efficient BOG after-condenser comprises a first shell, a second shell, a liquefied natural gas (LNG) inlet formed in the first shell, a pipe plate and a supporting grid, wherein the pipe plate and the supporting grid are located at the two ends of the first shell respectively; the pipe plate is connected with a BOG inlet; a plurality of micro pore pipes, fixed-interval rods and spiral flow guide plates are arranged between the pipe plate and the supporting grid; the spiral flow guide plates are provided with pipe pores; the pipe plate is provided with pipe plate pipe pores; the surfaces of the micro pore pipes are provided with micro pores; the micro pore pipes and the fixed-interval rods penetrate through the pipe holes in the spiral flow guide plates and are fixed between the pipe plate and the supporting grid in parallel; one end of the second shell is connected with the first shell through a connecting flange, and the other end of the second shell is connected with an LNG outlet; a static mixing unit is arranged inside the second shell. Compared with traditional BOG after-condensation equipment, the efficient BOG after-condenser is high in condensation efficiency, high in processing capacity, easy to operate and convenient to maintain and replace.

Owner:江苏中圣压力容器装备制造有限公司

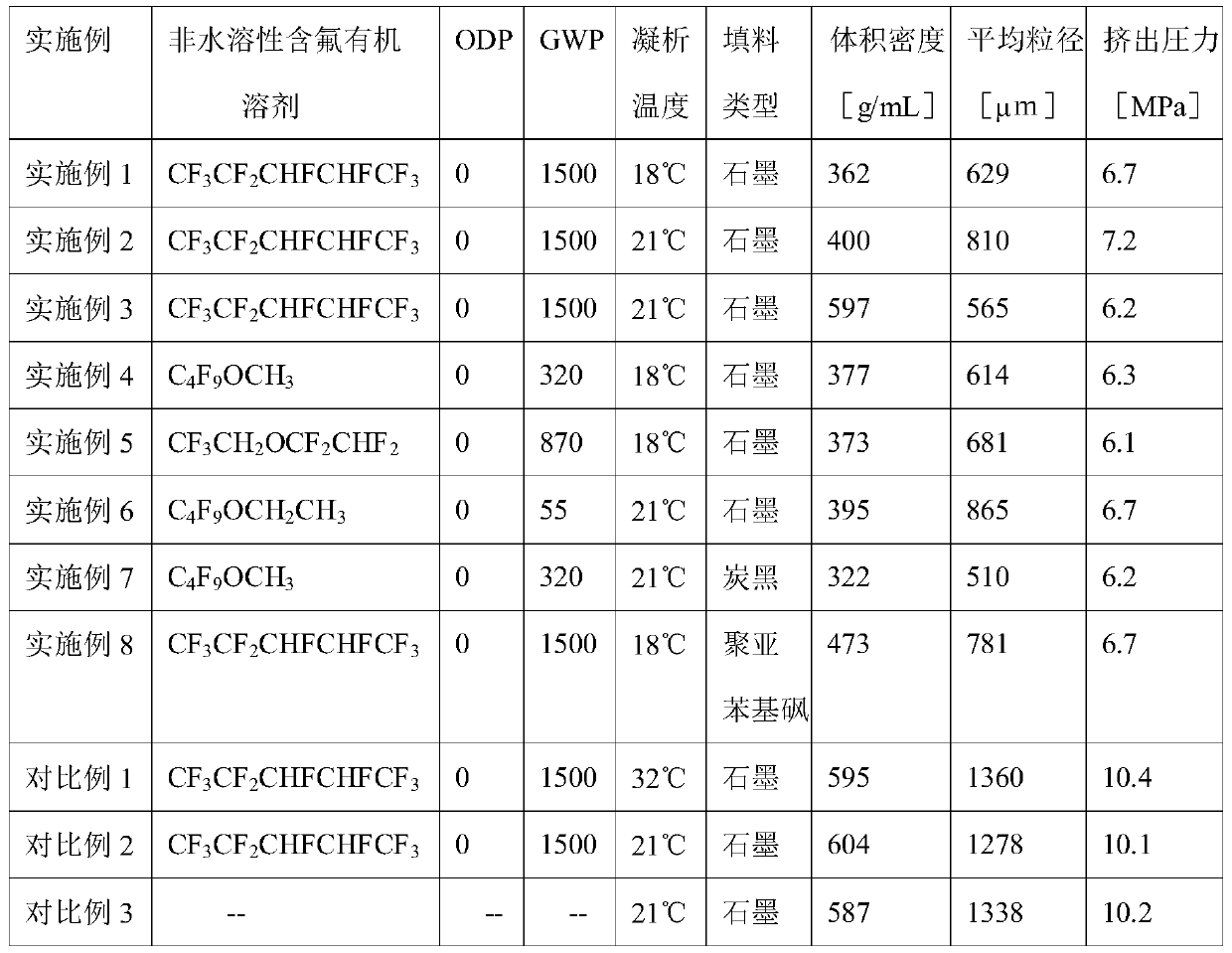

Preparation method of polytetrafluoroethylene packed dispersion resin

ActiveCN111234269ANarrow particle size distributionImprove liquidityTetrafluoroethylenePolymer science

The invention provides a preparation method of polytetrafluoroethylene packed dispersion resin. The method comprises the following steps: mixing the filler dispersion liquid with the polytetrafluoroethylene dispersion emulsion; uniform stirring the mixture, modulating the system temperature, adding a condensing agent, stirring the mixture until demulsification is started, adding a non-water-soluble fluorine-containing organic solvent which is a hydrogen-containing fluorocarbon (HFC type), perfluoroalkyl ether (PFAE type) or hydrofluoroether (HFE type) solvent, performing coagulation, and filtering, washing and drying the coagulated product to obtain the polytetrafluoroethylene packed dispersion resin. The polytetrafluoroethylene packed dispersion resin is uniform in filling, narrow in particle size distribution, good in fluidity, small in extrusion pressure and convenient to form and process. The preparation method is green, environmentally friendly and safe.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Extraction device and extraction method for volatile plant essential oil

ActiveCN109207262AReduce residual lossReduce lossesDistillation in boilers/stillsVapor condensationGas phaseWater vapor

An extraction device and an extraction method for volatile plant essential oil are disclosed. The device includes a distillation kettle, a gas phase booster pump, a partial condensation and liquid separation unit and a gas phase circulating pipeline. An outlet of the distillation kettle communicates with an inlet of the gas phase booster pump. An outlet of the gas phase booster pump communicates with an inlet of the partial condensation and liquid separation unit. The top of the partial condensation and liquid separation unit communicates with the distillation kettle through the gas phase circulating pipeline provided with a valve. The partial condensation and liquid separation unit is provided with an essential oil product outlet and an aromatic water outlet. The device can effectively increase the extraction efficiency of volatile essential oil, can greatly reduce steam consumption, can be achieved through upgrading and rebuilding a conventional industrial steam distillation device and has a wide application and promotion prospect.

Owner:WUHAN POLYTECHNIC UNIVERSITY

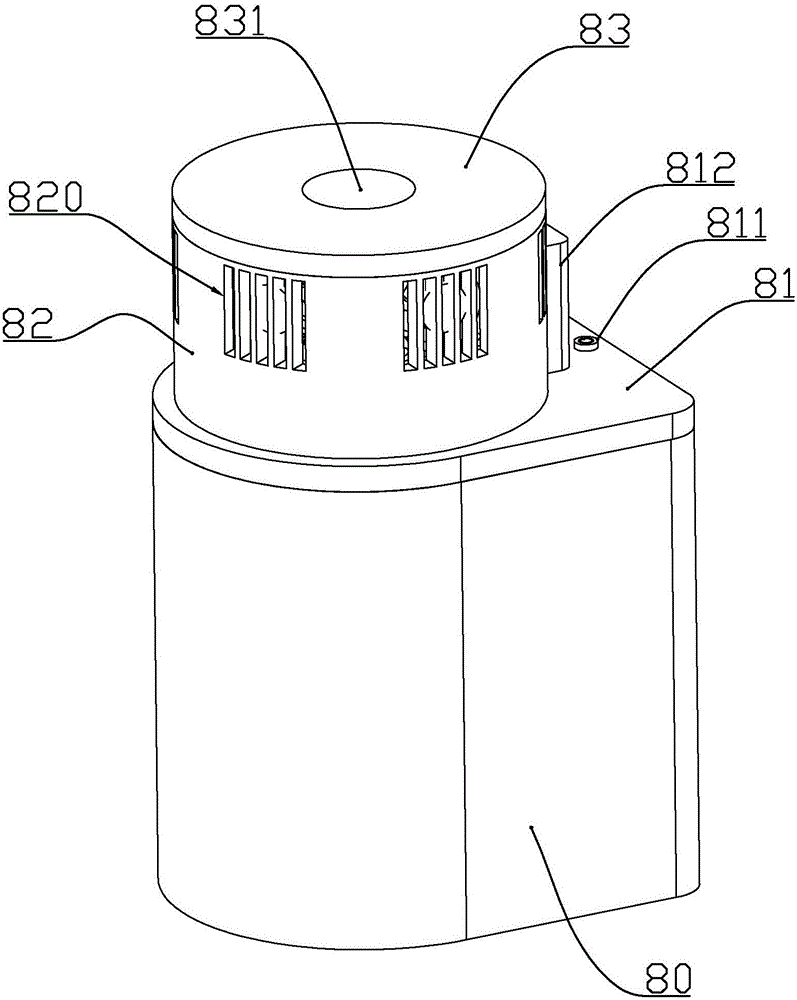

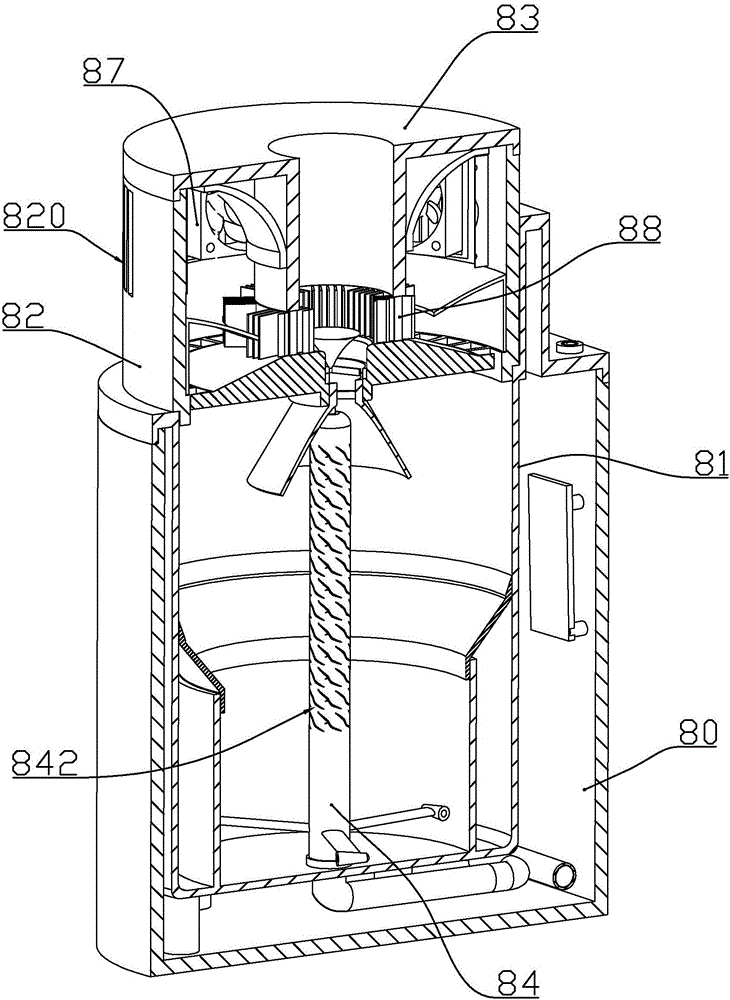

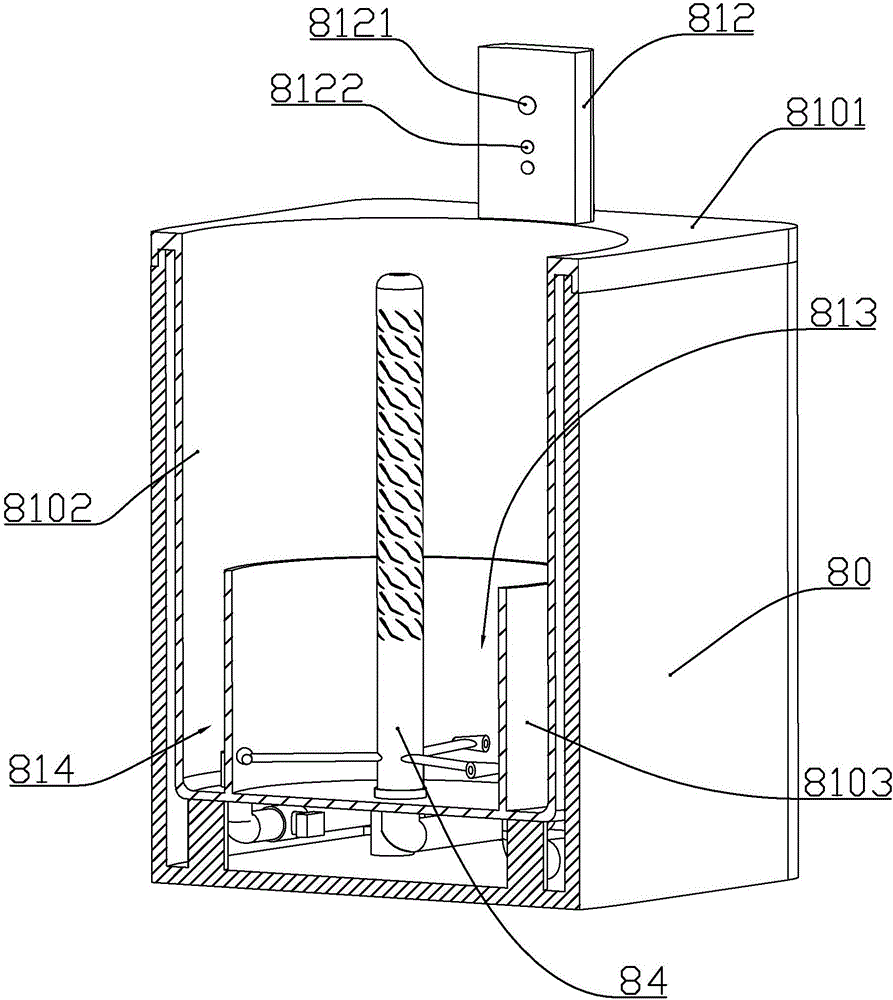

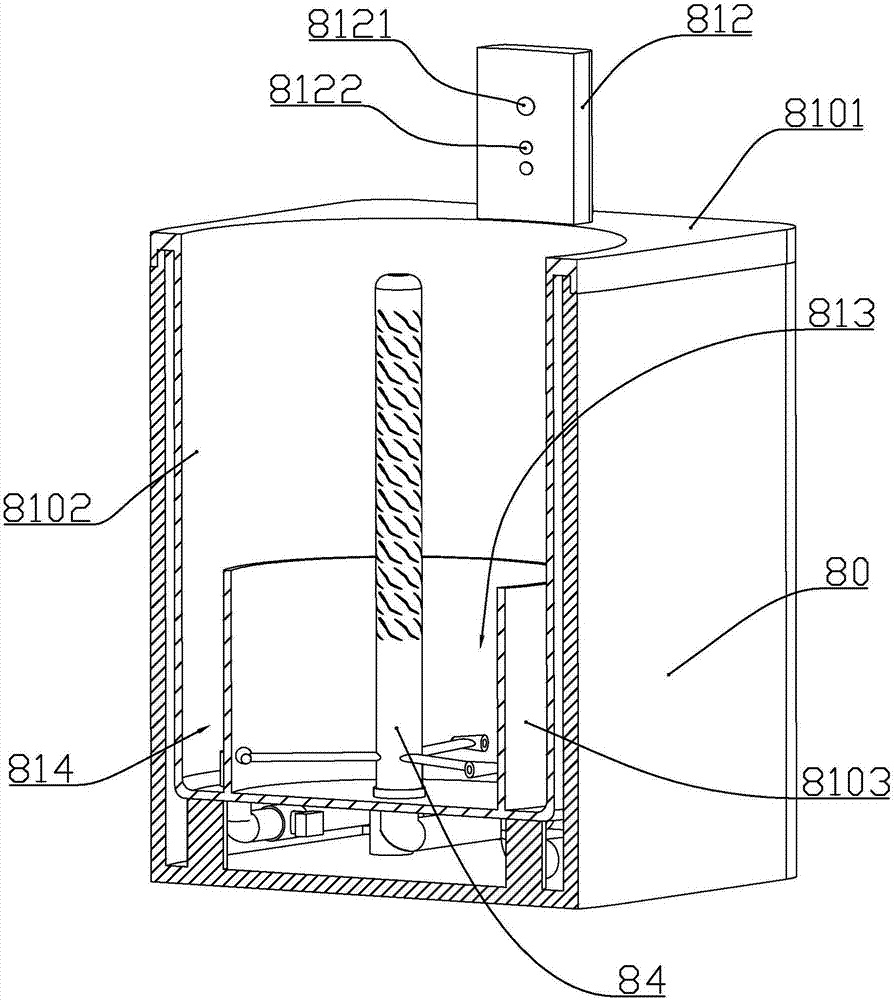

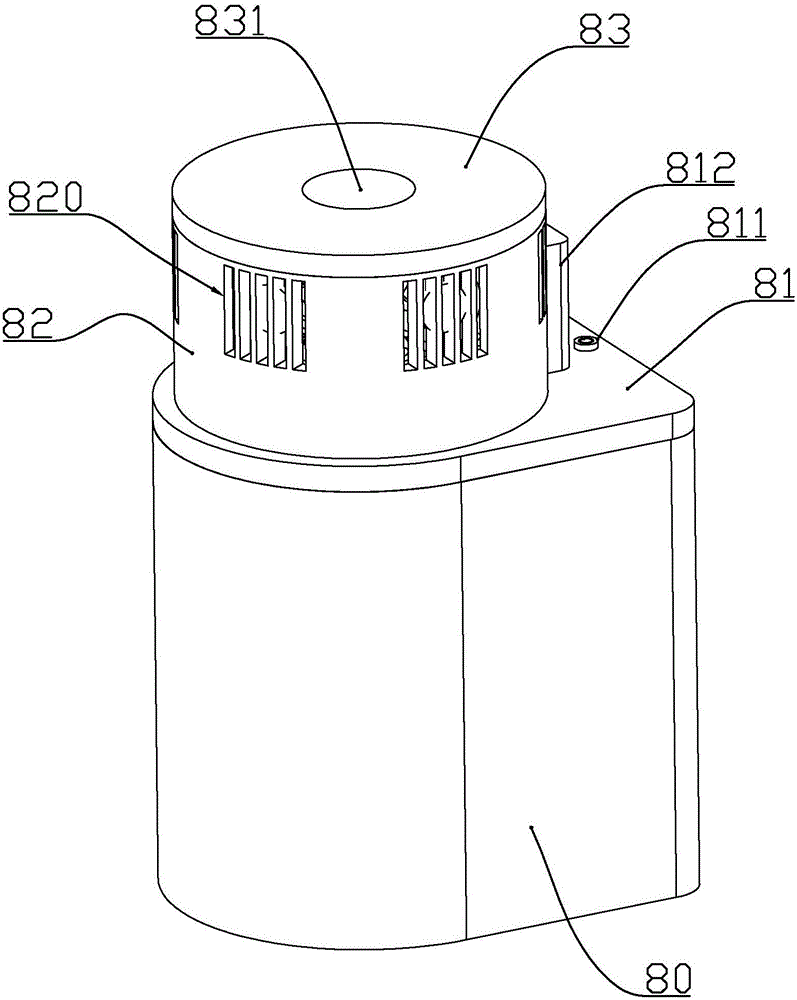

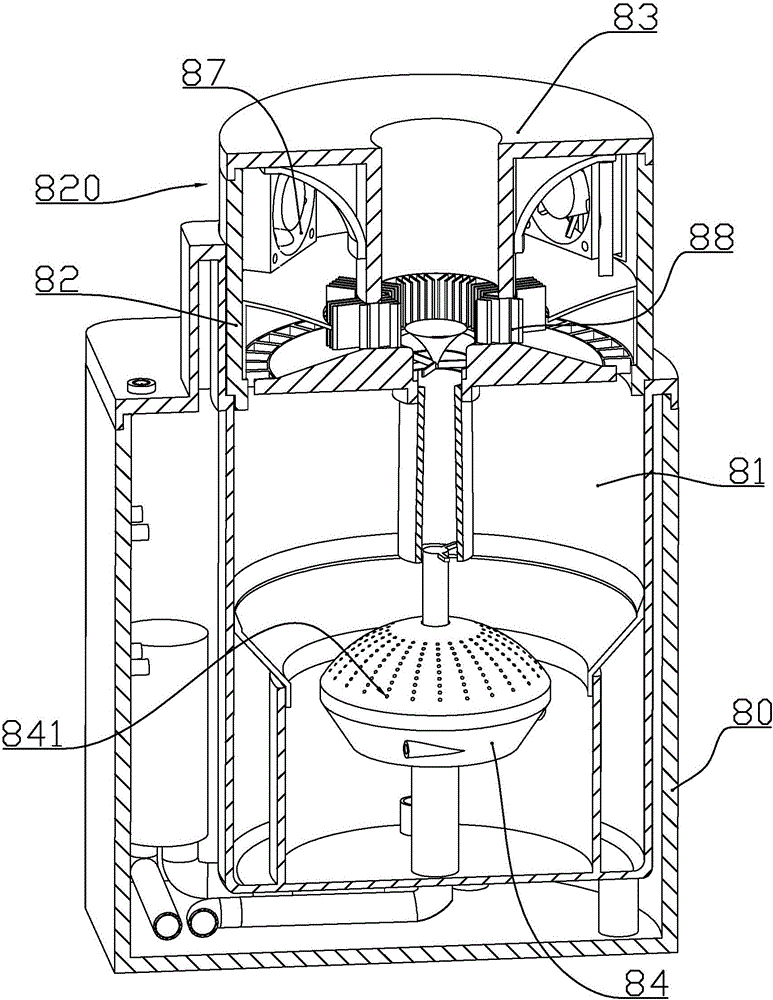

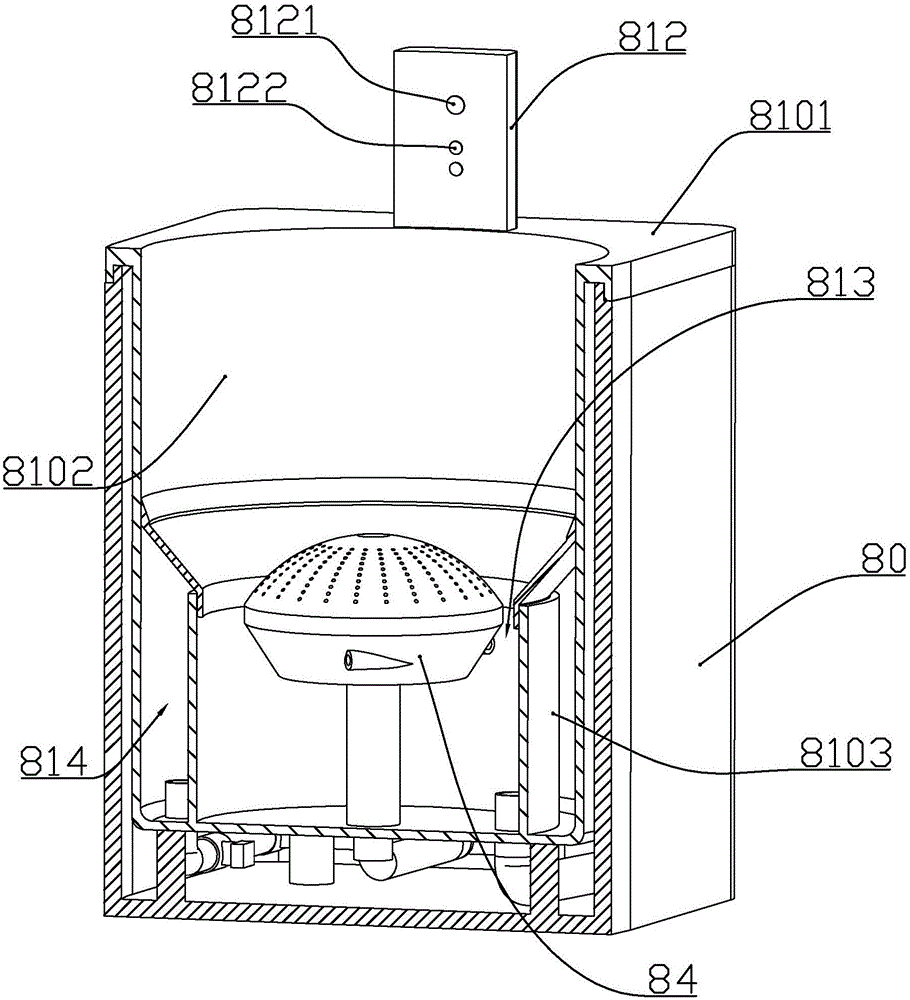

Air purifying machine

ActiveCN105664625AReduce widthIncrease contact areaUsing liquid separation agentSeparation devicesWater storageWastewater

The invention discloses an air purifying machine. The air purifying machine comprises an outer machine casing, and an inner machine casing which is mounted in the outer machine casing; the inner machine casing comprises a cylindrical water barrel; an annular partition plate is formed in the bottom of the water barrel; a water storage barrel is formed in the inner periphery of the annular partition plate in the water barrel; a waste water storage barrel is formed in the outer periphery of the annular partition plate in the water barrel; an inverted conical water guide plate is mounted on the annular partition plate; the lower end of the water guide plate extends to the inner side of the annular partition plate; the upper end of the water guide plate is adhered to the inner wall of the water barrel; a water curtain water inlet joint is formed in the center of the bottom of the water storage barrel; a water pumping joint is formed at the position, which is different from the position of the water curtain water inlet joint, at the bottom of the water storage barrel; a waste water joint is formed at the bottom of the waste water storage barrel; a filter and a water pump are also mounted in the space between the outer machine casing and the inner machine casing; a water spraying column is rotatably connected to the upper part of the water curtain water inlet joint in a sleeving manner; a plurality of groups of water spraying holes are formed in the part, higher than the annular partition plate, of the side wall of the water spraying column in an axial direction at equal intervals. The air purifying machine has a good effect on purifying air, and is energy-saving and environment-friendly.

Owner:贵州合心慧能科技有限公司

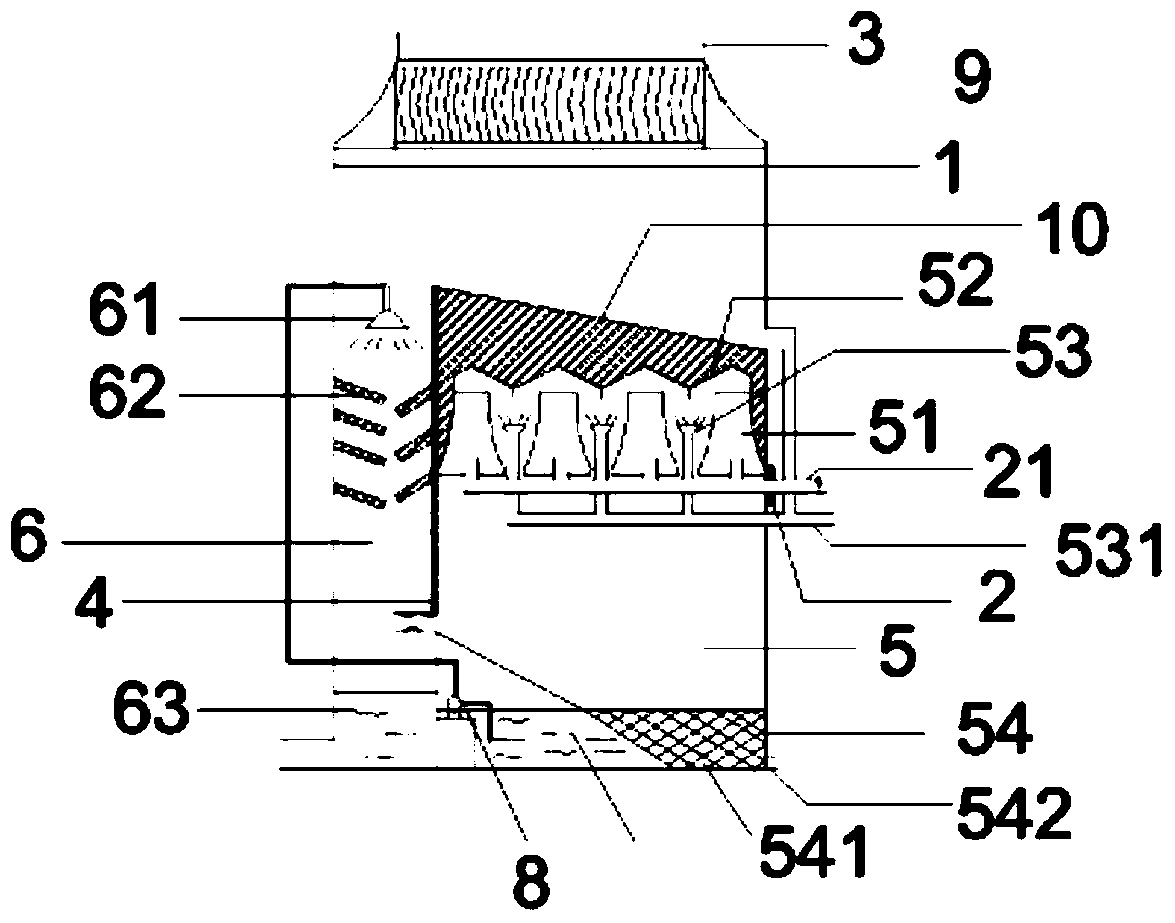

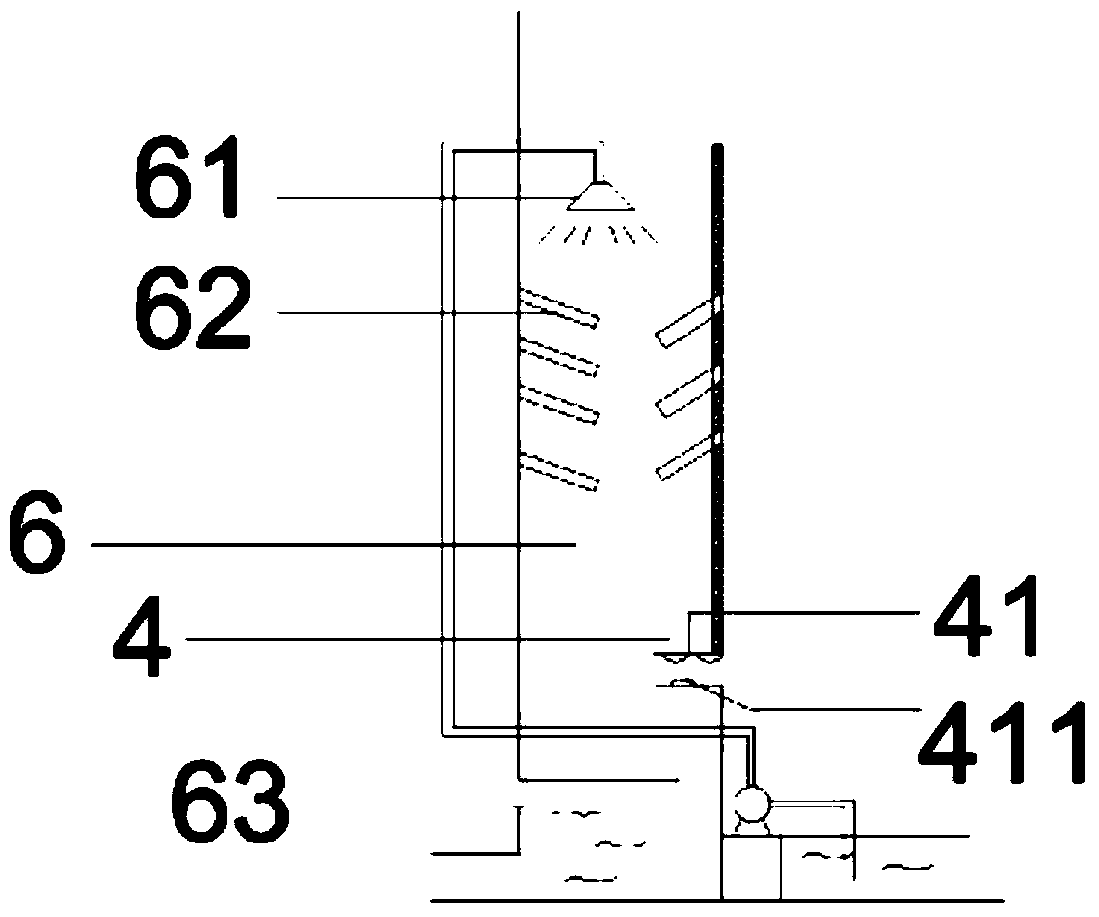

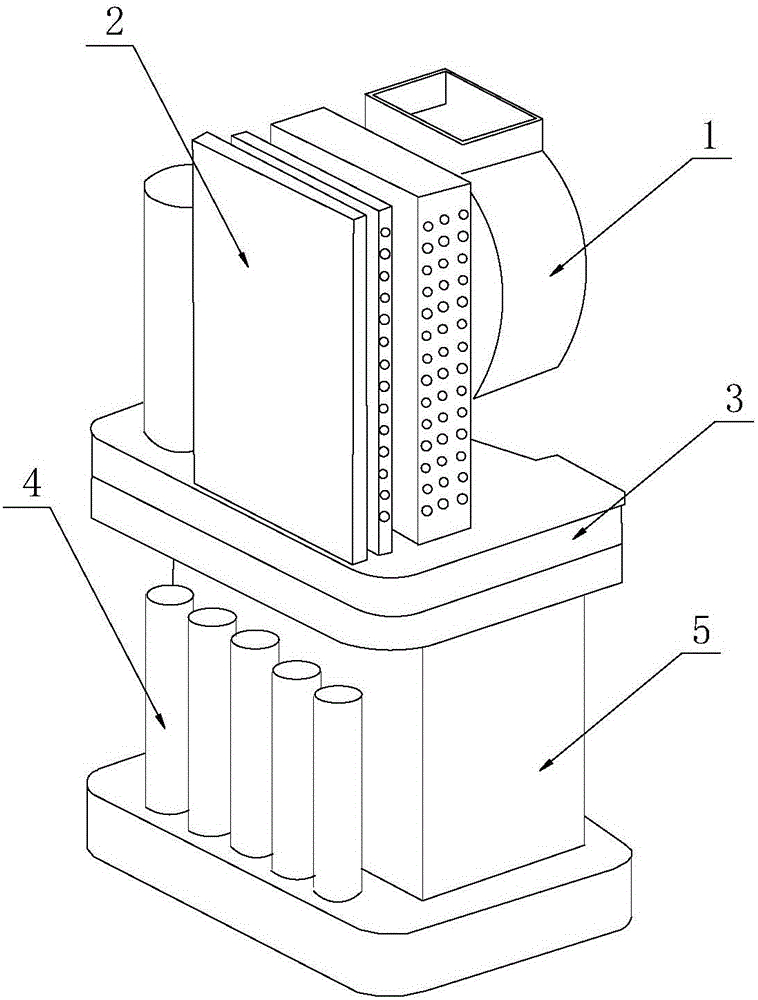

Climbing film type multi-effect water distillator

ActiveCN102417266BIncrease productionEasy to install and connectMultistage water/sewage treatmentRefluxWater storage

The invention discloses a climbing film type multi-effect water distillator, and belongs to the field of distilled water equipment. The multi-effect water distillator comprises a frame; the frame is provided with evaporators connected sequentially through a raw water pipeline; a condensing device is arranged above the evaporators; the condensing device and the evaporators are connected with a pre-heater through a pure steam pipeline; the raw water inlet of the evaporator is connected with the pre-heater; the inner part of the evaporator is divided into four sections, namely a steam-water separation section, a reflux defoaming section, an evaporation section and a water storage chamber sequentially from top to bottom; evaporating pipes arranged longitudinally are arranged in the evaporation section; and the side walls of the evaporators are provided with through holes. In the multi-effect water distillator, the water quantity in the evaporating pipes of the evaporators is completely the same, and the evaporation quantity in the evaporating pipes is also the same in the heat exchange process, so the efficiency of the evaporating pipes is consistent; the water distribution structuresare from bottom to top, so that complete and uniform water distribution of the evaporating pipes is realized; and the multi-effect water distillator is used for preparing the distilled water by usingthe climbing film principle, so that uniform water distribution and full steam-water separation are ensured, and the medical distilled water with high efficiency and good quality is prepared.

Owner:HEBEI CHINA ROSE PHARMA EQUIP

Novel air water maker with high water making efficiency

InactiveCN105839701AImprove water production efficiencyImprove anti-interference abilityGas treatmentDispersed particle filtrationAnti jammingPulp and paper industry

The invention relates to a novel air water maker with high water making efficiency. The novel air water maker comprises a condensation mechanism. The condensation mechanism comprises a heating assembly and a condensation assembly. The heating assembly is communicated with the condensation assembly. The condensation assembly comprises a body, an air inlet pipe arranged above the body, a water outlet pipe arranged at the bottom of the body and a condensation unit arranged in the body. According to the novel air water maker with high water making efficiency, in the condensation assembly, air is condensed through a condensation pipe, and condensate water is collected through an adsorber at the bottom end of the condensation pipe; a spiral coil pipe heat exchanger is adopted, so that full condensation in the condensation pipe is guaranteed, and the air condensation effect is improved; along with condensation of the air, high pressure is formed in the condensation pipe, air condensation is better promoted, and the air condensation effect is further improved. Furthermore, a pressure measuring circuit has high anti-jamming capability, and therefore the reliability of the air water maker is improved.

Owner:张萍

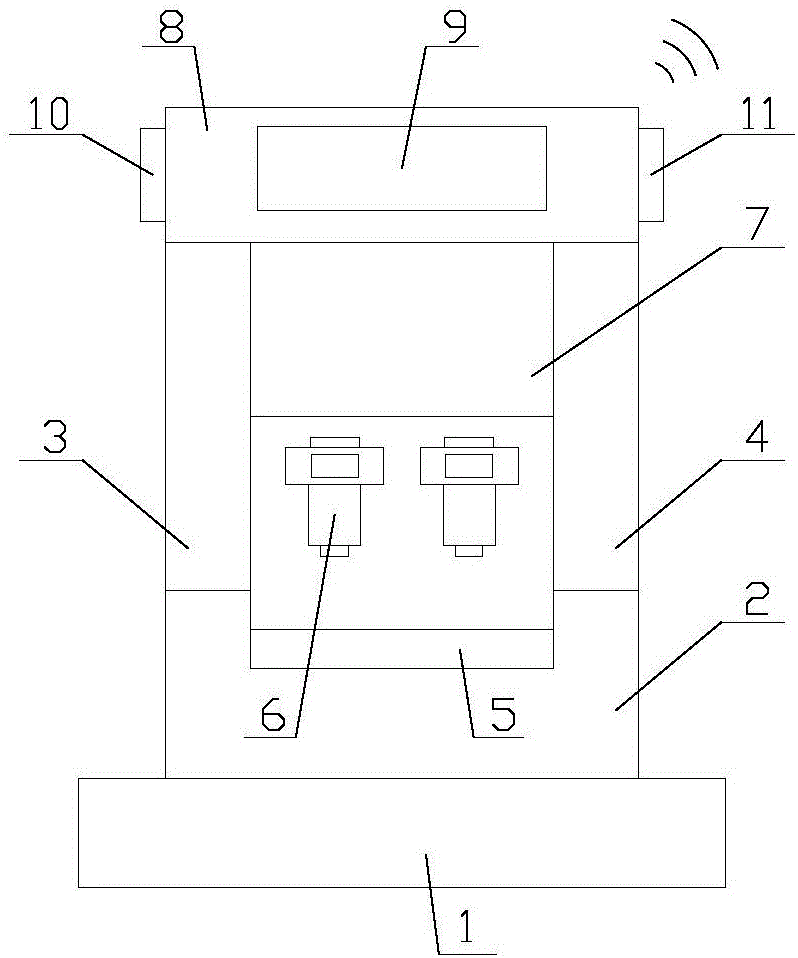

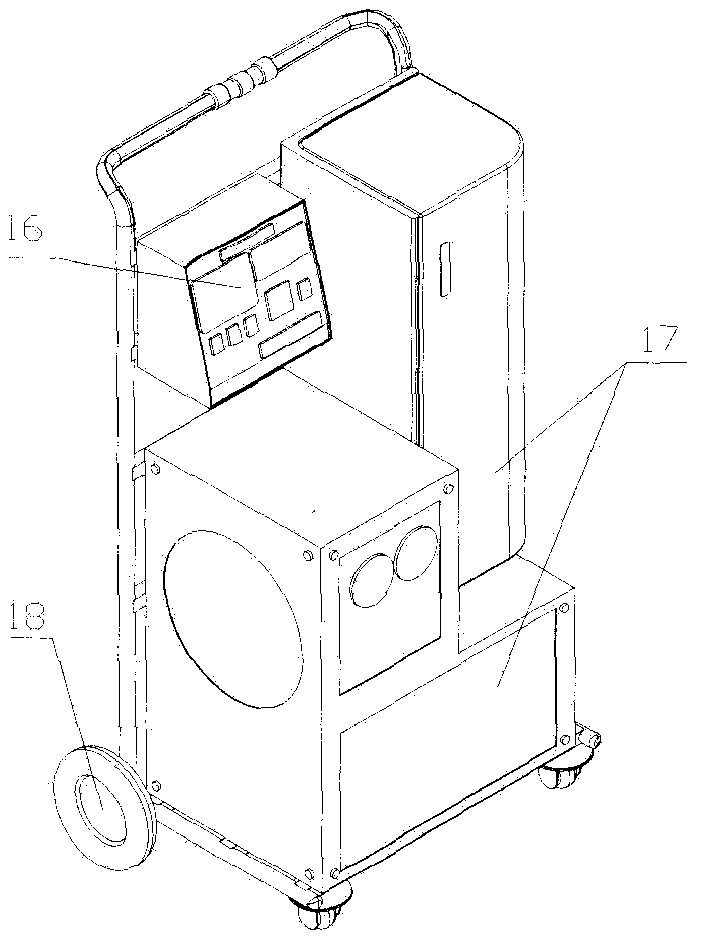

Efficient energy-saving intelligent air water generator

InactiveCN105780851AImprove water production efficiencyHigh practical valueProgramme control in sequence/logic controllersDrinking water installationWater storageEngineering

The invention relates to an efficient energy-saving intelligent air water generator.The water generator comprises a base, a condensation water generating mechanism, a water storage and water pumping mechanism and a compression refrigeration mechanism are arranged above the base, the compression refrigeration mechanism comprises a compression refrigeration device, a first pipe and a second pipe, and the compression refrigeration device is communicated with the compression refrigeration mechanism through the first pipe and the second pipe.According to the efficient energy-saving intelligent air water generator, temperature detection is conducted on air at the positions of temperature sensors through the temperature sensors in an air inlet pipe and an air outlet pipe, when the allowable value is not reached, the air is made to flow back into a condensation water generating pipe for re-condensation through a backflow pipe, thereby sufficient condensation is conducted on the air, and water generation efficiency of the air water generator is improved; besides, through a frequency control circuit, maximum working efficiency of an air inlet mechanism can be guaranteed, the energy-saving effect is achieved, meanwhile, an integrated circuit has the advantages of being low in price and stable in performance, and practical value of the air water generator is raised.

Owner:北京睦合达信息技术有限公司

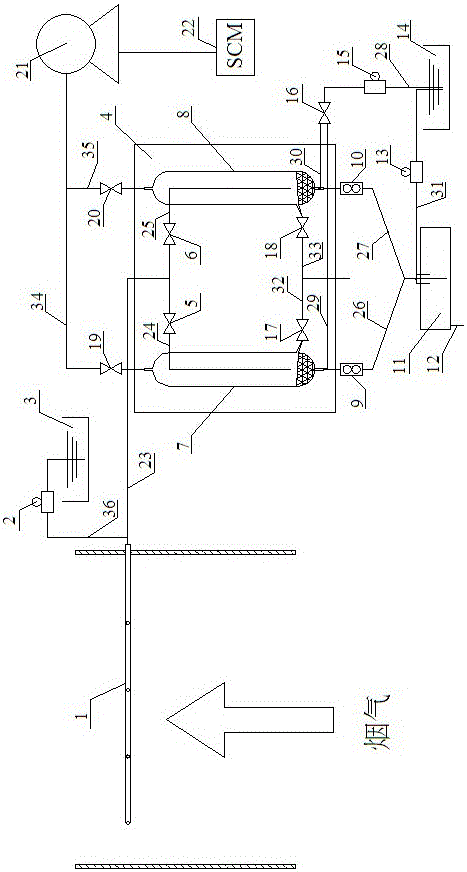

Device and method for measuring ammonia escape content in flue gas and ammonia escape content in smoke dust simultaneously

The invention relates to a device and method for measuring ammonia escape content in flue gas and ammonia escape content in smoke dust simultaneously. At present, no device and method which are accurate in measurement and capable of measuring ammonia escape content in flue gas and ammonia escape content in smoke dust simultaneously exist. The device is characterized in that one end of an air guide pipe is connected with one end of a sampling pipe, the other end of an absorption liquid supply pipe is connected with the air guide pipe, one end of a first air guide branch pipe and one end of a second air guide branch pipe are both connected with the other end of the air guide pipe, the other end of the first air guide branch pipe is connected with a first condensation cylinder, the other end of the second air guide branch pipe is connected with a second condensation cylinder, and an analyzer and a flowmeter are both connected with a single-chip microcomputer. The method comprises the steps that the first condensation cylinder and the second condensation cylinder conduct sampling alternately in sequence, the analyzer conducts analysis, the ammonia content in sampled flue gas is obtained, the flowmeter conducts measurement, the volume of the sampled flue gas is obtained, and thereby the ammonia escape concentration in the sampled flue gas is obtained. The device and method for measuring the ammonia escape content in the flue gas and the ammonia escape content in the smoke dust simultaneously are accurate in measurement, and the ammonia content in the flue gas and the ammonia escape content in the smoke dust can be measured simultaneously.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

An air cleaner

ActiveCN106861327AFully contactedImprove purification effectUsing liquid separation agentSeparation devicesAir cleaningEngineering

An air cleaner is disclosed. The air cleaner includes an external casing and an inner casing mounted in the external casing. The inner casing includes a cylindrical water drum. An annular separating plate is formed at the bottom of the water drum. A water storage drum is formed at the inner circumference of the annular separating plate and in the water drum, and a waste water storage drum is formed in the water drum and at the outer circumference of the annular separating plate. The annular separating plate is mounted with an inverted-cone water guiding plate. The lower end of the water guiding plate extends to the inside of the annular separating plate, and the upper end of the water guiding plate is adhered to the inner wall of the water drum. A water curtain water-feeding connector is formed at the middle of the bottom of the water storage drum. A water suction connector is formed at a position that is different from the position of the water curtain water-feeding connector and at the bottom of the water storage drum. A waste water connector is formed at the bottom of the waste water storage drum. A filter and a water pump are mounted in space between the external casing and the inner casing. A water spraying column rotationally sleeves the upper part of the water curtain water-feeding connector. A part, of the water spraying column, the side wall of which is higher than the annular separating plate is provided with a plurality of groups of water spraying holes along the axial direction in an equidistant manner. The air cleaning effects of the air cleaner are good, and the air cleaner is energy-saving and environmentally friendly.

Owner:JIANGSU ANTAI SAFETY TECH CO LTD

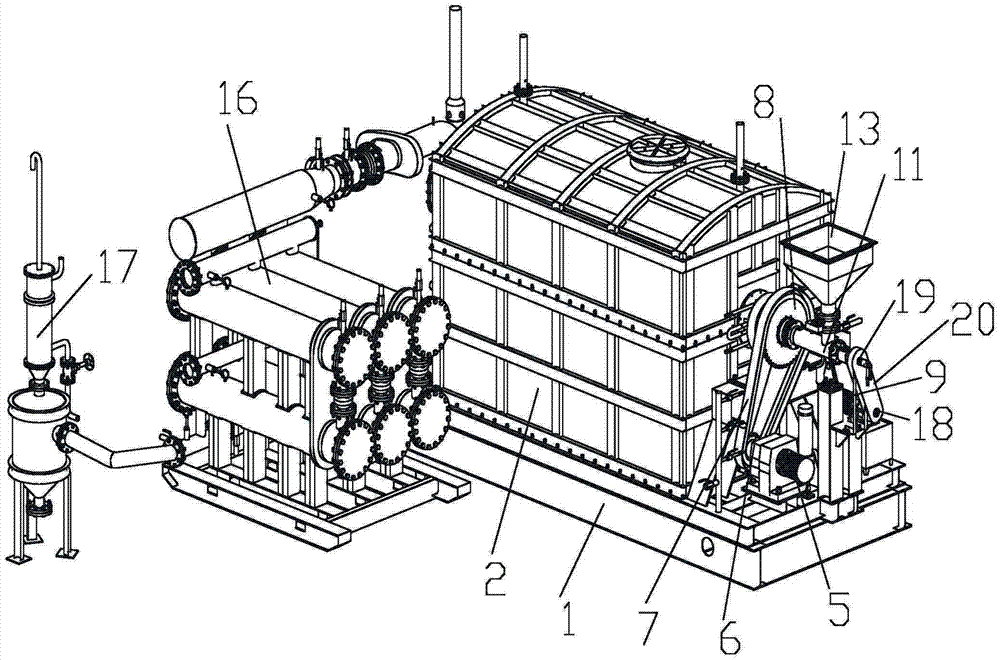

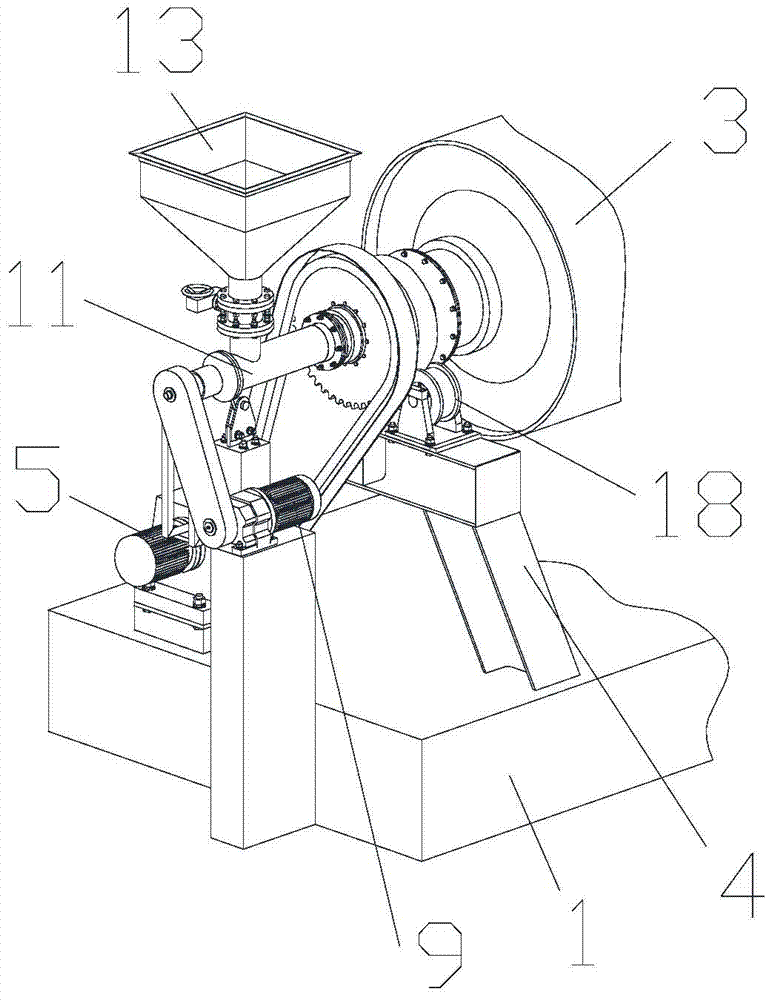

Tilting type continuous acrylic cracking furnace

ActiveCN104119222ARealize continuous feeding functionFully condensedOrganic compound preparationCarboxylic acid esters preparationSprocketDrive motor

The invention provides a tilting type continuous acrylic cracking furnace which is characterized in that a tilting type platform is arranged on the upper end surface of a base; a furnace body is arranged on the tilting type platform; a drum is arranged in the furnace body and supporting shafts at two ends of the drum are supported on supporting frames at two outer ends of the furnace body through roller wheels; a driving chain wheel I is arranged on an output shaft of a driving motor I and drives a driven chain wheel I arranged on a supporting shaft at one end of the drum through a chain I; a driving chain wheel II is arranged on an output shaft of a driving motor II; a driven chain wheel II is arranged at one end of a water-cooling type spiral feeding device; the driving chain wheel II drives a driven chain wheel II through a chain II; the lower end of a feeding hopper is hermetically communicated with one end of the water-cooling type spiral feeding device; the other end of the water-cooling spiral feeding device is dynamically sealed with the supporting shafts of the drum and is communicated with the inlet end of the drum; the outlet end of the drum is communicated with the inlet end of a primary condensation device; the outlet end of the primary condensation device is communicated with the inlet end of a secondary condensation device; a liquid outlet of the secondary condensation device is communicated with a container tank. According to the tilting type continuous acrylic cracking furnace, continuous feeding and continuous heating cracking can be achieved, residual gas is fully condensed and residues on the inner wall of the drum can be easily removed. The tilting type continuous acrylic cracking furnace has relatively high practical values.

Owner:宝鸡市晋旺达机械设备有限公司

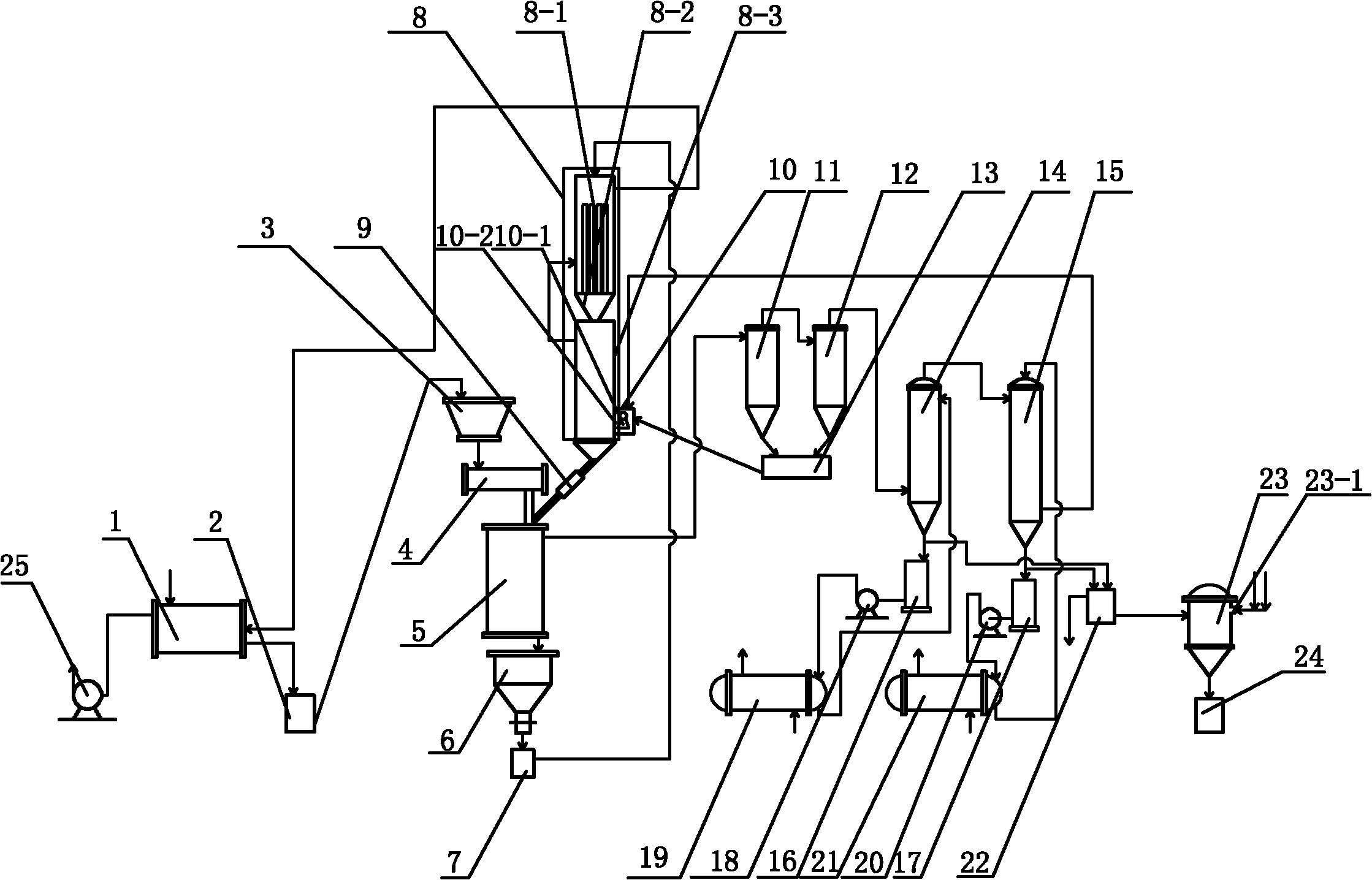

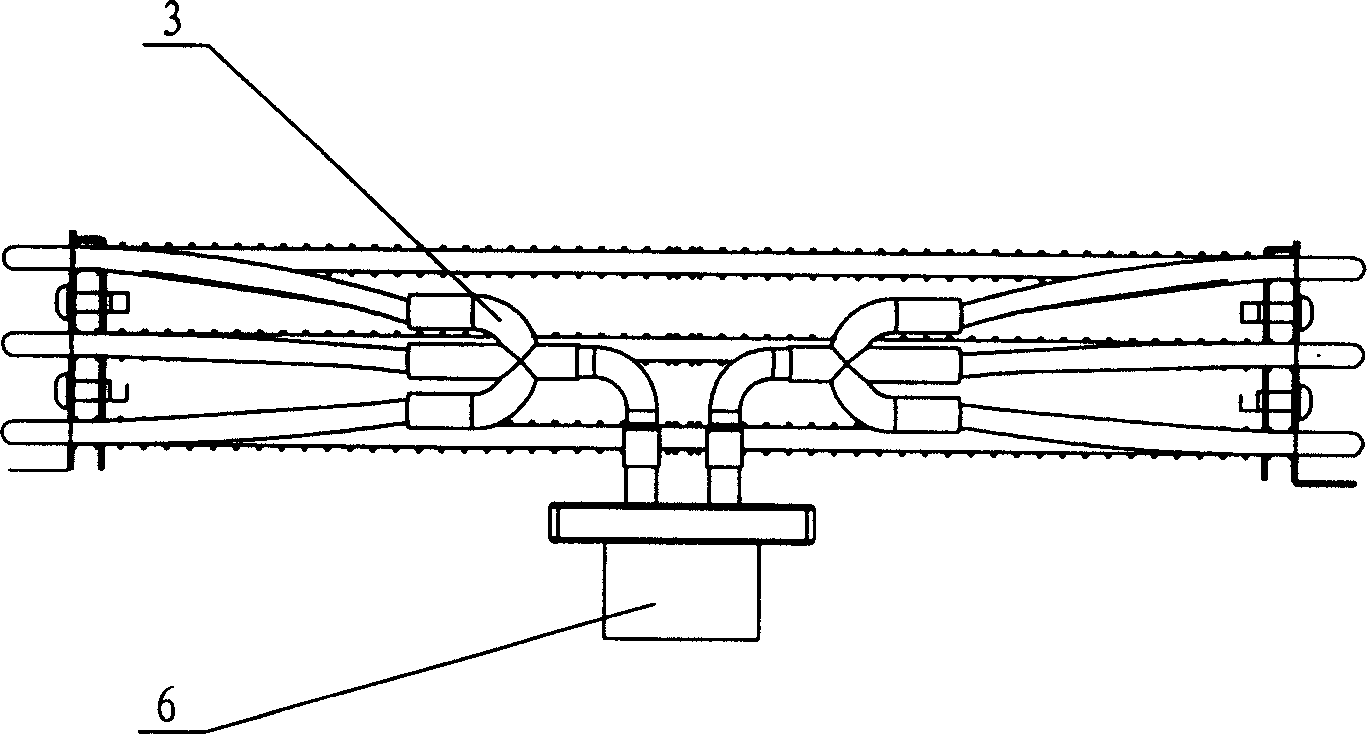

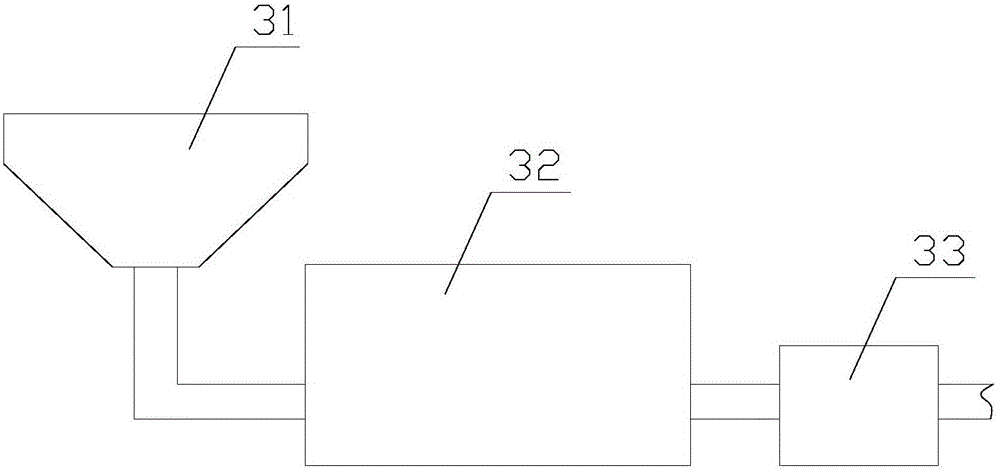

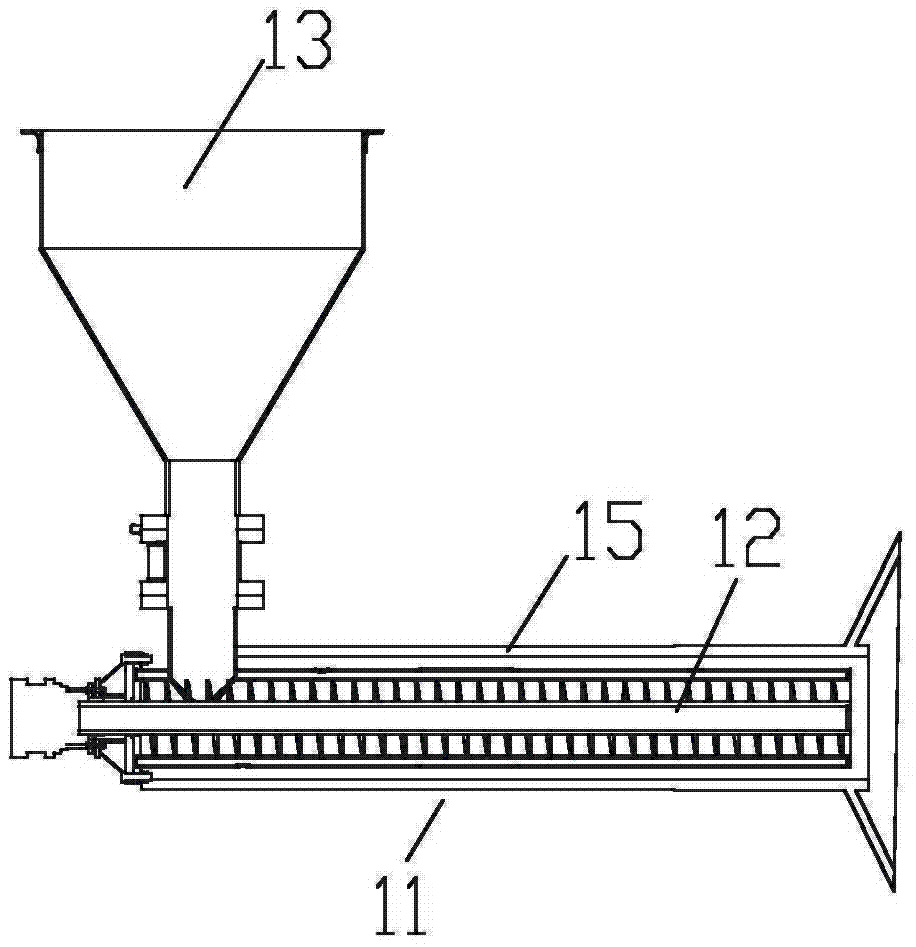

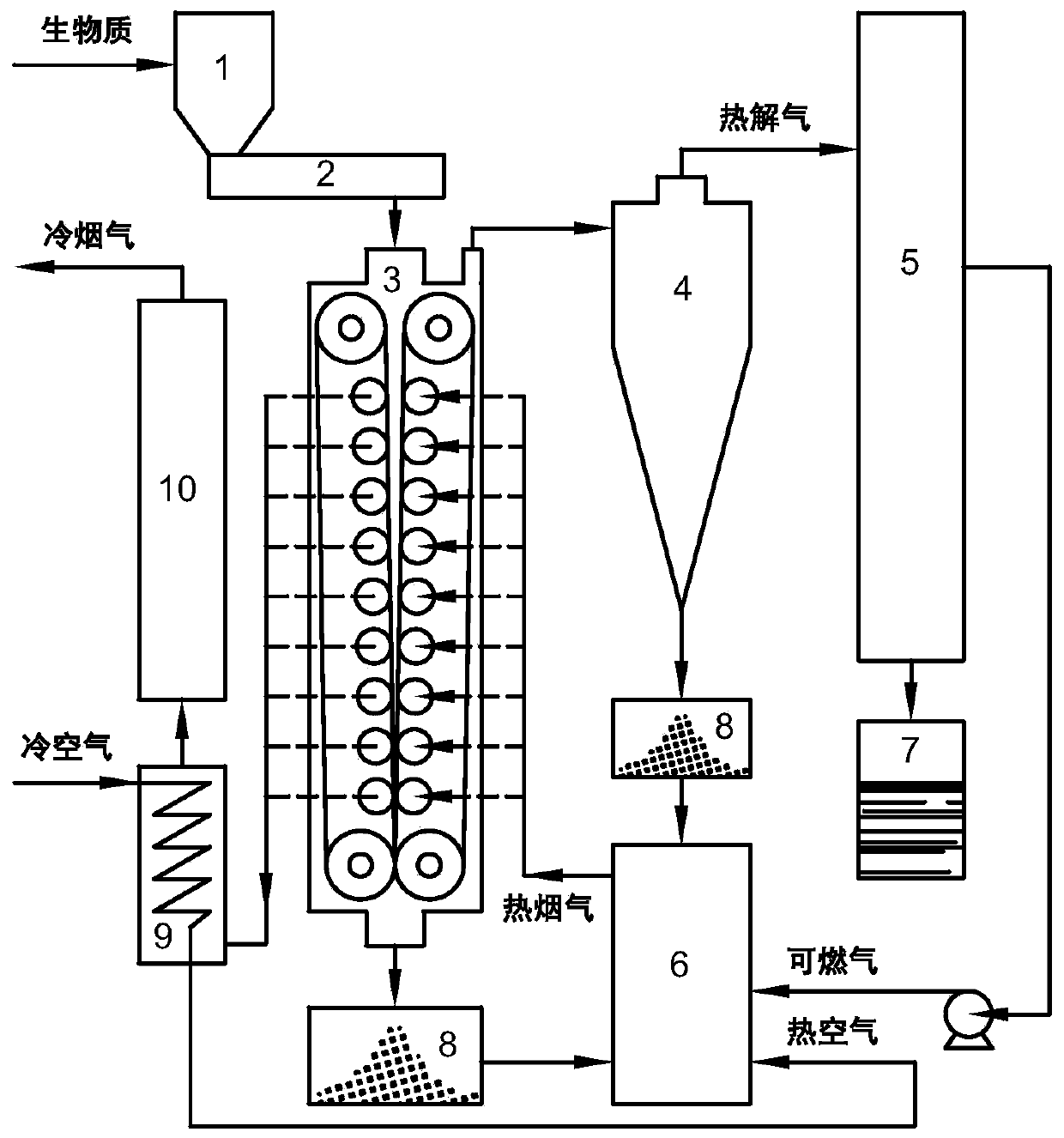

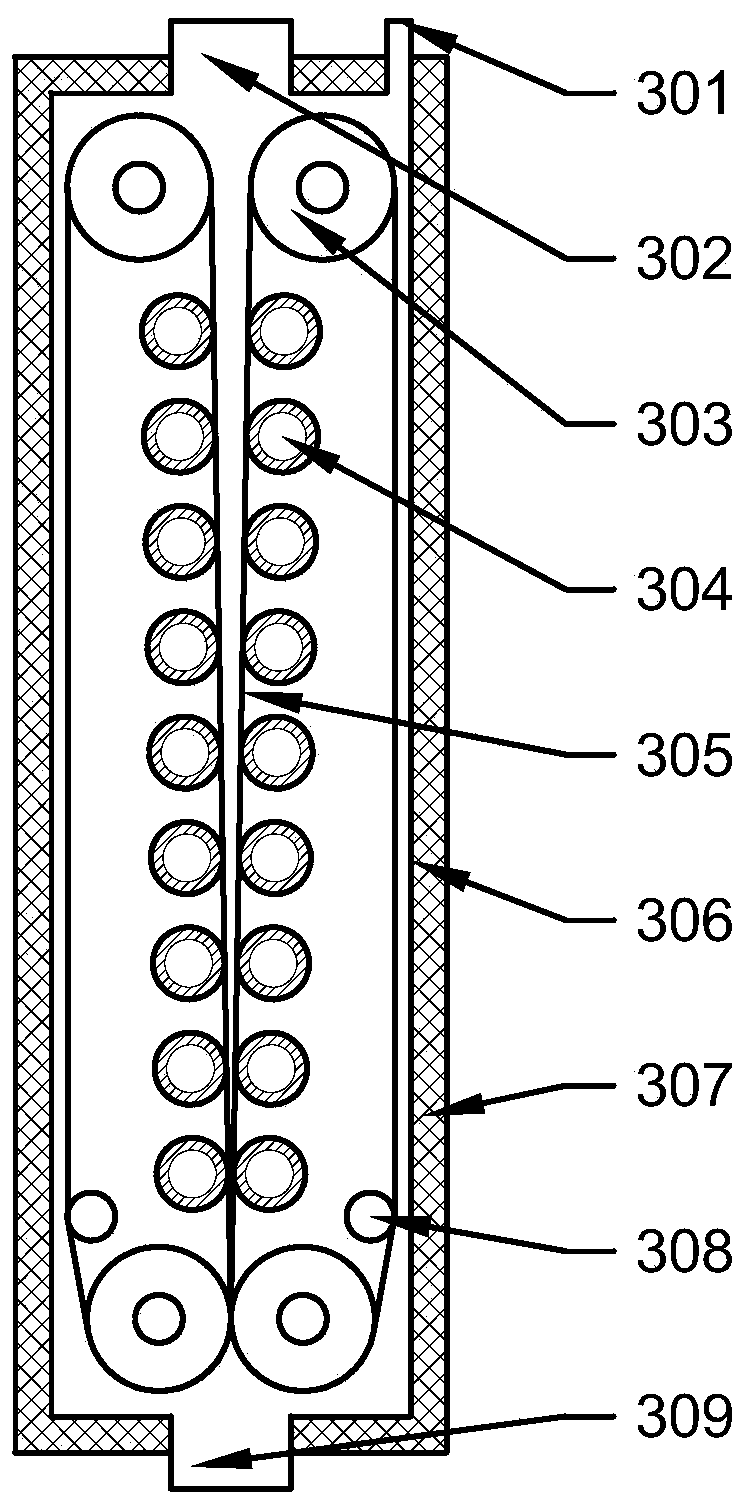

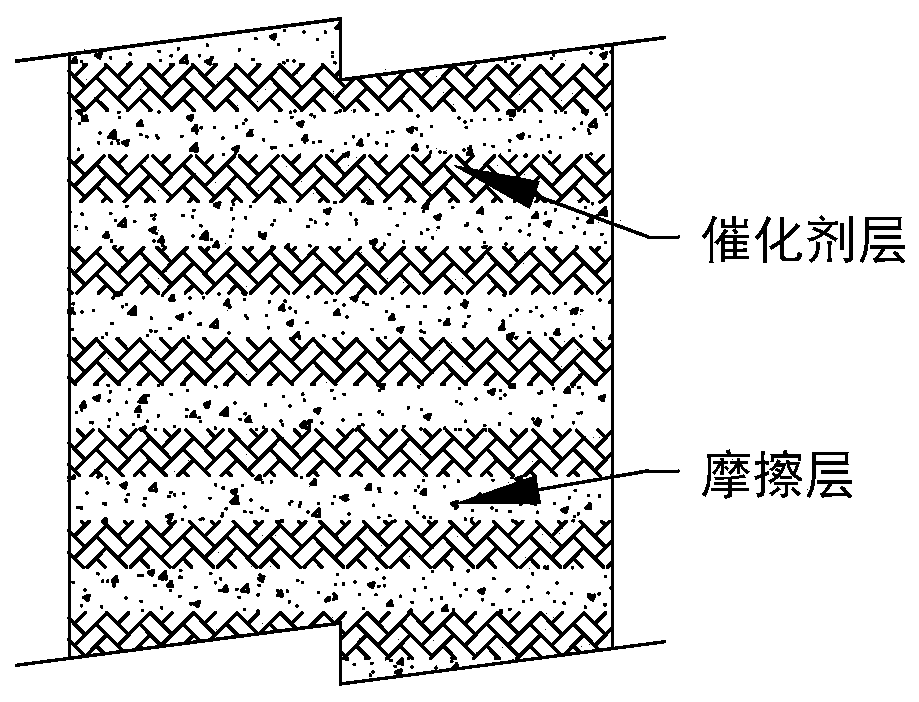

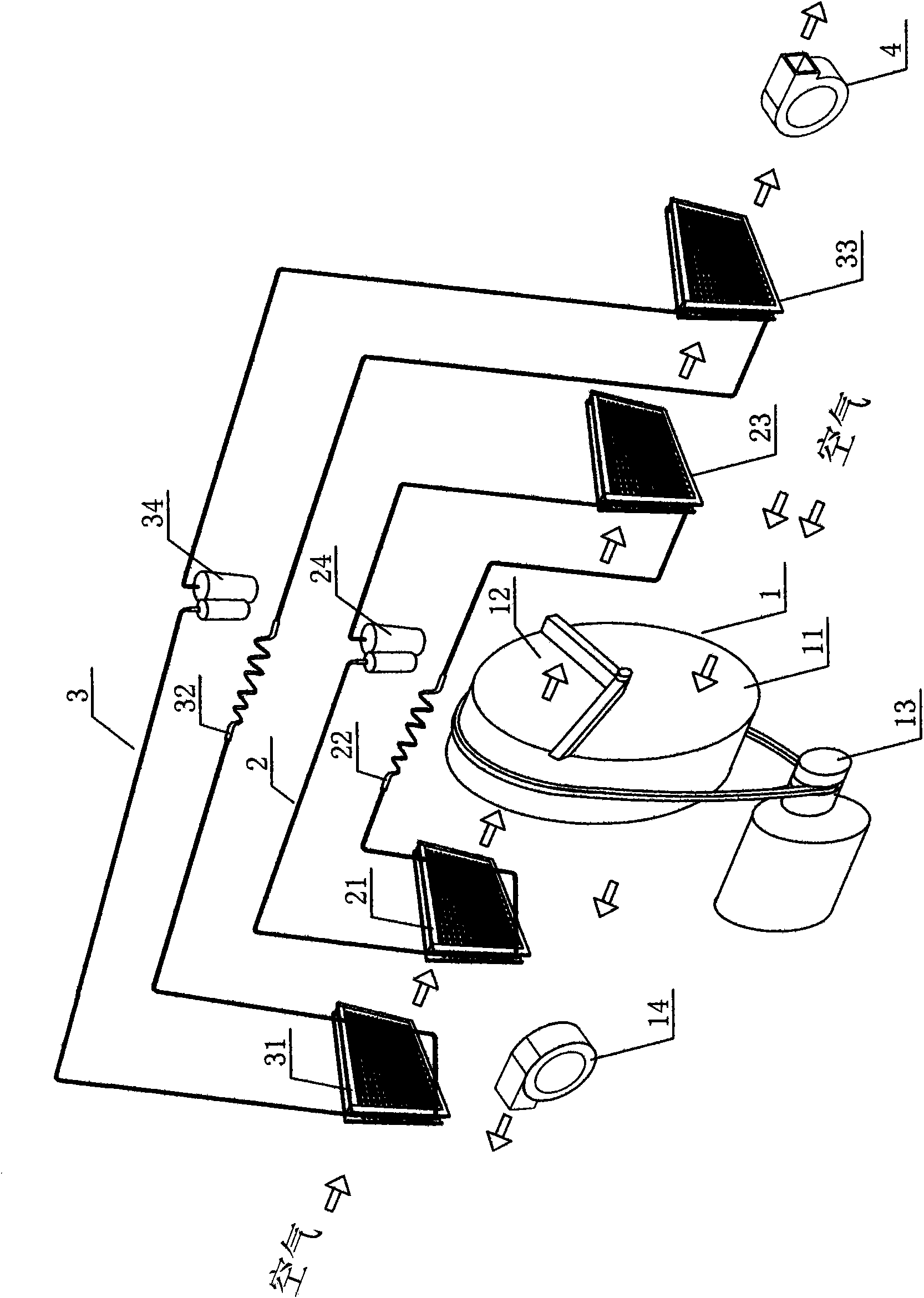

Grinding belt-type device for rapid catalytic pyrolysis of biomass and method

ActiveCN110003927ARapid condensationFully condensedBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisCombustion system

The invention belongs to the field of biomass energy utilization, and relates to a grinding belt-type device for rapid catalytic pyrolysis of biomass and a method. The device comprises a hopper, a feed system, a grinding belt-type pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a combustion system, a bio-oil collection tank, a charcoal collection tank, an airpreheating system and a flue gas purification system, wherein the grinding belt-type pyrolysis reactor comprises grinding belts, heating tubes, driving drums, tensioning devices, a sealed casing, a feed inlet, a discharge opening and a gas outlet. Pretreated material particles are continuously sheared and rubbed by the grinding belts with speed difference on two sides, and are heated by the multi-layer heating tubes to continuously pyrolyze on the surface while stripping the residual charcoal, so that a catalyst and heat can be fully fed inside the particles; the pyrolysis gas is rapidly condensed by gas-solid separation to obtain high-grade bio-oil fuel or bio-oil rich in specific high value-added products; combustible gas and coke produced by combustion generate high-temperature flue gas for heating the heating tubes, so as to achieve an autothermal pyrolysis process.

Owner:北京博霖环境科技有限公司

Method and device for getting water from dry air

InactiveCN101936021ALow costReduce energy consumptionDrinking water installationAgricultural engineeringRefrigeration

The invention relates to a method and a device for getting water from dry air. The method comprises: after air passes through the processing area of a dry runner, moisture in air is held back, and the other puff of air passes through the regeneration area of the dry runner after being heated to take away moisture which is held back; and the moisture is condensed after being cooled. The device comprises the dry runner, a high-temperature refrigerator and a low-temperature refrigerator, wherein after the air passes through the processing area of the dry runner, the moisture in air is held back; the other puff of air is heated after passing through the condenser of the low-temperature refrigerator and the condenser of the high-temperature refrigerator, and the temperature rises; then the air passes through the regeneration area of the dry runner to take away the moisture which is held back; and finally, the moisture is condensed when temperature is lowered after the air through the evaporator of the high-temperature refrigerator and the evaporator of the low-temperature refrigerator. The invention saves cost and lowers energy consumption; two independent refrigeration systems respectively operate to take away the moisture on the dry runner; and then the moisture is fully condensed by passing through the two independent refrigeration systems again. The invention has obvious effect.

Owner:马军

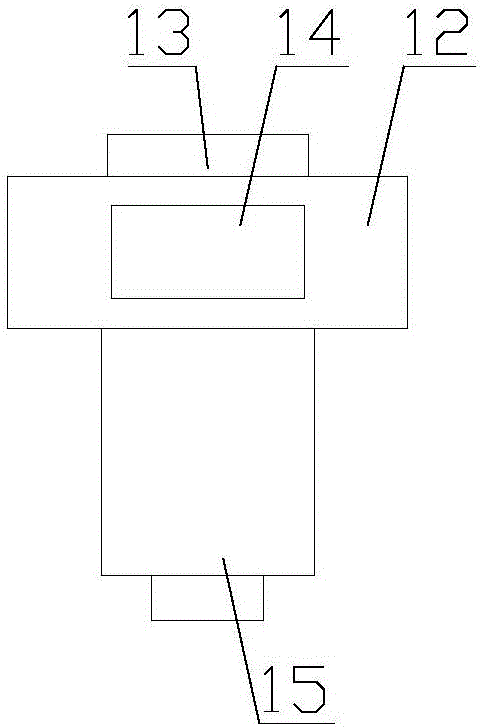

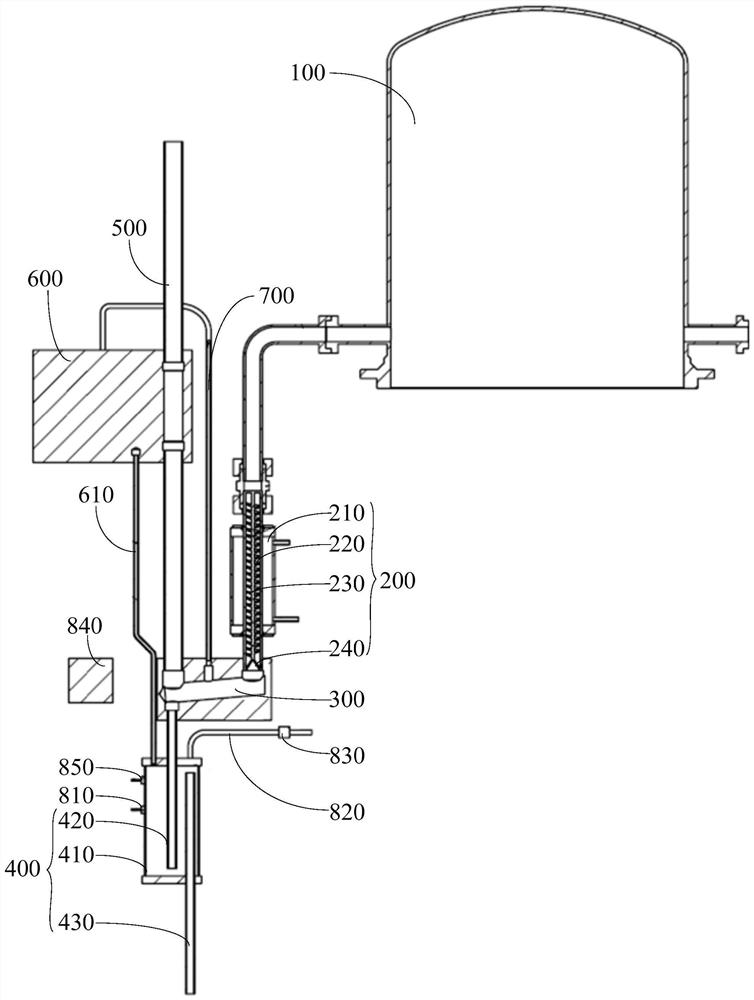

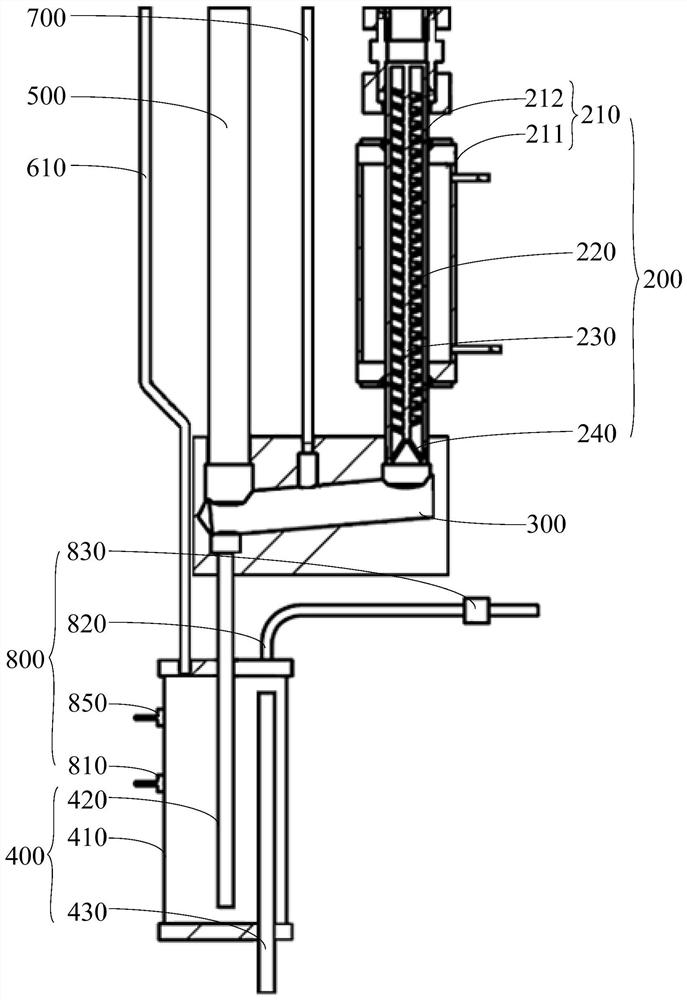

Semiconductor processing equipment

PendingCN112864054AReduce resistanceGuaranteed detection accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProcess equipmentMechanical engineering

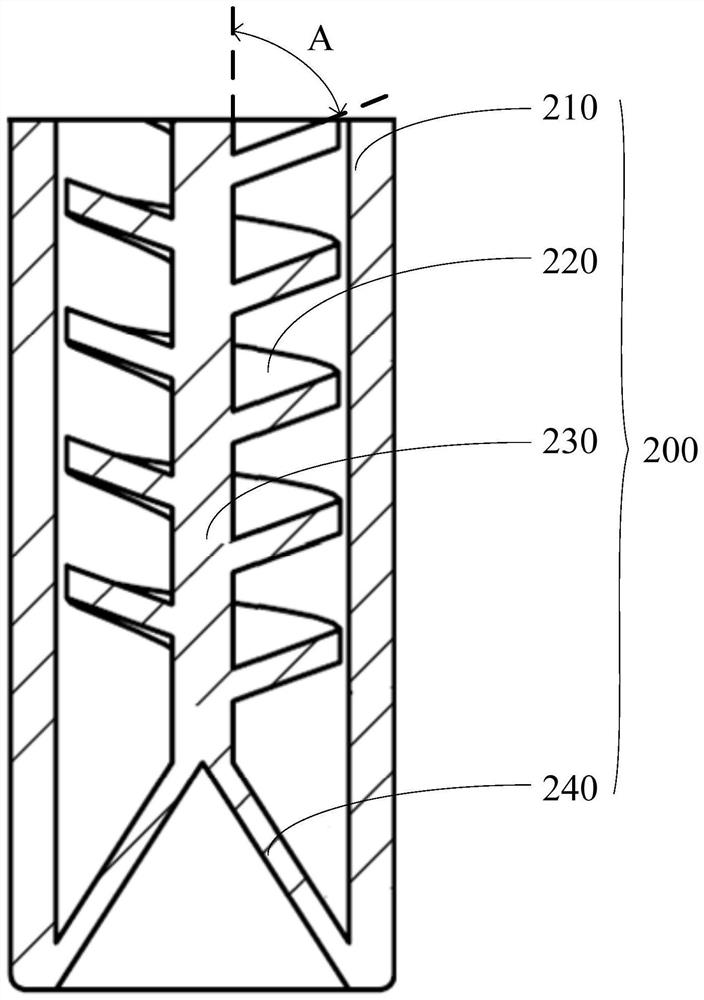

The invention discloses semiconductor processing equipment, which comprises a reaction chamber (100), a condenser (200), a switching part (300) and a water box (400), wherein the reaction chamber (100), the condenser (200), the switching part (300) and the water box (400) are communicated in sequence, the condenser (200) comprises a pipe body (210) and a spiral damping sheet (220) arranged in the pipe body (210), the spiral damping sheet (220) is provided with a spiral face facing the air inlet end opening of the pipe body (210), and the included angle (A) between the spiral face and the axis direction of the pipe body (210) is smaller than 90 degrees. According to the scheme, the problem that the process effect is not ideal due to the fact that semiconductor process equipment cannot quickly respond to pressure changes can be solved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

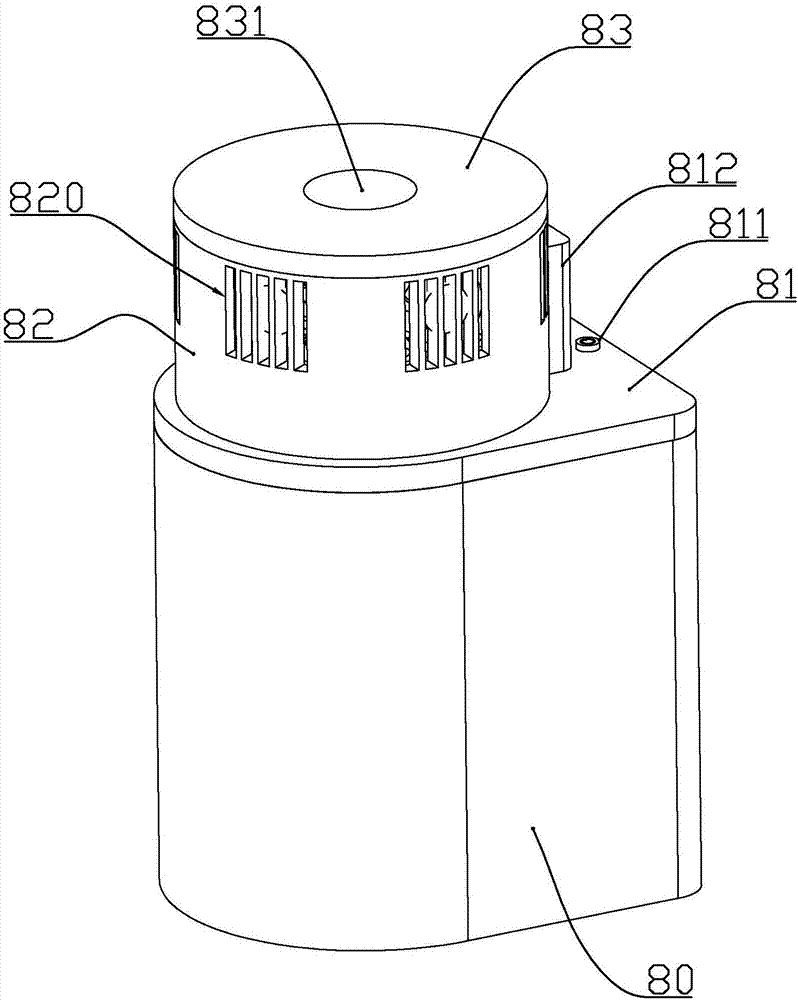

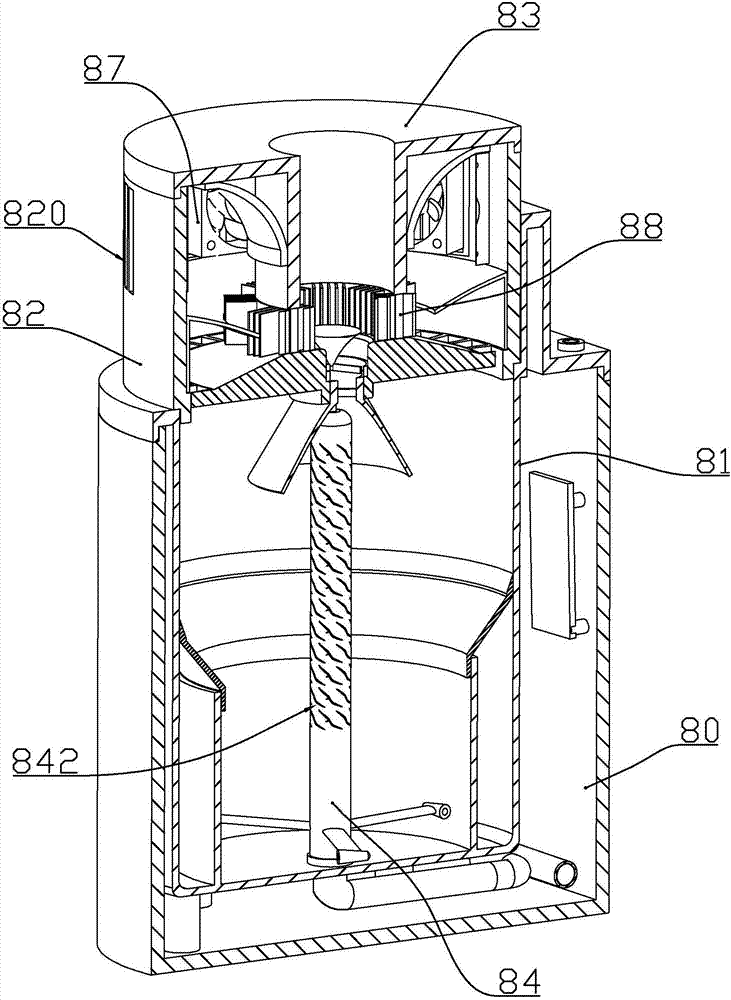

A high-efficiency air tritiated water vapor condensation collection device in the field

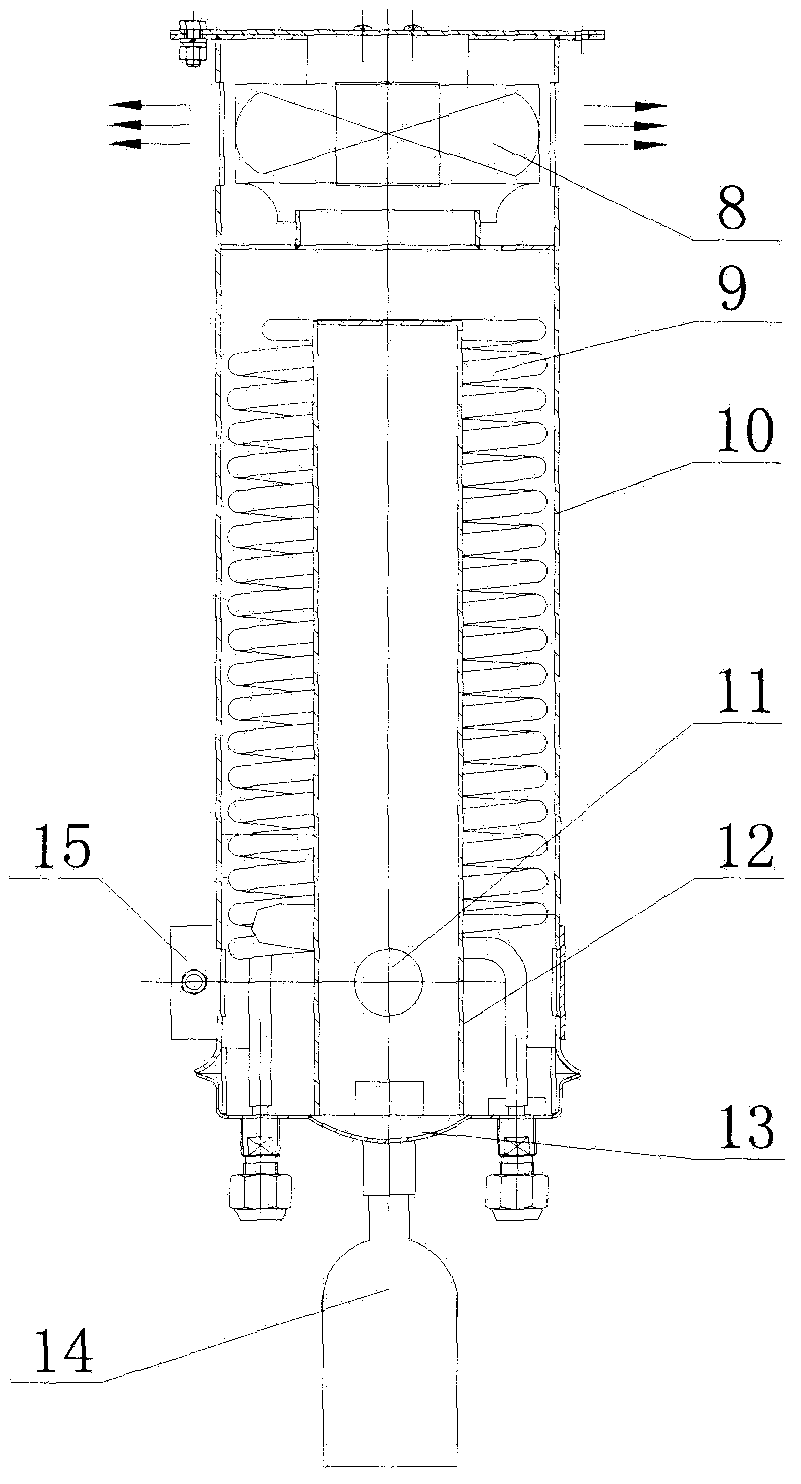

ActiveCN106134450BWide operating temperature rangeEasy maintenanceNuclear energy generationWithdrawing sample devicesCentral cylinderOperating temperature range

An outdoor high-efficiency air tritiated water vapor condensation collection device includes an evaporator assembly, a capillary tube, a thermal expansion valve, a one-way valve, a condenser, an electromagnetic reversing valve, and a compressor. The evaporator assembly includes a fan, a spiral finned tube, and an external Cylinder body, air inlet, central cylinder, water collection bucket, collection bottle, spiral finned tube coiled on the outer surface of the central cylinder, spiral finned tube and central cylinder are sleeved inside the outer cylinder together, the fan is located on the top of the outer cylinder, and the air inlet Arranged on the outer surface of the outer cylinder, the bottom of the outer cylinder is equipped with a water collecting bucket, and the outlet of the water collecting bucket receives the collecting bottle. When the dew point temperature corresponding to the ambient temperature is higher or lower than 0°C, the vapor formed by the compressor working on the gaseous refrigerant passes through different circulation paths, so that the tritiated water vapor contained in the air condenses into water on the spiral finned tube And flow into the collection bottle along the water collecting bucket. The device of the invention has the advantages of simple structure, wide working temperature range, convenient maintenance and strong versatility, and is suitable for various field working environments.

Owner:BEIJING SATELLITE MFG FACTORY

Air purifier adopting water curtain for filtration

ActiveCN105664626AImprove purification effectComprehensive contactUsing liquid separation agentAir purifiersFiltration

The invention discloses an air purifier adopting a water curtain for filtration. The air purifier comprises an outer purifier housing and an inner purifier housing, wherein the inner purifier housing comprises a cylindrical water bucket; an annular partition is formed at the bottom of the water bucket; a water storage bucket is formed on the inner circumference of the annular partition in the water bucket; a wastewater storage bucket is formed on the outer circumference of the annular partition in the water bucket; a water guide plate is mounted on the annular partition; the upper end of the water guide plate fits the inner wall of the water bucket; a water inlet connector of the water curtain is formed in the middle of the bottom of the water storage bucket; a water pumping connector is formed in a position, opposite to the water inlet connector of the water curtain, at the bottom of the water storage bucket; a wastewater connector is formed at the bottom of the wastewater storage bucket; a filter and a water pump are further mounted in a space between the outer purifier housing and the inner purifier housing; a water spraying seat is rotationally connected to the upper part of the water inlet connector of the water curtain in a sleeving manner; a spherical water spraying plate is formed at the upper part of the water spraying seat; water spraying holes are uniformly formed in the surface, higher than the annular partition, of the water spraying plate; and the water outlet directions of the water spraying holes are arranged along the radius of the water spraying plate. The air purifier is good in air purification effect, energy-saving and environmentally-friendly.

Owner:索罗贝格过滤消声器制造(苏州)有限公司

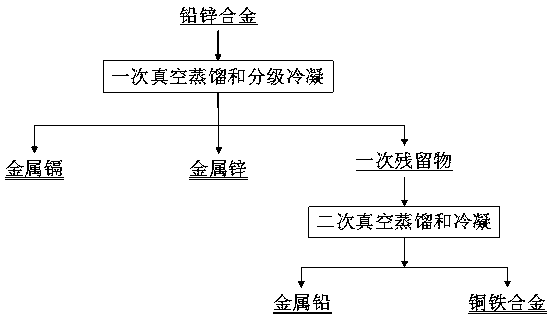

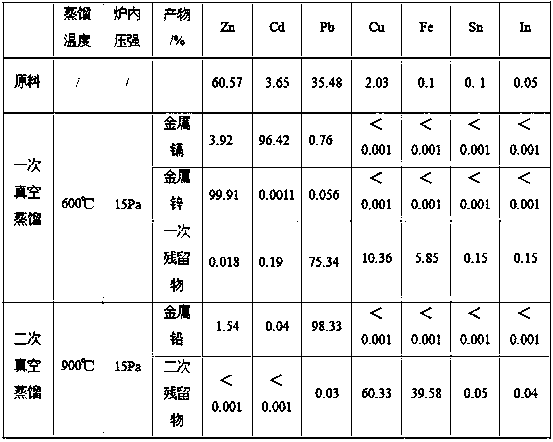

Method of separating and recovering plumbum and zinc from Pb-Zn alloy

The invention relates to a method of separating and recovering plumbum and zinc from a Pb-Zn alloy, and belongs to the technical field of alloys. The method comprises the following steps that the Pb-Zn alloy is subjected to primary vacuum distillation under the condition that the temperature is 500-700 DEG C and the pressure is 1-30 Pa, and primary volatile matters and primary residues are obtained; after the primary volatile matters are subjected to fractional condensation, metal zinc and metal cadmium are obtained; the primary residues obtained in Step 1 are subjected to secondary vacuum distillation under the condition that the temperature is 800-1000 DEG C and the pressure is 1-30 Pa, and secondary volatile matters and secondary residues of a Cu-Fe alloy are obtained; and the obtainedsecondary volatile matters are condensed at 300 DEG C, and the metal plumbum is obtained. Through gradient condensation, the zinc and plumbum in the volatile matters can be sufficiently condensed, sothat the purity degrees of the zinc and plumbum obtained by separating and recovering are raised advantageously.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com