Preparation method of polytetrafluoroethylene packed dispersion resin

A technology of polytetrafluoroethylene and dispersed resin, which is applied in the field of polymer material preparation, can solve the problems of high ozone depletion potential, non-compliance with environmental protection, safety, fire and explosion, etc., and achieve low global warming potential and pasty Low extrusion pressure and easy molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

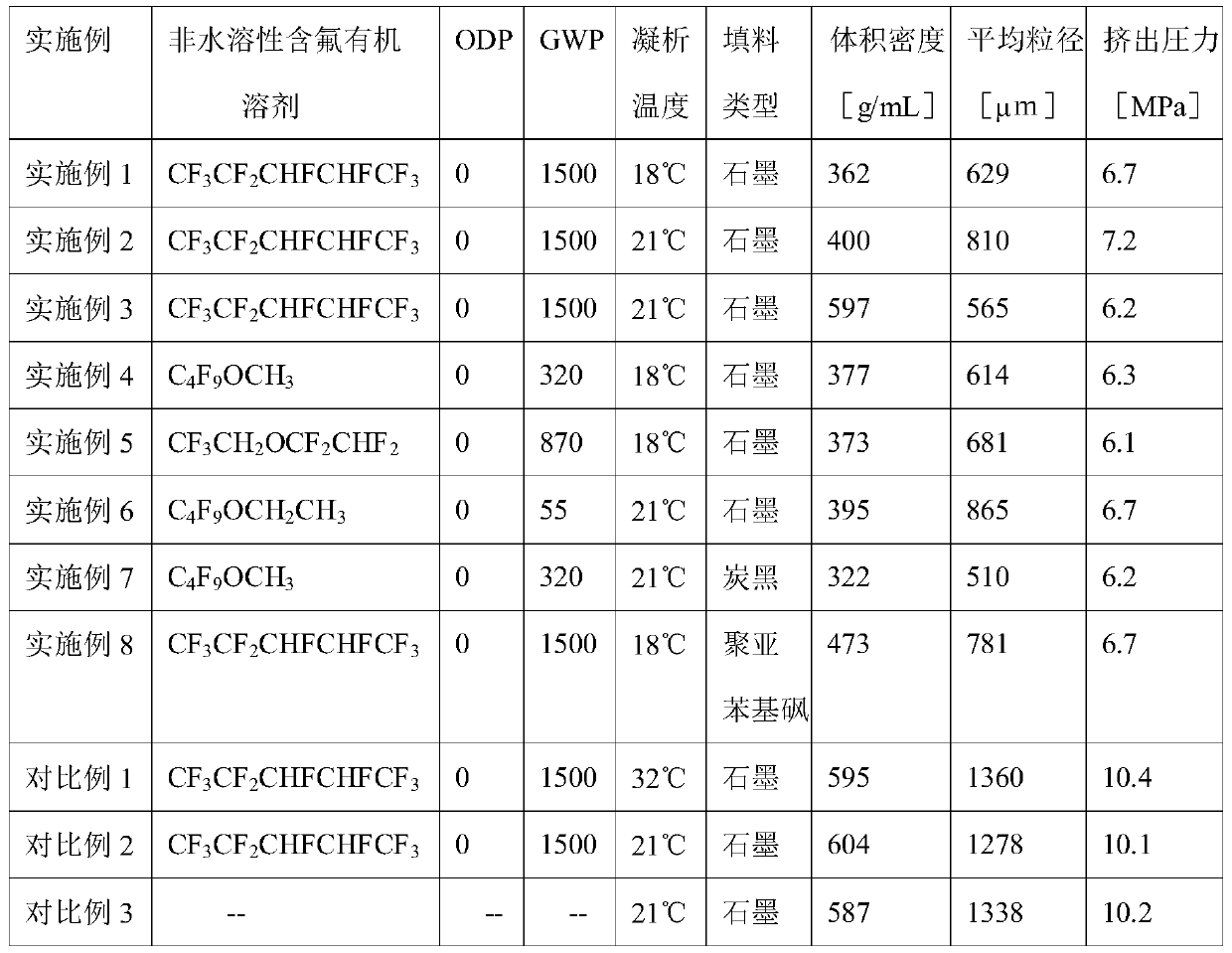

Examples

Embodiment 1

[0040] A kind of preparation method of filling polytetrafluoroethylene dispersion resin, comprises steps as follows:

[0041] (1) Add 170g of graphite powder with an average particle size of 2 μm into 500mL of deionized water containing 5.1g of non-ionic surfactant nonylphenol polyoxyethylene ether NP-15, stir and disperse evenly to obtain a graphite powder dispersion;

[0042] (2) The graphite powder dispersion obtained in step (1) is added to a coagulation tank with a multi-stage stirring blade with an internal volume of 12L, and the average particle diameter added is 220nm, the standard relative specific gravity SSG is 2.160, and the solid content is 10.88 6172g of polytetrafluoroethylene dispersion emulsion, stirred for 3 minutes at a stirring speed of 400rpm, mixed uniformly, adjusted the system temperature to 18°C, added 1mL of nitric acid solution with a mass fraction of 65%, continued to stir for 4 minutes, and the reaction system started Enter the demulsification stat...

Embodiment 2

[0045] A kind of preparation method of filling polytetrafluoroethylene dispersion resin, comprises steps as follows:

[0046] (1) Add 170g of graphite powder with an average particle size of 2 μm into 500mL of deionized water containing 5.1g of non-ionic surfactant nonylphenol polyoxyethylene ether NP-15, stir and disperse evenly to obtain a graphite powder dispersion;

[0047] (2) The graphite powder dispersion obtained in step (1) is added to a coagulation tank with a multi-stage stirring blade with an internal volume of 12L, and the average particle diameter added is 220nm, the standard relative specific gravity SSG is 2.160, and the solid content is 10.88 6172g of polytetrafluoroethylene dispersion emulsion, stirred for 3 minutes at a stirring speed of 400rpm, mixed uniformly, adjusted the temperature of the system to 21°C, added 1mL of nitric acid solution with a mass fraction of 65%, continued to stir for 4 minutes, and the reaction system started Enter the demulsificati...

Embodiment 3

[0050] A kind of preparation method of filling polytetrafluoroethylene dispersion resin, comprises steps as follows:

[0051] (1) Add 170g of graphite powder with an average particle size of 2 μm into 500mL of deionized water containing 5.1g of non-ionic surfactant nonylphenol polyoxyethylene ether NP-15, stir and disperse evenly to obtain a graphite powder dispersion;

[0052] (2) The graphite powder dispersion obtained in step (1) is added to a coagulation tank with a multi-stage stirring blade with an internal volume of 12L, and the average particle diameter added is 220nm, the standard relative specific gravity SSG is 2.160, and the solid content is 10.88 6172g of polytetrafluoroethylene dispersion emulsion, stirred for 3 minutes at a stirring speed of 400rpm, mixed uniformly, adjusted the temperature of the system to 21°C, added 1mL of nitric acid solution with a mass fraction of 65%, continued to stir for 4 minutes, and the reaction system started Enter the demulsificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com