Sewage treatment system and sewage treatment method

A technology of sewage treatment system and sewage treatment method, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

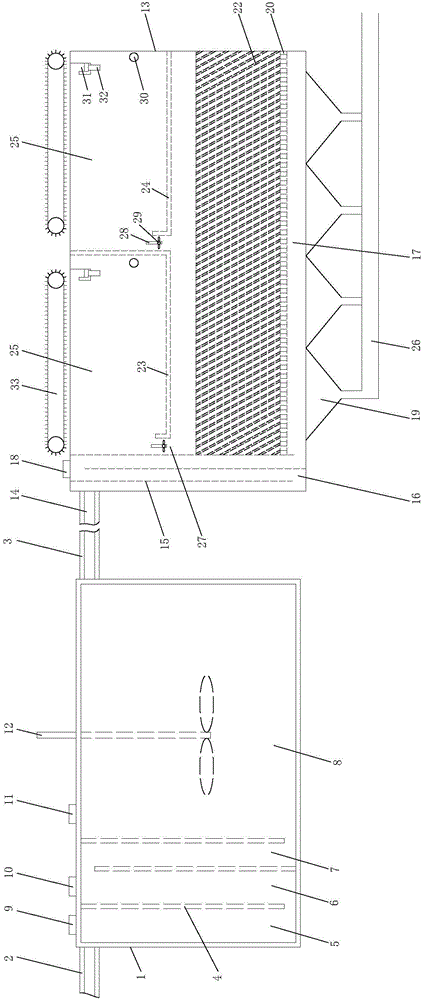

[0021] Embodiment 1 sewage treatment system

[0022] Such as figure 1 As shown, the sewage treatment system consists of a flocculation tank and a sedimentation tank.

[0023] The flocculation tank is as follows: the upper end of the tank body I (1) is provided with a sewage inlet (2) and a reaction water outlet (3), and one end of the sewage inlet (2) in the tank body I (1) is provided with 3 baffles Ⅰ(4) divides the pool body (1) into chamber Ⅰ(5), chamber Ⅱ(6), chamber Ⅲ(7) and chamber Ⅳ(8) in turn, and the upper end of chamber Ⅰ(5) is provided with a sodium hydroxide inlet (9), the upper end of chamber II (6) or chamber III (7) is provided with calcium chloride inlet (10), the upper end of chamber IV (8) is provided with aluminum chloride inlet (11), and the upper end of chamber IV (8) is provided with Stirring device (12).

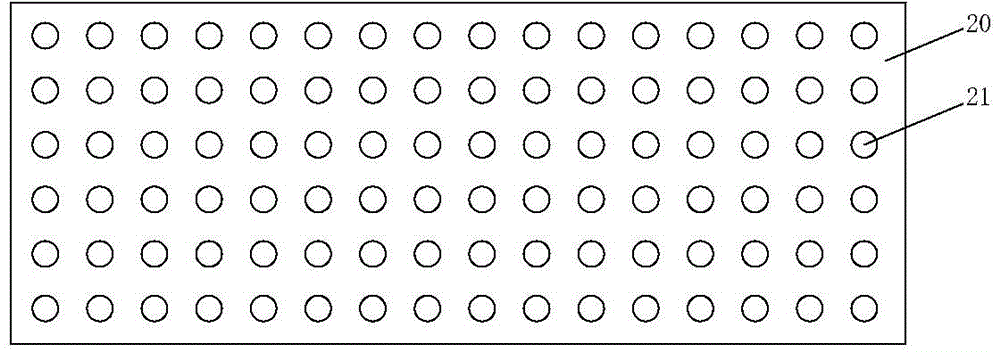

[0024] Described settling tank is: the upper end of pond body II (13) is provided with reaction inlet (14), and reaction inlet inlet (14) one end i...

Embodiment 2

[0026] Embodiment 2 sewage treatment method

[0027] Adopt the sewage treatment system of embodiment 1, method is as follows:

[0028] 1. Flocculation treatment: The sewage enters the flocculation tank through the sewage inlet (2), enters the chamber IV (8) through the chamber I (5), chamber II (6) and chamber III (7) in turn, and enters the chamber IV (8) through the sodium hydroxide inlet (9 ) is fed into sodium hydroxide to adjust the pH to be 8-9, and the calcium chloride aqueous solution that is 20% by weight is fed into through the calcium chloride inlet (10) to produce foam, and in the chamber IV (8), through the aluminum chloride The inlet (11) is fed with 10% aluminum chloride aqueous solution by weight, stirred to produce a large amount of flocculent matter, and the reaction water containing the flocculent matter is sent into the sedimentation tank through the reaction water outlet (3).

[0029] 2. Sedimentation treatment: The reaction water containing flocculated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com