Tilting type continuous acrylic cracking furnace

A tilting, acrylic technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of easily damaged cracking kettle, uneven heating, hidden safety hazards, etc., to improve production efficiency and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

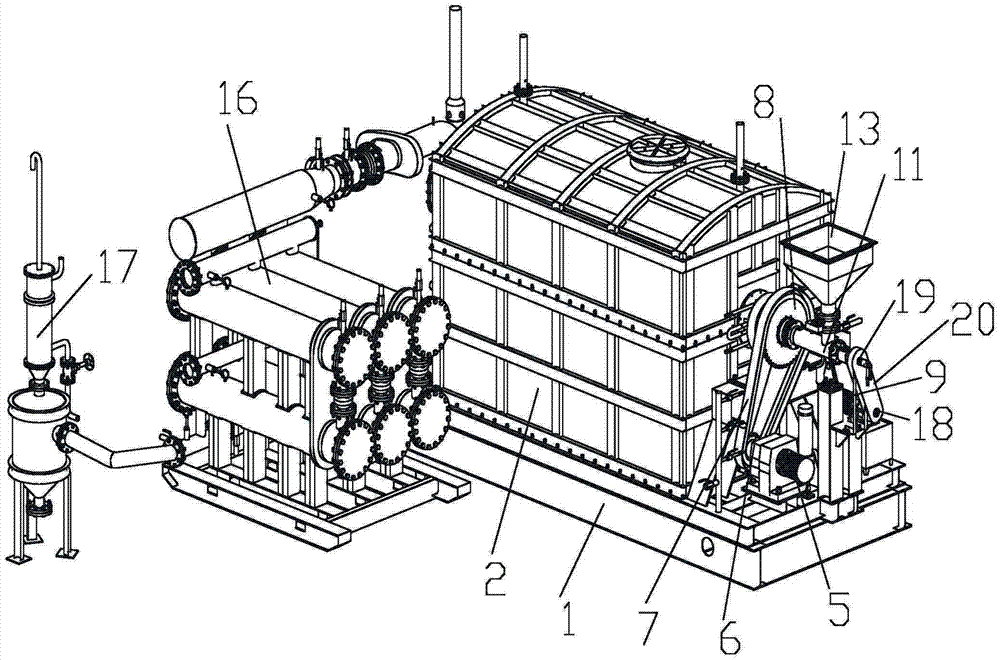

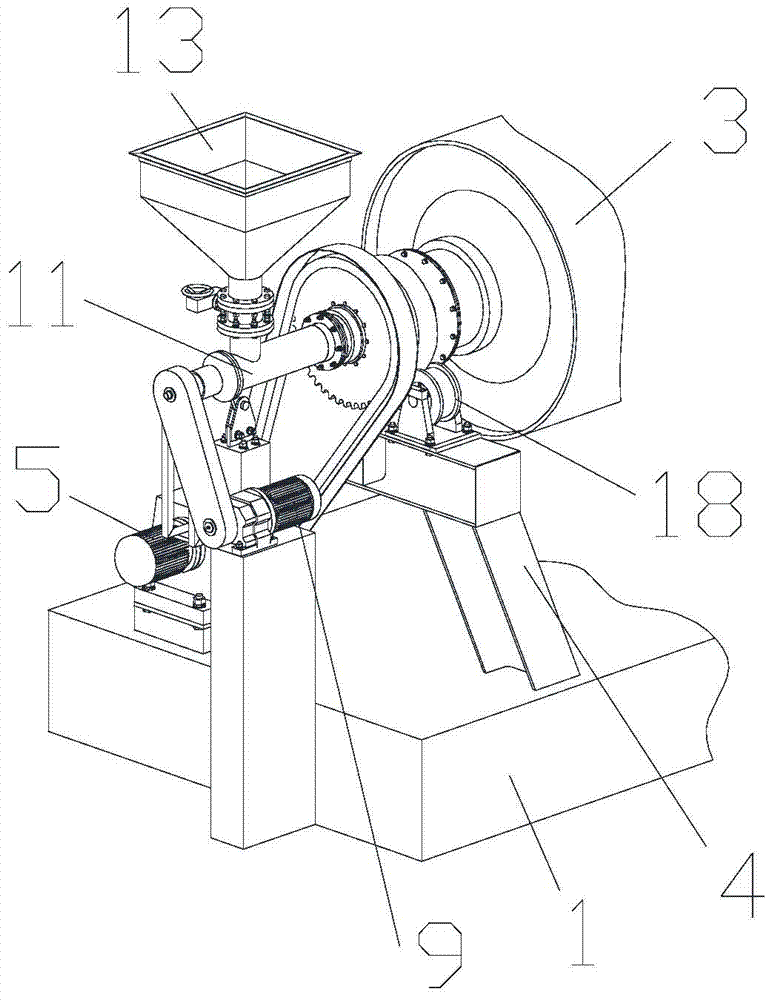

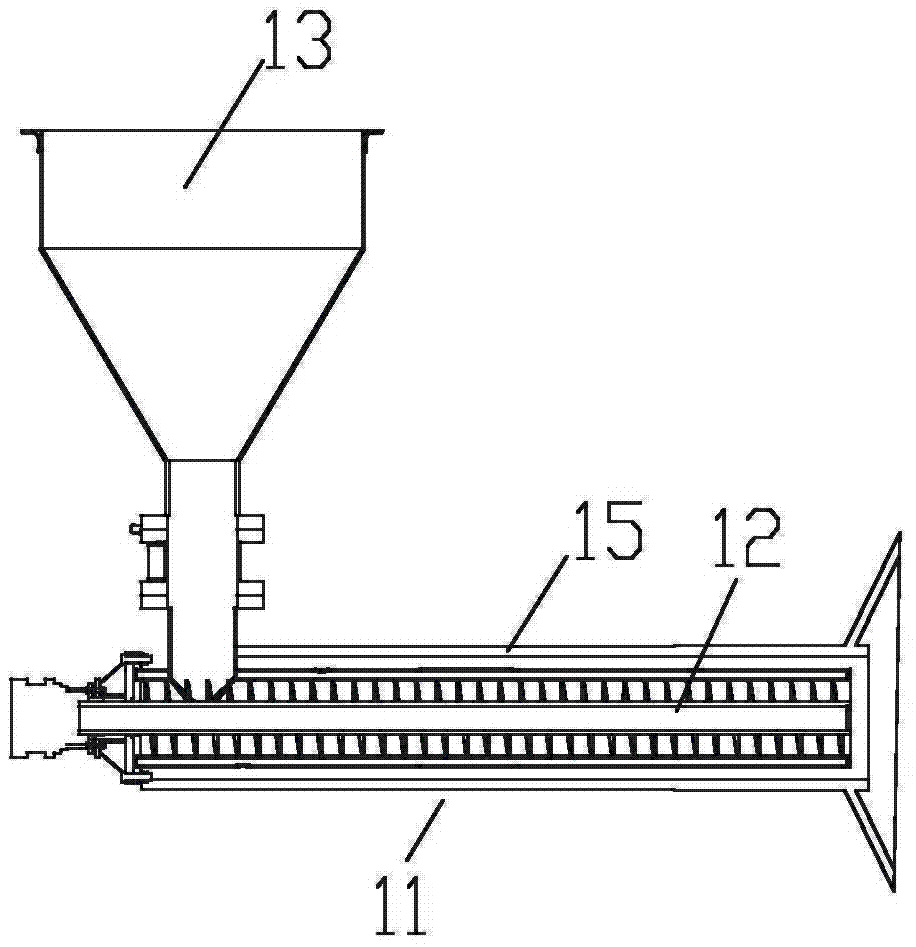

[0021] Attached below Figure 1-6 An embodiment of the present invention is described.

[0022] The tilting continuous acrylic cracking furnace has a base 1, and the upper end surface of the base 1 is provided with a tilting platform. Specifically, the tilting platform includes a jacking platform 2 and a jacking hydraulic cylinder 10. The bottom end of the jacking platform 2 is connected to the One side of the upper end surface of the base 1 is hinged, and the other side of the upper end surface of the base 1 is provided with a jacking hydraulic cylinder 10 , and the piston rod of the jacking hydraulic cylinder 10 telescopically lifts or lowers the other end of the bottom of the jacking platform 2 . A furnace body 2 is arranged on the tilting platform, and a drum 3 is arranged in the furnace body 2, and the support shafts at both ends of the drum 3 are supported on the support frames 4 at the two outer ends of the furnace body 2 through rollers 18, and the output shaft of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com