Method of separating and recovering plumbum and zinc from Pb-Zn alloy

A technology for separation, recovery and alloying, applied in the field of alloys, can solve the problems of accumulation of impurities, affecting the properties of zinc, and high impurity content, and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

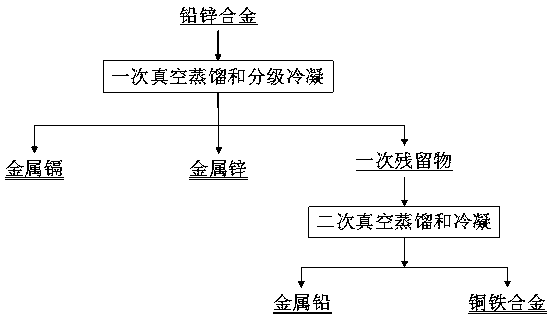

[0020] Such as figure 1 Shown, this is separated and recovered the method for lead and zinc by lead-zinc alloy, and its concrete steps are as follows:

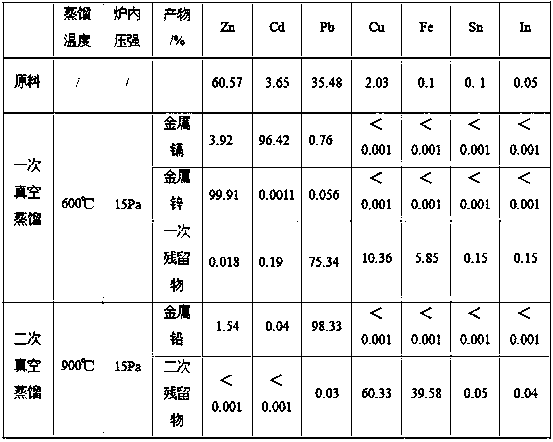

[0021] Step 1. Perform a vacuum distillation of the lead-zinc alloy (the components are shown in Table 1) at a temperature of 600°C and a pressure of 30Pa to obtain primary volatiles and primary residues;

[0022] Step 2. The primary volatile matter obtained in step 1 is subjected to graded condensation to obtain metal zinc and metal cadmium; the primary residue obtained in step 1 is subjected to secondary vacuum distillation at a temperature of 800° C. and a pressure of 30 Pa to obtain secondary Volatile matter and secondary residues of copper-iron alloys; among them, graded condensation first condenses at a condensation temperature of 365°C to 415°C to obtain metal zinc, and in the process of metal zinc condensation, it first undergoes two temperature gradients [390°C, 415°C] and (365°C ℃, 390℃) to obtain metal zinc by grad...

Embodiment 2

[0028] Such as figure 1 Shown, this is separated and recovered the method for lead and zinc by lead-zinc alloy, and its concrete steps are as follows:

[0029] Step 1. Perform a vacuum distillation of the lead-zinc alloy (the components are shown in Table 2) at a temperature of 500°C and a pressure of 10 Pa to obtain primary volatiles and primary residues;

[0030] Step 2, the primary volatile matter obtained in step 1 is subjected to graded condensation to obtain metal zinc and metal cadmium; the primary residue obtained in step 1 is subjected to secondary vacuum distillation at a temperature of 900 ° C and a pressure of 10 Pa to obtain secondary Volatile matter and secondary residues of copper-iron alloy; Among them, graded condensation is firstly condensed at a condensation temperature of 325°C to 415°C to obtain metal zinc, and in the process of metal zinc condensation, it is firstly cooled and condensed under a temperature gradient (365°C, 415°C] Metal zinc is obtained, ...

Embodiment 3

[0036] Such as figure 1 Shown, this is separated and recovered the method for lead and zinc by lead-zinc alloy, and its concrete steps are as follows:

[0037] Step 1. Perform a vacuum distillation of the lead-zinc alloy (the components are shown in Table 3) at a temperature of 700°C and a pressure of 1Pa to obtain primary volatiles and primary residues;

[0038] Step 2, the primary volatile matter obtained in step 1 is subjected to graded condensation to obtain metal zinc and metal cadmium; the primary residue obtained in step 1 is subjected to secondary vacuum distillation at a temperature of 1000 ° C and a pressure of 1 Pa to obtain secondary Volatile matter and secondary residues of copper-iron alloy; Among them, graded condensation is firstly condensed at a condensation temperature of 355°C to 415°C to obtain metallic zinc. Metal zinc is obtained, and then condensed at a constant temperature of 355°C to obtain metal zinc; the remaining volatile matter is condensed at a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com