Grinding belt-type device for rapid catalytic pyrolysis of biomass and method

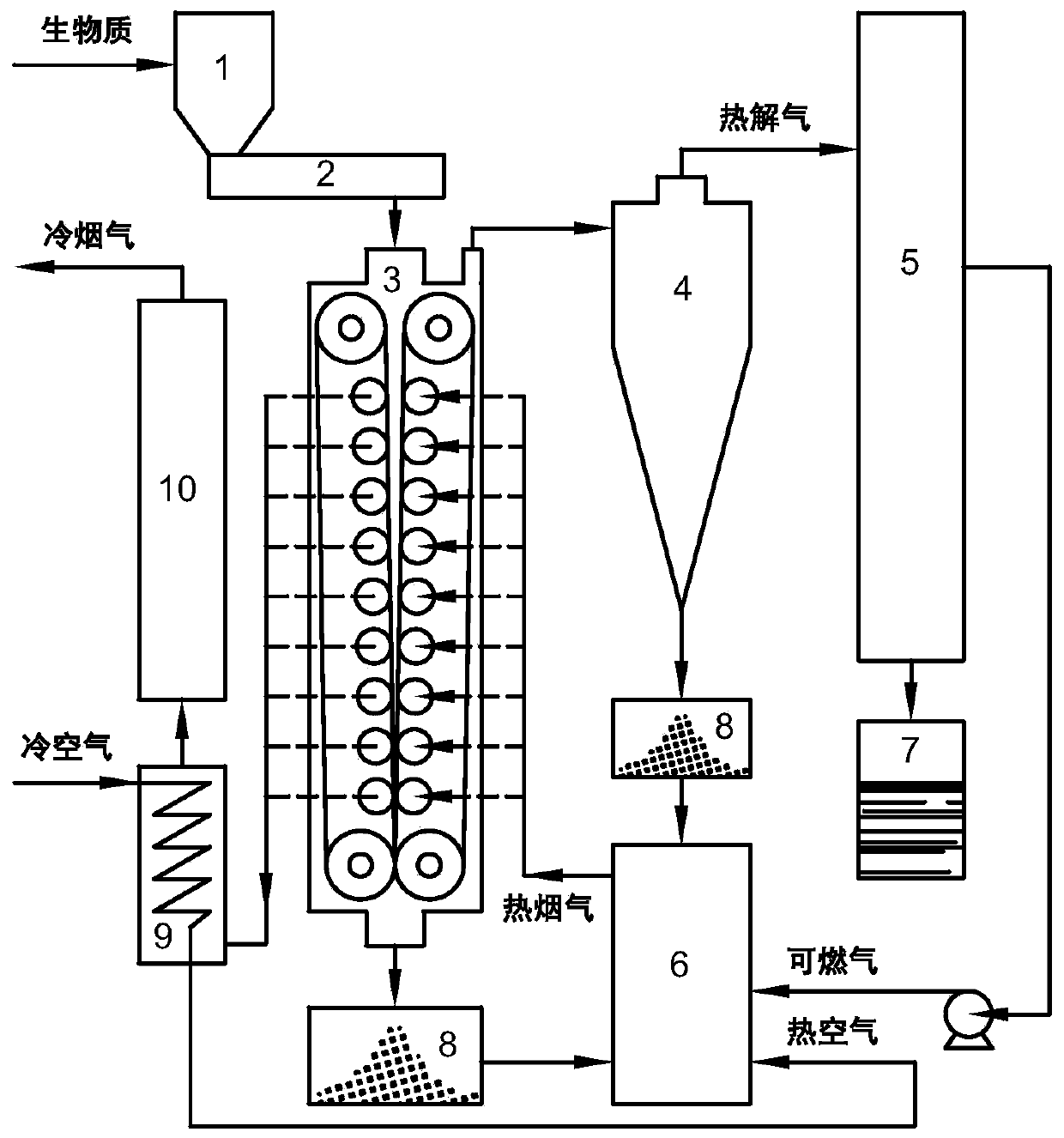

A technology for catalytic pyrolysis and biomass, which is applied in the field of biomass energy utilization, can solve the problems of difficulty in ensuring the catalytic effect of catalysts, difficulty in condensing pyrolysis gas, and large loss of condensation heat, and achieves convenient regulation, compact structure, and increased processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

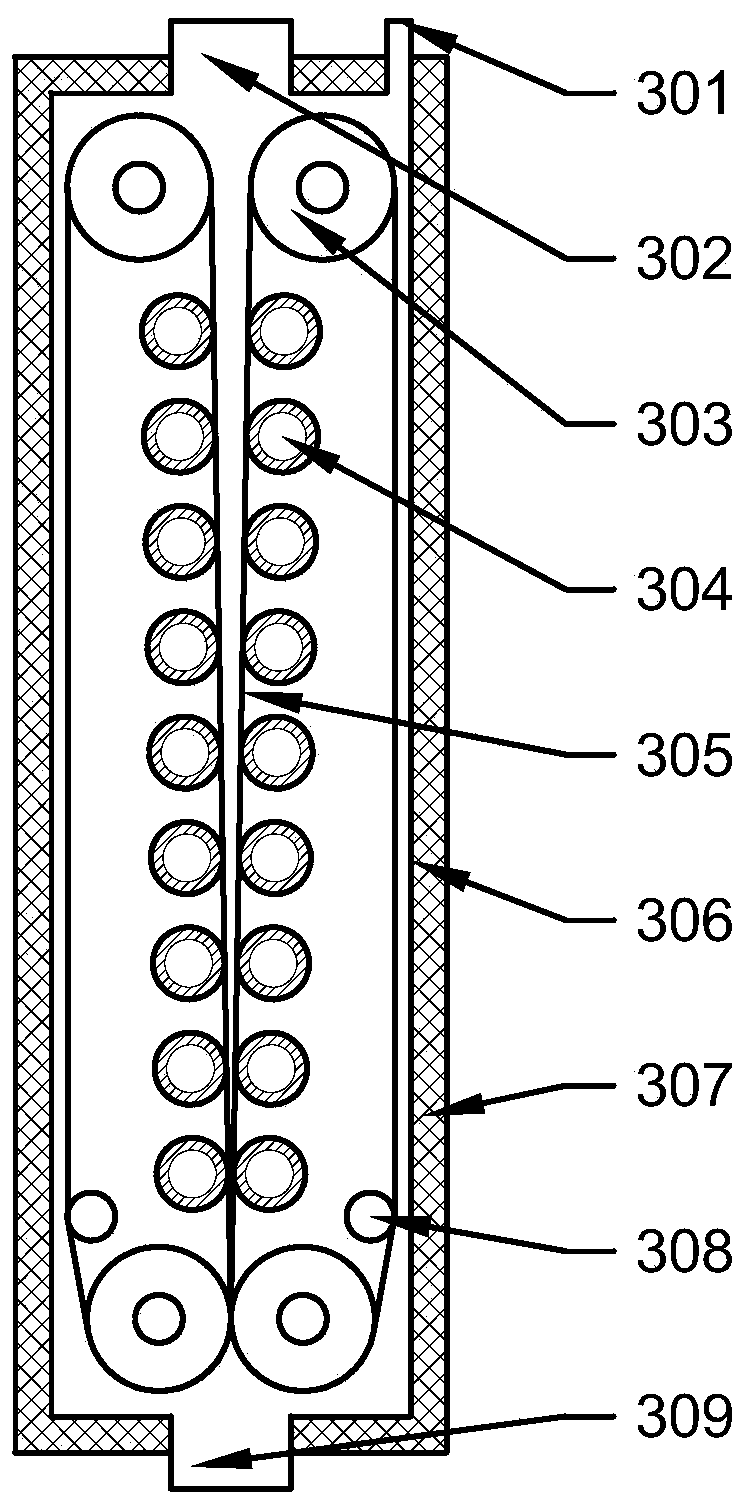

[0047] Walnut shells with a moisture content of 6wt% are crushed to an average particle size of 10mm, passed through the screw feeding system 2 at a feed rate of 150kg / h, and then entered into the abrasive belt pyrolysis reactor 3; the abrasive belt 305 is all friction layers , prepared by using friction coating; the grinding belt on one side adopts a downward running speed of 10m / min, and the grinding belt on the other side adopts an upward running speed of 6m / min; the temperature of the flue gas entering the grinding belt pyrolysis reactor 3 is 740°C , the temperature in the pyrolysis reactor was measured to be 510°C; after the pyrolysis product was separated from gas and solid and condensed, a three-phase pyrolysis product was obtained, wherein the yield of coke was 27.1wt%, and the yield of bio-oil was 52.1wt%. The combustible gas yield was 20.8 wt%.

Embodiment 2

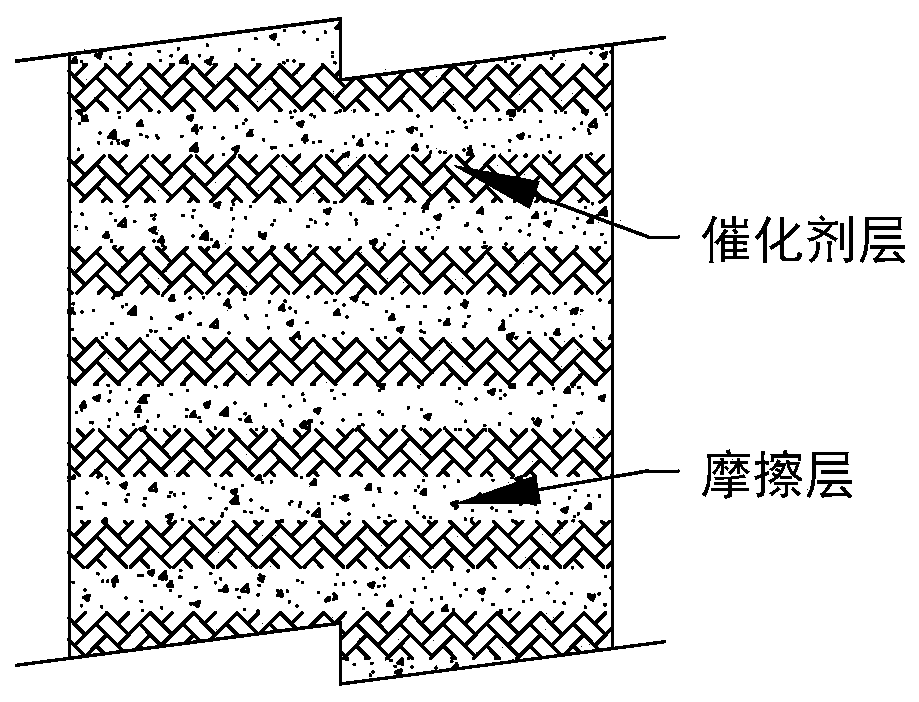

[0049] Poplar with a moisture content of 8wt% is crushed to an average particle size of 10 mm, and fed into the grinding belt pyrolysis reactor 3 through the screw feeding system 2 at a feed rate of 100 kg / h; the grinding belt 305 adopts a catalytic type , and the friction layer and the catalyst layer are arranged alternately at an interval of 10mm; the friction layer is made of friction coating, and the catalyst layer is loaded on the grinding belt by solid phosphoric acid; one side of the grinding belt runs downward at a speed of 16m / min, and the other side of the grinding belt runs upward at 12m / min; the flue gas temperature entering the heating pipe 304 is 450°C, ensuring that the temperature in the pyrolysis reactor is maintained at 300°C; the pyrolysis product is obtained after gas-solid separation and pyrolysis gas condensation Bio-oil of glucosone, the yield of L-glucosone is 8.1wt%.

Embodiment 3

[0051] The corncob that moisture content is 6wt% is crushed to the average particle diameter and is 10mm; Send into grinding belt type pyrolysis reactor 3 with feed rate 120kg / h by screw feed system 2 subsequently; By regulating motor power, ensure The grinding belt on one side runs downward at a speed of 12m / min, and the grinding belt on the other side runs upward at a speed of 8m / min; the friction belt only uses the friction coating, and the catalyst ZnCl 2 Introduced by directly impregnating raw materials during raw material pretreatment, the measured load is 16.3wt%; the temperature of the flue gas entering the grinding belt pyrolysis reactor 3 is 510°C, and the temperature in the pyrolysis reactor is 340°C; After the pyrolysis product is separated from gas and solid and condensed from the pyrolysis gas, the three-phase pyrolysis product of solid, liquid and gas is obtained, and the yields of each are 44.2%, 46.5% and 9.3%, respectively, and the yield of the target product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com