Condensation type heat exchange plate and condensation type heat exchanger with same

A technology of condensing heat exchangers and heat exchange plates, which is applied in the field of condensing heat exchange, can solve the problems of low condensation rate, poor corrosion resistance, and poor stability of the main heat exchanger and condensing heat exchangers, and achieve enhanced heat exchange Thermal effect, strong sealing, rapid heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

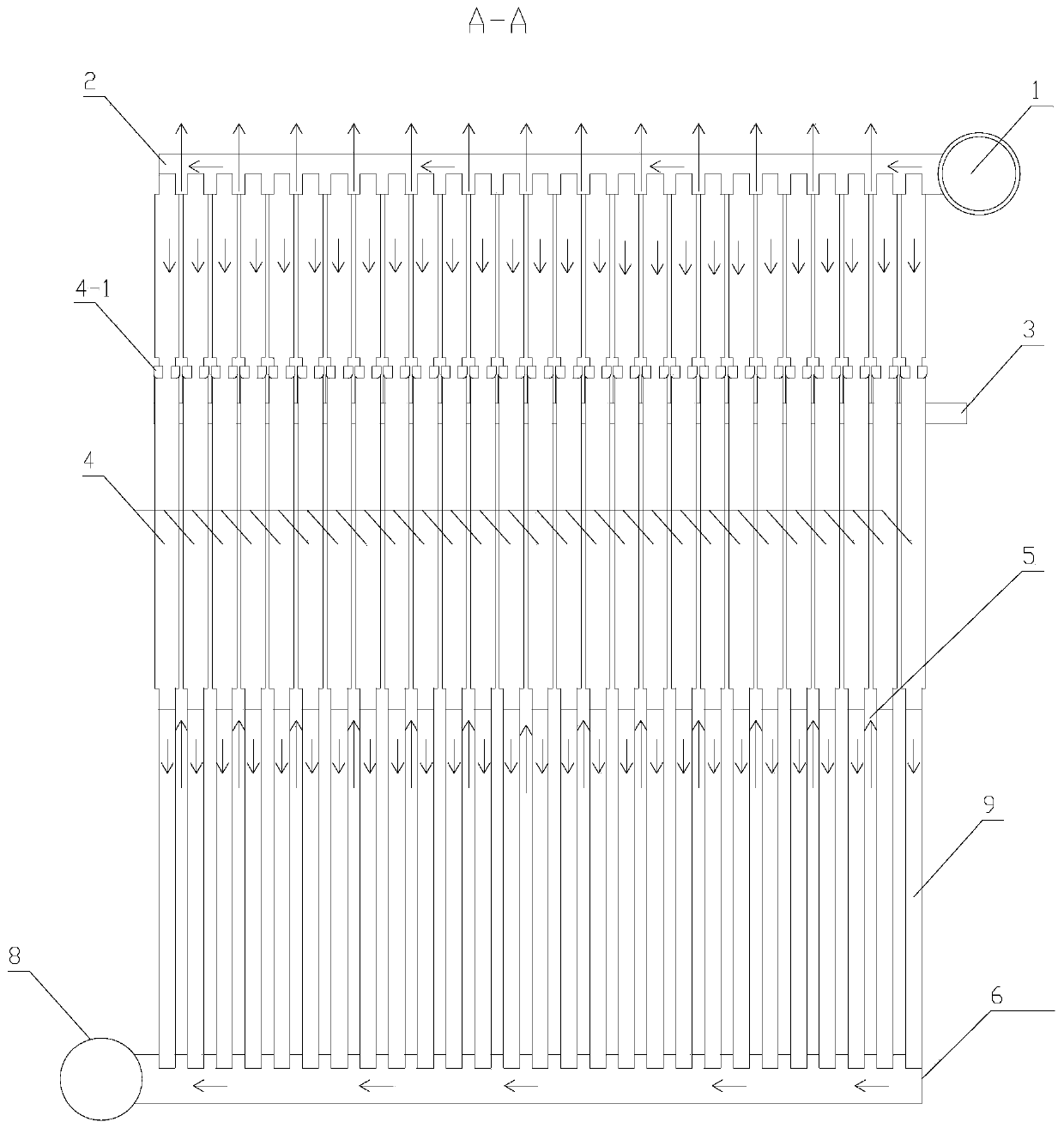

[0026] see Figure 4 to Figure 7 The interior of the heat exchange plate 4 is separated by a partition plate 4-3 to form a number of parallel arc-shaped water passages 4-2, and the upper and lower ends of the heat exchange plate 4 are respectively provided with connecting pipes connected to the water inlet pipe and the water outlet pipe. Port 4-5, the position of the connecting port 4-5 is provided with a water hole 4-6, and the two ends of the inner cavity of the heat exchange plate connected by the water hole 4-6 are respectively provided with a water collection space 4-8 and all water passages The channels are connected; both sides of the heat exchange plate 4 are provided with fins 4-4.

[0027] For details, see Figure 4 , the fins 4-4 are arc-shaped fins with the same shape as the partition plate 4-3 inside the heat exchange plate, and their positions correspond to the positions of the partition plates one by one.

[0028] see Figure 4 to Figure 6 Condensate water co...

Embodiment 2

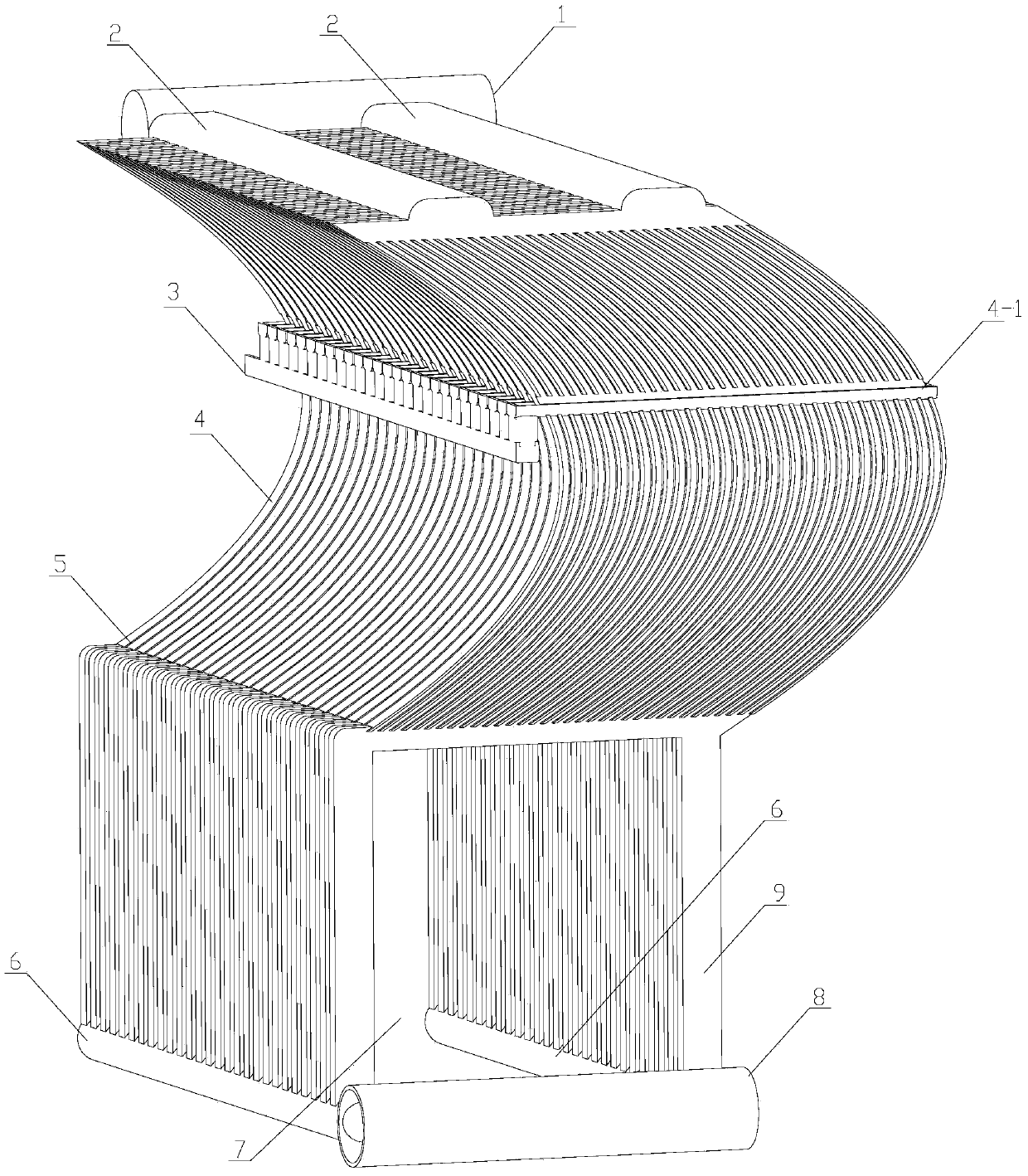

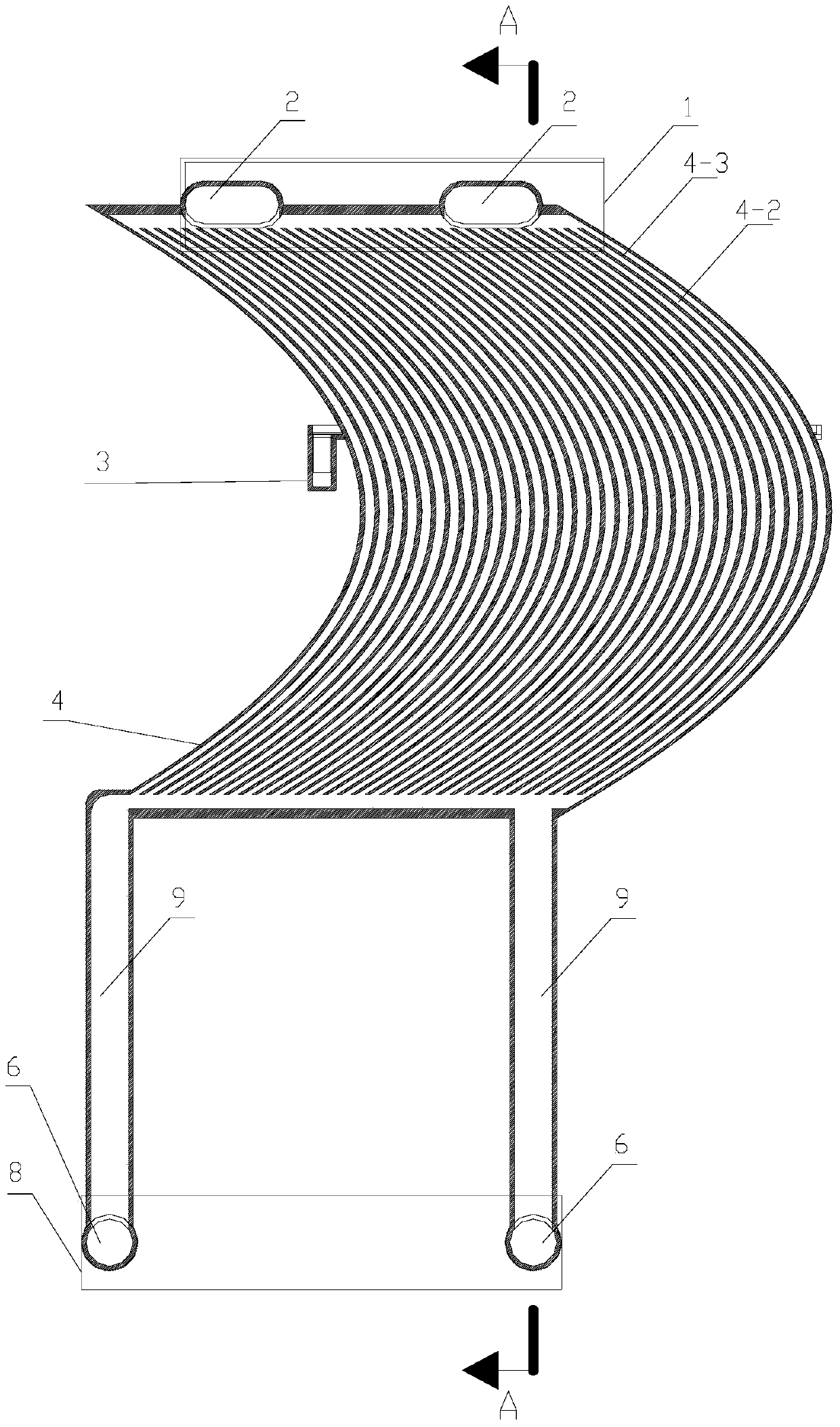

[0032] see in conjunction Figure 1 to Figure 3 , a condensing heat exchanger formed by combining the condensing heat exchange plates in Example 1 side by side, the flue gas pipeline of the condensing heat exchanger is surrounded by the fins 4-4 outside the adjacent heat exchange plates The gap between the plates is 5, and the water passage is the water passage 4-2 inside the heat exchange plate 4. There is a certain gap between the adjacent heat exchange plates 4, and the two sides of the entire heat exchanger are sealed with aluminum skins. Form an upward flue gas channel. The space enclosed by the downcomer 9 at the bottom of the heat exchange plate 4 is the combustion chamber 7, the top of the condensing heat exchanger is provided with a water inlet pipe 1 connected in parallel with the water hole at the top of the heat exchange plate 4, and the bottom is provided with an outlet pipe 8 It is connected in parallel with the water hole at the bottom of the heat exchange plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com