Gas-liquid separation type sleeve evaporator

A gas-liquid separation and evaporator technology, applied in evaporator/condenser, refrigeration and liquefaction, refrigeration components, etc., can solve the problems that the liquid phase cannot be effectively spread, complex gas-liquid two-phase flow, stratified flow is inevitable, etc. , to achieve the effects of saving materials, enhancing disturbance, and reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further illustrate the present invention below in conjunction with accompanying drawing.

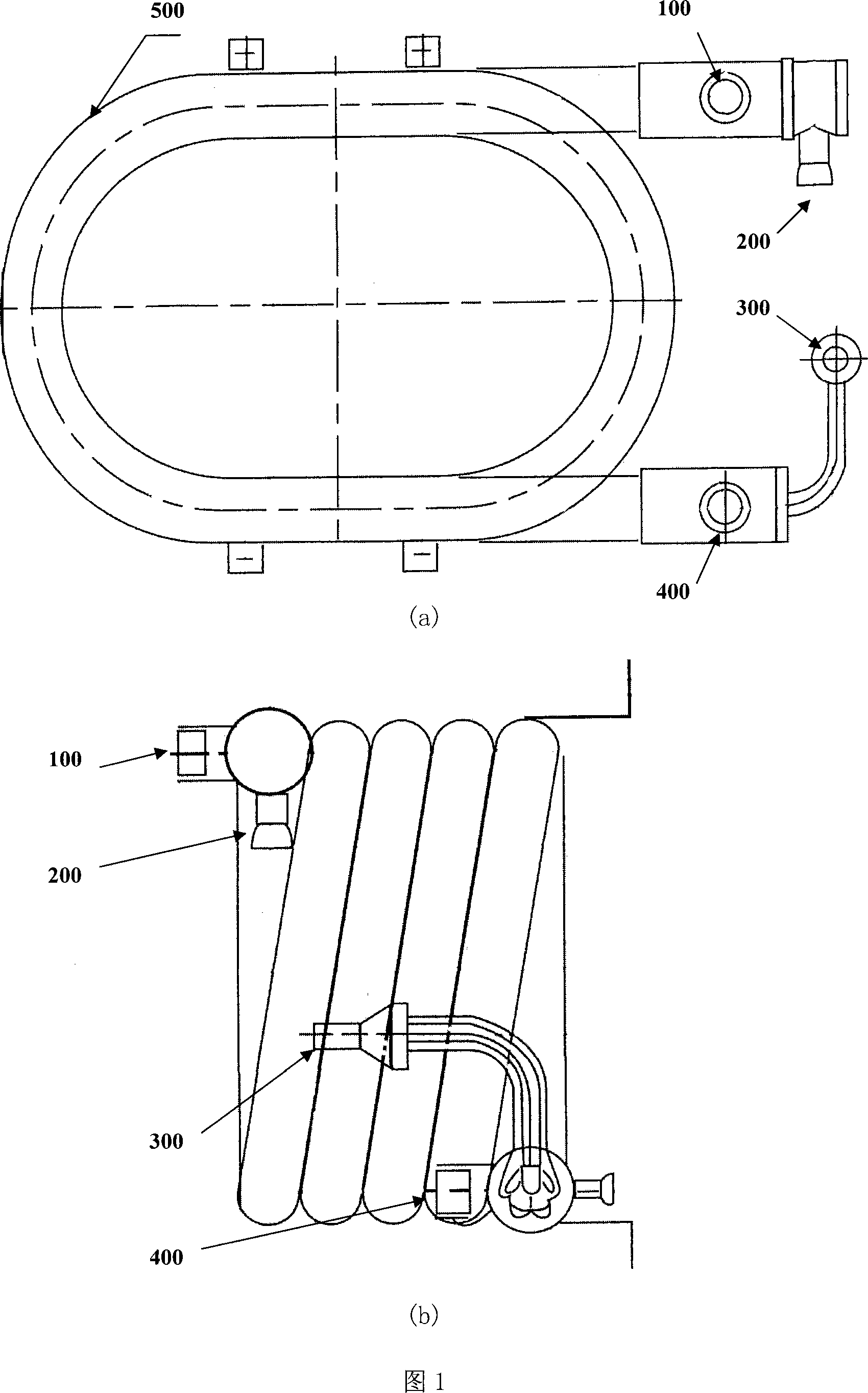

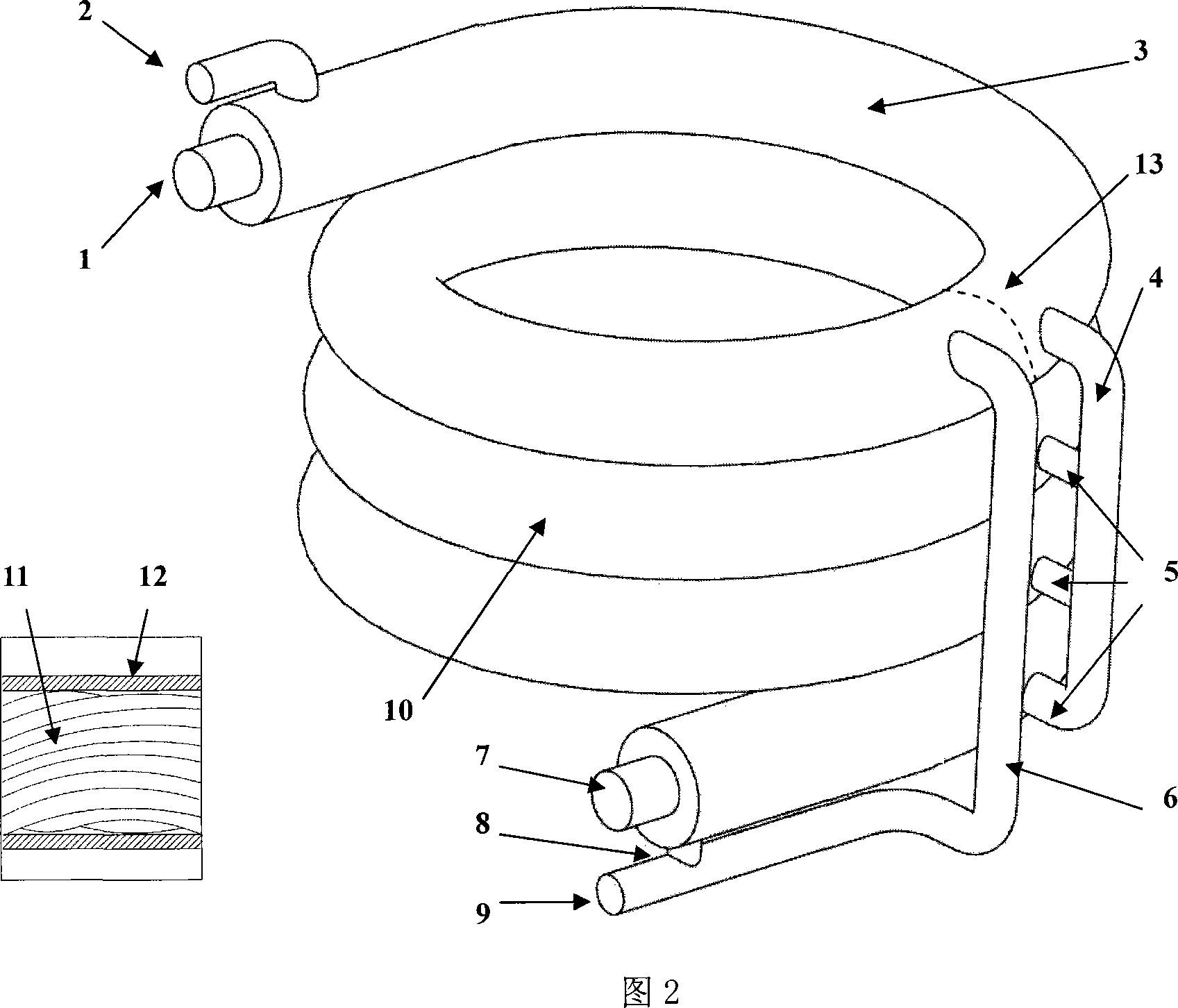

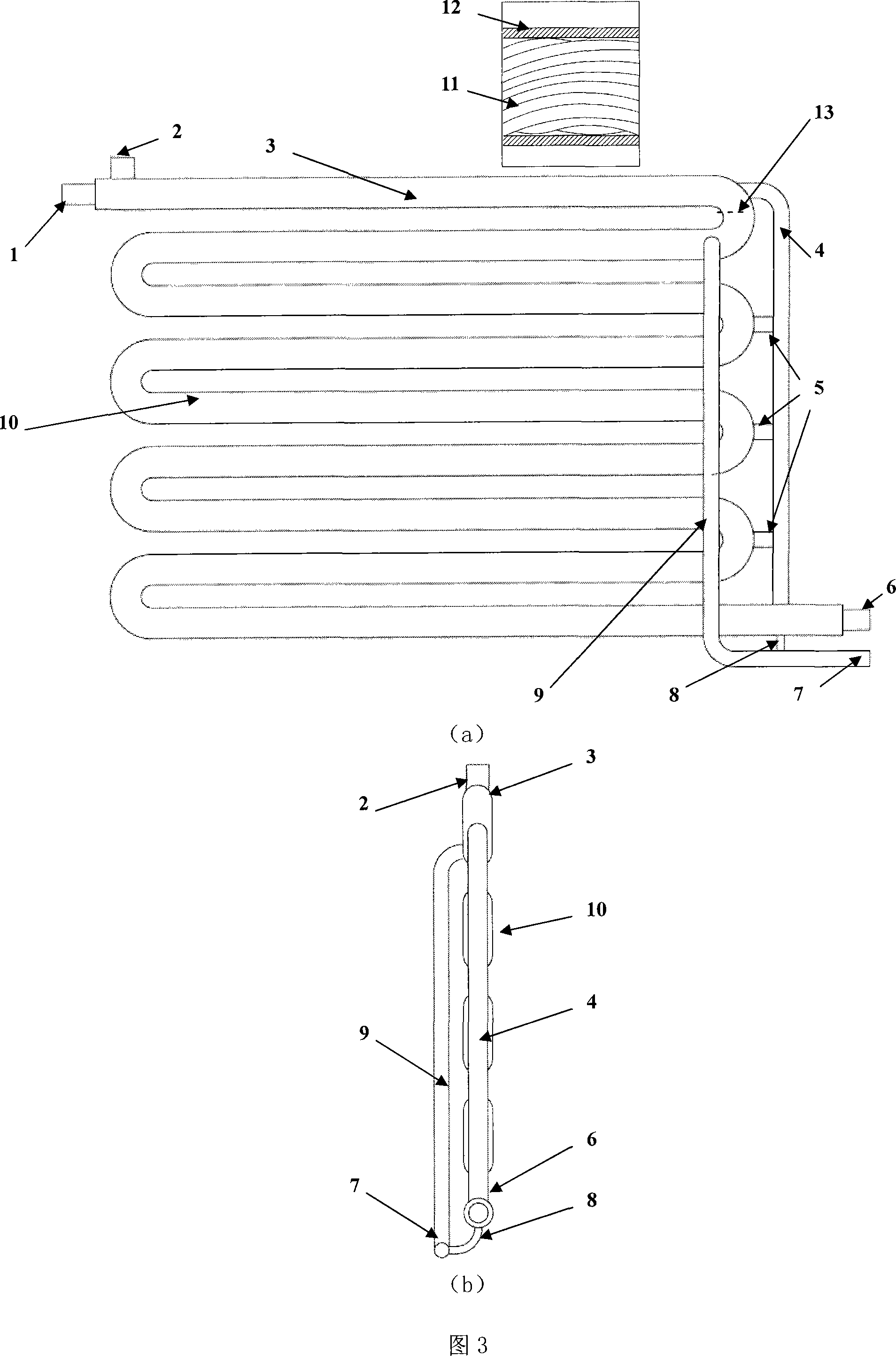

[0021]Fig. 2 is a schematic diagram of a spiral gas-liquid separation casing evaporator according to the present invention. Among them, 1. heating liquid (cooled liquid or water, the same below.) inlet, 2. evaporated liquid (or refrigerant, the same below.) steam outlet, 3. spiral superheating section, 4. gas collection and exhaust pipe, 5. Gathering exhaust port, 6. Evaporated liquid inlet pipe, 7. Heated liquid outlet, 8. Residual evaporated liquid liquid phase return port pipe, 9. Evaporated liquid inlet, 10. Spiral heat exchange section, 11. Twist the inner tube bundle, 12. the outer tube, 13. the separation device. In the helical casing evaporator, the outer casing (12) and several inner tubes (11) in which helically twist and distribute form the basic heat exchange part, and the whole is in a spiral shape. One end of the inner tube is the heating liquid inlet (1), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com