Device and method for producing biological fuel oil by quickly cracking biomass

A biofuel and biomass technology, which is applied in the preparation of biofuels, liquid hydrocarbon mixtures, and the petroleum industry, can solve the problems of heat carrier heating temperature without precise temperature control, poor continuity of actual production, and low energy utilization. Achieve the effect of simple structure, favorable industrial production and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

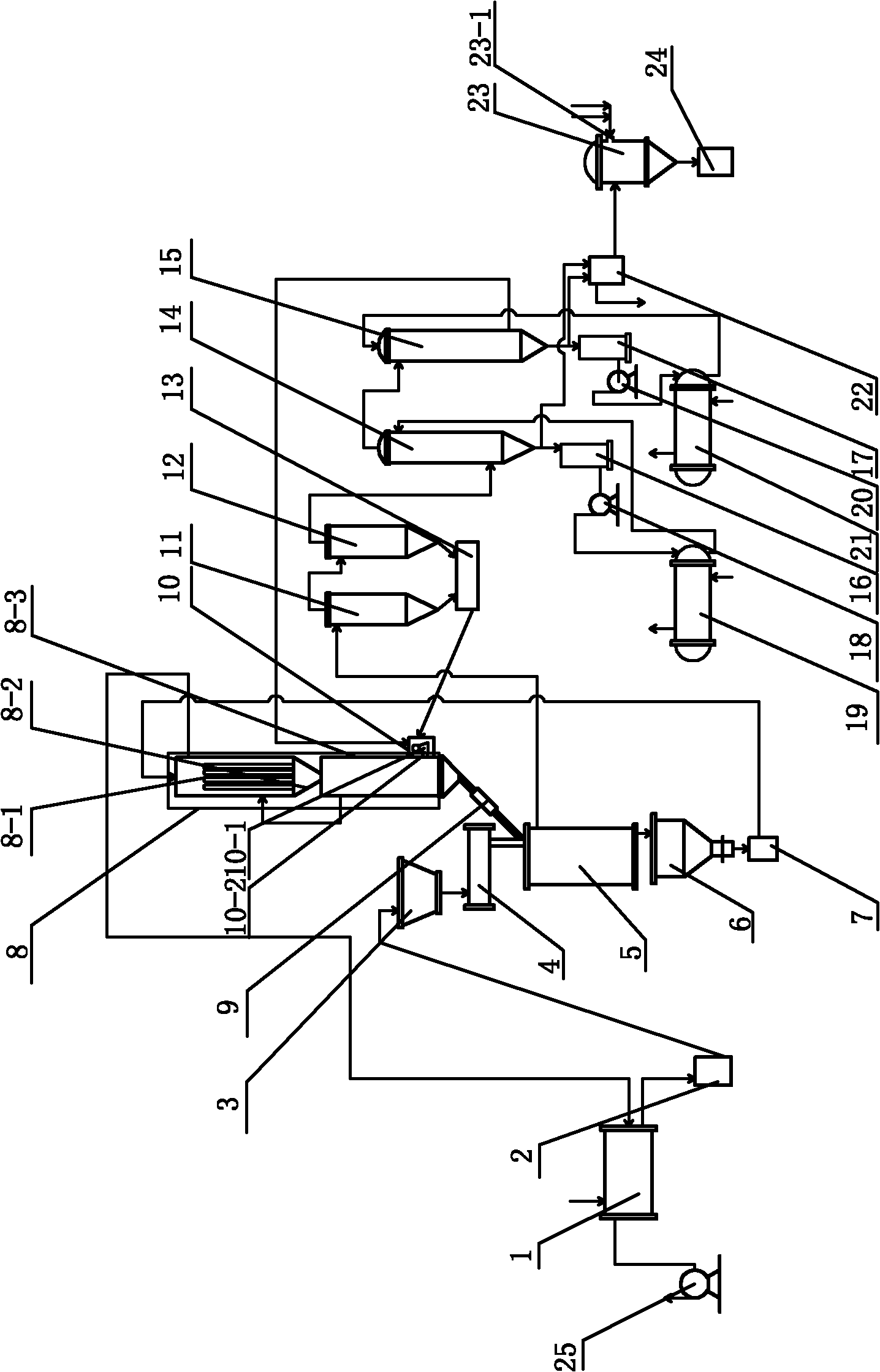

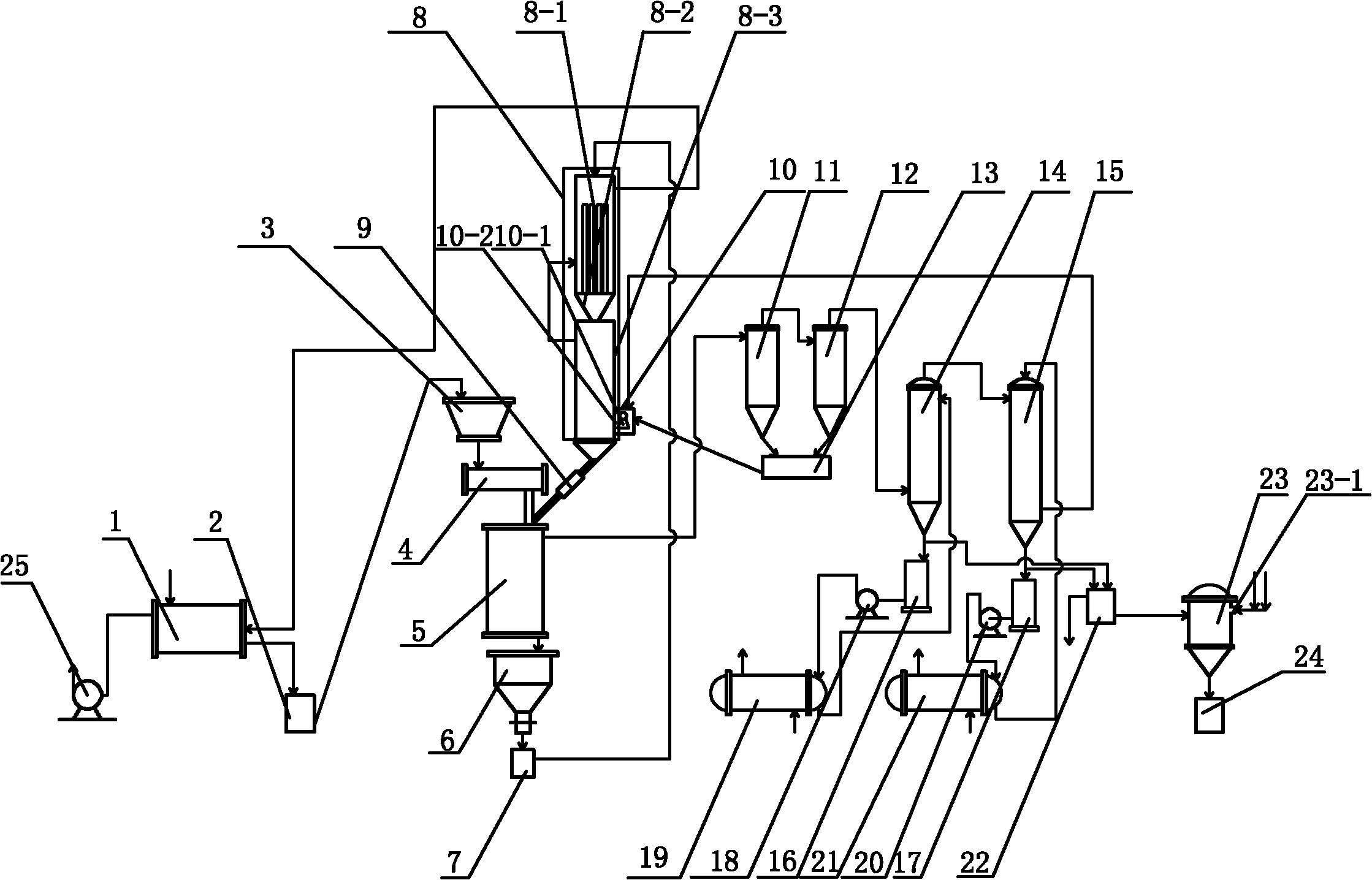

[0018] Specific implementation mode one: combine figure 1 Description of this embodiment, the device of this embodiment includes a dryer 1, a powder mill 2, a storage hopper 3, a feeding mechanism 4, a cracking reactor 5, a heat carrier collection box 6, a heat carrier lifting bucket 7, and a heat carrier heating device 8 , Heat carrier temperature precision control device 9, heat energy supply device 10, primary separator 11, secondary separator 12, carbon collection box 13, primary condenser 14, secondary condenser 15, first condensate storage tank 16 , the second condensate storage tank 17, the first pump 18, the first heat exchanger 19, the second pump 20, the second heat exchanger 21, the biofuel product collection box 22 and the induced draft fan 25, the drying machine 1 and the pulverizer The machine 2 is connected, the powder making machine 2 is connected with the storage hopper 3, the storage hopper 3 is connected with the feed port of the cracking reactor 5 through t...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the condensate outlet end of the primary condenser 14 of this embodiment communicates with the first condensate storage tank 16, and the first condensate storage tank 16 communicates with the first heat exchanger 19 through the first pump 18, The first heat exchanger 19 communicates with the condensate inlet port of the primary condenser 14, the condensate outlet port of the secondary condenser 15 communicates with the second condensate storage tank 17, and the second condensate storage tank 17 passes through the second pump 20 communicates with the second heat exchanger 21, the second heat exchanger 21 communicates with the condensate inlet port of the secondary condenser 14, and the biofuel outlet ports of the primary condenser 14 and the secondary condenser 15 are connected with the biofuel product The collection box 22 is connected, and the flue gas generated in the heat energy sup...

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1Describe this embodiment, the thermal energy supply device 10 of this embodiment is made up of noncondensable gas burner 10-1 and combustion chamber 10-2, and noncondensable gas burner 10-1 is arranged in the combustion chamber 10-2, and thermal energy supply device 10 is arranged under the side of the heat carrier heating device 8 . Other components and connections are the same as those in the first embodiment.

[0021] Specific implementation mode four: combination figure 1 Describe this embodiment, the heat carrier heating device 8 of this embodiment is made up of heating pipe 8-1, heat carrier flow control valve 8-2 and a group of inclined partitions 8-3, and heating pipe 8-1 is arranged at the heat carrier heating Above the device 8, a group of inclined partitions 8-3 are installed below the heat carrier heating device 8, and the heating pipe 8-1 communicates with a group of inclined partitions 8-3 through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com