Titanium sponge preparation technique and titanium sponge reaction furnace

A technology of sponge titanium and reaction furnace, which is applied in the field of metal smelting to achieve the effects of reducing pollution, good heat preservation effect, and ensuring smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

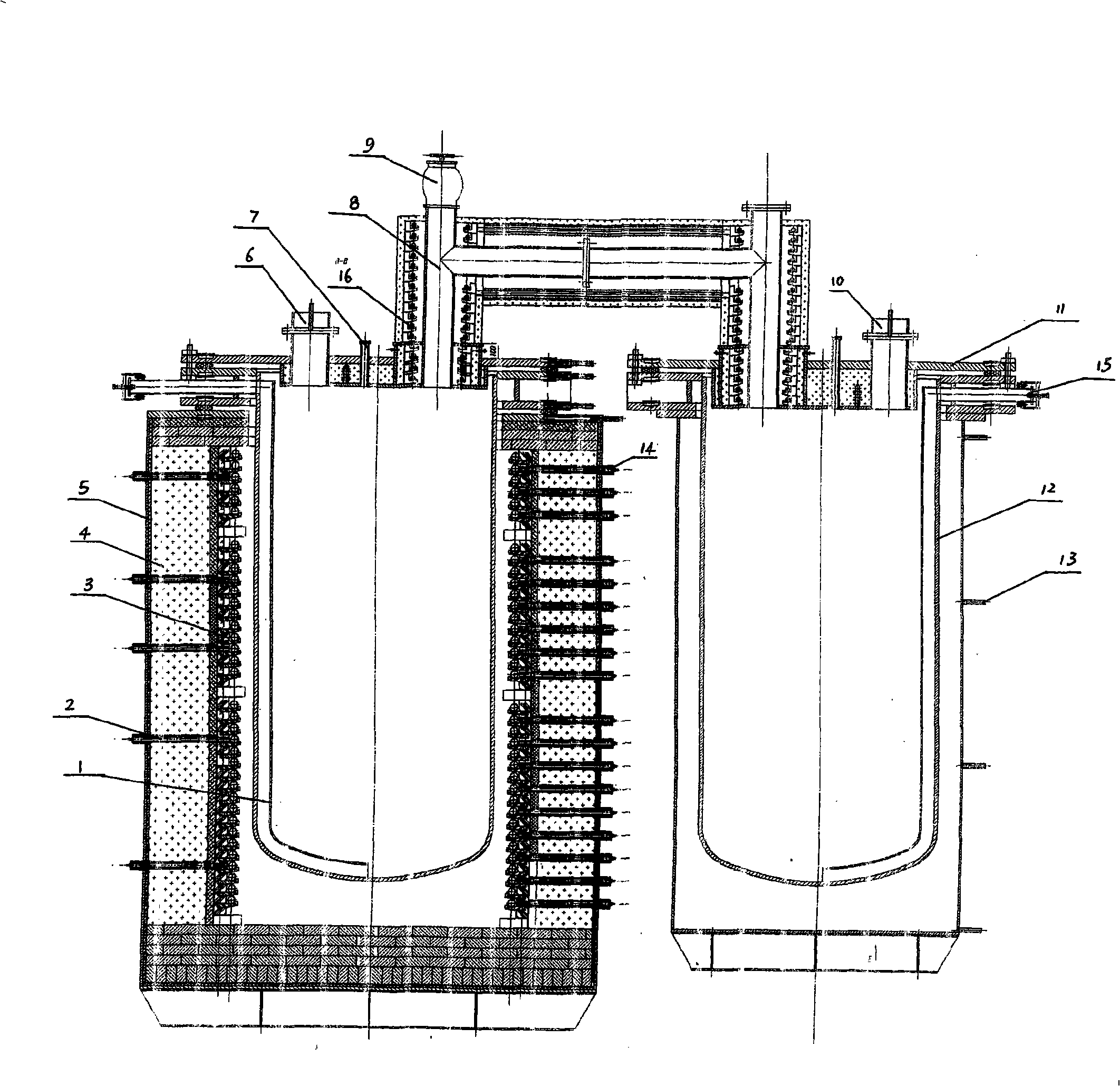

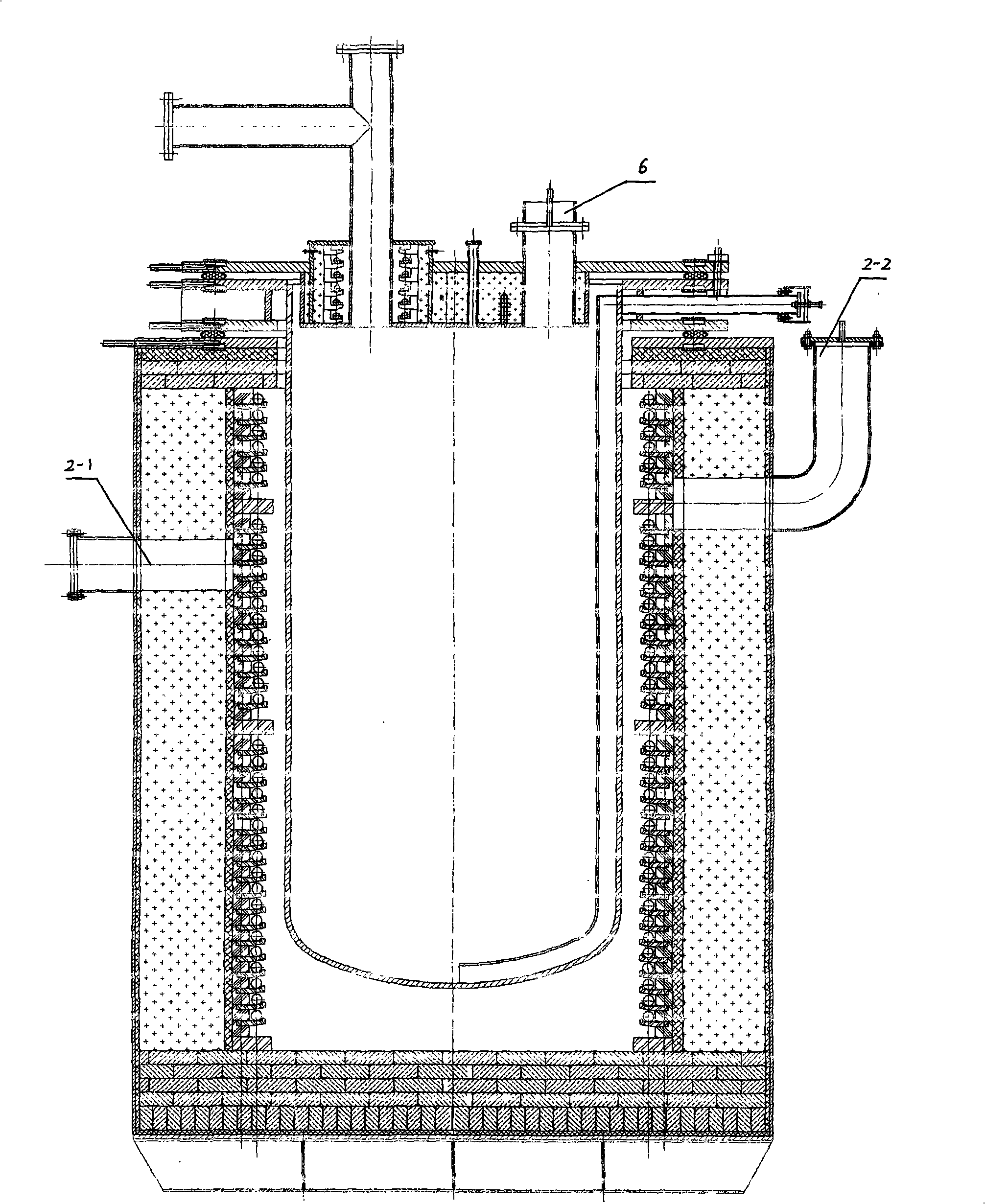

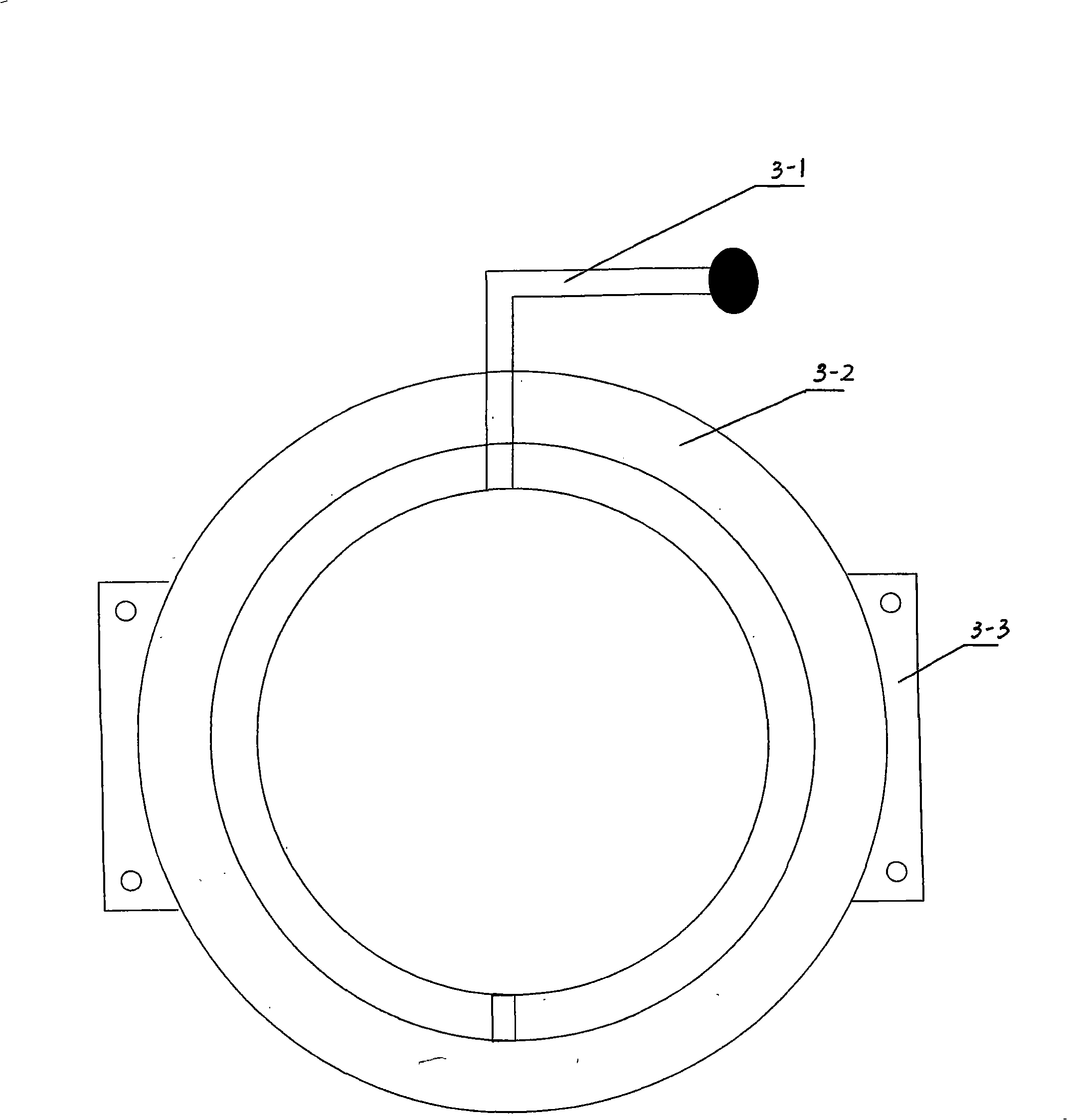

[0022] Such as figure 1 , 2 , 3 provides the specific implementation of the sponge titanium reaction furnace of the present invention. It includes a reaction tank 1 and a cooling tank 12; a heating wire 3 is fixed outside the inner wall of the reaction tank 1, and the heating wire 3 is connected to a conductive rod 14; the reaction tank 1 is wrapped with an insulating layer 4 and a furnace wall 5; Pipe 6; cooling tank 12 has a cooling water jacket, and its top is communicated with cooling tank evacuation pipe 10, and reaction tank 1 and cooling tank 12 are fixed and arranged side by side with big cover 11 on both sides respectively and between the two with center pipe (8 ) is communicated, an inner heating jacket 16 is wrapped around the center pipe 8, and a discharge pipe 15 is communicated at the top of the cooling tank 12. A control valve is installed in the evacuation pipe 6, and the control valve includes a valve body 3-2, a valve switch 3-1 and a valve connector 3-3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com