Membrane separation method and membrane separation device

A membrane separation and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve problems such as membrane separation performance degradation, shorten stirring time, inhibit separation performance degradation, and inhibit sludge volume. or the effect of membrane fouling

Inactive Publication Date: 2010-08-25

KURITA WATER INDUSTRIES LTD

View PDF3 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because industrial water, urban water supply, well water, etc. usually contain humic acid, fulvic acid organic matter, biological metabolites such as sugars produced by algae, synthetic chemical substances such as surfactants, etc., membrane fouling substances that pollute the membrane, Therefore, there is a problem that if membrane separation treatment is performed, these membrane fouling substances are adsorbed on the surface of the membrane, and the membrane separation performance is degraded.

However, there is a new problem that if a polymer coagulant is added, the polymer coagulant remaining in the water will be adsorbed on the subsequent membrane to contaminate the membrane, deteriorating the separation performance of the membrane

However, in the method of this Patent Document 1, it is necessary to add an inorganic coagulant and a polymer coagulant to the water to be treated, and then add an inorganic coagulant. Therefore, a simpler method is being sought.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach 1

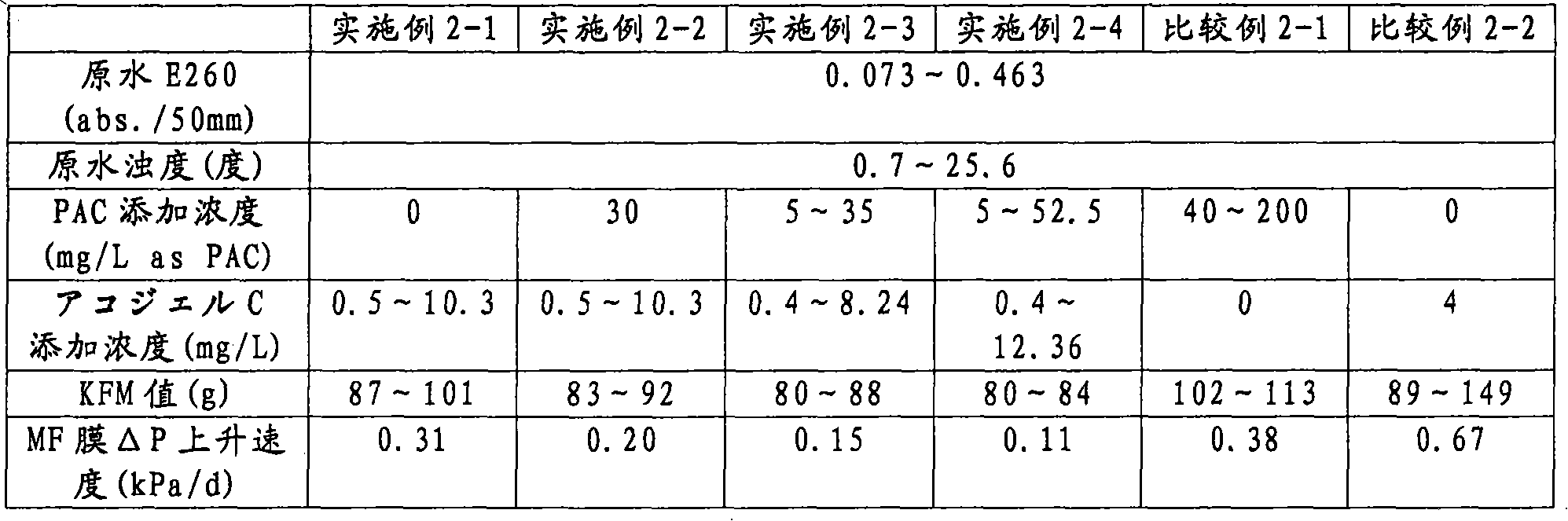

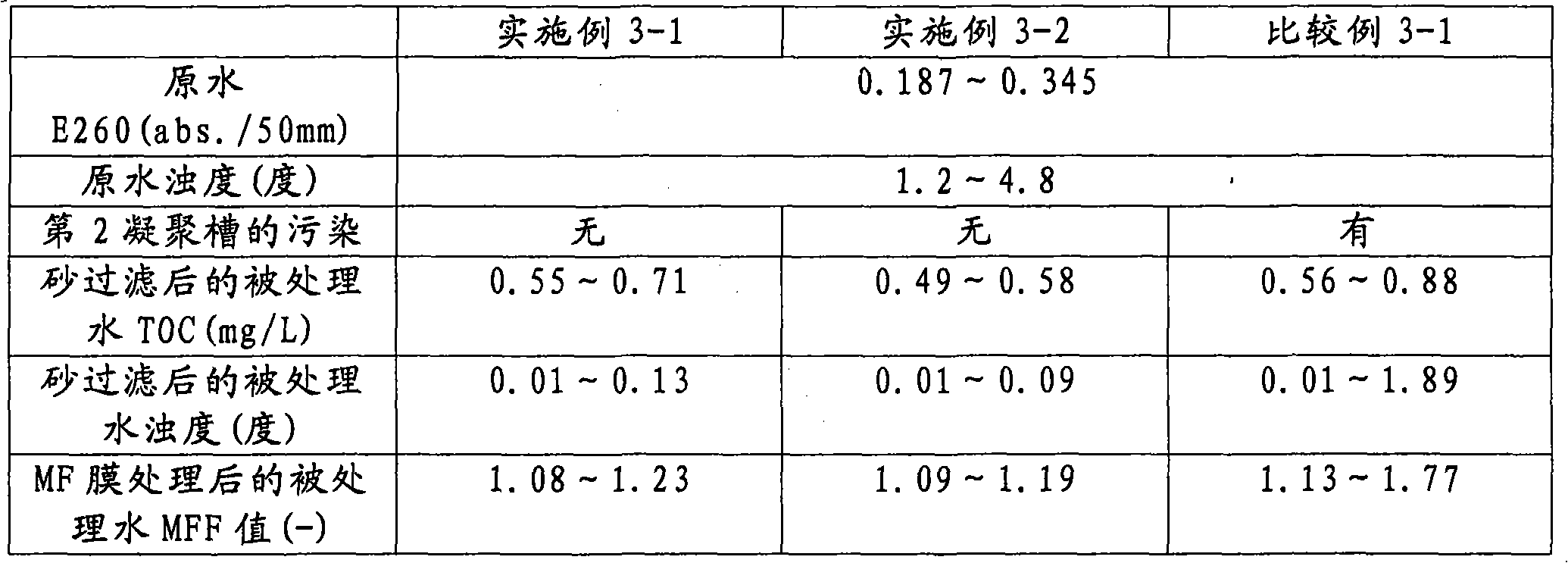

Embodiment 1-1

Embodiment 1-2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Login to View More

Abstract

Disclosed are a membrane separation method and a membrane separation device, each of which enables to reduce deterioration in membrane separation performance during membrane separation of water to be processed by reducing adsorption of membrane contaminating materials contained in the water onto the membrane surface. Specifically, water to be processed is subjected to membrane separation after being added with particles made of a cationic polymer which swells but does not substantially dissolve in water.

Description

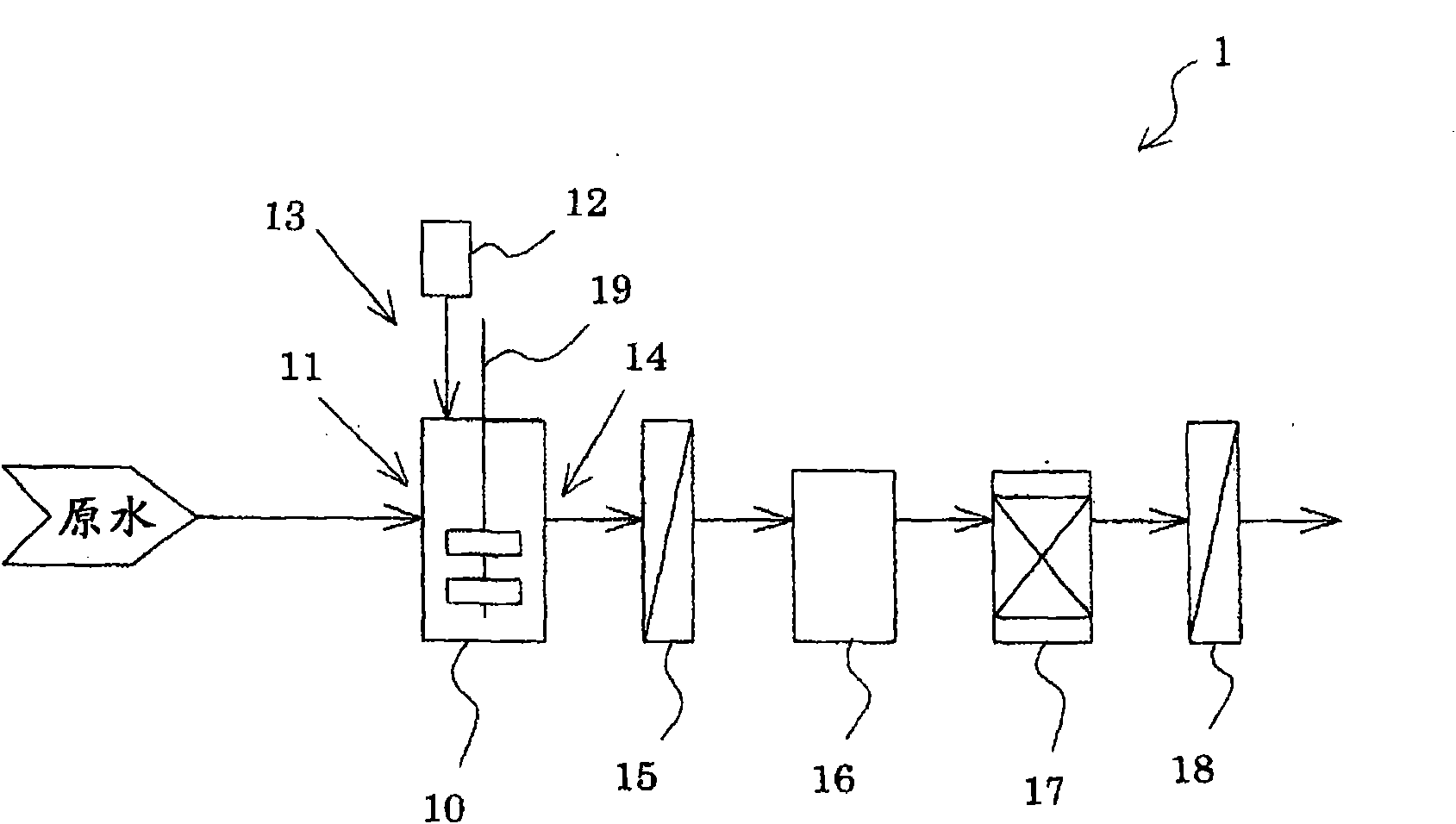

Membrane separation method and membrane separation device technical field The invention relates to reducing the adsorption and inhibition of membrane pollutants contained in the treated water on the surface of the membrane when the treated water such as industrial water, urban water supply, well water, river water, lake water, and factory waste water is subjected to membrane separation treatment. Membrane separation method and membrane separation device for deterioration of membrane separation performance. Background technique As a method of treating industrial water, urban water supply, well water, river water, lake water, factory wastewater, etc. to be treated to produce pure water, for example, there are methods of passing water through microfiltration membranes (MF membranes), ultrafiltration membranes, etc. (UF membrane), reverse osmosis membrane (RO membrane) and other membrane separation treatment methods. Because industrial water, urban water supply, well water, e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/44B01D61/02B01D61/16B01D61/58C02F1/28C02F1/42C02F1/52C02F9/00

CPCC02F1/441B01D2311/263B01D61/58B01D2321/164C02F1/66C02F1/54B01D2311/246C02F2101/301C02F1/283C02F2209/20C02F1/42B01D61/16B01D2311/2623B01D61/12C02F2303/20C02F2209/003C02F2001/425B01D2311/2642C02F1/56C02F2101/34C02F2001/422B01D61/04B01D61/025C02F1/44C02F1/5245C02F2001/007B01D65/02C02F2209/06B01D2321/04B01D2317/025C02F1/442C02F1/5209C02F2209/001C02F1/5272C02F1/285B01D61/22B01D61/145C02F1/5236C02F2209/21B01D2311/2626C02F2101/30B01D61/147C02F1/24B01D2311/06C02F2209/11C02F2303/16B01D2311/04C02F1/444B01D65/08B01D2321/168C02F1/28C02F1/52C02F9/00

Inventor 多田景二郎大泽公伸佐藤茂池田宏之

Owner KURITA WATER INDUSTRIES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com