A filtering material made of non-woven charcoal cloth

A technology of filter material and non-woven fabric, which is applied in the field of carbon-laminated non-woven fabric filter material and its manufacturing process, can solve the problems of reducing the purification effect of the material and losing the performance of activated carbon, and achieves a simple manufacturing process, low production cost and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

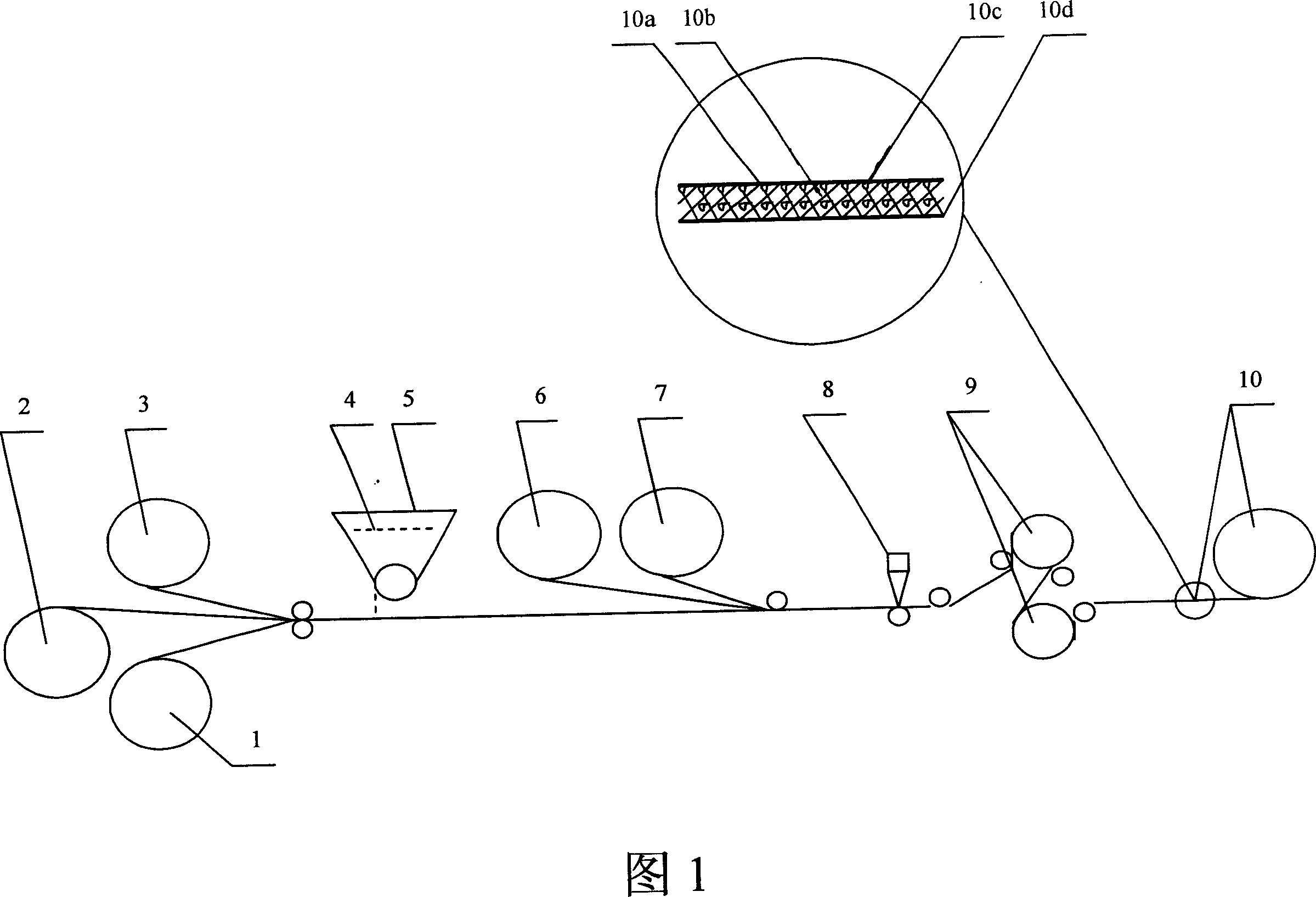

[0018] As shown in FIG. 1 , the filter material 10 of carbon-inserted non-woven fabric includes an upper layer of non-woven fabric 10a, a middle layer of reticular non-woven fabric 10b, activated carbon particles 10c and a lower layer of non-woven fabric 10d.

[0019] The manufacturing process of the carbon sandwich non-woven filter material is as follows: as shown in Figure 1, the lower non-woven fabric 1, the first layer of hot-melt adhesive film 2, and the middle layer of mesh non-woven fabric 3 are unrolled by the unwinder, and Press, middle, and top are stacked in sequence, and then the activated carbon particles 4 are sprinkled on it with a granulator 5, and then the second layer of hot melt adhesive film 6 and the lower layer of non-woven fabric 7 are sequentially stacked on it, Then, it is composited by the ultrasonic composite machine 8, and then thermally composited by the thermal composite machine 9. The surface temperature of the hot roller is controlled at 150°C-18...

Embodiment 2

[0021] As shown in FIG. 1 , the filter material 10 of carbon-inserted non-woven fabric includes an upper layer of non-woven fabric 10a, a middle layer of reticular non-woven fabric 10b, activated carbon particles 10c and a lower layer of non-woven fabric 10d.

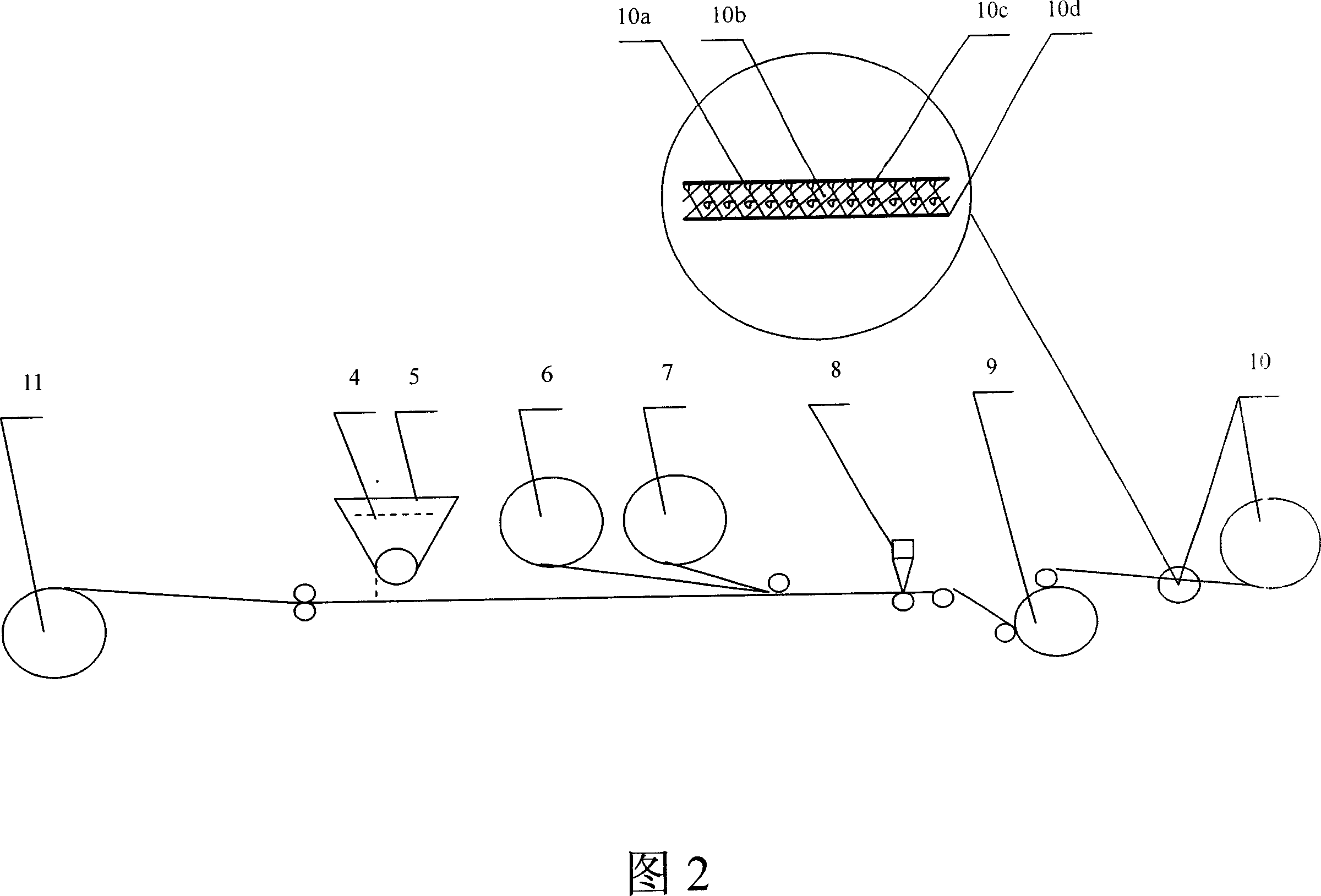

[0022] The manufacturing process of carbon sandwich non-woven filter material is shown in Figure 1. The lower layer of non-woven fabric 1, the first layer of hot-melt adhesive film 2, and the middle layer of mesh non-woven fabric 3 are unrolled through the unwinder, and sequentially pressed Lay up in the order of lower, middle and upper, and then use the granulator 5 to spread the activated carbon particles 4 on it, and then lay the second layer of hot melt adhesive film 6 and the lower layer of non-woven fabric 7 sequentially on it, and then, Composite finished product 10 is made by ultrasonic composite machine 8, and it is wound up.

Embodiment 3

[0024] As shown in Fig. 1, the filter material 10 of interlaced charcoal non-woven fabric comprises an upper layer of non-woven fabric 10a, a middle layer of reticular non-woven fabric 10b, activated carbon particles 10c and a lower layer of non-woven fabric 10d.

[0025] The manufacturing process of carbon sandwich non-woven filter material is shown in Figure 1. The lower layer of non-woven fabric 1, the first layer of hot-melt adhesive film 2, and the middle layer of mesh non-woven fabric 3 are unrolled through the unwinder, and sequentially pressed Lay up in the order of lower, middle and upper, and then use the granulator 5 to spread the activated carbon particles 4 on it, and then lay the second layer of hot melt adhesive film 6 and the lower layer of non-woven fabric 7 sequentially on it, and then, Carry out thermal lamination with heat laminating machine 9 again, and the surface temperature of hot roller is controlled at 160 ℃-180 ℃ to make finished product 10, and it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com