Method for manufacturing digital PCR (polymerase chain reaction) chip based on mineral-oil saturated PDMS (polydimethylsiloxane) material

A mineral oil and chip technology, applied in biochemical equipment and methods, microbial determination/inspection, biomass post-processing, etc., can solve the problems of unstoppable PDMS chip material absorption, complex process conditions, etc., and achieve easy promotion and observation. The method is simple and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

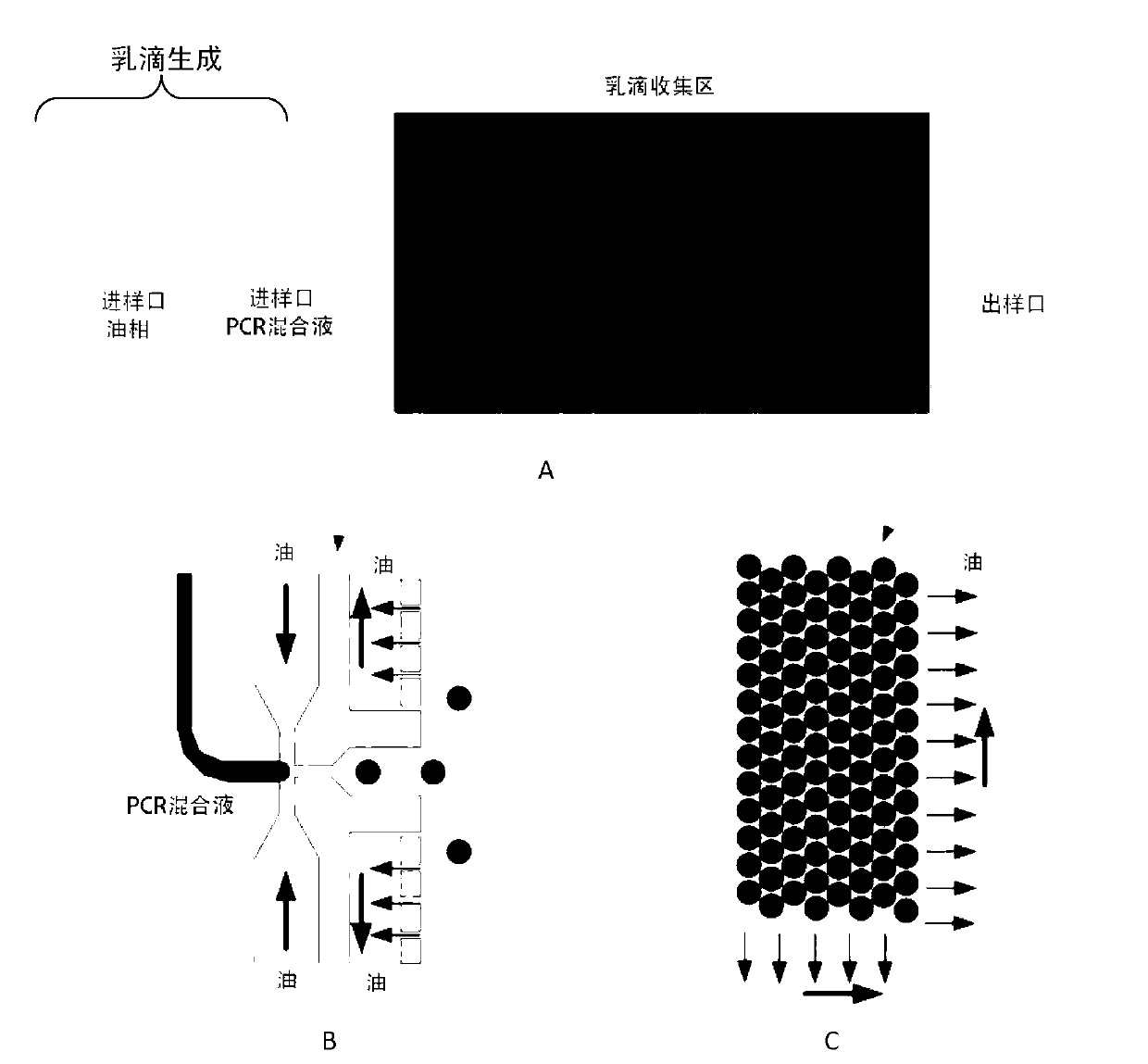

[0035] Embodiment 1: the design of mold and making ( figure 1 )

[0036] The present invention studies the influence of various chip structures and positive and negative pressure sampling on the stability of milk droplet formation, and finally finds that the cross-flow (ie "ten" type) negative pressure sampling method has low requirements for external equipment and generates milk droplets. Good dimensional stability.

[0037] The chip is composed of two parts: milk drop generation and milk drop collection, and the milk drop is generated by cross-flow negative pressure. First use CAD software to design the pattern and print the mask, and then use the photoresist SU8 2050 to fabricate the micropipeline and injection tank structure on the silicon wafer (see figure 1 ), the width of the oil phase sampling pipeline: 200 microns, the PCR mixed liquid sampling pipeline: 60 microns, the focusing shrinkage tube: 40 microns; the microcolumn diameter in the cavity: 100 microns; the fen...

Embodiment 2

[0038] Embodiment 2: the preparation of PDMS chip

[0039] After the silicon wafer is fabricated, single-layer and double-layer PDMS chips are fabricated by molding. First, add 10ml of paraffin oil to the PDMS prepolymer, mix PDMS and paraffin oil thoroughly, then mix the mixed liquid phase and curing agent (mass ratio 10:1), vacuumize and degas, and pour On the above-mentioned mold, in addition, thinly coat a layer of PDMS mixed with paraffin oil on the glass slide, let it stand for 1 hour, put it on a hot plate at 65°C for 30 minutes to pre-cure, peel off the PDMS poured on the mold, punch holes, and The pipe surface and the coated glass coating surface are bonded together, and a cover glass is added above the sampling tank to prevent the negative pressure sampling tank from sinking. Finally, put the bonded PDMS in 85°C Heat on a hot plate for 10 minutes to bond.

Embodiment 3

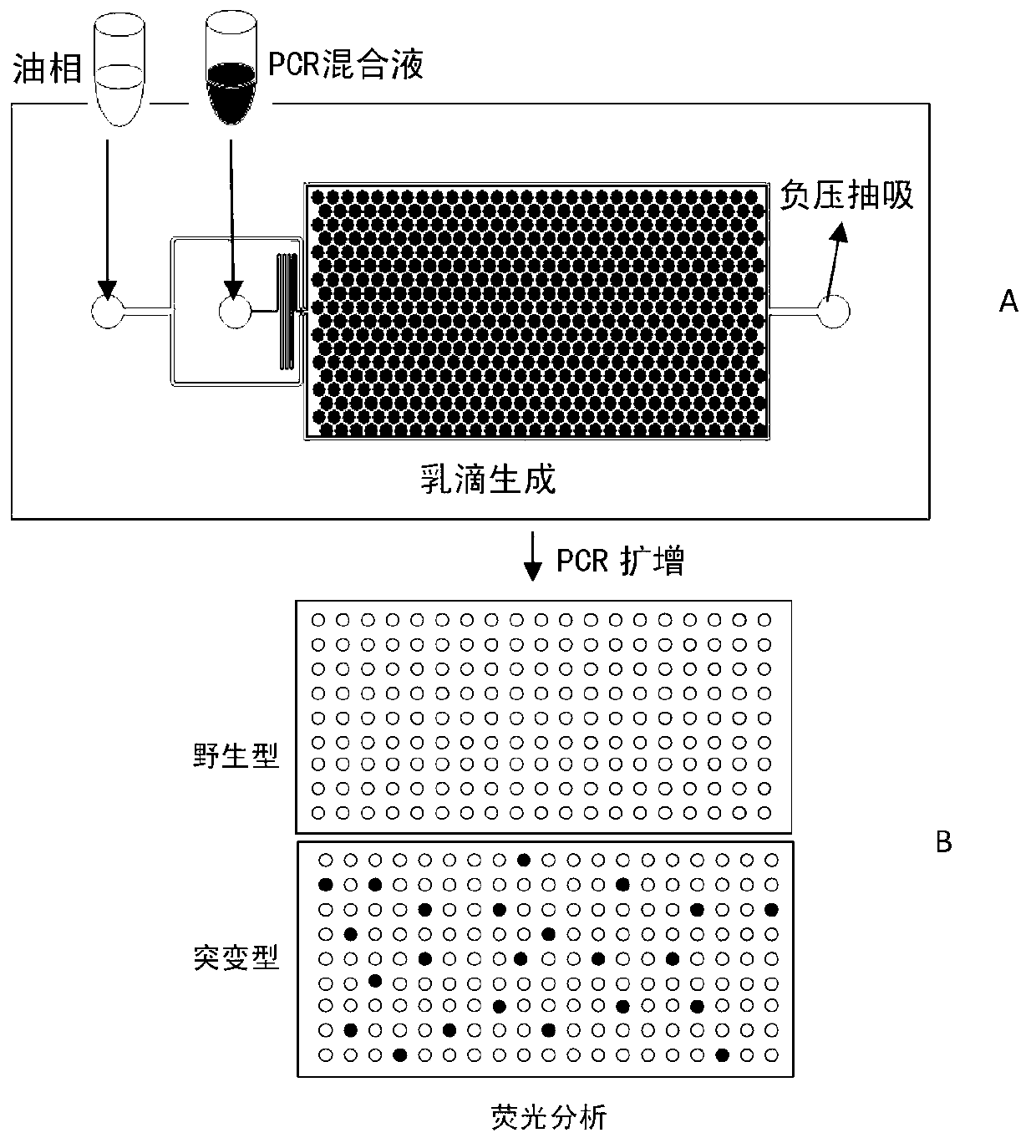

[0040] Embodiment 3: the generation of milk droplet ( figure 2 )

[0041] PCR premix: 20ul premix contains 10ul Roche 480 Probe Premix, each 250nM EGFR gene exon 19 upstream and downstream primers, 200nM TaqMan probe, 10ng genomic DNA.

[0042] First prepare the PCR premix, inject the PCR premix into the injection port, inject liquid paraffin containing emulsifier (containing 3% Abil EM90) into the oil inlet, place the syringe on the pump, connect the injection end to the infusion thong, and insert the thong into the pump. The suction hole is connected to a simple negative pressure pump (COSMO, Double Type 12000) at the end, and the suction speed is set to medium speed. Flow towards the sample outlet, at the cross structure of the chip ( figure 1 B), under the action of paraffin oil on both sides, cut to form nano-liter milk droplets (about 50 μm in diameter). Under the action of microdams (see figure 1 C, the size between the micro-dams is less than 20 μm), the emulsion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com