Patents

Literature

402 results about "Emulsion droplet" patented technology

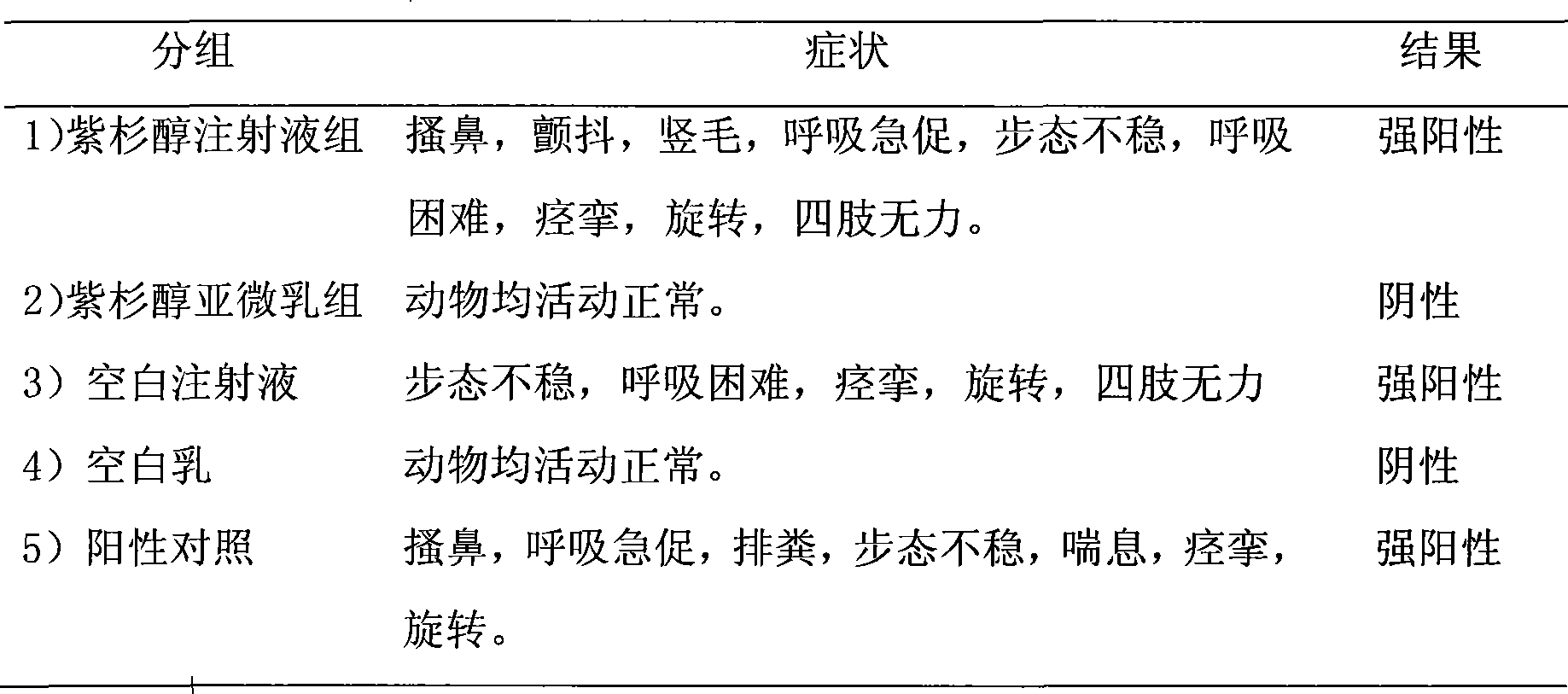

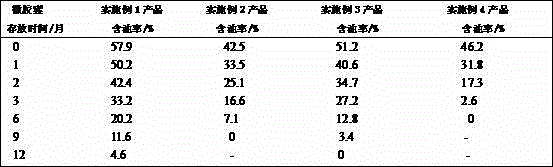

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorocarbon emulsion stabilizing surfactants

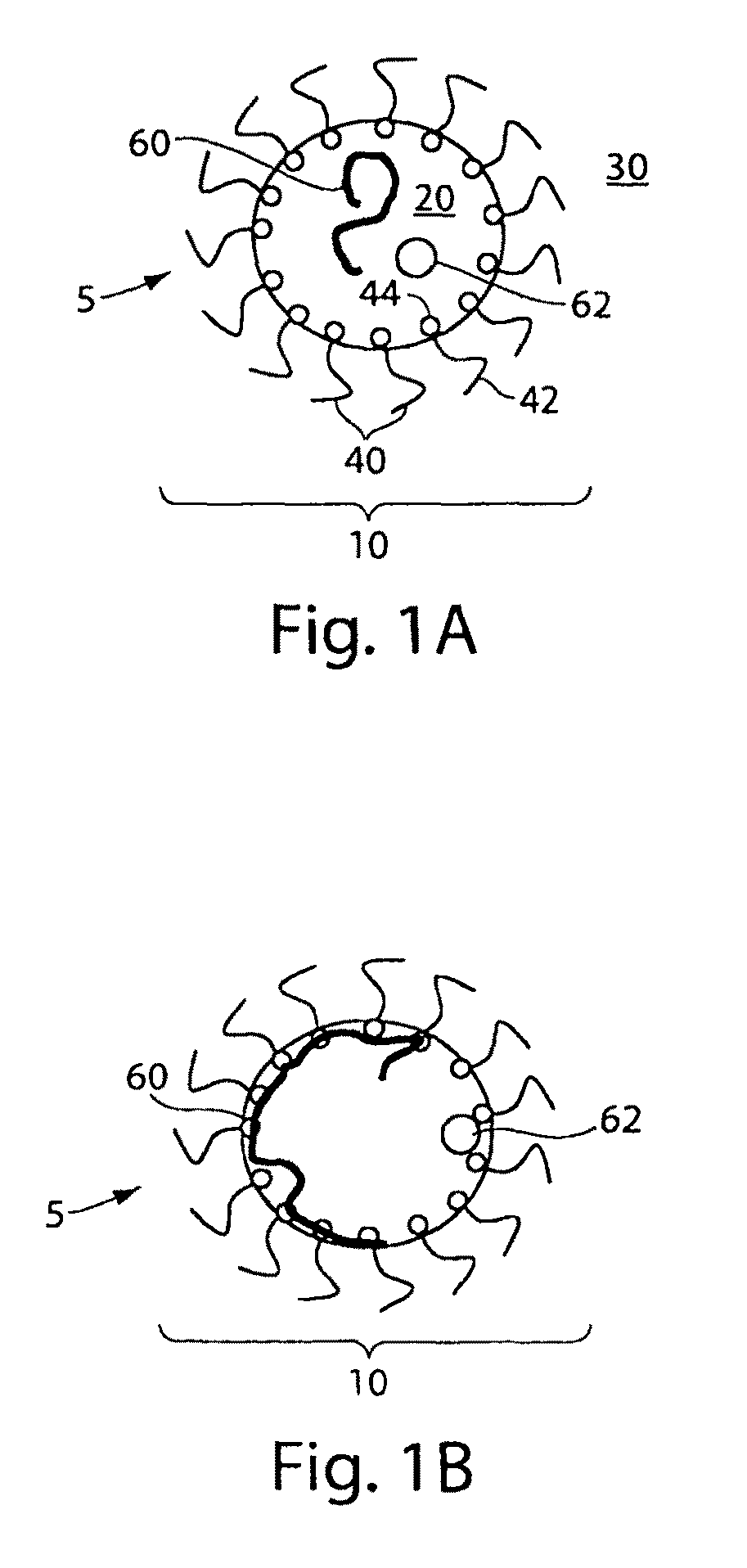

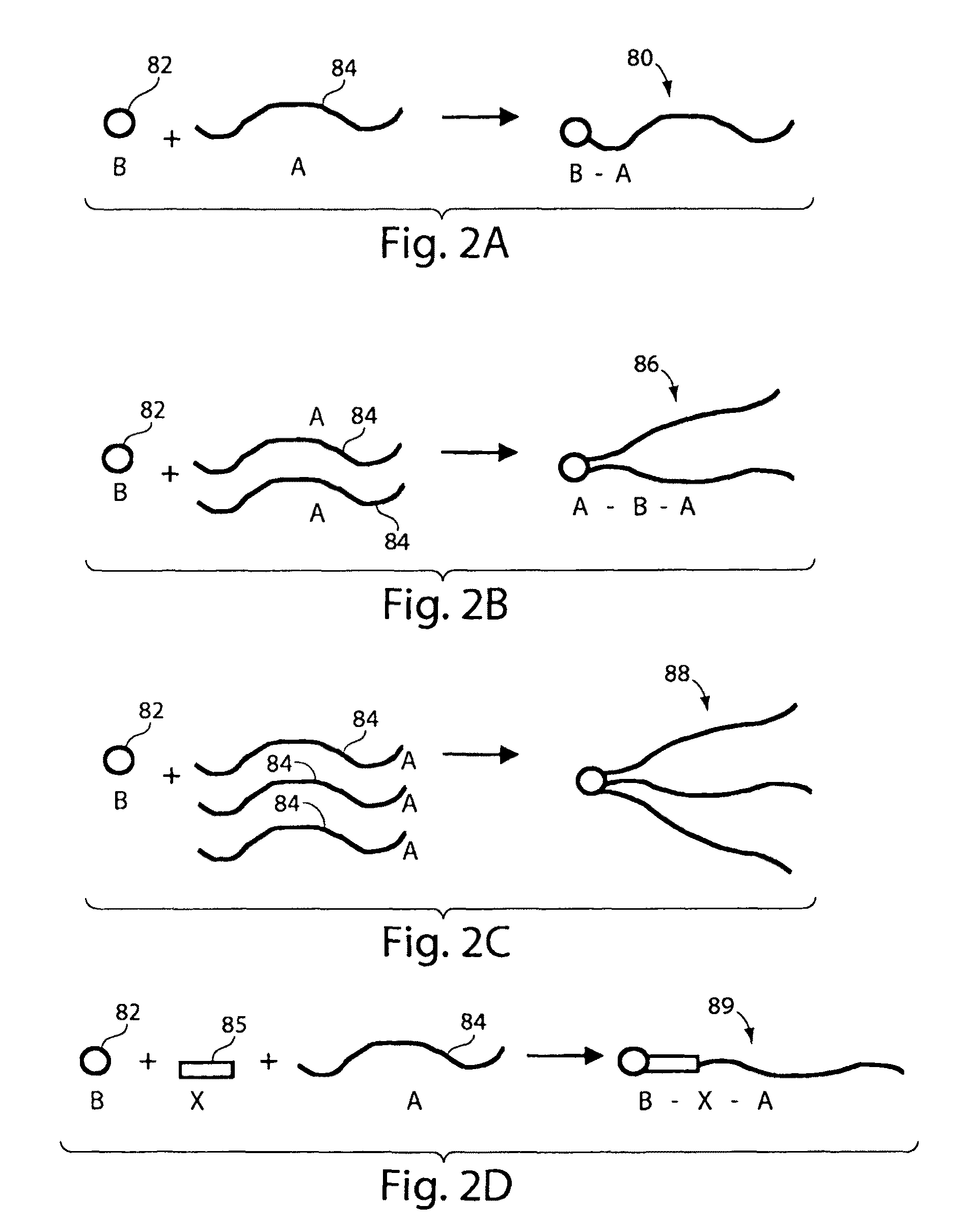

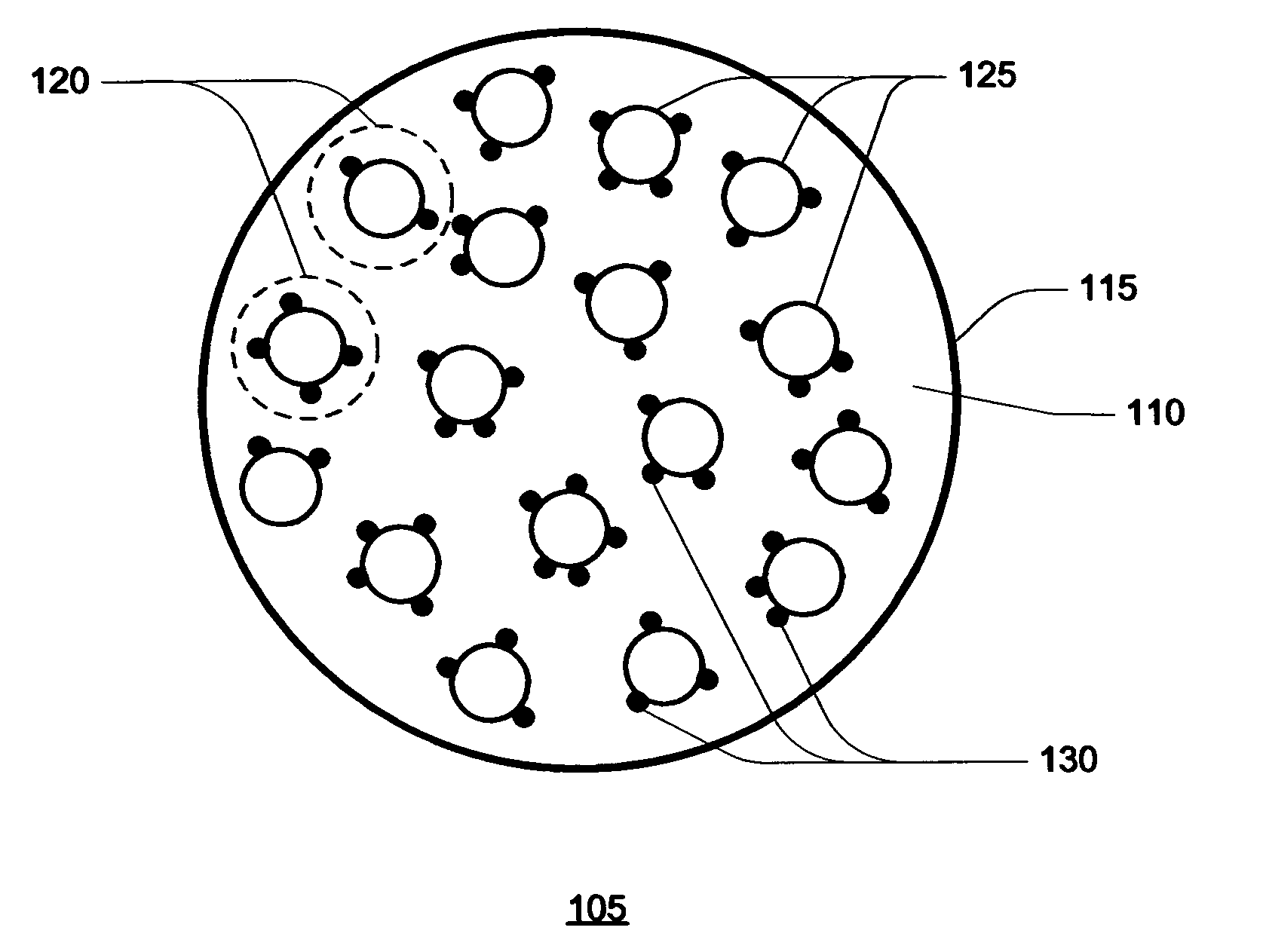

Surfactants (e.g., fluorosurfactants) for stabilizing aqueous or hydrocarbon droplets in a fluorophilic continuous phase are presented. In some embodiments, fluorosurfactants include a fluorophilic tail soluble in a fluorophilic (e.g., fluorocarbon) continuous phase, and a headgroup soluble in either an aqueous phase or a lipophilic (e.g., hydrocarbon) phase. The combination of a fluorophilic tail and a headgroup may be chosen so as to create a surfactant with a suitable geometry for forming stabilized reverse emulsion droplets having a disperse aqueous or lipophilic phase in a continuous, fluorophilic phase. In some embodiments, the headgroup is preferably non-ionic and can prevent or limit the adsorption of molecules at the interface between the surfactant and the discontinuous phase. This configuration can allow the droplet to serve, for example, as a reaction site for certain chemical and / or biological reactions. In another embodiment, aqueous droplets are stabilized in a fluorocarbon phase at least in part by the electrostatic attraction of two oppositely charged or polar components, one of which is at least partially soluble in the dispersed phase, the other at least partially soluble in the continuous phase. One component may provide collodial stability of the emulsion, and the other may prevent the adsorption of biomolecules at the interface between a component and the discontinous phase. Advantageously, surfactants and surfactant combinations of the invention may provide sufficient stabilization against coalescence of droplets, without interfering with processes that can be carried out inside the droplets.

Owner:BIO RAD LAB INC +2

Hydrophilic polymeric material and method of preparation

InactiveUS6218440B1Allows preparationStable maintenanceOther chemical processesPharmaceutical non-active ingredientsHydrophilic monomerPolymer science

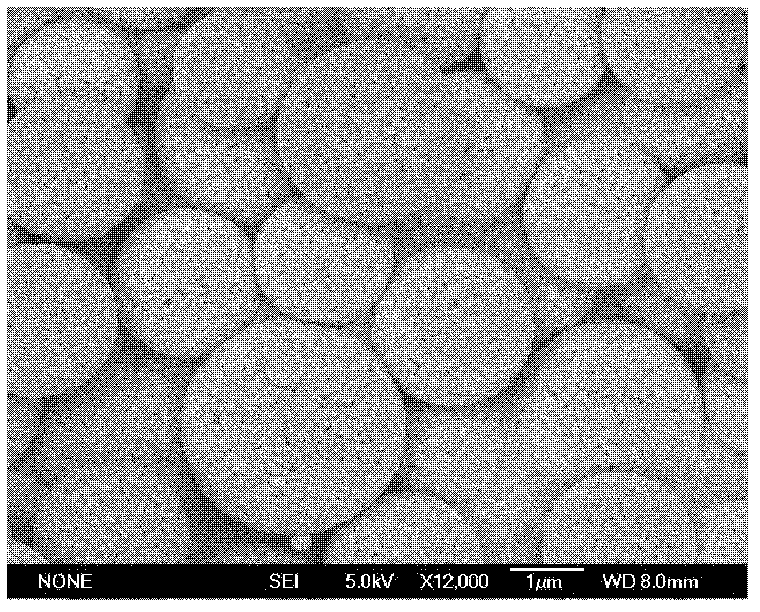

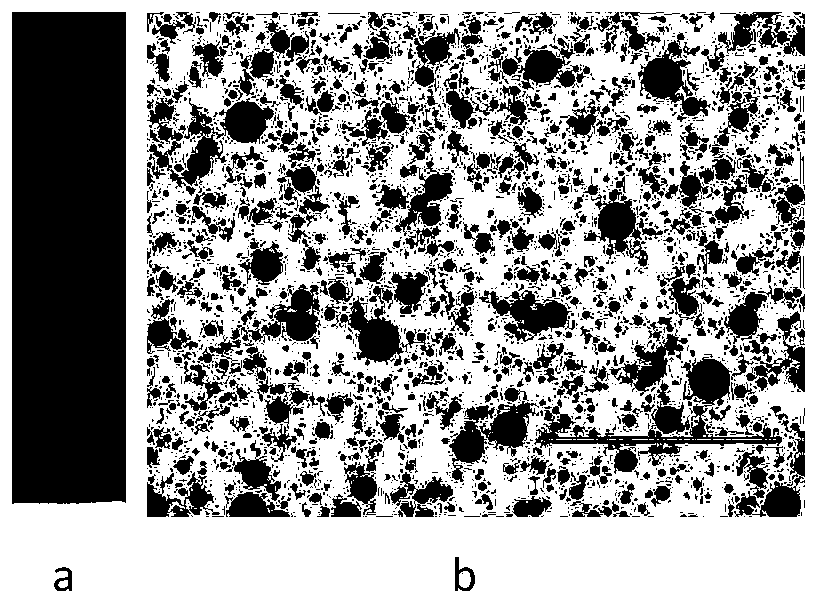

The present invention relates to a porous crosslinked hydrophilic polymeric material having cavities joined by interconnecting pores wherein at least some of the cavities at the interior of the material communicate with the surface of the material. The present invention also relates to a process for producing the polymeric material. This process involves combining a hydrophilic monomer phase with an oil discontinuous phase to form an emulsion, and polymerizing the emulsion. The emulsion can be a high internal phase emulsion (i.e., a "HIPE"). The polymeric material can be produced in a variety of forms. In one embodiment the emulsion is suspended in an oil suspension medium, and emulsion droplets are polymerized to produce polymeric microbeads.

Owner:SUNSTORM RES CORP

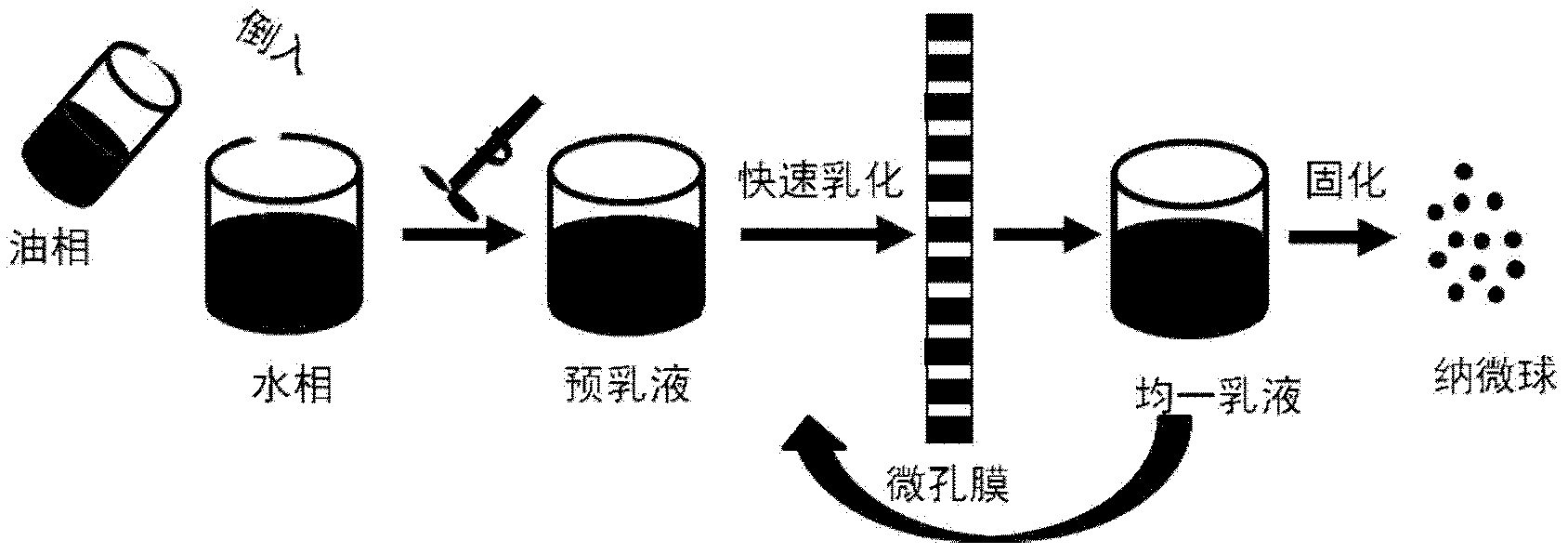

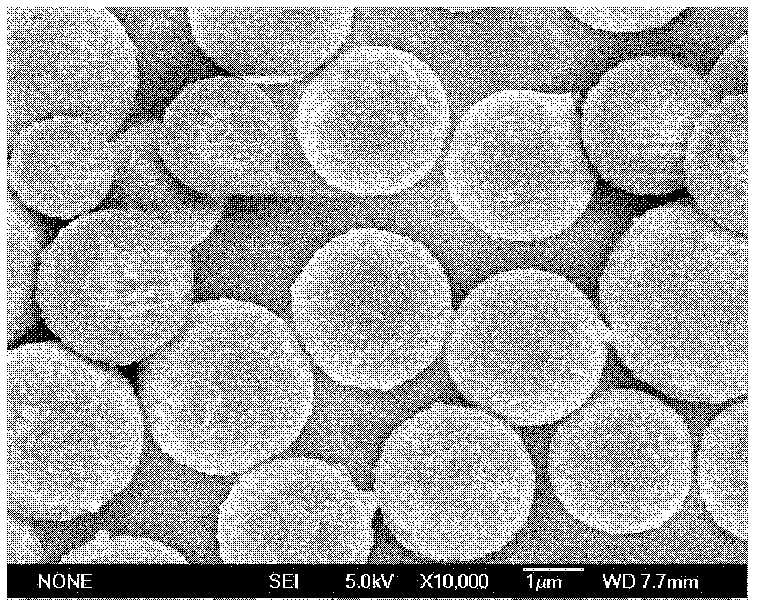

Polymer nanomicrosphere product with uniform and controllable size and preparation method thereof

The invention relates to a polymer nanomicrosphere product with uniform and controllable size and a preparation method thereof. The preparation method comprises the following steps: preparing polymerizable olefine monomers, an initiator, assistants and the like into an oil phase, and preparing water, a stabilizer, an emulsifier and the like into a water phase; and mixing the oil phase and water phase into an O / W pre-emulsion, quickly passing the pre-emulsion through a uniform-pore-size microporous membrane under pressure to form a uniform-particle-size O / W emulsion, and polymerizing and curing emulsion droplets in the emulsion into the uniform-particle-size polymer nanomicrospheres. The average particle size of the microspheres can be controlled within the range of tens of nanometers to 50 micrometers, and the particle size distribution coefficient C.V. is smaller than 20%. The method has the advantages of simple steps, favorable batch repetitiveness, uniform and controllable particle size, no need of subsequent screening and the like, is easy to control, can easily implement large-scale production, and therefore, has the characteristics of fewer emissions and low preparation cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

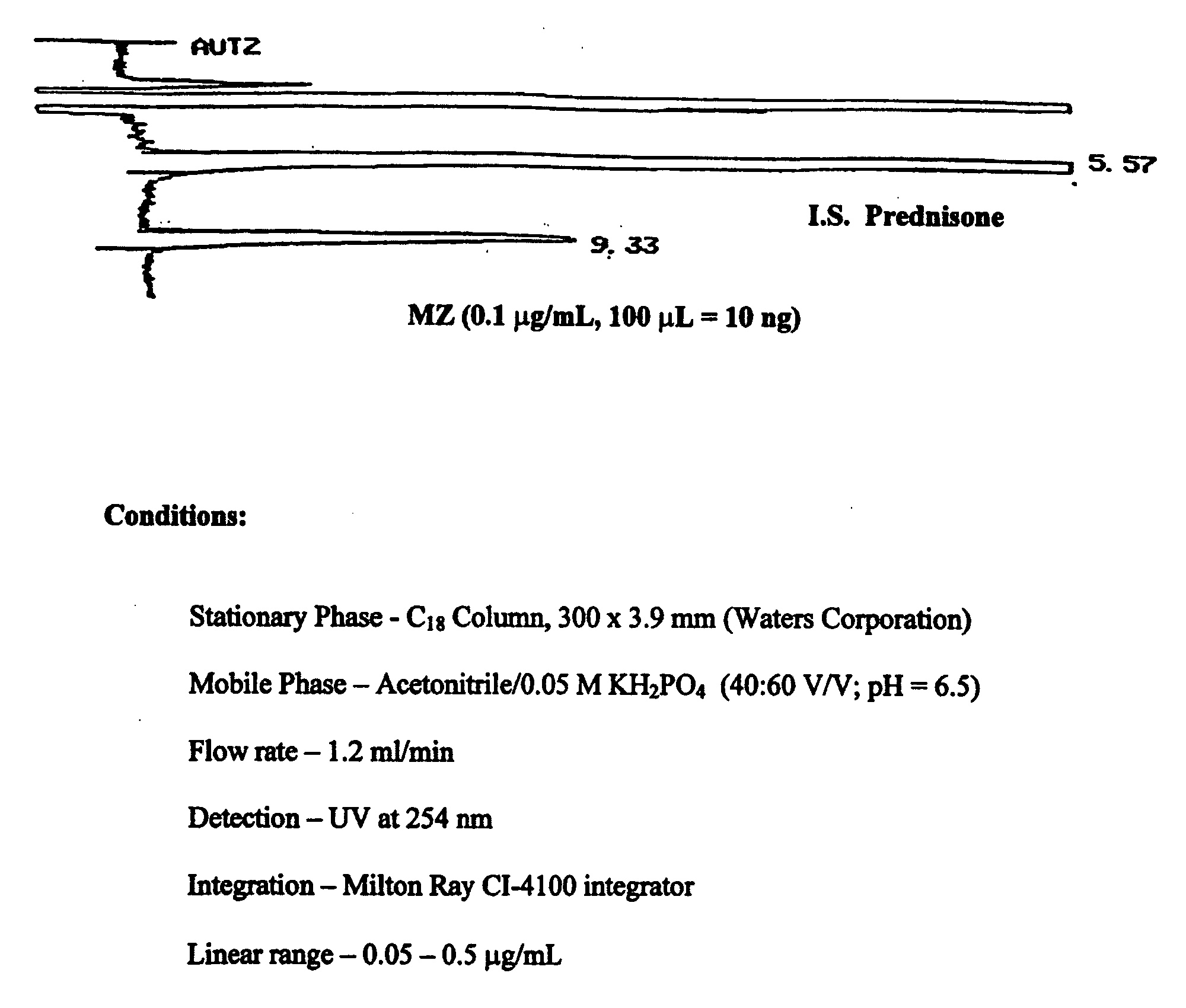

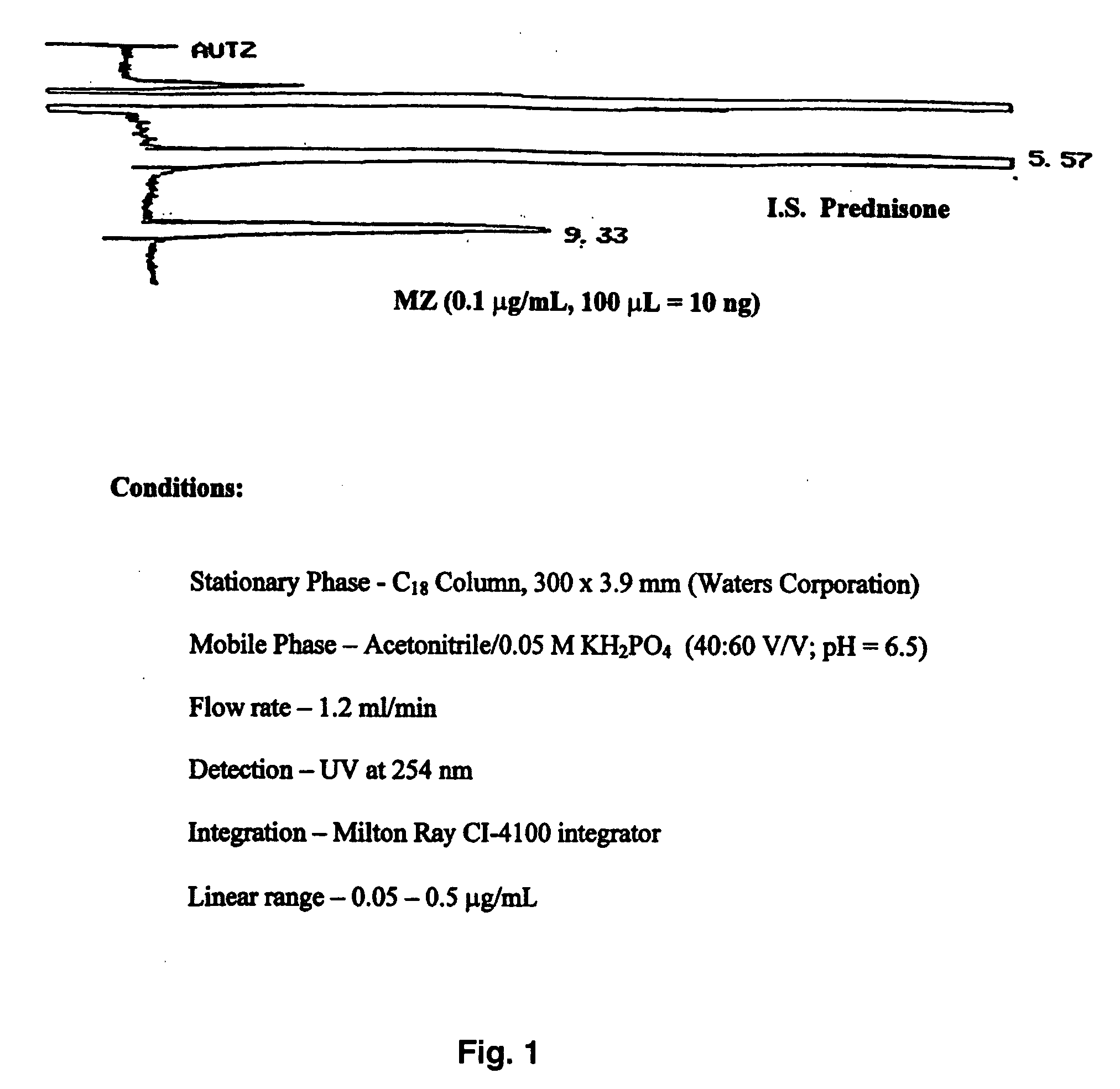

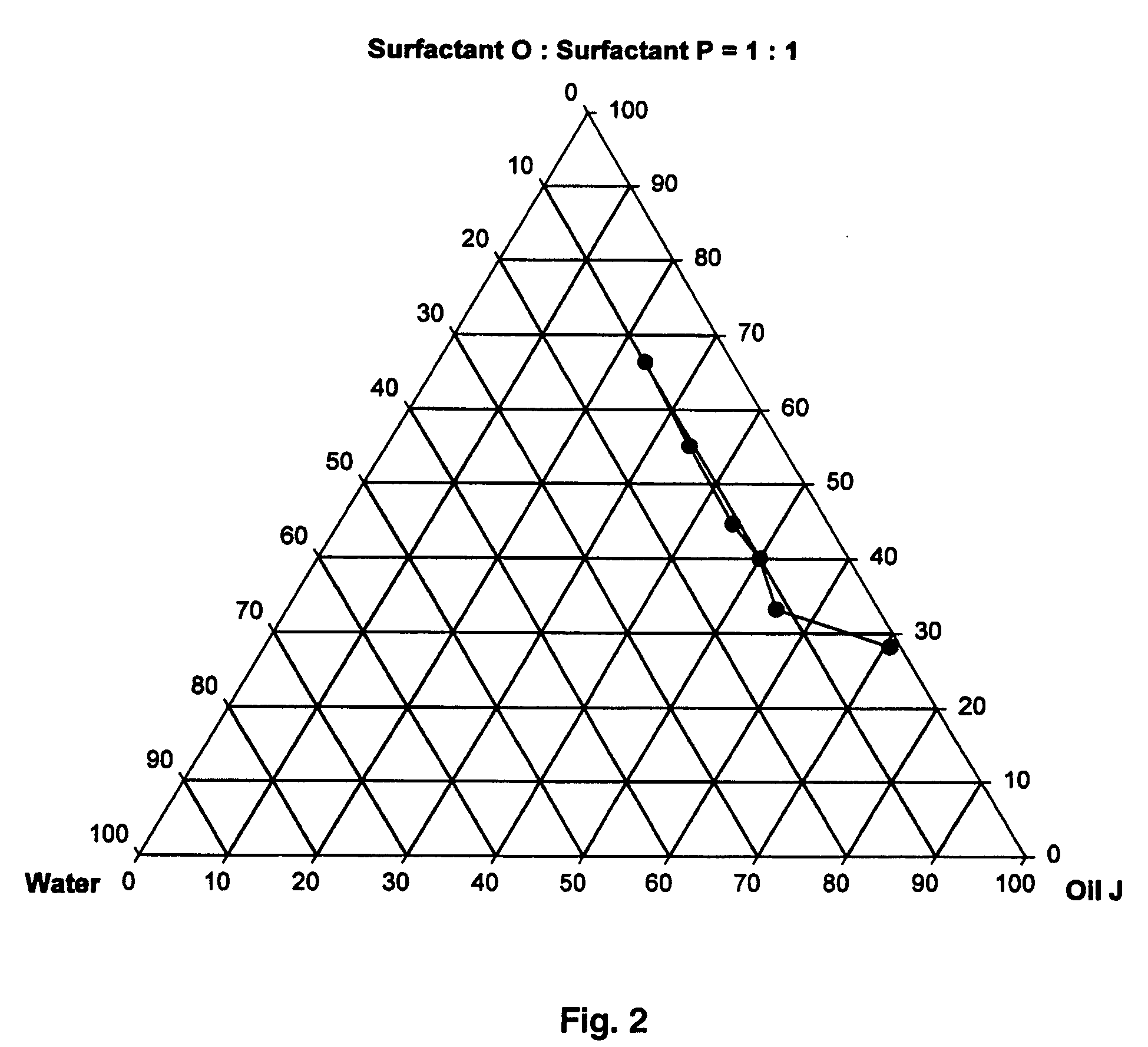

Parenteral and oral formulations of benzimidazoles

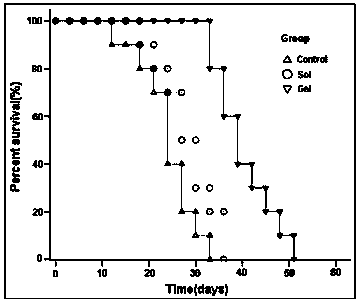

ActiveUS20090048322A1Good treatment effectImprove drug solubilityOrganic active ingredientsBiocideBenzimidazole derivativeMebendazole

Provided herein are drug delivery systems, such as self-nanoemulsifying drug delivery systems, self-emulsifying drug delivery systems and parenteral microemulsion formulations, suitable for parenteral or oral delivery to a subject. The drug delivery systems may comprise a benzimidazole derivative, e.g., mebendazole, an oil, a surfactant, a cosurfactant and a dipolar aprotic solvent in a microemulsion formulation. Also provided are methods for improving the bioavailability of a benzimidazole derivative during treatment of a pathophysiological condition by using a formulation combining a particular emulsion droplet diameter and ratio of the surfactant:cosurfactant therein, for increasing concentration and retention of a benzimidazole derivative in the lung via a parenterally administerable microemulsion with droplet size of about 35 nm to less than 100 nm and for defining hemolytically safe microemulsions of a benzimidazole derivative during a therapeutic treatment via a parenterally administerable microemulsion with a surfactant:cosurfactant content by weight of about 6% to 48%.

Owner:UNIV HOUSTON SYST

Process for preparing nano silicon dioxide-acrylate composite emulsion

The preparation process of nanometer composite silica-acrylate emulsion includes the following steps: mixing small molecular alcohol, silane as coupling agent, deionized water and acid solution through stirring; adding the hydrolyzed product of nanometer silica and silane as coupling agent into benzene derivative solvent under the protection of inert gas via stirring; centrifugal separation, flushing with alcohol or acetone and vacuum drying to obtain modified nanometer silica; dispersing acrylate monomer into fine emulsion; mixing the modified silica, anionic or non-ionic emulsifier, stabilizer and water, emulsifying and adding soluble persulfate or liposoluble peroxide; and adding the fine emulsion into the mixed solution to obtain the nanometer composite silica-acrylate emulsion. The present invention has less environmental pollution and is suitable for industrial application.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for manufacturing digital PCR (polymerase chain reaction) chip based on mineral-oil saturated PDMS (polydimethylsiloxane) material

ActiveCN103343092AOptimizationSimple methodBioreactor/fermenter combinationsBiological substance pretreatmentsPcr chipOil phase

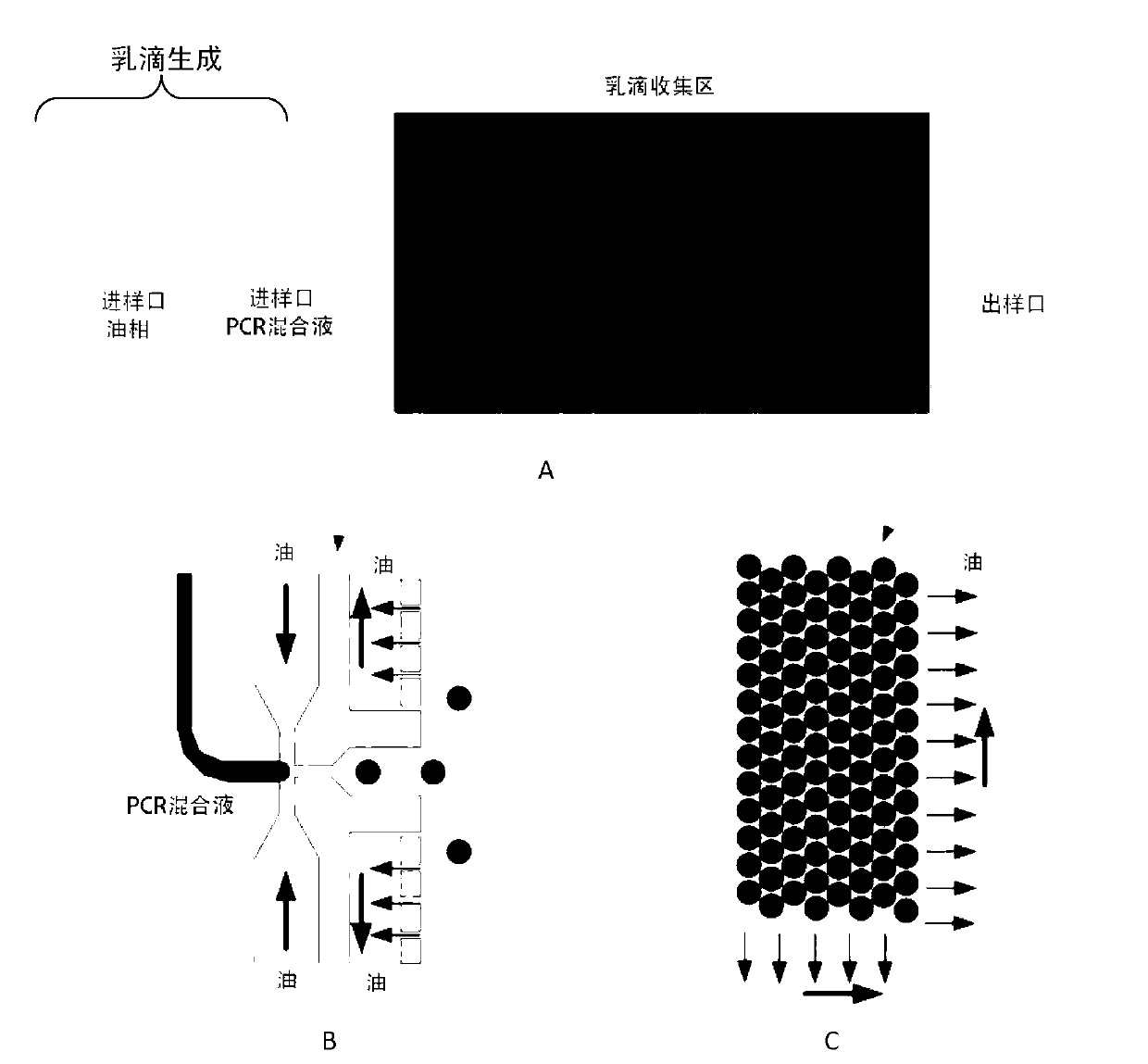

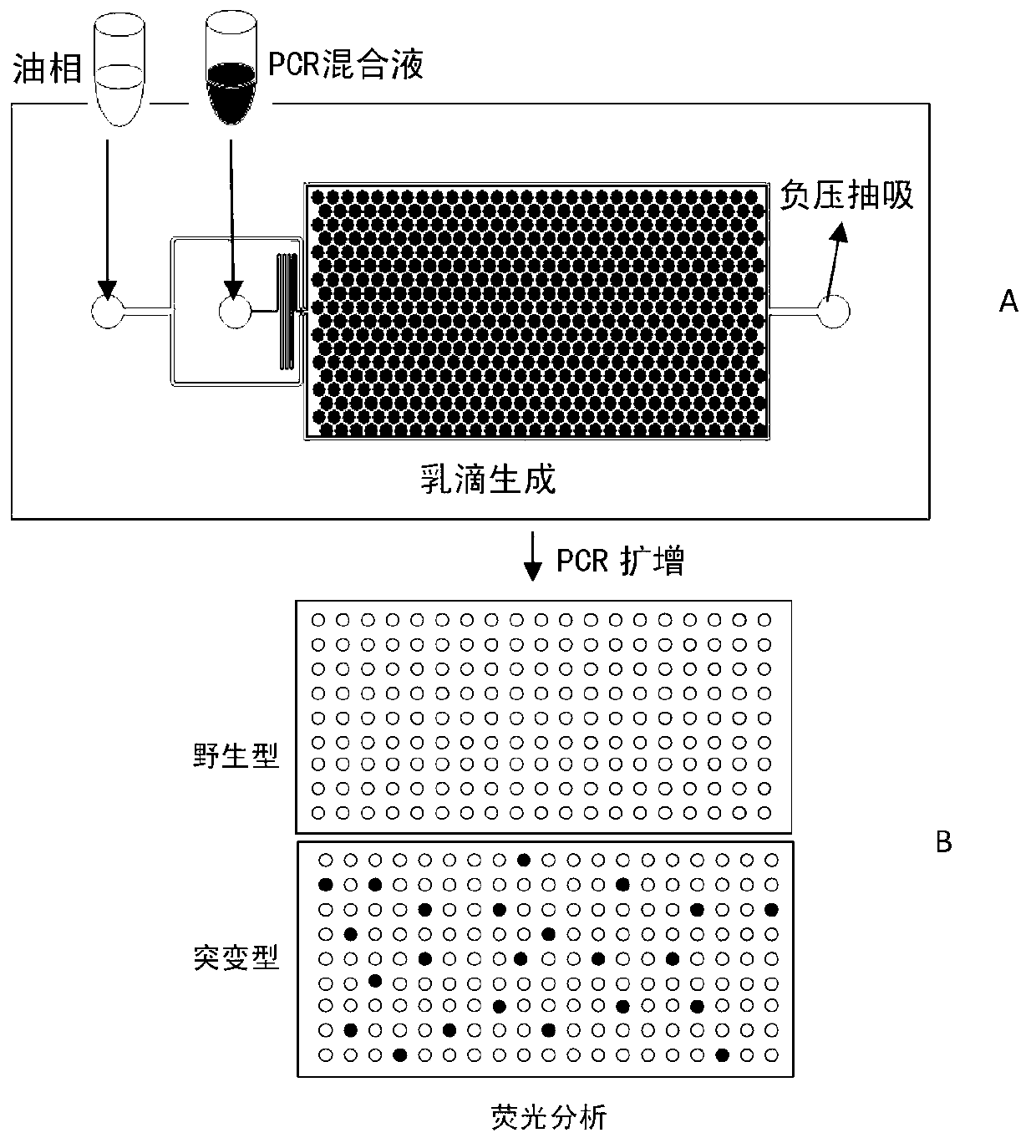

The invention relates to a method for manufacturing a digital PCR (polymerase chain reaction) chip based on a mineral-oil saturated PDMS (polydimethylsiloxane) material. The method is characterized in that the digital PCR chip based on PDMS is prepared from a PDMS monomer of a certain amount of mineral oil (liquid paraffin) and comprises an emulsion droplet generation structure and an emulsion droplet collection structure. After the emulsion droplets are made and collected on the same chip, the emulsion droplets are subjected to PCR amplification on the same chip. The phagocytosis to the oil phase in the digital PCR system by the PDMS of the chip can be avoided, the emulsion droplets can be kept stable during PCR, and the stability of the PCR can be guaranteed. In addition, compared with the existing technology of the digital PCR chip, the method provided by the invention is low in cost, is convenient to operate and has a very wide application prospect.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

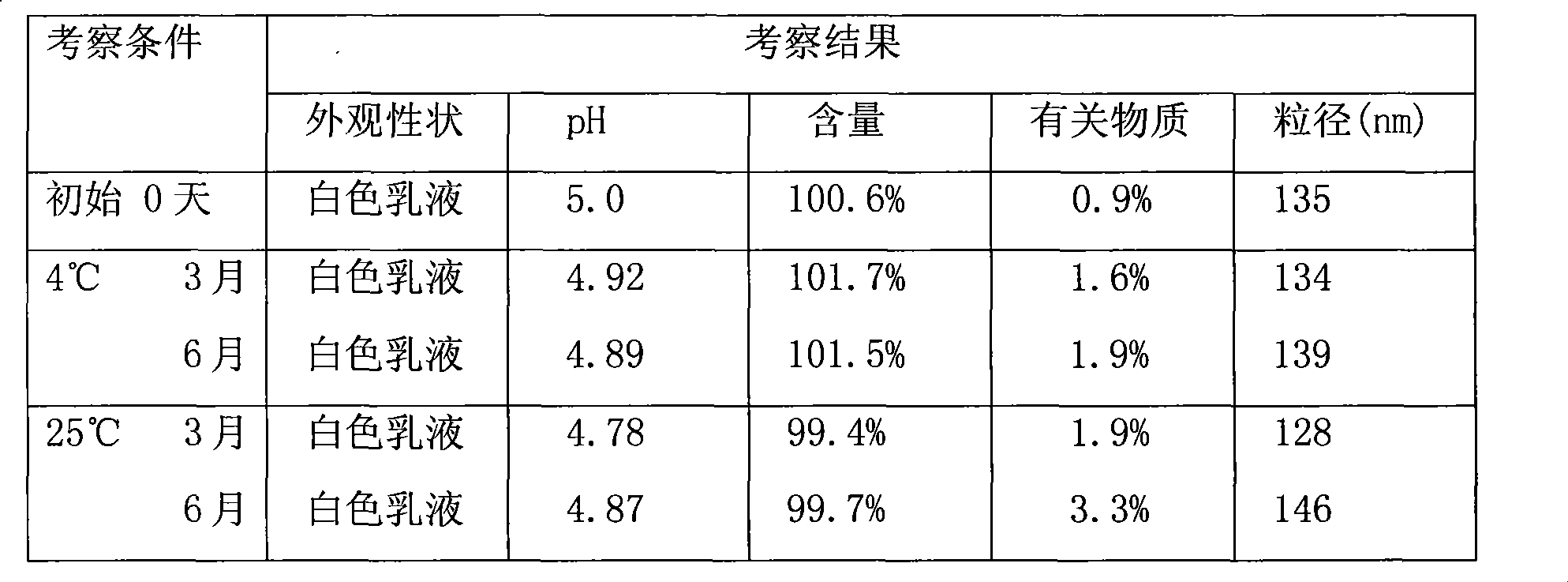

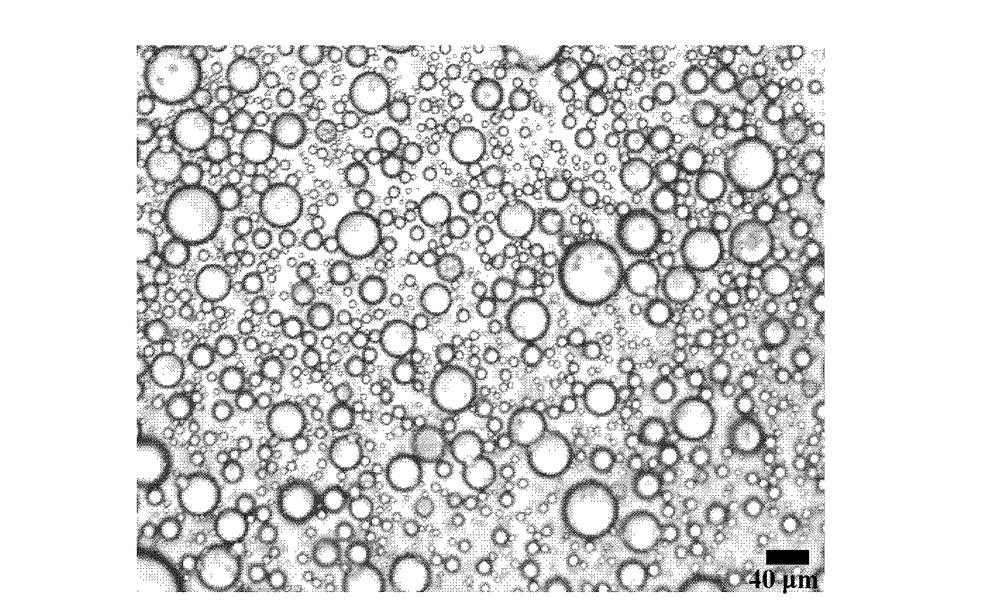

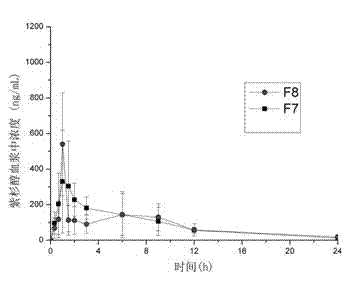

Paclitaxel submicron emulsion using lipid composite as middle carrier

ActiveCN101396343AOvercome the shortcomings that are not conducive to making liquid formulationsHigh drug loadingOrganic active ingredientsEmulsion deliveryLipid formationFreeze-drying

The invention discloses a paclitaxel submicron emulsion with a lipid compound as an intermediate carrier. With the paclitaxel lipid compound as the intermediate carrier, the paclitaxel is solved in oil phase, and water phase, emulsifier and auxiliary emulsifier are added. Emulsion droplet grain diameter is less than 600nm; the proportion of the oil phase and the water phase is 5 to 95 to 35 to 65; and the drug loading quantity is 0.25mg / ml to 5mg / ml if counted according to the paclitaxel. The prepared submicron emulsion has high drug loading quantity, is resistant for autoclaving and has stable quality after long time storage. The submicron emulsion can be made into intravenous drip transfusion directly, as well as into dry emulsion by a freeze drying technology, and when being used, the submicron emulsion is added with physiological saline or glucose to be diluted into intravenous drip.. The submicron emulsion uses nontoxic refined plant oil as the oil phase and phospholipid as the emulsifier, drug is coated in the oil phase, and thereby the submicron emulsion reduces the irritation and the adverse reaction of the paclitaxel preparation and has good safety.

Owner:BEIJING WEHAND BIO PHARMA CO LTD

Method for preparing microcapsule

InactiveCN101811014ALow costReduce pollutionMicroballoon preparationMicrocapsule preparationHas active ingredientSolid particle

The invention discloses a method for preparing a microcapsule. The method comprises the following steps of: mixing and dispersing inorganic particles serving as stabilizing agents, aqueous solution and oil phase containing active ingredients to prepare water-in-oil type emulsion; or mixing and dispersing the inorganic particles serving as the stabilizing agents, the oil phase containing the active ingredients and water to prepare the water-in-oil type emulsion; performing the hydrolysis reaction on silicate ester and / or titanate on the oil-water interface under the stirring condition, forming membranoid substances by combining the hydrolysis product with the inorganic particles distributed on the oil-water interface, and packing emulsion droplets containing the active ingredients; and then removing the continuous phase through filtering, centrifuging or distilling, and washing to obtain the microcapsule, wherein the oil phase is the silicate ester, the titanate, silicate ester and titanate or an organic solvent containing the silicate ester or / and the titanate. In the method for preparing the microcapsule, the solid particles are replaced by surfactants, so that the method reduces the pollution of pesticide water emulsion products to the environment, and also reduces the production cost of the pesticide water emulsion simultaneously.

Owner:XIAN UNIV OF SCI & TECH

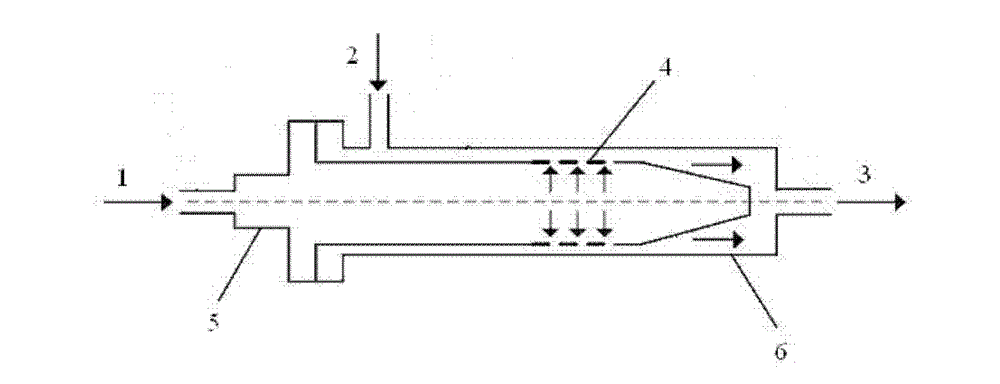

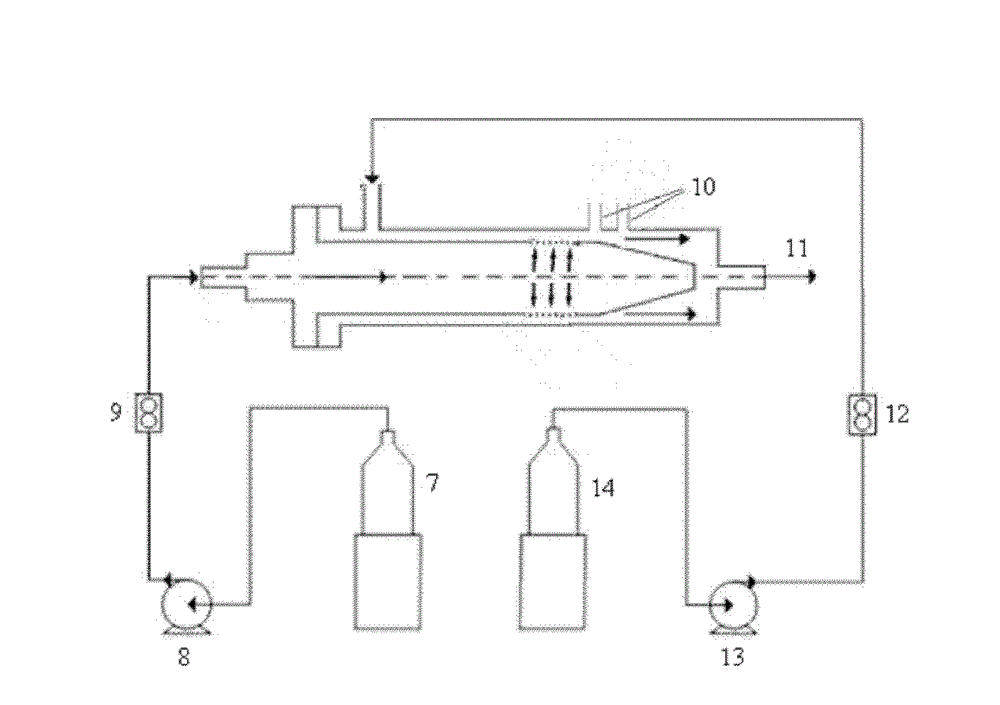

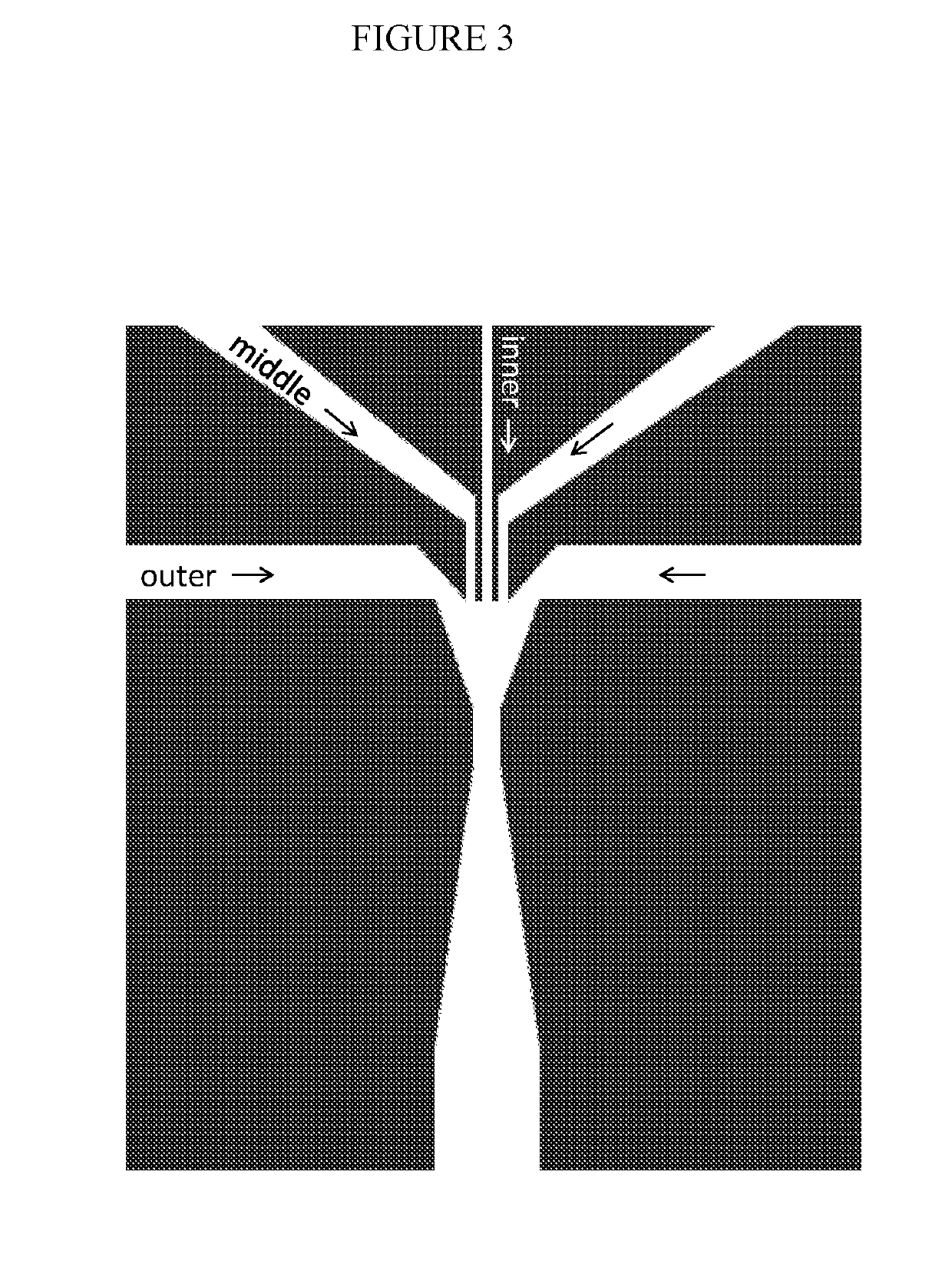

Method for preparing monodisperse emulsion

InactiveCN102794119AUniform particle sizeQuality improvementFlow mixersMixing methodsContact formationEmulsion droplet

The invention discloses a method for preparing monodisperse emulsion and belongs to the technical field of emulsion. The monodisperse emulsion is prepared by using a tube-in-tube annular channel reactor; a continuous phase is introduced into an outer tube of the tube-in-tube annular channel reactor, a disperse phase is introduced into an inner tube of the tube-in-tube annular channel reactor, and the continuous phase and the disperse phase fully contact on micropore parts to form the emulsion; and according to the method, equipment is simple, cost is low, flux is high, and continuous operation can be realized, so that the preparation cycle can be greatly shortened, and production efficiency is improved. The emulsion prepared by the method is high in quality, stable in performance, and high dispersibility; and emulsion droplets are uniform in particle size.

Owner:BEIJING UNIV OF CHEM TECH

Litsea cubeba oil microcapsule and preparation method thereof

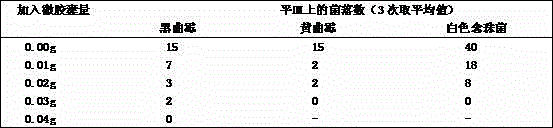

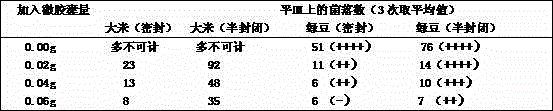

The invention discloses a litsea cubeba oil microcapsule and a preparation method thereof, and belongs to the technical field of mouldproof and insecticidal capsules. The litsea cubeba oil microcapsule is characterized by being prepared by the complex coacervation of litsea cubeba oil taken as a core material, sodium alginate taken as a main wall material and an aqueous solution which contains 1% to 5% of chitosan and 2% to 5% of anhydrous calcium chloride and is taken as a coagulating bath solution, wherein the mass ratio of the sodium alginate to the litsea cubeba oil is 1:(1-4). The preparation method mainly comprises the following steps: firstly preparing an emulsion A of the sodium alginate and the litsea cubeba oil; then preparing the aqueous solution of the chitosan and the anhydrous calcium chloride as the coagulating bath solution B; dripping the emulsion A into the coagulating bath solution B; and solidifying the mixture for certain time and then filtering the mixture, thereby obtaining the litsea cubeba oil microcapsule. Thus, the litsea cubeba oil microcapsule which is high in litsea cubeba oil content, long in service time and good in mouldproof and insecticidal effect and the preparation method of the litsea cubeba oil microcapsule are provided. The litsea cubeba oil microcapsule is mainly used for performing mouldproof and insecticidal functions on grains as well as on clothes.

Owner:JIAYING UNIV +1

Efficient deep dyeing promoter, and preparation and after treatment application methods thereof

ActiveCN104074053ASmall fastnessImproves the appearance of dark colorsFibre treatmentMethacrylateAcetic acid

The invention discloses an efficient deep dyeing promoter, and preparation and after treatment application methods thereof. The efficient deep dyeing promoter comprises 14-40 percent of DHMP, 0.5-6 percent of a cross-linking agent, 0.05-2 percent of a cationic emulsifier, 0.05-2 percent of a non-ionic emulsifier, 0.0015-0.4 percent of a water-soluble azo initiator, 0.005 to 0.5 percent of glacial acetic acid and 60 to 85 percent of deionized water. The efficient deep dyeing promoter provided by the invention is prepared by adopting a cationic polymerization method, and the preparation method comprises pre-emulsified liquid preparation, primer preparation and pre-emulsion dripping method polymerization reaction. The efficient deep dyeing promoter is applied through a two-step treatment application process with silicone emulsion. After the adoption of the efficient deep dyeing promoter, and the application method thereof, the deepening rate can greatly exceed the deepening rate in the prior art and can reach 80 percent and above, the colour difference is small, the hand feeling is improved, and influences on dry and wet rubbing fastness and soaping fastness of the fabric are small.

Owner:DYMATIC CHEM

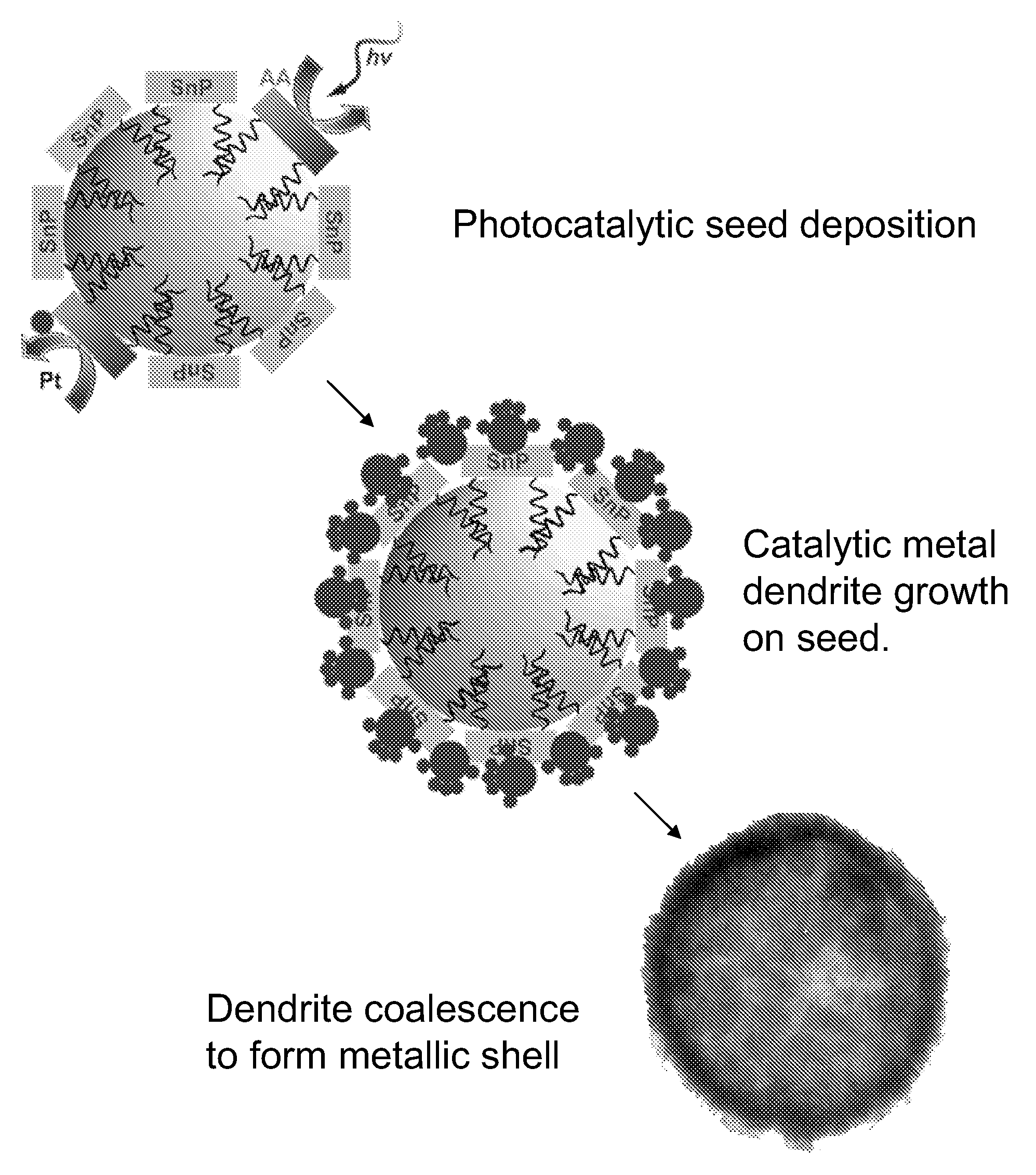

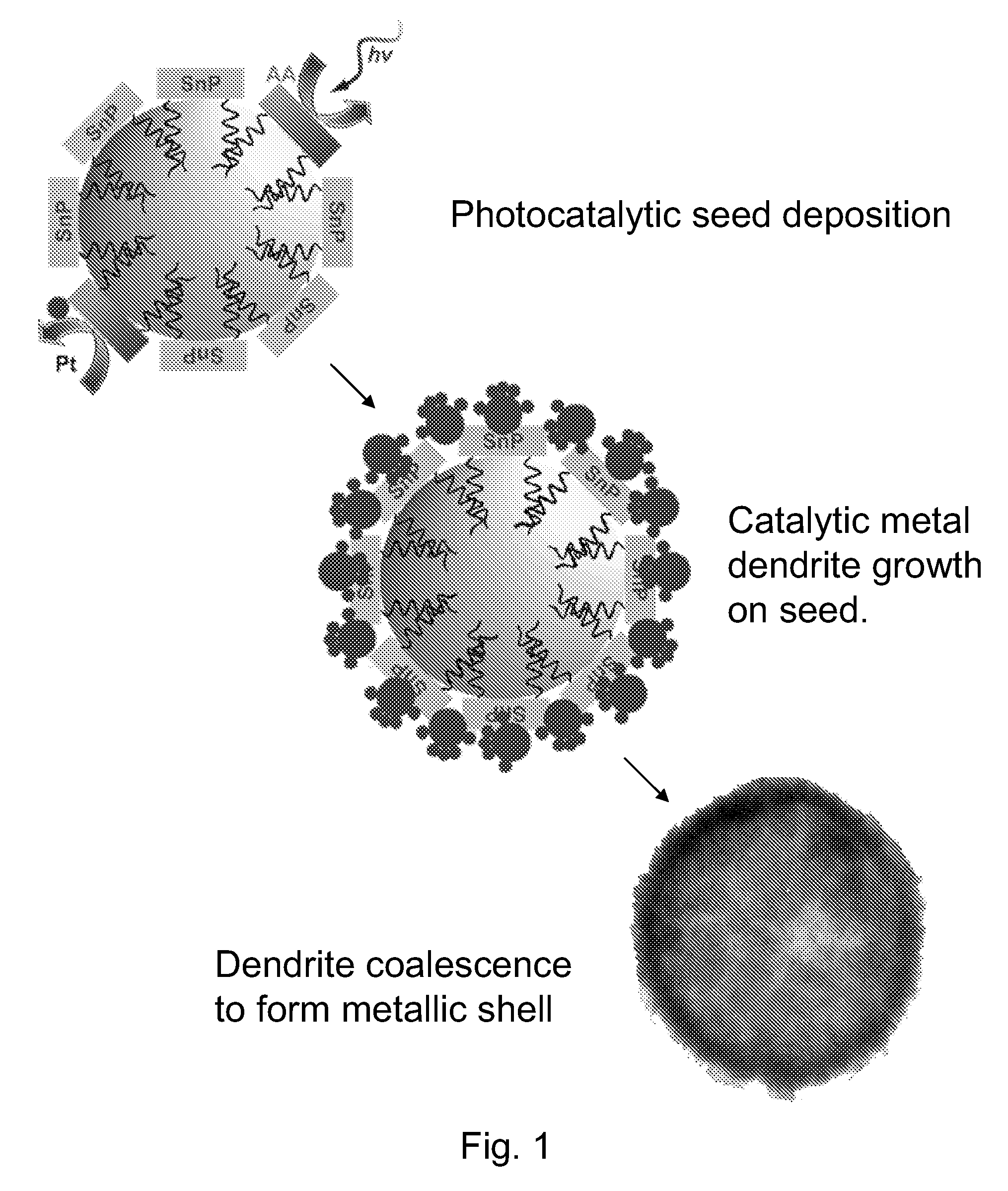

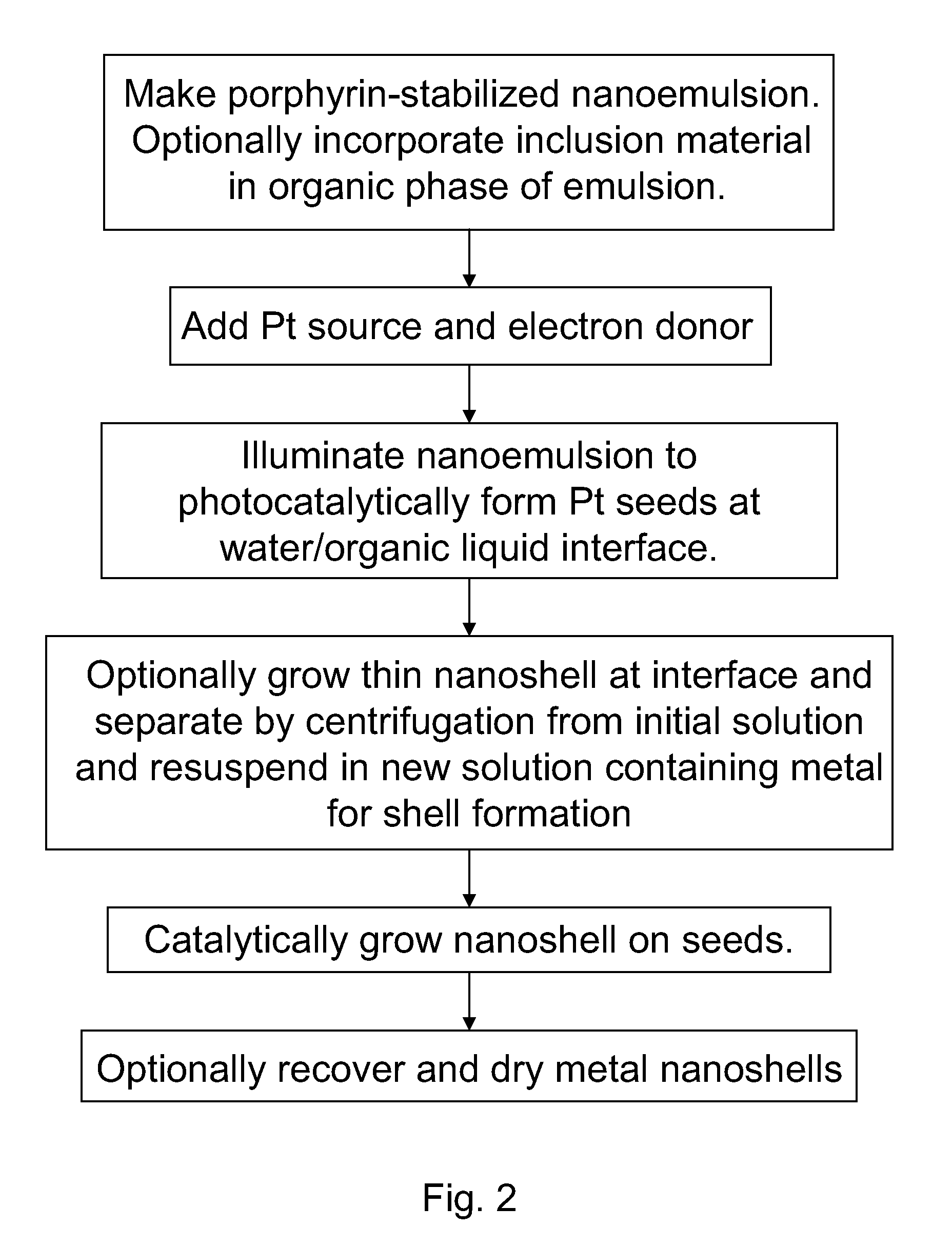

Synthesis of metallic nanoshells on porphyrin-stabilized emulsions

Metal nanostructures formed by photocatalytic interfacial synthesis using a porphyrin-stabilized emulsion template and the method for making the nanostructures. Catalyst-seeded emulsion droplets are employed as templates for hollow-nanoshell growth. The hollow metal nanospheres may be formed with or without inclusions of other materials.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

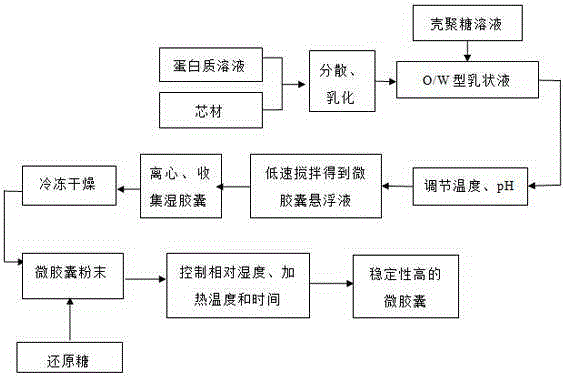

Highly stable protein-chitosan complex coacervation crosslinked microcapsule and preparation method thereof

The present invention provides a highly stable protein-chitosan complex coacervation crosslinked microcapsule and a preparation method thereof. The method is as below: first mixing a core material with a protein solution, conducting high-speed dispersion to form an O / W type emulsion, then adding a chitosan solution, adjusting the pH value, conducting a coacervation reaction on the protein and chitosan through electrostatic interaction to form a complex coacervation phase settled surrounding the core material emulsion droplets to obtain microcapsules, collecting the microcapsules by centrifugation, lyophilizing to obtain a microcapsule powder, then mixing the microcapsule powder with reducing sugar, then separating the protein from reducing sugar by the chitosan, and heating to trigger Maillard reaction of chitosan respectively with reducing sugar and protein, so as to initiate crosslinking to improve the stability of the microcapsules. The method of the present invention is simple, safe, efficient and applicable to mass production, and can be widely used in embedding of the core materials with good thermal stability. The present invention has important significance to the development of highly stable protein-chitosan complex coacervation crosslinking microcapsule system and promotion of coacervation microencapsulation technology in practical application in the food industry.

Owner:QINGDAO AGRI UNIV

Removal of PCB and other halogenated organic contaminants found in ex situ structures

Emulsified systems of a surfactant-stabilized, biodegradable water-in-solvent emulsion with bimetallic particles contained with the emulsion droplets are useful at removing PCBs from ex situ structures. The hydrophobic emulsion system draws PCBs through the solvent / surfactant membrane. Once inside the membrane, the PCBs diffuse into the bimetallic particles and undergo degradation. The PCBs continue to enter, diffuse, degrade, and biphenyl will exit the particle maintaining a concentration gradient across the membrane and maintaining a driving force of the reaction.

Owner:NASA +1

Preparing method of nanoscale vitamin microemulsion

InactiveCN101647598AEasy to operateStir wellAnimal feeding stuffFood shapingAntioxidantHigh pressure

The invention relates to a preparing method of nanoscale vitamin microemulsion. The microemulsion is prepared by adding vitamin, emulsifier, co-emulsifier and antioxidant in pure water to form a dispersed system with stable thermodynamics. The preparing technology is mainly characterized in that production process needs no high pressure homogenization processing, and can be finished by simply mechanically stirring, which greatly lowers energy consumption and saves production cost; the average grain diameter of the emulsion droplet of prepared microemulsion is 20 nm. The invention greatly improves bioavailability and stability of vitamin, can be widely used in industries of feed and additive thereof, pet health products, cosmetics, medicine, health products, beverage and the like.

Owner:曹金党

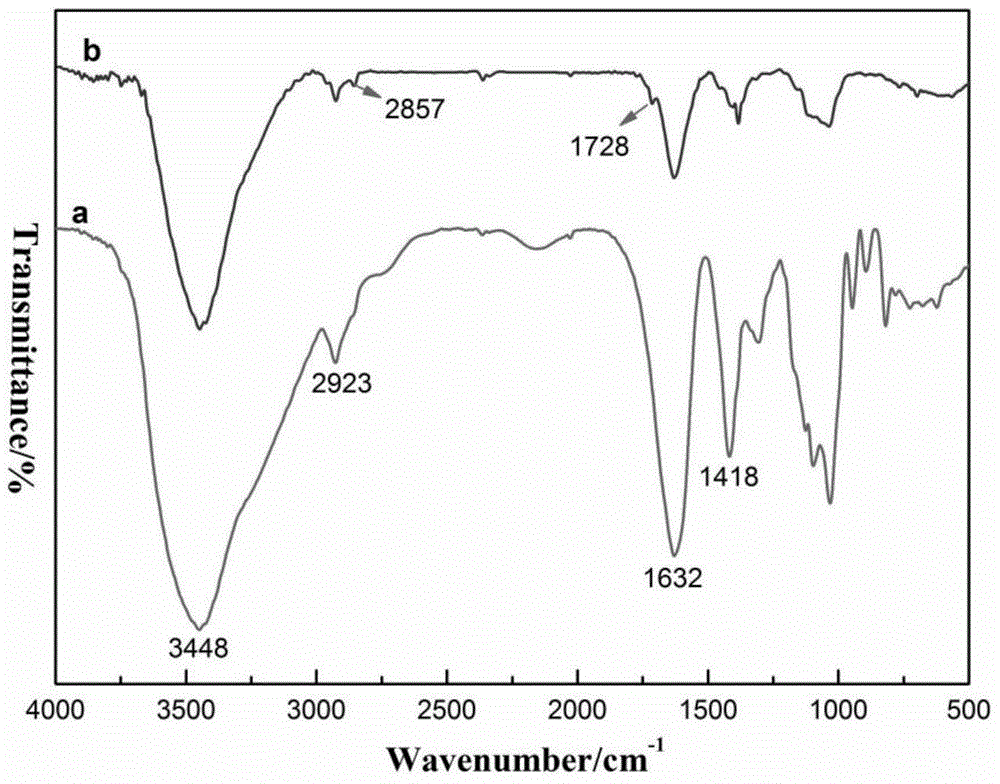

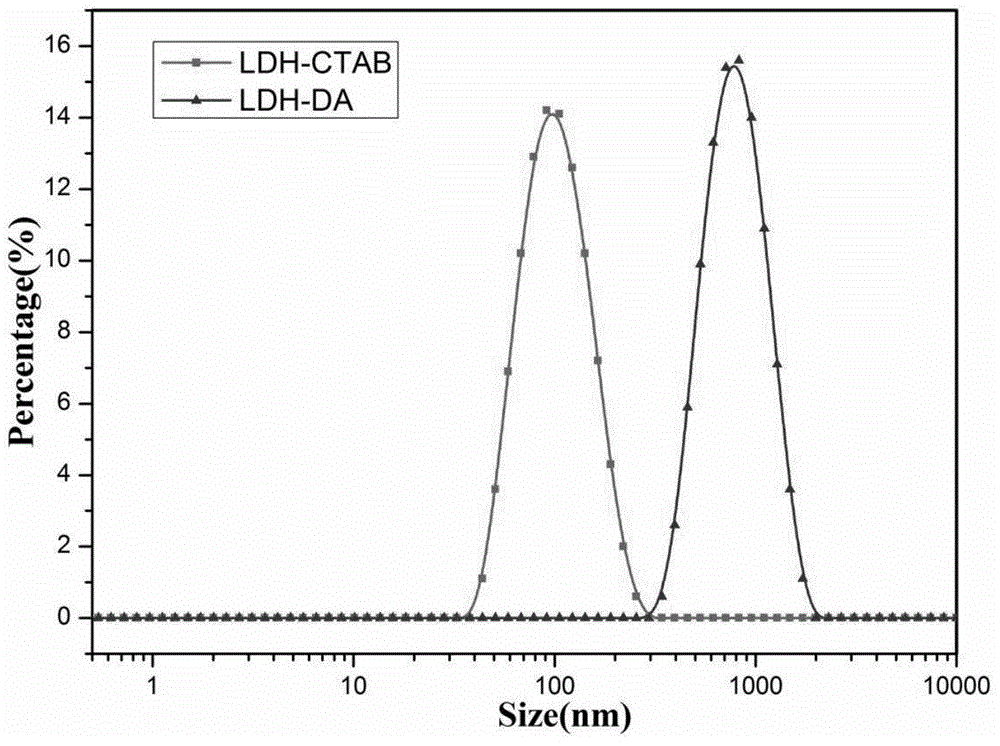

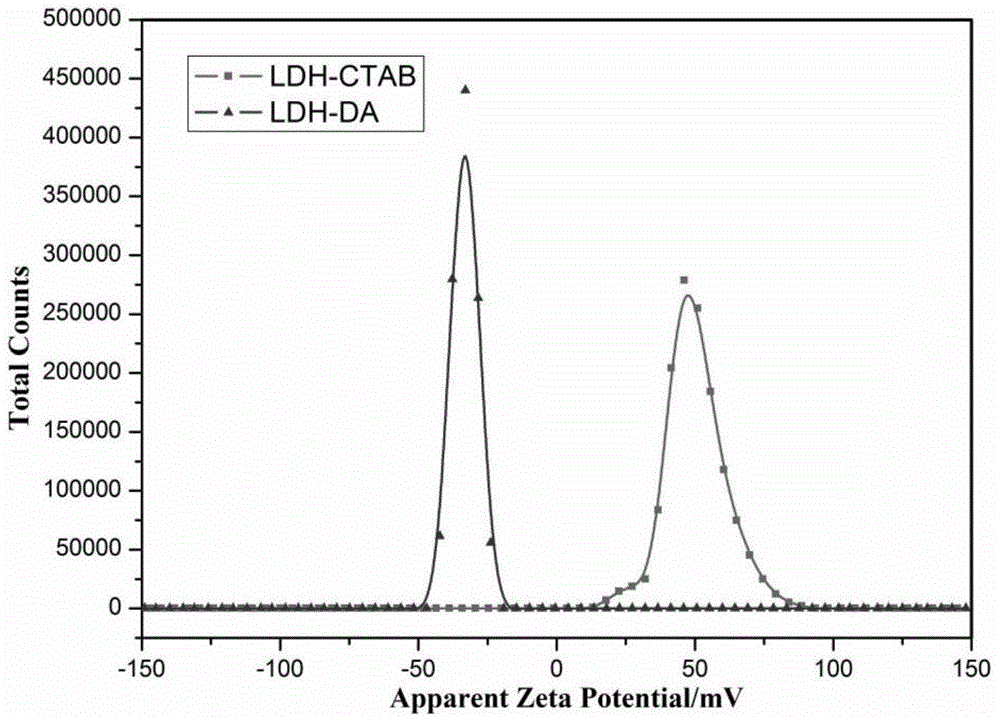

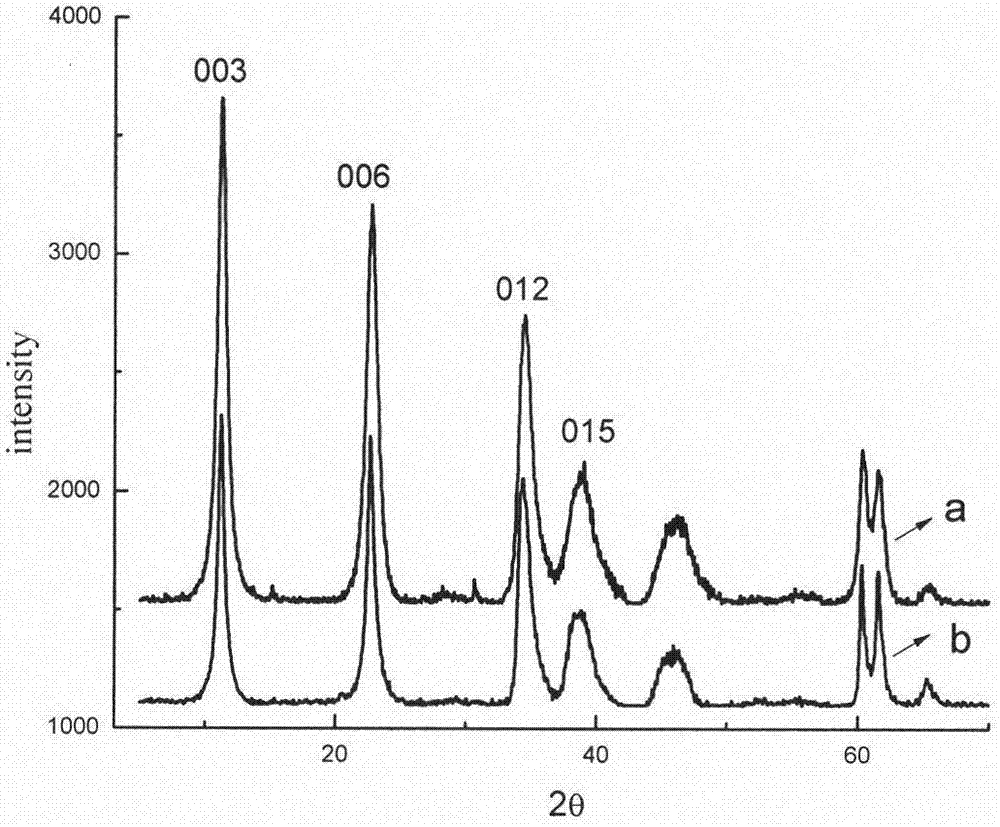

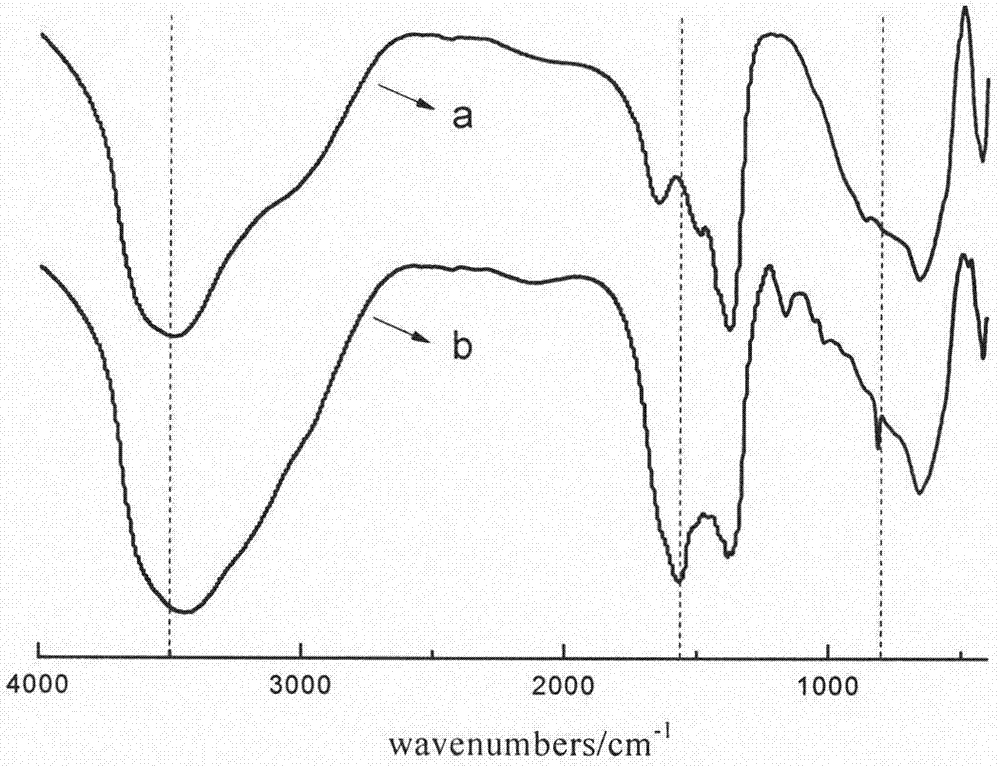

Preparation method of drug-loading Pickering emulsion

ActiveCN104823970AGood sustained release effectExtend the delivery applicationBiocideAnimal repellantsEmulsion dropletAqueous dispersion

The invention relates to the technical field of drug controlled release, and in particular relates to a preparation method of a drug-loading Pickering emulsion. A coupling esterification reaction is conduced to produce lauryl alcohol sodium alginate; modified sodium alginate and flake inorganic LDH nanoparticles with positively charged surface are used as emulsifiers; in an aqueous dispersion system, solid particles and anionic polymeric surfactant are closely integrated to form a layer of dense oil / water interfacial film through electrostatic interaction, so as to prepare the stable sustained-release drug-loading Pickering emulsion. A hydrophobic pesticide lambda-cyhalothrin can be embedded in the emulsion droplets to form a drug-store microemulsion small environment, so as to further improve the drug loading amount and release properties of Pickering emulsion on the drug, and expand the application of Pickering emulsion to pesticide drug delivery. The invention has good application prospects in the fields of pesticides and biological medicament transmission.

Owner:HAINAN UNIVERSITY

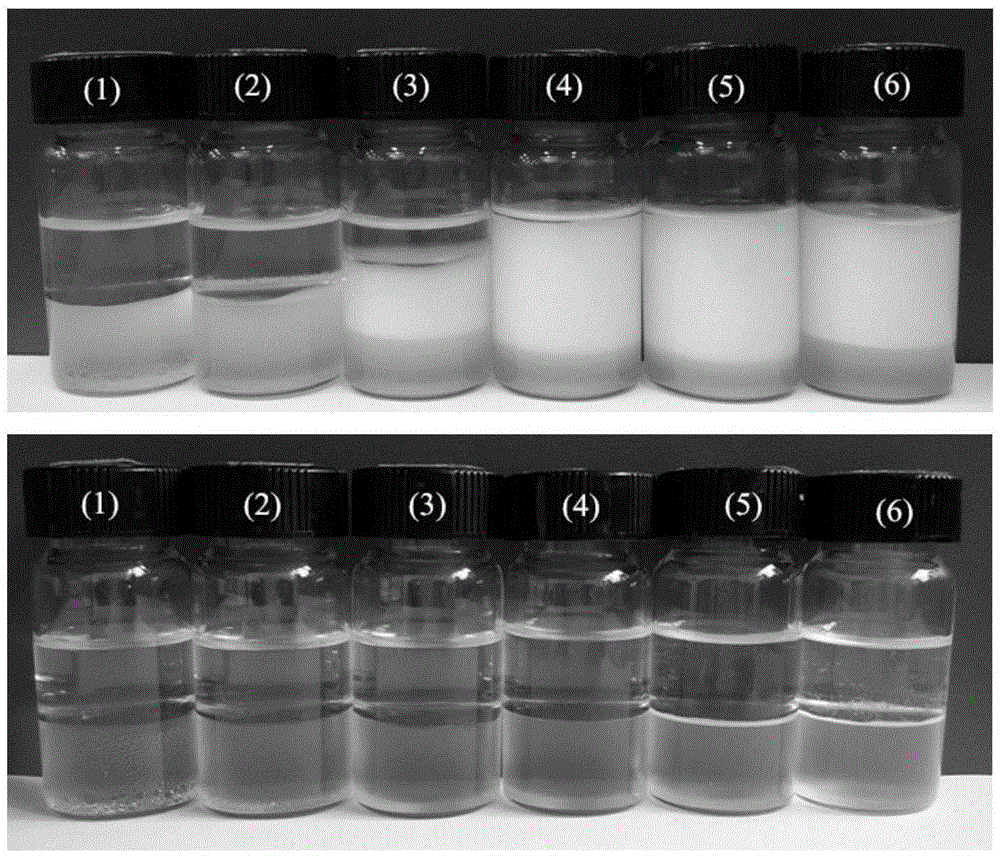

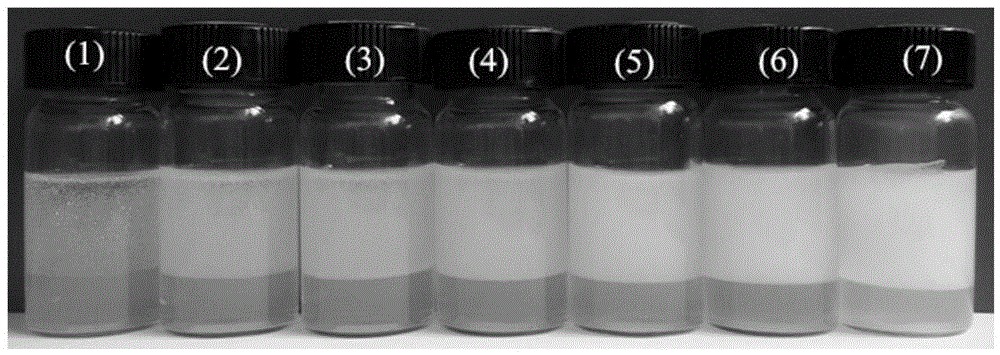

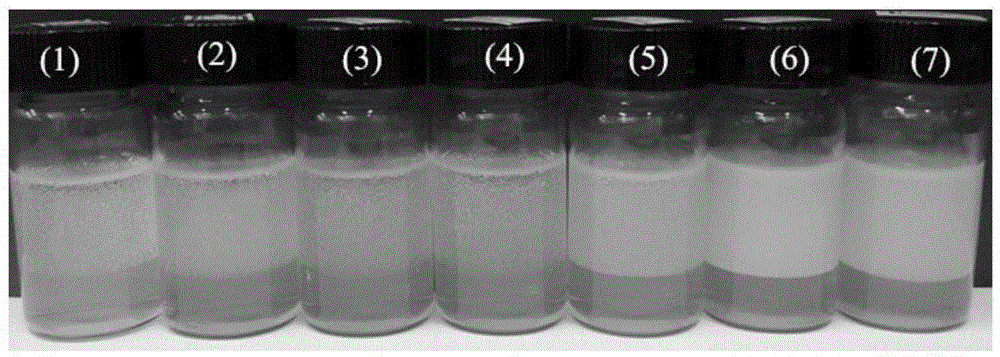

Composite emulsifier with double stimulus-response performance

ActiveCN105536641AImprove efficiencyChange droplet sizeTransportation and packagingMixingSilica particleRoom temperature

A composite emulsifier with double stimulus-response performance belongs to the field of colloid and interface chemistry. The emulsifier comprises the non-modified commercial nano-silica particles and a double stimulus-response surfactant. The nano-silica particles have primary particle diameter of 20-200nm, usage concentration of 0.1%-3.0% (with water phase as the reference). An emulsion stabilized by the emulsifier belongs to a Pickering emulsion; introduction of N2 or air into the emulsion at 50-70 DEG C leads to inactivation of the emulsifier and demulsification of the emulsion; but introduction of CO2 into the system at room temperature restores activity of the emulsifier, and the stable Pickering emulsion can be obtained after homogenization of the system; and under irradiation of UV of higher than 300nm, the emulsion droplets have larger diameter, so that the composite emulsifier has a double stimulus-response performance.

Owner:无锡颐景丰科技有限公司

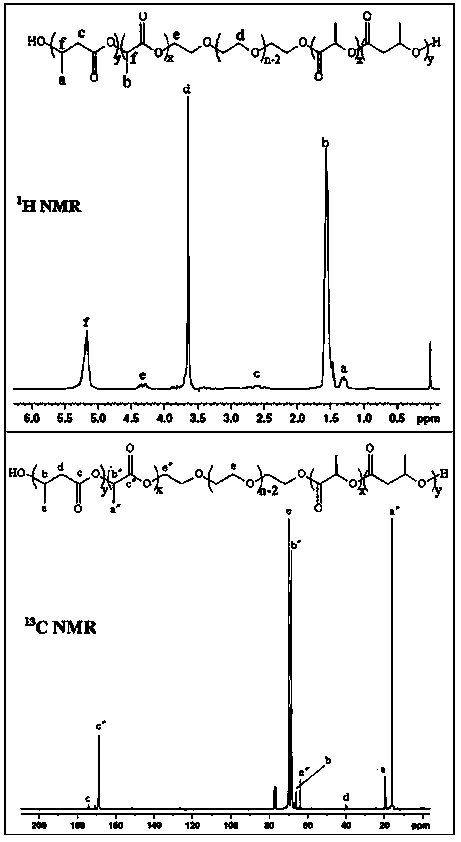

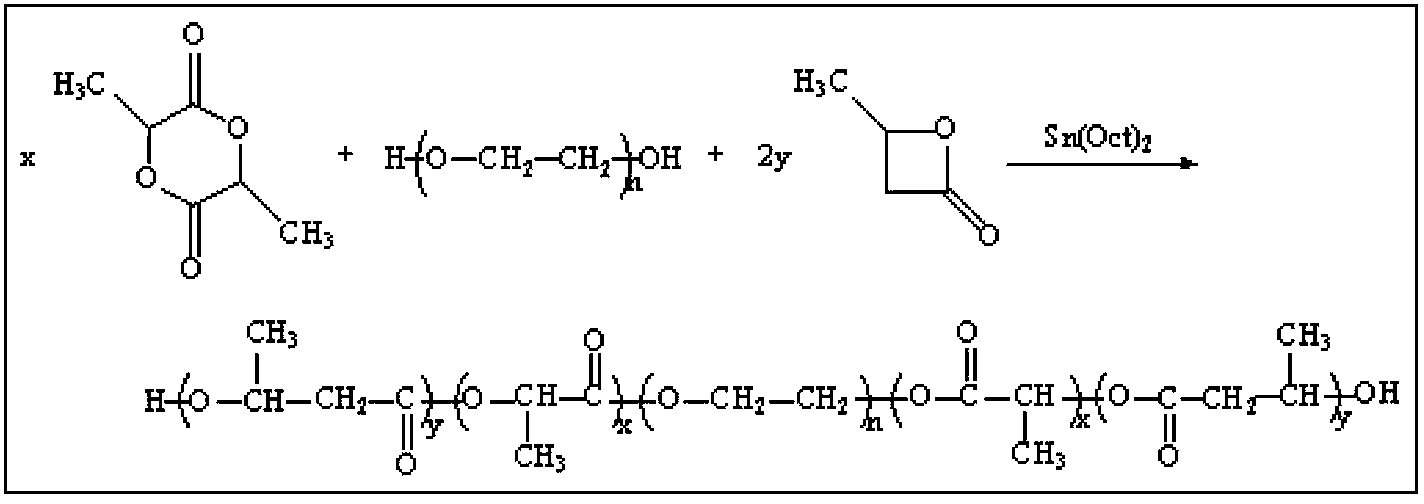

Preparation and application of biodegradable thermosensitive in-situ hydrogel

InactiveCN103405773AThe synthesis process is easy to controlAdjustable structurePharmaceutical non-active ingredientsNasal cavityLactide

The invention relates to preparation and an application of a biodegradable thermosensitive in-situ hydrogel. The hydrogel is prepared by the following steps: by taking a water soluble amphiphilic thermosensitive block polymer polybutyrolactone lactide-polyethylene glycol-polymer polybutyrolactone lactide as a carrier material, dispersing or dissolving the medicine in aqueous liquor thereof; or dispersing particles such microballoon, lipidosome and emulsion droplets which load the medicine in the aqueous liquor. When the temperature is lower than the phase inversion temperature, the hydrogel exists in form of a liquid which can be delivered by way of injection and the like. When temperature at the delivery part is raised to body temperature, the hydrogel gelates and the medicine is slowly released by way of diffusion or / and corrosion, and the release rate of the medicine can be adjusted by changing concentration, molecular weight, proportion of hydrophilic blocks and hydrophobic blocks or block constitution of the polymer. The hydrogel can be delivered by way of eyes, transdermal delivery, vagina, urethra, rectum, nasal cavity and ears.

Owner:FANTAI INST OF CHEM MEDICINES NANJING

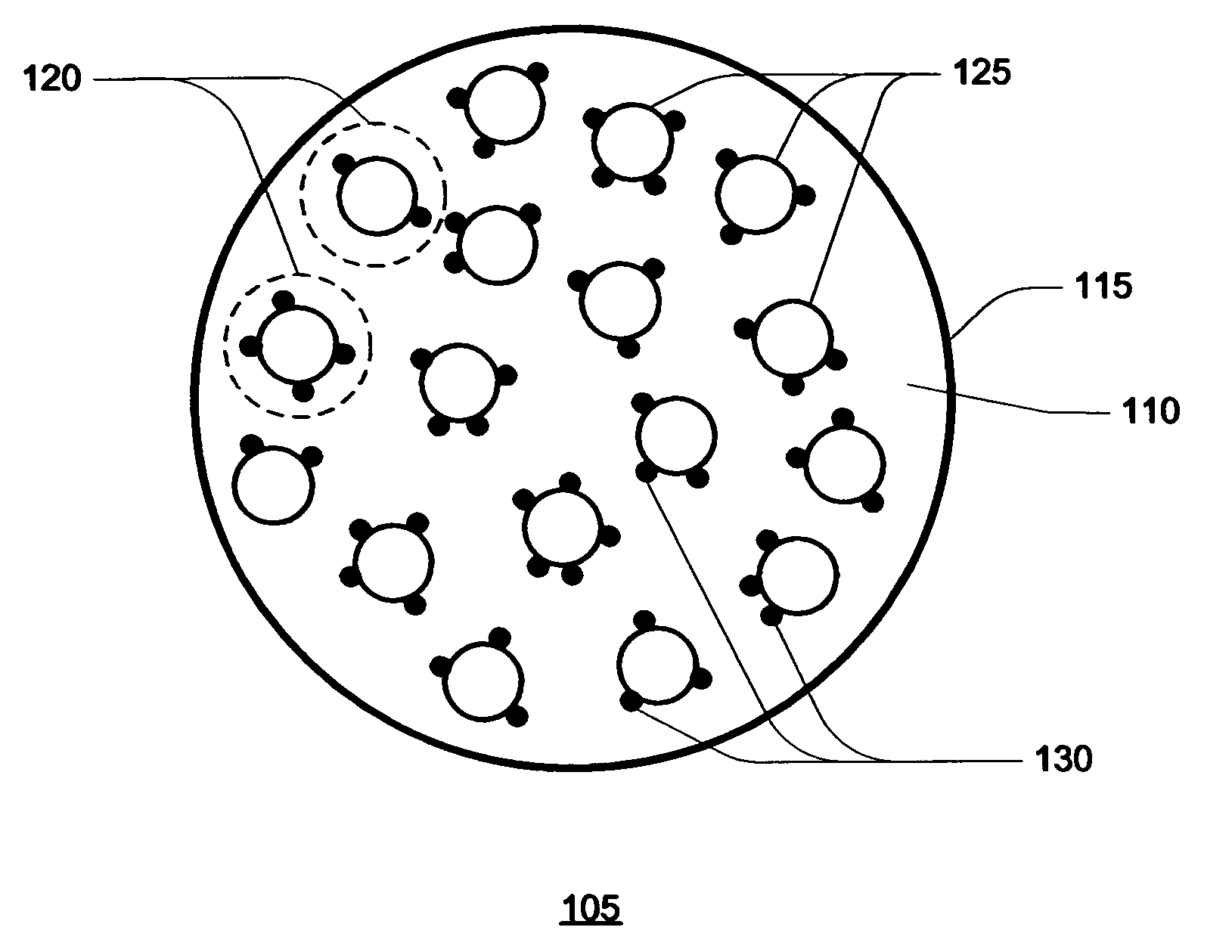

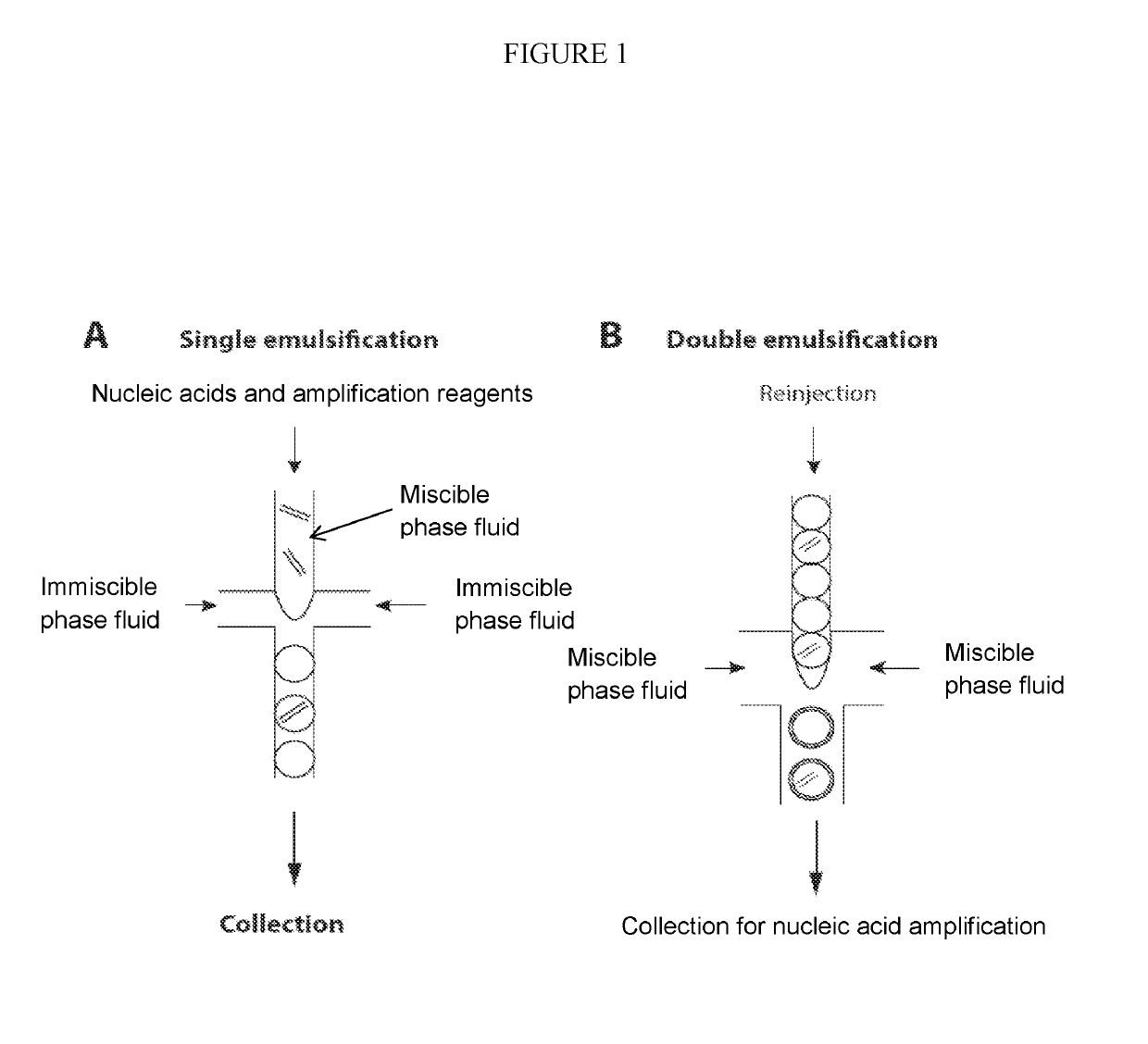

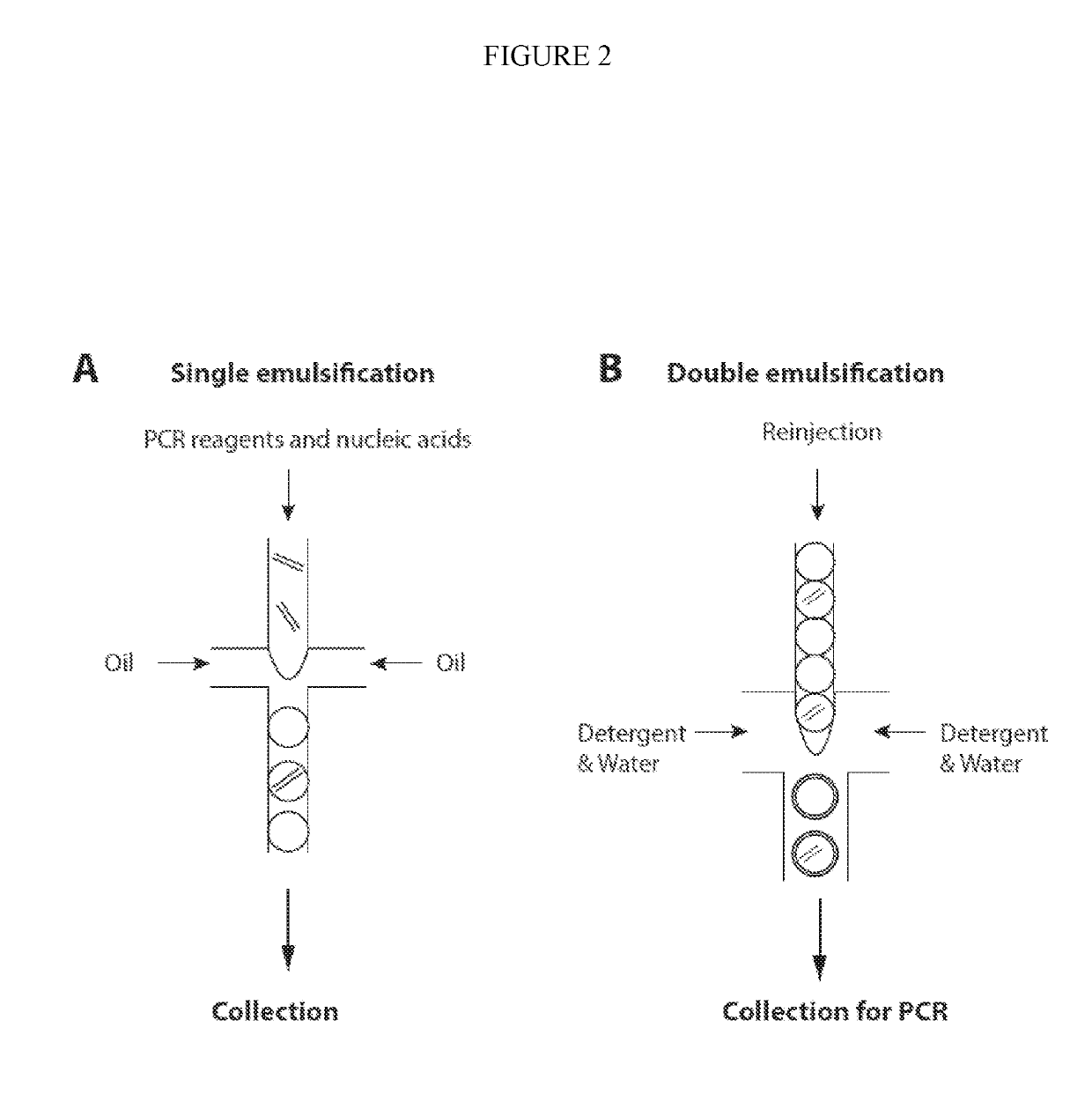

Combined multiple-displacement amplification and PCR in an emulsion microdroplet

ActiveUS20190218594A1Easy to identifySequencing is facilitatedHeating or cooling apparatusMicrobiological testing/measurementNucleic acid amplification techniqueVirus

The methods and systems described herein provide an improved emulsion droplet based nucleic acid amplification method, which allows nucleic acids contained in biological systems to be detected, quantitated and / or sorted based on their sequence as detected with nucleic acid amplification techniques, e.g., polymerase chain reaction (PCR). The nucleic acids can be free floating or contained within living or nonliving structures, including particles, viruses, and cells. The nucleic acids can include, e.g., DNA or RNA.

Owner:RGT UNIV OF CALIFORNIA

Magnetic nanoparticle/macromolecular Janus microparticle and preparation method and application thereof

ActiveCN105513741ANovel methodSimple processOrganic/organic-metallic materials magnetismMicroballoon preparationMagnetite NanoparticlesMicroparticle

The invention discloses a magnetic nanoparticle / macromolecular Janus microparticle and a preparation method and application thereof. The method comprises the following steps: (1) respectively charging a dispersion phase and a continuous phase into different passages in a micro-fluidic chip, finally mixing the dispersion phase with the continuous phase, and obtaining a single-emulsion-drop system on the other end of the micro-fluidic chip, wherein the dispersion phase is prepared from magnetic nanoparticles, a macromolecular polymer and an organic solvent, and the continuous phase is an aqueous solution of a surface active agent; (2) standing the single-emulsion-drop system obtained in the step (1) at room temperature, then standing in a magnetic field, after the standing is completed, heating to remove the organic solvent in the system, and washing with water. The method is novel, simple in process, common in equipment, good in operability and powerful in functions. The obtained microparticle is good in single monodispersion and has magnetism; and other functional materials can be added, so that integration of multiple functions of the material is realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

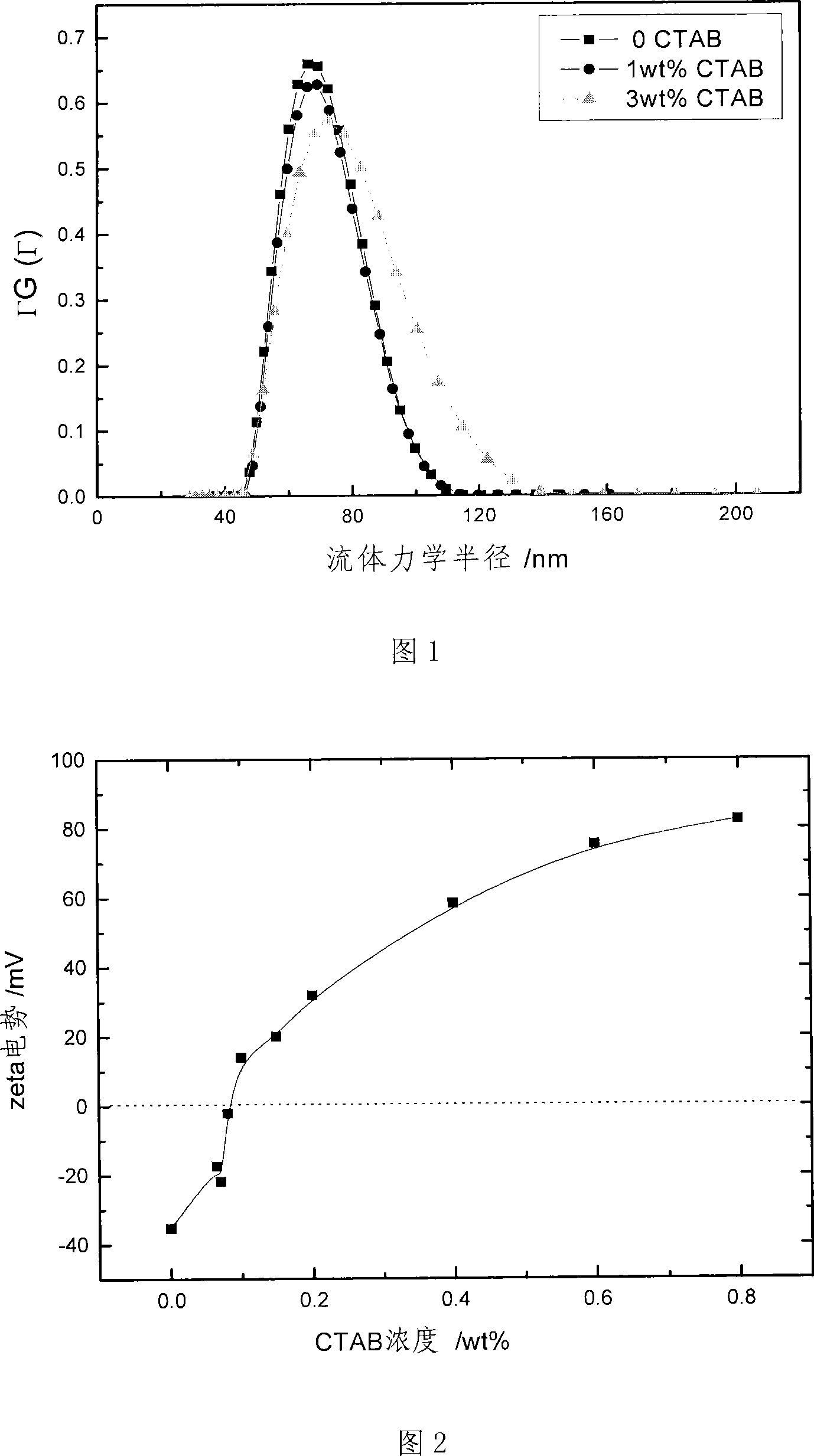

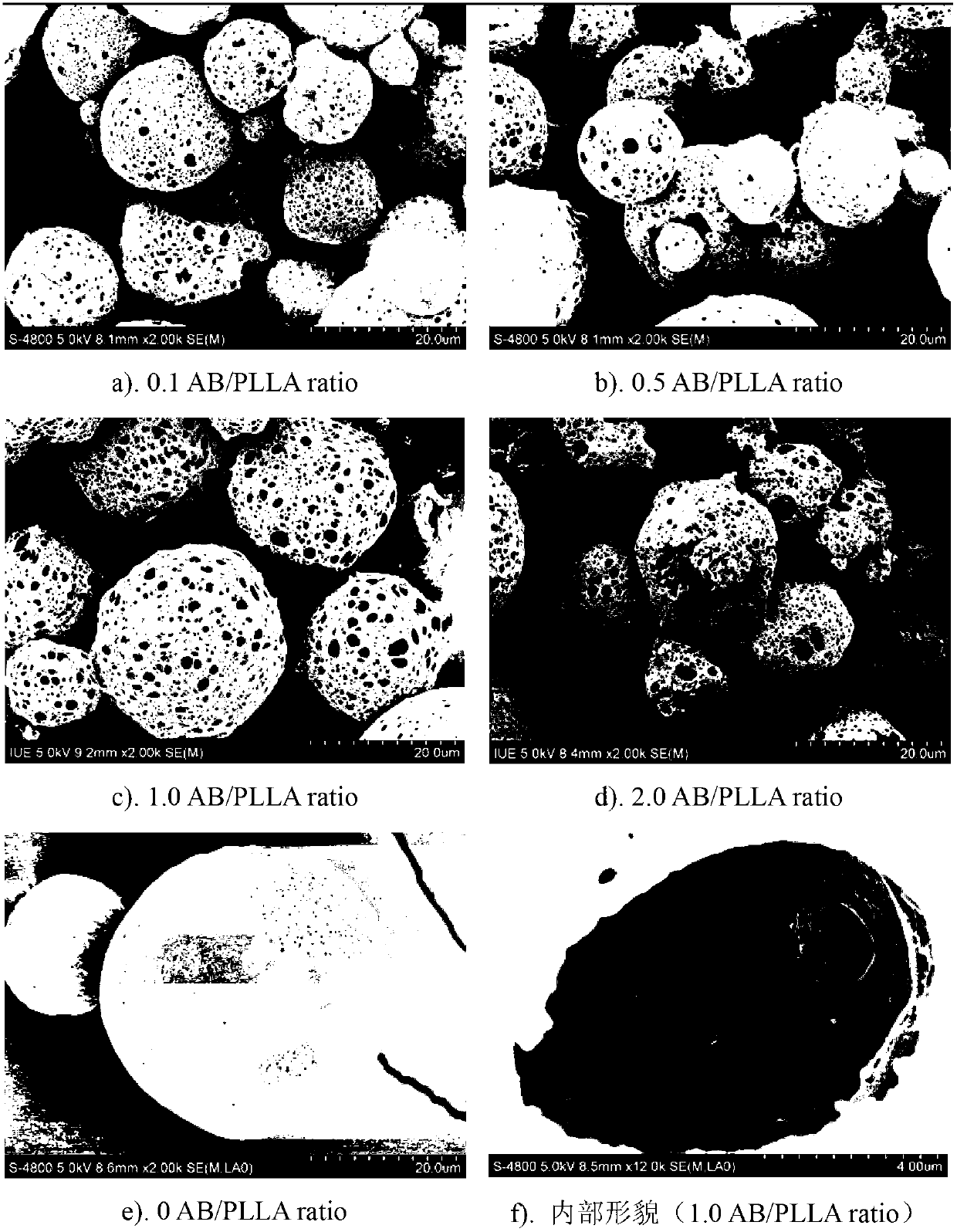

Paraffin nano emulsion with positive charge and preparation method thereof

InactiveCN101168686ANarrow particle size distributionImprove stabilityWax physical treatmentParaffin waxOil phase

The invention discloses a preparation method of paraffin wax nanometer emulsion with positive electricity. Oil phase liquid paraffin, nonionic surfactant and water are added into a reactor together, are heated and blended up to the emulsifying temperature, are blended for certain time and then cooled down quickly, thereby, the paraffin wax nanometer emulsion is obtained, and then cationic surfactant is added into the paraffin wax nanometer emulsion and blended, so as to obtain the paraffin wax nanometer emulsion with positive electricity. The invention also discloses the paraffin wax nanometer emulsion with positive electricity produced by using the method, and the emulsion has the advantages that the emulsion particle size is small, the particle size distribution is narrow, the stability is good, the preparation method of the invention is simple, and the charged amount of the emulsion droplet can be controlled conveniently.

Owner:SHANDONG UNIV

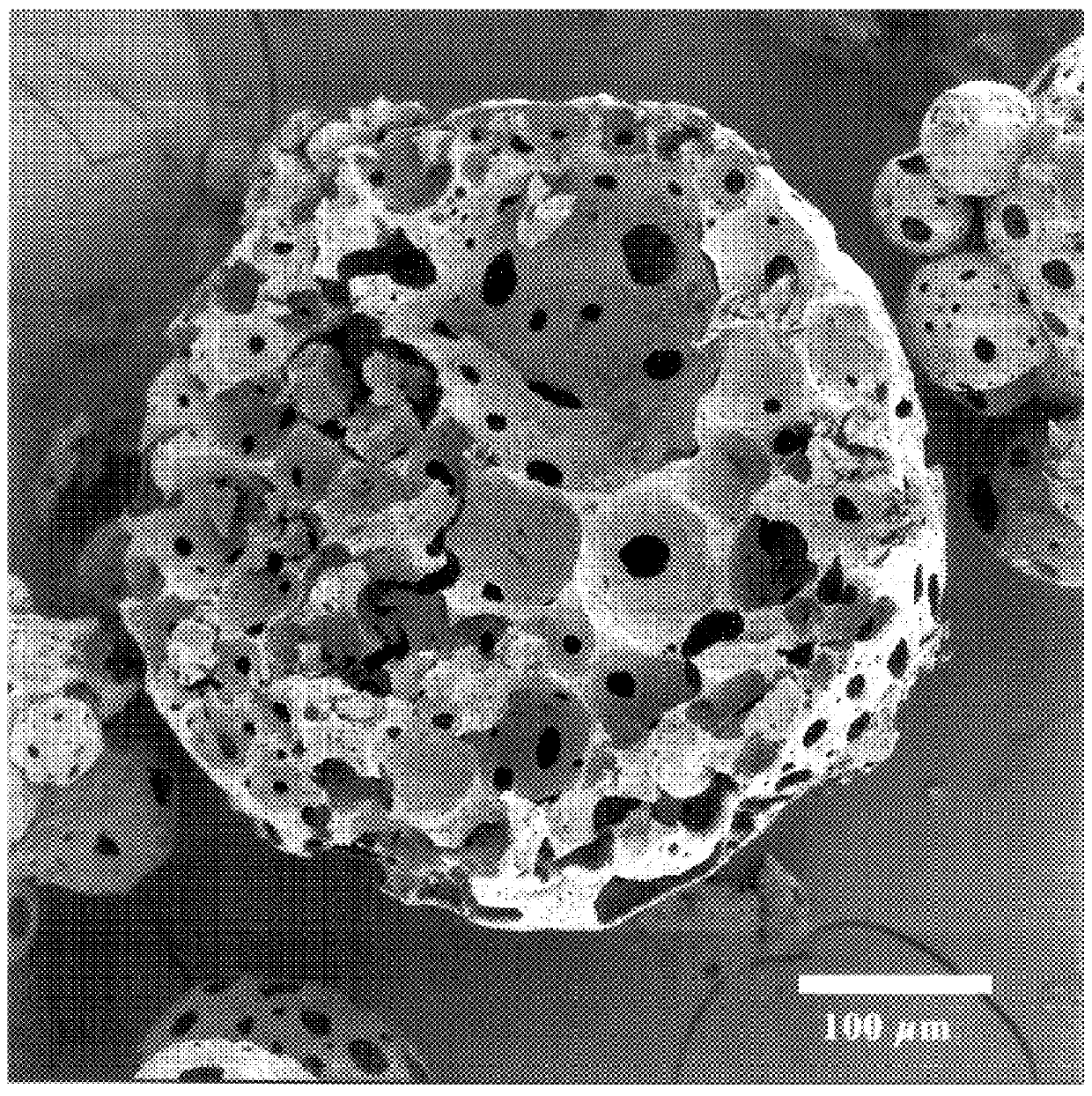

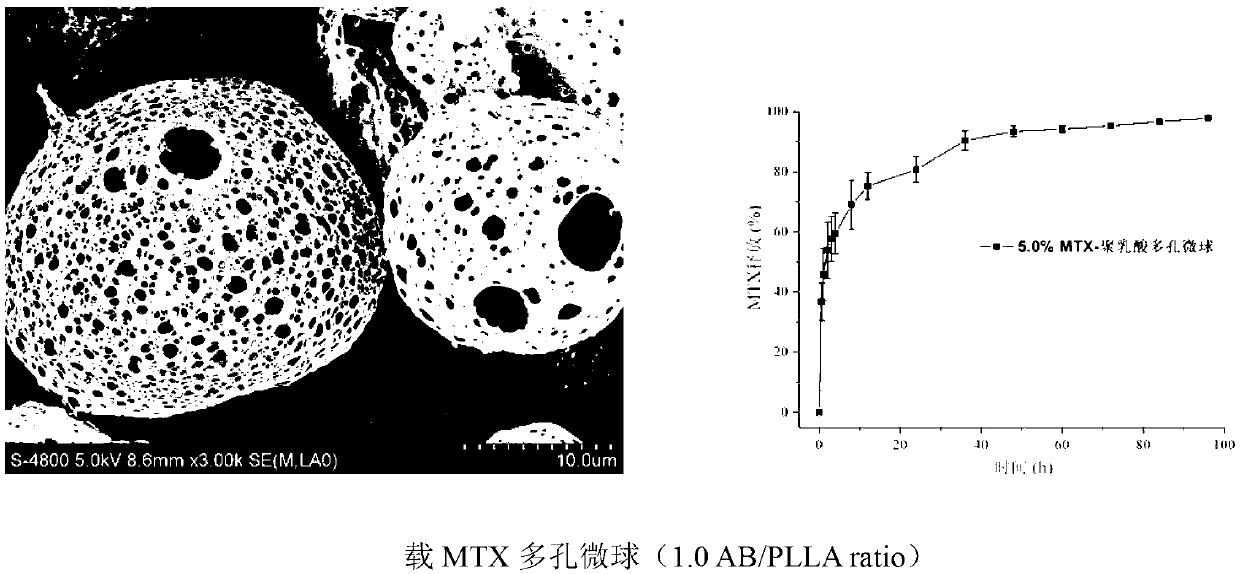

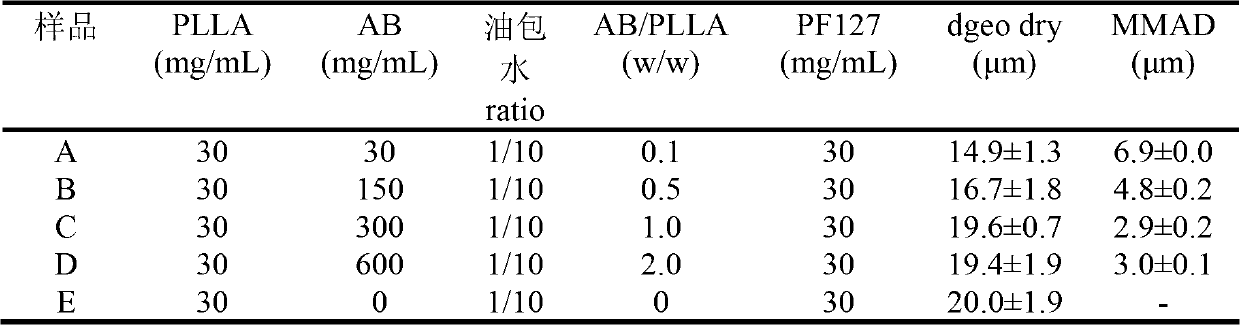

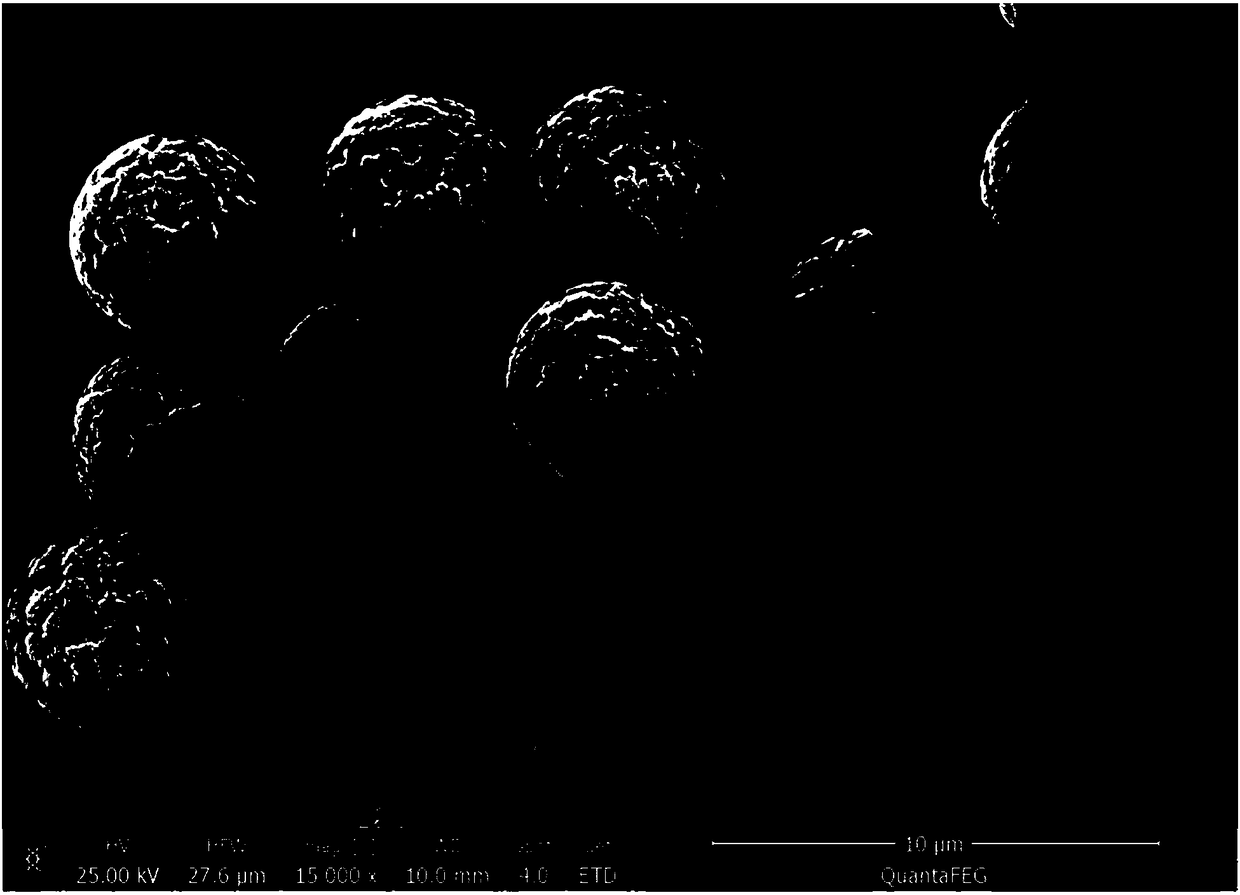

Method of preparing porous polymer microspheres by high voltage electrostatic anti-solvent process

ActiveCN102941043AInorganic non-active ingredientsMicroballoon preparationPolymer scienceDecomposition

The present invention discloses a method of preparing porous polymer microspheres by high voltage electrostatic anti-solvent process. Under the effect of high voltage electrostatic force, water-in-oil emulsion is discharged from an injection needle and is added dropwise to an anti-solvent. The organic solvent in the water-in-oil emulsion and the anti-solvent are miscible with each other, so that the polymer droplets takes the water emulsion droplets as nucleus and are cured and precipitated on surfaces of the nucleus, and the polymer microsphere structure containing pore-foaming agent water emulsion droplets is formed. The gas generated by ammonium hydrogen carbonate decomposition inside the microspheres because of emulsification opens holes on the surfaces of the polylactic acid microspheres to generate the porous structural microspheres. The present invention can be used for preparing drug carriers for inhaled pulmonary drug delivery. The experimental results show that: porous microspheres having a large geometric particle size can be prepared under ideal process parameters; the degree of sphericity is good, the surface is rough, the surface has a large number of pores of different sizes, and the interior is filled with through-hole structure; and increasing the input amount of ammonium hydrogen carbonate, the geometric particle size of the product can be significantly improved and the aerodynamic diameter can be reduced.

Owner:HUAQIAO UNIVERSITY

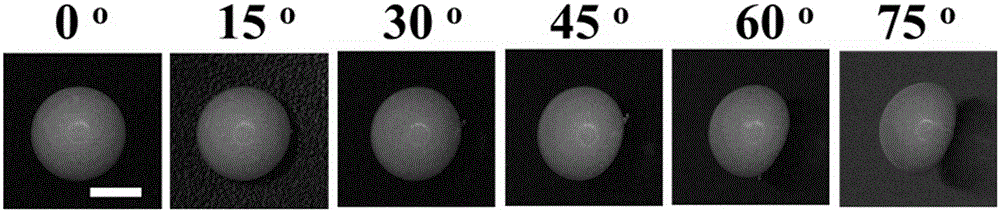

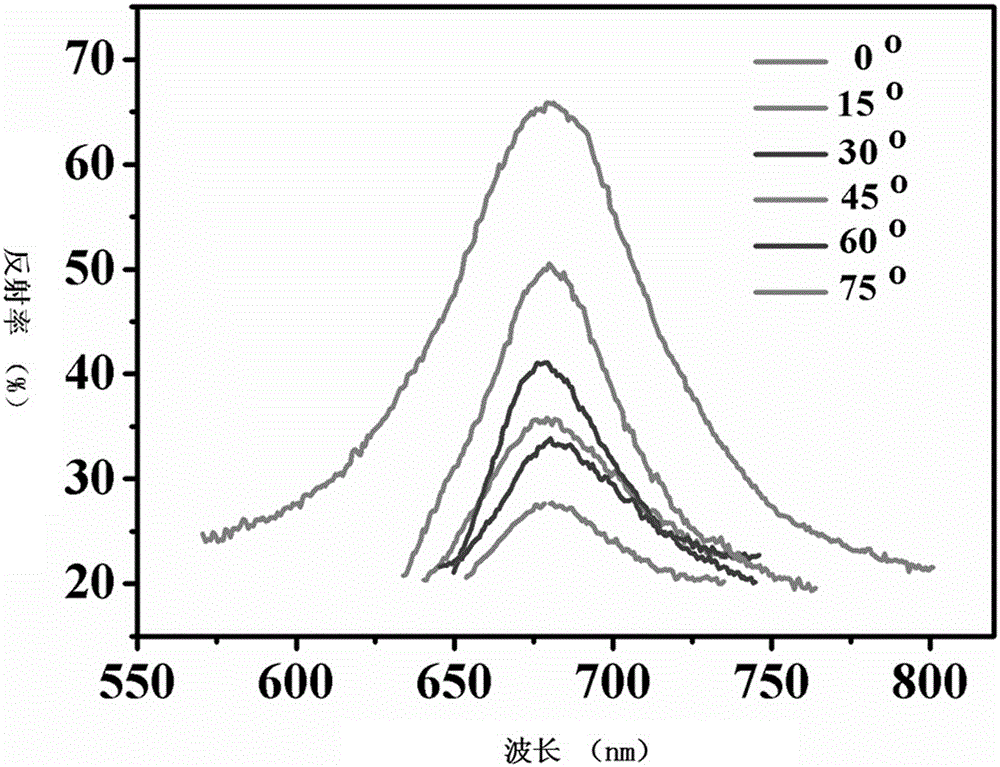

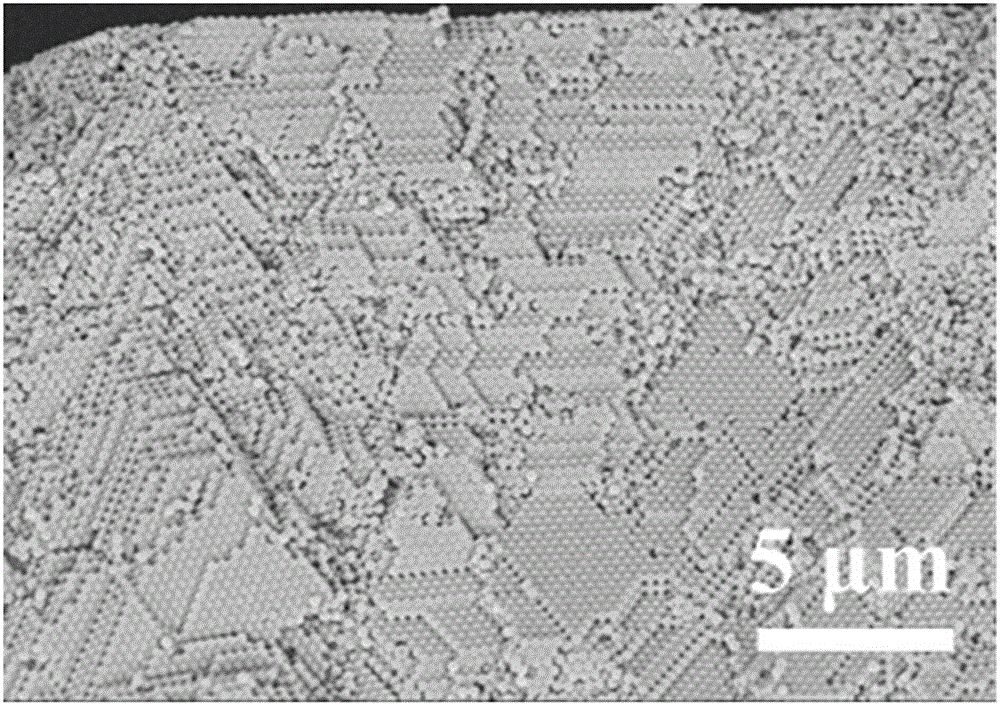

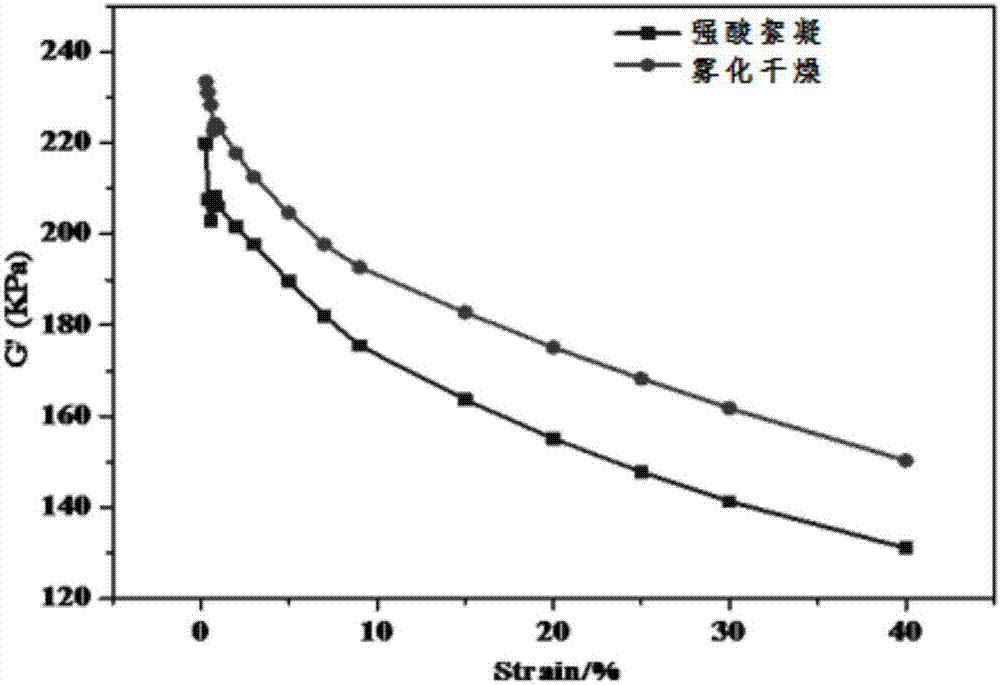

Morphology-controllable and color angle-independent photonic crystal particle and preparation method thereof

InactiveCN105177714ASimple control of shapeEliminate color angle dependenceFrom gel statePolycrystalline material growthMicrosphereSpherical shaped

The invention discloses a morphology-controllable and color angle-independent photonic crystal particle and its preparation method. The preparation method comprises the following steps: mixing Fe3O4 nanoparticles, carbon black nanoparticles, graphene nanoparticles or a mixture of the Fe3O4 nanoparticles, carbon black nanoparticles and graphene nanoparticles with an emulsion containing monodisperse colloidal microspheres; printing a mixture obtained onto a superhydrophobic substrate by a spraying, dispensing or inkjet mode so as to form emulsion droplets with diameter being 11microns -1.6 mm; and drying to obtain the ellipsoidal color angle-independent colored photonic crystal particle with its length-diameter ratio being controllable. The photonic crystal particle is colourfast and environmentally friendly and has a wide application prospect in fields of pigment, display, sensing and the like.

Owner:HEBEI NORMAL UNIV

Preparation method of color-changing fibers

InactiveCN110528116ASimple unit structureGuaranteed normal color renderingConjugated synthetic polymer artificial filamentsDye addition to spinning solutionFiberPolyolefin

The invention provides a preparation method of color-changing fibers. The preparation method comprises the steps of preparation of color-changing powder and preparation of color-changing fibers applying the powder; the color-changing powder is prepared from polyolefin, photochromic dyes, an antioxidant, an ultraviolet absorber and a sensitizer, all the materials are uniformly mixed and granulatedthrough melting, then pulverized at low temperature and sieved to obtain the color-changing powder with a desired particle size, the powder is blended with a fiber-forming polymer, the color-changingpowder is further sheared and dispersed under the shearing function of a twin screw rod and uniformly distributed in the fiber-forming polymer in the form of solid emulsion droplets to form a core layer material of the color-changing fibers, and the core layer is wrapped with a fiber-forming polymer skin layer containing a functional auxiliary agent to obtain the photochromic fibers of a skin-corestructure. The color-changing fibers prepared by means of the method are suitable for various photochromic dyes, high in applicability and operability and simple in preparation method and have a goodcolor development effect, long service life, excellent mechanical properties and broad application prospects in the field of textiles and garments.

Owner:SHANGHAI DIFANG TEXTILE TECHCAL FLOCKING

Method for preparing graphene/rubber composite material

ActiveCN107325343ARealize secondary dispersionImprove the level of micro-dispersionPolymer scienceEvaporation

The invention belongs to the technical field of rubber wet-method mixing, and in particular relates to a method for preparing a graphene / rubber composite material. The method comprises the following three steps of preparing a rubber master batch mixed solution, preparing a rubber master batch and preparing a composite material, namely firstly, preptreating packing by using stirring and ultrasonic atomization techniques so as to form a packing emulsion, ejecting the packing emulsion to the surface of a high-temperature article through high gas pressure by using a packing pre-dispersion sudden heating crushing technique, performing sudden heating crushing on packing emulsion droplets so as to achieve secondary dispersion on the packing in a rubber substrate, further implementing a high-temperature evaporation drying technique, performing sudden heating crushing dispersion on a packing pre-dispersed material, placing prepared wet-method mixing rubber in a high-temperature environment, performing instantaneous evaporation on moisture of the rubber, performing high-quality dispersion on the cured packing in the rubber substrate, and finally preparing a packing / rubber composite material by using a common sealed mixing machine. The method is scientific and reliable in principle, practical, simple and convenient to prepare, high in preparation efficiency, wide in application prospect and good in environmental-friendliness.

Owner:QINGDAO UNIV OF SCI & TECH

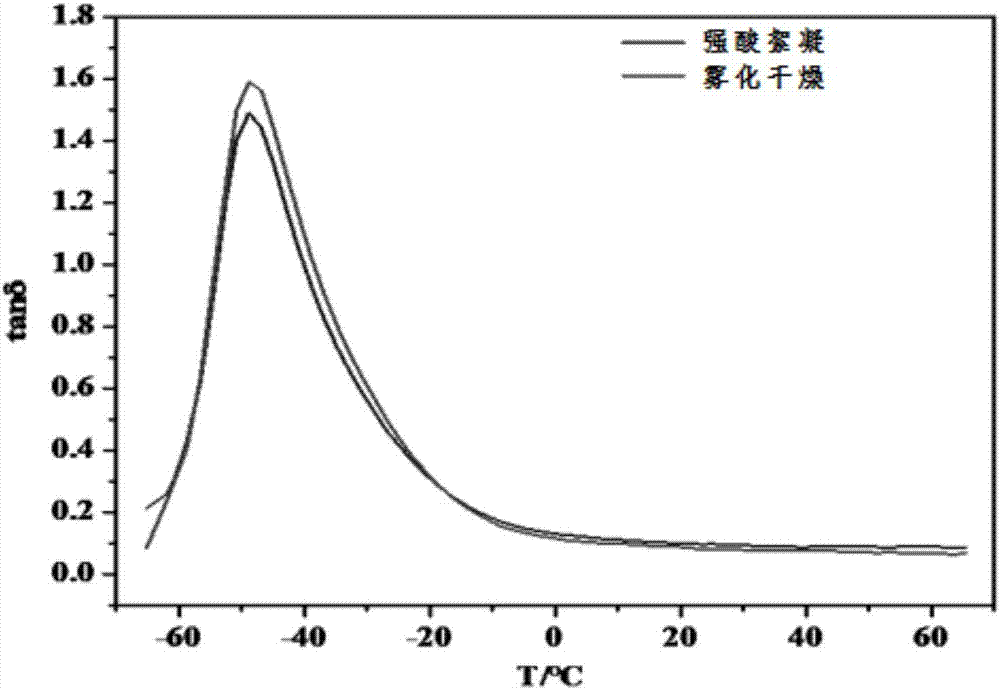

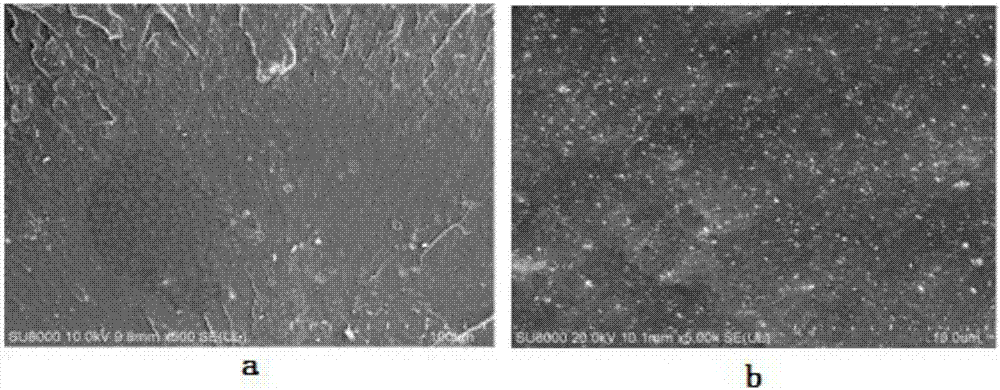

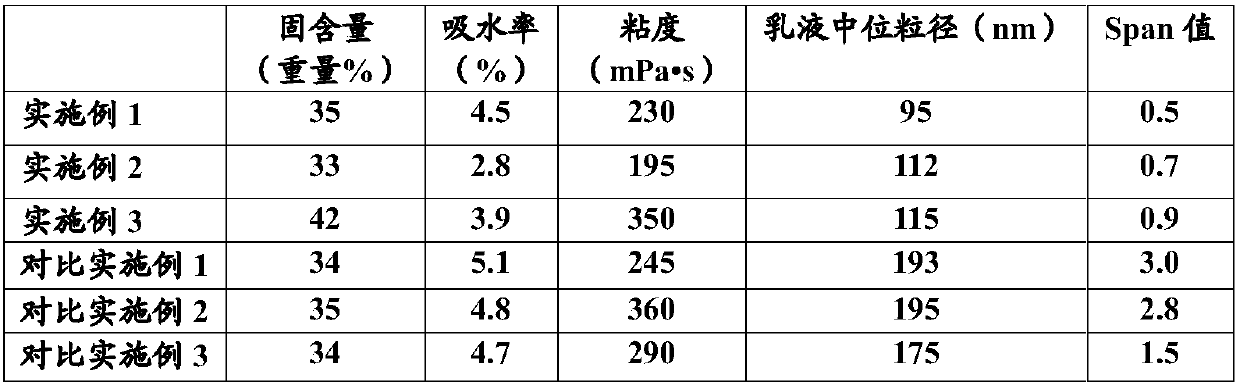

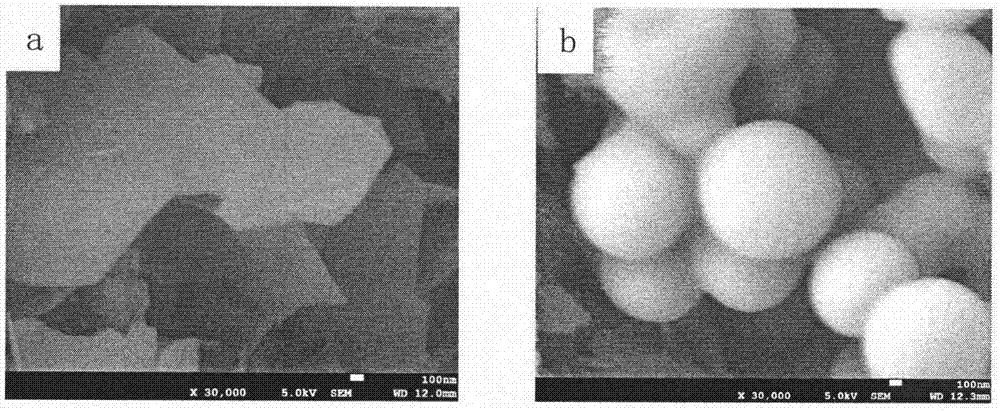

Acrylic monomer modified polyurethane emulsion as well as preparation method and application thereof

The invention relates to acrylic monomer modified polyurethane emulsion. The solid content of the emulsion is 25%-60% by weight, wherein acrylic monomers account for 10%-90% by weight of polyurethane,the median particle size D50 of emulsion droplets is 90-150 nm, and the particle size distribution index Span value is larger than 0.1 and smaller than 1.3. The invention also relates to a preparation method and an application of the polyurethane emulsion. The modified polyurethane emulsion has higher solid content and better stability, and an emulsifier is not needed to increase the stability ofthe emulsion.

Owner:优美特(北京)环境材料科技股份公司

Preparation method of MF (melamine-formaldehyde) resin-coated Mg/Al-LDHs (magnesium/aluminum-layered double hydroxide) microcapsule

ActiveCN106861571AImprove heat resistanceImprove water resistanceMicroballoon preparationMicrocapsule preparationIn situ polymerizationFire retardant

The invention relates to a preparation method of an MF (melamine-formaldehyde) resin-coated Mg / Al-LDHs (magnesium / aluminum-layered double hydroxide) microcapsule. The preparation method comprises the following steps of firstly mixing melamine and formaldehyde according to a molar ratio of 1 to (2 to 4), so as to prepare a clear and transparent MF prepolymer; then, using deionized water as a dispersing medium, and preparing a flame retardant agent Mg / Al-LDHs into a core emulsion under the action of an emulsifying agent; using an in-situ polymerizing method to coat the MF prepolymer around capsule core emulsion droplets, adjusting the pH (potential of hydrogen) value of a solution to weak acid, and enabling the MF prepolymer to further complete condensation reaction at the surface of the Mg / Al-LDHs, so as to generate an insoluble latticed crosslinking structure, and form a capsule wall with certain thickness and strength; finally, using absolute ethyl alcohol to wash for multiple times, drying at the temperature of 60 DEG C, and grinding, so as to obtain the MF-coated Mg / Al-LDHs microcapsule. The preparation method has the advantages that the synergistic flame-retardant function of the nitrogen flame-retardant agent and the Mg / Al-LDHs is fully realized, and the problem of poor dispersivity and compatibility of the flame-retardant agent in a substrate is solved; meanwhile, the preparation technology is simple, and the cost is low.

Owner:NANJING FORESTRY UNIV

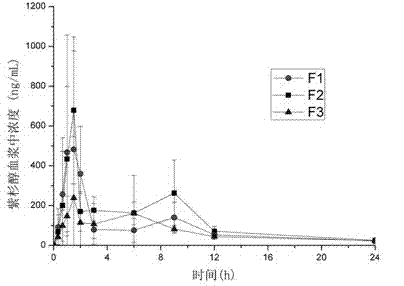

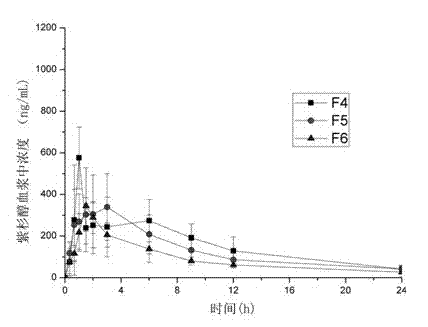

Preparation of solid dispersions and oral preparations of paclitaxel and homologous compounds thereof

InactiveCN103083240AImprove bioavailabilityPowder deliveryOrganic active ingredientsCelluloseDrug content

The invention relates to preparation of solid dispersions and oral preparations of paclitaxel and homologous compounds thereof, wherein solid dispersions and solid dispersion microspheres are prepared to increase rapid release and oversaturation maintenance of paclitaxel and homologous compounds thereof so as to increase bioavailability. According to the present invention, a carrier is hydroxypropylmethylcellulose acetate succinate or hydroxypropylmethylcellulose tetrabutyl titanate, or / and a mixture of hydroxypropylmethylcellulose acetate succinate and micro-powder silica gel or a mixture of hydroxypropylmethylcellulose tetrabutyl titanate and micro-powder silica gel; the drug and macromolecule are dissolved into a mixing solvent of a good solvent and a liquid bridging agent, and the obtained drug-containing solution is slowly added to a poor solvent under a stirring effect; under a shearing force effect of stirring, the drug-containing solution is emulsified and dispersed in the poor agent to form temporary translucent emulsion droplets, the emulsion droplets continuously diffuse to the poor solvent along with the good solvent and the bridging agent, and the drug and the macromolecule in the emulsion droplet are oversaturated so as to gradually solidify to form the solid dispersion microspheres; and the prepared solid dispersion microspheres have characteristics of a size particle of 100-600 mum, a yield of more than 80%, and a drug content of 5-35%.

Owner:SHENYANG PHARMA UNIVERSITY

Preparation method of monodisperse agarose superparamagnetic micro-sphere

InactiveCN108250495AGood monodispersityMagnetic content controllableMicroballoon preparationMicrocapsule preparationCross-linkWater based

The invention provides a monodisperse agarose superparamagnetic micro-sphere and a preparation method thereof. The preparation method comprises the following steps: 1) preparing magnetic nano-particles by adopting a co-precipitation method, and performing surface modification to obtain monodisperse water-based magnetic fluid; 2) coating the surfaces of the magnetic nano-particles with an inorganicshell layer with certain thickness by adopting a gel-sol method so as to enhance the acid resistance, alkali resistance and oxidation resistance of the magnetic nano-particles; 3) dispersing the magnetic nano-particles with a core-shell structure in an agarose aqueous solution with certain concentration, extruding the magnetic nano-particles into an oil phase by the high-pressure shear action ofa template method, changing the pore sizes of micro-pores of a template, the extrusion pressure, the flow rate of the oil phase, the variety and concentration of emulsifying agents and other conditions so as to obtain a W / O type emulsion droplet solution with a uniform size, and after performing cooling, washing and vacuum drying to obtain an agarose superparamagnetic micro-sphere cluster; and 4)transferring the micro-sphere cluster into a conical flask, and performing solidification under the action of alkali, a reducing agent and a cross-linking agent to obtain the agarose superparamagneticmicro-sphere.

Owner:SUZHOU WEIDU BIOTECH CO LTD

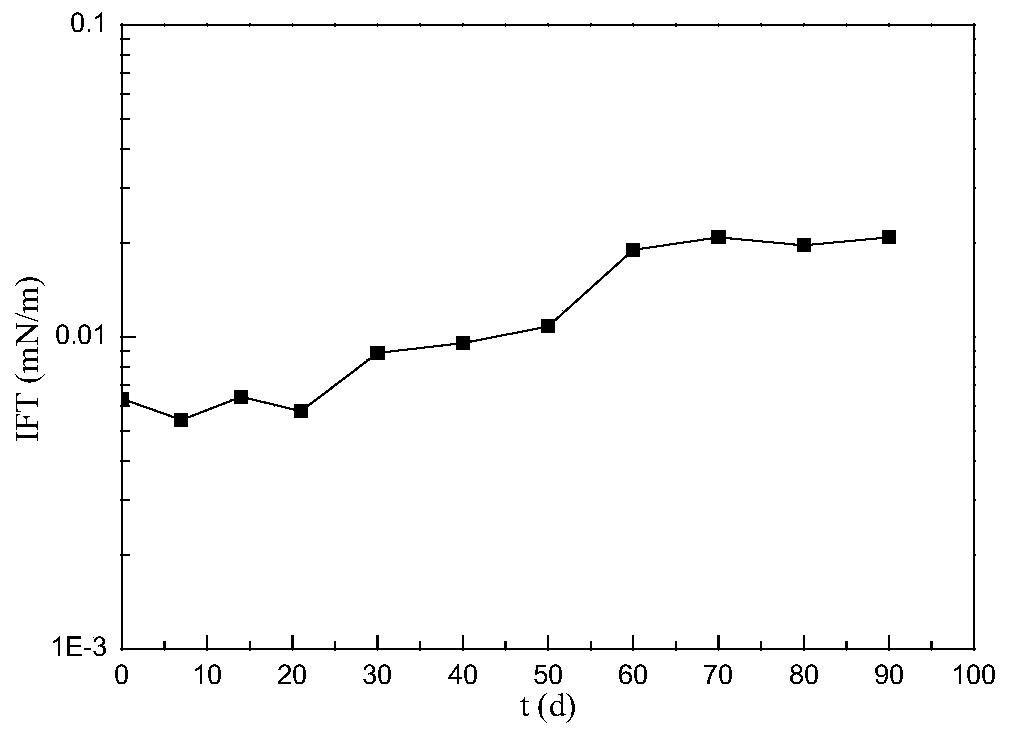

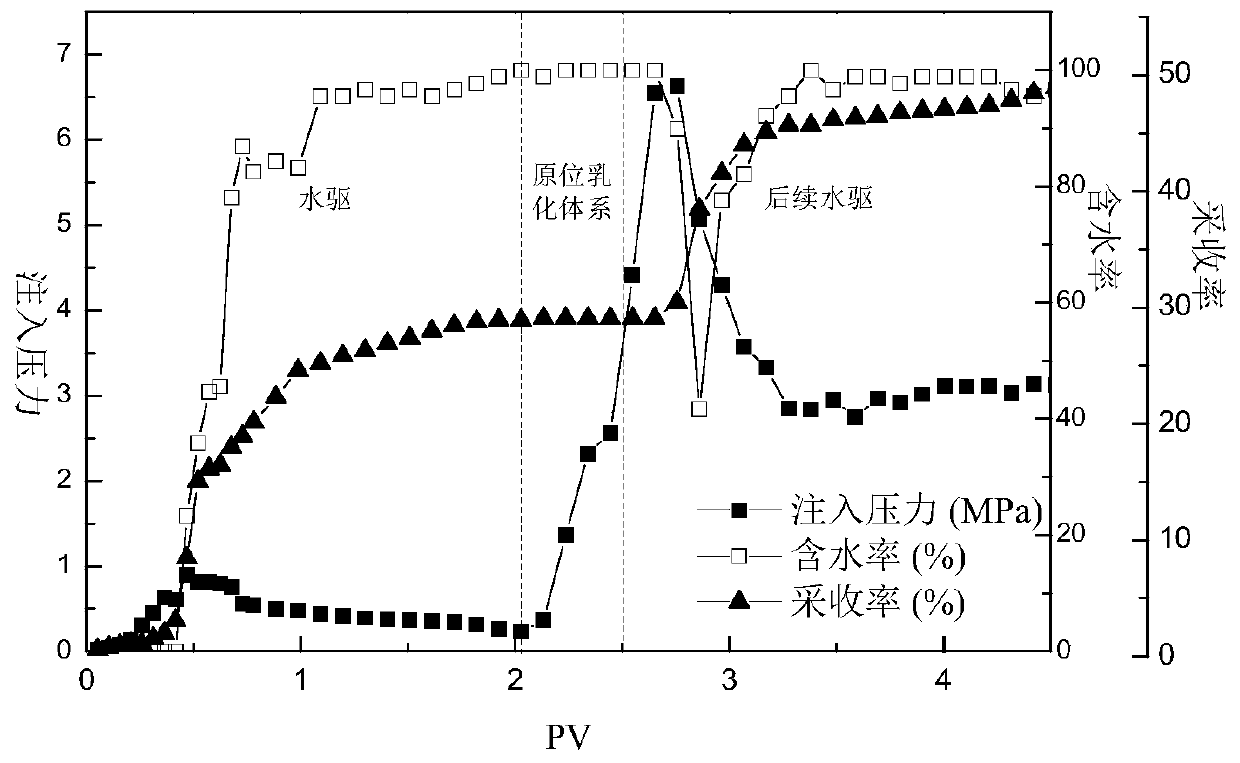

High-temperature high-salt oil reservoir in-situ emulsion system and application thereof

ActiveCN110016329AIncrease viscosityImprove mobility ratioDrilling compositionPorous mediumAlkylphenol

The invention discloses a high-temperature high-salt oil reservoir in-situ emulsion system and an application thereof. The in-situ emulsion system comprises 0.1-0.3% of alkylphenol(alcohol) polyoxyethylene ether sulfonate, 0.05-0.1% of sodium dodecyl sulfate, 0.05-0.1% of nano silicon dioxide and the balance of water. The interfacial tension of the in-situ emulsion system and crude oil can reach 10 <-2>-10<-3> mN / m, and under a shearing condition, the crude oil and water can form an O / W emulsion, and viscosity of the emulsion is greater than viscosity of water, so that the mobility ratio can be effectively improved. When being applied to chemical flooding of a high-temperature high-salt oil reservoir, emulsion droplets can block large pores in a porous medium through a Jamin effect, heterogeneity of a reservoir stratum is improved, and a low-permeability layer is started, so that the recovery rate is greatly improved. Meanwhile, the anti-aging property of the system under a high-temperature high-salt condition is good, and the oil-displacing requirement of high-temperature high-salt oil reservoirs can be met.

Owner:SOUTHWEST PETROLEUM UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com