Preparation and application of biodegradable thermosensitive in-situ hydrogel

A hydrogel and temperature-sensitive technology, applied in the field of medicine, can solve the problems of short drug release time, high triglycerides, and low hydrogel strength, and achieve adjustable drug release rate, adjustable structure, The effect of the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

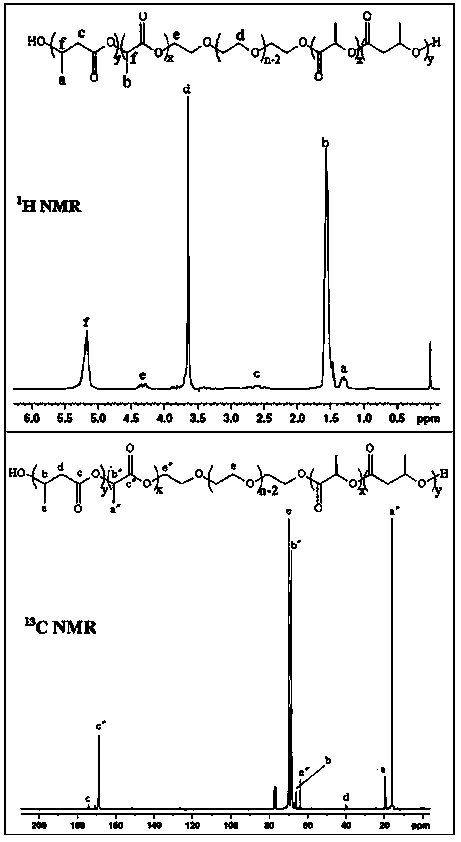

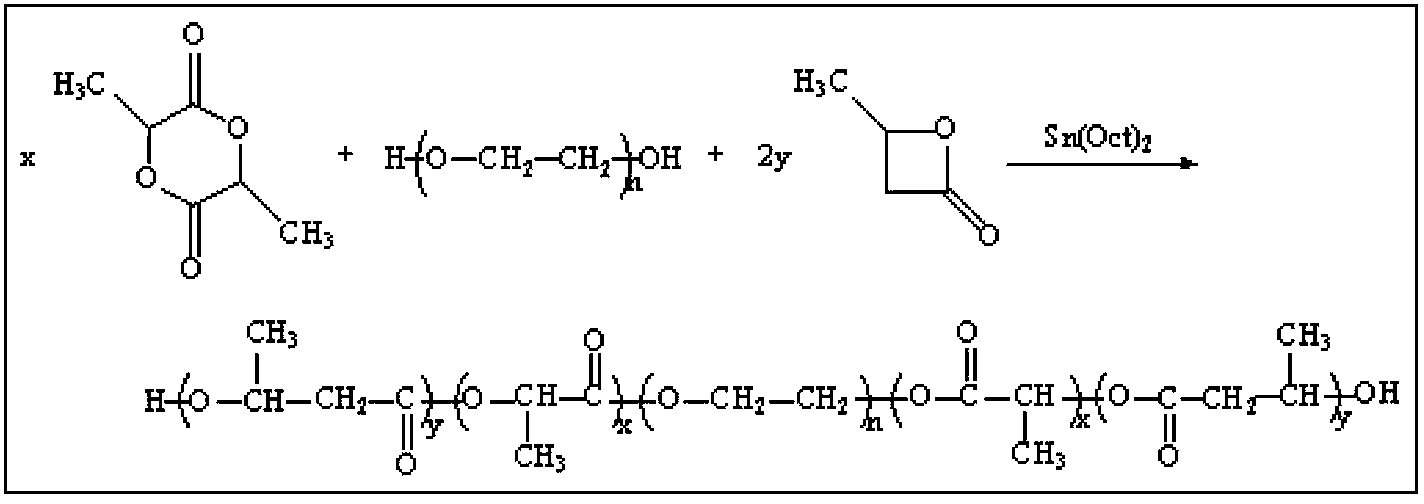

[0036] Firstly, the reactants were purified as follows: PEG and lactide (LA) were dried under reduced pressure at room temperature, and β-butyrolactone (β-BL) was heated to reflux with calcium hydride for 1 hour, and then distilled under reduced pressure.

[0037] The specific synthesis steps are: weigh PEG respectively 1500 4.0g and LA9.0g were placed in a dry three-necked flask, heated to 130°C in an oil bath to melt, and continuously vacuumed under magnetic stirring to remove the residual moisture in it. After 2h, under the protection of nitrogen, add β- BL1.0g and 0.3% (w / w, relative to monomer mass) of Sn(Oct) 2 , after repeated vacuum-filling with nitrogen, the temperature was raised to 150° C. for 6 h under the protection of nitrogen. After the reaction is completed, let it cool to room temperature, add an appropriate amount of distilled water, wash repeatedly in a water bath at about 75°C to remove unreacted monomers or low molecular weight products, freeze-dry, and s...

Embodiment 2

[0039] Take by weighing an appropriate amount of polymer synthesized in Example 1, add distilled water, and magnetically stir at room temperature to dissolve, and prepare respectively a polymer solution with a concentration of 10, 15, 20, 25 and 30%, and use the vial inversion method to measure its phase transition temperature. and draw a phase diagram.

Embodiment 3

[0041] Get the polymkeric substance synthesized in the example 1, preparation concentration is the polymer aqueous solution of 0.5%. The particle size of micelles at different temperatures was determined by dynamic light scattering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com