Preparation method of iron carbide composite electrode material coated with nitrogen and sulfur doped with carbon

A composite electrode and carbon coating technology, applied in nanotechnology for materials and surface science, battery electrodes, circuits, etc., can solve the problem of uneven distribution of iron carbide particles, cumbersome preparation process operations, difficult to control doping methods, etc. The problem is that the synthesis process is easy to control, the process is simple, and the preparation cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

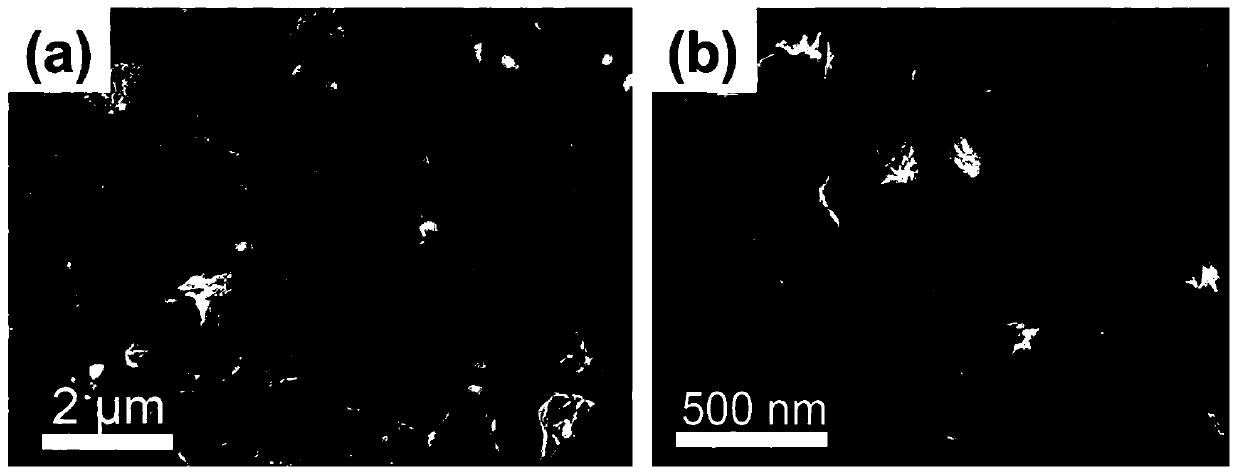

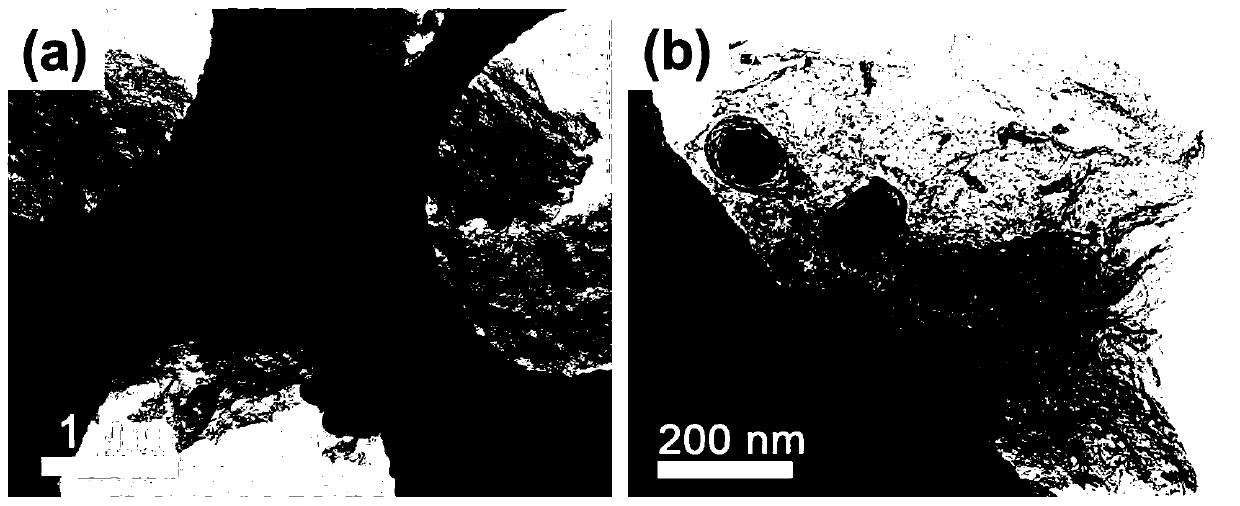

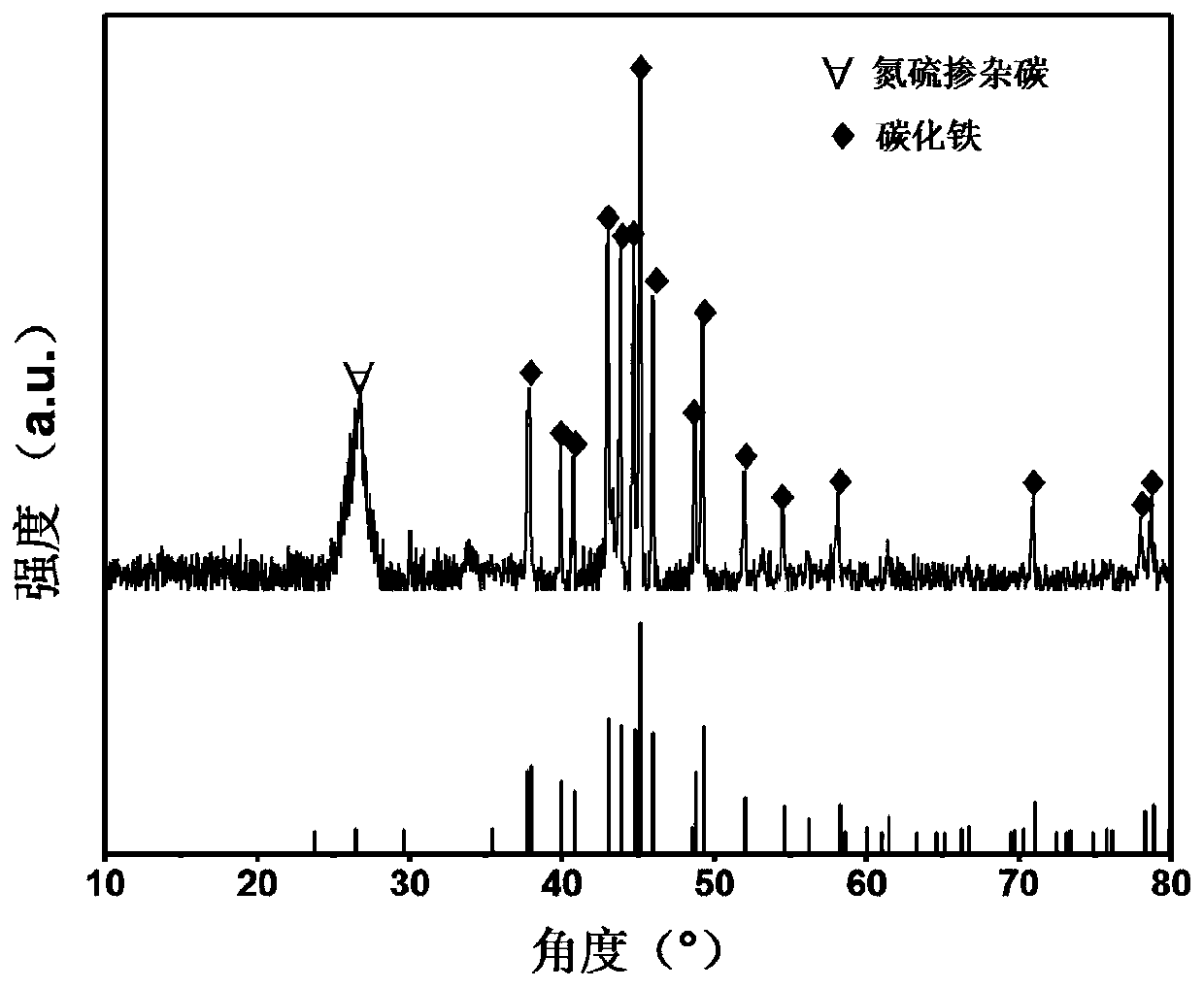

[0027] The preparation method of nitrogen-sulfur-doped carbon-coated iron carbide composite electrode material, the specific operation steps are as follows:

[0028] (1) Get ferric chloride hexahydrate 2mmol, thiourea 100mmol and glucose 1mmol respectively according to ferric chloride hexahydrate, thiourea and glucose into a molar ratio of 2:100:1, and ferric chloride hexahydrate, thiourea Mix with glucose, and dissolve in 100ml of deionized water and ethanol in a solvent mixed at a volume ratio of 2:1, stir evenly and heat to 90°C to evaporate the solvent until dry powder is obtained;

[0029] (2) Put the dry powder obtained in step (1) into a tube furnace for heat treatment in argon. The heating rate of the heat treatment is 2°C / min, and the temperature is raised to 800°C, kept for 1 hour, and then cooled to room temperature to obtain black Powder; wherein, the inert atmosphere flow rate is controlled at 60cc / min;

[0030] (3) Add the black powder obtained after cooling in ...

Embodiment 2

[0032] The preparation method of nitrogen-sulfur-doped carbon-coated iron carbide composite electrode material, the specific operation steps are as follows:

[0033] (1) According to ferric nitrate nonahydrate, thiourea and glucose into a molar ratio of 1:100:1, take 1 mmol of ferric nitrate nonahydrate, 100 mmol of thiourea and 1 mmol of glucose respectively, mix ferric nitrate nonahydrate, thiourea and glucose, and dissolve In a solvent composed of 100ml of deionized water and ethanol in a volume ratio of 1:1, stir evenly and heat to 90°C to evaporate the solvent until a dry powder is obtained;

[0034] (2) Put the dry powder obtained in step (1) into a tube furnace for heat treatment in argon. The heating rate of the heat treatment is 5°C / min, and the temperature is raised to 900°C, kept for 1 hour, and then cooled to room temperature to obtain black Powder; wherein, the inert atmosphere flow rate is controlled at 80cc / min;

[0035] (3) Add the black powder obtained after ...

Embodiment 3

[0037] The preparation method of nitrogen-sulfur-doped carbon-coated iron carbide composite electrode material, the specific operation steps are as follows:

[0038] (1) Get ferric chloride hexahydrate 5mmol, thiourea 100mmol and glucose 1mmol respectively according to ferric chloride hexahydrate, thiourea and glucose into a molar ratio of 5:100:1, and ferric chloride hexahydrate, thiourea Mix with glucose, and dissolve in 100ml of deionized water and ethanol in a solvent with a volume ratio of 1:1, stir evenly and heat to 90°C to evaporate the solvent until a dry powder is obtained;

[0039] (2) Put the dry powder obtained in step (1) into a tube furnace for heat treatment in an inert atmosphere of argon. The heating rate of the heat treatment is 10°C / min, and the temperature is raised to 1000°C, kept for 1 hour, and then cooled to room temperature. Obtain black powder; Wherein, inert gas flow rate is controlled at 30cc / min;

[0040](3) Add the black powder obtained after co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com