Hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and catalyst technology, which can be used in refining to remove heteroatoms, etc., can solve the problems of high energy consumption of the device, insufficient reaction conditions, and weak design of the catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

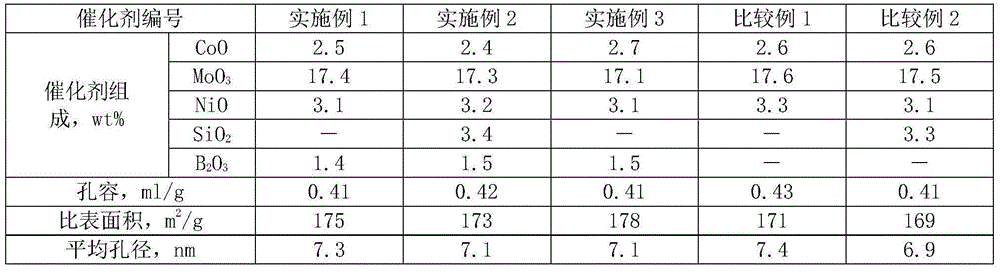

Examples

Embodiment 1

[0031] (1) γ-Al 2 o 3 Preparation of vector

[0032] Weigh 1000g of silicon-free pseudo-boehmite powder, 30g of Tianqing powder, 30g of citric acid, and 700ml of 3-5% dilute nitric acid, mix them evenly, extrude them with an extruder, dry them at 110°C for 10 hours, and dry them in an air atmosphere. Calcined at 650°C for 5 hours to obtain γ-Al 2 o 3 carrier.

[0033] (2) Ni-B / γ-Al 2 o 3 preparation of

[0034] Prepare 1000ml impregnation solution: weigh 107.6g of tartaric acid and add it to 600ml of deionized water, stir and heat to 50°C, weigh 83.6g of nickel nitrate (industrial grade) and 14.7g of ammonium hydrogen borate (industrial grade) into the solution , boiled for 1.5 hours, added dilute ammonia to adjust the pH value of the solution to 5.0. After cooling to room temperature, the solution was transferred to a volumetric flask, and water was added to make the volume to 1000ml to obtain an impregnating solution containing nickel and boron.

[0035] Weigh the p...

Embodiment 2

[0040] (1) Silicon-containing γ-Al 2 o 3 Preparation of vector

[0041] Weigh 1000g of silicon-containing pseudo-boehmite, 45g of Tianqing powder, 35g of oxalic acid, 680ml of 3-5% dilute nitric acid and mix evenly, extrude with an extruder, dry at 100°C for 14 hours, and dry at 500°C in an air atmosphere Calcined for 8 hours to obtain silicon-containing γ-Al 2 o 3 carrier.

[0042] (2) Ni-B / silicon-containing γ-Al 2 o 3 preparation of

[0043] Prepare 1000ml impregnation solution: weigh 140.0g oxalic acid and add it to 600ml water, stir and heat to 50°C, weigh 45.5g basic nickel carbonate (industrial grade) and 25.3g p-toluene boric acid (industrial grade) solution, boiled for 1.5 hours, cooled to room temperature, transferred the solution to a volumetric flask, added water to make the volume 1000ml, and obtained an impregnating solution containing nickel and boron.

[0044] Weigh the silicon-containing γ-Al prepared by 500g step (1) 2 o 3 For the carrier, measure 3...

Embodiment 3

[0049] (1) γ-Al 2 o 3 Preparation of vector

[0050] Weigh 1000g of silicon-free pseudo-boehmite powder, 30g of Tianqing powder, 30g of citric acid, and 700ml of 3-5% dilute nitric acid, mix them evenly, extrude them with an extruder, dry them at 120°C for 2 hours, and dry them in an air atmosphere. Calcined at 800°C for 3 hours to obtain γ-Al 2 o 3 carrier.

[0051] (2) Ni-B / γ-Al 2 o 3 preparation of

[0052] Prepare 1000ml impregnation solution: weigh 140.0g oxalic acid and add it to 600ml water, stir and heat to 50°C, weigh 45.5g basic nickel carbonate (industrial grade) and 25.3g p-toluene boric acid (industrial grade) solution, boiled for 1.5 hours, cooled to room temperature, transferred the solution to a volumetric flask, added water to make the volume 1000ml, and obtained an impregnating solution containing nickel and boron.

[0053] Weigh 500g γ-Al 2 o 3 As for the carrier, measure 375ml of the prepared impregnation solution containing nickel and boron, impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com