Preparation method for cationic side chain esterified-grafted highly-mud-resistant cement dispersing agent

A kind of cement dispersant, cation technology, applied in the field of high mud resistance type dispersant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

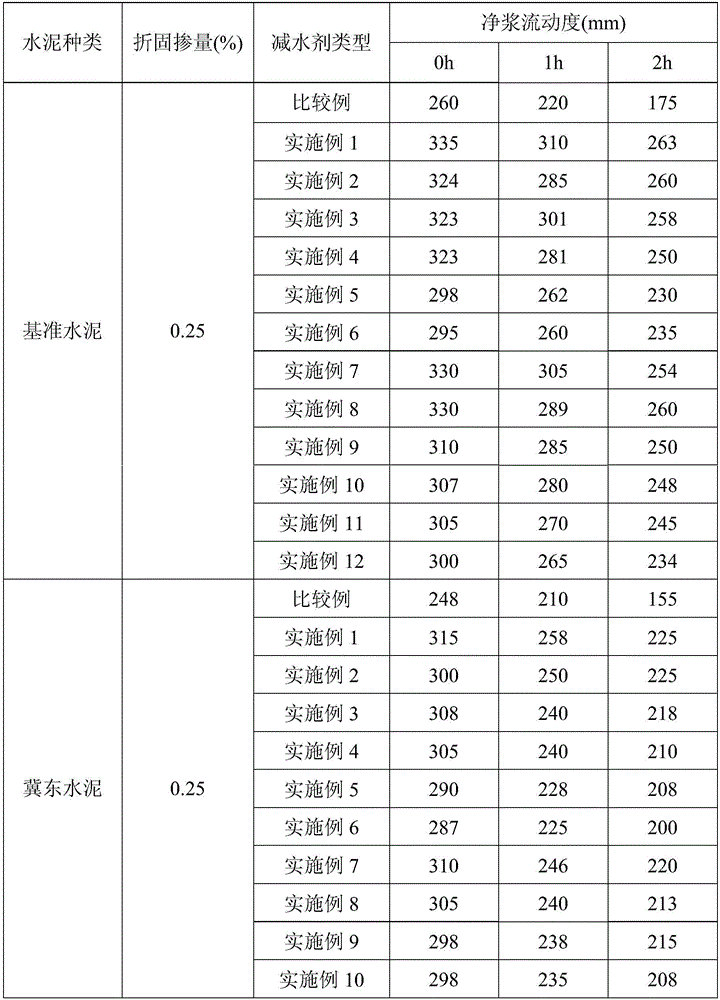

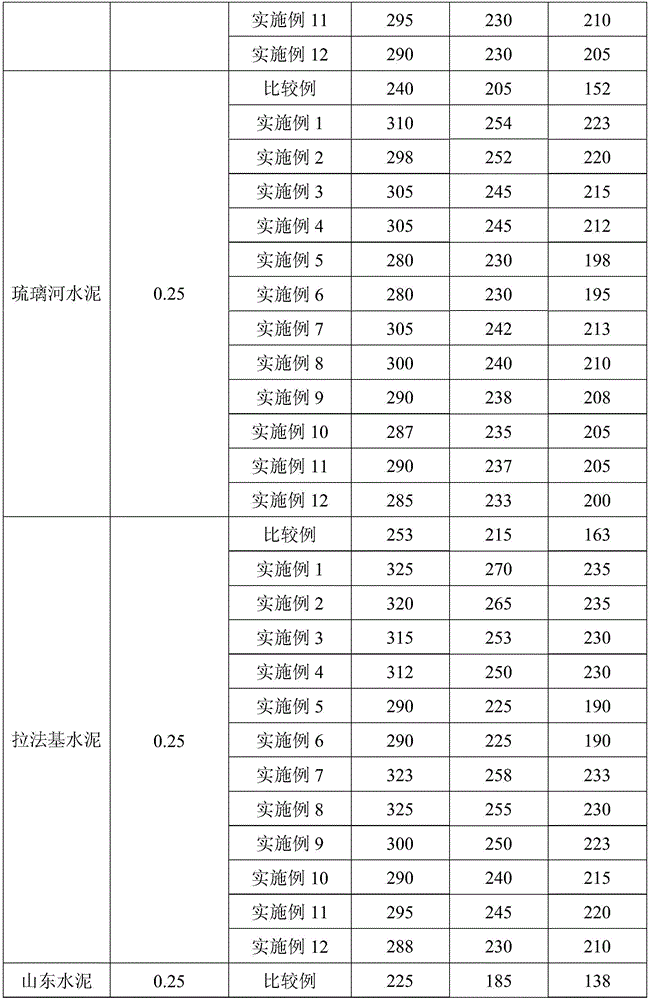

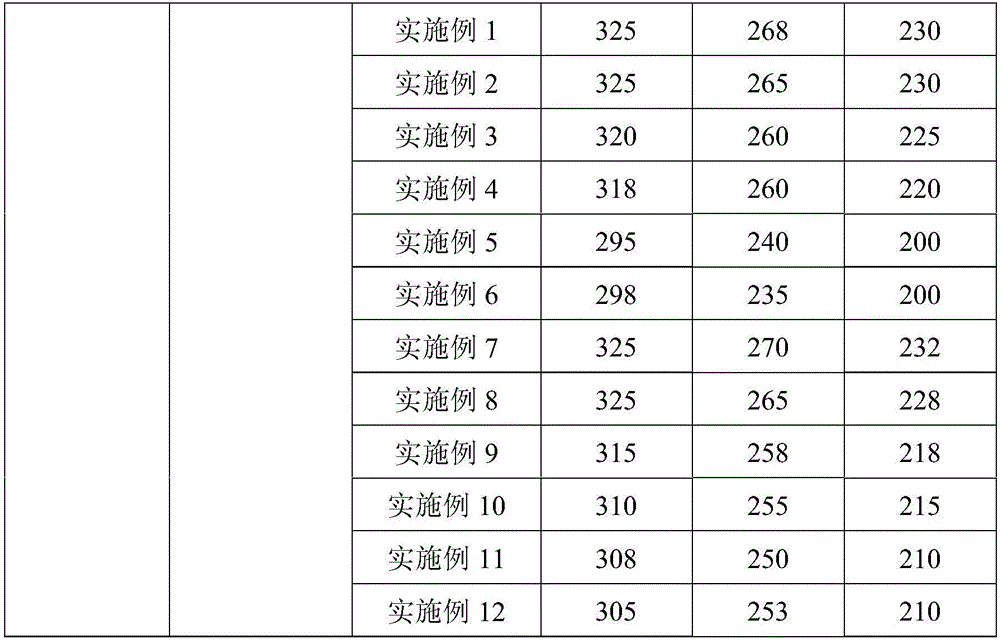

Examples

Embodiment 1

[0027] First, 7.21g of acrylic acid, 8.65g of water, 0.91g of mercaptoacetic acid and 5.1g of ammonium persulfate with a mass fraction of 18% were added to the reactor, and the interval between each feeding was 9 minutes, and the temperature was raised to 75°C to carry out the polymerization reaction for 7 hours. , to obtain the polycarboxylic acid main chain aqueous solution; then add 12.89g trimethylallyl ammonium chloride, 1.41g n-butanol and 700.41g water in another reactor successively, and the reactor is filled with nitrogen and deoxygenated repeatedly 4 times for 15 After 10 minutes, seal it, add 0.52g of cerium ammonium nitrate, stir for 25 minutes until it is mixed evenly, continue to heat up to 35°C for polymerization reaction, and react for 12 hours to obtain an aqueous solution of hydroxyl-terminated cation side chains, and then add the obtained Polycarboxylic acid main chain aqueous solution and 50.4g methoxypolyethylene glycol (molecular weight = 2400), warming up...

Embodiment 2

[0029] After the cement dispersant solution with a concentration of 40% obtained in Example 1 was stored at 6° C. for 20 days, its implementation effect was measured.

Embodiment 3

[0031] First 7.83g of methacrylic acid, 1.18g of itaconic acid, 13.51g of water, 1.38g of mercaptopropionic acid and 12.29g of ammonium persulfate with a mass fraction of 22% were added to the reactor, and the temperature was raised to 55°C at intervals of 20 minutes each time. Polymerization reaction was carried out at ℃ for 8 hours to obtain an aqueous solution of polycarboxylic acid main chain; Water, the reactor was filled with nitrogen repeatedly 3 times to remove oxygen for 20 minutes, then sealed, added 5.37g of ammonium cerium sulfate, stirred for 18 minutes until it was mixed evenly, continued to heat up to 50°C for polymerization reaction, and reacted for 8 hours to obtain terminal hydroxyl cations side chain aqueous solution, then respectively add the obtained polycarboxylic acid main chain aqueous solution and 30g polyethylene glycol (molecular weight = 1200) in the reactor, heat up to 68 ° C, until the polyethylene glycol (molecular weight = 1200) is in a liquid st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com