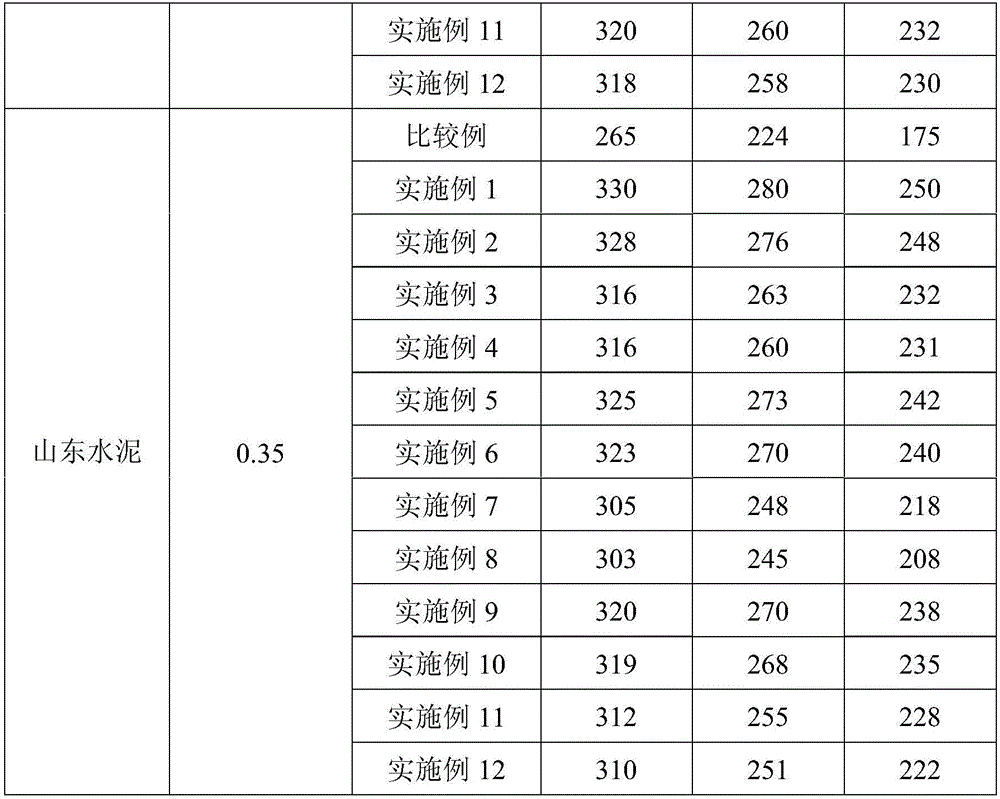

Patents

Literature

115results about How to "Good mud resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and preparation method thereof

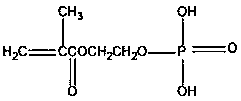

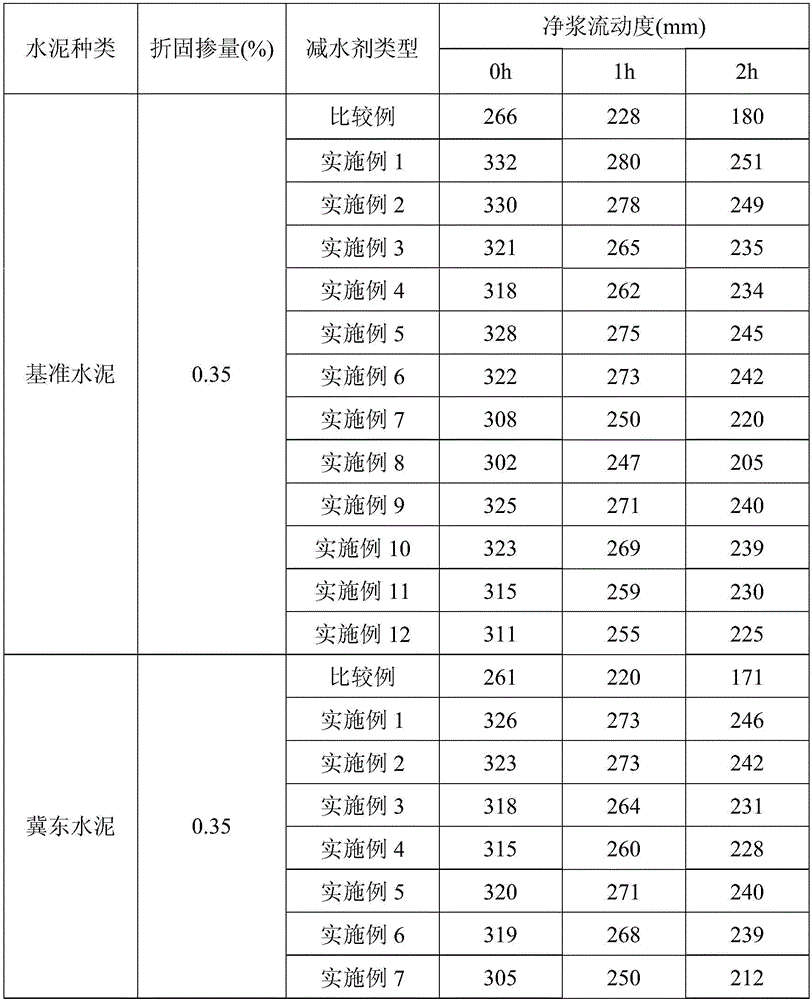

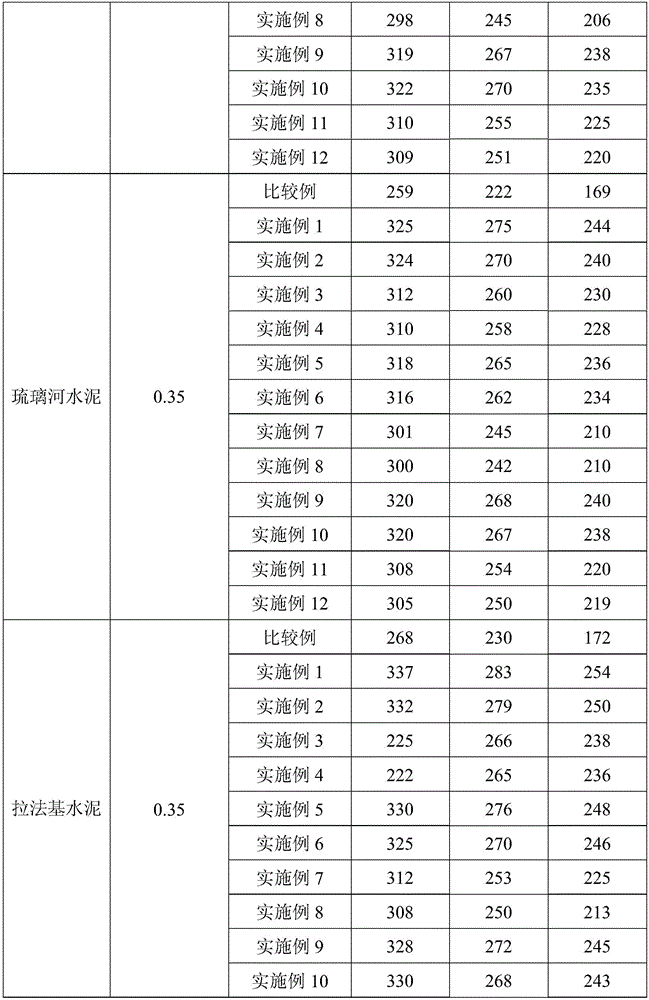

The invention discloses a phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and a preparation method thereof. The water reducer is prepared from the following raw materials: isopentenol polyoxyethylene ether, hydrogen peroxide, acrylic acid, an unsaturated phosphoric acid monomer, deionized water, a reducing agent, and a chain transferring agent. The chain transferring agent is one of mercaptoethanol, mercaptoacetic acid and mercaptopropionic acid. The unsaturated phosphoric acid monomer is prepared from 2-phosphono-1,2,4-butanetricarboxylic acid, p-toluenesulfonic acid and hydroquinone. The preparation method for the water reducer comprises adding isopentenol polyoxyethylene ether and deionized water into a reaction vessel, uniformly stirring, heating, keeping warm, adding oxygen peroxide, then dropwise adding a material solution by employing a constant-flow pump, continuing to keep warm for reacting for 1-1.5 h after dropwise adding of the material solution is finished, naturally cooling to room temperature, and adjusting the pH value of the obtained product to 5-6 by using an alkaline solution. The phosphoric-acid-base modified polycarboxylic-acid water reducer possesses good sulfate ion resisting capability and sludge resisting capability, thereby satisfying engineering demand.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer and preparation method thereof

InactiveCN109626859AStrong adsorption capacity and dispersion performanceImprove dispersionCarboxylic esterDibasic acid

The invention relates to the technical field of concrete admixtures, in particular to a clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer and a preparation method thereof. With polyether macromonomers, unsaturated carboxylic acid, unsaturated carboxylic ester, dibasic acid anhydride, a crosslinking agent, amide monomers, unsaturated phosphate ester, phosphate, an oxidizing agent , a reducing agent, a chain transfer agent, a neutralizing agent and water as raw materials, the clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer is synthesized at normal temperature. Ester groups, amide groups and phosphate ester are introduced into the molecular structure of the polycarboxylate superplasticizer, and light crosslinking of the polycarboxylate superplasticizer is realized through the long-chain ester crosslinking agent, so that the superplasticizer has a good clay-resisting and slump-retaining effect and has the advantages of low mixing amount, high water reducing rate, high adaptability to clay-containing sand, good slump retaining performance and the like; besides, only normal-temperature polymerization is needed, the processis simple, the production cost is low, and the superplasticizer is suitable for industrial production.

Owner:山西黄河新型化工有限公司

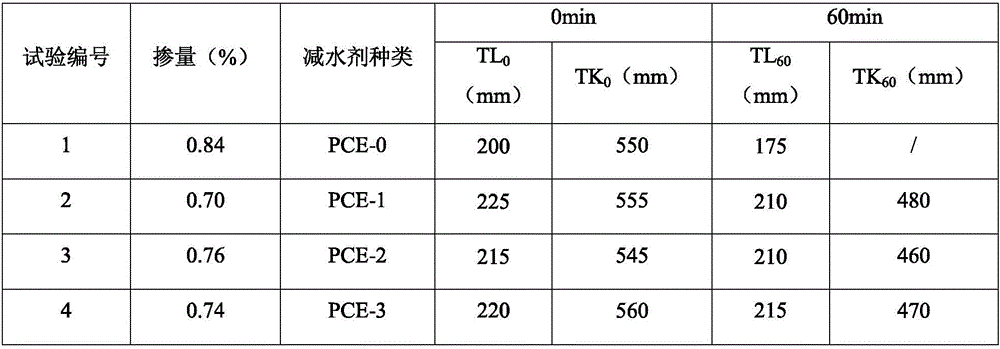

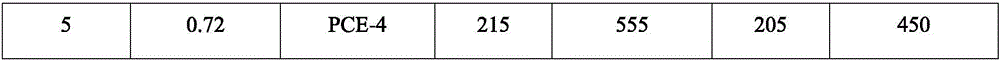

Super-early-strength PCE (polycarboxylate ether) superplasticizer and preparation method thereof

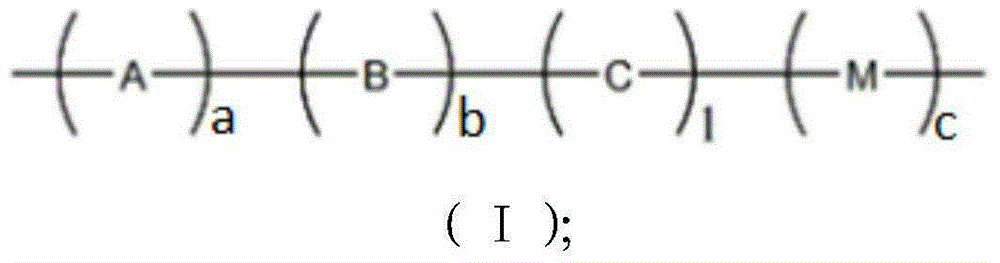

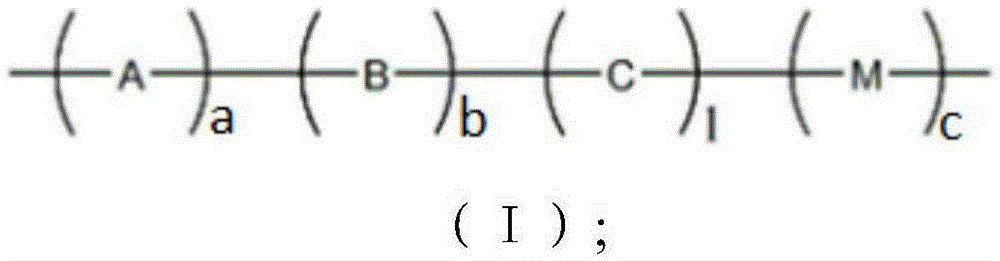

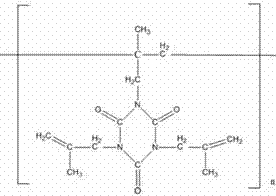

The invention provides a super-early-strength PCE (polycarboxylate ether) superplasticizer. The super-early-strength PCE superplasticizer is a compound shown in formula (I) and is synthesized with active macro-monomers used as raw materials, the space hindrance effect of the superplasticizer is further improved, and meanwhile, positive ions with good cement resistance are introduced in molecules, so that the superplasticizing rate, the cement resistance and the cement adaptability of the superplasticizer are increased. The superplasticizer has better tolerance and cannot have a continuous intercalation reaction with the cement. The positive ions of the super-early-strength PCE superplasticizer can inhibit expansion of the cement so as to reduce adsorption of the cement to an additive. The super-early-strength PCE superplasticizer can accelerate the hydration function of the cement and has the super-early-strength function. The super-early-strength PCE superplasticizer has super-early-strength and cement-resistant functions in common concrete.

Owner:GUANGDONG REDWALL NEW MATERIALS

Preparation method of mud-resistant type polycarboxylate superplasticizer

The invention relates to a preparation method of a mud-resistant type polycarboxylate superplasticizer. First, polyethylene glycol monomethyl ether and acrylic acid are used as raw materials and synthetized into polyethylene glycol monomethyl ether methyl acrylate. Then, the prepared polyethylene glycol monomethyl ether methyl acrylate is copolymerized with mixed liquid which is made from the acrylic acid and diacrylamide sodium dimethallyl sulphonate and mixed liquid which is made from ammonium persulfate and mercaptoethanol, alkaline compounds are added to regulate a pH value to 7-8 after reaction, and the mud-resistant type polycarboxylate superplasticizer is obtained. In the preparation method, technical parameters and conditions, such as raw material ratio, the used amount of chain transfer agents and initiators, copolymerization temperature, time and the like are determined. The reaction conditions are mild, the adopted equipment is simple, the equipment investment is small, the technology is reasonable, and the operation is simple and favorable for industrial production.

Owner:江苏汇迪建材有限公司

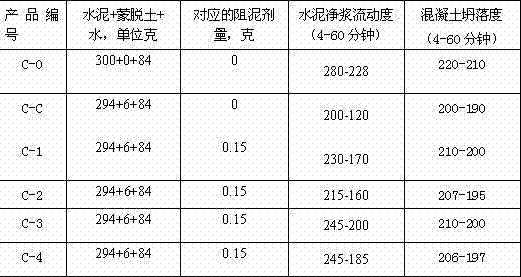

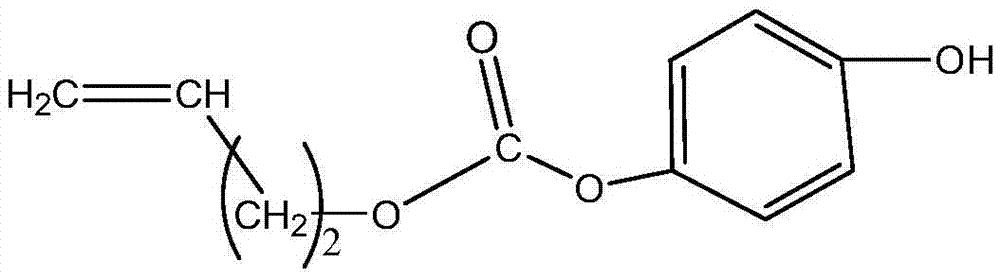

Preparation method for anti-mud-type polycarboxylic-acid water-reducing agent and application thereof

The invention discloses a preparation method for an anti-mud-type polycarboxylic-acid water-reducing agent and application thereof. The method is used to improve production efficiency of the anti-mud-type polycarboxylic-acid water-reducing agent, save energy and reinforce anti-mud performance and gradual plasticity-maintaining property of the anti-mud-type polycarboxylic-acid water-reducing agent. The preparation method for the anti-mud-type polycarboxylic-acid water-reducing agent provided by the invention comprises the following steps: under the normal temperature condition of 5 to 35 DEG C, mixing isobutylene alcohol polyoxyethylene ether and maleic anhydride-beta-cyclodextrin and then dissolving the mixture in water; adding a mixed solution of acrylic acid and p-styryl formate; adding hydrogen peroxide; under the protection of nitrogen, adding a mixed solution of mercaptopropionic acid and ascorbic acid, a mixed solution of acylic acid and p-styryl formate, and sodium dithionite; and adding an aqueous sodium hydroxide solution and adjusting the pH value to 6 to 7 so as to obtain the anti-mud-type polycarboxylic-acid water-reducing agent. The anti-mud-type polycarboxylic-acid water-reducing agent provided by the invention has a cup-shaped structure.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

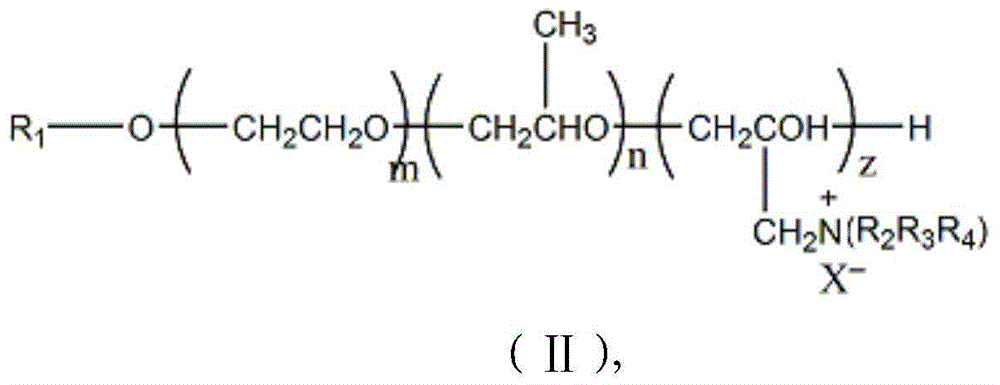

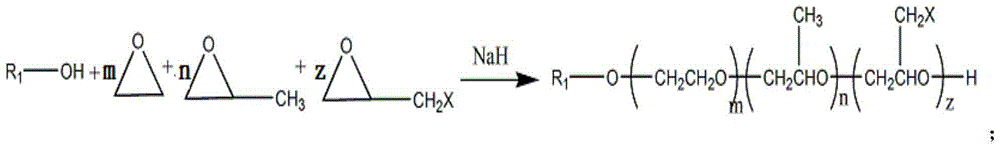

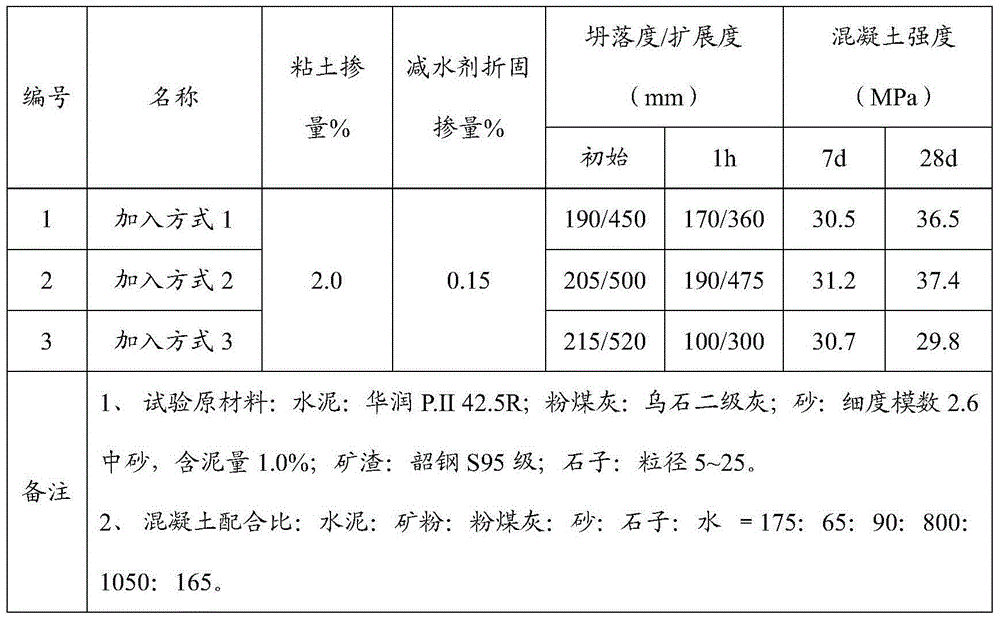

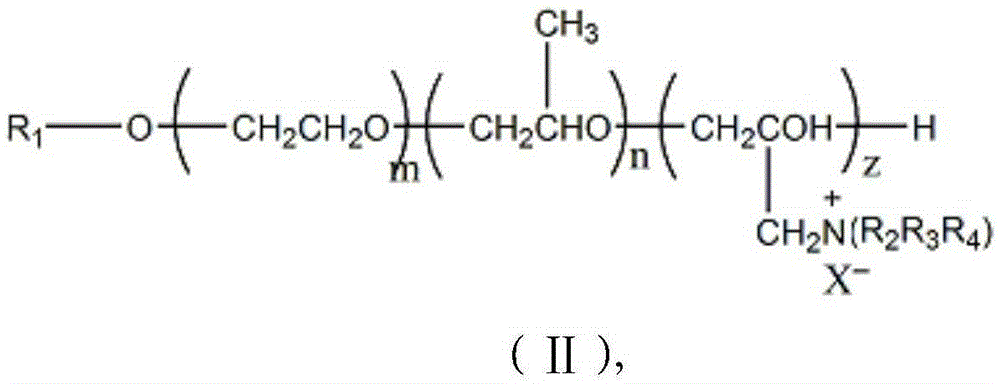

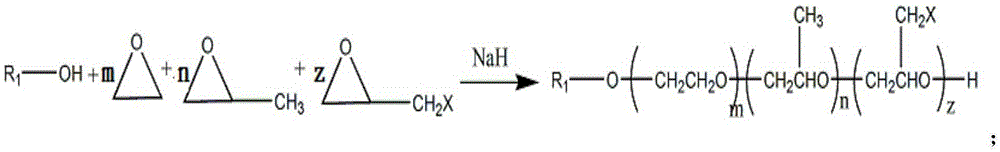

Aqueous polymer solution with anti-mud or mud-resistance performances and preparation method thereof

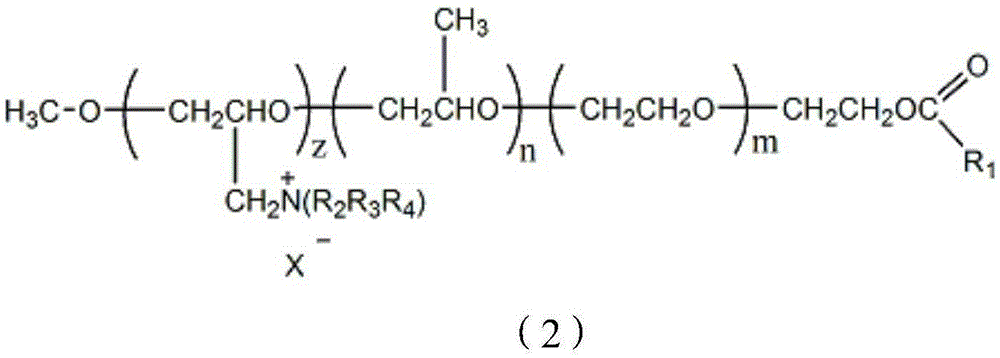

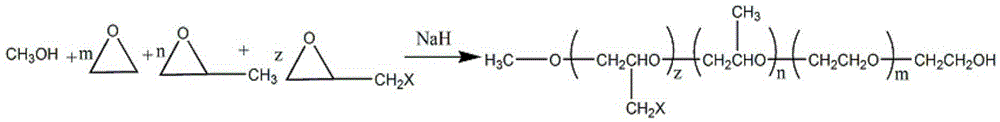

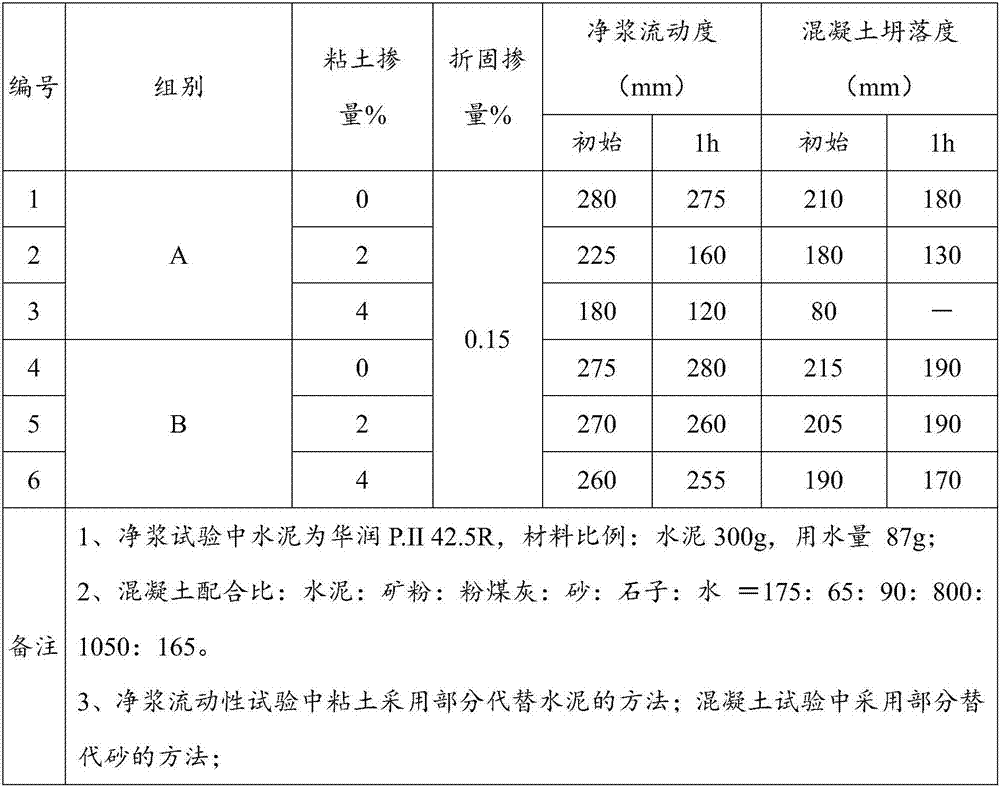

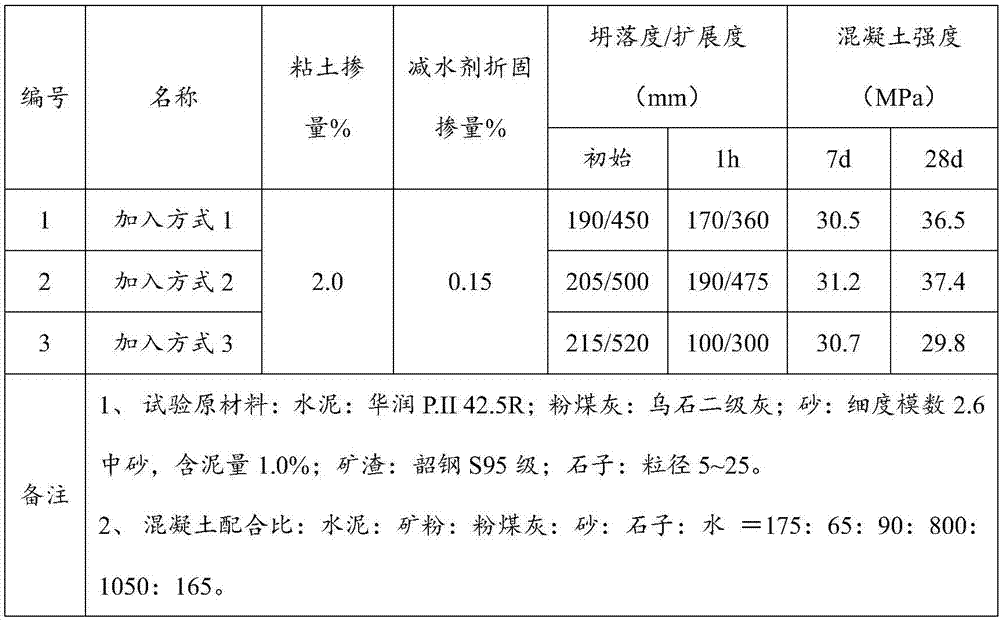

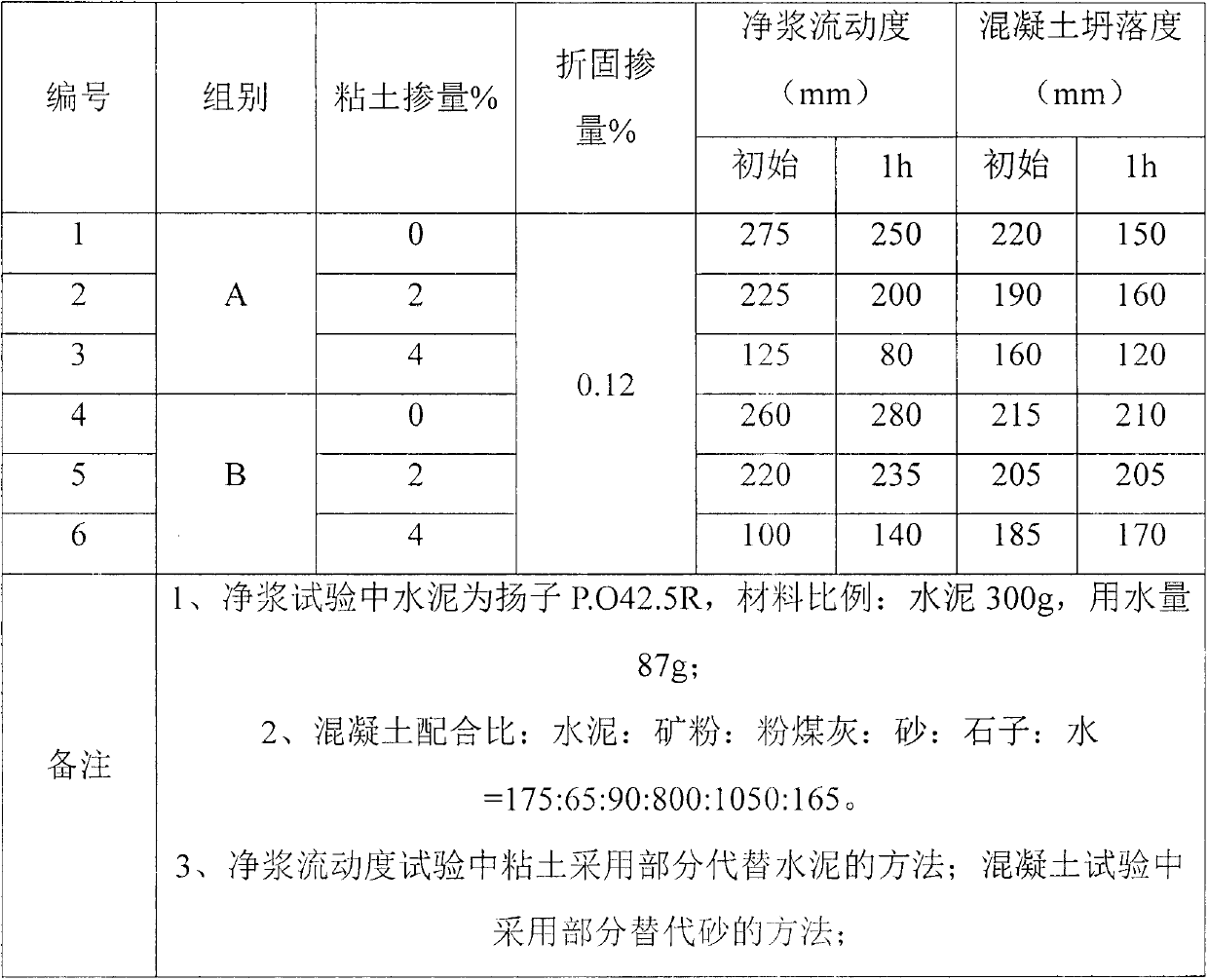

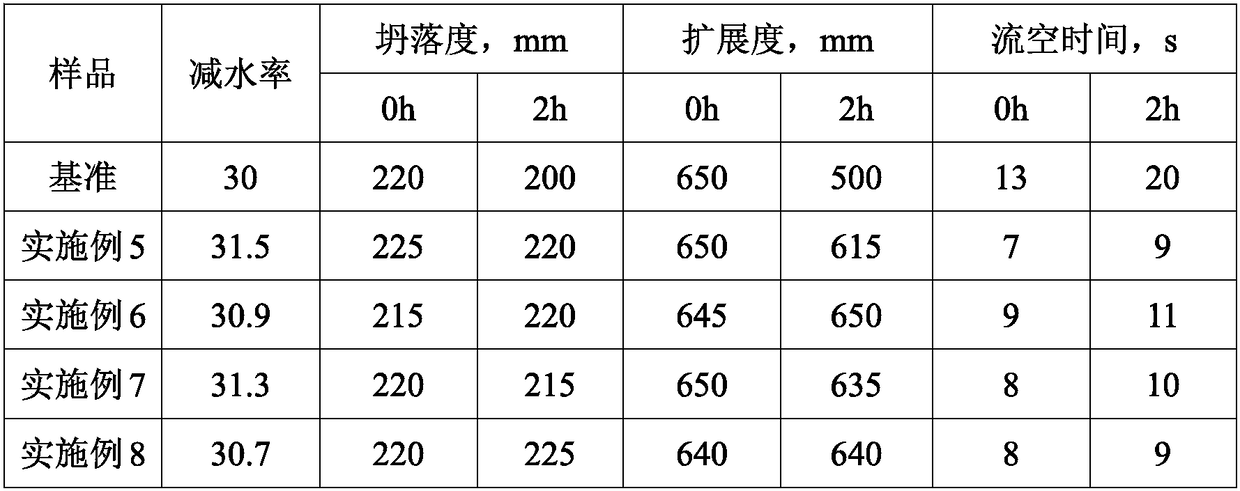

The invention discloses an aqueous polymer solution with anti-mud or mud-resistance performances and a preparation method thereof. The technical scheme employed by the invention is relatively good in anti-mud or mud-resistance effects, and can be individually used and added, and also mixedly used with a polycarboxylate water reducer, thereby being capable of improving the anti-mud or mud-resistance performance of the polycarboxylate water reducer. The invention is characterized in that (1) the molecular structure is novel, a main chain has ester groups and cationic, the aqueous polymer solution has relatively good effect on ordinary sand and gravel materials, especially for sand and gravel materials being high in mud content, and if the aqueous polymer solution is individually used, a mixing amount of the solid is 0.01-0.22 % based on weight of all gelling materials; (2) the molecular structure has no retarder components, and different seasons do not influence a normal coagulation time of concrete; and (3) the aqueous polymer solution can be used together with the water reducer or individually used, and thus is better than similar products in markets; and the products in the markets can only be individually used, but not be mixed with the water reducer simultaneously.

Owner:JIANGSU OXIRANCHEM CO LTD

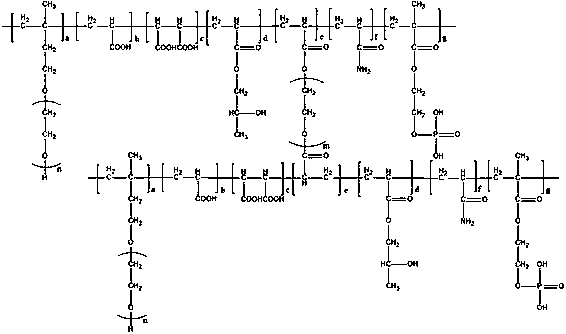

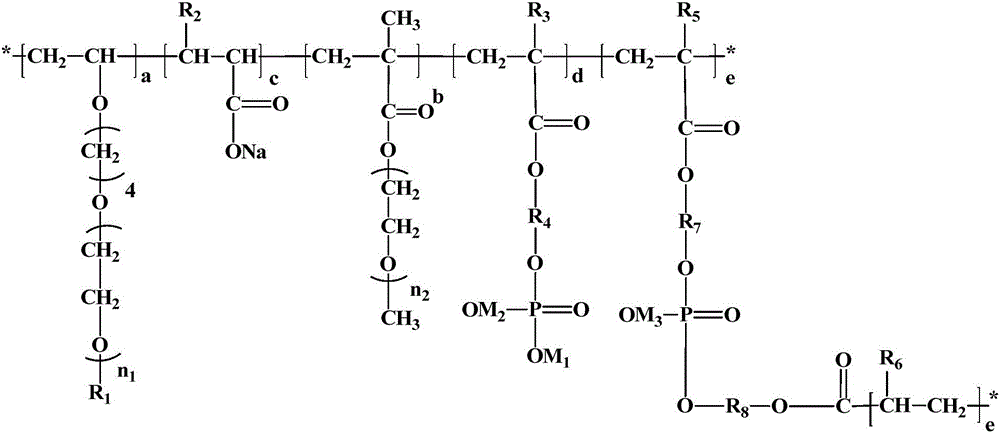

Crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer and preparation method thereof

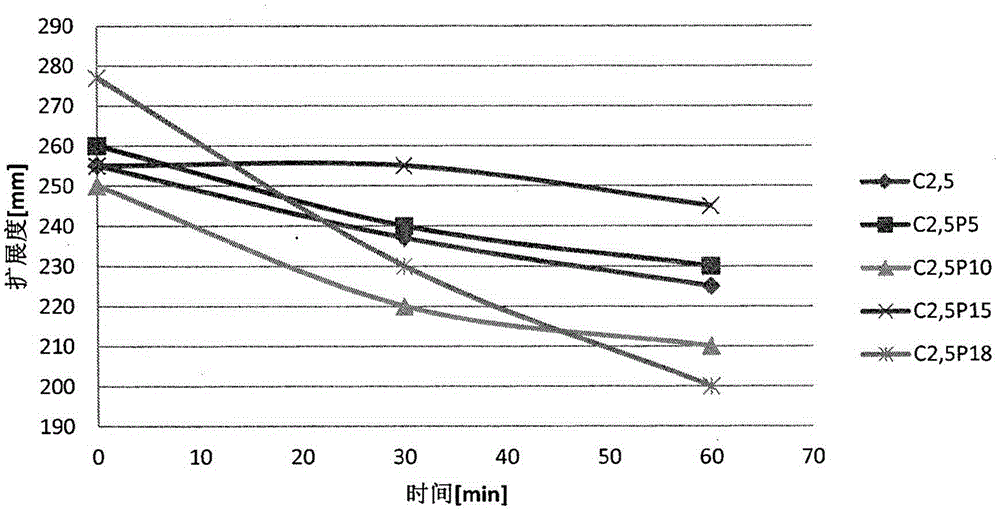

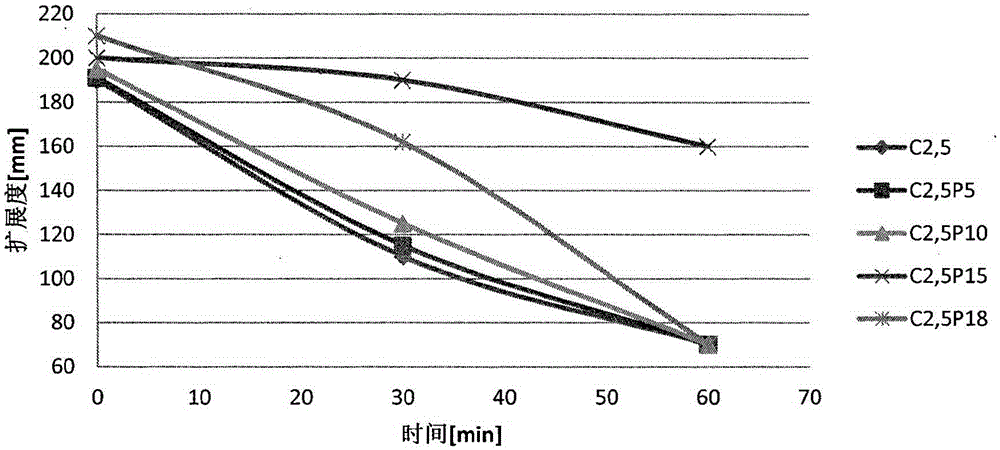

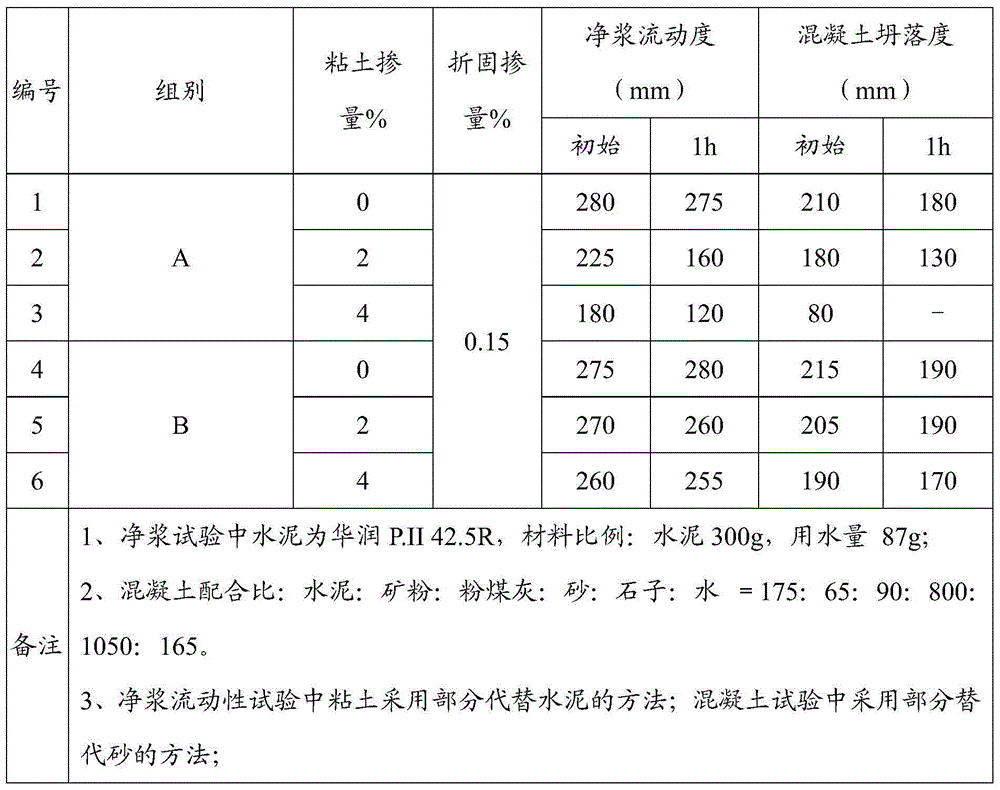

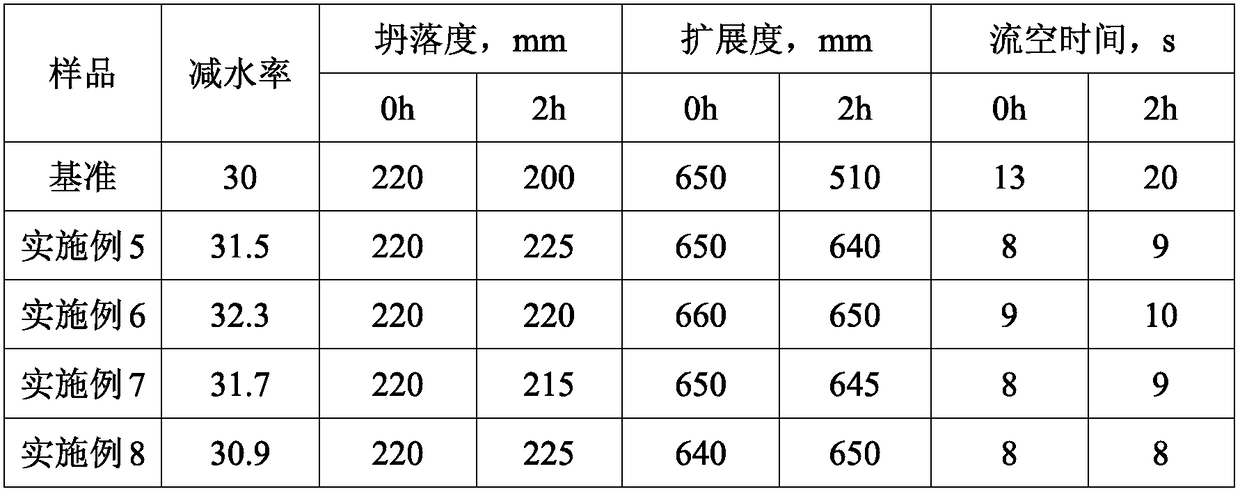

ActiveCN106046269AEven distribution of side chainsImprove workabilityPolymer sciencePhosphomonoesters

The invention discloses a crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer and a preparation method thereof. The crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer has the number-average molecular weight of 10000-100000 and has a structural formula as shown in the specification. Under the synergistic effect of various groups, the polycarboxylate superplasticizer formed by copolymerization of 4-hydroxybutyl-vinyl polyoxyethylene ether, unsaturated acid, unsaturated phosphomonoester and unsaturated phosphodiester has the advantages of high water-reducing rate, high slump loss resistance, high peaceability, mud-resistant property and low dosage sensibility.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Polycarboxylate superplasticizer with effects of mud resistance and viscosity reduction and preparation method thereof

The invention relates to the technical field of concrete additives and particularly relates to a polycarboxylate superplasticizer with effects of mud resistance and viscosity reduction and a preparation method thereof. The polycarboxylate superplasticizer is prepared from the following raw material components: polyether macromonomer, unsaturated carboxylic acid, functional monomer, initiator and achain transfer agent, wherein the functional monomer is an olefin polymer compound containing ester functional groups. The polycarboxylate superplasticizer with effects of mud resistance and viscosity reduction can be used for ensuring the water-reducing rate, reducing adsorption of clay on polycarboxylate ions and improving the viscosity of concrete, achieves uniformity of high mud resistance and high water reducing dispersion, and has important practical application value and market prospect.

Owner:科之杰新材料集团河南有限公司

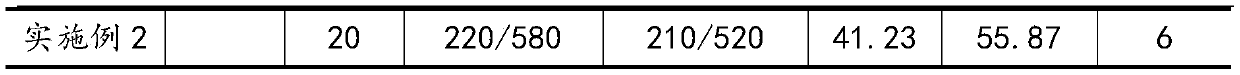

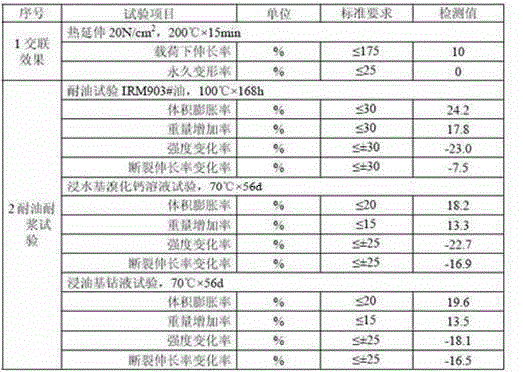

Irradiation crosslinking slurry-resistant halogen-free flame-retardant cable material used for petroleum platform and preparation method thereof

ActiveCN104927176AGood compatibilityImprove mechanical propertiesPlastic/resin/waxes insulatorsAntioxidantSlurry

The invention provides an irradiation crosslinking slurry-resistant halogen-free flame-retardant cable material used for a petroleum platform and a preparation method thereof. The material is composed of the following raw materials by weight: 25 to 55 parts of ethylene vinyl acetate copolymer, 10 to 20 parts of ethylene-vinyl acetate-carbon monoxide terpolymer, 25 to 45 parts of polyethylene, 5 to 15 parts of copolymer polyethylene grafted maleic anhydride, 8 to 10 parts of carbon black, 120 to 160 parts of a halogen-free flame retardant, 0.7 to 1.8 parts of a coupling agent, 1.5 to 3 parts of a crosslinking sensitizer, 1.4 to 2.4 parts of an antioxidant, 2 to 4 parts of silicone and 0.5 to 1.2 parts of a lubricant, wherein the ethylene vinyl acetate copolymer has a vinyl acetate VA content of 33% and a melt index of 0.2 g / 10min. According to the invention, the irradiation crosslinking slurry-resistant halogen-free flame-retardant cable material with low smoke, no toxicity, simple and convenient custom irradiation processing and low investment cost used for a petroleum platform and a preparation method thereof are provided; meanwhile, a halogen-free flame-retardant slurry-resistant sheathing material which meets the standards of halogen-free / anti-slurry cables used for a Norway NEK606 offshore platform can be produced.

Owner:中广核三角洲(江苏)塑化有限公司

Polycarboxylate superplasticizer with super high early strength and preparation method of polycarboxylate superplasticizer

ActiveCN105271900AIncreased steric hindranceHigh water reduction rateIntercalation reactionSuperplasticizer

The invention provides a polycarboxylate superplasticizer with super high early strength. The polycarboxylate superplasticizer with super high early strength is a compound shown in the formula (I) and is synthesized with an active macromonomer as the raw material, cations are introduced into molecules while the steric hindrance effect of the superplasticizer is further improved, the cations have good soil resistance, so that the water-reducing rate of the superplasticizer is increased, and the soil resistance and the cement adaptability of the superplasticizer are improved. The polycarboxylate superplasticizer has better tolerance for soil and does not have an intercalation reaction with the soil. The cations of the polycarboxylate superplasticizer with super high early strength can inhibit soil expansion, so that admixture adsorption by the soil is reduced. The polycarboxylate superplasticizer with super high early strength can accelerate hydration of cement and has the super high early strength function. The polycarboxylate superplasticizer with super high early strength has super high early strength and soil resistance functions when applied to common concrete.

Owner:GUANGDONG REDWALL NEW MATERIALS

Polycarboxylate superplasticizer with super high early strength and preparation method of polycarboxylate superplasticizer

ActiveCN105271902AIncreased steric hindranceHigh water reduction rateHydration reactionSuperplasticizer

The invention discloses a polycarboxylate superplasticizer with super high early strength and a preparation method of the polycarboxylate superplasticizer. A molecular structure of the polycarboxylate superplasticizer with super high early strength contains cationic charges, a hydration reaction of cement is promoted, strength development of hardened concrete is accelerated, and the super high early strength function is realized; the polycarboxylate superplasticizer has specific cement particle dispersion capability by the aid of specific amphiphilic structure and steric hindrance effect, the water-reducing rate is high, and the soil resistance is good.

Owner:GUANGDONG REDWALL NEW MATERIALS

A kind of preparation method and application of mud-resistant polycarboxylate superplasticizer

The invention discloses a preparation method for an anti-mud-type polycarboxylic-acid water-reducing agent and application thereof. The method is used to improve production efficiency of the anti-mud-type polycarboxylic-acid water-reducing agent, save energy and reinforce anti-mud performance and gradual plasticity-maintaining property of the anti-mud-type polycarboxylic-acid water-reducing agent. The preparation method for the anti-mud-type polycarboxylic-acid water-reducing agent provided by the invention comprises the following steps: under the normal temperature condition of 5 to 35 DEG C, mixing isobutylene alcohol polyoxyethylene ether and maleic anhydride-beta-cyclodextrin and then dissolving the mixture in water; adding a mixed solution of acrylic acid and p-styryl formate; adding hydrogen peroxide; under the protection of nitrogen, adding a mixed solution of mercaptopropionic acid and ascorbic acid, a mixed solution of acylic acid and p-styryl formate, and sodium dithionite; and adding an aqueous sodium hydroxide solution and adjusting the pH value to 6 to 7 so as to obtain the anti-mud-type polycarboxylic-acid water-reducing agent. The anti-mud-type polycarboxylic-acid water-reducing agent provided by the invention has a cup-shaped structure.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

Preparation method of sulfide mineral collector

The invention relates to a preparation method of sulfide mineral collector. The method comprises the following steps: sodium sulfide and phosphoric acid are weighed according to the mol ratio of 2 to 3:3 to 6 and added into a gas generator; generated gas is collected and charged into a high-pressure reactor charged with 10 to 13 C of fatty alcohol, thorium oxide catalyst or strongly acid cation resin; the mol ratio of the alcohol to gas is kept to be 1 to 2:1.2 to 2.5; the reaction is performed for 6 to 8 h under the condition that the pressure is 12 to 15 MPa and the temperature is 300 to 450 DEG C to obtain liquid mixture; distillate is collected by distillation under normal pressure at 180 to 300 DEG C according to different carbon numbers, and after the refracting index is detected to be qualified, transparent, colorless and adhesive liquid substance with peculiar odor is obtained, which is the sulfide mineral collector. By adopting the sulfide mineral collector, sulphide ore can be efficiently recovered without active agent, the overall recovery of the sulphide ore reaches larger than 89 percent, and the production cost is reduced.

Owner:广西华锡集团股份有限公司 +1

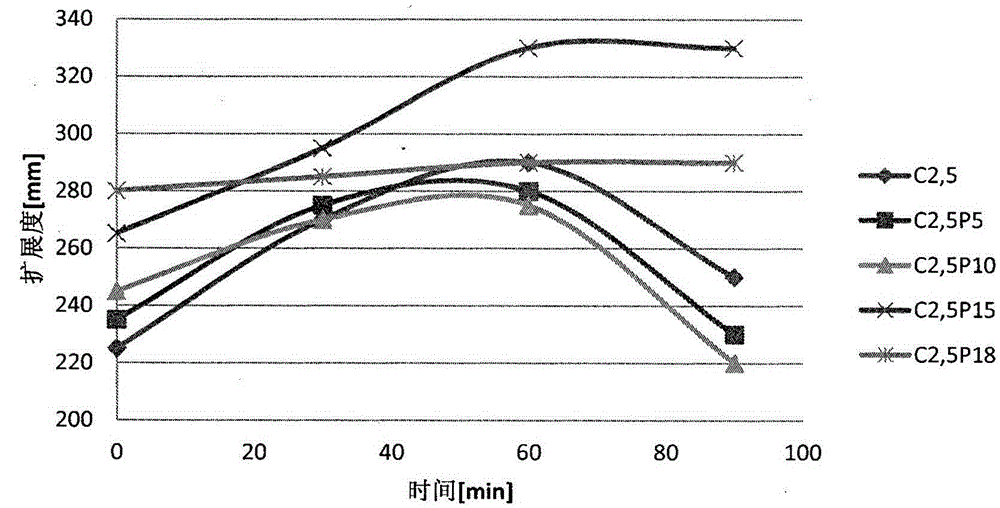

Mud resistant slow release type slump retaining agent containing cyclodextrin side group and preparation method thereof

The invention discloses a mud resistant slow release type slump retaining agent containing a cyclodextrin side group and a preparation method thereof. The method synthesizes a mud resisting ester monomer by introducing a beta-cyclodextrin structural unit with appropriate steric hindrance and better water solubility to be subjected to an esterification reaction with fumaric acid. In alkaline environment of cement hydration, with the slow release of the mud resisting ester monomer, the beta-cyclodextrin introduced into the molecular structure of a water reducer can effectively weaken interpenetration between water reducer molecules and a clay layer because particles of the beta-cyclodextrin distribute in a range of 0.53-1.78 nm which is close to 1.44-1.86 nm that is the interlayer spacing ofbentonite, and so the polycarboxylic acid water reducer is good in mud resistance and slump retaining effect. Meanwhile, a phosphoric acid monomer is introduced into the molecular structure of the water reducer to further improve the mud resisting effect. The mud resistant slump retaining type polycarboxylic acid water reducer containing a cyclodextrin side group prepared by the method of the invention has the advantages of low dosage, long slump retaining time, strong mud resistance and the like, and is easy in synthesis process, safe, environmentally friendly and low in production cost.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

Preparation method for muddy-resistant polycarboxylate water-reducer

The invention discloses a muddy-resistant polycarboxylate water-reducer and a preparation method thereof. The muddy-resistant polycarboxylate water-reducer comprises the following raw materials: a maleic acid, triethanolamine, polyoxyethylene monomethyl ether, acrylamide, a crylic acid, isoamyl polyoxyethylene ether, a maleic acid grafted glucose phosphate derivative and water. The preparation method for the muddy-resistant polycarboxylate water-reducer is green and environmental, the water reducing dispersibility is good, the muddy-resistant effect is remarkable, the adaptability to mud-containing aggregate is strong, and the cost performance is high. The production process is green and environmental without the three waste emission, and accords with a concept of green and environmental protection and sustainable development.

Owner:南京建高新材料科技有限公司

Preparation method of cross-linked viscosity-reducing polycarboxylate water reducer

ActiveCN109265052AStrong adsorption capacityImprove competitive adsorption capacityPhosphateWater reducer

The invention discloses a preparation method of a cross-linked viscosity-reducing polycarboxylate water reducer. The preparation method comprises the following steps: (1) preparing esterification monomers; (2) performing the copolymerization reaction; and (3) performing the neutralization reaction. According to the preparation method of the invention, allyl alcohol monomers are copolymerized withesterification monomers obtained by esterifying two or three carboxyl groups in little 2-butane phosphate-1,2,4-tricarboxylic acid, polyether macro momoners, 2-methyl allyl oxyethyl phosphorylcholineand unsaturated acid prepare the cross-linked viscosity-reducing polycarboxylate water reducer, and while phosphate, carboxylate radicals, quaternary ammonium salt and ester groups are introduced intoa polymer molecular structure, the polymer structure is slightly cross-linked. The cross-linked viscosity-reducing polycarboxylate water reducer prepared by the method has viscosity reducing performance, also has water reducing, slump loss resisting and mud resisting properties, and solves the problems of high viscosity, poor mixing property and fast loss due to high mud content in a concrete rawmaterial.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

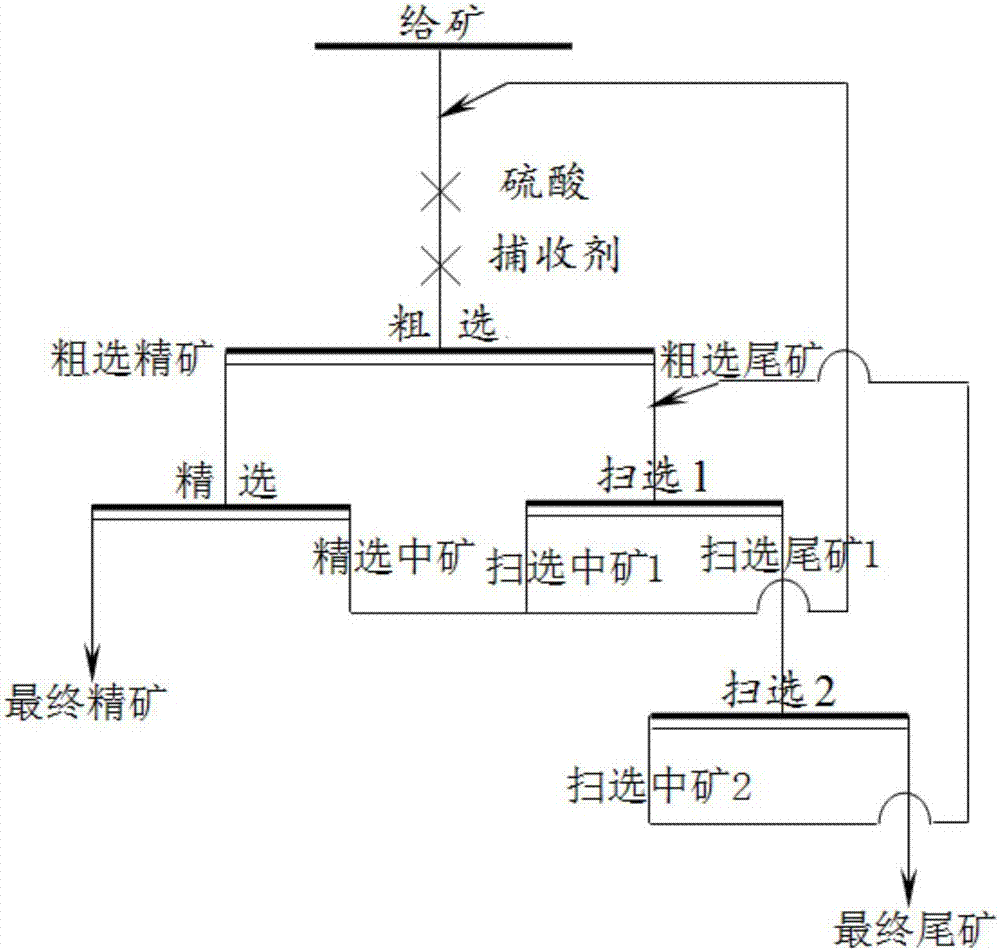

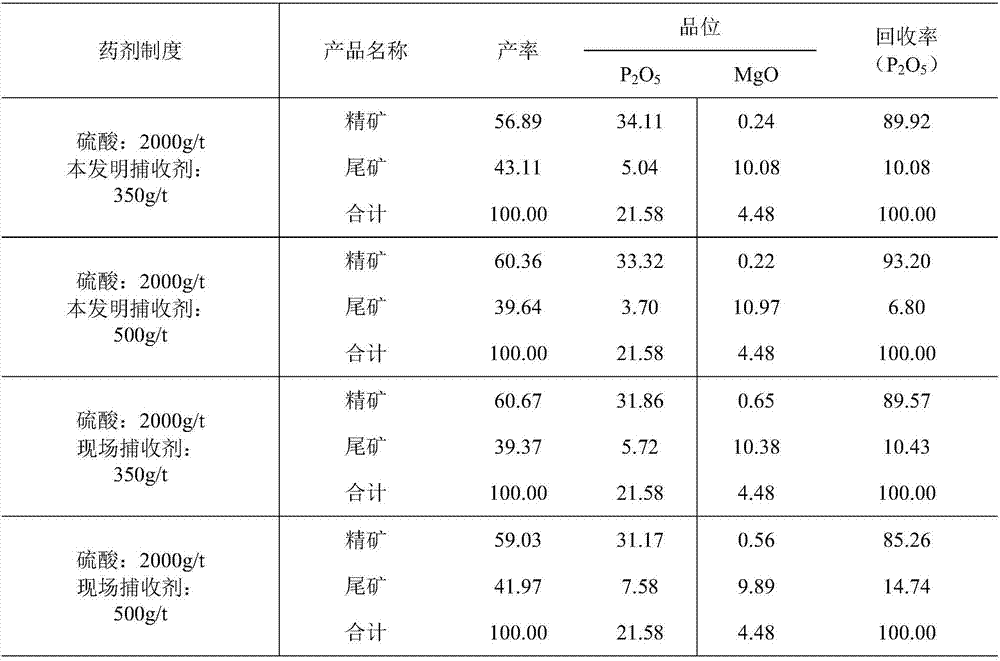

Collophanite reverse flotation collector and preparation method and application method thereof

ActiveCN106944263AGood mud resistanceThe flotation index is stableFlotationHigh phosphateOrganic layer

The invention discloses a collophanite reverse flotation collector and a preparation method and an application method thereof, and belongs to the technical field of solid mineral resource separation. Vacuum five-line phenol extract oil, a diluent, fuming sulphuric acid, sodium hydroxide and the like are used as raw materials, after raw oil and the diluent are mixed according to a certain mass percent, the fuming sulphuric acid is fed into a reaction still for sulfonation, stirring and washing are conducted after a sulfonation reaction is completed, still standing is conducted for layering, an organic layer is taken for primary saponification in a saponification reaction still, and sulphonate is obtained; and the obtained sulphonate and soy acid are compounded into a mixture according to a certain mass percent, the mixture is subjected to secondary saponification, and the anionic high-calcium (high-magnesium) collophanite reverse flotation collector is obtained. The collector is simple in preparation process, high in adaptability (such as the temperature and the ore pulp pH), good in mud resistance, high and stable in flotation index, low in cost and free of toxicity; and when the collector is applied to high-calcium (high-magnesium) collophanite flotation, the high-phosphate concentrate grade (P2O5) can be remarkably improved, the recovery rate of high-phosphate concentrate can be remarkably increased, and the impurity content of the concentrate is lowered.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

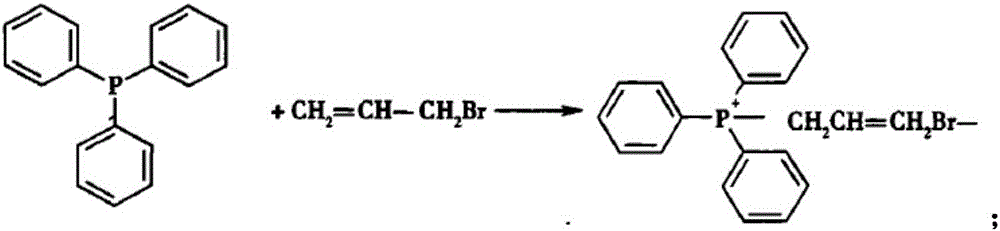

Method for preparing ester soil-resistant and slump-retaining type polycarboxylic acid water reducing agents

The invention discloses a method for preparing ester soil-resistant and slump-retaining type polycarboxylic acid water reducing agents. The method includes steps of (1), carrying out reaction shown as a graph on triphenyl phosphine and allyl bromide in carbon tetrachloride according to a molar ratio of 1:1.0-1.5 to prepare unsaturated amphoteric quaternary phosphorus salt; (2), carrying out esterification reaction; (3), carrying out copolymerization reaction. The method has the advantages that the manufactured unsaturated amphoteric quaternary phosphorus salt is introduced into low-sensitivity soil-resistant type polycarboxylic acid water reducing agents in synthesis procedures, effects of inhibiting or reducing the activity of soil can be realized by side chains of cation groups of the quaternary phosphorus salt, accordingly, the water reducing agent adsorption of the soil can be reduced, effects of adsorbing and dispersing cement can be respectively realized by carboxylic acid radical ions and polyether side chains in molecular structures, and the ester soil-resistant and slump-retaining type polycarboxylic acid water reducing agents have soil-resistant adaptability.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Phosphoric acid-modified polycarboxylate water reducer with high adaptability and preparation method thereof

The invention discloses a phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and a preparation method thereof. The water reducer is prepared from the following raw materials: isopentenol polyoxyethylene ether, hydrogen peroxide, acrylic acid, an unsaturated phosphoric acid monomer, deionized water, a reducing agent, and a chain transferring agent. The chain transferring agent is one of mercaptoethanol, mercaptoacetic acid and mercaptopropionic acid. The unsaturated phosphoric acid monomer is prepared from 2-phosphono-1,2,4-butanetricarboxylic acid, p-toluenesulfonic acid and hydroquinone. The preparation method for the water reducer comprises adding isopentenol polyoxyethylene ether and deionized water into a reaction vessel, uniformly stirring, heating, keeping warm, adding oxygen peroxide, then dropwise adding a material solution by employing a constant-flow pump, continuing to keep warm for reacting for 1-1.5 h after dropwise adding of the material solution is finished, naturally cooling to room temperature, and adjusting the pH value of the obtained product to 5-6 by using an alkaline solution. The phosphoric-acid-base modified polycarboxylic-acid water reducer possesses good sulfate ion resisting capability and sludge resisting capability, thereby satisfying engineering demand.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

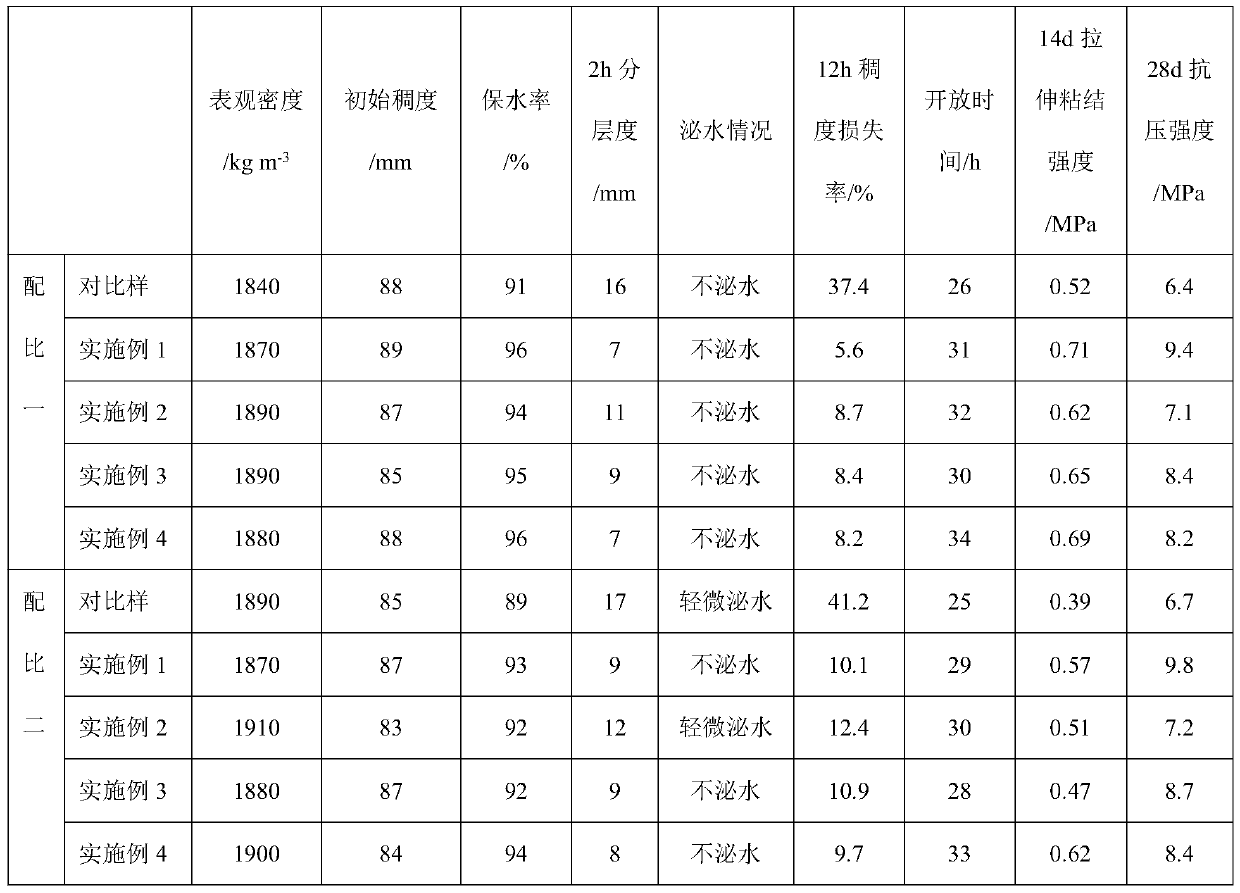

Machine-made sand wet-mixed mortar admixture and preparation method thereof

The invention discloses a machine-made sand wet-mixed mortar admixture and a preparation method thereof. The machine-made sand wet-mixed mortar admixture is formed by compounding a special water reducing agent for wet-mixed mortar, a retarder, a water locking and retaining agent and a stabilizer, wherein maleimide alkyl acid and hydroxypropyl acrylate are introduced into the special water reducingagent for the wet-mixed mortar, so the problem that high mud content and high powder content of machine-made sand wet-mixed mortar influence absorption of an admixture and the water retaining property and the wrapping property of mortar are solved. According to the machine-made sand wet-mixed mortar admixture disclosed by the invention, the consistency and the water retention rate of machine-madesand wet-mixed mortar are improved, so the opening time of the mortar is prolonged, and the problems of complex compounding, considerable small functional materials, easy layering of a finished product and the like of a general wet-mixed mortar admixture are solved.

Owner:云南森博混凝土外加剂有限公司

Preparation method for cationic side chain esterified-grafted highly-mud-resistant cement dispersing agent

ActiveCN106117564AExpanding the theoretical connotation of the design-structure-performance of moleculesBroaden research ideasPolymer sciencePolyethylene glycol

The invention discloses a preparation method for a cationic side chain esterified-grafted highly-mud-resistant cement dispersing agent, and belongs to the field of dispersing agents. The preparation method comprises the following steps: performing free radical polymerization on an unsaturated carboxylic acid monomer serving as a reactant to obtain a polycarboxylic acid main chain under the action of an initiator and a chain transfer agent, performing free radical polymerization on an unsaturated cationic quaternary ammonium salt monomer serving as a reactant to obtain a hydroxyl-terminated cationic side chain under an oxidization-reduction initiation system formed by high-valence ceric salt and alcohol, and performing esterification-grafting reaction on the polycarboxylic acid main chain, the hydroxyl-terminated cationic side chain and a polyethylene glycol compound in the presence of a catalyst. According to the preparation method, a process is simple and easy to control, and the preparation method is low in cost, energy-saving, efficient, environment-friendly and free of pollution; a composite side chain structure is modified and synthesized by a molecular structure design, so that side chain steric hindrance effects are successfully achieved, cationic charge arrangement is successfully implemented, water reduction and slump retaining characteristics and clay side effect suppression capabilities higher than those of an ordinary polycarboxylic acid water reducing agent are achieved, and the dispersing agent has broad market prospect and great popularization and application potential.

Owner:BEIJING UNIV OF TECH

Special early strength type admixture for concrete for pre-fabricated members

The invention provides a special early strength type admixture for concrete for pre-fabricated members. The technical problem solved by the invention is mainly to provide an admixture capable of improving the early strength of concrete for the pre-fabricated members in winter. The special early strength type admixture mainly comprises the following components in percentage by weight: 15-25% of polycarboxylate water reducing type mother liquor, 6-15% of polycarboxylate slump loss resisting type mother liquor, 6-12% of an early strength component, 3-8% of an anti-mud component, 1-3% of an anti-segregation component and the balance of water. The prepared admixture provided by the invention has the outstanding advantages that the water-reducing rate is high and the early strength effect is obvious; the adaptability to cement is good and the effect is also remarkable in the case of high mud content in sand and gravel; the raw materials used for production are free of pungent odor or toxicity and are green and environmentally-friendly; the components are free of chloride ions and have no corrosion or damage effect on reinforcing steel bars of the pre-fabricated members.

Owner:UNIV OF JINAN

Concrete and mortar slump-retaining anti-mud stabilizing agent and preparation method thereof

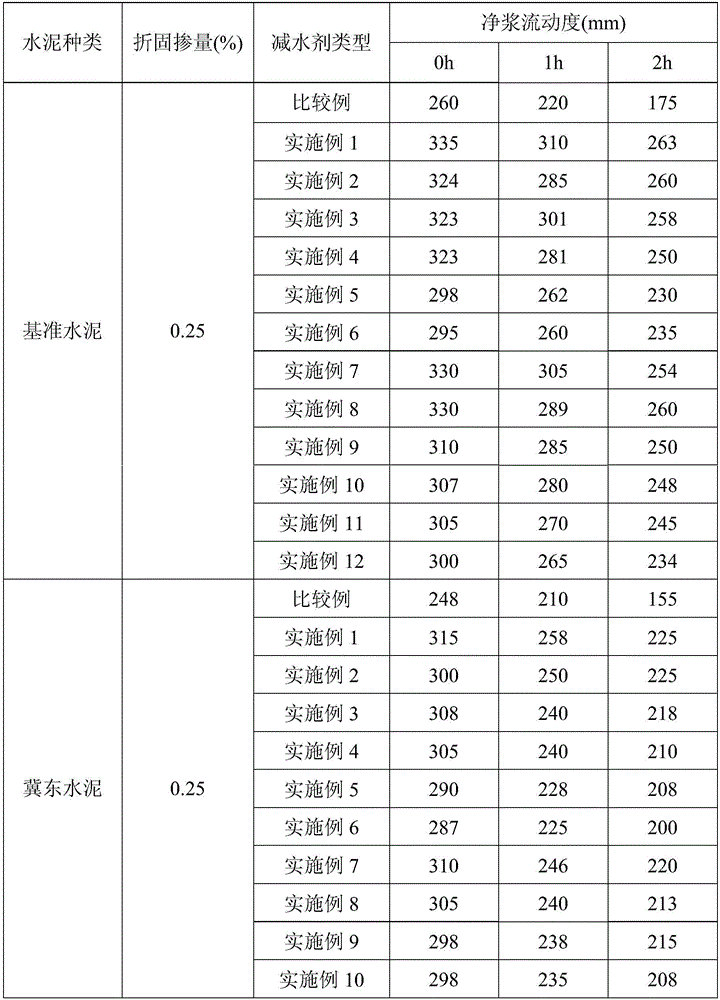

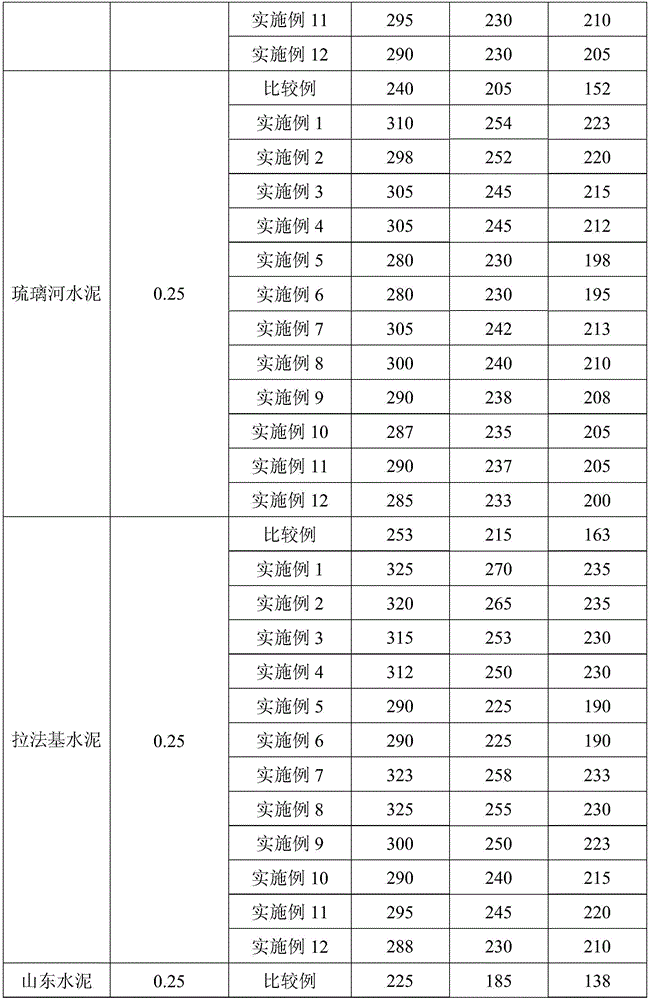

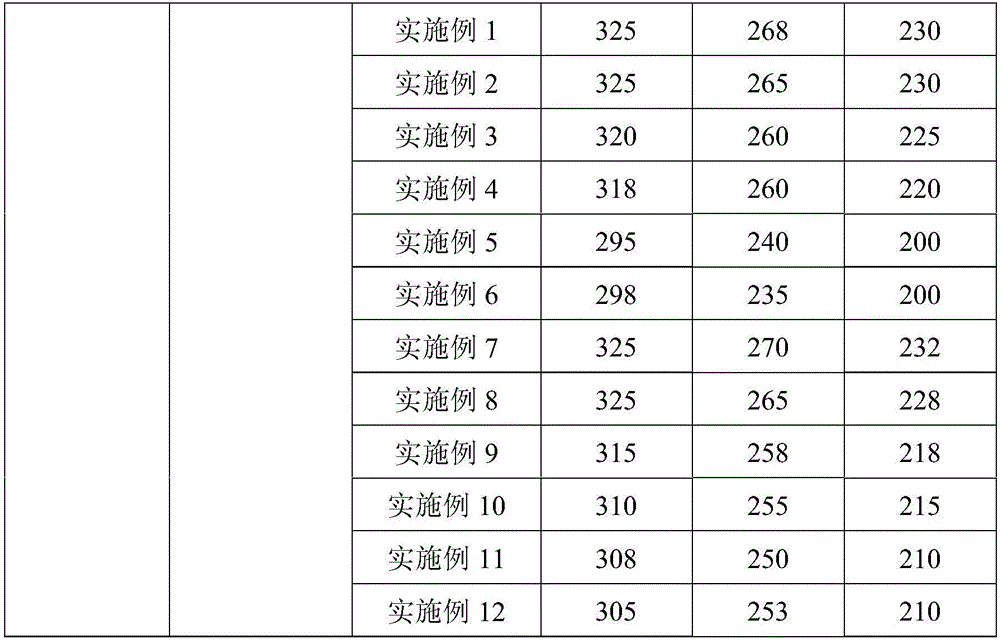

The invention provides a slump-retaining anti-mud stabilizing agent for concrete and mortar and a preparation method thereof. The product is prepared by mixing unsaturated polyether, unsaturated carboxylic acid or anhydride, unsaturated carboxylic ester, unsaturated amide propanesulfonic acid, a chain transfer agent, an initiator, a reducing agent, alkali, water and the like according to a certain mass percentage. The stabilizing agent is a chemical additive applied to concrete and mortar, when the workability of the concrete or the mortar is obviously reduced due to the fact that the concrete or the mortar sand and stone materials contain excessive mud, stone powder, flocculating agents and the like, and the state of fresh concrete and mortar can be stabilized; Thus, the workability, the slump retaining property, the pumpability, the viscosity reduction property, the mud resistance, the flocculant resistance, the uniformity and the consistency of concrete or mortar are improved.

Owner:FUKE TECH (SUZHOU) CO LTD +1

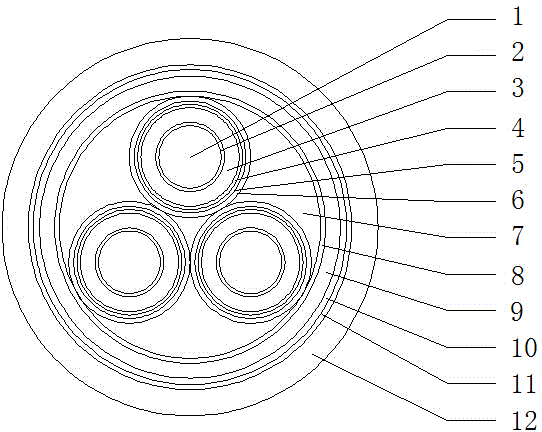

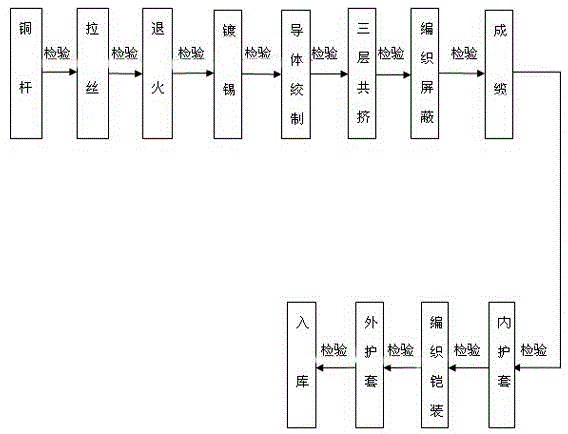

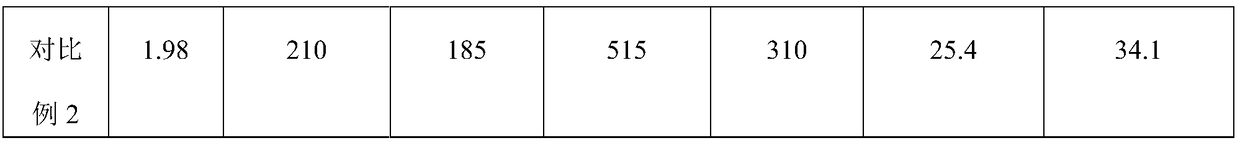

Halogen-free mud resistant medium voltage power cable for offshore oil platform and manufacturing method thereof

InactiveCN104900330AEnsure corrosionEnsure tensile strengthPower cables with screens/conductive layersInsulated cablesEnvironmental resistanceElectric power transmission

The present invention discloses a halogen-free mud resistant medium voltage power cable for an offshore oil platform and a manufacturing method thereof. The cable comprises a coble core which is formed by twisting a plurality of insulated wire cores. The gap of the wire cores is provided with a halogen-free flame retardant glass fiber rope filling layer. A first wrapping layer with a halogen-free flame retardant glass fiber tape is overlapped outside the cable core. An inner sheath made from extruding thermoset radiation cross-linked halogen-free low-smoke flame retardant and mud resistant polyolefin is extruded outside the first wrapping layer. A tinned copper wire armored layer is rotatingly woven outside the inner sheath. A second wrapping layer with a halogen-free flame retardant glass fiber tape is overlapped outside the armored layer. An outer sheath made of thermoset radiation cross-linked halogen-free low-smoke flame retardant and mud resistant polyolefin is extruded at the outermost layer of the cable. The cable has flame retardant, halogen free, lead free, asbestos free, mud resistance, oil resistance, heat resistance, corrosion resistance and tensile characteristics and excellent electrical, mechanical and environmental protection functions, and the cable can be widely used in the power transmission system of an offshore oil platform.

Owner:WUXI CITY HENG HUI CABLE

Method for preparation of high mud resistant polycarboxylic acid dispersant by unsaturated halogenated hydrocarbon copolymerization and grafting with cationic side chain

ActiveCN106188557AThe polymerization process is mild and stableLess side effectsAlcoholPolyethylene glycol

Belonging to the field of dispersants, the invention provides a method for preparation of high mud resistant polycarboxylic acid dispersant by unsaturated halogenated hydrocarbon copolymerization and grafting with a cationic side chain. The method consists of: employing an unsaturated carboxylic acid monomer, an unsaturated halogenated hydrocarbon monomer, an unsaturated cationic quaternary ammonium salt monomer, a polyethylene glycol compound and the like as the raw materials, firstly conducting main chain copolymerization, then polymerizing the cationic side chain, performing functionalization, and finally carrying out etherification grafting so as to synthesize the excellent performance high mud resistant polycarboxylic acid dispersant material with unsaturated halogenated hydrocarbon copolymerized and grafted with cationic side chain, i.e. taking unsaturated carboxylic acid and unsaturated halogenated hydrocarbon as the reactants, conducting free radical polymerization to obtain a carboxylic acid-halogenated hydrocarbon copolymer main chain, using high valence cerium salt-alcohol to initiate polymerization of an unsaturated cationic quaternary ammonium salt monomer so as to obtain a hydroxyl terminated cationic side chain, then modifying the hydroxyl terminated cationic side chain and the polyethylene glycol compound to obtain a functionalized side chain, and carrying out etherification grafting of the functionalized side chain on the carboxylic acid-halogenated hydrocarbon copolymer main chain. The method provided by the invention realizes high water reduction, slump loss resistance, high clay resistance and other multiple effects.

Owner:BEIJING UNIV OF TECH

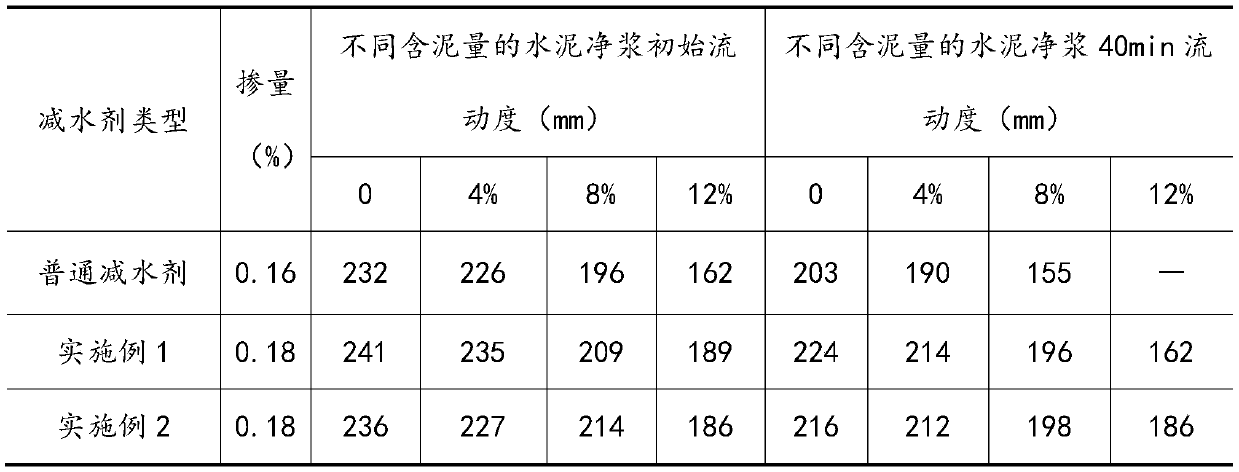

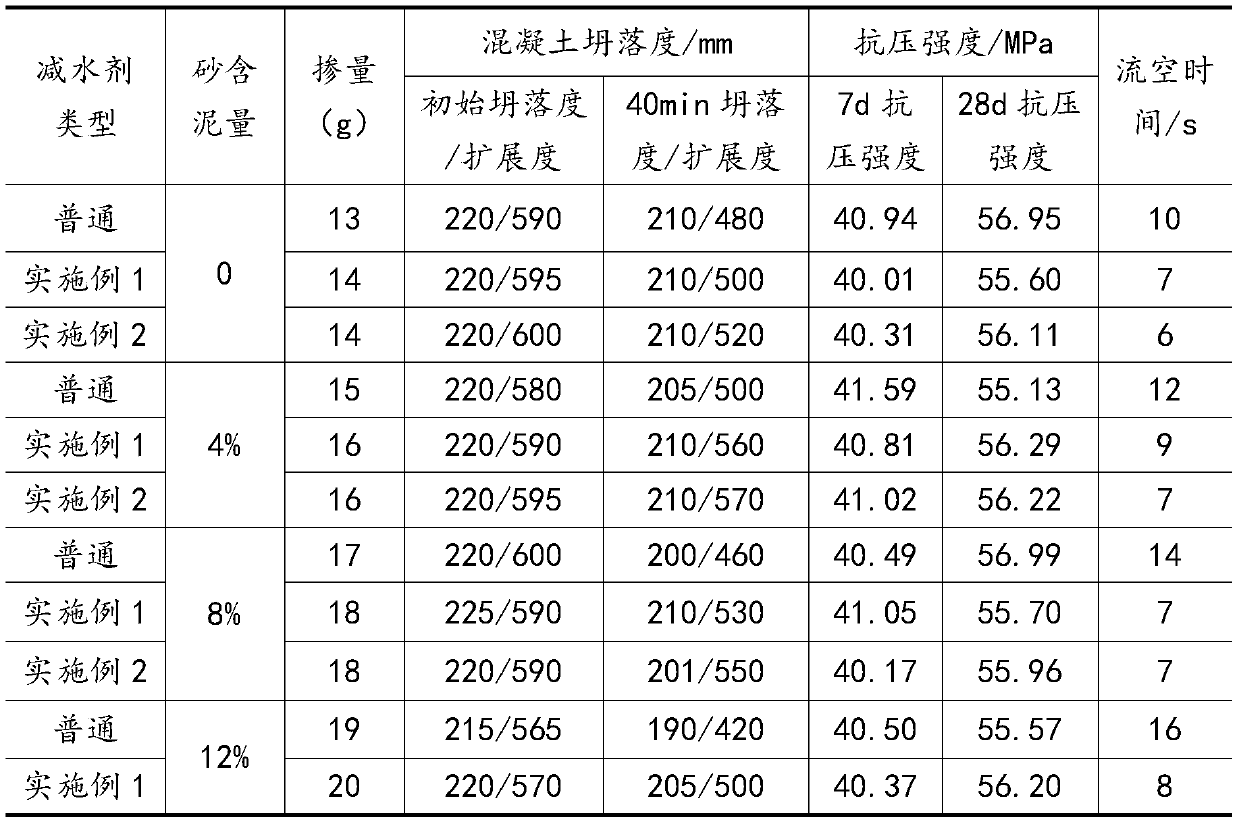

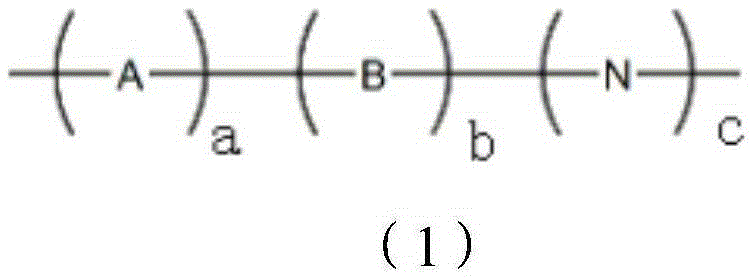

Mud resistant type water reducing agent and preparation method therefor

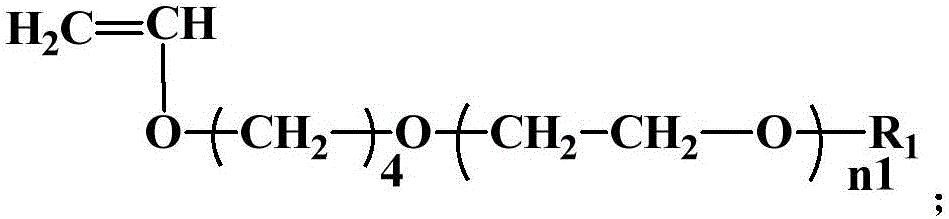

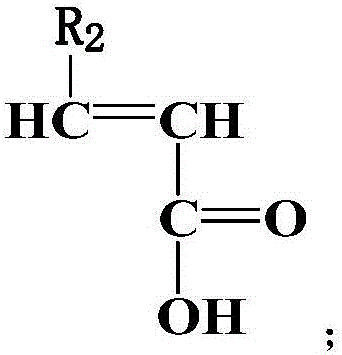

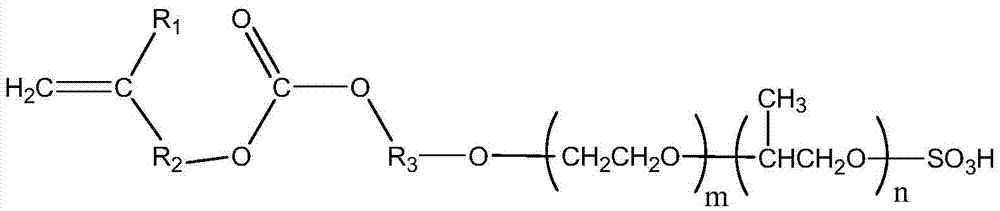

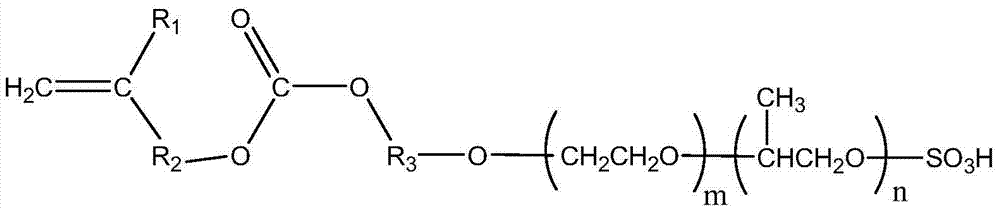

The invention provides a mud resistant type water reducing agent and a preparation method therefor. The water reducing agent is prepared by copolymerizing a monomer A, a monomer B and a monomer C. The monomer B is unsaturated carboxylic acid monomers; the monomer C is unsaturated ester monomers. The structure of the monomer A is shown in the description: R1 is hydrogen or methyl; R2 is alkylidene with 1 to 5 carbon atoms; R3 is phenylene or benzylene; m and n are integers greater than zero, m is greater than or equal to 1 and less than or equal to 180, and n is greater than or equal to 1 and less than or equal to 3.

Owner:JIANGSU OXIRANCHEM CO LTD

Viscosity-reducing type polycarboxylic acid water reducing agent preparation method

ActiveCN109180876ALightly crosslinkedStructural stretchCross-link2-methacryloyloxyethyl phosphorylcholine

The invention discloses a viscosity-reducing type polycarboxylic acid water reducing agent preparation method, which comprises: (1) preparing an esterification monomer; (2) carrying out a copolymerization reaction; and (3) carrying out a neutralization reaction. According to the present invention, the viscosity-reducing type polycarboxylic acid water reducing agent is prepared by co-polymerizing 2-allyloxyethanol, a blend, VPEG, 2-methacryloyloxyethyl phosphorylcholine and an unsaturated acid, such that the phosphate radical, the carboxylate radical, the quaternary ammonium salt and the estergroup are introduced into the molecular structure of the polymer while the polymer structure is lightly cross-linked, wherein the product obtained by the esterification of the single carboxy in 2-phosphonobutane-1,2,4-tricarboxylicacid prepared by a 2-phosphonobutane-1,2,4-tricarboxylicacid esterification reaction, the product obtained by the esterification of the two carboxy in a small amount of2-phosphonobutane-1,2,4-tricarboxylicacid and the product obtained by the esterification of the three carboxy in a small amount of 2-phosphonobutane-1,2,4-tricarboxylicacid form the blend; and the prepared viscosity-reducing type polycarboxylic acid water reducing agent has advantages of viscosity reducing, water reducing, slump retaining and mud resistance, and can solve the problems of high viscosity, poor workability and rapid loss due to the high mud content in the current concrete raw materials.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

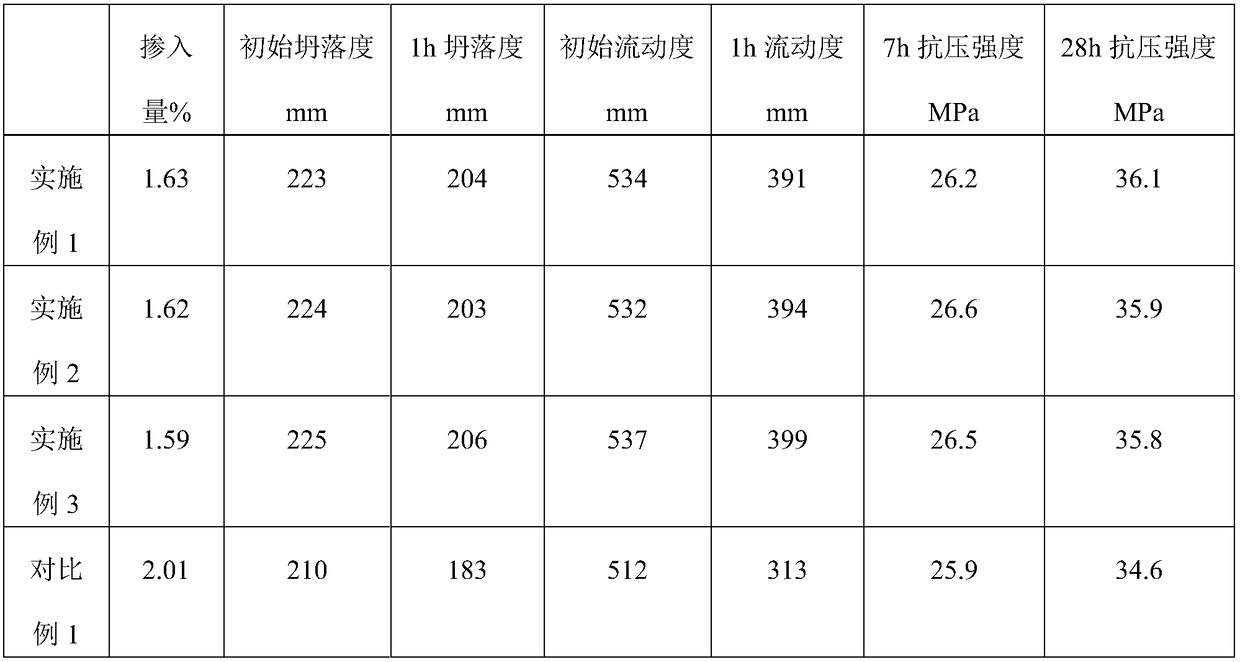

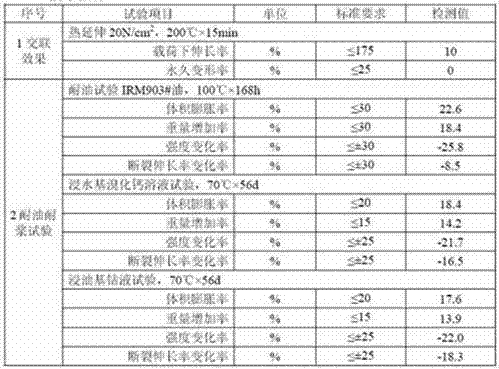

Polycarboxylate mother liquor with high water-reducing, slump-retaining and sludge-resisting properties and manufacturing method thereof

The invention provides a polycarboxylate mother liquor with high water-reducing, slump-retaining and sludge-resisting properties and a manufacturing method thereof. The polycarboxylate mother liquor is composed of 28 to 40 parts of a polyether superplasticizer macromonomer, 3 to 8 parts of acrylic acid, 0.1 to 0.9 part of sodium hypophosphite, 0.1 to 0.8 part of hydrogen peroxide with a concentration of 30%, 0.1 to 0.6 part of ammonium persulfate, 0.1 to 0.3 part of vitamin C and 58 to 65 parts of deionized water. The polycarboxylate mother liquor with high water-reducing, slump-retaining andsludge-resisting properties provided by the invention is compatible in water-reducing and slump-retaining properties on the basis of the prior art; the performance of high sludge-resisting property isincreased; and a formula for a superplasticizer mother liquor with high water-reducing, sludge-resisting and slump-retaining properties is obtained.

Owner:张玉广

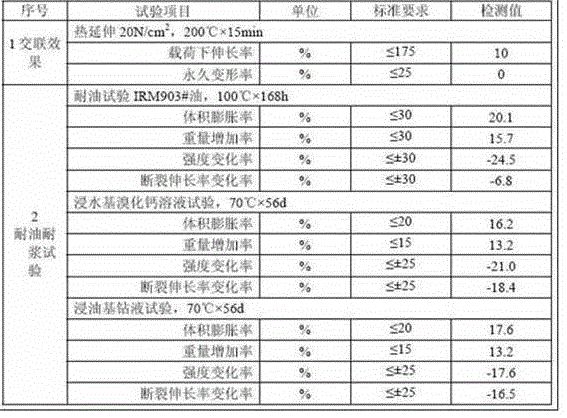

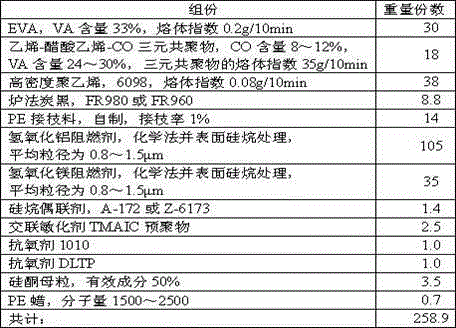

Oil-resistant and mud-resistant irradiation-crosslinking flame-retardant cable material

ActiveCN107236182AImprove mechanical propertiesGood compatibilityPlastic/resin/waxes insulatorsFire retardantMechanical property

The invention relates to an oil-resistant and mud-resistant irradiation-crosslinking flame-retardant cable material. The cable material contains the following components in parts by weight: an ethylene-vinyl acetate copolymer, an ethylene-vinyl acetate-carbon monoxide terpolymer, high-density polyethylene, a polyethylene grafted maleic anhydride copolymer, carbon black, an aluminum hydroxide flame retardant, a magnesium hydroxide flame retardant, a coupling agent, a crosslinking sensitizer, an antioxidant, silicone and a lubricant, wherein the content of vinyl acetate VA in the ethylene-vinyl acetate copolymer is 33%, and the melt index of the ethylene-vinyl acetate copolymer is 0.2g / min; and the crosslinking sensitizer is a trimethyl allyl isocyanate TMAIC prepolymer, the polymerization degree n is 2-10, a monomer of the prepolymer is trimethyl allyl isocyanate TMAIC, and the molecular weight is 291.35. The cable material is low in smoke and toxic-free, the commissioned irradiation processing is simple and convenient, and the consistency of a filling and a base material in a blended material is improved, and the mechanical property of the material is improved.

Owner:中广核高新核材科技(苏州)有限公司

Preparation method of high mud-resistant concrete water reducer with graft copolymerized cationic side chains

ActiveCN106117468BAchieving a Transformation in Application PerformanceExpanding the theoretical connotation of the design-structure-performance of moleculesSide chainPolyethylene glycol

The invention discloses a preparation method of a highly mud resistant water reducing agent with graft copolymerization of a cation side chain for concrete, belonging to the field of water reducing agents. The highly mud resistant water reducing agent material with graft copolymerization of a cation side chain for concrete is synthesized by a method of carrying out cation side chain polymerization reesterification first and then graft copolymerization, i.e. an unsaturated cation quaternary ammonium salt monomer as a reactant carries out free radical polymerization in an oxidation-reduction initiation system composed of high-valence cerium salt and alcohols to obtain a terminal hydroxyl cation side chain, then unsaturated carboxylic acid, the terminal hydroxyl cation side chain and methoxy polyethylene glycol carry out esterification under the effect of a catalyst to produce two macromonomers, and then an unsaturated carboxylic acid monomer, a cation side chain macromonomer and a polyether side chain macromonomer as reactants carry out free radical graft copolymerization under the effects of an initiator and a chain transfer agent to obtain the highly mud resistant water reducing agent with graft copolymerization of the cation side chain for concrete. The process of the preparation method has the advantages of simple steps, high efficiency, immediacy, convenience in regulation and control, energy saving and environment protection, a composite side chain structure is synthesized creatively, and the effects of water reducing, slump loss resistance and inhibition in clay side effects are realized.

Owner:中铁一局集团工业贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com