Preparation method of cross-linked viscosity-reducing polycarboxylate water reducer

A technology of viscous polycarboxylate and water reducer, which is applied in the field of construction admixtures, can solve the problems of polycarboxylate water reducer dispersibility and dispersion retention, increase of concrete viscosity, large consumption of sand and gravel, etc., and achieve improvement Competing adsorption capacity, slowing down the rate of hydration, and the effects of large steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

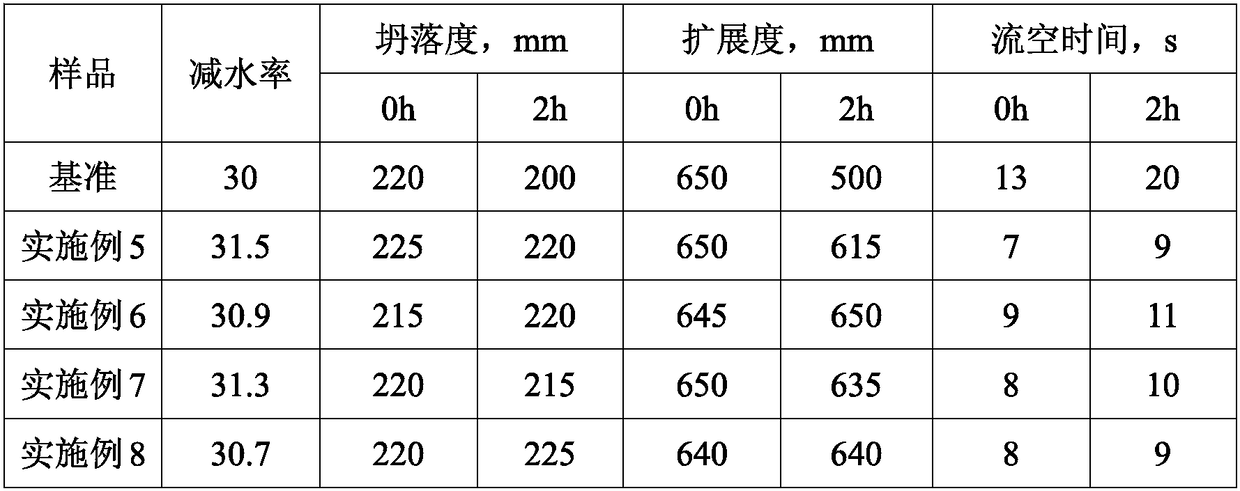

Examples

Embodiment 1

[0026] 25g allyl alcohol, 80g 2-phosphobutane-1,2,4-tricarboxylic acid, 1g dibutyl tin oxide and 0.15g hydroquinone are added in the first reactor that condensing device is housed, in Under the protection of nitrogen, keep the temperature at 120°C for 6 hours. After the reaction, cool down to 40°C to obtain a product mainly of 2-phosphobutane-1,2,4-tricarboxylic acid carboxyl group esterified by a single ester and a small amount of 2-phosphobutane- The carboxyl group in 1,2,4-tricarboxylic acid is esterified by double esterification and esterification monomer A1 of three esterification products.

Embodiment 2

[0028] 20g3-chloroallyl alcohol, 80g2-phosphobutane-1,2,4-tricarboxylic acid, 1.2g vitriol oil and 0.1g p-hydroxyanisole are added in the first reactor equipped with condensing device, in Under the protection of nitrogen, keep the temperature at 110°C for 6 hours. After the reaction, cool down to 40°C to obtain a product mainly of 2-phosphobutane-1,2,4-tricarboxylic acid carboxyl group esterified by a single ester and a small amount of 2-phosphobutane- The carboxyl group in 1,2,4-tricarboxylic acid is esterified by double esterification and esterification monomer A2 of three esterification products.

Embodiment 3

[0030]40g allyl hydroxyethyl ether, 80g 2-phosphobutane-1,2,4-tricarboxylic acid, 0.9g heteropolyacid and 0.1g phenothiazine are added in the first reactor equipped with condensing device, Under the protection of nitrogen, keep the temperature at 110°C for 6 hours, and after the reaction, cool down to 40°C to obtain the product mainly of 2-phosphobutane-1,2,4-tricarboxylic acid carboxyl group being single esterified and a small amount of 2-phosphobutane -Esterification monomer A3 of carboxyl group in 1,2,4-tricarboxylic acid being double esterified and three esterified products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com