Functional suspended stuffing

A suspended filler and functional technology, which is applied in the field of functional suspended fillers and their production, can solve the problems of small increase in surface area of functional fillers with distribution density and limited increase in microbial biomass, so as to increase the surface area and improve the purification capacity. , the effect of lush growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

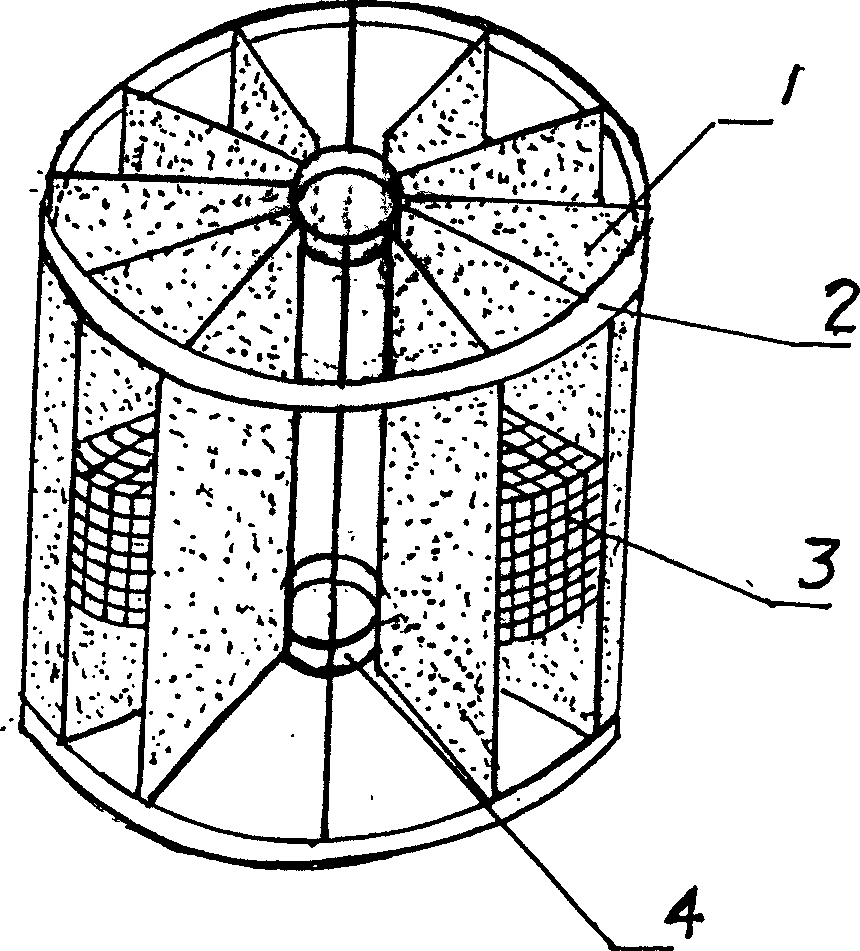

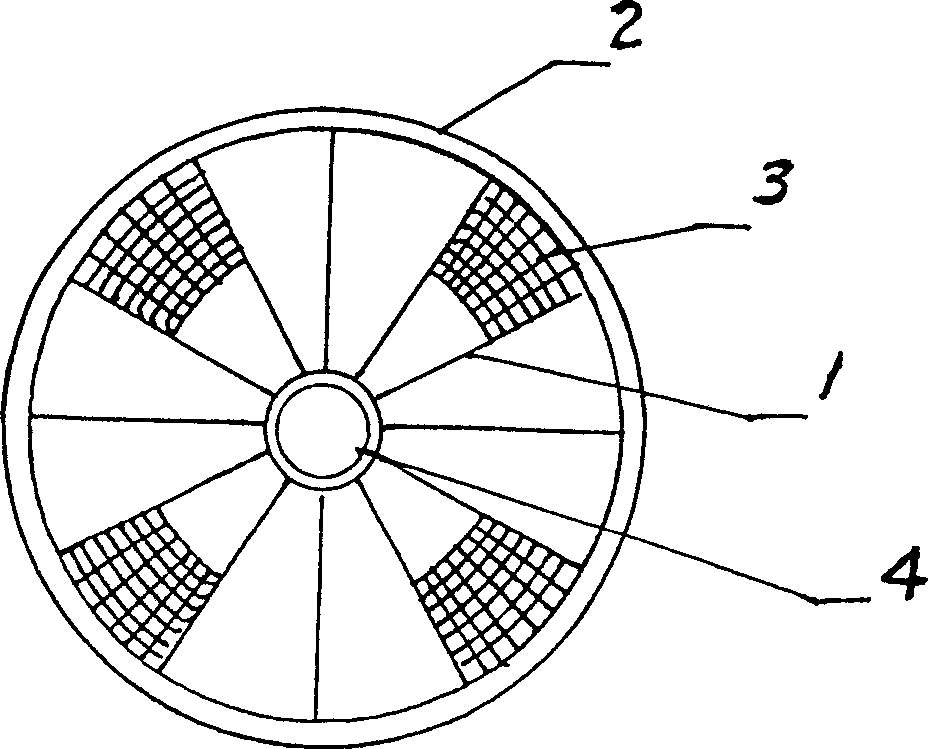

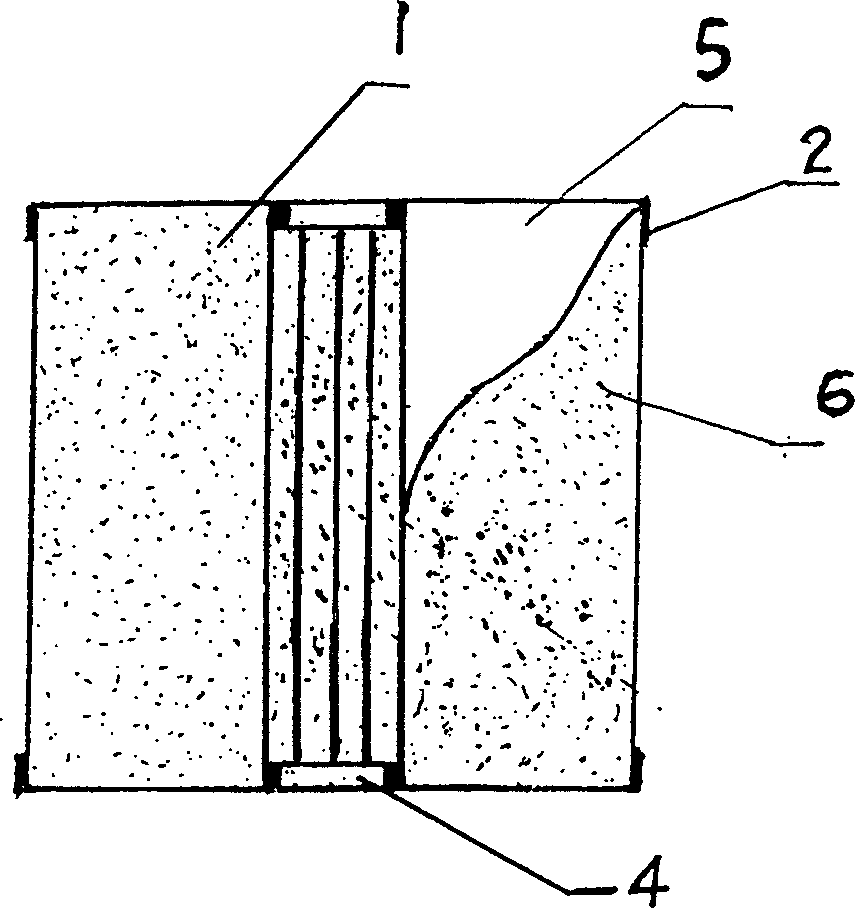

[0016] figure 1 It is a cylindrical structure filler of the present invention, which is composed of a composite wing plate 1, a fixed connection ring 2, a water-repellent foam plastic 3, and a middle fixed ring 4. Composite wing plate 1 is made of nylon wing plate 5, functional water treatment material 6 is made of powdered zeolite, activated carbon, diatomaceous earth, ceramsite, activated aluminum, and manganese sand, and is bonded by surface thermal bonding or surface adhesive Composite on the surface of wing plate 5. The wing plate 5 is fixedly connected with the fixed connection ring 2 and the middle fixed ring 3 through its outer side up and down and its inner side up and down. By sandwiching a certain amount of water-repellent foam plastics 4 between some composite wing plates 1, the specific gravity of the filler of the present invention is adjusted so that it is close to one, so that it can be fully fluidized for water treatment during aeration. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com