Preparation method of porous cellulose acetate micropellet adsorbent

A technology of cellulose acetate and cellulose diacetate, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., to achieve the effects of reducing pollution, good adsorption capacity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

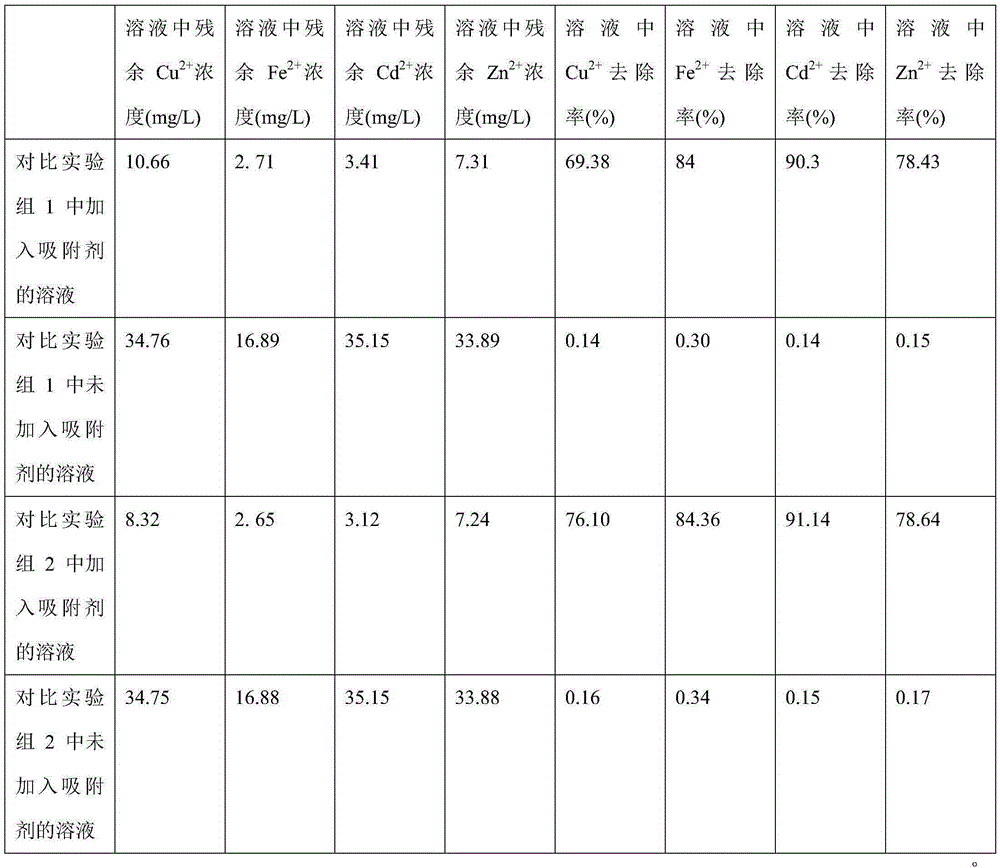

Examples

Embodiment 1

[0021] A preparation method of porous cellulose acetate microsphere adsorbent, specifically comprising the steps of:

[0022] Step 1, extract the cellulose acetate in the filter by Soxhlet extraction: collect 100 cigarette butts, remove the remaining shredded tobacco in the cigarette butts, cut the fiber stick wrapping paper with a blade, take out the fiber stick (reject the burnt fiber stick), Obtain 20 grams of fiber rods; divide it into multiple times, wrap the fiber rods with filter paper, put them into the leaching column of the Soxhlet apparatus, add 100mL95% industrial ethanol in the distillation flask, connect to the condenser, heat to reflux on the heating mantle, and heat The reaction temperature of reflux is 100°C, carry out immersion and extraction, observe the color of ethanol in the overflow tube, stop the reaction when the color of ethanol changes from dark yellow to colorless, the time is about 2-3 hours; take out the cellulose diacetate rod full of ethanol and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com