Patents

Literature

98 results about "Fumaropimaric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fumaropimaric acid; fumaropimaric acid, disodium salt, (4alpha,8alpha,12alpha,13R,14R)-isomer; from MeSH. Depositor-Supplied Synonyms. Chemical names and identifiers provided by individual data contributors and associated to PubChem Substance records. Synonyms of Substances corresponding to a PubChem Compound record are combined.

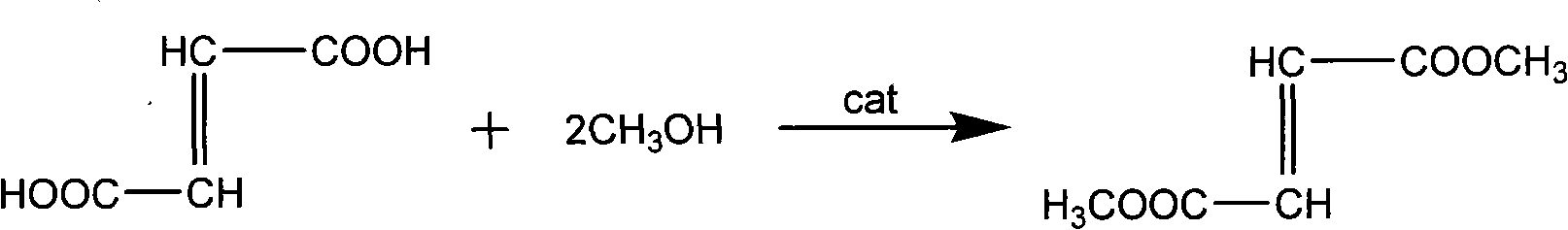

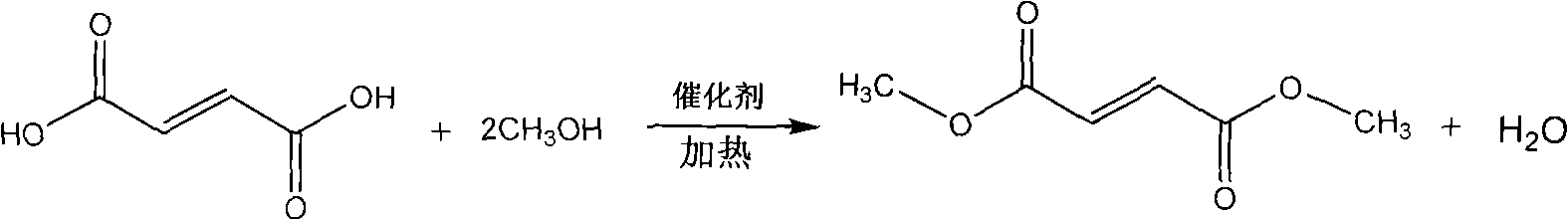

Novel synthesis process for dimethyl fumarate

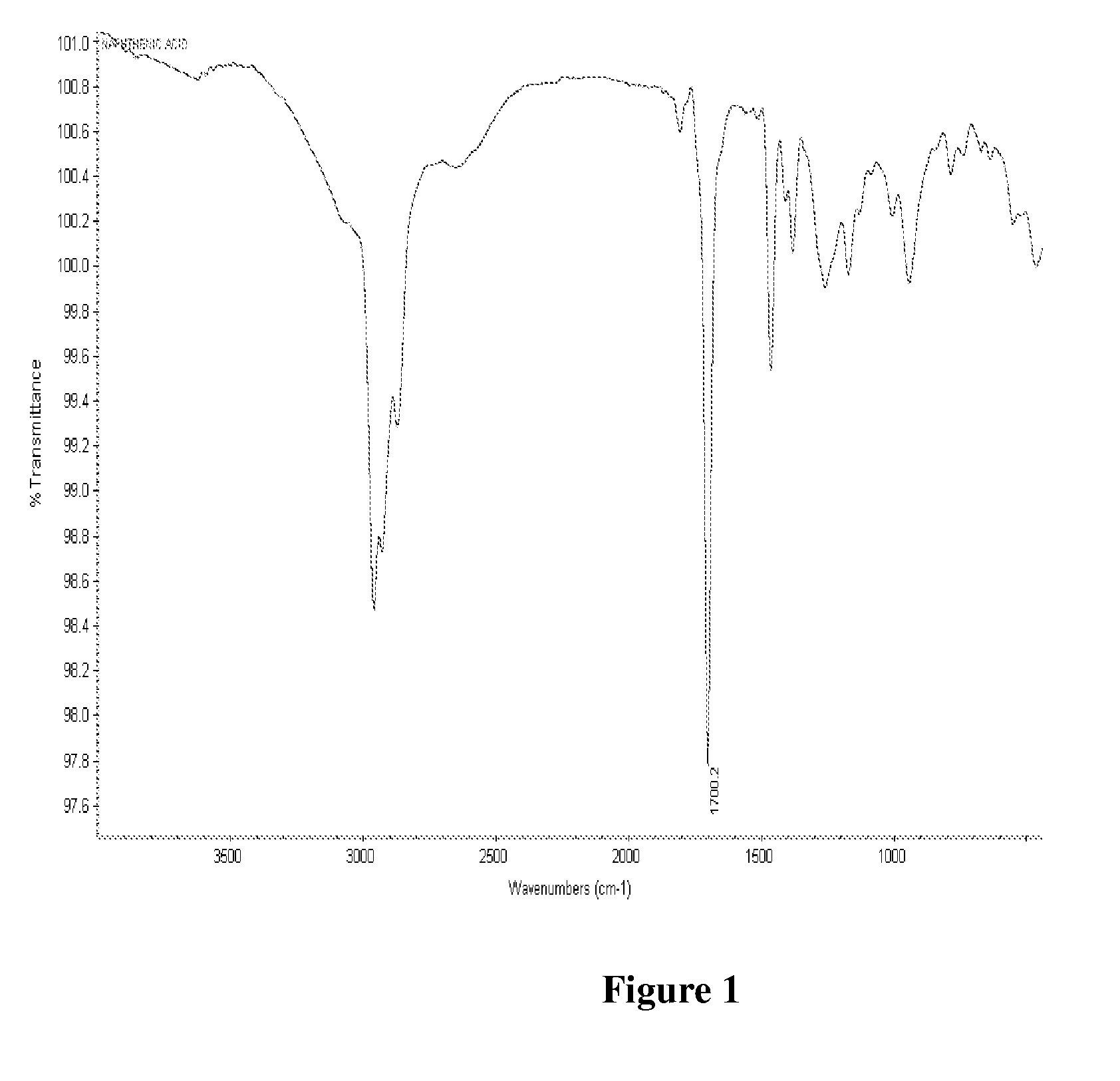

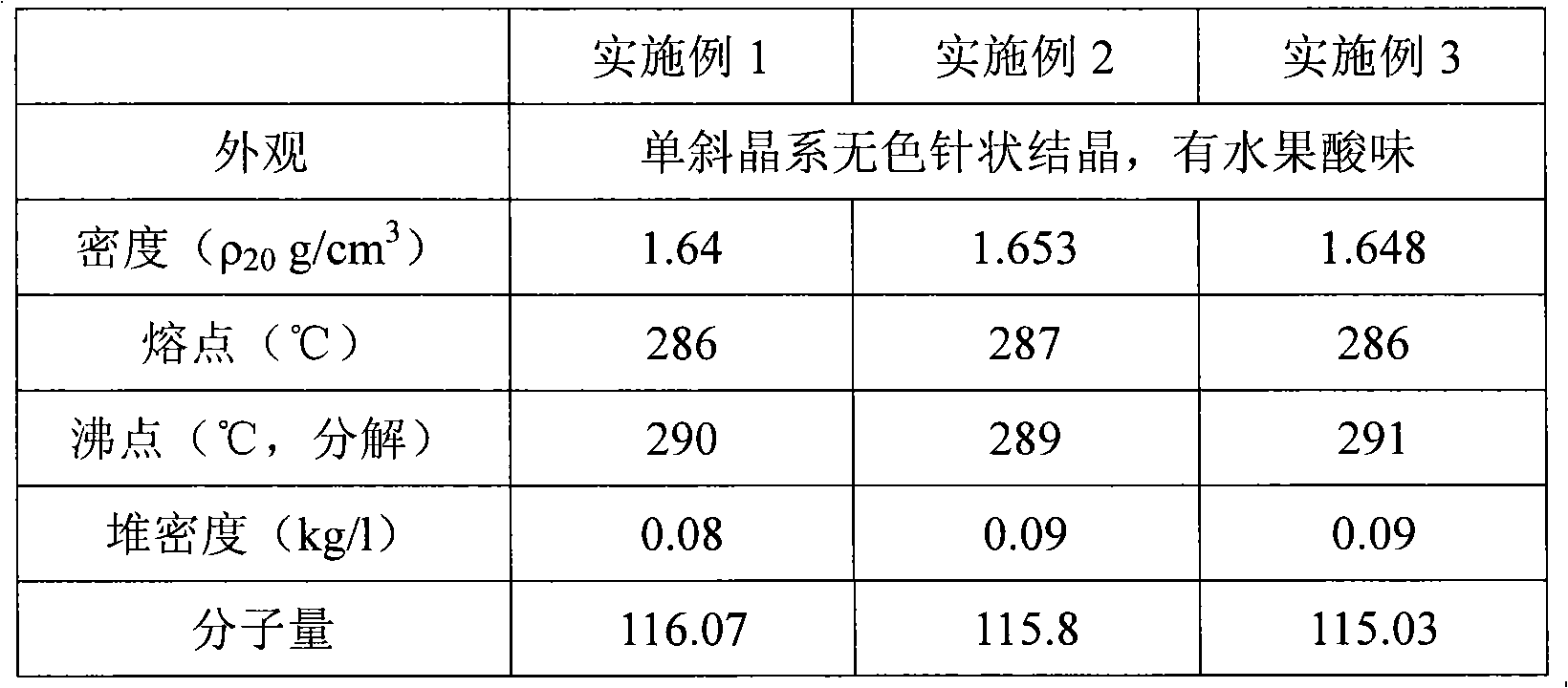

InactiveCN101318901AReduce dosageGood choiceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFumaropimaric acidFumaric acid

The invention relates to a new process for synthesizing an antiseptic, namely dimethyl fumarate, wherein, two stages of esterification between a fumaric acid and methanol under the action of a catalyst are performed to generate the dimethyl fumarate; the catalyst is a cerous methylsulfonic acid. With application of the new process and the catalyst, the shortcomings of the prior art are overcome and production cost can be reduced effectively; and the new process has simple post-processing, less environmental pollution and good development and application prospect.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

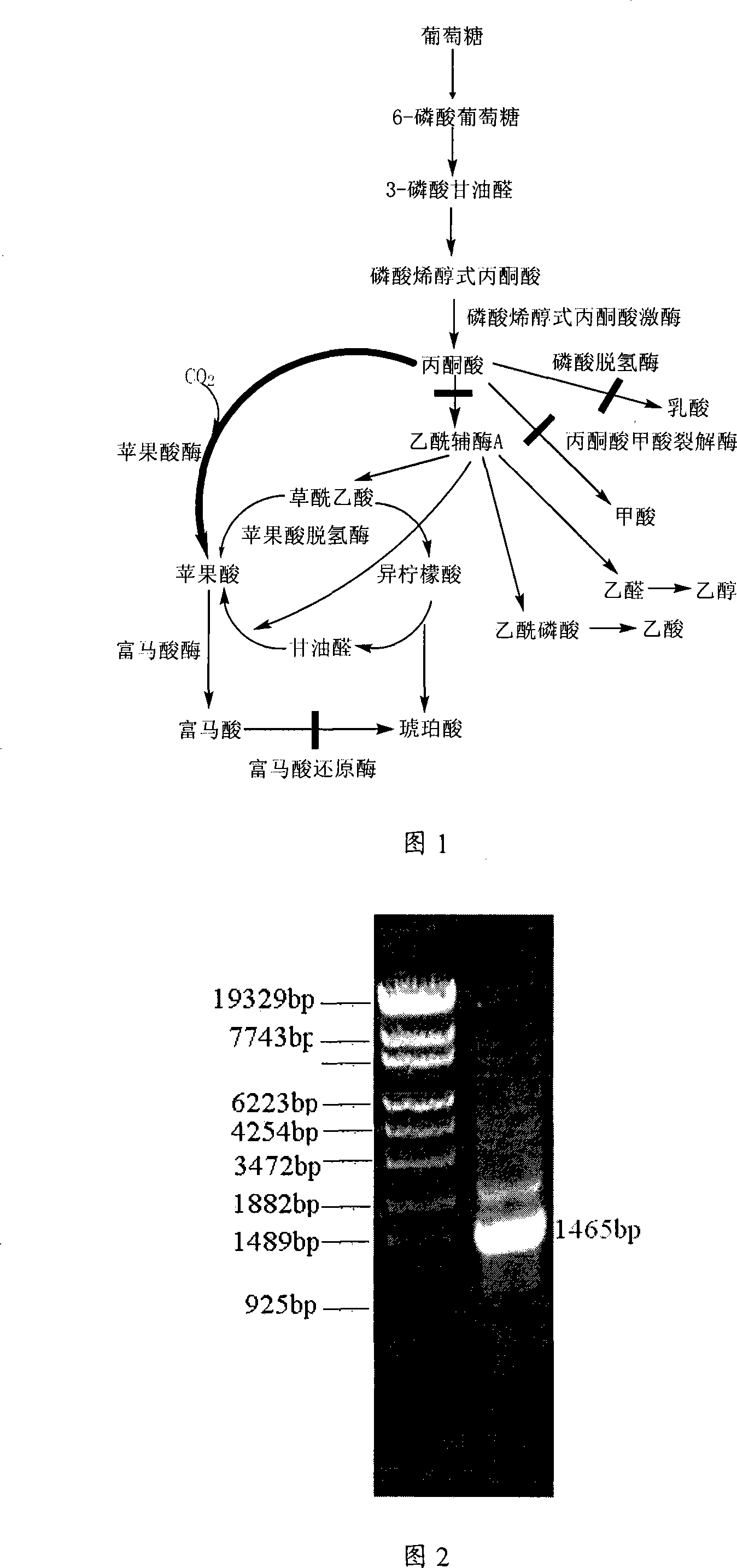

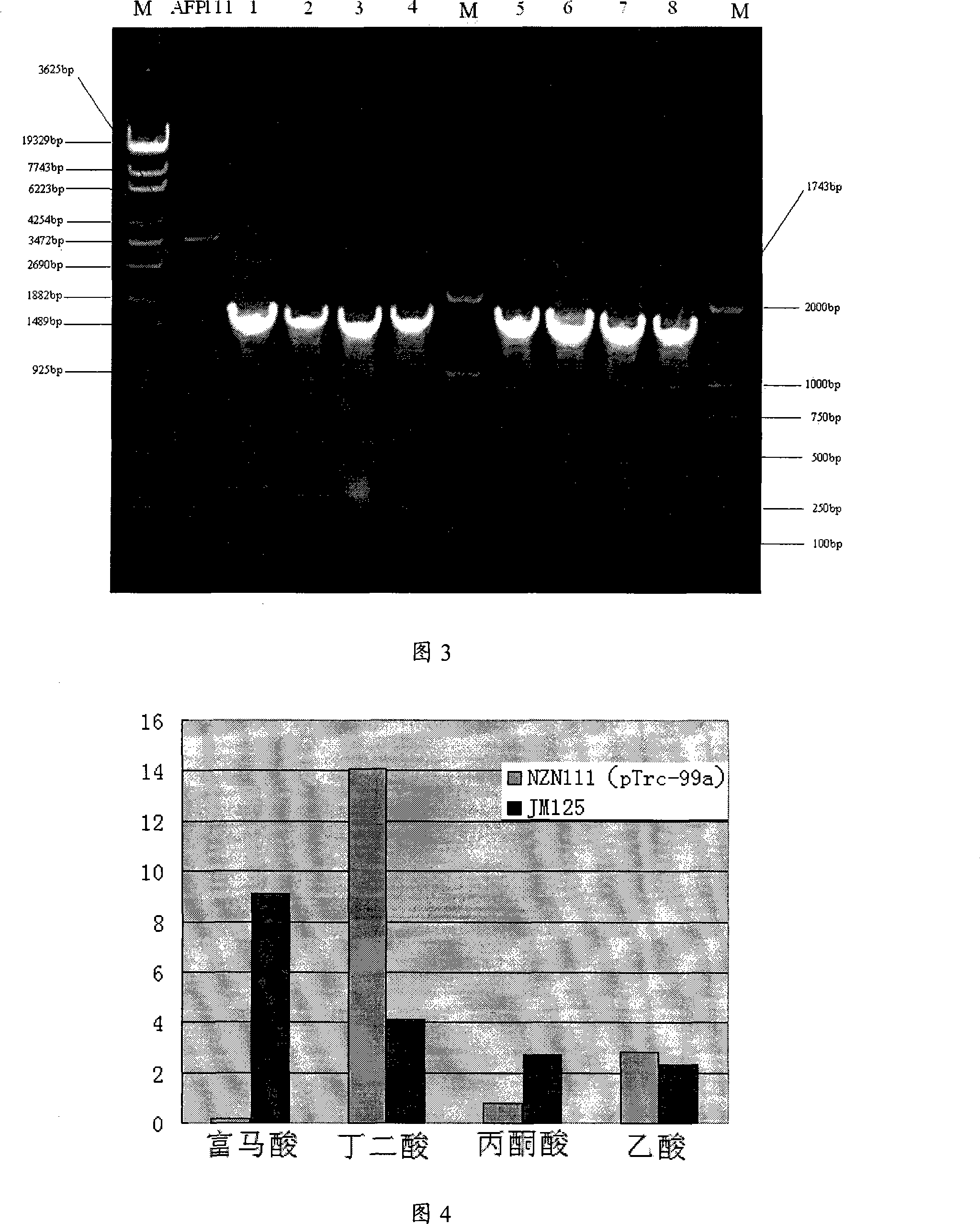

Novel constructed high-yield fumaric acid gene engineering bacterium and method for producing fumaric acid thereby

The invention discloses a method for constructing genetic engineering bacterial strain Escherichia coli JM125 producing boletic acid and method for producing acid. The constructing process comprises inactivation or out-knocking enzymes in facultative microbiology which has abilities of reduction boletic acid and degrading acetonic acid, and exceeding expressing NAD regeneration. The following steps of two-stage fermentation experiment using constructed Escherichia coli are (1) activating bacillus coli is transferred to enrichment medium and cultured to improve biomass. (2) The treated bacterium liquid membrane obtained by aerobic cultivation is transferred into LB culture medium which contains 20 to 100g / L amylaceum and certain concentration carbonates to produce fumaric acid by anaerobic fermentation.

Owner:NANJING UNIV OF TECH

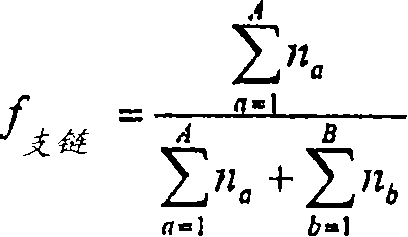

Oil soluble comb polymers

The invention relates to comb polymers which comprise, in the main chain, repeating units which are derived from polyolefin-based macromonomers, and repeating units which are derived from low molecular monomers which are selected from the group consisting of styrene monomers having 8 - 17 carbon atoms, alkyl(meth)acrylates having 1 - 10 carbon atoms in the alcohol group, vinyl esters having 1 - 11 carbon atoms in the acyl group, vinyl ethers having 1 - 10 carbon atoms in the alcohol group, (Di)alkylfumarates having 1 - 10 carbon atoms in the alcohol group, (Di)alkylmaleates having 1 - 10 carbon atoms in the alcohol group and mixtures of said monomers. The molar branching degree lies in the region between 0.1 - 10 mol. % and the comb polymer represents the sum of at least 80 wt. %, in relation to the weight of the repeating units, on repeating units which are derived from polyolefin-based macromonomers, and repeating units which are selected from low molecular monomers which are selected from the group consisting of styrene monomers having 8 - 17 carbon atoms, alkyl(meth)acrylates having 1 - 10 carbon atoms in the alcohol group, vinyl esters having 1 - 11 carbon atoms in the acyl group, vinyl ethers having 1 - 10 carbon atoms in the alcohol group, (Di)alkylfumarates having 1 - 10 carbon atoms in the alcohol group, (Di)alkylmaleates having 1 - 10 carbon atoms in the alcohol group, and mixtures of said monomers.

Owner:EVONIK OPERATIONS GMBH

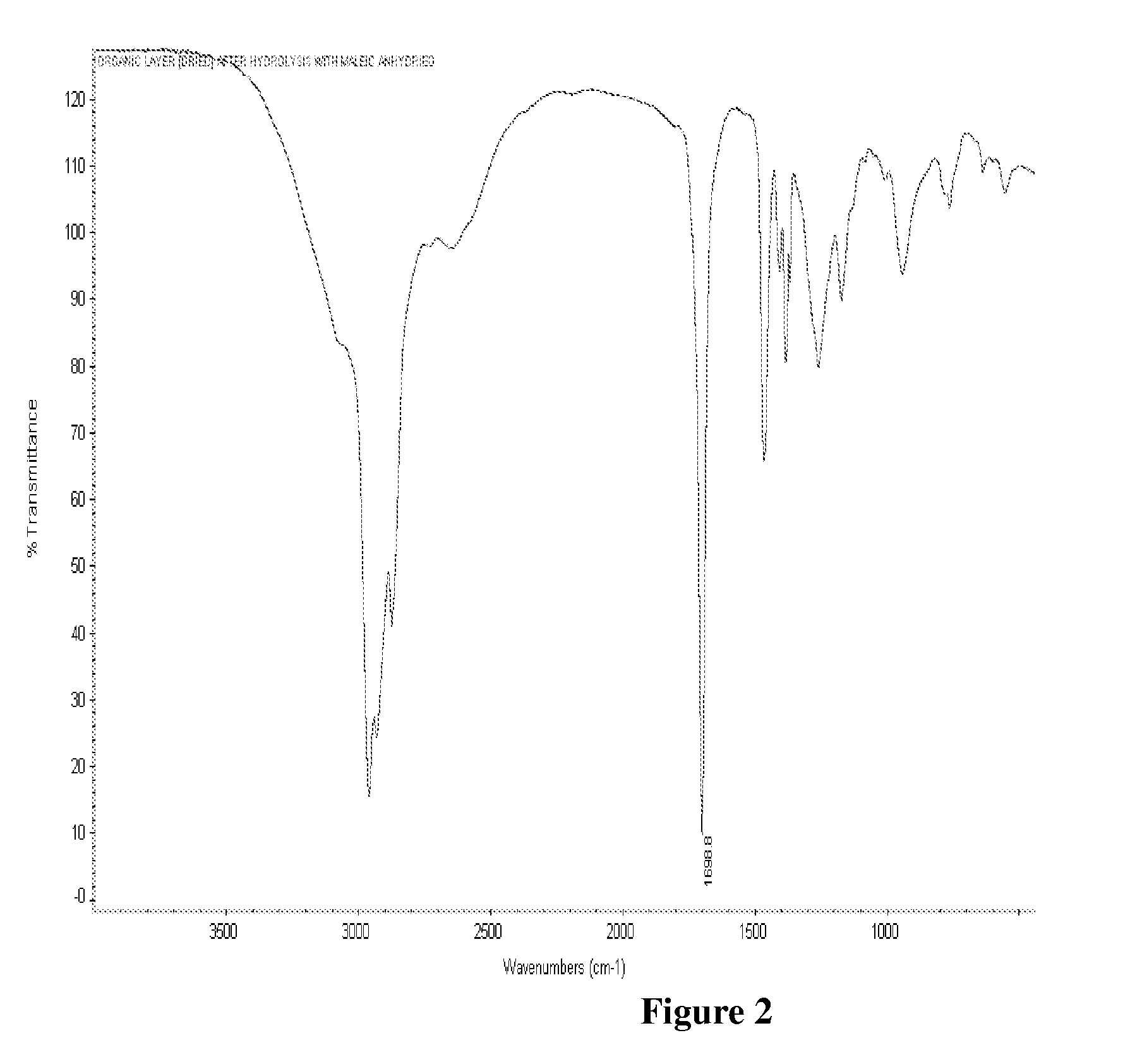

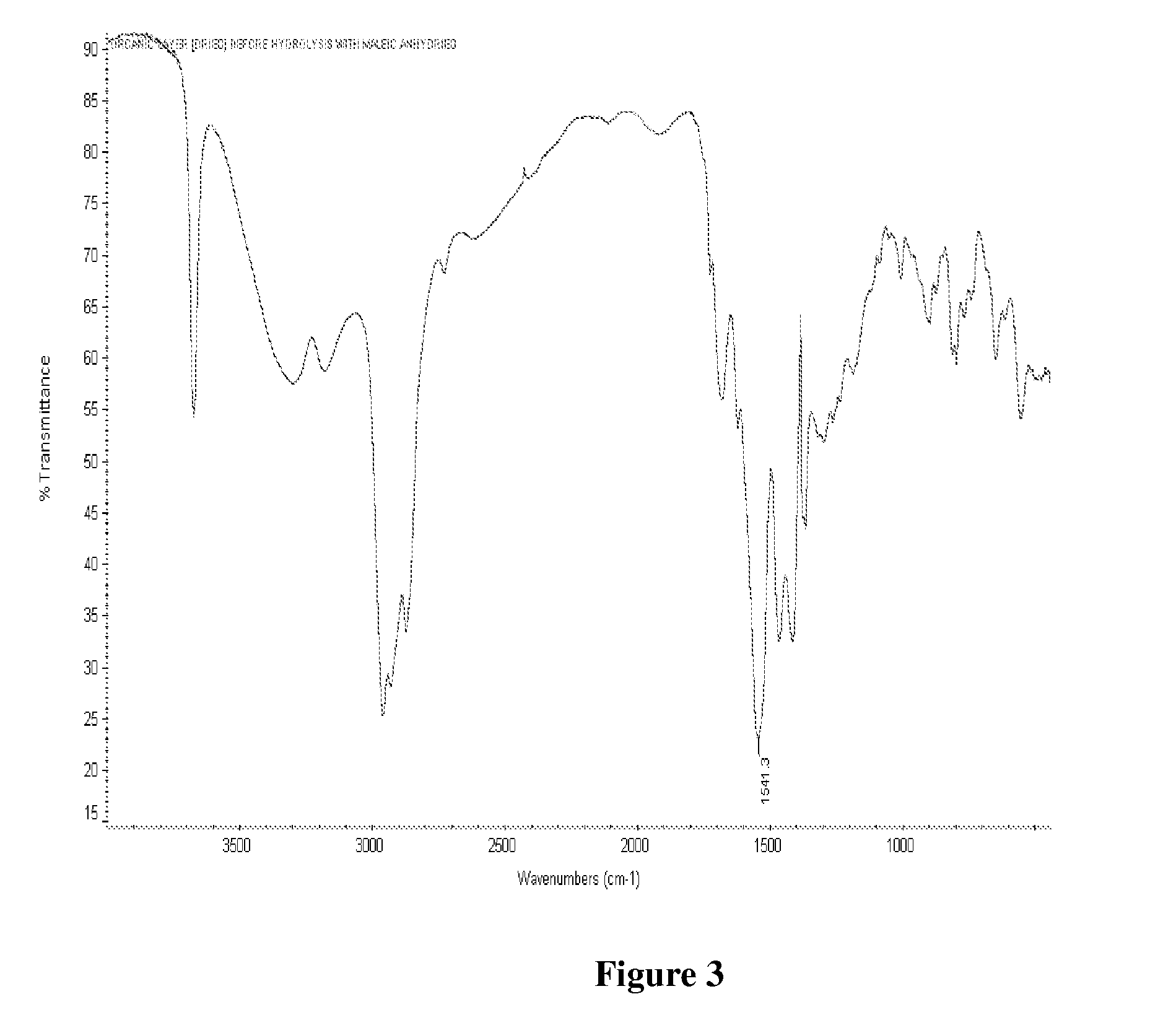

Method of removal of calcium from hydrocarbon feedstock

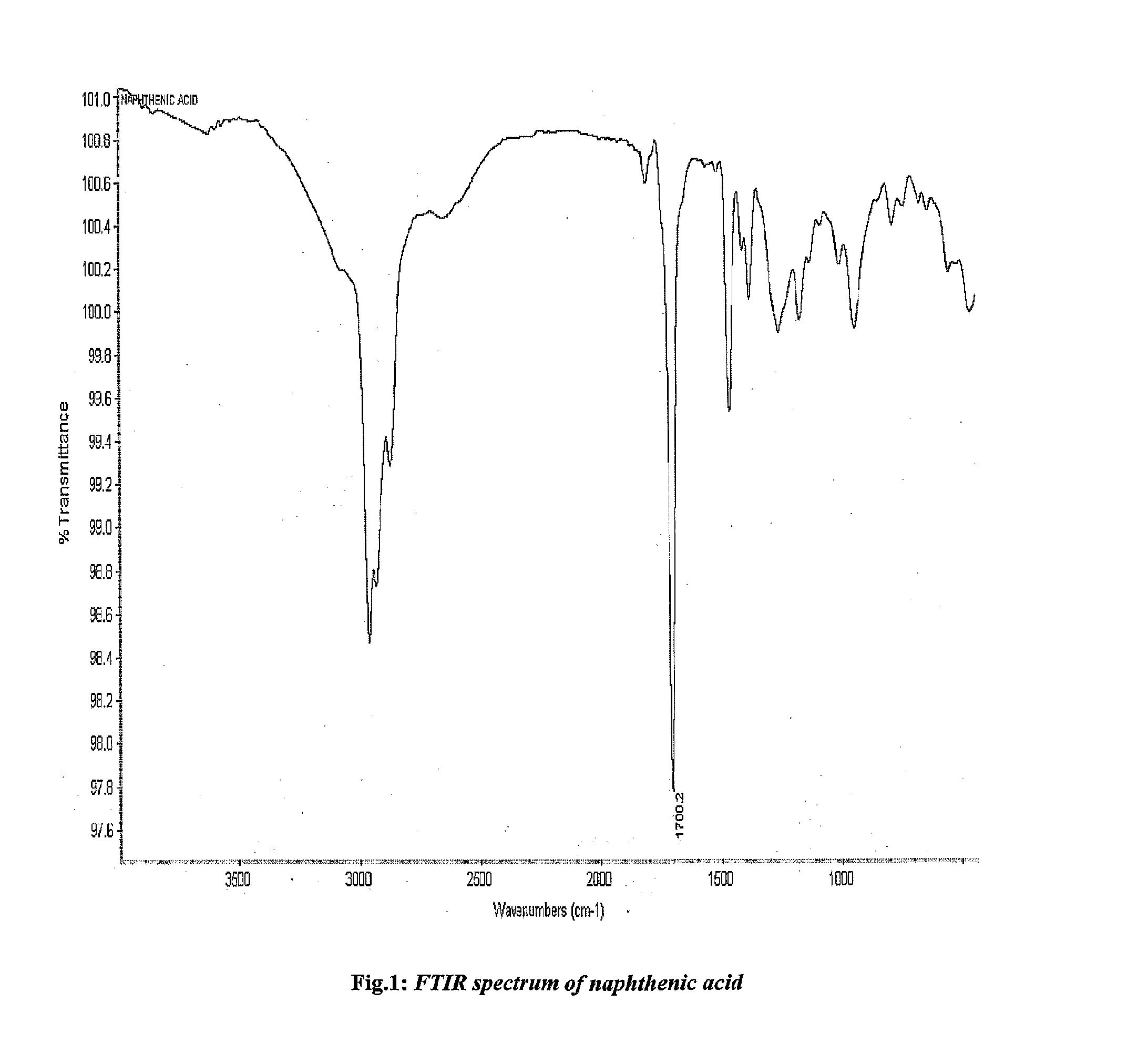

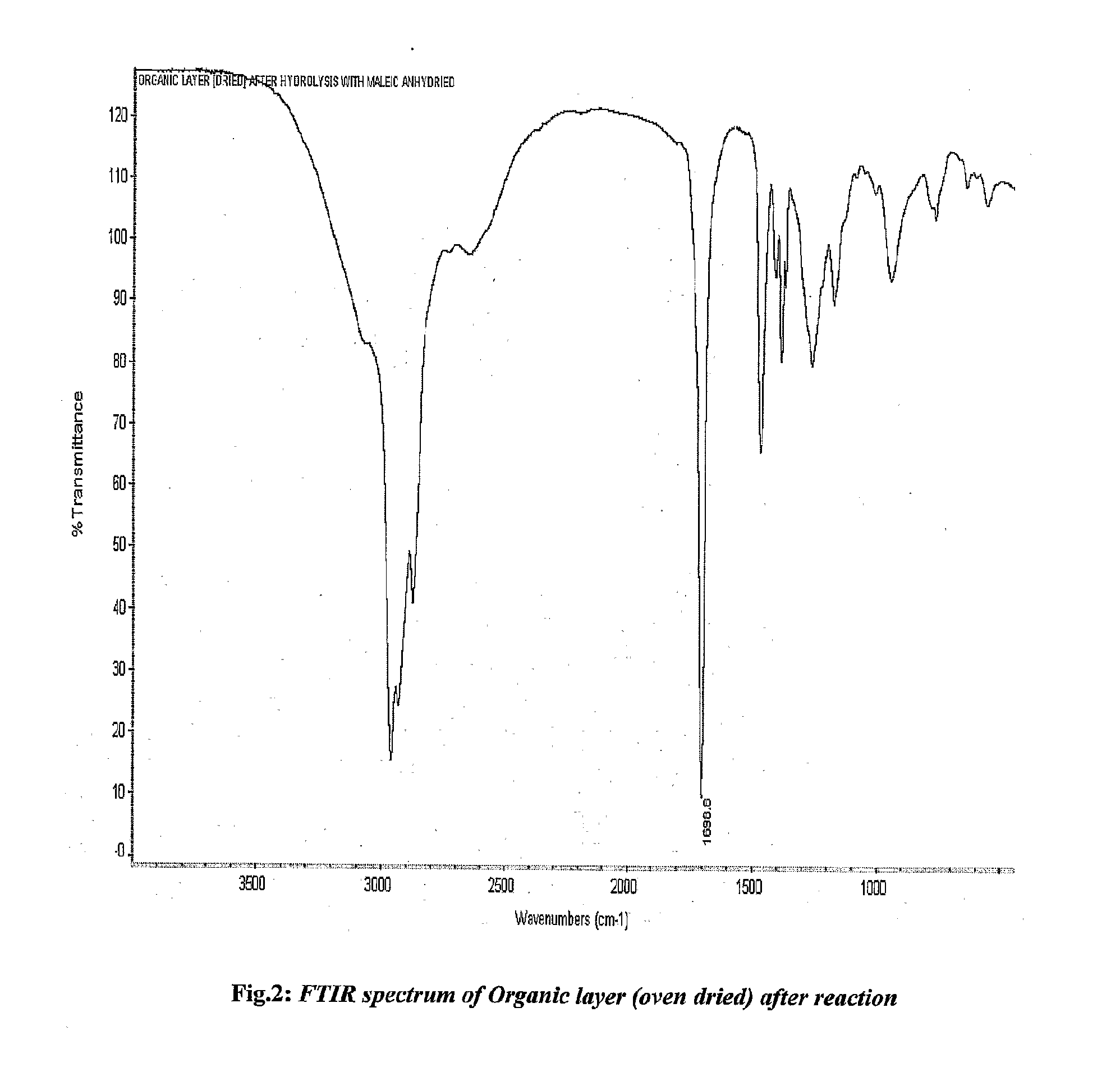

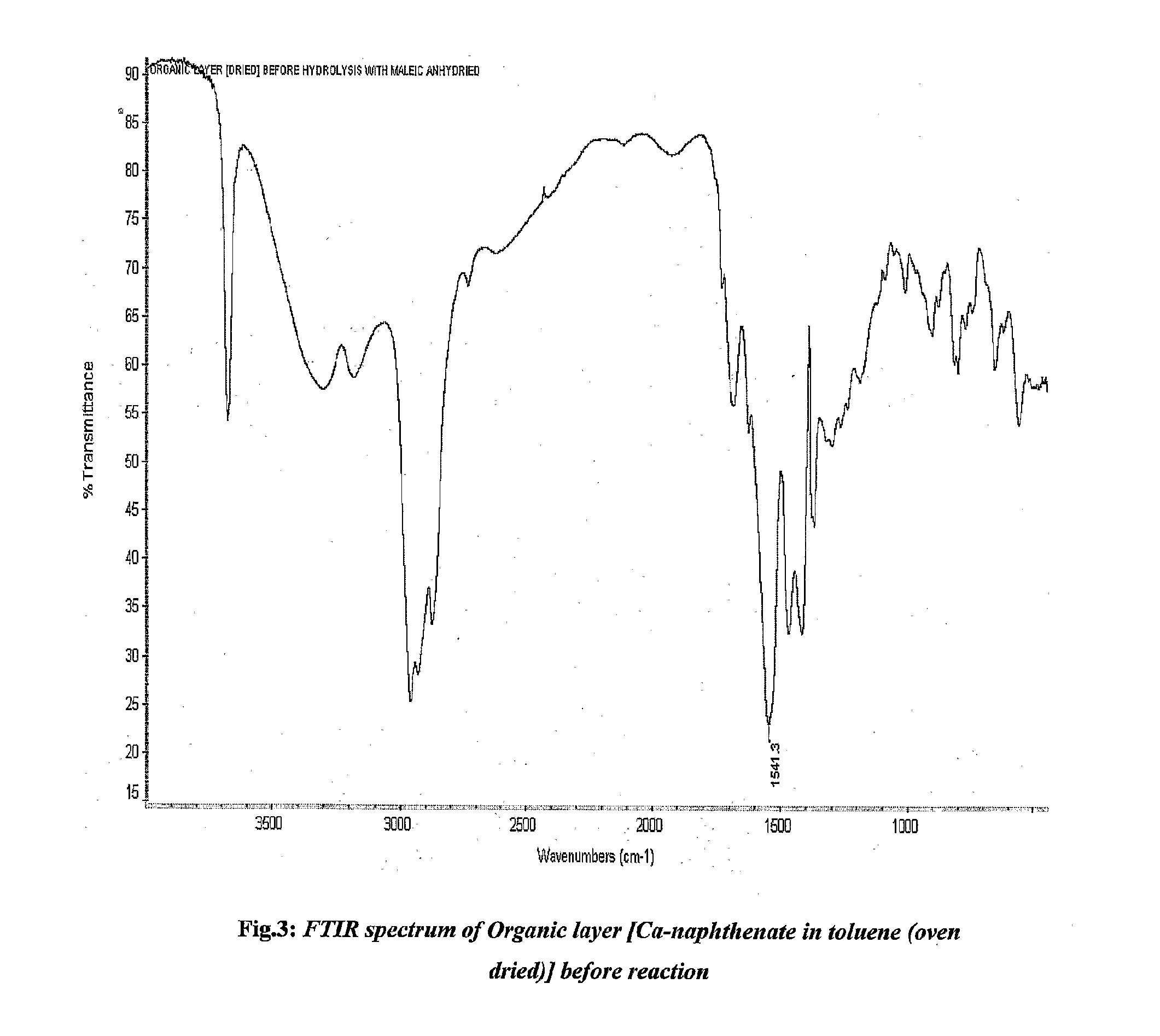

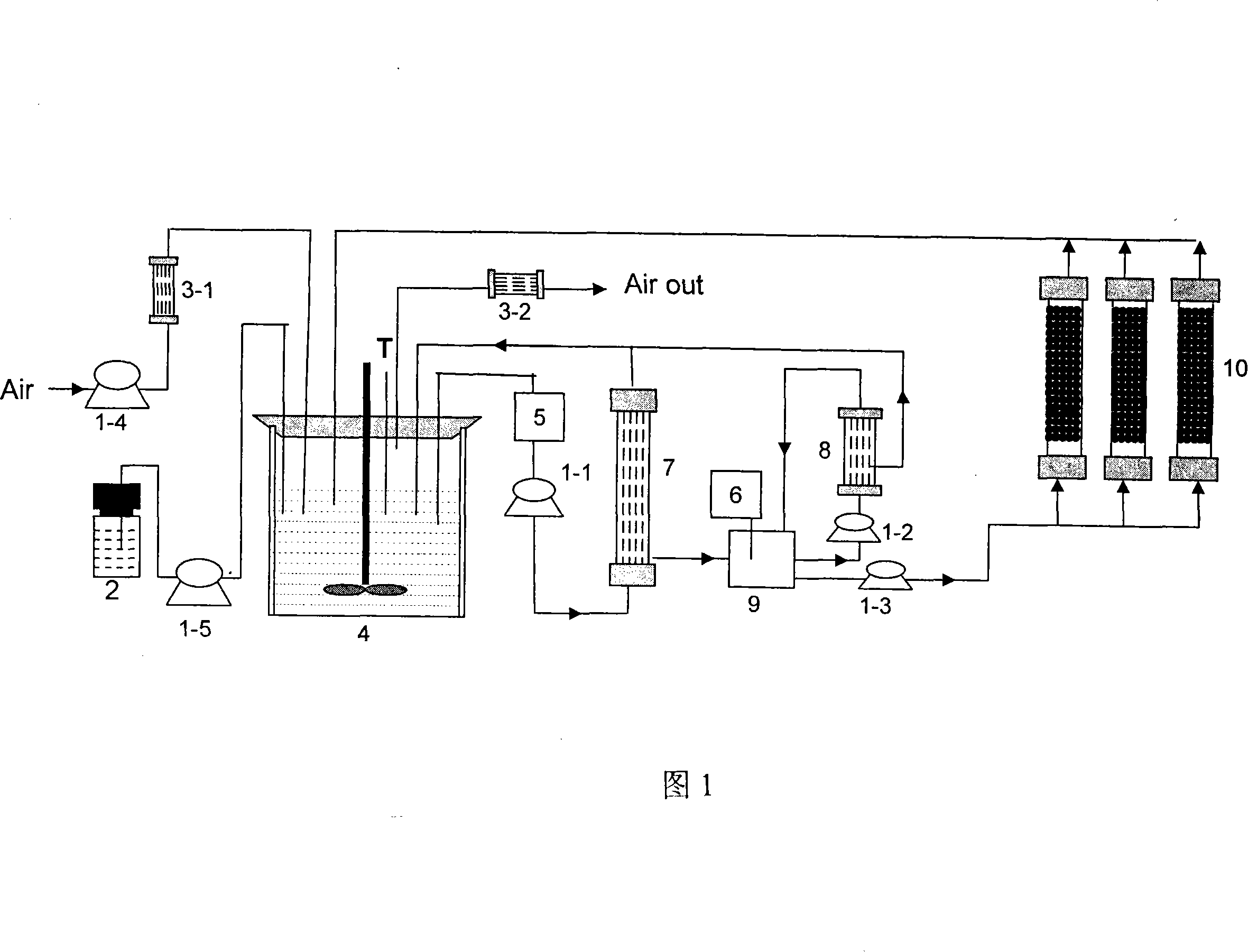

InactiveUS20100163457A1Treatment with plural serial refining stagesRefining with acid-containing liquidsFumaropimaric acidDesalter

The invention relates to field of processing hydrocarbon feedstock including crude oil, wherein metals such as calcium are removed. In the face of the rising prices of crude oil, refiners are forced to process opportunity crudes such as DOBA, which pose many problems including fouling of equipment due to certain metallic salts, such as calcium napthenate. Calcium, which cannot be removed from crude oil during normal desalting process, poses very serious problems. The invention provides method for removal of calcium, wherein crude oil is mixed, with effective metal removing amount of aqueous extraction solution of an additive comprising a chemical compound selected from a group consisting of metallic acid, maleic anhydride or fumaric acid or salts or derivatives thereof, enabling separation of hydrocarboneous phase and aqueous phase containing metal ions, in crude desalter. Only hydrocarboneous phase devoid of calcium is processed further, thereby preventing fouling of equipment.

Owner:DORF KETAL CHEM (I) PTE LTD

Method for producing maleic anhydride through benzene process and absorbing maleic anhydride with solvent

InactiveCN103044368ASimple processNo environmental problemsOrganic chemistryFumaropimaric acidBenzene

The invention discloses a method for producing maleic anhydride through a benzene process. The method comprises the steps of: enabling a maleic anhydride gas and air mixture obtained by oxidizing benzene and air with an oxidizer to pass a solvent absorption tower and be absorbed by a solvent, separating the maleic anhydride from the solvent containing the maleic anhydride through a desorber, enabling the separated coarse maleic anhydride to enter a refining tower and be refined to prepare the maleic anhydride finished product, and regenerating the separated solvent for recycling. According to the method, a non-water recovery technology is adopted, lots of energy consumption for evaporation and dehydration is reduced, the generation of impurities such as fumaric acid is avoided, the recovery rate of the maleic anhydride is increased, the equipment investment is reduced, and the cost is saved.

Owner:WEIFANG YUANLI CHEM

Method for separating and extracting fumaric acid

InactiveCN101235394ALittle loss of activityImprove filtration efficiencyMicroorganism based processesFermentationFiberFumaropimaric acid

The invention belongs to the technical field of biological engineering, which relates to a method for separating and extracting boletic acid in situ in the process of utilizing rhizopus oryzae fermentation to prepare boletic acid. The invention aims at the special physicochemical properties of boletic acid, when rhizopus oryzae free cell is utilized to ferment, the invention adopts a hollow fiber ultrafilter membrane, concentration by nanofiltration and ion exchange adsorption coupling technique to separate and extract boletic acid. The operation condition of the method is mild, separation selectivity is strong, activity loss of somatic cell is small, fermentation efficiency of rhizopus oryzae is effectively improved, process flow of utilizing a biological method to synthesize boletic acid is reduced, and meanwhile, the invention utilizes a nanofiltration device to concentrate fermentation liquor in the process of reacting and separating, which greatly improves adsorption capacity of ion exchange resin to boletic acid, and material consumption and energy consumption are relatively lower, and waste and secondary pollutants which are produced are relative little. The reacting and separating process of the method are fast, complete, and operation stability is excellent, the method is a high-effective and novel mass transfer separation coupling strengthening technique, which has wider industrialized production prospect.

Owner:NANJING UNIV OF TECH

Method of removing metals from hydrocarbon feedstock using esters of carboxylic acids

ActiveUS20090283449A1Improve efficiencyReduce total usageWorking-up pitch/asphalt/bitumen by selective extractionOther chemical processesFumaropimaric acidMethyl group

Method of removing metals from hydrocarbon feedstock using esters of carboxylic acids, and additives for the same, are provided, wherein hydrocarbon stream such as crude oil containing metals and slats thereof, such as calcium and calcium naphthenate, is mixed with an effective metal-removing-amount of an aqueous extraction-solution of non-precipitating and non-fouling additive comprising a chemical compound selected from a group consisting of methyl or ethyl or propyl or isopropyl mono- and / or di-esters of any of three carboxylic acids, such as, maleic acid, maleic anhydride, or fumaric acid or an appropriate combination of said esters, or an appropriate combination of any of said esters with any of said three acids, enabling formation of a hydrocarbonous phase and an aqueous phase containing the metal ions; and separating aqueous phase.

Owner:DORF KETAL CHEM (I) PTE LTD

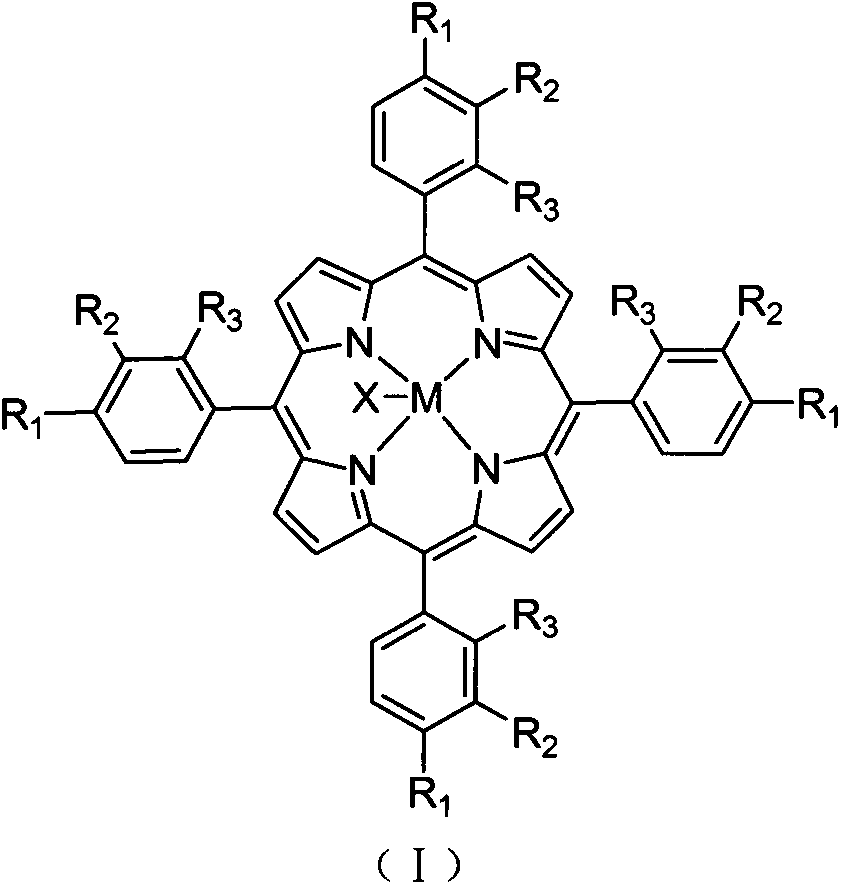

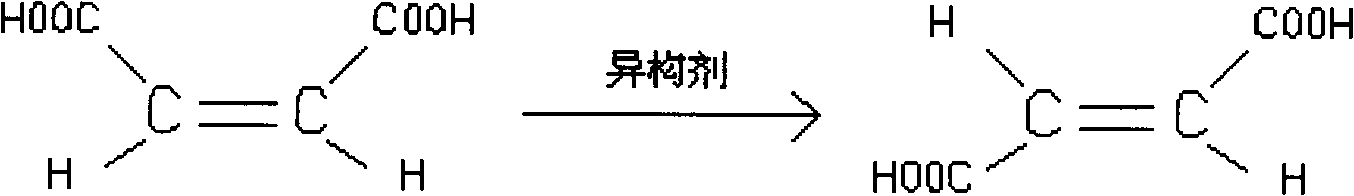

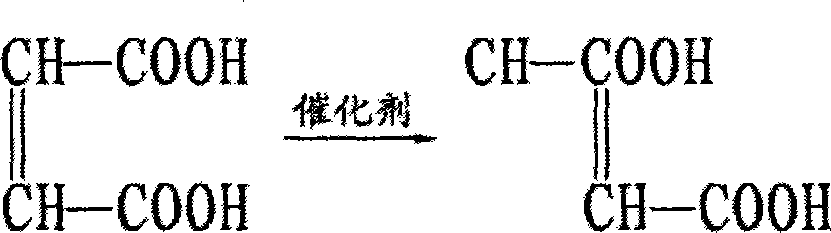

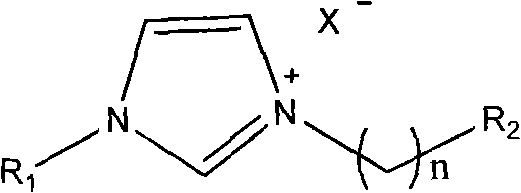

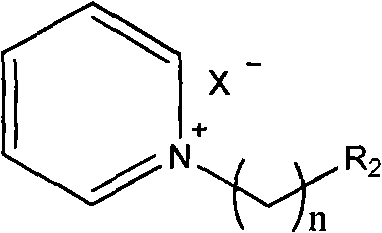

Method for preparing fumaric acid through cis-trans isomerization of maleic acid

InactiveCN103204773AReduce dosageHigh catalytic efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFumaropimaric acidN dimethylformamide

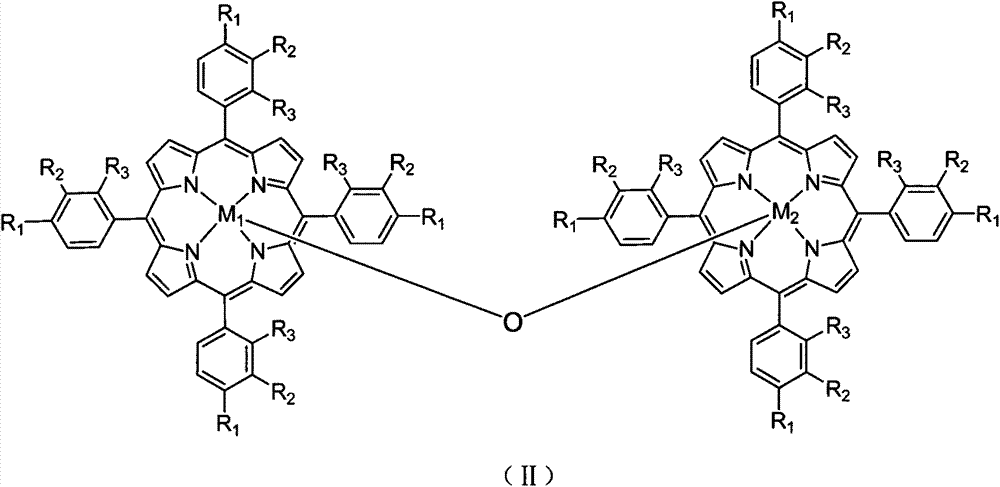

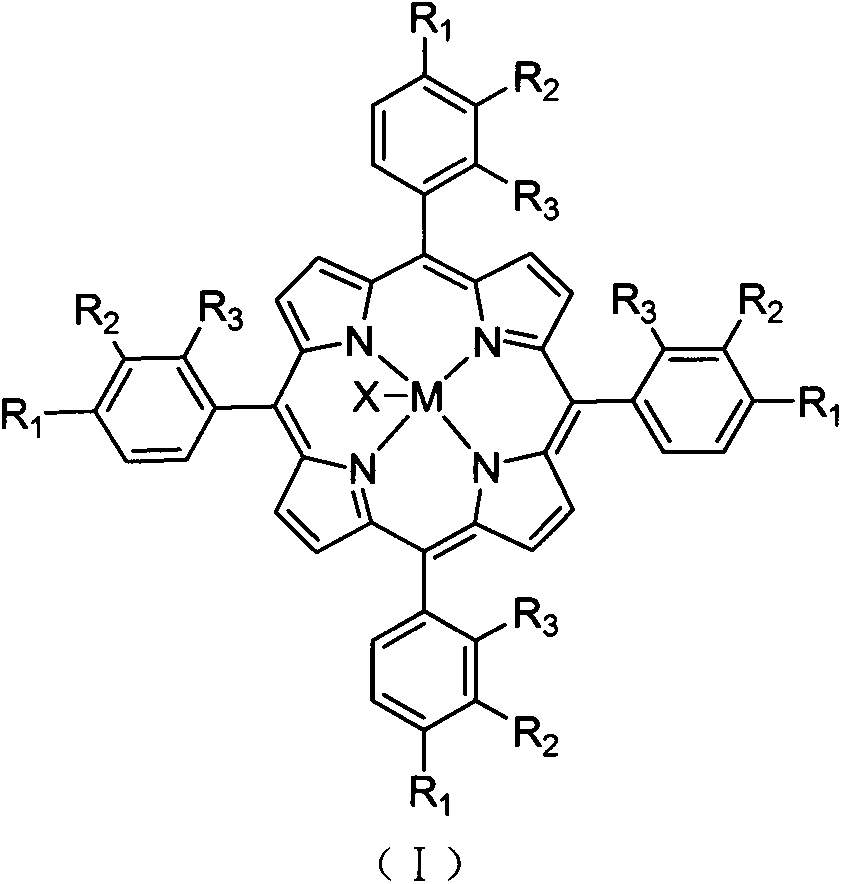

The invention discloses a method for preparing fumaric acid through the cis-trans isomerization of maleic acid. The method comprises the following steps of: taking maleic acid as a raw material in the presence of air or oxygen according to the mass ratio of raw material to the solvent being 1:1-1:80, wherein the solvent contains N,N-dimethylformamide (DMF), dimethyl sulfoxide (DMSO), ethyl acetate, benzene, methylbenzene or nitrobenzene; controlling conditions that the reaction pressure is under 0.1-1.2Mpa and the temperature is 50-150 DEG C, reacting for 1-12 hours by taking monometallic porphyrin in formula (I) or mu-oxo bimetal porphyrin in formula (II) or immobilized metal porphyrin formed as catalysts, wherein the concentration of the catalysts is 5-160PPM; and performing isomerization of maleic acid to obtain the product fumaric acid. The method has the following technical effects of being small in catalyst usage amount, high in catalytic efficiency, free from corrosion action to the equipment, high in conversion rate, high in product yield, and low in production cost.

Owner:XIANGTAN UNIV

High-durability high-efficiency nano antimicrobial water-based wood paint and preparation method thereof

InactiveCN105647362AReasonably control the contentImprove stabilityAntifouling/underwater paintsPaints with biocidesFumaropimaric acidWater based

The invention discloses a high-durability high-efficiency nano antimicrobial water-based wood paint which comprises the following components in parts by weight: 15-20 parts of water-based polyurethane resin emulsion, 15-20 parts of water-based acrylic modified polyurethane resin emulsion, 20-30 parts of water-based alkyd resin emulsion, 5-10 parts of polycarboxylic acid betaine methyl methacrylate, 6-9 parts of hydroxyethyl cellulose, 8-12 parts of sodium hexametaphosphate, 5-10 parts of nitrocellulose ester, 2-4 parts of fumaropimaric acid, 1.5-3 parts of nano titanium oxide, 1-3 parts of nano porous silicon oxide, 0.8-1.3 parts of nano zinc oxide, 1-1.8 parts of nano hydroxyapatite, 1-2 parts of pH regulator, 4-6 parts of defoaming agent, 1-3 parts of dispersing agent, 1-2 parts of leveling agent and 10-20 parts of deionized water. The wood paint has the advantages of broad spectrum, high efficiency, durable antimicrobial property, high stability, favorable adhesion resistance, favorable scratch resistance, favorable closeness and low VOC (volatile organic compound) content.

Owner:HUZHOU NEW AOKE CHEM CO LTD

Method for preparing high-softening-point rosin glyceride from fumaric acid

InactiveCN101818027AMake up for the lack of low softening pointLow costNatural resin chemical modificationFumaropimaric acidChewing gum

The invention discloses a method for preparing high-softening-point rosin glyceride from a fumaric acid. The method comprises the following steps of: firstly, modifying rosin by using the fumaric acid; secondly, esterifying the modified rosion with glycerine; and finally, synthesizing a high-softening-point fumaric acid rosin glyceride product having a softening point of 100 to 150 DEG C. The modified rosin glyceride product prepared by the method has the characteristics of low cost, high softening point, high stability and good mouth-feel, is safe and reliable and can be applied in the industries of beverages, chewing gums and the like.

Owner:WUZHOU PINE CHEM

Preparation method of high-purity fumaric acid tenofovir disoproxil fumarate

InactiveCN104230992AGood yieldIncrease productionGroup 5/15 element organic compoundsFumaropimaric acidOrganic solvent

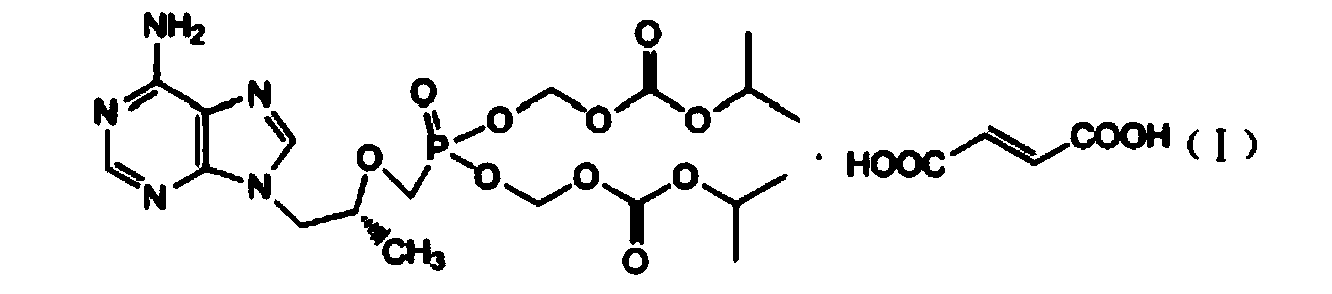

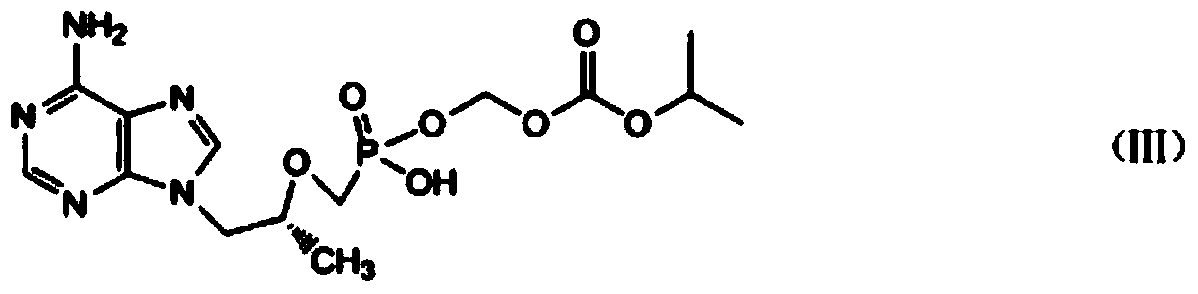

The invention discloses a preparation method of high-purity fumaric acid tenofovir disoproxil fumarate. The method comprises the following steps: (1) preparing tenofovir; (2) preparing tenofovir disoproxil fumarate, carrying out condensation reaction between tenofovir and chloromethyl isopropyl carbonate in an organic solvent under the action of a catalyst, purifying the product to obtain the tenofovir disoproxil fumarate, wherein the catalyst is a mixture of triethylamine and tetrabutylammonium bromide which are in the molar ratio of (22-30) to (1.5-3.0); the ratio of the triethylamine to the organic solvent is (22-30mol) to (150L-200L); and (3) preparing fumaric acid tenofovir disoproxil fumarate, salifying tenofovir disoproxil fumarate and fumaric acid which are obtained in the step (2), carrying out suction filtration, and drying to obtain the fumaric acid tenofovir disoproxil fumarate. According to the preparation method, dual catalysts are adopted in the process of preparing the tenofovir disoproxil fumarate, so that the yield and the efficiency of the tenofovir disoproxil fumarate are effectively increased, and the reaction process of the whole reaction is greatly shortened.

Owner:TAICANG YUNTONG BIOCHEM ENG

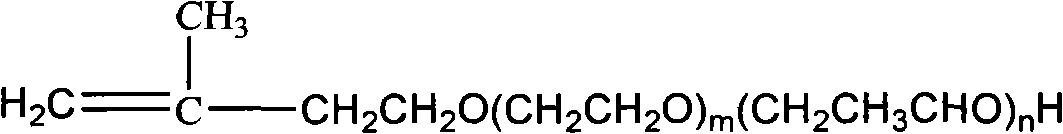

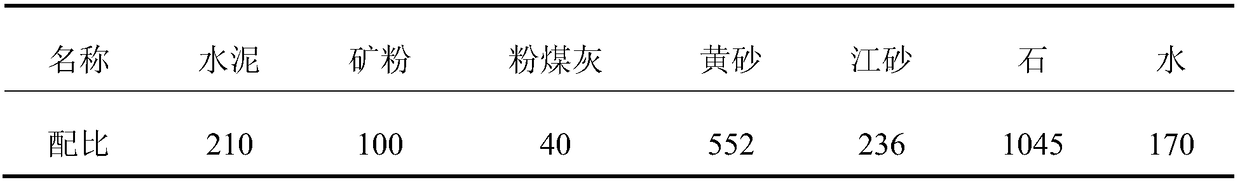

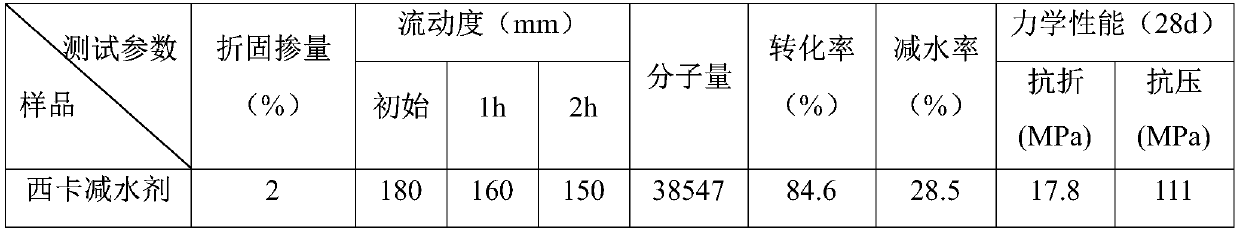

Preparation method of polycarboxylic acid water reducer

The invention discloses a preparation method of polycarboxylic acid water reducer, which is suitable in Gale Area of Xinjiang. The water reducer is prepared by polymerizing 20-60 percent of methyl and alkenyl polyoxyethylene polyoxypropylene ether (OXAB-501), 10-30 percent of acrylic acid (AA) and 20-60 percent of three monomers of fumaric acid as the raw materials under the action of H2O2-rongalite redox initiator. The concrete made out of the above water reducer has the advantages of favorable collapse performance, no environmental pollution, more effective ingredients and higher water reducing rate. Preparation method of the water reducer has the characteristics of simple operation and low cost, thereby providing the technical support for concrete construction in Gale Area of Xinjiang.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

Fumaric acid producing method

InactiveCN101781188AGood for healthIncrease the rate of isomerizationOrganic compound preparationCarboxylic compound preparationFumaropimaric acidIsomerization

The invention relates to a fumaric acid producing method, in particular to a fumaric acid producing method by using phthalic anhydride oxidizing reaction tail gas absorbing acid water as raw material. The method comprises the following steps of: a. adding a maleic acid water solution from a phthalic anhydride producing device into a bleaching kettle, and adding active carbon to carry out adsorption bleaching; b. adding the filter liquor filtered in the previous step into a reaction kettle, adding phosphoric acid and a dimethoxy family (selenium / zinc) composite catalyst to carry out isomerization reaction, wherein the weight ratio of the dimethoxy selenium amido to dimethoxy telluride amido in the dimethoxy family (selenium / zinc) composite catalyst is 1: 0.1-0.5; c. in the crystallizing kettle, cooling and crystallizing the acid water solution converted into the fumaric acid under the stirring state, and cooling to the acid water temperature of 30 DEG C; stirring, discharging material to solid and liquid separating equipment, and drying the solid matters by drying equipment to obtain the fumaric acid finished product. The invention can enhance the quality of the fumaric acid.

Owner:ZHENJIANG KAIPU CHEM TECH CO LTD

Corrosion resistant resin of oxirene-ester in high molecular weight and producing method

A formula for preparing epoxy vinyl ester resin is featured as that soft monomer of acrylic acid is used main raw material for synthesis by unsaturated monocarboxylic acid, fumaric acid and toluene diisocyanate are used as chain extendor. The production process of toluene diisocyanate being chain-extended in styrene solution at 60 degree i.e. diluting first and then chain extending is disclosed.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

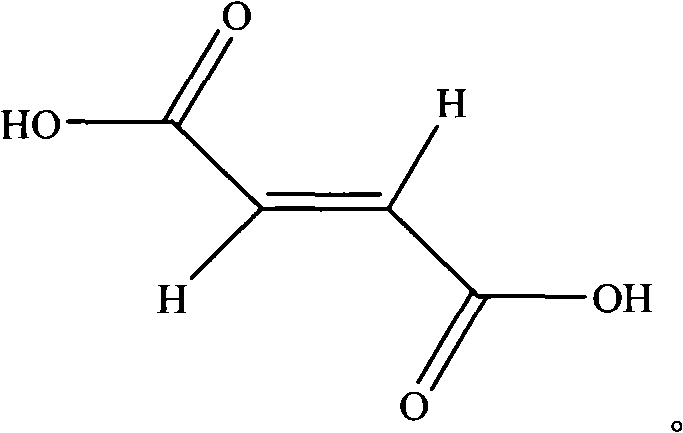

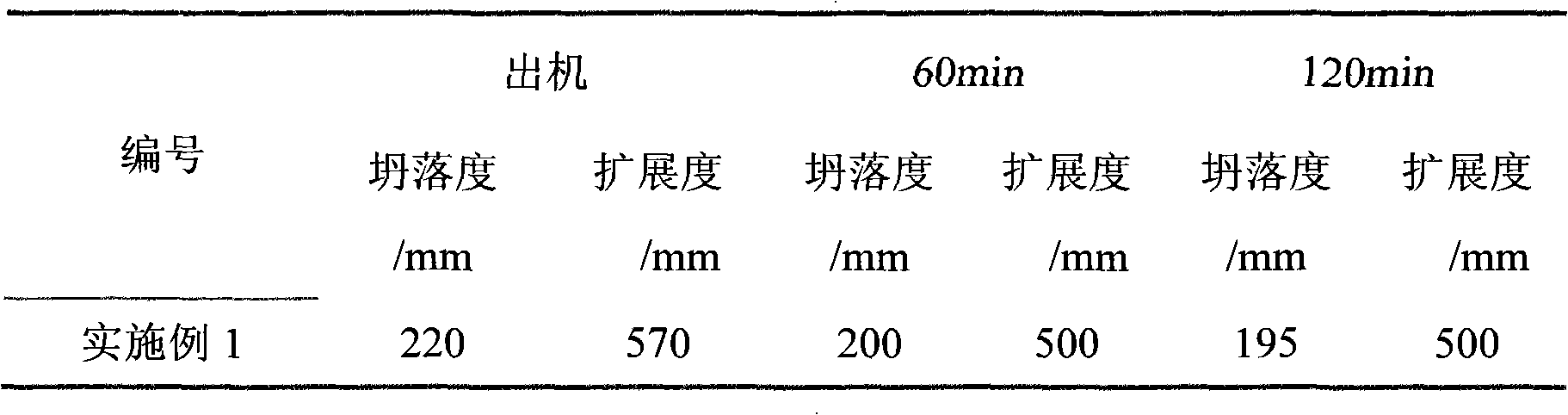

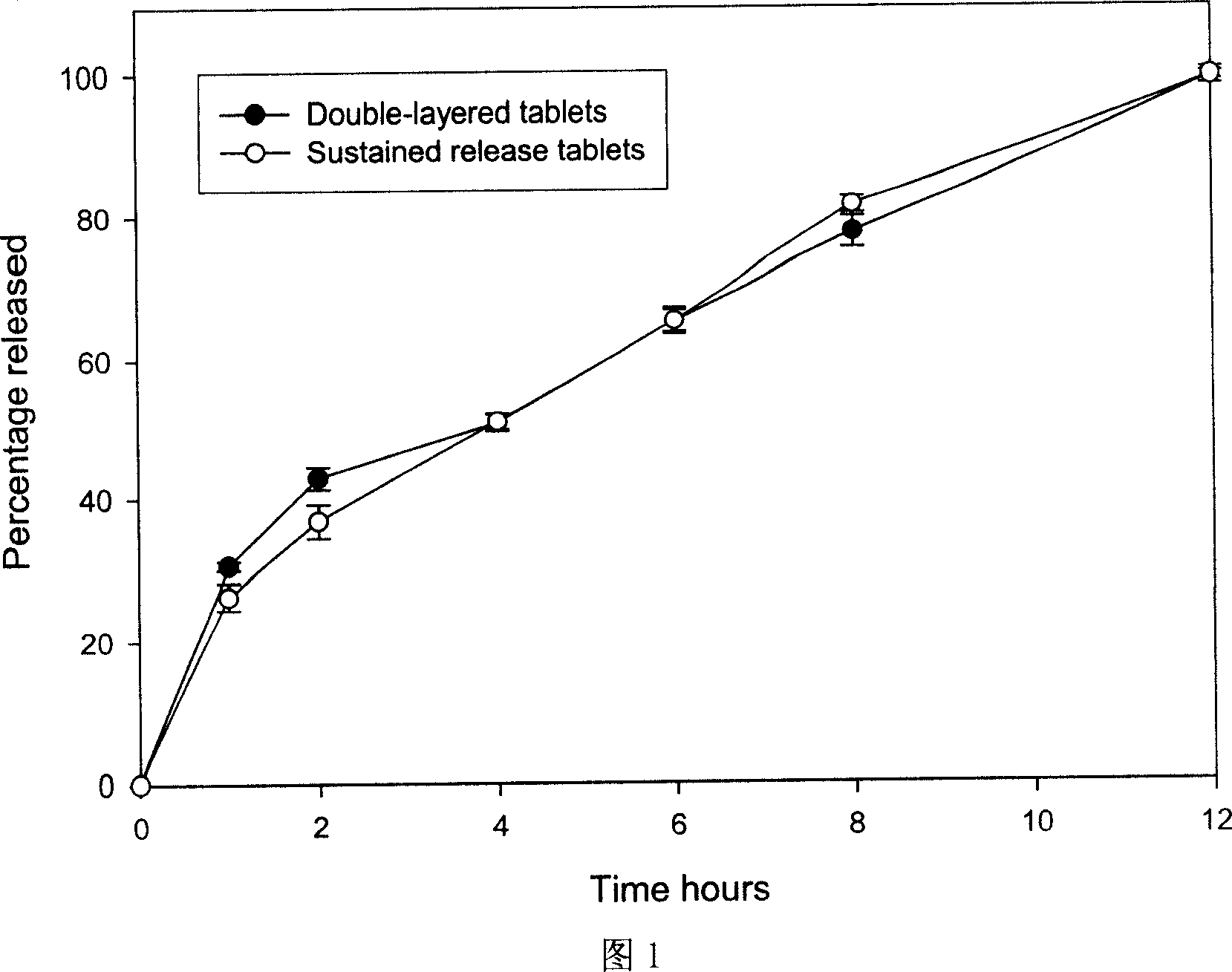

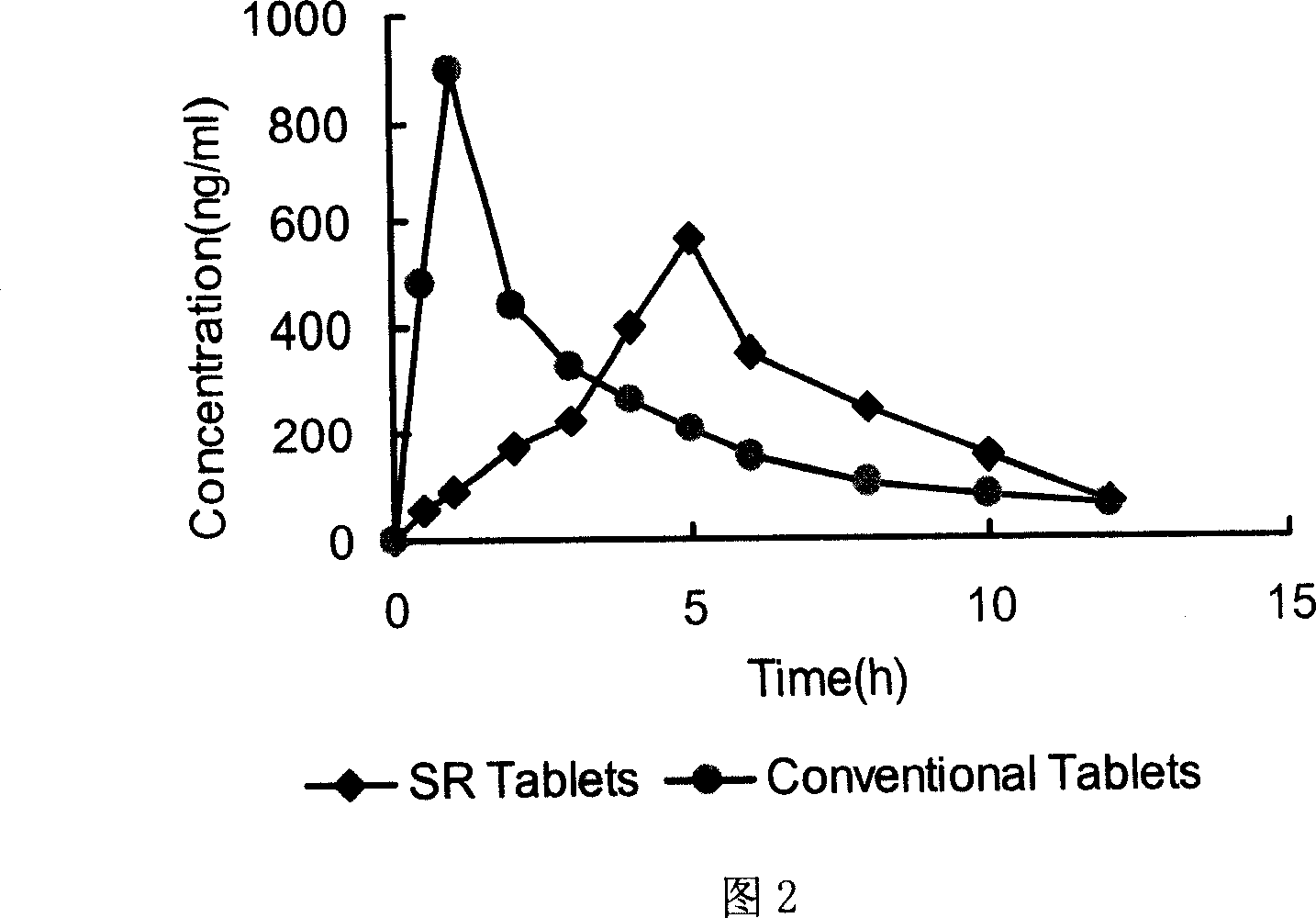

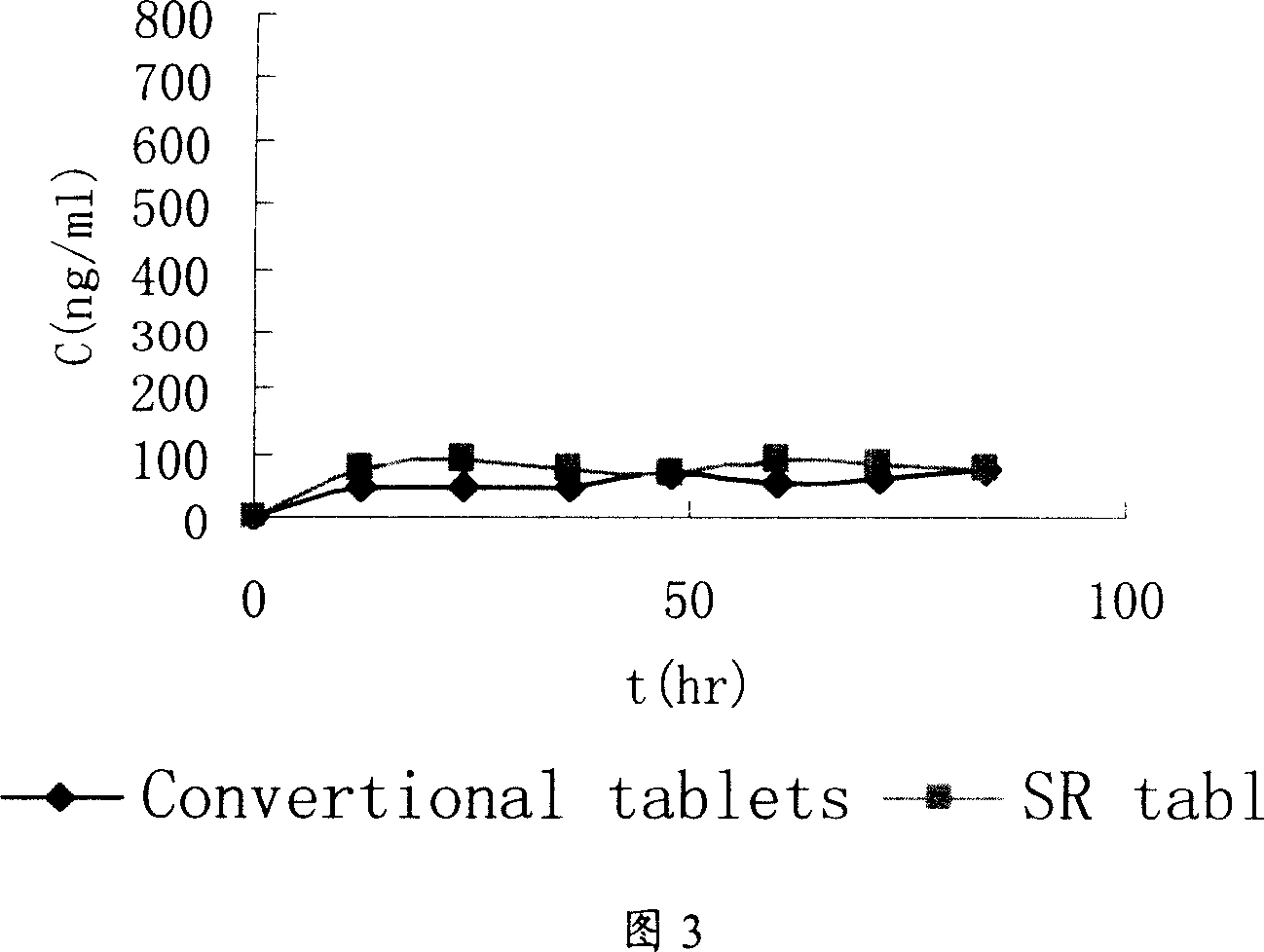

Maleic acid trimebutine slow release tablet comprising quick release part and preparing method thereof

ActiveCN1927185AActive ingredients are well absorbedPromote absorptionDigestive systemEster active ingredientsFumaropimaric acidTrimebutine

This invention concerns a the maleic acid trimebutine sustained-releasing tablets with rapid releasing part and preparation of pharmaceutical pharmaceuticals, including double slice and tablet mixed and suppressed by particles with different releasing characteristics, it is found in the invention that after the maleic acid trimebutine and fumaric acid being mixed and granulated, the stability and compressibility of the maleic acid trimebutine is improved, and its citation moist is lowered, and it can be used for preparation of the praeparatum of the present invention, the present invention includes the rapid releasing part and sustained-releasing part.

Owner:KAIKAII YUANSHENG PHARMA CO LTD

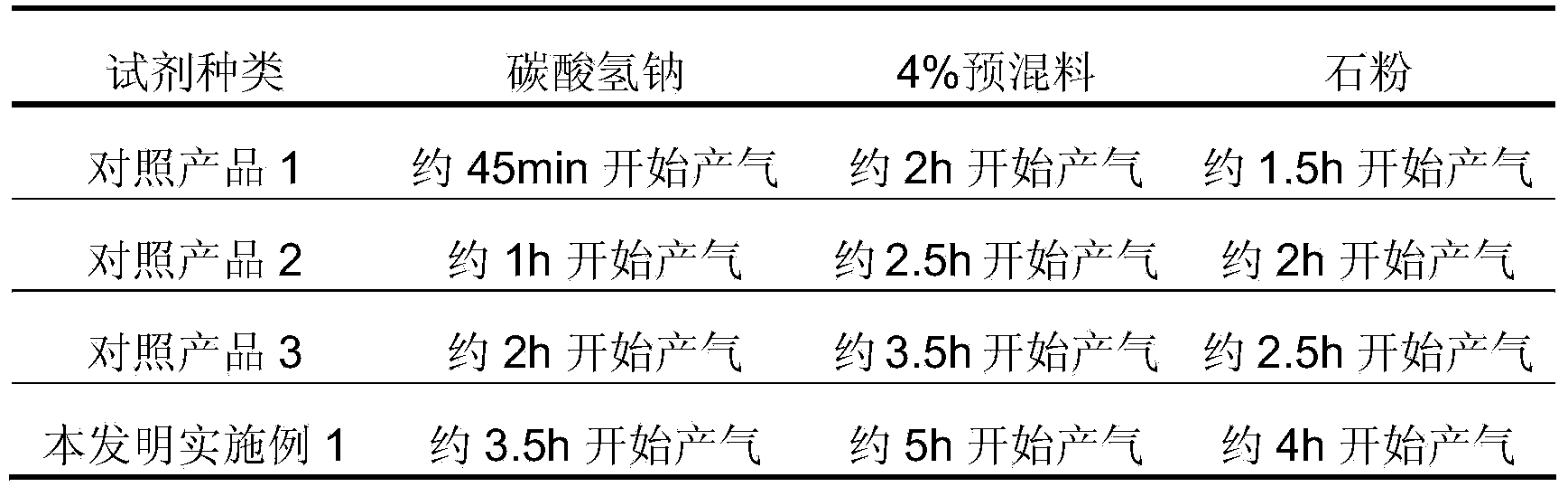

Coated acidifying agent for feed and preparation method thereof

InactiveCN104222630AImprove adsorption capacityEffective acidificationAnimal feeding stuffFumaropimaric acidPeristaltic pump

The invention relates to a preparation method of a coated acidifying agent for a feed. The preparation method comprises the following steps: firstly, adsorbing phosphoric acid; uniformly mixing silicon dioxide with phosphoric acid to completely adsorb phosphoric acid; putting a phosphoric acid adsorbate into a fluidized bed coating machine; spraying coating liquid into the coating machine by a peristaltic pump to perform coating granulation; and uniformly mixing a coated product with citric acid and fumaric acid to obtain the finished product. The acidifying agent prepared by the preparation method is a combination of organic and inorganic materials and the releasing speed of the acidifying agent can be effectively lowered; a coating film wrapping grains is a protective film so that the contact between the acidifying agent and alkaline substances in the feed, a premix and the like is reduced, and the acidifying effect of the acidifying agent is enhanced. The growth and reproduction of effective microbial communities, such as probiotics, can be facilitated to generate organic acids and other antibacterial substances, so that the pH value in gastrointestinal tracts is further reduced, and the growth of harmful bacteria is inhibited. The organic acids which are gradually released in digestive tracts also have a complexing effect and are combined with microelements in the feed, the premix and the like so as to promote the absorption in small intestinal tracts.

Owner:上海邦成生物工程有限公司

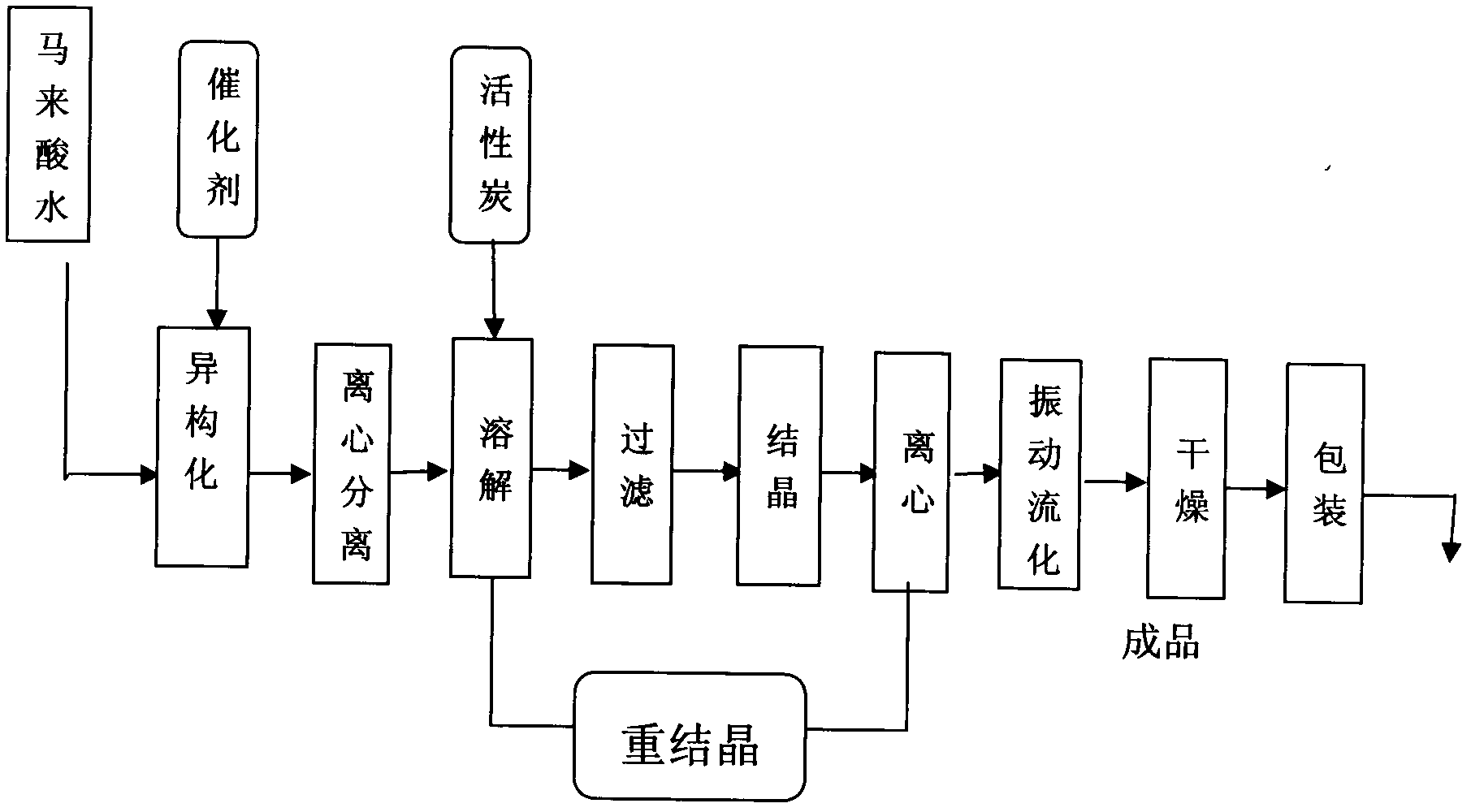

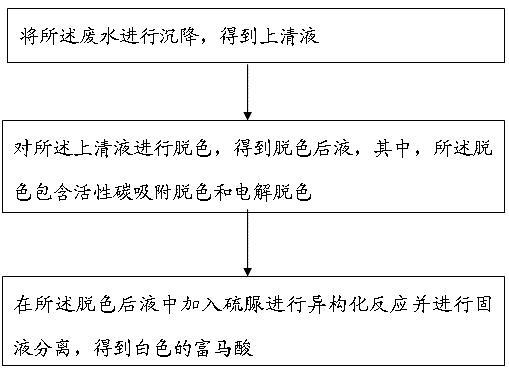

Method for producing fumaric acid by maleic anhydride waste water

InactiveCN103204772AAchieve reuseSolve production problemsOrganic compound preparationCarboxylic compound separation/purificationFumaropimaric acidIsomerization

The invention relates to a method for producing fumaric acid by maleic anhydride waste water. The method comprises an isomerization reaction process of the maleic anhydride waste water, a centrifugal separation process of fumaric acid head products, a dissolution and decoloration process of the fumaric acid, a filtration process, a crystallization and re-crystallization process of the fumaric acid, a centrifugation process and a drying and packaging process of the fumaric acid. Specifically, the method comprises the steps of adding a catalyst to the maleic anhydride waste water to carry out the isomerization reaction, adding activated carbon to carry out dissolution and decoloration, filtration and crystallization and re-crystallization after the centrifugal separation, then centrifuging, drying and packaging to obtain the fumaric acid. With the method, the fumaric acid in waste acid water generated in production process by using the maleic anhydride can be fully recovered and industrial grade fumaric acid products can be made, so that discharging amount of waste can be reduced maximally, valuable fumaric acid resource can be recovered, and reutilization of the resource is realized. The preparation method is simple and controllable in process, relatively low in cost and has significant social and economic benefits.

Owner:XINJIANG JINYUAN GASOLINEEUM CHEM

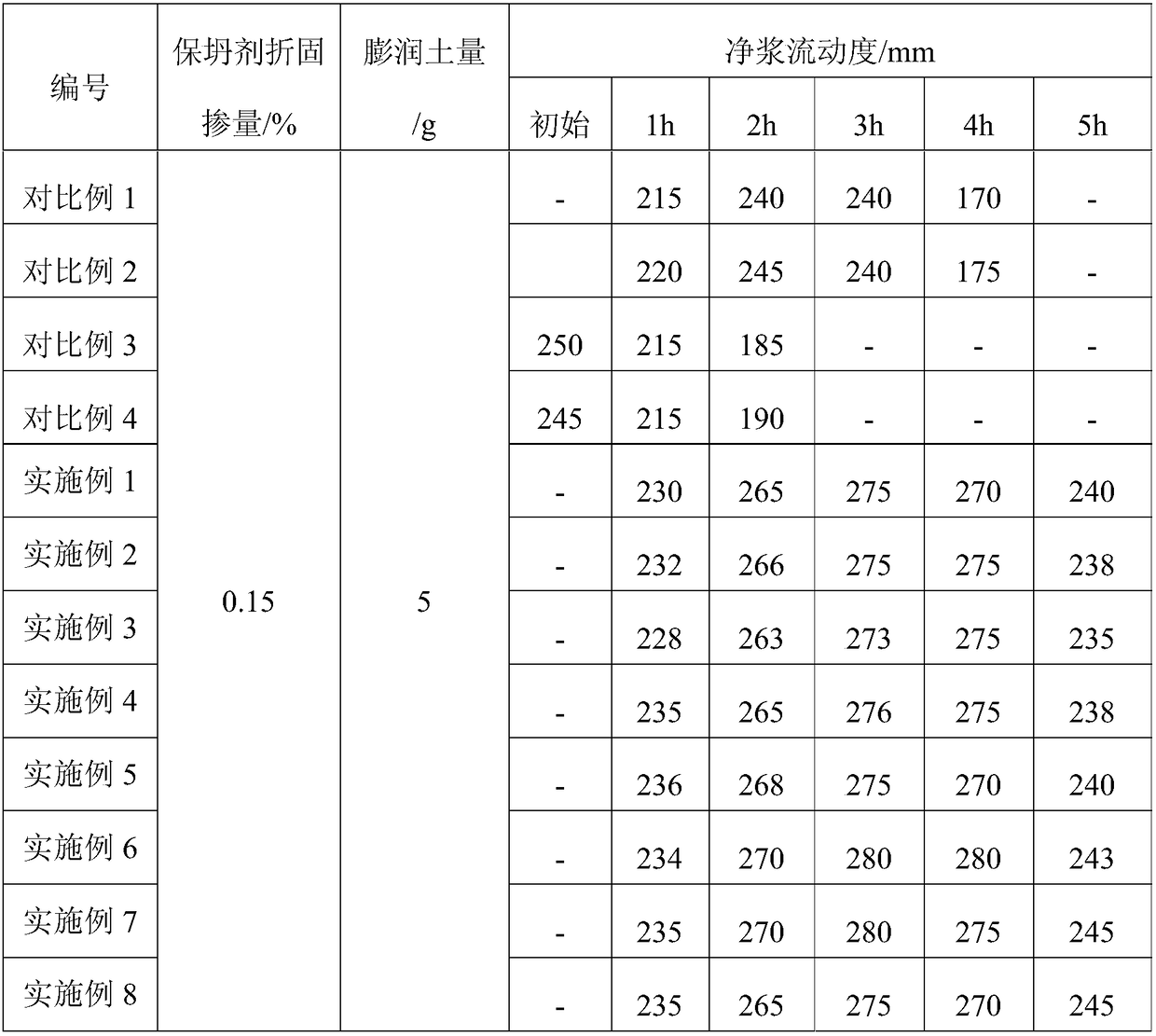

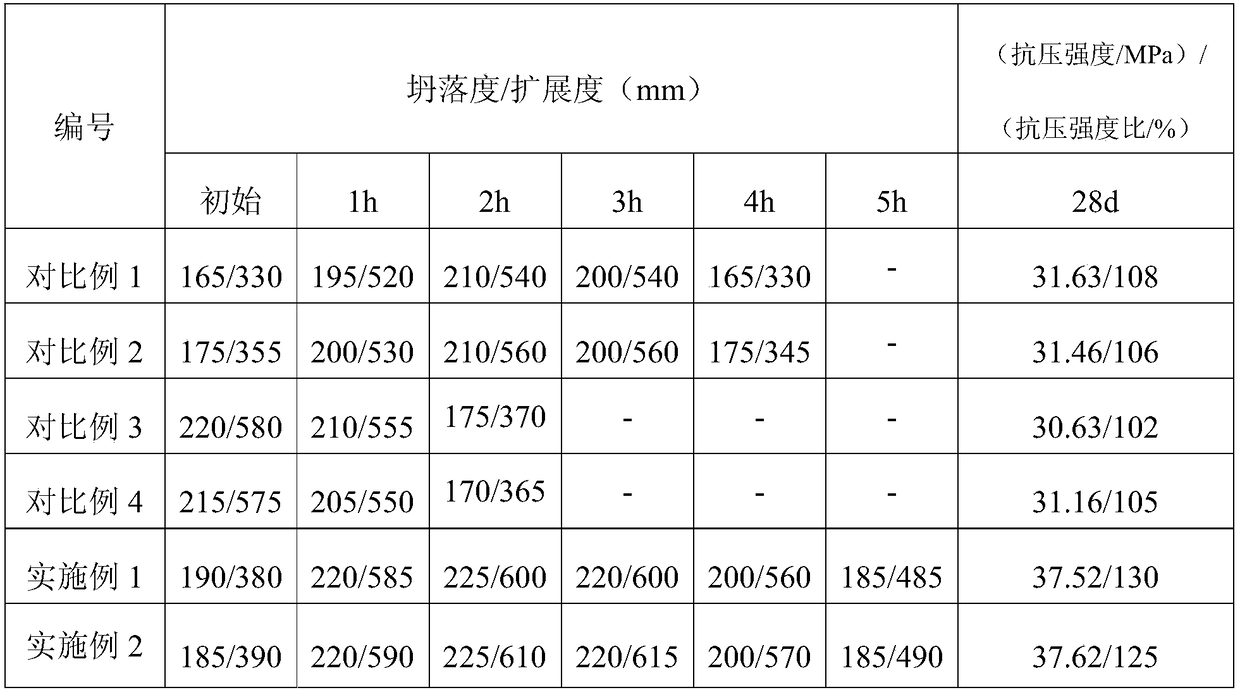

Mud resistant slow release type slump retaining agent containing cyclodextrin side group and preparation method thereof

The invention discloses a mud resistant slow release type slump retaining agent containing a cyclodextrin side group and a preparation method thereof. The method synthesizes a mud resisting ester monomer by introducing a beta-cyclodextrin structural unit with appropriate steric hindrance and better water solubility to be subjected to an esterification reaction with fumaric acid. In alkaline environment of cement hydration, with the slow release of the mud resisting ester monomer, the beta-cyclodextrin introduced into the molecular structure of a water reducer can effectively weaken interpenetration between water reducer molecules and a clay layer because particles of the beta-cyclodextrin distribute in a range of 0.53-1.78 nm which is close to 1.44-1.86 nm that is the interlayer spacing ofbentonite, and so the polycarboxylic acid water reducer is good in mud resistance and slump retaining effect. Meanwhile, a phosphoric acid monomer is introduced into the molecular structure of the water reducer to further improve the mud resisting effect. The mud resistant slump retaining type polycarboxylic acid water reducer containing a cyclodextrin side group prepared by the method of the invention has the advantages of low dosage, long slump retaining time, strong mud resistance and the like, and is easy in synthesis process, safe, environmentally friendly and low in production cost.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

Process for preparing fumaric acid by spraying acid water to benzene anhydride oxidized tail gas

ActiveCN101024608AEliminate environmental pollutionAvoid timeOrganic compound preparationCarboxylic compound separation/purificationFumaropimaric acidAcid water

The invention relates to a technology to make fumaric acid. The feature is that benzene anhydride oxidation tail gas spraying acid takes isomerization under effect of thiourea catalyst after removing phthalic acid and decoloring. The invention has the advantages of simple technology, low cost, obvious economic and environment benefits.

Owner:山东宏信化工股份有限公司

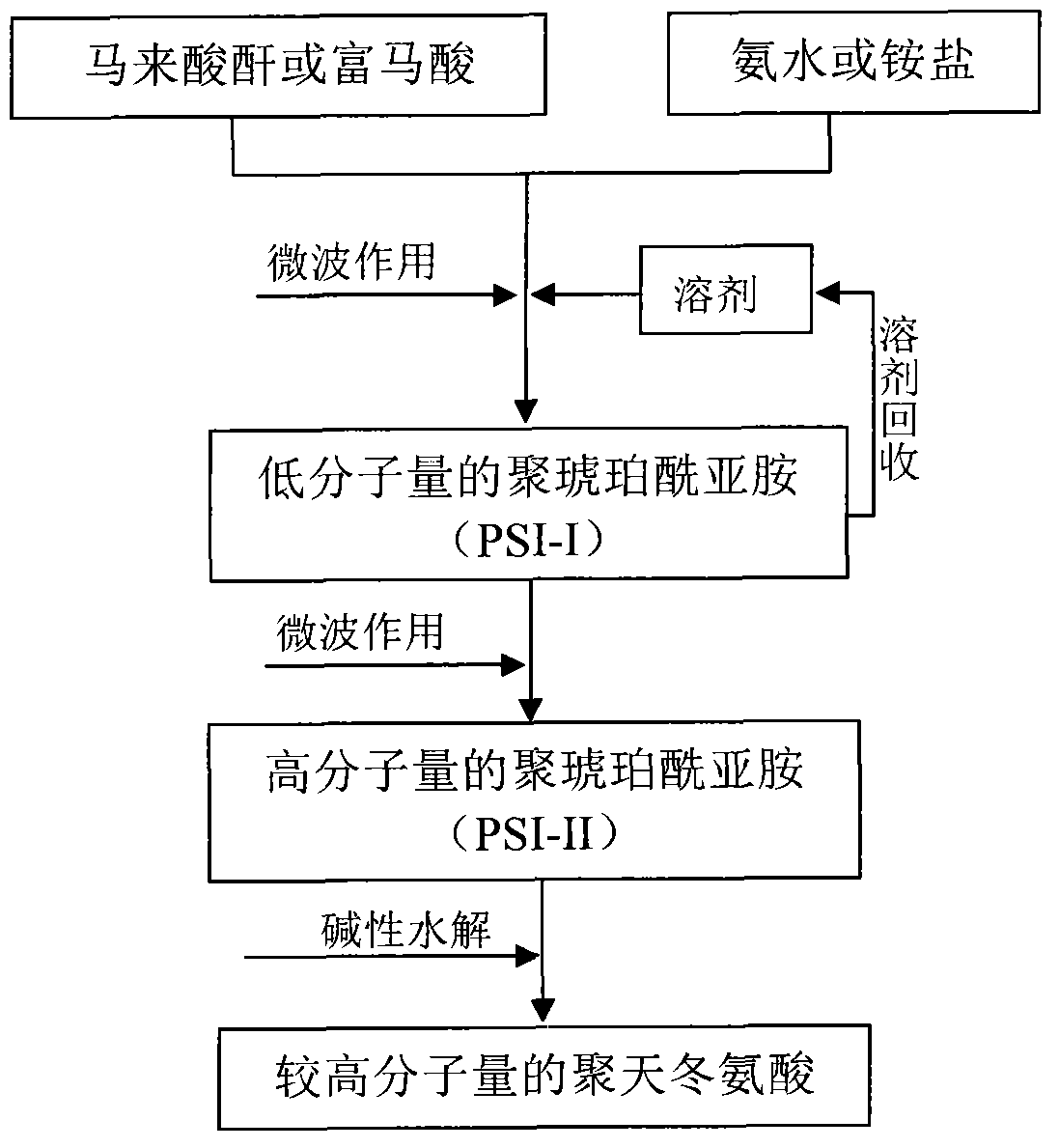

Polyaspartic acid synthesized by microwave half-solvent method

ActiveCN102796263AImprove performanceHigh molecular weightScale removal and water softeningFumaropimaric acidSynthesis methods

The invention relates to a synthesis method of a high-molecular-weight polyaspartic acid, particularly a polyaspartic acid synthesized by a microwave half-solvent method. The invention aims to overcome the defects of low molecular weight of the product, unstable antiprecipitation property, difficulty in solvent separation and the like in the existing microwave synthesis method. The synthetic process comprises the following two steps: 1. by using maleic anhydride or fumaric acid and ammonia water or ammonium salt as raw materials, adding a small amount of solvent, and radiating with microwaves, of which the frequency is 915+ / -50 MHz or 2450+ / -50 MHz and the power is 200-20000W, for 1-40 minutes to synthesize the low-molecular-weight polysuccinimide (PSI-I), wherein the solvent is recycled completely; and 2. by using the PSI-I as the raw material, radiating with microwaves, of which the frequency is 915+ / -50 MHz or 2450+ / -50 MHz and the power is 400-50000W, under the condition of no solvent for 1-30 minutes to synthesize the high-molecular-weight polysuccinimide (PSI-II), and hydrolyzing the PSI-II to obtain the high-molecular-weight polyaspartic acid. The invention has the advantages of simple technique, no need of solvent separation, obviously higher product molecular weight, obviously higher antiprecipitation property, high reaction speed, high yield, energy saving, low pollution and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

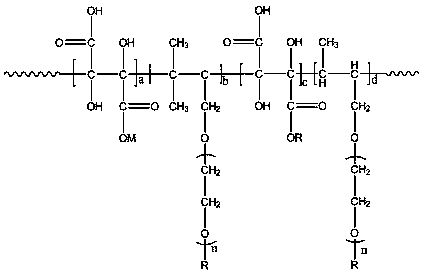

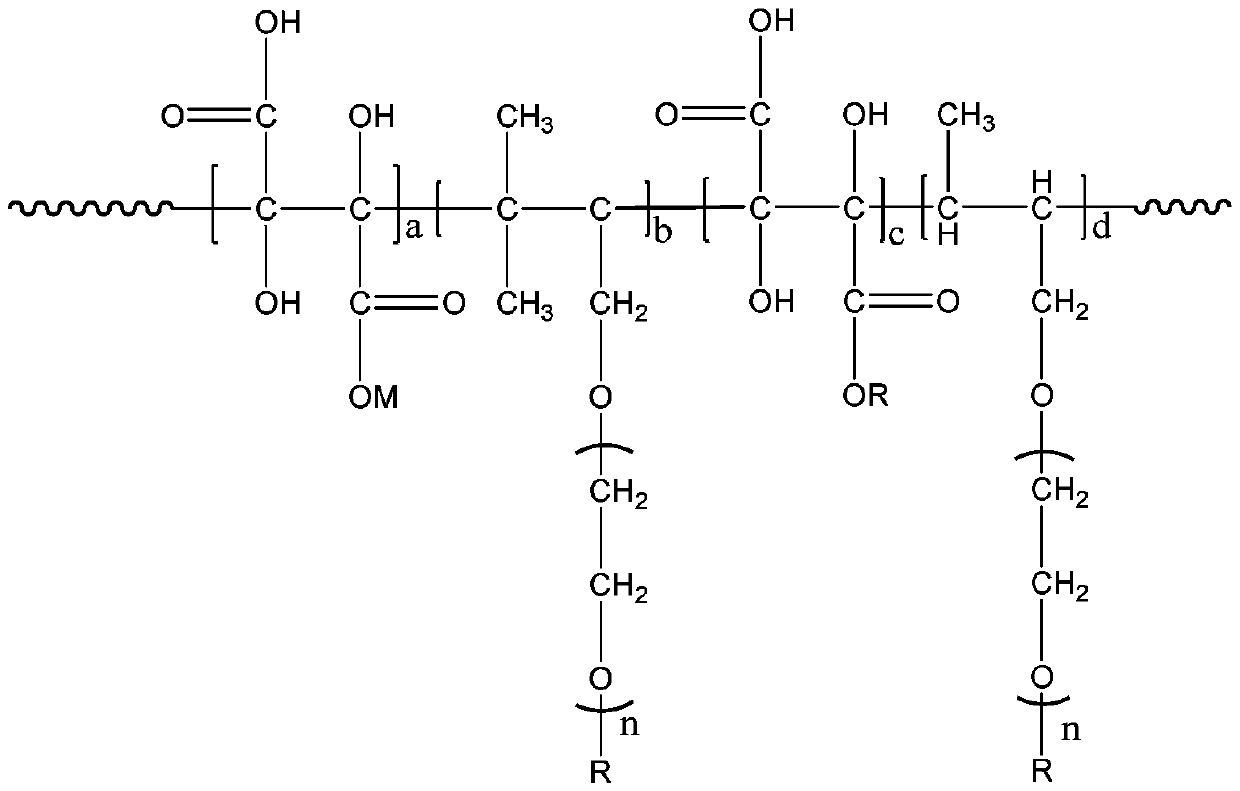

Viscosity reduction high efficiency water-reducing polycarboxylate superplasticizer and preparation method thereof

The invention relates to a viscosity reduction high efficiency water-reducing polycarboxylate superplasticizer and a preparation method thereof. The superplasticizer is prepared by intermittent dropwise adding of macromonomers like TPEG monomer, unsaturated hydroxy acid monomer or its derivative, or unsaturated acid with a trans-structure for free radical polymerization reaction under the action of a reductant, an oxidant and a chain transfer agent. The anchoring group and side chain in the superplasticizer are molecular structures in block distribution, and can give full play to electrostaticrepulsion and steric-hinerance effect. In addition, the hydroxyl, carboxyl and other polar groups introduced by the unsaturated hydroxy acid monomer or its derivative monomer increase the proportionof hydrophilic groups and reduce the surface tension of the cement pore solution. In addition, in terms of the trans-structural body represented by fumaric acid and dihydroxyfumaric acid derivatives,because of the special structure, i.e. the stiffness of the monomer itself and the distribution of two carboxyl groups on the opposite side of the side chain, a stretching structure easily exhibits inspace to reduce the possibility of molecular chain entanglement and significantly increase the adsorption effect of the polycarboxylate superplasticizer on the cement surface, thereby enhancing the viscosity reduction effect of the polycarboxylate superplasticizer.

Owner:HUNAN UNIV

Preparation method of dimethyl fumarate

InactiveCN102757346AHigh catalytic activityHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFumaropimaric acidAlcohol

The invention relates to a preparation method of dimethyl fumarate. According to the preparation method of the dimethyl fumarate, fumaric acid and methanol are taken as raw materials, an acid-functionalized ionic liquid is taken as a catalyst, and an acid-alcohol esterification reaction is carried out under relatively mild conditions so as to synthesize the dimethyl fumarate. The catalyst used in the preparation method is high in activity, low in using amount and easy to separate, recycle and reuse; the defects of difficult catalyst recovery, environment pollution and equipment corrosion in the prior art are overcome; and the preparation method of the dimethyl fumarate has a very good industrial application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

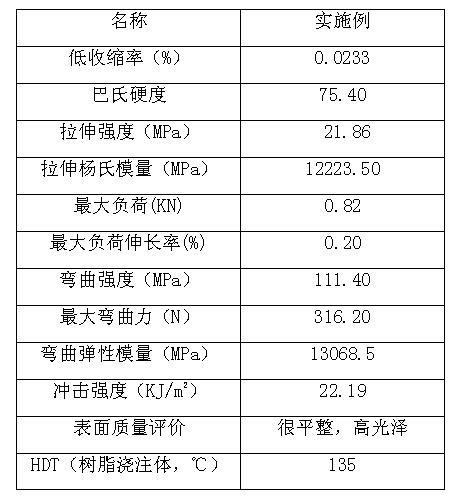

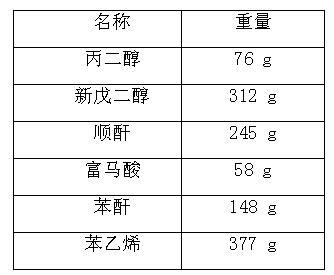

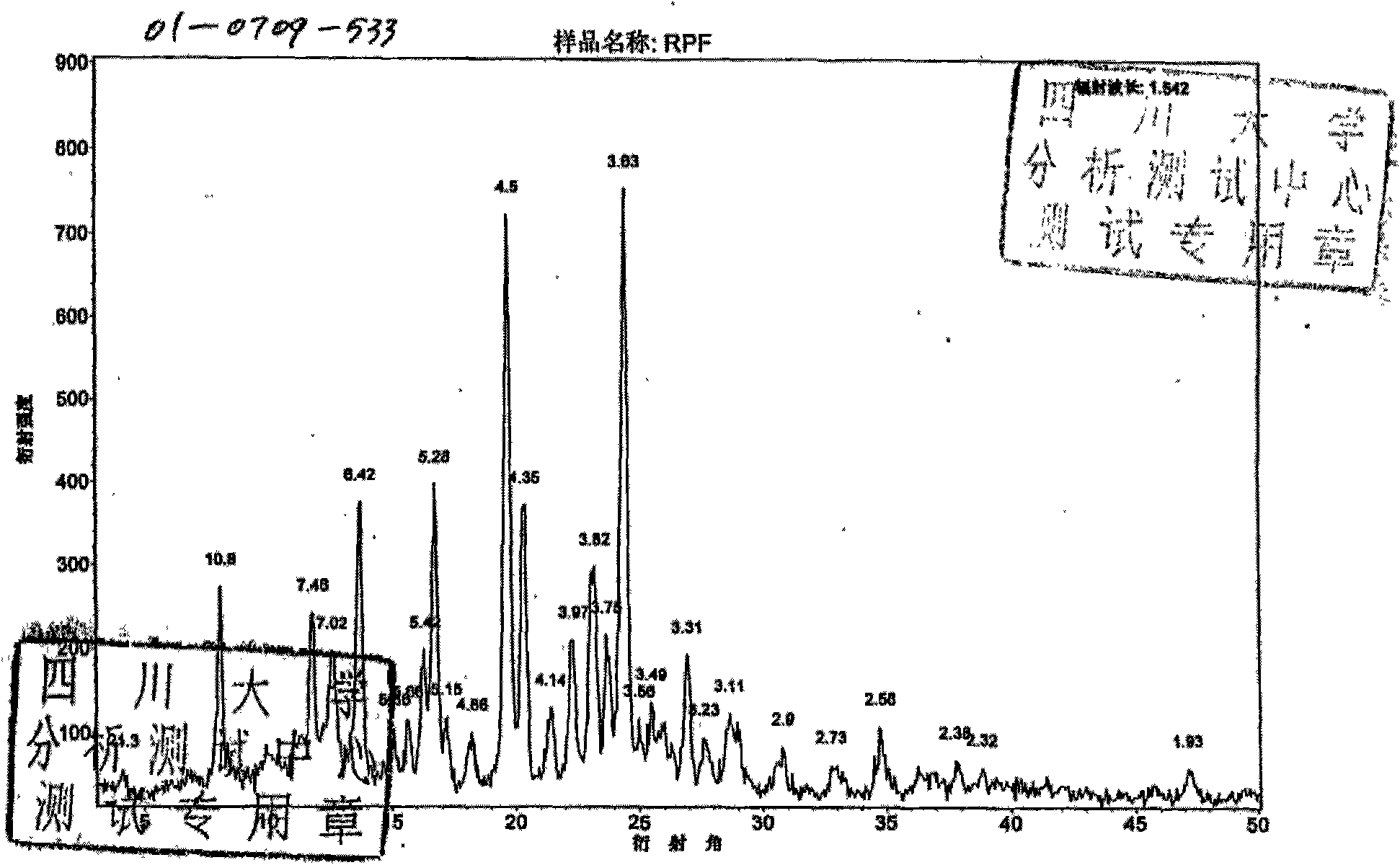

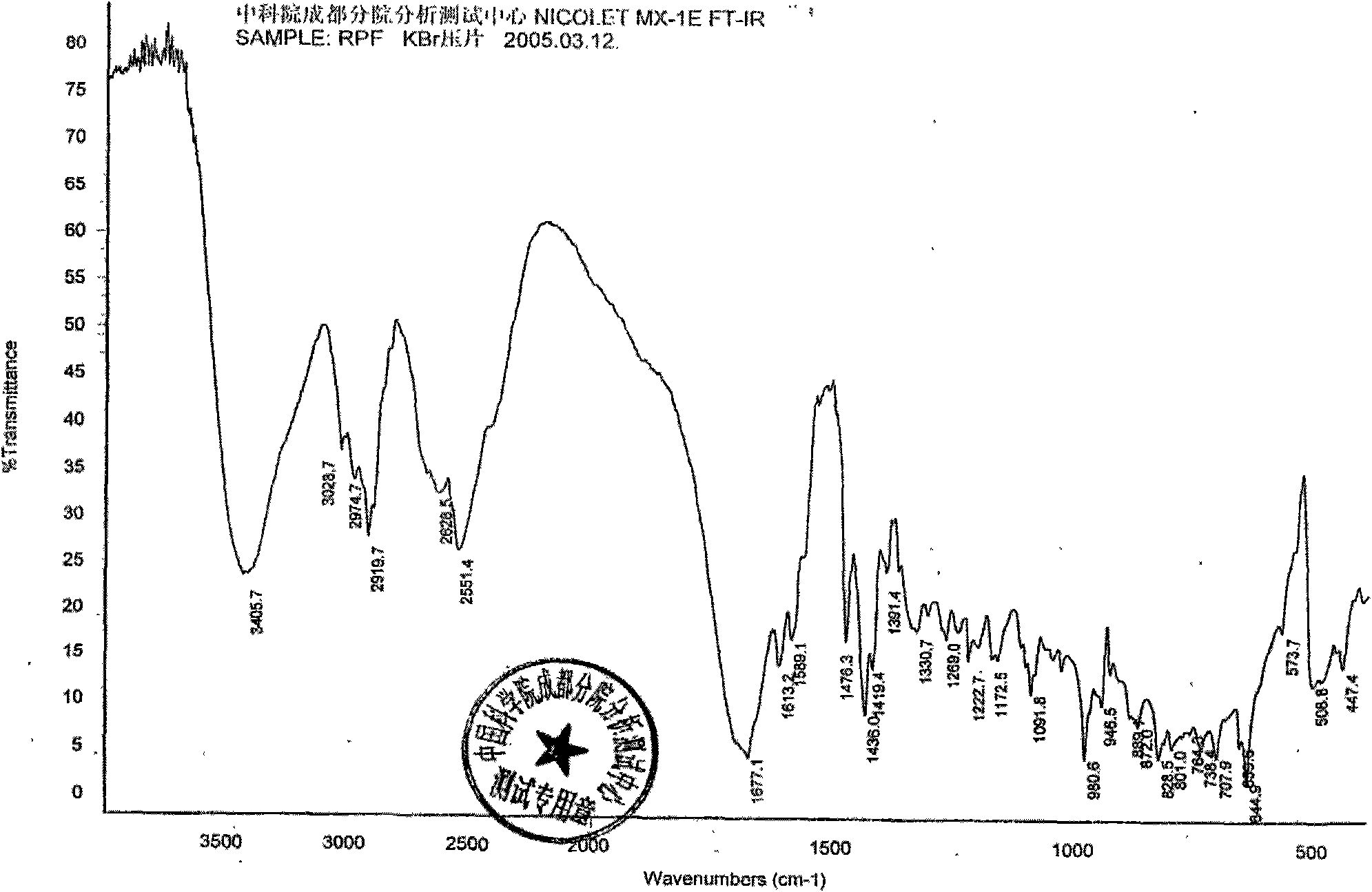

Unsaturated polyester resin for sheet or bulk molding compound and preparation method thereof

The invention relates to the technical field of preparation of high molecular materials, in particular to a preparation method of an unsaturated polyester resin for a sheet or bulk molding compound. The unsaturated polyester resin is prepared by performing esterification on small molecular dibasic alcohol, unsaturated dibasic acid or acid anhydride and dissolving polymer which is formed by polycondensation in inhibitor-containing styrene. The preparation method of the unsaturated polyester resin comprises the following steps of: putting propylene glycol, dineopentyl alcohol, maleic anhydride and fumaric acid into a heating and stirring device in proportion; introducing nitrogen gas for protection; stirring, heating and discharging water; controlling a fraction head temperature and a reaction temperature until acid value is 70 to 80mgKOH / g; increasing the reaction temperature until the acid value is less than 30mgKOH / g and cooling to 150 DEG C; pouring into solution containing styrene and an inhibitor for dilution; and keeping a dilution temperature at 60 to 80 DEG C. The unsaturated polyester resin has high reaction activity, and a molding compound product has extremely excellent advantages of high surface glossiness, high heat resistance, high weather resistance, high water resistance, high acid resistance, high alkali resistance and the like.

Owner:CHANGZHOU HUAKE POLYMERS

Method for preventing fumaric acid deposits in the production of maleic acid anhydride

InactiveUS20090143601A1Improve industrial scale preparationHigh complexityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsFumaropimaric acidOrganic solvent

The present invention provides a process for preventing fumaric acid deposits in the preparation of maleic anhydride, comprising the following steps:a) absorption of a C4-dicarboxylic acid or of a derivative from a crude product mixture into an organic solvent or water as an absorbent,b) removal of the C4-dicarboxylic acid or of a derivative from the absorbent,the absorbent thus recovered being catalytically hydrogenated fully or partly and recycled fully or partly into the absorption stage (a).

Owner:BASF AG

Method for salifying or recrystallization of rupatadine fumarate

The invention provides a method for preparing rupatadine fumarate, which is suitable for actual large-scale industrial production and has high yield and quality and excellent stability. A preparation method for the salifying of the rupatadine fumarate comprises the following step of performing a salifying reaction on rupatadine and fumaric acid in a mixed solvent, wherein the mixed solvent is a mixed solvent of acetone and water in a volume ratio of 5-20:1. In addition, the rupatadine fumarate also can be subjected to recrystallization in the mixed solvent.

Owner:NANJING VARSAL MEDICINE TECH DEV +1

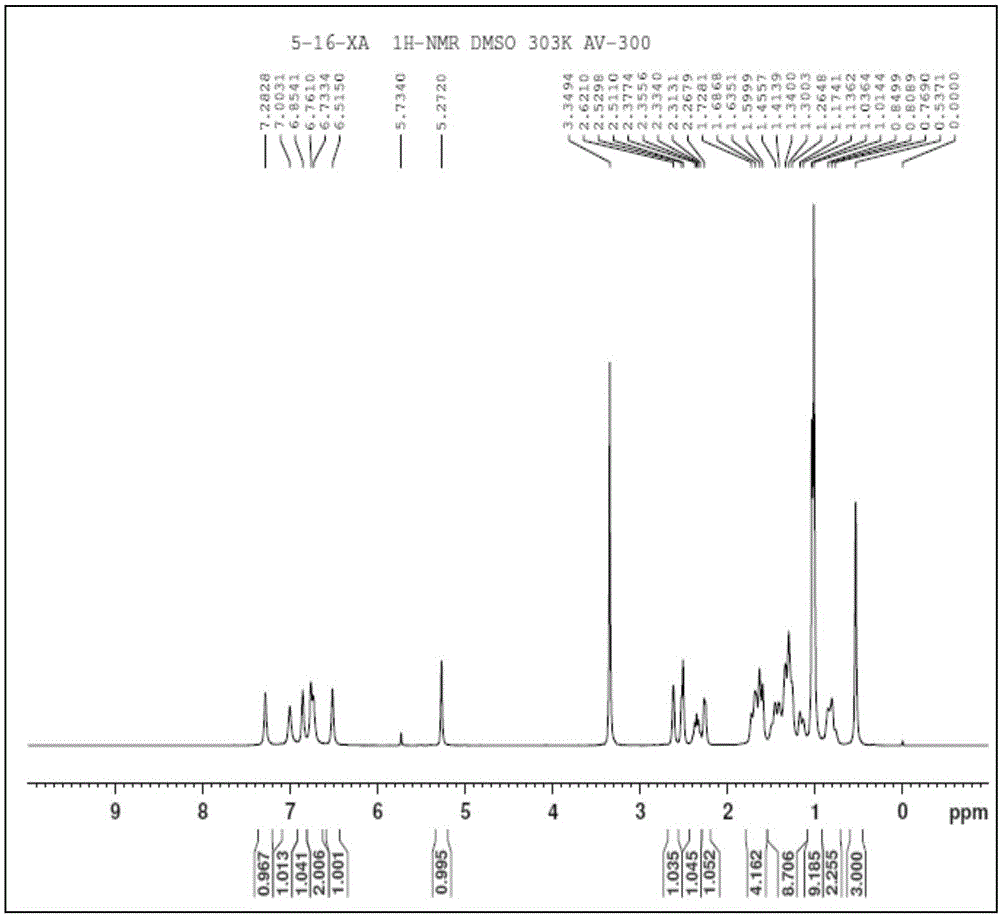

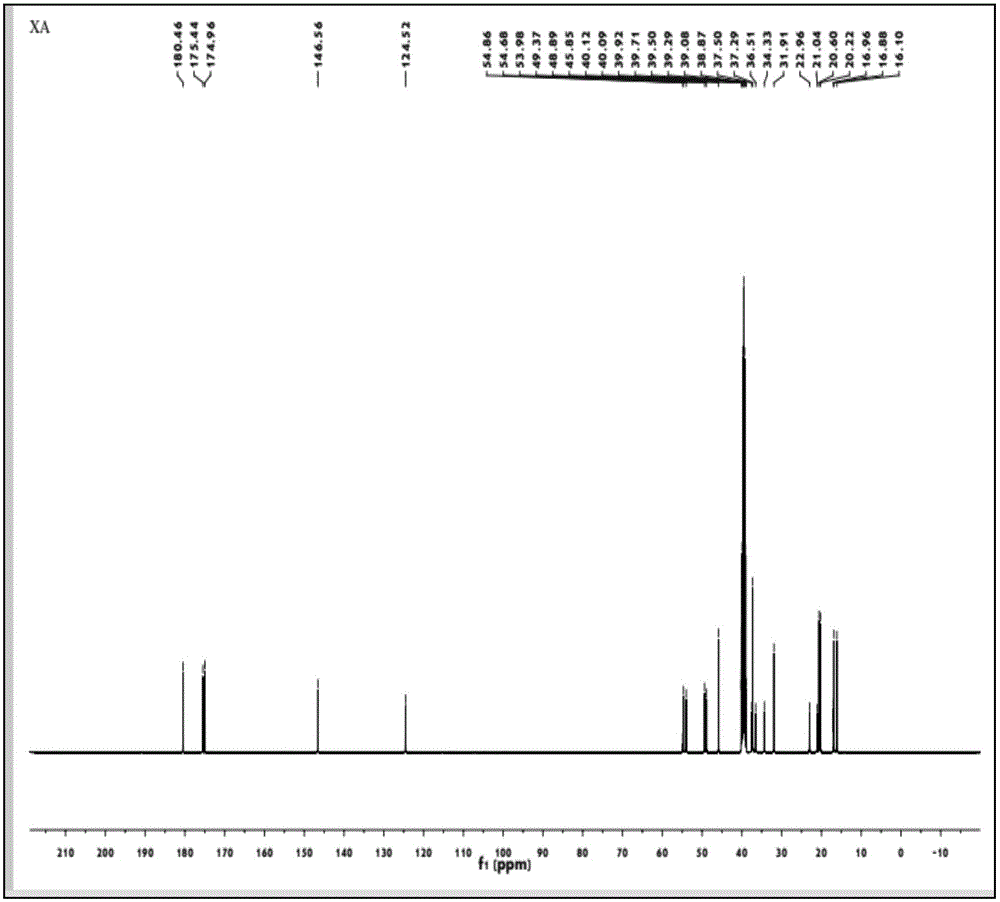

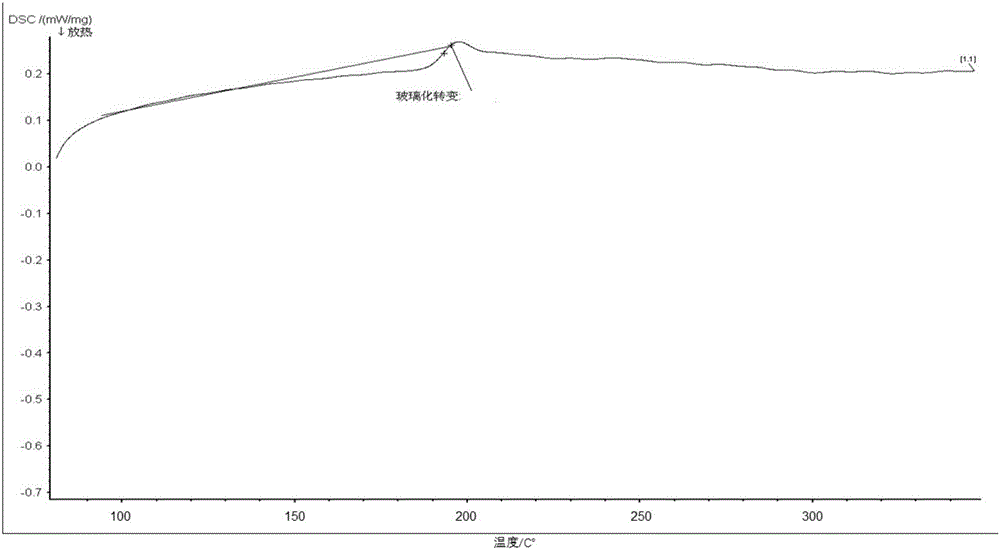

Fumaropimaric acid modified acrylamide compound, preparation method thereof and polymer prepared by fumaropimaric acid modified acrylamide compound

ActiveCN106748855AEnvironmentally friendlyNo pollution in the processOther chemical processesOrganic compound preparationFumaropimaric acidPolymer science

The invention discloses a fumaropimaric acid modified acrylamide compound, a preparation method thereof and a polymer prepared by the fumaropimaric acid modified acrylamide compound. A structural formula of the fumaropimaric acid modified acrylamide compound is shown in the description. As the fumaropimaric acid modified acrylamide compound is synthesized by taking fumaropimaric acid, a by-product of rosin which is a natural biomass resource, as a raw material, and then the fumaropimaric acid modified acrylamide polymer is obtained through polymerization of the fumaropimaric acid modified acrylamide compound, a synthesis step and a reaction device are simple, the operation is convenient, and the problems of poor heat resistance, difficulty in separation, slow reaction speed, low recycling use performance and the like and the technical problems of environment protection and safety are all solved due to excellent heat resistance, excellent adsorption performance to heavy metals and capability of being repeatedly used for multiple times of the obtained polymer.

Owner:NANJING FORESTRY UNIV

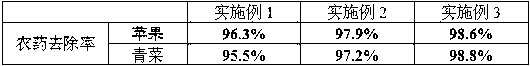

Fruit and vegetable washing agent

InactiveCN102864030AEffectively remove pollutionInorganic/elemental detergent compounding agentsCationic surface-active compoundsFumaropimaric acidBenzoic acid

The invention provides a fruit and vegetable washing agent which comprises, by weight, 10-30 parts of triethanolamine oleate, 1-5 parts of sodium dodecyl benzene sulfonate, 15-35 parts of ethanol, 15-35 parts of organic acid, and 10-40 parts of sodium salt. The organic acid is fumaric acid, citric acid or benzoic acid. The sodium salt is sodium chloride, sodium citrate or sodium acetate. The fruit and vegetable washing agent is diluted to aqueous solution of 1%-5% when used, pollution of lead, cadmium ions and pesticides to vegetables and fruits can be effectively removed by direct washing or soaking, and the pesticide removal rate can reach over 96%.

Owner:SUZHOU GULI BIOTECH

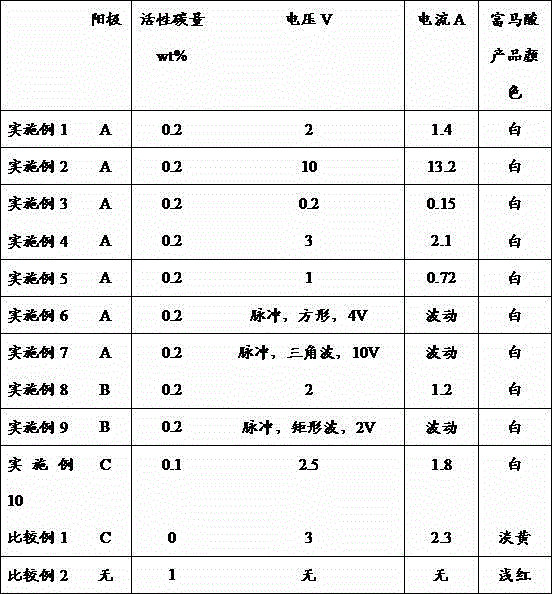

Method for recovering fumaric acid from phthalic anhydride wastewater

ActiveCN103553899ACompliant with feed grade standardsEfficient decompositionOrganic compound preparationCarboxylic compound separation/purificationFumaropimaric acidIsomerization

The invention provides a method for recovering fumaric acid from phthalic anhydride wastewater. The method comprises the following steps: (1) settling the wastewater to obtain supernatant; (2) decolorizing the supernatant to obtain decolorized liquid, wherein the decolorization comprises active carbon adsorptive decolorization and electrolytic decolorization; (3) adding thiourea into the decolorized liquid to perform isomerization reaction and performing solid-liquid separation so as to obtain white fumaric acid. According to the method for recovering the fumaric acid from the phthalic anhydride wastewater provided by the embodiment of the invention, organic impurities, which are unlikely to be dissolved in water, in the phthalic anhydride wastewater can be effectively decomposed in combination with the active carbon adsorptive decolorization and the electrolytic decolorization when the phthalic anhydride wastewater is subjected to decolorization treatment, so that the fumaric acid which meets the feed-stage standard can be prepared.

Owner:KUNSHAN MAYMUSE ENVIRONMENTAL TECH

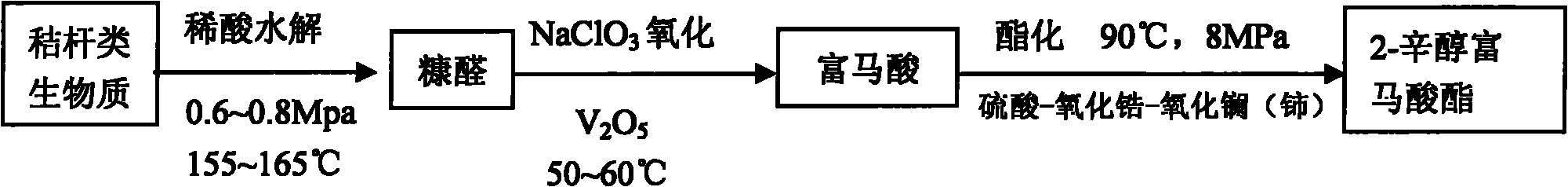

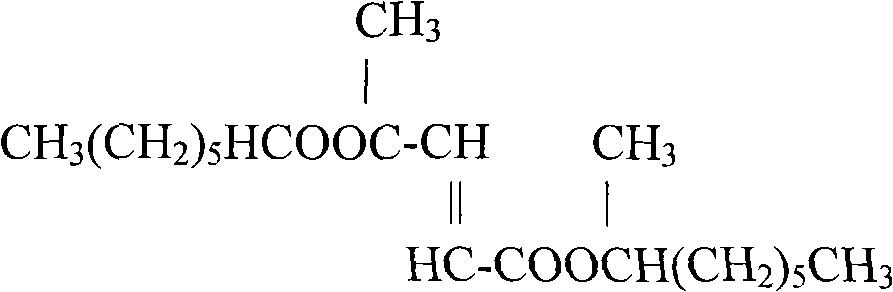

Method for preparing fumaric acid ester by using plant straws

InactiveCN101863765AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationFumaropimaric acidPolyester

The invention discloses a method for preparing fumaric acid ester by using plant straws. The method comprises the following sequential steps: 1) leading the plant straws to carry out acid hydrolysis reaction so as to prepare furfural; 2) leading the furfural to carry out oxidation reaction so as to prepare fumaric acid; and 3) leading the fumaric acid and 2-octanol to carry out esterification reaction so as to prepare the fumaric acid ester. The 2-octanol fumaric acid ester prepared by the method not only is the main indispensable raw material for producing novel high-performance synthetic lubricating oil polyester oil, but also has high product purity and high yield; and in addition, the invention also opens up a new material resource and method for producing the 2-octanol fumaric acid ester, and provides a practical way for industrial production of the 2-octanol fumaric acid ester and the plant straws and comprehensive utilization of the plant straws.

Owner:北京雷恩新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com