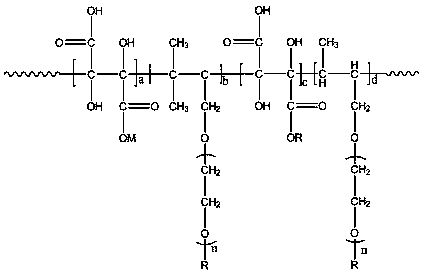

Viscosity reduction high efficiency water-reducing polycarboxylate superplasticizer and preparation method thereof

A technology of water-reducing polycarboxylic acid and water-reducing agent, applied in the field of water-reducing agent for concrete and its preparation, can solve the problems of inability to completely solve practical problems, low concrete fluidity, increase construction cost, etc. Water reduction rate and viscosity reduction effect, surface tension reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

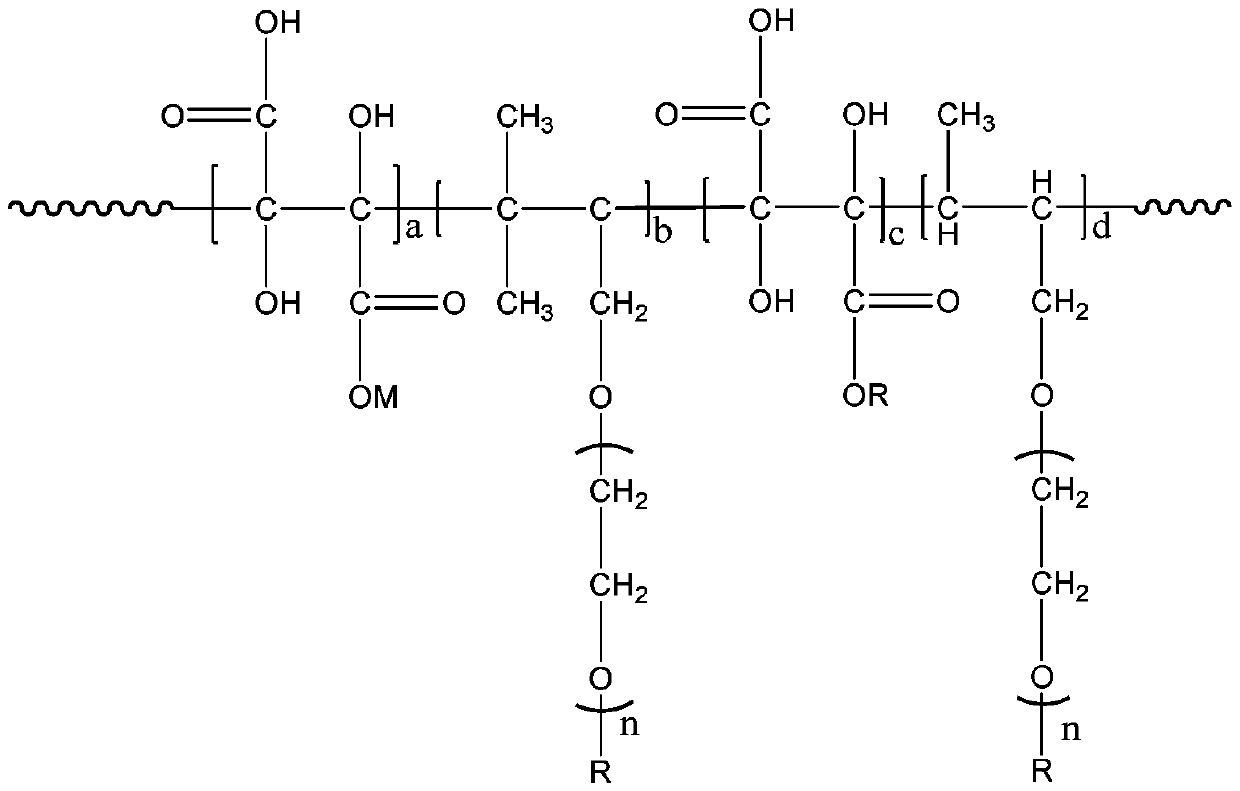

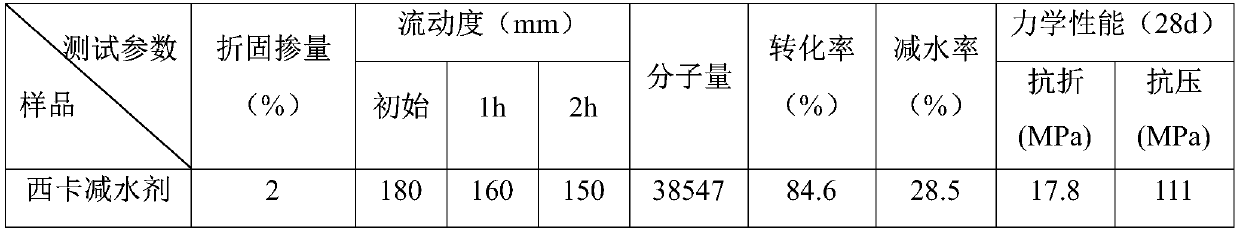

Examples

Embodiment 1

[0028] First weigh 137g of isopentenol polyoxyethylene ether with a molecular weight of 2400, 8.2g of dihydroxyfumaric acid and 100g of water and put them into a four-neck flask for stirring. After all the monomers are dissolved, pour 1.8g of hydrogen peroxide and stir 1-2min, then start to gradually add 0.3g ascorbic acid and 30g water A liquid, 0.76g mercaptothiol and 50g water B liquid at the same time, after AB liquid is added dropwise for 1 hour, weigh 8.2g of dihydroxy fumaric acid and add it to the flask At the same time, continue to add AB solution dropwise, add AB solution dropwise for 2 hours, keep warm for 2 hours after both are completed at the same time, and finally neutralize with sodium hydroxide to pH 6.7. That is, the viscosity-reducing high-efficiency water-reducing polycarboxylate superplasticizer PC-1 is obtained.

Embodiment 2

[0030] First weigh 140g of isopentenol polyoxyethylene ether with a molecular weight of 2400, 12g of dihydroxyfumaric acid and 100g of water and stir in a four-necked flask. After all the monomers are dissolved, pour 1.8g of hydrogen peroxide and stir for 1 -2min, then began to gradually dropwise add 0.3g ascorbic acid and 30g water A solution, 0.36g mercaptothiol, 0.36g mercaptopropionic acid and 50g water B solution, after AB solution was added dropwise for 1h, weigh 12g of dihydroxy Fumaric acid was added to the flask, and at the same time, the AB solution was continued to be added dropwise, and the AB solution was added dropwise for a total of 2 hours. After the two were completed at the same time, the reaction was kept for 2 hours, and finally neutralized with sodium hydroxide to a pH of 6.7. That is, the viscosity-reducing high-efficiency water-reducing polycarboxylate superplasticizer PC-2 is obtained.

Embodiment 3

[0032]First weigh 150g of isopentenol polyoxyethylene ether with a molecular weight of 2400, 6g of dihydroxyfumaric acid and 100g of water and stir in a four-neck flask. After the monomers are completely dissolved, pour 2.0g of hydrogen peroxide and stir for 1 -2min, then start to gradually add dropwise the A solution of 0.53g ascorbic acid and 30g water, the B solution of 0.8g mercaptothiol and 50g water at the same time, after the AB solution is added dropwise for 1h, add 6g of dihydroxy fumaric acid into the flask, At the same time, continue to add AB solution dropwise, add AB solution dropwise for 2 hours, keep warm for 2 hours after both are completed at the same time, and finally neutralize with sodium hydroxide until the pH is 6.7. That is, the viscosity-reducing high-efficiency water-reducing polycarboxylate superplasticizer PC-3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com