Patents

Literature

32results about How to "Increase the effective adsorption capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

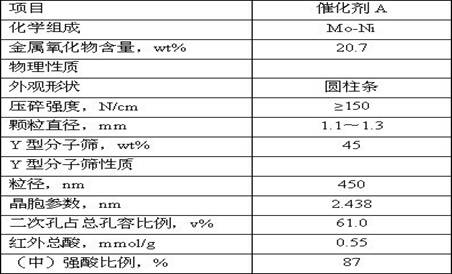

Method for preparing aromatic hydrocarbons from catalytic diesel oil through hydro-conversion

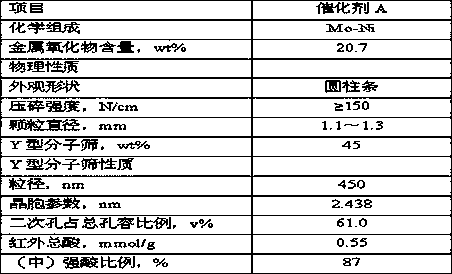

ActiveCN109777514AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesNaphthaHydrogen

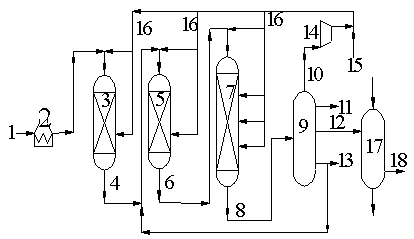

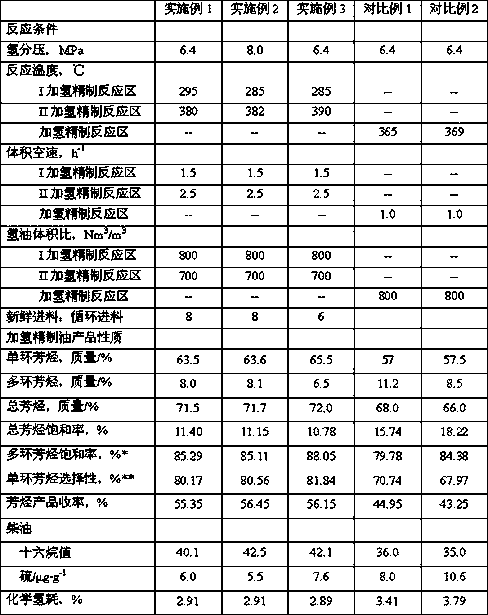

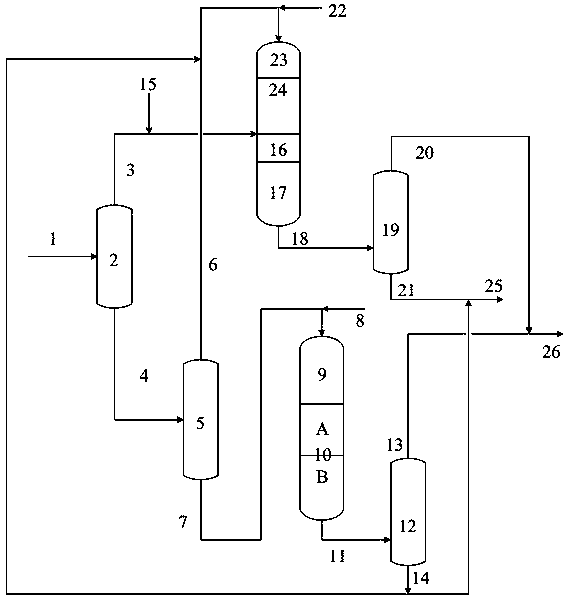

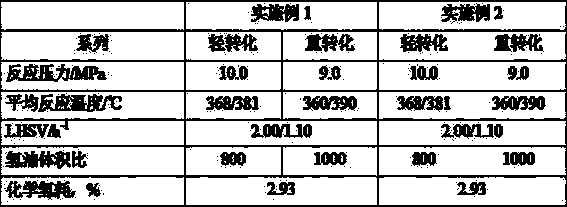

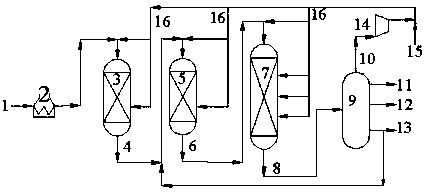

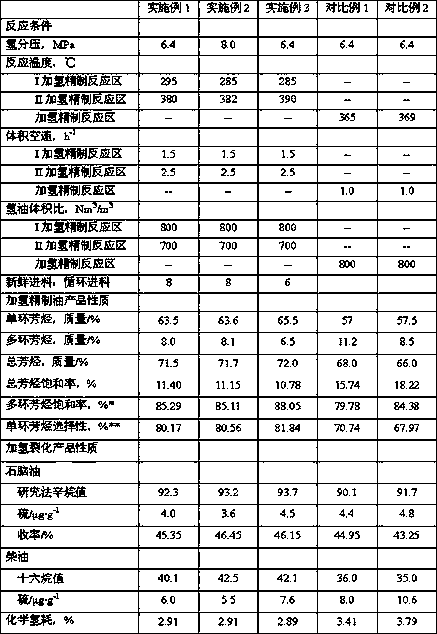

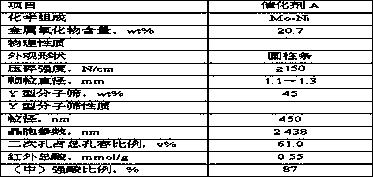

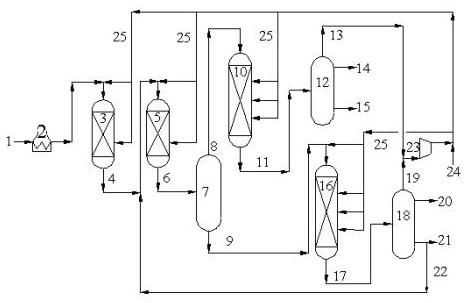

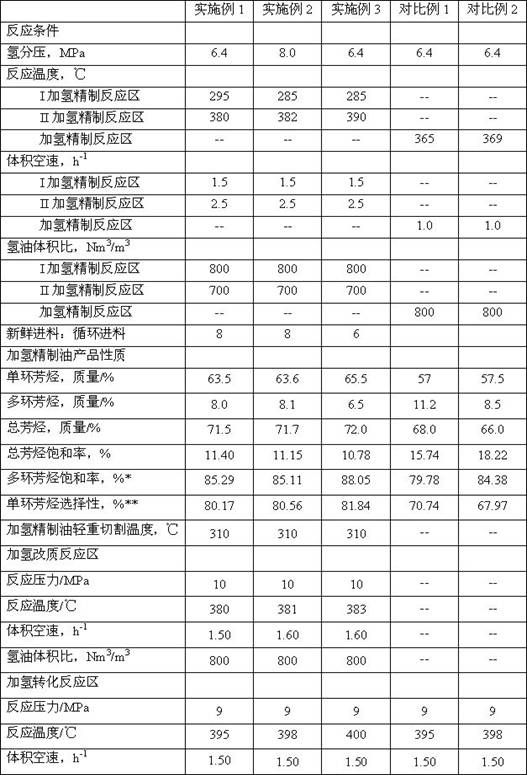

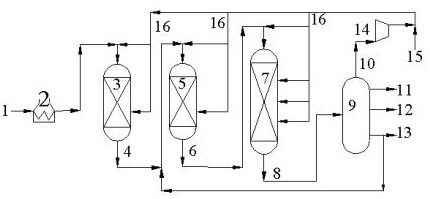

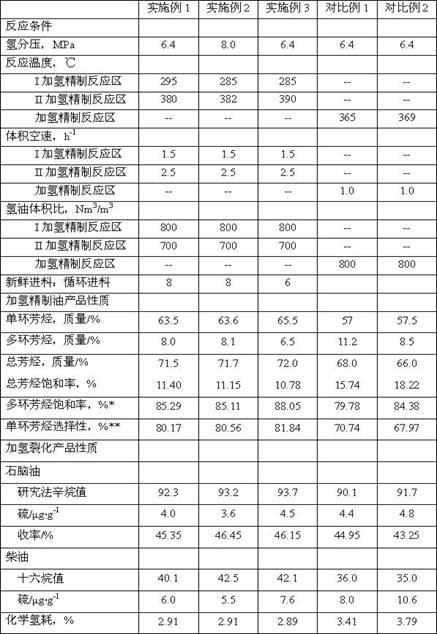

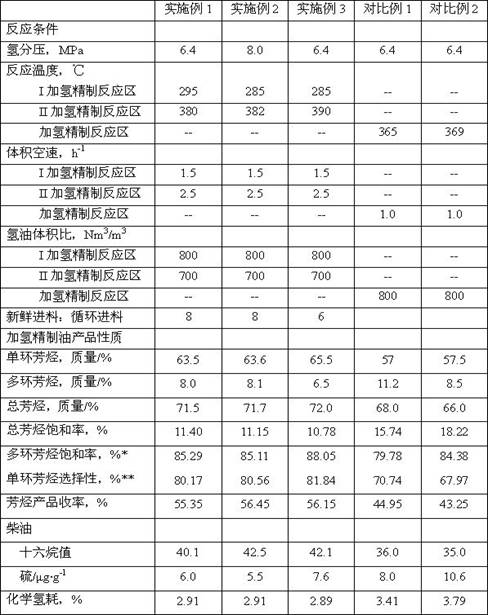

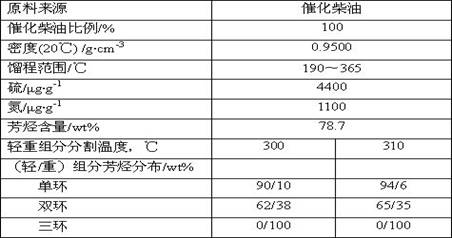

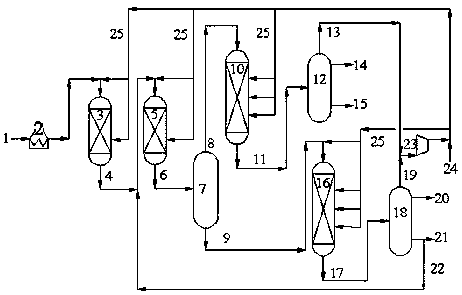

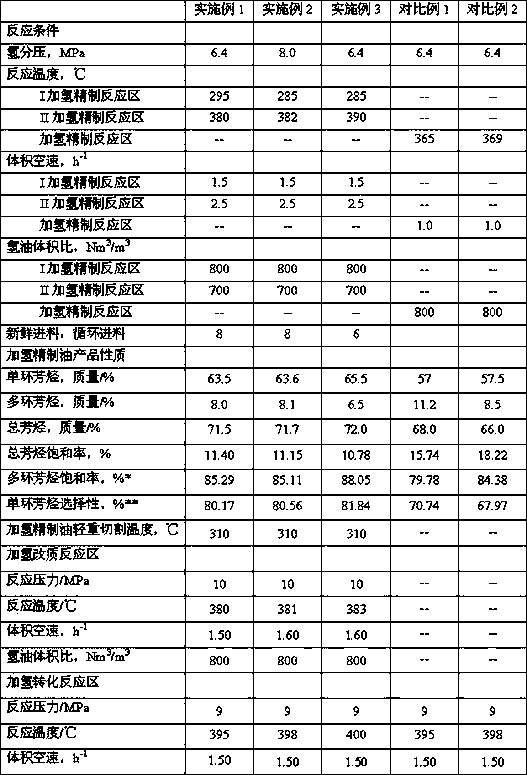

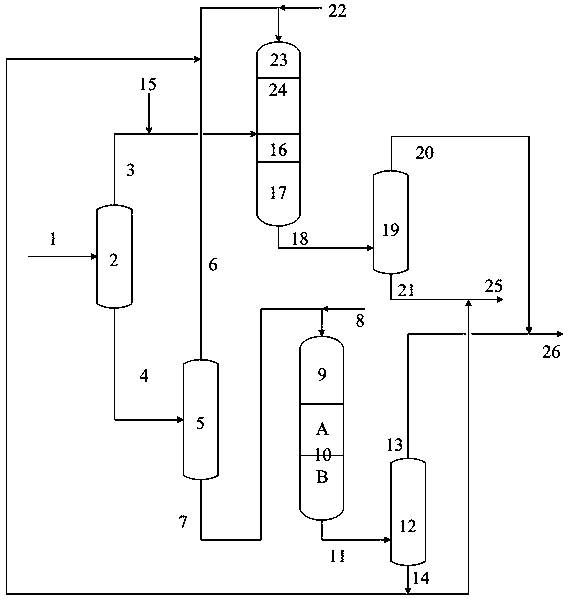

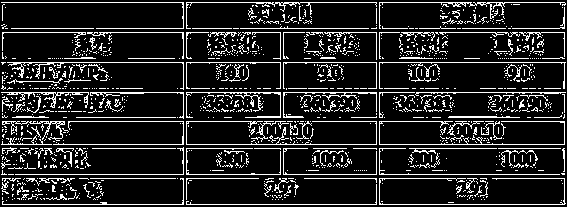

The invention discloses a method for preparing aromatic hydrocarbons from catalytic diesel oil through hydro-conversion. The method comprises the following steps: (1) mixing high aromatic hydrocarboncatalytic diesel oil with circulating hydrogen and feeding the mixture into a hydrofining reaction zone I for reaction; (2) mixing generated oil obtained in the step (1) with circulating hydrogen, andfeeding the mixture into a hydrofining reaction zone II for further reaction, wherein the reaction temperature is 30-120 DEG C higher than that of the hydrofining reaction zone I, and the liquid hourly space velocity is 0.2-1.5 h<-1> lower than that of the hydrofining reaction zone I; (3) mixing the generated oil obtained in the step (2) with circulating hydrogen and feeding the mixture into a hydrocracking reaction zone for hydrocarbon hydro-conversion reaction; and (4) enabling the generated oil obtained in the step (3) to pass through a separation and fractionation system to obtain gas, light naphtha, heavy naphtha and diesel oil fractions, returning part of diesel oil to a hydrofining reaction zone II, and discharging the other part of the diesel oil from a device; and (5) feeding theheavy naphtha fraction obtained in the step (4) into an aromatic hydrocarbon extraction system to obtain an aromatic hydrocarbon product. By the coupling hydrocracking-aromatic hydrocarbon extractionprocess method for processing catalytic diesel oil raw materials, the yield of the aromatic hydrocarbons can be increased effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

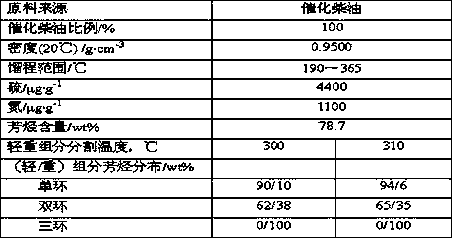

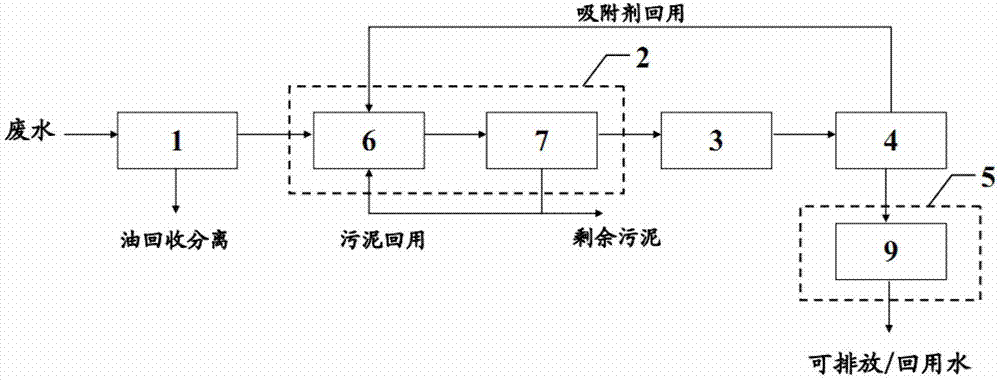

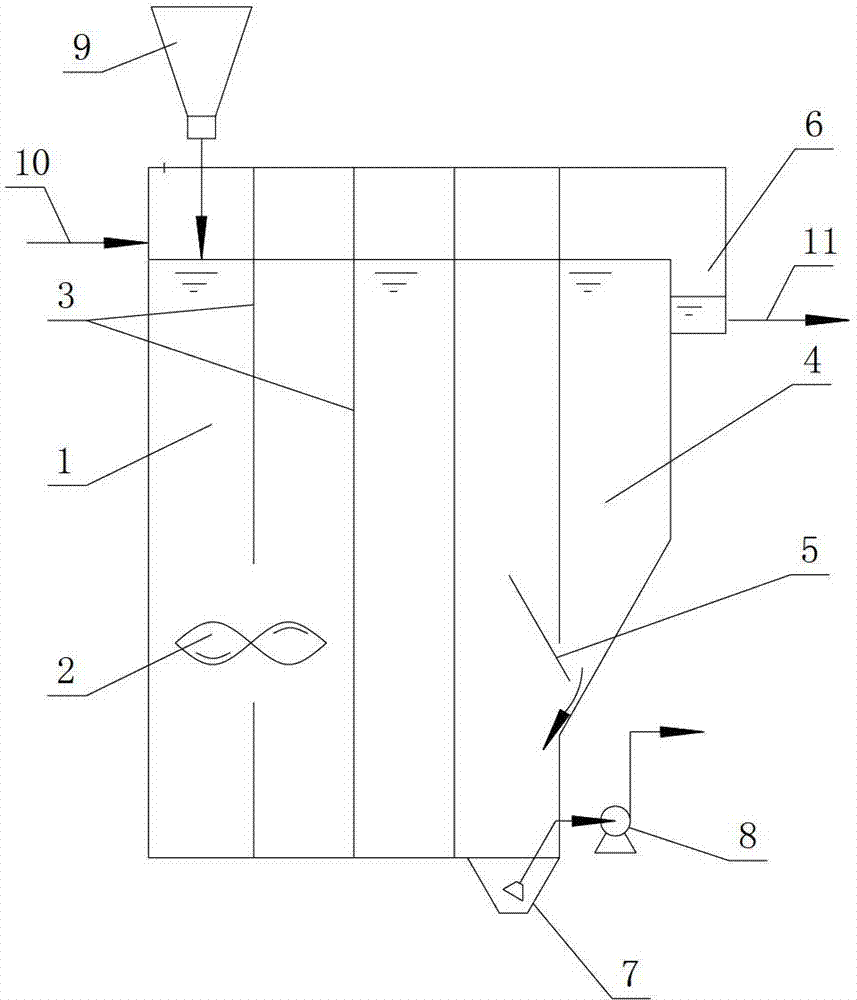

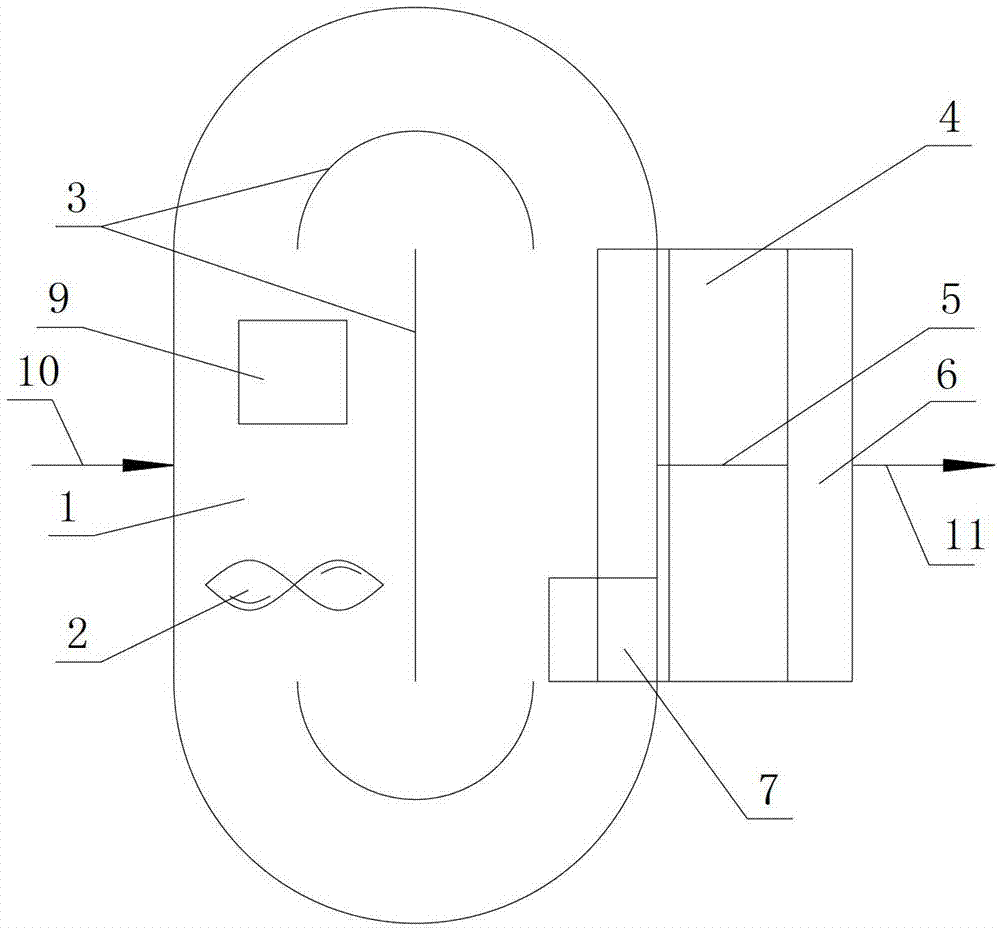

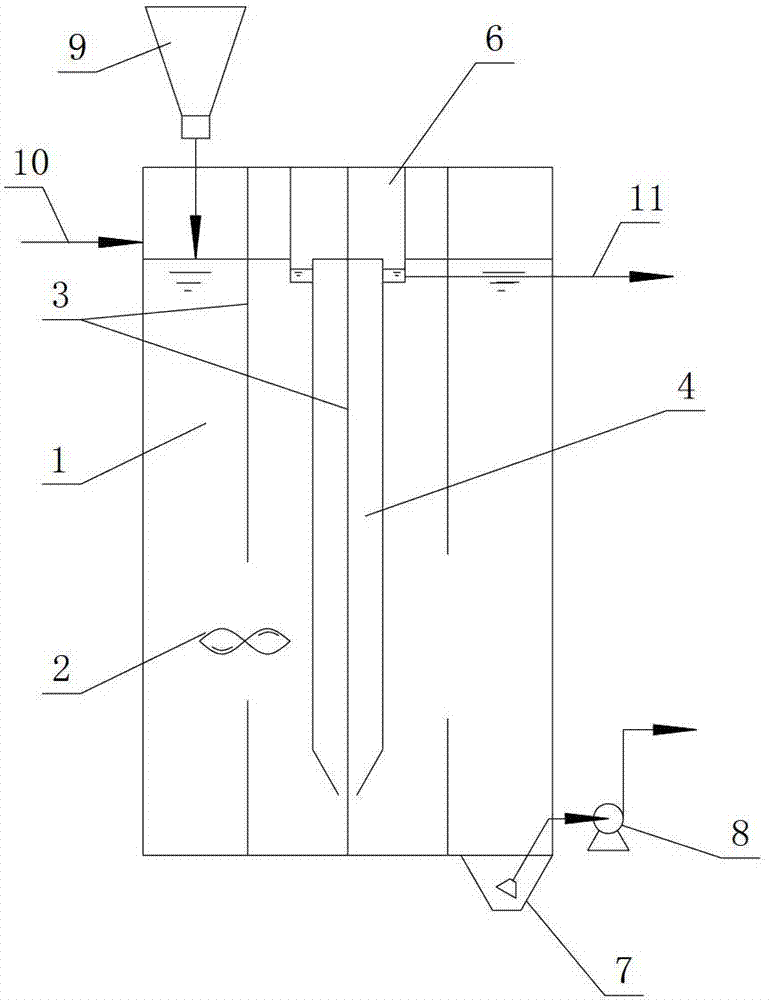

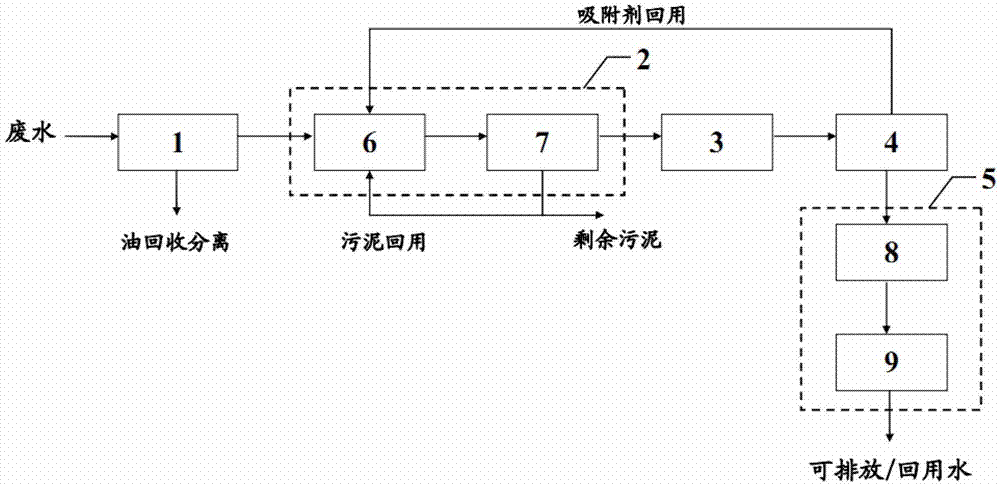

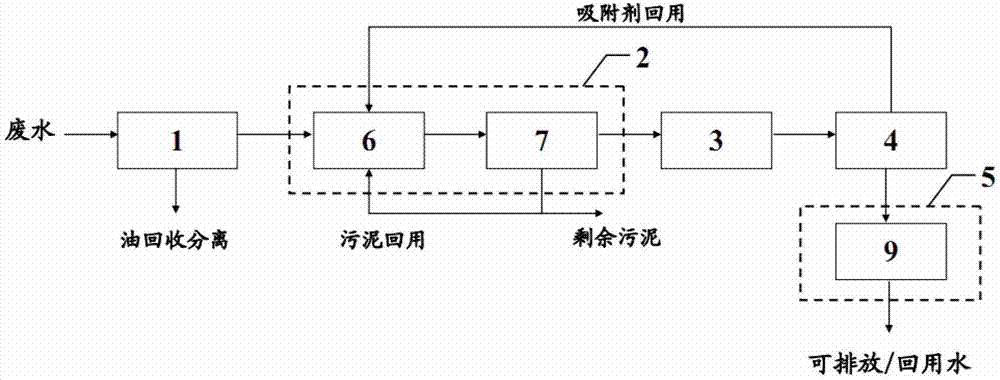

Slack coal pressure gasification wastewater resourceful treatment method and treatment system as well as application

InactiveCN103288311AAchieve reuseProportionally largeMultistage water/sewage treatmentFlocculationSludge

The invention provides a slack coal pressure gasification wastewater resourceful treatment method. The treatment method sequentially comprises the following steps of: (1) performing oil-water separation on the wastewater to obtain wastewater after the oil-water separation treatment; (2) treating the wastewater obtained by the step (1) by use of active sludge, and performing mud-water separation to obtain wastewater after the active sludge treatment; (3) adding an adsorbent into the wastewater obtained by the step (2), and performing solid-liquid separation to obtain wastewater after the adsorption separation treatment; (4) adding a flocculating agent and / or flocculation aid into the wastewater obtained by the step (3), and precipitating to obtain wastewater after the coagulation clarifying treatment; and (5) treating the wastewater obtained by the step (4) by use of a filter material loaded with microorganisms to obtain dischargeable / recyclable water. The invention also provides a system for the method to realize resourceful treatment on the wastewater, and application of the treatment method or treatment system in treating slack coal pressure gasification wastewater.

Owner:DATANG INT CHEM TECH RESINST

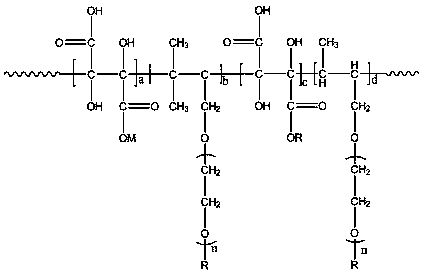

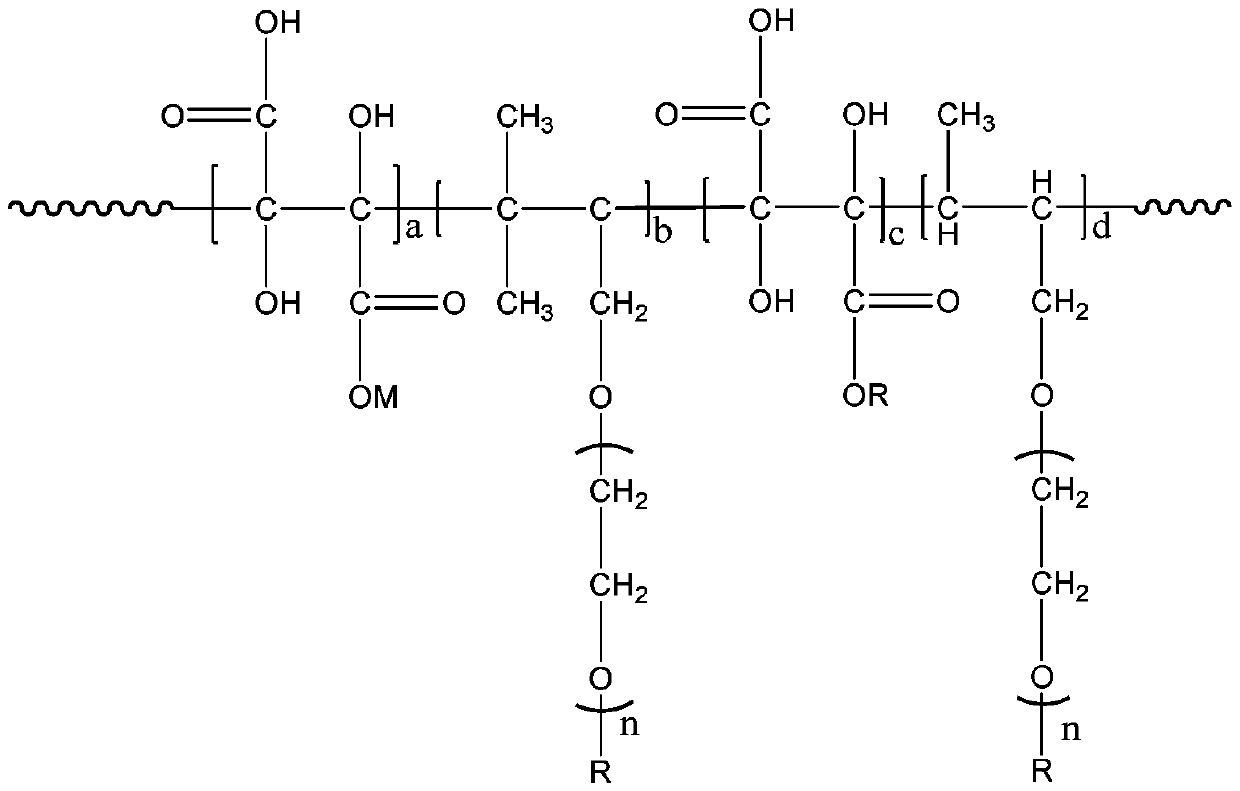

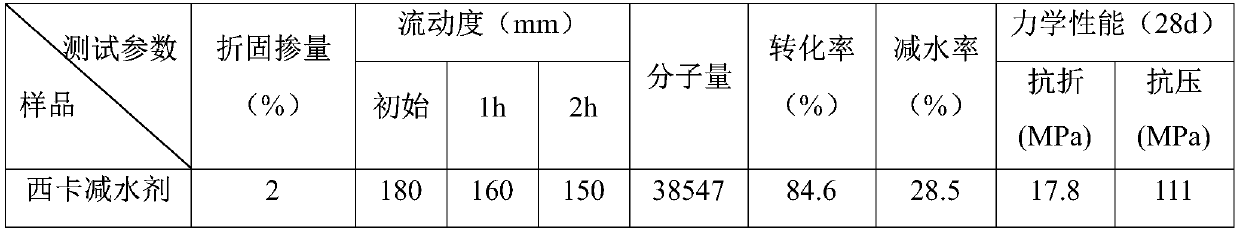

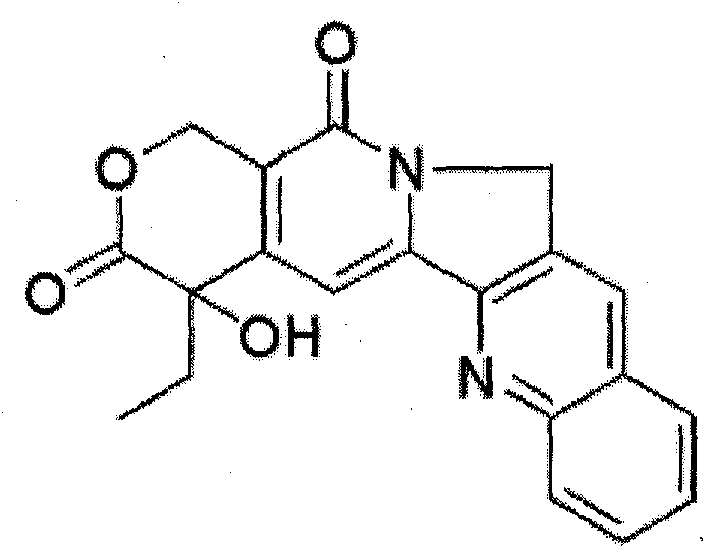

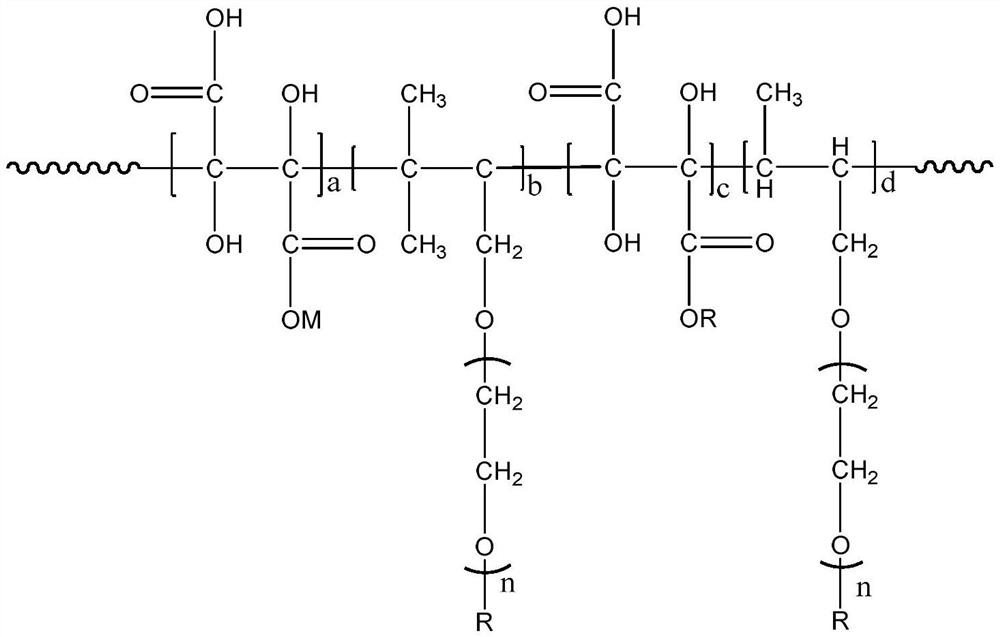

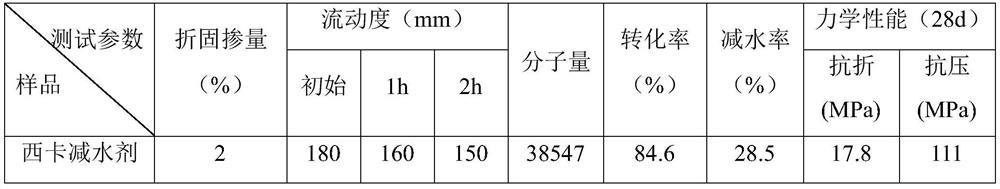

Viscosity reduction high efficiency water-reducing polycarboxylate superplasticizer and preparation method thereof

The invention relates to a viscosity reduction high efficiency water-reducing polycarboxylate superplasticizer and a preparation method thereof. The superplasticizer is prepared by intermittent dropwise adding of macromonomers like TPEG monomer, unsaturated hydroxy acid monomer or its derivative, or unsaturated acid with a trans-structure for free radical polymerization reaction under the action of a reductant, an oxidant and a chain transfer agent. The anchoring group and side chain in the superplasticizer are molecular structures in block distribution, and can give full play to electrostaticrepulsion and steric-hinerance effect. In addition, the hydroxyl, carboxyl and other polar groups introduced by the unsaturated hydroxy acid monomer or its derivative monomer increase the proportionof hydrophilic groups and reduce the surface tension of the cement pore solution. In addition, in terms of the trans-structural body represented by fumaric acid and dihydroxyfumaric acid derivatives,because of the special structure, i.e. the stiffness of the monomer itself and the distribution of two carboxyl groups on the opposite side of the side chain, a stretching structure easily exhibits inspace to reduce the possibility of molecular chain entanglement and significantly increase the adsorption effect of the polycarboxylate superplasticizer on the cement surface, thereby enhancing the viscosity reduction effect of the polycarboxylate superplasticizer.

Owner:HUNAN UNIV

E-liquid carrier for low temperature heat-not-burn cigarette

ActiveCN109938399AIncrease the effective adsorption capacityReduce the problem of uneven adsorptionTobacco treatmentFiberHeat not burn

The invention provides an E-liquid carrier for a low temperature heat-not-burn cigarette, which comprises a plant fiber adsorption carrier mainly used for adsorbing tobacco extract and an inorganic material adsorption carrier mainly used for adsorbing plant essence, wherein the plant fiber adsorption carrier and the inorganic material adsorption carrier form a core-shell structure. The E-liquid carrier provided by the invention uses the plant fiber / inorganic porous material core-shell structure to respectively suck E-liquid components with different viscosities to replace a current mode of directly using a tobacco filling material, so that the uniformity of the E-liquid volatilization taste is effectively improved.

Owner:杭州森翼科技有限公司

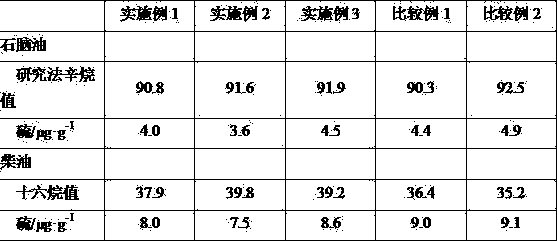

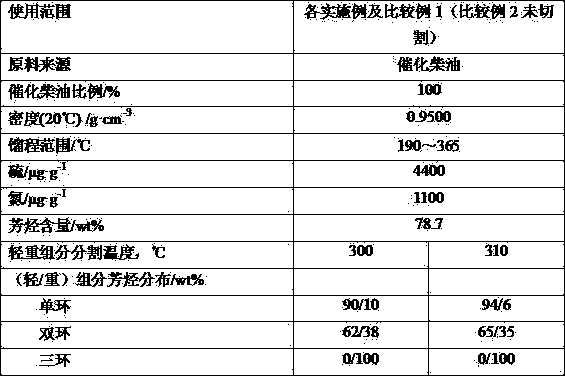

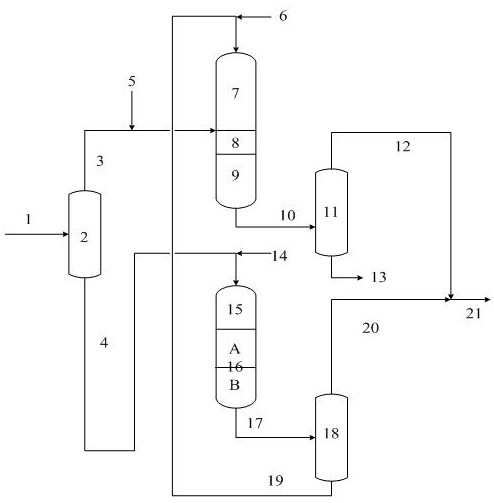

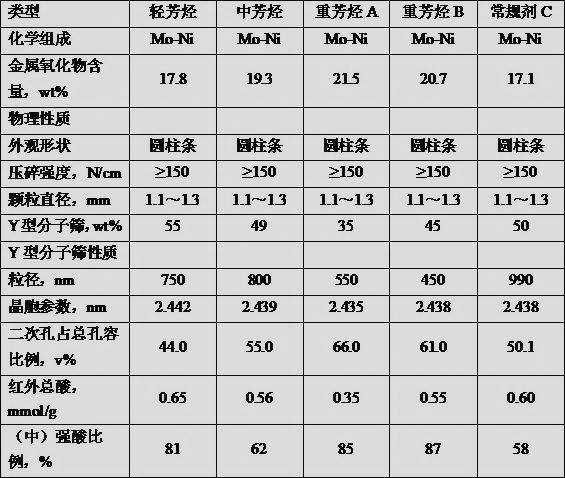

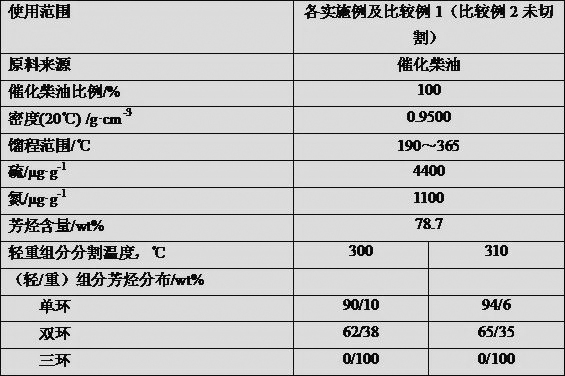

Processing treatment method of catalytic diesel

ActiveCN108102709AEasy to handleImprove targetingHydrocarbon oil crackingTreatment with hydrotreatment processesGasolineHydrocarbon

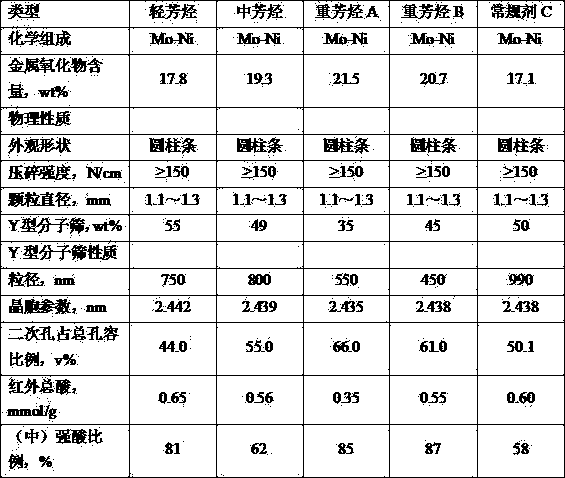

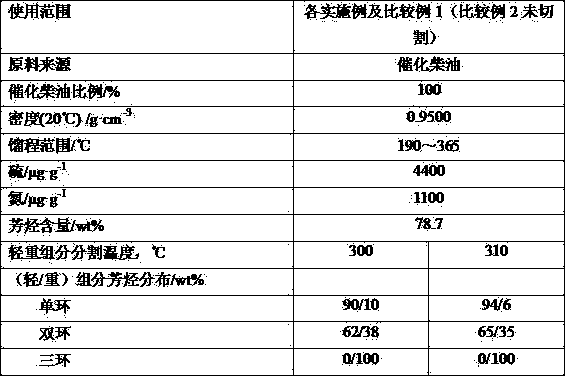

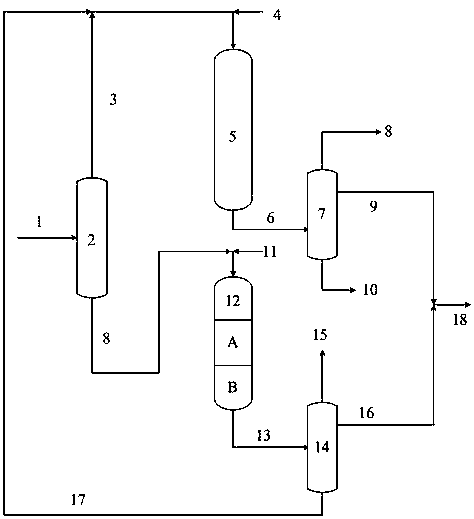

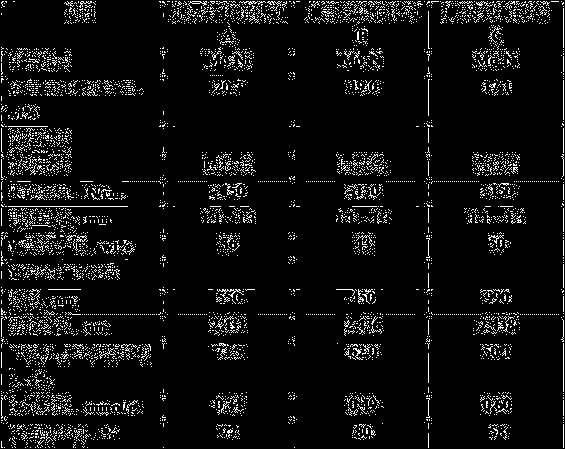

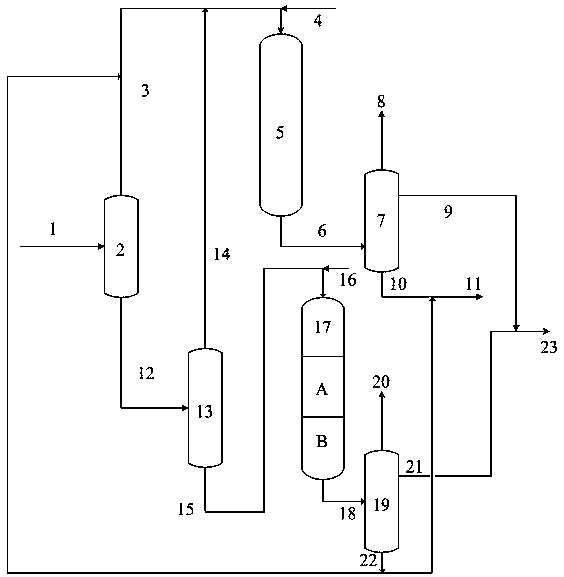

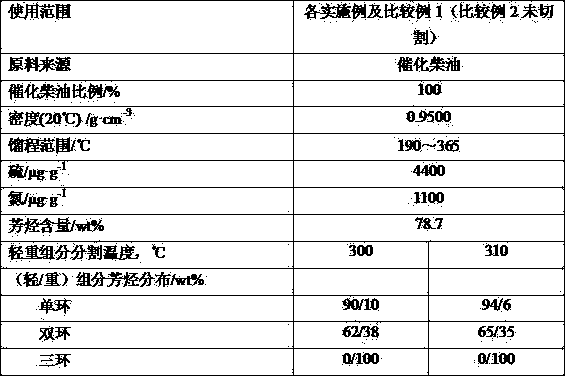

The invention discloses a processing treatment method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjectedto hydrofining and hydro-conversion reactions, and gasoline and diesel components are obtained; the heavy components are separated, and a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained; the non-triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, the triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, and gasoline components and diesel components are obtained; a gasoline product is obtained after gasoline from all parts is mixed, and a diesel product is obtained after diesel components from all parts are mixed. Through the reasonable separation and processing process, different types of raw materials can be selectively and independently processed, so that qualified gasoline and dieselproducts can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

A processing method of modified soybean fibers

InactiveCN107700203AHigh tensile strengthImproves tensile strength propertiesBiochemical fibre treatmentHeat resistant fibresFiberBiological activation

A processing method of modified soybean fibers is disclosed. The method is characterized in that the method includes (1) a step of surface etching, namely a step of adding soybean fibers into a plasmamachine and performing surface treatment; (2) a soaking step, namely a step of soaking the etched soybean fibers into an activating agent solution, performing activation, and then soaking the soybeanfibers in an antibacterial solution; (3) a step of ionization treatment, namely a step of soaking the soaked soybean fibers into a treating agent, performing ionization treatment, adding a sodium silicate solution into an ionization tank, and performing a second time of ionization; (4) a step of high-pressure temperature changing, namely a step of drying the ionized soybean fibers until the watercontent is 7-9%, then putting the soybean fibers into a temperature changing oven, and performing temperature changing treatment; and (5) a step of oxidation, namely a step of oxidizing the temperature-changed soybean fibers in a vacuum tank.

Owner:安徽华祺汽车装饰有限公司

Processing method of catalytic diesel

ActiveCN108102702AHigh Yield High OctaneReduced activityTreatment with hydrotreatment processesHydrocarbon oils treatment productsContact reactionGasoline

The invention discloses a processing method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjected to a conversion reaction in a bed layer containing a light aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and converted diesel are obtained; the heavy components are subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and diesel fractions are obtained; the diesel fractions obtained through conversion of heavy componentsare subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, a reaction effluent is then subjected to a contact reaction with a light component hydro-conversion catalyst; the converted gasoline obtained from each part is mixed, and high-quality gasoline is obtained. Through the reasonable separation and processing process, different types of raw materials can beselectively and independently processed, so that the qualified gasoline product with high octane value can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of catalytic diesel oil

ActiveCN108102713AGreat suitability and pertinenceImprove product qualityTreatment with hydrotreatment processesHydrocarbon oils treatment productsChemistryGasoline

The invention discloses a processing method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected to hydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is subjected to hydrofining and hydroconversion, and a gasoline component and a dieseloil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that qualified gasoline and diesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil .

Owner:CHINA PETROLEUM & CHEM CORP +1

White clay adsorption refining method used for waste lubricating oil regeneration

InactiveCN109705972AIncrease the effective adsorption capacityGood decolorization effectLubricant compositionAbsorption capacityNitrogen

The invention discloses a white clay adsorption refining method used for waste lubricating oil regeneration, and belongs to the technical field of white clay refining. The white clay adsorption refining method used for waste lubricating oil regeneration comprises following steps: bought decolored white clay is introduced into a material cabin of an activation furnace, the activation furnace is turned on, heating temperature is controlled to be 300 to 550 DEG C for 2 to 4h of activation, wherein it is ensured that after activation, the water content of decolored white clay is reduced to be lower than 3%, in activation process, dry nitrogen is adopted for continuous purging, and nitrogen gas purging pressure is controlled to be 0.1 to 0.3MPa; after activation, an obtained material is introduced into a transfer material tank, and the transfer material tank is sealed for material cooling. According to the white clay adsorption refining method used for waste lubricating oil regeneration, nitrogen protection equipment heating is adopted to increase the effective absorption capacity of activated white clay, after activation, the white clay is protected with dry nitrogen gas, and is introduced into a lubricating oil refining equipment rapidly, so that oil refining and decoloring effect is improved, white clay using amount is reduced, output amount of secondary hazardous waste in process is reduced, and environment pollution is reduced further.

Owner:江苏森茂能源发展有限公司

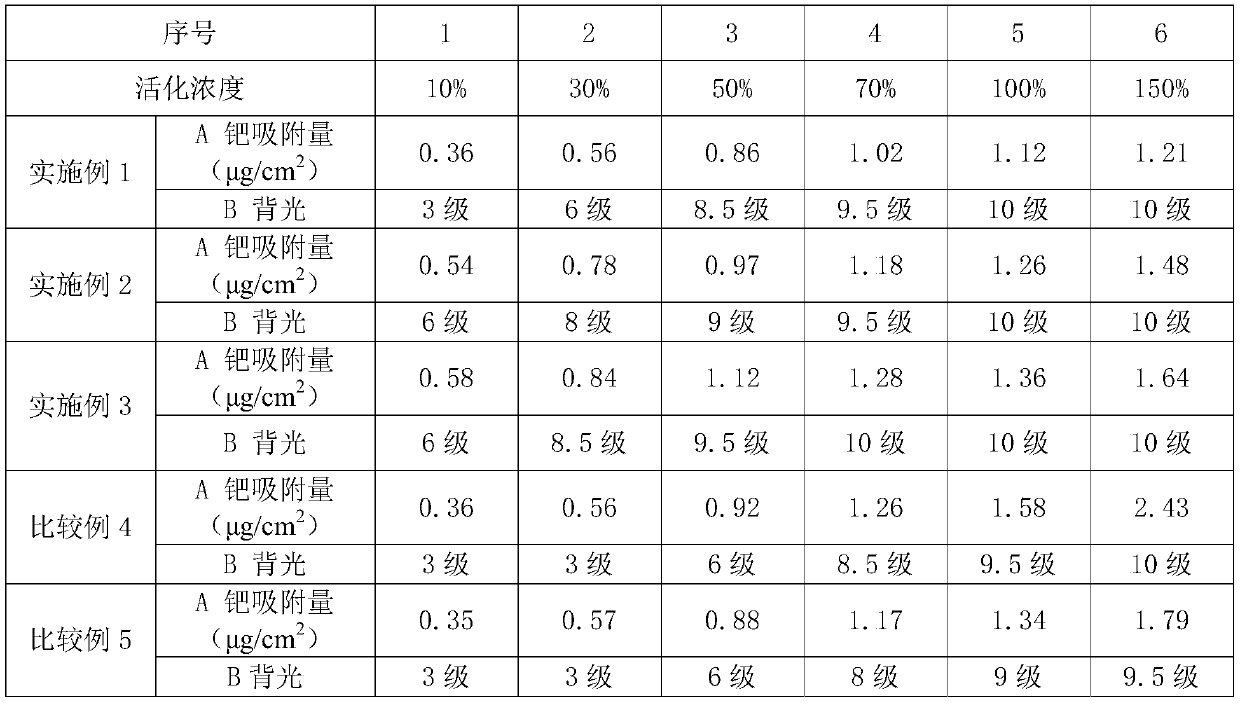

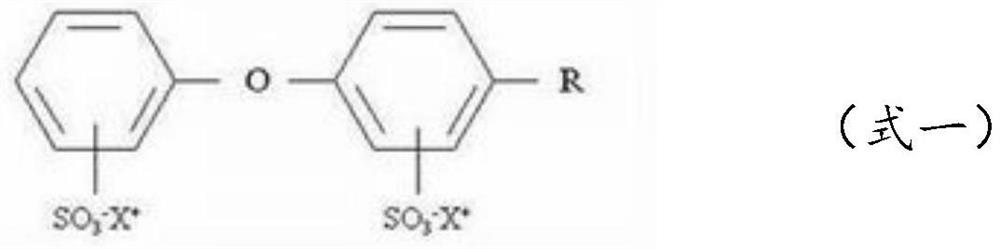

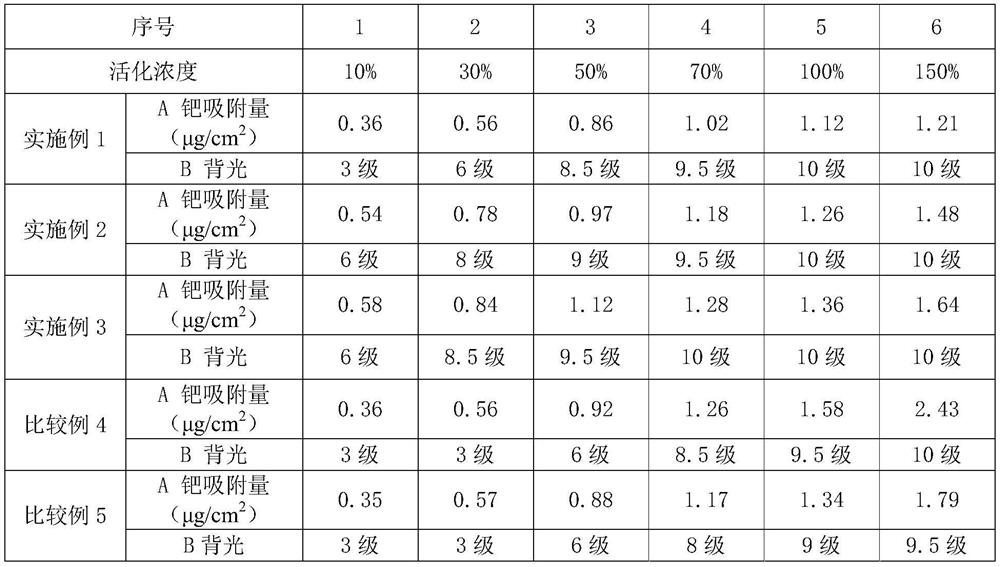

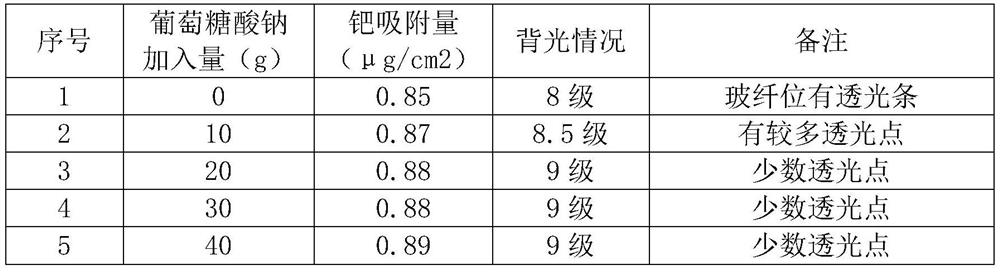

Cleaning and finishing agent and application method thereof

ActiveCN109825375AIncrease the effective adsorption capacityImprove backlightInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsZeta potentialGlass fiber

An embodiment of the invention discloses a cleaning and finishing agent and an application method thereof. The cleaning and finishing agent comprises sodium gluconate, ammonium chloride, polyethylenepolyamine, lower alcohol, a non-ionic surfactant, an anionic surfactant and deionized water. Compared with a cleaning and finishing agent in the prior art, the cleaning and finishing agent has the advantages that the sodium gluconate, ammonium chloride, polyethylene playamine, lower alcohol, non-ionic surfactant, anionic surfactant and deionized water are used to treat the surface of a pore ring of a PCB board, and glass fiber exposed in the surface of the pore ring is cleaned through sodium gluconate and ammonium chloride; the surface of pore ring resin can be treated by polyethylene polyamine; pore walls can be wetted through the lower alcohol and non-ionic surfactant; the resin and glass fiber on the pore ring surface can be modified through the anionic surfactant to enable the surfaceof the pore ring to form high Zeta potential, effective adsorption capacity of a palladium activator is increased, backlight of electroless copper plating is improved, and the situation of hole-without-copper is reduced.

Owner:湖南互连微电子材料有限公司

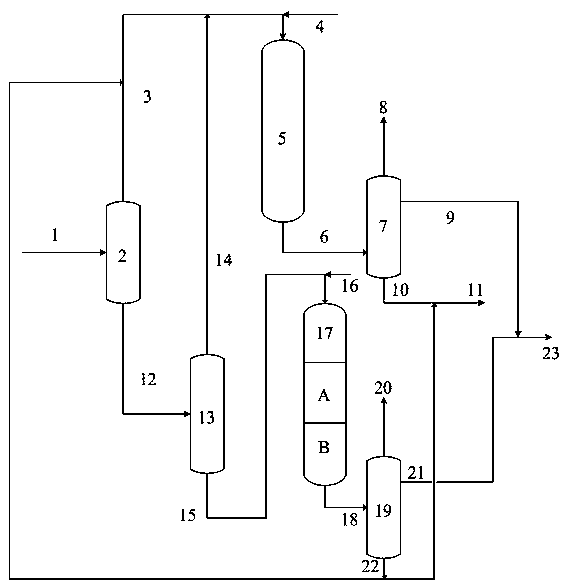

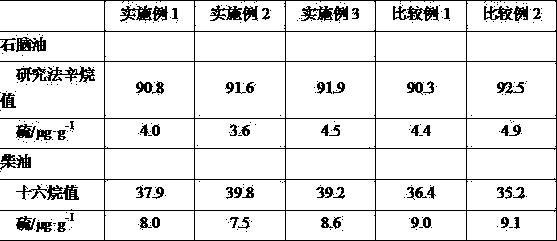

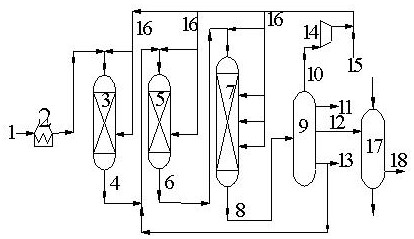

Catalytic diesel oil hydro-conversion method

ActiveCN109777511AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a catalytic diesel oil hydro-conversion method. The catalytic diesel oil hydro-conversion method comprises the following steps: (1) mixing high aromatic hydrocarbon catalytic diesel oil with circulating hydrogen and feeding the mixture into a hydrofining reaction zone I for reaction; (2) mixing generated oil obtained in the step (1) with circulating hydrogen, and feeding the mixture into a hydrofining reaction zone II for further reaction, wherein the reaction temperature is 30-120 DEG C higher than that of the hydrofining reaction zone I, and the liquid hourly space velocity is 0.2-1.5 h<-1> lower than that of the hydrofining reaction zone I; (3) mixing the generated oil obtained in the step (2) with circulating hydrogen, feeding the mixture into a hydrocracking reaction zone for hydrocarbon hydro-conversion reaction; and (4) enabling the generated oil obtained in the step (3) to pass through a separation and fractionation system to obtain gas, light naphtha, heavy naphtha and diesel oil fractions, returning part of diesel oil to the hydrofining reaction zone II, and discharging the other part of the diesel oil from the device. By the catalytic diesel oil hydro-conversion method, the yield of aromatic hydrocarbons can be increased effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing treatment method of catalytic diesel oil

ActiveCN108102703AIdeal comprehensive processing effectLow operating costTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineHydrocarbon

The invention discloses a processing treatment method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected tohydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is separated, a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained, the obtained triaromatic hydrocarbon component is subjected to hydrofining and hydroconversion, and a gasoline component and a diesel oil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that inferior catalytic cracking diesel oil can be reasonably used to produce qualified gasoline anddiesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

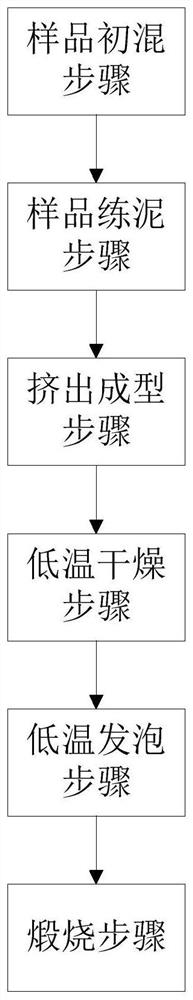

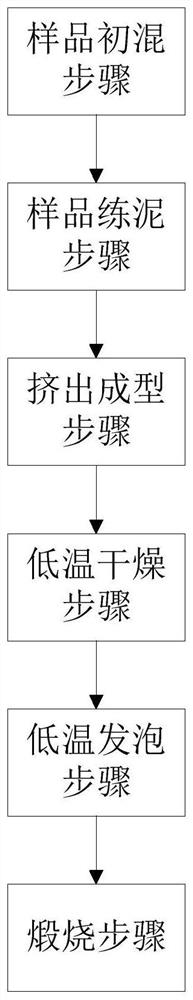

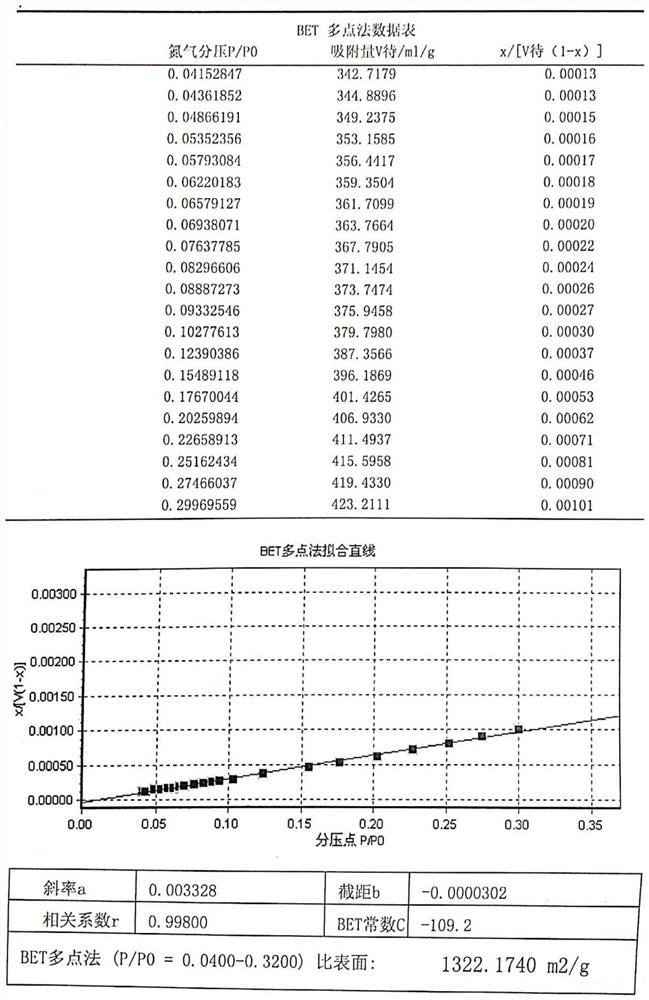

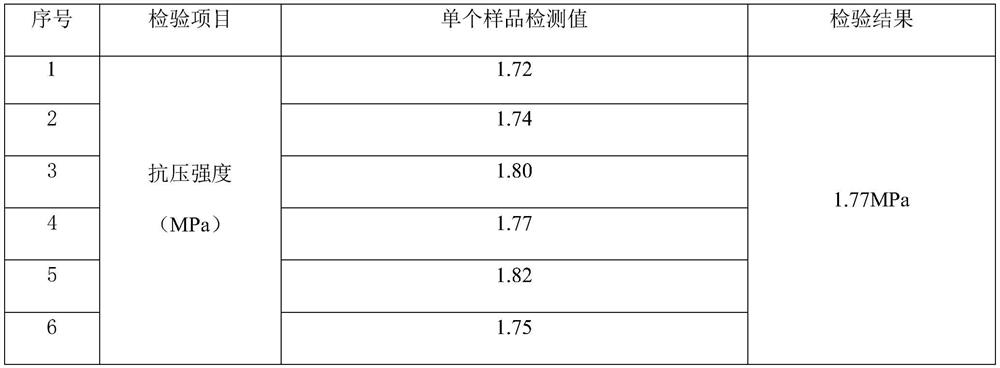

Preparation method of light honeycomb molecular sieve purification module

ActiveCN112755955ALow densityLarge specific surface areaOther chemical processesAluminium silicatesMolecular sieveFoaming agent

The embodiment of the invention discloses a preparation method of a light honeycomb molecular sieve purification module. The preparation method comprises the following steps: a sample primary mixing step: putting weighed molecular sieve raw powder, a binder and a foaming agent into a mixer, and stirring and mixing until the materials are uniform; a sample pugging step: adding the weighed surfactant, continuously stirring, and putting the muddy blank into a pugging mill for extrusion; an extrusion molding step: putting the smelted pug into a low-pressure vacuum extruder for molding and extrusion; a low-temperature drying step: placing the wet green body in a low-temperature dry environment; a low-temperature foaming step: performing low-temperature foaming on the wet green body; calcining, namely calcining the blank at high temperature to obtain the light honeycomb molecular sieve. By manually controlling foaming and pore-forming, more hollow structures are obtained, so that the overall density of the honeycomb molecular sieve is reduced, the specific surface area of the honeycomb molecular sieve module is increased, contact adsorption of waste gas components and the honeycomb molecular sieve is more facilitated, and the unit effective adsorption capacity is improved.

Owner:GANNAN NORMAL UNIV +1

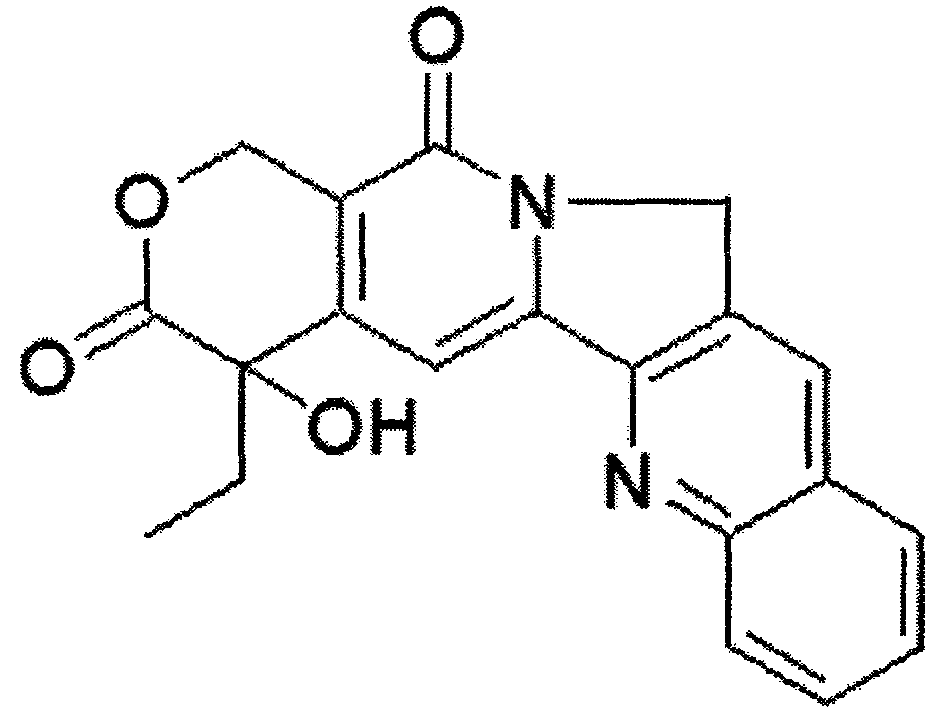

Camptothecin separation and purification method

ActiveCN105061447AAdvantages of separation and purification methodsReduce contentOrganic chemistryChromatographic separationPurification methods

The purpose of the present invention is to disclose a camptothecin separation and purification method, particularly a technology for preparing high-purity camptothecin by using diatomaceous earth filtration, membrane separation technology, macroporous adsorption resin column chromatography adsorption and chromatography column preparation integration purification. With the method of the present invention, the problems that the selectivity of extraction and adsorption on the target compound is low, the purity of the prepared camptothecin is not high, and the multiple extraction-recrystallization way has disadvantages of high organic solvent consumption, labor consuming, time consuming, poor economy, high industrial production and serious environmental pollution are solved.

Owner:HUNAN XINLI BIOLOGICAL SCI & TECH +1

A kind of separation and purification method of camptothecin

ActiveCN105061447BReduce contentReduce consumptionOrganic chemistryChromatographic separationPurification methods

The purpose of the present invention is to disclose a camptothecin separation and purification method, particularly a technology for preparing high-purity camptothecin by using diatomaceous earth filtration, membrane separation technology, macroporous adsorption resin column chromatography adsorption and chromatography column preparation integration purification. With the method of the present invention, the problems that the selectivity of extraction and adsorption on the target compound is low, the purity of the prepared camptothecin is not high, and the multiple extraction-recrystallization way has disadvantages of high organic solvent consumption, labor consuming, time consuming, poor economy, high industrial production and serious environmental pollution are solved.

Owner:HUNAN XINLI BIOLOGICAL SCI & TECH +1

A kind of viscosity-reducing high-efficiency water-reducing polycarboxylate water-reducer and its preparation method

A viscosity-reducing high-efficiency water-reducing polycarboxylate water-reducer and its preparation method, the water-reducer is composed of macromonomers such as isopentenol polyoxyethylene ether monomers, unsaturated hydroxy acid monomers or derivatives thereof, Or the unsaturated acid with trans structure is prepared by free radical polymerization under the action of reducing agent, oxidizing agent and chain transfer agent by intermittent dropping. The anchor groups and side chains in the water reducer of the present invention are block-distributed molecular structures, which can give full play to the electrostatic repulsion and steric hindrance effects; in addition, the hydroxyl groups introduced by unsaturated hydroxyacid monomers or their derivative monomers Polar groups such as carboxyl and carboxyl groups increase the proportion of hydrophilic groups and reduce the surface tension of the cement pore solution; in addition, the trans structure represented by fumaric acid and dihydroxy fumaric acid derivatives, due to its special The structure, that is, the rigidity of the monomer itself and its two carboxyl groups are distributed on the opposite side of the side chain, which makes it easy to show a stretched structure in space, reduces the possibility of molecular chain entanglement, and significantly increases the polycarboxylate superplasticizer. Adsorption on the surface of cement, thereby improving the viscosity-reducing effect of polycarboxylate superplasticizer.

Owner:HUNAN UNIV

Method for producing high-quality gasoline and diesel oil by catalyzing diesel oil

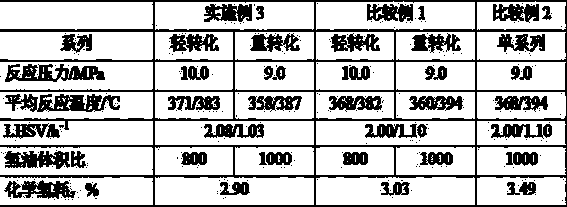

ActiveCN109777494BIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesReaction temperatureEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of catalytic diesel oil

ActiveCN108102702BImprove product qualityIdeal comprehensive processing effectTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystProcess engineering

The invention discloses a processing method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjected to a conversion reaction in a bed layer containing a light aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and converted diesel are obtained; the heavy components are subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and diesel fractions are obtained; the diesel fractions obtained through conversion of heavy componentsare subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, a reaction effluent is then subjected to a contact reaction with a light component hydro-conversion catalyst; the converted gasoline obtained from each part is mixed, and high-quality gasoline is obtained. Through the reasonable separation and processing process, different types of raw materials can beselectively and independently processed, so that the qualified gasoline product with high octane value can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of catalytic diesel oil hydrogenation conversion method

ActiveCN109777511BIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesPetroleum naphthaEngineering

The invention discloses a method for catalytic diesel hydrogenation conversion, which comprises the following steps: (1) high-aromatic catalytic diesel oil is mixed with circulating hydrogen and entered into I hydrorefining reaction zone for reaction; (2) the produced oil obtained in step (1) is mixed with Circulating hydrogen is mixed into II hydrofining reaction zone for further reaction, the reaction temperature is 30~120℃ higher than I hydrofining reaction zone, and the liquid hourly volume space velocity is 0.2~1.5h lower than I hydrofining reaction zone ‑1 ; (3) The generated oil obtained in step (2) is mixed with circulating hydrogen into the hydrocracking reaction zone for hydrocarbon hydroconversion reaction; (4) The generated oil obtained in step (3) is passed through a separation and fractionation system to obtain gas, light Naphtha, heavy naphtha, diesel fraction, part of the diesel is recycled back to the II hydrotreating reaction zone, and part of the diesel is sent out of the unit. The catalytic diesel hydrogenation conversion method provided by the method can effectively increase the production of aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

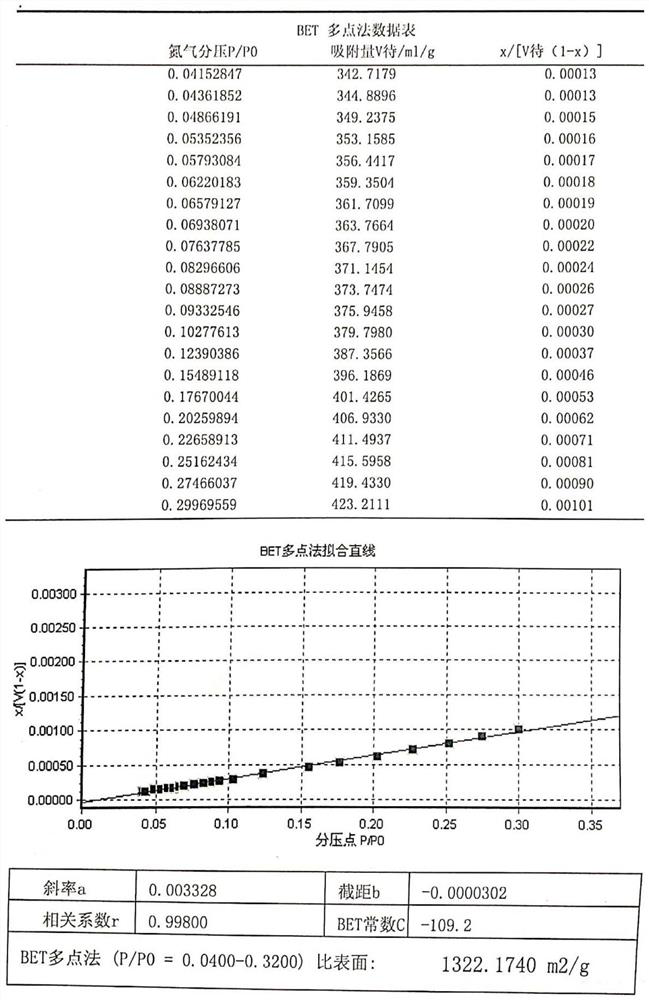

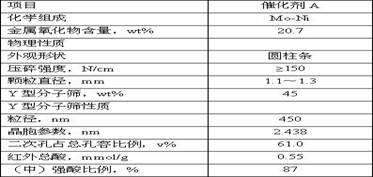

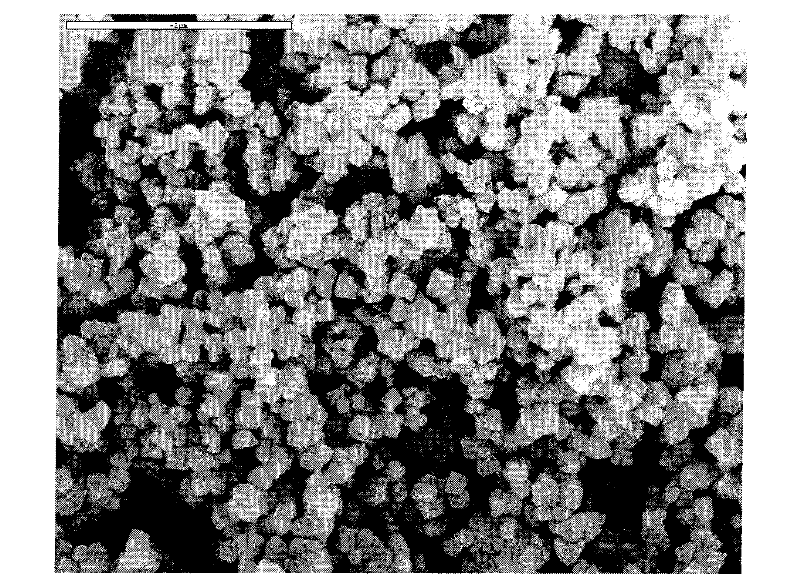

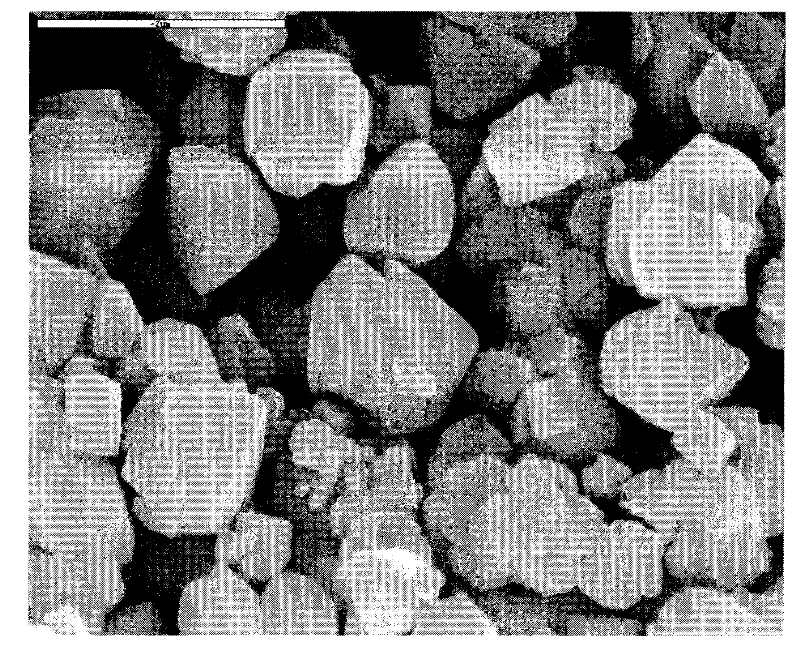

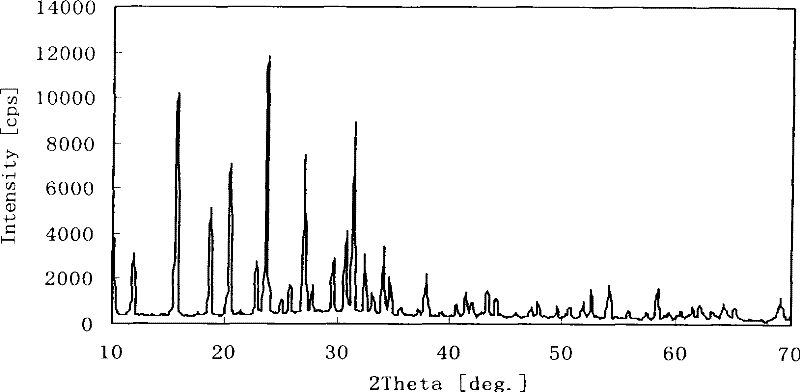

NaY-type molecular sieves and preparation method thereof

ActiveCN101722023BHigh reactivityHigh surface energyMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses microcrystal NaY-type molecular sieves and a preparation method thereof. In the microcrystal NaY-type molecular sieves, the molar ratio of SiO2 to Al2O3 is 4.0 to 6.0, and the average particle size is 100 to 700 nanometers. The microcrystal NaY-type molecular sieves are prepared by a method combining low-temperature synthesis directing agent, low-temperature synthesis gel and two-stage variable-temperature dynamic crystallization. The NaY-type molecular sieves have a relative crystallinity of over 80 percent after being roasted in the air at 600 DEG C for 3 hours or after undergoing hydrothermal treatment with vapor at 650 DEG C for 1 hour, as well as high thermostability and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of processing method of catalytic diesel oil

ActiveCN108102703BIdeal comprehensive processing effectLow operating costTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineProcess engineering

The invention discloses a processing treatment method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected tohydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is separated, a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained, the obtained triaromatic hydrocarbon component is subjected to hydrofining and hydroconversion, and a gasoline component and a diesel oil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that inferior catalytic cracking diesel oil can be reasonably used to produce qualified gasoline anddiesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

A low-temperature non-burning cigarette smoke oil carrier

ActiveCN109938399BIncrease the effective adsorption capacityReduce the problem of uneven adsorptionTobacco treatmentPlant fibrePhysical chemistry

The invention provides a low-temperature non-combustible cigarette oil carrier, which includes a plant fiber adsorption carrier that mainly absorbs smoke oil extracts and an inorganic material adsorption carrier that mainly absorbs plant essences. The plant fiber adsorption carrier and the inorganic adsorption carrier form a core. shell structure. The e-liquid carrier of the present invention uses a core-shell structure of plant fiber / inorganic porous material to adsorb e-liquid components of different viscosities, replacing the current method of directly using tobacco filling materials, and effectively improving the volatilization and mouthfeel uniformity of e-liquid.

Owner:杭州森翼科技有限公司

Preparation method of light honeycomb molecular sieve purification module

ActiveCN112755955BLow densityLarge specific surface areaOther chemical processesAluminium silicatesMolecular sieveFoaming agent

The embodiment of the present invention discloses a preparation method of a lightweight honeycomb molecular sieve purification module, which includes: a sample initial mixing step: putting the weighed molecular sieve raw powder, binder, and foaming agent into a mixer for stirring and mixing until uniform; the sample mud refining step: add the weighed surfactant and continue to stir, put the muddy billet into the mud mixer for extrusion; extrusion molding step: put the refined mud into a low-pressure vacuum extruder Extruding in the middle of the process; low-temperature drying step: placing the wet green body in a low-temperature drying environment; low-temperature foaming step: foaming the wet green body at low temperature; . The present invention obtains more hollow structures by artificially controlling foaming and pore formation, thereby reducing the overall density of the honeycomb molecular sieve, increasing the specific surface area of the honeycomb molecular sieve module, which is more conducive to the contact adsorption between exhaust gas components and honeycomb molecular sieve, and improving the effective adsorption of the unit capacity.

Owner:GANNAN NORMAL UNIV +1

Integral reactor for liquid-phase adsorption and solid-liquid separation, application thereof and water treatment method

InactiveCN103304063BSmall particle sizeFast adsorption rateMultistage water/sewage treatmentSorbentWater quality

Owner:DATANG INT CHEM TECH RESINST

A method for catalytic diesel hydrogenation conversion to aromatics

ActiveCN109777514BIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesNaphthaReaction temperature

The invention discloses a method for producing aromatics by catalytic diesel hydrogenation conversion, which comprises the following steps: (1) high aromatics catalytic diesel oil is mixed with circulating hydrogen and enters I hydrorefining reaction zone for reaction; (2) the product obtained in step (1) Oil and circulating hydrogen are mixed into II hydrofinishing reaction zone for further reaction, the reaction temperature is 30~120℃ higher than I hydrofinishing reaction zone, and the liquid hourly volume space velocity is 0.2~1.5h lower than I hydrofining reaction zone ‑1 ; (3) The generated oil obtained in step (2) is mixed with circulating hydrogen into the hydrocracking reaction zone for hydrocarbon hydroconversion reaction; (4) The generated oil obtained in step (3) is passed through a separation and fractionation system to obtain gas, light Naphtha, heavy naphtha, diesel fraction, part of the diesel is recycled back to the II hydrorefining reaction zone, and part of the diesel is sent out of the unit; (5) The heavy naphtha fraction obtained in step (4) enters the aromatics extraction system to obtain aromatics products. The method provides a coupled hydrocracking-aromatics extraction process for processing catalytic diesel raw materials, which can effectively increase the production of aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-quality gasoline and diesel oil by catalytic diesel oil

ActiveCN109777494AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesGasolineReaction temperature

The invention discloses a method for producing high-quality gasoline and diesel oil by catalytic diesel oil. The method comprises the following steps: (1) mixing high aromatic hydrocarbon catalytic diesel oil with circulating hydrogen and feeding the mixture into a hydrofining reaction zone I for reaction; (2) mixing generated oil obtained in the step (1) with circulating hydrogen and feeding themixture into a hydrofining reaction zone II for reaction, wherein the reaction temperature is 30-120 DEG C higher than that of the hydrofining reaction zone I; (3) dividing the generated oil obtainedin the step (2) into a light component and a heavy component; (4) mixing the light component obtained in the step (3) with circulating hydrogen and feeding the mixture into a hydro-upgrading reactionzone, and separating the generated oil to obtain a gasoline fraction and a diesel oil fraction; (5) feeding the heavy component obtained in the step (3) with circulating hydrogen and feeding the mixture into a hydro-conversion reaction zone, enabling the generated oil to pass through a separation system to obtain gas, gasoline and diesel oil fractions; and (6) mixing the gasoline obtained in the step (4) with the gasoline obtained in the step (5) to obtain a qualified gasoline product, and mixing the diesel oil obtained in the step (4) with the diesel oil obtained in the step (5) to obtain a qualified diesel oil product. By the method, high-quality fuel oil products can be produced. Compared with other technologies, the method has the characteristics of low chemical hydrogen consumption and flexible adjustment of product structures.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of cleaning agent and using method thereof

ActiveCN109825375BIncrease the effective adsorption capacityImprove backlightInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsGlass fiberActive agent

An embodiment of the invention discloses a cleaning and finishing agent and an application method thereof. The cleaning and finishing agent comprises sodium gluconate, ammonium chloride, polyethylenepolyamine, lower alcohol, a non-ionic surfactant, an anionic surfactant and deionized water. Compared with a cleaning and finishing agent in the prior art, the cleaning and finishing agent has the advantages that the sodium gluconate, ammonium chloride, polyethylene playamine, lower alcohol, non-ionic surfactant, anionic surfactant and deionized water are used to treat the surface of a pore ring of a PCB board, and glass fiber exposed in the surface of the pore ring is cleaned through sodium gluconate and ammonium chloride; the surface of pore ring resin can be treated by polyethylene polyamine; pore walls can be wetted through the lower alcohol and non-ionic surfactant; the resin and glass fiber on the pore ring surface can be modified through the anionic surfactant to enable the surfaceof the pore ring to form high Zeta potential, effective adsorption capacity of a palladium activator is increased, backlight of electroless copper plating is improved, and the situation of hole-without-copper is reduced.

Owner:湖南互连微电子材料有限公司

Processing method of catalytic diesel oil

ActiveCN108102709BEasy to handleImprove targetingHydrocarbon oil crackingTreatment with hydrotreatment processesPhysical chemistryGasoline

The invention discloses a processing treatment method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjectedto hydrofining and hydro-conversion reactions, and gasoline and diesel components are obtained; the heavy components are separated, and a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained; the non-triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, the triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, and gasoline components and diesel components are obtained; a gasoline product is obtained after gasoline from all parts is mixed, and a diesel product is obtained after diesel components from all parts are mixed. Through the reasonable separation and processing process, different types of raw materials can be selectively and independently processed, so that qualified gasoline and dieselproducts can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

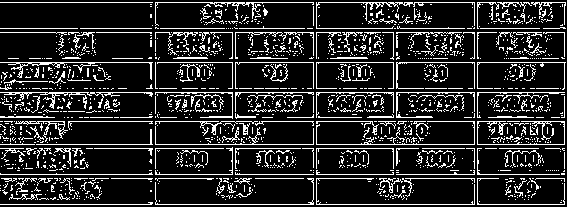

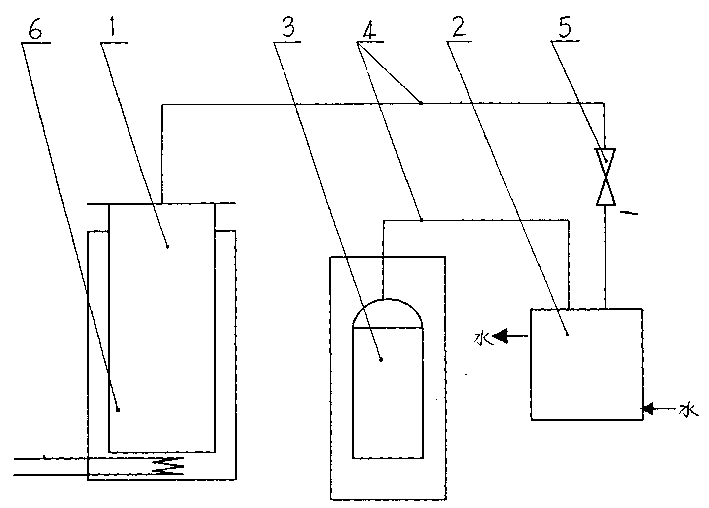

Adsorption and absorption coupling refrigerating appts.

InactiveCN1107850CLarge adsorption capacityIncreased refrigeration evaporationClimate change adaptationEnergy efficient heating/coolingEvaporatorEngineering

An adsorption-absorption coupled refrigerating device is composed of adsorber, condenser and evaporator. A valve is mounted to pipeline between adsorber and condenser. Said adsorber and evaporator are jacketed unit in the form of casing. The heat exchanger is installed in the jacket of adsorber. Cooling medium is in the jacket of evaporator. Its advantages are simple structure, no need of rectifying unit, the working pressure close to ordinary pressure, low cost and high refrigerating efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Slack coal pressure gasification wastewater resourceful treatment method and treatment system as well as application

InactiveCN103288311BAchieve reuseProportionally largeMultistage water/sewage treatmentMicroorganismFlocculation

The invention provides a slack coal pressure gasification wastewater resourceful treatment method. The treatment method sequentially comprises the following steps of: (1) performing oil-water separation on the wastewater to obtain wastewater after the oil-water separation treatment; (2) treating the wastewater obtained by the step (1) by use of active sludge, and performing mud-water separation to obtain wastewater after the active sludge treatment; (3) adding an adsorbent into the wastewater obtained by the step (2), and performing solid-liquid separation to obtain wastewater after the adsorption separation treatment; (4) adding a flocculating agent and / or flocculation aid into the wastewater obtained by the step (3), and precipitating to obtain wastewater after the coagulation clarifying treatment; and (5) treating the wastewater obtained by the step (4) by use of a filter material loaded with microorganisms to obtain dischargeable / recyclable water. The invention also provides a system for the method to realize resourceful treatment on the wastewater, and application of the treatment method or treatment system in treating slack coal pressure gasification wastewater.

Owner:DATANG INT CHEM TECH RESINST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com