Integral reactor for liquid-phase adsorption and solid-liquid separation, application thereof and water treatment method

A liquid-phase adsorption and solid-liquid separation technology, which is applied in the field of environmental technology and water treatment, can solve the problems of difficult dosing and discharge of adsorbents, low adsorption efficiency, and small water treatment volume, and achieves improved solid residence time and adsorption efficiency. The effect of high and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

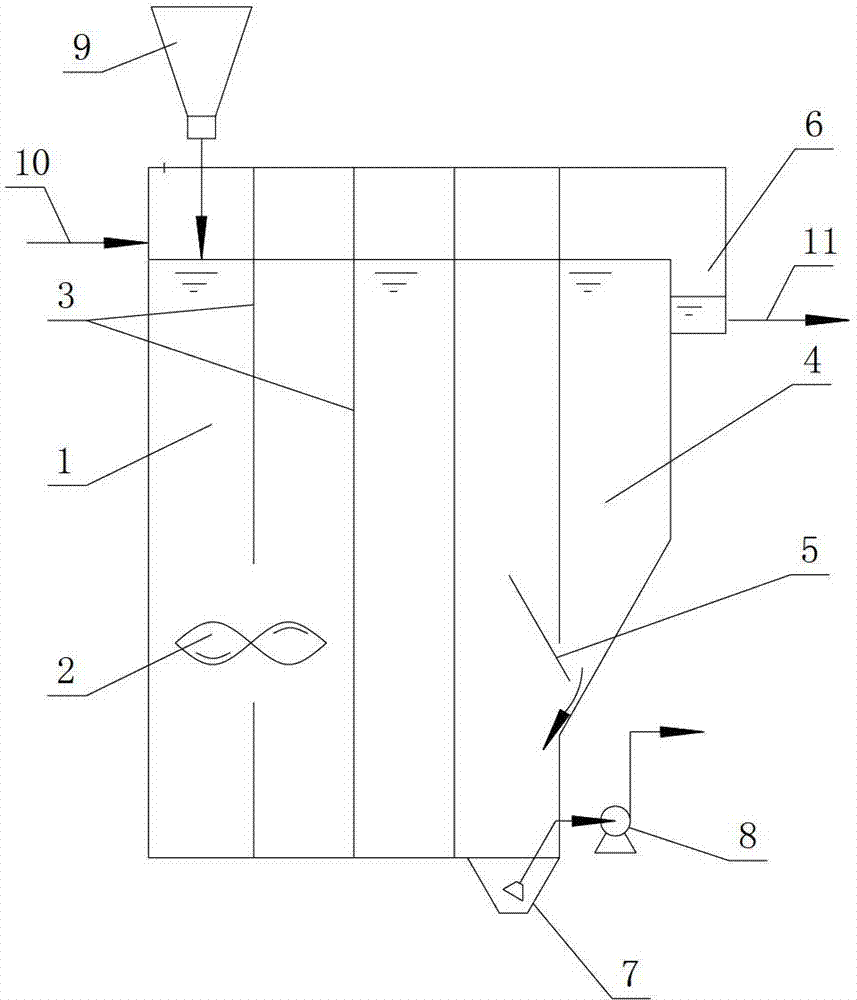

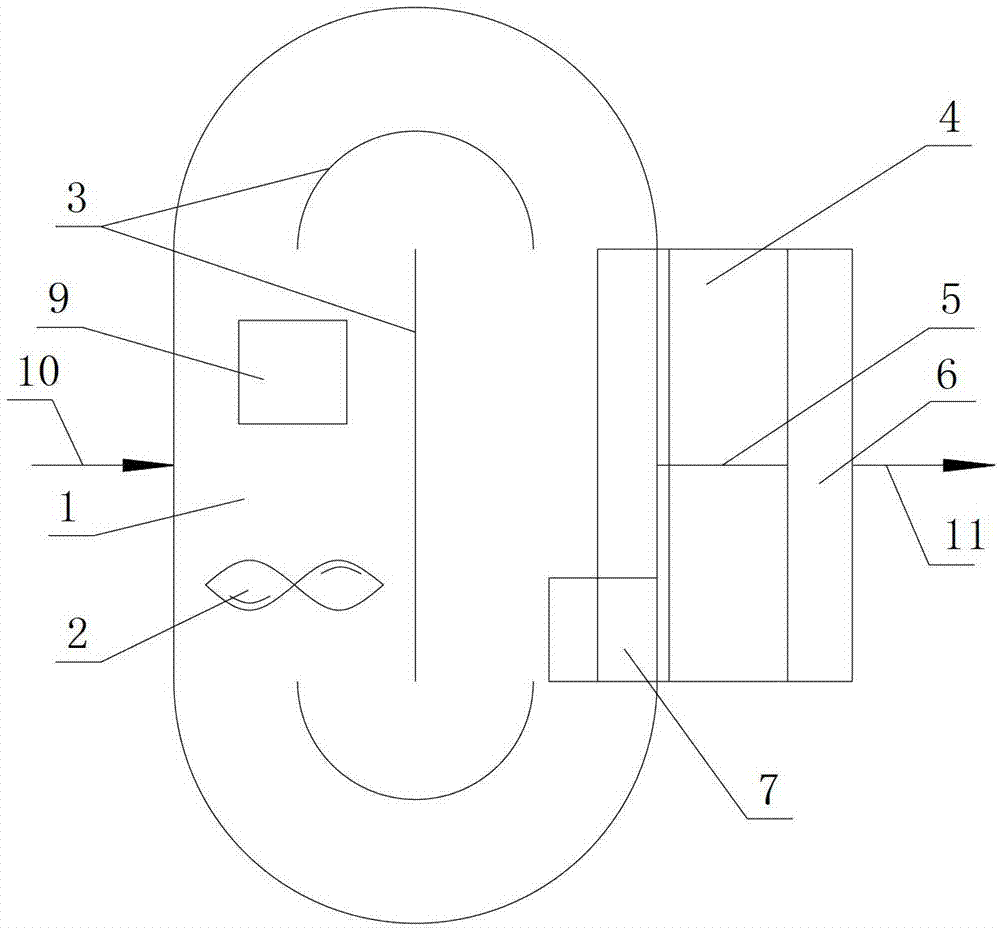

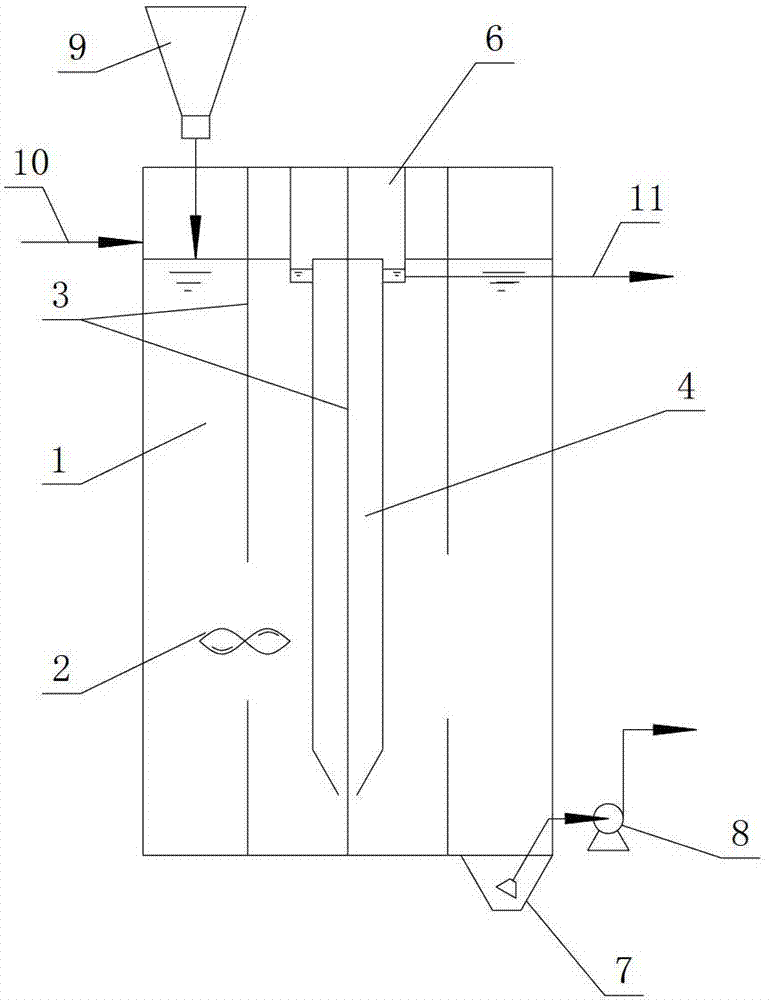

[0054] figure 1 and figure 2 It is a schematic structural diagram of an embodiment of the liquid phase adsorption-solid-liquid separation integrated reactor of the present invention, including:

[0055] A liquid-phase adsorption area (1) with a cover plate is provided on the top, and the liquid-phase adsorption area (1) is a ditch-shaped shell connected end to end;

[0056] Dosing equipment (9) arranged above the liquid-phase adsorption area (1), fixed on the top of the cover plate and connected to the liquid-phase adsorption area (1), such as a single-screw feeder or a double-screw feeder;

[0057] Set inside the liquid-phase adsorption area (1) and separate the liquid-phase adsorption area into a loop corridor, it is composed of any one or more of vertical plates, arc-shaped plates, deflectors, deflector walls and swirl plates diversion assembly (3);

[0058] At least one mixer (2) uniformly arranged in the middle and lower part of the water depth along the loop corridor...

Embodiment 2

[0067] Figure 5 It is a schematic flow diagram of the water treatment method of the present invention. In this embodiment, the liquid to be treated is crushed coal pressurized gasification waste water.

[0068] Such as Figure 5 As shown, in the water treatment method of the present invention, the liquid to be treated (12) is preferably passed through the liquid-phase adsorption-solid-liquid separation integrated reactor (13) connected in sequence with the powdered adsorbent (17), and the Coagulation reactors (14) with additives (19), such as pipeline mixers or mixing reaction tanks, and coagulation clarifiers (15), such as advection sedimentation tanks, vertical flow sedimentation tanks, radial flow sedimentation tanks, inclined flow Tube sedimentation tank or mechanical clarifier to obtain effluent with significantly improved water quality (16). Among them, the exhausted adsorbent in the liquid-phase adsorption-solid-liquid separation integrated reactor (13) is treated b...

Embodiment 3

[0087] According to the steps in Example 2, when the liquid to be treated (12) is crushed coal pressurized gasification wastewater, the present invention can also be carried out using the following parameters:

[0088] (1) Parameters in the liquid phase adsorption-solid-liquid separation integrated reactor (13):

[0089] Powdered active coke particle size: <0.15mm,

[0090] Hydraulic retention time in the liquid phase adsorption zone: 6h,

[0091] Solid concentration in the liquid phase adsorption zone (that is, the mass of adsorbent solids per unit volume): 5kg / m 3 ,

[0092] Water velocity in the liquid phase adsorption zone: 1.5m / s,

[0093] Powdered active coke residence time: 12h,

[0094] Hydraulic retention time in the solid-liquid separation zone: 10min,

[0095] The solid concentration discharged from the external discharge equipment: 20kg / m 3 ;

[0096] (2) Parameters in the coagulation reactor (14):

[0097] Hydraulic retention time: 5min,

[0098] Polyalumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com