Patents

Literature

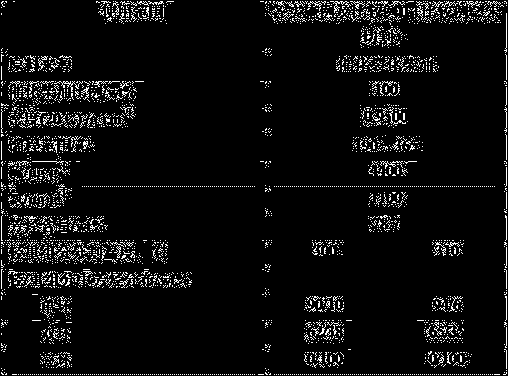

50results about How to "Increase payload capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

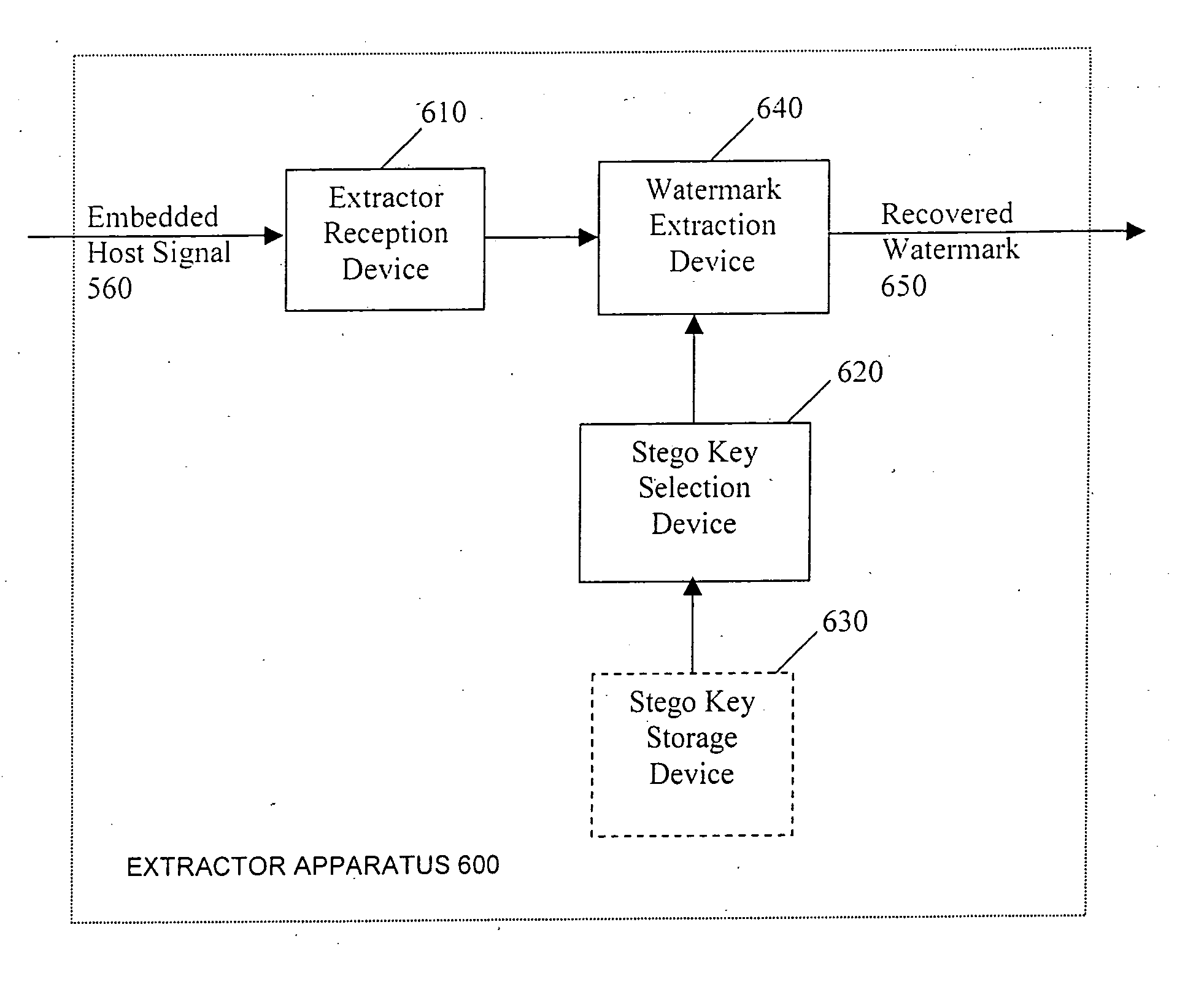

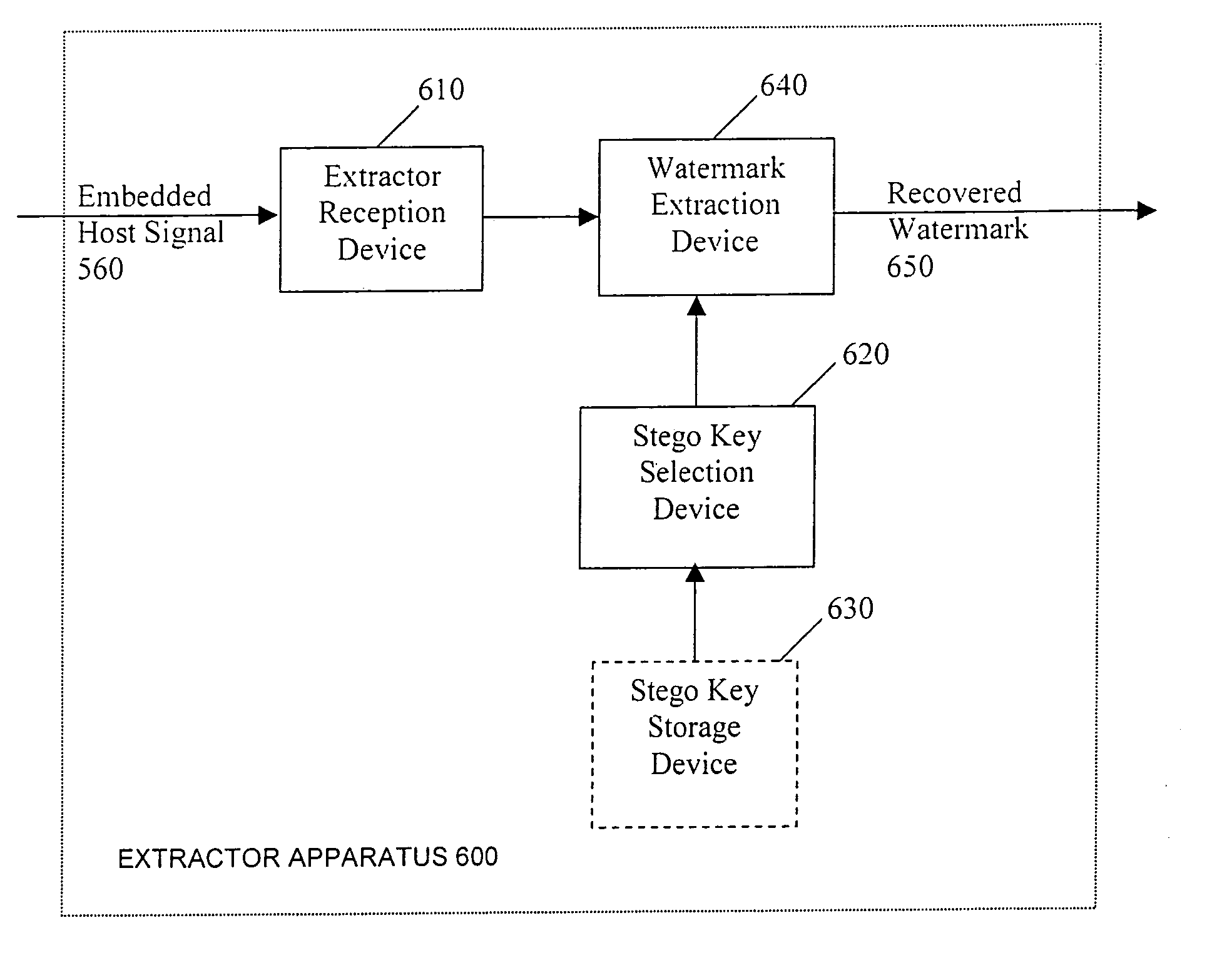

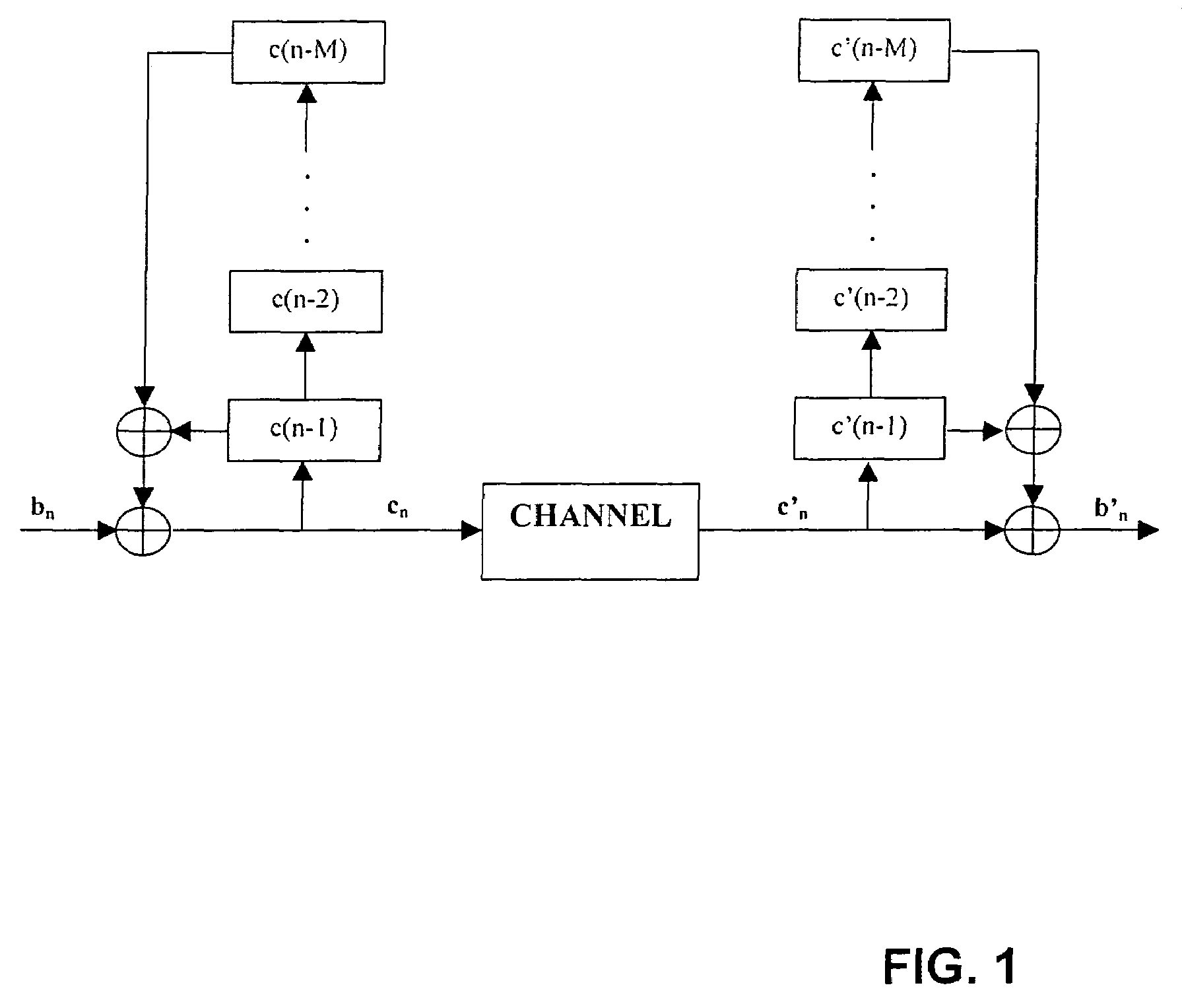

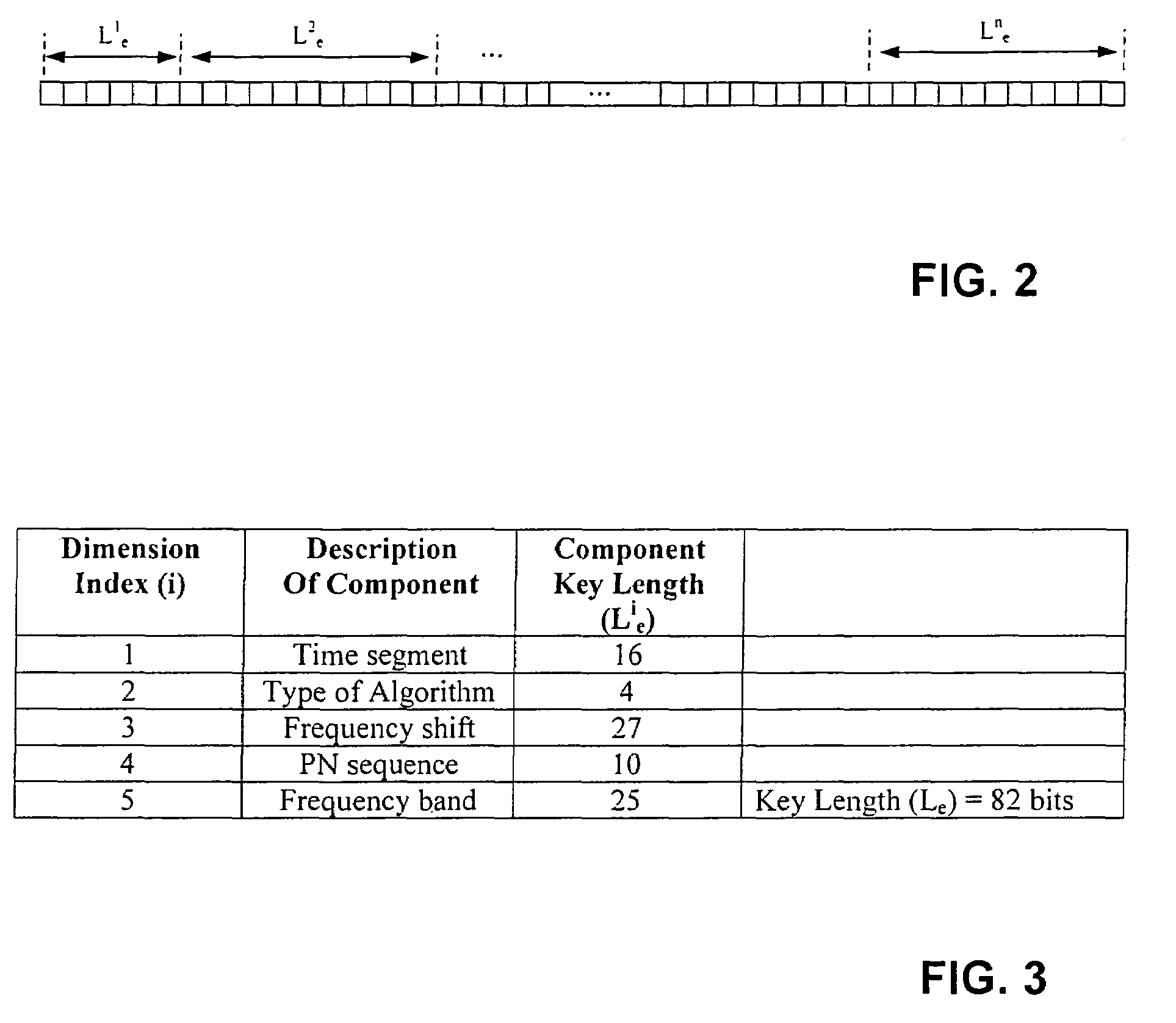

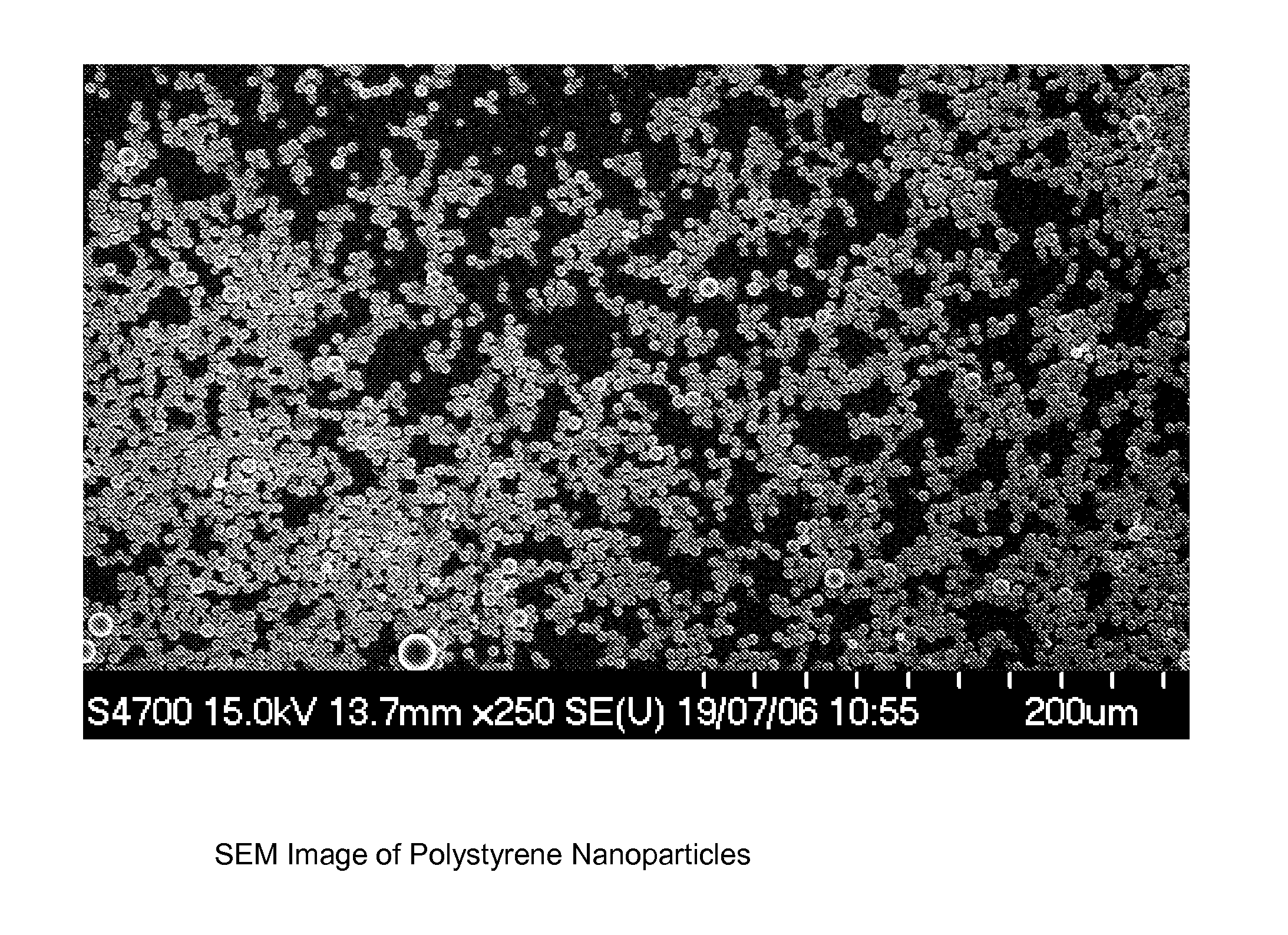

System reactions to the detection of embedded watermarks in a digital host content

InactiveUS20060239503A1Increase payload capacityIncreased payload capacityUser identity/authority verificationSpeech analysisSystem requirementsSystem recovery

Methods for adapting the operation of a system in response to the detection of embedded watermarks from a digital host content are provided. A digital host content is received and examined for the presence of watermarks. In response to the detection of embedded watermarks and in accordance with the value, type, density or spacing of the detected watermarks, one or more system reactions may take place. These reactions include conditionally allowing the system to resume its normal operation, prohibiting the system from resuming its normal operation, degrading the quality of the digital host content or changing the security status of the digital host content. In response to the extraction of weak watermarks that do not meet the desired system requirements, the extraction operation may be modified or extended to enable the detection of strong watermarks.

Owner:IP ACQUISITIONS LLC

System reactions to the detection of embedded watermarks in a digital host content

InactiveUS7369677B2Increase payload capacitySacrificing complexityUser identity/authority verificationSpeech analysisSystem requirementsSystem recovery

Methods for adapting the operation of a system in response to the detection of embedded watermarks from a digital host content are provided. A digital host content is received and examined for the presence of watermarks. In response to the detection of embedded watermarks and in accordance with the value, type, density or spacing of the detected watermarks, one or more system reactions may take place. These reactions include conditionally allowing the system to resume its normal operation, prohibiting the system from resuming its normal operation, degrading the quality of the digital host content or changing the security status of the digital host content. In response to the extraction of weak watermarks that do not meet the desired system requirements, the extraction operation may be modified or extended to enable the detection of strong watermarks.

Owner:IP ACQUISITIONS LLC

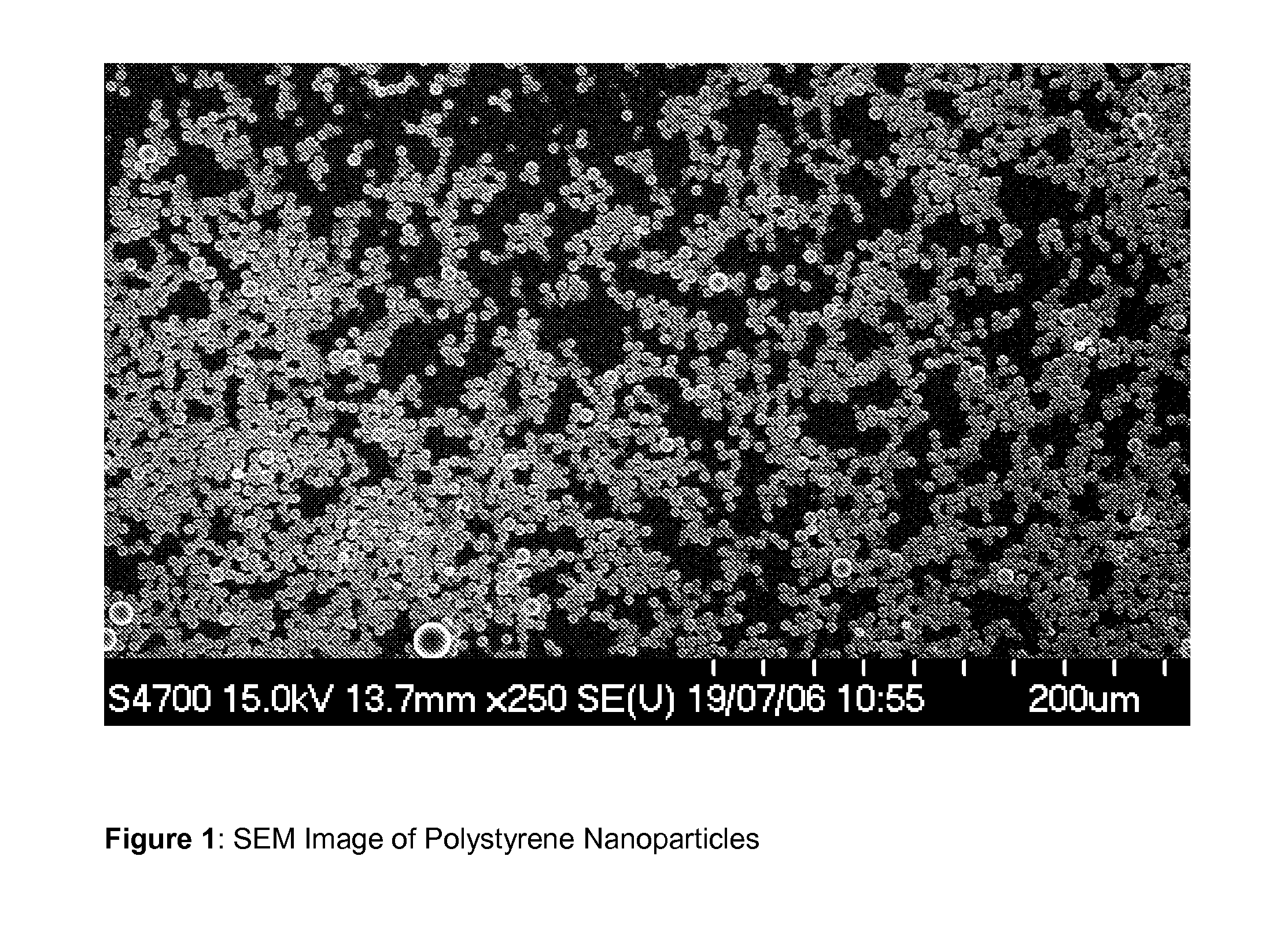

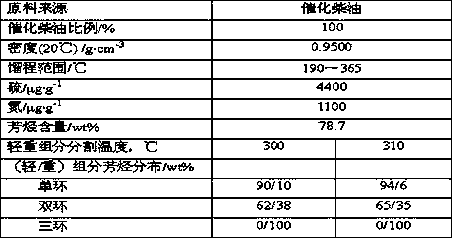

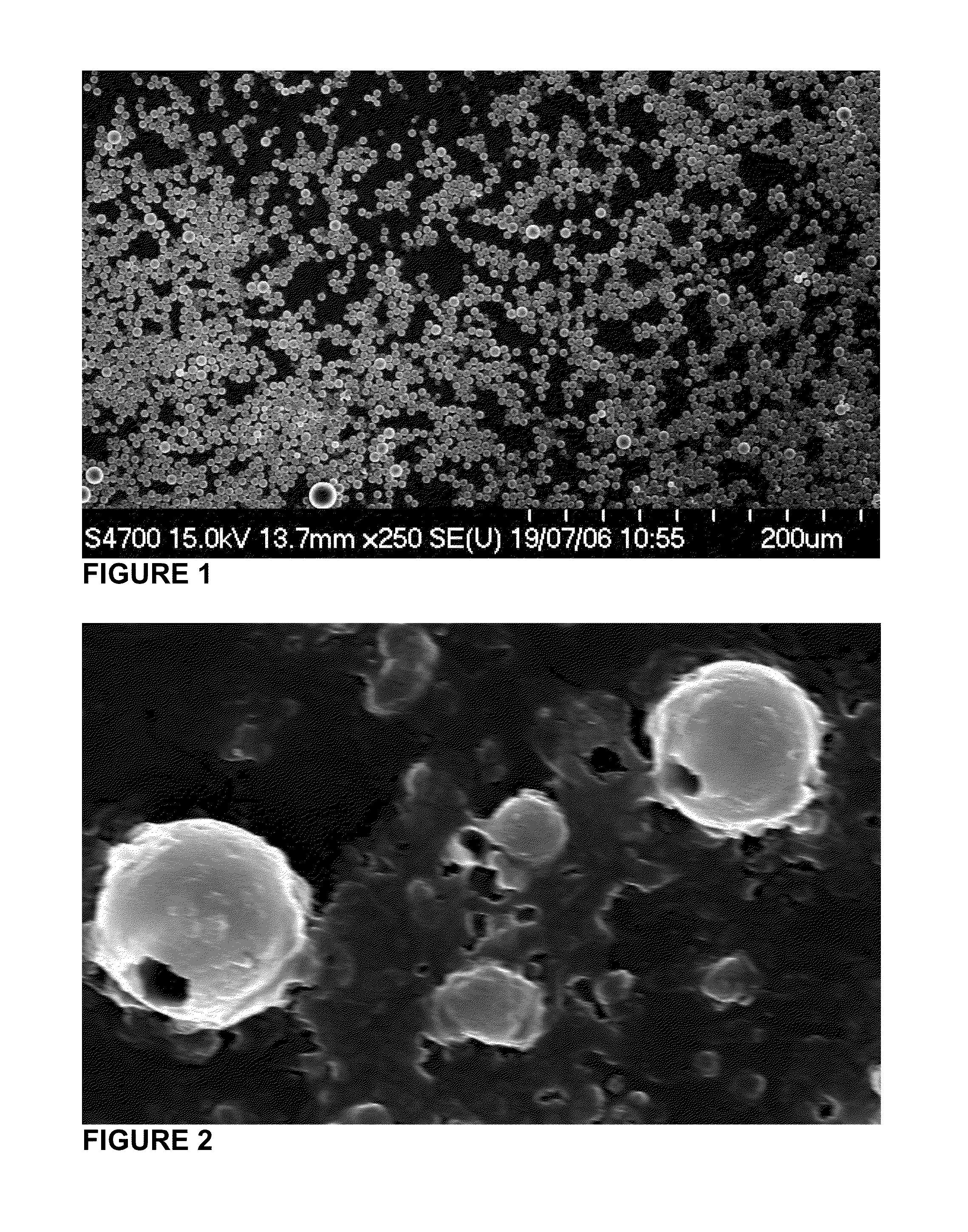

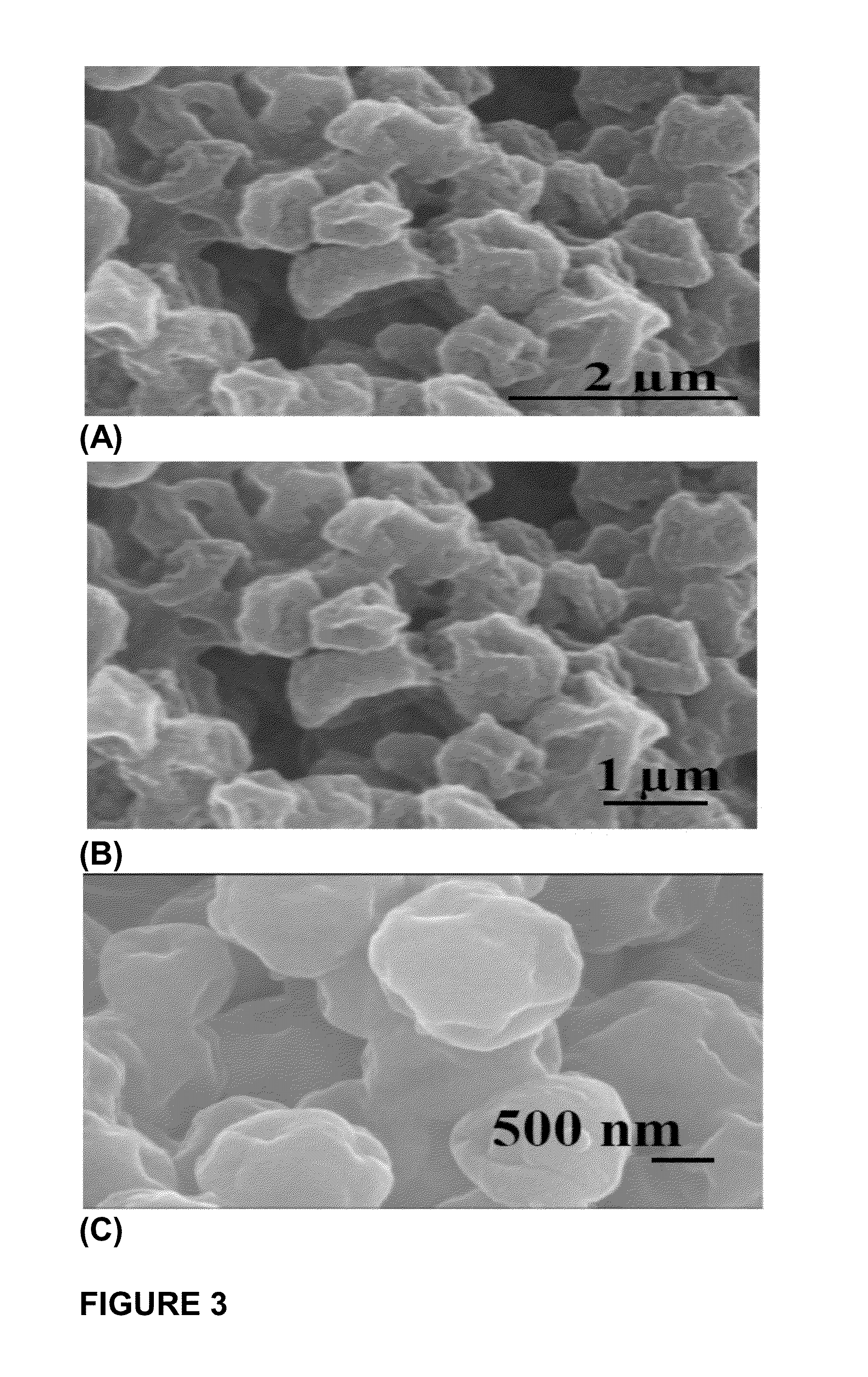

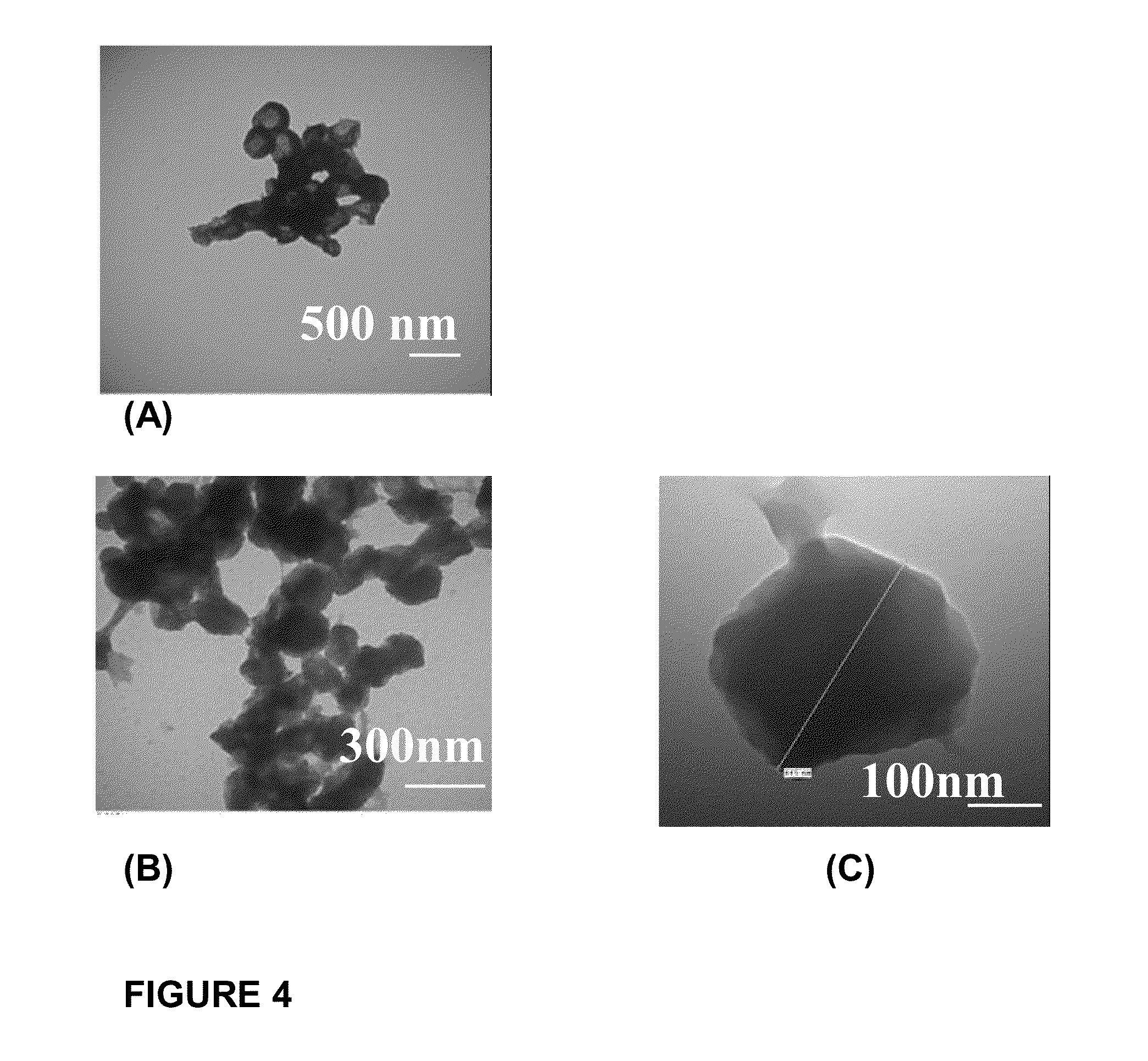

Hollow biodegradable nanospheres and nanoshells for delivery of therapeutic and/or imaging molecules

InactiveUS20110123456A1Increase payload capacityIncrease load capacityUltrasonic/sonic/infrasonic diagnosticsOrganic active ingredientsBiomedical engineering

A polymeric hollow nanoshell or nanosphere for release of an agent is described, wherein the hollow nanosphere comprises at least one biodegradable polymer, characterised in that the polymer is cross-linked. The biodegradable mono-disperse nanospheres described are suitable for use as carriers of biomolecules, therapeutic agents and / or imaging agents.

Owner:THE NAT UNIV OF IRELAND GALWAY

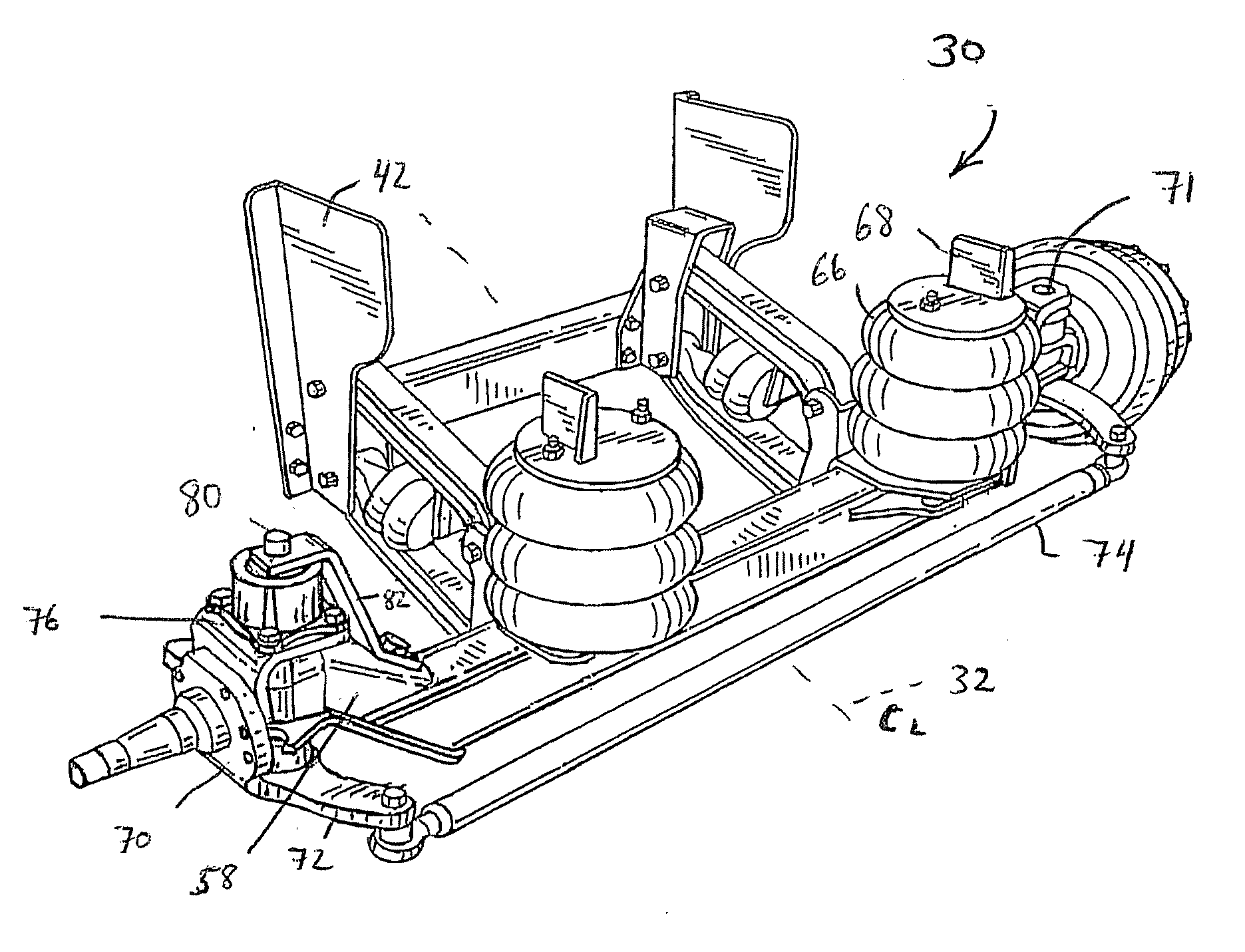

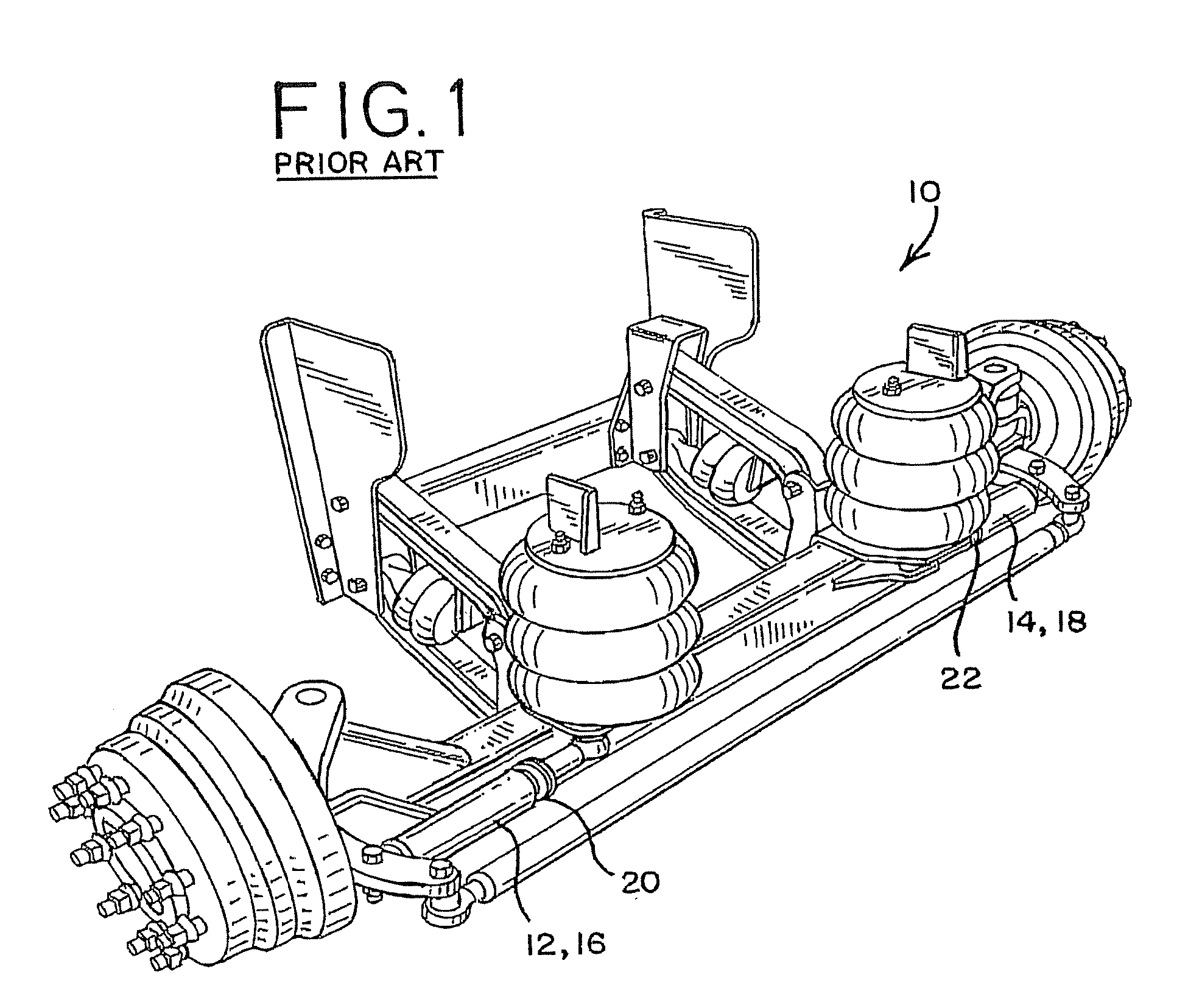

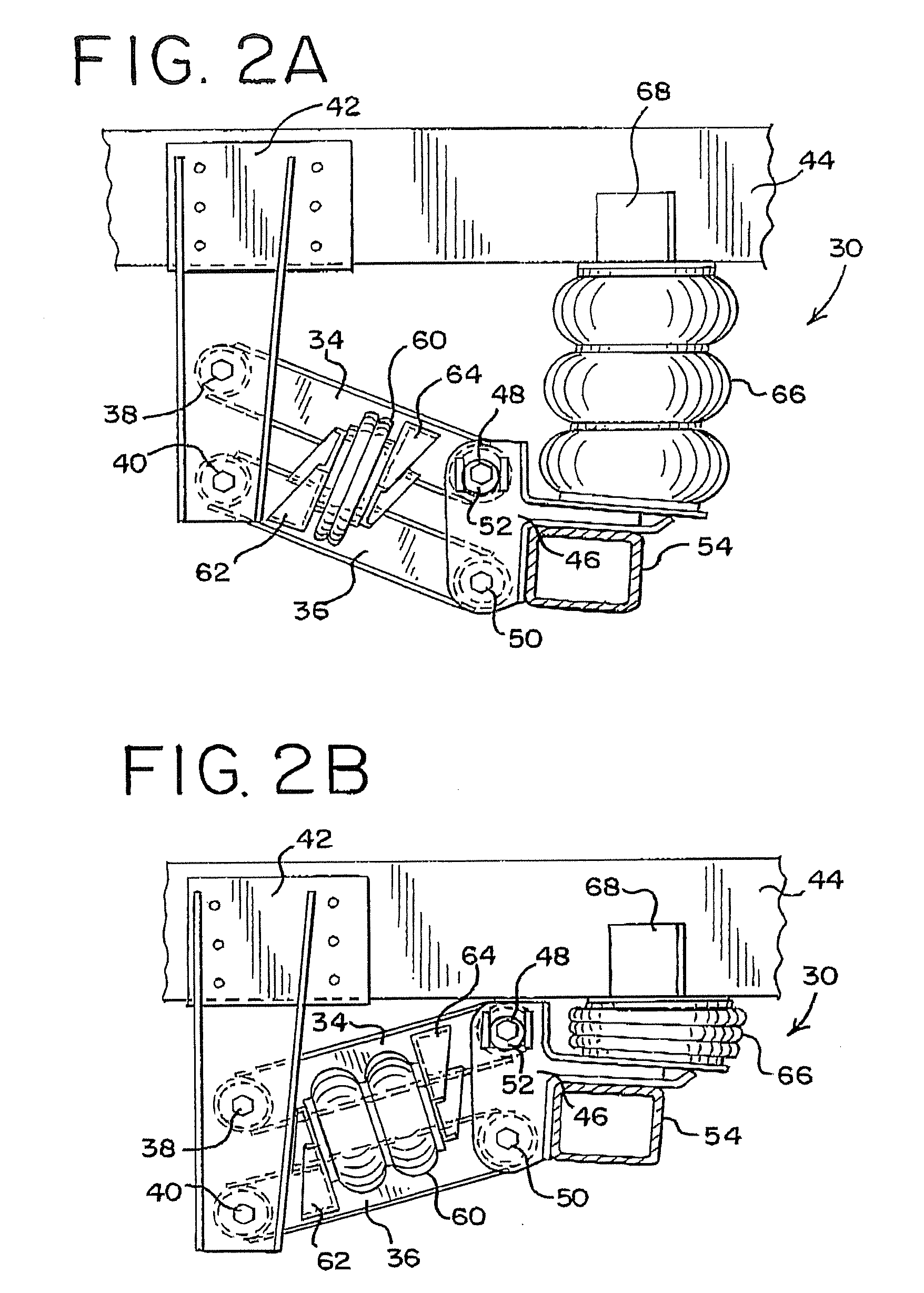

Self-steering axle suspension system having a rotary stabilizer

ActiveUS20080018070A1Low maintenanceIncrease payload capacityLiquid resistance brakesSpringsAutomotive engineeringSnubber

A self-steering axle suspension system utilizing a rotary damper coaxially aligned with and acting directly about the king pin centerline on one side of the vehicle is disclosed. When used as such, the rotary damper constitutes a rotary stabilizer. The rotary stabilizer is used to control the steerability of the self-steering axle suspension system and has a self-centering axle mechanism incorporated therein.

Owner:HENDRICKSON USA L L C

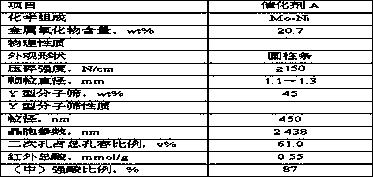

Catalyst by taking modified alumina as carrier and preparation method thereof

InactiveCN104815661AIncrease payload capacityGood dispersionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsAluminateMetal

The invention relates to a catalyst by taking modified alumina as a carrier and a preparation method thereof. The catalyst by taking modified alumina as the carrier is composed of active metal oxide and modified alumina, wherein the mol ratio of auxiliary agent metal aluminate to alumina in the modified alumina is 1: 5-75, and the active metal oxide accounts for 2.0-30% of final catalyst by weight composition. The catalyst has the advantages of good activity, good stability and long service life used for a ft synthesis reaction.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

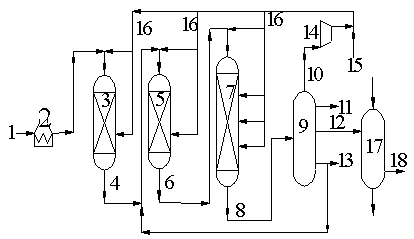

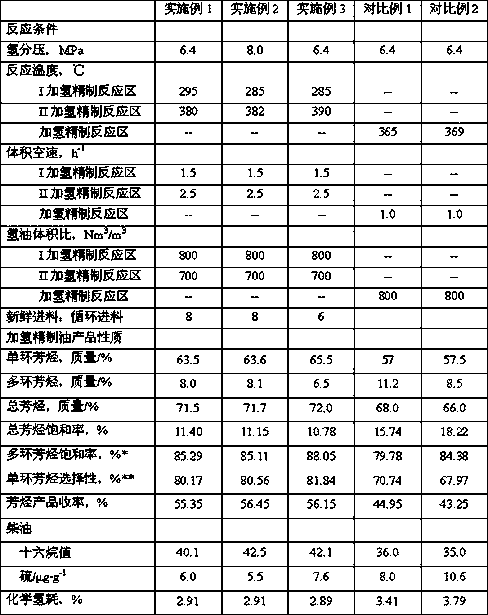

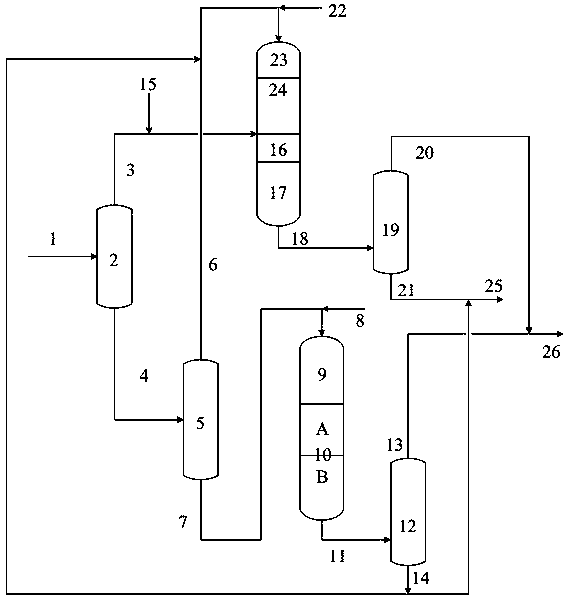

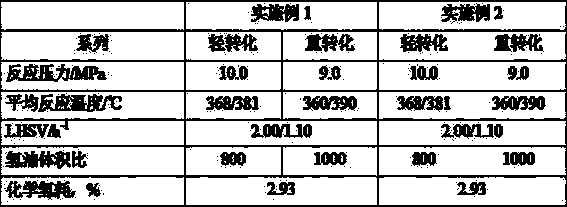

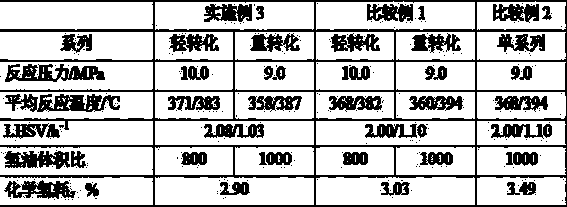

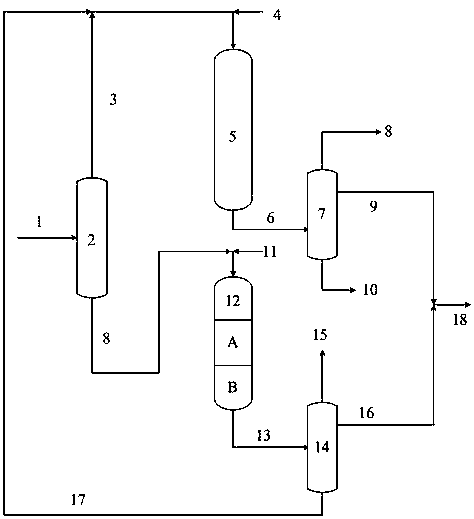

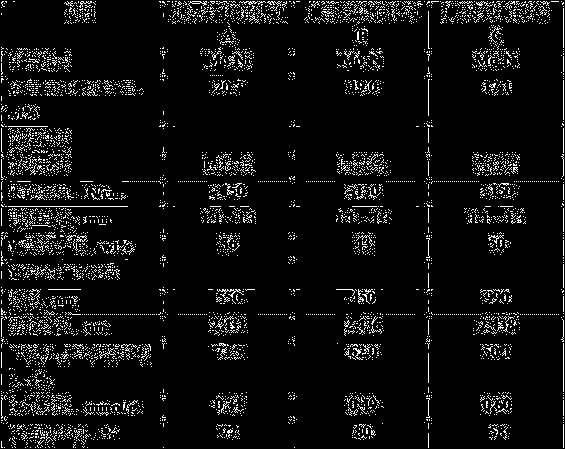

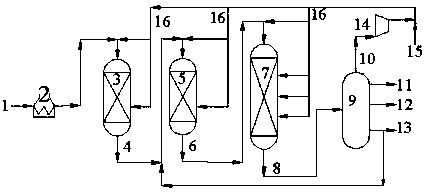

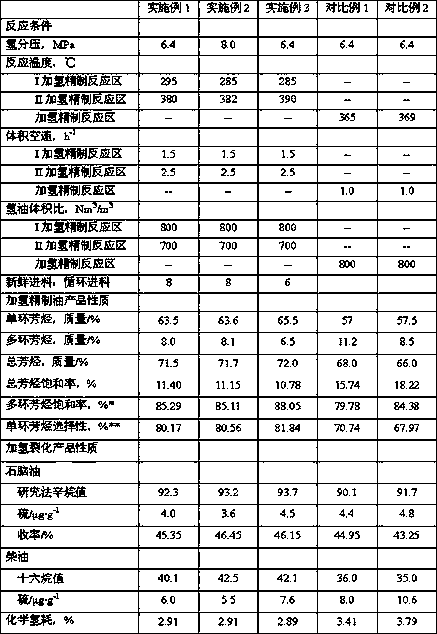

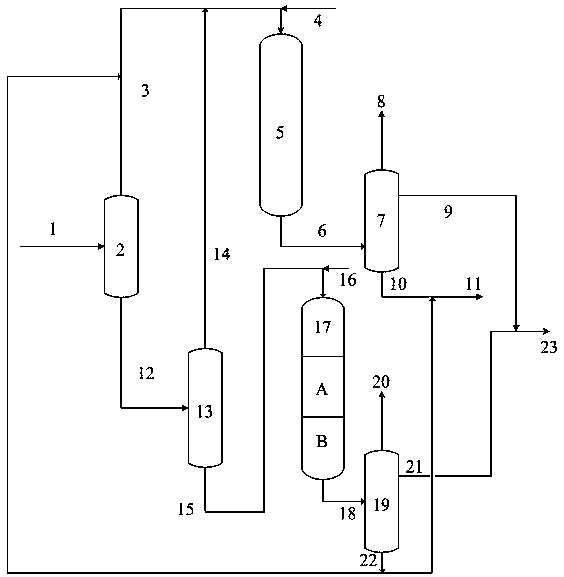

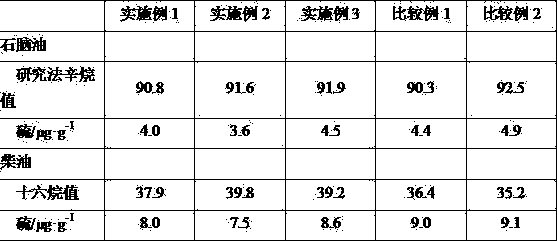

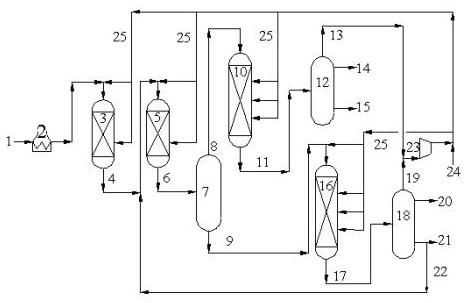

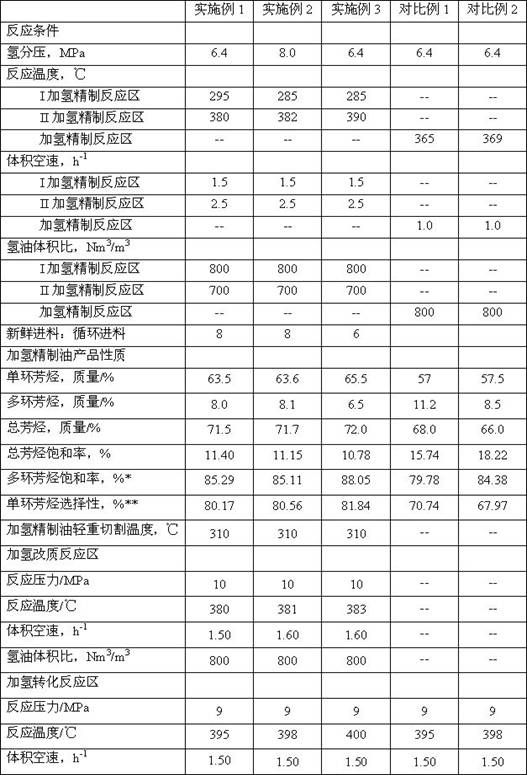

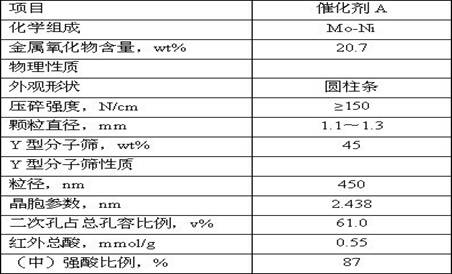

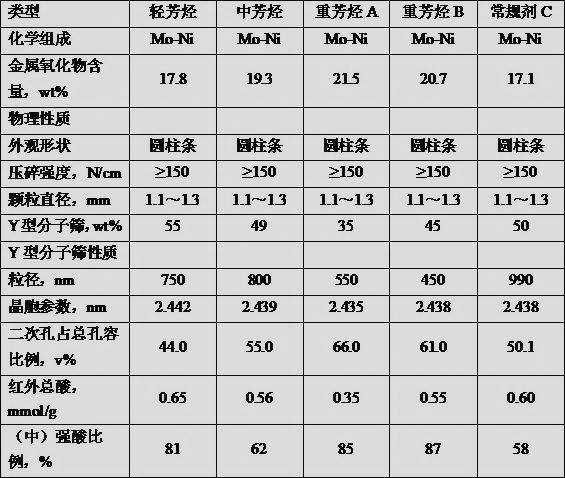

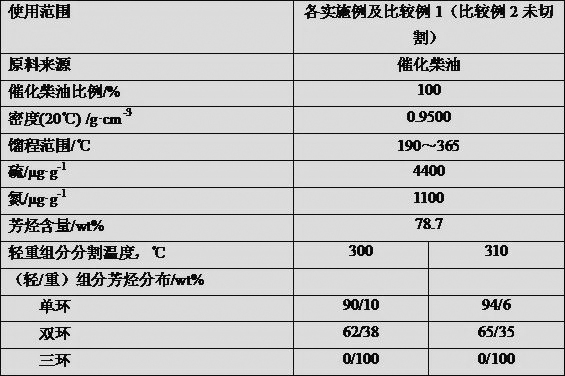

Method for preparing aromatic hydrocarbons from catalytic diesel oil through hydro-conversion

ActiveCN109777514AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a method for preparing aromatic hydrocarbons from catalytic diesel oil through hydro-conversion. The method comprises the following steps: (1) mixing high aromatic hydrocarboncatalytic diesel oil with circulating hydrogen and feeding the mixture into a hydrofining reaction zone I for reaction; (2) mixing generated oil obtained in the step (1) with circulating hydrogen, andfeeding the mixture into a hydrofining reaction zone II for further reaction, wherein the reaction temperature is 30-120 DEG C higher than that of the hydrofining reaction zone I, and the liquid hourly space velocity is 0.2-1.5 h<-1> lower than that of the hydrofining reaction zone I; (3) mixing the generated oil obtained in the step (2) with circulating hydrogen and feeding the mixture into a hydrocracking reaction zone for hydrocarbon hydro-conversion reaction; and (4) enabling the generated oil obtained in the step (3) to pass through a separation and fractionation system to obtain gas, light naphtha, heavy naphtha and diesel oil fractions, returning part of diesel oil to a hydrofining reaction zone II, and discharging the other part of the diesel oil from a device; and (5) feeding theheavy naphtha fraction obtained in the step (4) into an aromatic hydrocarbon extraction system to obtain an aromatic hydrocarbon product. By the coupling hydrocracking-aromatic hydrocarbon extractionprocess method for processing catalytic diesel oil raw materials, the yield of the aromatic hydrocarbons can be increased effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hollow biodegradable nanospheres and nanoshells for delivery of therapeutic and/or imaging molecules

InactiveUS20140004251A1Increase payload capacityIncrease load capacityPowder deliveryMicroencapsulation basedCross-linkImaging agent

A polymeric hollow nanoshell or nanosphere for release of an agent is described, wherein the hollow nanosphere comprises at least one biodegradable polymer, characterised in that the polymer is cross-linked. The biodegradable mono-disperse nanospheres described are suitable for use as carriers of biomolecules, therapeutic agents and / or imaging agents.

Owner:THE NAT UNIV OF IRELAND GALWAY

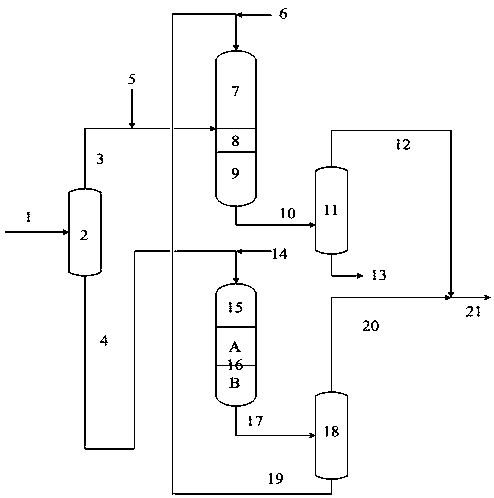

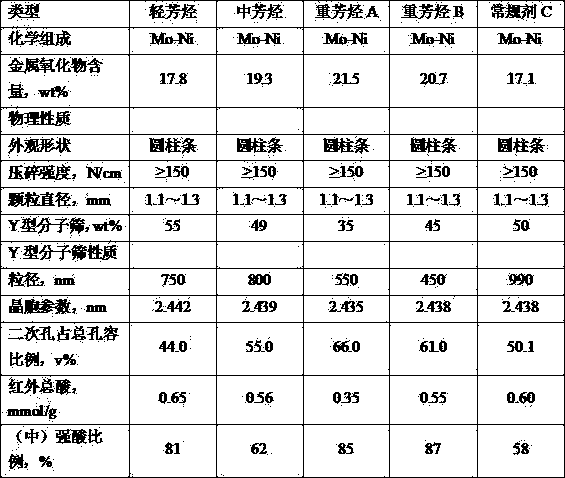

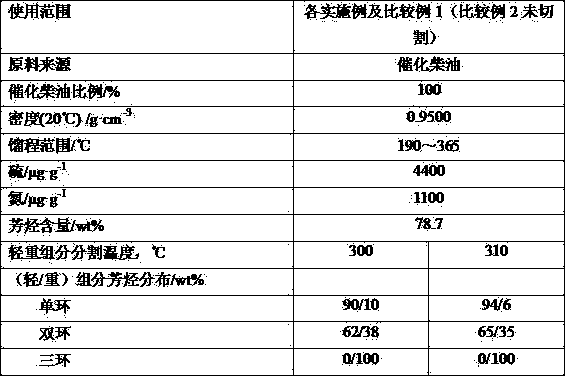

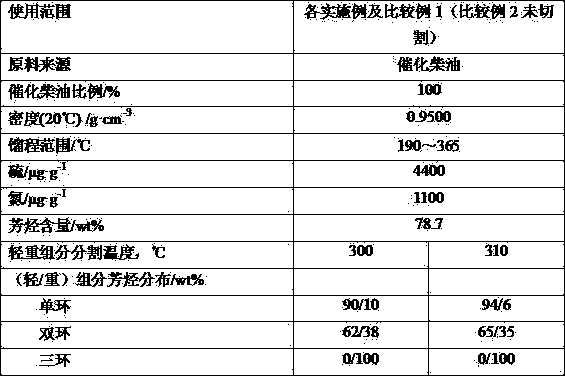

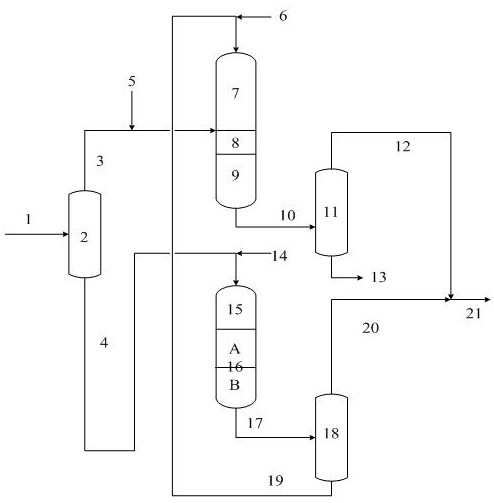

Processing treatment method of catalytic diesel

ActiveCN108102709AEasy to handleImprove targetingHydrocarbon oil crackingTreatment with hydrotreatment processesGasolineHydrocarbon

The invention discloses a processing treatment method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjectedto hydrofining and hydro-conversion reactions, and gasoline and diesel components are obtained; the heavy components are separated, and a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained; the non-triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, the triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, and gasoline components and diesel components are obtained; a gasoline product is obtained after gasoline from all parts is mixed, and a diesel product is obtained after diesel components from all parts are mixed. Through the reasonable separation and processing process, different types of raw materials can be selectively and independently processed, so that qualified gasoline and dieselproducts can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of catalytic diesel

ActiveCN108102702AHigh Yield High OctaneReduced activityTreatment with hydrotreatment processesHydrocarbon oils treatment productsContact reactionGasoline

The invention discloses a processing method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjected to a conversion reaction in a bed layer containing a light aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and converted diesel are obtained; the heavy components are subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and diesel fractions are obtained; the diesel fractions obtained through conversion of heavy componentsare subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, a reaction effluent is then subjected to a contact reaction with a light component hydro-conversion catalyst; the converted gasoline obtained from each part is mixed, and high-quality gasoline is obtained. Through the reasonable separation and processing process, different types of raw materials can beselectively and independently processed, so that the qualified gasoline product with high octane value can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

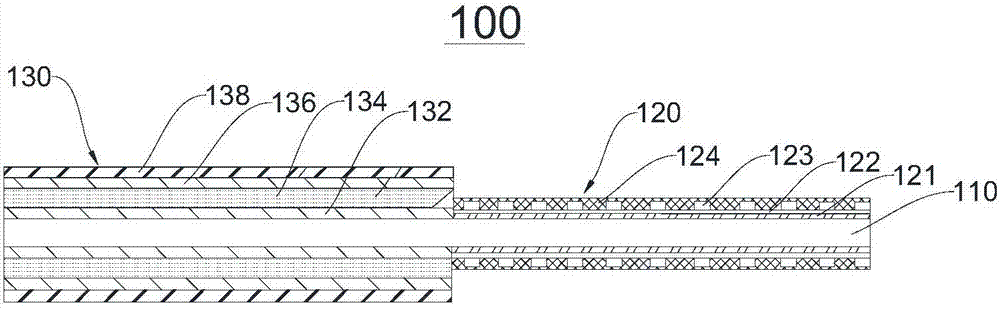

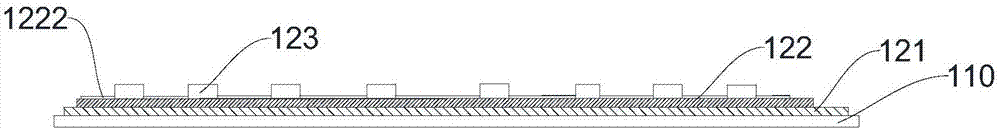

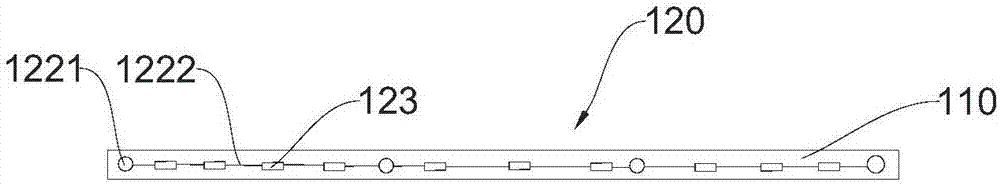

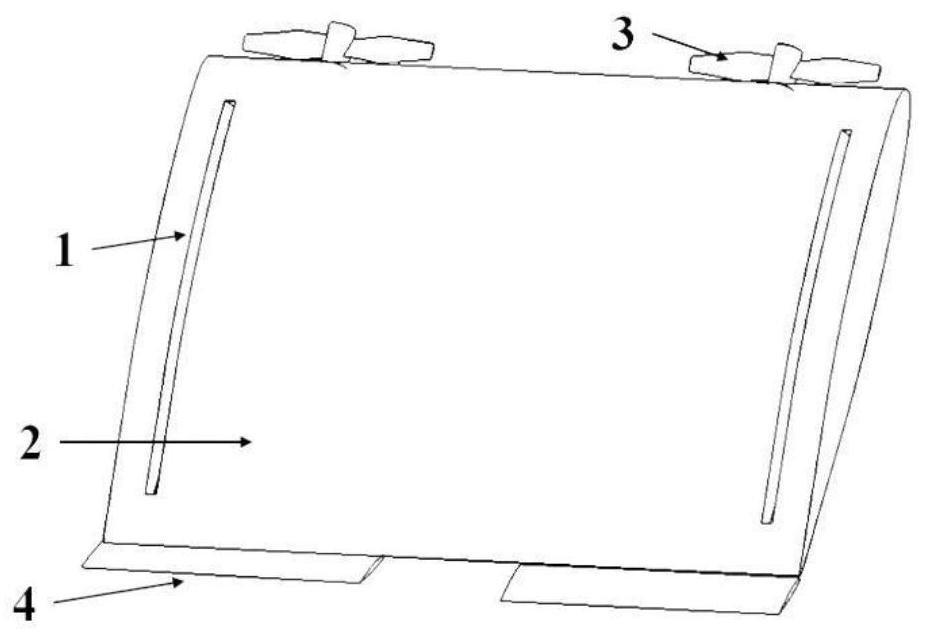

Flexible LED lamp filament and LED lamp

InactiveCN106969276AEven heat distributionImprove cooling effectElectric circuit arrangementsElectroluminescent light sourcesFluorescenceEngineering

The invention provides a flexible LED lamp filament and an LED lamp and belongs to the field of LED lamp filaments. The flexible LED lamp filament comprises a flexible base plate, a plurality of LED chips, an insulating layer, fluorescent glue and a circuit layer. The flexible base plate comprises a luminous part and a radiating part. The distance between every two adjacent LED chips in the multiple LED chips is reduced gradually in the direction from the center of the luminous part to the two ends of the luminous part, and thus heat in the middle of the luminous part during usage of the flexible LED lamp filament is reduced. In addition, the heat of the luminous part of the flexible LED lamp filament can be further emitted through the radiating part of the flexible base plate, then the radiating ability and effective load ability of the flexible LED lamp filament are improved, and the effects of energy conservation and environment protection are achieved.

Owner:四川客临光电科技有限公司

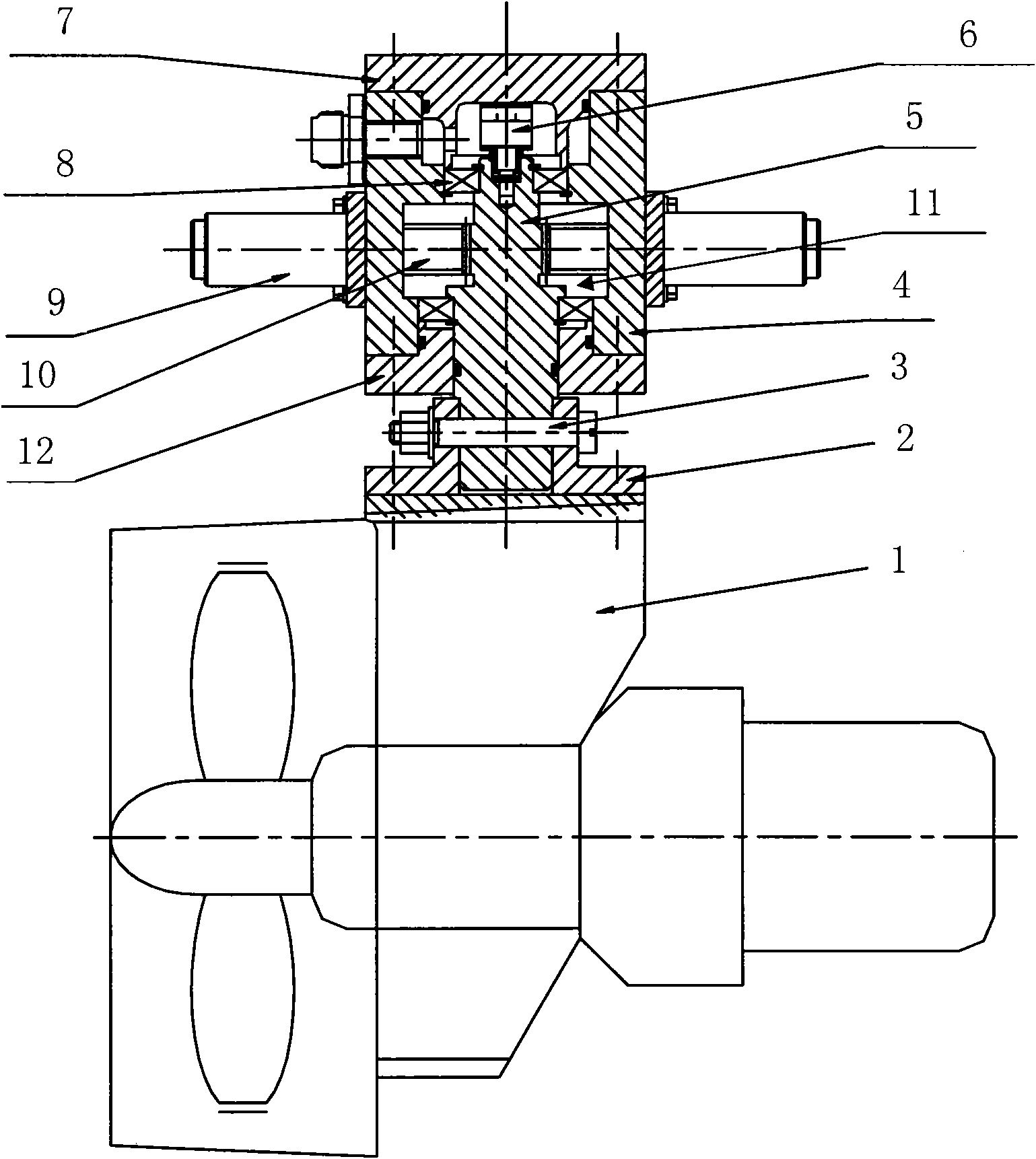

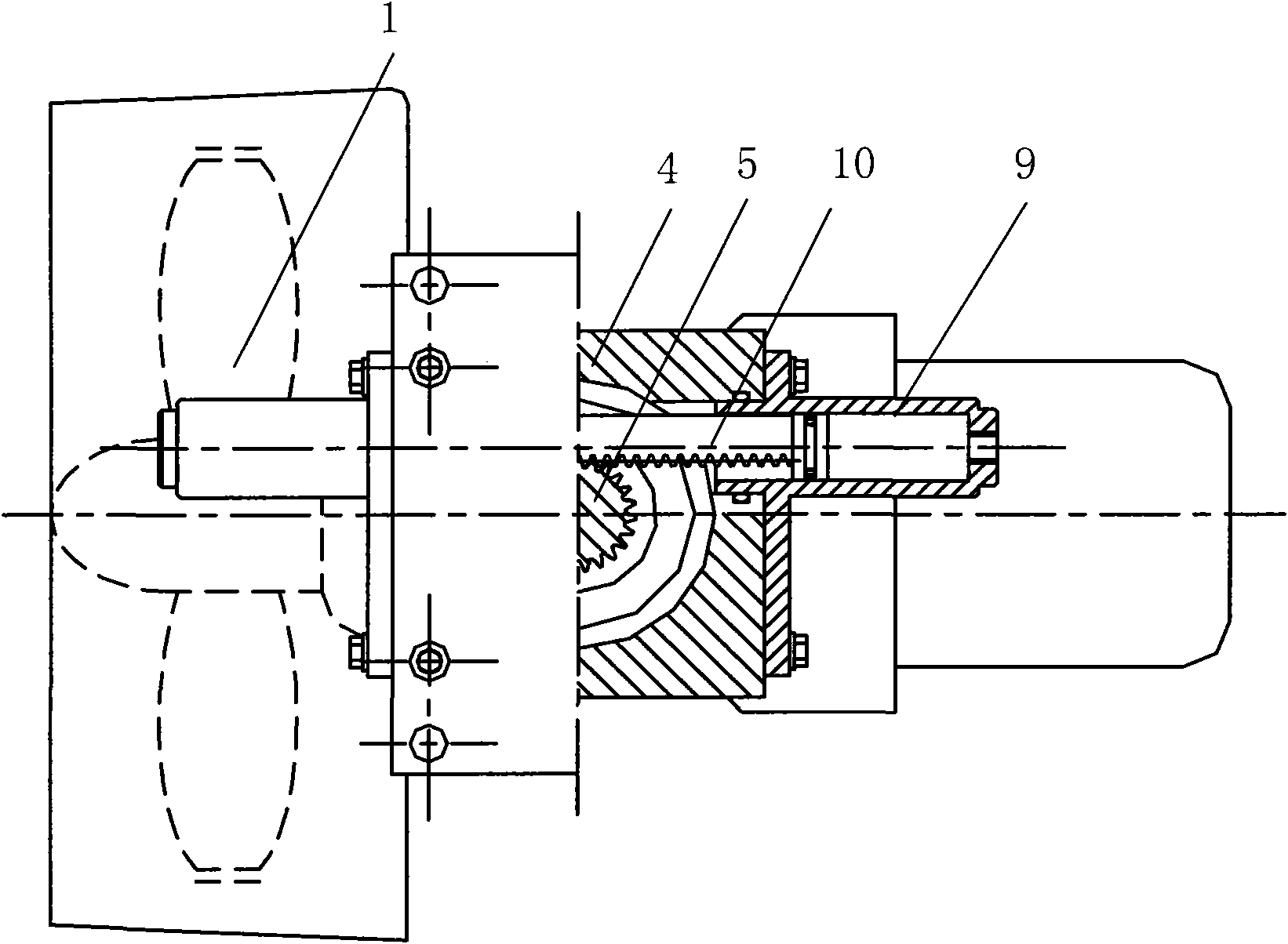

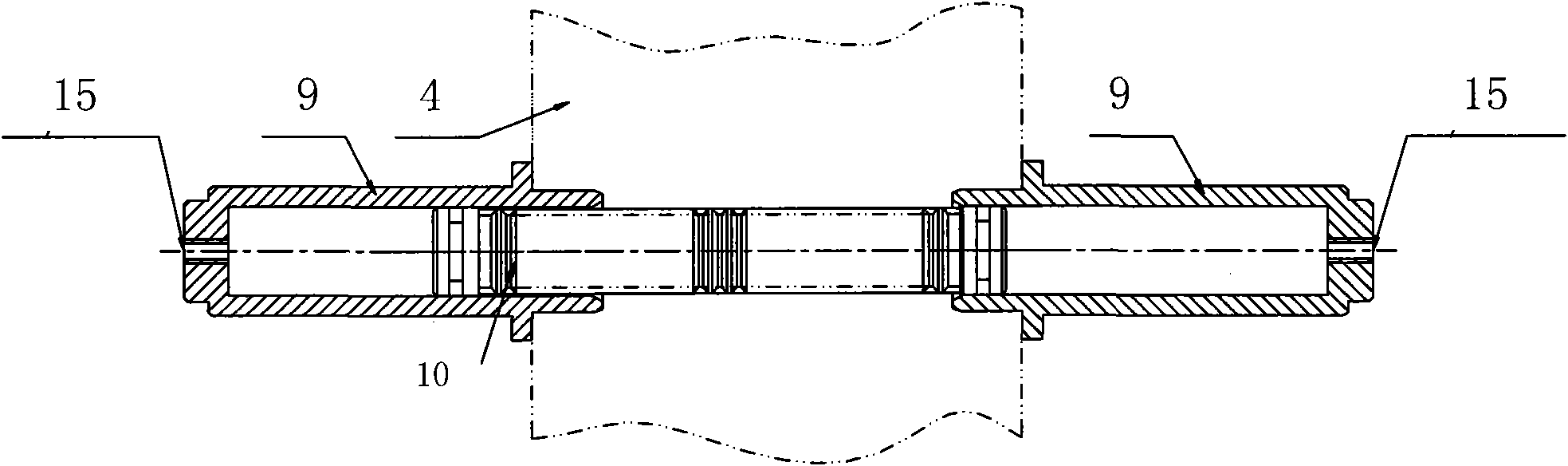

Oscillating type propeller

InactiveCN101941517AReduce the number of installationsLight weightPropulsive elements of non-rotary typeTransmission with non-mechanical gearingCouplingEngineering

The invention relates to an oscillating type propeller which is applicable to an underwater vehicle for an underwater robot. The oscillating type propeller comprises a propeller and an oscillating mechanism, wherein the oscillating mechanism is connected with the propeller by an oscillating shaft arranged in the oscillating mechanism, the oscillating mechanism comprises a case, the oscillating shaft, a mounting flange, a driving mechanism and an end cover, the mounting flange is arranged at one end of the case, the end cover is mounted at the other end of the case, the oscillating shaft is arranged in the case and extends out of the end cover, the driving mechanism is penetrated through the case, is arranged on the case and is connected with the oscillating shaft in the case, the mountingflange and the end cover respectively form tight coupling with the case, the end cover and the oscillating shaft, and a closed cavity is formed in the case. By using the driving mechanism to drive the oscillating shaft to rotate, the invention can realize the free real-time on-line adjustment on the position and the angle of the propeller in the range of the plane perpendicular to the oscillatingshaft + / - 90 degrees, thereby changing the power output characteristics of the underwater vehicle, greatly improving the moving performance controllability and adaptability to complicated underwater environment of the underwater vehicle, and achieving the advantages of simple and reliable application and easy arrangement.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Processing method of catalytic diesel oil

ActiveCN108102713AGreat suitability and pertinenceImprove product qualityTreatment with hydrotreatment processesHydrocarbon oils treatment productsChemistryGasoline

The invention discloses a processing method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected to hydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is subjected to hydrofining and hydroconversion, and a gasoline component and a dieseloil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that qualified gasoline and diesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil .

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic diesel oil hydro-conversion method

ActiveCN109777511AIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a catalytic diesel oil hydro-conversion method. The catalytic diesel oil hydro-conversion method comprises the following steps: (1) mixing high aromatic hydrocarbon catalytic diesel oil with circulating hydrogen and feeding the mixture into a hydrofining reaction zone I for reaction; (2) mixing generated oil obtained in the step (1) with circulating hydrogen, and feeding the mixture into a hydrofining reaction zone II for further reaction, wherein the reaction temperature is 30-120 DEG C higher than that of the hydrofining reaction zone I, and the liquid hourly space velocity is 0.2-1.5 h<-1> lower than that of the hydrofining reaction zone I; (3) mixing the generated oil obtained in the step (2) with circulating hydrogen, feeding the mixture into a hydrocracking reaction zone for hydrocarbon hydro-conversion reaction; and (4) enabling the generated oil obtained in the step (3) to pass through a separation and fractionation system to obtain gas, light naphtha, heavy naphtha and diesel oil fractions, returning part of diesel oil to the hydrofining reaction zone II, and discharging the other part of the diesel oil from the device. By the catalytic diesel oil hydro-conversion method, the yield of aromatic hydrocarbons can be increased effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

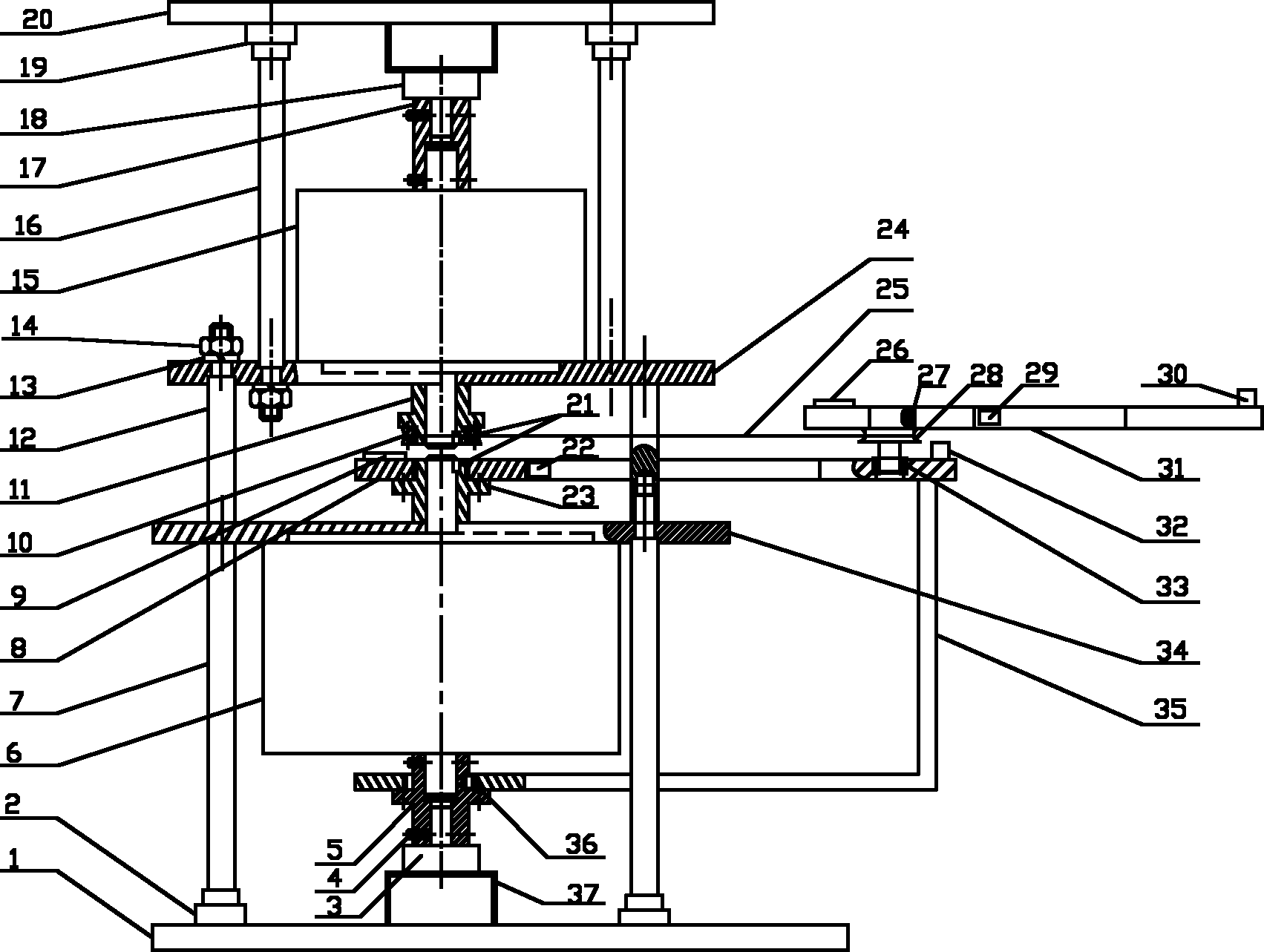

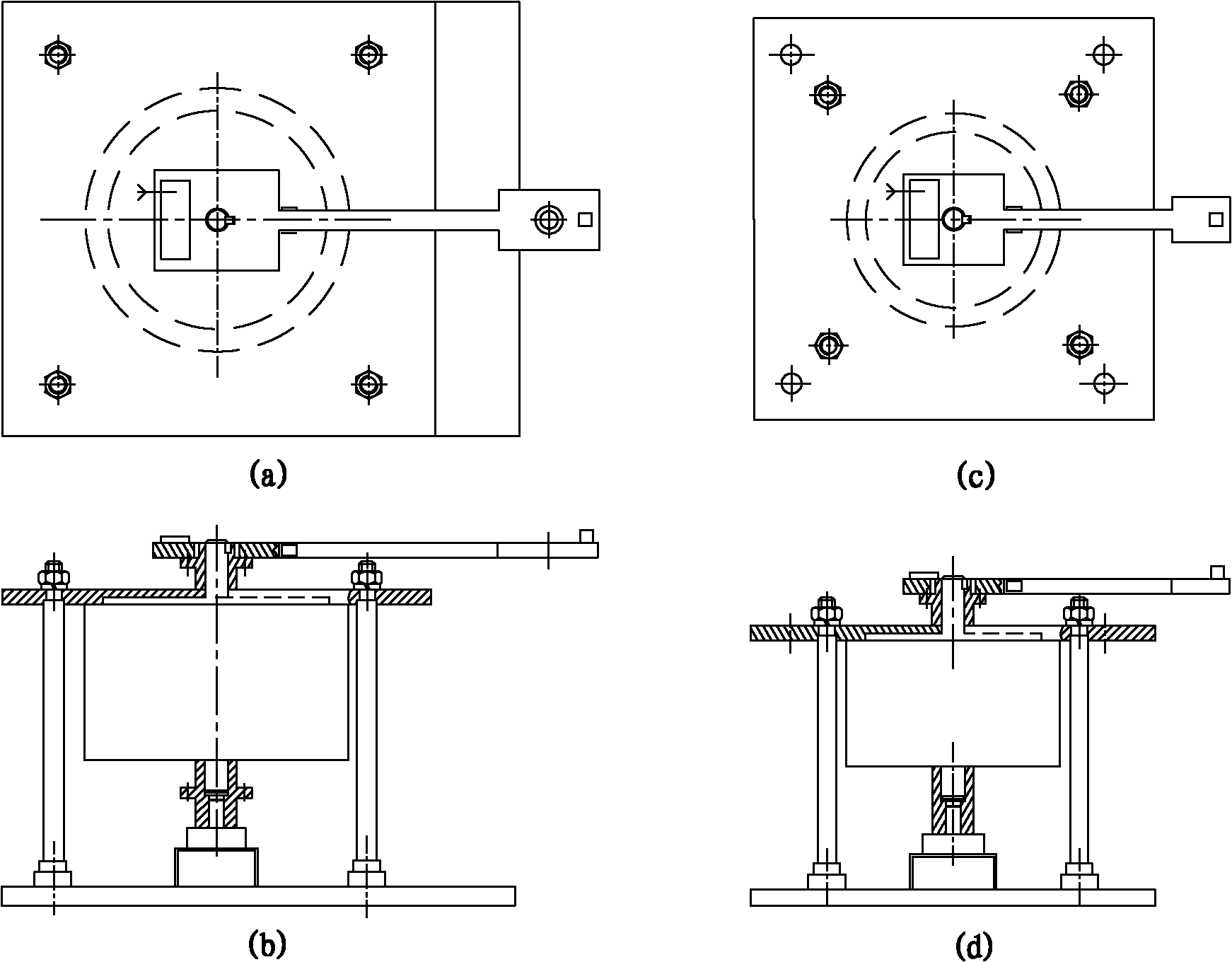

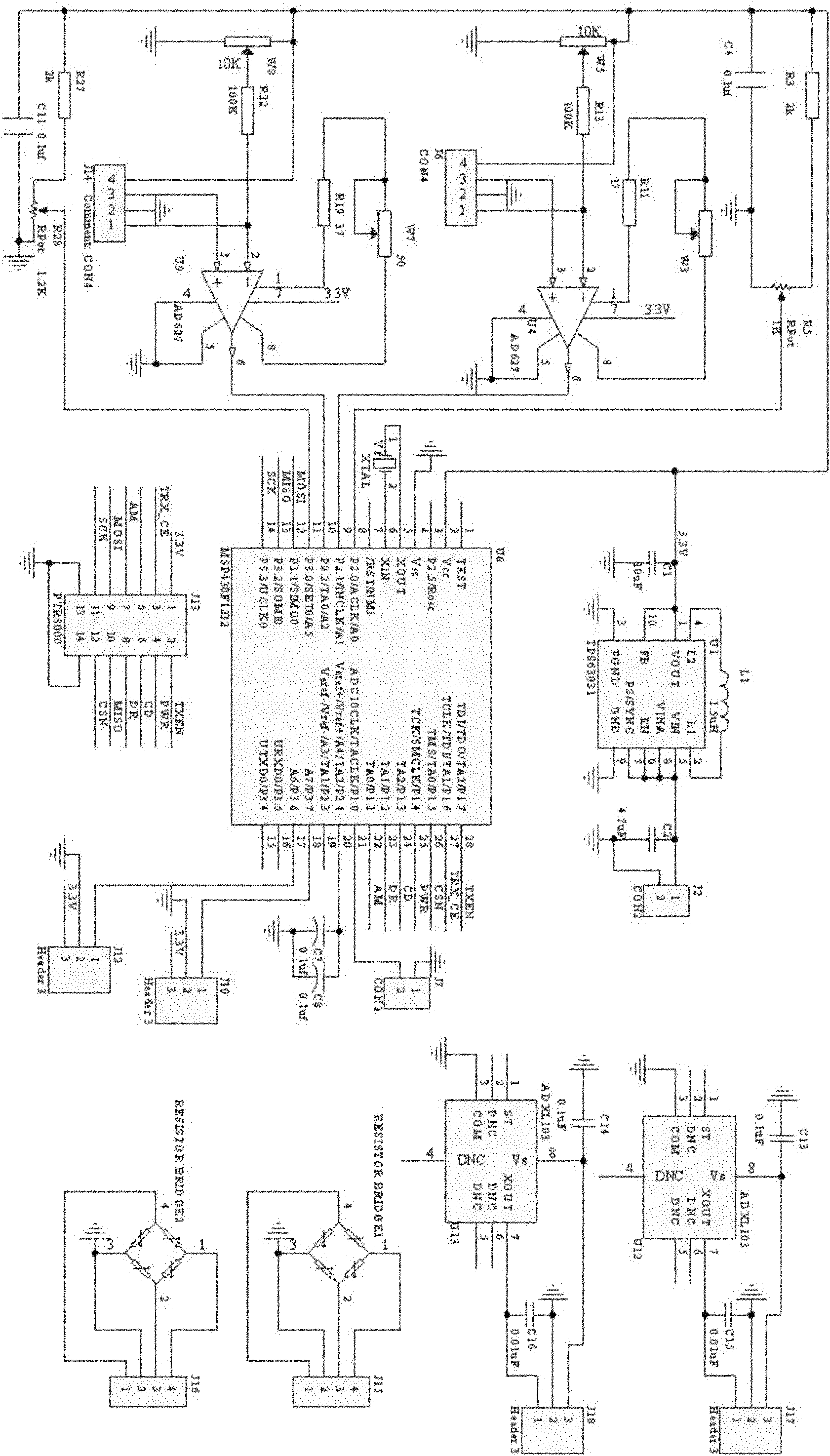

Two-degree of freedom fictitious force feedback device capable of being divided into single-degree of freedom teleoperation devices

InactiveCN101980108AIncrease payload capacityReduce transmissionInput/output for user-computer interactionGraph readingTorque motorFictitious force

The invention discloses a two-degree of freedom fictitious force feedback device capable of being divided into single-degree of freedom teleoperation devices. Four circular stand columns are connected with a faceplate and a bottom plate to form a large rack, and a large-torque motor is perpendicularly and fixedly connected below the faceplate; a large simple pendulum arm with a force sensor and an acceleration sensor is fixedly connected to the upper end of a rotating shaft of the large-torque motor through a first coupling band, and an angular displacement sensor is connected to the lower end of the rotating shaft; four short stand columns of which the lower ends are connected with the circular stand columns support a small rack formed by connecting a small faceplate with a base plate through four small stand columns; a small-torque motor is arranged on the small faceplate positioned below the small rack, and the shaft axes of the large-torque motor and the small-torque motor are coincided with each other; a friction transmission wheel is fixedly connected to a rotating shaft of the small-torque motor through a third coupling band; and the root of a small simple pendulum arm similar to the large simple pendulum arm is fixedly connected to the upper end of a transmission wheel shaft arranged on the end part of the large simple pendulum arm vertically, and the transmission wheel shaft is connected with the friction transmission wheel through a steel wire. The device can be divided into a master single-degree of freedom teleoperation device and a slavery single-degree of freedom teleoperation device, and has the characteristics of dual purpose with one machine and low cost, and is flexible to use and convenient to assemble and disassemble.

Owner:CENT SOUTH UNIV

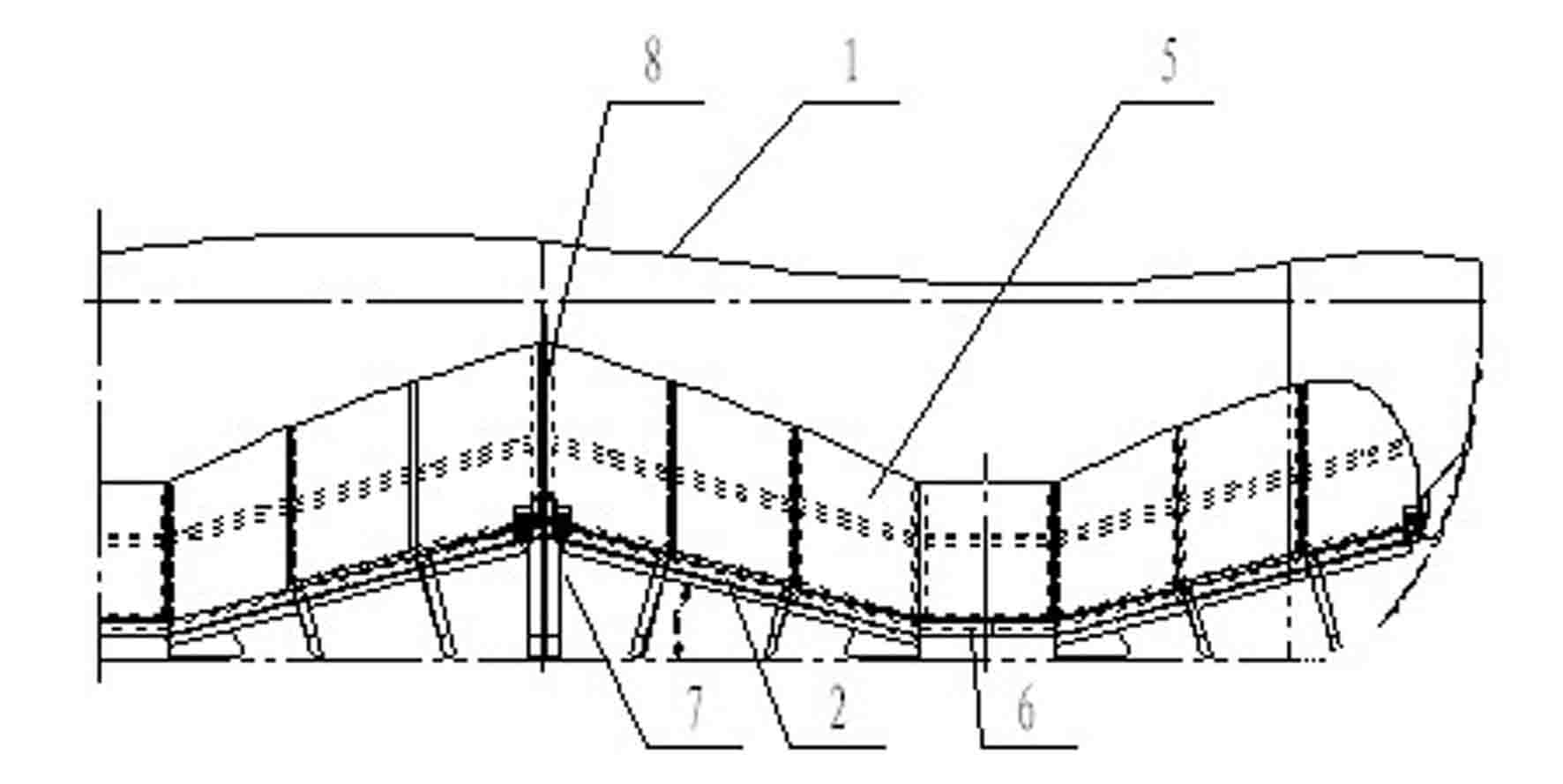

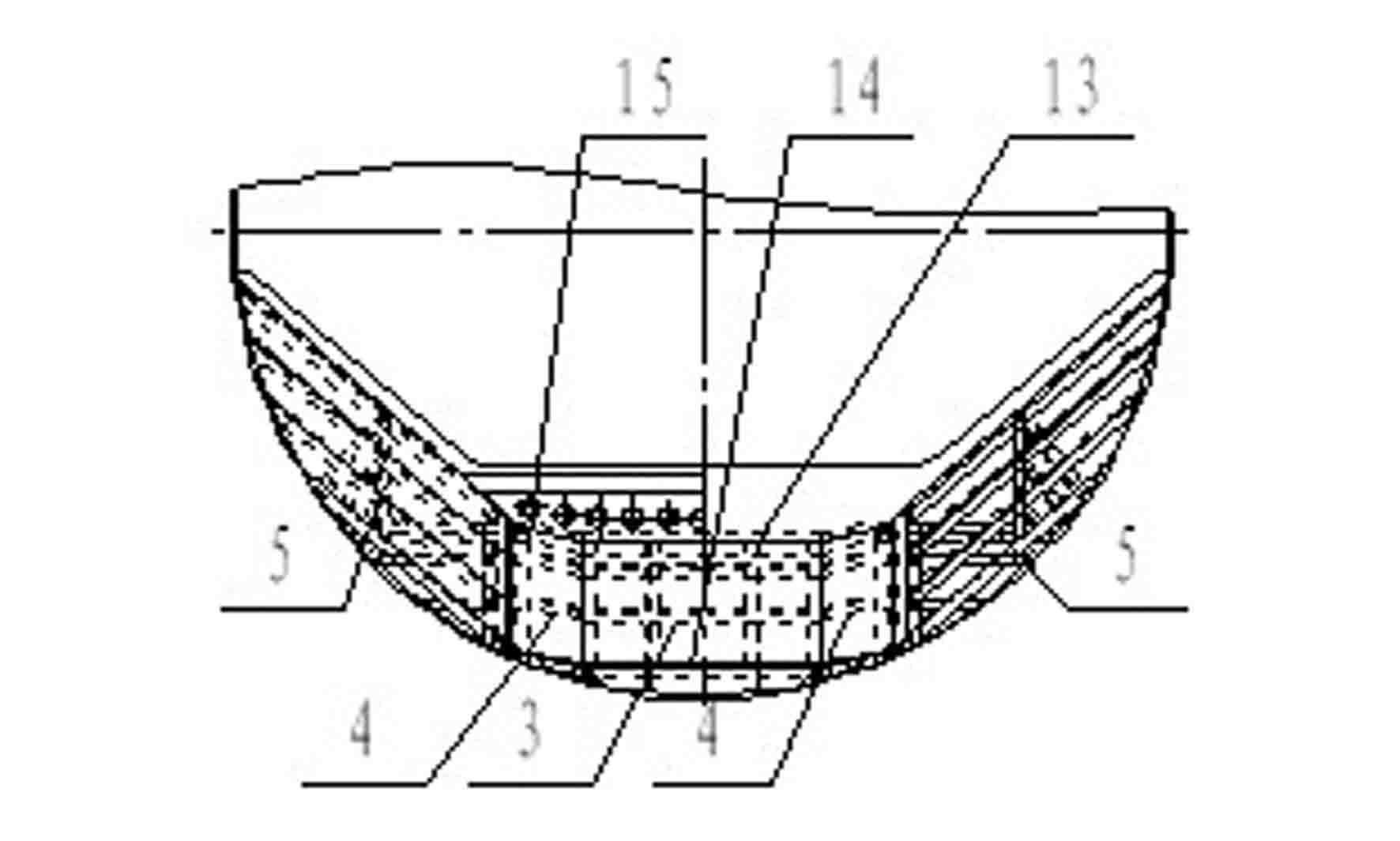

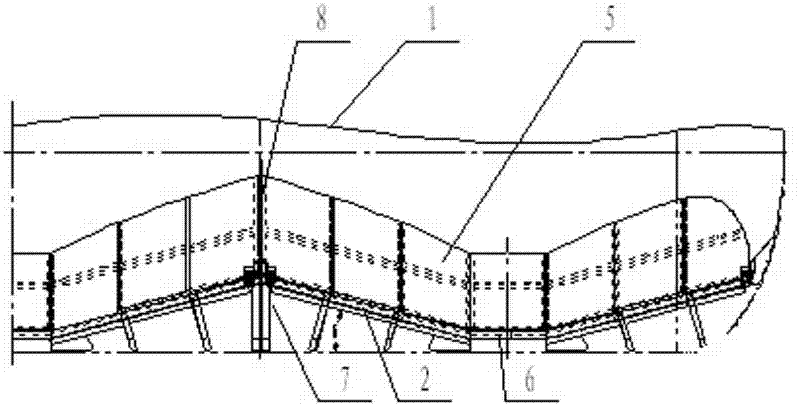

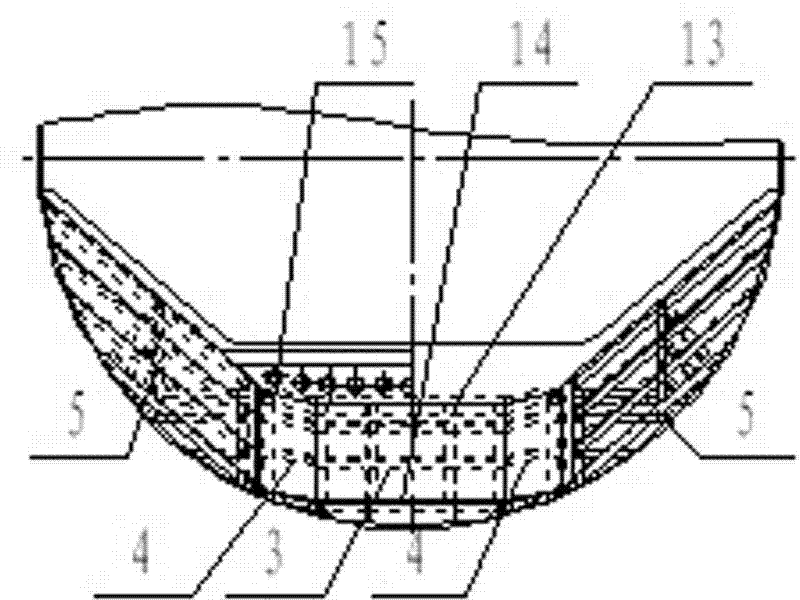

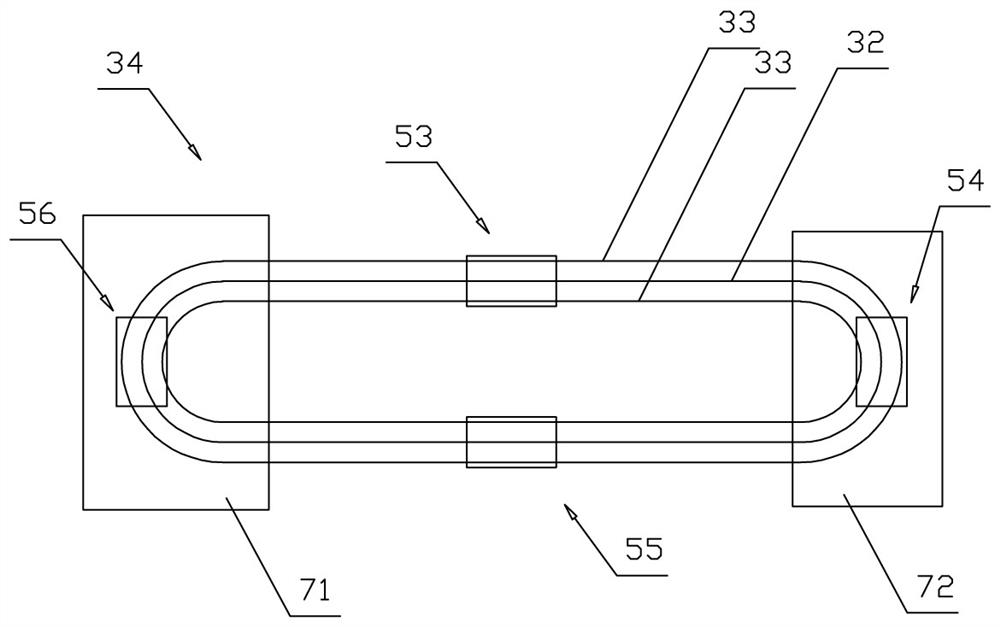

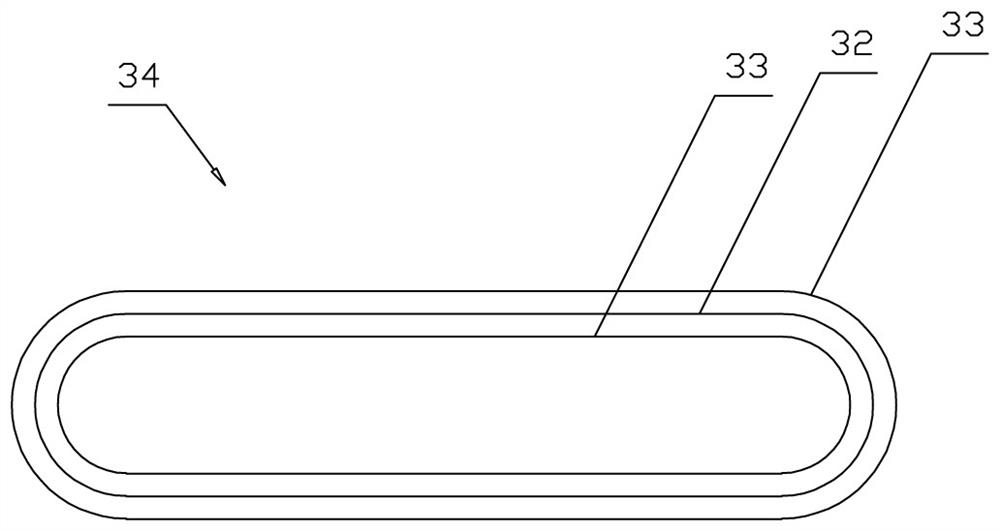

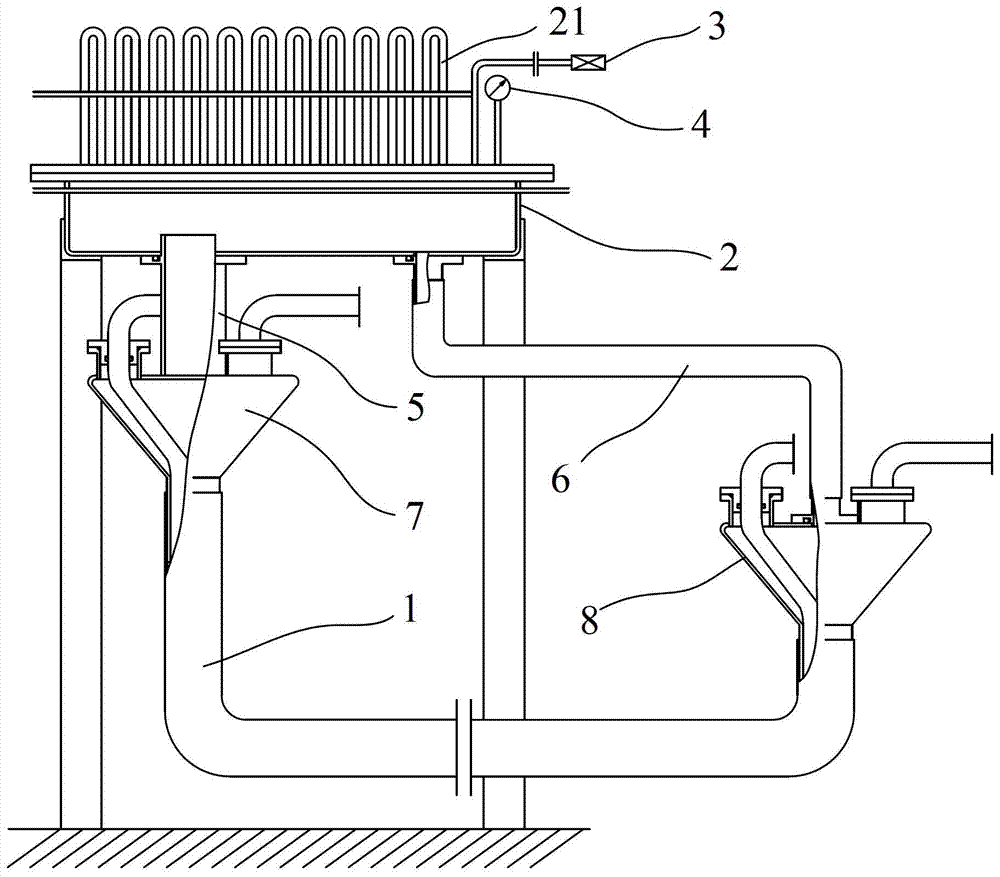

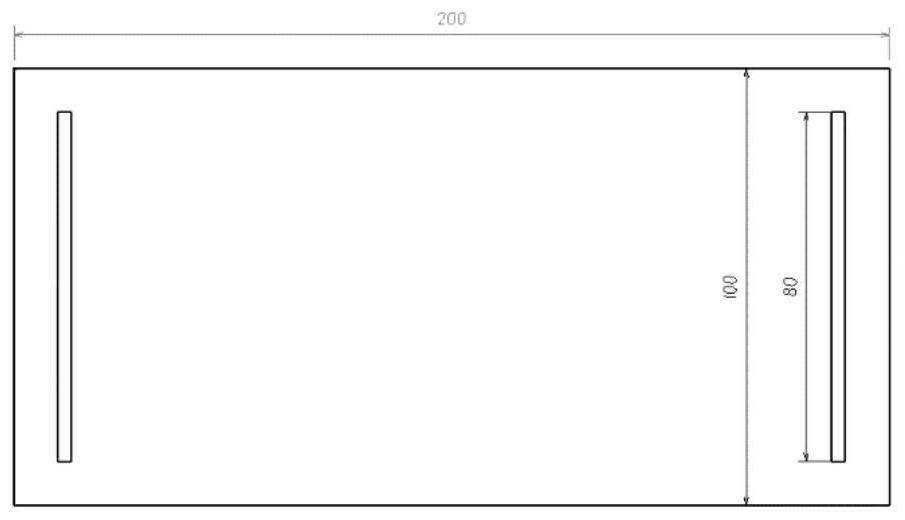

Tubular bag type fluidized bed device for bulk powder material tank truck

ActiveCN101966901ASolve the problems exposed in the applicationReduce void volumeLarge containersTank truckEngineering

The invention relates to a material conveying device, in particular to a tubular bag type fluidized bed device for a bulk powder material tank truck, which overcomes the shortcomings of the conventional large-chute type fluidized bed device. The tubular bag type fluidized bed device comprises a chute type fluidized bed consisting of tilting fluidized bed surfaces, wherein a master air chamber is arranged below the tilting fluidized bed surfaces; each tilting fluidized bed surface comprises a fluidized bed plane, a fluidized bed slope and a lateral bevel board which are laid by fluidized bed components; the fluidized bed component comprises a hollow tube bag type air chamber which is formed by connecting an air permeation layer and an enclosed later and provided with a corrugated lining plate; and one end of the hollow tube bag type air chamber of each fluidized bed component is provided with a blast pipe communicated with the master air chamber and the other end of the hollow tube bag type air chamber is sealed by a trim strip. The fluidized bed device fully utilizes the tank space, reduces the center of gravity for car loaded, increases the load, reduces the tank capacity, increases the effective load volume; increases the fluidization area, facilitates the fluidization of the bulk materials, increases the unloading speed, and has the characteristics of convenience and safety of operation, good working condition and the like.

Owner:CRRC TAIYUAN CO LTD

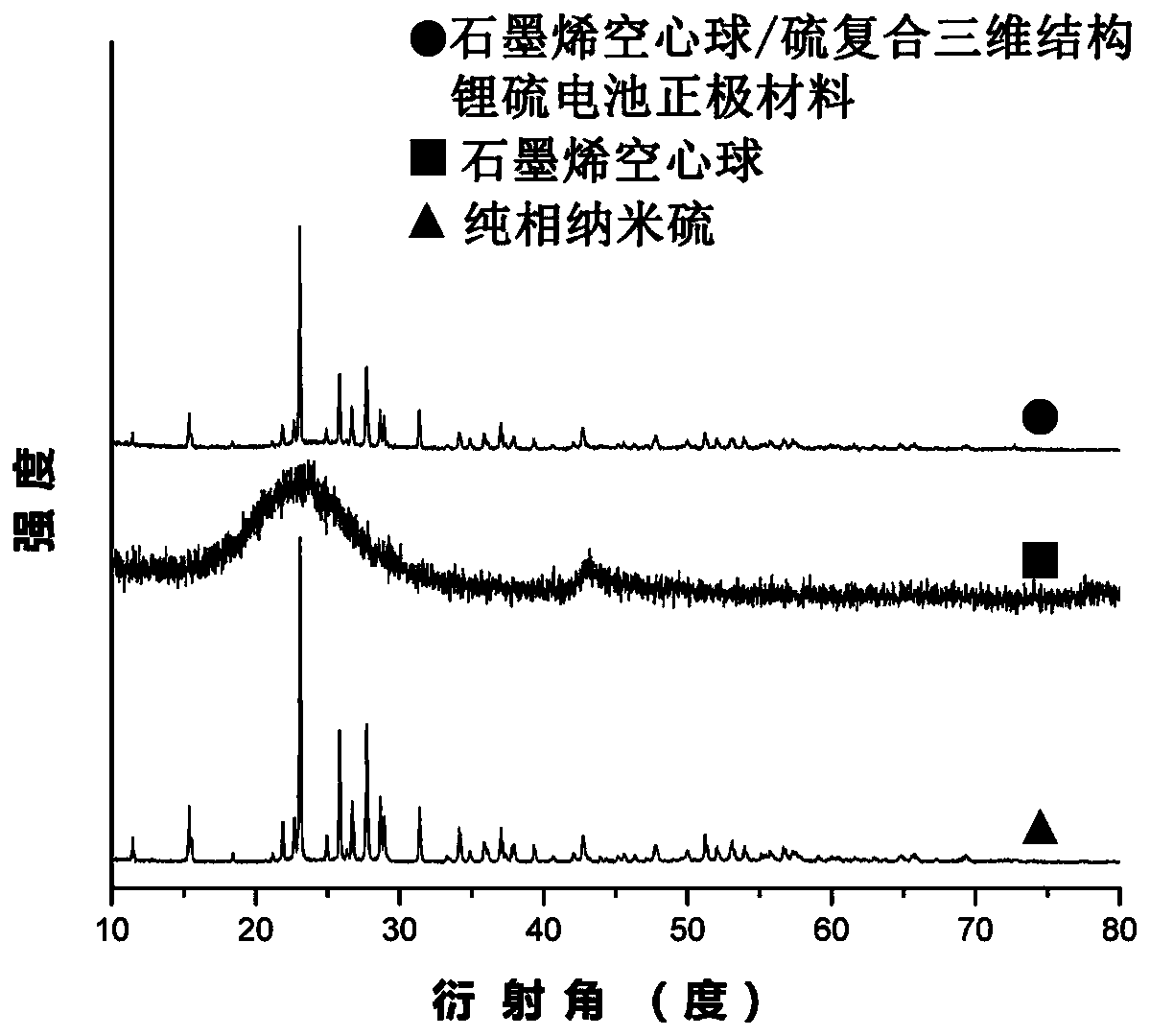

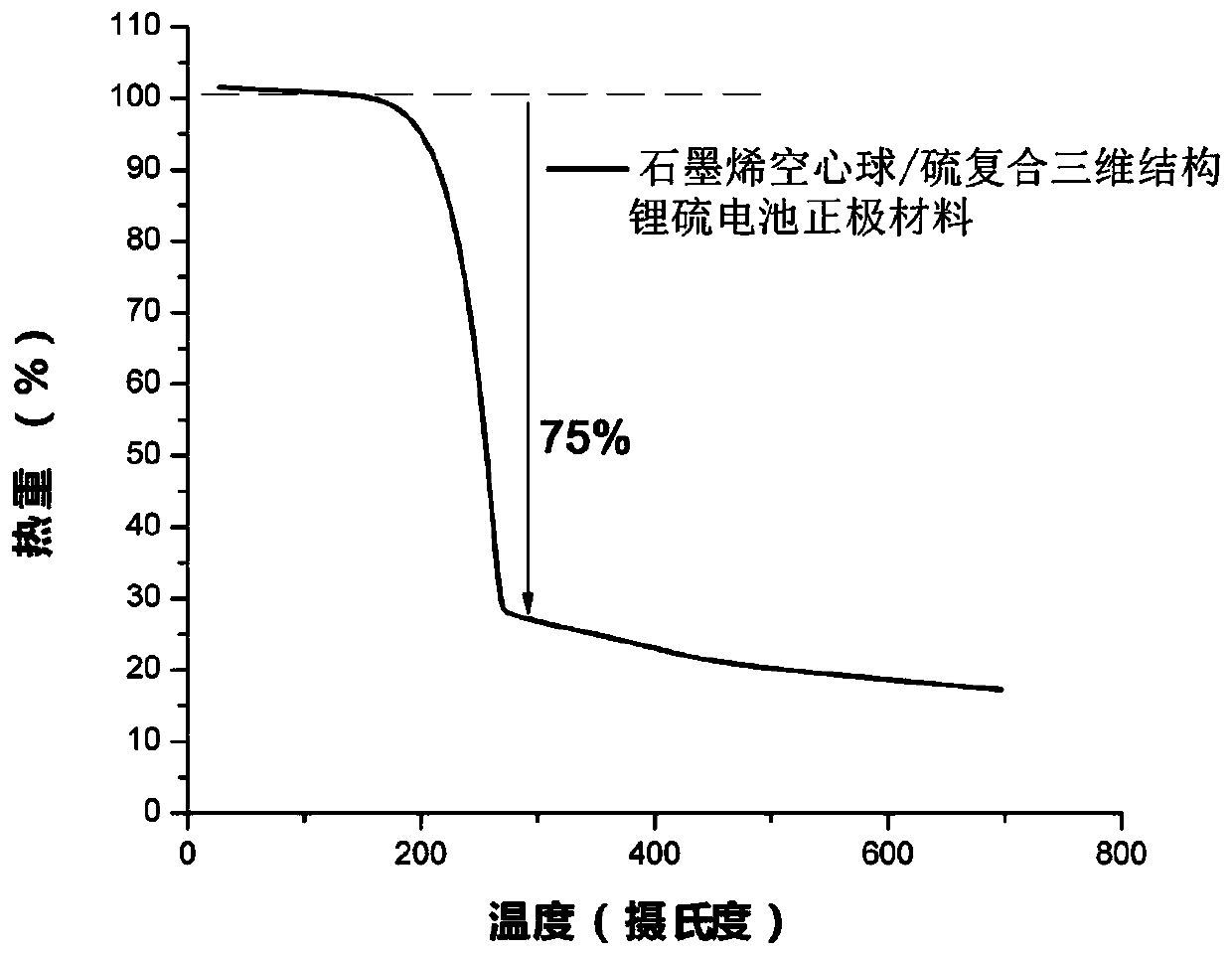

A kind of preparation method of lithium-sulfur battery cathode material

InactiveCN106981649BLow costIncrease productionCell electrodesLi-accumulatorsLithium–sulfur batteryInstability

The invention relates to an electrode composed of active materials, in particular to a lithium-sulfur battery anode material preparation method. Graphene is structurally modified for preparing graphene hollow spheres by a template method and spray drying technology combined pore forming technology, and then ball milling and hot-melt sulfur doping processes are adopted for preparing a graphene hollow sphere-sulfur combined three-dimensional lithium-sulfur battery anode material. Defects of low effective sulfur loading quantity, evident polysulfide 'aero effect', evident lithium-sulfur battery volume expansion effect and battery electrochemical performance instability of lithium-sulfur battery anode materials prepared in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

A kind of catalyst of modified silicon dioxide and its loaded cobalt, preparation method and application

ActiveCN104841434BIncrease payload capacityGood dispersionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsCobalt(II,III) oxideSilicon dioxide

A modified silicon dioxide and its cobalt-loaded catalyst, its preparation method and application. A Fischer-Tropsch synthesis catalyst for modified silicon dioxide and its loaded cobalt, characterized in that the catalyst is made up of tricobalt tetroxide and modified silicon dioxide, wherein the mol ratio of silicate and silicon dioxide in the modified silicon dioxide is 1: 6.25~25, the weight composition of tricobalt tetroxide accounts for 10%~40% of the final catalyst. The catalyst of the invention has the advantages of high activity and high stability when used in Fischer-Tropsch synthesis reaction.

Owner:中科潞安能源技术有限公司

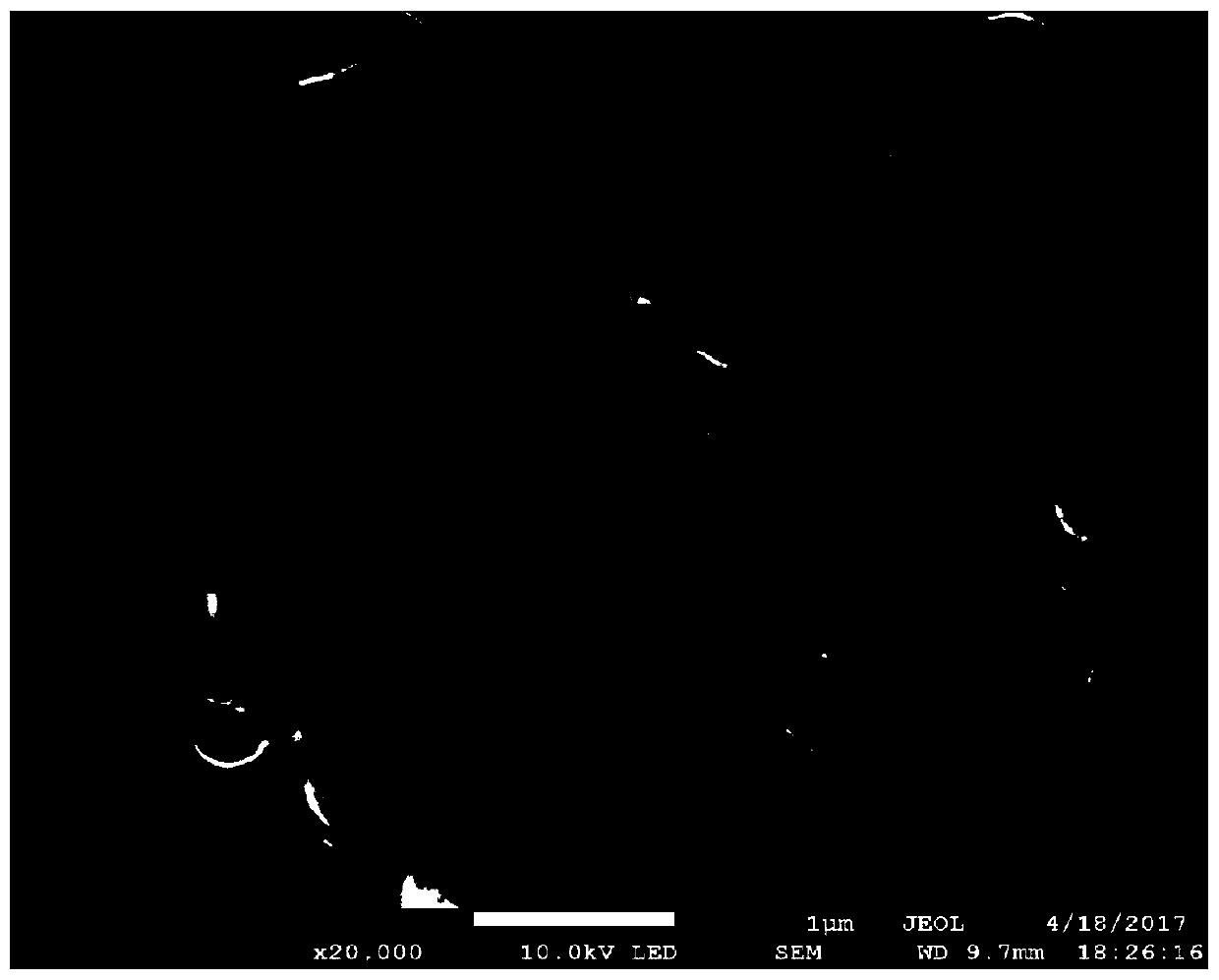

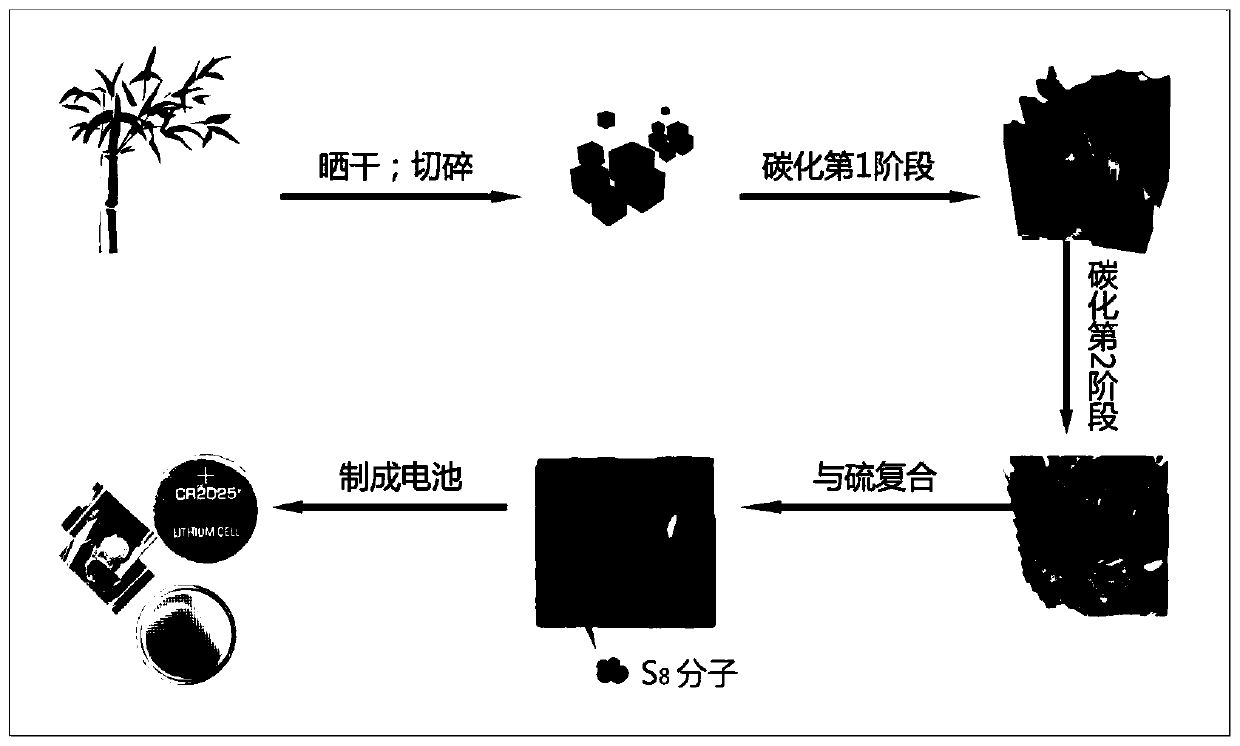

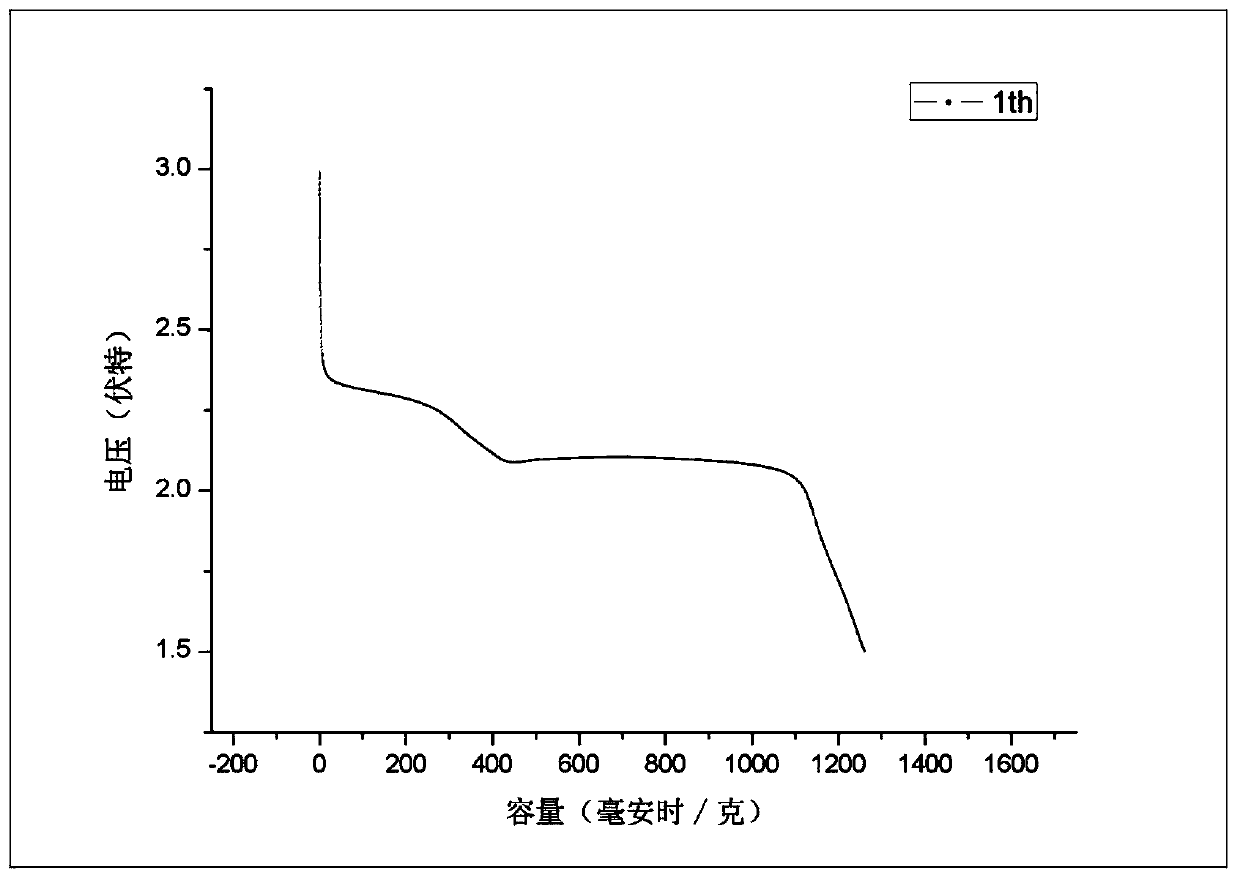

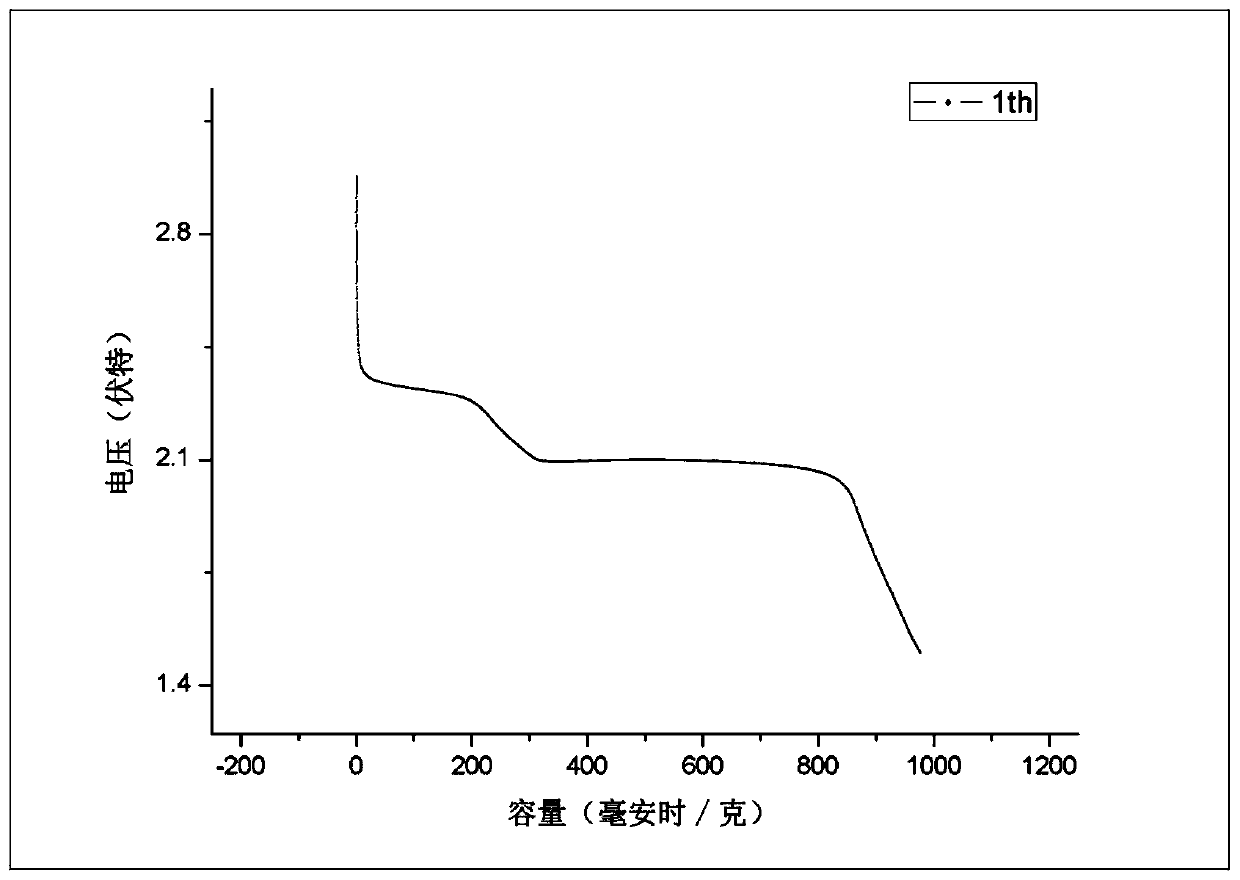

Preparation method of active bamboo charcoal/sulfur composite material and application thereof

InactiveCN110085817AHighlight substantiveSolve complexityCell electrodesNon-aqueous electrolyte cellsDischarge efficiencyReaction temperature

The invention relates to a preparation method of an active bamboo charcoal / sulfur composite material and an application thereof. The method comprises steps that S1, the active bamboo charcoal is prepared; and S2, the active bamboo charcoal / sulfur composite material is prepared, the activated bamboo charcoal and the nano-sulfur powder are placed in a ball mill for ball milling for 2-4 hours, the mixture obtained by ball milling is then placed in a reaction vessel taking polytetrafluoroethylene as a substrate for heating and insulation, the reaction time is 10-20 hours, the reaction temperatureis 100-300 DEG C, and the active bamboo charcoal / sulfur composite lithium sulfur battery cathode material is obtained. The method is advantaged in that problems of poor conductivity, severe volume expansion and low sulfur loading of the lithium sulfur primary battery anode material can be effectively solved, discharge efficiency, safety performance and energy density of a lithium sulfur primary battery are improved as a whole, and the shortcoming that the existing battery capacity in the lithium battery technology in the prior art is relatively low is overcome.

Owner:深圳市高能达电池有限公司

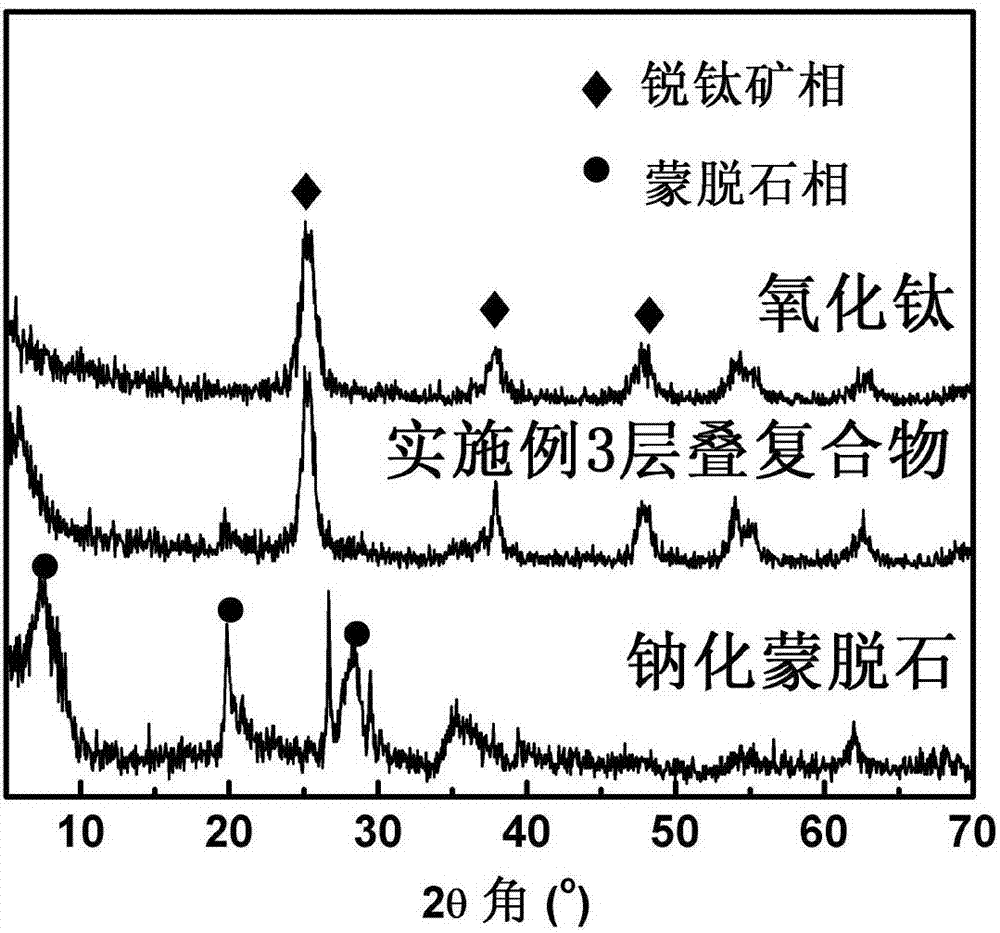

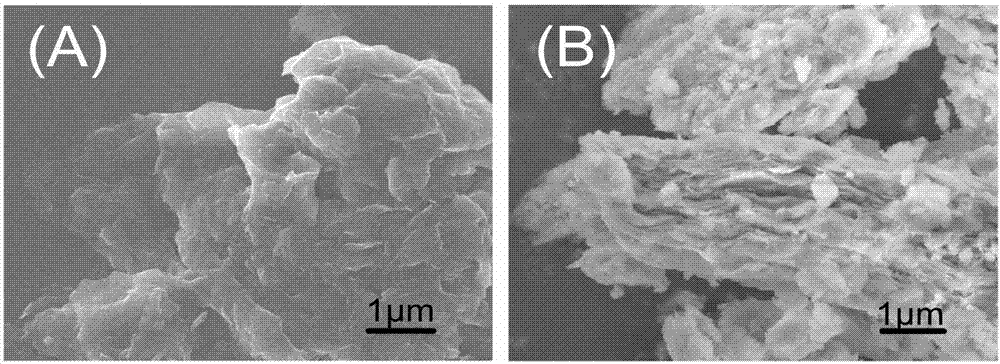

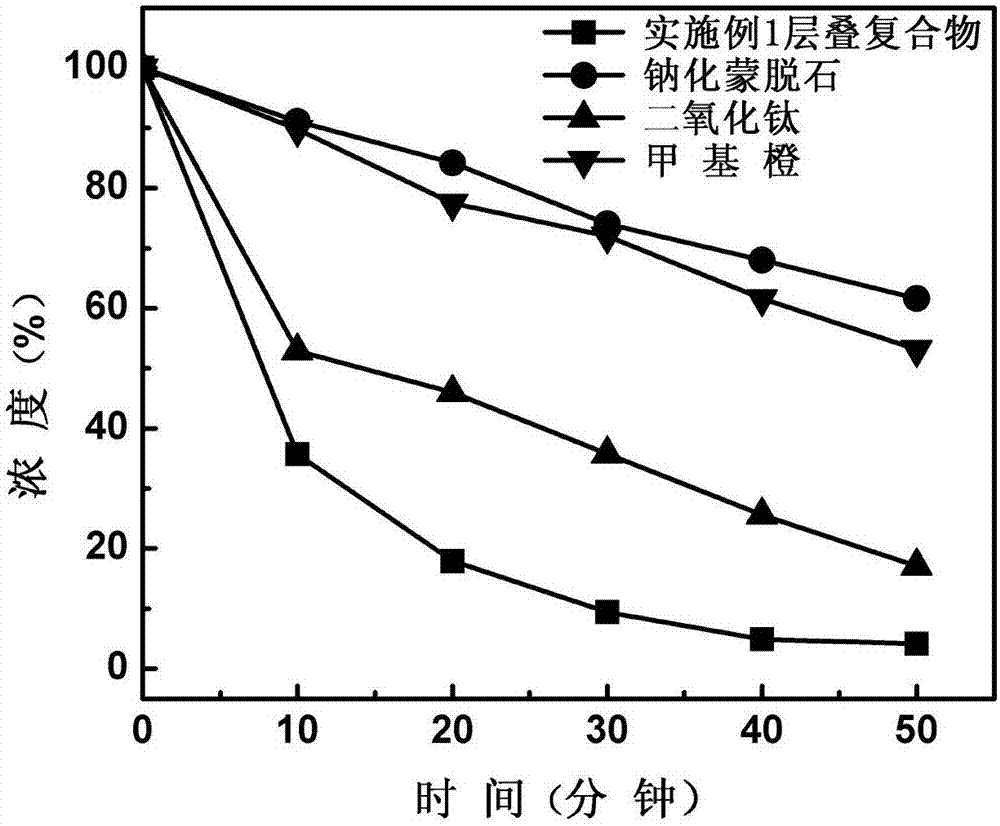

Laminated composite material of anatase and montmorillonite and preparation method thereof

ActiveCN107469801AIncrease payload capacityIncrease loadWater/sewage treatment by irradiationWater treatment compoundsSlurryTitanium oxide

The invention belongs to the field of mineral-based composite materials, and particularly relates to a laminated composite material of anatase and montmorillonite obtained from the process of regulating montmorillonite micro layer recombination by means of an acid-base environment, and a preparation method thereof. Firstly, a titanium-containing precursor slurry with the pH value of 6-10 is dropped into an alkaline dispersion liquid of sodium-modified montmorillonite, then the pH value of the system is adjusted to be 3-6, a hydrothermal reaction is conducted at 120-220 DEG C so as to realize the crystallization of titanium oxide and the laminated and alternated assembly of montmorillonite microlayers and anatase, and the obtained composite has excellent catalytic and adsorption functions. The method has the advantages that the process is simple, raw materials are cheap, no organic additive or organic titanium source is used, calcination is not needed, the environmental cost is low, the cost performance of the product is high, large-scale industrial production can be realized, and the obtained product has broad application prospects in the fields like catalysis, adsorption and sewage treatment.

Owner:JILIN UNIV

Processing treatment method of catalytic diesel oil

ActiveCN108102703AIdeal comprehensive processing effectLow operating costTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineHydrocarbon

The invention discloses a processing treatment method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected tohydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is separated, a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained, the obtained triaromatic hydrocarbon component is subjected to hydrofining and hydroconversion, and a gasoline component and a diesel oil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that inferior catalytic cracking diesel oil can be reasonably used to produce qualified gasoline anddiesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tubular bag type fluidized bed device for bulk powder material tank truck

ActiveCN101966901BSolve the problems exposed in the applicationReduce void volumeLarge containersTank truckEngineering

The invention relates to a material conveying device, in particular to a tubular bag type fluidized bed device for a bulk powder material tank truck, which overcomes the shortcomings of the conventional large-chute type fluidized bed device. The tubular bag type fluidized bed device comprises a chute type fluidized bed consisting of tilting fluidized bed surfaces, wherein a master air chamber is arranged below the tilting fluidized bed surfaces; each tilting fluidized bed surface comprises a fluidized bed plane, a fluidized bed slope and a lateral bevel board which are laid by fluidized bed components; the fluidized bed component comprises a hollow tube bag type air chamber which is formed by connecting an air permeation layer and an enclosed later and provided with a corrugated lining plate; and one end of the hollow tube bag type air chamber of each fluidized bed component is provided with a blast pipe communicated with the master air chamber and the other end of the hollow tube bagtype air chamber is sealed by a trim strip. The fluidized bed device fully utilizes the tank space, reduces the center of gravity for car loaded, increases the load, reduces the tank capacity, increases the effective load volume; increases the fluidization area, facilitates the fluidization of the bulk materials, increases the unloading speed, and has the characteristics of convenience and safetyof operation, good working condition and the like.

Owner:CRRC TAIYUAN CO LTD

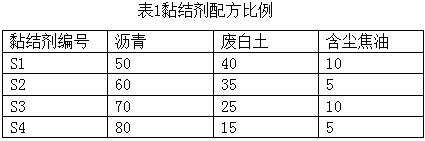

Preparation method of gasification formed coke used for Lurgi furnace

InactiveCN110564473AHigh mechanical strengthImprove thermal stabilitySolid fuelsGasification processes detailsAdhesiveCarbonization

The invention relates to the technical field of coal gasification production, and discloses a preparation method of gasification formed coke for a Lurgi furnace. The method specifically comprises thefollowing steps: pulverized coal with the particle size smaller than 3 mm is taken as a raw material, a coal gasification catalyst and the pulverized coal are mixed, and an adhesive is added to obtaina mixture, wherein the weight of the adhesive is 3-12% of that of the pulverized coal; and graphite is pressed into blocks, the mixture and the graphite are bonded together through carbonization, wherein the carbonization heating rate is 3-10 DEG C / min, the final temperature is 800-900 DEG C, and the constant-temperature time is 1-2 hours. According to the method provided by the invention, the graphite is used as a carrier to effectively react with formed coke, so that coal ash is reduced, the tail water treatment difficulty is reduced, the coal gasification conversion efficiency can be improved, and the prepared formed coke has the characteristics of high mechanical strength, high thermal stability and high reaction activity.

Owner:SHANXI LUAN COAL BASED SYNTHETIC OIL +1

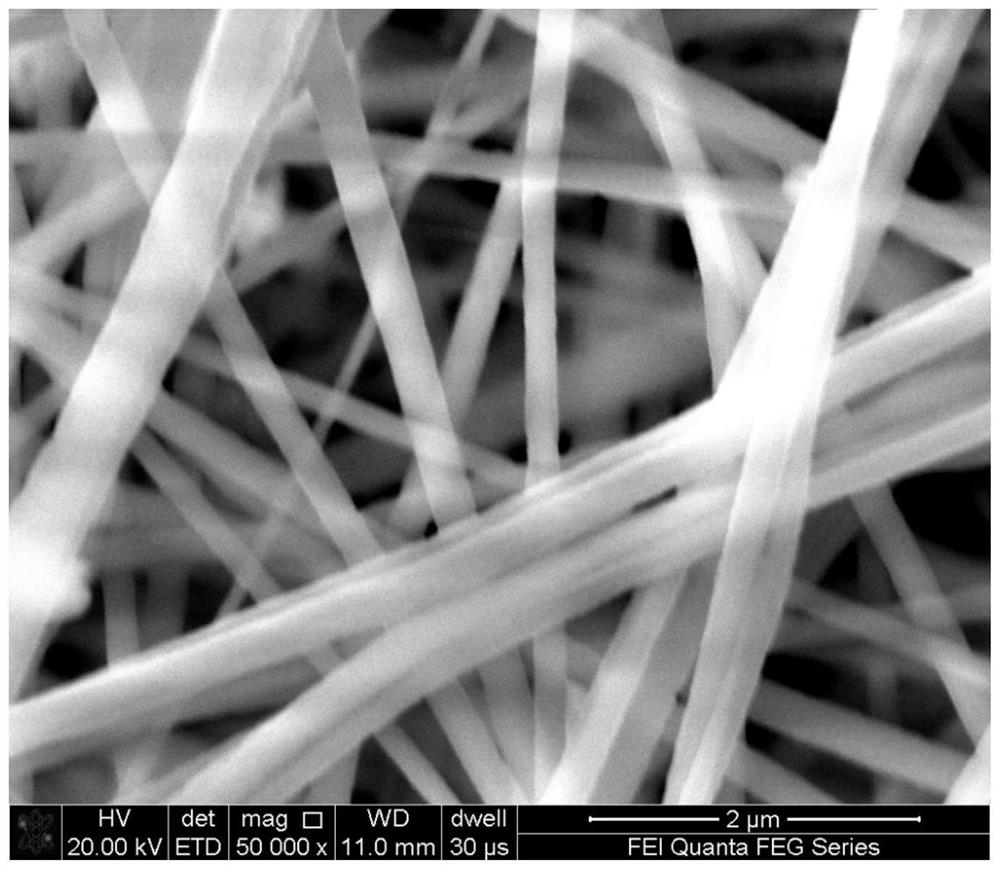

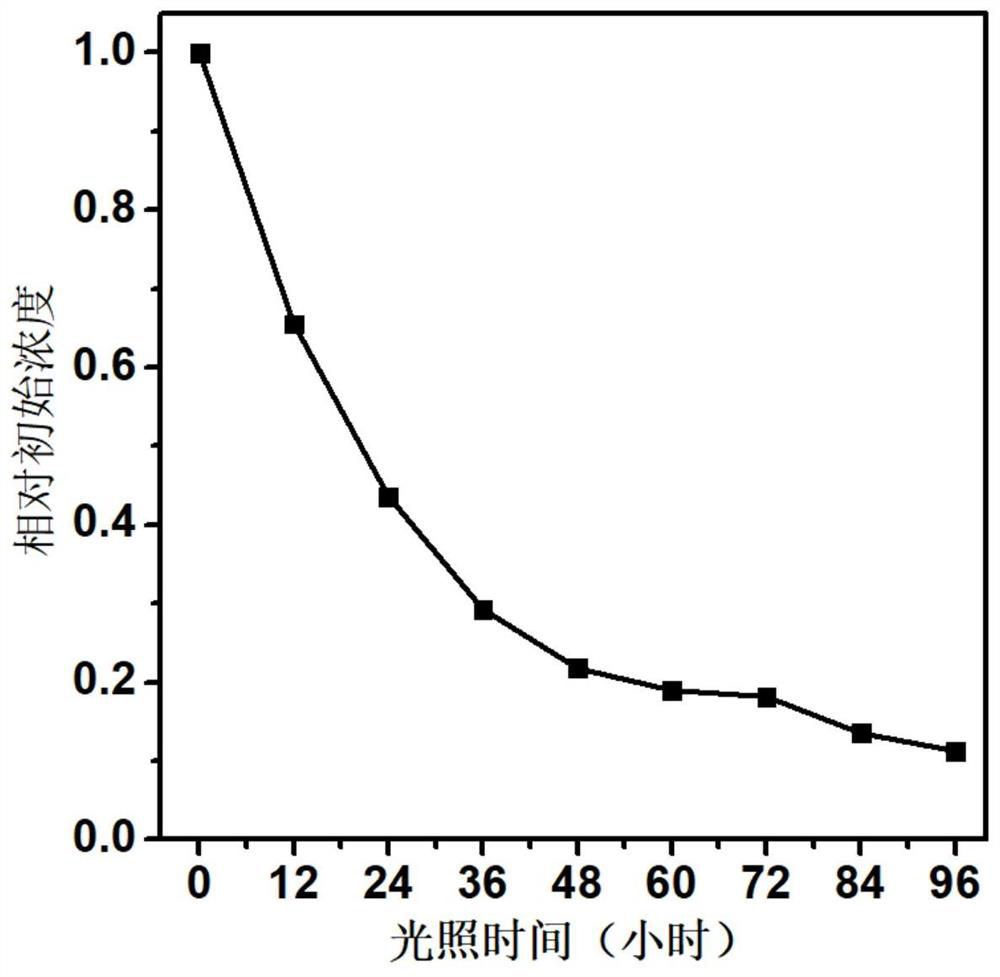

Photocatalytic fabric as well as preparation method and application thereof

ActiveCN113337900AImprove universalityEasy to synthesizeGas treatmentWater/sewage treatment by irradiationFiberSpinning

The invention discloses a photocatalytic fabric as well as a preparation method and application thereof, and belongs to the technical field of material chemistry and photocatalysis. The preparation method comprises the following steps of dissolving a metal precursor, a ligand and a polymer in a solvent together to obtain a spinning solution; and spinning the spinning solution into a fabric to obtain the fabric with the photocatalytic function. A metal complex catalyst in the photocatalytic fabric prepared by the invention is uniformly loaded on the surface of the fiber, the loading capacity is large, and the photocatalytic fabric has excellent visible light catalytic activity, is simple to synthesize, low in cost, non-toxic, environment-friendly and stable in physicochemical property, and has relatively high photocatalytic degradation efficiency when being applied to treatment of micro-polluted water or volatile organic compounds; and the method is compatible with an industrial fabric manufacturing process and has the potential of industrial mass production.

Owner:XI AN JIAOTONG UNIV

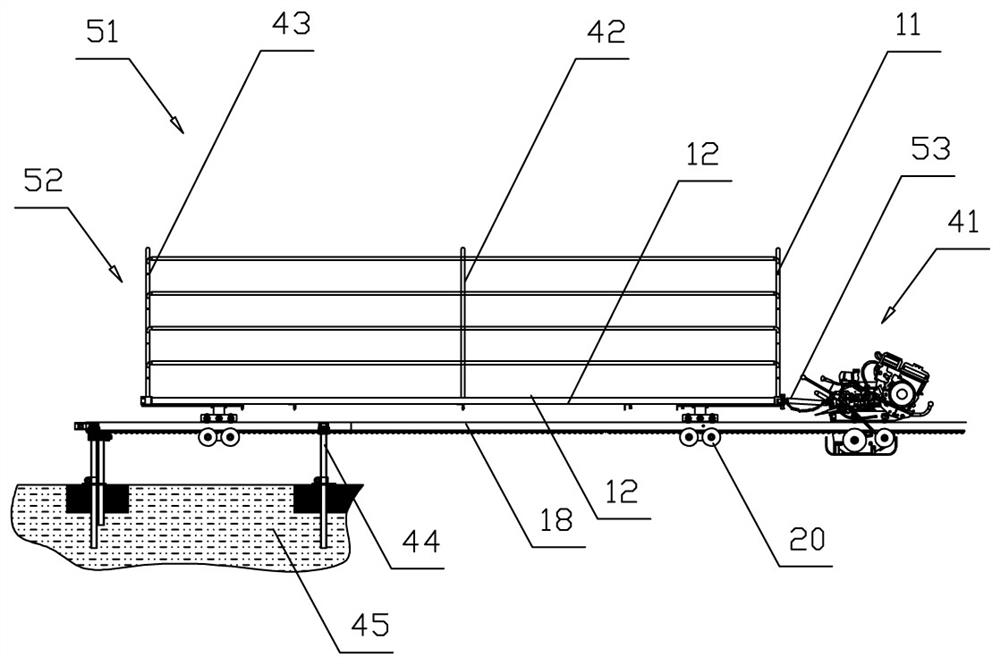

High-transport-capacity and high-efficiency rail transport vehicle and totally-closed breeding system

PendingCN113147797AIncrease capacityImprove transportation efficiencyMonorailsClimate change adaptationAnimal scienceDraft animals

The invention discloses a high-transport-capacity and high-efficiency rail transport vehicle and a totally-closed breeding system. The system comprises at least one breeding area used for breeding livestock and a rail transport vehicle connected with the breeding area. According to the invention, by arranging the rail transport vehicle to transport livestock in the breeding area, on the one hand, the working efficiency of transportation is improved; on the other hand, compared with transportation through a motor vehicle, the rail transportation vehicle is used for reducing dust generated in the transportation process in the breeding area, healthy growth of livestock in the breeding area is protected, the morbidity rate of the livestock is reduced, and the yield of the livestock is increased.

Owner:FUZHOU LIANGZHENG MACHINERY

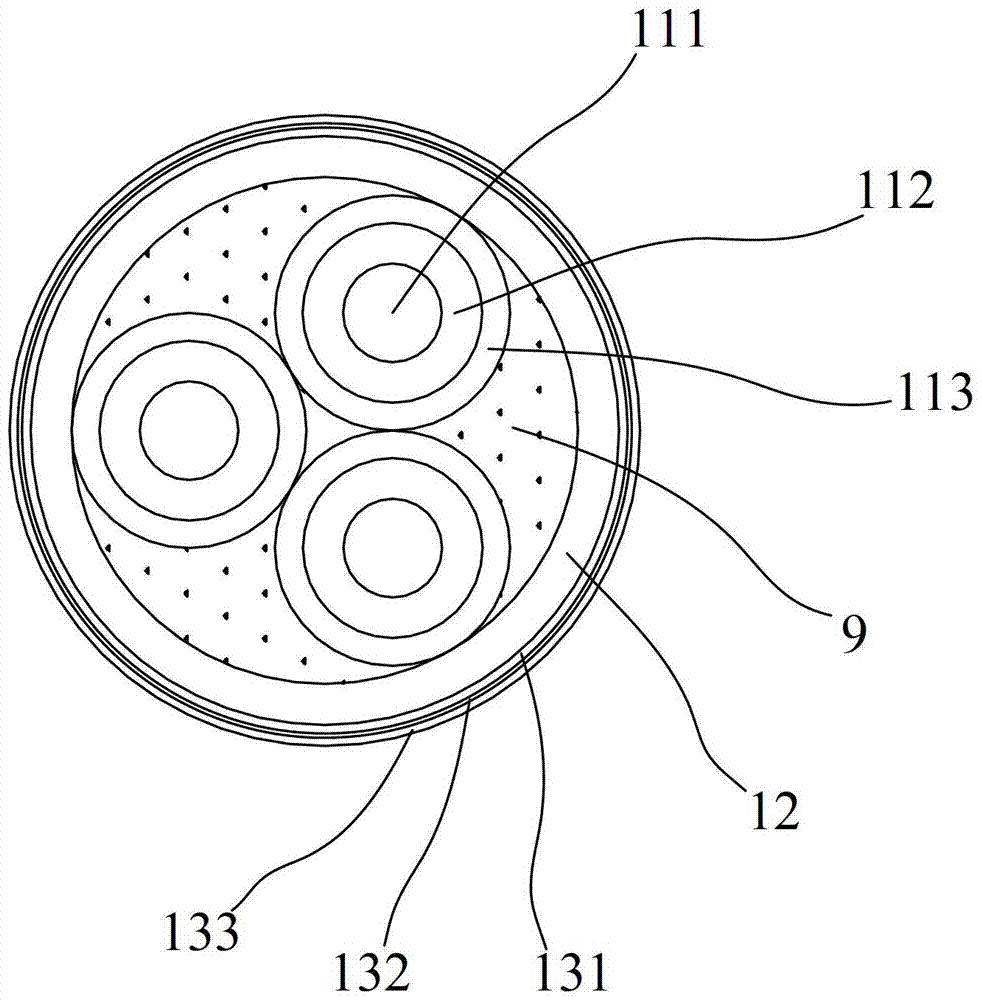

Evaporative internal cooling multi-core cable circulation system

ActiveCN104282383BEffective coolingEffectively helps to dissipate heatPower cables with screens/conductive layersInsulated cablesCarrying capacityEvaporation

The invention discloses an evaporative internal cooling multi-core cable circulation system, which comprises a cable containing cooling liquid and a cable cooling device, the cable cooling device includes an evaporation tank with a condensing part, one end of the cable It communicates with the evaporation tank through an evaporation connecting pipe, and the evaporation tank communicates with the other end of the cable through a return pipe. Through the application of the present invention, it can effectively help the cable to dissipate heat, thereby increasing the durability of the cable and improving the effective carrying capacity of the cable.

Owner:高桥防火科技股份有限公司

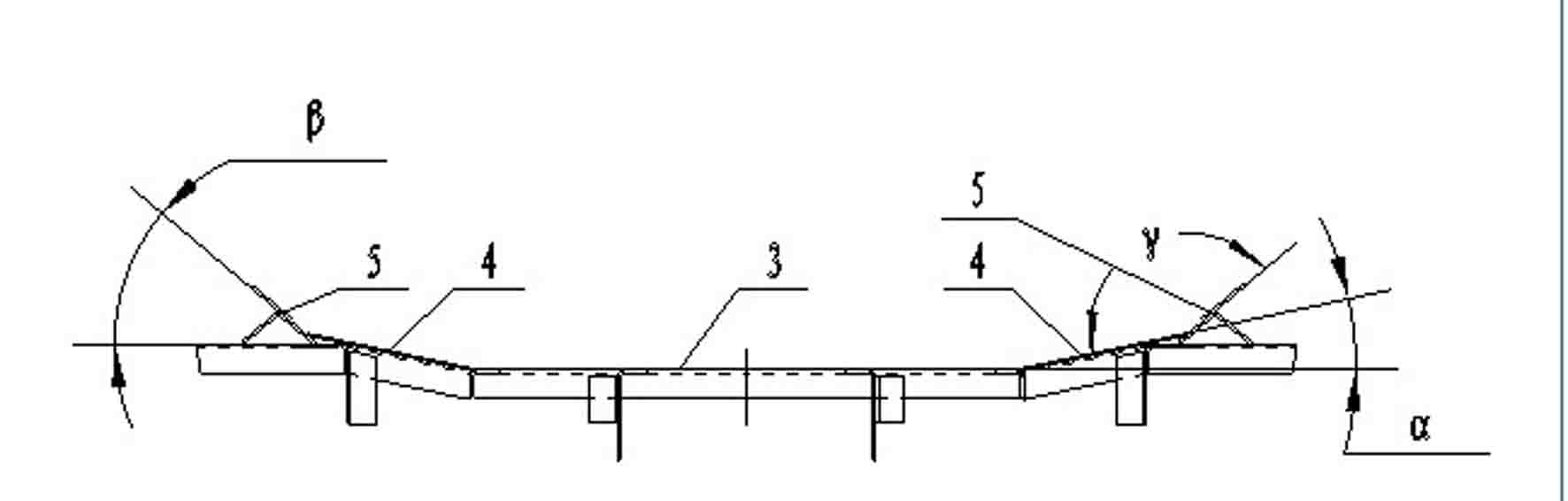

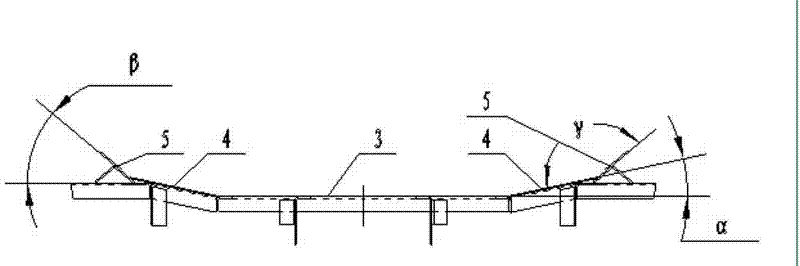

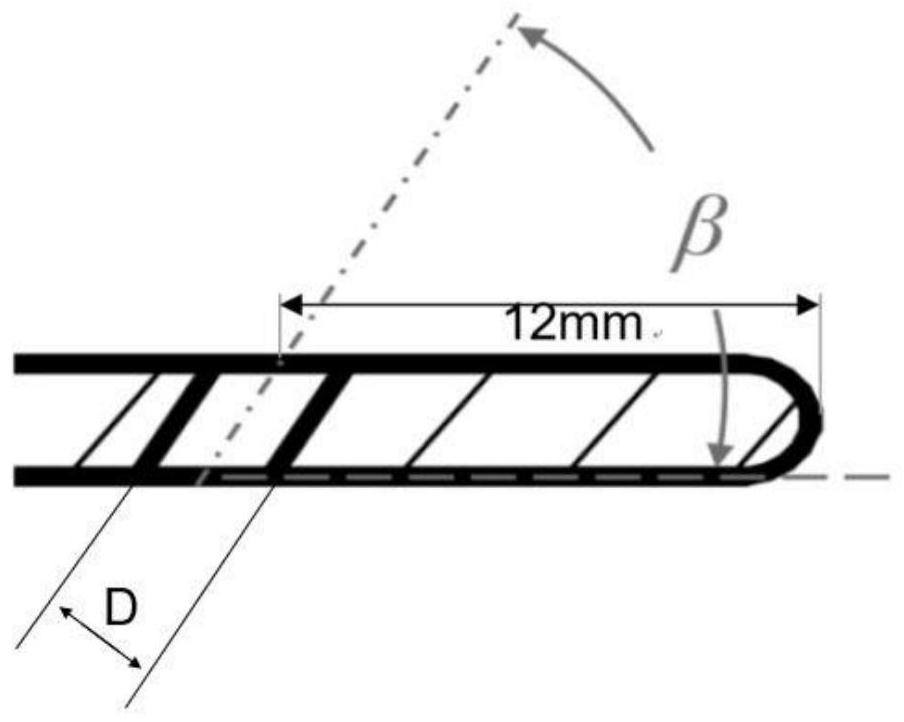

A micro-drone using chute bleed air wings

ActiveCN109050877BReduce or suppress large-amplitude self-induced roll oscillationsImprove aerodynamic performanceAll-wing aircraftBoundary layer controlsLeading edgeClassical mechanics

The invention proposes a novel miniature unmanned aerial vehicle using chute bleed air wings, which belongs to the field of miniature unmanned aerial vehicles. The invention comprises: a chute, a wing, a power system and a steering surface; wherein, the wing is a traditional rectangular wing, and chutes are processed at the wingtips on both sides of the wing; the width D of the chute is between 3 mm and 10 mm, The azimuth angle β of the chute changes from 30° to 150°; the power system is a pair of propeller engines, including two symmetrically installed propellers and motor drives, which are directly installed at the leading edge of the wing; the control surface includes a pair of Ailerons mounted symmetrically at the trailing edge of the wing. A new type of micro UAV using a chute bleed air wing proposed by the present invention can effectively suppress the self-induced roll oscillation phenomenon at a high angle of attack by using the chute bleed air wing as a new type of wing plane. And the structure is simple, and the design and processing are convenient.

Owner:BEIHANG UNIV

Method for producing high-quality gasoline and diesel oil by catalyzing diesel oil

ActiveCN109777494BIncrease saturation rateHigh selectivityTreatment with hydrotreatment processesReaction temperatureEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

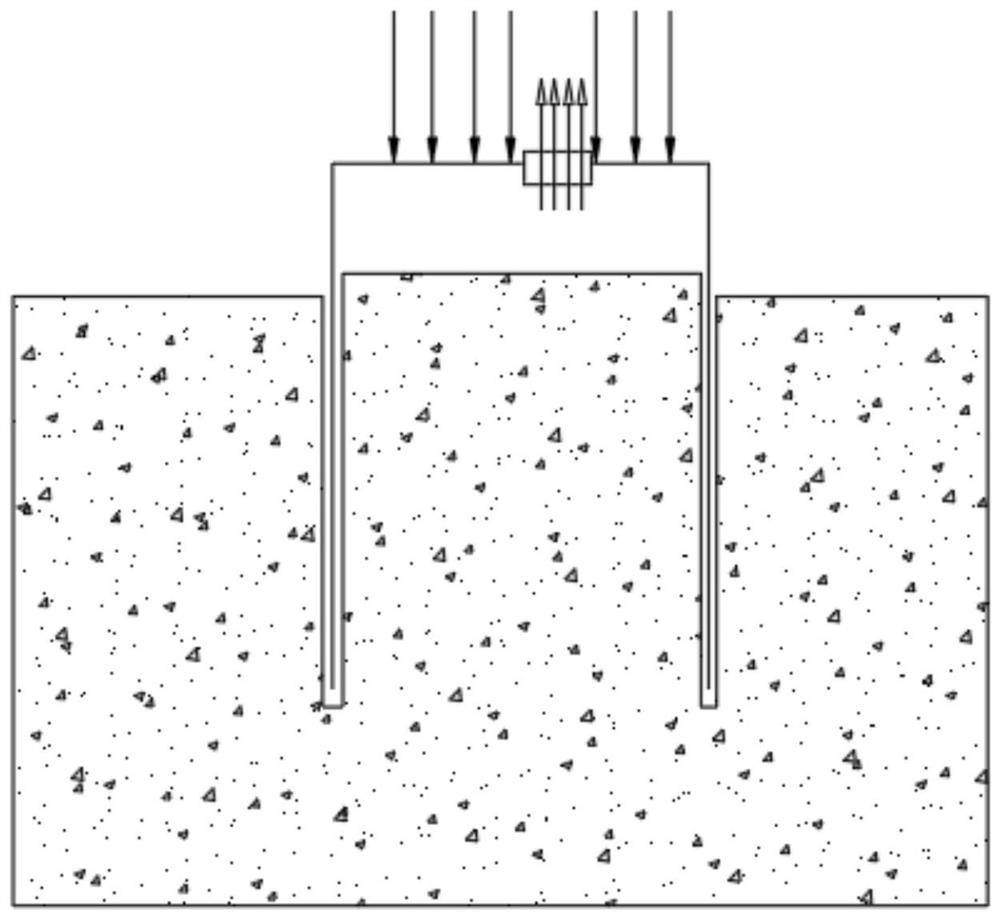

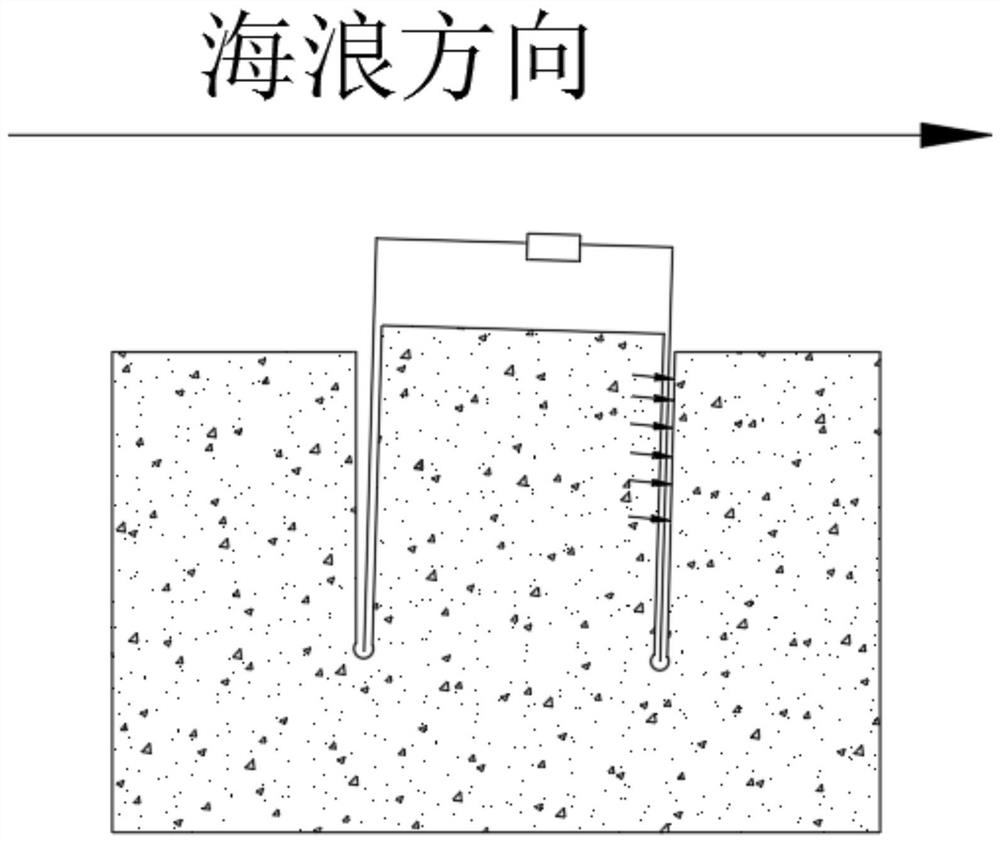

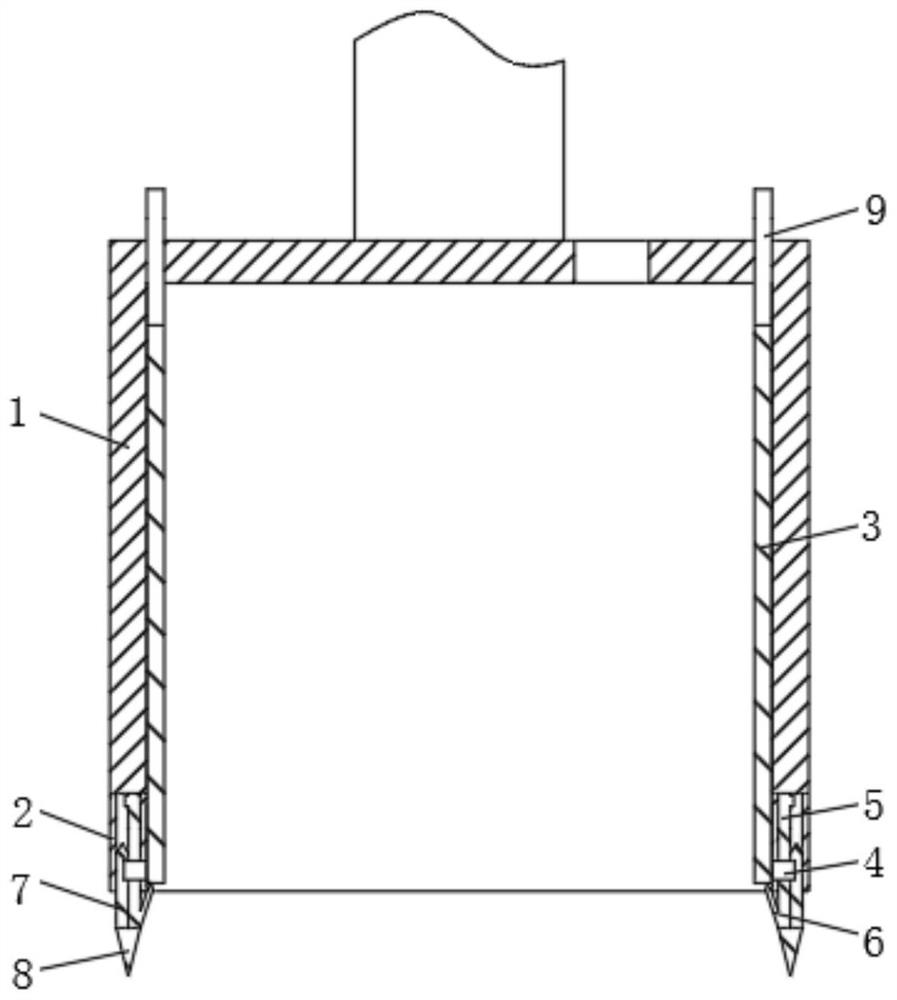

A suction type cylindrical foundation

ActiveCN110241839BIncrease payload capacityAvoid leaningFoundation engineeringSuction forceStructural engineering

The invention relates to the technical field of marine engineering equipment, and discloses a suction cylindrical foundation, which includes a cylinder body, an auxiliary cylinder is provided at the lower end of the cylinder body, movable ribs are provided on the inner wall of the cylinder body, and the auxiliary cylinder A connecting rod is provided at a position corresponding to the movable rib. The tips of the inner fixing claws, outer fixing claws and bottom fixing claws are obliquely inserted into the foundation soil to disperse the uneven load and expand the force between the foundation soil and the foundation soil, so that the strength of the foundation soil can still maintain the cylinder body. It is stable and greatly increases the effective load capacity of the suction cylindrical foundation. Secondly, the bottom fixing claws evenly distributed at the bottom of the auxiliary cylinder have strong puncture ability, which improves the soil penetration capacity of the suction cylindrical foundation and enhances the The ability to adapt to the strength of the submarine foundation reduces the need for manual excavation by divers. At the same time, one side can be properly loosened in advance to ensure the uniform speed of its entry into the soil and ensure its vertical entry into the soil.

Owner:TAIZHOU XINGDAO MACHINERY MFG

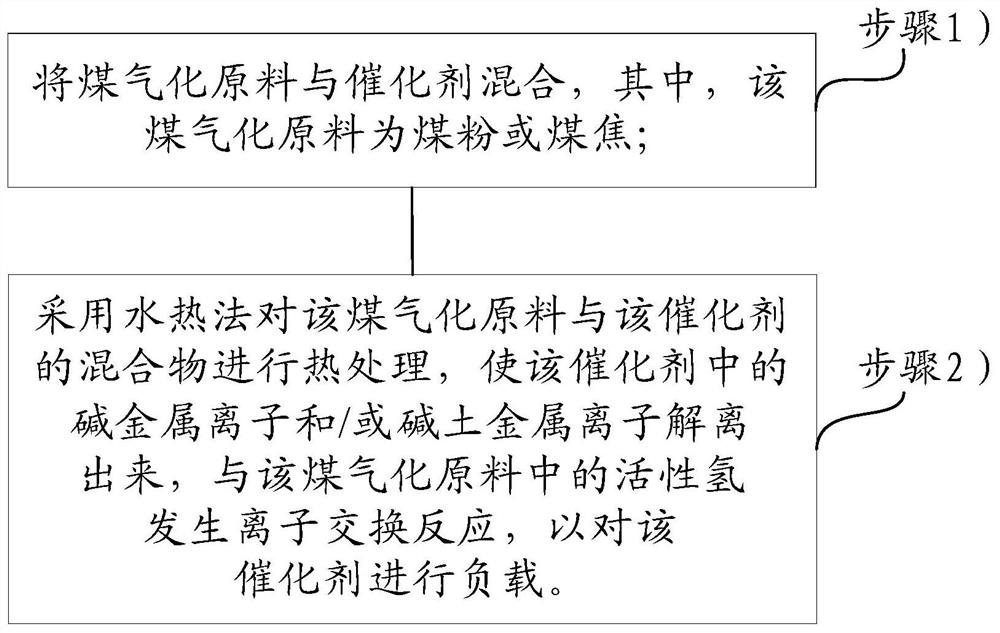

Catalyst loading method and coal catalytic gasification method

ActiveCN108753359BIncrease payload capacityImprove catalytic performanceGasification catalystsCombustible gas productionAlkaline earth metalPtru catalyst

The invention relates to the technical field of coal catalytic gasification, in particular to a loading method of a catalyst as well as a coal catalytic gasification method. The effective loading quantity of the catalyst can be improved and the catalytic effect of the catalyst can be improved, so that the coal gasification conversion efficiency can be improved. The embodiment of the invention provides the loading method of the catalyst. The loading method comprises the following steps: mixing a coal gasification raw material with the catalyst, wherein the coal gasification raw material is coalpowder or coke; performing heat treatment on a mixture of the coal gasification raw material and the catalyst, to dissociate alkali metal ions and / or alkaline earth metal ions out of the catalyst, and carry out an ion exchange reaction with active hydrogen in the coal gasification raw material, so that the catalyst is loaded. The embodiment of the invention is applied to preparation of methane through coal gasification.

Owner:ENN SCI & TECH DEV

Processing method of catalytic diesel oil

ActiveCN108102702BImprove product qualityIdeal comprehensive processing effectTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystProcess engineering

The invention discloses a processing method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjected to a conversion reaction in a bed layer containing a light aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and converted diesel are obtained; the heavy components are subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and diesel fractions are obtained; the diesel fractions obtained through conversion of heavy componentsare subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, a reaction effluent is then subjected to a contact reaction with a light component hydro-conversion catalyst; the converted gasoline obtained from each part is mixed, and high-quality gasoline is obtained. Through the reasonable separation and processing process, different types of raw materials can beselectively and independently processed, so that the qualified gasoline product with high octane value can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com