Photocatalytic fabric as well as preparation method and application thereof

A photocatalysis and fabric technology, applied in the fields of material chemistry and photocatalysis, can solve the problems of unsuitable catalyst particles, and achieve the effects of excellent visible light catalytic activity, stable physical and chemical properties, and easy synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a photocatalytic fabric, comprising:

[0025] First, the metal precursor with a concentration of 0.001-0.1mol / L, the ligand with a concentration of 0.002-0.4mol / L and the polymer with a concentration of 50-500g / L are completely dissolved in a solvent at 0-80°C to obtain a colored and transparent Spinning solution, wherein the concentration of the ligand is 2 to 4 times that of the metal precursor; the metal precursor includes a mixture of one or more of soluble bismuth, manganese, iron, cobalt, nickel, cadmium, antimony and lead salts , and soluble metal salts include chloride, nitrate, acetate or citrate; add acid to the easily hydrolyzed metal ion in the spinning solution to adjust the pH value to be less than 2, and the easily hydrolyzed metal ion includes bismuth or antimony, said Acids include hydrochloric acid, sulfuric acid or nitric acid; ligands include one or more mixtures of dithiocarbamate, trithiocyanate, porphy...

Embodiment 1

[0033]The preparation method includes: first, 0.2mmol of bismuth chloride, 0.7mmol of sodium diethyldithiocarbamate and 1g of polyacrylonitrile are completely dissolved in 10mL of N,N-dimethylformamide at 25°C, and then hydrochloric acid is added Adjust the pH to be less than 2 to obtain a yellow and transparent spinning solution; then place the spinning solution in an electrospinning machine, apply a voltage of 25kV at 25°C for electrospinning, and obtain N,N-dimethylformamide after volatilization Bismuth diethyldithiocarbamate photocatalytic fabric.

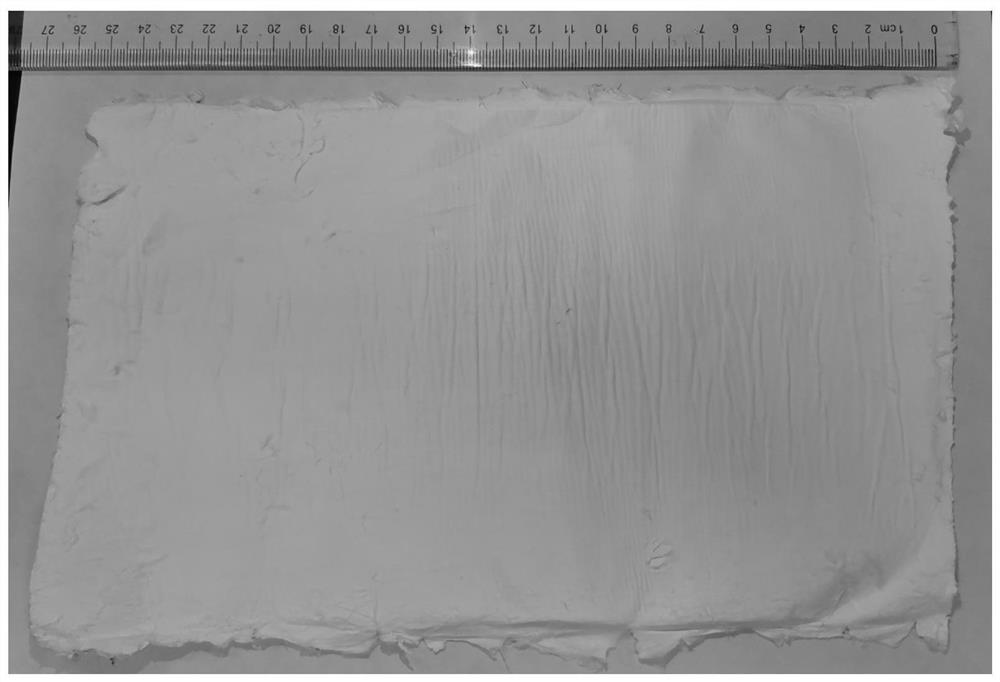

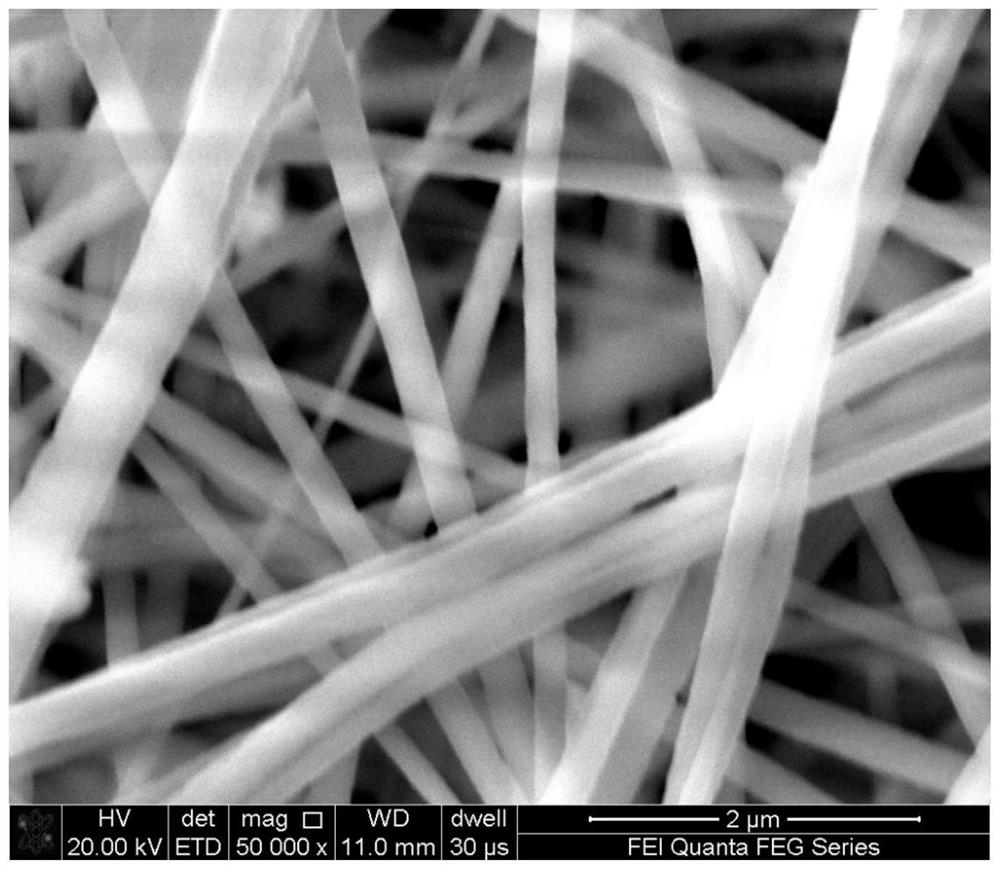

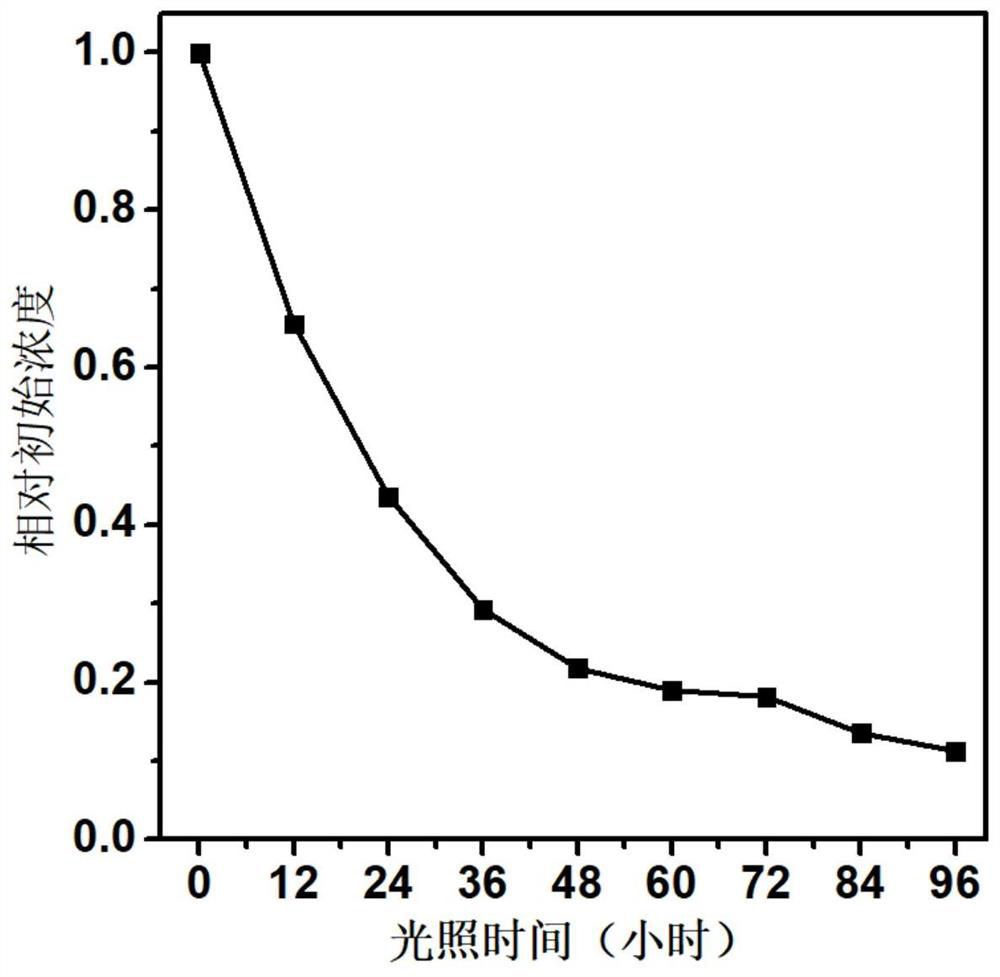

[0034] The photocatalytic fabric product that embodiment 1 prepares is as figure 1 shown, from figure 1 It can be seen that the product is a colored fabric in appearance, indicating that it has visible light absorption characteristics; it is observed with a scanning electron microscope, as shown figure 2 As shown, the microstructure of the product is a porous nanofiber structure, the fiber diameter is tens of nanometers, and...

Embodiment 2

[0036] The preparation method includes: firstly, 0.2 mmol of bismuth acetate, 0.7 mmol of sodium dibutyldithiocarbamate and 1 g of polystyrene are completely dissolved in 10 mL of dimethyl sulfoxide at 30° C., and then hydrochloric acid is added to adjust the pH to less than 2. A yellow transparent spinning solution is obtained; then the spinning solution is subjected to solution spinning at 60° C., and after dimethyl sulfoxide volatilizes, a photocatalytic fabric of bismuth dibutyldithiocarbamate is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com