Preparation method of active bamboo charcoal/sulfur composite material and application thereof

A technology of activated bamboo charcoal and composite materials, applied in the direction of electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of low sulfur load, low battery specific capacity, poor conductivity, etc., and achieve energy density and high-power discharge The effects of capacity improvement, specific capacity improvement, and energy density improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

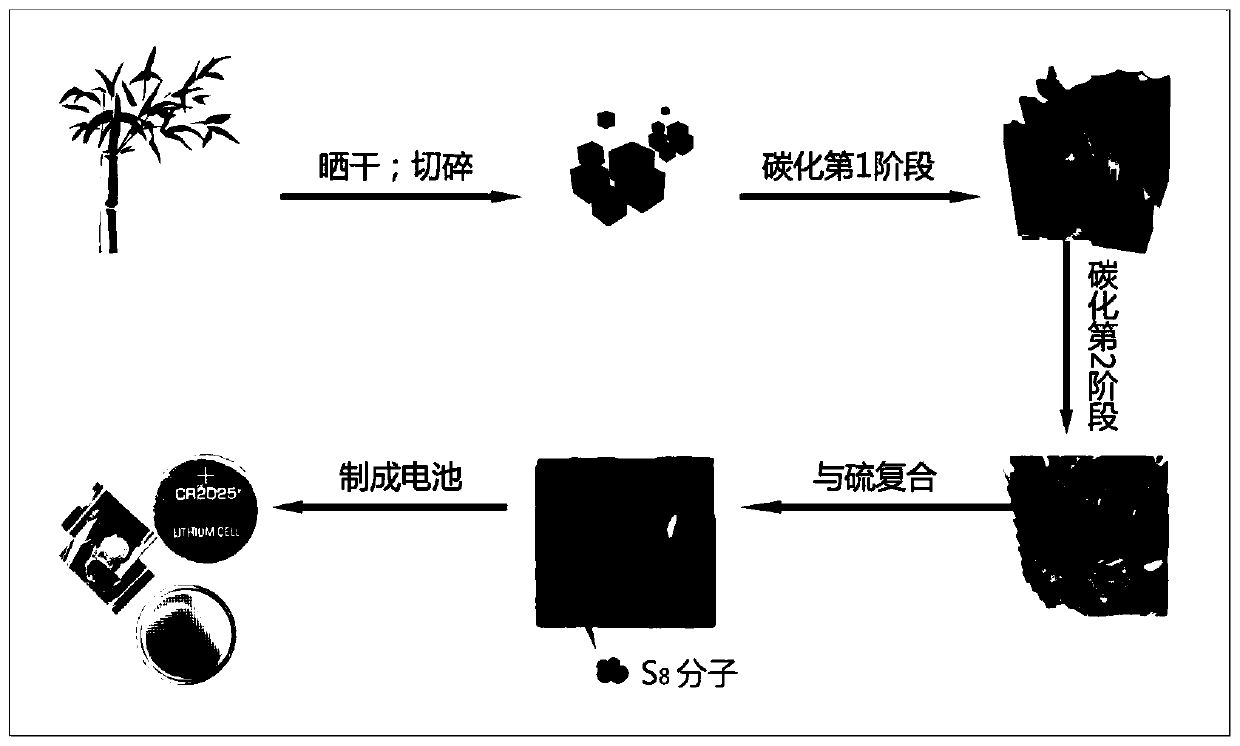

[0035] The first step is to prepare activated bamboo charcoal:

[0036] Cut the dried moso bamboo into small pieces with a diameter of about 2 mm; place it in a tube furnace protected by argon, first pass argon gas into the quartz tube of the tube furnace at a rate of 50 mL / min, and wait until After exhausting the air, keep the same ventilation rate to feed argon, and raise the temperature to 300°C at a rate of 10°C / min; then raise the temperature to 700°C at a rate of 2°C / min, and keep it at this temperature for 1h; Then close the argon inlet valve and open the CO 2 The gas inlet valve is changed to feed CO at a rate of 50mL / min. 2 gas, and heated up to 1000°C at a rate of 10°C, and kept at this temperature for 1 hour. Thus made activated bamboo charcoal with high conductivity and porous structure; (the air inlet valve is a metal three-way air inlet valve)

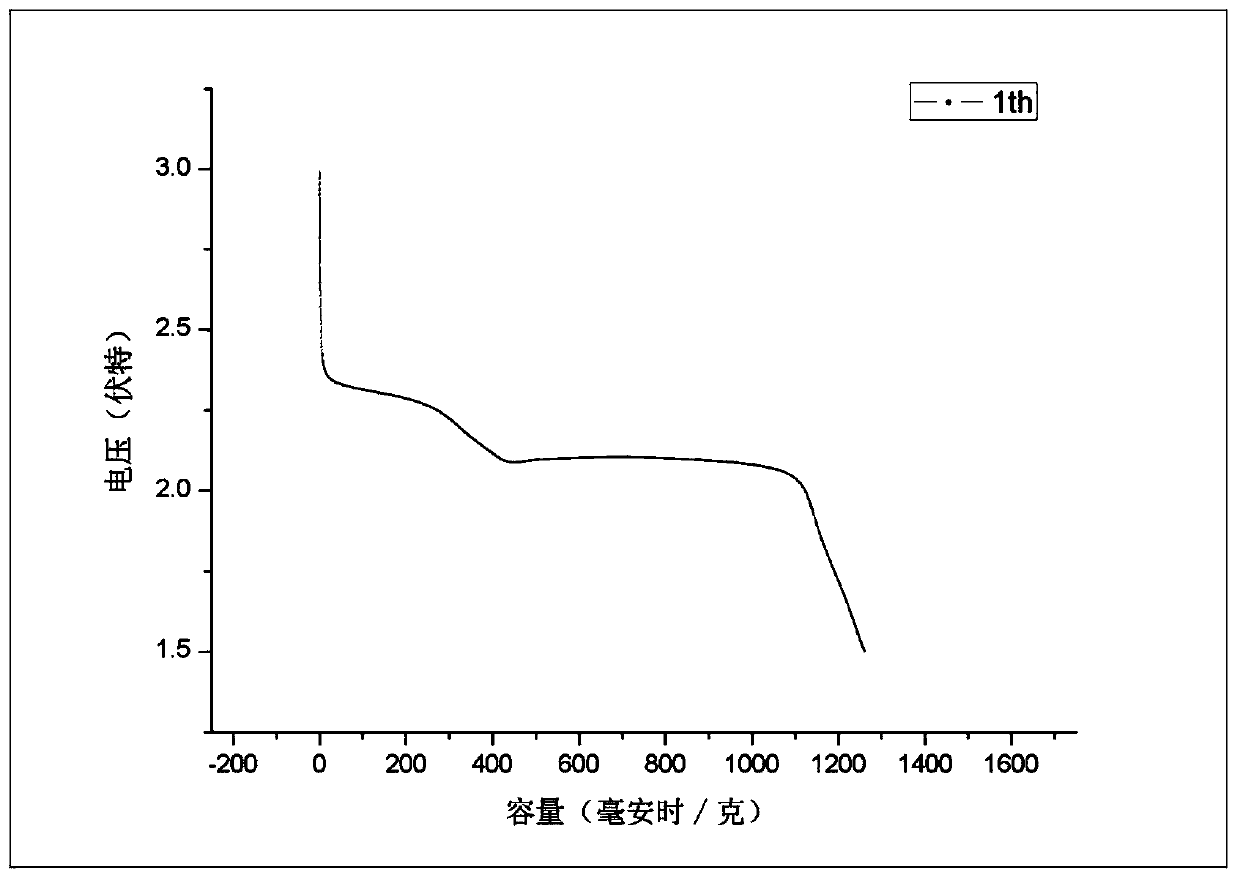

[0037] The second step is to prepare the positive electrode material of activated bamboo charcoal / sulfur composite l...

Embodiment 2

[0045] Others are the same as embodiment 1, and the difference is the first step:

[0046] Place the chopped moso bamboo fragments in a tube furnace under the protection of argon, first pass argon gas into the quartz tube of the tube furnace at a rate of 50mL / min, after the air is exhausted, keep the same rate of ventilation Inject argon, and raise the temperature to 700°C at a heating rate of 10°C / min, and keep at this temperature for 4.5h.

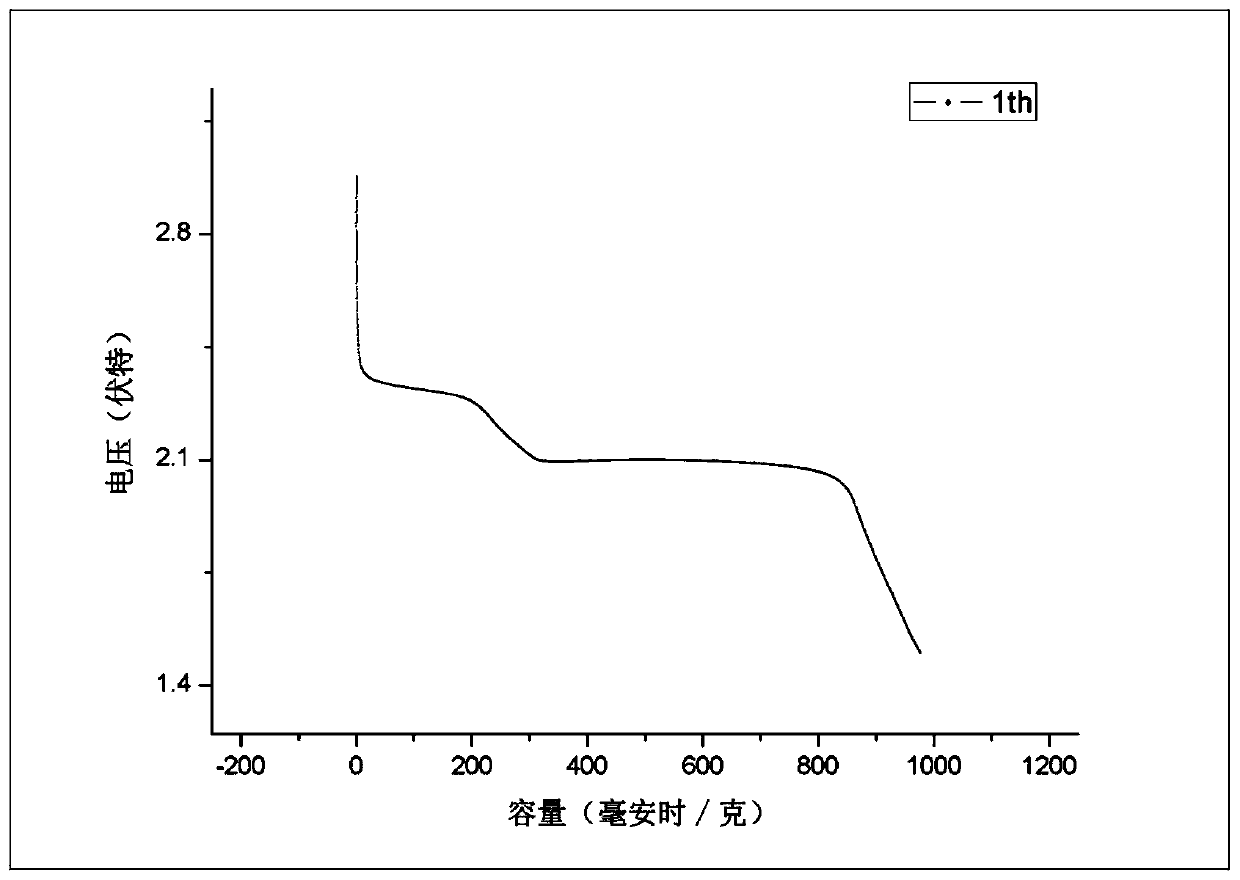

[0047] image 3 When the activated bamboo charcoal / sulfur composite material prepared in this example is used as the positive electrode of the lithium-sulfur battery, the first discharge curve at a current density of 0.1C. The first discharge specific capacity is 978mAh / g, which is 302mAh / g lower than that of Example 1. This is because the bamboo undergoes a severe dehydration reaction at 300-700°C. It is too late to be discharged with the inert gas, causing the bamboo to become "paste". The bamboo charcoal obtained by carbonization ha...

Embodiment 3

[0049] Others are the same as embodiment 1, and the difference is the second step:

[0050] Weigh the required activated bamboo charcoal and nano-sulfur powder according to the mass ratio of 1:3.

[0051] Figure 4 The first discharge curve at a current density of 0.1C when the activated carbon / sulfur composite material prepared in this example is used as the positive electrode of a lithium-sulfur battery. The lithium-sulfur battery with activated bamboo charcoal / sulfur composite material as the positive electrode has a specific capacity of 998mAh / g for the first time, and the sulfur content is 60wt.%.

[0052] From the above examples, it can be seen that the present invention uses bamboo as a raw material to prepare conductive bamboo charcoal with a porous structure through a one-step process combining high-temperature carbonization and high-temperature activation. Lithium-sulfur batteries prepared from this material as a sulfur-loading material have excellent discharge spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com