Tubular bag type fluidized bed device for bulk powder material tank truck

A fluidized bed and cargo technology, which is applied to the field of tube bag type fluidized bed devices for bulk powder cargo tankers, achieves the effects of easy maintenance and replacement, good working conditions, and easy and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

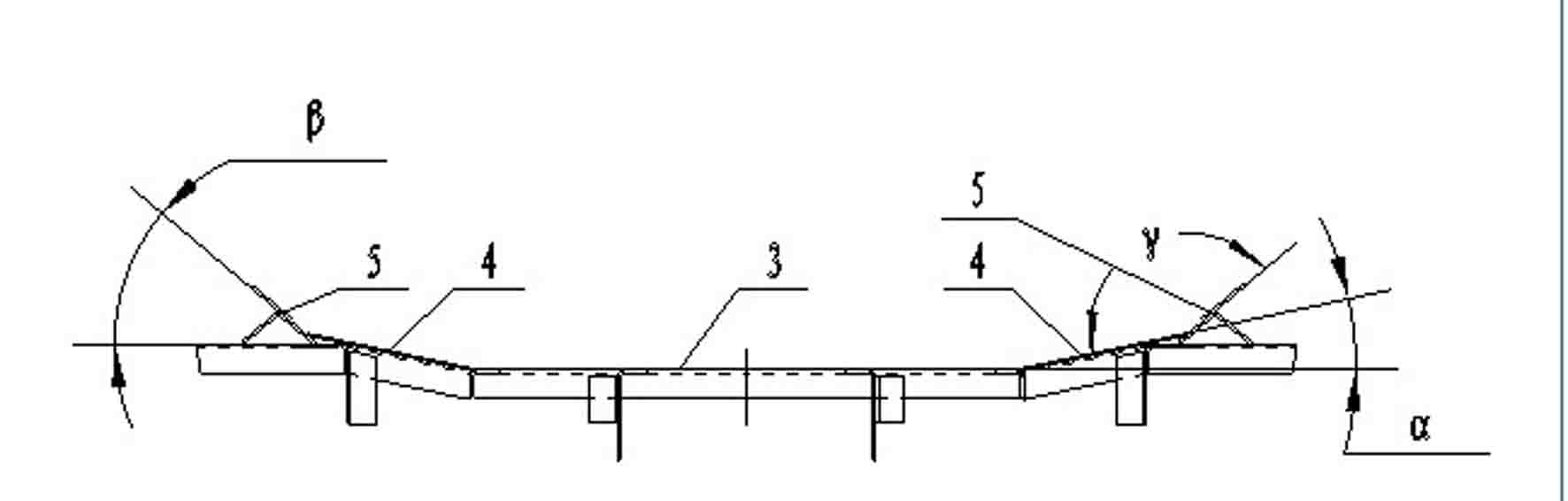

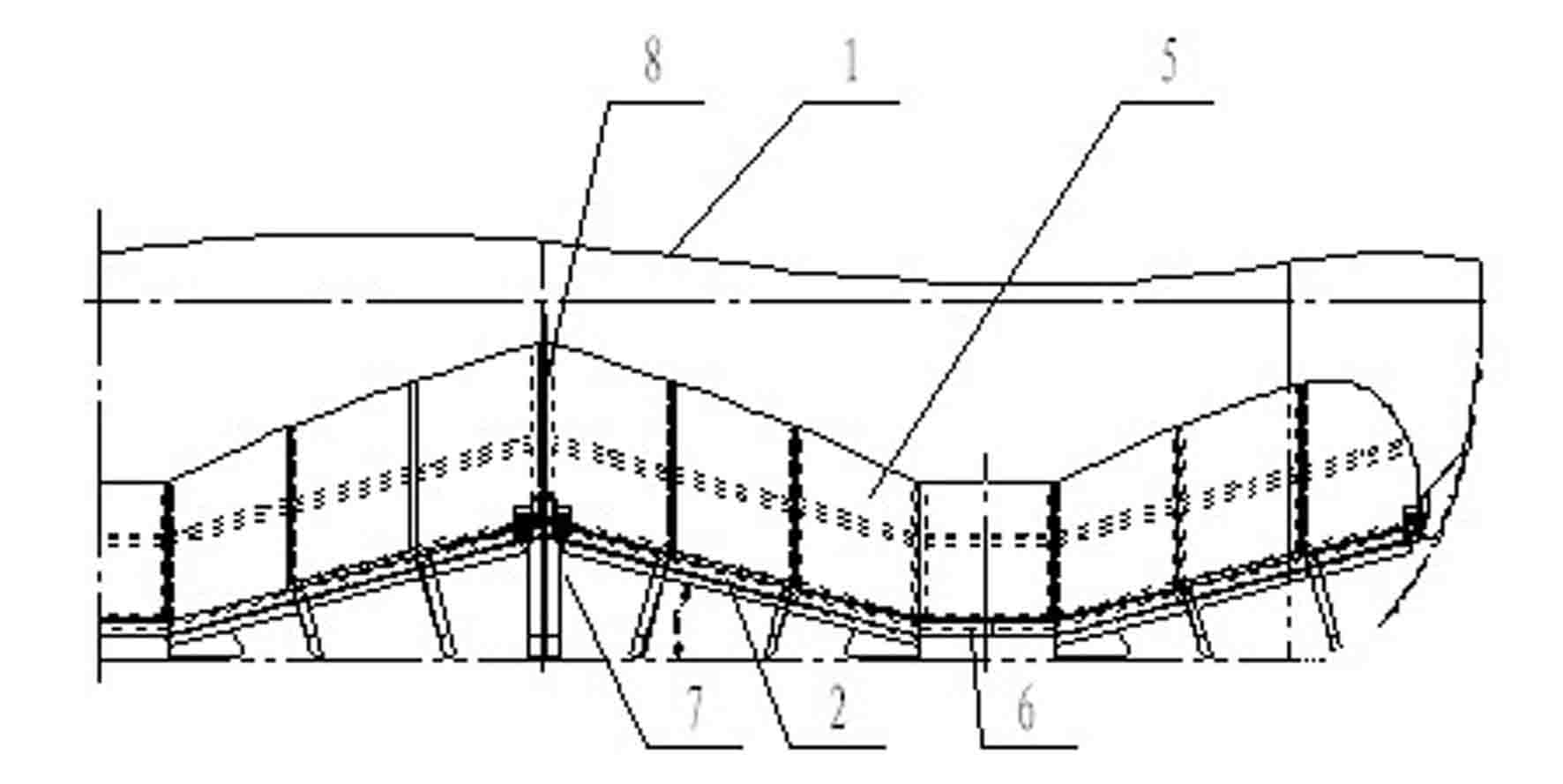

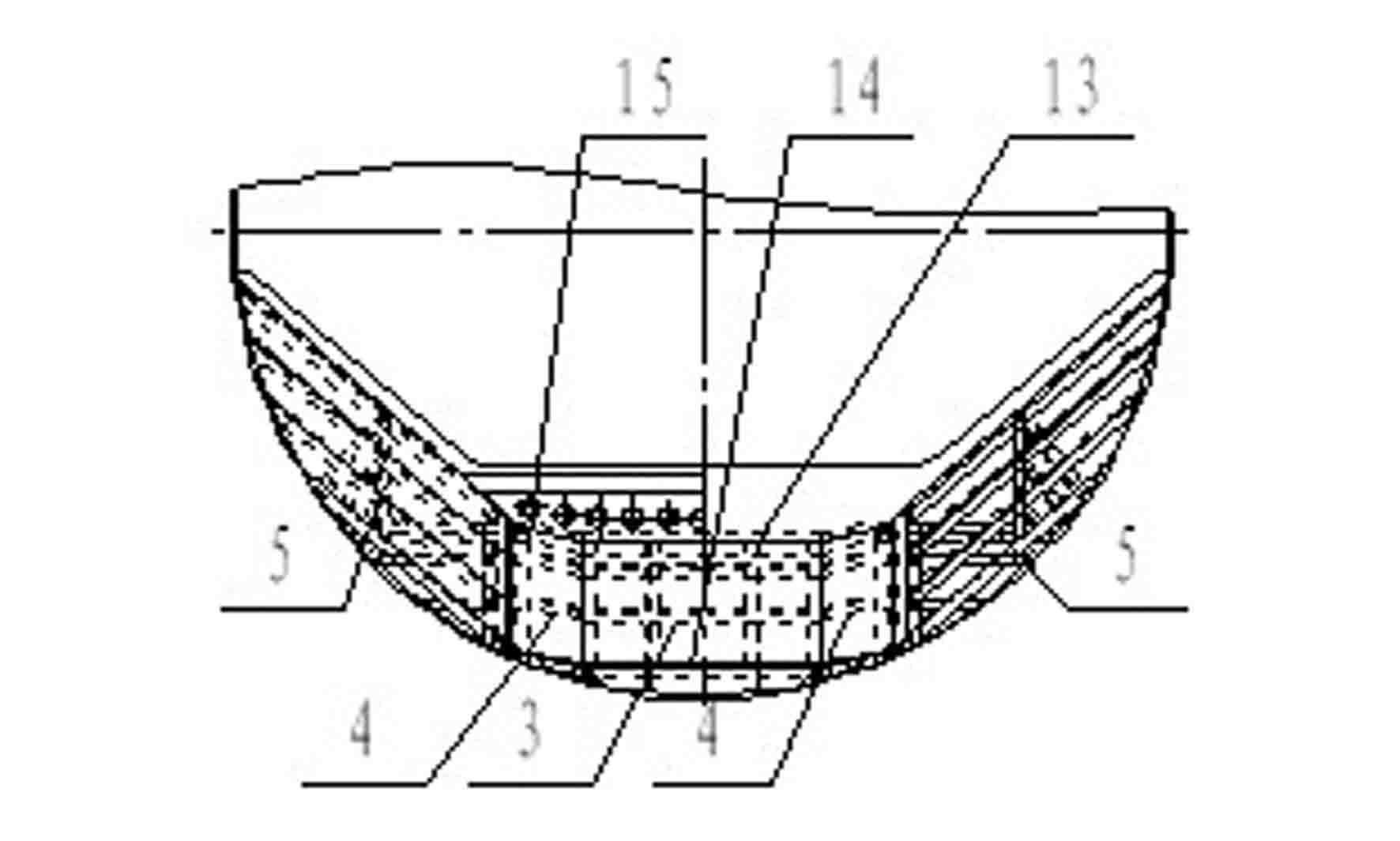

[0029] Bulk powder cargo tanker bag type fluidized bed unit, such as figure 2 As shown, it includes at least two chute-type fluidized beds arranged along the axial direction of the tank body 1 and respectively composed of two inclined fluidized-bed surfaces 2 at an angle to each other, forming a phase of the chute-type fluidized bed The included angle δ between two adjacent inclined fluidized bed surfaces 2 is 145°~155°, and the lower part of two adjacent chute fluidized beds is closed by a partition 8, each of which becomes an independent total air chamber 7 , the total air chamber is connected to the air inlet pipeline system through the air inlet pipe of the tank body, and the lower tank body of each chute type fluidized bed is respectively equipped with an air inlet and a windshield, making it a relatively independent unloading unit , between the lowest ends of two adjacent inclined fluidized bed surfaces 2, there is an unloading bell mouth installation port 6 (for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com