Patents

Literature

114results about How to "Easy to fluidize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petroleum recovery and cleaning system and process

InactiveUS20050161372A1Enhancing petroleum recoveryIncrease productionInorganic/elemental detergent compounding agentsLiquid separation auxillary apparatusProcess equipmentPetroleum product

Owner:AQUA TECH LLC

Catalyst for full methanation of carbon dioxide and preparation method thereof

ActiveCN101884927AImprove fluidization qualityHigh strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationThermal stability

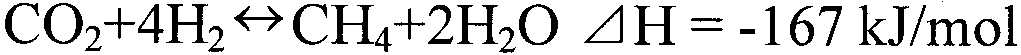

The invention discloses a catalyst for full methanation of carbon dioxide, which belongs to the technical field of methanation of carbon dioxide. In the catalyst, spherical gamma-Al2O3 is used as a carrier, Ni and Fe are used as active ingredients, and MgO, La2O3 or CeO2 is used as an auxiliary agent. The catalyst is prepared by adopting an ordered soaking method through drying, roasting and reduction. The catalyst comprises the following components in percentage by mass: 60 to 80 percent of gamma-Al2O3, 10 to 20 percent of NiO, 5 to 15 percent of Fe2O3, 1 to 10 percent of MgO, and 1 to 10 percent of La2O3 or CeO2. Under the reaction conditions that the pressure is between 3.0 and 5.0MPa, the volume airspeed of the raw material gas is 5,000 to 10,000 per hour and the ratio of H2 to CO2 is 4.1, both the CO2 conversion rate and the CH4 selectivity can be close to 100 percent. The catalyst has the characteristics of high strength, good thermal stability, carbon deposition resistance, easy fluidization and the like.

Owner:TSINGHUA UNIV

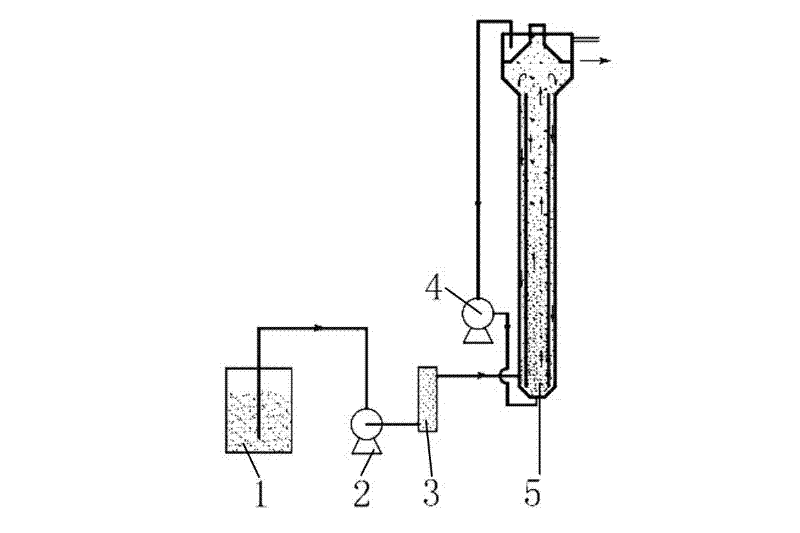

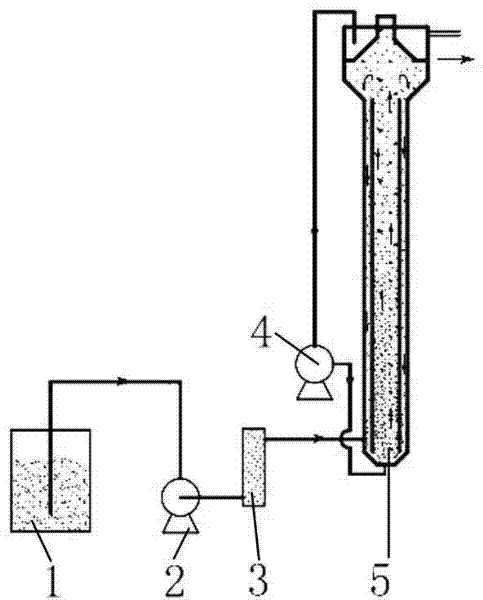

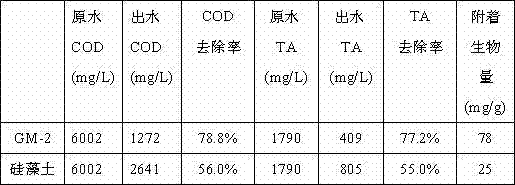

Multi-hole foam glass carrier for fast mass transfer biological fluidized bed and preparation method and application thereof

InactiveCN102515551AEvenly distributedImprove chances of interphase contactTreatment with anaerobic digestion processesBiocompatibilityFoam glass

The invention relates to a multi-hole foam glass carrier for a fast mass transfer biological fluidized bed and a preparation method and application thereof, which belong to sewage disposal technology. The multi-hole foam glass carrier is prepared by using waste glass as a raw material to be composited with volcanic rocks, coal ash, coal gangue, furnace clinker, iron powder, aluminum powder, binding agents, foaming agents, foam stabilizer and fluxing agents by weight, and multi-hole foam glass is obtained by stages of preheating, fast sintering, foaming, fast cooling and annealing. The preparation process of the multi-hole foam glass carrier is simple in route, easy to control and low in cost, and the prepared carrier is stable in performance, high in porosity, large in specific surface area, resisting in impact, good in mechanical performance, high in biocompatibility, favorable to efficient fixing of the microorganism, and suitable to the fast mass transfer biological fluidized bed. The multi-hole foam glass carrier solves the problem that biological immobilization carriers in the prior art are easy to abrade, small in bio-film formation amount, low in mass transfer effects and the like in the fast mass transfer biological fluidized bed. The preparation method opens up new approaches for preparing the biological carriers, and fills blank spaces in using of foam glass materials in sewage disposal.

Owner:NANJING UNIV OF TECH

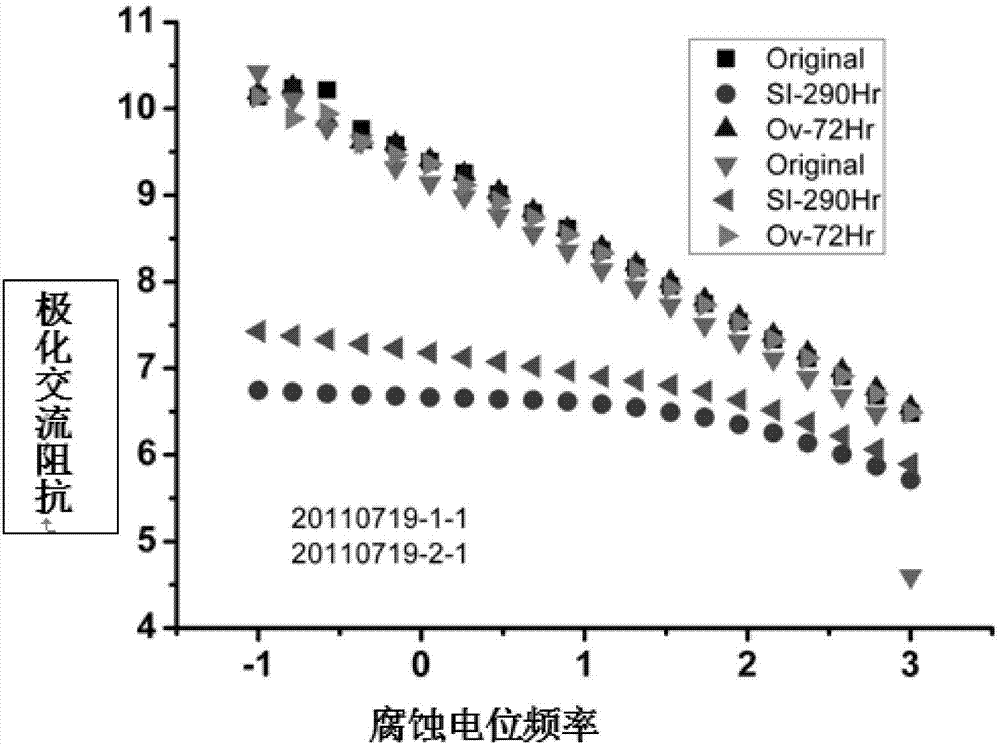

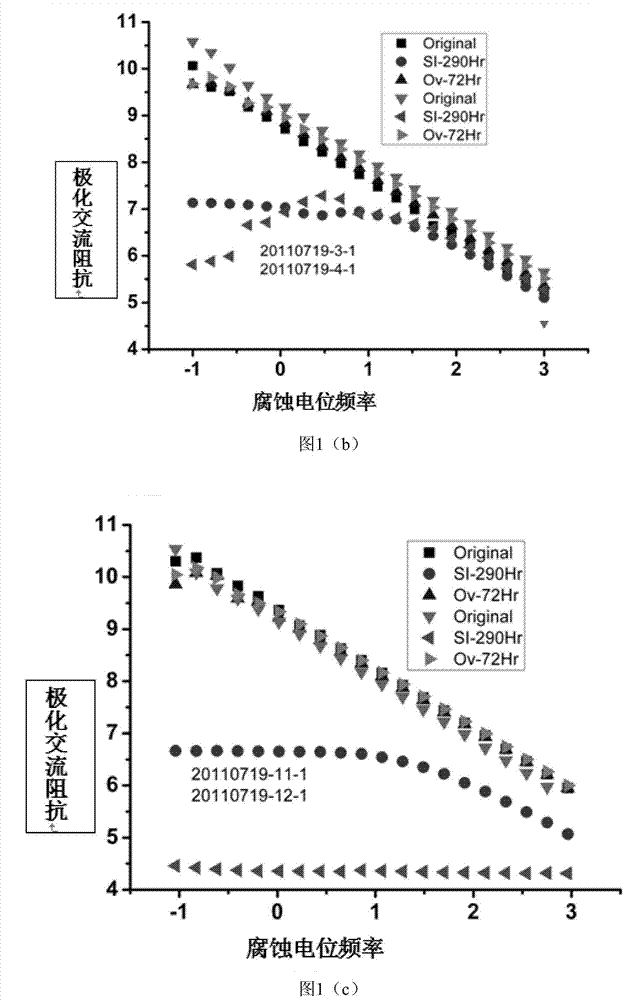

Special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating as well as preparation method and application of coating

ActiveCN104710908AHigh glass transition temperatureLight weightAnti-corrosive paintsPolyurea/polyurethane coatingsNano al2o3Conductive materials

The invention relates to a special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating. The special anticorrosion conductive powder coating is prepared from the following raw materials in parts by weight: 500-900 parts of film-forming resin and curing agent, 0-200 parts of glass flakes, 0-350 parts of filler, 15-50 parts of auxiliaries, 5-100 parts of conductive material and 1-5 parts of nanometer aluminum oxide or nano fumed silica. The powder coating has the characteristics of a high glass transition temperature, low specific gravity which is generally less than or equal to 1.1g / cm<3>, and easiness for fluidization; even though hundreds of tons of powder is added to a 20m deep well, the powder can be fluidized easily and uniformly; in case of too high specific gravity and difficult fluidization, the vertical shaft dip-coating method can not be utilized; the powder aims at a hot-dip coating construction process, and the film formed by the coating has surface conduction characteristics and high temperature water boiling resistance, and therefore, the coating is suitable for anti-corrosion coating of long linear workpieces such as mine mining anti-explosion gas pipelines, natural gas pipelines and liquefied gas pipelines; the coating is adaptive to the vertical shaft fluidized beds as deep as 20m, and still has good fluidity, which cannot be realized by common powders easily.

Owner:阜阳市诗雅涤新材料科技有限公司

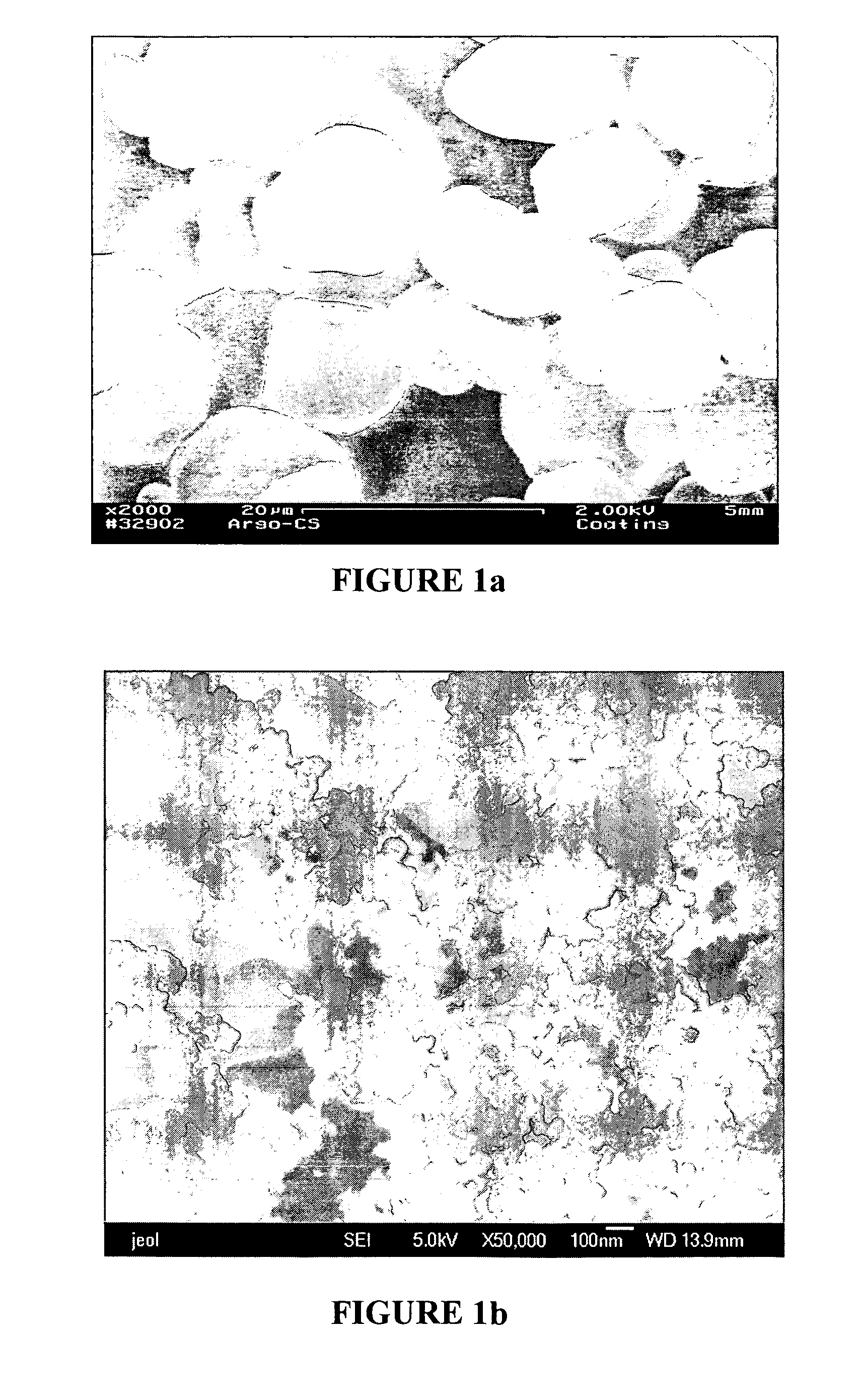

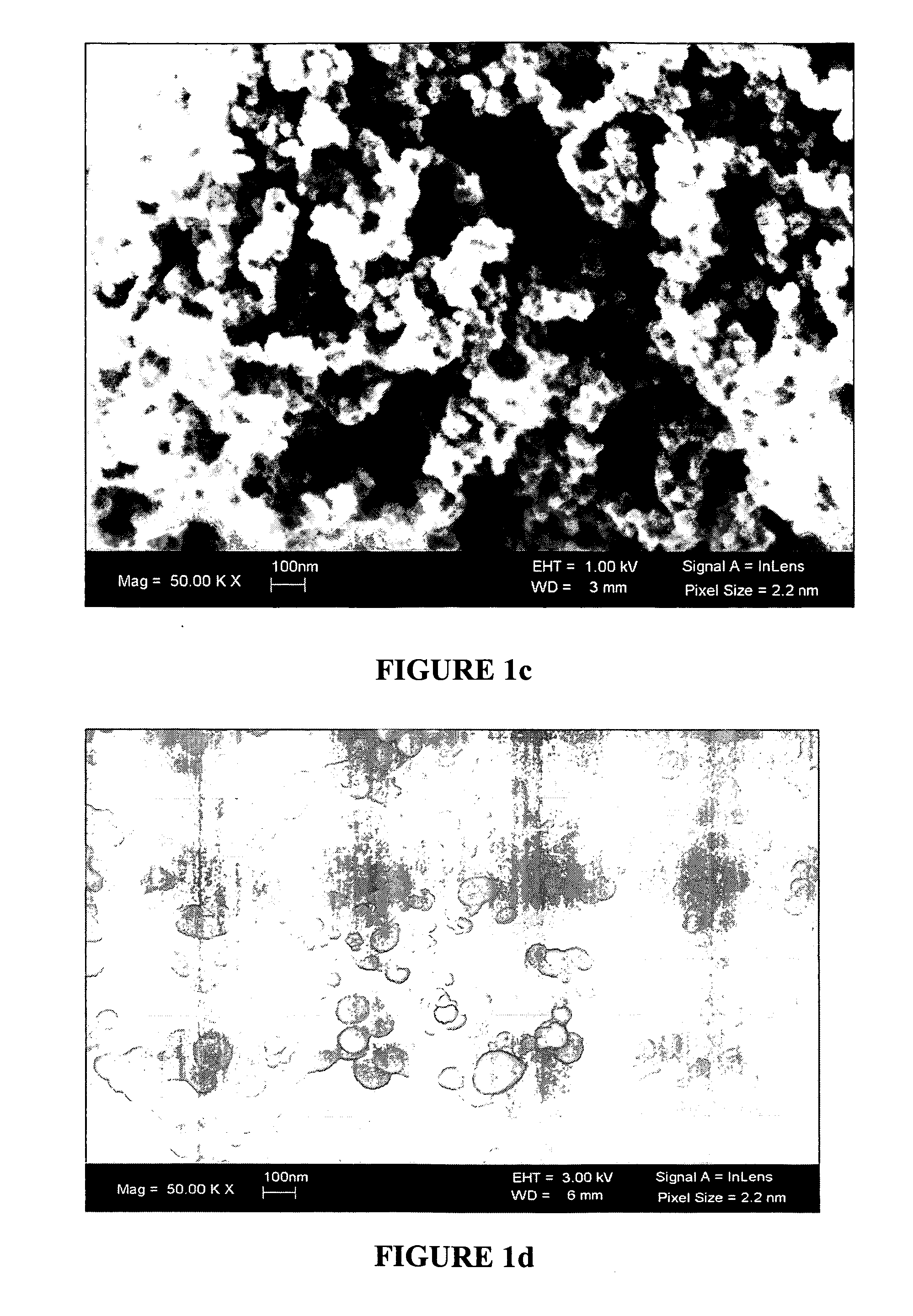

Dry coating and downstream processing of cohesive powders

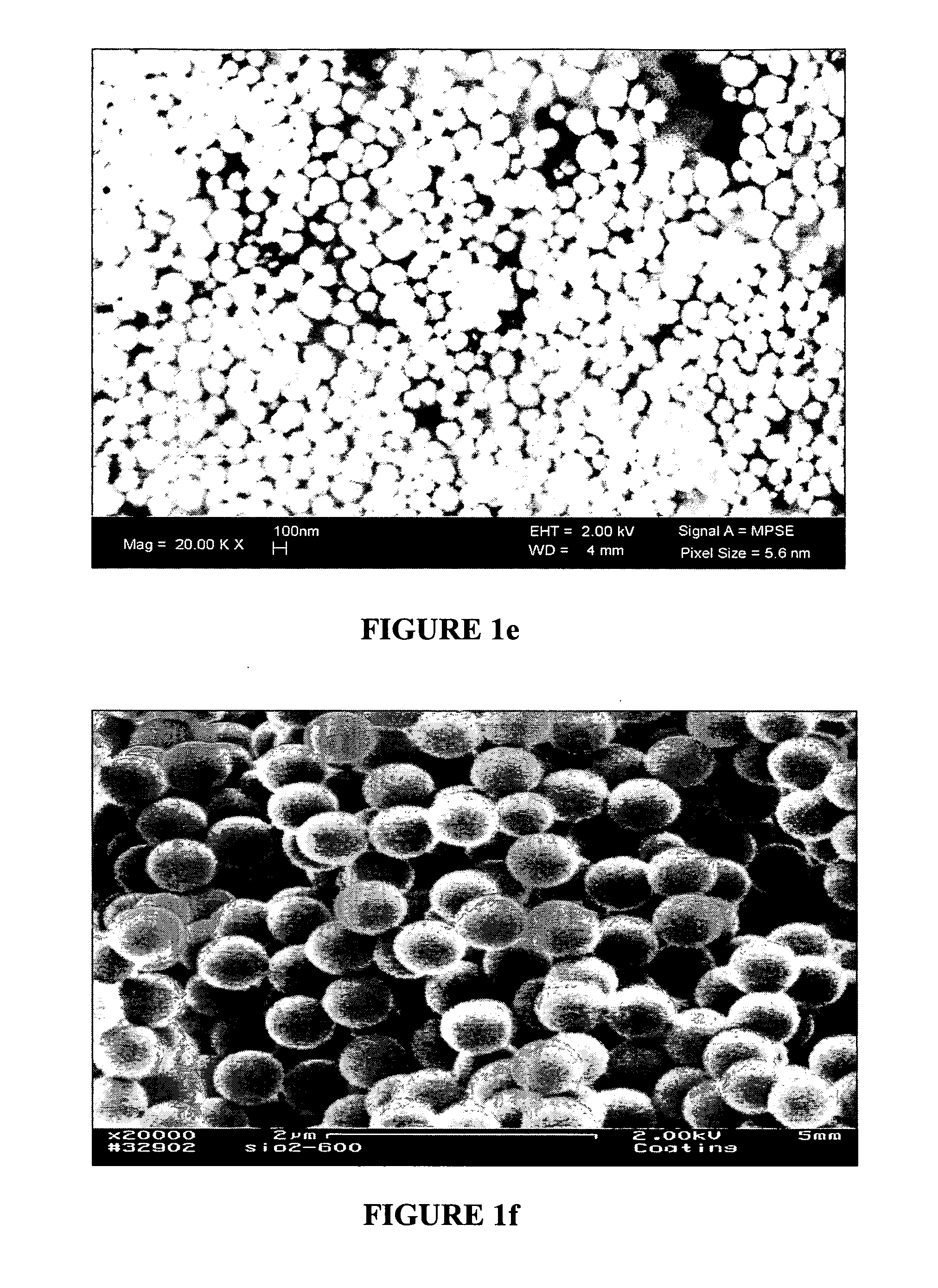

InactiveUS20070053846A1Improve cohesionEasy to processPowder deliveryTransportation and packagingDownstream processingIngested food

The present disclosure is directed to systems and methods for dry particle coating of cohesive powders, and to the dry coated particles / powders produced thereby. The present disclosure is further directed to systems and methods for dry coating of cohesive particles, particularly nanosized particles, to provide enhanced flowability and other advantageous physical and / or functional properties. The disclosed systems and methods offer downstream processing advantages, e.g., for purposes of subsequent fluidization, coating, granulation and / or other particle processing operations, and have applicability in wide ranging industries, including specifically paint-related applications, pharmaceutical applications, food-related applications, cosmetic applications, defense-related applications, electronics-related applications, toner and ink-related applications, and the like.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Horizontal integrated three phase inner circulation fluidized reactor and its biological reaction process

InactiveCN1648069ANovel structureImprove capacity utilizationBiological water/sewage treatmentSludgeWastewater

The horizontal integrated three-phase internally circulating fluidized reactor has reactor box, guide plate and inclined precipitating plate to separate the rector box into three regions, lower filtering net, microporous aerator in the lower part of the upward flow region, water collector in the upper part of the mud-water separating region, and mud water valve in the lower part of the mud-water separating region. The bioreaction process inside the fluidized reactor includes: pumping organic waste water into the reactor and adding porous foamed sponge; introducing air into the microporous aerator for aeration; draining clear water via the water collector and depositing sludge to downward flow region; and draining rest sludge via the sludge exhausting valve.

Owner:SOUTHEAST UNIV

Novel functional suspension filler

InactiveCN1532152APlay a role in biological regenerationPromote sheddingSustainable biological treatmentBiological water/sewage treatmentWastewaterSewage

The novel functional suspension filler is used in processing various organic sewage. The functional water processing material grains or blocks are sandwiched in plastic plates to form composite winged plate and are used as the main carrier for microbe to attach and propagate on them to form biomembrane with flourishing growing microbes. The functional suspension filler contains water repellent foamed plastic to regulate water specific weight, so that the functional suspension filler may be fluidized together with water and gas and the mass transferring of microbe, organic matter in waste water and oxygen in the air is reinforced. The functional water processing material can adsorb and enrich pollutant in waste water to raise the elimination of pollutant effectively, and the microbe can regenerate the functional material biologically. The present invention has high organic sewage processing effect.

Owner:TONGJI UNIV

Non-woven cloth suspension filler

InactiveCN102838203AChange propertiesImprove adhesionSustainable biological treatmentBiological water/sewage treatmentFerric oxalateAntioxidant

The invention discloses a non-woven cloth suspension filler which is prepared by the following constituents in parts by weight with the conventional method: 40-50 parts of polyethylene, 25-35 parts of polypropylene, 6-10 parts of carbon black, 3-7 parts of ferric oxalate, 4-6 parts of magnesium oxalate and 1-2 parts of antioxidant. The specific gravity of the non-woven cloth suspension filler is closed to that of water. No fixing support is required. The filler can suspend in the water in a pool with aeration stirring and is uniformly fluidized in the whole pool. The energy consumption is low, and the non-woven cloth suspension filler has a good prospect.

Owner:金宝玲

Magnesium ammonium phosphate-electrooxidation integrated device and simultaneous nitrogen and phosphorus removing method thereof

ActiveCN105668717ASave on medicine costsSynchronous removalWater contaminantsPhosphorus compoundsNitrogenMagnesium ammonium phosphate

The invention discloses a magnesium ammonium phosphate-electrooxidation integrated device and a simultaneous nitrogen and phosphorus removing method thereof and belongs to the field of wastewater treatment.The magnesium ammonium phosphate-electrooxidation integrated device comprises a magnesium ammonium phosphate-electrooxidation crystallization system and a nitrogen electrooxidation system.The magnesium ammonium phosphate-electrooxidation crystallization system comprises a reaction base and an anode B.The nitrogen electrooxidation system comprises a reaction base and an anode A.Each reaction base comprises an electrochemical instrument, a selector switch, a reference electrode, scrap iron, a cathode and a reactor, wherein the reference electrode and the cathode are connected in parallel through wires and vertically suspended in the reactor after being connected with the electrochemical instrument, the scrap iron can be suspended in the reactor through magnetic force stirring, and the selector switch is connected with the electrochemical instrument through a wire and then are connected with the anode A and the anode B in a switching mode.Just through simple electrode switching, the simultaneous nitrogen and phosphorus removing effect can be achieved, operation is easy, automatic running can be achieved, and no new pollution sources are generated.

Owner:JINGDEZHEN CERAMIC UNIV

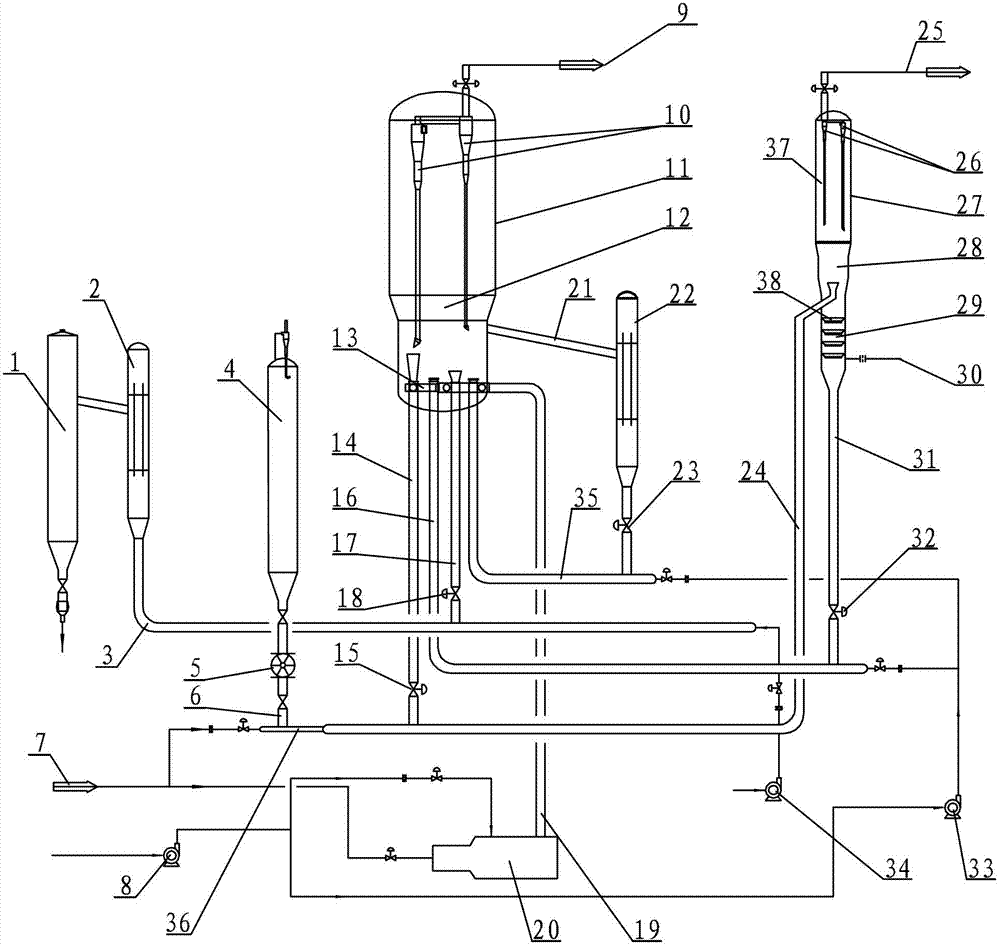

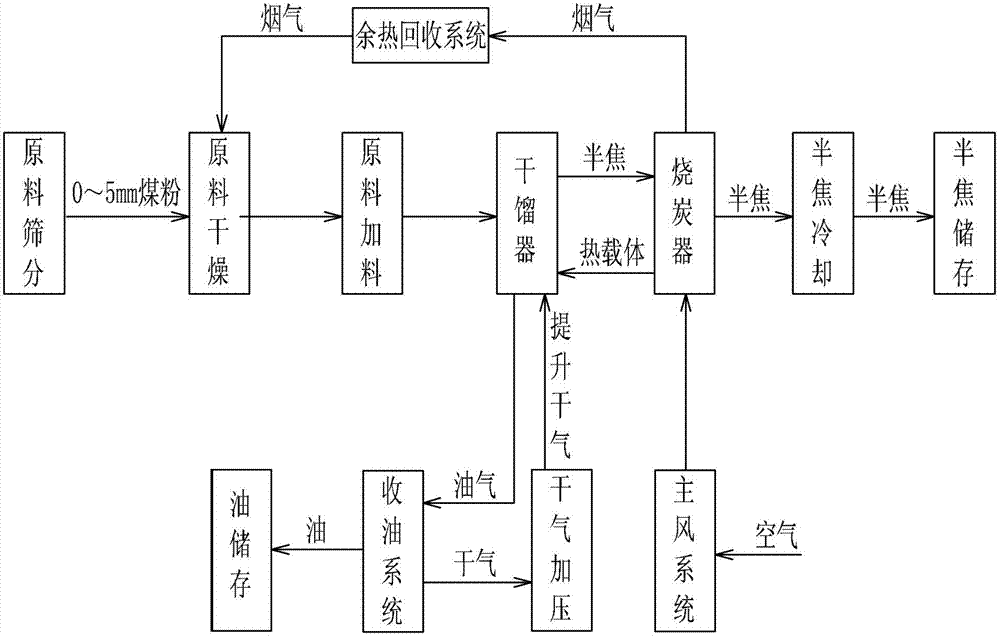

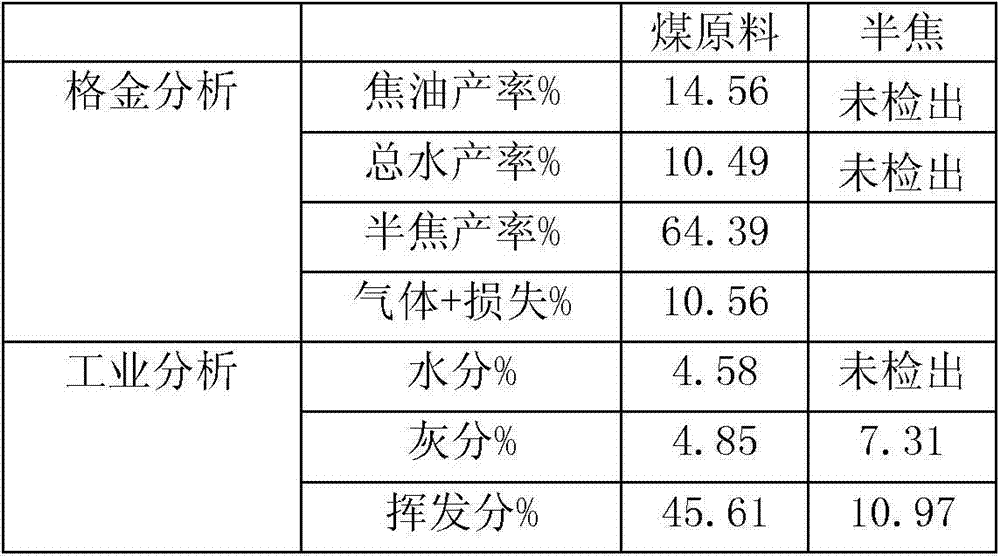

Composite pulverized coal destructive distillation device and method

InactiveCN103113905AReduce fluidizing gas volumeHigh yieldSpecial form destructive distillationCoalDry gas

The invention discloses a composite pulverized coal destructive distillation device and method and relates to a pulverized coal destructive distillation device and method so as to solve the problem that a hot carrier and pulverized coal are not ideally mixed in a mixer in the conventional coal fluidization destructive distillation technology. According to the device, one end of a hot carrier vertical pipe is connected with a raising pipe reactor, and the other end of the hot carrier vertical pipe is connected with a charring device; and one end of the raising pipe reactor is introduced with dry gas, and the other end of the raising pipe reactor is communicated with a destructive distillation reactor. The method comprises the following steps: 1, mixing high-temperature semicoke and pulverized coal in the raising pipe reactor, and carrying out a destructive distillation reaction; 2, inputting one part of high-temperature semicoke in the charring device into the raising pipe reactor through the hot carrier vertical pipe, and allowing the other part of high-temperature semicoke to enter a semicoke cooler through a discharging vertical pipe so as to be discharged into a semicoke storage tank after cooling; 3, reacting oil gas and semicoke coke in the destructive distillation reactor; and 4, returning the semicoke fine powder back to the destructive distillation reactor, allowing the semicoke fine powder to enter the charring device to serve as partially combusted semicoke through a semicoke conveying pipe, and raising the temperature to become a hot carrier after combustion. The device and the method are used for destructive distillation of pulverized coalwith the particle size of less than or equal to 5mm.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

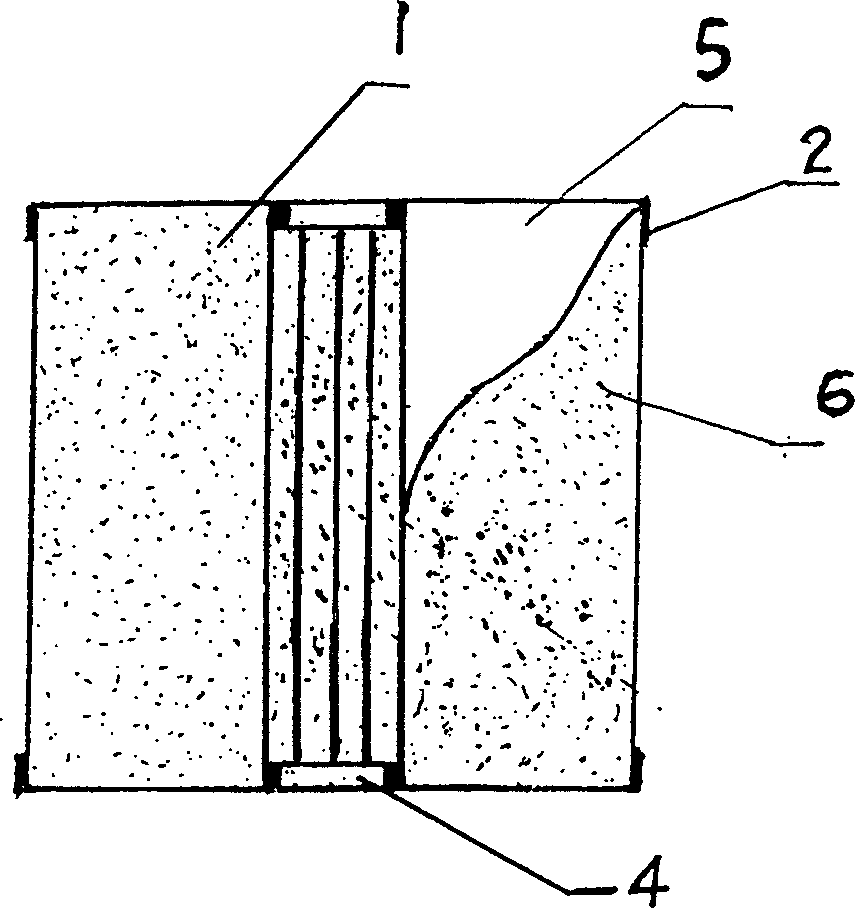

Functional suspended stuffing

InactiveCN1526660AIncrease surface areaStrong adsorption capacityEnergy based wastewater treatmentSustainable biological treatmentComposite wingAdhesive

The present invention relates to one kind o water processing functional suspended stuffing and its preparation technology, and the functional suspended stuffing is suitable for treatment of various kinds of waste water. Winged plates for stuffing, fixed connecting ring and middle connecting ring are made with polar plastic and connected to form an integral, and powdered functional water processing material is covered onto the surface of the winged plates via hot binding or adhesion with surface adhesive to constitute composite winged plates. The present invention has convenient making, great surface area, high water processing capacity and convenient maintenance with less back flushing needed.

Owner:TONGJI UNIV

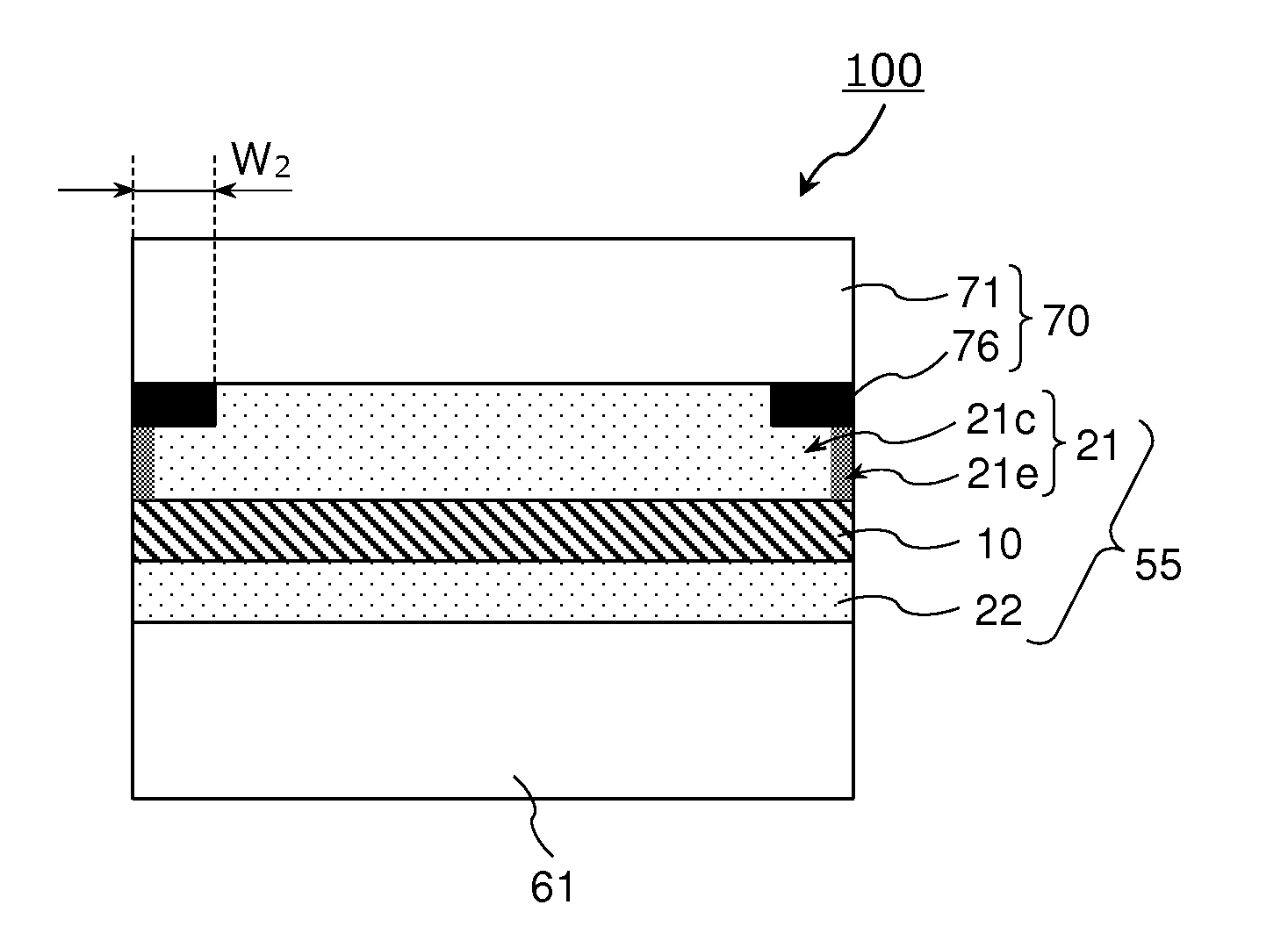

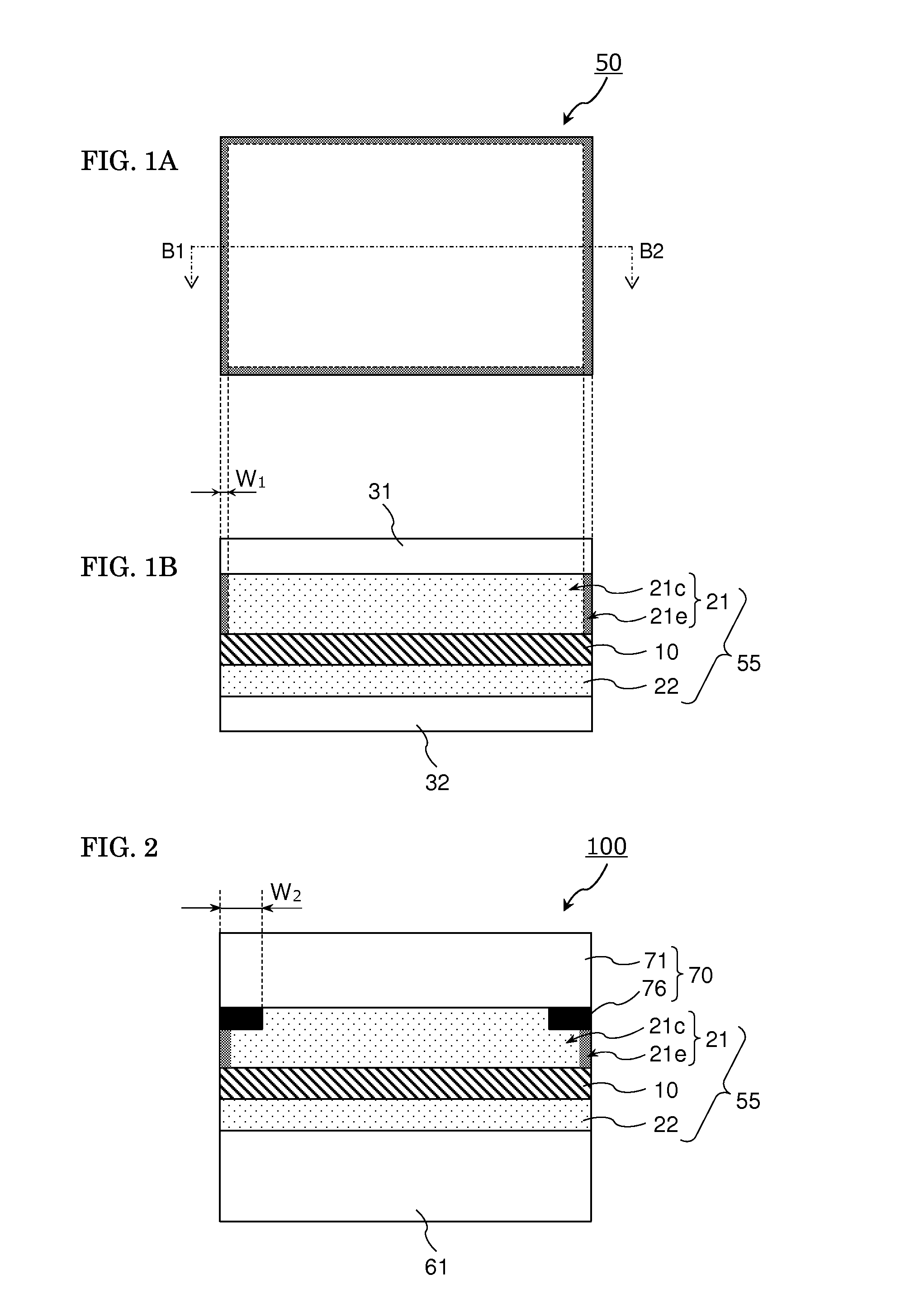

Optical film with pressure sensitive adhesive and production method thereof, and method for producing image display device

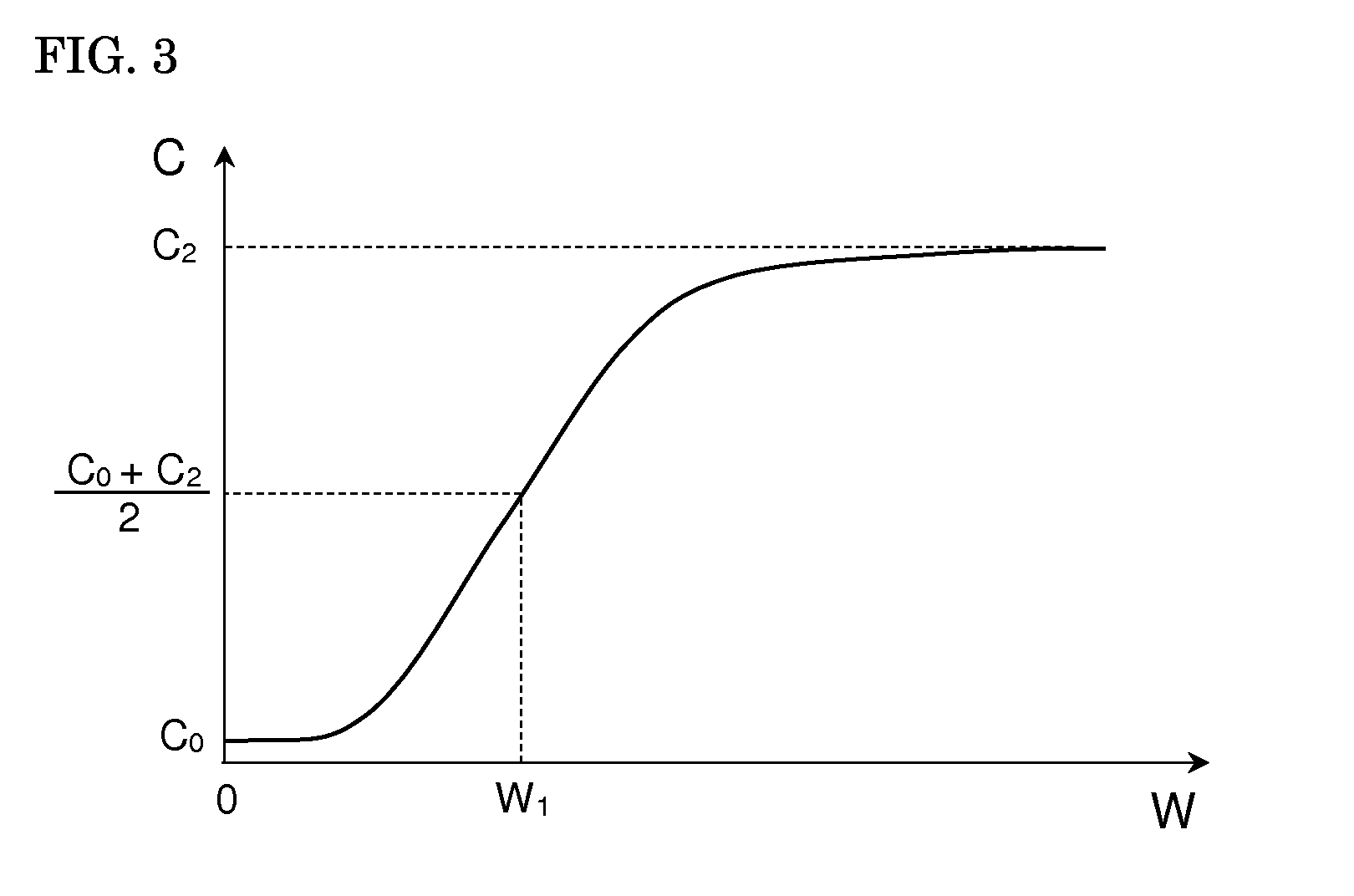

InactiveUS20160102229A1Improve adhesionImprove liquidityLamination ancillary operationsAdhesive articlesIn planeDisplay device

The optical film with a pressure sensitive adhesive comprises an optical film including a polarizing plate, a first pressure sensitive adhesive layer provided on first main surface of the optical film, and a second pressure sensitive adhesive layer provided on second main surface of the optical film. The first pressure sensitive adhesive layer has a thickness of 30 μm or more. In the first pressure sensitive adhesive layer, a fluidity of a pressure sensitive adhesive at an end surface is lower than a fluidity of the pressure sensitive adhesive at an in-plane central part.

Owner:NITTO DENKO CORP

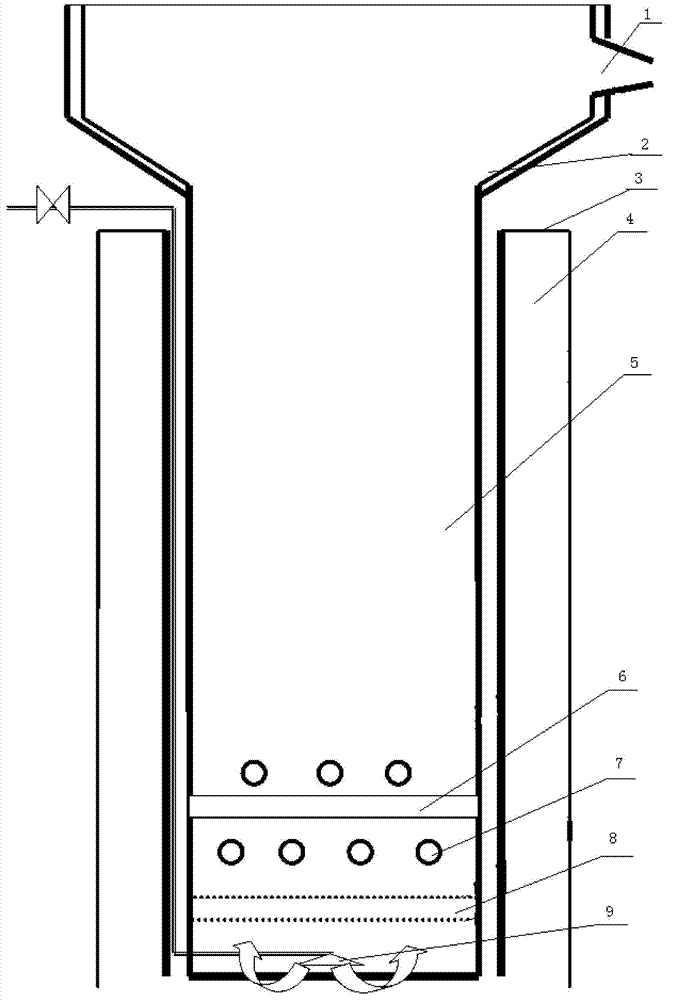

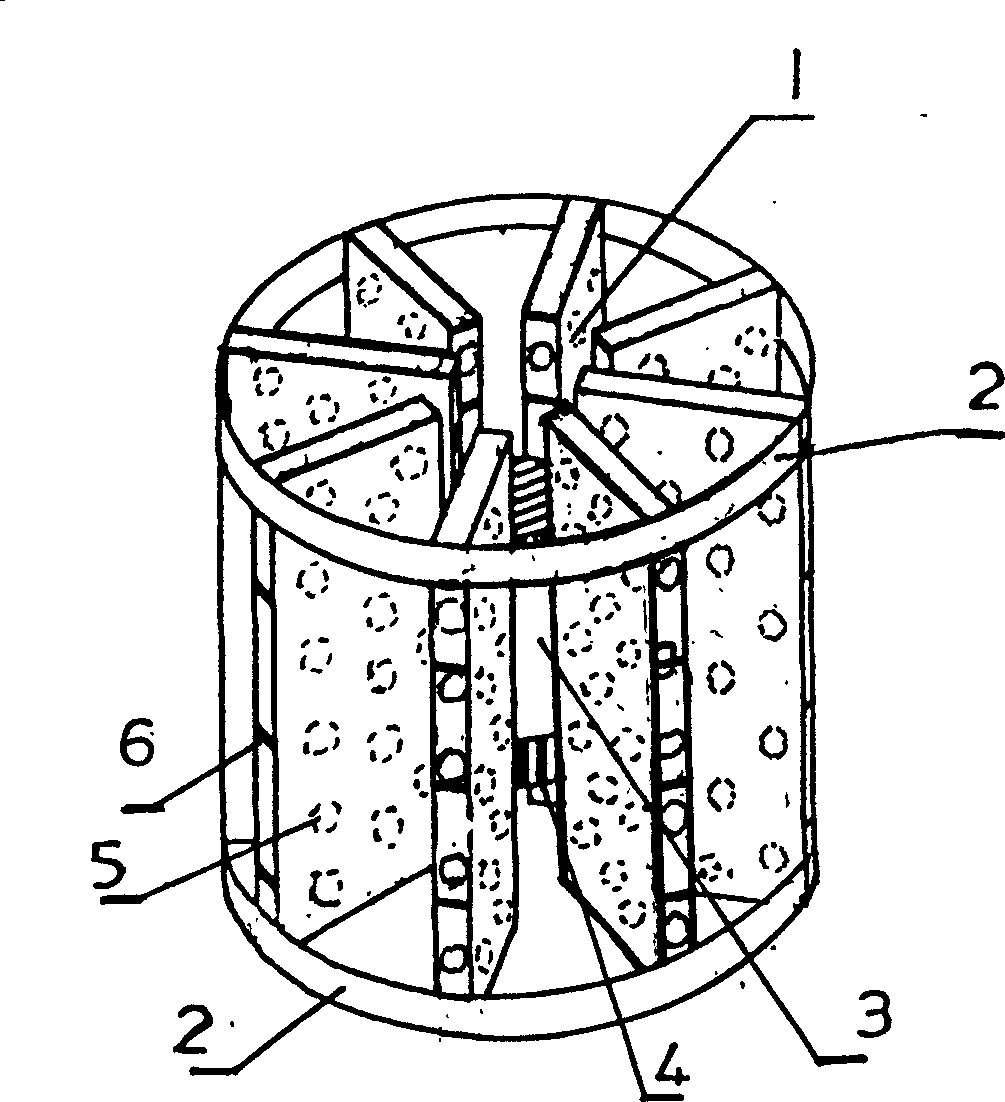

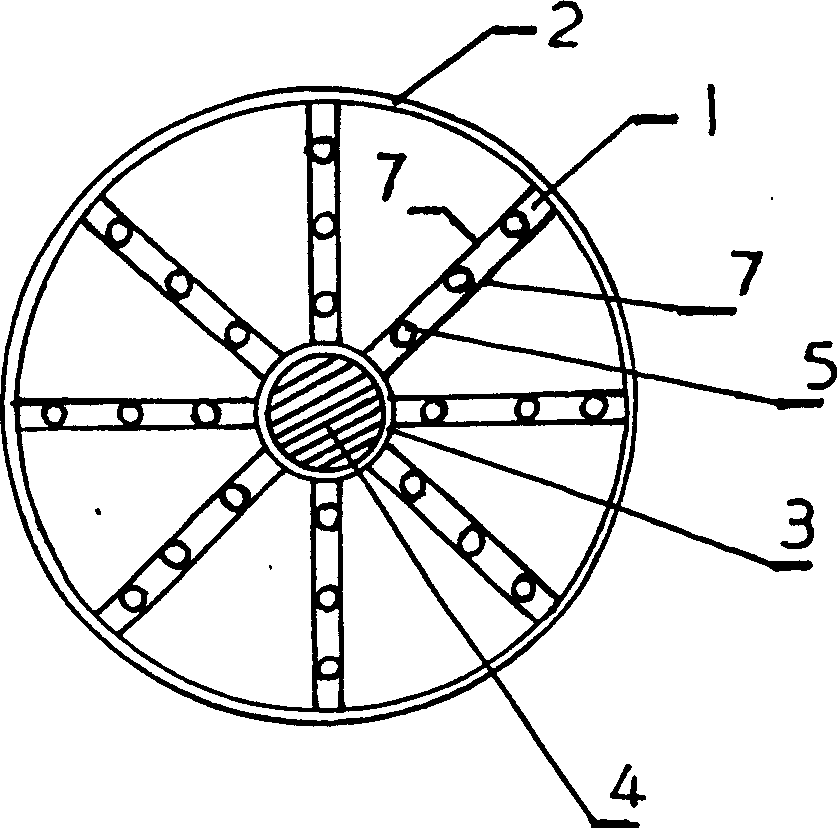

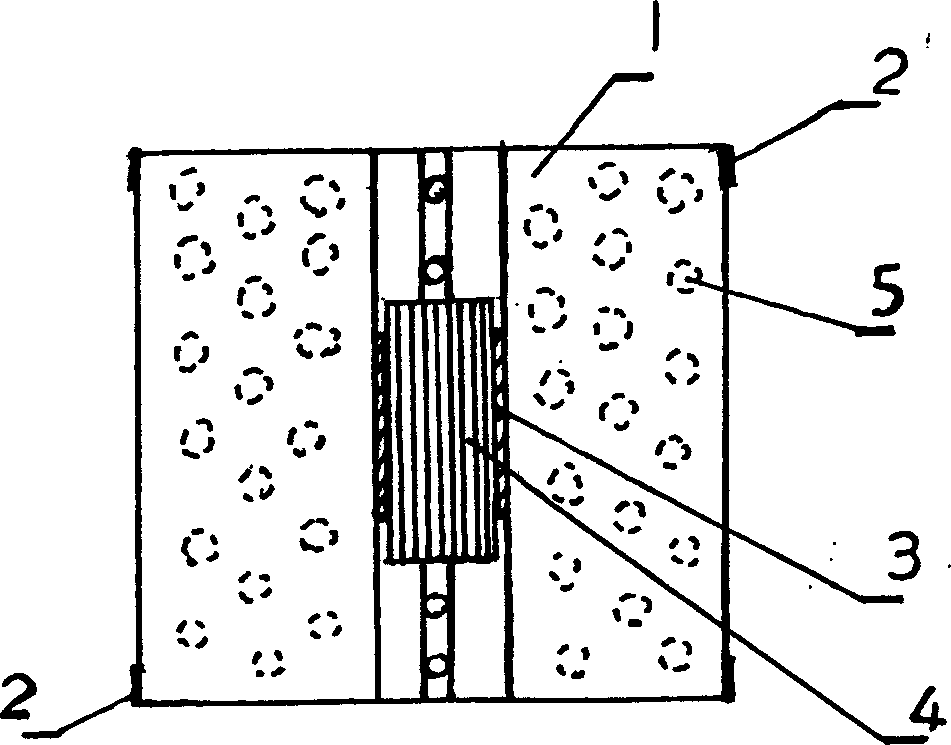

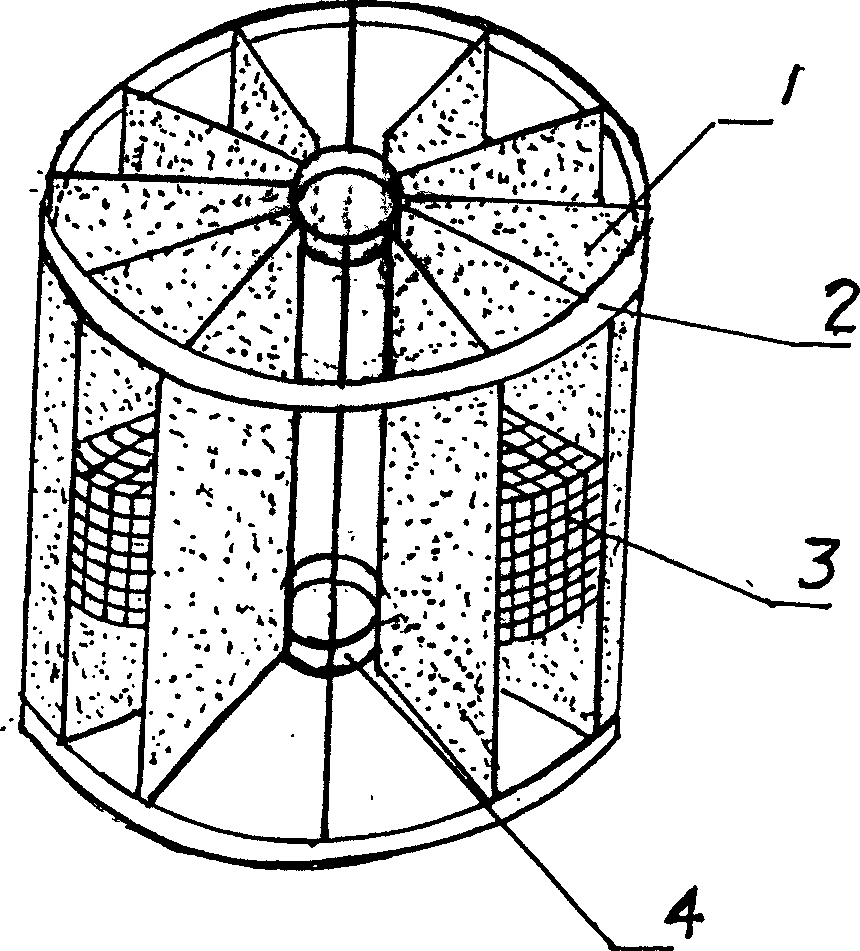

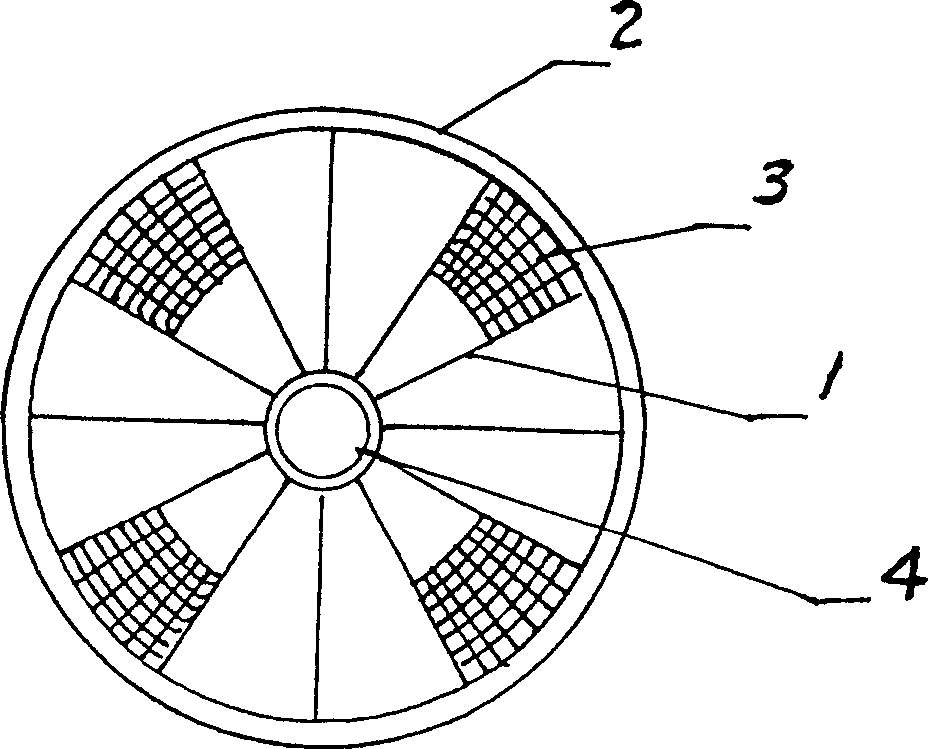

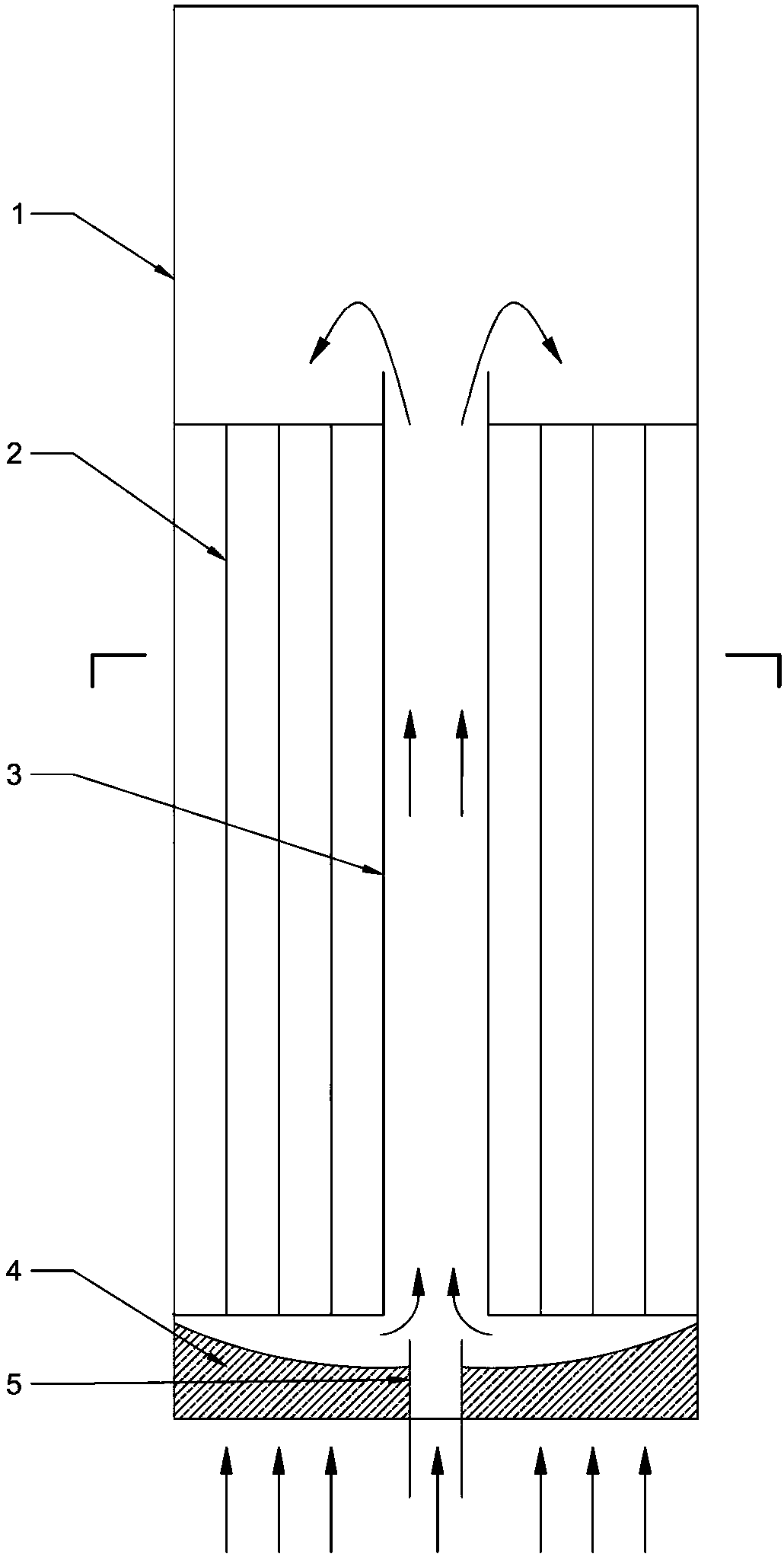

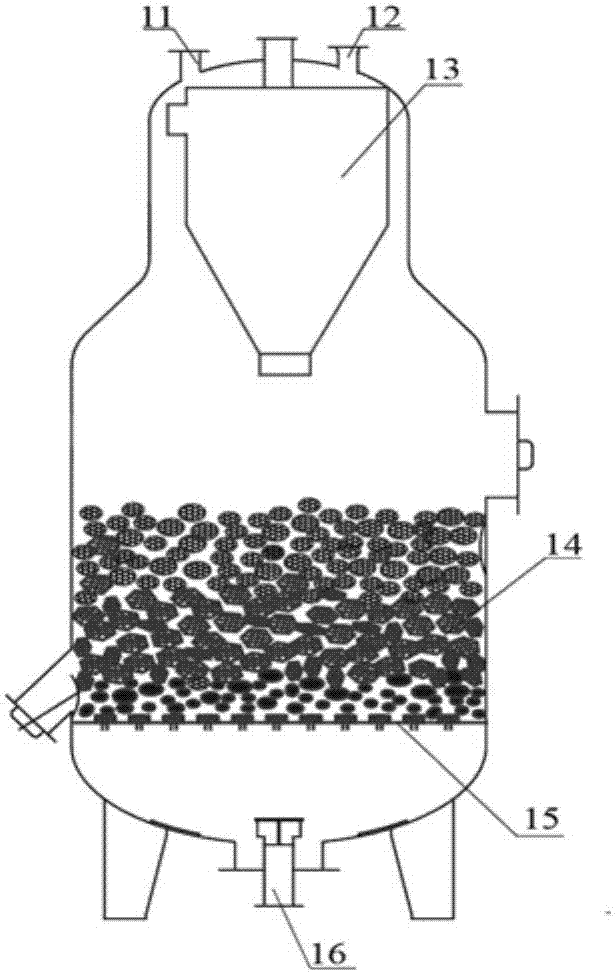

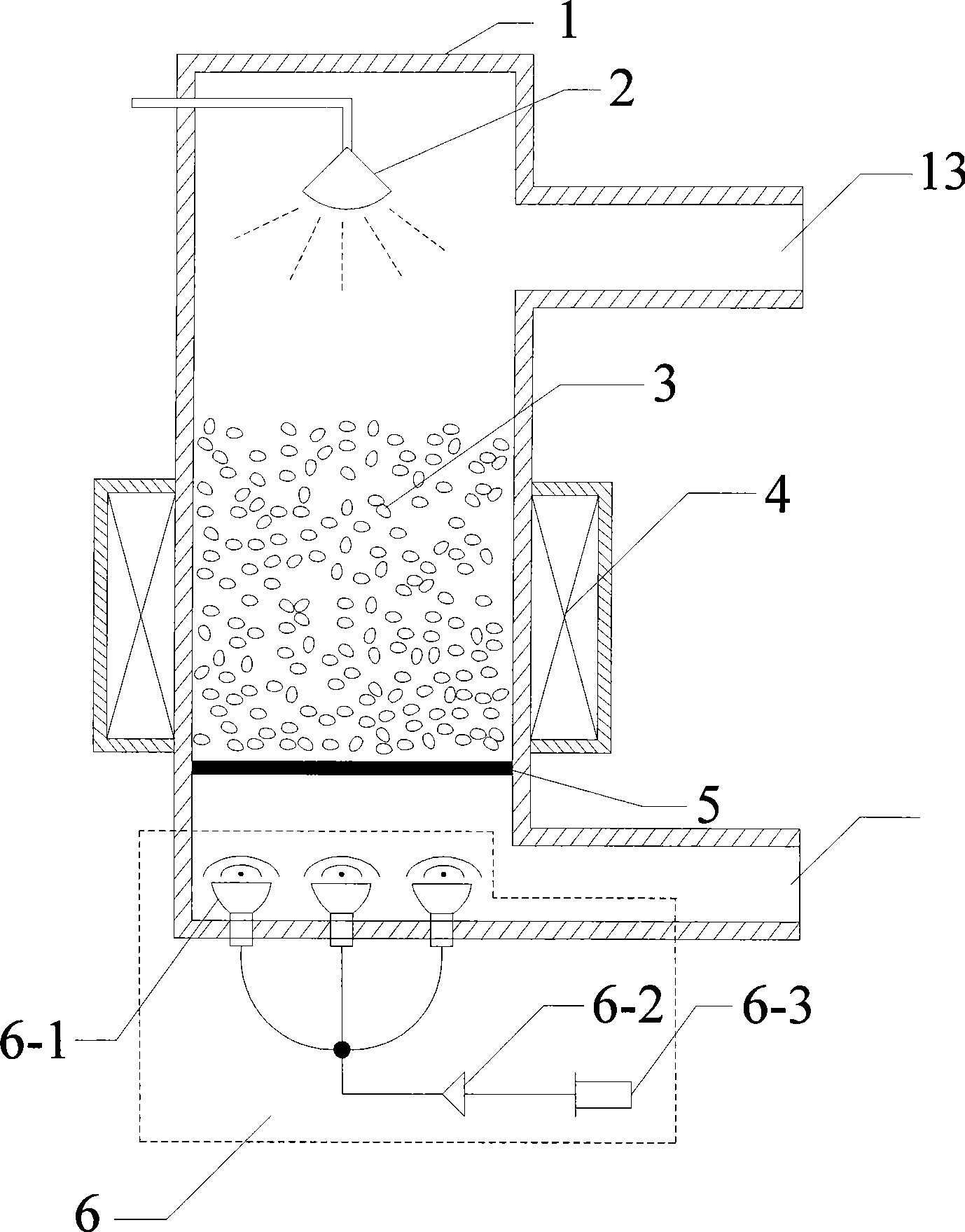

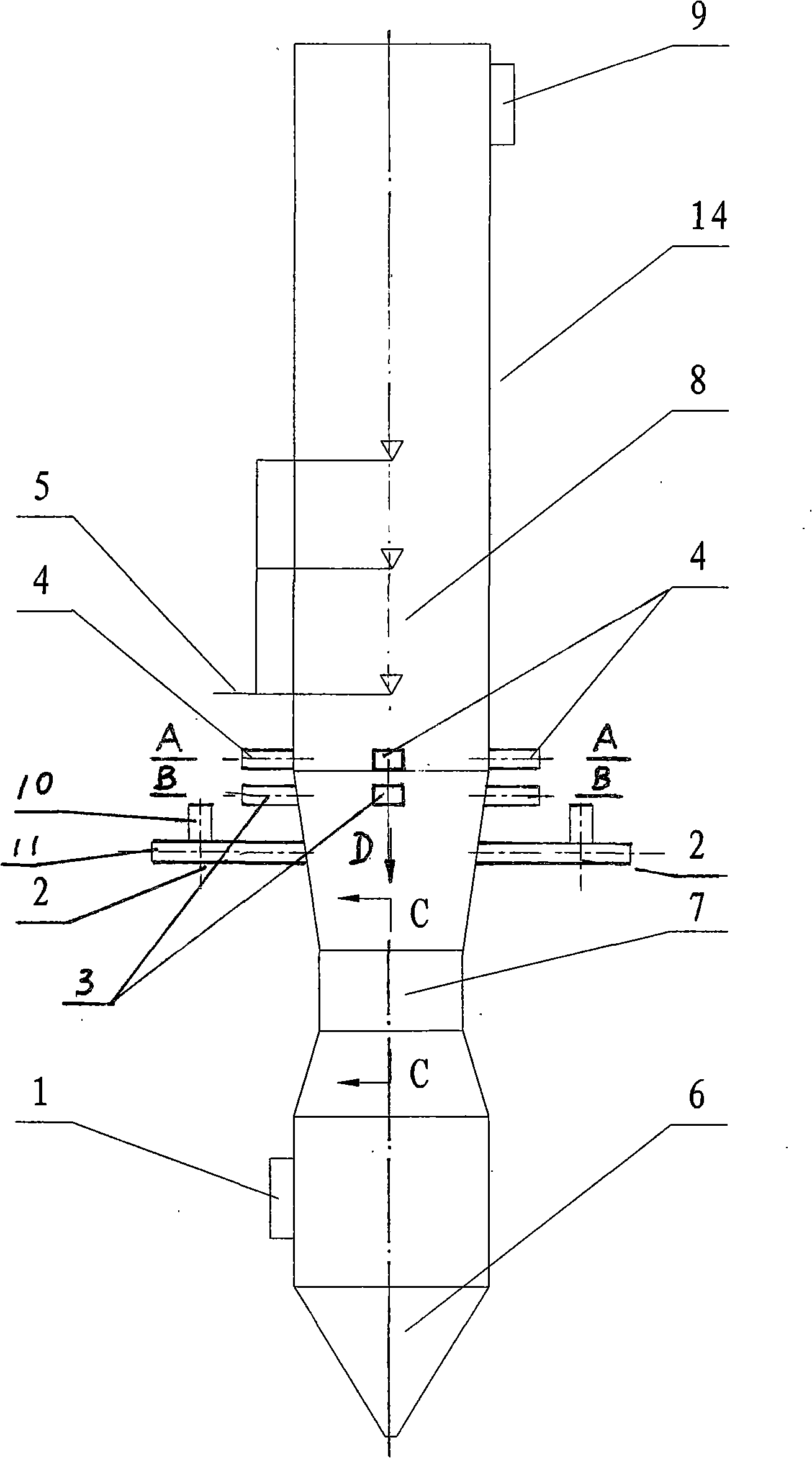

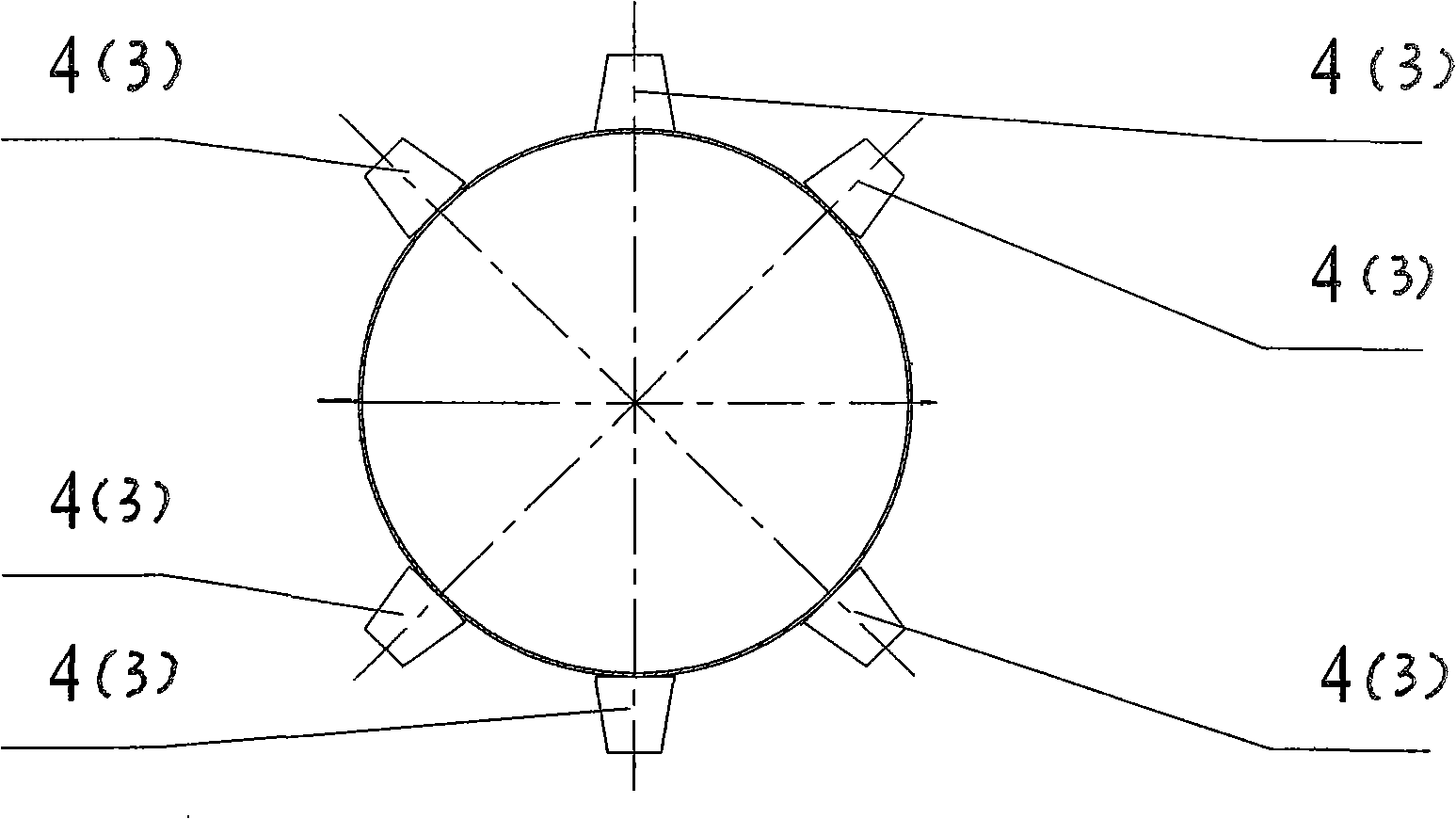

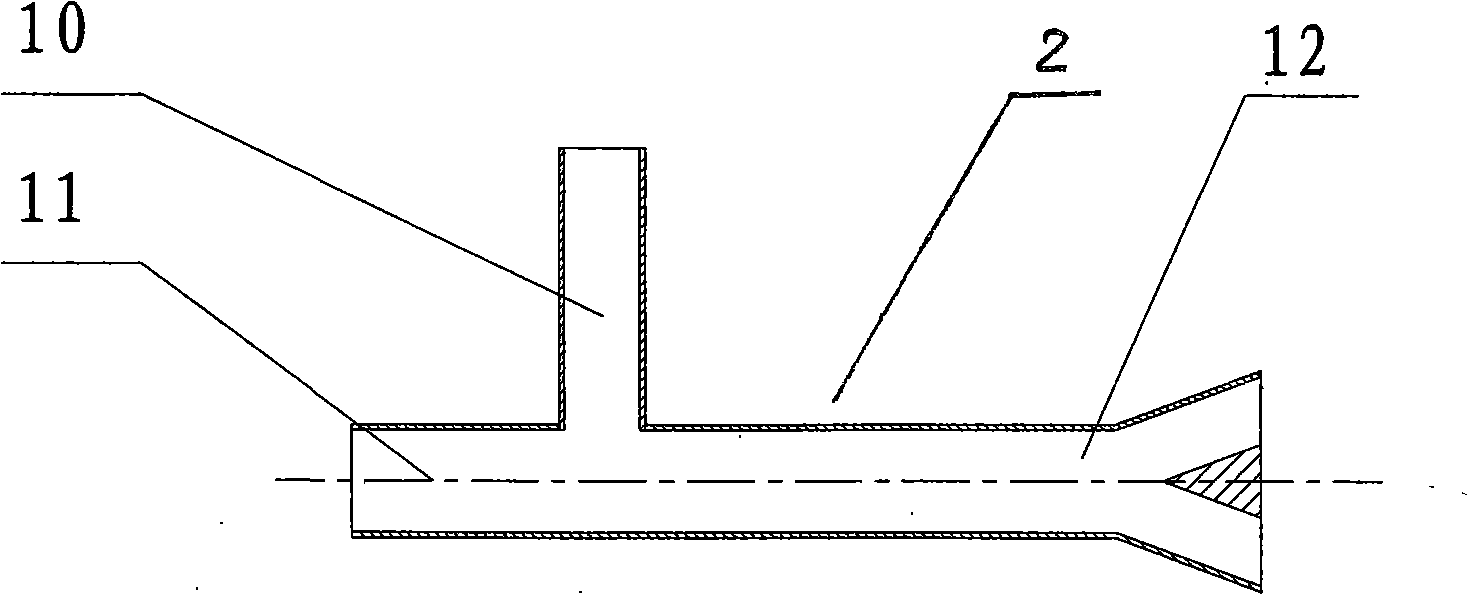

Fluidized bed capable of organizing ultrafine particles to be mixed in orderly manner

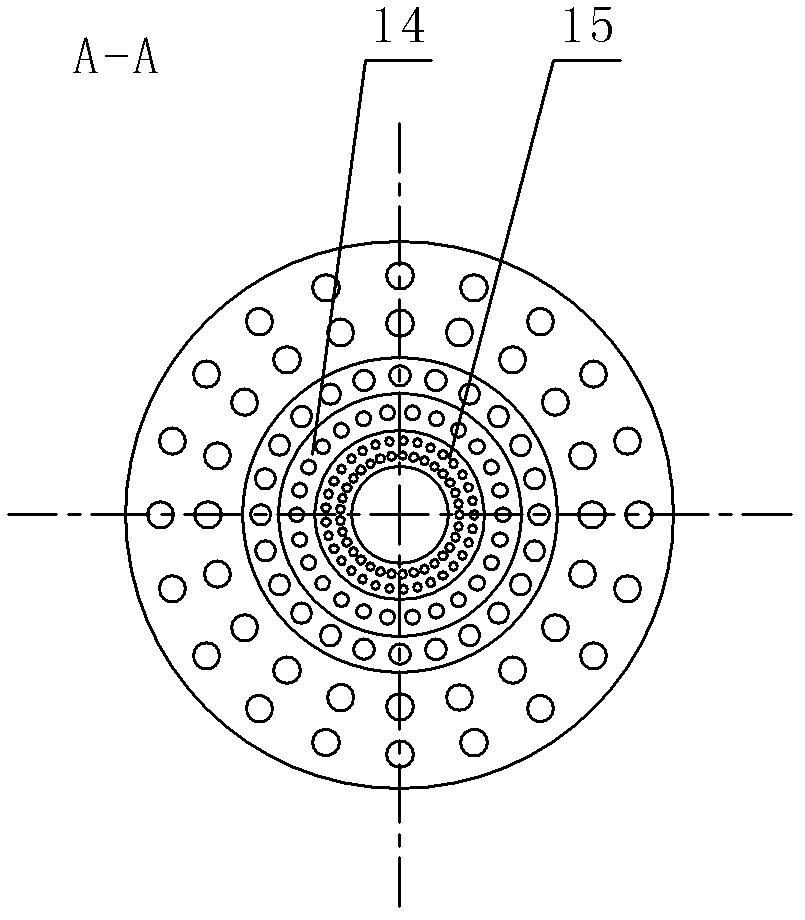

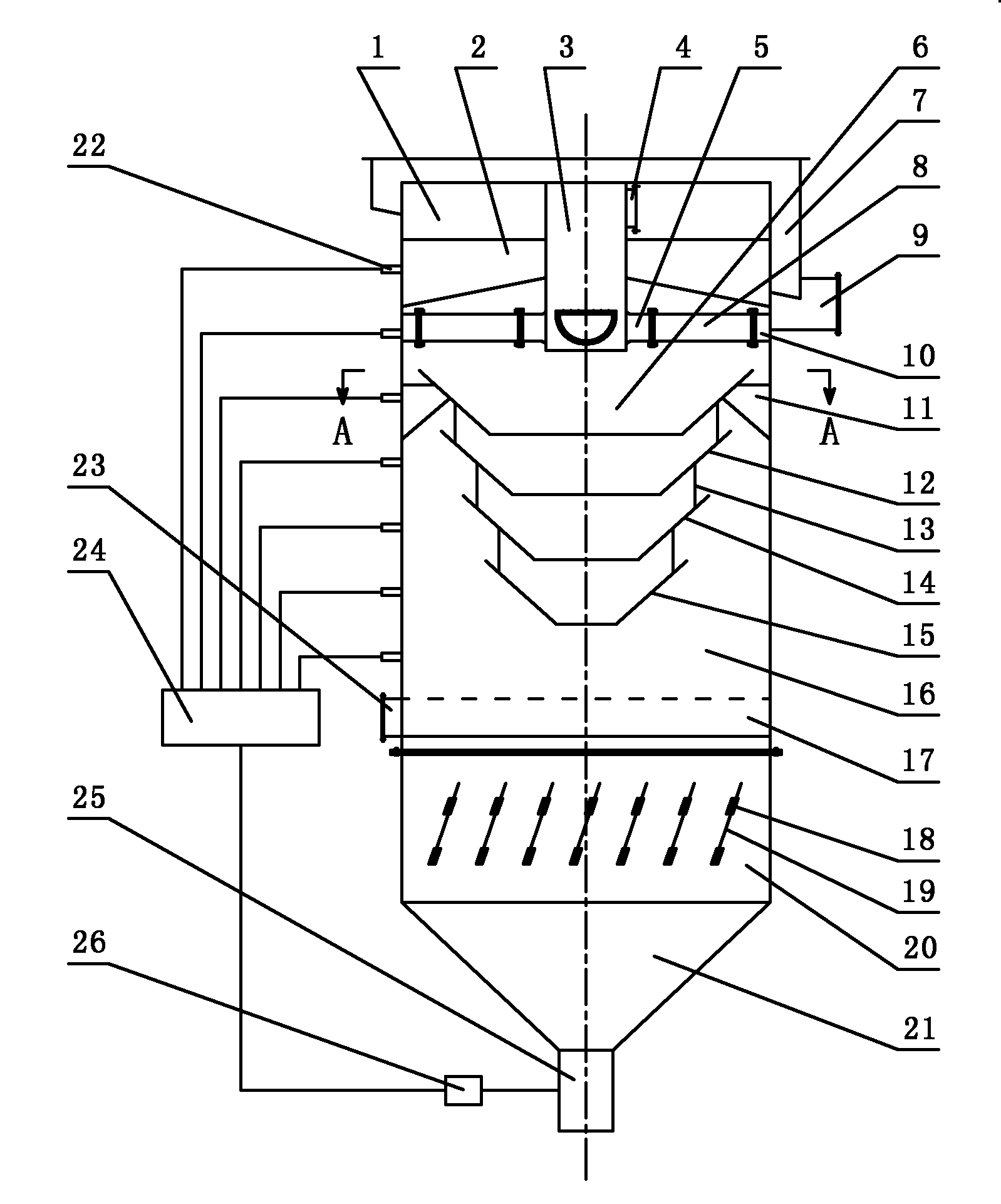

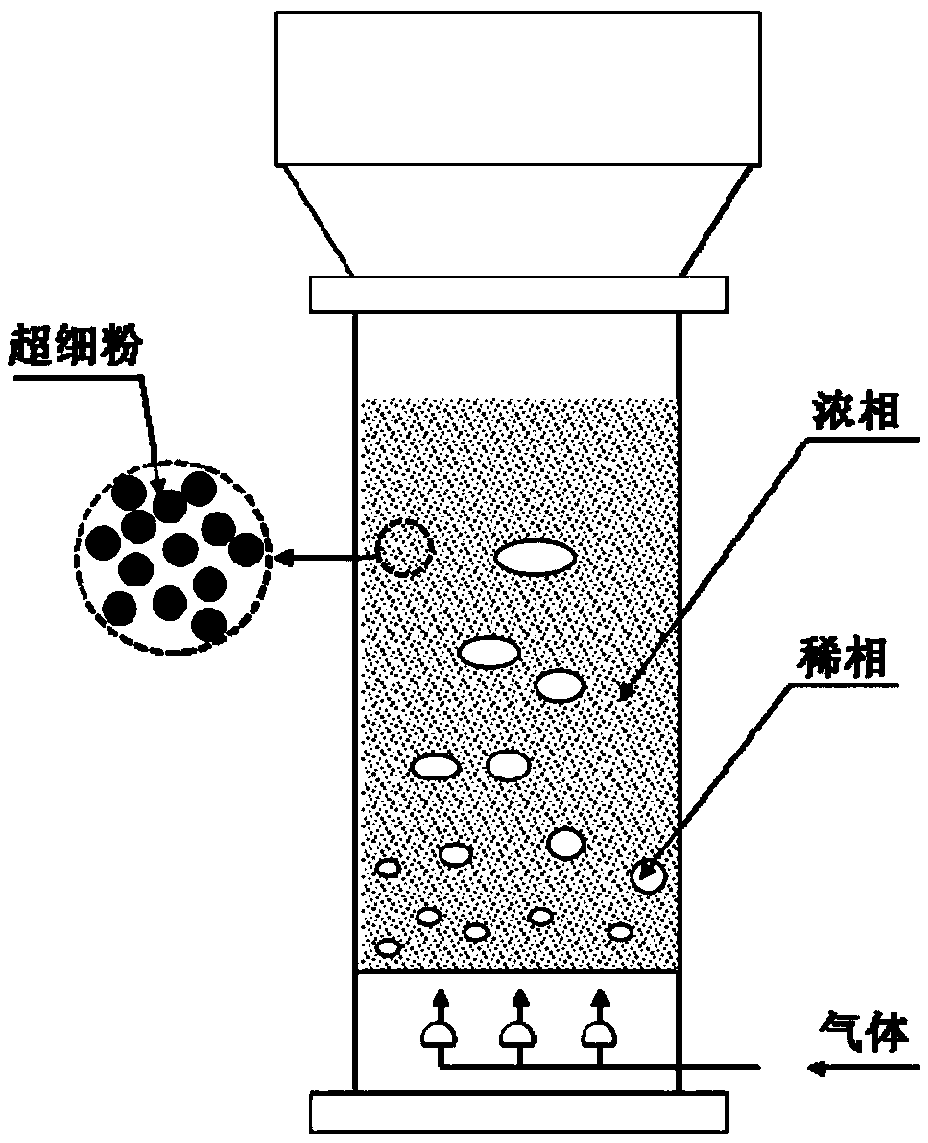

InactiveCN108579654APromote aggregationSuppresses the effects of backmixingTransportation and packagingChemical/physical/physico-chemical reactor detailsEngineeringUltrafine particle

The invention discloses a fluidized bed capable of organizing ultrafine particles to be mixed in an orderly manner. The fluidized bed comprises a flow guiding pipe arranged in the middle of an outer cylinder, a grid-type baffle arranged in an annular area located between the flow guiding pipe and the outer cylinder, an air distribution plate arranged under the flow guiding pipe and the grid-type baffle, and a central jet pipe corresponding to the flow guiding pipe and arranged in the middle of the air distribution plate. The fluidized bed disclosed by the invention can organize the ultrafine fluidized bed particles to be mixed in the orderly manner, enhance circulating flow of the particles in the bed, improve gas-solid two-phase contact efficiency, and better improve fluidization of the ultrafine particles; and the fluidized bed has stable operation and is easy to maintain.

Owner:SOUTHEAST UNIV

Liquid-solid interference fluidized bed separator as well as separating method and application thereof

The invention provides a liquid-solid interference fluidized bed separator as well as a separating method and application thereof. The separator mainly comprises a separator shell, a feeding device, a guide device, a fluid distributing device, a floating matter collecting device, a sediment collecting device and a control system, wherein the feeding device mainly comprises a vertical feeding pipe and an overflow pipe, the sediment collecting device mainly comprises an inclined plate, and the control system comprises a plurality of pressure sensors. The separating method comprises the steps of: feeding by adopting the vertical feeding pipe and the overflow pipe; carrying out secondary uniform distribution and step size grading on discharged materials of the overflow pipe by adopting the guide device; determining a separating zone of a fluidized bed by adopting the pressure sensors; and arranging the inclined plate in a lower cylinder body of the separator to improve treating capacity and density control precision of the separator. The separator has the advantages of simple and compact structure, good stability, convenience for operation and capability of greatly improving density uniformity and stability of the fluidized bed, thereby the separating performance of the separator is improved and the application range of the separator is widened.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Treating process of water-rich aluminium hydroxide sludge

InactiveCN1398800AEasy to operateSave freezer spaceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludge cakeFluidized bed

The present invention is a treatment method for water-rich aluminium hydroxide sludge. Water-rich aluminium hydroxide sludge is rolled into sheet, and then it is frozen in a multiple-process and multiple-section belt conveyer type freezer with freezing temperature of minus 30 to minus 10 deg.C for 30-60 min; it is dewatered in a normal temperature-water thawing tank, low-vacuum filtered or squeezed to obtain wet sludge cake; and it is dried in a multiple-partition hot-carrier fluidized bed with industrial waste gas at 70-90 deg.C for 30-60 min to obtain the dry aluminium hydroxide sludge product. The present invention has the features of easy operation, low power consumption, low cost and no pollution.

Owner:FUZHOU UNIV

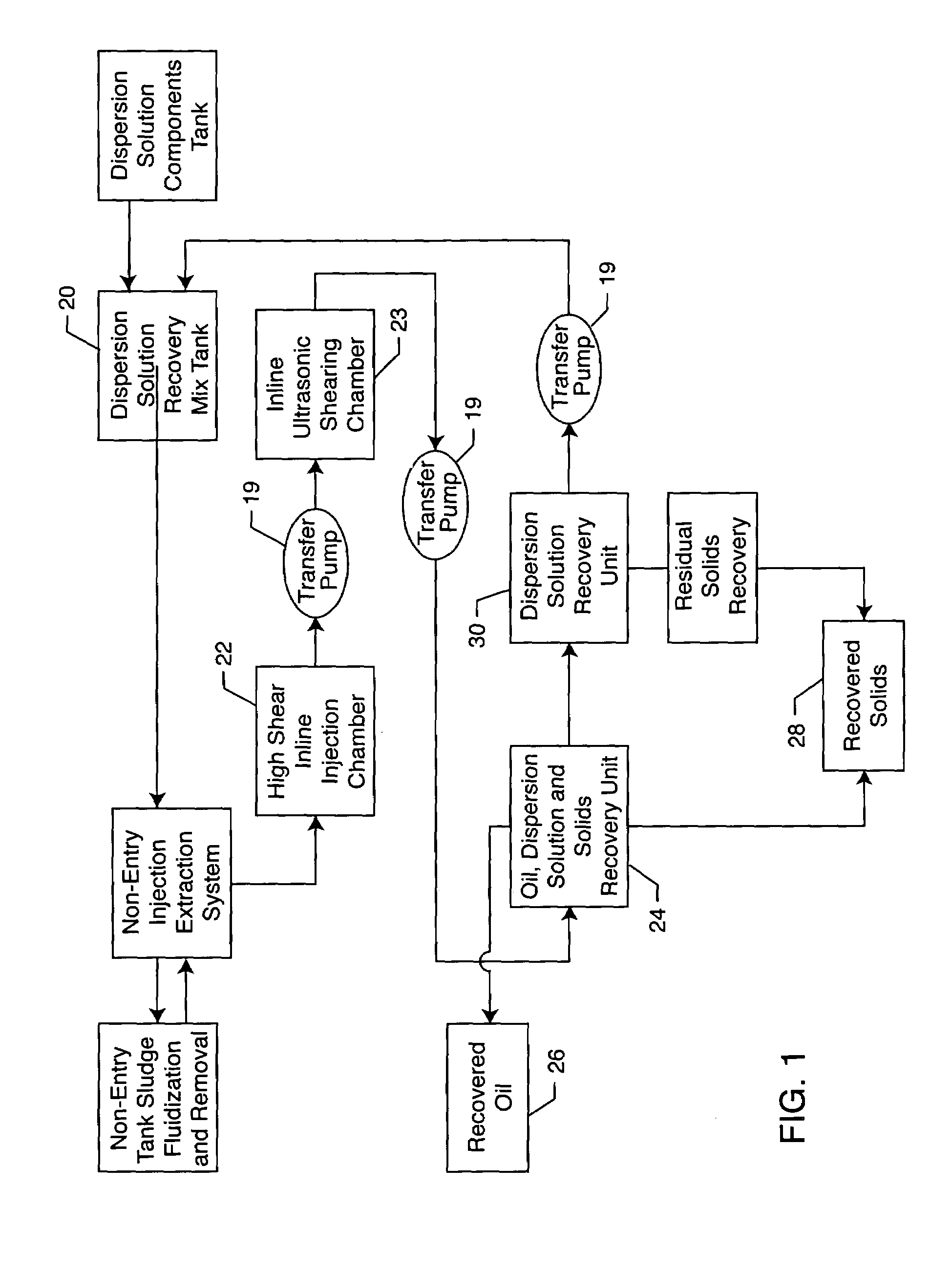

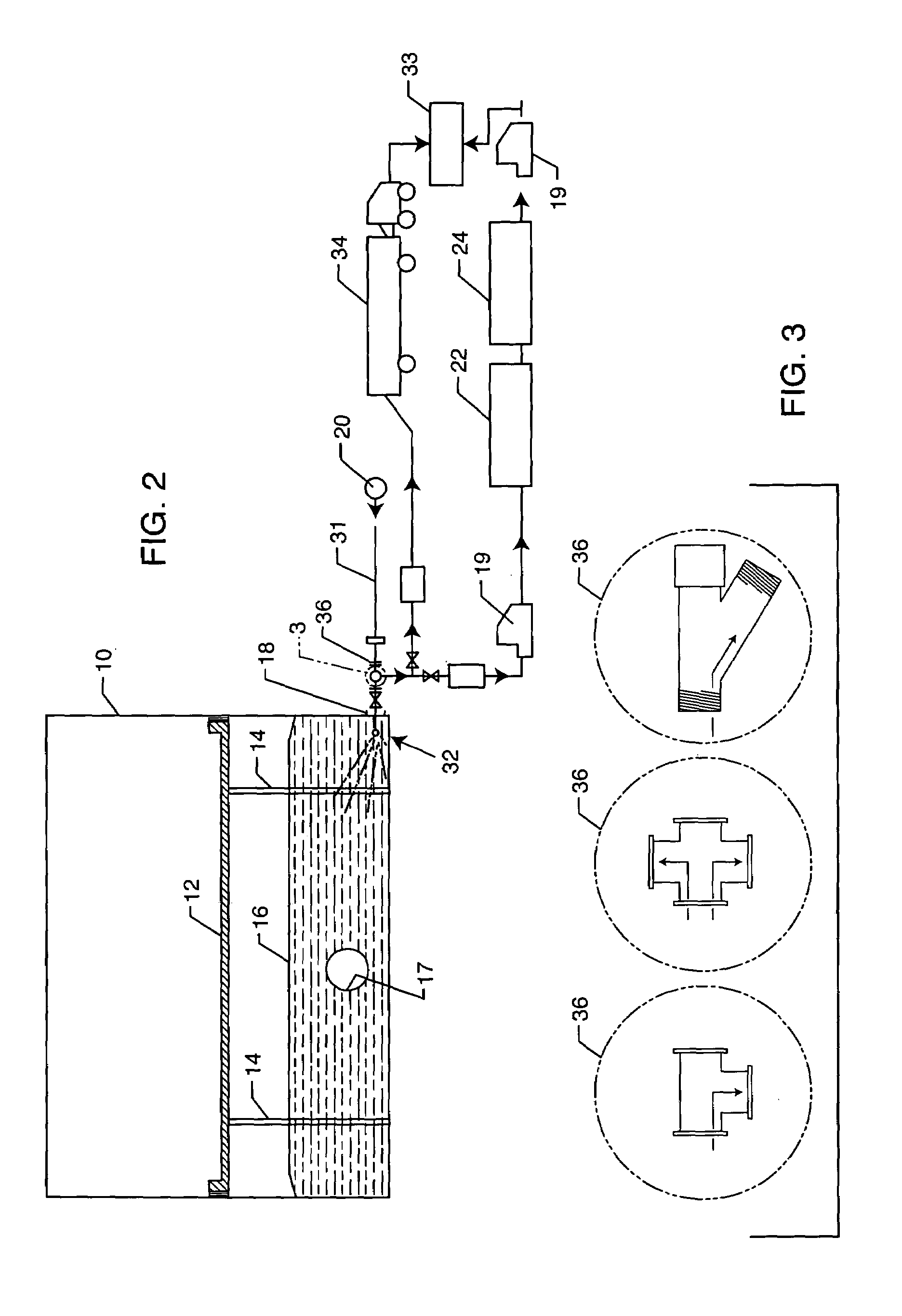

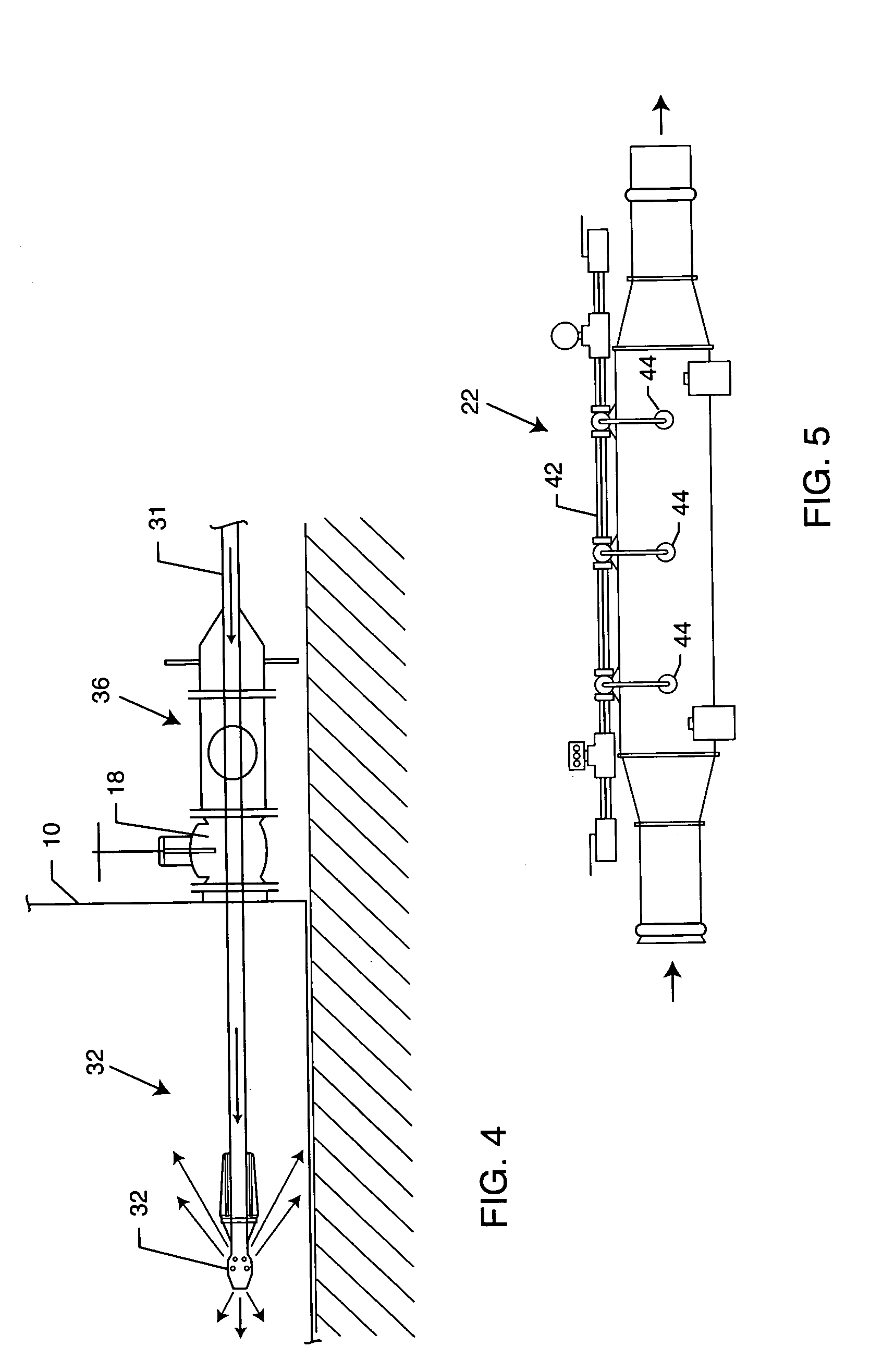

Petroleum recovery and cleaning system and process

InactiveUS7594996B2Quality improvementIncrease productionInorganic/elemental detergent compounding agentsLiquid separation auxillary apparatusProcess equipmentPetroleum product

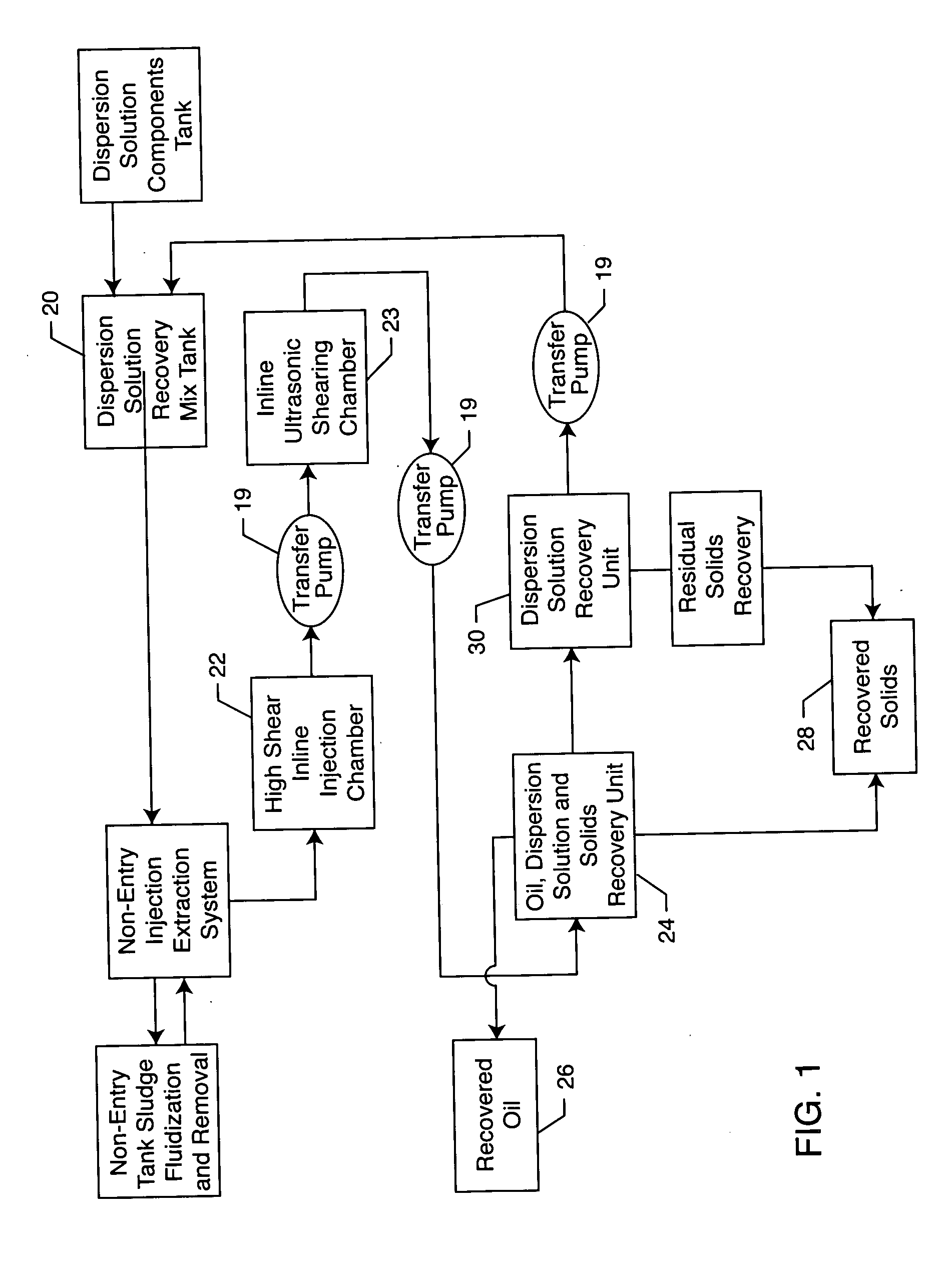

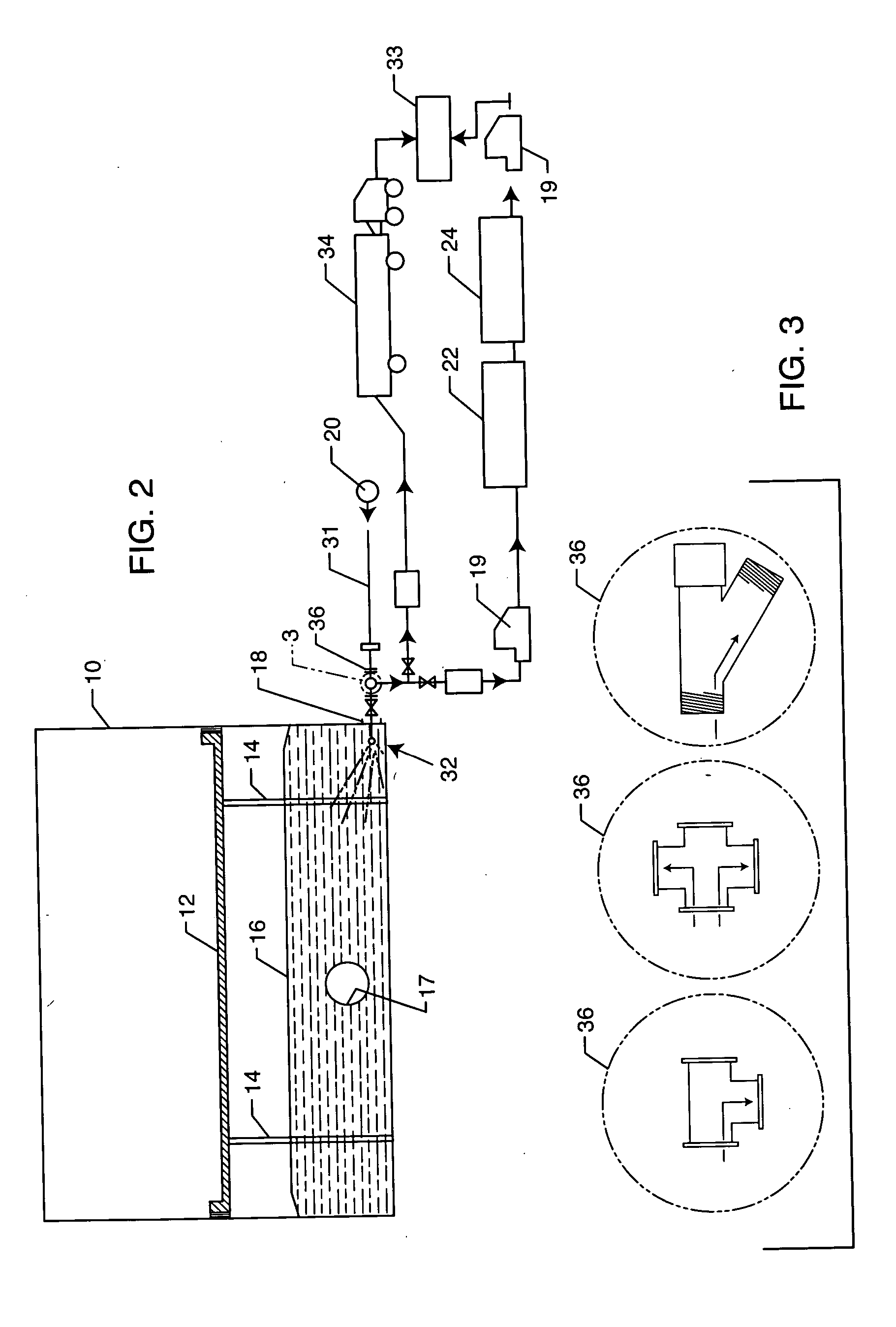

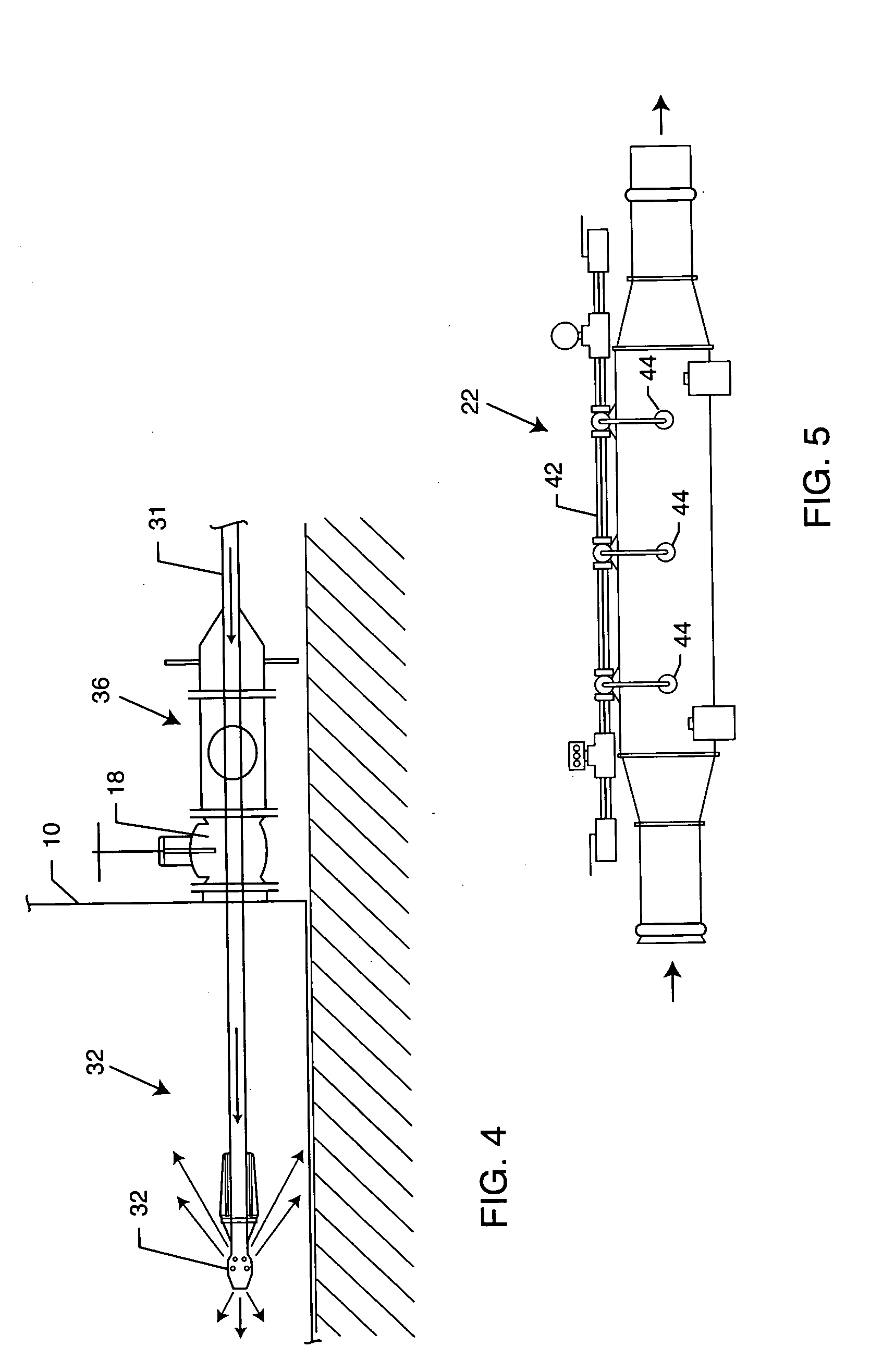

A system and process are provided for recovering and / or cleaning residual or waste petroleum products such as sludge accumulated within a storage tank or upon process equipment surfaces, or from inorganic materials such as sand or clay, and the like. The system and process include a negatively charged aqueous-based dispersion fluid, which is contacted with the petroleum product under controlled relatively high pressure and high shear conditions for fluidizing hydrocarbon molecules and for preventing such molecules from adherence to process equipment surfaces, or contaminants such as sand or clay. Additional mechanical separation as by subjecting the mixed petroleum product and dispersion fluid slurry to sonic vibration may also be employed. The thus-fluidized slurry of petroleum products, dispersion fluid, and inorganic materials can be separated by conventional techniques, as by settling and / or flotation, for further individual processing and / or re-use.

Owner:AQUA TECH LLC

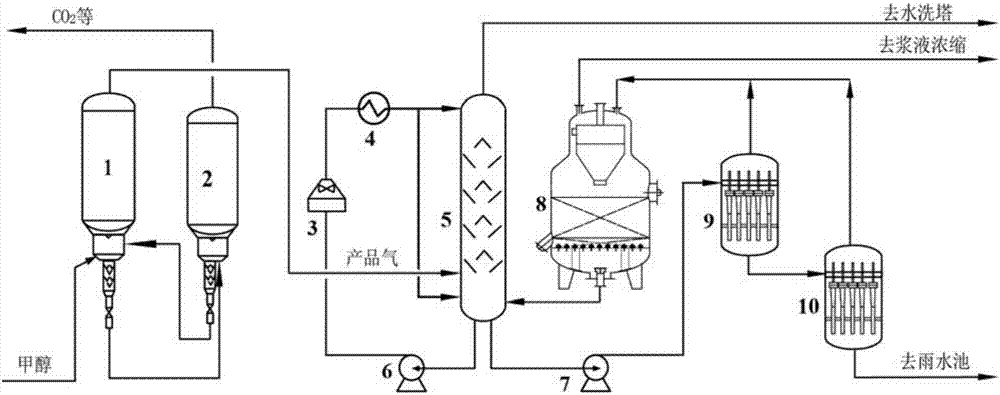

Ranking method of separation media in boiling bed separator

ActiveCN107512787AImprove filtering effectSimple and fast operationWater/sewage treatment by centrifugal separationTreatment involving filtrationCycloneRanking

The invention discloses and relates to a ranking method of separation media in a boiling bed separator. The method comprises the steps that a whirlcone is arranged at the upper part of the boiling bed separator; during the regeneration, the separation media in a filtering bed layer of the boiling bed separator is in a complete fluidized state; the separation media upwards enters the whirlcone; after cyclone ranking, the separation media flows out from the whirlcone in a sequence from high specific gravity to low specific gravity; after the back flushing regeneration is completed, the separation media is continuously used for purifying process water generated in a MTO (Methanol To Olefin) process, wherein the filtering bed layer of the boiling bed separator is formed by multiple layers of different separation media; the separation media particle size distribution is downwards reduced layer by layer; the specific gravity of the separation media is downwards increased layer by layer.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Two-pore zeolite microsphere and preparation method thereof

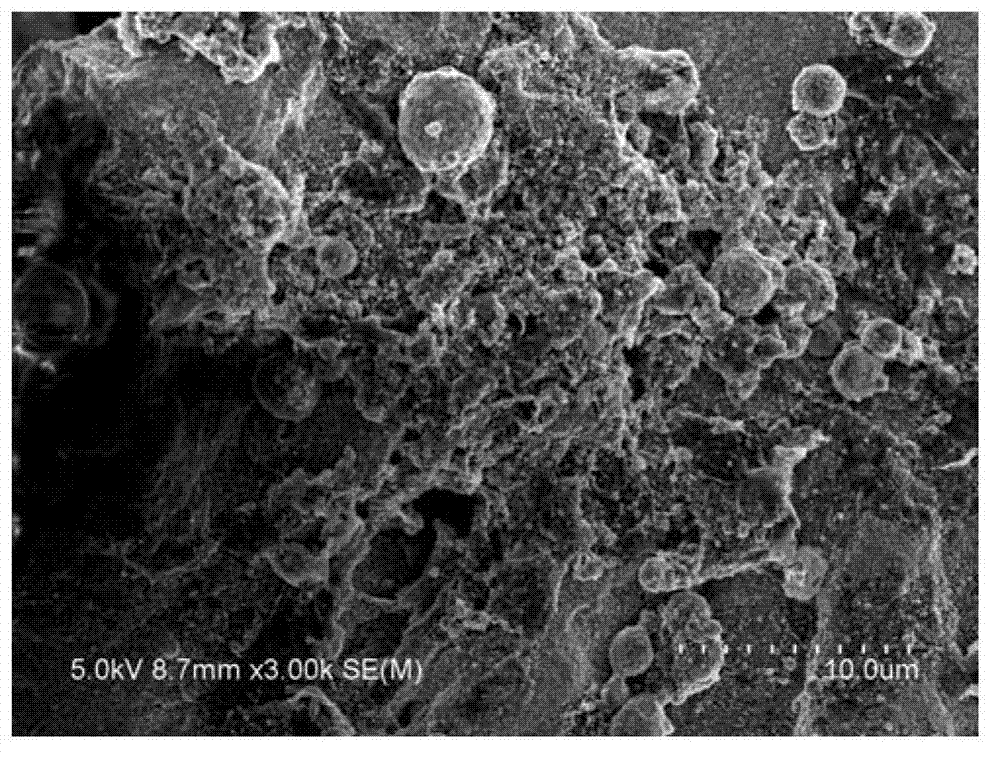

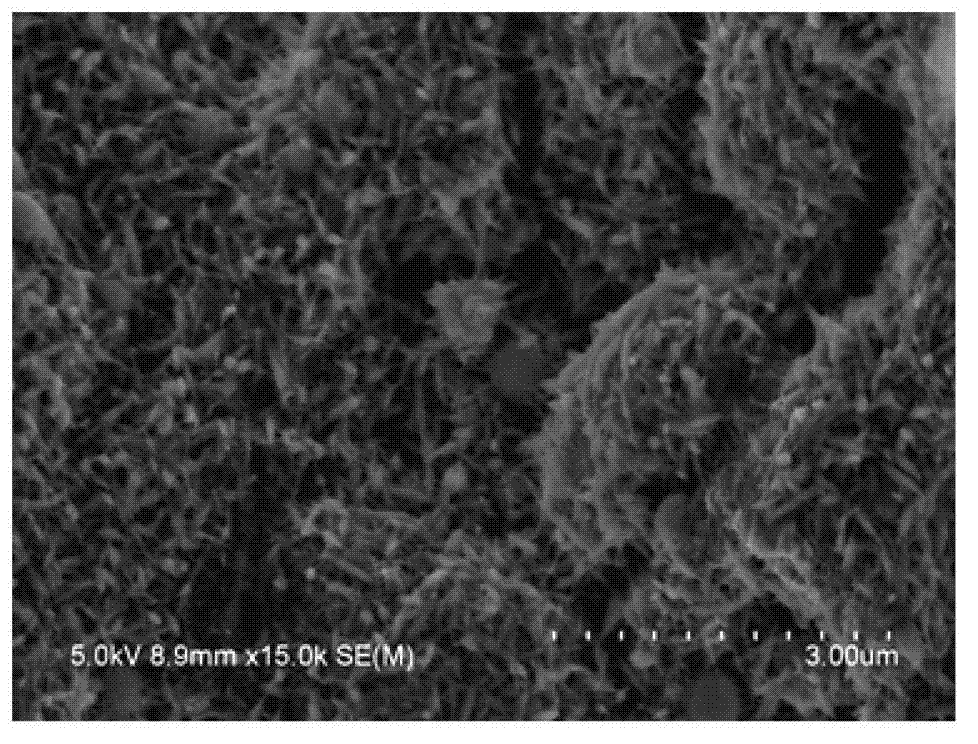

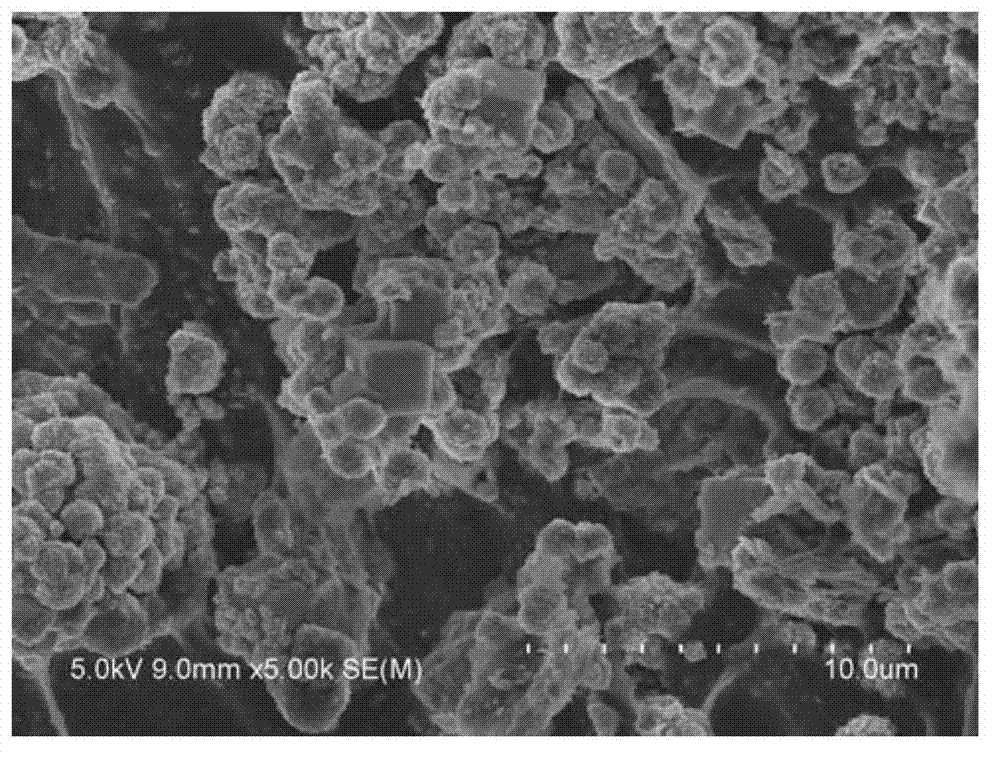

ActiveCN103084143AWith compressive strengthEasy to fluidizeCatalyst carriersWater/sewage treatment by irradiationPore distributionMicrosphere

The invention discloses a two-pore zeolite microsphere and a preparation method thereof. The diameter of the microsphere is 4-6mm, the water absorption is 18-24%, the apparent density is 610-630kg / m<3>, and the compressive strength is greater than or equal to 6MPa. Compared with the prior art, the prepared super-light micropore-mesopore two-pore zeolite microsphere has certain compressive strength, is easily fluidized and prevents water loss; with micropore and mesopore two-model pore distribution, the diffusion path of molecules can be shortened, the specific surface area is large, and the adsorption exchange ability is relatively strong; and the two-pore zeolite microsphere can be applied to deep treatment of industrial wastewater, and also can be used as a carrier of an aerobic (anaerobic) microorganism / photocatalyst of an aerobic (anaerobic / photocatalysis) fluidized bed reactor in the field of water (wastewater) treatment. The invention provides a new green efficient method for expanding the application of industrial waste fly ash to the field of environmental protection.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Primary Air Distribution Method for Circulating Fluidized Bed Boiler

InactiveCN102278744AUniform fluidizationEasy to fluidizeFluidized bed combustionApparatus for fluidised bed combustionAir preheaterFluidized bed

The invention discloses a method for distributing primary air of a circulating fluidized bed boiler, and relates to the technology of a circulating fluidized bed boiler. There is an air chamber at the bottom, and the air chambers are not connected to each other; each air chamber is connected to the air preheater of the boiler through an air pipe; each air pipe is equipped with an air flow measuring device and an adjustment device. device; when the boiler is running, adjust the air flow regulating device to control the primary air volume flowing into each air chamber. The method of the invention can improve the uniformity of the primary air distribution of the circulating fluidized bed boiler, especially the large capacity circulating fluidized bed boiler.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

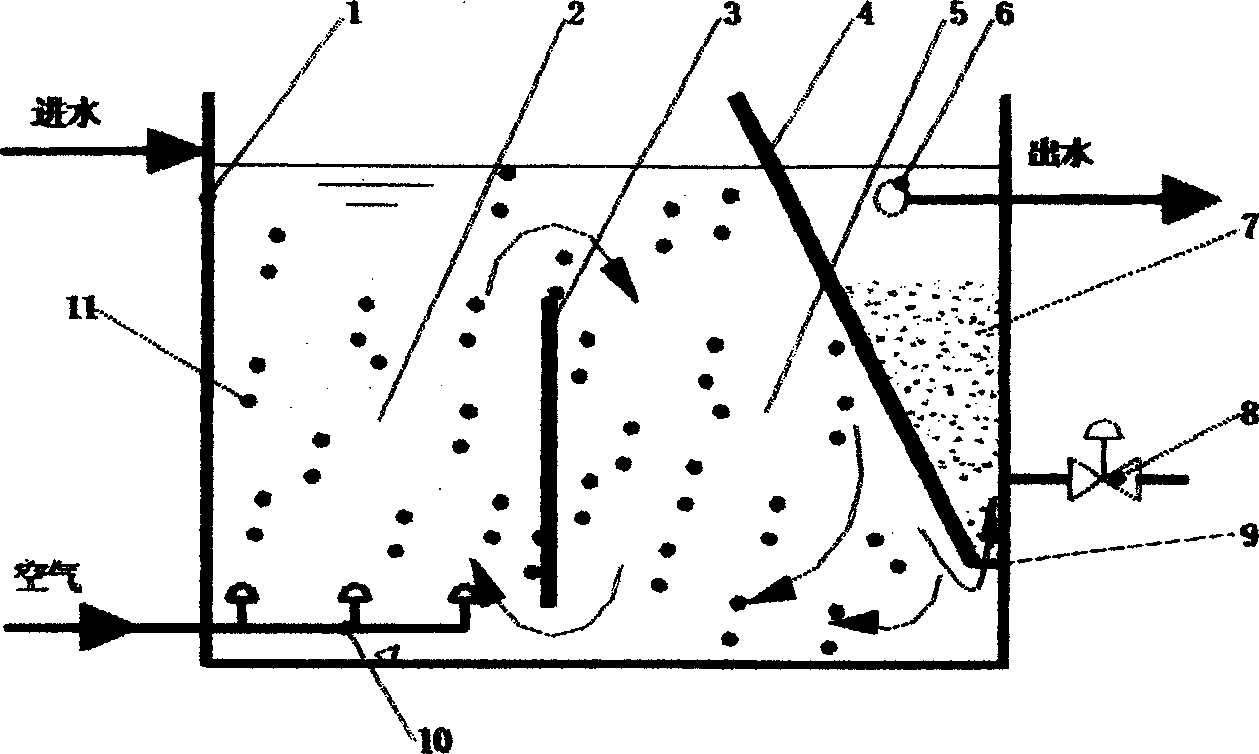

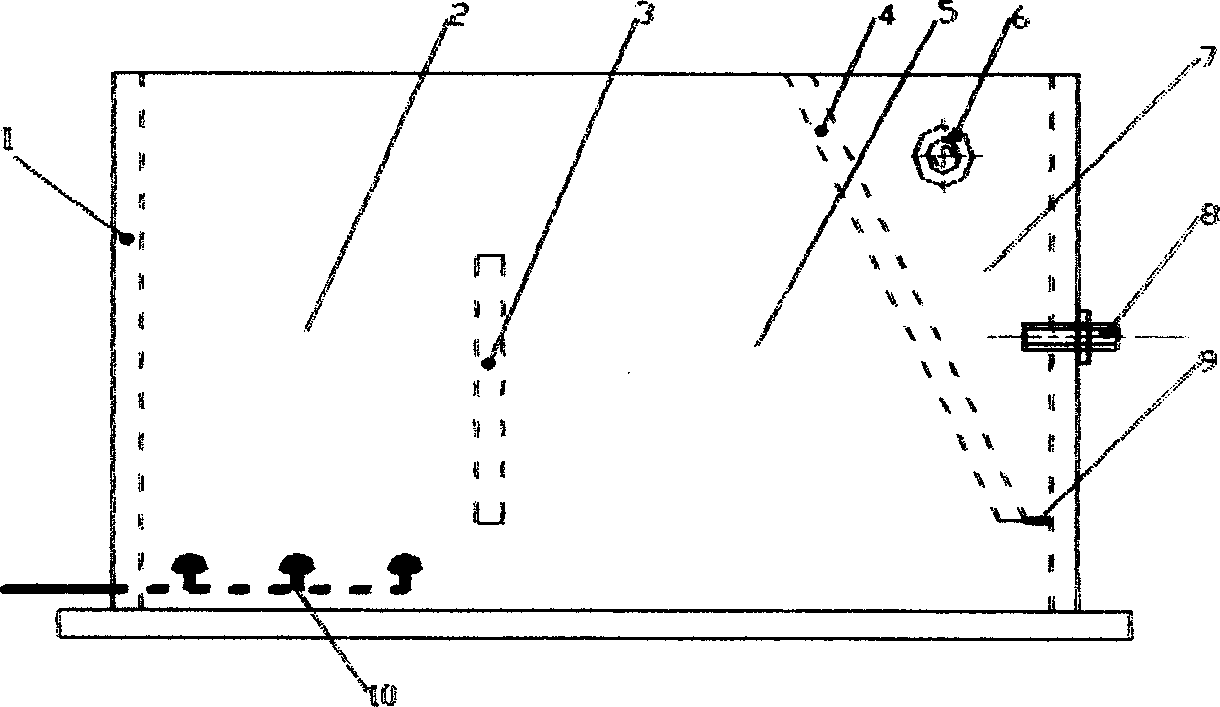

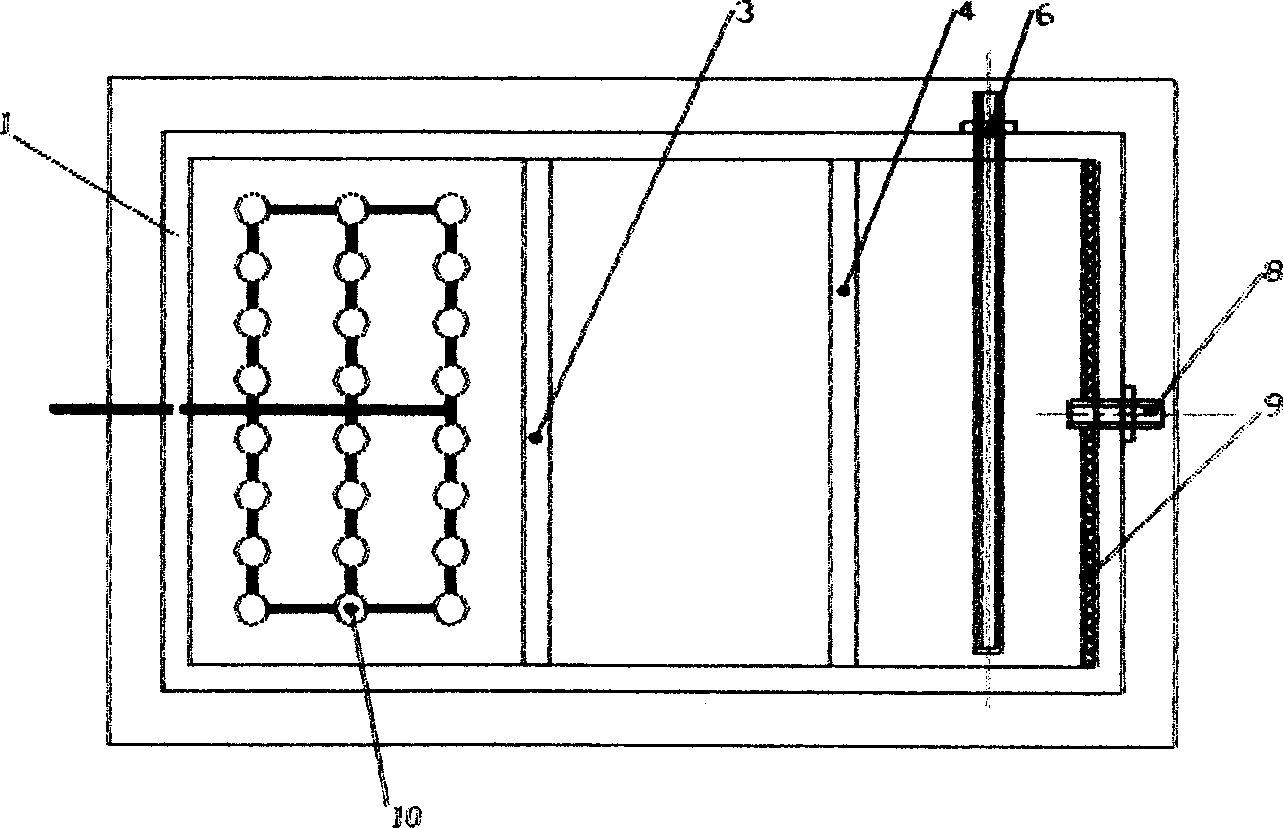

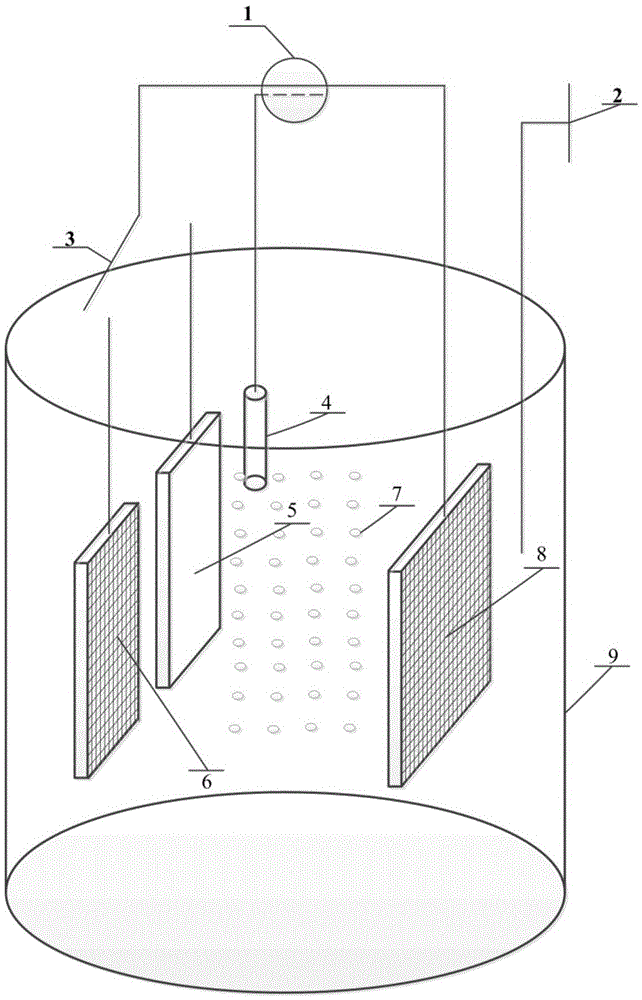

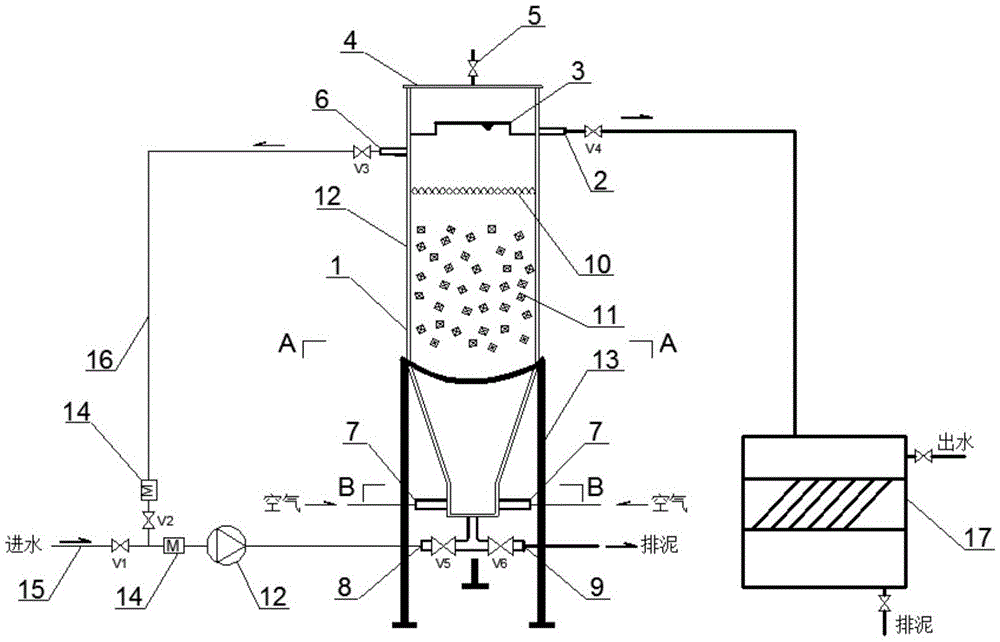

Novel aerobiont fluidized bed reactor and technology thereof

ActiveCN105129977AEasy to handleUniform fluidizationSustainable biological treatmentBiological water/sewage treatmentExhaust valveFluidized bed

The invention relates to a novel aerobiont fluidized bed reactor and a technology thereof. The novel aerobiont fluidized bed reactor comprises a reactor tank, a water outlet, an exhaust valve, an air inlet, a water inlet, a sludge discharge pipe, swastika-shaped biological stuffing, an outer support, a flow meter, a water inlet pipe and a tilted plate settling pond. The technology for treating sewage by means of the novel aerobiont fluidized bed reactor comprises the steps that 1, sludge is acclimated; 2, the biological stuffing is added; 3, sludge is discharged after aeration is performed; 4, sewage is led in and then aeration is performed; 5, sludge is discharged; 6, the COD removal rate is calculated; 7, the fourth, fifth and sixth steps are repeatedly executed, and the amount of sewage to be treated and the sewage amount are increased gradually after the COD removal rate is higher than 50%; 8, the amount of the sewage to be treated reaches 25-50% of the effective volume of the reactor tank, and water outlet and backflow are started when the COD removal rate is higher than 80%; 9, the treated water is drained into the tilted plate settling pond through the water outlet.

Owner:许建民

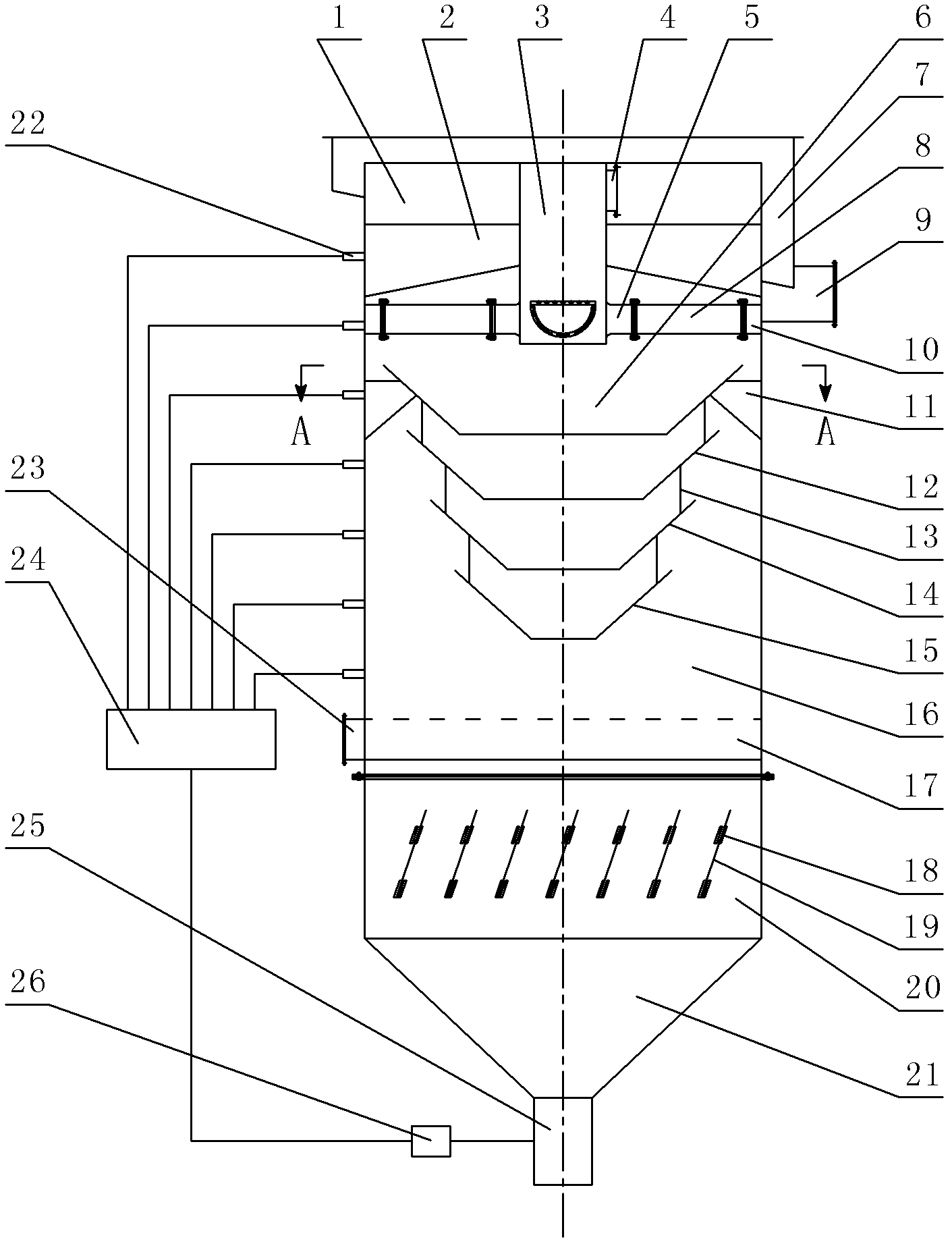

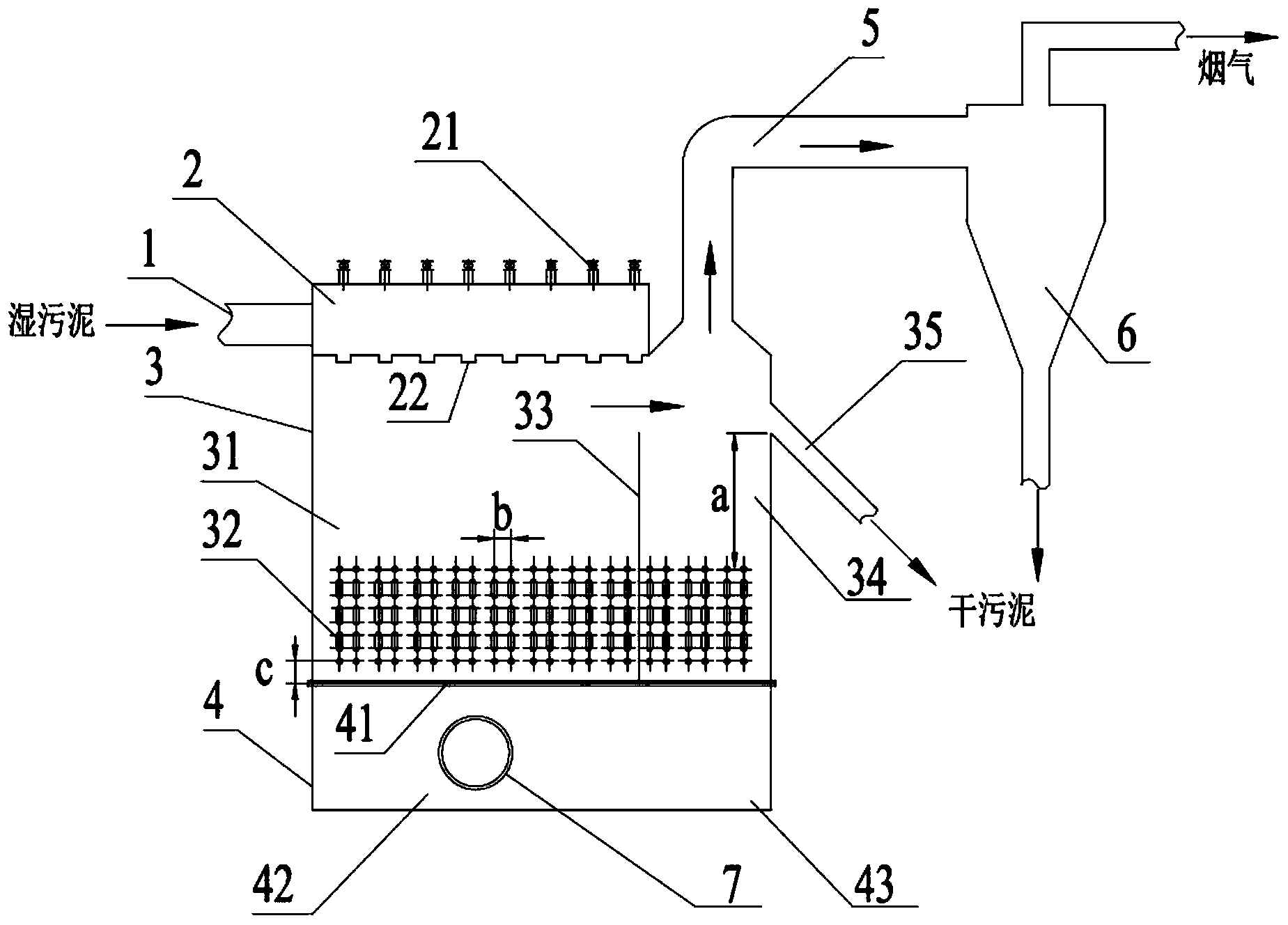

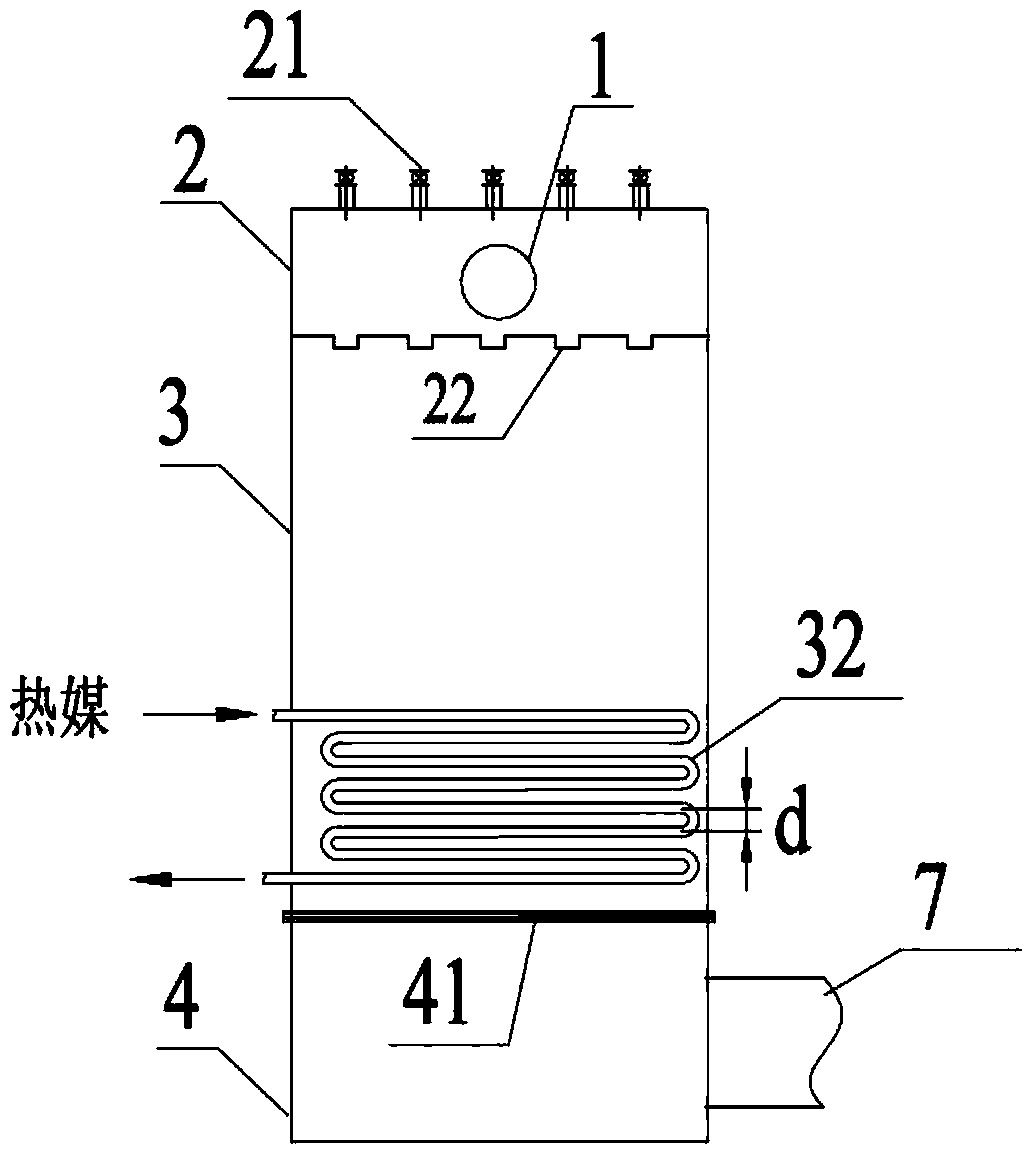

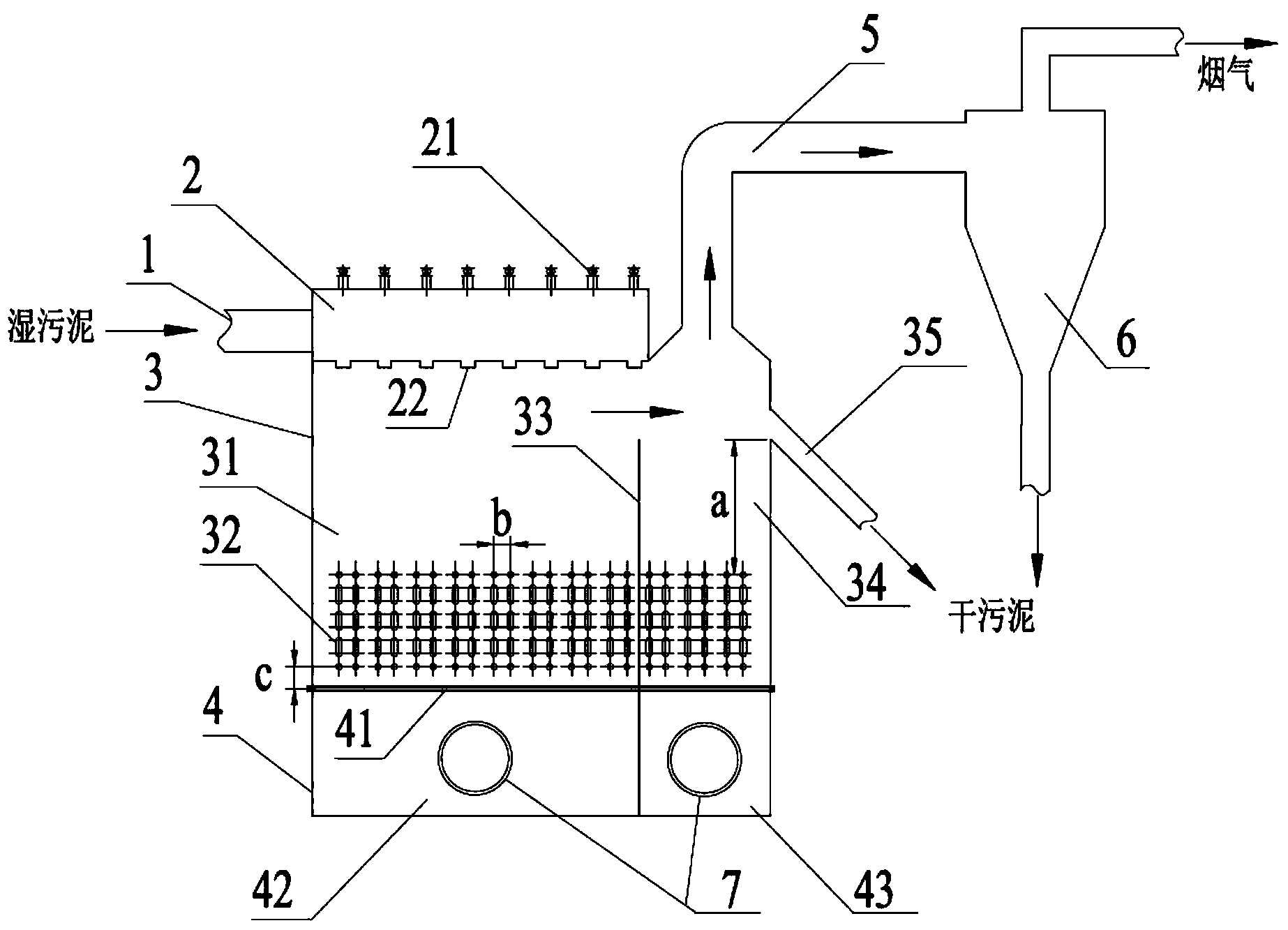

Double-chamber fluidized bed sludge dryer

ActiveCN104058571AGuaranteed uptimeUnblock in timeSludge treatment by de-watering/drying/thickeningWater contentSpray nozzle

A double-chamber fluidized bed sludge dryer comprises a distribution chamber, an air chamber, a drying chamber, a cyclone separator and the like. The double-chamber fluidized bed sludge dryer is mainly characterized in that the side end surface of the distribution chamber is connected with a wet sludge feeding pipe, a plurality of ball valves are arranged on the upper end surface of the distribution chamber, a plurality of sludge spraying nozzles are arranged on the lower end surface of the distribution chamber, the centers of the ball valves coincide with the centers of the sludge spraying nozzles in the vertical direction, the air chamber and the drying chamber are respectively divided into two corresponding sub-chambers, the first air sub-chamber is filled with 67%-75% of total air, and 67%-75% of the total heat exchange surface of a heater is formed in the first drying sub-chamber. Under the condition that the work of the dryer is not influenced, the sludge spraying nozzles blocked by sundries like braided straps mixed in sludge can be quickly unblocked. In addition, the double-chamber fluidized bed sludge dryer has the advantages that feeding is uniform, dry sludge particulates are uniform in water content, the energy consumption is low, the drying efficiency is high, and operation is reliable.

Owner:SOUTHEAST UNIV

Dedusting and desulfurizing fluid bed reactor with combined action of sound and magnetism

InactiveCN101480578ALarge adjustment rangeStrong adjustabilityDispersed particle separationEnergy based chemical/physical/physico-chemical processesSpiral coilLoudspeaker

The invention relates to a dedusting and desulfurization fluid bed reactor with acoustomagnetic combined function, which belongs to the technical field of environment-friendly equipment. The invention solves the problems that the prior dedusting and desulfurization reactor has low dedusting and desulfurization efficiency and cannot radically treat the pollution of particle substances absorbed by the human body. In the dedusting and desulfurization fluid bed reactor with acoustomagnetic combined function, the lower part of the right side wall of a cylinder body is provided with a flue gas inlet, the upper part of the right side wall of the cylinder body is provided with a flue gas outlet, and a grid plate is fixedly arranged inside the cylinder body in the horizontal direction. A speaker is arranged on the bottom inside the cylinder body, and a sound wave output end of the speaker faces to the grid plate. The inside of the cylinder body is filled with magnetic bed materials which are distributed above the grid plate, magnetism generating spiral coils are wound on the outer wall of the cylinder body, the position of the magnetism generating spiral coils corresponds to that of the magnetic bed materials, and an atomizing spray head penetrates through the outer wall of the cylinder body and is hoisted above the magnetic bed materials in the cylinder body. The invention is applicable to various occasions for preventing and controlling the pollution of flue gas and the dedusting and the desulfurization of the flue gas.

Owner:HARBIN INST OF TECH

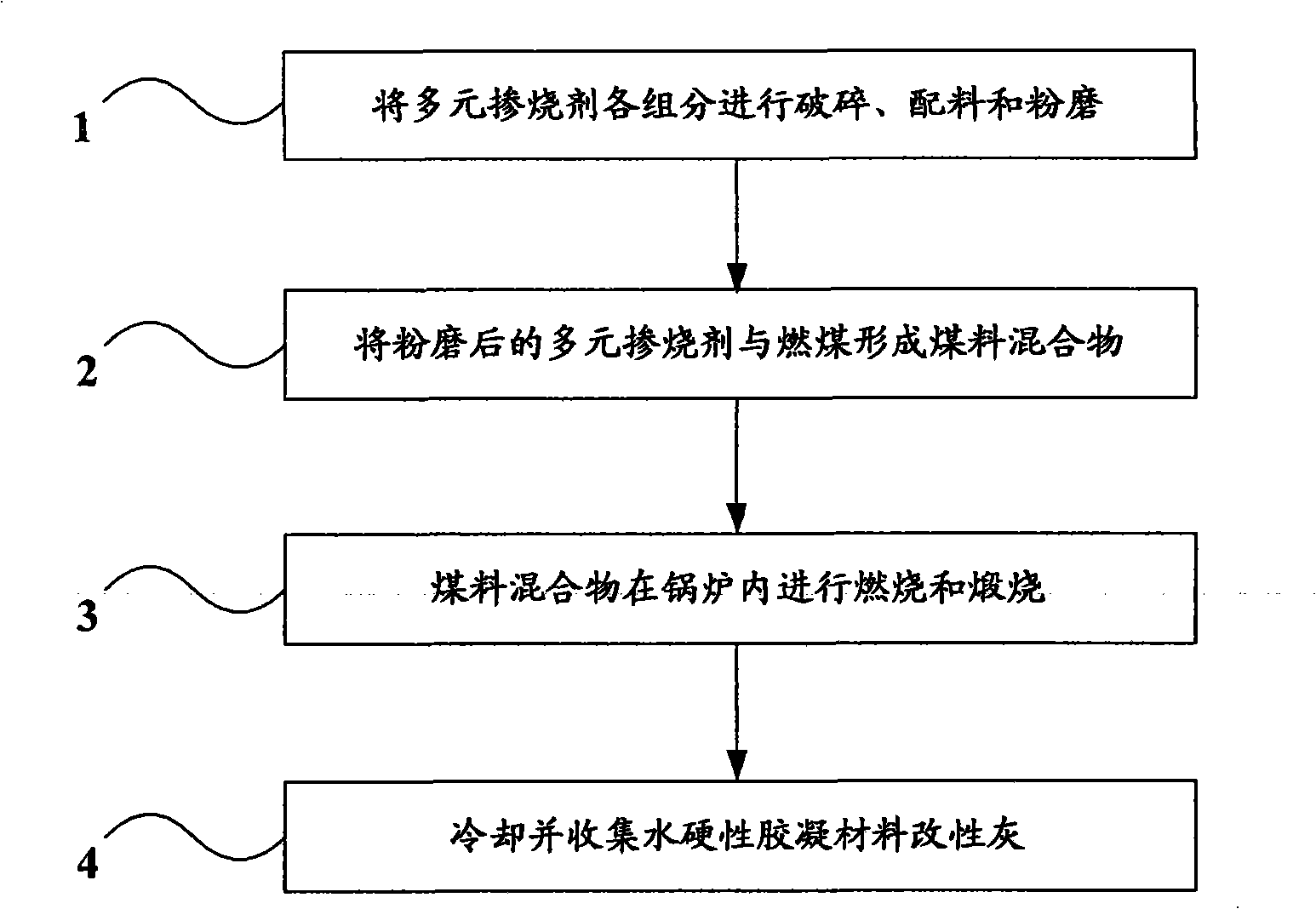

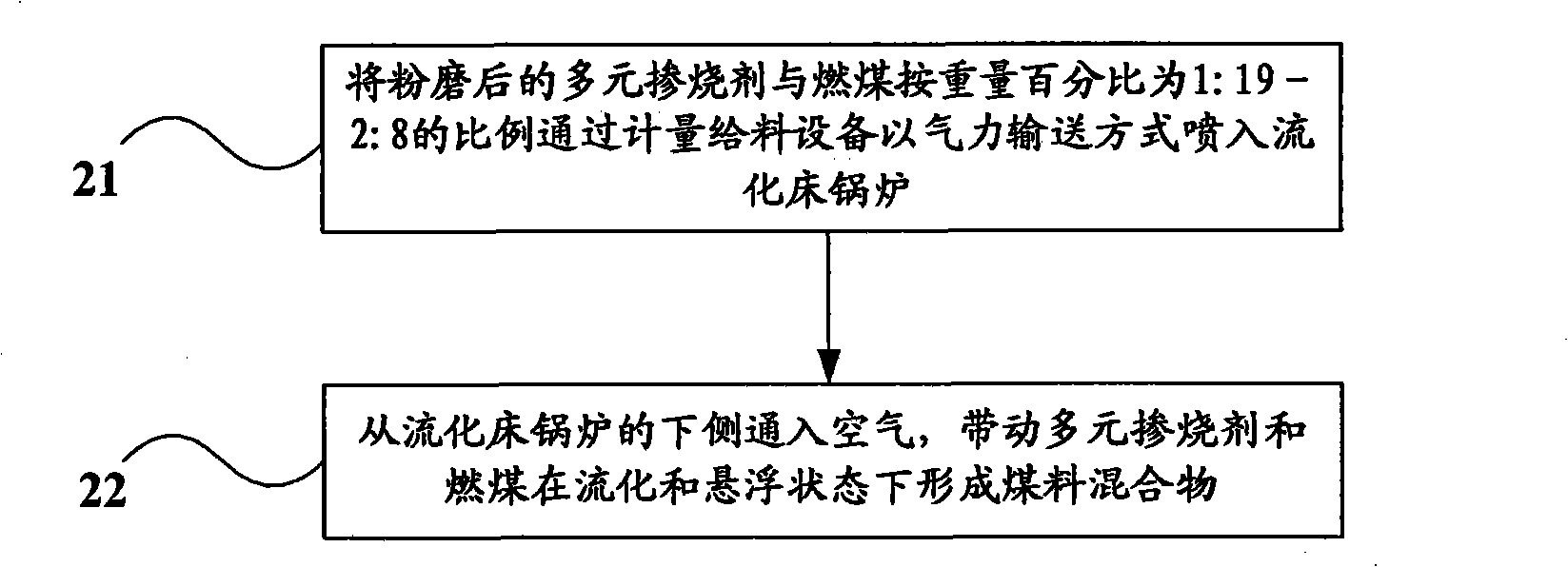

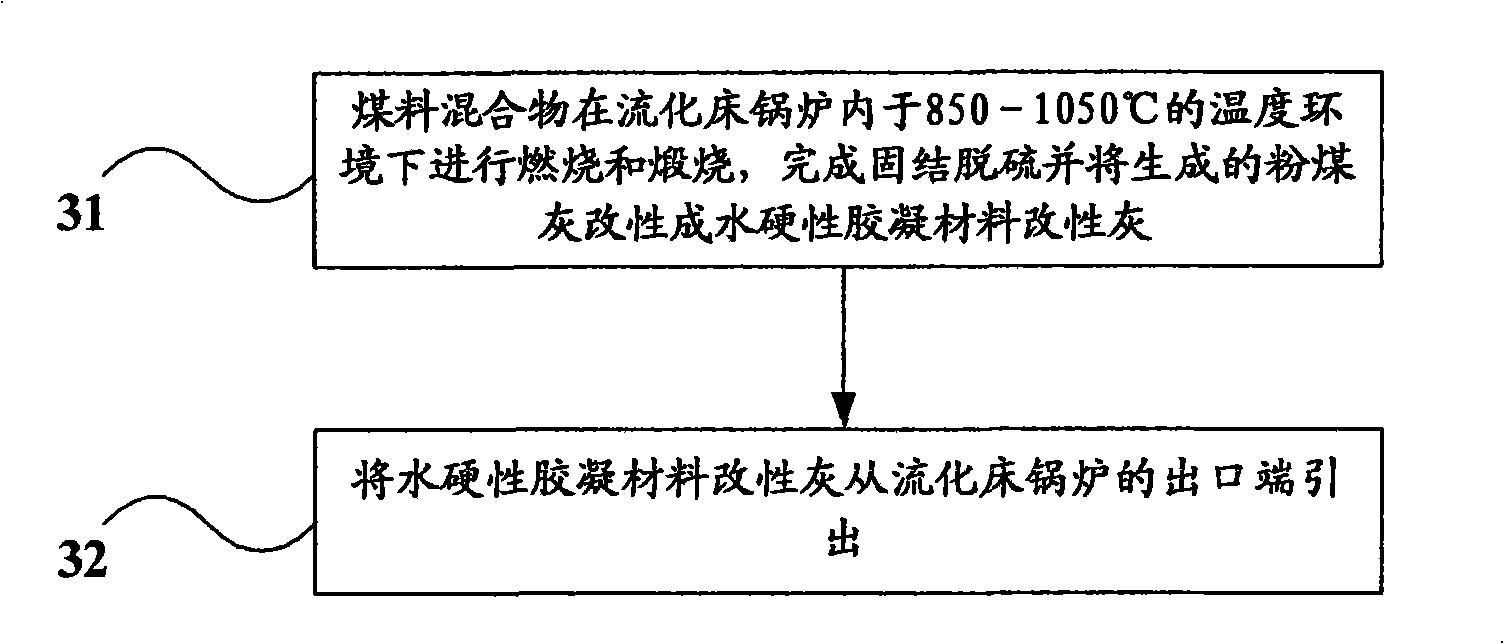

Multicomponent co-combustion agent and use method thereof

ActiveCN101314742AIncreased Strength and DurabilityLower combustion temperatureSolid fuelsSlagCoal fired

The invention relates to a multi-doped sintering agent and the usage thereof. The multi-doped sintering agent consists of a main material and a core material, wherein the main material includes one or any combination of carbide slag, soda slug, quick lime or limestone; the core material includes mineralizer, salt-melting medium and coke slag bulking agent. The usage of the multi-doped sintering agent comprises the following steps: crushing, mixing and pulverizing each component of the multi-doped sintering agent; mixing the pulverized multi-doped sintering agent with coal to form a coal mixture; burning and calcining the coal mixture in a boiler; and cooling and collecting hydraulic binding material modified ash. The multi-doped sintering agent can reduce the carbon content of fly ash and reduce the coal consumption of the boiler and can achieve high-efficiency solid desulfurization. The hydraulic binding material active ash produced after the coal burning has wide purposes, thus achieving multiple purposes of one boiler and achieving good effects of fluidized-bed combustion boiler such as environment protection, energy conservation and high-efficiency waste utilization.

Owner:中科院科技服务有限公司

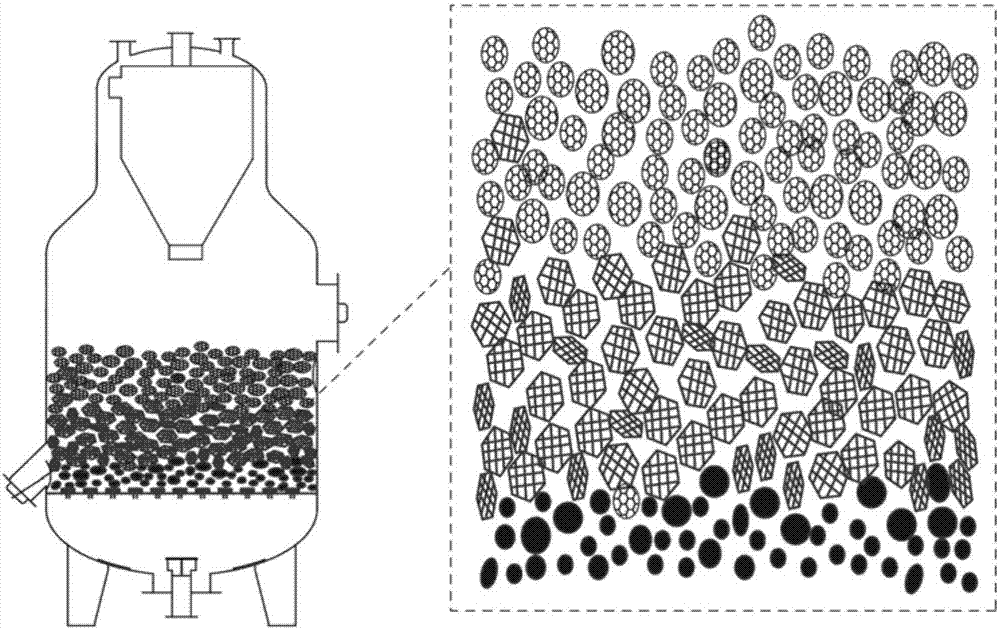

Gas-solid fluidized bed reactor with high inflation rate, method for realizing high inflation rate of fluidized bed and applications of gas-solid fluidized bed reactor and method

ActiveCN109046187AImprove gas-solid reaction efficiencyIncrease chance of contactChemical/physical processesRough surfaceGas solid

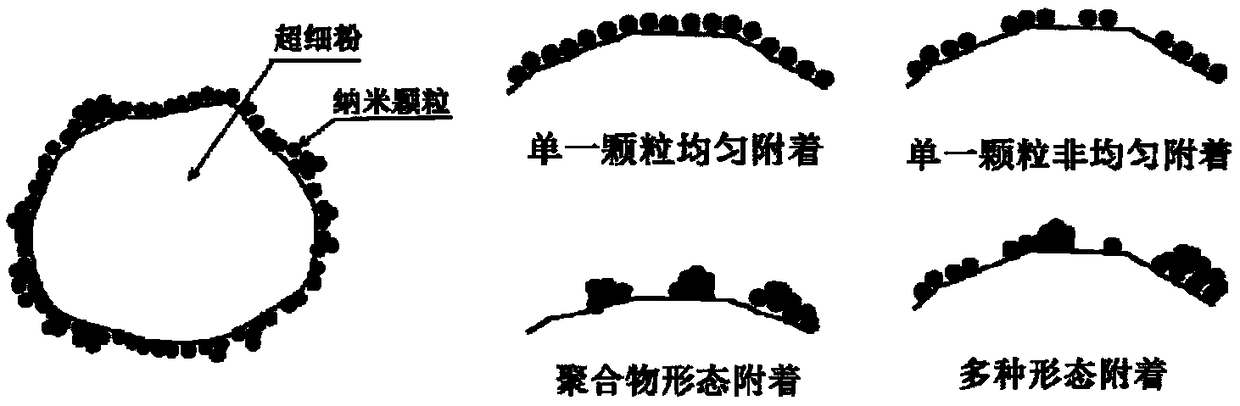

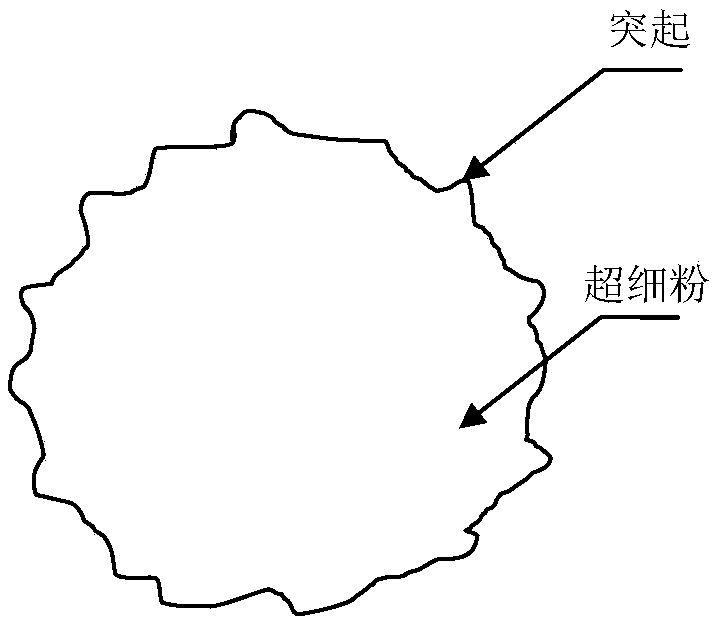

The invention provides a gas-solid fluidized bed reactor with high inflation rate, a method for realizing the high inflation rate of a fluidized bed and applications of the gas-solid fluidized bed reactor and the method. The reactor comprises a concentrated phase and a dilute phase, wherein the concentrated phase contains gas and solid particles, inflation rate of the concentrated phase is as highas 60%-85% and is remarkably higher than that of a common fluidized bed reactor, the solid particles are C<+> particles and comprise 50% or higher of Geldart C-type ultrafine powder and a small quantity of nano-particles, and part of the nano-particles are uniformly or non-uniformly attached to the particle surface of the Geldart C-type ultrafine powder in a single-particle or agglomerate form temporarily or permanently; or the C<+> particles at least comprise Geldart C-type ultrafine powder with a rough surface, and the rough surface of the Geldart C-type ultrafine powder is caused by irregular particle shape or micron-size bulges on the surface. The inflation rate of the concentrated phase in the reactor is quite high, the specific surface area of the particles is quite large, contact efficiency of gas-solid phases can be obviously improved, and gas-solid two-phase reaction and physical gas-solid contact process are facilitated.

Owner:天津西敦津洋环保科技有限公司

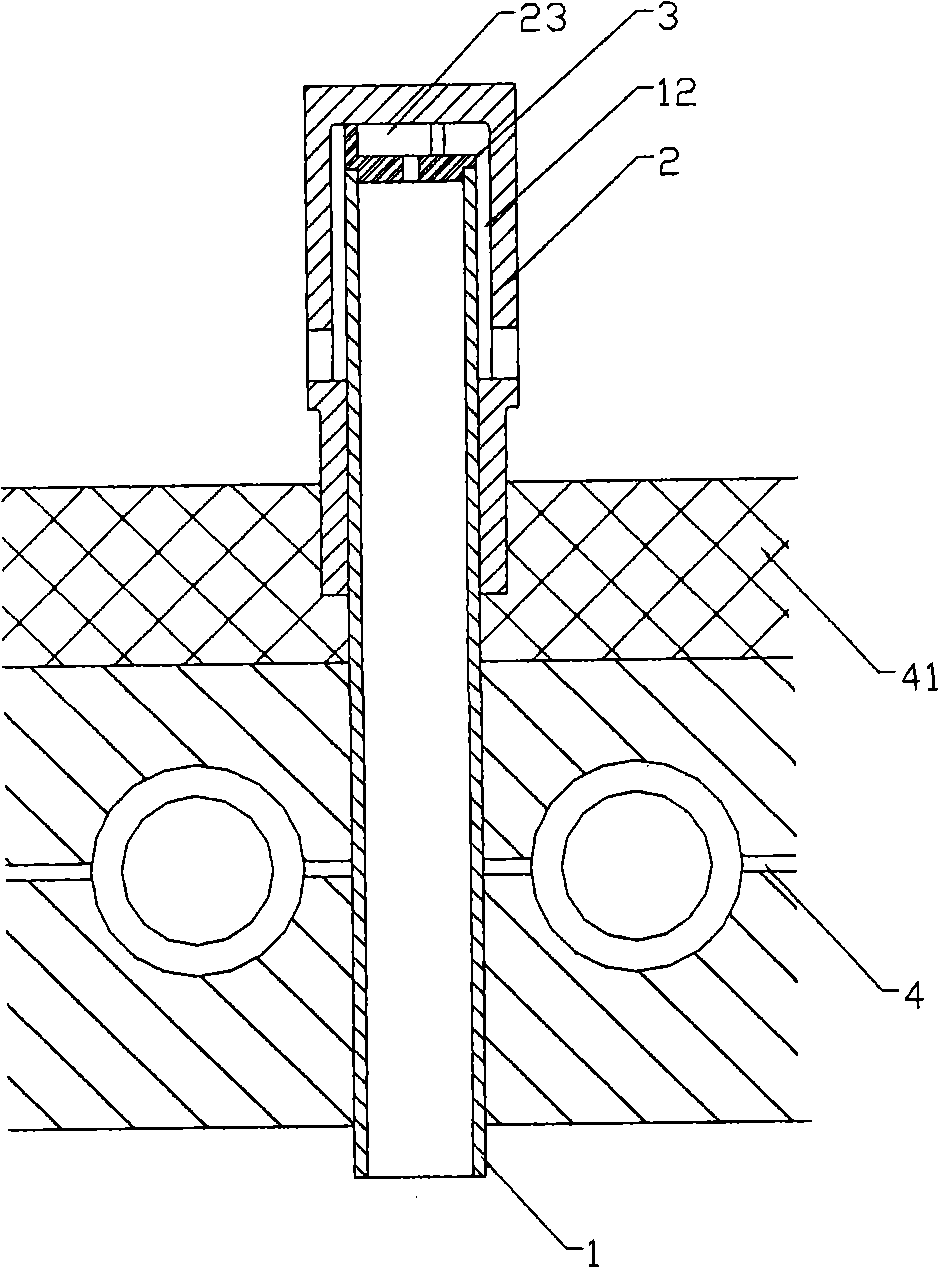

Embedded type cylindrical blast cap with throttling block

ActiveCN101543754ALarge range of design resistanceLarge resistance rangeChemical/physical processesFluidized bedOuter Cannula

The invention relates to an embedded type cylindrical blast cap with a throttling block, which belongs to the technical field of fluidized beds. The embedded type cylindrical blast cap comprises an embedded pipe and an outer sleeve pipe, wherein the embedded pipe is coaxially sleeved in the outer sleeve pipe, and a circular seam is limited between the embedded pipe and the outer sleeve pipe; the embedded pipe penetrates through and is fixedly connected in an air distribution plate, and through holes are arranged on the side wall of the outer sleeve pipe; the embedded type cylindrical blast cap further comprises a throttling block, the throttling block is of a disc shape, and at least one throttling hole interpenetrating the upper and the lower surfaces is arranged on the throttling block; the throttling block is covered and fixed at the opening at the upper end of the embedded pipe, a deflection area communicated with the circular seam is arranged between the inner surface of a top plate of the outer sleeve pipe and the upper surface of the throttling block, and the deflection area is communicated with the inner cavity of the embedded pipe; and the sum of the flow areas of all the through holes on the side wall of the outer sleeve pipe, the flow area of the deflection area, the flow area of the circular seam and the flow area of the inner cavity of the embedded pipe are all larger than that of the throttling hole. The embedded type cylindrical blast cap with the throttling block can accurately control the resistance of the blast cap during the manufacturing and the installing processes.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

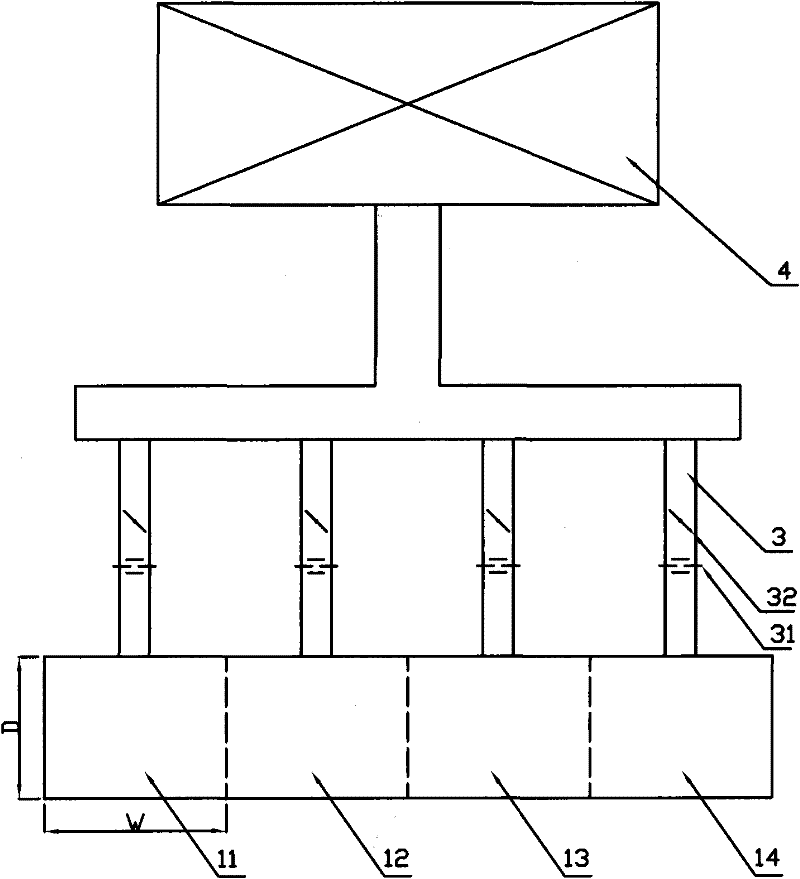

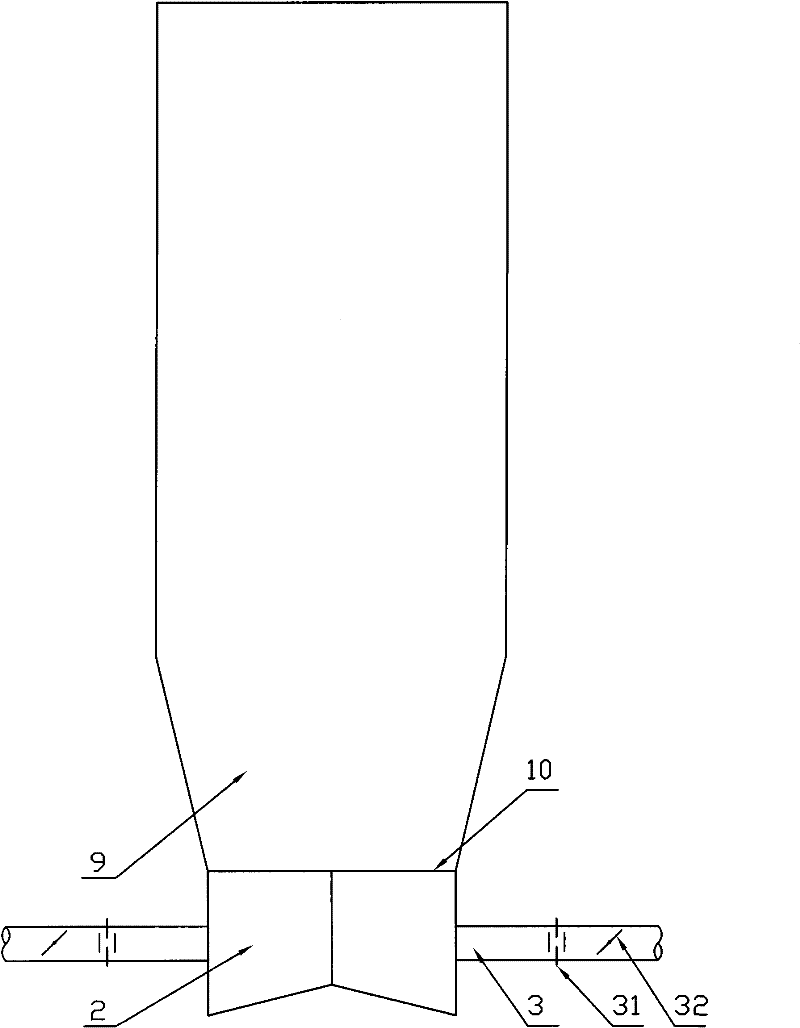

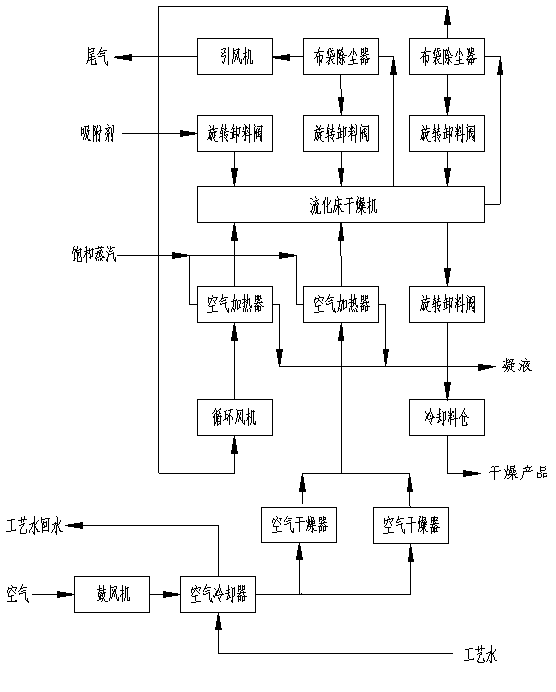

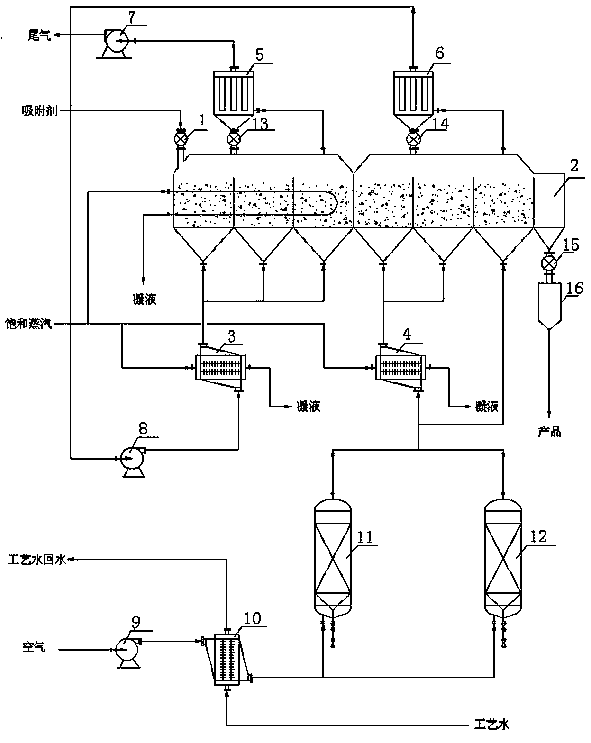

Drying and cooling integrated device for aromatic hydrocarbon adsorbent multi-chamber fluidized bed

InactiveCN103900347AImproved dwell time distributionImprove distributionDrying solid materials with heatHearth type furnacesFluidized bed dryingSorbent

The invention relates to a drying and cooling integrated device for an aromatic hydrocarbon adsorbent multi-chamber fluidized bed. The bottom of the fluidized bed is provided with a multi-hole sieve plate. Vertical baffles are arranged above the sieve plate and sequentially divide the fluidized bed into a dehydration chamber, a drying chamber, a cooling chamber and an unloading chamber in the automatic feeding opening direction. A saturated steam heating pipeline is arranged in the dehydration chamber, and tail gas, with low water content, exhausted from the drying chamber is used as carrier gas of the dehydration chamber so as to improve the system heat efficiency. According to the drying and cooling integrated device, dehydrating, drying, cooling and unloading of the aromatic hydrocarbon adsorbent are carried out in the same equipment, the process and the equipment are simplified to the maximum degree, the automation degree and the integration degree are high, and the functionality is high.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Circulating fluid bed flue gas desulfurization tower

The invention relates to the technology field of combustion equipment, and discloses a stack gas desulfurization tower of a circulating fluid bed, which is used for smoke gas purification. The stack gas desulfurization tower comprises a purified smoke gas outlet, an atomizing water jet apparatus, recycling ash nozzles, a desulfurizer inlet, and a smoke gas inlet which are arranged on a tower body. The stack gas desulfurization tower is characterized in that functional air nozzles are arranged on the tower body and positioned under recycling ash nozzles; at least a wind-pressure desulfurizer jet apparatus is arranged on the tower body and positioned under the functional air nozzles; a plurality of Venturi nozzles are arranged inside a Venturi throat in the tower body; the wind-pressure desulfurizer jet apparatus has the structure that an air inlet pipe is provided, the desulfurizer inlet is arranged on the air inlet pipe, and a diffuser nozzle is arranged on the head end of the air inlet pipe, wherein, the head end of the air inlet pipe extends into the tower body; the recycling ash nozzles and the functional air nozzles are both a plurality of nozzles. The stack gas desulfurization tower has the advantages of reasonable structure, low investment, low running cost, reliable running, high efficiency, wide application range, etc.

Owner:NORTHEAST DIANLI UNIVERSITY +1

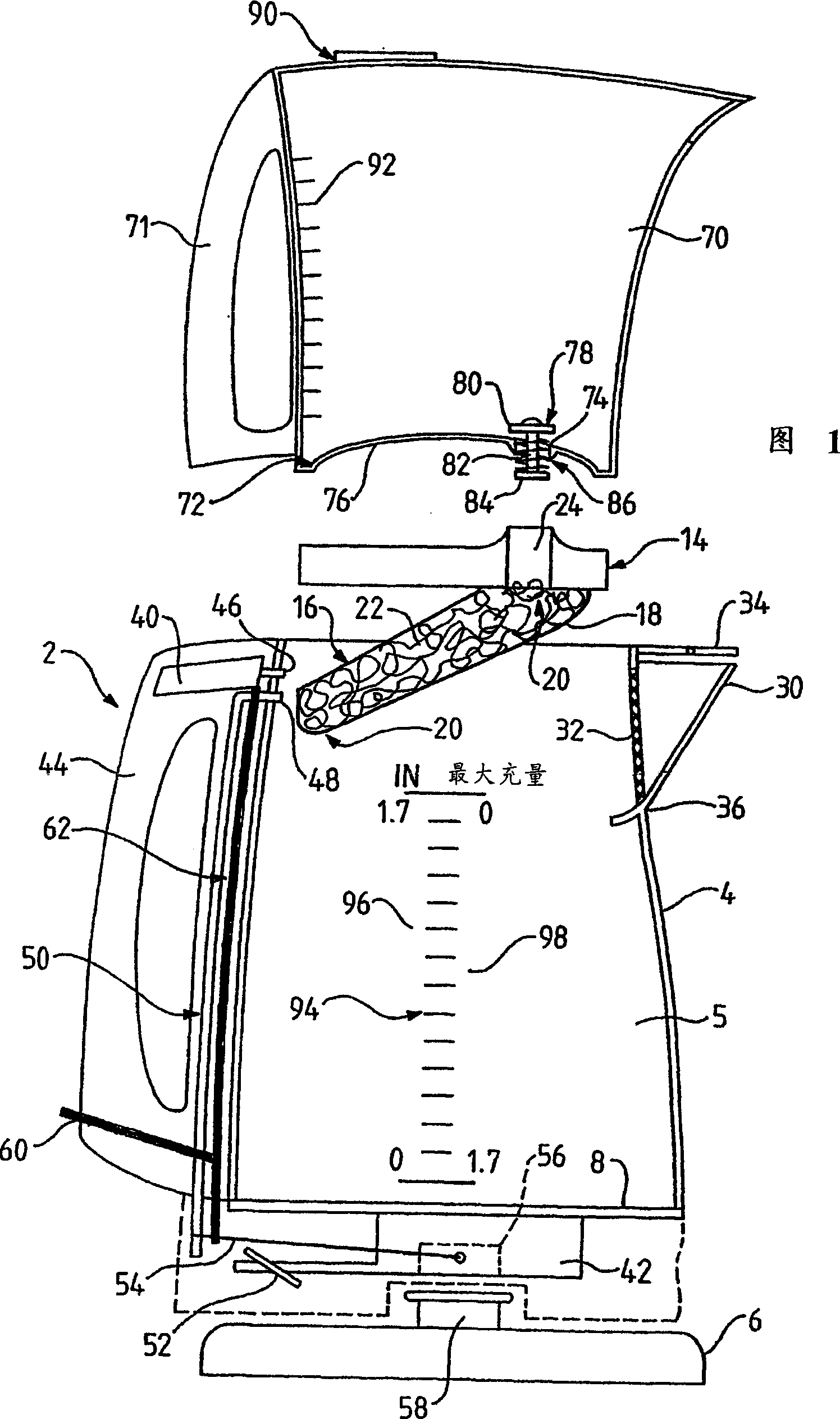

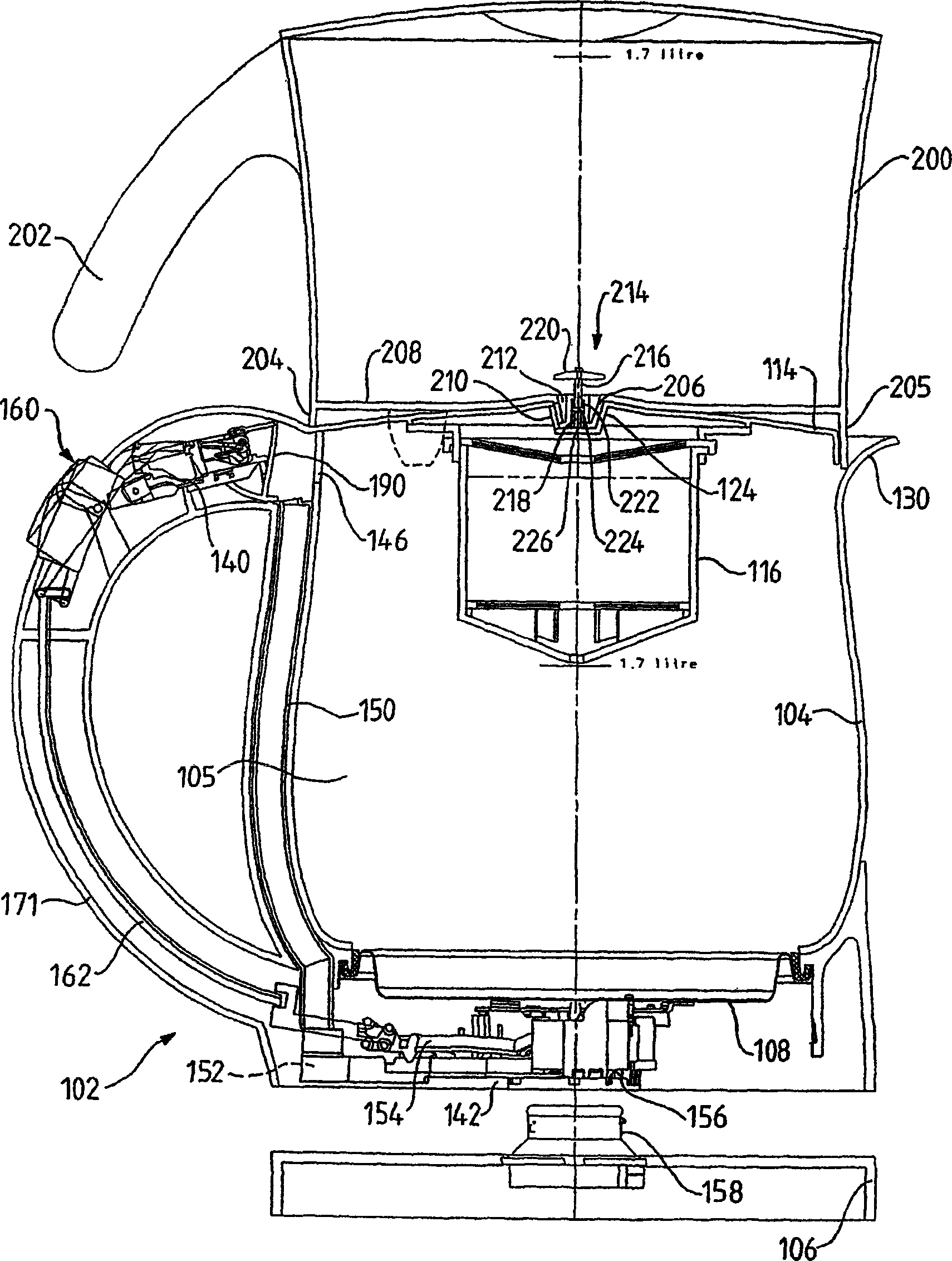

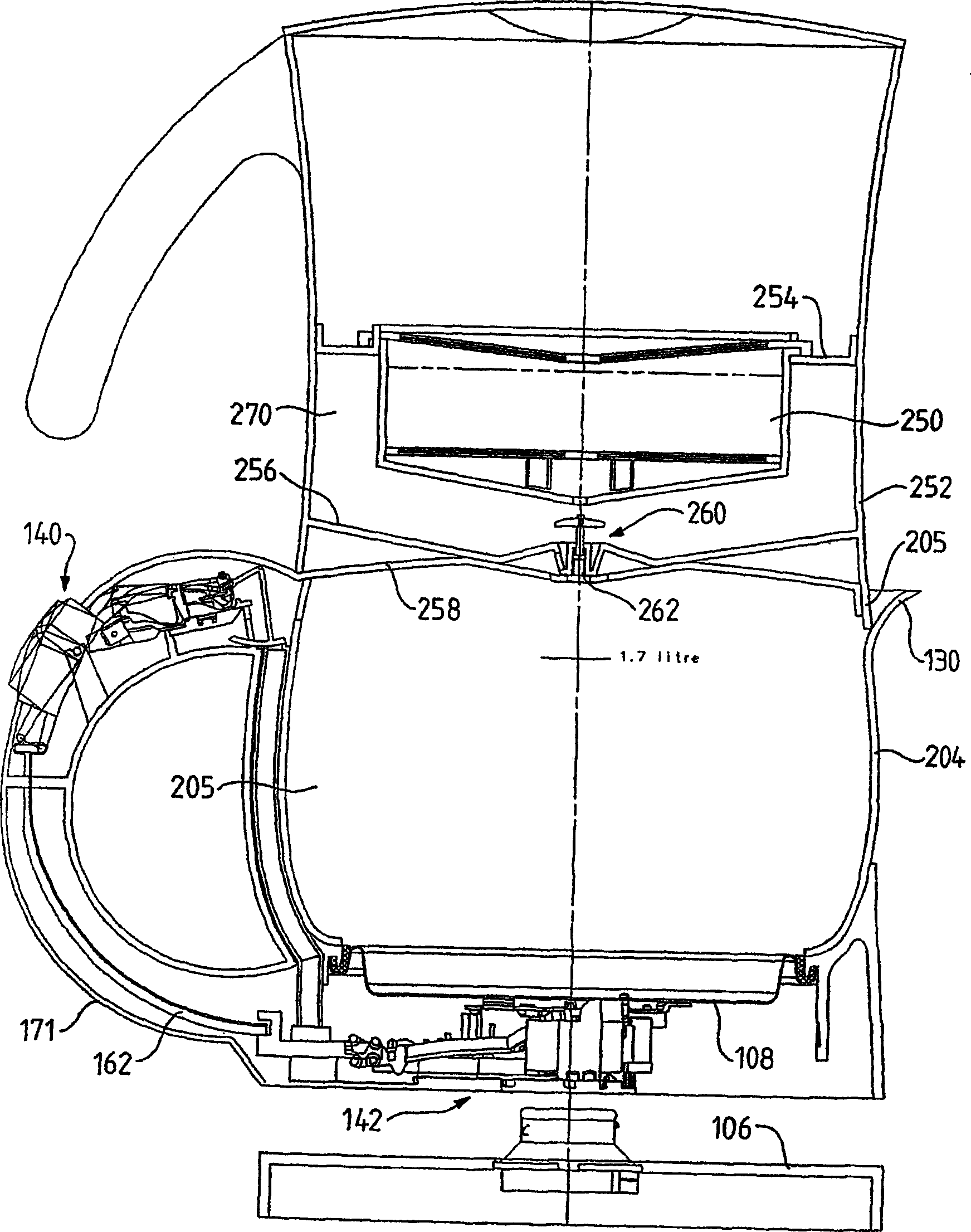

Electric water heating appliances

InactiveCN1593306AEasy to fluidizeReduce compactionWater treatment parameter controlSpecific water treatment objectivesEngineeringFluid warmer

Owner:STRIX LTD

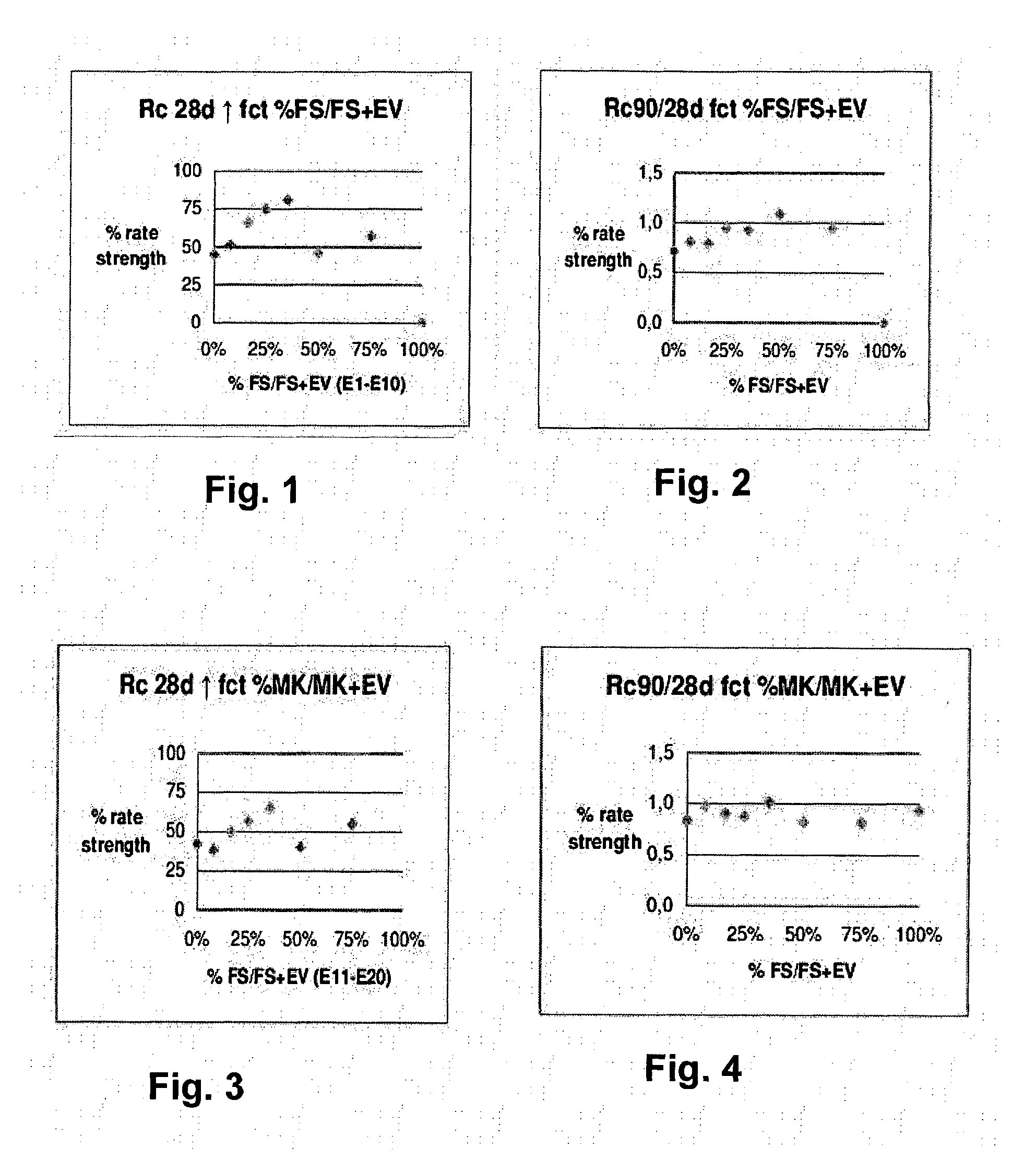

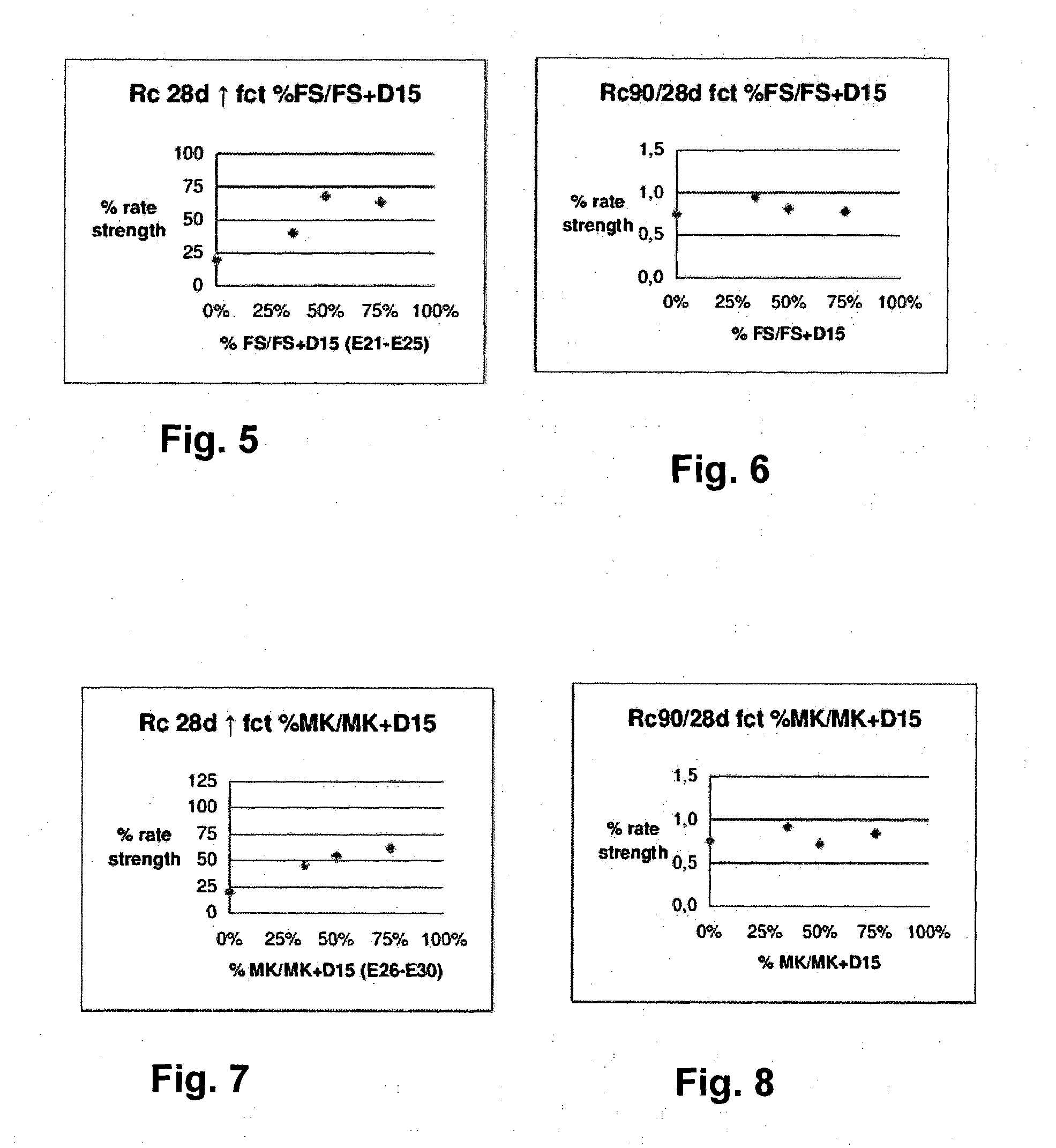

Process for the preparation of cement, mortars, concrete compositions containing a calcium carbonate - based filler containing an organosiliceous material, the said "filler(s) blend" being treated with a superplastifier, cement compositions and cement products obtained, and their applications

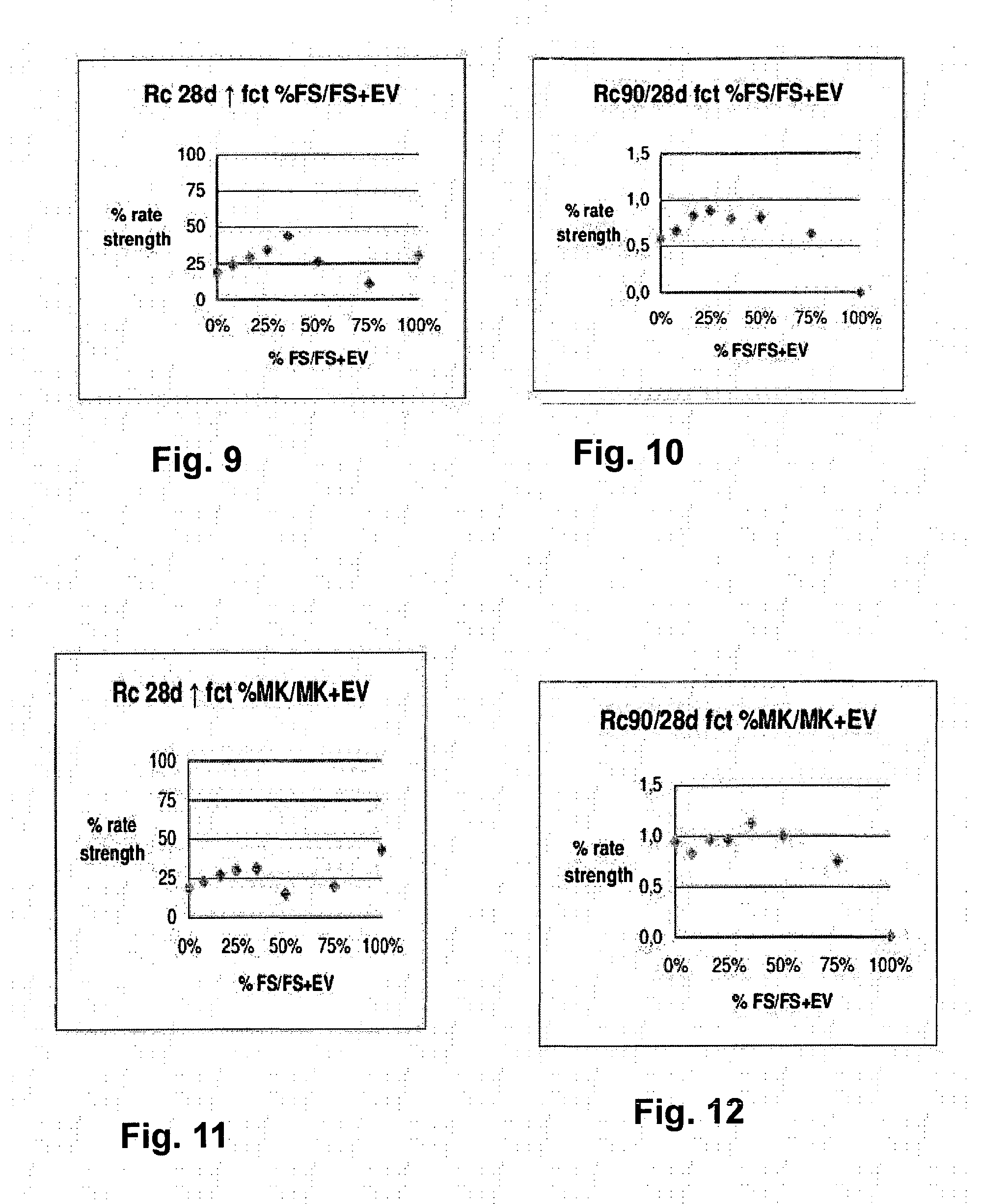

InactiveUS20150007754A1Easy to fluidizeEasy to fixSolid waste managementRotary stirring mixersCompressive strengthUltimate tensile strength

Process for the preparation of cement / mortar / concrete compositions or systems, (for simplicity hereafter “cement” compositions or systems), featuring an improved compressive strength Rc namely at 28 days and 90 days, containing at least a “carbonate-based filler”, comprising at least one step where the said at least one “carbonate-based filler” is mixed or blended with at least one aluminosiliceous material, and the obtained “fillers blend” is treated with an efficient treating amount of at least one treating agent consisting of or comprising superplastifier(s); PRODUCT comprising at least a “carbonate-based “filler”” as defined and at least an aluminosiliceous material, what provides a “fillers blend”; cement compositions, use of the said “fillers(s) blends” and cement composition; cement elements or cement products” obtained from the said “cements compositions”, such as construction or building blocks.

Owner:OMYA INT AG

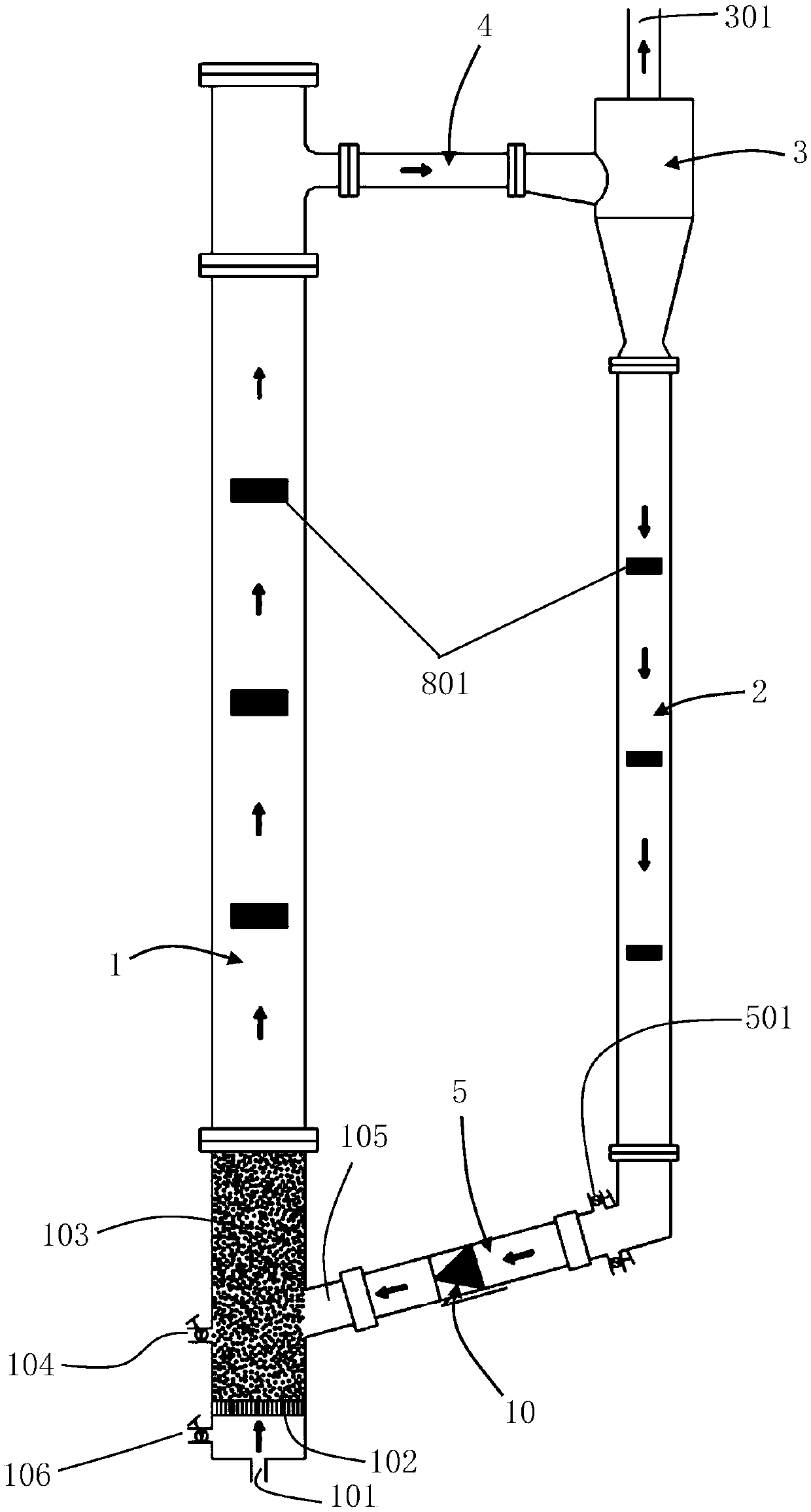

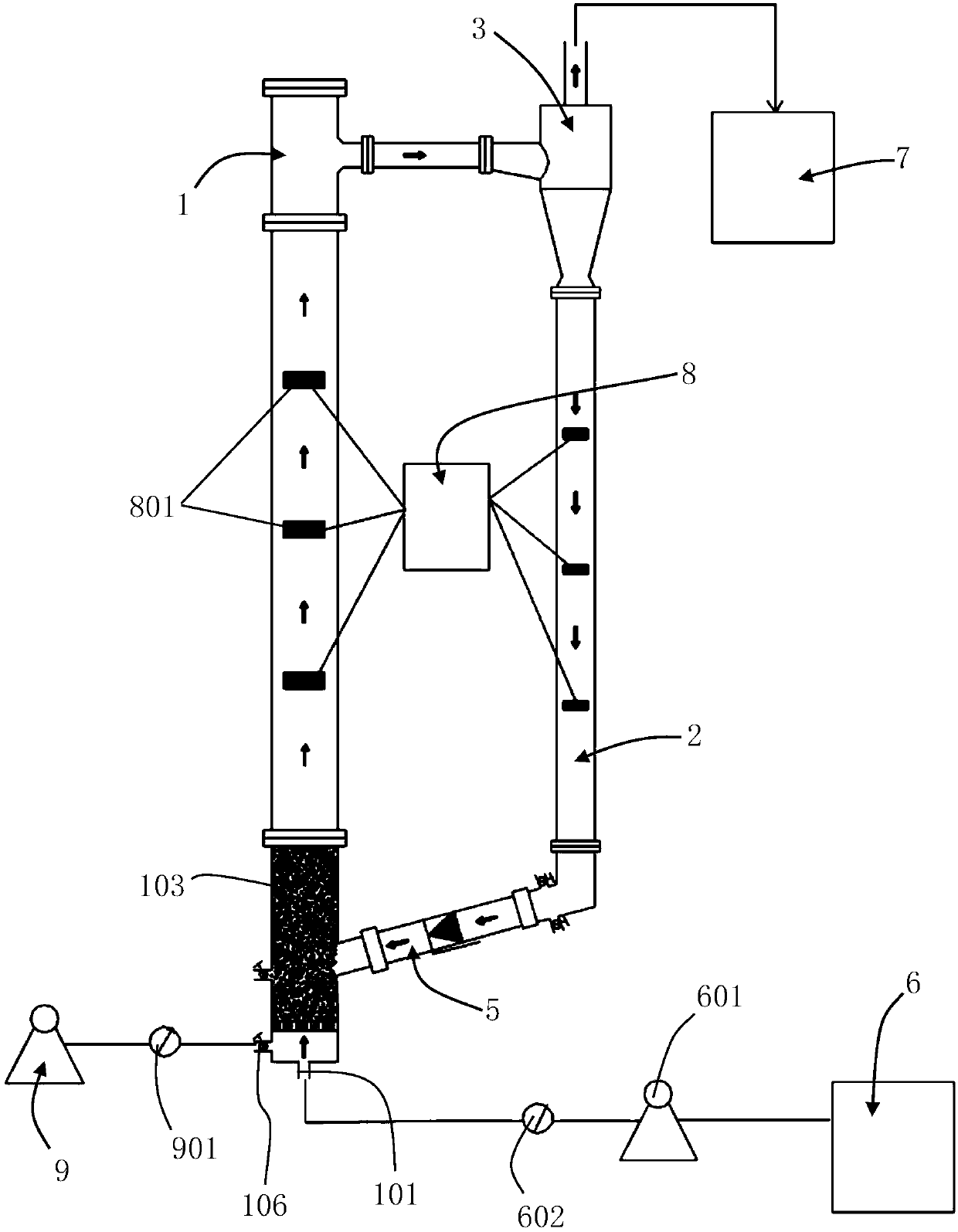

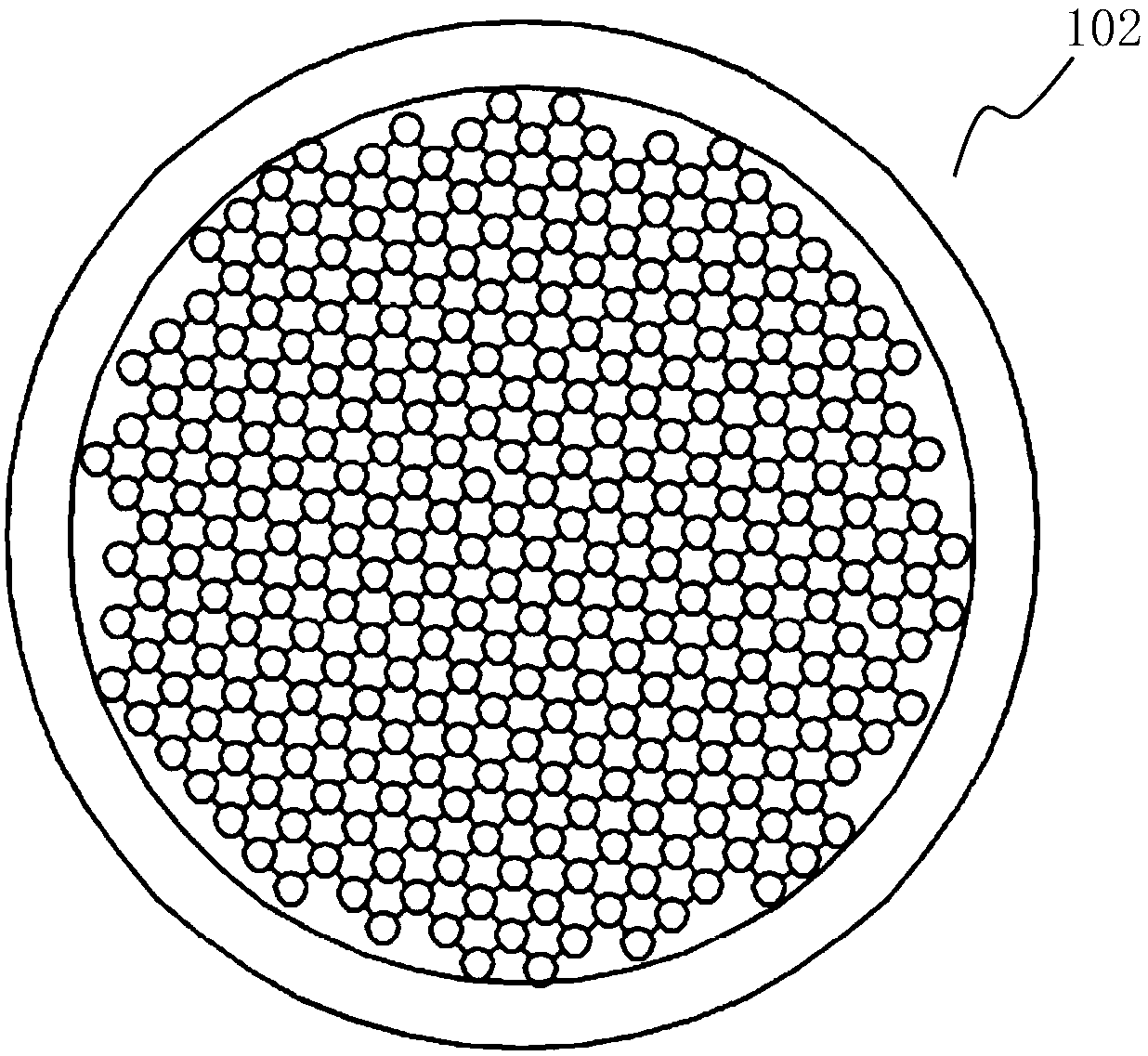

Oil-water separator of circulating fluidized bed

InactiveCN109626618AReduce the numberEasy to fluidizeWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesFluidized bedCentrifugation

The invention relates to an oil-water separator of a circulating fluidized bed, which comprises a lifting pipe, wherein a liquid inlet is arranged at the bottom of the lifting pipe, the liquid inlet is communicated with a liquid storage tank, a liquid inlet distribution plate is arranged above the liquid inlet, a plurality of oil absorption particles are stacked on the liquid inlet distribution plate, and a material inlet and outlet and a material return port are positioned on side wall of the lifting pipe, the material inlet and outlet and the material return port are all positioned above theliquid inlet distribution plate; a descending pipe, wherein the top of the descending pipe is provided with a liquid-solid cyclone separator, the liquid-solid cyclone separator is communicated with the upper part of the lifting pipe through a connecting pipe, and an overflow port at the top of the liquid-solid cyclone separator forms a first liquid outlet; a material return pipe, wherein one endof the material return pipe is communicated with the bottom of the descending pipe, the other end of the material return pipe is communicated with the material return port, and the material return pipe is provided with a second liquid outlet. According to the invention, the secondary separation of two phases of oil and water can be achieved through the adsorption action of oil absorption particlesand the centrifugation action of the liquid-solid cyclone separator, and the oil-water separation efficiency is improved.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com