Patents

Literature

50results about How to "Save on medicine costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

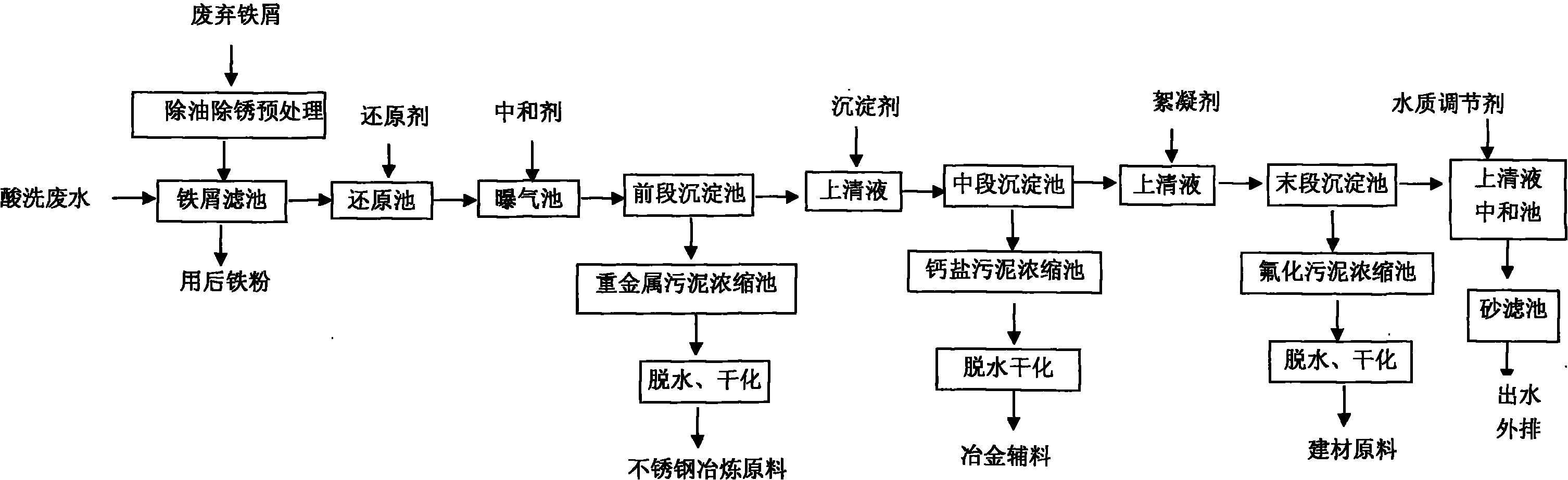

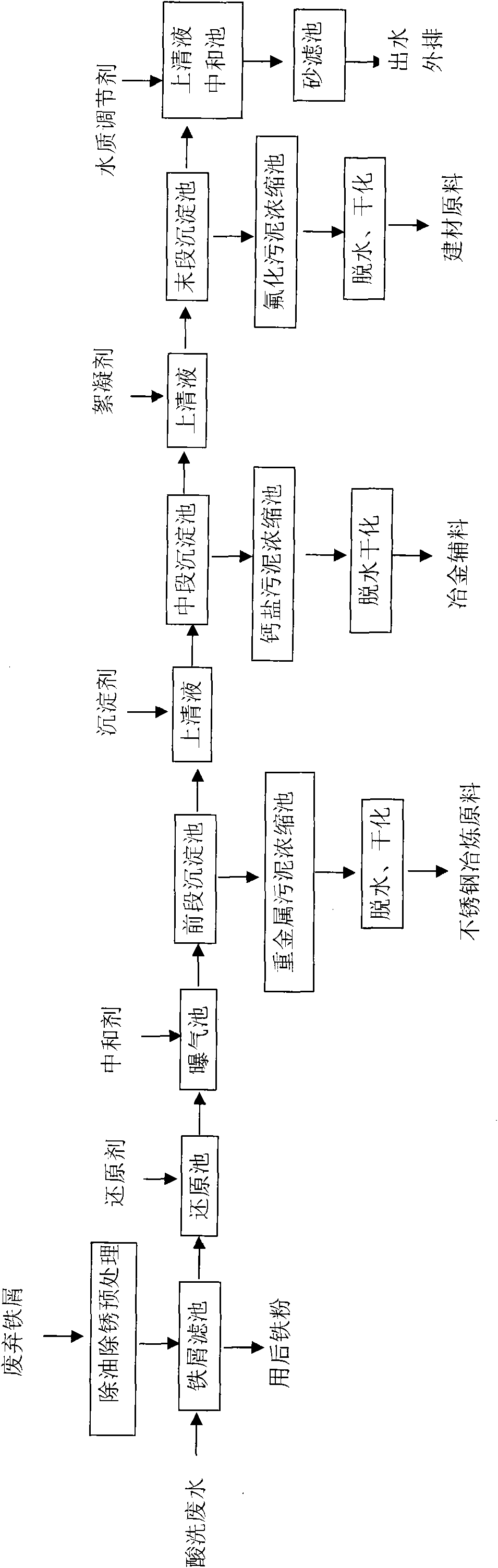

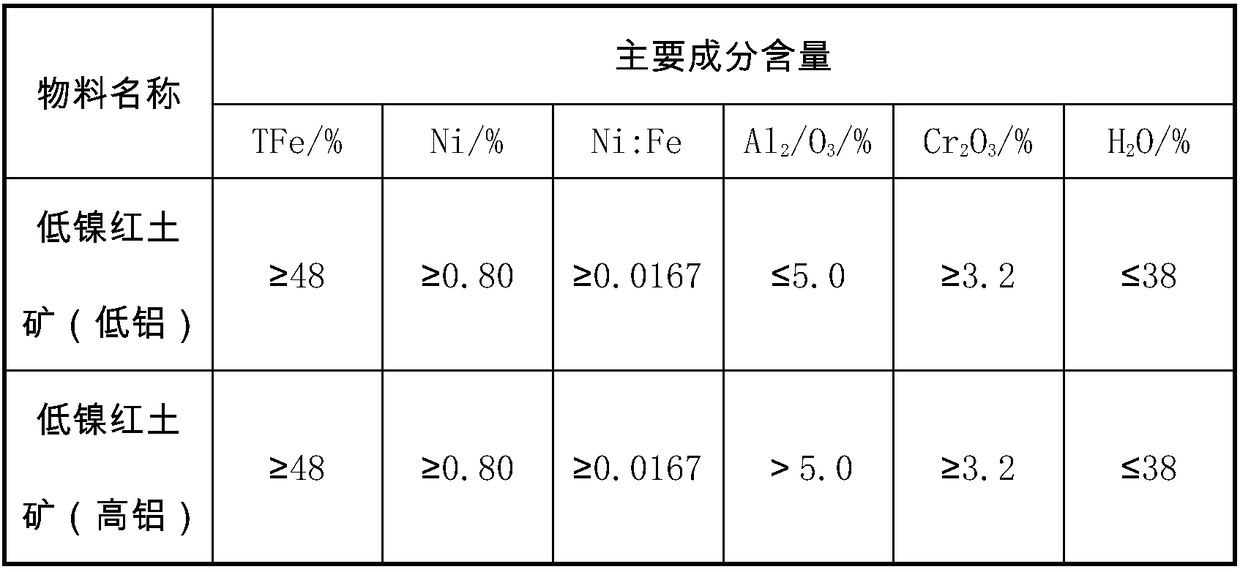

Processing method of stainless steel cold rolling pickling wastewater

ActiveCN101811792AIncrease dosageIncrease productionSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processScrapHexavalent chromium

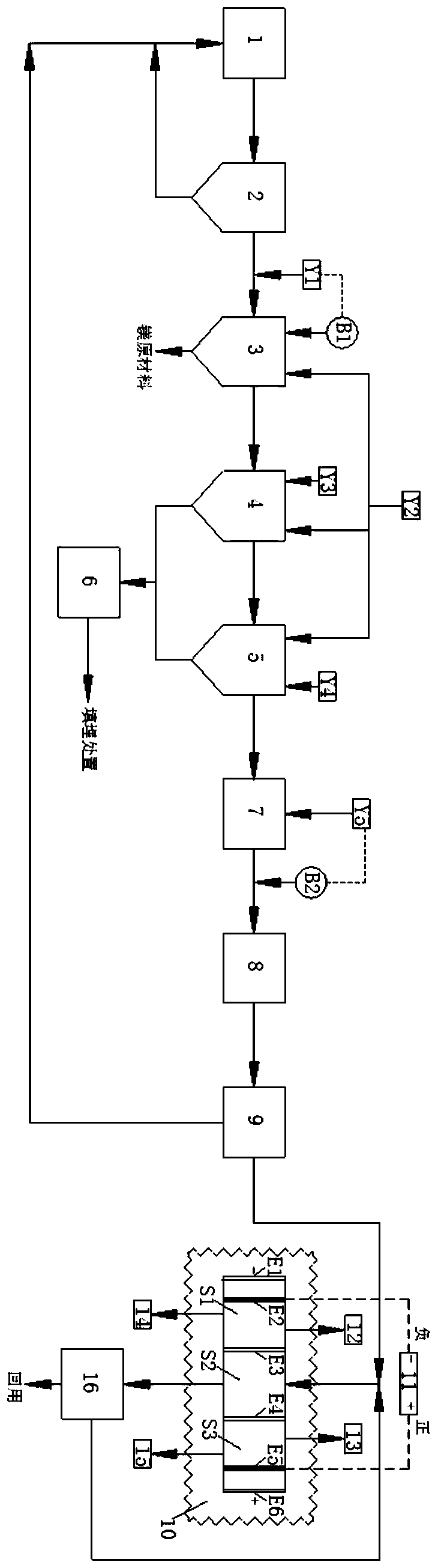

The invention relates to a processing method of stainless steel cold rolling pickling wastewater. The pickling wastewater enters a hexavalent chrome secondary reduction pool after the actions of micro-electrolysis and hexavalent chrome preliminary reduction of a scrap iron filtering pool; the reduced wastewater enters a front-segment precipitation tank after neutralization and aeration, heavy metal sludge is concentrated and dehydrated, and the heavy metal sludge and scrap iron after the use of the scrap iron filtering pool are recycled and used as stainless steel smelting raw materials; middle-segment precipitation is carried out after a primary supernatant acts with a precipitant, and dehydrated and dried fluoride sludge is recycled and used as a metallurgical adjuvant material; final-segment precipitation is carried out after a secondary supernatant continues to act with a flocculating agent to obtain calcium salt which can be used as a building material raw material; and after the three segments of precipitation of acidic wastewater, the final third level supernatant reaches a standard and is discharged through water quality regulation and sand filtering. The invention has the advantages of less investment, low wastewater processing cost, convenient maintenance and the like, and not only can effectively utilize discarded scrap iron of a stainless steel enterprise, but also can greatly lower the subsequent wastewater processing cost and the operating load.

Owner:BAOSHAN IRON & STEEL CO LTD

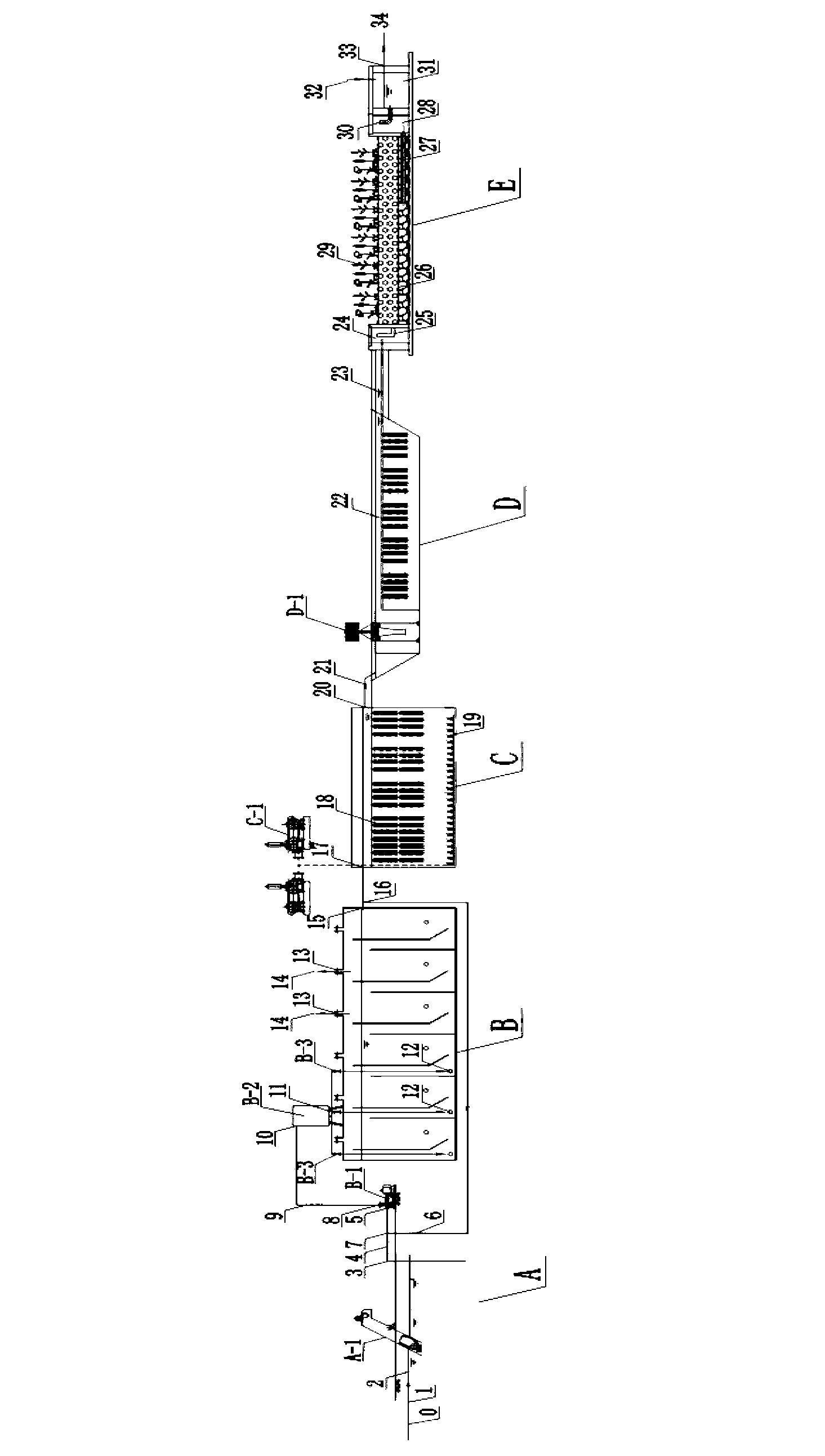

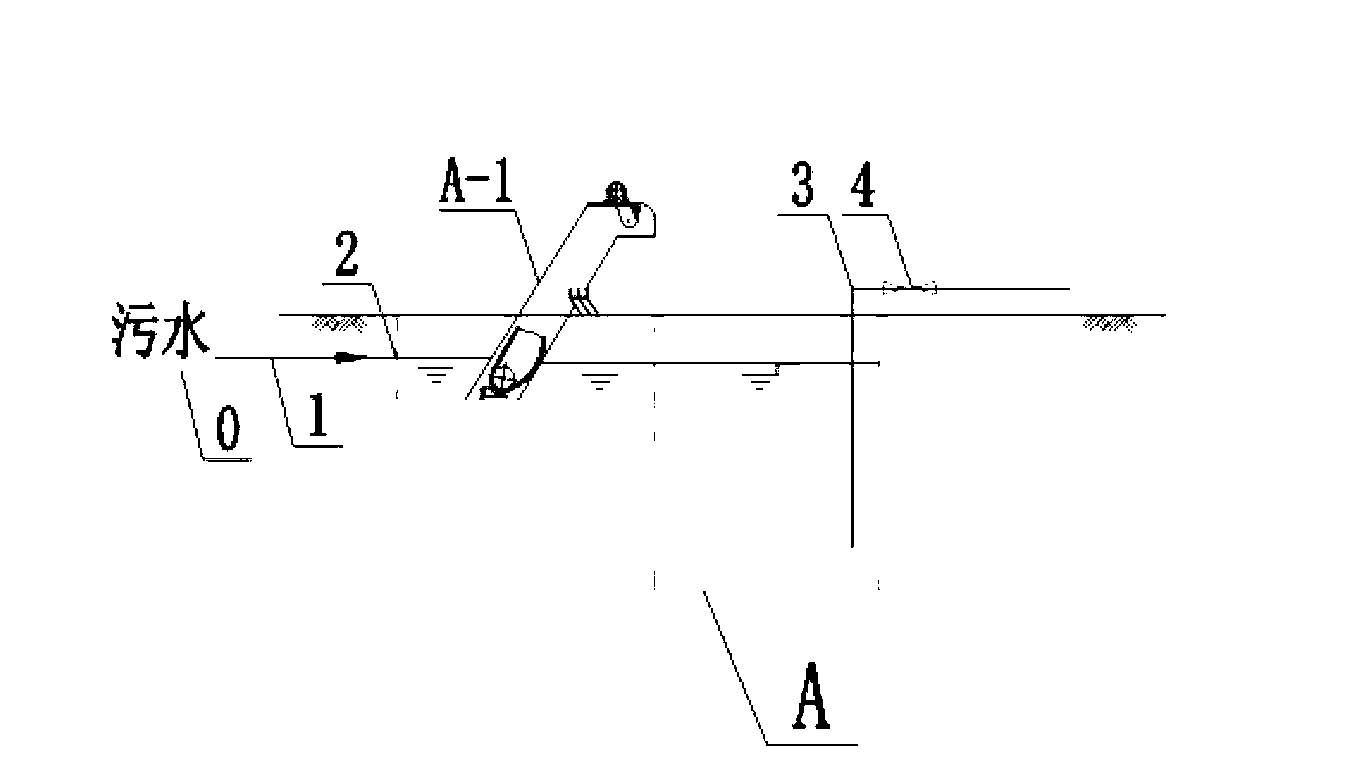

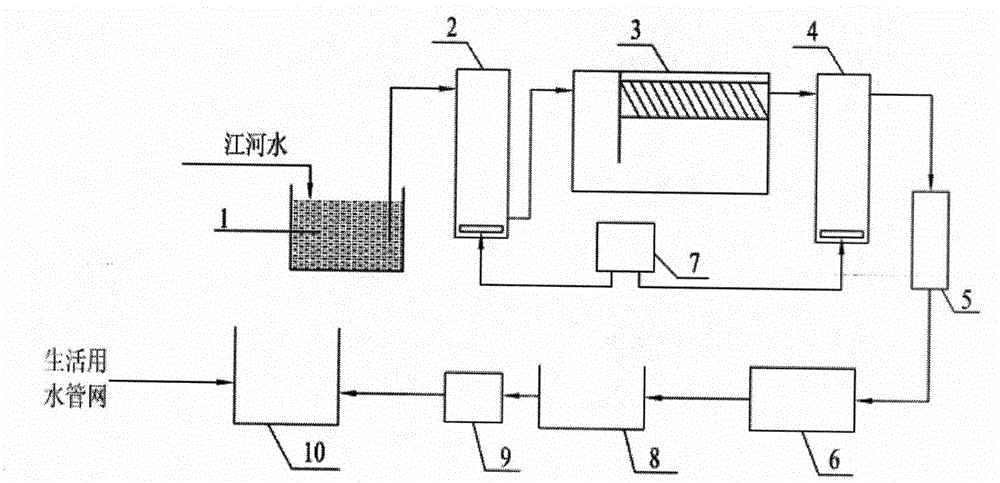

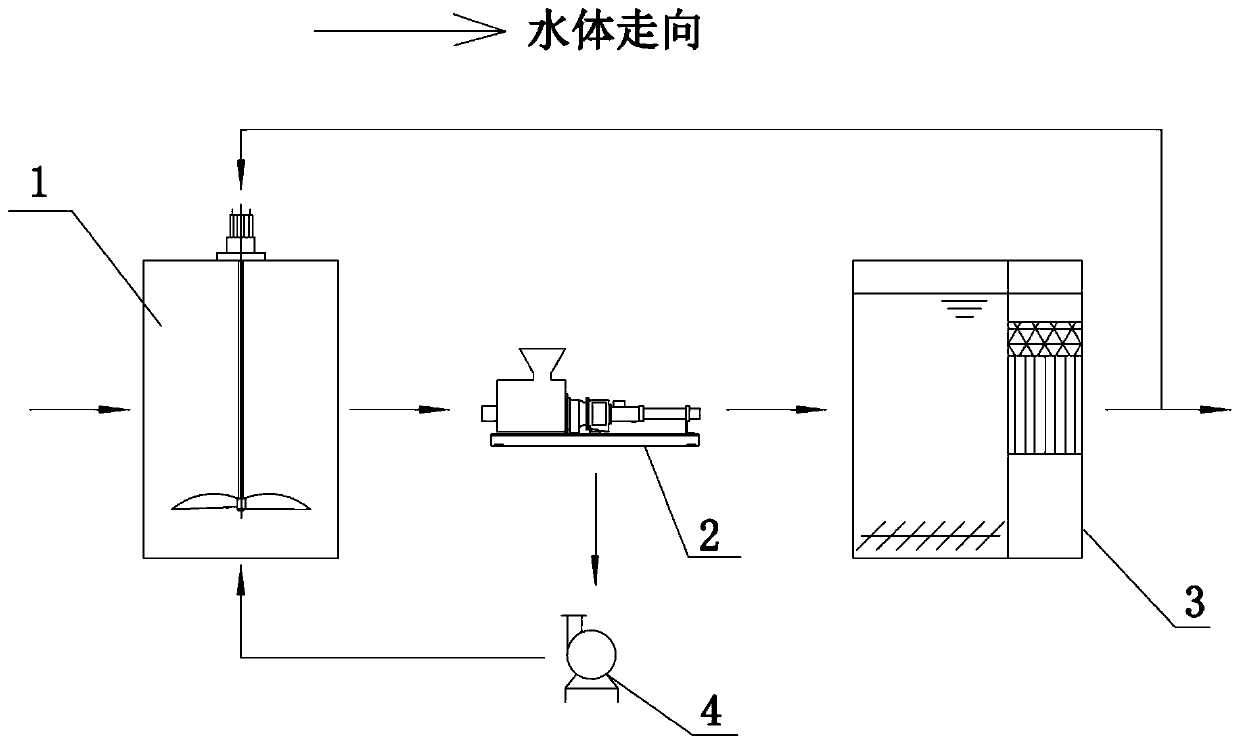

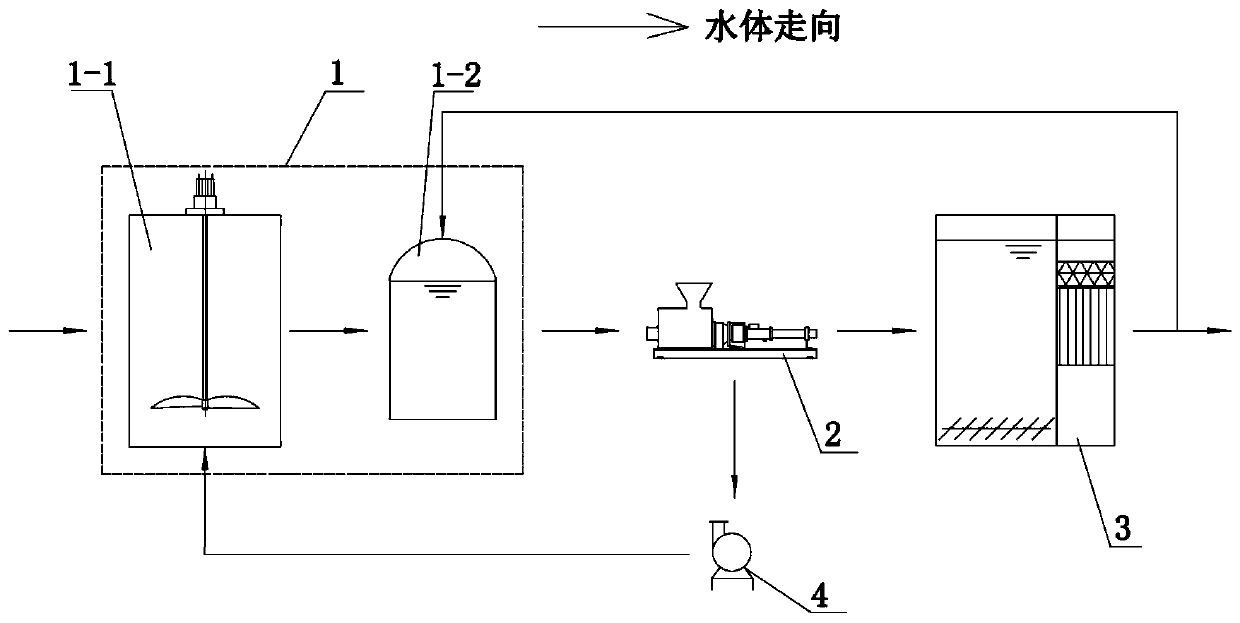

Low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method

ActiveCN102701521AEasy to handleReduce load ratioEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

Desulfurization waste water zero discharge processing system and processing method

InactiveCN106365371AQuality assuranceSave on medicine costsWater treatment parameter controlWater contaminantsSludgeClarifier

The invention discloses a desulfurization waste water zero discharge processing system and a processing method. The desulfurization waste water zero discharge processing system comprises a regulation sedimentation basin, triple connecting tanks, a defecator and a nanofilter which are connected in sequence, wherein the concentrated water outlet end of the nanofilter is connected with a mistorizer which sprays the concentrated water into a chimney flue; the triple connecting tanks include a neutralization tank, a reaction tank and a flocculation tank which are connected in sequence, wherein the neutralization tank is communicated with the water outlet of the regulation sedimentation basin, and is used for adjusting the pH value of desulfurization waste water, so that bicarbonate ions in the desulfurization waste water are removed; the reaction tank provides a reaction chamber for removing calcium ions in the desulfurization waste water; the flocculation tank is connected with the defecator. The desulfurization waste water zero discharge processing system and the processing method have the advantages of saving the cost of the agent for removing magnesium ions in the desulfurization waste water, reducing the quantity of sludge, lowering the operating cost, using no lime milk and improving the site working conditions. The sodium chloride salt in the waste water is purified and then crystallized, thus the recycle of the sodium chloride salt in the desulfurization waste water is achieved, the solid waste disposal cost is reduced, and certain economic benefits are produced.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

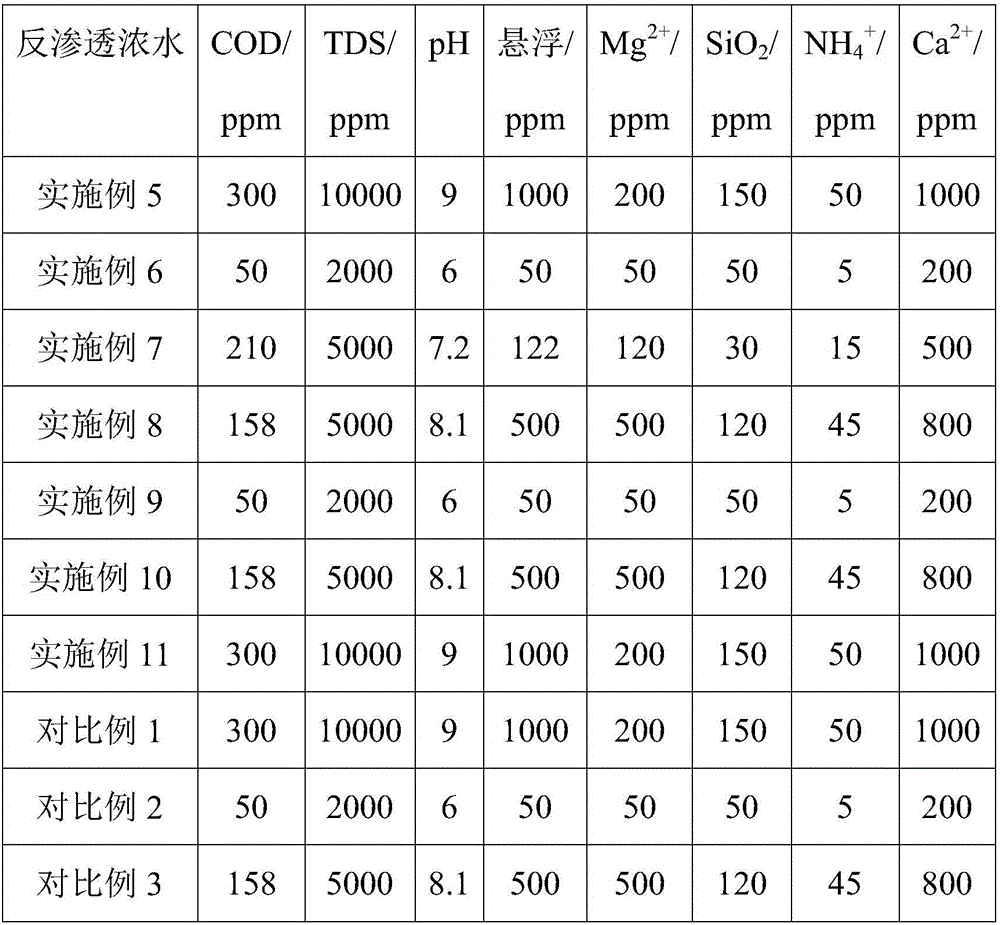

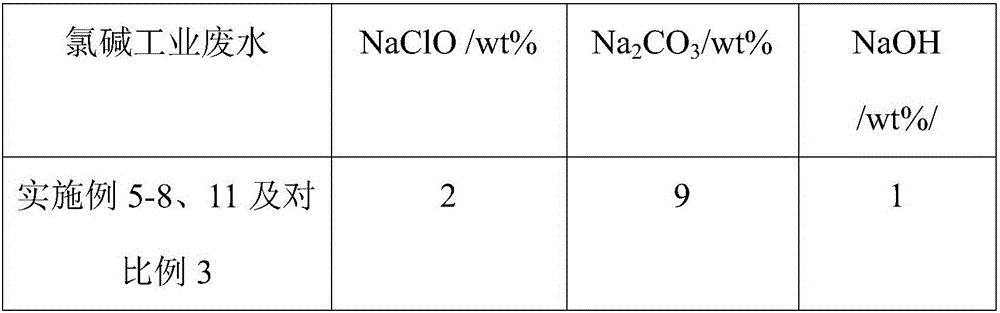

Reverse osmosis concentrated water treatment method

ActiveCN106219816AIncrease profitRelieve pressureHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystCatalytic oxidation

The invention discloses a reverse osmosis concentrated water treatment method which comprises the following steps: (1) adding a precipitator and an oxidizing agent into reverse osmosis concentrated water, filtering to obtain a clear liquid, and adding a catalyst used for water treatment into the clear liquid to implement catalytic oxidation to obtain primary treatment water, wherein the acquisition of the primary treatment water further preferentially comprises adsorbing a liquid subjected to catalytic oxidation; (2) performing reverse osmosis treatment on the primary treatment water to obtain secondary reverse osmosis water and secondary reverse osmosis concentrated water; (3) adding the oxidizing agent into the secondary reverse osmosis concentrated water for oxidation to obtain an effluent, wherein the effluent is used for direct discharge, and the acquisition of the effluent further preferentially comprises adsorbing a liquid subjected to oxidation. According to the reverse osmosis concentrated water treatment method, 75-85wt% of water is recycled, the overall use ratio of the water is improved, meanwhile, a small part of water left is treated to reach the discharge standard, the economic input is low, and the method is simple and is easy to operate.

Owner:WANHUA CHEM GRP CO LTD

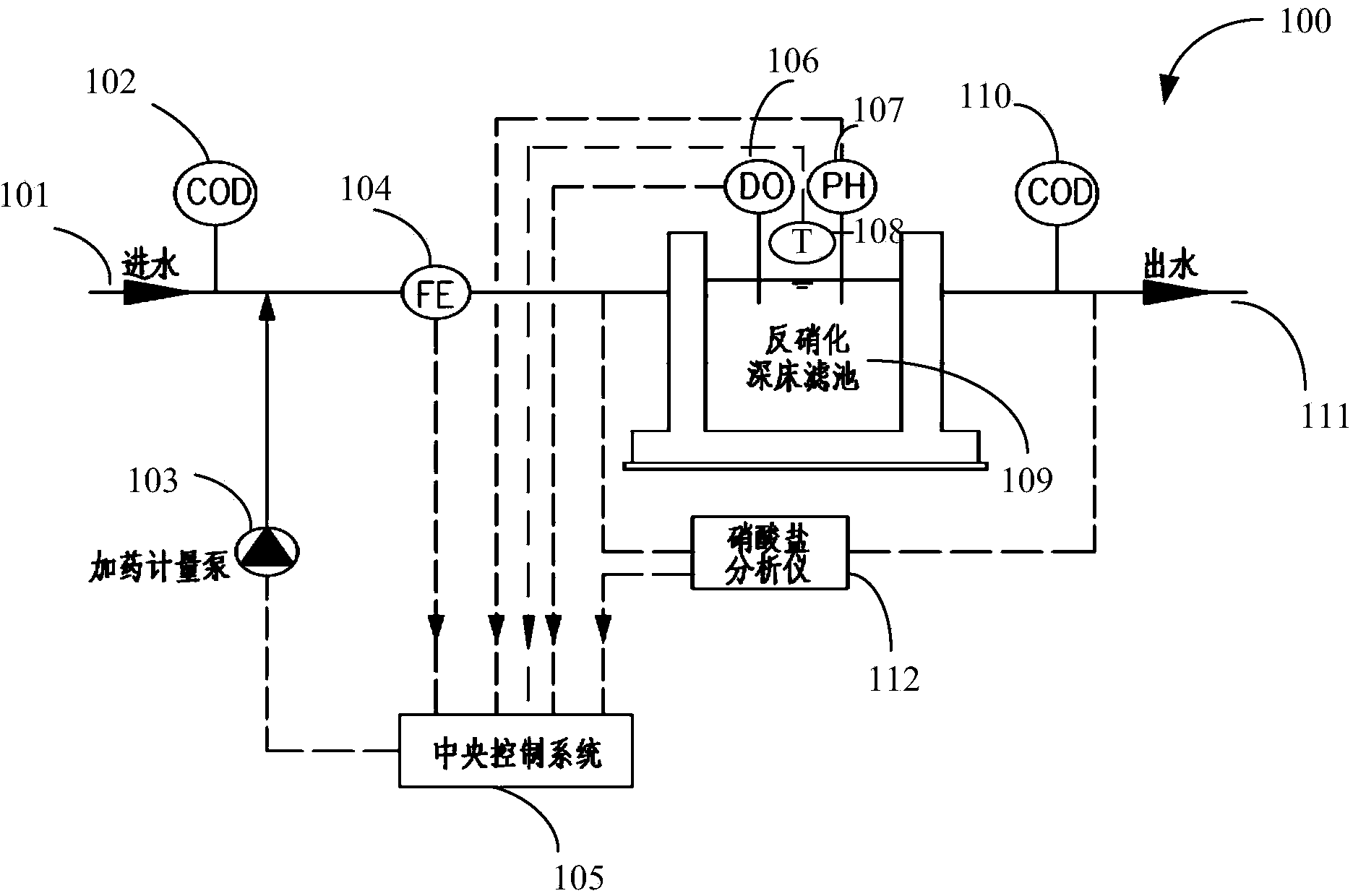

Intelligent precise dosing system for denitrification deep-bed filter carbon source

ActiveCN103864209AImprove denitrification effectSolve efficiency problemsTreatment with anaerobic digestion processesChemical oxygen demandControl signal

The invention provides an intelligent precise dosing system for a denitrification deep-bed filter carbon source. The system is used for acquiring at least one parameter thereof on the basis of different phases of running to provide control signals for a dosing metering pump, wherein during the first phase, a control signal for the dosing metering pump is generated according to theoretical calculation and on the basis of the acquired COD (chemical oxygen demand), flow, dissolved oxygen, temperature and pH value signals, and the parameters on which calculation is based every time, and the calculation results are stored as historical records; during the second phase, searching and matching are carried out according to the historical parameters accumulated during the first phase so as to generate a control signal for the dosing metering pump; and during the third phase, curve fitting is carried out on the historical parameters accumulated during the first phase and the second phase, the control value of the dosing metering pump is used as an unknown function, the acquired signal parameters are used as control functions, an empirical calculation formula is obtained by fitting, and a control signal for the dosing metering pump is calculated according to the empirical formula.

Owner:CSD BEIJING E P DEV CO LTD

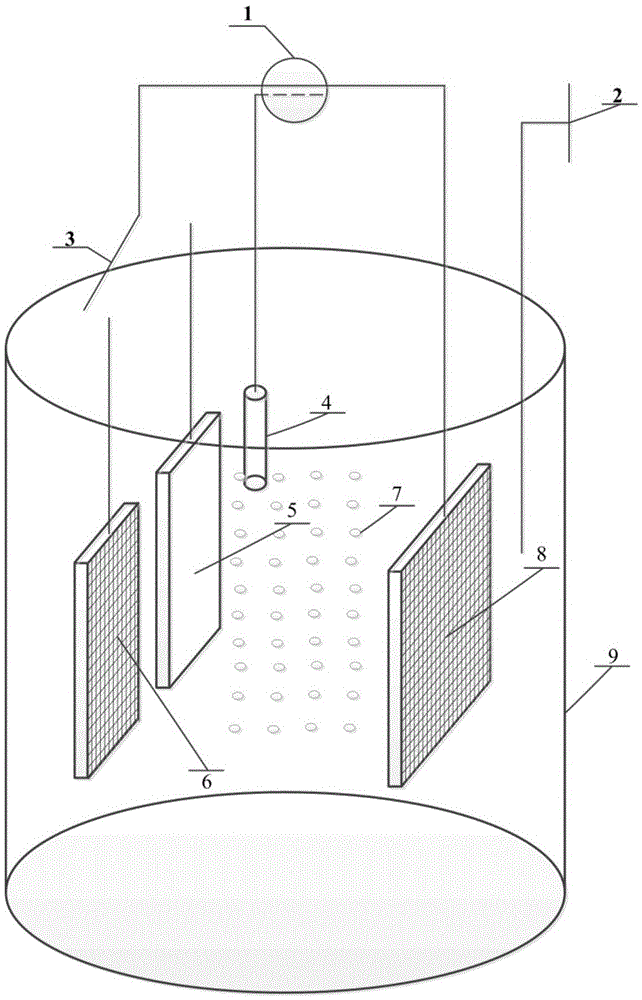

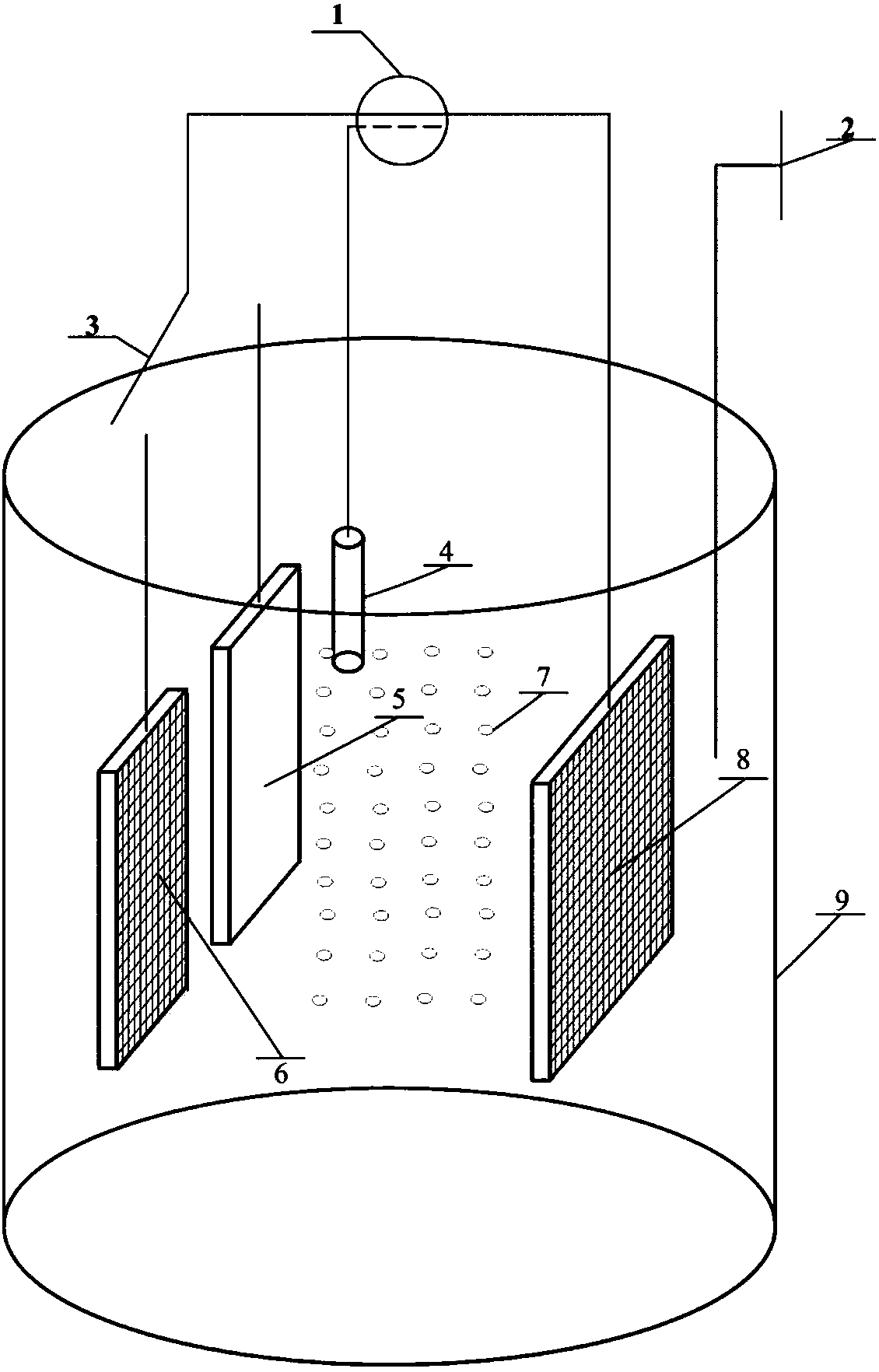

Magnesium ammonium phosphate-electrooxidation integrated device and simultaneous nitrogen and phosphorus removing method thereof

ActiveCN105668717ASave on medicine costsSynchronous removalWater contaminantsPhosphorus compoundsNitrogenMagnesium ammonium phosphate

The invention discloses a magnesium ammonium phosphate-electrooxidation integrated device and a simultaneous nitrogen and phosphorus removing method thereof and belongs to the field of wastewater treatment.The magnesium ammonium phosphate-electrooxidation integrated device comprises a magnesium ammonium phosphate-electrooxidation crystallization system and a nitrogen electrooxidation system.The magnesium ammonium phosphate-electrooxidation crystallization system comprises a reaction base and an anode B.The nitrogen electrooxidation system comprises a reaction base and an anode A.Each reaction base comprises an electrochemical instrument, a selector switch, a reference electrode, scrap iron, a cathode and a reactor, wherein the reference electrode and the cathode are connected in parallel through wires and vertically suspended in the reactor after being connected with the electrochemical instrument, the scrap iron can be suspended in the reactor through magnetic force stirring, and the selector switch is connected with the electrochemical instrument through a wire and then are connected with the anode A and the anode B in a switching mode.Just through simple electrode switching, the simultaneous nitrogen and phosphorus removing effect can be achieved, operation is easy, automatic running can be achieved, and no new pollution sources are generated.

Owner:JINGDEZHEN CERAMIC UNIV

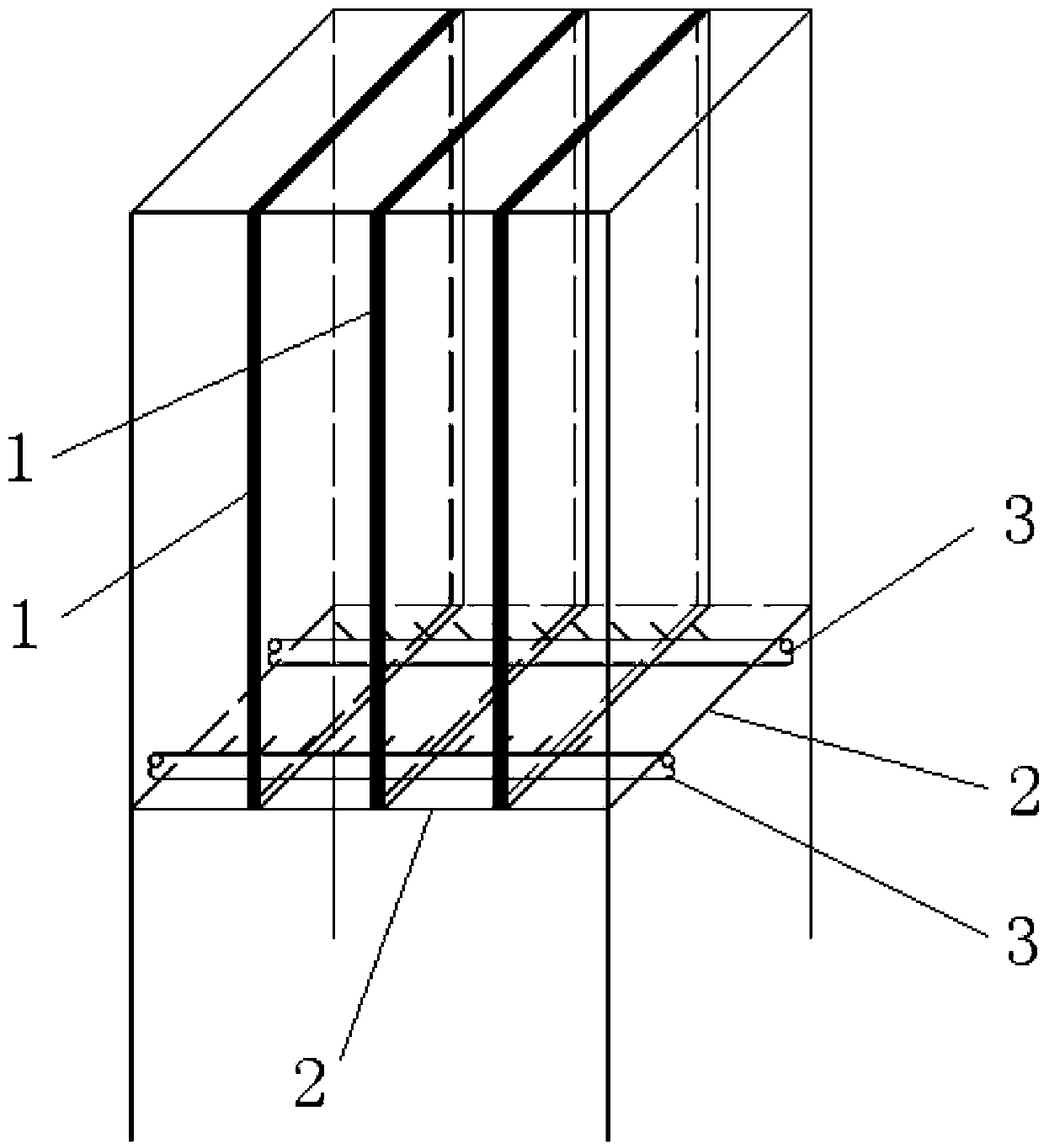

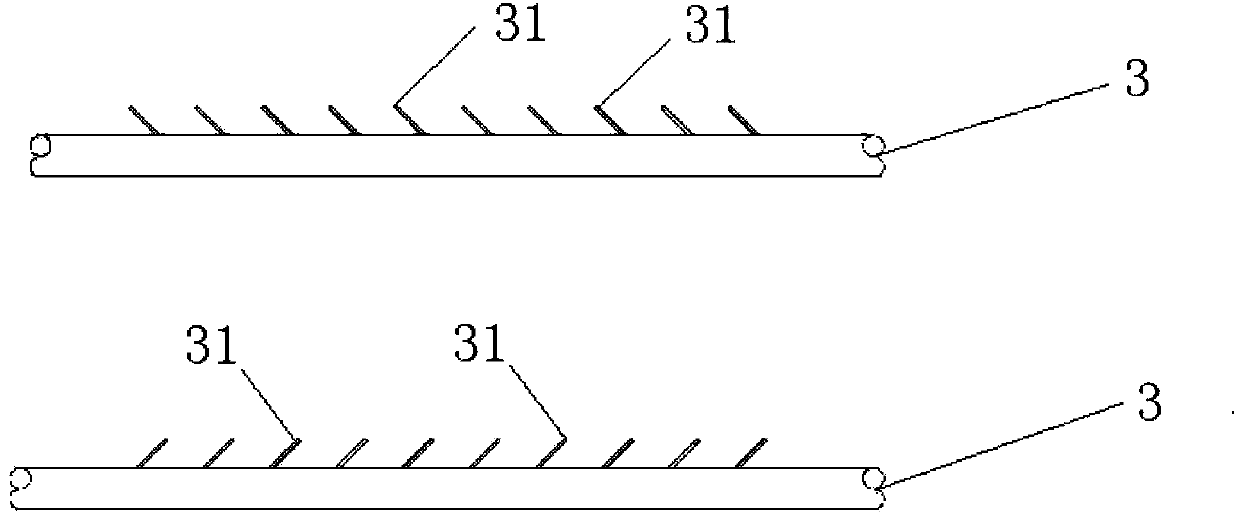

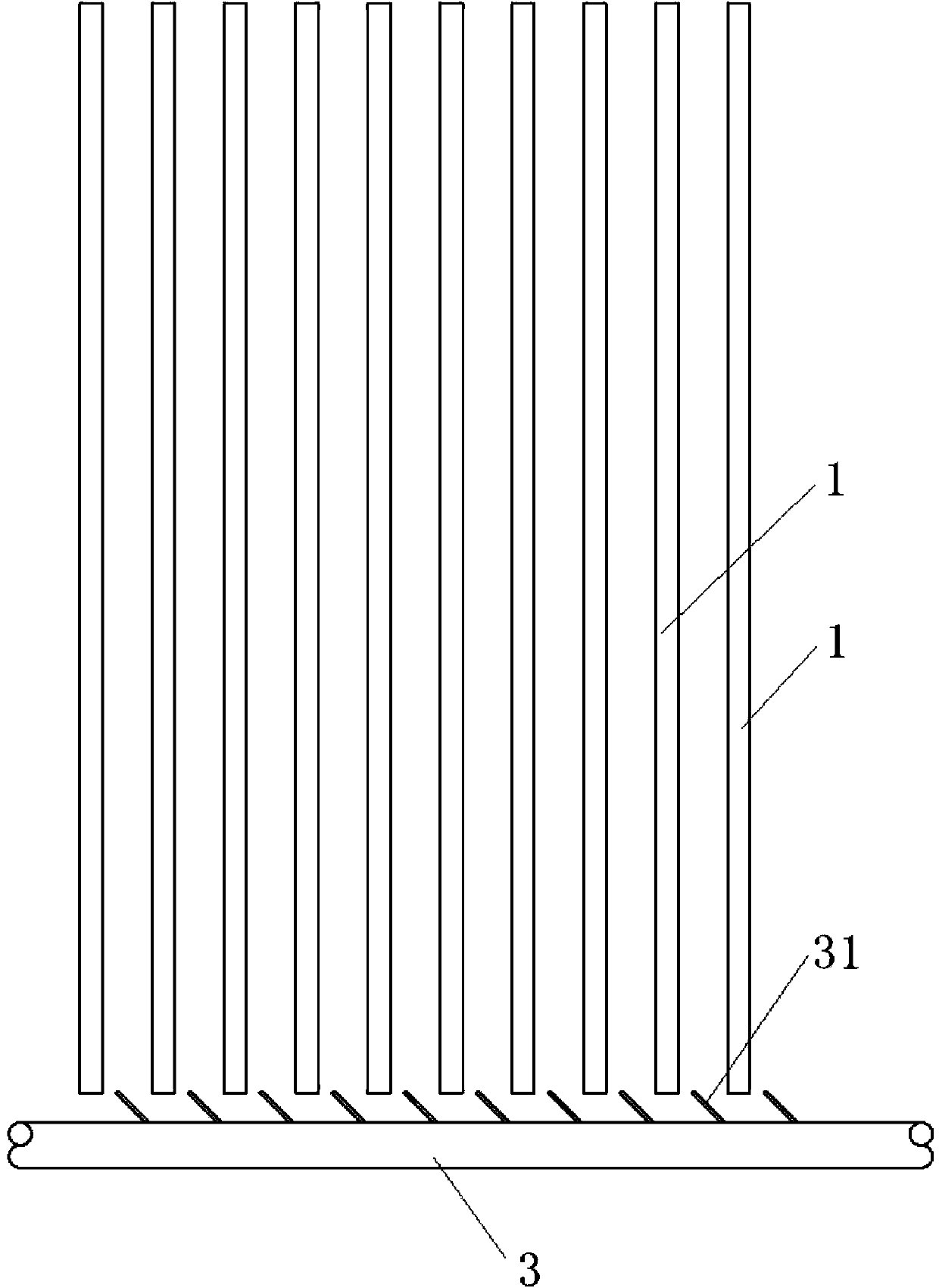

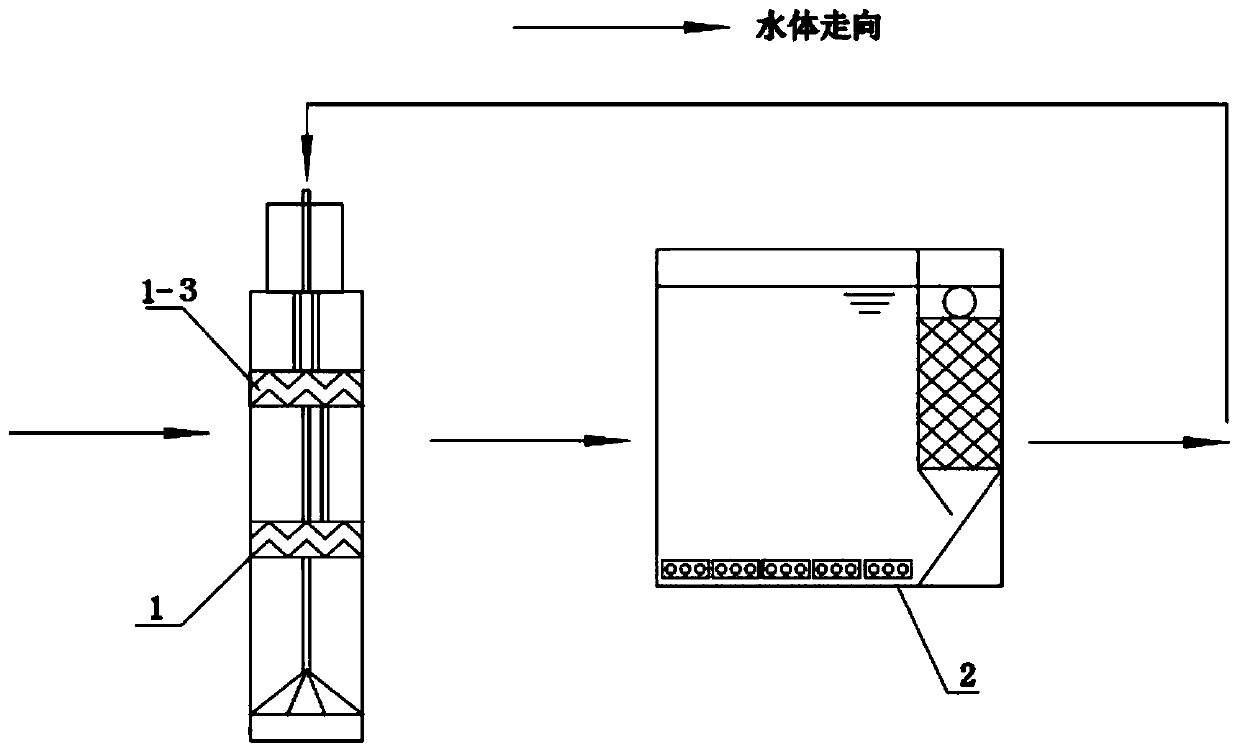

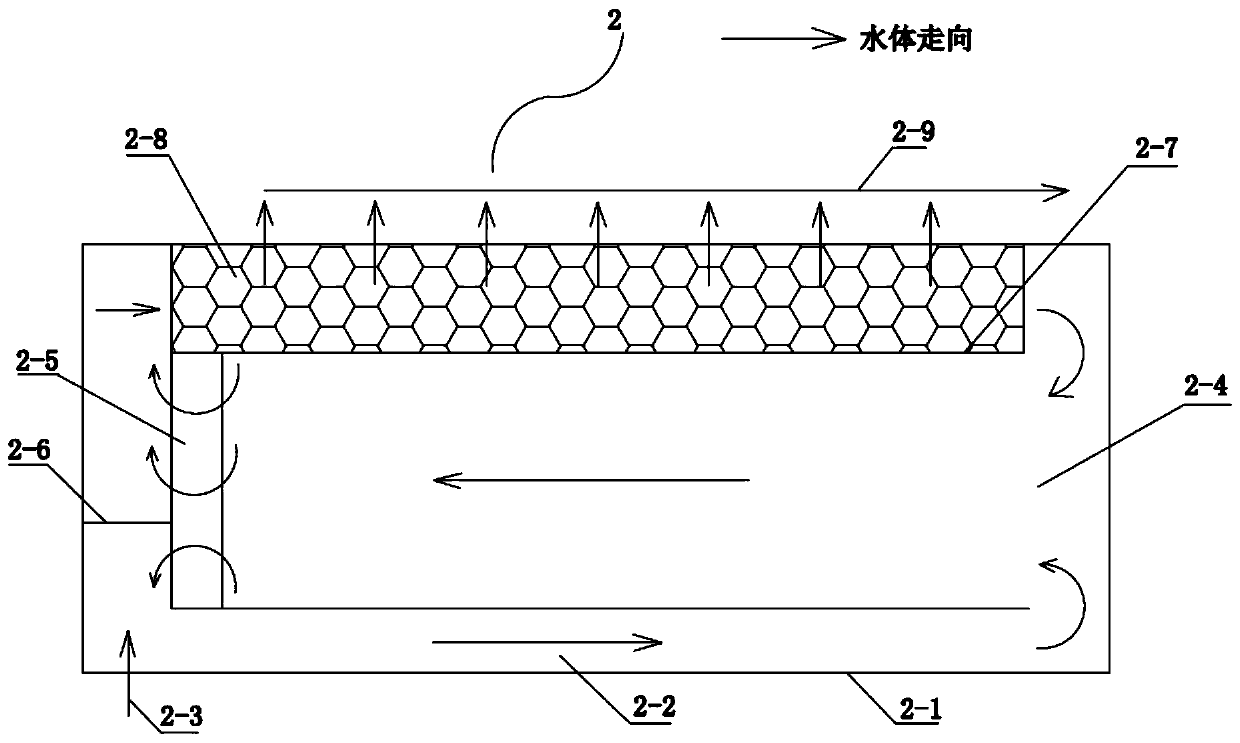

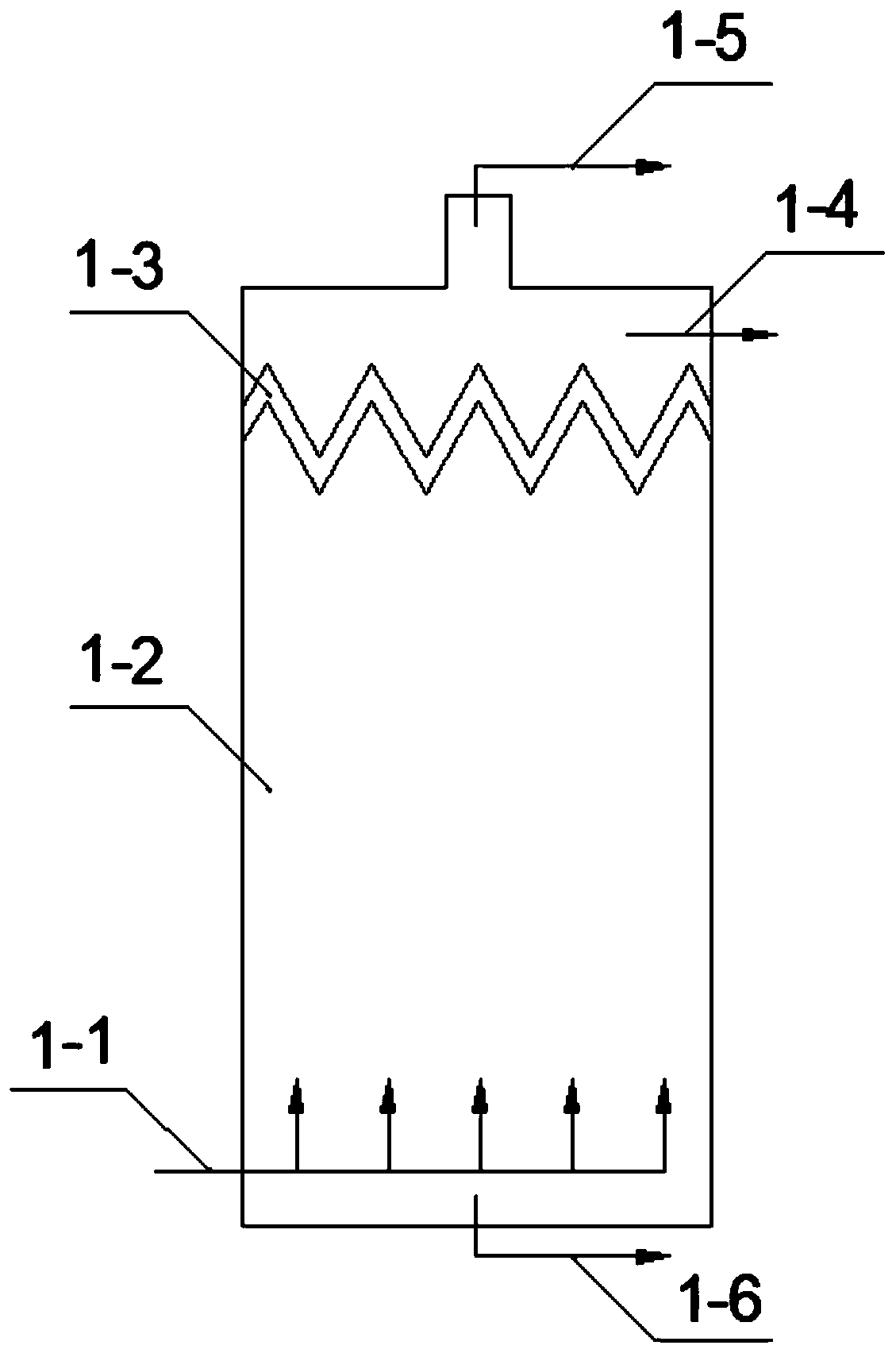

Self-cleaning MBR flat sheet membrane module and cleaning method thereof

InactiveCN103463988AWill not affectOff-line cleaning cycle extensionSemi-permeable membranesBiological water/sewage treatmentCleaning methodsProduct gas

The invention provides a self-cleaning MBR flat sheet membrane module and a cleaning method thereof. The self-cleaning MBR flat sheet membrane module comprises a plurality of flat sheet membrane elements (1) stacked at intervals and a framework (2) used for fixing the flat sheet membrane elements (1), wherein the edges of the flat sheet membrane elements (1) are provided with at least two aerator pipes (3), and the aerator pipes (3) are provided with a plurality of nozzles (31) ejecting gas towards the flat sheet membrane elements (1). With the self-cleaning MBR flat sheet membrane module and the cleaning method thereof, self-cleaning of the MBR flat sheet membrane module in operation is realized, and anti-pollution capability of the module is greatly improved. During long-term operation, the MBR flat sheet membrane module does not need cleaning, and even, on-line chemical cleaning can be cancelled; thus, the usage amount of chemical agents is reduced, operation flux of the MBR flat sheet membrane module is effectively ensured, and stability of long-time running of an MBR system is improved.

Owner:LG ELECTRONICS CHINA RANDD CENT SHANGHAI CO LTD

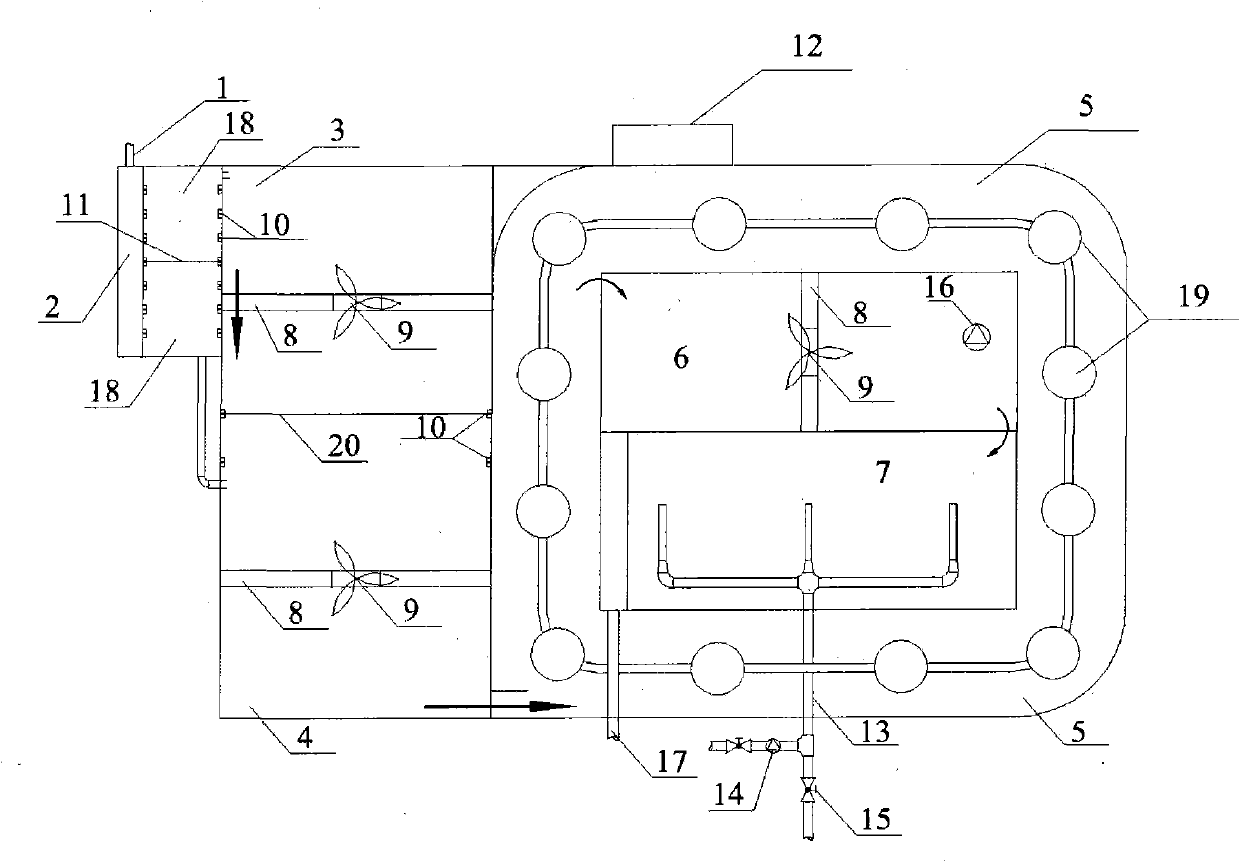

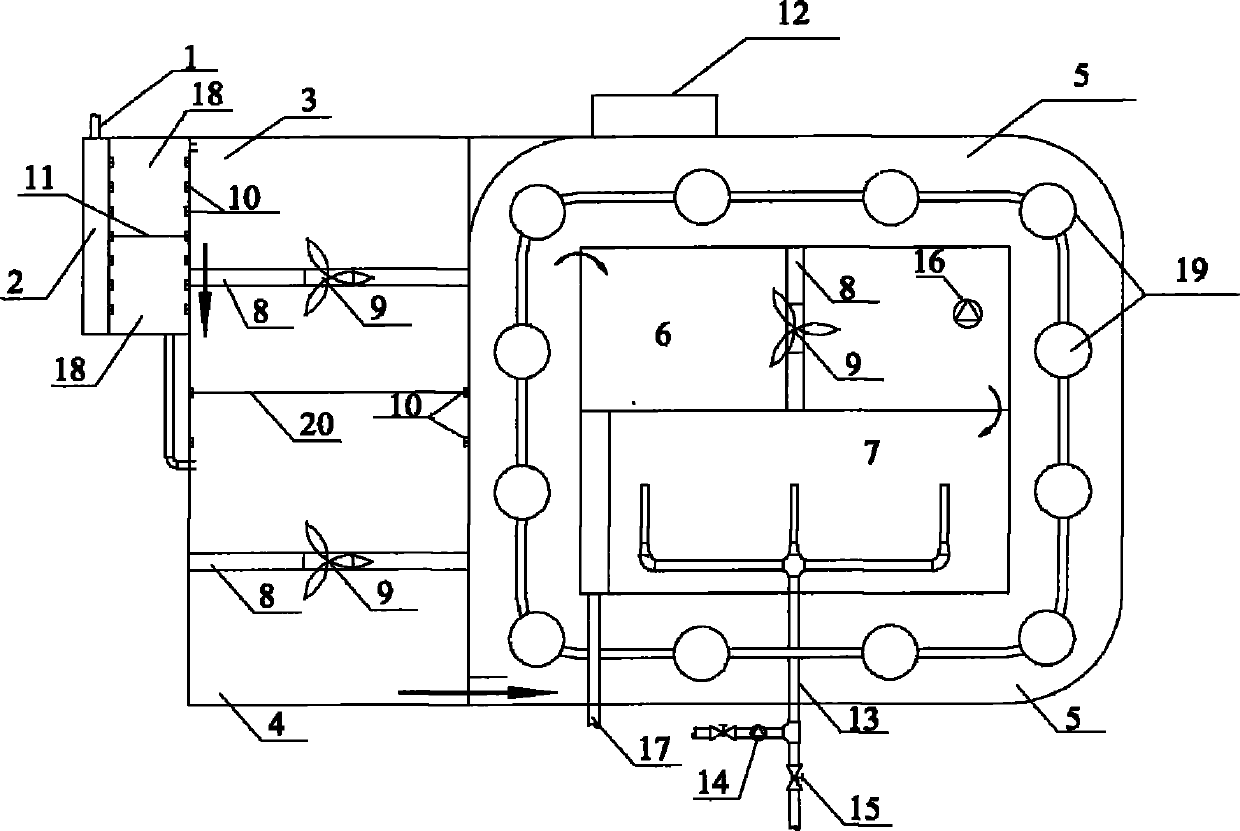

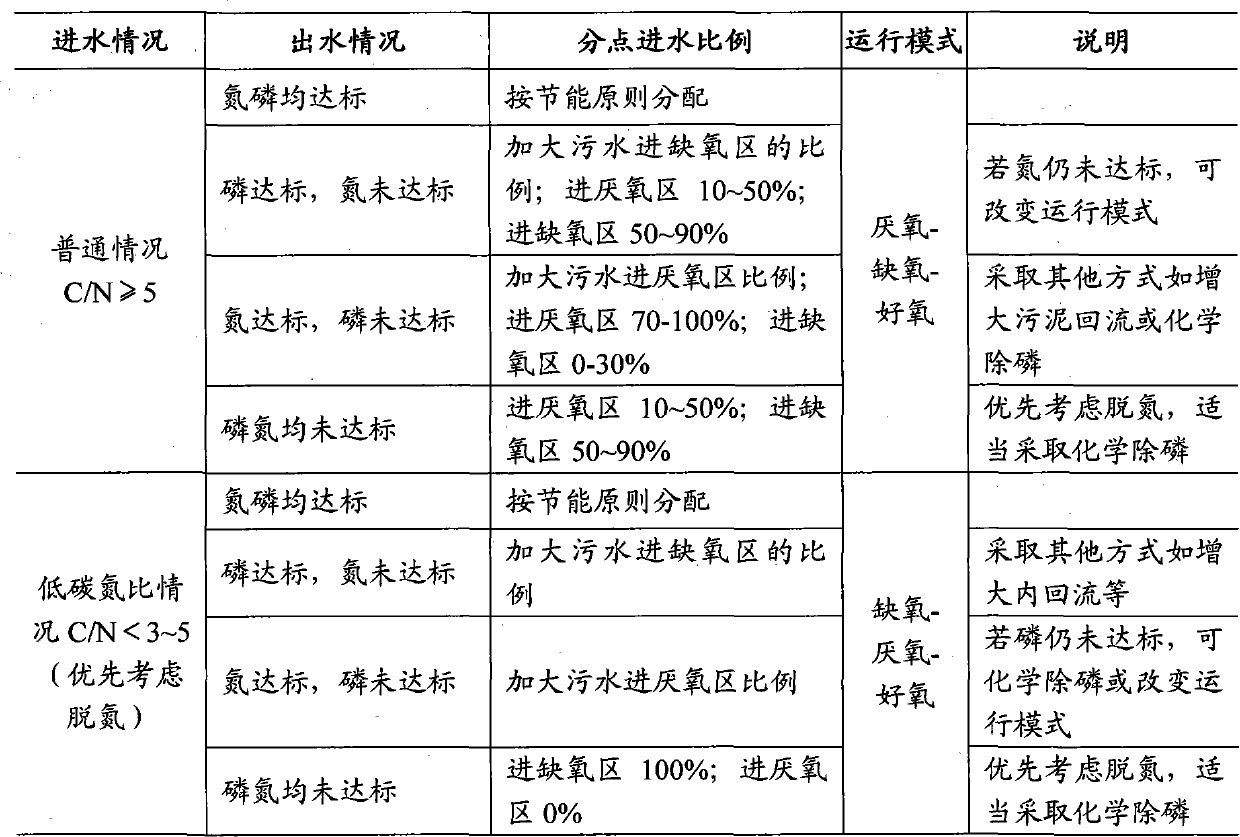

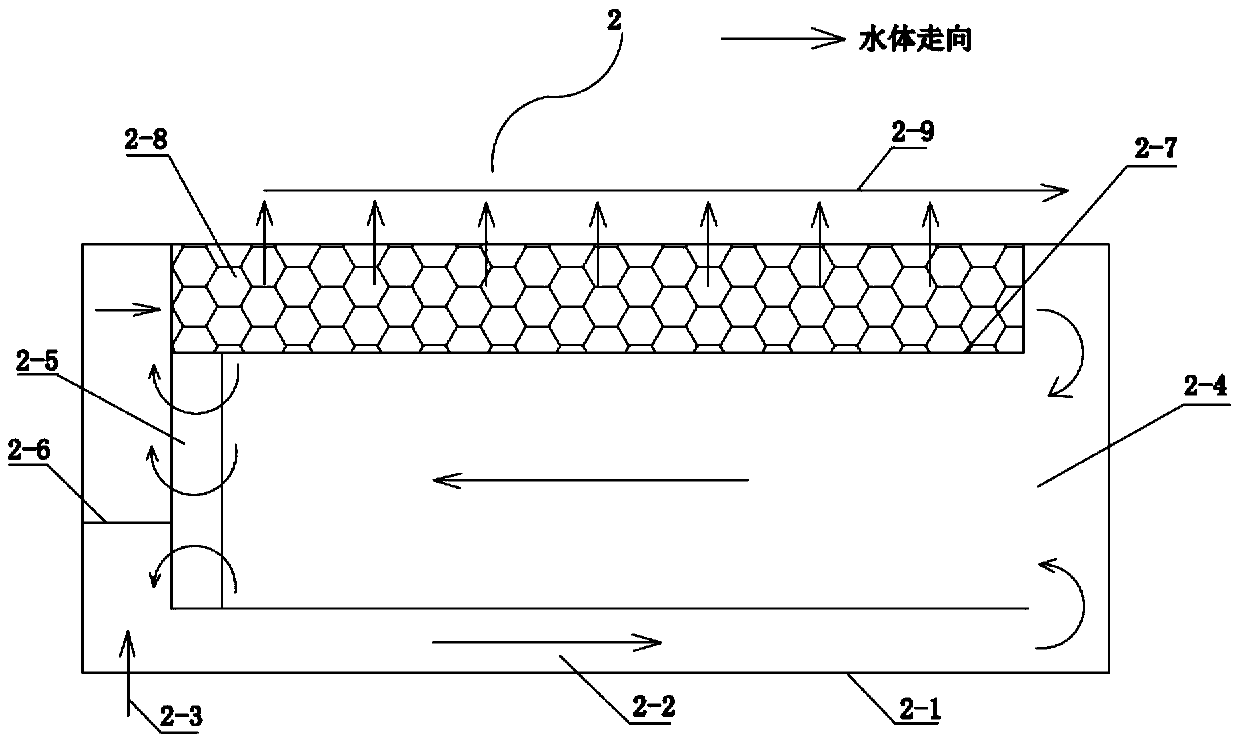

Anaerobic-anoxic-hypoxic integrated reactor and application thereof

InactiveCN101767876ASmall footprintSave on medicine costsTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesDegasificationHigh energy

The invention relates to the field of environmental protection and sewage treatment, in particular to an anaerobic-anoxic-hypoxic integrated reactor. The anaerobic-anoxic-hypoxic integrated reactor is characterized in that: the anaerobic-anoxic-hypoxic integrated reactor comprises an anaerobic zone (3), an anoxic zone (4), a hypoxic aeration zone (5), a degasification zone (6), a sedimentation zone (7), a water inlet pipe (1), a sludge removing pipe (13) and a water outlet pipe (17); the anaerobic zone (3), the anoxic zone (4), the hypoxic aeration zone (5), the degasification zone (6) and the sedimentation zone (7) are sequentially arranged along the direction of water flow and are communicated by underwater holes; the sedimentation zone (7) is provided with the sludge removing pipe (13) and the water outlet pipe (17); as a water distribution tank (2) is provided, the proportion of sewage entering the anaerobic zone (3) and the anoxic zone (4) can be flexibly adjusted; in addition, a movable zone partition plate (20) is provided and can adjust the volume as well as functional location of the anaerobic zone (3) and the anoxic zone (4). The invention can effectively solve the problems of poor effect of synchronously removing nitrogen and phosphorus, insufficient carbon sources, high energy consumption and the like during the running of the traditional A2O reactor.

Owner:HOHAI UNIV +1

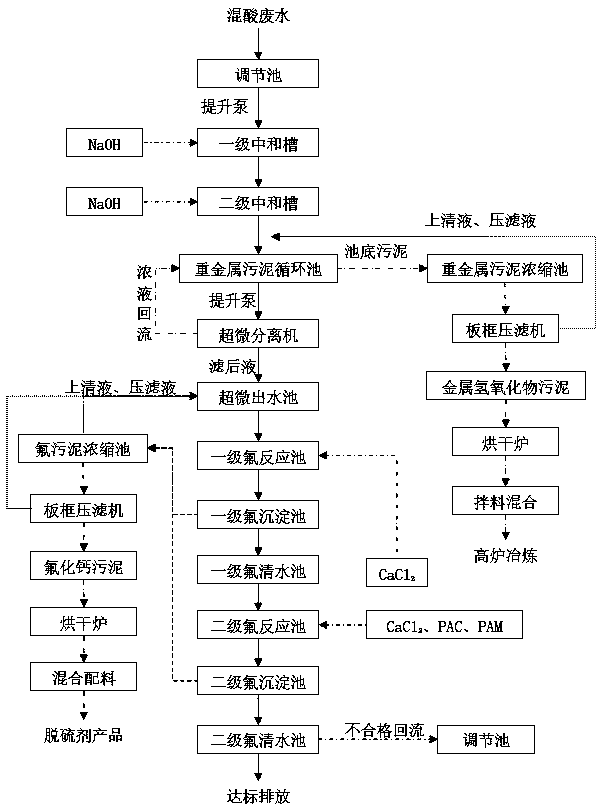

Method for recycling mixed-acid wastewater generated from metal pickling

InactiveCN108218025AImprove water qualityReduce dosageSludge treatment by de-watering/drying/thickeningTreatment involving filtrationSludgeFiltration

The invention discloses a method for recycling metal hydroxide sludge, generated after liquid alkali neutralization, and calcium fluoride sludge resources, generated after calcium chloride solution adding, from mixed-acid wastewater generated from steel industry pickling. The method mainly comprises the steps: subjecting the mixed-acid wastewater to reduction, then, adding liquid alkali, and carrying out concentrating by an ultramicro separator and press filtration by a press filter, so as to recycle metal hydroxide sludge (with the solid content of 50%); adding calcium chloride to produced water of the ultramicro separator, and then, carrying out precipitating, concentrating and pressure filtration, thereby recycling calcium fluoride sludge (with the solid content of 50%). According to the method, valuable metal ions and calcium fluoride sludge can be recycled from pickling mixed-acid wastewater, harmful dangerous solid wastes are not generated, the waste is changed into the valuable,the economic benefit of sewage treatment is improved, and the treatment cost is reduced.

Owner:YIXING XINDE ENVIRONMENTAL PROTECTION TECH

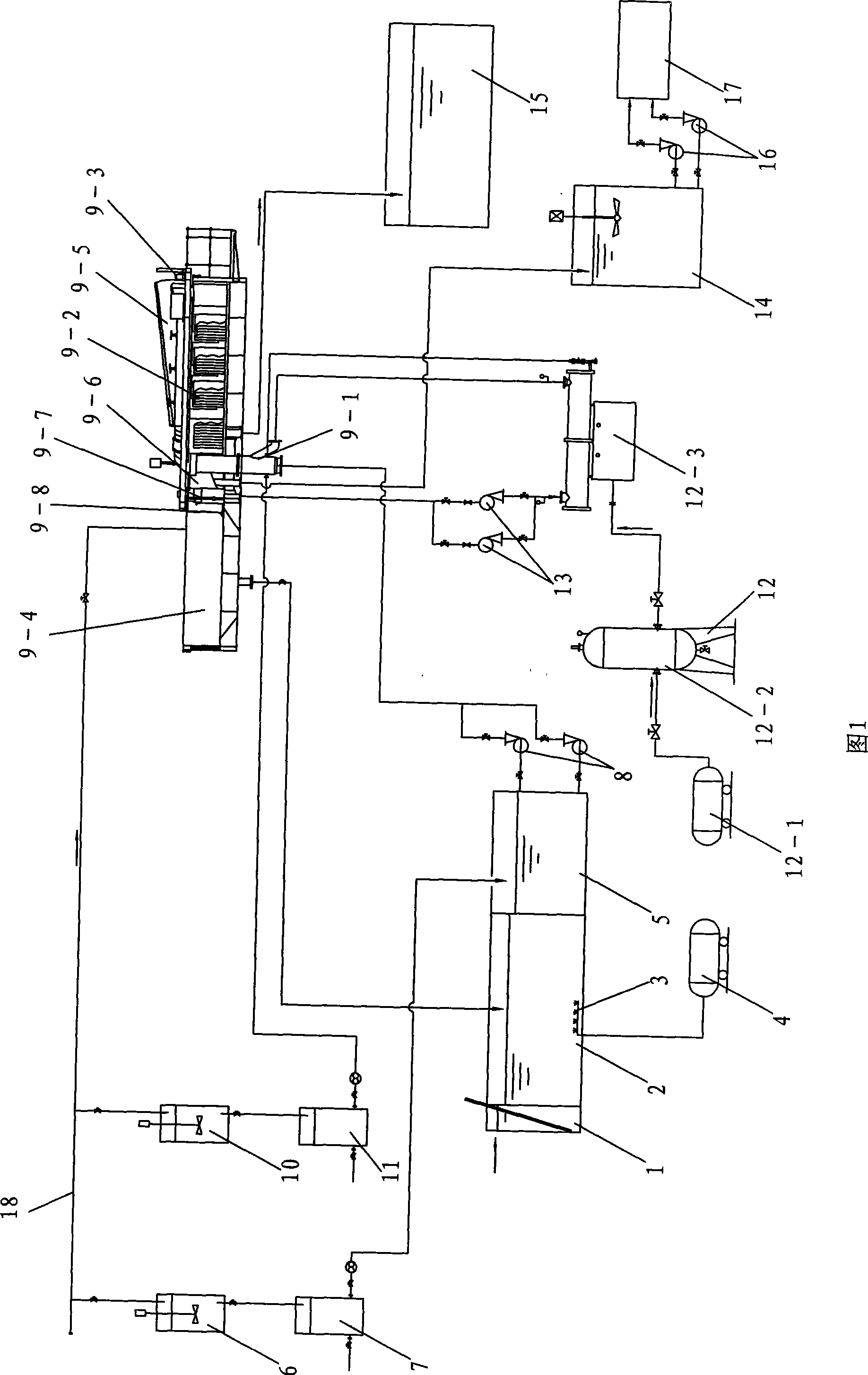

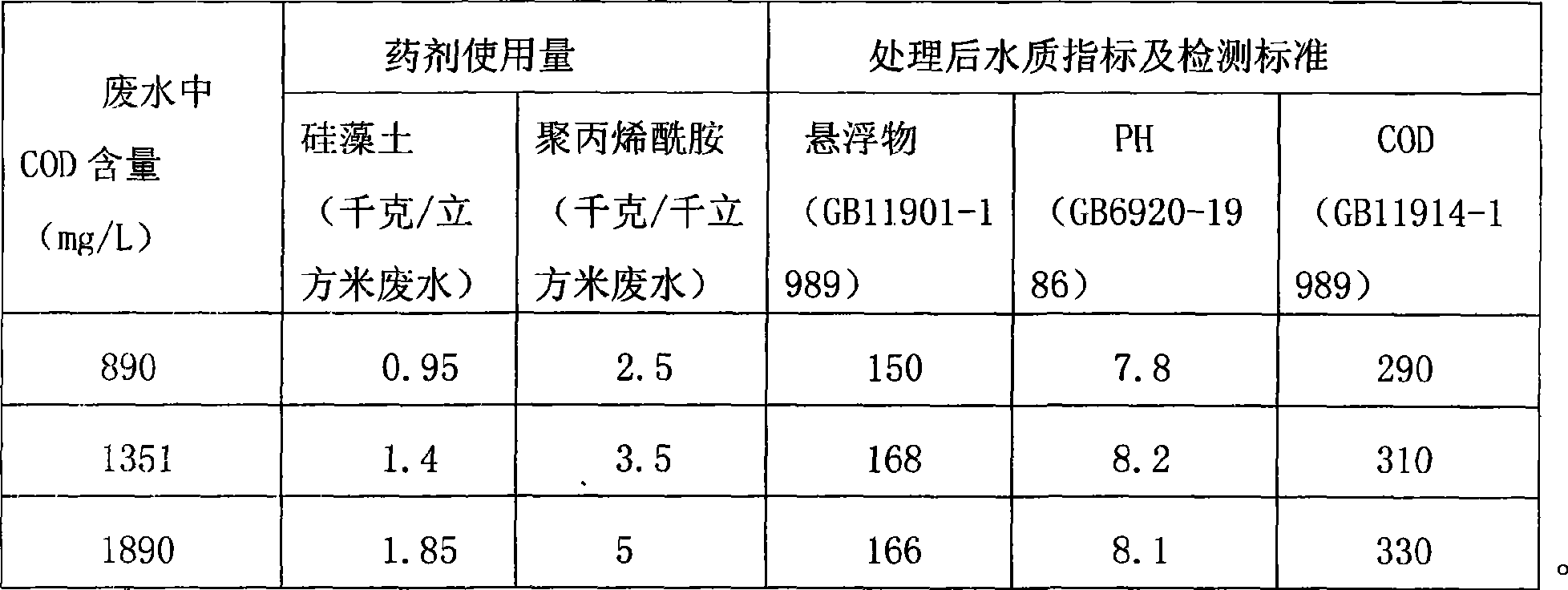

Glass fibre wastewater pretreatment method

ActiveCN101434439ASolve the problem of large fluctuations in water qualitySave on medicine costsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationGlass fiberPretreatment method

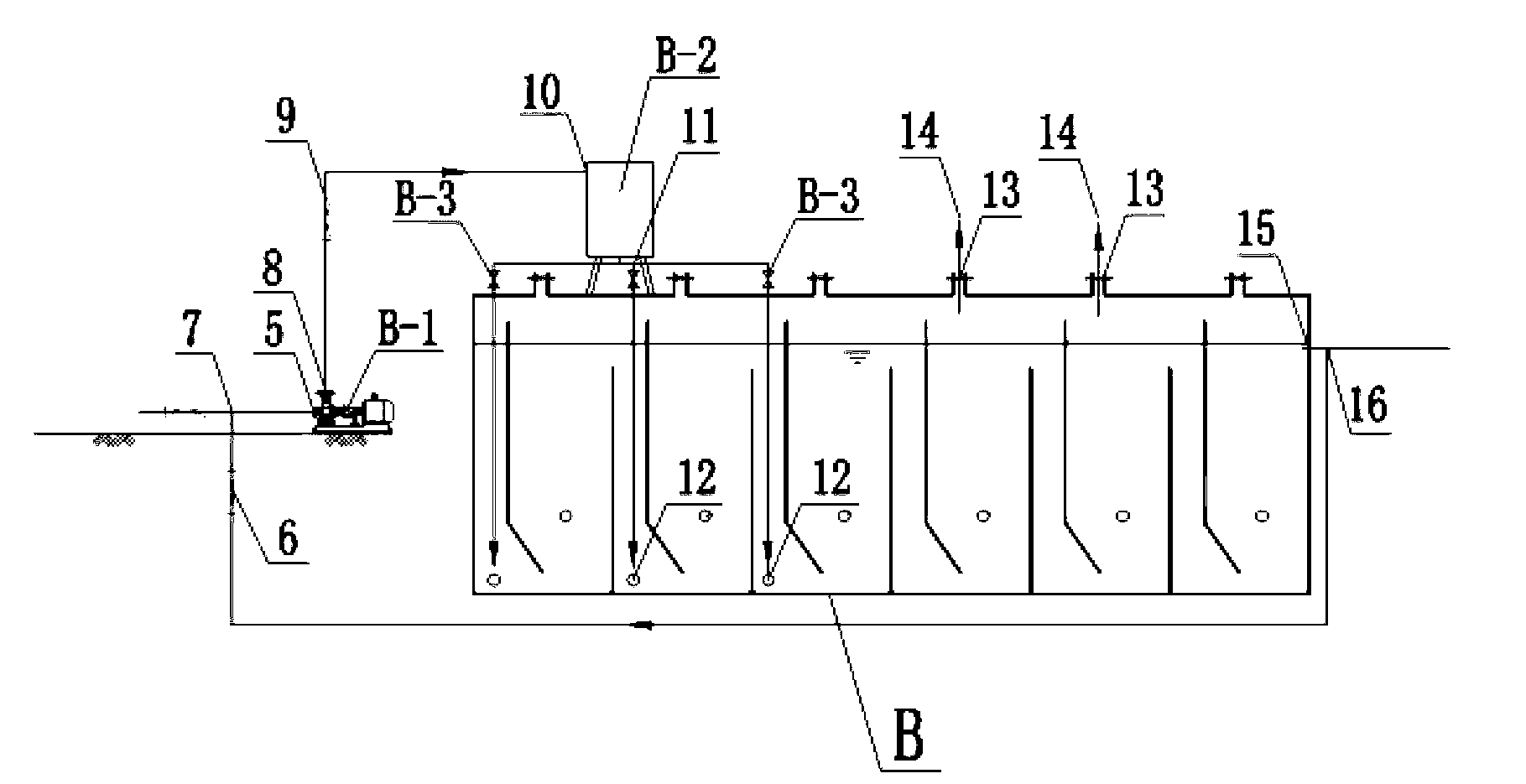

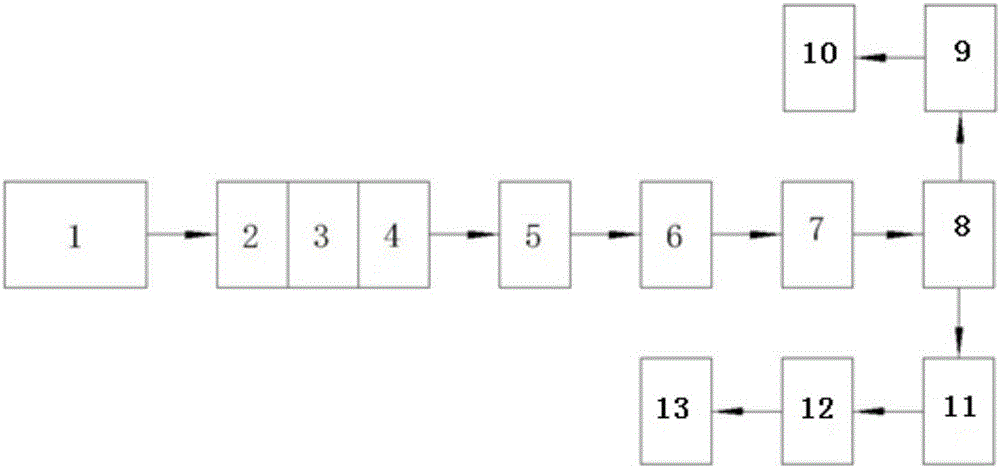

The invention relates to a pretreatment method of glass fiber wastewater, which comprises the following steps: B. a kieselguhr solution is added in a glass fiber wastewater reaction pool so as to be fully reacted with the wastewater; C. the wastewater is pumped to an air flotation water purifier, a coagulant aid is added into the intake of the air flotation water purifier, the wastewater and the coagulant aid are mixed with part of small bubbles which carry positive charges and are produced by a gas-dissolving system, so that the small bubbles can be adsorbed by pollutants in the coagulant aid and the wastewater, can enter an air flotation water distribution system in a bridging way and can realize solid-liquid separation. Following the step C of the invention, a step D can also be set, which removes scum pollutants floating after separation, solid materials flow automatically to a scum pool, and clear water separated to the bottom is automatically discharged into a clear water pool. A step E can also be set after the step D, wherein, the scum in the scum pool is sent to a sludge dewatering system by a sludge pump for carrying out dewatering treatment. The method of the invention reduces the occupation area of a wastewater pretreatment plant, saves costs on wastewater treatment, and causes the glass fiber wastewater to reach the national third-level discharge standard by one-time physicochemical treatment.

Owner:JUSHI GRP CO

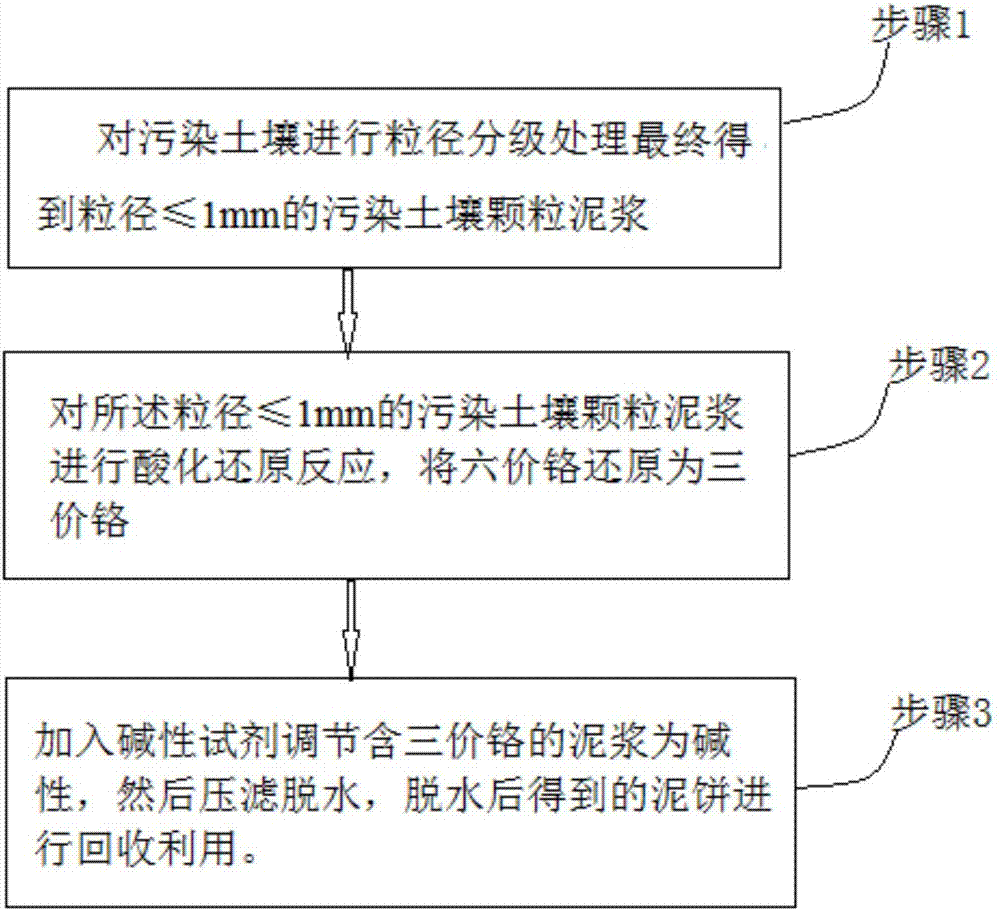

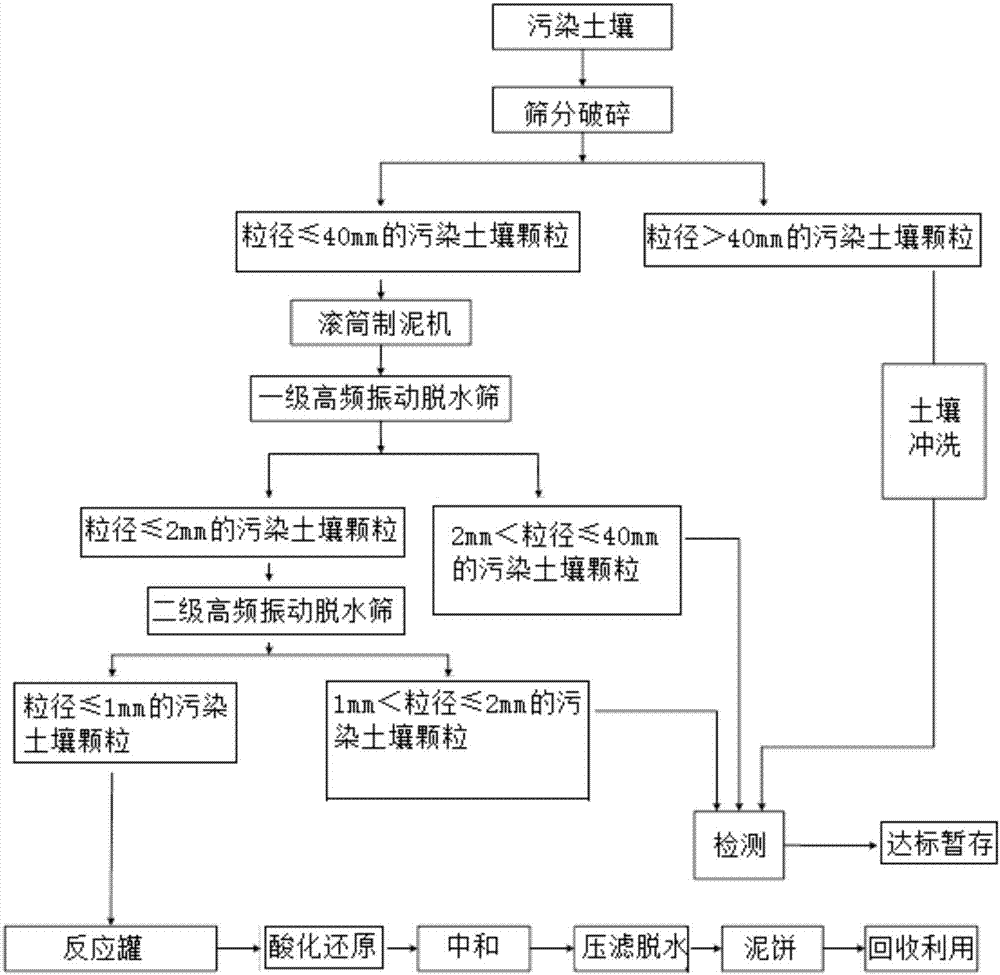

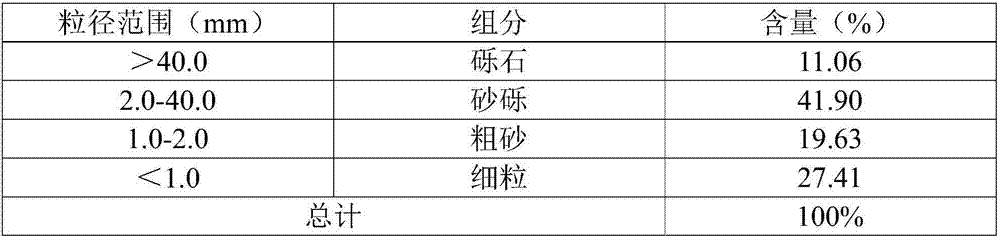

Restoration process for polluted soil containing hexavalent chromium

InactiveCN107214186AReduce secondary pollutionSave on medicine costsContaminated soil reclamationEconomic benefitsPollution

The invention discloses a restoration process for polluted soil containing hexavalent chromium. The restoration process is applicable to coarse grained soil. The restoration process comprises the following steps that 1, the polluted soil is subjected to grain diameter grading treatment and dehydrated, and polluted soil grain mud with the grain diameter smaller than or equal to 1 mm is finally obtained; 2, polluted soil grain mud with the grain diameter smaller than or equal to 1 mm is subjected to an acidizing reduction reaction, and the hexavalent chromium is reduced to be trivalent chromium; and 3, an alkaline reagent is added for adjusting the mud containing the trivalent chromium to be alkaline, filter pressing and dehydration are carried out, and a mud cake obtained after dehydration is recycled. The polluted soil is subjected to reduction grain diameter grading treatment at first to enable pollutant to be transferred to fine grained mud with the grain diameter smaller than 1 mm, then, chemical reduction medicament is added, chemical medicament is greatly saved, the trivalent chromium is recycled, soil environment risks are eliminated, and meanwhile certain economic benefits are obtained. Meanwhile, according to the restoration process, water is adopted for reduction screening, the restoration cost is reduced, and secondary pollution to the environment is small.

Owner:BEIJING GEOENVIRON ENG & TECH

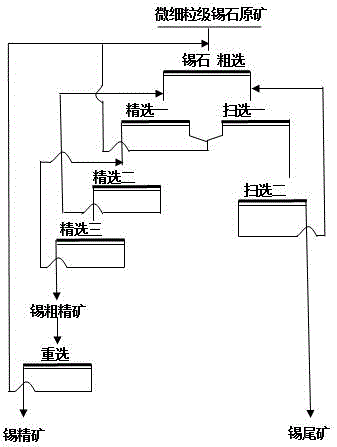

Method for recycling micro-fine particle class cassiterite

The invention relates to a method for recycling micro-fine particle class cassiterite and belongs to the technical field of beneficiation. According to the method, a chemical formed through synthesis of main raw materials of hydroxylamine hydrochloride and methyl benzoate and combination of styrene phosphoric acid and the like is adopted as a collector, flotation is conducted on the micro-fine particle cassiterite under the circumstance that no inhibitor is needed, flotation rough concentrate is subjected to reselection and concentration to obtain final concentrate, and reselection tailings return to flotation to form a flotation-reselection combined process. The advantages that the flotation recycling rate is high, and the reselection concentrate grade is high are utilized effectively, so that the high recycling rate is obtained while the qualified cassiterite concentrate grade is obtained. Through the flotation-reselection combined method, the resource utilization rate of the micro-fine particle class cassiterite difficult to recycle can be increased effectively, and good economic benefit is achieved.

Owner:KUNMING UNIV OF SCI & TECH

Method for recovering chromic acid and water from chromeplating rinse water

ActiveCN101575119AAchieve enrichmentRealize closed loopWaste water treatment from metallurgical processChromium trioxideWater vaporLiquid water

The invention relates to the technical field of chromate waste water treatment, and in particular discloses a method for reclaiming chromic acid and water from chromeplating rinse water. The method comprises the following steps: rinsing chromium-plated parts from a coating bath in a first-level washing reclaiming tank, a second-level washing reclaiming tank until the last-level washing reclaiming tank in turn; refluxing the rinse water in the last-level washing reclaiming tank to the previous level reclaiming tank in turn and finally to the first-level washing reclaiming tank; overflowing the chromium-containing rinse water in the first-level washing reclaiming tank to a circulating reclaiming tank, and heating the rinse water to a temperature of 50 DEG C by a heating device; pumping the rinse water into a vacuum evaporator by a circulating pump so that the water content is evaporated and chromic acid concentrated solution is left at the bottom of the evaporator; refluxing the chromic acid concentrated solution to the circulating recovery tank, and performing circulating evaporation in the vacuum evaporator again; and pumping finally concentrated chromic acid into a chrome-plating bath for reclaiming by a chromic acid reclaiming pump. The top of the vacuum evaporator is connected with a condensate water reclaiming tank through an ejector vacuum pump, and a cooling device in the condensate water reclaiming tank condensates water vapor into liquid water which is overflowed to the last-level washing reclaiming tank from the condensate water reclaiming tank for recycling. The method can recycle the chromic acid and the water in the chromeplating rinse water on line, save the significant cost required by a chemical method control, and reclaim resources.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

Method for treating high-concentration organic wastewater by anaerobic-aerobic deep coupling

InactiveCN111333191ALight inhibitionImprove efficiencyWater treatment parameter controlWater contaminantsActivated sludgeAmmoniacal nitrogen

The invention relates to a method for treating high-concentration organic wastewater by anaerobic-aerobic deep coupling. The method comprises the following steps: introducing organic wastewater into an anaerobic reaction unit, and sufficiently mixing the organic wastewater with anaerobic granular sludge added into the anaerobic reaction unit in advance to perform anaerobic reaction; enabling anaerobic effluent obtained after anaerobic reaction to enter an aerobic reaction unit, and removing nitrogen through a synchronous nitrification and denitrification process; flowing part of effluent of the aerobic reaction unit back to the anaerobic reaction unit and fully diluting and mixing the part of effluent with the raw organic wastewater and granular sludge to carry out anaerobic reaction, andenabling the other part of effluent to enter a next treatment process or discharging the other part of effluent after reaching the standard. According to the invention, the anaerobic and aerobic reaction units are coupled to treat wastewater; anaerobic effluent enters the aerobic unit, the DO value in the water body of the aerobic unit is controlled, denitrification is effectively completed, thereflux ratio of the aerobic effluent is controlled, and the aerobic effluent returns to the anaerobic unit again, so that the ammonia nitrogen concentration in the anaerobic reactor is reduced, the activated sludge amount in the anaerobic reactor is ensured, and the anaerobic reaction efficiency is effectively improved.

Owner:恩格拜(武汉)生态科技有限公司

Magnesium ammonium phosphate-urea slow-release fertilizer and preparing method thereof

InactiveCN108467309AReduce solubilityLong releaseAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMagnesium phosphateGranularity

The invention discloses a magnesium ammonium phosphate-urea slow-release fertilizer and a preparing method thereof, and belongs to the technical field of resource comprehensive utilization. The methodincludes the following steps of firstly, grinding magnesium ammonium phosphate and modified starch into small particles, and conducting evenly mixing to form a magnesium ammonium phosphate and modified starch mixture; secondly, placing the mixture obtained in the first step into a disc granulator; thirdly, spraying water on the rotating magnesium ammonium phosphate and modified starch particles through an atomizing method; fourthly, slowing adding the urea ground into small particles to the magnesium ammonium phosphate and modified starch particles in the third step; fifthly, spraying water for granulating; sixthly, repeatedly executing the second step, the third step, the fourth step and the fifth step through the slow adding mode after the material is converted into the particles with the granularity of about 1 mm; seventhly, conducting stable granulating to obtain the magnesium ammonium phosphate-urea slow-release fertilizer. The magnesium ammonium phosphate-urea slow-release fertilizer particles are formed with the magnesium ammonium phosphate particles and the urea particles through the layer-by-layer wrapping mode, and the releasing speed of the urea is effectively controlled.

Owner:JINGDEZHEN CERAMIC INSTITUTE

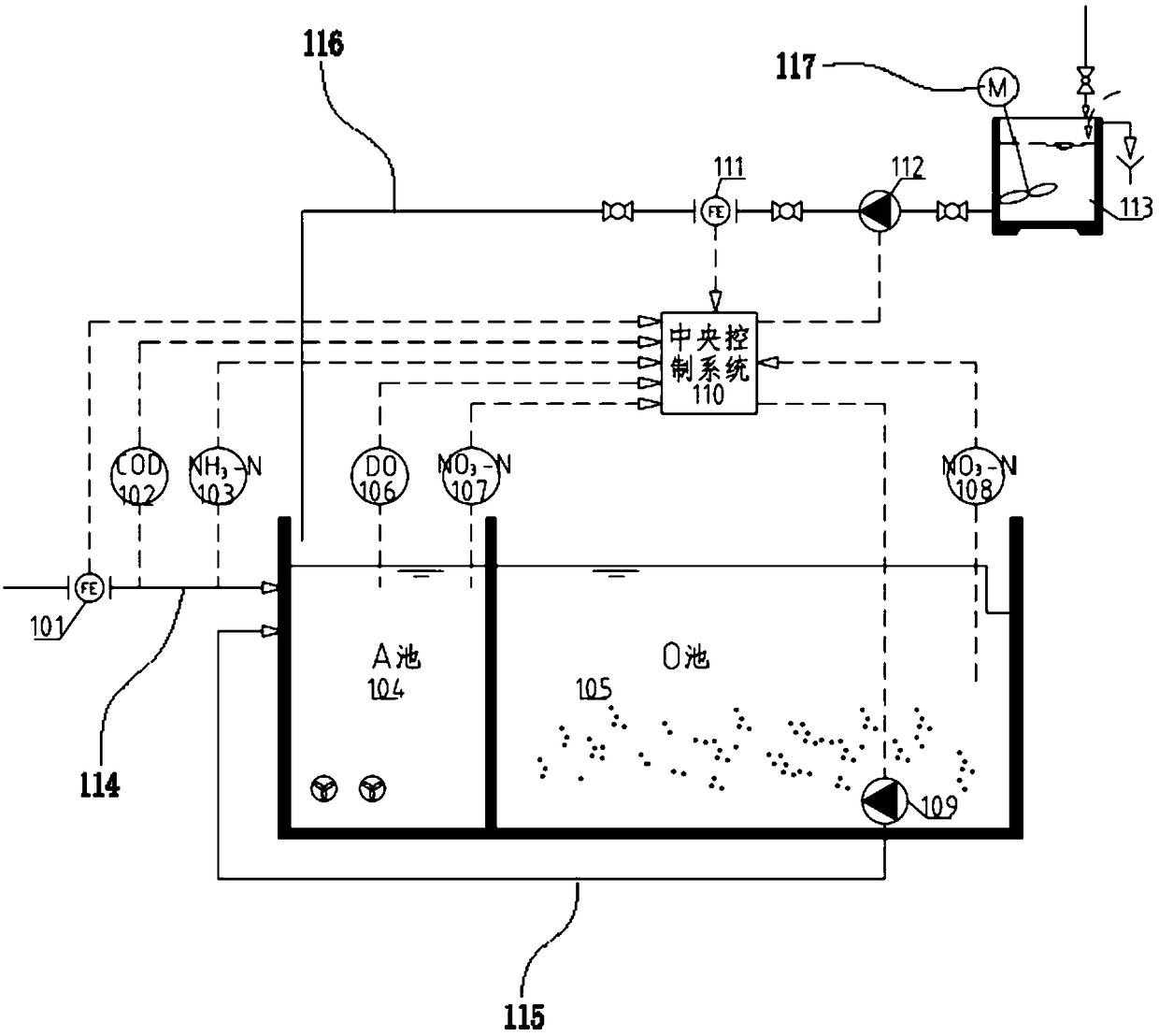

Optimization control apparatus for denitrification carbon source addition in AO process

InactiveCN109279695AAccurate volume control dataSave on medicine costsBiological treatment regulationWater contaminantsRefluxControl system

The invention provides an optimization control apparatus for denitrification carbon source addition in the AO process. The apparatus comprises an A pool, an O pool, a first pipeline, a second pipeline, a third pipeline, an agitator, a water inlet flowmeter, a water inlet COD analyzer, a water inlet ammonia nitrogen analyzer, a dissolved oxygen instrument, a first nitric acid nitrogen sensor and determinator, a second nitric acid nitrogen sensor and determinator, a frequency conversion internal reflux pump, a central control system, a carbon source addition flowmeter, a frequency conversion carbon source addition pump and a carbon source box. The problems of poor denitrification stability, low efficiency and feedback delay existing in a traditional biological A / O denitrification technologyare solved, and the problems existing at present that the control precision is insufficient, the carbon source waste is easily caused, the production cost is increased, and the water output which is stably up to the standard is difficult to be ensured are also solved.

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

Inorganic gel deep profile control and flooding method in high salt oil reservoir.

InactiveCN111219162AImprove retentionImprove the blocking effectFluid removalSealing/packingChemical reactionSoftened water

The invention belongs to the technical field of oil recovery, and particularly relates to an inorganic gel deep profile control and flooding method in a high salt oil reservoir. The inorganic gel deepprofile control and flooding method includes the steps that first, the composition analysis of injected water ions is carried out, based on the analysis results, the concentration of Na2CO3 needed toremove Ca<2+> and Mg<2+> from injected water is calculated, finally, the injected water is mixed with the Na2CO3 in proportion, a gravity or rotational flow method is used for removing CaCO3 and MgCO3, and softened water is obtained; a main agent Na2SiO3 solution and isolation solution are prepared by the softened water; and at least five rounds of alternating injection are adopted to inject theisolation solution, the main agent, the isolation solution and the injected water into the oil reservoir sequentially. The chemical reaction between Ca<2+> and Mg<2+> in the injected water and the added Na2SiO3 in the deep part of the high permeability oil reservoir is used for forming inorganic gel CaSiO3 and MgSiO3 so that the purposes of the permeability of a high permeability layer and the diversion of deep solution flow can be achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

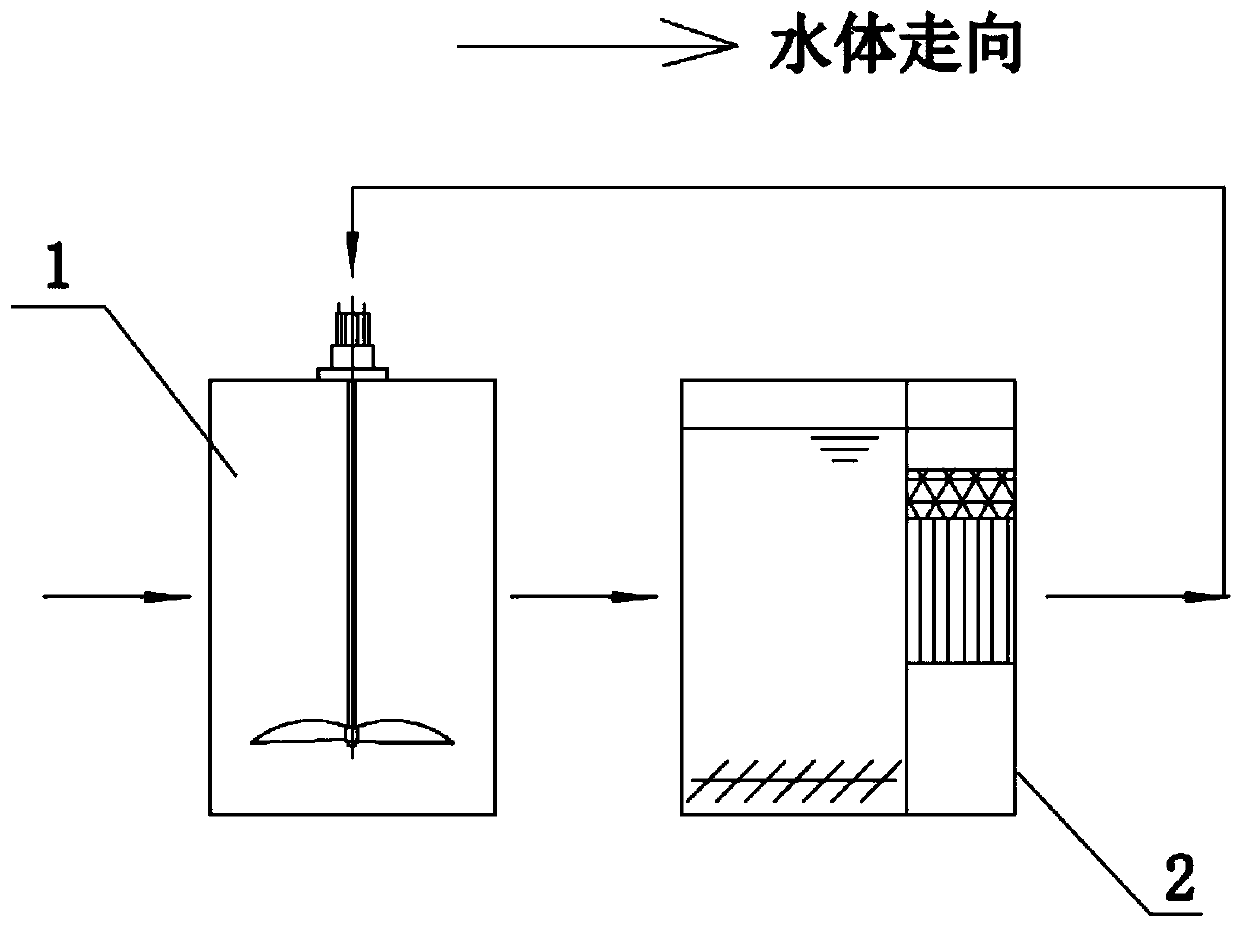

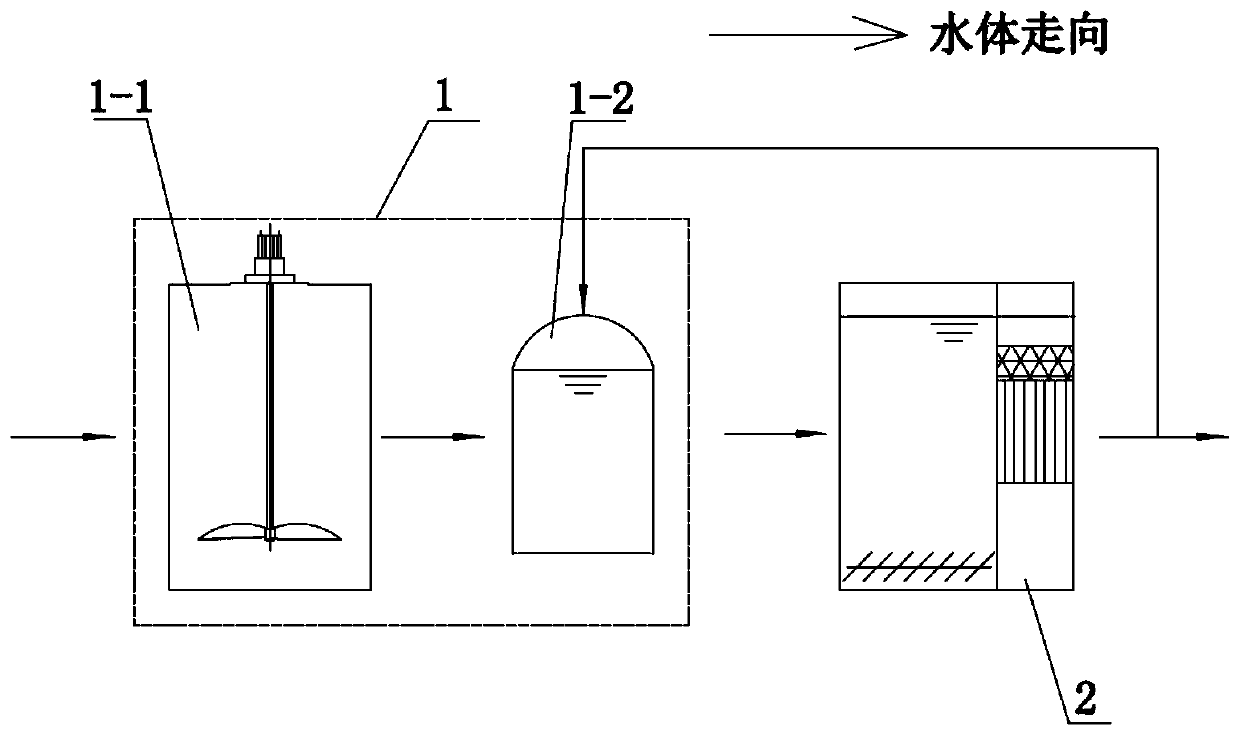

Emergent riverway water treatment device

InactiveCN106145287AGood processing effectShort processWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationSpecific gravityMagnetic powder

The invention discloses an emergent riverway water treatment device which comprises a dosing system, a magnetic efficient precipitation system and a dehydration system. The dosing system comprises a first reaction stirring box, a second reaction stirring box, a third reaction stirring box and a reagent storage tank, and stirrers are arranged in the reaction stirring boxes. The magnetic efficient precipitation system comprises a precipitation pond and a magnetic powder separator. The dehydration system adopts a volute dehydration machine. The emergent riverway water treatment device is good in treatment effect, outlet water is equivalent to ultra-filtered outlet water, the emergent riverway water treatment device utilizes large specific gravity and micro-magnetic field effect of the magnetic powder, a flow is short, the whole treatment process can be completed within 10 minutes, the impact-resistant load capability is strong, and the emergent riverway water treatment device can still stably operate under the condition of high water yield or high pollution load. The emergent riverway water treatment device is small in occupied area, is integrated to be a container type device, is convenient to move and flexible in operation, low in investment cost and long in service life, and the device cost, construction cost and operating cost are low.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

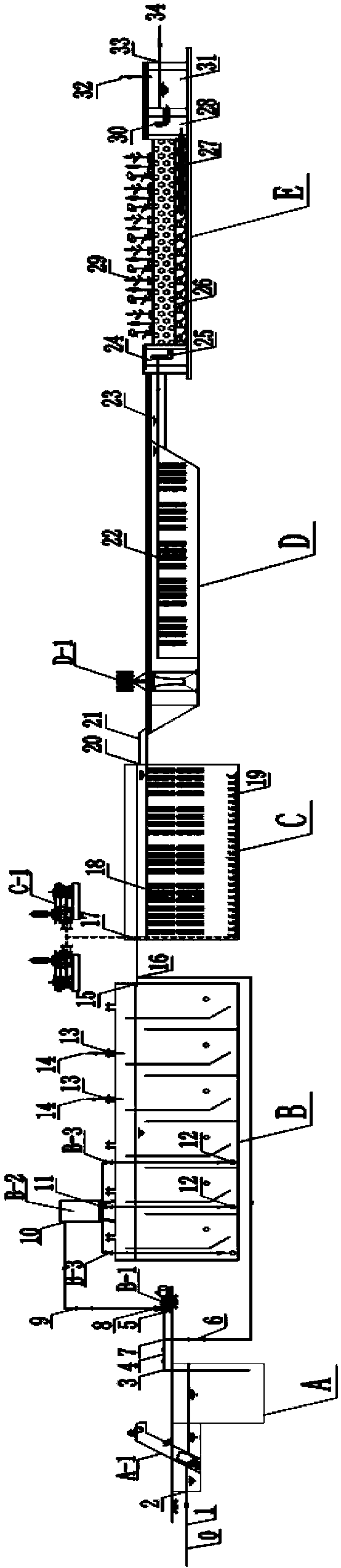

Coal-fired power plant desulfurization wastewater resource treatment system and coal-fired power plant desulfurization wastewater resource treatment method

PendingCN110937735AImplement resourcesRealize alkali makingSludge treatmentMultistage water/sewage treatmentSulfate radicalsElectrolysis

The invention discloses a coal-fired power plant desulfurization wastewater resource treatment system and a coal-fired power plant desulfurization wastewater resource treatment method. The system comprises a concentration electrolysis three-chamber reactor, a desulfurization system, a pre-sedimentation tank, a magnesium resource reaction clarification tank, a heavy metal reaction clarification tank, a sulfate radical deep removal reaction clarification tank, a neutralization tank, an ultrafiltration system, a nanofiltration system, a reverse osmosis system, a calcium hydroxide feeding system,a coagulant and coagulant aid mixed feeding system, a sulfate radical composite precipitator feeding system and a hydrochloric acid feeding system, wherein an electrodialysis cathode, an electrolysisinert electrode cathode, an electrodialysis anode membrane, an electrodialysis cathode membrane, an electrolysis inert electrode anode and an electrodialysis anode are sequentially arranged in the concentration electrolysis three-chamber reactor. With the system and the method, the investment cost and the operation cost can be reduced, and the resource acid production and alkali production of desulfurization wastewater can be achieved.

Owner:HUANENG POWER INT INC +1

Method for producing impurity-bearing liquid calcium chloride by utilization of converter dedusting wastewater

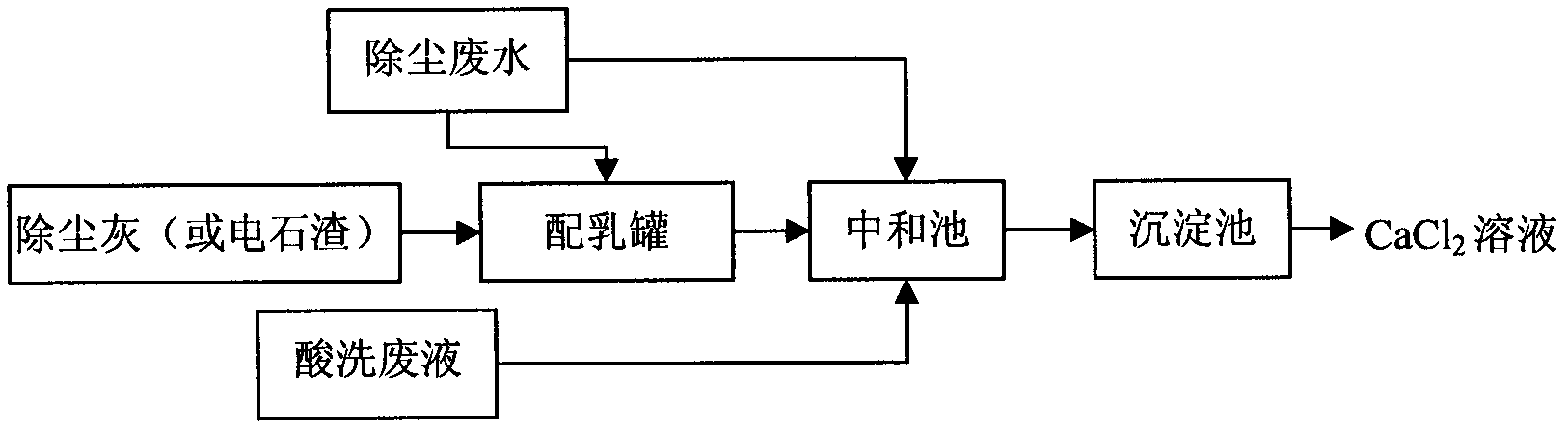

ActiveCN102826582AReduce processing costsSave on medicine costsCalcium/strontium/barium chloridesSlagEmulsion

The invention discloses a method for impurity-bearing liquid calcium chloride by the utilization of converter dedusting wastewater. Materials for the production of the impurity-bearing liquid calcium chloride comprise the converter dedusting wastewater, a pickling waste liquid and dust or carbide slag. The method comprises the following steps of: a, examining mole concentration of HCl in the pickling waste liquid and mass percentage of CaO in the dust or carbide slag; calculating mole number of the added converter dedusting wastewater, dust or carbide slag and pickling waste liquid required by each unit volume of an impurity-bearing CaCl2 solution according to the mole concentration of the impurity-bearing CaCl2 solution which is expected to be prepared and according to the formula of CaO+2HCl=CaCl2+H2O, and calculating the volume of the added converter dedusting wastewater and the pickling waste liquid and the weight of dust or carbide slag which are required by each unit volume of the impurity-bearing CaCl2 solution according to the mole concentration of HCl in the pickling waste liquid and mass percentage of CaO in dust or carbide slag; b, preparing an emulsion by the use of the dust or carbide slag and the converter dedusting wastewater in an emulsion preparation pot; c, respectively adding the emulsion prepared from the step b, the pickling waste liquid and the converter dedusting wastewater into a neutralization pond; and d, allowing the solution obtained from the step c to flow into a settler for static settlement. The clear upper layer is the impurity-bearing liquid calcium chloride solution.

Owner:ANGANG STEEL CO LTD

Circulating cooling water filling purification system

InactiveCN104355467AImprove hydration water qualityIncrease the concentration factorWater treatment parameter controlWater treatment compoundsOzone generatorDistributed control system

The invention discloses a circulating cooling water filling purification system which comprises a reservoir, a pre-ozone contact tower, a coagulative precipitation tank, a post-ozone contact tower and an electrochemical processor which are sequentially communicated, wherein a filter is arranged between the post-ozone contact tower and the electrochemical processor; an ozone generator is arranged between the pre-ozone contact tower and the post-ozone contact tower; the water outlet of the post-ozone contact tower is connected to the water inlet of the filter; the electrochemical processor is communicated with the reservoir; the reservoir is communicated with a circulating cooling tank; the circulating cooling tank is connected to a domestic water supply pipe network; a water filling pump is arranged on a pipeline between the reservoir and the circulating cooling tank; a high-low level gauge is mounted in the circulating cooling water tank; and the water filling pump and the high-low level gauge are connected to a distributed control system (DCS) in a control room. The circulating cooling water filling purification technology disclosed by the invention can be used for improving the operating efficiency and concentration multiple of circulating water, and is beneficial to energy conservation and emission reduction; moreover, the purification device is also conductive to relieving equipment corrosion during working, and the serve life of the equipment is prolonged.

Owner:浙江安耐杰科技股份有限公司

Steelmaking converter smoke-gas washing water quality controlling method

InactiveCN101229950AGuarantee normal productionSave on medicine costsMultistage water/sewage treatmentSodium carbonateMethyl orange

The invention relates to a method for regulating the quality of washing water for flue gas in a steel-making converter, which is an optimized regulation proposal of softening method of sodium carbonate by analyzing and determining the relationship between regulation of water alkalinity and hardness. The method for regulating the quality of washing water for flue gas in the converter comprises the following steps: when two times of a P alkalinity value is smaller than / equal to a M alkalinity value, NaOH is added into the washing water for flue gas in the converter, until two times of the P alkalinity value is larger than the M alkalinity value, which means 2P is larger than M and P is not equal to M; when P is equal to M, the sodium carbonate is added into the water, wherein, the P alkalinity value is the alkalinity measured by applying phenolphthalein as indicator and is phenolphthalein alkalinity, and the M alkalinity value is the alkalinity measured by applying methyl orange as indicator and is the total alkalinity. The system of washing water for flue gas in the converter adopts a manner of total recycle. The method can cause the quality of the washing water for flue gas in the converter to reach good softening effect and can solve the problem of scaling in the system of washing water for flue gas in the converter, which adopts total recycle with zero discharge to reduce pollution.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Urbsewage treatment method

ActiveCN102701521BImprove working environmentLow costMultistage water/sewage treatmentEnergy based wastewater treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

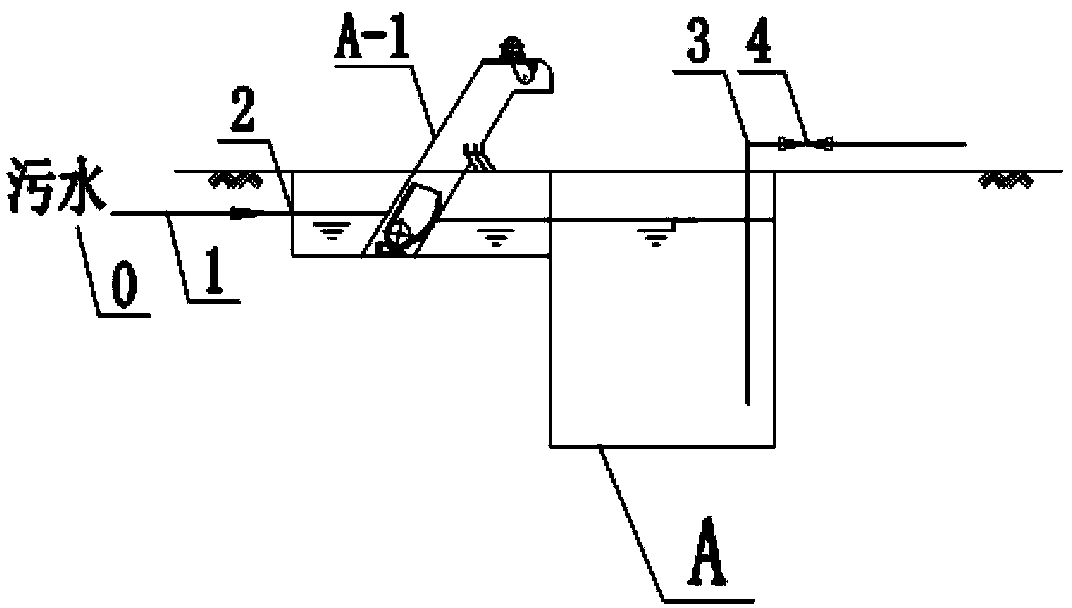

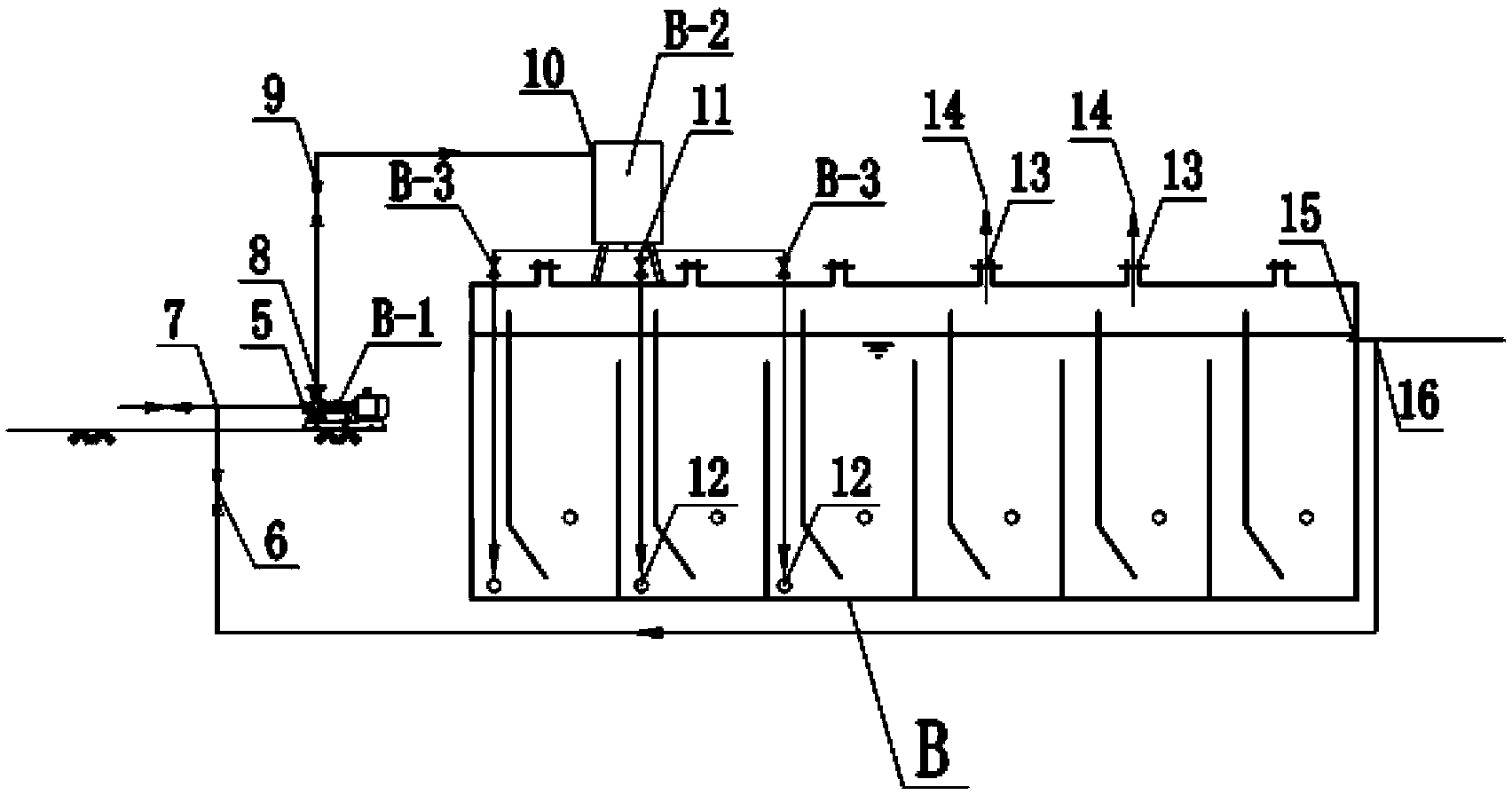

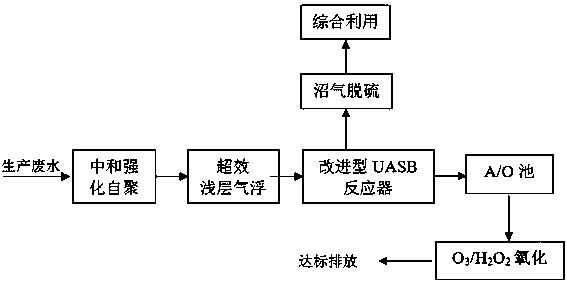

Method for treating production wastewater of methyl methacrylate produced by isobutene oxidation method

InactiveCN110015808ASave on medicine costsIncrease reaction volume loadWater contaminantsTreatment with aerobic and anaerobic processesNutrientMethyl methacrylate

The invention provides a method for treating wastewater of methyl methacrylate produced by an isobutylene oxidation method. The method comprises the following steps: adjusting the pH value of MMA production wastewater to be 10-10.5, stirring and reacting for a certain time, strengthening the self-polymerization reaction of aldehyde substances, and mixing and homogenizing the reacted wastewater with other production wastewater. The homogenized wastewater is subjected to super-efficient shallow air floatation to remove most of aldehyde self-polymers with inhibition effect on growth of microorganisms, and the inhibition effect on biochemical treatment is reduced. Nutrient salt is added into the gas floating effluent to enter an improved UASB anaerobic reactor for anaerobic biochemical treatment, the trace element nutrient salt helps to improve the volumetric load and COD removal efficiency of the anaerobic reaction, and the wastewater subjected to the anaerobic biochemical treatment is treated by an A / O aerobic biochemical treatment and an O3 / H2O2 oxidation method, so that the standard discharge is finally achieved. The method provided by the invention has the advantages of strong pertinence, high treatment efficiency, stable and reliable water yielding and the like.

Owner:河南君和环保科技有限公司

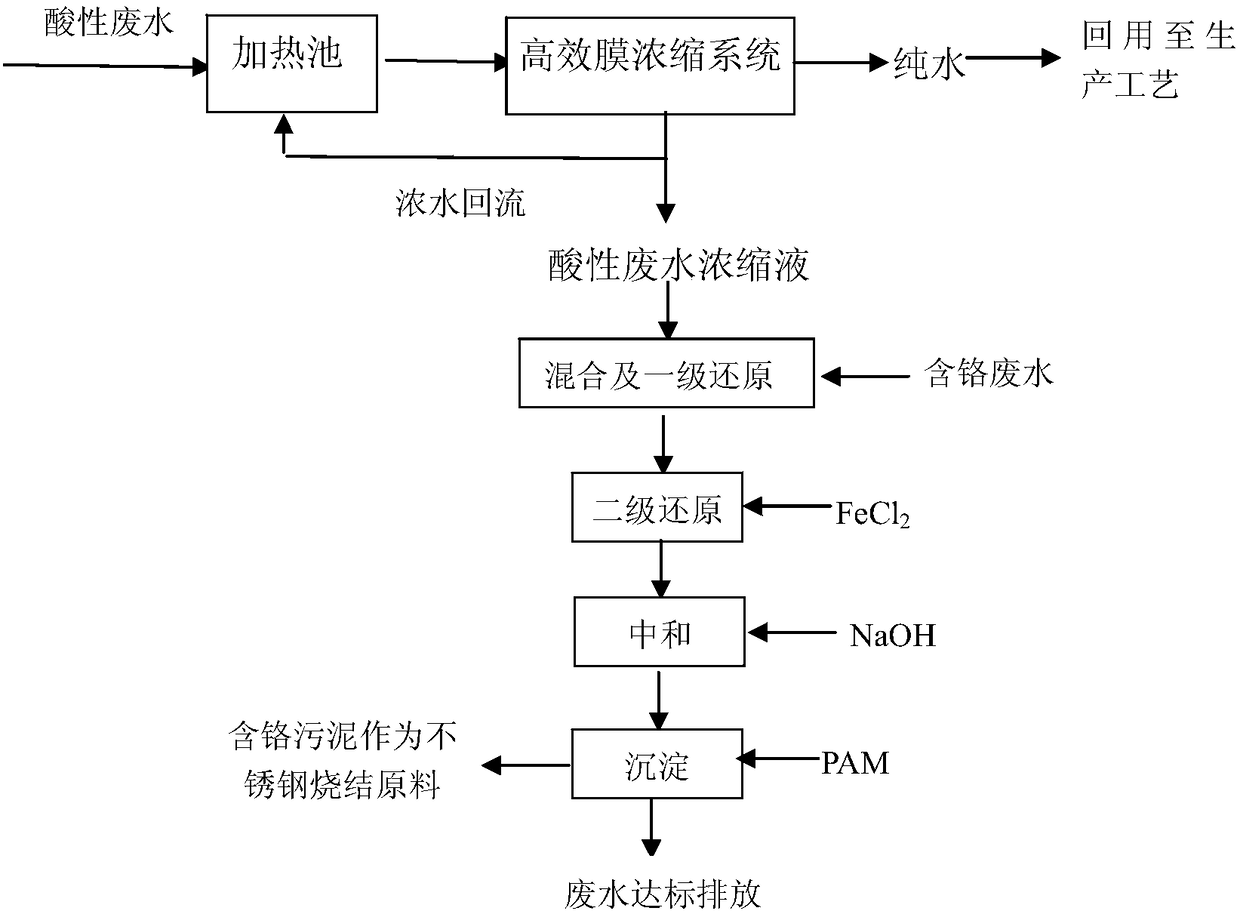

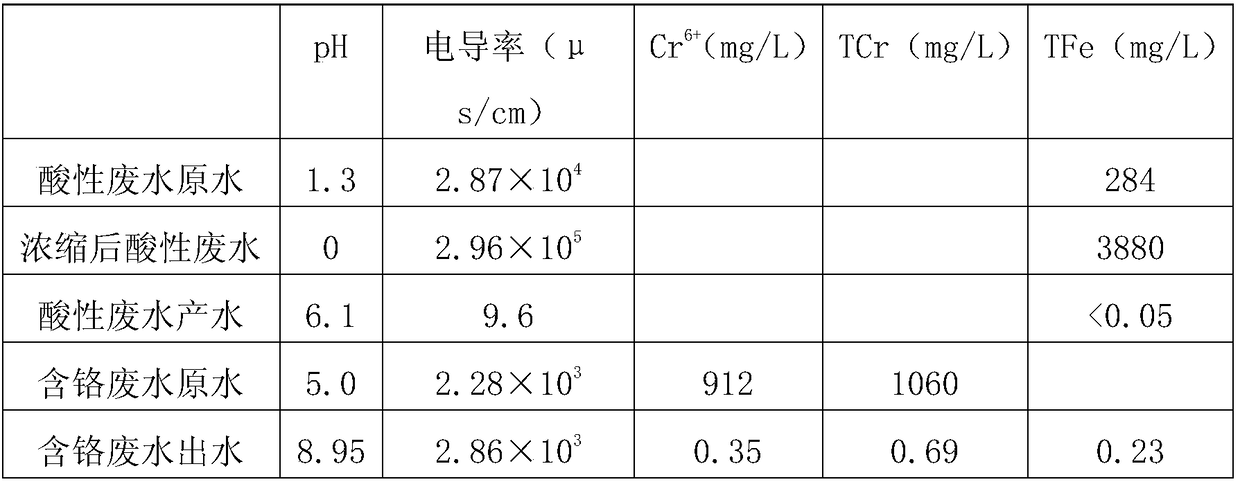

Method for co-treating chromium-containing wastewater and acidic wastewater

InactiveCN108083529ALow running costEmission reductionWater contaminantsWater/sewage treatment bu osmosis/dialysisParticulatesSludge

A method for co-treating chromium-containing wastewater and acidic wastewater includes the following steps: filtering pretreating of the acidic wastewater, to be more specific, filtering particulate matters of 5-30 mu m or more; (2) film concentration of the acidic wastewater, to be more specific, using a high-efficiency film concentration technology for concentration the filtered acidic wastewater; and heating the filtered cold-rolled acidic wastewater to 50 to 100 DEG C until the concentration of the acid in the concentrated liquid is greater than 2 to 10%; (3) mixing of the acidic wastewater concentrate with the chromium-containing wastewater, wherein the acid in the acidic wastewater concentrate can be used to adjust the pH of the chromium-containing wastewater to 2-5; and (4) neutralization and precipitation. According to the method, the operating cost of the waste water is saved, the amount of discharged waste water and the sludge production are reduced, the disposal cost of chromium-containing sludge is saved, and the method has good social and environmental benefits.

Owner:BAOSHAN IRON & STEEL CO LTD

Anaerobic-aerobic deep coupled method for treating high-concentration organic wastewater

InactiveCN110790379AHigh outputLight inhibitionWater treatment parameter controlWater contaminantsNitrogen removalBiogas production

An anaerobic-aerobic deep coupled method for treating high-concentration organic wastewater comprises the following steps: crushing and screening organic waste, and feeding the slurry from filtrationinto an anaerobic reaction unit for anaerobic fermentation to obtain biogas and biogas slurry; subjecting the biogas slurry after the anaerobic reaction to a synchronous nitrification and denitrification process in an aerobic reaction unit for nitrogen removal; and returning part of effluent from the aerobic reaction unit to the anaerobic reaction unit to be fully diluted and mixed with the raw slurry of organic waste for anaerobic reaction, while discharging the other part of the effluent into next treatment process or discharging the rest effluent on standard. According to the invention, theeffluent from the anaerobic reaction is discharged into the aerobic unit, and the DO value of the water in the aerobic unit is controlled to complete nitrogen removal; then, the effluent from the aerobic reaction is returned to the anaerobic unit again at a controlled reflux ratio for circular reaction; and therefore, the biogas production rate of anaerobic reaction can be increased, while the water quality of the effluent from the aerobic reaction can be higher.

Owner:恩格拜(武汉)生态科技有限公司

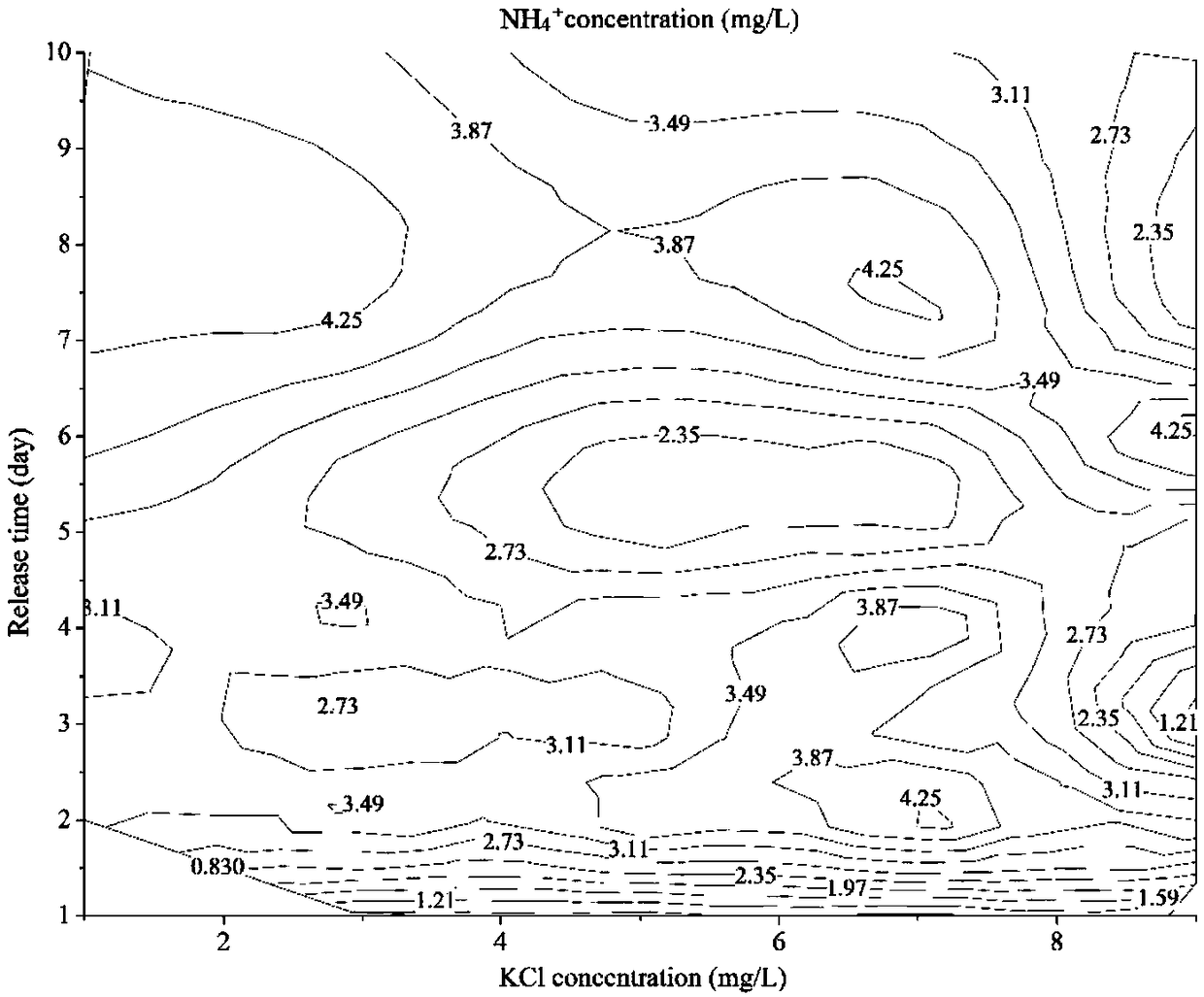

Method for simultaneous removal of nitrogen and phosphorus

ActiveCN108178249ASave on medicine costsSynchronous removalWater contaminantsPhosphorus compoundsElectrolysisPhosphate

Belonging to the wastewater treatment field, the invention discloses a method for simultaneous removal of nitrogen and phosphorus. The method for simultaneous removal of nitrogen and phosphorus includes the steps of: A. injecting wastewater containing nitrogen and phosphorus into a reactor; B. connecting a reference electrode, an electrochemical instrument and a cathode well; C. switching a change-over switch to an anode B, regulating the current and voltage of the electrochemical instrument, and using a magnesium alloy electrode as the anode B material; D. starting magnetic stirring to let scrap iron in a fluidized suspension state; E. adjusting the pH to weak alkalinity; F. turning on the power, and carrying out electrolytic reaction to remove phosphate and part of ammonia nitrogen in wastewater to obtain the product magnesium ammonium phosphate crystal; G. switching the change-over switch to an anode A, and maintaining other lines and the electrochemical instrument at an on-state; H. converting redundant ammonia nitrogen and nitrate nitrogen to nitrogen under the action of electrooxidation; and I. at the end of the reaction, turning off the power, discharging the supernatant, and then recovering the precipitate. The method provided by the invention can achieve simultaneous removal of nitrogen and phosphorus through simple switching of electrodes.

Owner:JINGDEZHEN CERAMIC UNIV

Method for treating high-solid-content organic wastewater by anaerobic-aerobic deep coupling

ActiveCN110790378AHigh outputLight inhibitionWater treatment parameter controlWater contaminantsFiltrationBiogas production

The invention relates to a method for treating high-solid-content organic wastewater by anaerobic-aerobic deep coupling. The method comprises the following steps: crushing and screening organic wastes, adding a slurry liquid obtained by filtration into an anaerobic reaction unit, and carrying out anaerobic fermentation to obtain biogas and biogas slurry; introducing anaerobic outlet water into a solid-liquid separation unit for solid-liquid separation, and enabling separated biogas residues to return into the anaerobic reaction unit through a sludge backflow pump; enabling separated biogas slurry to enter an aerobic reaction unit, and removing nitrogen through a synchronous nitrification and denitrification process; and enabling part of outlet water of the aerobic reaction unit to flow back to the anaerobic reaction unit and undergo full dilution and mixing with organic waste raw slurry liquid for an anaerobic reaction, and enabling the other part of the outlet water to enter a next treatment process or be discharged after reaching the standard. According to the method, the anaerobic outlet water enters the solid-liquid separation unit, suspended solids are separated out, outlet water enters the aerobic reaction unit, the DO value in the water body of the aerobic reaction unit is well controlled, denitrification is completed, then a backflow ratio of aerobic outlet water is controlled and part of the aerobic outlet water returns to the anaerobic reaction unit again, the reaction is circulated, the anaerobic biogas production rate is increased, and meanwhile the water quality of the aerobic outlet water is higher.

Owner:恩格拜(武汉)生态科技有限公司

Nitrile glove production technological waste water treatment technological method

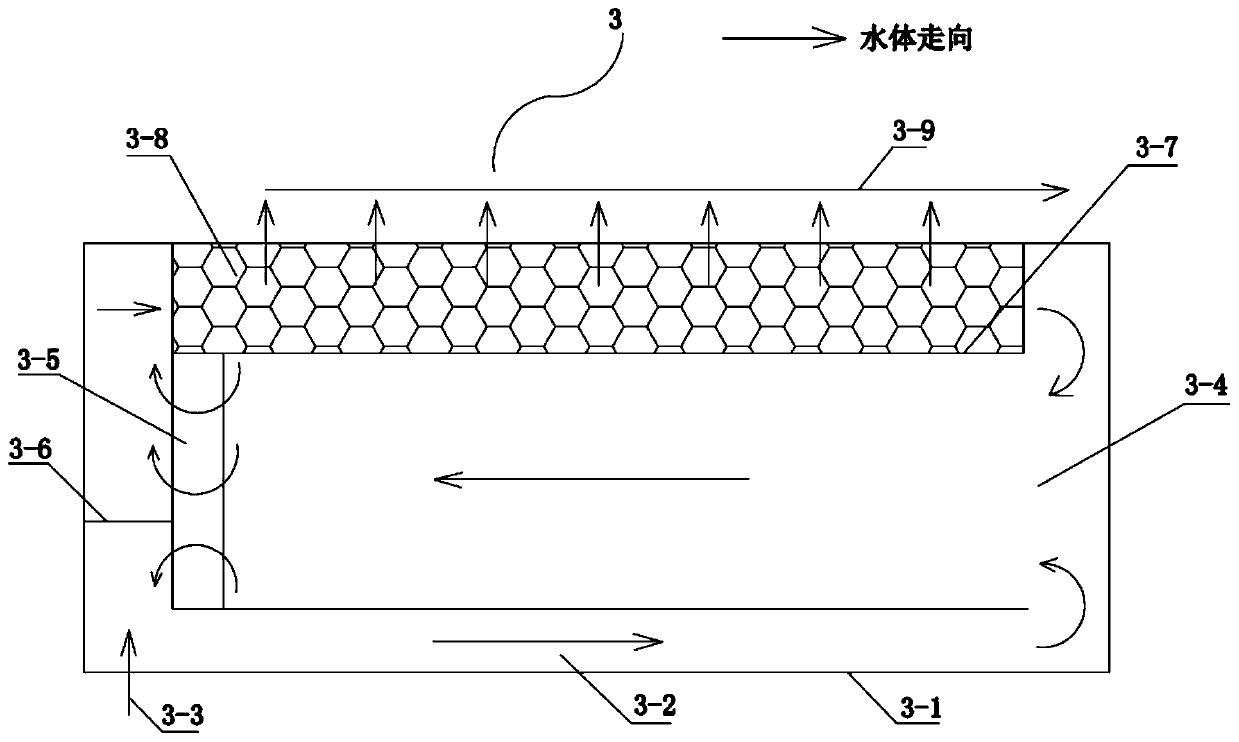

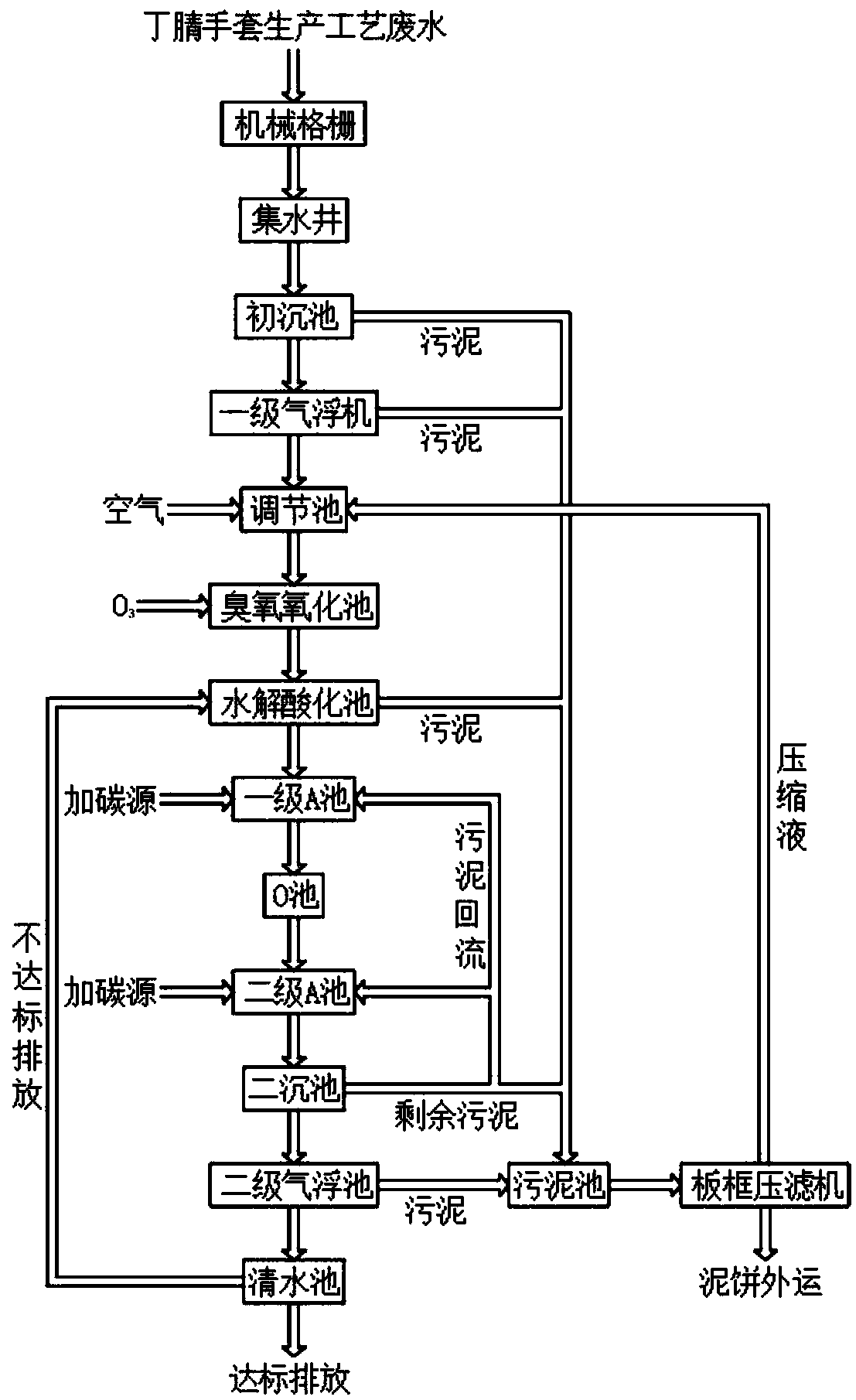

InactiveCN109607974AThe treatment effect is stableSave on medicine costsWater contaminantsTreatment involving filtrationPollutantEngineering

The invention relates to a treatment method of nitrile glove production technological waste water, and belongs to the technical field of organic waste water treatment. The method comprises is characterized in that the waste water sequentially passes through a grating, a water collecting well, an initial sedimentation tank, a first-stage air flotation machine, a regulating tank, an ozone oxidationtank, a hydrolytic acidification tank, a first-stage A tank, an O tank, a second-stage A tank, a second-stage air floatation machine and a clear water tank, and the waste water is finally discharged after standards are reached. The method has the advantages that the operation cost is low, the operation is simple, suspended solid, COD, total nitrogen and the like in a nitrile glove production technology can be efficiently removed, and finally the waste water reaches the first-level A discharging standard of <Discharge Standard of Pollutants in Urban Sewage Treatment Plant> (GB 18918-2002).

Owner:NANJING SHOUFAN ENVIRONMENTAL PROTECTION TECH CO LTD

Sulfur autotrophic nitrogen sulfur double-removing process in sewage treatment plant

InactiveCN110372082ASave on medicine costsLow costWater contaminantsBiological sludge treatmentBiogasChemistry

The invention discloses a sulfur autotrophic nitrogen sulfur double-removing process in a sewage treatment plant. Nitrate nitrogen is contained in effluent of the sewage treatment plant, and hydrogensulfide is contained in biogas generated through sludge digestion of the sewage treatment plant, the effluent is mixed with the biogas (and adding alkali), the hydrogen sulfide is dissolved in the effluent, and desulfurization of the biogas is realized; and the effluent dissolved with the hydrogen sulfide is subjected to sulfur autotrophic denitrification reaction, denitrificationof the effluent is realized.

Owner:ENVIRONMENTAL PROTECTION RES INST OF LIGHT IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com