Coal-fired power plant desulfurization wastewater resource treatment system and coal-fired power plant desulfurization wastewater resource treatment method

A technology for desulfurization wastewater and coal-fired power plants, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems affecting the comprehensive utilization of ash, high investment and operating costs, and reduce the cost of chemicals , low operating costs, low investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

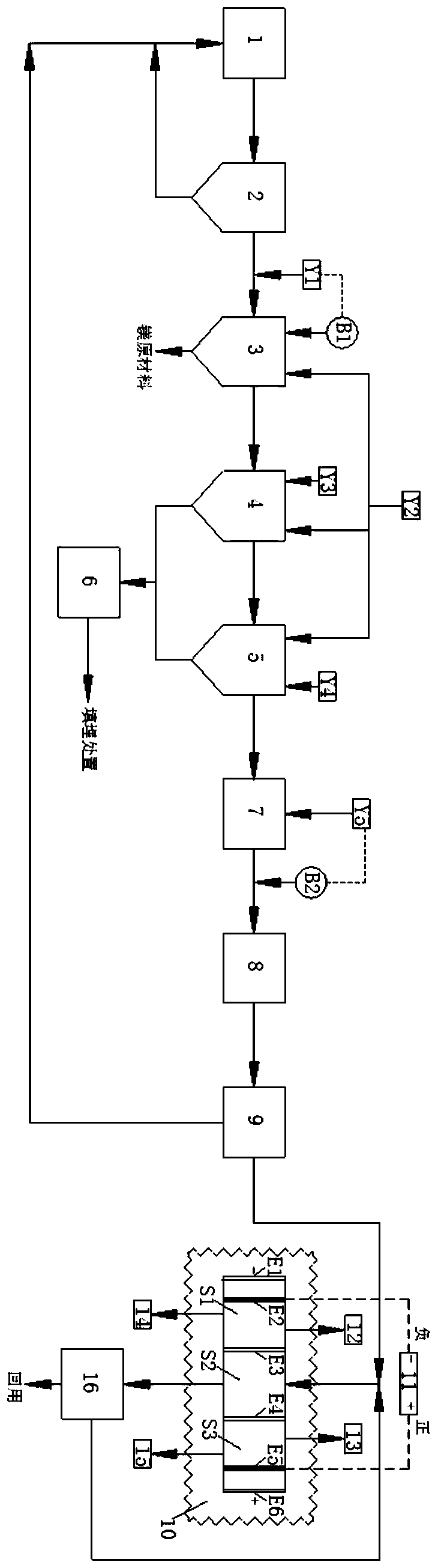

[0032] refer to figure 1, the coal-fired power plant desulfurization wastewater resource treatment system of the present invention includes a concentrated electrolysis three-chamber reactor 10, a desulfurization system 1, a pre-sedimentation tank 2, a magnesium resource recovery reaction clarification tank 3, a heavy metal reaction clarification tank 4, and a sulfate radical removal depth Reaction clarification tank 5, neutralization tank 7, ultrafiltration system 8, nanofiltration system 9, reverse osmosis system 16, calcium hydroxide dosing system Y1, coagulant and coagulant mixed dosing system Y2, sulfate compound precipitation Agent dosing system Y4 and hydrochloric acid dosing system Y5; concentrated electrolysis three-chamber reactor 10 is sequentially equipped with electrodialysis cath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com