Method for treating high-solid-content organic wastewater by anaerobic-aerobic deep coupling

A high solid content, organic wastewater technology, applied in aerobic and anaerobic process treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of lack, cell lethal damage, anaerobic reaction failure, etc. The effect of improving shock load resistance, light inhibition, and biogas output improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

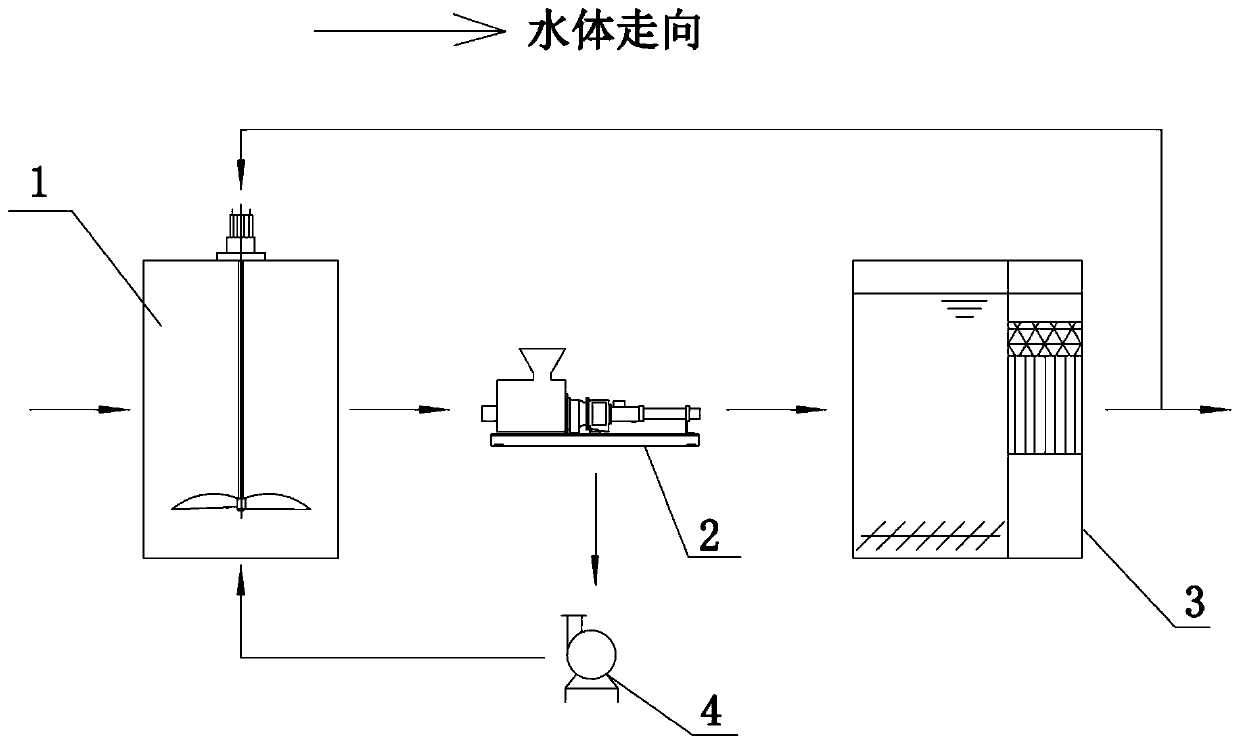

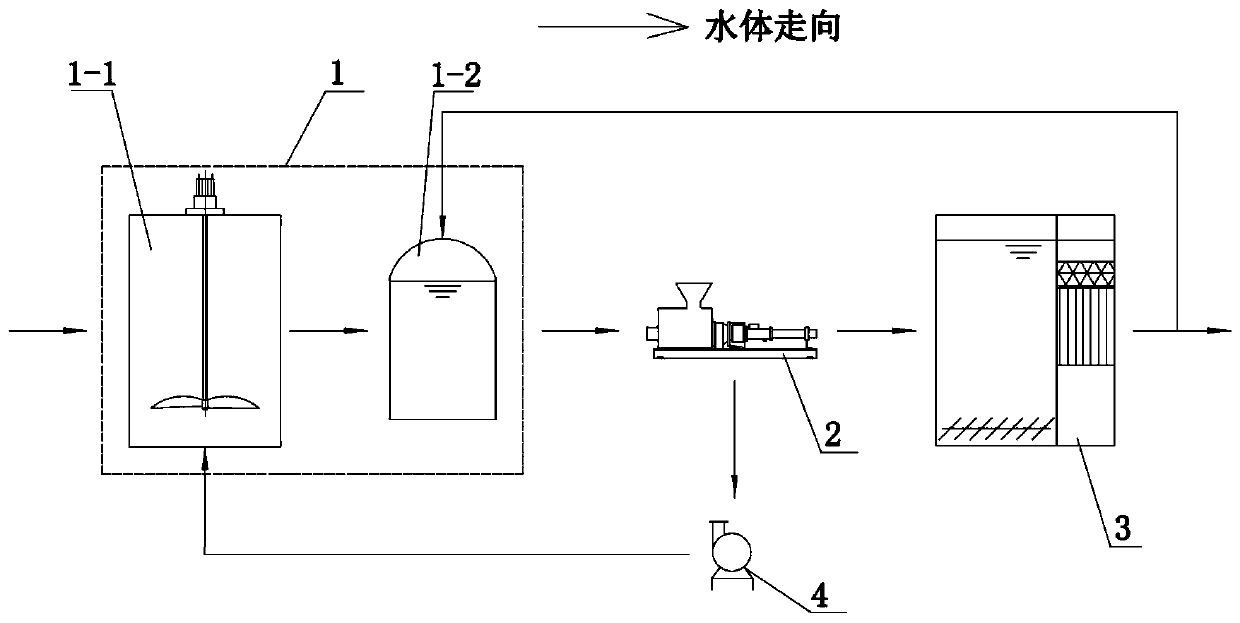

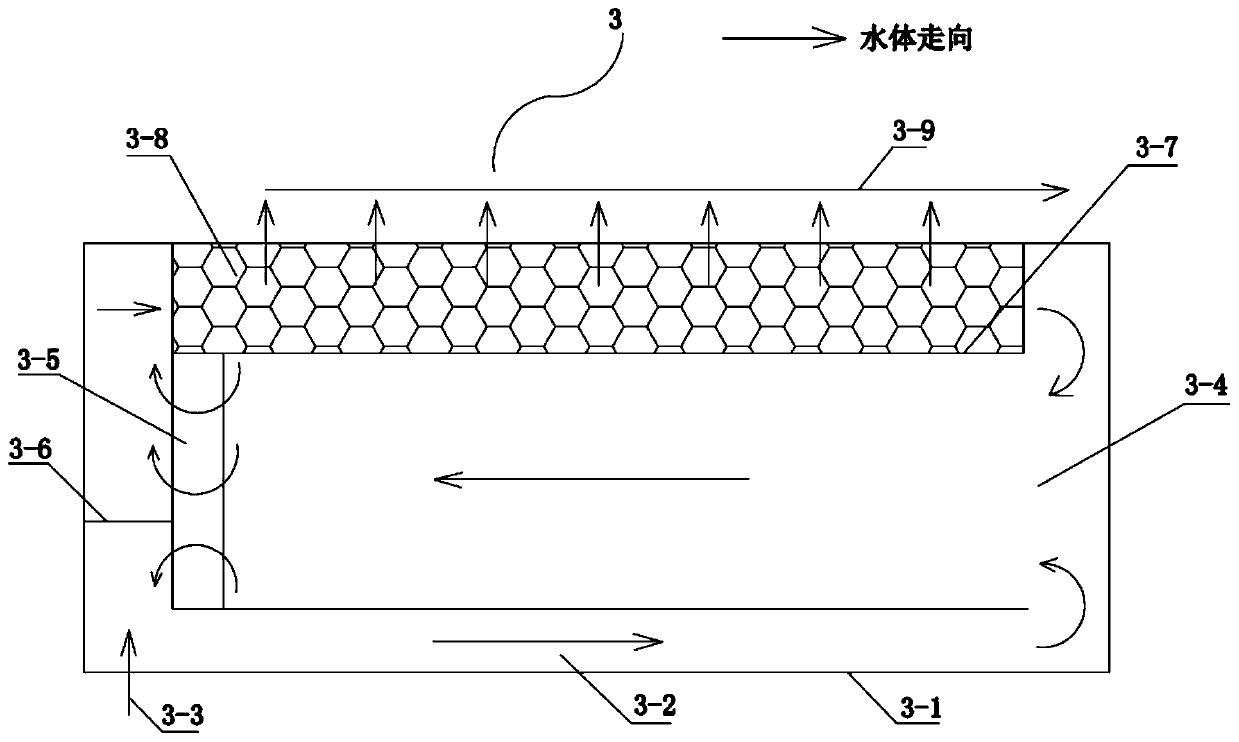

[0048] A pig farm has 13,500 sows and 150,000 fattening pigs. The manure cleaning method is water-soaked manure mode. The manure and sewage discharge Q=2000m³ / d. Raw water indicators: COD≤18000mg / L, TKN≤1300mg / L, TS<4% , require effluent COD<150mg / L, ammonia nitrogen<100mg / L, and have energy utilization requirements. According to the project requirements, the following process flow is designed: solid-liquid separation unit, anaerobic reaction unit and aerobic reaction unit. The solid-liquid separation unit includes grille, slag separation tank and solid-liquid separator. The anaerobic treatment unit adopts IC reactor, and the aerobic treatment unit adopts synchronous nitrification and denitrification process.

[0049] S1: Feces and sewage pass through the grille, slag separation tank, and solid-liquid separator in sequence, and the floating matter, small particles, and suspended matter in the sewage are intercepted and separated, and after collection, they are composted to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com