Intelligent precise dosing system for denitrification deep-bed filter carbon source

A nitrification deep bed and denitrification technology, which is applied in the direction of anaerobic digestion treatment, etc., can solve the problems of less control parameters, system failure, and low system fault tolerance rate, and achieve the effects of increasing production costs, saving chemical costs and electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

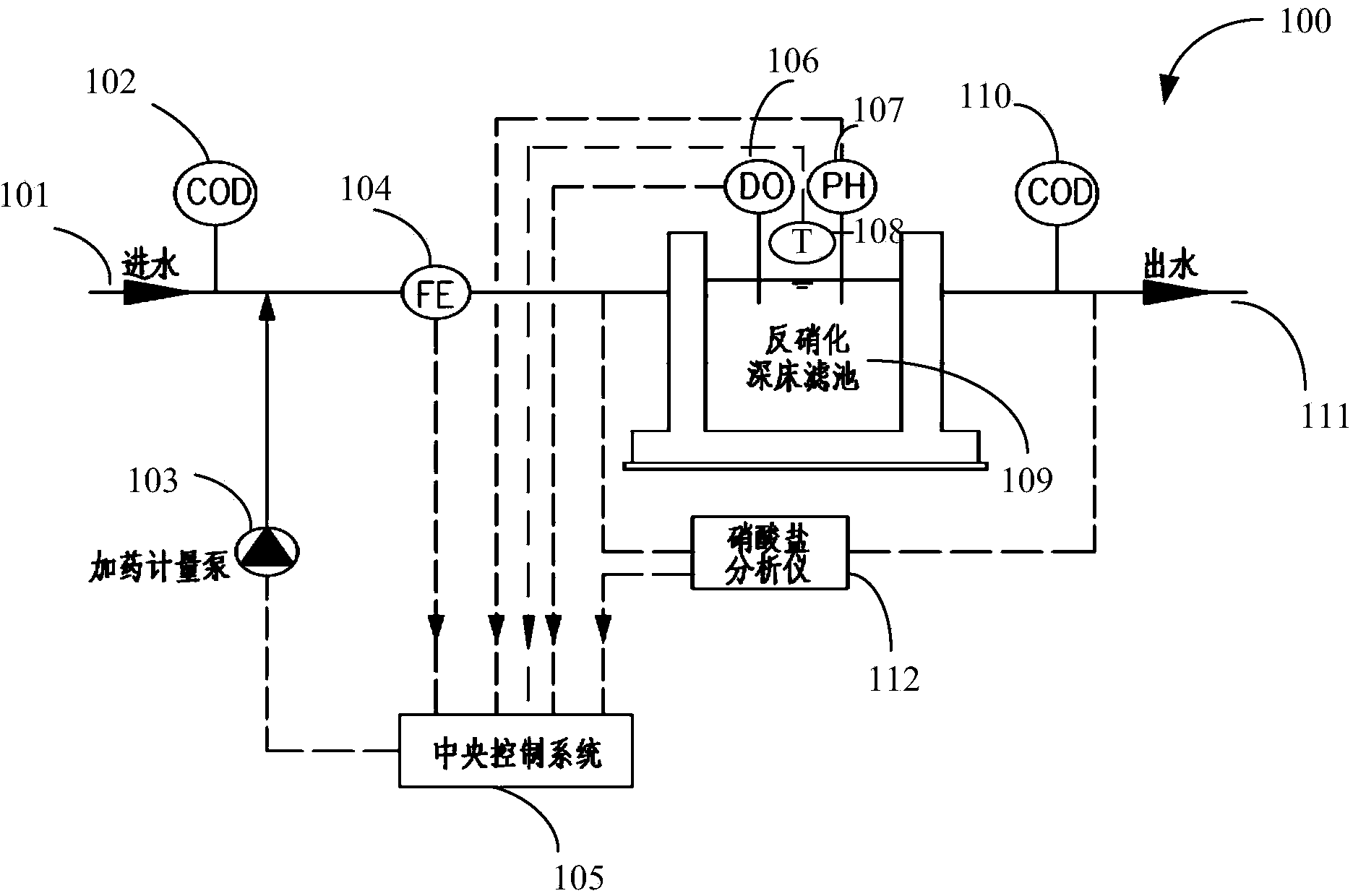

[0018] According to an embodiment of the present invention, a denitrification deep bed filter carbon source intelligent precision dosing system such as figure 1 As shown, the denitrification deep bed filter carbon source intelligent precision dosing system 100 includes a water inlet 101, a COD (chemical oxygen demand) water inlet detector 102, a dosing metering pump 103, an inlet water flow meter 104, a central Control system 105, dissolved oxygen meter 106, PH meter 107, temperature meter 108, denitrification deep bed filter 109, COD effluent detector 110, water outlet 111 and import and export nitrate analyzer 112.

[0019] The COD water inlet detector 102 is connected to the water inlet 101 for detecting the chemical oxygen demand of the incoming water. A dosing metering pump 103 is connected between the COD influent detector 102 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com