Patents

Literature

46results about How to "Achieve simultaneous removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

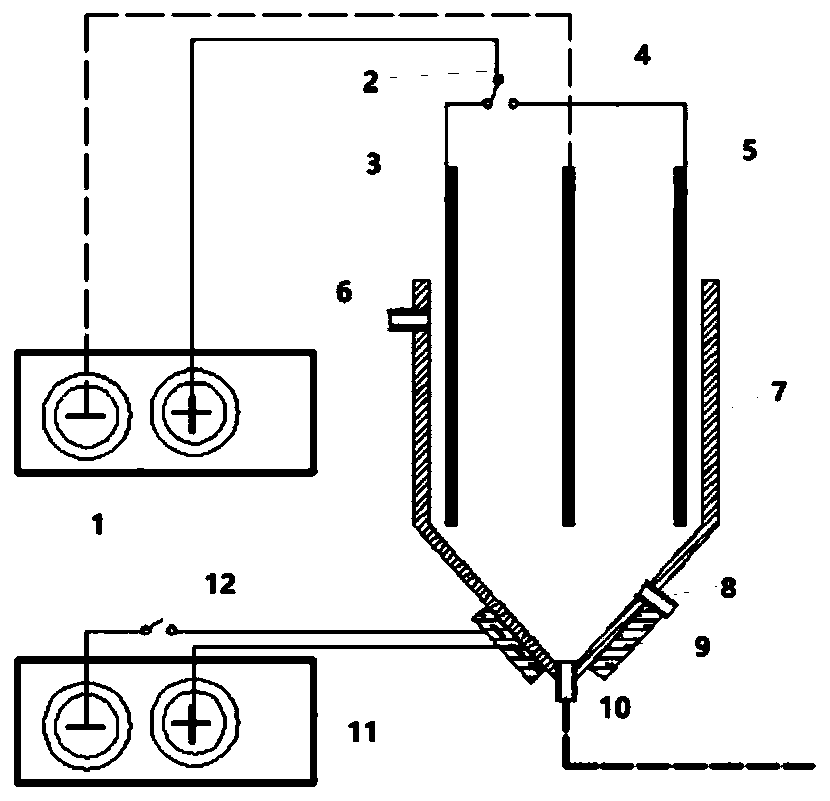

Electric complex-strengthening repairing method and device of heavy metal-organic co-contaminated soil

InactiveCN102513348APromote migrationImprove removal efficiencyContaminated soil reclamationHypochloritePersulfate

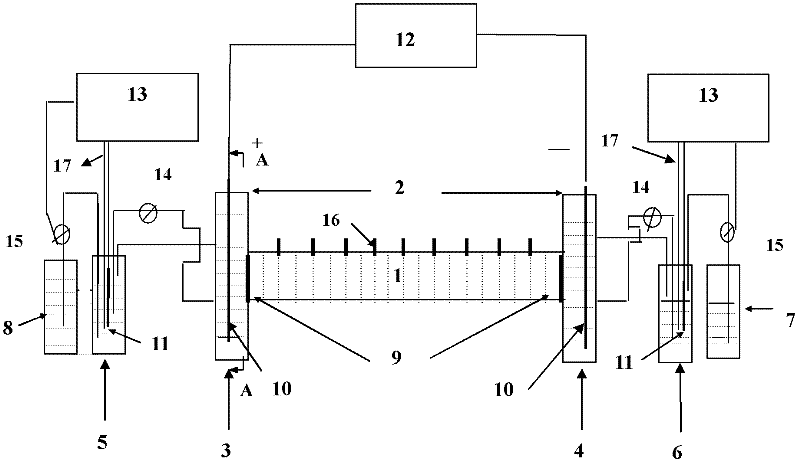

The invention provides an electric complex-strengthening repairing method and device of heavy metal-organic co-contaminated soil. The method provided by the invention comprises the following steps of: filling contaminated soil into an electric repairing device, and then adding an oxidant into a cathode electrolyte and an anode electrolyte or directly spraying the oxidant on the contaminated soil, wherein the oxidant comprises hydrogen peroxide, pypocholoride and persulfate; applying a direct-current electric field on a cathode and an anode, wherein the strength of the electric field is 0.5-2 V / cm; and controlling the pH values of the cathode electrolyte and the anode electrolyte to be 3-11. By selecting the suitable for oxidant and controlling the pH value of the electrolyte, the migration of the heavy metal can be effectively increased and the removing efficiency is improved; and meanwhile, the oxidant is used for effectively degrading organic pollutants when the pollutants are migrated, thereby relieving the post-treatment and simultaneously removing the heavy metal and the organic pollutants.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

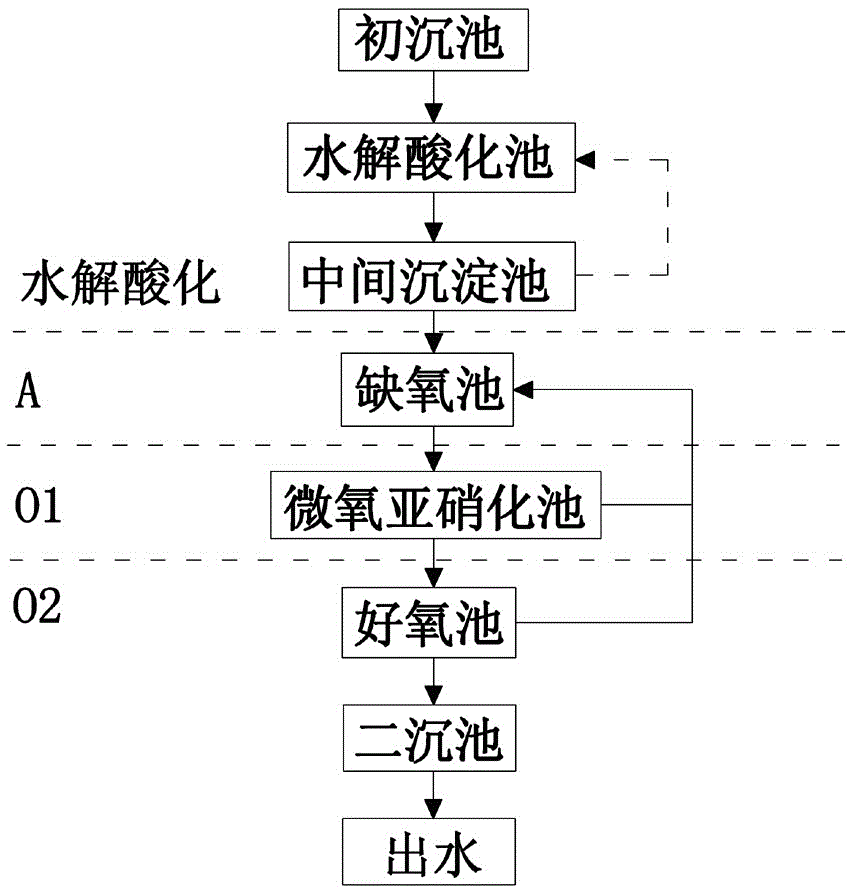

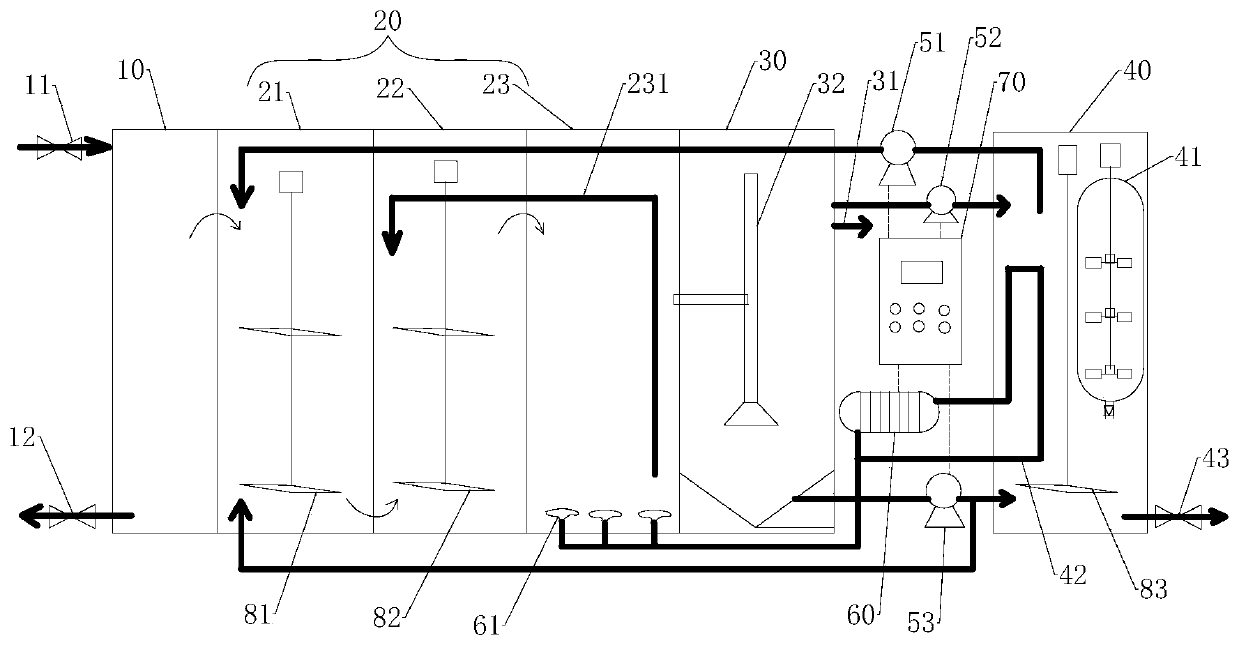

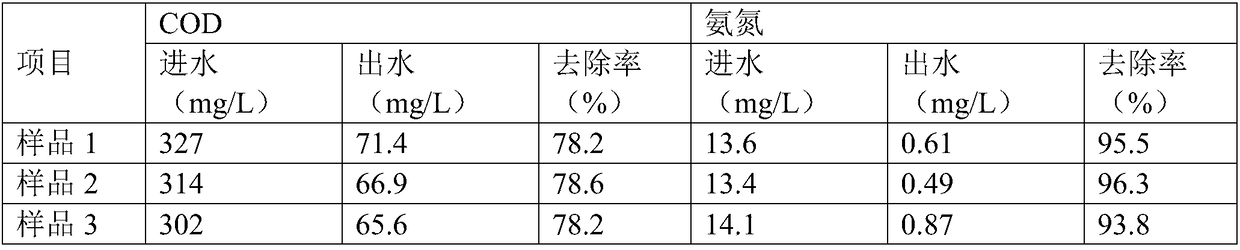

High-ammonia-nitrogen low-C/N-ratio wastewater treatment system and treatment technique

ActiveCN105585122AImprove denitrification effectAchieve simultaneous removalTreatment with aerobic and anaerobic processesNitrogen fertilizerReflux

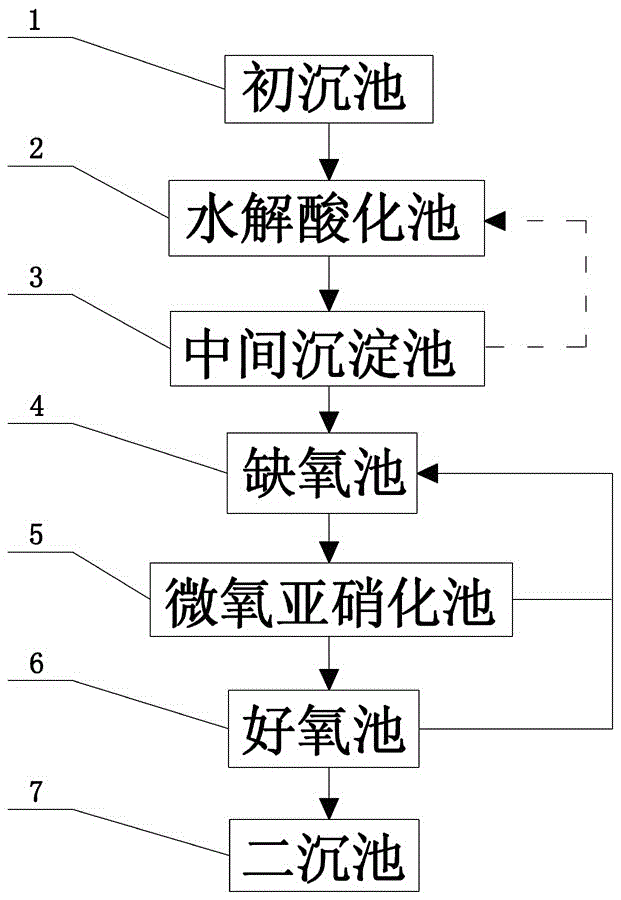

The invention relates to a high-ammonia-nitrogen low-C / N-ratio wastewater treatment system and treatment technique, belonging to the technical field of wastewater treatment. The system comprises a hydrolysis acidification tank, an anoxic tank, a microaerobic nitrosification tank and an aerobic tank, wherein the hydrolysis acidification tank communicates with the anoxic tank; the anoxic tank is connected with the microaerobic nitrosification tank through a pipeline; the microaerobic nitrosification tank is connected with the aerobic tank through a pipeline; a nitrosification liquid reflux pipeline is arranged between the microaerobic nitrosification tank and the anoxic tank; and a nitrosification solution reflux pipeline is arranged between the aerobic tank and the anoxic tank. The treatment system and treatment technique have favorable enhancement effects on wastewater treatment and reconstruction of leather wastewater, synthetic ammonia and nitrogen fertilizer techniques, and are suitable for treating high-ammonia-nitrogen low-C / N-ratio wastewater. The treatment system and treatment technique have the advantages of favorable denitrification effect and low operating cost, and can achieve the goal of simultaneously removing ammonia nitrogen and total nitrogen.

Owner:湖州至美生物科技有限公司

Compound contaminated soil remediation agent and application method

InactiveCN106833657AImprove repair effectAchieve simultaneous removalOther chemical processesContaminated soil reclamationSoil remediationSoil conditioner

The invention discloses a compound contaminated soil remediation agent, which comprises a remediation agent and a soil conditioner. An application method of the compound contaminated soil remediation agent comprises the following steps of (1) mixing the remediation agent with soil so as to cure the soil; (2) after finishing curing, applying the soil conditioner. Aiming at contaminated soil of a complex contaminated source, the compound contaminated soil remediation agent provided by the invention can be used for removing organic and heavy metal contaminants at the same time, and is simple in compositions, simple and convenient to operate, wide in application range, remarkable in effect, and free of secondary pollution at the same time.

Owner:HUATIAN ENG & TECH CORP MCC +1

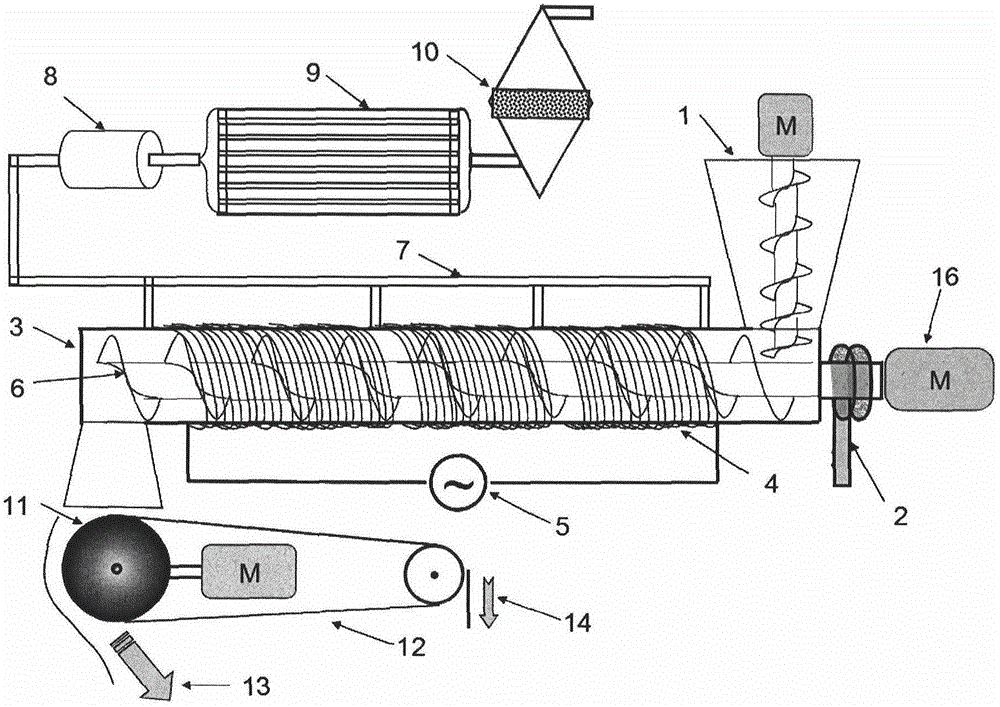

Magnetic separation enhanced type electromagnetic thermal desorption method and device for remediating soil

InactiveCN105983569AFast temperature controlFast control timeContaminated soil reclamationElectromagnetic heatingThermal desorption

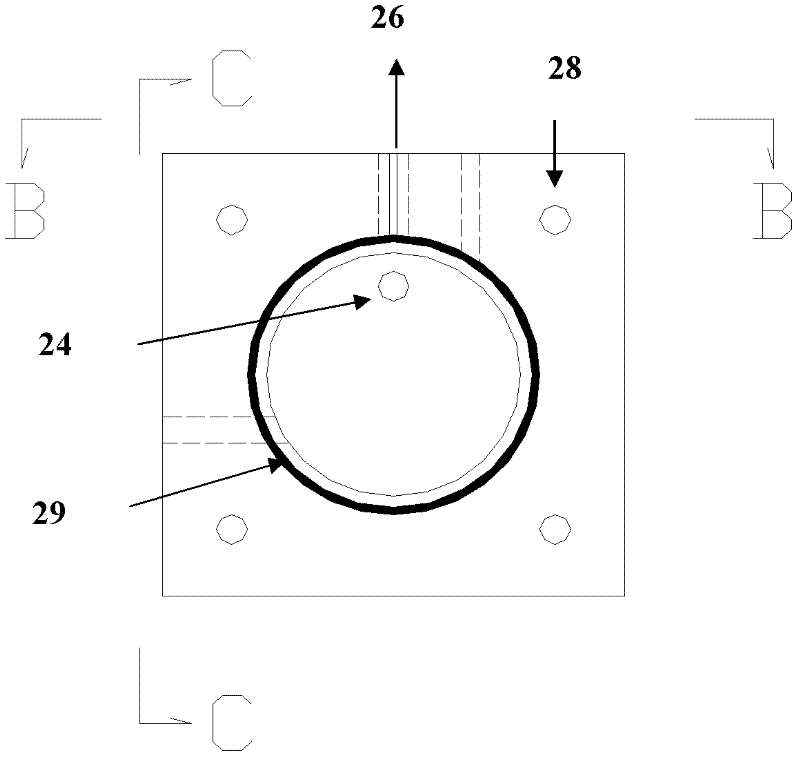

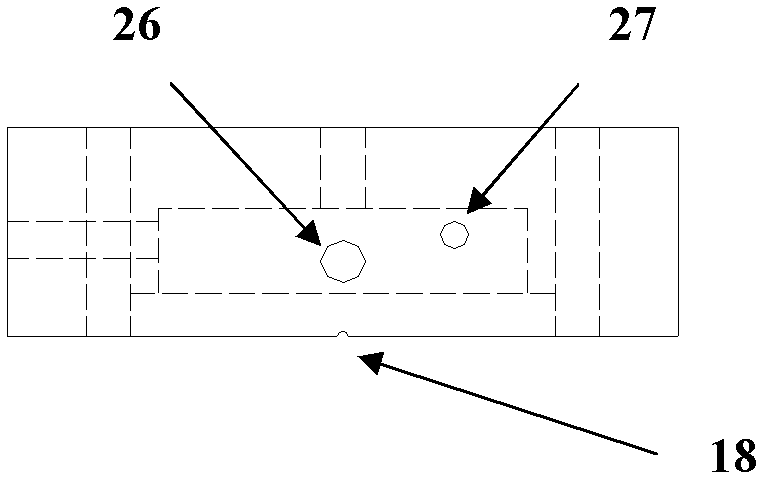

The invention provides a magnetic separation enhanced type electromagnetic thermal desorption method and device for remediating contaminated sites. The method is characterized in that ferromagnetic materials, such as reducing iron powder, are doped into contaminated soil in an ex-situ mixing and stirring manner, the contaminated soil spirally stirred is heated by using electromagnetism, and a thermal desorption heat transfer gasifying effect is improved through the in-situ electromagnetic eddy heating of the ferromagnetic materials; the reaction activity and oxidation reduction capability of the ferromagnetic materials are improved when the ferromagnetic materials produce heat; after thermal desorption is finished, the ferromagnetic materials of which the surfaces react and adsorb pollutants can be separated from the contaminated soil through magnetic separation, recycled and reutilized; and the continuous remediation of contaminated soil is realized. The device also can be used for the in-situ remediation of contaminated soil. After the ferromagnetic materials are added to the soil in situ through a ploughing stirring device, the soil is heated in situ by utilizing an electromagnetic induction coil to carry out excitation eddy heating in the contaminated soil, pollutants are desorbed, and at the same time, the reaction activity of the magnetic materials(for example, reducing iron powder) can be improved; and after reaction is finished, the iron powder can be separated from the contaminated soil through a magnetic separation technology. The device also can be placed in soil to realize in-situ oxidation reduction degradation. The method and device are suitable for the in-situ thermal desorption remediation of circumjacent large area of low-concentration contaminated soil.

Owner:李泽唐

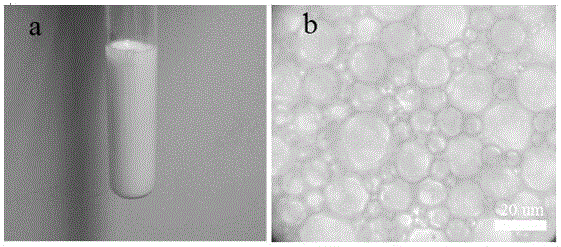

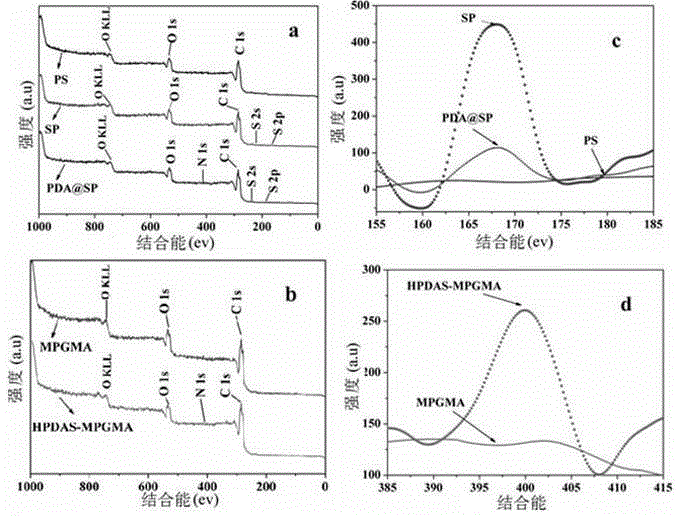

Method for preparing porous difunctional adsorption material

InactiveCN105289540AImprove stabilityAchieve simultaneous removalIon-exchange process apparatusOther chemical processesCypermethrinGlycidyl methacrylate

The invention relates to a method for preparing a porous difunctional adsorption material, which belongs to the technical field of the environment functional material. According to the invention, the method uses Hypermer 2296 to obtain a stabilize high internal phase emulsion, an oil phase comprises a monomer methyl acrylic glycidyl ester, a cross-linking agent divinyl benzene, a solvent toluene and an initiator azodiisobutyronitrile, a water phase is a potassium sulfate aqueous solution; after the water phase and oil phase are mixed, a stable water-in-oil emulsion is prepared after stirring preparation, a macroporous foam polymer is prepared after thermal initiation polymerization; then dopamine microspheres are grafted to a macroporous foamed material by a biology adhesion method; and finally, tetrahydrofuran is used for removing sulfonated styrene core and shell to obtain the macroporous material adhered with the hollow dopamine. The product has the characteristics of water-soluble performance and oil solubility of two materials, the hollow dopamine can effectively increase a specific surface area of the material and metal ions can be absorbed; the macroporous foam contains a lot of ester groups and are convenient for adhesion of trifluoro-cypermethrin, and two harmful substances can be removed simultaneously.

Owner:JIANGSU UNIV

Method for quickly starting short-cut nitrification and denitrification of ammonia-containing wastewater

ActiveCN103373764AReduce the difficulty of startingImprove processing efficiencyTreatment with aerobic and anaerobic processesHigh concentrationActivated sludge

The invention relates to a method for quickly starting short-cut nitrification and denitrification of ammonia-containing wastewater. The method comprises the following steps of: firstly putting inocula into a bioreactor, wherein the inocula are enriched nitrobacteria or mixtures of the nitrobacteria and aerobic activated sludge in sewage plants; adopting the two operation modes including batch injection and continuous injection to start a system; and adding the nitrobacteria during batch injection, and adding denitrifiers during continuous injection. Compared with the prior art, the method has the advantages of low start requirement, high start speed, capability of treating high-concentration ammonia-containing wastewater and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

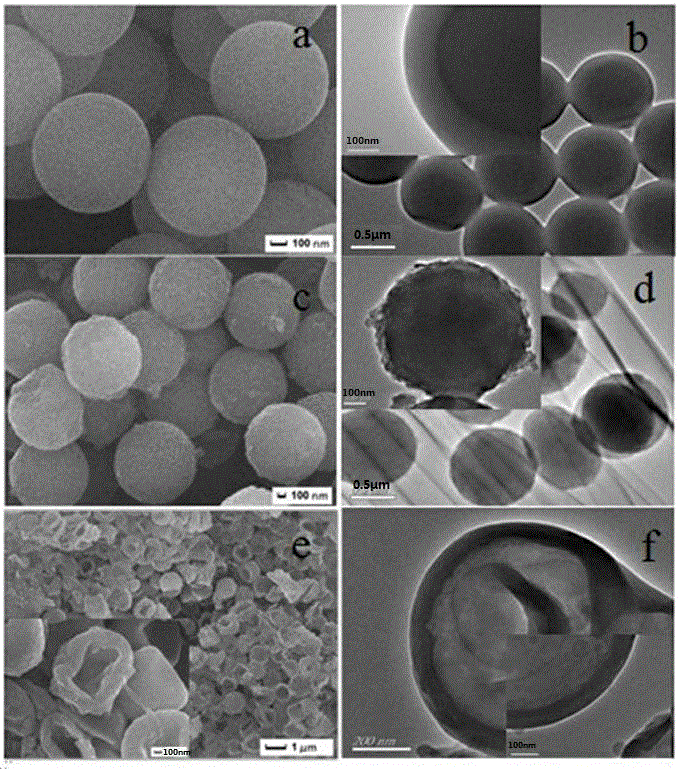

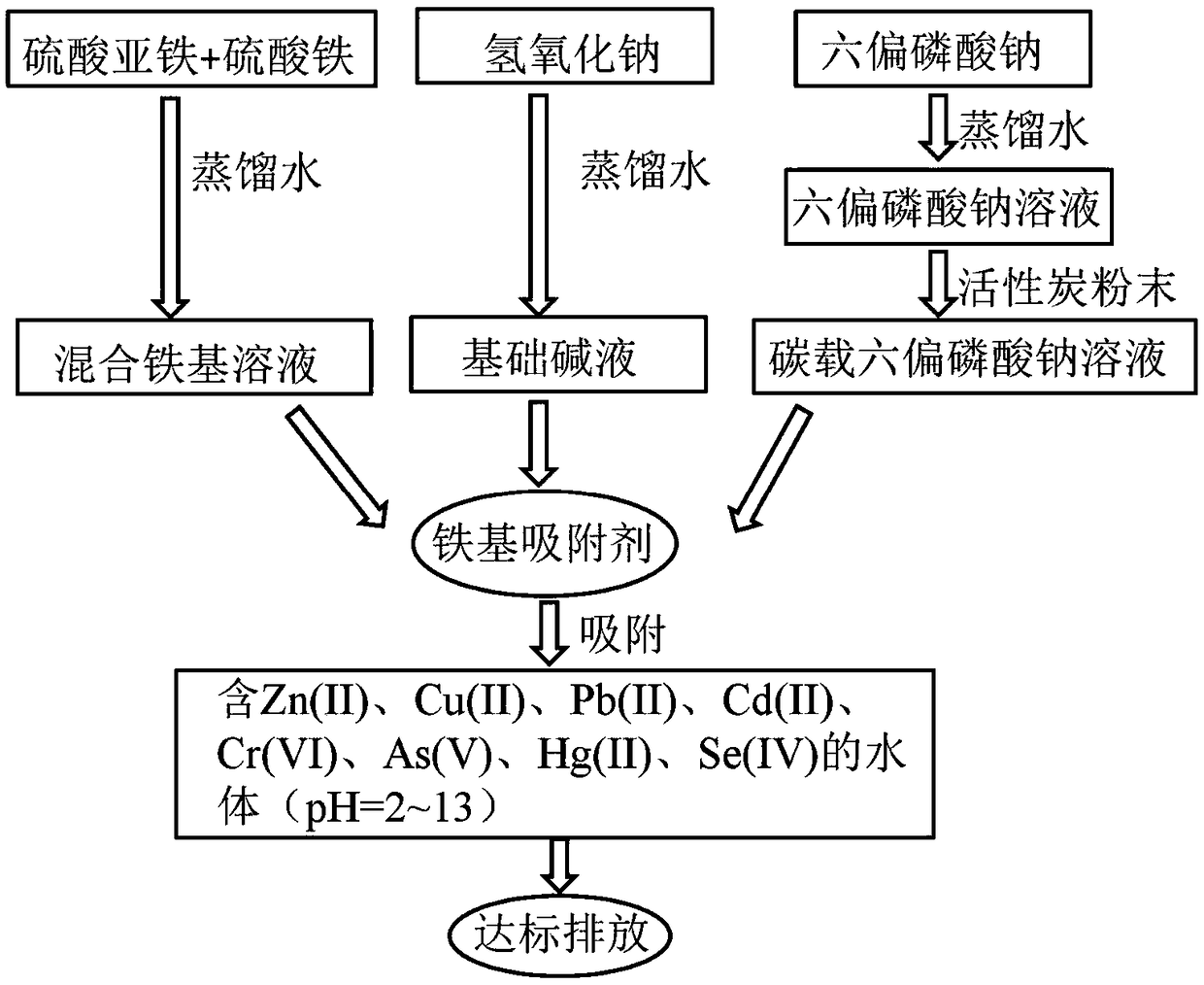

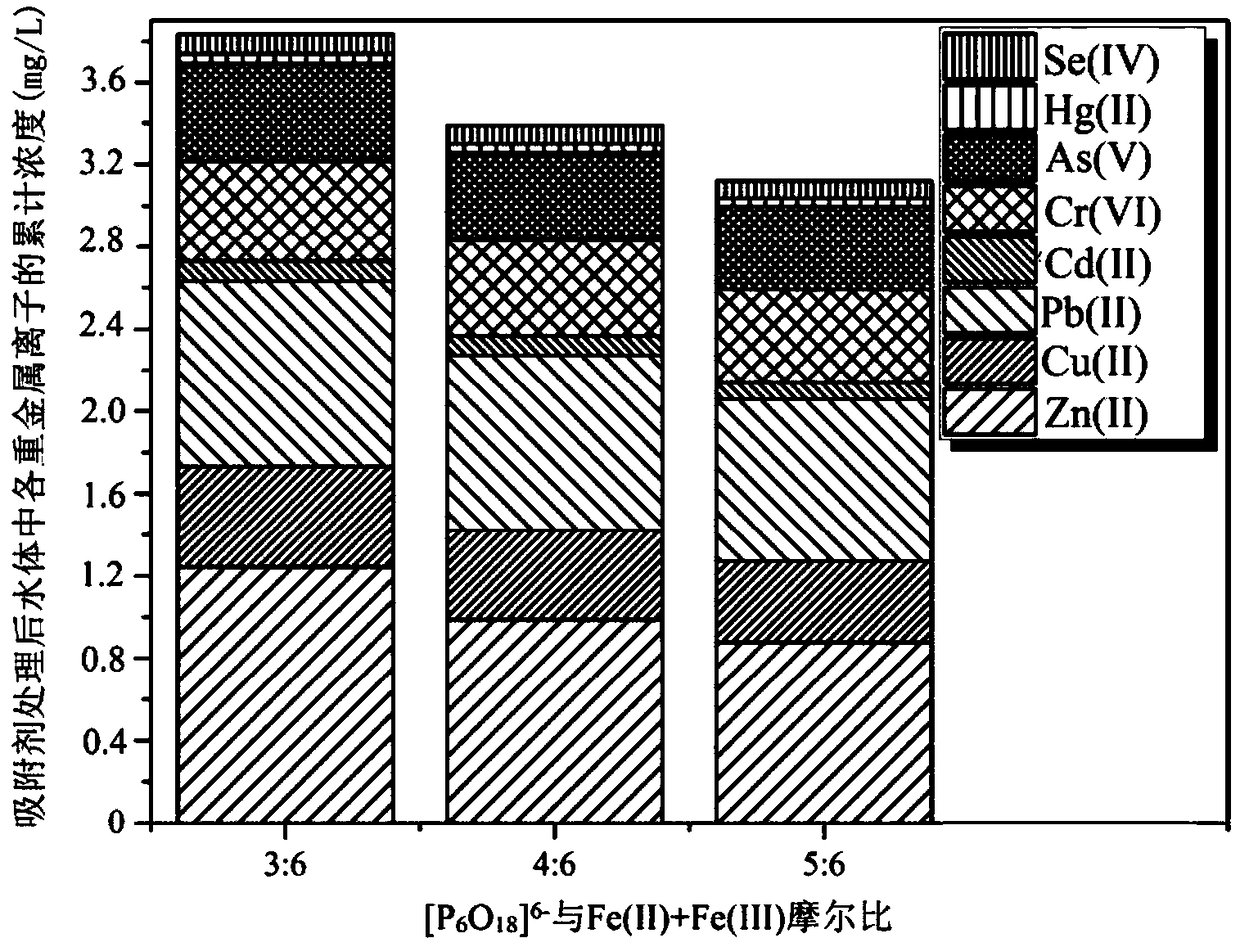

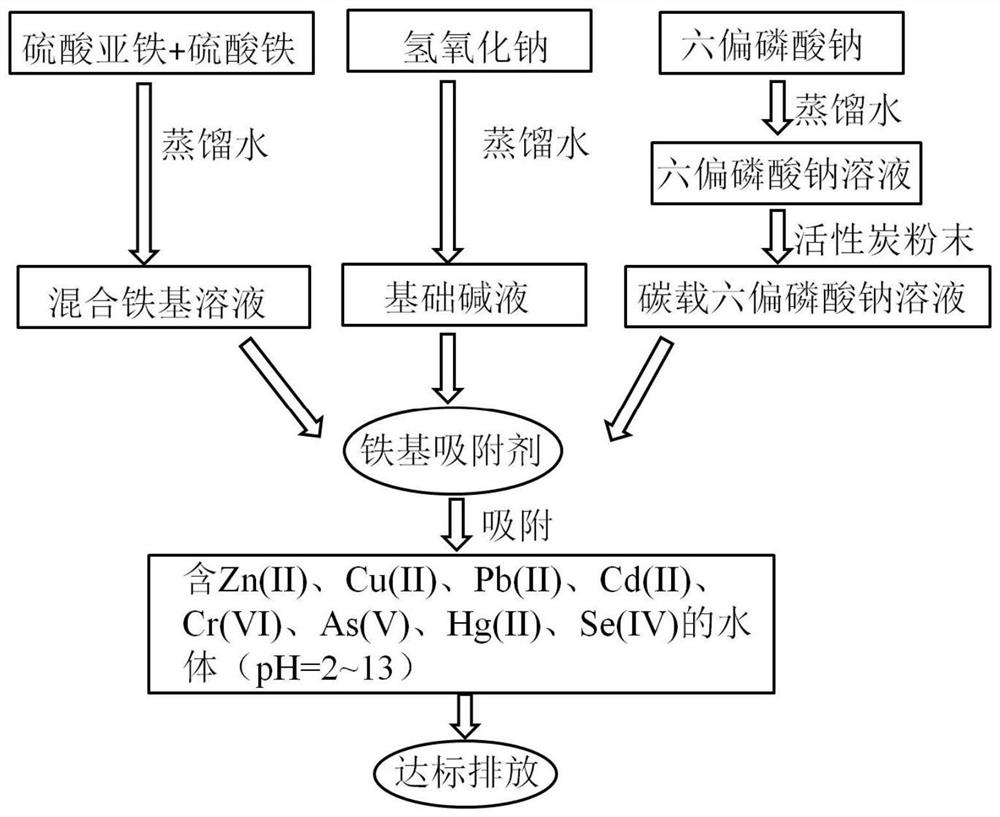

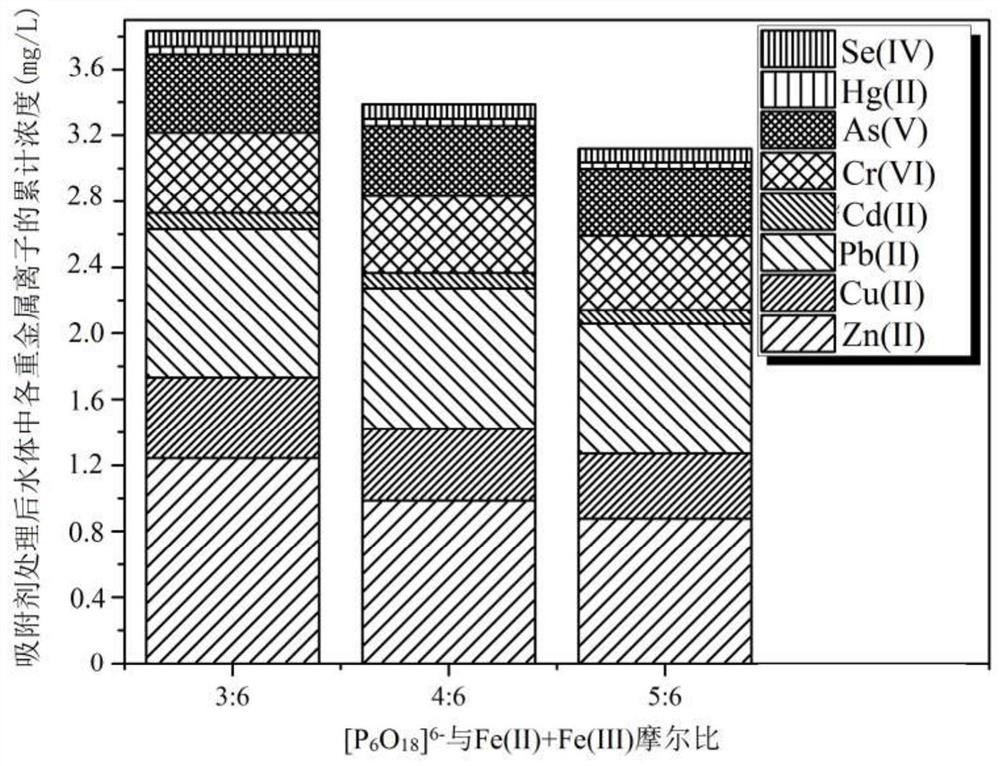

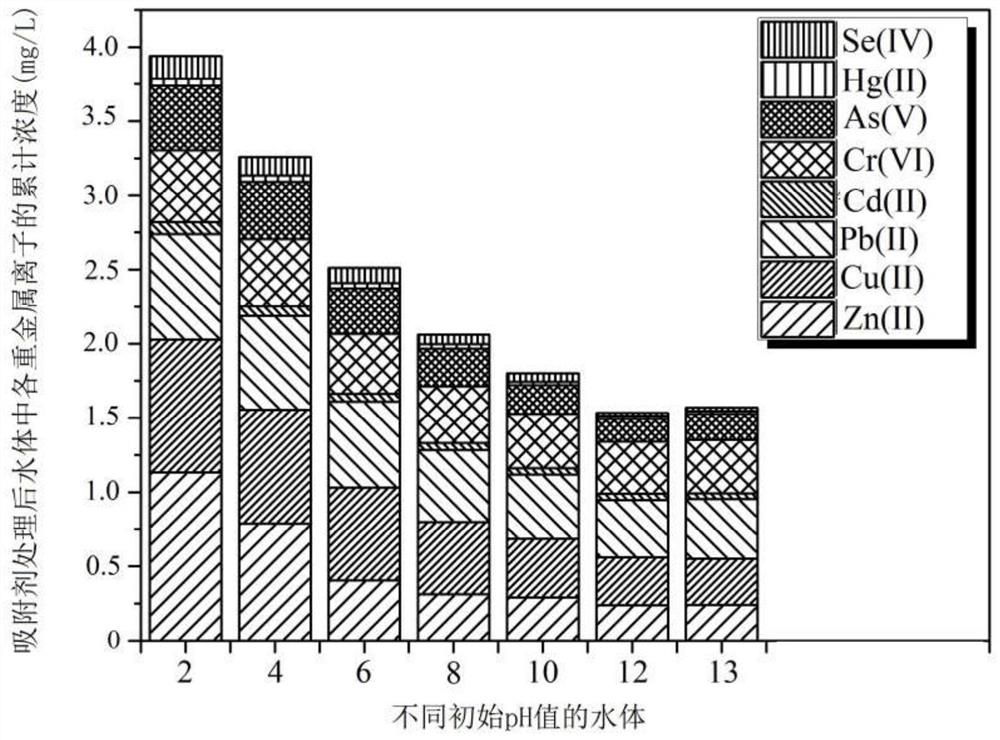

Iron-based adsorbent and preparation method thereof

ActiveCN109126717AReduce oxidation ratePromote generationOther chemical processesWater contaminantsActivated carbonSorbent

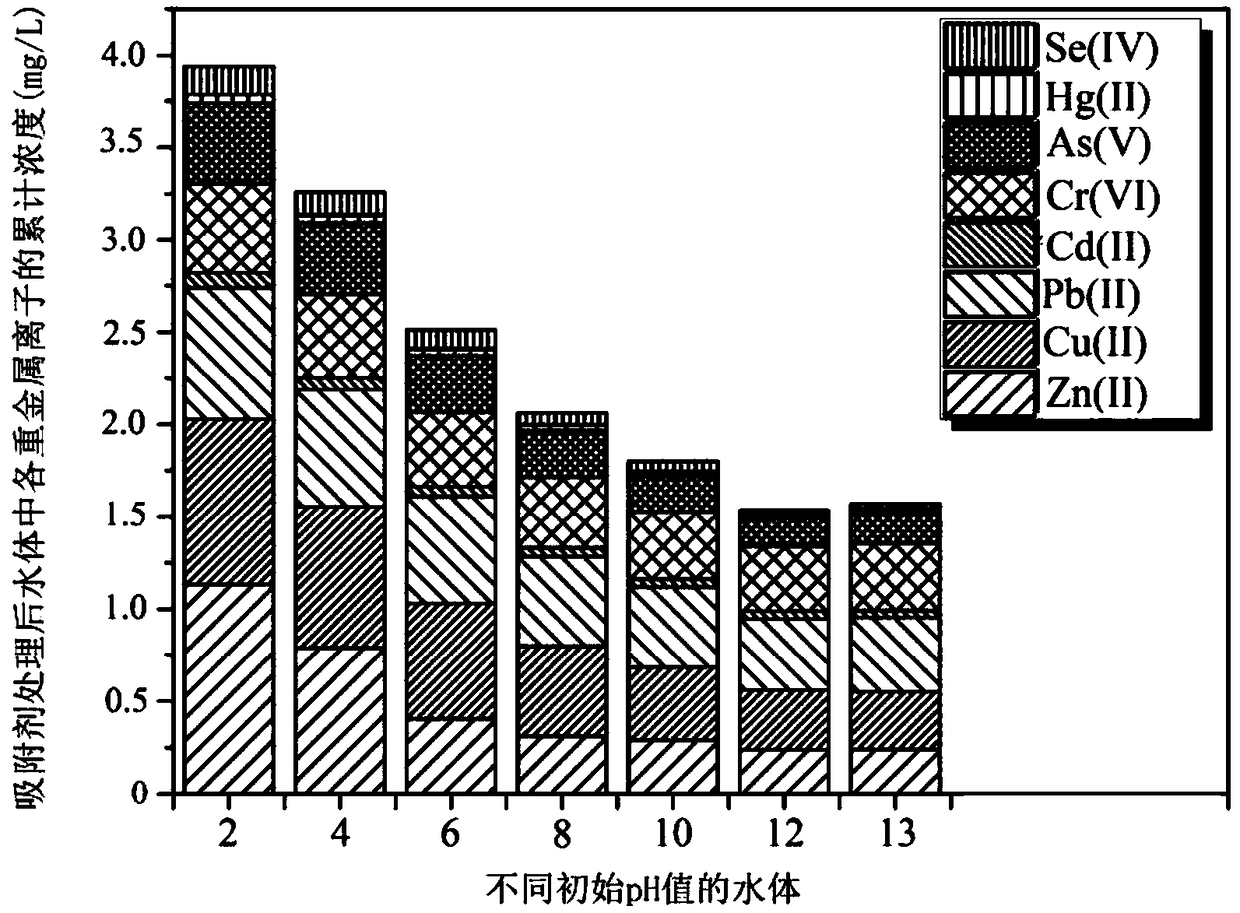

The invention discloses an iron-based adsorbent and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving ferrous sulfate and ferric sulfate into water, and sealing and stirring so as to obtain a mixed iron-based solution; (2) dissolving sodium hydroxide into water, and sealing and stirring so as to obtain a basic alkali liquid; (3) dissolving sodium hexametaphosphate into water, and sealing and stirring so as to obtain a sodium hexametaphosphate solution; (4) mixing activated carbon with the sodium hexametaphosphate solution, and sealing and stirring so as to obtain a carbon-carried sodium hexametaphosphate solution; (5) synchronously mixing the basic alkali liquid and the sodium hexametaphosphate solution, or the basic alkali liquid and the carbon-carried sodium hexametaphosphate solution, with the mixed iron-based solution, sealing so as to obtain slurry, carrying out vacuum drying, and grinding, thereby obtaining the iron-based adsorbent. The iron-based adsorbent has good acid resistance, adsorption properties and stability, and is capable of removing Zn(II), Cu(II), Pb(II), Cd(II), Cr(VI), As(V), Hg(II) and Se(IV) in a water body ofwhich the pH value is 2-13.

Owner:合肥净龙环保科技有限公司

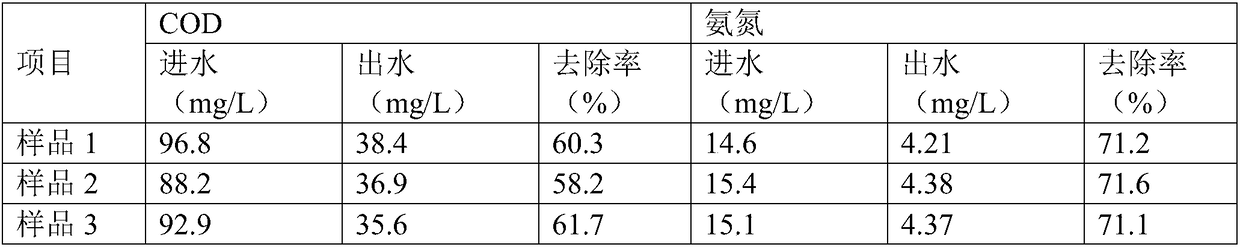

High-concentration livestock and poultry breeding wastewater treatment method

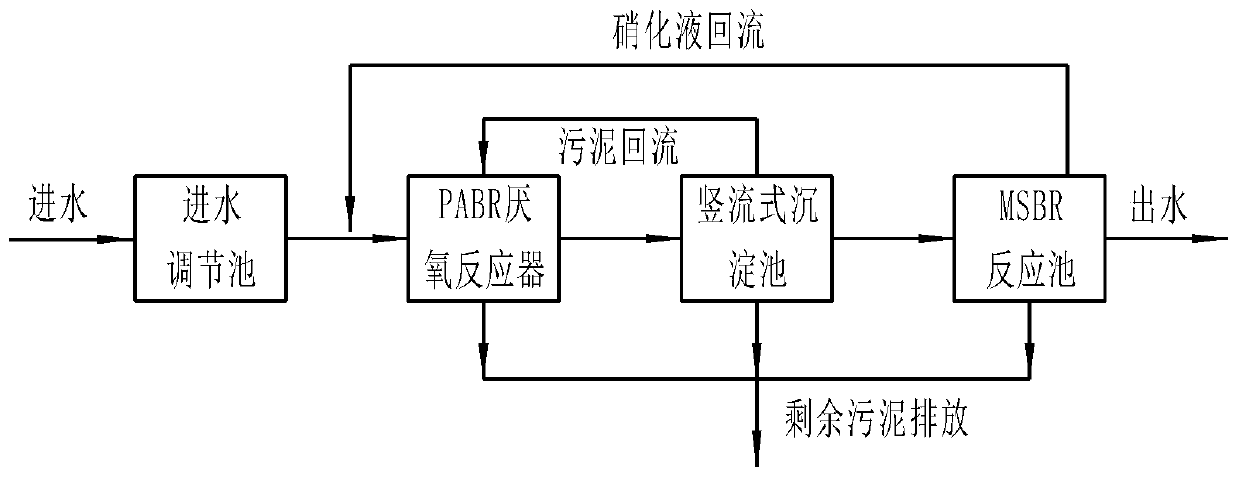

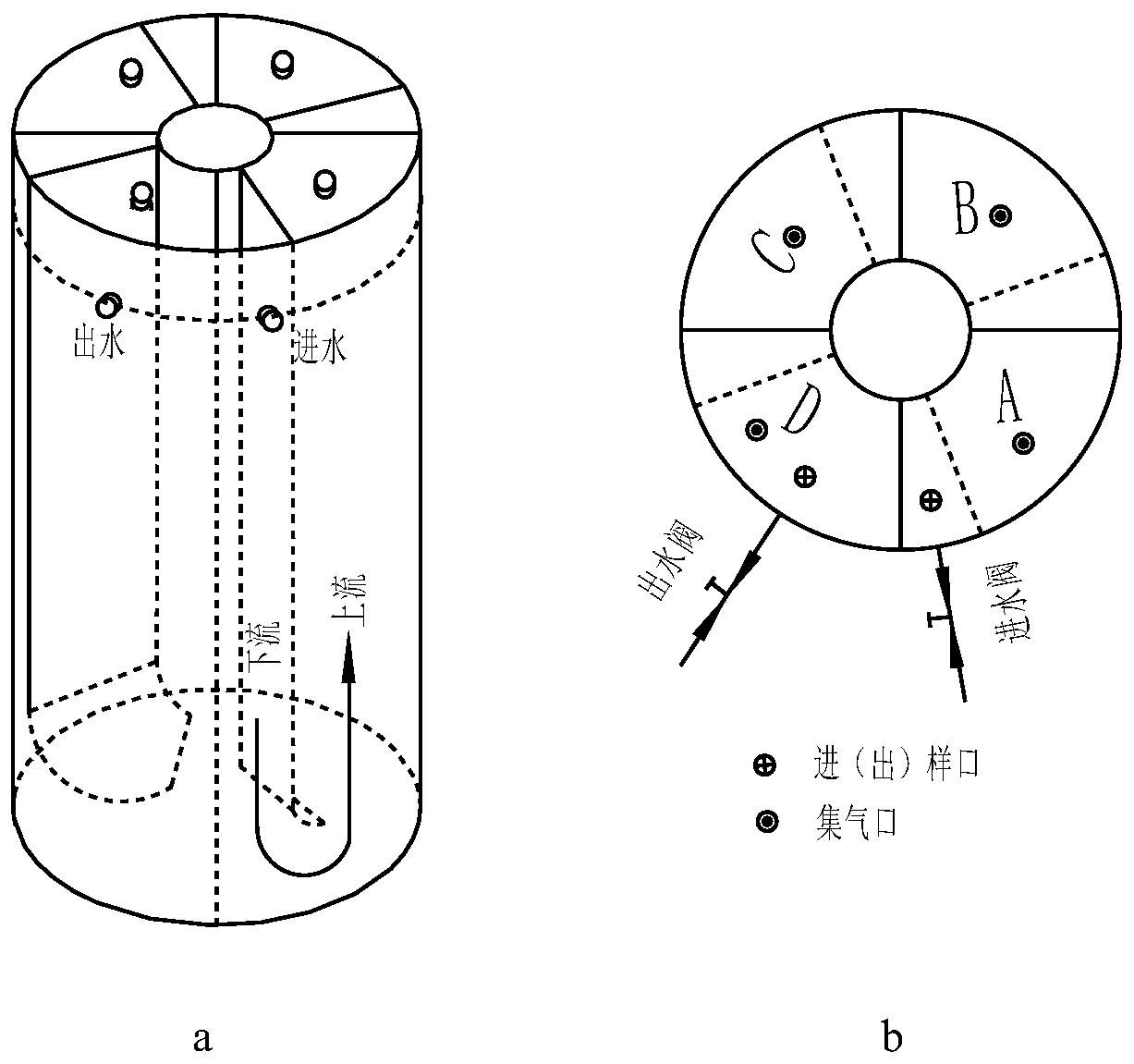

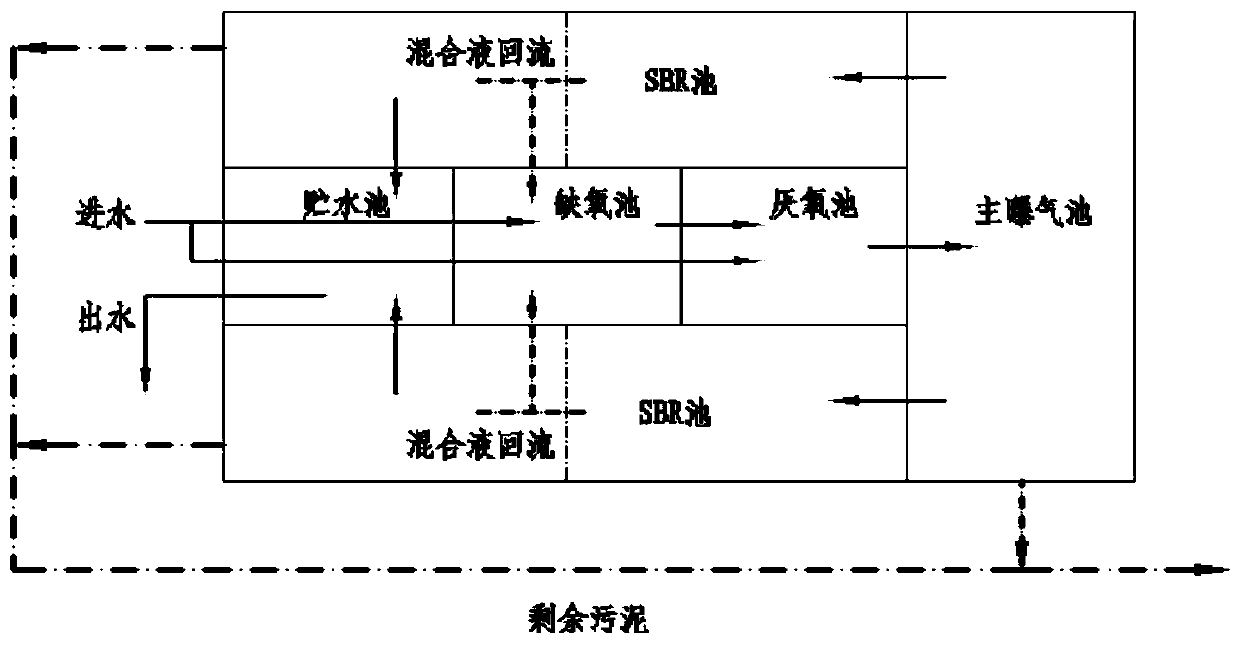

ActiveCN110015812AAlkalinity preventionReasonable distributionWater treatment parameter controlWater contaminantsHigh concentrationMethane production

The invention discloses a high-concentration livestock and poultry breeding wastewater treatment method. The denitrification methane production treatment is carried out by using a PABR reactor to mainly remove organic matters in the livestock and poultry wastewater and the nitrate nitrogen in a backflow liquid, and then the short-range nitrification denitrification treatment is carried out by using a MSBR reaction tank. According to the treatment method, the PABR denitrification methane production coupled with the MSBR short-range nitrification denitrification is utilized to treat the high-concentration livestock and poultry breeding wastewater, so that different microbial populations can better play respective functions in the PABR and MSBR reactors, and the efficient removal of the organic matters, ammonia nitrogen and nitrate nitrogen in the livestock and poultry breeding wastewater can be realized.

Owner:泰州学院

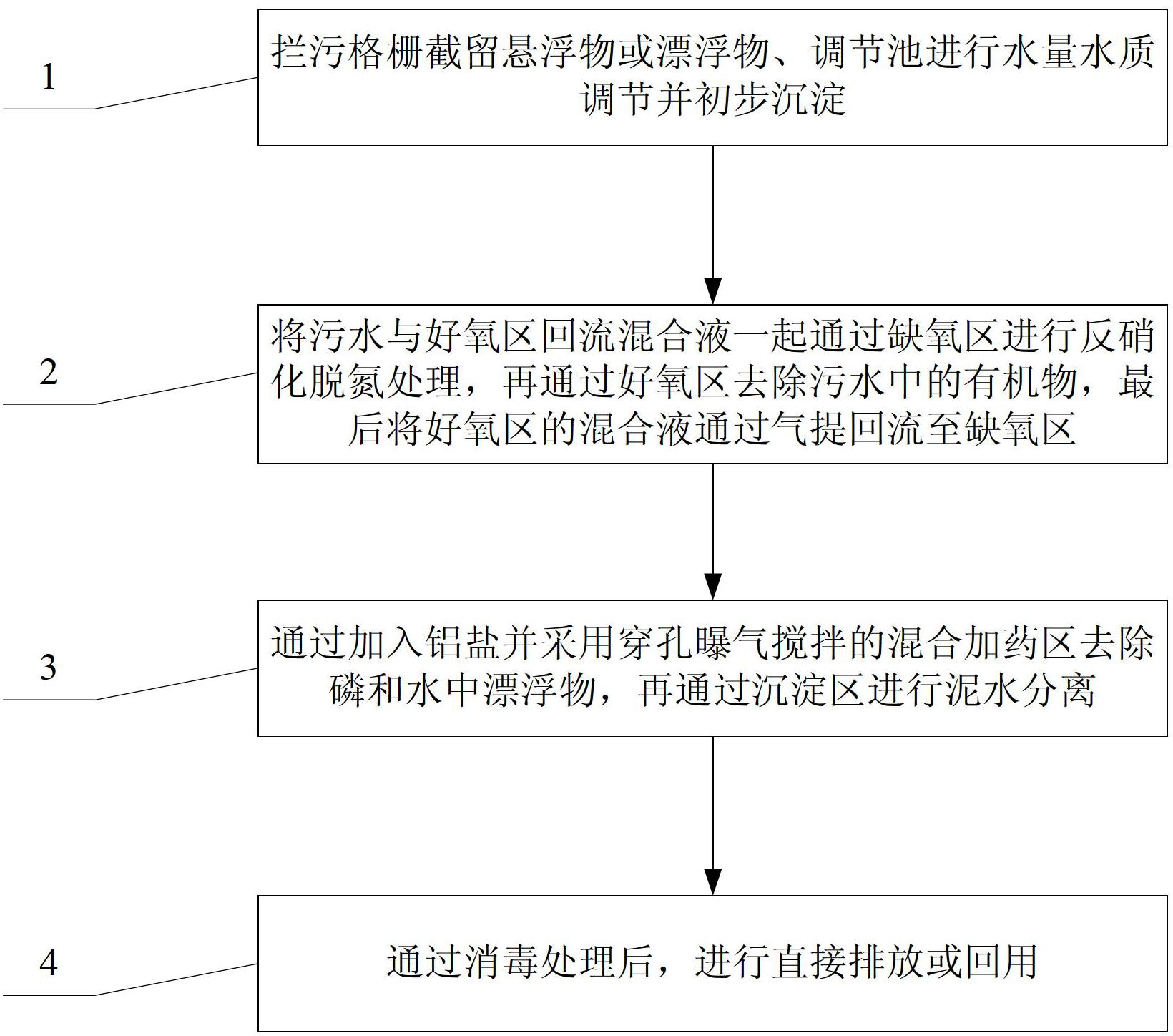

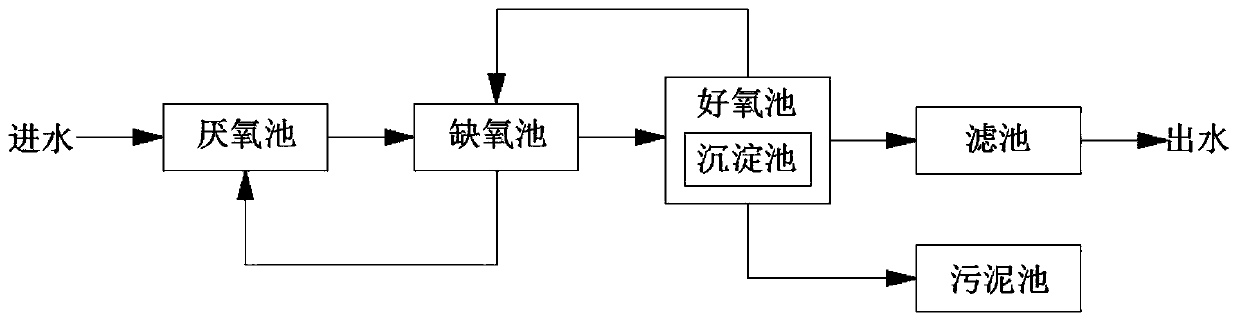

Sewage treatment method

InactiveCN102690029AAchieve simultaneous removalReduce outputMultistage water/sewage treatmentSludgeWater quality

The invention provides a sewage treatment method which comprises steps as follows: a sewage blockage grid traps large suspended substances or floating substances in sewage, and a regulating tank regulates the water quantity and water quality of the sewage and performs preliminary precipitation; the sewage and aerobic zone reflux mixed liquor together pass through an anoxic zone to perform denitrification treatment, and pass through an aerobic zone to remove organic substances in the sewage, and the mixed liquor of the aerobic zone flows back to the anoxic zone through air stripping; and phosphorus is removed from the residual sewage after air stripping by adding an aluminum salt with a preset concentration and adopting a mixed feed zone using perforated aeration stirring, and the sewage which has passed through the mixed feed zone passes through a settling zone to perform sludge-water separation. The invention can simultaneously remove nitrogen and phosphorus in the sewage and implement low sludge yield; and the invention has the characteristic of small occupied area, is simple top operate and maintain, conforms to the requirements of the countryside for technical rationality and economical efficiency, and has wide application prospects.

Owner:SOUNDGRP CO LTD

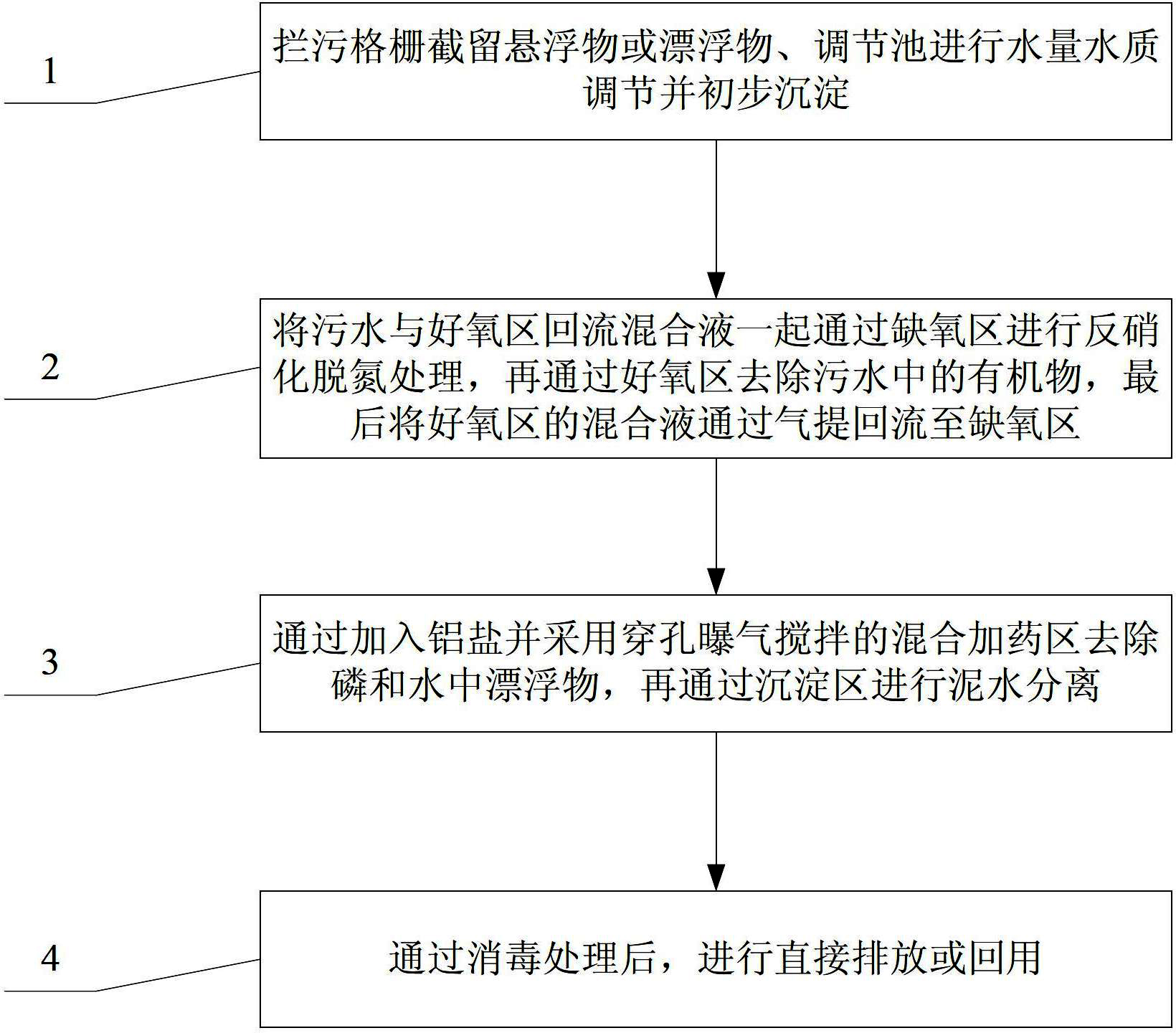

Synchronous anaerobic denitrification and desulfurization process

InactiveCN101007681AAchieve simultaneous removalRealize resourcesNitrogen preparationSulfur preparation/purificationChemistrySulfide

The invention discloses a synchronous anaerobic denitrifying desulfurizing technique, which is characterized by the following: adopting anaerobic digestive sludge or anaerobic active sludge with organic wastewater with sulfate as inoculating material; oxidizing sulfate into elemental sulfur; reducing nitrite into nitrogen; setting the density of nitrite and sulfate at 20-2270mg N / L and 30-1920mg S / L with molar rate at 0.5-4.0; controlling reacting temperature at 20-35 deg.c and pH value at 6-9; setting the hydraulic retaining time for 0.08-2.0d; using nitrite as electron acceptor and sulfate as electron provider; realizing the removal of two pollutions without providing oxygen.

Owner:ZHEJIANG UNIV

Method for synchronously removing heavy metals and organic matters from wastewater

ActiveCN107324587AImprove recovery abilitySimple processWater treatment parameter controlWater treatment compoundsIndustrial wastewater treatmentIon

The invention relates to a method for synchronously removing heavy metals and organic matters from wastewater. The method comprises four steps, namely anoxic reaction, incubation reaction, aerobic reaction and precipitation reaction, and problems and defects in an existing heavy metal and organic matter coexisting industrial wastewater treatment technology are solved. Compared with the prior art, the method provided by the invention has the advantages that a catalyst with a molecular oxygen activating function is generated in situ by virtue of regulation heavy metal ions in wastewater, molecular oxygen is catalyzed to produce a strong oxidization species, and oxidation and degradation of organic pollutants are catalyzed while heavy metal crystals and precipitates are removed, so that wastes are treated by using wastes creatively, green oxidization is realized, a treatment working procedure is shortened, treatment efficiency is improved, economic cost is reduced, and technology industrialization application is promoted.

Owner:TONGJI UNIV

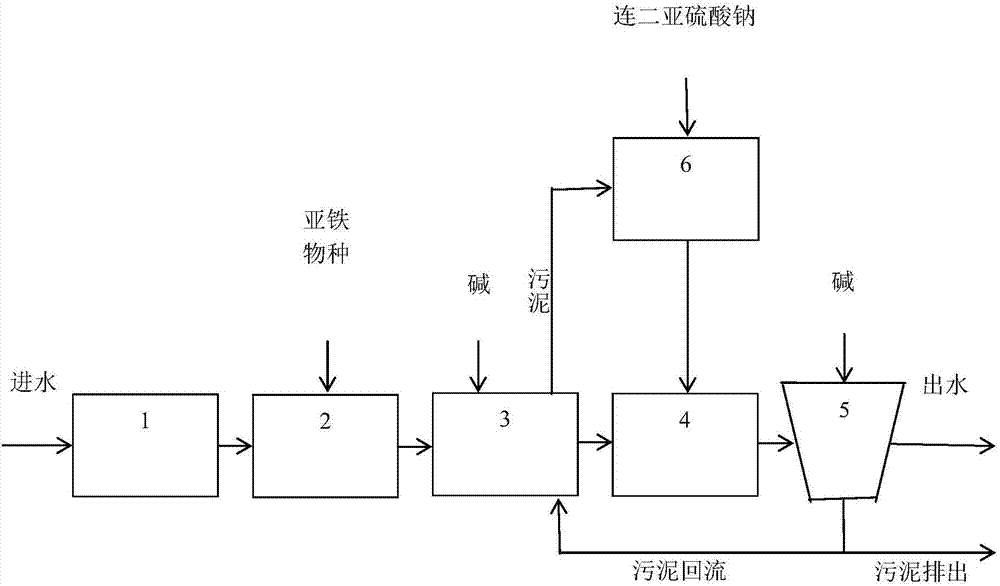

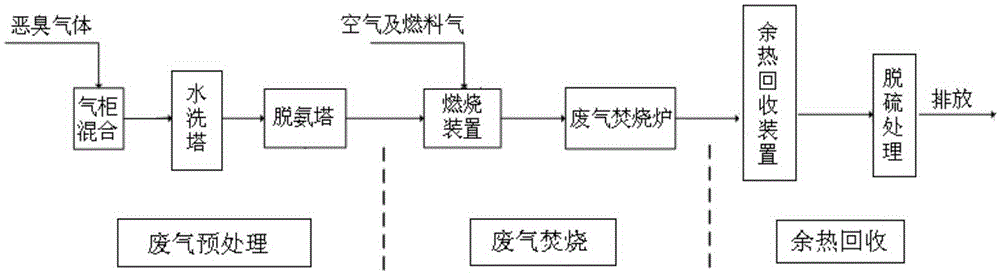

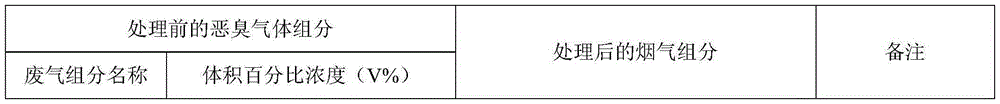

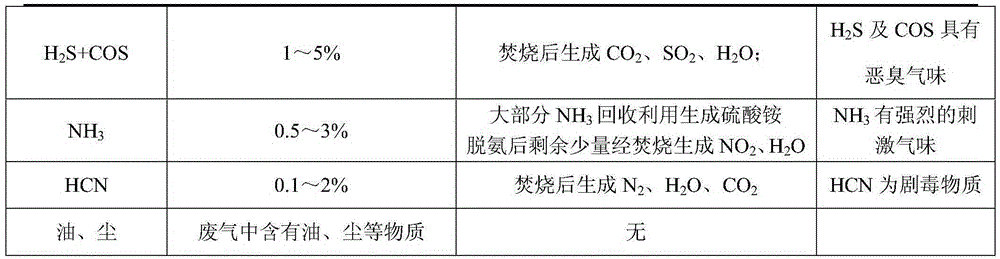

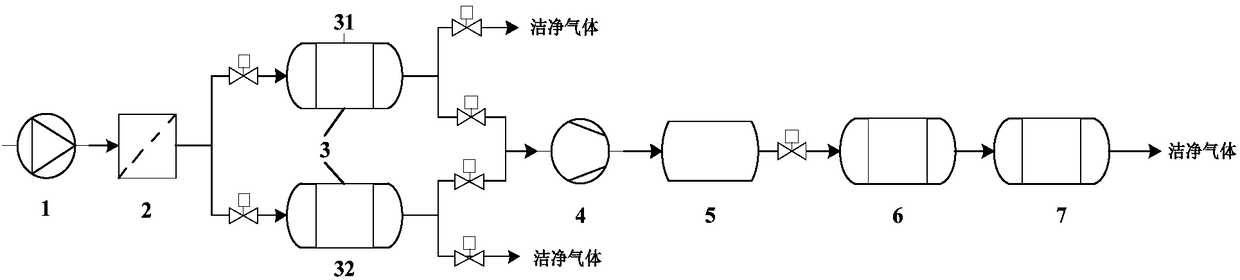

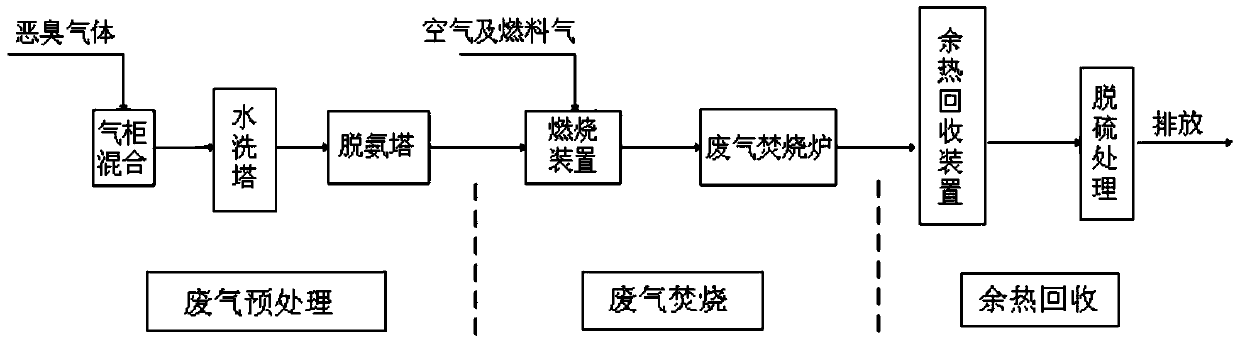

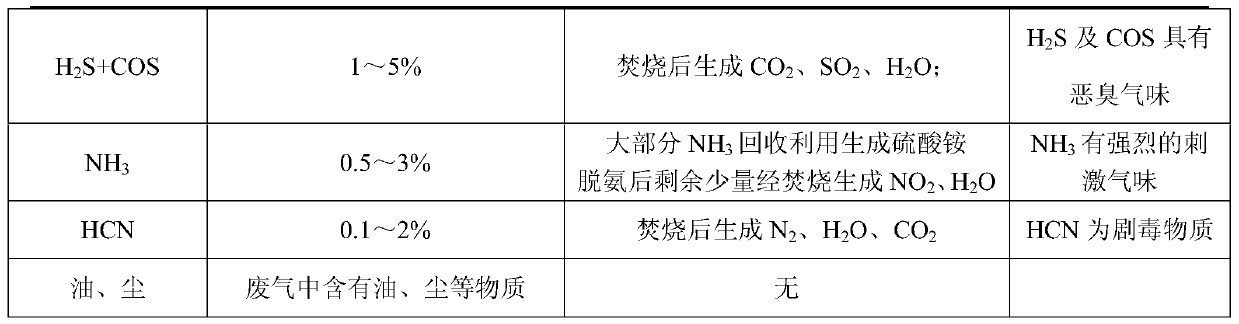

Technique for combined treatment of various foul gases in coal chemical industry

ActiveCN105387472AAchieve simultaneous removalEasy to operateGas treatmentUsing liquid separation agentCombustionTherapeutic effect

The invention relates to a technique for combined treatment of various foul gases in the coal chemical industry and belongs to the technical field of waste gas treatment in the coal chemical industry. The treatment technique comprises the steps that (1) waste gas pretreatment is conducted, foul gases are introduced into a water-washing tower to be subjected to deoiling and dedusting, and then the foul gases enter a deamination tower for deamination treatment; (2) waste gas incineration is conducted, the gases are introduced into a combustion device, the combusted gases enter a waste gas incinerator to be completely incinerated and decomposed, and the purposes of deodorization and degassing are achieved; and (3) high-temperature smoke enters a waste heat recycling device for waste heat recycling after being treated through the waste gas incinerator, and the smoke is subjected to up-to-standard emission after desulfurization treatment. According to the treatment technique, the foul gases are completely incinerated and decomposed into components such as SO2, CO2, H2O, NO and NO2, and the purposes of deodorization and harmful gas removal are achieved. By means of the treatment technique, the purpose of treating the various foul gases simultaneously in the coal chemical industry can be achieved, and the technique for combined treatment of the various foul gases in the coal chemical industry is economical, easy to operate, safe, environmentally friendly and complete and good in waste gas treatment effect.

Owner:SEDIN ENG +1

Device and method for treating kitchen waste with rural domestic sewage

ActiveCN109942084AAchieve simultaneous removalSmall footprintGas production bioreactorsTreatment with aerobic and anaerobic processesRural areaSludge

The invention provides a device and method for treating kitchen waste with rural domestic sewage. The device comprises a water storage tank, an AAO system, a secondary sedimentation tank, a fermentation tank, a fermented mixture refluxing system, a secondary effluent drainage system and a sludge drainage system, wherein the water storage tank is communicated with the AAO system, and the AAO systemis communicated with the secondary sedimentation tank; a water outlet is formed in the secondary sedimentation tank, and is used for draining secondary effluent in the secondary sedimentation tank; akitchen waste pretreatment tank is arranged in the fermentation tank, and is used for pretreating kitchen waste; and pretreated kitchen waste is released into fermentation mixture in the fermentationtank and is fermented. According to the technical scheme, domestic sewage treatment and kitchen waste treatment are combined, domestic sewage and kitchen waste in rural areas can be removed at the same time, and a novel way is provided with harmless, reduced and resourced treatment of rural domestic sewage and kitchen waste.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

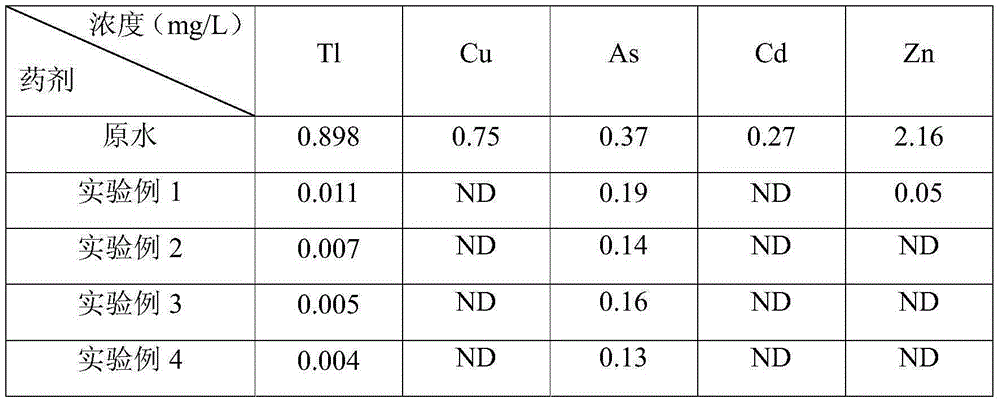

Heavy metal collecting agent and thallium-removal method used for sintering desulfurization waste water

ActiveCN105254075AAchieve simultaneous removalReduce dosageWater contaminantsMultistage water/sewage treatmentEpoxyWater treatment

The invention relates to a heavy metal collecting agent and a thallium-removal method used for sintering desulfurization waste water. The method is divided into two stages, wherein the first-stage treatment comprises the steps of adjusting the thallium-containing waste water to be alkaline, and adding coagulant; the second-stage treatment comprises the steps of adding agentia and coagulant to supernatant obtained after solid-liquid separation of the first-stage treatment, and effluent is drained outward directly after being subjected to press filtering. The agentia is prepared from, by weight, 20-30% of urea, 1-3% of linear chain small molecule amine substances, 4-9% of carbon disulfide, 0.4-0.7% of epoxy chloropropane, 0.5-0.8% of surfactant and the balance water. A preparation method comprises the steps of adding water for being mixed with urea, amine substances and epoxy chloropropane, stirring the mixture for a certain time at the room temperature, then dropwise adding carbon disulfide, continuing with the reaction, after a period of time passes, raising the temperature, continuing stirring, after the reaction is completed, lowering the temperature to the room temperature, adding surfactant, stirring the mixture uniformly, and obtaining the product. According to the heavy metal collecting agent and the thallium-removal method used for sintering the desulfurization waste water, the agentia is added to the thallium-containing waste water to be treated, and metal complex is formed after the mixture is stirred sufficiently. By means of the process, thallium and other heavy metal ions in the sintering desulfurization waste water can be effectively removed, environmental pollution is avoided, and waste water treatment cost is effectively lowered.

Owner:GUANGDONG PROVINCIAL ACADEMY OF ENVIRONMENTAL SCI

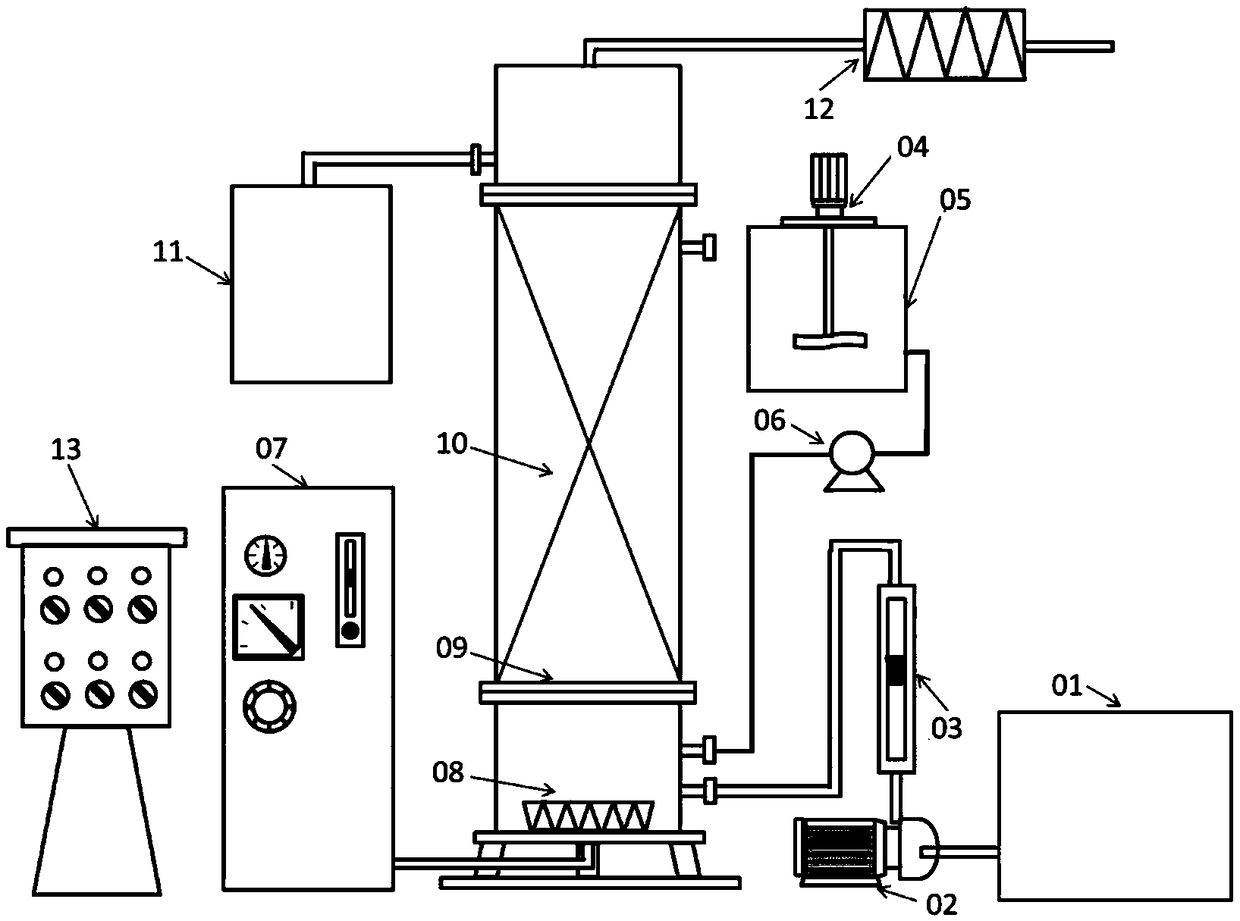

Device and method for removing reverse osmosis concentrated water organic matter and ammonia nitrogen at same time

PendingCN109264845AHigh degree of automationEasy to operateWater treatment parameter controlWater/sewage treatment by oxidationHypochloriteAtmospheric air

The invention relates to a device and method for removing reverse osmosis concentrated water organic matter and ammonia nitrogen at same time, and belongs to the field of industrial wastewater treatment. In an adjusting pool, reverse osmosis concentrated water is injected into the bottom of a catalysis ozone reaction tower through a water pump, a chemical adding pump pumps chemicals in a chemicaladding box into the bottom of the catalysis ozone reaction tower, and meanwhile ozone generated by an ozone generator is injected into an aeration disc at the bottom of the catalysis ozone reaction tower; the chemicals, the reverse osmosis concentrated water and ozone are mixed at the bottom to be introduced into a catalyst bed layer, water overflowing occurs on the upper portion of the catalysisozone reaction tower, overflowing water enters a deoxidization stabilization pool, tail gas of the catalysis ozone reaction tower is collected and enters a tail gas breaking device to break residua ozone, and finally the tail gas is discharged into atmosphere. The organic matter and ammonia nitrogen in the reverse osmosis concentrated water are removed at the same time through a catalytic ozonation reaction or catalytic ozonation and a persulfate or hypochlorite oxidation coupling reaction. The device is simple, high in automation degree and high in operability; the treated water outlet concentration can meet the demand for up-to-standard discharge or further treatment.

Owner:DALIAN UNIV OF TECH

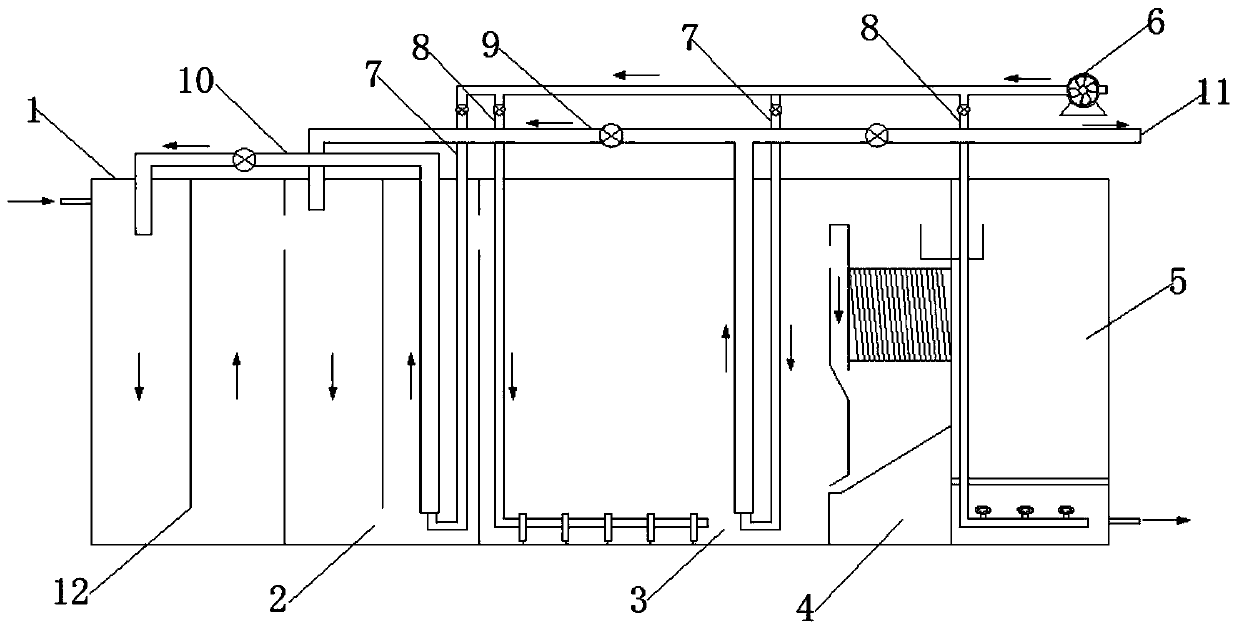

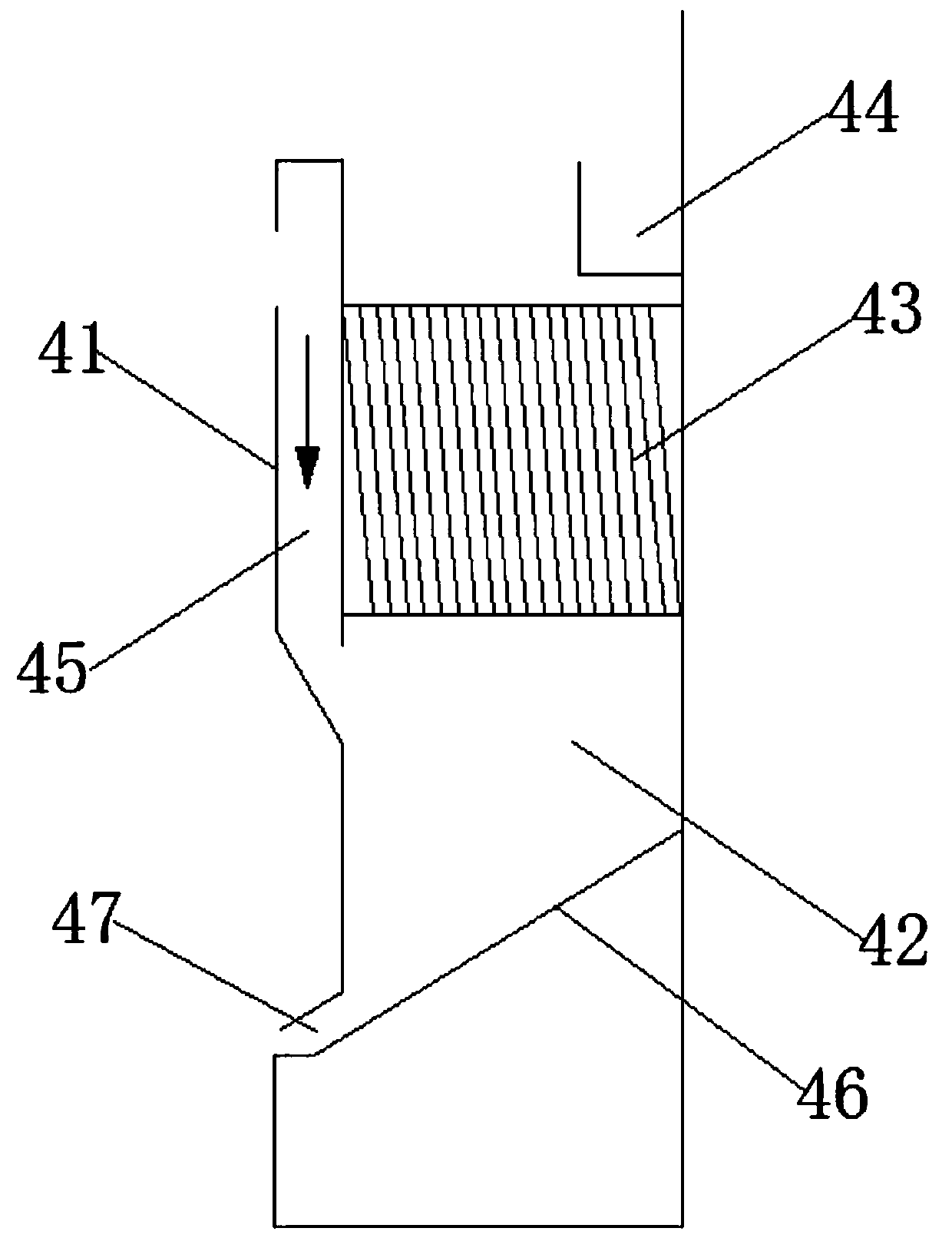

Device for treating sewage by SNAGS-synergetic nitrification and aerobic granular sludge

PendingCN111233153AEfficient combinationReduce use costWater contaminantsBiological treatment apparatusSludgeSewage

The invention belongs to the technical field of sewage treatment, in particular to an SNAGS-synergistic nitrification aerobic granular sludge sewage treatment device. The device comprises an anaerobictank, an anoxic tank, an aerobic tank, a filter tank and a gas stripping reflux device, which are sequentially arranged in a water inlet direction; a sedimentation tank is arranged at one end, closeto the filter tank, in the aerobic tank; supernatant precipitated in the precipitation tank overflows and then flows into the filter tank; discharging from a water outlet pipe at the bottom of the filter tank after filtering; the gas stripping reflux device mainly comprises a first reflux pipe, a second reflux pipe and two gas stripping pipes; mixed liquid in the aerobic tank flows back to the front end of the anoxic tank through a first return pipe. The device overcomes the defects in the prior art, adopts an aerobic sewage treatment technology taking biochemical reaction and precipitation integration as a core; wherein the biochemical pool and the precipitation pool are combined at high efficiency and a gas stripping technology is employed to replace a pump structure, so that the devicereduces the use cost and occupied area, is more convenient in control method, and is suitable for small and medium-sized urban domestic sewage and river water treatment.

Owner:ANHUI JINDALAI ENVIRONMENT ENG CO LTD

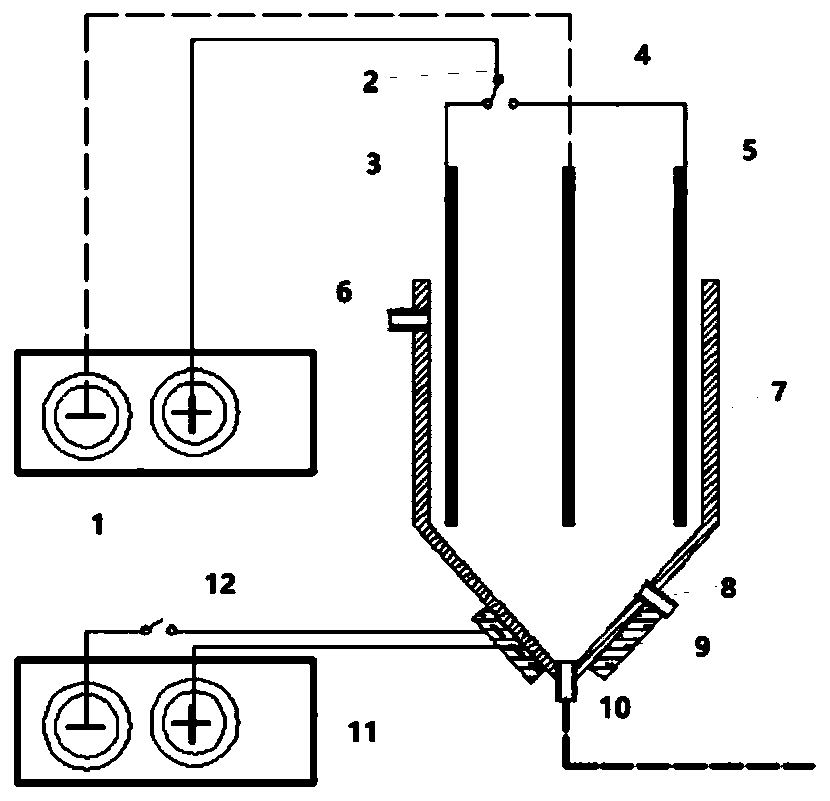

Nitrogen-containing organic wastewater electrochemical treatment reactor and method for enabling electroflocculation sludge to achieve magnetic separation performance

PendingCN109912105AMagneticAchieve simultaneous removalWater contaminantsMultistage water/sewage treatmentElectrochemical responseChemical treatment

The invention discloses a nitrogen-containing organic wastewater electrochemical treatment reactor and a method for enabling electroflocculation sludge to achieve a magnetic separation performance. Onthe basis that the method removes a pollutant in the nitrogen-containing organic wastewater at the same time, a strongly magnetic iron compound is formed in the traditional electroflocculation sludge, so that the electroflocculation sludge achieves the magnetic performance. The core of the method is to introduce two anodes, one is an iron anode, the other is a Ti / RuO2 anode, the iron anode and the Ti / RuO2 anode work alternatively to create a transient-state oxidation-deoxidation environment for a system, and the accumulation of the strongly magnetic Fe3O4 and gamma-Fe2O3 is promoted. Based onthe method, the invention further provides the electrochemical reactor, the electrochemical reactor is widely suitable for removing total nitrogen and COD (Chemical Oxygen Demand) in the treatment ofthe nitrogen-containing organic wastewater (like domestic wastewater, industrial wastewater, landfill leachate and the like) containing an electroflocculation treatment unit, meanwhile, the electroflocculation sludge becomes magnetic, and the rapid magnetic separation of the sludge is achieved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

A kind of quick start-up method for short-range nitrification and denitrification of ammonia-containing wastewater

ActiveCN103373764BReduce the difficulty of startingImprove processing efficiencyTreatment with aerobic and anaerobic processesActivated sludgeDenitrifying bacteria

The invention relates to a quick start-up method for short-range nitrification and denitrification of ammonia-containing wastewater. First, the inoculum is put into a bioreactor, and the inoculum is enriched nitrifying bacteria, or a mixture of nitrifying bacteria and aerobic activated sludge of a sewage plant ; The system is started in two modes of intermittent water intake and continuous water intake; nitrifying bacteria are added during intermittent water intake, and denitrifying bacteria agents are added during continuous water intake. Compared with the prior art, the method of the invention has the advantages of less stringent start-up requirements, fast start-up speed, high-concentration ammonia-containing wastewater and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

System and method for disposing large blast capacity low concentration mixed harmful gas

InactiveCN108114571APurification applicableAchieve simultaneous removalGas treatmentDispersed particle separationSorbentGas concentration

The invention provides a system and a method for disposing large blast capacity low concentration mixed harmful gas. The system comprises a purification, regeneration and adsorption device, a catalytic combustion and purification device and a tail end purification and adsorption device connected successively. By combining the harmful gas concentration and removal technology, the catalytic combustion technology and the tail end purification technology, the problem that the harmful gas which is low in concentration is hard to dispose is solved in an assisted manner by means of adsorption and desportion of the harmful gas. By proportioning various adsorbents and the harmful gas correspondingly and reasonably, the problem that various types of harmful gas cannot be purified at the same time issolved; the tail end purification technology avoids generation of secondary pollution. According to the system and the method provided by the invention, the mixed harmful gas can be efficiently purified, and the concentration of the harmful gas can be reduced to be below the concentration of national environment-friendly demand.

Owner:上海穗杉实业股份有限公司

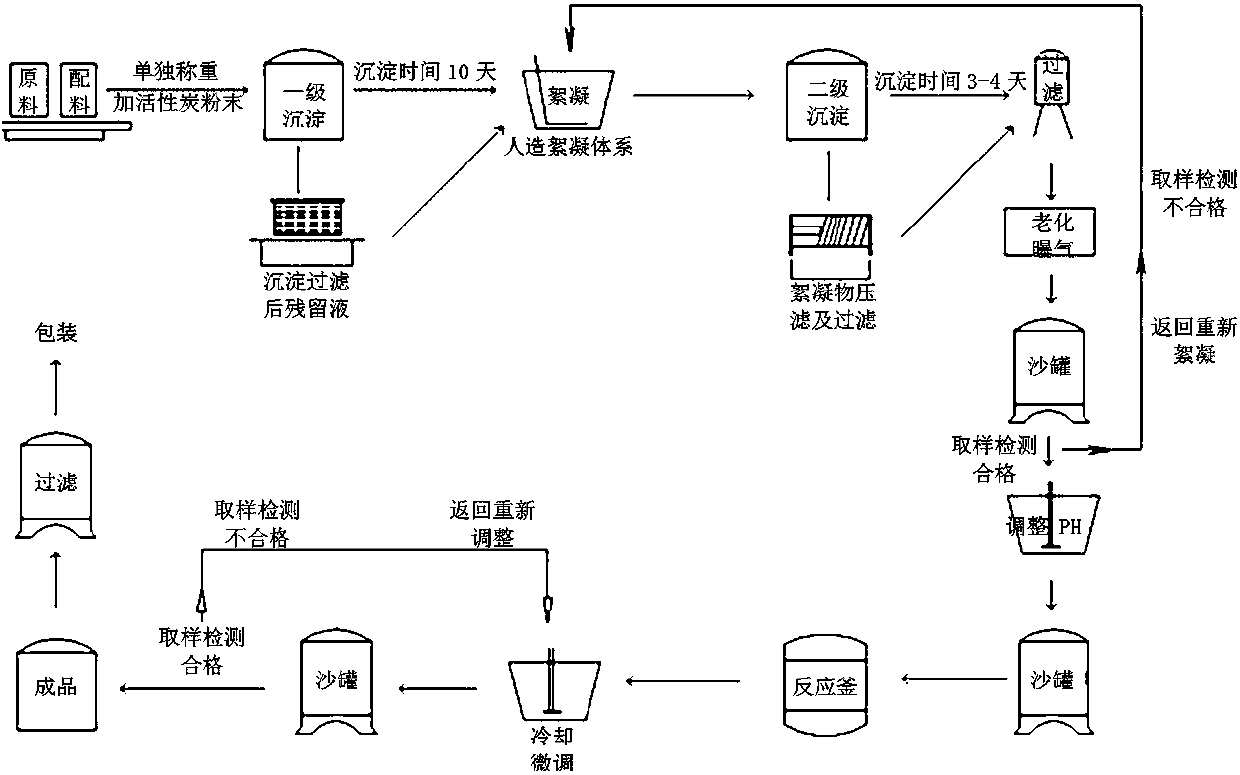

Regeneration treatment method for lithium bromide solution in absorption refrigerator

The invention relates to a regeneration treatment method for a lithium bromide solution in an absorption refrigerator. The regeneration treatment method comprises the steps: (1) raw material collection; (2) ingredient preparation; (3) artificial flocculation system establishment; (4) aging aeration; (5) pH value regulation; (6) reactor high temperature concentration; (7) cooling; (8) fine tuning; (9) clay pot circulating filtration; and (10) packaging and storage. Different sustained release preparations in the lithium bromide solution and various metal ions affecting the effect of the refrigerator can be effectively removed, meanwhile, the content of various corrosive anions is greatly reduced, various impurities can be effectively removed, the quality of a waste lithium bromide solution is effectively improved, so that the recycle of the waste lithium bromide solution is realized; and various harmful substances in the lithium bromide solution can be simultaneously removed with high efficiency and low cost, supervising the process by special personnel at any time is not needed, and the automatic starting or stopping can be realized by time or temperature setting, so that the labor efficiency is increased.

Owner:镇江市富来尔制冷工程技术有限公司

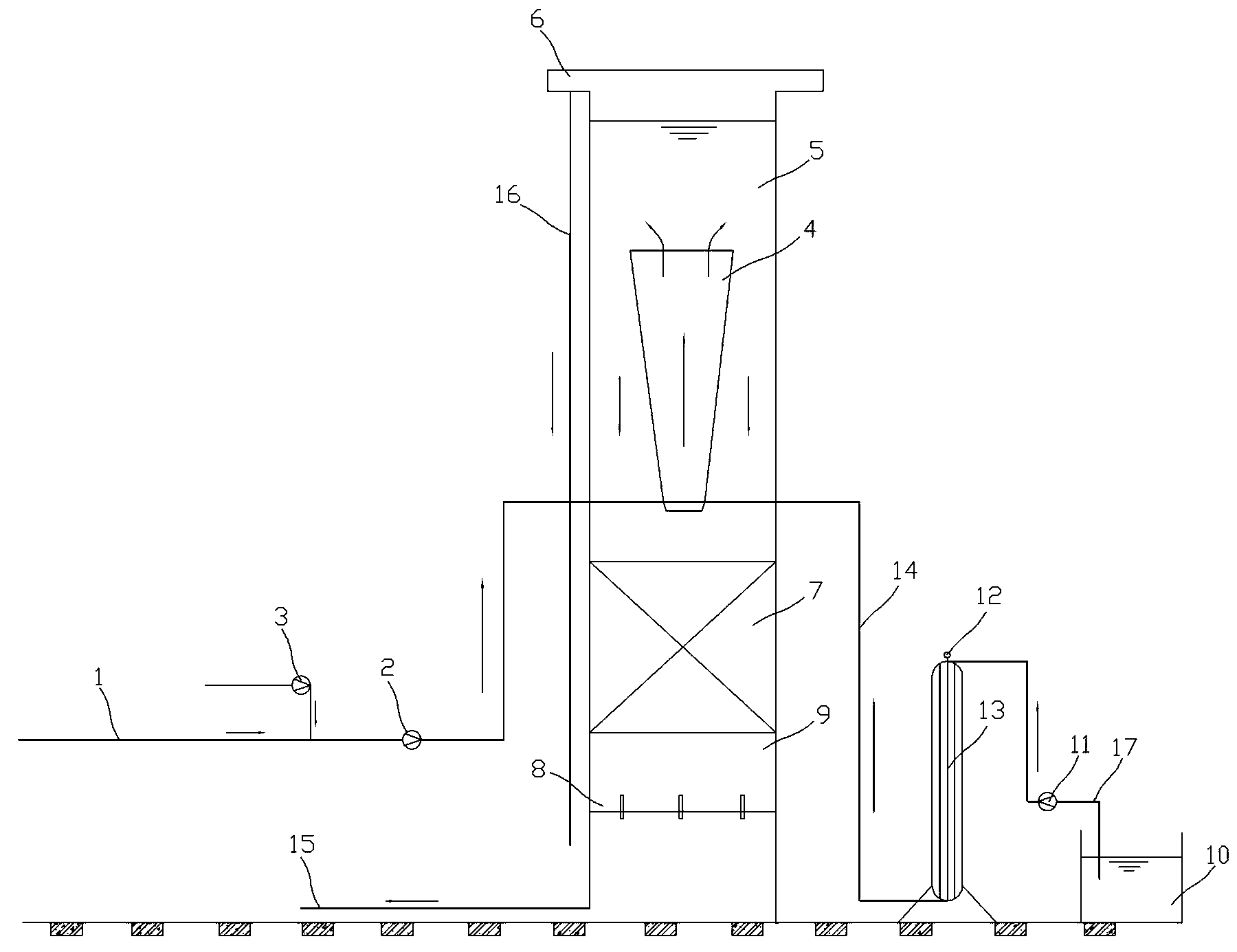

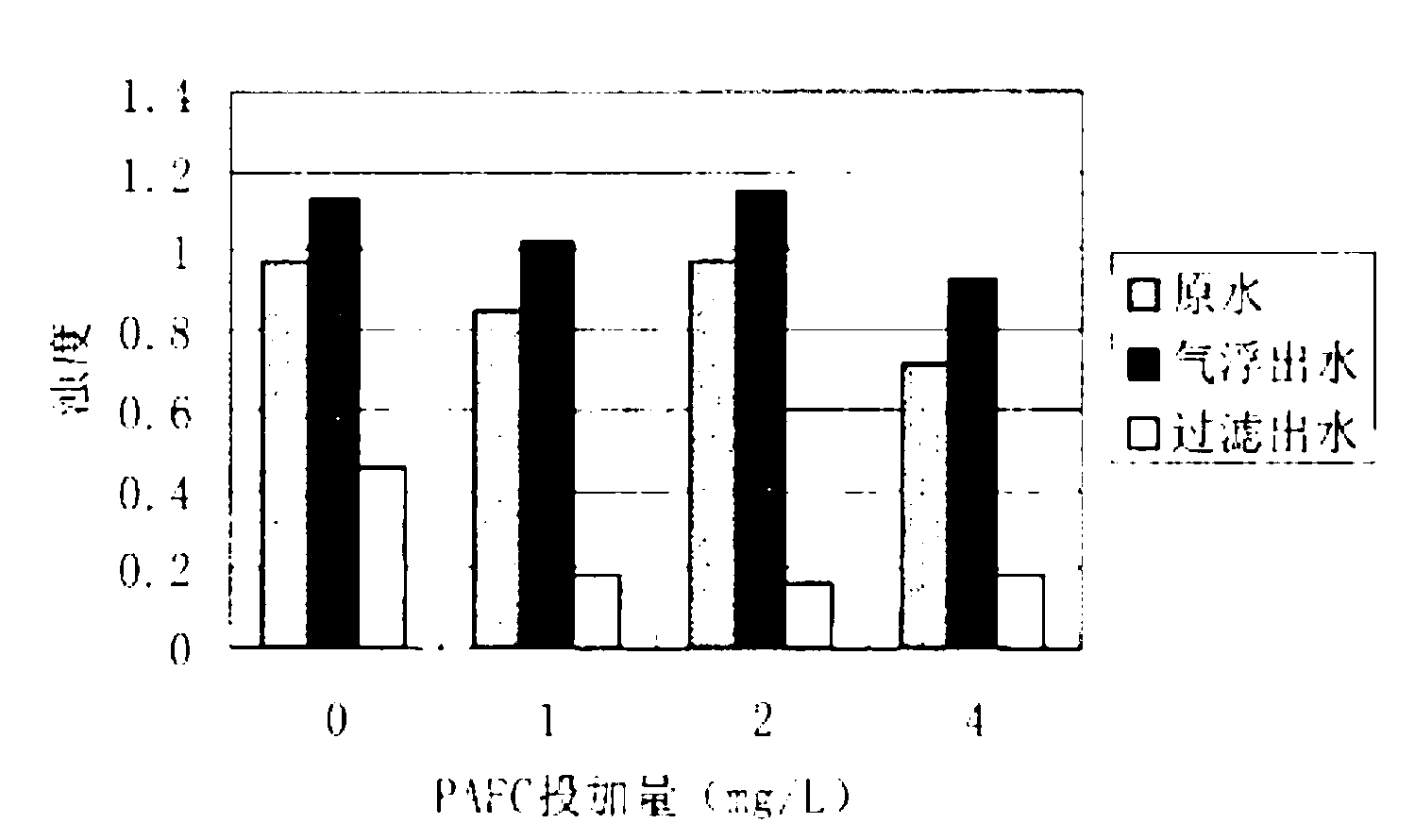

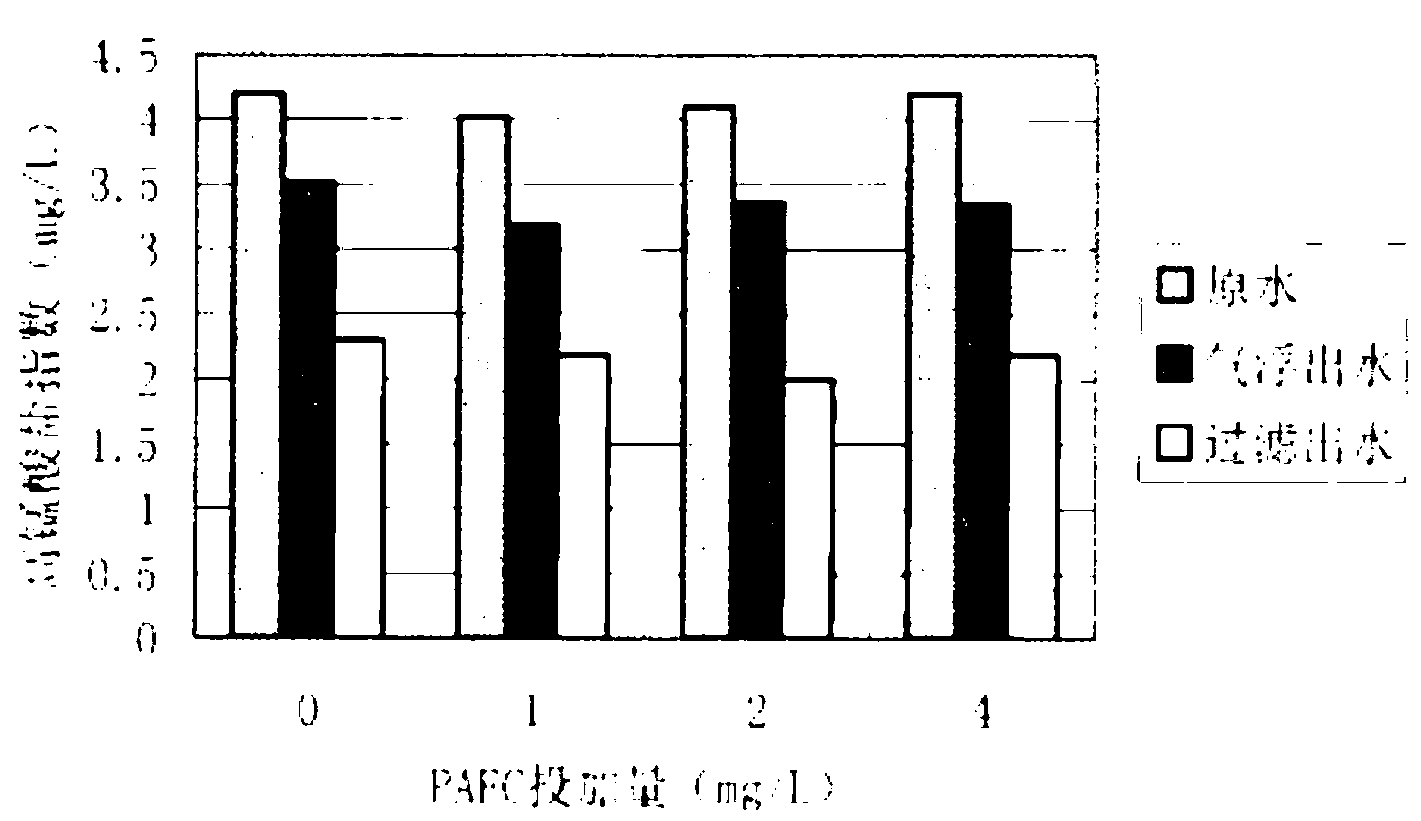

Floatation/filtration-integrated polluted water advanced treatment device and method

InactiveCN103011509AAchieve simultaneous removalEasy to transformMultistage water/sewage treatmentActivated carbonWater source

The invention relates to a floatation / filtration-integrated polluted water advanced treatment device and method. The device comprises a floatation / filtration tank and a dissolved air cylinder, wherein the floatation / filtration tank comprises a floatation unit and a filtration unit which are arranged up and down; a contact reaction chamber is arranged in the floatation unit, the bottom is sequentially communicated with a raw water source and the dissolved air cylinder through a pipeline, and a separation region of the floatation unit is arranged above the contact reaction chamber; the filtration unit has the same cross section as the separation region of the floatation unit; the filtration unit sequentially comprises an activated carbon filtering layer, a quartz sand filtering layer and a gravel supporting layer from top to bottom; and the bottom of the filtration unit is respectively communicated with a water back flush pipeline and an air back flush pipeline. The invention integrates floatation and filtration, highly integrates multiple pollution removal mechanisms, and can simultaneously remove algae and organic substances; the preoxidation-reinforced floatation / filtration tank technique widens the adaptability to raw water, and enhances the pollutant elimination capacity; and the removal rate of algae, algal poison and smelly substances exceeds 90%, and the removal rate of permanganate index exceeds 50%, so that the water quality is comprehensively improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

A joint treatment process for multiple malodorous gases in coal chemical industry

ActiveCN105387472BAchieve simultaneous removalEasy to operateGas treatmentUsing liquid separation agentTherapeutic effectCombined treatment

Owner:SEDIN ENG +1

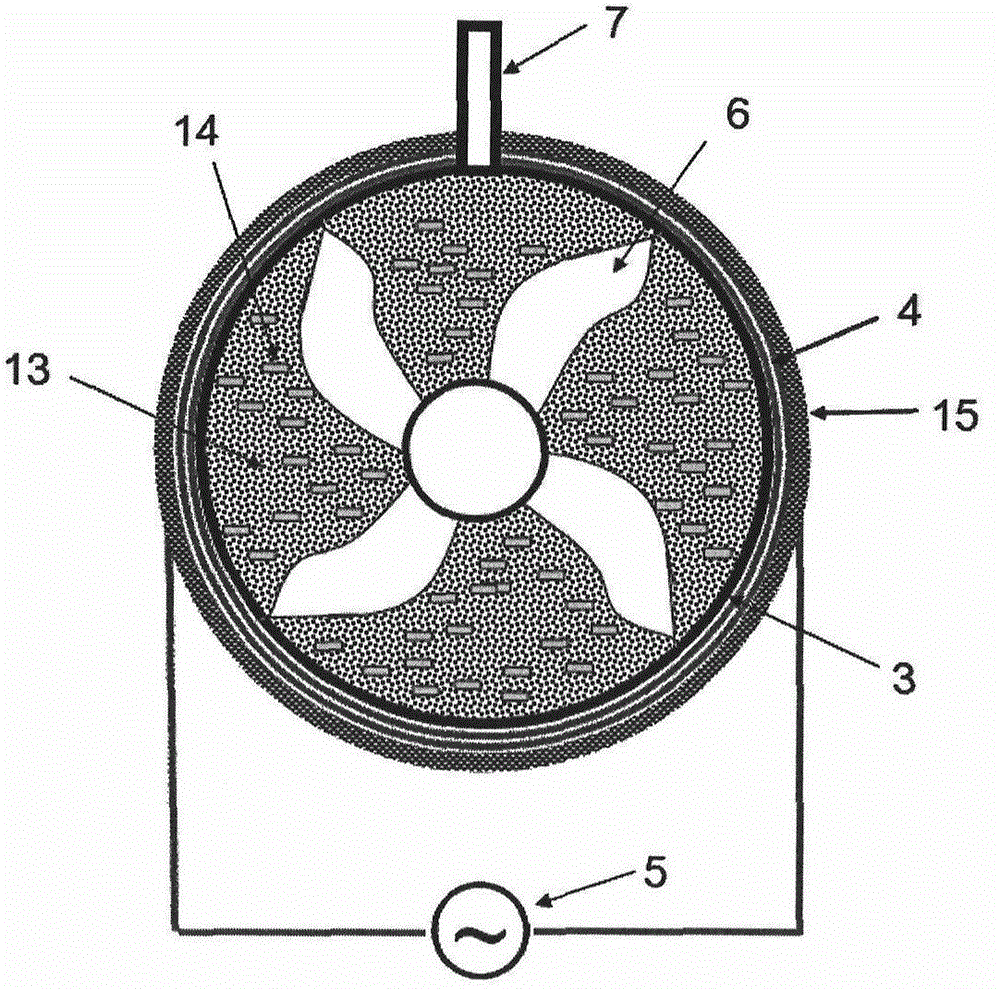

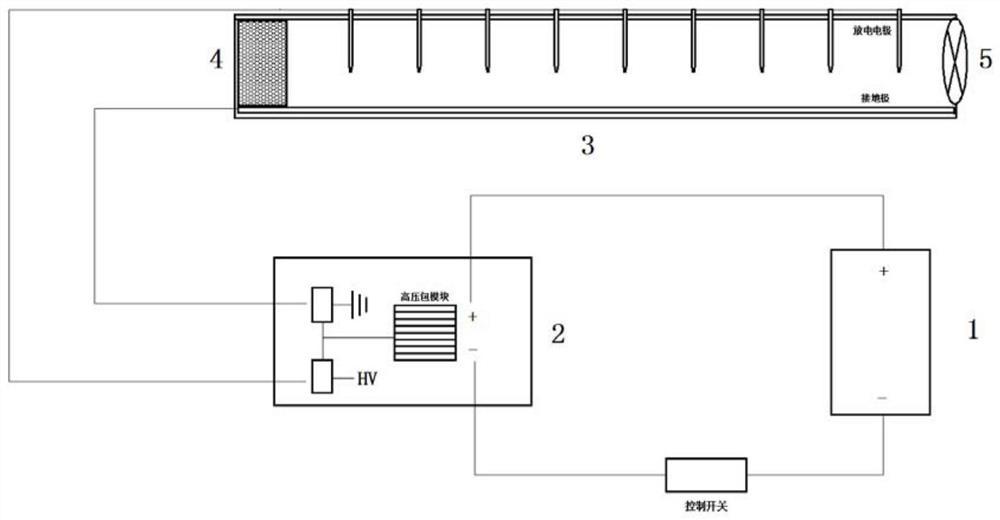

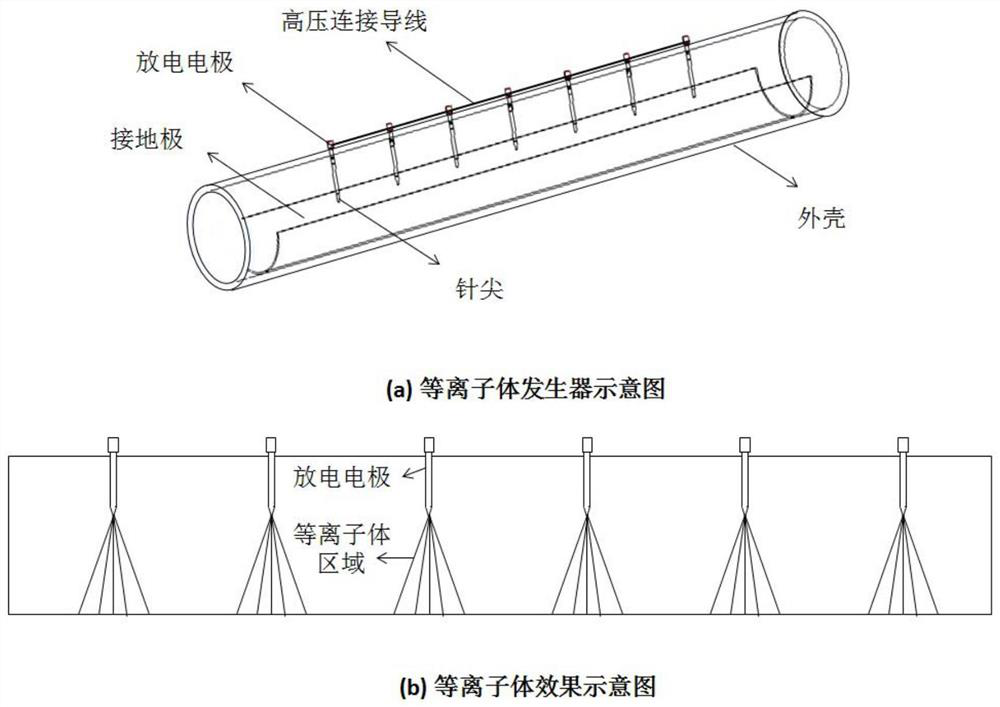

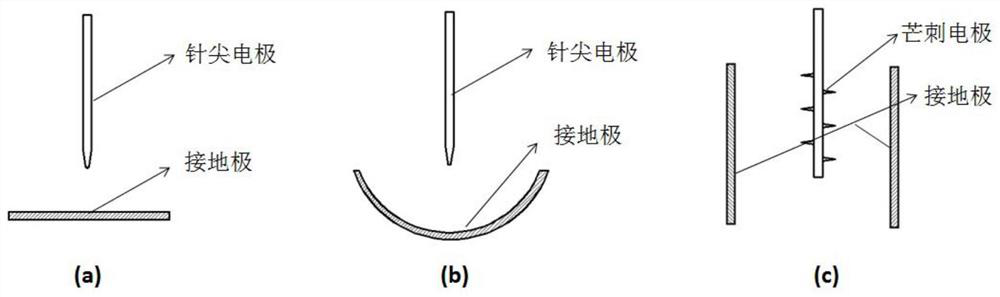

Portable multifunctional air purification method and device

InactiveCN112413784AAchieve simultaneous removalMethod is feasibleMechanical apparatusLighting and heating apparatusAir decontaminationHigh voltage

The invention provides a portable multifunctional air purification method and device. The method comprises the steps of (a) connecting a direct-current power supply to a direct-current transformer tooutput ultra-high voltage required for generating purified air plasma; (b) connecting the ultra-high voltage output by the direct-current transformer to a discharge electrode of a plasma generating device, and connecting the other electrode to the ground at the same time; (c) putting a catalytic module into the plasma generating device to efficiently catalyze air pollutants; and (d) starting the plasma generating device and a built-in fan to purify the air. The device provides the portable multifunctional air purification device for efficiently removing the pollutants such as PM25 and VOCs (volatile organic compounds).

Owner:SHANGHAI JIAO TONG UNIV

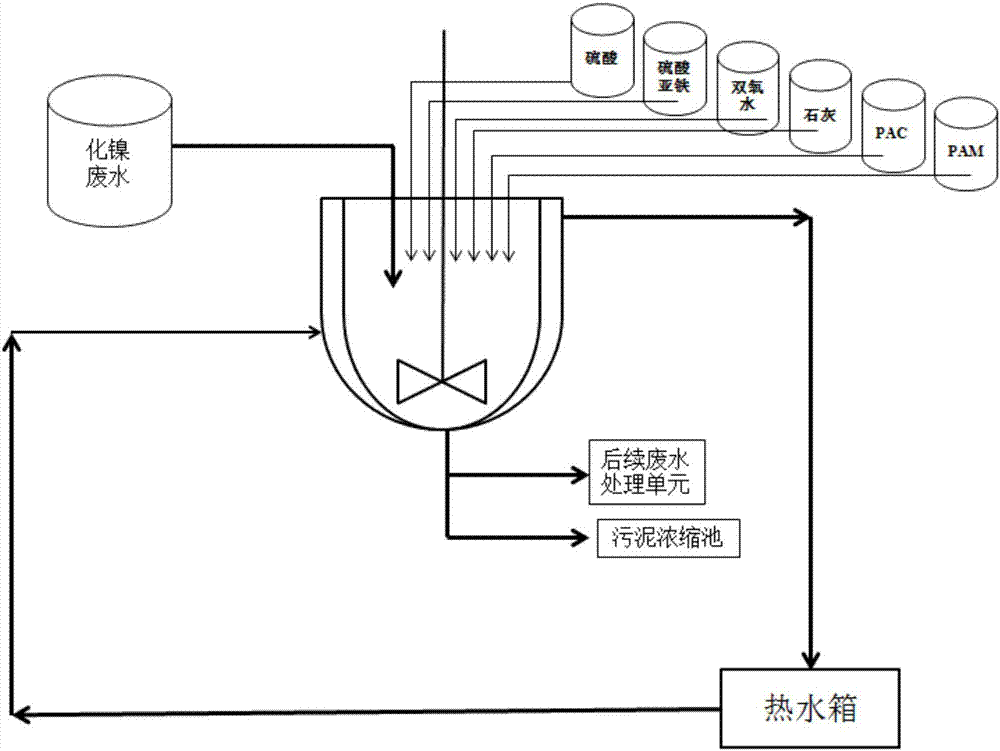

Treatment system and treatment method of nickel-containing wastewater

InactiveCN107055876AIncrease oxidation rateAchieve simultaneous removalWater treatment compoundsWater contaminantsWater treatment systemPhosphate

The invention provides a treatment system and a treatment method of nickel-containing wastewater. The treatment system of the nickel-containing wastewater comprises a reaction device, a heat supply device for heating the reaction device and a stirring device located in the reaction device. The treatment system of the nickel-containing wastewater is a reaction and sedimentation integrated intermittent treatment device and can increase the oxidation rate of hypophosphite; chemical nickel and phosphate are removed simultaneously.

Owner:SUZHOU WINNER ENVIRONMENTAL TECH

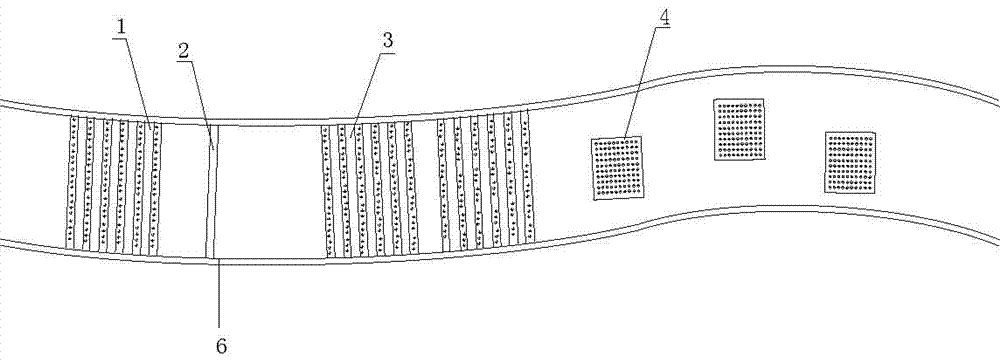

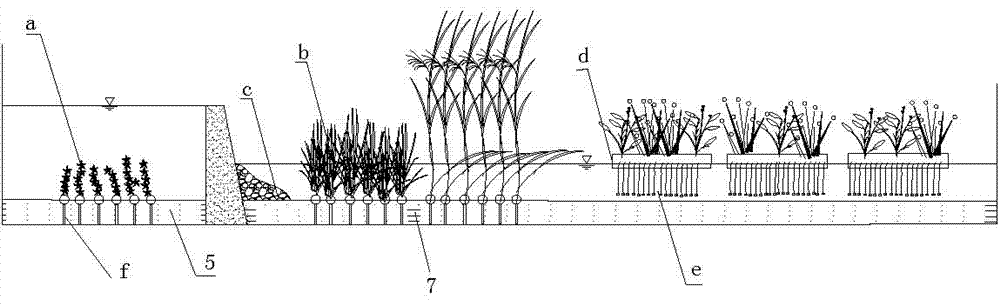

A method for constructing an ecological purification system for sediment-polluted shallow and narrow rivers

ActiveCN105060637BAchieve simultaneous removalWill not affect floodingClimate change adaptationMultistage water/sewage treatmentRiver routingSludge

Owner:ZHENGZHOU UNIV

Iron-based adsorbent and preparation method thereof

ActiveCN109126717BReduce oxidation ratePromote generationOther chemical processesWater contaminantsIron sulfateSODIUM METAPHOSPHATE

The invention discloses an iron-based adsorbent and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving ferrous sulfate and ferric sulfate into water, and sealing and stirring so as to obtain a mixed iron-based solution; (2) dissolving sodium hydroxide into water, and sealing and stirring so as to obtain a basic alkali liquid; (3) dissolving sodium hexametaphosphate into water, and sealing and stirring so as to obtain a sodium hexametaphosphate solution; (4) mixing activated carbon with the sodium hexametaphosphate solution, and sealing and stirring so as to obtain a carbon-carried sodium hexametaphosphate solution; (5) synchronously mixing the basic alkali liquid and the sodium hexametaphosphate solution, or the basic alkali liquid and the carbon-carried sodium hexametaphosphate solution, with the mixed iron-based solution, sealing so as to obtain slurry, carrying out vacuum drying, and grinding, thereby obtaining the iron-based adsorbent. The iron-based adsorbent has good acid resistance, adsorption properties and stability, and is capable of removing Zn(II), Cu(II), Pb(II), Cd(II), Cr(VI), As(V), Hg(II) and Se(IV) in a water body ofwhich the pH value is 2-13.

Owner:合肥净龙环保科技有限公司

Synchronous anaerobic denitrification and desulfurization process

InactiveCN100500592CIncrease concentrationAchieve simultaneous removalNitrogen preparationSulfur preparation/purificationReaction temperatureSulfide

Owner:ZHEJIANG UNIV

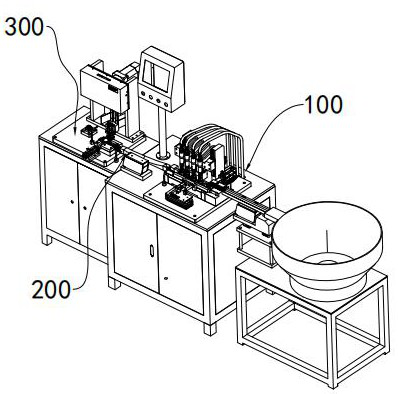

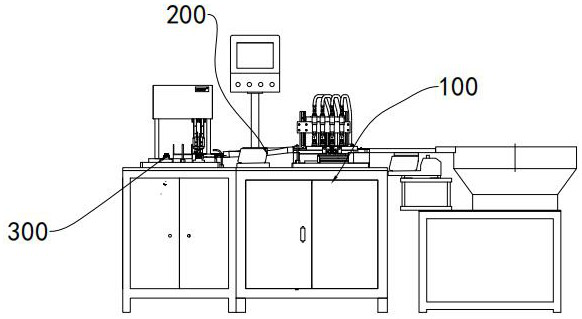

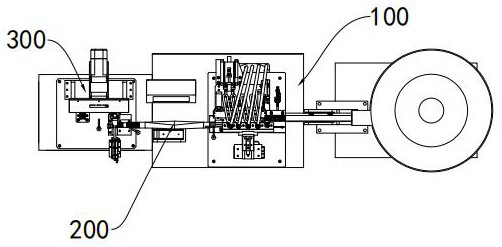

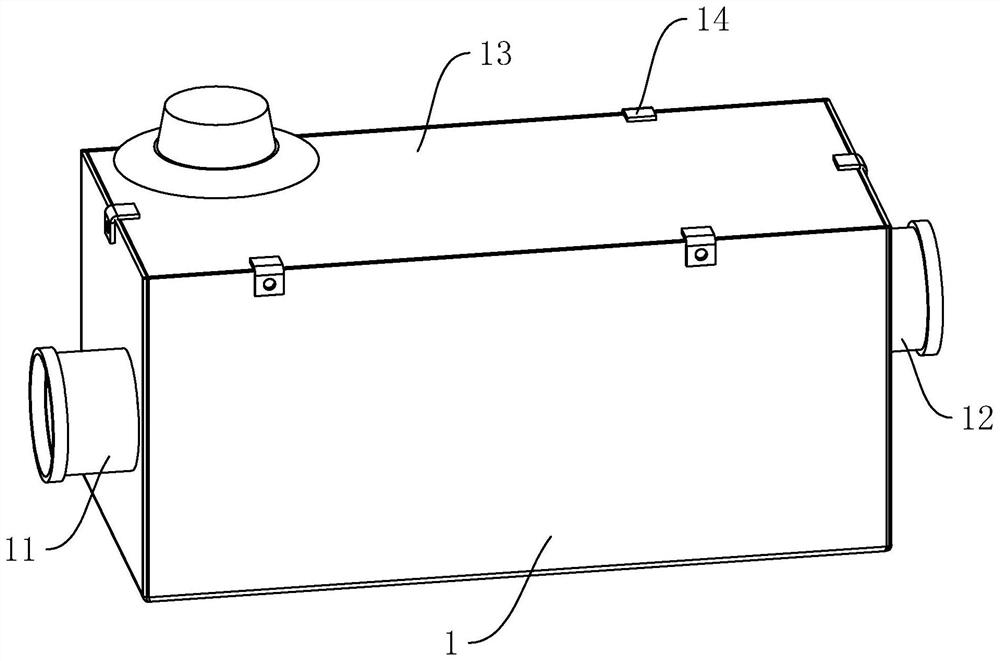

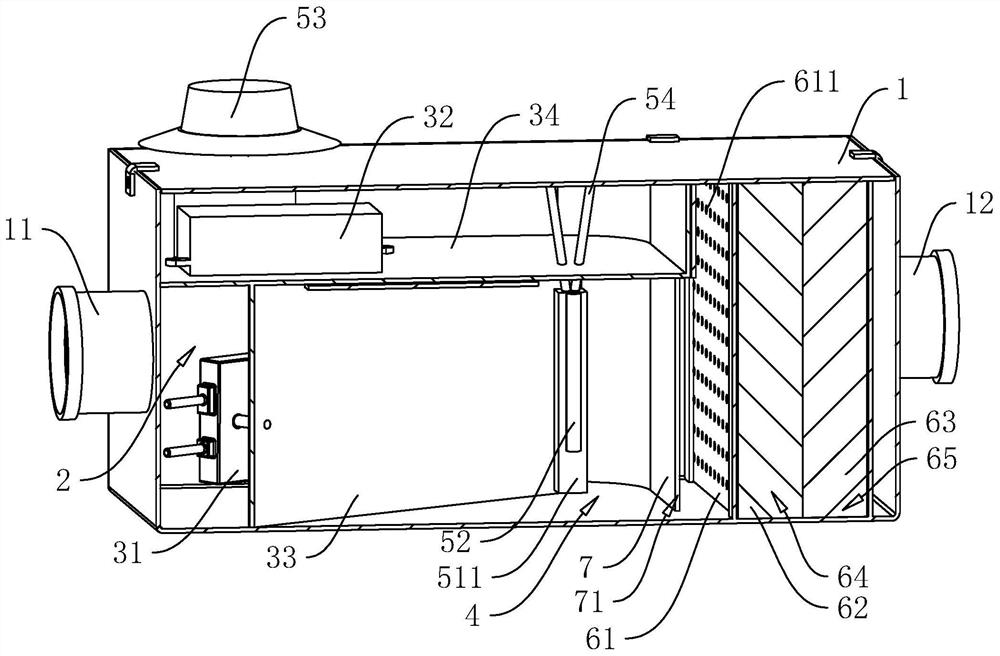

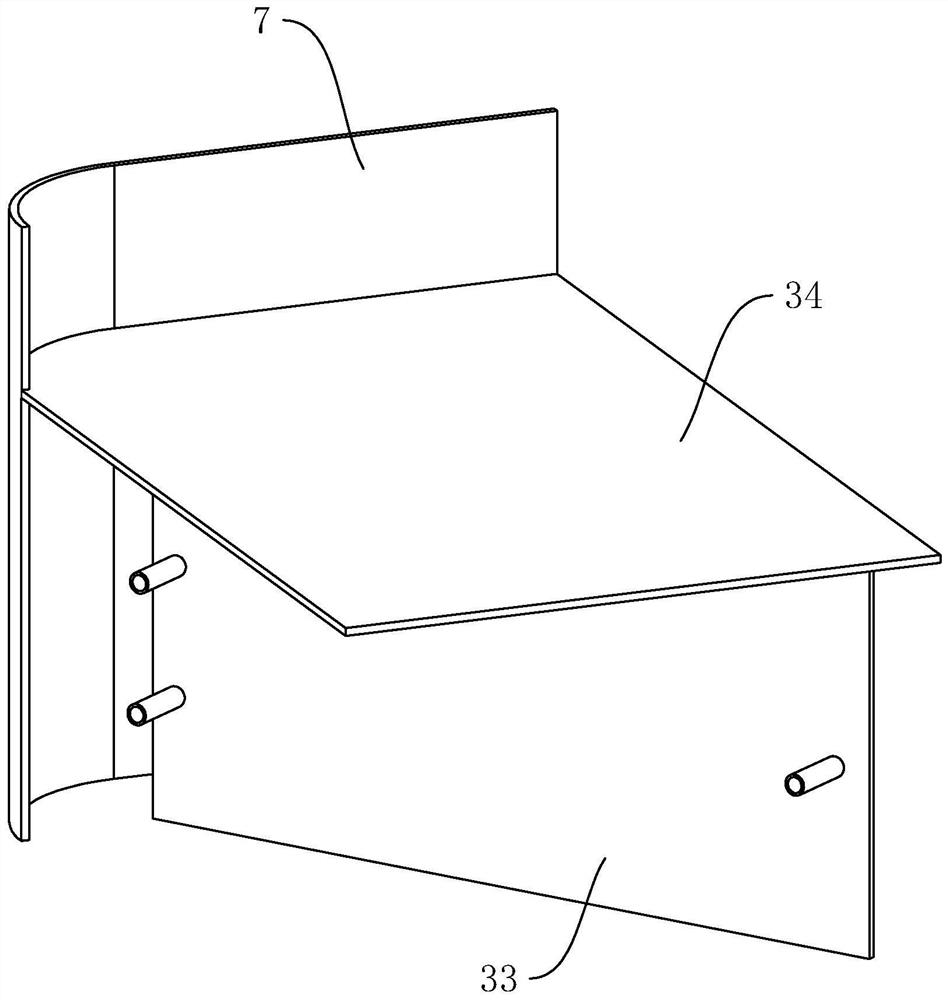

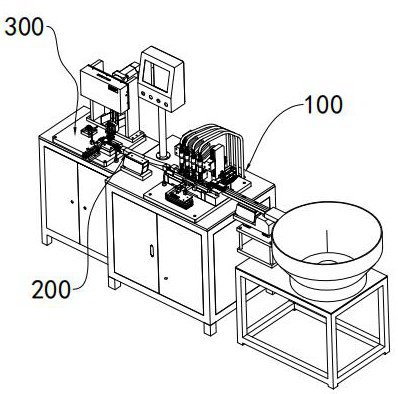

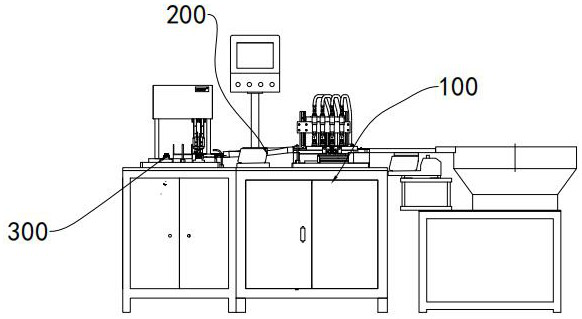

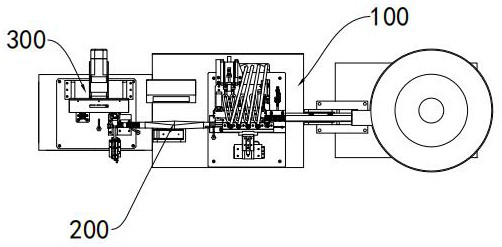

Image shell orifice burr removal mechanism and deburring equipment

ActiveCN113333834BAchieve simultaneous removalNo adverse damageFeeding apparatusMilling equipment detailsMotor driveMilling cutter

The invention discloses a deburring mechanism and deburring equipment for an orifice of an image shell, comprising a multi-axis motor, a plurality of connecting rod assemblies, a milling cutter assembly and a fixed platform arranged from bottom to top. The convex positioning block of the housing; the milling cutter assembly includes a cutter arbor and a rod-shaped milling cutter, and the rod-shaped milling cutter is mounted on the front end of the cutter arbor; the multi-spindle motor includes a plurality of output shafts, and the output shafts are connected with the first universal joint through the first universal joint. The lower end of the connecting rod assembly is connected, the connecting rod assembly extends upward in an inclined manner, and the upper end of the connecting rod assembly is connected with the cutter bar through the second universal joint; a spring is sleeved on the milling cutter assembly, so that the milling cutter assembly has a certain upper and lower Telescopic amount; the front end of the rod-shaped milling cutter extends to and pushes against the aperture of the image housing; the output shaft of the multi-axis motor drives the rod-shaped milling cutter to rotate through the connecting rod assembly, and the rotating rod-shaped milling cutter contacts in an elastically retractable manner on the image housing to remove orifice burrs.

Owner:IKD CO LTD

Low-temperature plasma catalytic degradation malodorous gas treatment equipment and malodorous gas treatment method

ActiveCN114377544AAchieve simultaneous removalHigh selectivityGas treatmentDispersed particle separationActivated carbonPtru catalyst

The invention relates to low-temperature plasma catalytic degradation malodorous gas treatment equipment and a malodorous gas treatment method. The malodorous gas treatment equipment comprises a box body provided with a gas inlet and a gas outlet; the plasma catalytic degradation area is arranged in the box body and communicated with the air inlet, a plasma generator is arranged in the plasma catalytic degradation area, and the inner wall of the box body in the area where the plasma catalytic degradation area is located is coated with a transition metal oxide coating; and the activated carbon treatment assembly is arranged in the box body, separates the gas outlet from the plasma catalytic degradation area, is filled with a carbon-based catalyst, and is used for synergistically catalytically degrading the malodorous gas in combination with ozone and plasma. According to the malodorous gas treatment equipment, low-temperature plasma and excessive ozone generated in the ionization process of the low-temperature plasma are combined with transition metal oxide and a carbon-based catalyst to catalyze and degrade malodorous gas, the treatment efficiency is high, the treatment effect is good, ozone generated when the plasma generator works is fully utilized, and the energy consumption is reduced. And secondary pollution caused by ozone is greatly reduced.

Owner:深圳市智盾环保科技有限公司

Image shell orifice burr removing mechanism and burr removing equipment

ActiveCN113333834AAchieve simultaneous removalNo adverse damageFeeding apparatusMilling equipment detailsMotor driveMilling cutter

The invention discloses an image shell orifice burr removing mechanism and burr removing equipment. The image shell orifice burr removing mechanism comprises a multi-spindle motor, a plurality of connecting rod assemblies, a milling cutter assembly and a fixing platform which are arranged from top to bottom, and a protruding positioning block used for positioning an image shell is arranged above the fixing platform; the milling cutter assembly comprises a cutter bar and a rod-shaped milling cutter, and the rod-shaped milling cutter is mounted at the front end of the cutter bar; the multi-spindle motor comprises a plurality of output shafts, the output shafts are connected with the lower ends of the connecting rod assemblies through first universal joints, the connecting rod assemblies extend upwards in an inclined mode, and the upper ends of the connecting rod assemblies are connected with the cutter bar through second universal joints; the milling cutter assembly is sleeved with a spring, so that the milling cutter assembly has a certain up-and-down stretching amount; the front end of the rod-shaped milling cutter extends to and abuts against an orifice of the image shell; and an output shaft of the multi-spindle motor drives the rod-shaped milling cutter to rotate through the connecting rod assemblies, the rotating rod-shaped milling cutter makes contact with the image shell in an elastic telescopic mode, and therefore hole opening burrs are removed.

Owner:IKD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com