Device and method for removing reverse osmosis concentrated water organic matter and ammonia nitrogen at same time

A technology for reverse osmosis concentrated water and organic matter, which is applied in chemical instruments and methods, water/sewage treatment, water treatment parameter control, etc., to achieve the effects of high removal efficiency, high degree of automation, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

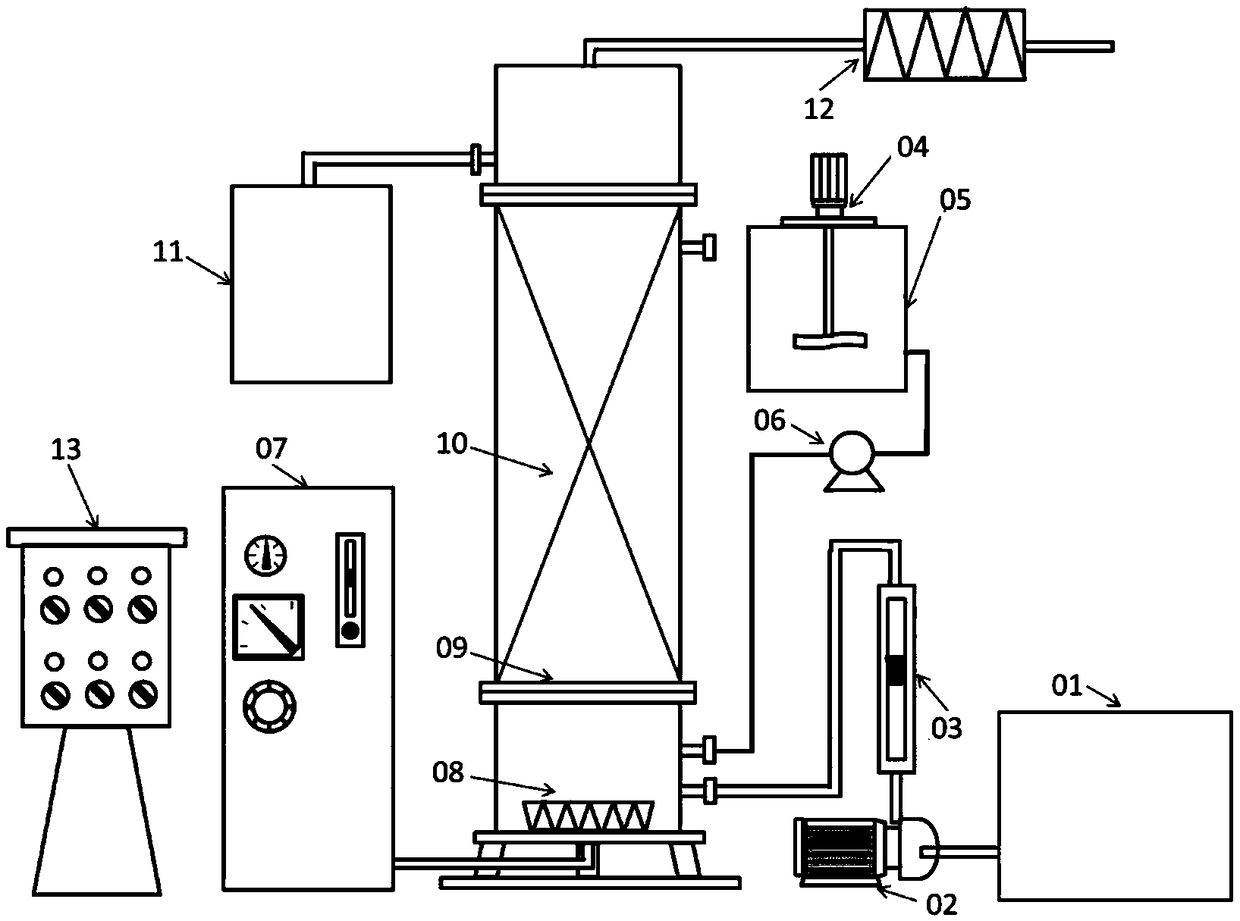

Method used

Image

Examples

Embodiment 1

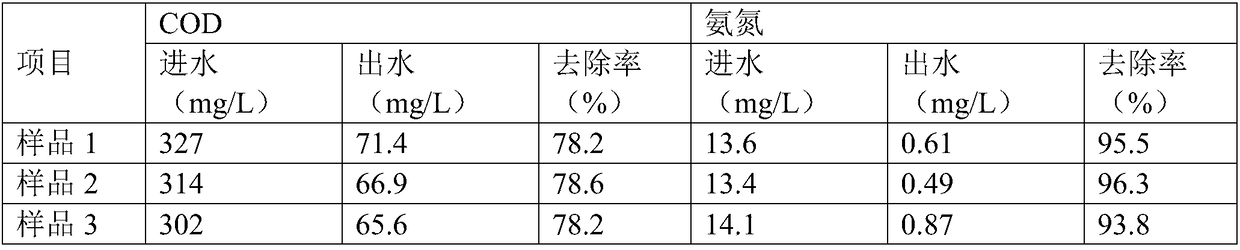

[0025] The reverse osmosis concentrated water output of a coking plant is 60m3 / h, the COD is about 310mg / L, and the ammonia nitrogen is about 14mg / L. Applying the device of the present invention, using a separate catalytic ozone oxidation treatment process, the catalyst is γ-Al 2 o 3 Load manganese-copper oxide, catalyze the oxidation reaction for 3 hours, do not add chemicals, and the ozone concentration is 330mg / L. The effluent COD is lower than 80mg / L and ammonia nitrogen is lower than 1.0mg / L. The average removal rates of COD and ammonia nitrogen are respectively are 78.3% and 95.2%, and the specific water quality indicators are shown in Table 1.

[0026] Table 1 Comparison of water quality indicators before and after reverse osmosis concentrated water treatment in a coking plant

[0027]

Embodiment 2

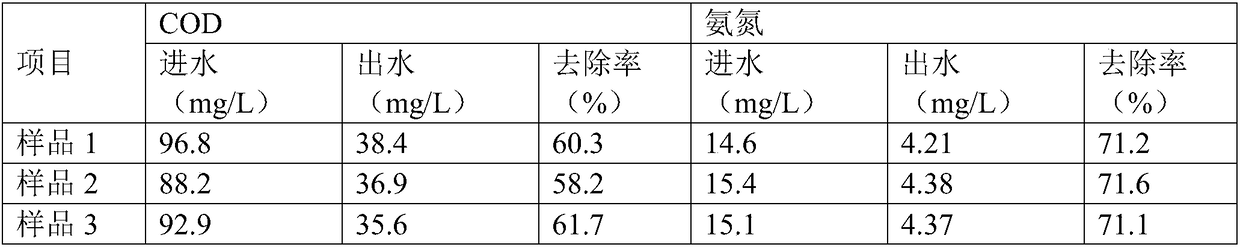

[0029] The production wastewater of a food factory is treated by the sewage treatment plant in the factory, and the biochemical effluent is reused after being treated by filtration, ultrafiltration, RO and other processes, and the reverse osmosis concentrated water produced is 160m 3 / h, COD is about 100mg / L, and ammonia nitrogen is about 15mg / L. Applying the device of the present invention, using catalytic ozone oxidation coupling persulfate oxidation treatment process, the catalyst is γ-Al 2 o 3 Load manganese-cerium oxide, react for 0.5h, add sodium persulfate at 30mg / L, ozone at 60mg / L, effluent COD less than 40mg / L, ammonia nitrogen less than 5.0mg / L, COD and ammonia nitrogen The removal rates were 60.1% and 71.3%, respectively, and the specific water quality indicators are shown in Table 2.

[0030] Table 2 Comparison of water quality indicators before and after reverse osmosis concentrated water treatment in a food factory

[0031]

Embodiment 3

[0033] The main sources of COD in the production wastewater of a titanium dioxide production plant are: reducing substances produced in the production process; organic substances brought in from carbide slag; SO 2 Wait. The volume of reverse osmosis concentrated water wastewater is 400m 3 / h, COD is about 200mg / L, and ammonia nitrogen is about 30mg / L. The device of the present invention is applied, and the catalytic ozone oxidation coupled hypochlorite oxidation treatment process is adopted, and the catalyst is γ-Al 2 o 3 Loading manganese-copper oxide, reacting for 3 hours, sodium hypochlorite dosage concentration is 40mg / L, ozone dosage concentration is 450mg / L, effluent COD is lower than 50mg / L, ammonia nitrogen is lower than 5.0mg / L, the removal rate of COD and ammonia nitrogen They are 79.1% and 70.4% respectively, and the specific water quality indicators are shown in Table 3.

[0034] Table 3 Comparison of water quality indicators before and after reverse osmosis co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com