High-ammonia-nitrogen low-C/N-ratio wastewater treatment system and treatment technique

A wastewater treatment system and wastewater treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of unstable denitrification effect and achieve the improvement effect , The effect of good denitrification effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

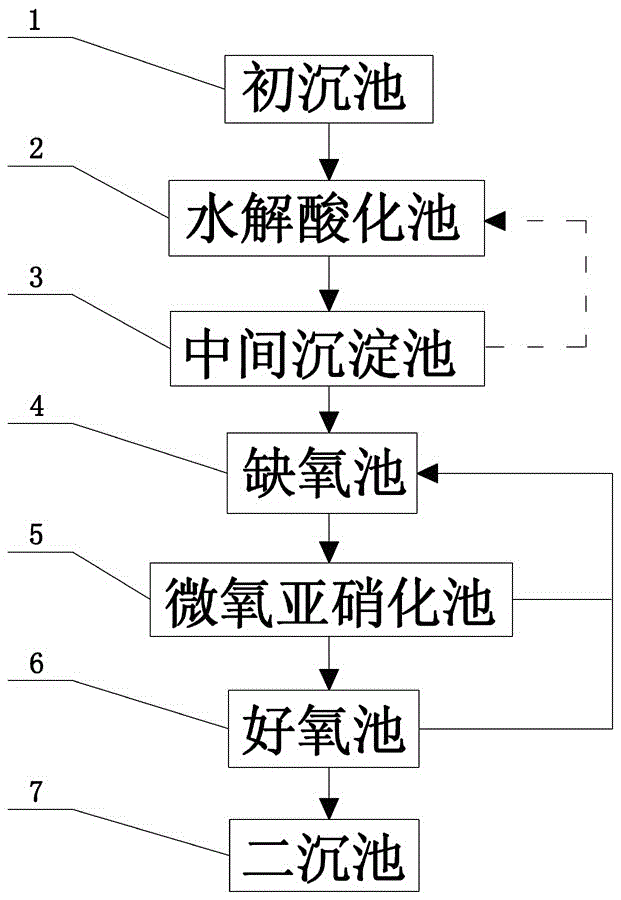

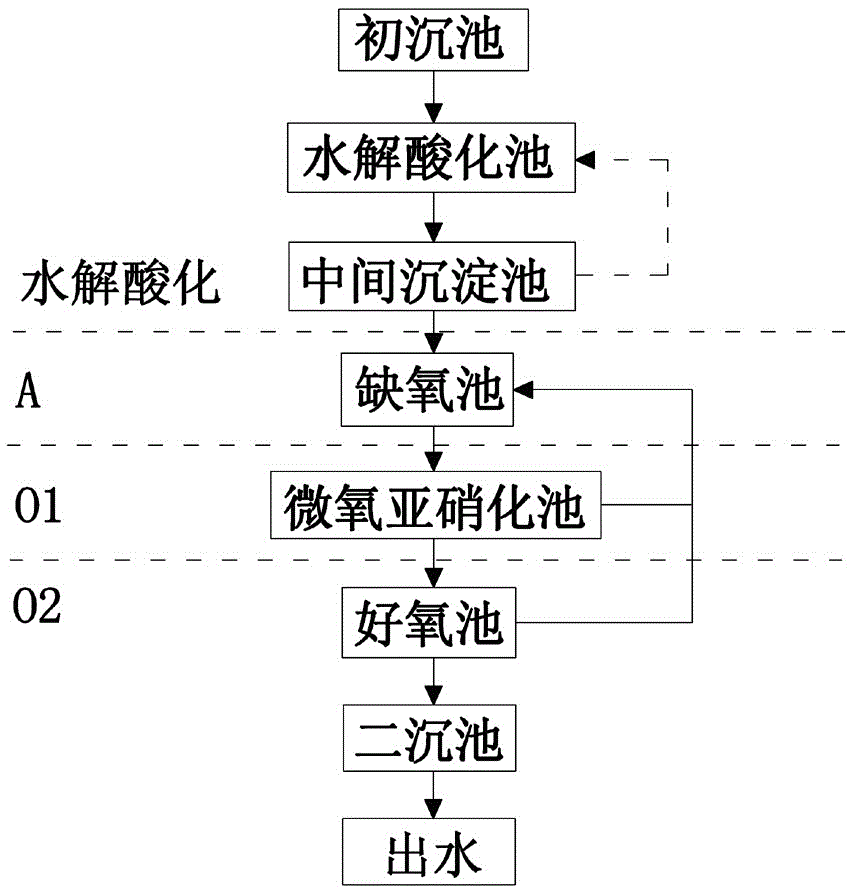

Embodiment 1

[0051] A sewage treatment plant is mainly industrial sewage, accounting for more than 80%. The industrial sewage is mainly synthetic leather DMF wastewater and textile wastewater, including some pharmaceutical wastewater and electroplating wastewater. The existing treatment biochemical process is "fine grid + cyclone grit chamber + adjustment, sedimentation tank + hydrolysis acidification tank + improved SBR + mechanical reaction tank flocculation tank + fiber filter D-type filter + ClO 2 Disinfection pool". Main influent water quality index COD Cr Average 250mg / L, NH 4 + -N average 51mg / L, total nitrogen average 71mg / L. COD of effluent after treatment by existing process Cr Average 47mg / L, NH 4 + -N average 13mg / L, total nitrogen average 22mg / L, NH 4 + -N, total nitrogen cannot meet the relevant effluent discharge standards. The combined process of "hydrolytic acidification tank + anoxic tank + micro-oxygen nitrosation tank + aerobic tank" was used to carry out the pi...

Embodiment 2

[0053] A chemical company has an annual production capacity of 120,000 tons of synthetic ammonia, 150,000 tons of urea, and 30,000 tons of methanol. During the production process, the company discharges about 1,700 m of ammonia nitrogen wastewater every day 3 . The combined process of "hydrolytic acidification tank + anoxic tank + micro-oxygen nitrosation tank + aerobic tank" was used to conduct pilot experiments on site, and the treatment scale of the pilot plant was 0.875m 3 / h, that is, the design wastewater treatment capacity of the pilot test process is 21m 3 / d. The anoxic pool, the micro-oxygen nitrosation pool and the aerobic pool were added with polyurethane sponge filler as the carrier, the hydrolytic acidification pool was inoculated with hydrolytic complex bacteria, Bacillus subtilis CM-A12, the anoxic pool was inoculated with denitrifying bacteria CM-NRD3, micro-oxygen subtilis The nitrification tank was inoculated with ammonia oxidizing bacteria CM-NRO14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com